Installation and Maintenance IM-708

Self-contained Air Conditioning System

Type SWP Vintage Sizes 18D thru 95D, 105E

MEA

Group: Applied Systems

Part Number: IM708

Date: February 2002

368-93-E

© 2001 McQuay International

Table of Contents

Introduction

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SWP-055-D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Vibration Isolators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Setting Factory Supplied Plenum. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Location/Service Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Removal of Shipping Restraints . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Relief Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Water Connections . . . . . . . . . . . . . . . . . . . . . . . . . 6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Condenser Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Condensate Drain Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Duct Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Supply Air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Return Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unit Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Unit Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Return Air and Outside Air Sensor. . . . . . . . . . . . . . . . . . . . . . . . . 14

Supply Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Lug Sizes For Single Disconnect or Power Block . . . . . . . . . . . . . 16

Control Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electrical Legend . . . . . . . . . . . . . . . . . . . . . . . . . 18

Typical Wiring Schematics . . . . . . . . . . . . . . . . . . 19

Figure 19. Power Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 20. Input Schematic, Discharge Air Control (DAC). . . . . . . 20

Figure 21. Input Schematic, Zone or Space Comfort Control (SCC) 21

Figure 22. Output Schematic, Actuator Control . . . . . . . . . . . . . . 22

Figure 23. Output Schematic, Auxiliary Fan Start/Stop Control . . 23

Figure 24. Output Schematic, Actuator Control . . . . . . . . . . . . . . 24

Figure 25. Output Schematic, Compressor Control (4 Compressors/4,

5 or 6 Stage) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 26. Output Schematic, Compressor Control (6 Compressors /

6 Stage) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Standard Controls . . . . . . . . . . . . . . . . . . . . . . . . . 27

High Pressure Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Low Pressure Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Compressor Motor Protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Proof of Airflow Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Frost Protection Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Clogged Filter Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Unit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Duct High Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Phase Fail/Under Voltage Protection . . . . . . . . . . . . . . . . . . . . . . 28

Duct Static Pressure Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Mounting instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Building Static Pressure Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Building pressurization applications . . . . . . . . . . . . . . . . . . . . 29

Freezestat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Condenser Water Flow Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Water Side Economizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Condenser Water, Head Pressure Control. . . . . . . . . . . . . . . . . . . 30

Variable Inlet Vanes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Adjustable Frequency Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Disconnect Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Dual Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Hot Water Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

System Check, Test and Start . . . . . . . . . . . . . . . 31

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Pre Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Fan start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Compressor start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Economizer start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Hot water start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Expansion valve superheat adjustment . . . . . . . . . . . . . . . . . 32

Refrigerant Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Variable air volume (VAV) start-up . . . . . . . . . . . . . . . . . . . . 34

Rpm changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Drive sheave alignment and belt tension . . . . . . . . . . . . . . . . 34

Final control settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Maintaining control parameter records . . . . . . . . . . . . . . . . . 35

System Maintenance . . . . . . . . . . . . . . . . . . . . . . . 36

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Motor Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . 37

Service and Warranty Procedure . . . . . . . . . . . . . 38

In Warranty Return Material Procedure . . . . . . . . . . . . . . . . . . . . . 38

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Product Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Check, Test and Start Procedure Form . . . . . . . . 39

Copyright © 2001 McQuay International. All rights reserved throughout the world.

2 IM708

Introduction

General Description

Models SWP018 through 105 are factory assembled, refrigerant charged and tested, water cooled packaged air conditioning units designed for ducted applications.

Each unit contains multiple hermetic compressors, water

cooled condensers, multi-circuit evaporator, thermal expansion valves, interconnecting refrigerant piping, forward

curved centrifugal fan, belt drive, fan motor, pleated filters

and all necessary operating and safety controls.

All rigging, installation, power and control wiring external to

the unit, and condenser water and condensate piping are the

responsibility of the installer.

The MicroTech II self-contained unit controller is standard

equipment. For a detailed description of the MicroTech II

components, input/output configurations, field wiring

options and requirements, and service procedures, refer to

Bulletin No. IM 710, "MicroTech II Self-contained Unit

Controller." For a description of operation and information

on using and programming the MicroTech II unit controller,

refer to the appropriate operation manual (see Table 1).

Table 1: Self-contained unit operation manual literature

UNIT CONTROL

CONFIGURATION

Variable Air Volume (VAV)

Discharge Air Control (DAC)

Constant Air Volume

Space Comfort Control (SCC)

Constant Air Volume

Discharge Air Control (DAC)

OPERATION MANUAL

BULLETIN NUMBER

OM711

OM712

OM711

Inspection

When the equipment is received, all items should be carefully checked against the bill of lading to insure a complete

shipment. The shipping receipt should not be signed until all

items have been accounted for. All units should be carefully

inspected for damage upon arrival. All shipping damage

should be reported to the carrier and a claim filed. The unit

serial plate should be checked before unloading the unit to be

sure that it agrees with the power supply available.

Nomenclature

SWP-055-D

Self-contained

Water cooled

Plenum discharge

IM708 3

Vintage

Nominal tons

Installation

Note: Installation and maintenance are to be performed

only by qualified personnel who are familiar with

local codes and regulations, and experienced with

this type of equipment.

CAUTION

Sharp edges and coil surfaces are a potential injury hazard.

Avoid contact with them.

Handling

Units are shipped with a protective covering which should

remain in place while the unit is being moved to its final

location. Note: Check for concealed damage as soon as possible.

Never allow any part of the unit to fall during unloading or

moving as this may result in serious damage. Units are provided with lifting lugs for rigging with a crane. If units are

lifted by crane, protection against chaffing damage by slings

or cable must be provided and spreader bars must be used

across the top of the cabinet to prevent any structural damage

to the frame.

The unit base frame will accept dollies or Johnson bars for

transporting the unit. Furniture dollies can be placed at both

ends of the chassis or at one end and a Johnson bar used at

the other end for maneuvering.

CAUTION

required. Foam rubber gasket is provided around the perimeter of unit top. Carefully set plenum. Attach with mounting

hardware provided with the plenum.

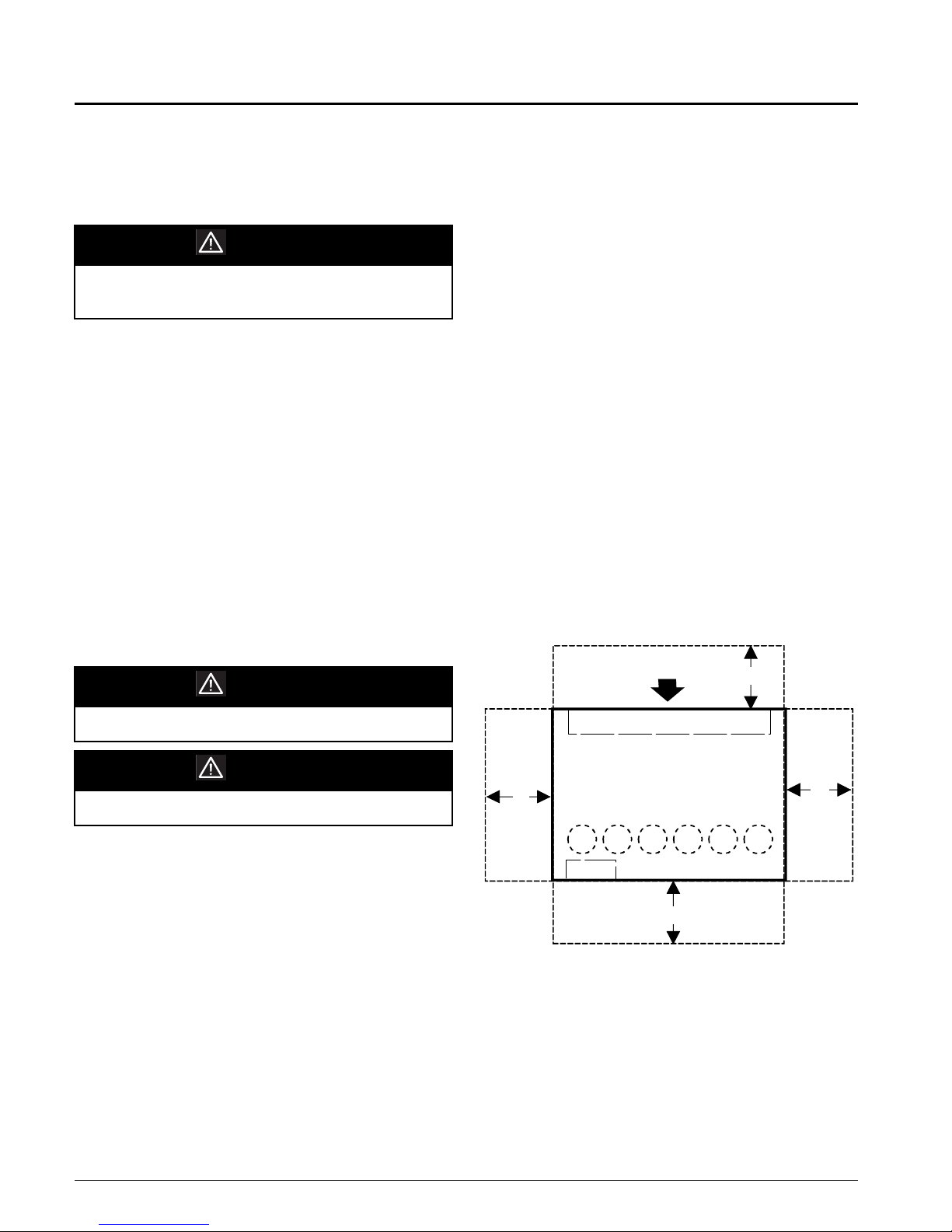

Location/Service Access

For good installation, service and maintenance access the

following recommended clearances should be followed.

Minimum clearances required by local, state, or federal

codes, such as the NEC take precedence over those listed

below. Clearance is required to allow room for side filter

access, mechanical cleaning of the condenser tubes and

economizer coil, access to expansion valves and other control components and to allow for possible fan shaft or compressor removal.

Unit front - 42"

Unit rear - 24"

Motor location side - 36"

Piping location side - 36"

Side without motor or piping -24"

Figure1. Recommended Service and Maintenance

Clearance

Airflow

24"

Do not attempt to install dollies in the center of the unit.

CAUTION

Units must not be moved in an upended position.

Floor surfaces must be protected when equipment is moved

across finished flooring. Plywood sheeting may be used to

protect surfaces and distribute weight loading.

Vibration Isolators

All units are provided with 1” neoprene isolation pads,

shipped separately. Pads are to be installed beneath the unit

and located at each corner and the center of each base channel. For units provided with more than six (6) isolator pads,

evenly space the additional pads under the front and rear

base channels.

Setting Factory Supplied Plenum

If the unit is provided with a factory plenum for field mounting, a forklift, slings or other suitable lifting means is

Evapora tor C oil

24"

or

36"

Compressors

1

35642

VFD

42"

36"

Removal of Shipping Restraints

Mechanical restraints are used to secure the spring mounted

fan during shipment. Restraints and shipping blocks must be

removed after unit has been set in its final location.

4 IM708

Refrigerant Piping

Pressure Relief Valves

All units have individual condensers per refrigerant circuit

and each condenser is provided with a spring loaded relief

valve. The valve is set to open when refrigerant pressure

reaches 400 psig. The relief valve will accommodate a 1/2"

flare connection for applications where it is necessary to

connect vent piping and run it outside the building.

CAUTION

When refrigerant is vented to the outside of the building,

the vent piping should be installed as recommended in

ASHRAE Standard 15-1994.

IM708 5

W ater Connections

General

Due to the variety of piping practices, it is advisable to follow the recommendations of local authorities. They can supply the installer with the proper building and safety codes

required for a safe and proper installation.

The piping should be installed with a minimum number of

bends and elevation changes for best performance. Piping

should contain:

1. Vibration eliminators to reduce vibration and noise

transmission to the building.

2. Shutoff valves to isolate the unit from the piping system

during unit servicing.

3. Manual or automatic air vent valves at the high points of

the system.

4. Some means of maintaining adequate system water

pressure (e.g., expansion tank or regulating valve).

5. Temperature and pressure indicators located at the unit

to aid in servicing.

6. A strainer or some means of removing foreign matter

from the water before it enters the pump. It should be

placed far enough upstream to prevent cavitation at the

pump inlet (consult pump manufacturer for recommendations). The use of a strainer will prolong pump life

and help maintain system performance.

7. Size piping to minimize system pressure drop.

mizer will typically elevate the water temperature by 5

to 10°F before entering the condenser, allowing suitable

condenser water temperatures whenever the tower supply temperature is 50°F or higher. Mechanical cooling is

locked out below 55°F EWT.

6. Head pressure control must be provided if entering condenser water temperatures will go below 55°F. Fan

cycling and/or modulating discharge dampers on the

cooling tower are often used, or a 3-way bypass around

the tower to maintain condenser water temperature.

Cooling tower control to maintain the temperature at

>55°F is generally more cost effective if multiple units

are in the loop. If valves are installed on the individual

SWP units, a single water regulating valve controlled by

circuit #1 head pressure should be used. The Lead/Lag

option needs to equal “NO”. When Lead/Lag equals

“NO” circuit #1 is always first on and last off. The

refrigerant pressure line from the valve should be connected to a gauge port on any liquid line service valve

located in the compressor #1 refrigerant circuit. Compressor #1 is located at the far left of the cabinet.

If the water regulating valve is placed in service with the

unit condensers, it should be installed in the water line leaving the condenser and should shut down to prevent water

from siphoning out of the condensers. For systems where a

constant pumping head is required, the water regulating

valve may be installed in a bypass line around the condensers. It must then open on falling discharge pressu re.

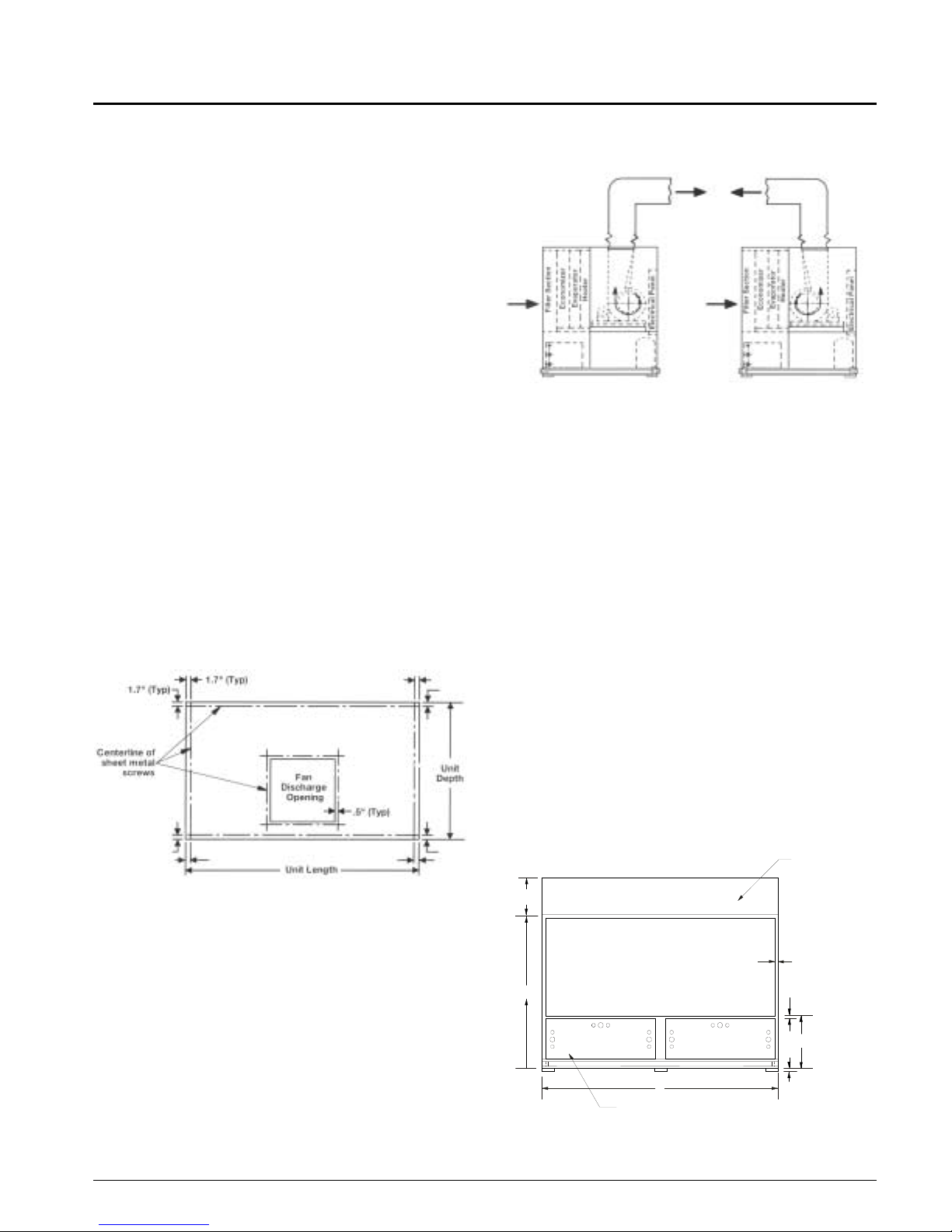

Condenser Piping

1. Units may be specified with water and condensate connections on either the left or right side of the unit.

2. All units have an individual condenser per refrigerant

circuit. All condensers are factory piped for a common

condenser water supply and a common condenser water

return connection.

3. Field piping connections are made to factory provided

piping located as indicated on the unit submittal drawings. The piping connections are run to the outside of

the unit cabinet. Connections are located behind a factory mounted shipping cover. All connections are copper sweat connections as indicated on unit dimensional

drawings.

4. Supply and return water connections must be made at

the proper locations as indicated by the dimensional

drawings. Supply (water in) connection is always the

lower connection.

5. Units with factory mounted water side economizer

should not require head pressure control. The econo-

These typical systems, depending on the specific application, must maintain a constant condensing pressure regardless of temperature conditions and must assure adequate

head pressure for proper thermal expansion valve operation.

A minimum head pressure of 180 psi (95°F condensing temperature) is recommended.

7. Condenser tube velocities must not exceed 10 feet per

second.

Figure2. Condenser Regulating Valve (refrigerant

pressure controlled

)

6 IM708

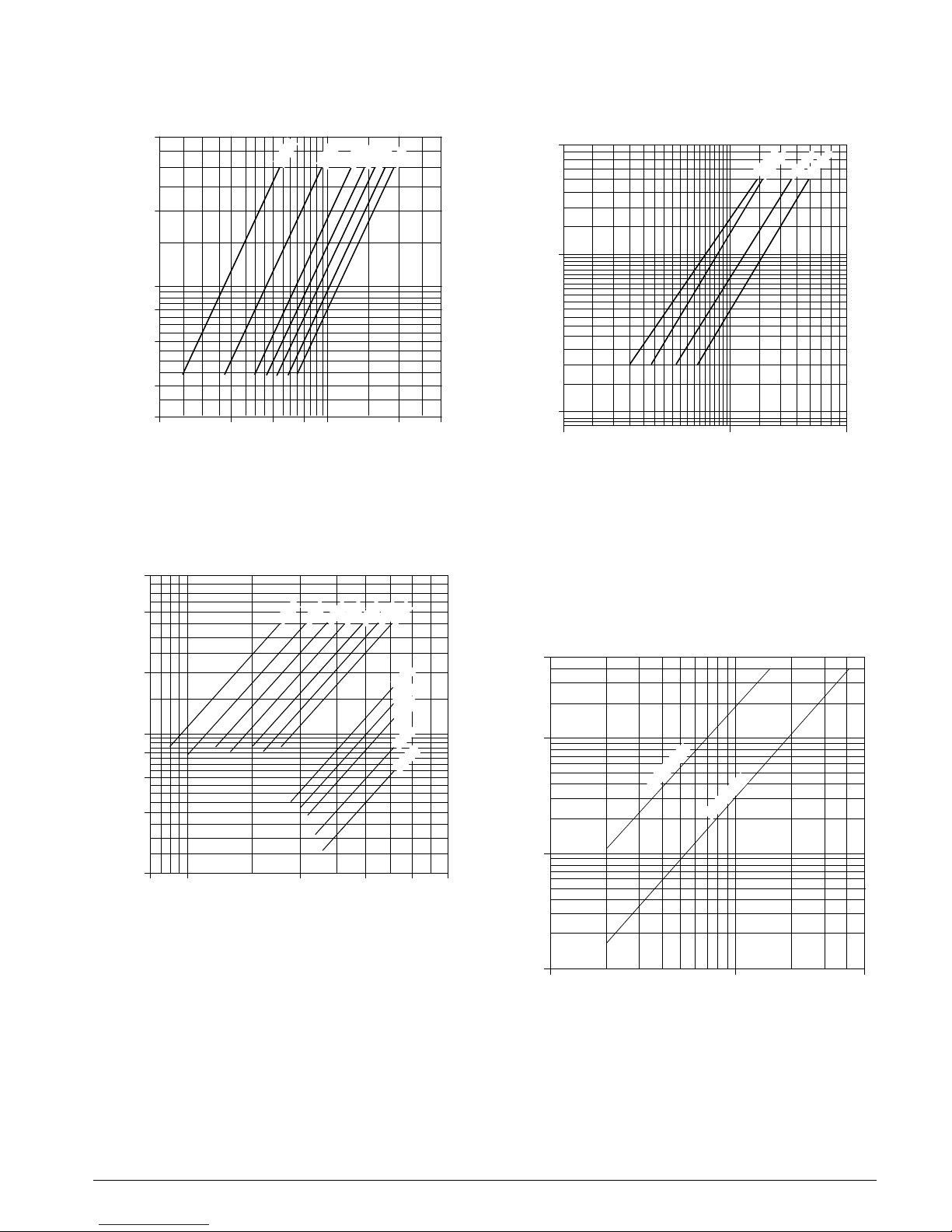

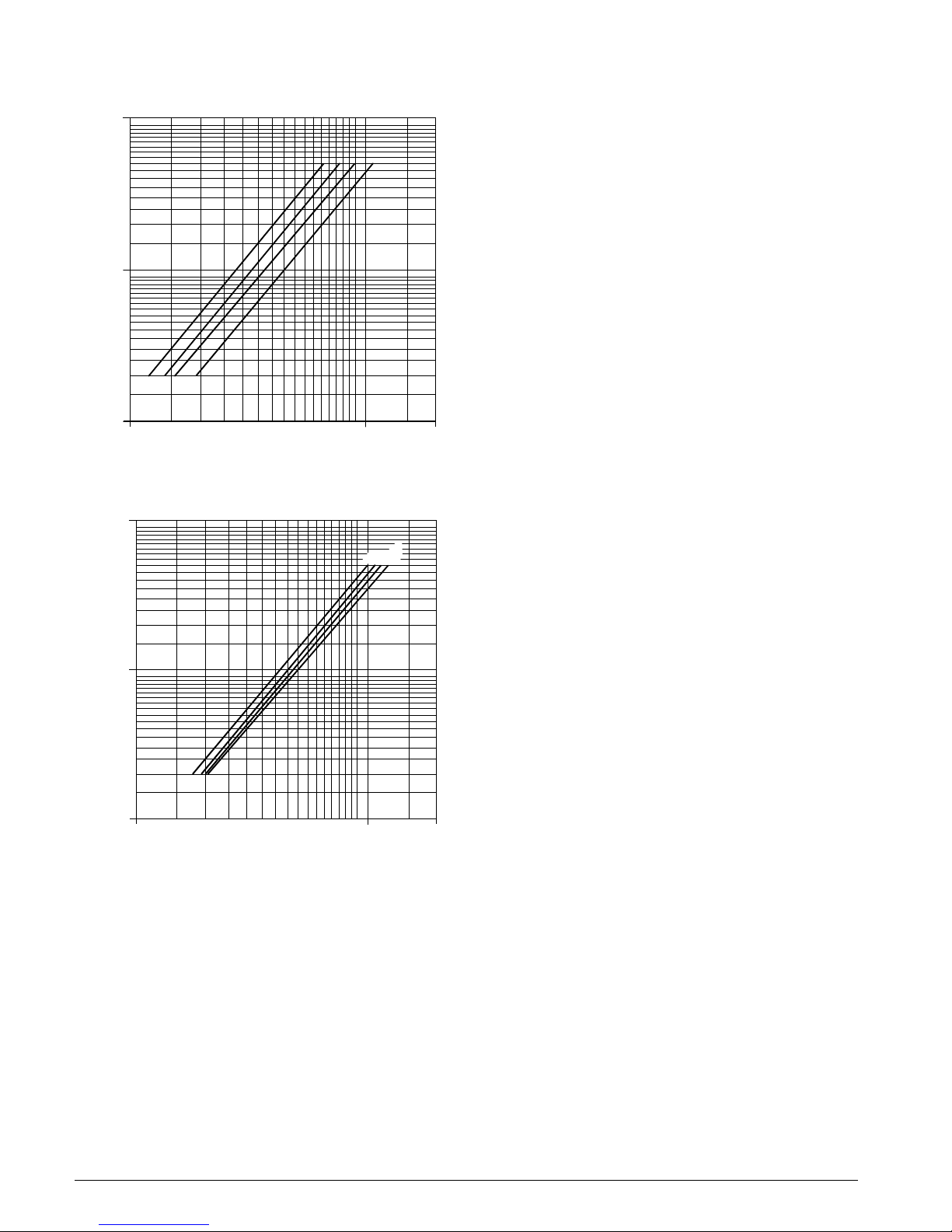

Figure3. Condenser water pressure drop SWP018 -

SWP040

40

24 HP

28 HP

12 HP

18 HP

32 HP

36 HP

40 HP

Figure5. Economizer water pressure drop, SPW018-

SPW105

50

035-040

045-095

105

018-028

20

O)

2

10

8

Pressure Drop (ft H

6

4

3

20

60 80

40

Condenser Flow Rate (gpm)

100

200 300

Note: HP = total unit compressor horsepower.

Figure4. Condenser water pressure drop SWP045 -

SWP105

60

O)

Pressure Drop (ft H

40

20

2

10

8

6

40HP

46HP

52HP

56HP

60HP

70HP

80HP

78HP

84HP

90HP

105HP

120HP

O)

2

10

Pressure Drop (ft H

1

Note:

10

Condenser Flow Rate (gpm)

!

Includes coil, control valves and interconnecting

100 500

piping.

"

Add this∆P to condenser ∆P to obtain unit ∆P

for pump selection.

Figure6. Water regulating valve pressure drop.

Head pressure control

40

10

O)

2

018-040

4

2

80 100

200 300

Condenser Flow Rate (gpm)

Note: HP = total unit compressor horsepower.

IM708 7

400 500

Pressure Drop (ft H

0.1

045-095

1

10

100

500

Condenser Flow Rate (gpm)

Figure7. Hot water coil pressure drop, SWP018 -

SWP040

100

018

035

023-028

040

O)

2

10

Pressure Drop (ft H

1

10

100

Water Flow Rate (gpm)

Hot water coil pressure drop, SWP045 - SWP105

100

Condensate Drain Connection

The condensate drain connection is 1 1/8" O.D.S. copper and

is located on the same end of the unit as the condenser water

connections. The drain is internally trapped at the factory

requiring no external trap. The condensate line should be

pitched away from the unit with a minimum slope of 1/8" per

foot.

Drain pans and the drain trap should be kept clean by periodic cleaning. A cleanout is provided as standard in the trap

to aid in cleaning.

200

O)

2

10

Pressur e Drop (ft H

1

10 100

Water Flow Rate (gpm)

055

045

065-095

105

200

8 IM708

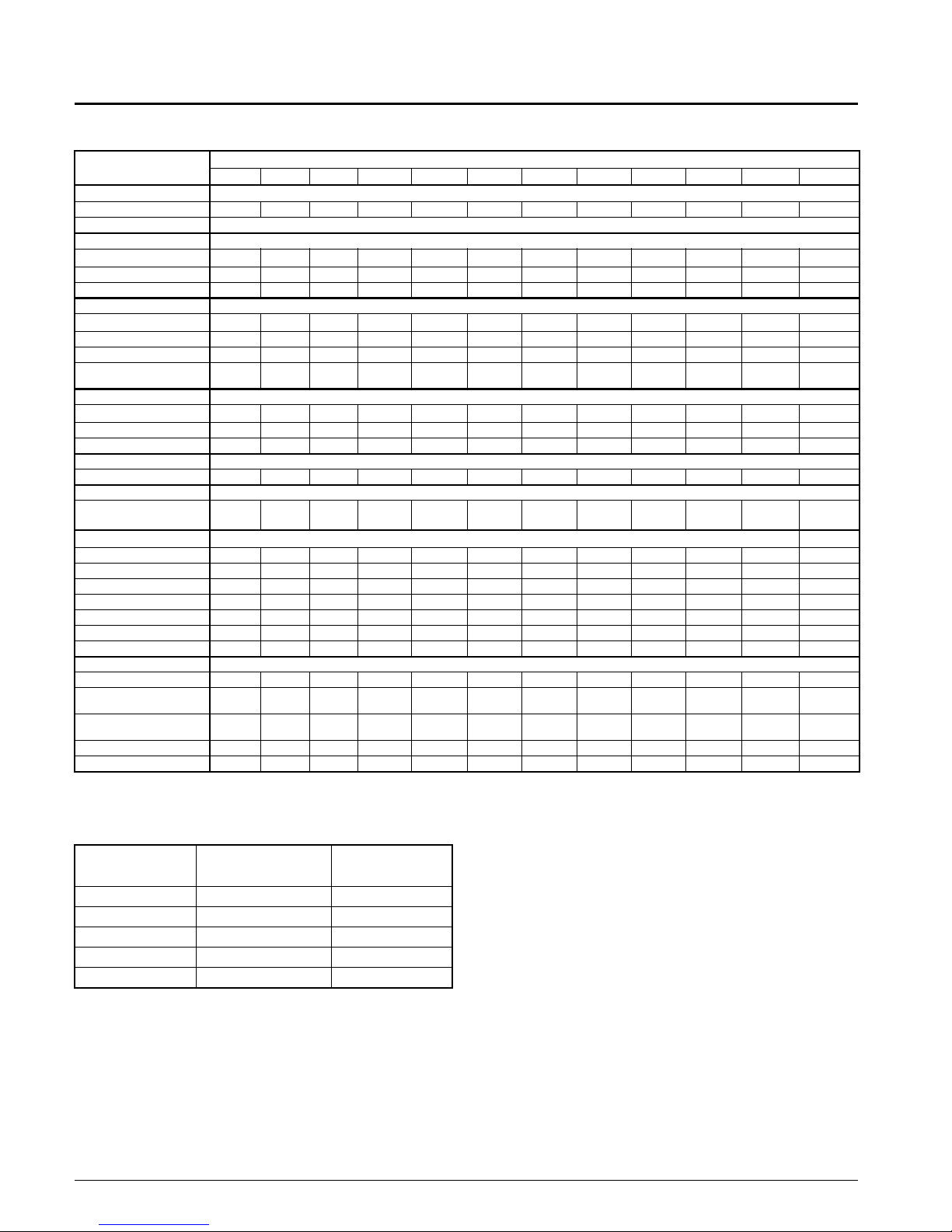

Duct Connections

Supply Air

For connection of supply ductwork directly to the unit, a

duct collar must first be mounted at the fan outlet, avoiding

the mounting screws located around the perimeter of the fan

discharge opening (see Figure 8). Fan discharge opening

sizes are indicated on the unit dimensional drawings. When

connecting ductwork to the unit, a canvas type connecting

collar is recommended.

Units are available in two fan configurations and should be

ducted as shown in Figure 9. Duct take-offs which go opposite to the direction of fan rotati on will result in an associated

system effect loss and reduced fan performance.

If a field fabricated plenum is used, duct take-off locations

should again be correctly oriented to the rotation of the fan to

minimize system losses. Refer to unit dimensional drawings

and Figure 8 for plenum mounting size requirements. Canvas type connectors are recommended at the duct connection

to the plenum.

Units are also available with a factory provided discharge

plenum. Supply duct connections to the plenum opening(s)

should include a canvas type connector. Plenum opening

sizes and locations will be indicated on the job submittal.

Figure8. Unit top detail

Figure9. Discharge duct configurations

Return Air

Return air to the unit can be arranged in two ways.

1. Ducted return

Return ductwork may be attached to the 2" flange around the

perimeter of the unit's return air opening (Refer to Figure

10). A canvas type duct connecting collar is recommended.

All ductwork connected to the unit should be of adequate

size and construction for the application. A canvas type connector is also recommended where the duct penetrates the

machine room wall(s). This will prevent vibration generated

by air movement in the duct from being transmitted out to

the occupied spaces.

Note: Do not obstruct unit access panel located below the

return opening.

2. Free return

The mechanical equipment room may be used as a return

plenum with no hard connection at the unit.

Note: Some building codes do not allow the use of the

mechanical room as a return plenum. Applicable

local codes should be checked for each installation.

Figure10.Back Elevation

(Optional)

Multi-Directional

Plenum

29”

K x L

Return Air Opening

D

B

Mechanical

Access

(See Notes)

(See Notes)

2.0” Typical

2.0”

M

1” Neoprene

Isolation Pads,

Shipped Separately

B25

IM708 9

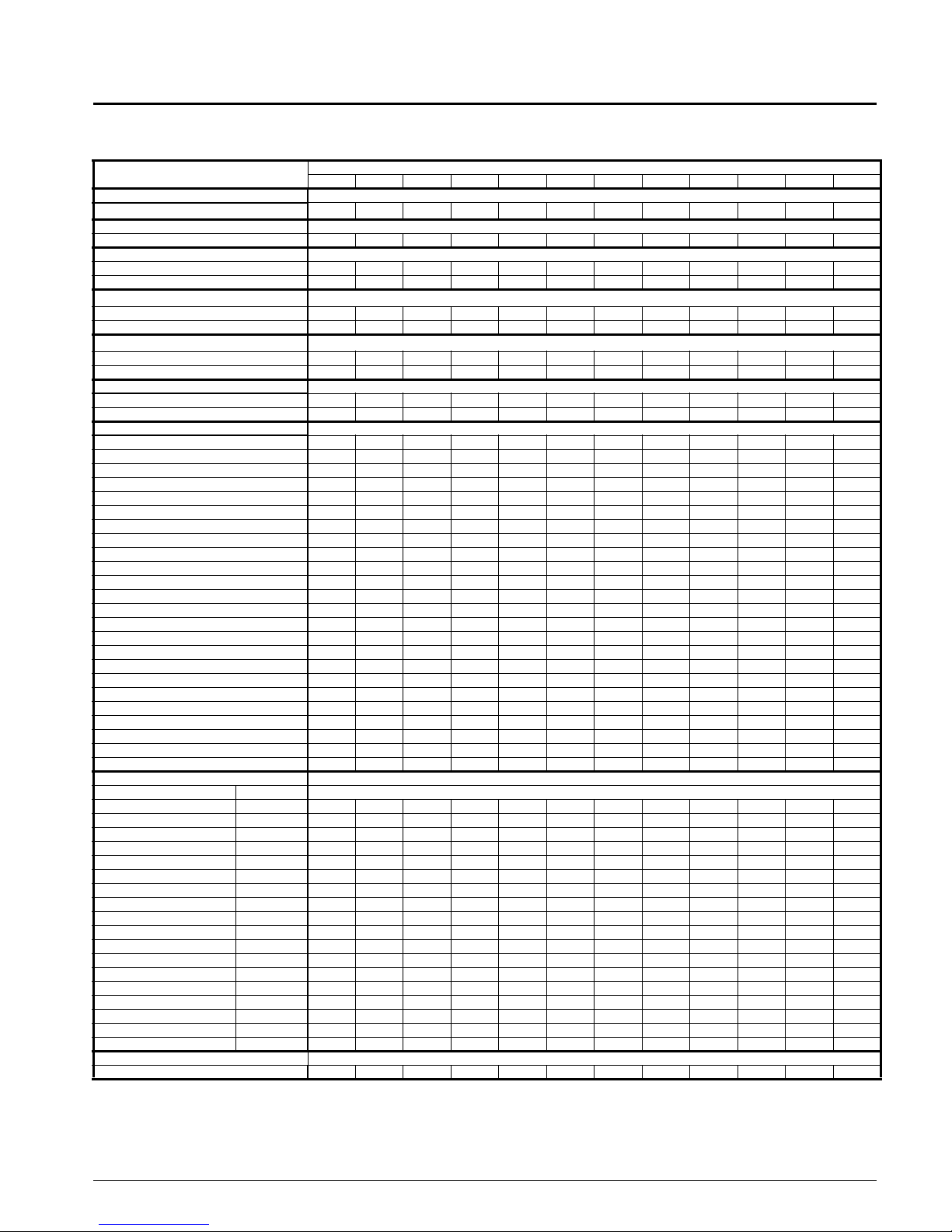

Physical Data

Table 2: SWP 018 Through SWP 105

Data

Compressor

Quantity 2, 3, 4 3, 4 4 4 4 4 4 4 4 4 4, 6 6

Size See Unit Data Plate

Evaporator Coil

Face Area (Ft.2)

Rows 4, 6 4, 6 4, 6 4, 6 4, 6 4, 6 6 6 6 6 6 6

Fpi 12 12 12 12 12 12 12 12 12 12 12 12

Waterside Economizer Coil

Face Area (Ft.2)

Rows 4444 4 4 4 4 4 4 4 4

Fpi 12 12 12 12 12 12 12 12 12 12 12 12

Maximum Working Pressure

(psig)

Hot Water Heating Coil

Face Area (Ft.2)

Rows 1, 2 1, 2 1, 2 1, 2 1, 2 1, 2 1, 2 1, 2 1, 2 1 1 1

Fpi 12 12 12 12 12 12 12 12 12 12 12 12

Electric Heat

Kw 34 34 34 34 34 68 68 68 68 68 68 68

Filters

(Quantity) Size 4” Depth

Evaporator Fan

Quantity 1111 1 1 1 1 1 1 1 1

Size 15 18 18 20 20 22 25 25 25 27 27 33

Minimum Horsepower 5 7.5 10 10 15 15 20 20 20 25 30 40

Maximum Horsepower 10 15 20 20 25 30 40 40 40 50 60 60

Minimum Design cfm, CV 2950 3825 4425 5825 6925 7675 9025 10375 11575 12775 13975 15800

Minimum Design cfm, VAV 4720 6120 7080 9320 11080 12280 14440 16600 18520 20440 22360 25280

Maximum Design cfm 7080 9180 10620 13980 16620 18420 21660 24900 27780 30660 33540 37920

Condenser

Quantity 2, 3, 4 3, 4 4 4 4 4 4 4 4 4 4, 6 6

Waterside Working Pressure

(psig)

Minimum Entering

Temperature (F)

Minimum GPM 25 41 53 66 69 94 105 105 121 134 138 180

Maximum GPM 88 108 125 159 166 215 237 237 251 349 358 493

a

a. Standard fan TSP limit is 5.5 inch of water. Consult your local McQuay sales representative for applications beyond this range.

018 023 028 035 040 045 055 065 070 080 095 105

11.8 15.3 17.7 23.3 27.7 30.7 36.1 41.5 46.3 51.1 55.9 63.2

11.8 15.3 17.7 23.3 27.7 30.7 36.1 41.5 46.3 51.1 55.9 63.2

400 400 400 400 400 400 400 400 400 400 400 400

9.3 12.8 15.2 20.2 24.5 26.8 30.4 35.8 39.9 44.4 48.3 51.9

(6)20x20x4

(2)25x20x4

(6)20x20x4

(2)25x20x4

400 400 400 400 400 400 400 400 400 400 400 400

55° 55° 55° 55° 55° 55° 55° 55 55° 55° 55° 55°

(6)20x20x4

(2)25x20x4

(10)25x20x4 (10)25x20x4 (12)25x20x4 (12)25x20x4 (18) 20x20x4 (6)16x20x4

SWP Model Size

(12)25x20x4

(3)20x20x4

(15)25x20x4

(6)16x20x4

(15)25x20x4

(4)16x20x4

(17)20x25x4

(1)16x25x4

Table 3: Compressor circuit charge

COMPRESSOR

(HP)

69 lbs.66

10 14 lbs. 112

13 18 lbs. 128

15 22 lbs. 256

20 27 lbs. 256

*Charge quantities listed are average. Actual cha rg e qu an tity is dependent on

individual unit evaporator coil circu iting. Actual char ge quantities are st amped

on each unit nameplate.

10 IM708

*REFRIGERANT

CHARGE PER

CIRCUIT (R-22)

OIL CHARGE

PER CIRCUIT

(OZ.)

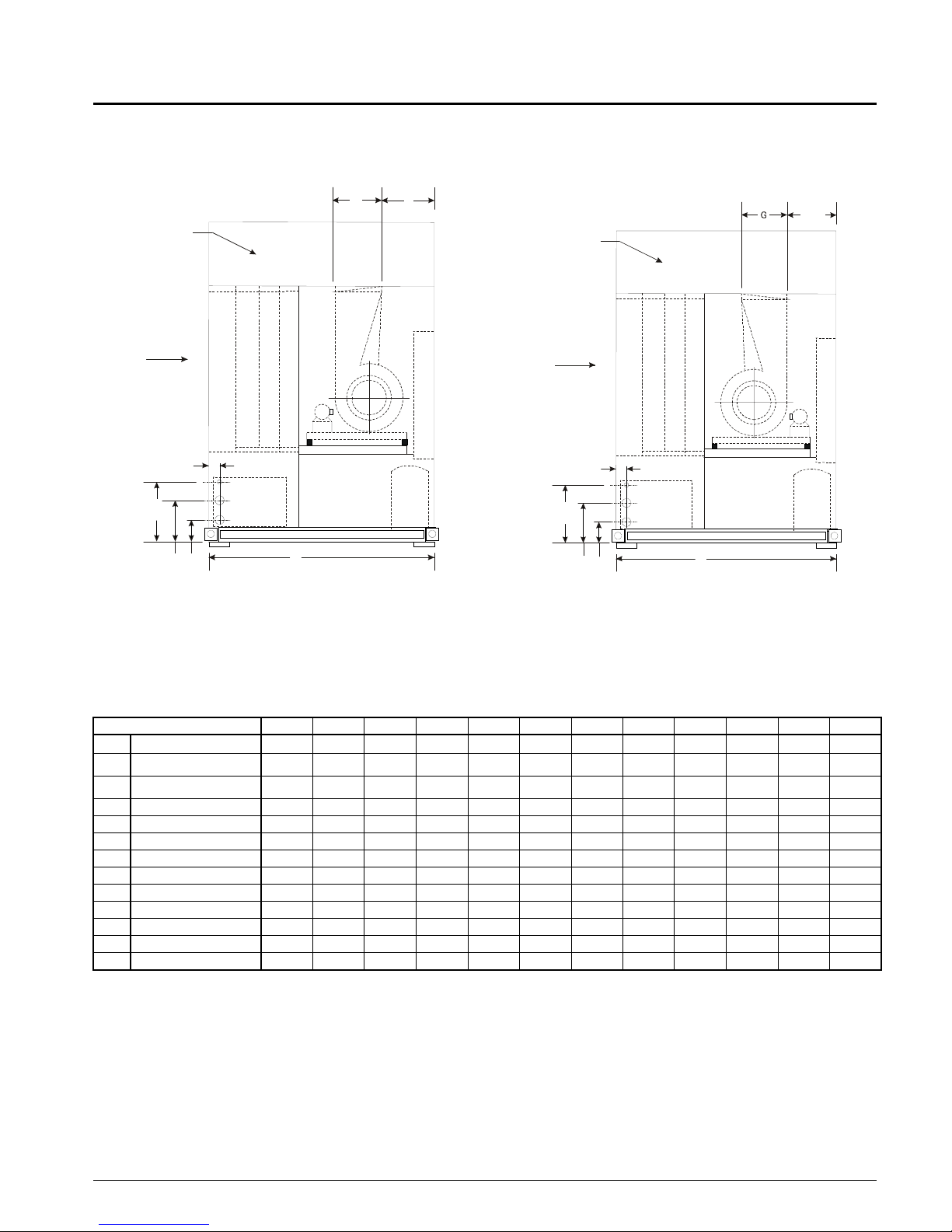

Dimensional Data

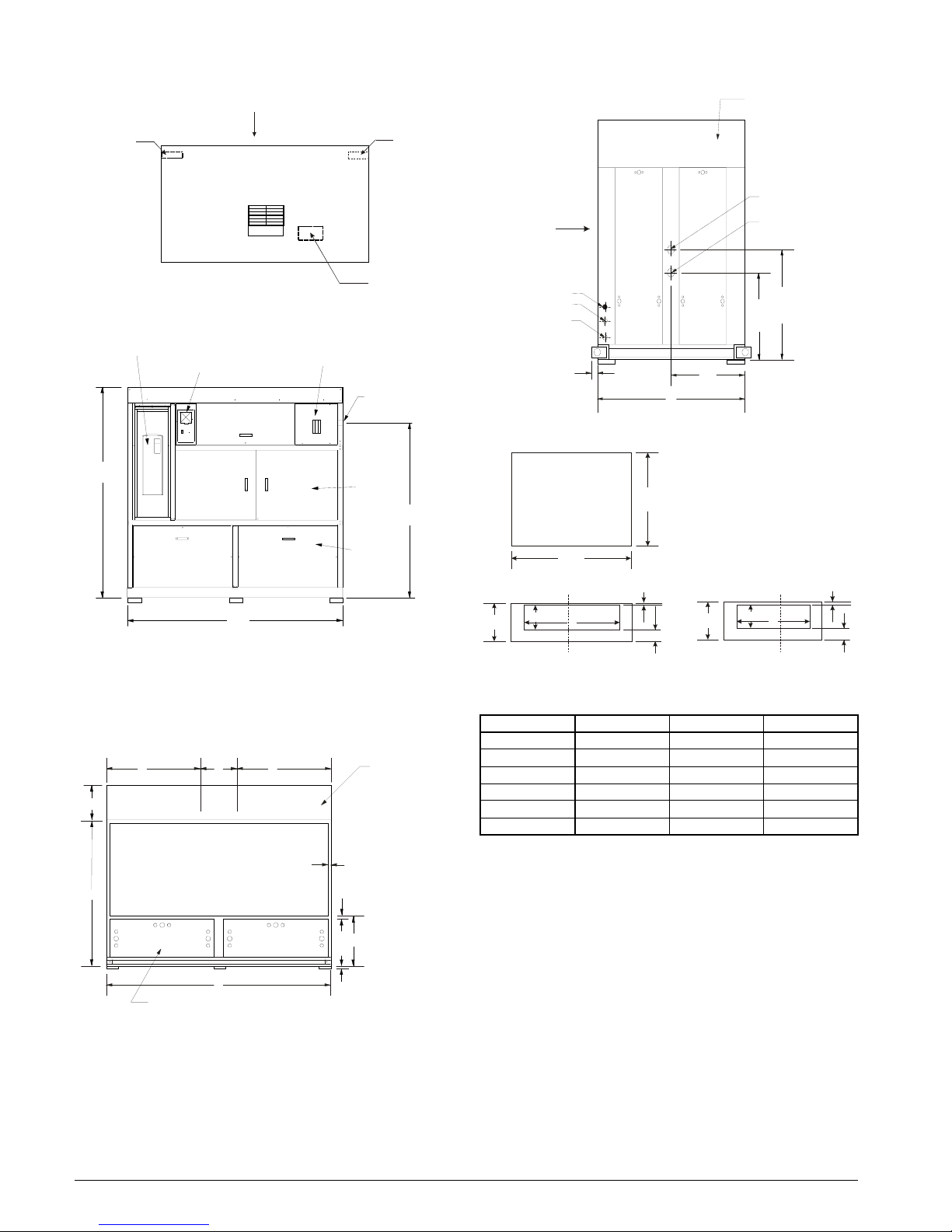

Figure 1 1. Left Side Front (CW) Disch arge with 0ptional

Multi-Directional Plenum

(Optional)

Multi-Directional

Plenum

(See Notes)

K x L Return Air

3.25”

19.0"

14.75”

8.75”

Filter Section

Outlet

Inlet

G

Heater

Evaporator

Economizer

A

J

Electrical Panel

A21

Figure 12. Left Side Back (CCW) Discharge with

0ptional Multi-Directional Plenum

9.63"

(18-95)

10.31

(Optional)

Multi-Directional

Plenum

(See Notes)

K x L Return Air

3.25”

19.0"

14.75”

Heater

Evaporator

Economizer

Filter Section

Outlet

Inlet

A

8.75”

(105)

Electrical Panel

A22

Note: Select unit arrangement on the unit selection.

Plenum can be shipped separately. Please indicate on the unit submittal. Indicate size and location of plenum openings on the unit submittal. All openings are on plenum centerline. For additional information refer to plenum certified drawing .

Table 4:

BASIC UNIT 018 023 028 035 040 045 055 065 070 080 095 105

A

B

D

FFan Disch. 18.62 21.88 21.88 24.75 24.75 27.25 31.25 31.25 31.25 34.25 34.25 47.25

G Fan Disch. ^ Opening 15.88 18.88 18.88 24.75 24.75 27.25 31.25 31.25 31.25 34.25 34.25 34.94

H Fan Disch. Location 32.69 31.06 31.06 37.62 37.62 46.38 44.38 44.38 50.38 54.88 60.88 54.40

J Fan Disch. Location 22.50 18.81 18.81 20.12 20.12 21.06 21.32 21.32 21.32 23.82 23.82 33.46

K Return Opening Height 41.44 41.44 41.44 51.44 51.44 51.44 51.44 62.20 62.20 62.20 62.20 70.20

L Return Opening Length 80.00 80.00 80.00 96.00 96.00 116.00 116.00 116.00 128.00 140.00 152.00 152.00

M Base of Return Opening 28.62 28.62 28.62 28.62 28.62 28.62 28.62 23.87 23.87 23.87 23.87 23.87

N Water Out/In (ODS) 2-1/8 2-1/8 2-1/8 2-5/8 2-5/8 2-5/8 3-1/8 3-1/8 3-1/8 3-1/8 3-1/8 3-1/8

P 1 Row HW Donn (ODS) 1-5/8 1-5/8 1-5/8 1-5/8 1-5/8 1-5/8 1-5/8 1-5/8 2-1/8 2-1/8 2-1/8 2-1/8

P 2 Row HW Conn (ODS) 1-5/8 1-5/8 1-5/8 1-5/8 1-5/8 2-1/8 2-1/8 2-1/8 2-1/8 - - -

b

Deptha

b

Lengtha

b

Heighta

a. Dimensions do not include handle, latch or fastener extensions.

b. For shipping dimensions add 4" (102mm) to depth, 8" (204mm) to length, and 4" (102mm) to height.

72.00 72.00 72.00 72.00 72.00 81.00 81.00 81.00 81.00 84.00 84.00 96.00

84.00 84.00 84.00 100.00 100.00 120.00 120.00 120.00 132.00 144.00 156.00 156.00

82.00 82.00 82.00 82.00 82.00 82.00 82.00 88.00 88.00 88.00 88.00 96.00

IM708 11

Figure 13. Unit Front Plan

Return Air

Left Side

Piping Connections

(See Notes)

Figure 14. Front Elevation

ASD (Optio nal)

MicroT ech II Panel

D

Supply

Fan Motor

Disconnect

Switch (Optional)

Power Entry

7/8" Pilot K.O.

Electrical

Access

(Optional)

Right Side

Piping Connections

(See Notes)

A23

72"

Figure 16. Left Side

K x L Return Air

1-1/8” ODS Drain

(N) W a te r O ut

(N) W ater In

Lifting Lug

1” Typ.

A/2

A

Figure 17. Discharge Plenum (Optional)

Plan View

Depth

Multi-Directional

(Optional)

Plenum

(See Notes, Page 11)

(P) Ho t W a te r O u t

(P) Ho t W a te r In

44.5”

38.5”

Mechanical

Access

B

Note: Service connections determined when facing the front of the

unit. Left-hand standard, right-hand optional. Please indicate on

the unit submittal.

Note: Unit sizes 018, 023 and 028 have a single mechanical access

panel in bottom front and bottom back.

Figure 15. Back Elevation

H H

29”

D

Mechanical

(See Notes)

F

K x L

Return Air O pening

B

Access

Multi-Directional

Plenum

(See Notes, Page 11)

2.0” Typical

2.0”

M

1” Neoprene

Isolation Pads,

Shipped Separately

(Optional)

Length

29”

Front/Back Elevation

H

A

3”

2” Min

29”

Left/Right Elevation

H

B

Table 5. Discharge Plenum

Unit Size Length (in.) Depth (in.) Height (in.)

018D-028D 84 72 29

035D-040D 100 72 29

045D-065D 120 81 29

070D 132 81 29

080D 144 84 29

095D-105D 156 84 29

3”

A27

2” Min

12 IM708

Unit Weights

Table 6. Unit and Component Weight in lbs.

Unit Weights

Basic Configuration

SWP basic unit

Filters

4" 30% or 65% efficiency 38 38 38 55 55 66 66 79 87 96 104 112

Evaporator Coil

6 Row, 12 fpi 250 294 321 417 468 506 577 642 693 755 819 926

4 Row, 12 fpi 206238257333368395------

Water Economizer Coil

4 Row, 12 fpi 306 338 357 458 493 520 598 648 678 723 820 927

Water weight 51 66 75 94 111 119 150 168 187 203 218 281

Hot Water Coil

1 Row, 12 fpi 71 97 114 130 158 160 170 200 328 337 345 371

Water weight 16 20 23 28 32 37 41 49 55 59 62 62

Electric Heat

34 KW 2020202020------68 KW -----40404040404040

Supply Fan Motors

3 HP ODP 71------ ---5 HP ODP 82------ ----

7.5 HP ODP 124124----- -- -10 HP ODP 144 144 144 144 - - - - - - 15 HP ODP - 185 185 185 185 185 - - - - 20 HP ODP - - 214 214 214 214 214 214 214 - - 25 HP ODP - - - - 266 266 266 266 266 266 - 30 HP ODP - - - - - 310 310 310 310 310 310 40 HP ODP ------404404404404404404

50 HP ODP ------- -452452452

60 HP ODP ------- --620620

75 HP ODP ------- ---836

3 HP TEFC 72------ ---5 HP TEFC 85------ ----

7.5 HP TEFC 140140----- ---10 HP TEFC 170 170 170 170 - - - - - - 15 HP TEFC - 235 235 235 235 235 - - - - 20 HP TEFC - - 300 300 300 300 300 300 300 - - 25 HP TEFC - - - - 330 330 330 330 330 330 - 30 HP TEFC - - - - - 390 390 390 390 390 390 40 HP TEFC ------510510510510510510

50 HP TEFC ------- -570570570

60 HP TEFC ------- --850850

75 HP TEFC ------- ---900

Compressor/Condens e r As sembly

(2)6HP 26 368------ ---(3)6HP 35 538538----- ---(4)6HP 43 699 699 699 699 - - - - - - (3)6HP, (1)10HP 57 - 843 843 843 843 - - - - - (2)6HP, (2)10HP 66 - - 974 974 974 - - - - - (1)6HP, (3)10HP 74 - - - 1115 1115 - - - - - (4)10HP 95 - - - 1263 1263 1263 1263 1263 - - - (2)10HP, (2)13HP 106 - - - - - 1404 1404 1404 - - - (4)13HP 118 - - - - - 1549 1549 1549 1549 - - (2)13HP, (2)15HP 129 - - - - - 1709 1709 1709 1709 1709 1709 (4)15HP 141 - - - - - 1867 1867 1867 1867 1867 1867 (2)15HP, (2)20HP 152 -------198219821982 1982 (4)20HP 190 ------- -2096 2096 (6)13HP 167 ------- --22652265

(3)13HP, (3)15HP 178 ------- --24792479

(6)15HP 188 ------- --26932693

(3)15HP, (3)20HP 209 ------- --29142914

(6)20HP 229 ------- --31353135

Discharge Plenum

Factory Installed, 29” 636 636 636 711 711 862 862 862 922 1003 1064 1064

a. Base Weight includes supply fan without motor.

b. Water economizer weight includes valves and piping.

c. The values in this table do not include water weight.

d. Hot water coil weight includes valve and piping.

a

b c

d

c

Water Weight

018 023 028 035 040 045 055 065 070 080 095 105

2226 2313 2318 2638 2643 3110 3279 3406 3734 4021 4246 4673

Unit Size

IM708 13

Field Wiring

General

Wiring must comply with all applicable codes and ordinances. Warranty is voided if wiring is not in accordance

with specifications. An open fuse indicates a short, ground or

overload. Before replacing a fuse or restarting a compressor

or fan motor, the trouble must be found and corrected. Copper wire is recommended for all power lead terminations.

Contact factory for information concerning aluminum wire

power lead terminations.

A single power terminal block is provided as standard and

wiring within the unit is done in accordance with the

National Electric Code. All branch circuits within the control

panel are individually fused. A single field supplied disconnect is required or a unit mounted nonfused disconnect can

be ordered with the unit.

A 7/8” knockout is located on the right-hand unit upright for

locating unit power entry. 24V field connections are suitable

for Class II wiring.

Unit Disconnect

Disconnecting means are addressed by Article 440 of the

National Electric Code (NEC) which requires 'disconnecting

means capable of disconnecting air conditioning and refrigerant equipment including motor-compressors, and controllers, from the circuit feeder." The disconnect switch should

be selected and located within the NEC guidelines. Location

requirements per NEC are that the disconnect be located in a

readily accessible position within sight (50 feet) of the unit.

A factory mounted nonfused disconnect is available.

Table 7. Compressor Motors

Compressor

HP

6

10

13

15

20

208/60/3 230/60/3 400/50/3 460/60/3 575/60/3

RLA LRA RLA LRA RLA LRA RLA LRA RLA LRA

17.9 156.0 16.2 156.0 8.1 70.0 8.1 70.0 6.5 54.0

31.2 239.0 28.2 239.0 14.1 125.0 14.1 125.0 11.3 80.0

35.6 350.0 32.0 350.0 16.0 158.0 16.0 158.0 12.8 125.0

42.1 425.0 38.0 425.0 19.0 187.0 19.0 187.0 15.2 148.0

74.0 360.0 67.2 360.0 33.6 180.0 33.6 180.0 36.9 144.0

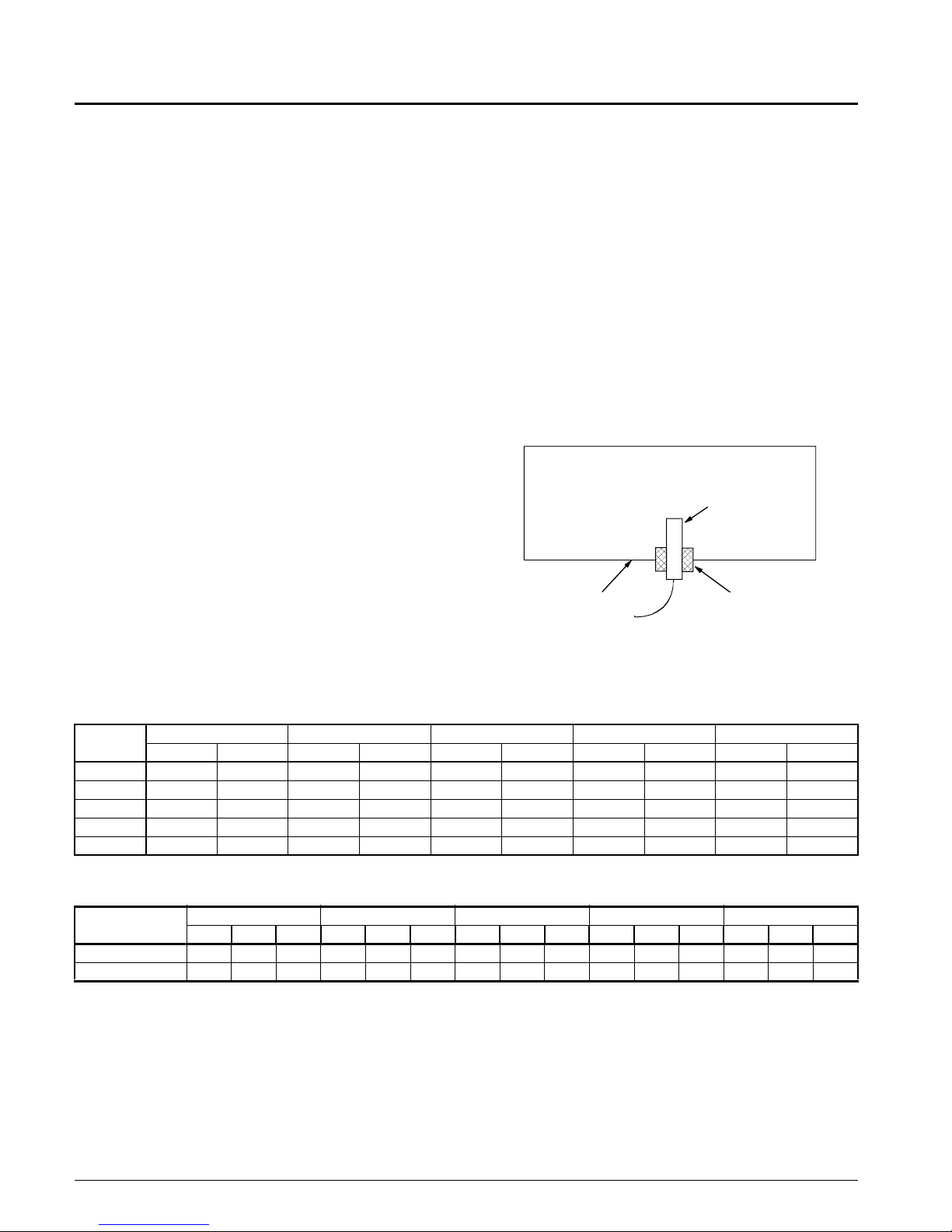

Return Air and Outside Air Sensors

All units are provided with a return air sensor. The outside

air sensor is optional and can be ordered with the unit. The

return air sensor is connected to the input control board and

is coiled up and placed in the control box of the unit for shipment. The return air sensor must be field installed in the

return air stream for proper unit operation. The outside air

sensor is shipped loose in a package and is located on the

floor of the fan section. The mixed air temperature sensor is

already installed at the inlet of the unit.

The sensors must be mounted in areas that are exposed to

representative temperature conditions. The sensor should be

mounted at a position that has good air mixing and does not

have stratification. The sensor can be mounted in the ductwork using a grommet, see Figure 18.

Figure 18. Return/Outside Air Sensor Mounting

Sensor

Ductwork

The return air sensor is connected to the unit’s input board at

location AI4, see IM710. The outside air sensor is field

wired to terminal strip TB2. The sensor is to be connected at

terminals 124 and 125.

Grommet

Table 8. Electric Heaters

SWP UNIT SIZE

018 - 040

045 - 105

14 IM708

208V/60HZ/3PH 230V/60HZ/3PH 400V/50HZ/3PH 460V/60HZ/3PH 575V/60HZ/3PH

kW MBH FLA kW MBH FLA kW MBH FLA kW MBH FLA kW MBH FLA

27.8 94 77.2 34 116 85.6 25.7 88 37.2 34 116 42.8 34 116 34.2

55.6 190 154.4 68 232 170.9 51.4 175 74.4 68 232 85.6 68 232 68.4

Table 9. SAF Motor Nameplate Amp Table

Horsepower TYPE

3

5

7.5

10

15

20

25

30

40

50

60

75

a. 460/60/3 motors are used. Derate nameplate horsepower to 0.83 to obtain actual horsepower.

High Efficiency 9.9 9.0 4.5 4.5 3.4

Premium Efficiency 9.3 8.2 4.1 4.1 3.1

High Efficiency 14.8 14.0 7.0 7.0 5.3

Premium Efficiency 15.7 13.6 6.8 6.8 5.2

High Efficiency 22.3 21.6 10.8 10.8 8.2

Premium Efficiency 22.3 20.0 10.0 10.0 7.4

High Efficiency 29.7 28.0 14.0 14.0 11.0

Premium Efficiency 29.0 25.8 12.9 12.9 10.3

High Efficiency 44.4 40.6 20.3 20.3 16.2

Premium Efficiency 43.4 37.8 18.9 18.9 14.1

High Efficiency 57.0 50.0 25.0 25.0 20.0

Premium Efficiency 57.0 49.0 24.5 24.5 18.9

High Efficiency 69.8 62.0 31.0 31.0 24.3

Premium Efficiency 70.5 61.0 30.5 30.5 24.2

High Efficiency 86.5 75.0 37.5 37.5 30.0

Premium Efficiency 83.3 72.4 36.2 36.2 29.8

High Efficiency 117.0 102.0 51.0 51.0 40.0

Premium Efficiency 110.0 96.0 48.0 48.0 38.0

High Efficiency 138.0 124.0 62.0 62.0 49.2

Premium Efficiency 137.0 120.0 60.0 60.0 47.5

High Efficiency 154.0 144.0 72.0 72.0 57.4

Premium Efficiency 159.0 140.0 70.0 70.0 56.0

High Efficiency 189.0 176.0 88.0 88.0 71.0

Premium Efficiency 195.0 170.0 85.0 85.0 65.5

208/60/3 230/60/3

FLA FLA FLA FLA FLA

400/50/3

a

460/60/3 575/60/3

IM708 15

Supply Power Wiring

1. Units require three-phase power supply.

2. Allowable voltage tolerances:

a. 60 Hertz

Nameplate 208V: Min.187V, Max. 229V

Nameplate 230V: Min.207V, Max. 253V

Nameplate 460V: Min.414V, Max. 506V

Nameplate 575V: Min.518V, Max. 632V

b. 50 Hertz

Nameplate 400V: Min. 342V, Max. 418V

3. Power lead wire sizing:

a. For units with cooling capability (all concurrent loads)

with or without hot water heating and circuits with

motor loads only:

MCA = 1.25 (largest motor RLA or FLA) + other loads

+ 2 amps.

b. For units with cooling capability and nonconcurrent

electric heat capability:

Lug Sizes For Single Disconnect or

Power Block

Table 10. Single Disconnect

UNIT VOLTAGE SIZE (AMPS)

018-028

018-028

018-028

035-040

035-040

035

040

045

045

045

055-070

055-070

055-070

080-095

080-095

080-095

095-105 (6 Comp)

095-105 (6 Comp)

095-105 (6 Comp)

a. Disconnect is 250 amps with electric heat.

Table 11. Lug Sizes For Single Disconnect

208/230 225

400/460 100

575 100

208/230 225

400/460 150

575 100

575 150

208/230 400

400/460

575 150

208/230 400

400/460 250

575 150

208/230 600

400/460 250

575 250

208/230 N/A

400/460 250

575 250

150

a

In the cooling mode, the loads will be composed of supply fan motor and compressors. In heating mode, the

loads will be composed of supply fan motor and electric

heater. The MCA is calculated for unit running in either

mode; the highest value obtained is used for the MCA.

(1)For unit in cooling mode:

MCA = 1.25 (largest RLA or FLA) + other loads + 2

amps.

(2)For unit in heating mode:

MCA = 1.25 (electric heat FLA + Fan FLA) + 2 amps.

4. Size wires in accordance with T able 310-16 or 310-19 of

the National Electrical Code.

5. Wires should be sized for a maximum of 3% voltage

drop.

DISCONNECT SIZE LUG SIZE

100

150

225

250

400

600

#6-2/0

#2-3/0

#3-300 MCM

#4-350 MCM

250 MCM-500 MCM

250 MCM-350 MCM

Table 12. Lug Sizes For Power Block

UNIT VOLTAGE LUG SIZE

018-045

055-105

055-105

Note: Use copper wire only.

ALL #6-400 MCM

400/460/575 #6-400 MCM

208/230 1/0-600 MCM

16 IM708

Control Center

All electrical controls are enclosed in a central control center

located at the front of the unit. The control center is divided

into two separate compartments, high and low voltage. The

lower compartment houses the high voltage components and

can be accessed through the “Electrical Access" panels indicated on the dimensional drawing. Behind these access panels are hinged dead front panels for further operator safety.

High voltage components include:

1. Fan Motor Contactor, M30

2. Fan Motor Overload, OL10

3. Fan Motor Fuse, FB10

4. Compressor Contactors, M1-M6

5. Compressor Fuses, FB1-FB6

6. Electric Heat Contactors, M11-M16

7. Transformer, T1, T2, T3

8. Disconnect Switch, DS1-DS2

9. Power Block, PB1-PB2

Figure 19. Typical Control Center Layout

High and Low Voltage Compartments

LonMark Communication Card

BACNet Communication Card

If the optional disconnect switch is provided, the switch handle is visible and accessible without removing any safety or

access panels.

Low voltage components are located in the upper left compartment, and include:

1. MicroTech II Main Control Board, MCB

2. Duct Static Pressure Sensor, SPS1

3. Optional 2nd Duct Static Pressure Sensor, SPS2

4. Optional BACNet Ethernet Communication Card,

5. Optional BACNet MSTP Communication Card,

6. Optional LonMark Communicati on Card,

7. Compressor Control Board, CCB #1

8. Compressor Control Board, CCB #2

(6 compressor units only)

Located on the face of the unit is the interactive MicroTech

II keypad/display, unit switch, system indicator light and

power indicator.

Note: IM710 has additional layout of the control center.

Phase Voltage

Monitor

Power Block

Disconnect Switch

(Optional)

Adjustable Frequency

Drive (Optional)

IM708 17

Transformer, Control Output, 24V, T3

Transformer, Control Output, 24V, T2

Duct Static Pressure Sensor

Transformer, Main Control, 115V, T1

Electrical Legend

Designation Description Standard Location Designation Description Standard Location

ACT1 ACTUATOR,VARIABLE INLET VANES SUPPLY FAN SEC-

ACT2 ACTUAT OR,BYPASS VALVE CONDENSER VALVE OAT OUTSIDE AIR TEMP. SENSOR EXTERNAL

ACT3 ACTUATOR,WATERSIDE ECONOMIZER WATERSIDE ECONO

AFD10 ADJUST.FREQUENCY DRIVE--SUPPLY FAN MAIN CONTROL PB1 POWE R BL OCK--TOTAL UNIT OR

CCB1,2 COMPR CONTROL BOARDS--REFRIG. CIR-

CUITS

COMPR#1-6 COMPRESSORS #1--6 COMPRESSOR SEC-

DAT DISCHARGE AIR TEMP. SENSOR NEAR FAN INLET PC7 PRESSURE CONTROL--PROOF AIRFLOW FAN SECTION

DHL DUCT HI-LIMIT FAN SECTION PM1 PHONE MODEM MAIN CONTROL

DS1 DISCONNECT--TOTAL UNIT OR COND/HEAT MAIN CONTROL PSR1,2 PRESSURE SENSOR,REFRIGERANT LIQ. SHUTOFF

DS2 DISCONNECT--SAF/RAF/CONTROLS MAIN CONTROL PVM1 PHASE VOLTAGE MONITOR MAIN CONTROL

EWT ENT. COND. WATER SENSOR COND. WATER INLET PVM2 PHASE VOLTAGE MONITOR MAIN CONTROL

F1 FUS E--CONTROL CIRCUIT MAIN CONTROL R11 RELAY--ELECTRIC HEAT STAGE 1 HW/S

FB10 FUSEBLOCK--SUPPLY FAN MAIN CONTROL R12 RELAY--ELECTRIC HEAT STAGE 2 HW/S

FB11,12 FUSEBLOCKS--ELECTRIC HEAT MAIN CONTROL R1-6 RELAYS--HI-PRESSURE MAIN CONTROL

FB1--6 FUSEBLOCKS--COMPRESSOR #1-6 MAIN CONTROL R18 RELAY--COOL ENABLE MAIN CONTROL

FB8 FUSEBLOCK--MAIN TRANSFORMER MAIN CONTROL R67 RELAY--ENABLE SUPPLY FAN MAIN CONTROL

FP1-6 FROST PROTECTION--REFRIG. CIRCUITS EVAP. COIL RAE RETURN AIR ENTHALPY EXTERNAL

FS1 FREEZESTAT CONTROL BT/DT COIL RAT RETURN AIR TEMP. SENSOR EXTERNAL

GRD GROUND ALL CONTROL BOX S1 SWITCH--SYSTEM ON/OFF MAIN CONTROL

HL13-14 HI-LIMITS, PWR, ELEC HEATERS ELECTRIC HEAT

HP1-6 HI-PRESSURE CONTROLS, REFRIG ON COMPRESSORS

HTR-11,12 ELECTRIC HEATERS DX COIL S8 SWITCH--COOL ENABLE MAIN CONTROL

HTR-15,16 ELECTRIC HEATERS DX COIL S9 SWITCH--HEAT MAIN CONTROL

HTR1-6 CRANKCASE HEATERS ON COMPRESSORS

HUM1 HUMIDSTAT SENSOR EXTERNAL SD2 SMOKE DETECTOR--RETURN FAN EXTERNAL

LP1-6 LO-PRESSURE CONTROLS, REFRIG ON COMPRESSORS

LWT LEAVING COND. WATER SENSOR COND. WATER OUT-

M10 CONTACTOR--SUPPLY FAN MAIN CONTROL T2 TRANSFORMER--CONTROL INPUT 24V MAIN CONTROL

M11,12 CONTACTORS--ELECTRIC HEAT CONTROL M AIN CONTROL T3 TRANSFORMER--CONTROL OUTPUT 24V MAIN CONTROL

M13,14 CONTACTORS--ELECTRIC HEAT SAFETY MAIN CONTROL TB10 TERMINAL BLOCK-- MAIN CONTROL

M15,16 CONTACTORS--ELECTRIC HEAT CONTROL MAIN CONTROL TB2 TERMINAL BLOCK--24V-FACTORY/FIELD MAIN CONTROL

M1-6 CONTACTORS--COMPR#1-6 MAIN CONTROL TB3 TERMINAL BLOCK--24V- MAIN CONTROL

M17,18 CONTACTORS--ELECTRIC HEAT SAFETY MAIN CONTROL TB4 TERMINAL BLOCK--24V-COMPRESSOR MAIN CONTROL

M30 CONTACTOR--INVERTER BYPASS MAIN CONTROL TB5 TERMINAL BLOCK--115V-FACTORY/FIELD MAIN CONTROL

MAT MIXED AIR TEMP SENSOR BEHIND FILTERS TB6 TERMINAL BLOCK--115V/24V FACTORY MAIN CONTROL

MCB1 MICROPROCESSOR CIRCUIT BOARD #1 MAIN CONTROL TB8 TERMINAL BLOCK-- MAIN CONTROL

MJ MECHANICAL JUMPERS ON TEMINAL

MP1-6 MOTOR PROTECTOR--COMPR#1-6 ON COMPRESSORS

NB1 NEUTRAL BLOCKS MAIN CONTROL WF1 CONDENSER WATER FLOW SWITCH NEAR CONDENSER

TION

VALVE

MAIN CONTROL PB2 POWER BLOCK--SAF/RAF/CONTROLS MAIN CONTROL

TION

JCT.BOX

#1-6

#1-6

#1-6

LET

BLOCKS

#1-6

OAE OUTSIDE AIR ENTHALPY EXTERNAL

OL10 OVERLOAD RELAY--SUPPLY FAN MAIN CONTROL

COMPR/HEAT

PC5 PRESSURE CONTROL--CLOGGED FILTER FAN SECTION

CLOSE

OPEN

S4,5 SWITCHES--INVERTER BYPASS MAIN CONTROL

S7 SWITCH--LOCAL ON/OFF TO CONTROLLER MAIN CONTROL

SD1 SMOKE DETECTOR--SUPPLY FAN EXTERNAL

SPS1,2 STATIC PRESSURE SENSORS--DUCT/BLDG MAIN CONTROL

T1 TRANSFORMER--MAIN CONTROL

(LINE/115V)

VM1 VALVE MOTOR #1--HEATING NEAR HOT WA T ER

VM5 VALVE MOTOR #5--COOLING NEAR CHILLED

ZNT1 ZONE TEMP. SENSOR--SETBACK FIELD INSTALLED

MAIN CONTROL

VALVES

MAIN CONTROL

MAIN CONTROL

MAIN CONTROL

INLET

WATER

1.

2.

3.

4.

5.

6.

7.

8.

9.

18 IM708

200

M/J

FIELD WIRING

TERMINA L

FIELD WIRING TERMINAL

TERMINAL P.C. BOARD FACTORY WIRED

WIRE NUMBER

WIRE CONNECTOR

OPTION BLOCK

PLUG IN CONNECTOR

MECHANICAL JUMPER

Typical Wiring Schematics

Figure 20. Power Schematic

IM708 19

Figure 21. Input Schematic, Discharge Air Control (DAC)

20 IM708

Figure 22. Input Schematic, Zone or Space Comfort Control (SCC)

IM708 21

Figure 23. Output Schematic, Actuator Control

22 IM708

Figure 24. Output Schematic, Auxiliary Fan Start/Stop Control

IM708 23

Figure 25. Output Schematic, Actuator Control

24 IM708

Figure 26. Output Schematic, Compressor Control (4 Compressors/4, 5 or 6 Stage)

IM708 25

Figure 27. Output Schematic, Compressor Control (6 Compressors / 6 Stage)

26 IM708

Standard Controls

High Pressure Switches

The high pressure switch (HP1-HP6) is a single pole pressure activated device that opens on a pressure rise. When the

switch opens it de-energizes the compressor circuit, shutting

down the compressor. The MicroTech II controller will display an alarm condition. Once the cause of the fault has been

identified and corrected, the unit may be manually reset

through the MicroTech II keypad/display interface. The control is attached to a Shrader fitting and is located at the compressor. To check the control, shut off water flow to the

condensers and observe the cutout point on a high pressure

gauge. The high pressure control should open at 360 psig

and close at 300 psig. After testing the high pressure control,

check the pressure relief device for leaks.

Low Pressure Switches

The low pressure switch (LP1-LP6) is a single pole pressure

activated device which closes on a pressure rise. It senses

evaporator pressure and is factory set to close at 60 psig and

open at 35 psig. Compressor operation is not allowed until

the switch closes. The low pressure switch is an automatic

reset control. If the condition occurs on any one compressor

three times in a 24-hour period, the alarm will have to be

manually reset through the MicroTech II keypad/display

interface to restart the compressor. The low pressure switch

is attached to a Shrader fitting and is located at the compressor.

Compressor Motor Protector

All compressors are thermally protected. All 13 horsepower

and larger compressors use a solid state protection device

(MP1 - MP6) located in the compressor junction box. Whenever the protection system opens the compressor is shut

down for a period of 36 minutes and an alarm indication is

made at the MicroTech II controller.

All 6 and 10 horsepower compressors have in-line protection. The control automatically resets when the alarm condition is removed and the time delay is satisfied.

If the condition occurs on any one compressor three times in

a 24-hour period, the alarm will have to be manually reset

through the MicroTech II keypad/display interface to restart

the compressor.

Proof of Airflow Switch

A positive proof of airflow switch (PC7) is provided with all

units. The switch is factory set to close at 0.2 inches of water

column. The switch has a field adjustable set point range of

0.17 to 5.0 inches of water column. Turn adjustment screw

clockwise to decrease differential pressure setting. Turn

adjustment screw counterclockwise to incre ase differential

pressure setting. In a constant volume system, if the fan system is energized and the minimum pressure setting of the

switch has not been reached, the unit will be shut down and a

loss of airflow alarm indicated at the MicroT ech II controller .

For variable air volume units, the unit will shutdown due to

loss of airflow only if the airflow switch is open AND the

duct static pressure is less than half the duct static pressure

setpoint. Once the reason for the fault has been corrected, the

unit can be manually reset through the MicroTech II keypad/display interface. PC7 is located in the fan section on the

motor side.

Frost Protection Switches

A frost protection switch (FP1-FP6) is used on each refrigerant circuit to protect against evaporator coil freeze up. The

frost protection switches are normally closed and open on a

drop in temperature. When a frosting condition is sensed the

compressor circuit is shutdown until the condition has been

removed. The frost protection control is an automatic reset

control. If the condition occurs on any one compressor three

times in a 24 hour period, the alarm will have to be manually

reset through the MicroTech II keypad/display interface to

restart the compressor. The MicroTech II control wi ll in dicate a warning when a frost condition exists. The temperature sensors are located on a return bend for each refrigerant

circuit.

Clogged Filter Switch

A clogged filter switch (PC5) is provided to indicate when

unit filters are to be changed. The switch is factory set to

close at 0.6 inches of H

set point range of 0.17 to 5.0 inches of H

screw clockwise to decrease differential pressure setting.

Turn adjustment screw counterclockwise to increase differential pressure setting. When the filter pressure differential

exceeds the switch setpoint, a clogged filter indication is

made at the MicroTech II controller. The unit is allowed to

continue operation. PC5 is located in the fan section on the

motor side.

O. The switch has a field adjustable

2

O. Turn adjustment

2

IM708 27

Unit Options

Duct High Limit

A duct high limit (DHL) pressure control is provided as standard with all units having variable air volume control. The

duct high limit is intended to protect the ductwork, etc. from

over pressurization caused by tripped fire dampers or a control failure. When the duct pressure exceeds the setting of the

control, the unit is de-energized via the MicroTech II controller and an alarm condition indicated. After the reason for

trip has been identified and corrected, the control can be

reset via the MicroTech II keypad/display interface.

The duct high limit is factory installed including sensing tubing, and preset for a 3.0" wc trip point. The control can be

readjusted in the field to match the specific ductwork of a

project. The switch has a field adjustable set point range of

0.17 to 5.0 inches of H2O. Turn adjustment screw clockwise

to decrease differential pressure setting. Turn adjustment

screw counterclockwise to increase differential pressure setting. DHL is located in the fan section on the motor side.

Phase Fail/Under Voltage Protection

The monitor is a microprocessor controlled device which

provides protection against three-phase electrical motor loss

due to low voltage, phase loss, voltage unbalance and phase

reversal. The microprocessor constantly monitors the threephase line voltages and detects these harmful power line

conditions. Whenever any of these conditions occur, the

SWP controls are deactivated and remain deactivated until

power line conditions return to an acceptable level. Trip and

reset delays have been provided to prevent nuisance tripping

due to rapid power fluctuations. The trip and reset delays are

field adjustable. The monitor also provides a variable line

voltage adjustment.

3. The sensing tube should be located in a nonturbulent

flow area of the duct. Keep several duct widths away

from take-off points, bends or neck downs.

Mounting instructions (See Figure 28)

1. Drill hole in duct at remote sensing point and install a

rubber grommet. Insert sensing tube 1/8" into the duct

and securely clamp tubing to the duct, being sure not to

stress or kink the tubing. The end of the sensing tube

must be smooth and cut straight across. An angle cut

will affect operation.

2. Clamp a second tube to the outside of the duct at the

location of the sensing point.

3. Run both tubes along the ductwork and back to the unit.

The tubing may be routed to the pressure sensor (SPS1)

by drilling two holes through the unit upright post. A

grommet must be used at each hole to protect the tubing

and seal the cabinet.

Note: To avoid confusion between "high" and "low" tubing,

it is recommended that two different tubing colors be

used and that this information be recorded, along with

the sensing point location, on the master building blueprints.

4. Connect tubing to the high and low ports on the sensor.

Figure 28

Duct Static Pressure Sensor

All units provided with variable air volume control include a

factory mounted static pressure sensor (SPS1). The unit can

also have an optional second static pressure sensor, SPS2.

The sensor is factory wired and requires field installation of

1/4" I.D. sensor tubing to the selected duct location.

Note: Be sure that tubing complies with local code

requirements. Flame retardant plastic or metal tubing may be required. Carefully select the ductwork

sensing point for the pressure sensor. Improper

location of the sensing point will result in unsatisfactory operation of the entire variable air volume

system. The following guidelines should be adhered

to:

1. Sense near the end of long duct runs to ensure that all

terminal box take-offs along the run will have adequate

static pressure to operate.

2. The end of the sensing tube must be perpendicular to the

airflow in order to sense only static pressure.

28 IM708

Building Static Pressure Sensor

If a unit has direct building static pressure control capability,

static pressure taps must be field installed and connected to

pressure sensor SPS1 in the unit. This sensor is located on

the control panel.

The two static pressure sensing taps must be carefully

located and installed. Improper location or installation of the

sensing taps will cause unsatisfactory operation. Following

are pressure tap location and installation recommendations

for both building envelope and lab, or "space within a

space," pressure control applications. The installation must

comply with local code requirements.

CAUTION

Condenser Water Flow Switch

Fragile sensor fittings. May damage pressure

sensor.

If tubing must be removed from a pressure sensor fitting, use care. Do not wrench the tubing

back and forth to remove or the fitting may break

off.

Building pressurization applications

1. Install a tee fitting with a leak-tight removable cap in

each tube near the sensor. This will facilitate connecting

a manometer or pressure gauge if testing is required.

2. Locate the building pressure (HI) tap in the area that

requires the closest control. Typically, this is a ground

level floor that has doors to the outside.

3. Locate the building tap so that it is not influenced by

any source of moving air (velocity pressure). These

sources may include air diffusers or outside doors.

4. Connect the tube to the 1/4 inch HI fitting on sensor

SPS1. Assure that the sensor does not support the

weight of the tubing; use tube clamps or some other

means.

5. Locate the reference pressure (LO) tap on the roof. Keep

it away from the condenser fans, waIls, or anything else

that may cause air turbulence. Mount it high enough

above the roof so that it is not affected by snow. If the

reference tap is not connected to the sensor, unsatisfactory operation will result.

6. Use an outdoor static pressure top (Dwyer A306 or

equivalent) to minimize the adverse effects of wind.

Place some type of screen over the sensor to keep out

insects. Loosely packed cotton works well.

7. Route the outdoor tap tube out of the main control panel

through a small field-cut opening in the edge of the control wiring raceway cover. Cut this "mouse hole" in the

vertical portion of the edge. Seal the penetration to prevent water from entering. Connect the tube to the 1/4

inch LO fitting on sensor SPS1.

Freezestat

A non-averaging type freezestat (FS1) is available to protect

hydronic coils from subfreezing temperatures. If the unit has

an economizer coil the control is mounted on the entering

face of the economizer coil. If the unit does not have an

economizer coil the control will be mounted on the leaving

face of the hot water coil. Upon sensing a hazardous temperature, the unit will shutdown, open hydronic control valves

and send an alarm indication via the MicroTech II controller.

The freezestat has a field adjustable setpoint range of 35°F to

40°F. The setpoint may be changed by turning the adjustment screw until pointer is opposite the desired cutout point.

The adjustment screw is accessible at the bottom of the control or at the top when the cover is removed.

A pressure differential type flow switch (WF1) is available

to verify flow to the unit condensers before compressor operation is allowed. The flow switch is factory installed in the

unit next to the condenser piping connections. If a loss of

condenser water flow is sensed, the cooling will be locked

out via the MicroTech II controller. When flow is restored,

the unit will automatically reset.

The factory settings for the water flow switch N.O. contacts

are as follows:

Unit Size Close Adj. Open Adj.

Ft. wc Range Ft. wc Range

018D-040D

045D-105D

3.0 +0.0 1.5 +0.5

-0.5 -0.5

4.5 +0.0 3.0 +0.5

-0.5 -0.5

Water Side Economizer

A completely factory installed, piped and controlled water

side economizer system is available on any constant or variable air volume system. Whenever the entering water temperature is more than 3°F (adjustable at the MicroTech II

keypad/display) below the mixed air temperature to the unit,

the control valves modulate to provide cooling directly from

the tower water. The economizer system can be used to provide 100% of the cooling demand or supplement mechanical

cooling by precooling the return air. The economizer system

consists of a water coil and two, two-way control valves. The

unit's MicroTech II controller will modulate the control

valves to satisfy the cooling demand whenever the entering

water is suitable. When the control valves are in the 90%

open position, the unit's compressors will be allowed to be

staged on to satisfy the cooling load. When the entering

water temperature is no longer suitable, the economizer control valve will close and the unit will be on 100% mechanical

cooling.

Two valve control arrangements are available from the factory. The first maintains full flow through the unit condensers at all times. This control arrangement is used for systems

with constant pumping systems. For installations with a variable pumping system, the control valves will be sequenced

such that flow is removed from the unit whenever cooling is

not required. A mechanical clutch is provided on each valve

to manually close or open the valves.

The economizer system is factory piped and the coil takes

advantage of the same drain pan and condensate connection.

Air may be vented from the economizer coil by using the

uppermost clean out plug. The torque requirement for the

cleanout plugs is 10 inch-lb.

IM708 29

Condenser Water, Head Pressure

Control

An optional condenser head pressure control valve is available on units without water side economizer. This option

permits operation with entering water temperatures below

55°F . The valve is a two-way regulating valve controlled via

MicroTech II to maintain refrigerant head pressure .

Variable Inlet Vanes

An optional variable inlet vane assembly is available for

variable air volume applications. The assembly consists of

inlet funnels with integral sets of lever-actuated radial vanes,

one assembly for each side of the fan. The vanes, upon opening, direct air in the direction of wheel rotation.

The vanes rotate 90 degrees from closed to full open in

response to the factory installed actuator motor. The actuator

is controlled by the unit's MicroTech II controller. The inlet

vanes operate in unison and are properly adjusted and tested

before the unit leaves the factory. The start-up contractor

must check the adjustments and retighten all bolts and ball

joints to insure that shipping and handling has not caused

misalignment.

Adjustable Frequency Drive

As an option an adjustable frequency drive (AFD), is available for airflow modulation. A manually activated bypass

contactor is provided to allow system operation in the event

of drive service.

Static pressure is controlled by the unit mounted MicroTech

II controller. Indication of current airflow is available at the

MicroTech II controller. Static pressure is sensed by one or

two factory mounted duct sensors. The installer provides and

installs the sensor tubing from unit mounted sensor(s) to duct

location(s). The static pressure setpoint is keypad adjustable

through the MicroTech II DDC controller.

All variable air volume units include field adjustable duct

high limit safety control to protect ductwork from excessive

duct pressure.

Disconnect Switch

A factory mounted, nonfused main circuit interrupter for disconnecting the main electrical power is available. The switch

is located at the front of the unit on the control panel and is

accessible without unit penetration. The lug size information

is provided in Tables 11 and 12.

Dual Power Supply

The dual power block is an option for the power supply. This

allows the fan motor and control circuit to be isolated from

the compressor circuit. If the unit has the optional electric

heat it will be circuited with the compressors.

Electric Heat

Optional electric heat is available. Heat is controlled by the

unit's MicroTech II unit controller to maintain setpoint. The

heaters are factory installed and wired including branch fusing and all safety controls.

Hot Water Control

A factory mounted, 1 or 2 row hot water coil is available,

with or without factory mounted control valve. The hot

water control valve is controlled by the unit's MicroTech II

controller to provide morning warm-up heat or heat for constant volume application.

30 IM708

System Check, Test and Start

WARNING

Electric shock hazard. Failure to bond the

frame of this equipment to the building electrical ground by use of the grounding terminal provided or other acceptable means may

result in electric shock. Disconnect electric

power before servicing equipment.

General

Only qualified personnel should perform the start-up and

service of this equipment. A representative of the owner or

the operator should be present during start-up to receive

instruction in the operation, care and adjustment of the unit.

To assure proper warranty coverage, the unit must be put

through a check, test and start-up procedure. The completed

check test and start form (supplied with each unit) must be

signed and returned to McQuay International.

Note: Always open power disconnect switch before open-

ing service panels.

Pre Start-up

1. Check that the unit is completely and properly installed

with ductwork connected. Check that all construction

debris is removed and filters are clean.

2. With all electrical disconnects open, check all electrical

connections to be sure they are tight. Although all factory connections are tight before shipment, some loosening may have resulted from shipping vibration.

3. Check all compressor valve connections for tightness to

avoid refrigerant loss at start-up. Although all factory

connections are tight before shipment, some loosening

may have resulted from shipping vibration. Refer to

Table 13 for proper valve torque values.

4. Check tightness of setscrews in bearings, drives, and fan

wheels. If retightening is needed, make certain fan

wheels are centered between the inlet openings and setscrews are torqued per Table 14.

5. Check that the fan rotates freely. Check belt tension and

alignment.

6. Check that the unit condenser water connections and

condensate drain connections have been made.

7. Before attempting to operate the unit, review the control

layout description to become familiar with the control

locations. Review all equipment service literature and

the unit wiring diagrams supplied with each unit.

Review optional controls to determine which are

included in the unit.

8. Make sure that the return air temperature sensor and

optional space temperature sensor, if used, have been

installed in the return air duct and that the wiring terminations have been made at the unit Input Board.

9. Make sure that entering and leaving condenser water

temperature sensors are mounted.

10. Make sure that the optional duct static pressure sensor is

connected to the duct with appropriate tubing. The unit

may have one optional static pressure sensor, SPS1. The

other option would be that or SPS1 and SPS2.

11. Check the voltage of the unit power supply and see that

it is within the ±10% tolerance that is allowed. Phase

voltage unbalance must be within ±2%.

12. Check the unit power supply wiring for adequate

ampacity and a minimum insulation rating of 75°C.

13. Verify that all mechanical and electrical inspections

have been completed per local codes.

14. Open the compressor suction and discharge shutoff

valves until backseated. Always replace valve seal caps.

15. The following must be done only for uni ts with 20 hp

compressors. Making sure unit switch S7 is in the

"OFF" position, throw the main power disconnect to

"ON." This will energize the crankcase heaters. Wait a

minimum of 24 hours before starting up the unit.

Table 13. Valve Torques

COUPLING

NUT SIZE

INCH

1.00 7±1 32±2 55+5

1.25 7±1 32±2 90+10

1.75 7±1 45±3 205+15

GAGE PORT

CAP TORQUE

LBS-FT

STEM CAP

TORQUE

LBS-FT

COUPLING

NUT TORQUE

LBS-FT

Table 14. Setscrew Torque

SETSCREW DIAMETER TORQUE MIN. (FT.-LBS.)

#10 4.3

1/4” 10.0

5/16” 20.0

3/8” 25.0

Start-up

General

All units are factory tested to assure proper operation in the

field.

1. Close disconnect switch with switch S7 in the "OFF"

position. Allow crankcase heaters to operate for 24

hours.

2. Power should now be supplied to the MicroTech II controller and the LEDs on MCB1 should follow the normal startup sequence.

IM708 31

3. Set internal MicroTech II time clock or external time

clock if used.

4. Set cooling setpoint to a value which will assure a full

call for cooling.

5. Start the auxiliary equipment for the installation such as

water pumps, cooling towers, etc.

Fan start-up

1. Place the unit into the "FAN ONLY" mode through the

keypad:

System summary:

Control Mode:

Off

Auto

Heat/Cool

Heat only

Cool only

Fan only

2. Turn switch S7 to "ON". The supply air fan should start

and run.

3. Observe fan rotation. If fan is rotating backward,

reverse two legs of the main unit supply power. Unit

compressors are factory “phased” to match the supply

fan. Do not reverse internal fan motor power leads as

this will result in the compressor being out of phase. If

fan does not run:

a. Check the control circuit fuse F1.

b. Check control transformer fuse FB7.

c. Verify that the fan overload is not tripped.

d. Check the fan motor power fuses.

e. Trace the circuits.

Compressor start-up

With the supply air fan operational, prepare for compressor

operation. Note: The unit is shipped with the refrigeration

service valves closed. Backseat (open) the suction, discharge

and liquid line valves and replace service caps.

Connect service gauges and crack valves off the backseat

position (one turn forward). Verify that the unit has not lost

its refrigerant charge due to shipping damage or leaks. The

20 hp compressor have crankcase heaters that need to be verified they are operating. These should operate at least 24

hours before starting compressors.

1. Set Cooling Control Setpoint, menu 13, to a value which

will assure a call for full cooling.

2. Place unit into the “COOL ONLY” mode through key-

pad/display.

3. If desired, the MicroTech internal control timers can be

reduced to 20 seconds. The amount of time it operates in

this “Fast” mode can be entered through the keypad:

Setup/Service

Timer setting

Service

Note: "Fast" timers should only be used to verify

sequencing of compressors during start-up. The

timer must be returned to "Normal" for proper unit

operation.

Do not allow compressors to come on repeatedly in the

"Fast" timer mode as this may damage compressors and/or

will indicate "Motor Protector Failure" under compressor

alarms.

The compressors should now start. Start compressors one at

a time, beginning with compressor number 1. Facing the

unit, from left to right, compressors are numbered #1, #3, #4

and #2.

If the compressor motor hums but does not run, verify that

the unit is getting three phase power.

The compressors should run continuously. If a compressor

cycles on the low pressure switch:

a. Verify that the circuit is not low on charge.

b. Check for low airflow.

c. Check for clogged filters.

d. Check for restricted ductwork.

e. Check for very low mixed air temperatures to the unit.

f. Verify that all the distributor tubes, expansion valve and

liquid line components are feeding the evaporator coil.

g. Verify that all fan section access panels are in place.

h. Verify that the suction service valves and the liquid line

service valves are completely open.

i. Verify that all sensor inputs are connected.

Economizer start-up

The economizer is modulated to maintain the cooling setpoint. With entering water temperature more than 3°F below

the mixed air return to the unit, place the water sensor in a

cold bath if supply water to the unit is too warm, and the unit

calling for cooling, observe that the economizer control

valve modulates open. Readjust control setting or remove

the sensor from the bath and observe that the economizer

control valve drives closed.

Hot water start-up

The hot water valve is modulated to maintain the discharge

heating setpoint. To verify the hot water valve operation,

adjust the heating setpoint through the keypad:

Temperatures

Zone heating

OCC HTG SPT

Set the heating setpoint to a temperature greater than the

control temperature plus the dead band. Note the cooling setpoint must be higher than the heating setpoint. With the heating setpoint set properly the hot water valve should modulate

open. T o close the hot water valve adjust the heating setpoint

below the control temperature minus the dead band. After

testing the hot water valve, return the heating setpoint to its

proper setting.

Expansion valve superheat adjustment

It is very important that superheat is set properly. It should

be between 10°F and 12°F under full load conditions. Lower

entering air conditions, lower airflow rates and higher condensing temperatures reduce the load on the expansion

valve. Under reduced load conditions, the superheat could be

32 IM708

as low as 6°F to 8°F. Insufficient superheat will cause liquid

floodback to the compressor and possible liquid slugging.

Excessive superheat will reduce system performance and

shorten compressor life. Verify that the sensing bulb is properly located (see Figure 23) and securely strapped to the

refrigerant line. Turn the adjusting stem clockwise to

increase superheat. Adjust the stem (maximum one turn at a