Page 1

Installation & Maintenance Data

IM 368-7

Group: PTAC

Part No.: 106018472

Date: November 2003

Suite™ Incremental

®

PTAC/PTHP Conditioner

©2003 McQuay International

®

Page 2

Table of Contents

Installation ......................................................................... 2

Inspection..........................................................................2

Nomenclature....................................................................3

Wall Opening Requirements .............................................3

Wall Sleeve Installation

Frame & Brick ............................................................4

Panel Wall Construction.............................................5

Thick Wall Construction .............................................6

Wall Sleeve Extension

Louver Frame.............................................................7

Subbase Installation..........................................................8

Installation of Optional Condensate Drain Kit ................... 9

Installation of Louvers .....................................................10

Installation of Chassis .....................................................10

Adjusting Temperature Limiting Device........................... 11

Electrical Service............................................................. 1 1

Equipment Startup .......................................................... 11

Remote Mounted Thermostat ......................................... 12

Scheduled Maintenance .................................................12

Recommended Spare Parts............................................13

Refrigeration Cycle .........................................................13

Troubleshooting Chart...............................................14, 15

Approximate Shipping Weights ....................................... 15

Wiring Diagrams............................................16, 17, 18, 19

Installation

The installation of this equipment shall be in accordance with the regulations of authorities having jurisdiction and all

applicable codes. It is the responsibility of the installer to determine and f ollow the applicable codes. Sheetmetal parts, sel ftapping screws, clips and such items inherently have sharp edges, and it is necessary that the installer exercise caution.

This equipment is to be installed only by an experienced installation company which employs trained personnel.

Inspection

When the equipment is received all items should be carefully

checked against the bill of lading to be sure all crates and

cartons have been received. All units should be carefully inspected

for damage when received. If any damage is noticed, the carrier

should make the proper notation on the delivery receipt acknowledging the damage. The carrier should also fill out a Carrier

Inspection Report. The McQuay International Traffic

Department should then be contacted.

The unit nameplate should be checked to make sure the

voltage agrees with the power supply available.

Suite II Series Comfort Conditioner is designed and built for

through-the-wall installation in either new or existing buildings

The self-contained refrigerant system delivers cooling to the desired space. Heating can be accomplished with electric

resistance, hydronic or with reverse cycle heating options.

Each conditioner consists of the following components:

1. Heating/Cooling Chassis — Shipped separate.

2. Cabinet/Wall Sleeve — Shipped separate.

3. Outdoor Louver — Shipped in a separate carton.

4. Subbase (not shown) — Optional on all 208V and 230V

heat pump and electric heat units. Standard for all 265V

and for hydronic heater option. Shipped in a separate

carton.

Figure 1. Exploded View of Complete Unit (Shown Without Subbase)

IM 368 / Page 2 of 20 (Rev 11/03)

Page 3

MCQUA Y PT AC/PTHP

P DES 1 009 E Z 60

Product Category

P = PTAC

Product Identifier

see box below (Suite)

Design Series

1 = A Design

Nominal Capacity

007 = 7,000

009 = 9,000

012 = 12,000

015 = 15,000

McQuay PTAC/PTHP Product Identifiers

DEA = Suite II, 2 motor, automatic damper

DEC = A/C & Elec/Hyd Htg Chassis w/Corr. Protection

DEH = Suite II, 2 motor, hydronic w/standby

DEI = Suite II, 2 motor, IAQ

DES = A/C & Heating (Elec/Hyd) Chassis

DHA = Suite II, 2 motor, heat pump, automatic damper

DHC = H/P w/ Electric Heat & Corrosion Protection

DHI = Suite II, 2 motor, heat pump, IAQ

DHS = H/P w/ Electric Heat

Heating Options

35 = 2.5 kw

41 = 3.5 kw

48 = 5.0 kw

62 = Hydronic, normally open

63 = Hydronic, normally closed

Coil Options

(None)

Voltage

A = 115 - 60 - 1

C = 208 - 60 - 1

J = 265 - 60 - 1

SEA = A/C w/Electric Heat & Automatic OA Damper

SEC = A/C w/Electric Heat & Corrosion Protection

SEH = A/C w/Hydronic Heat & Standby

(Emergency) Power

SEI = A/C w/Electric Heat & IAQ Power Vent Kit

SES = A/C & Heating (Elec/Hyd) Chassis

SHA = A/P w/Electric Heat & Automatic OA Damper

SHC = H/P w/ Electric Heat & Corrosion Protection

SHI = H/P w/ Electric Heat & IAQ Power Vent Kit

SHS = H/P w/Electric Heat

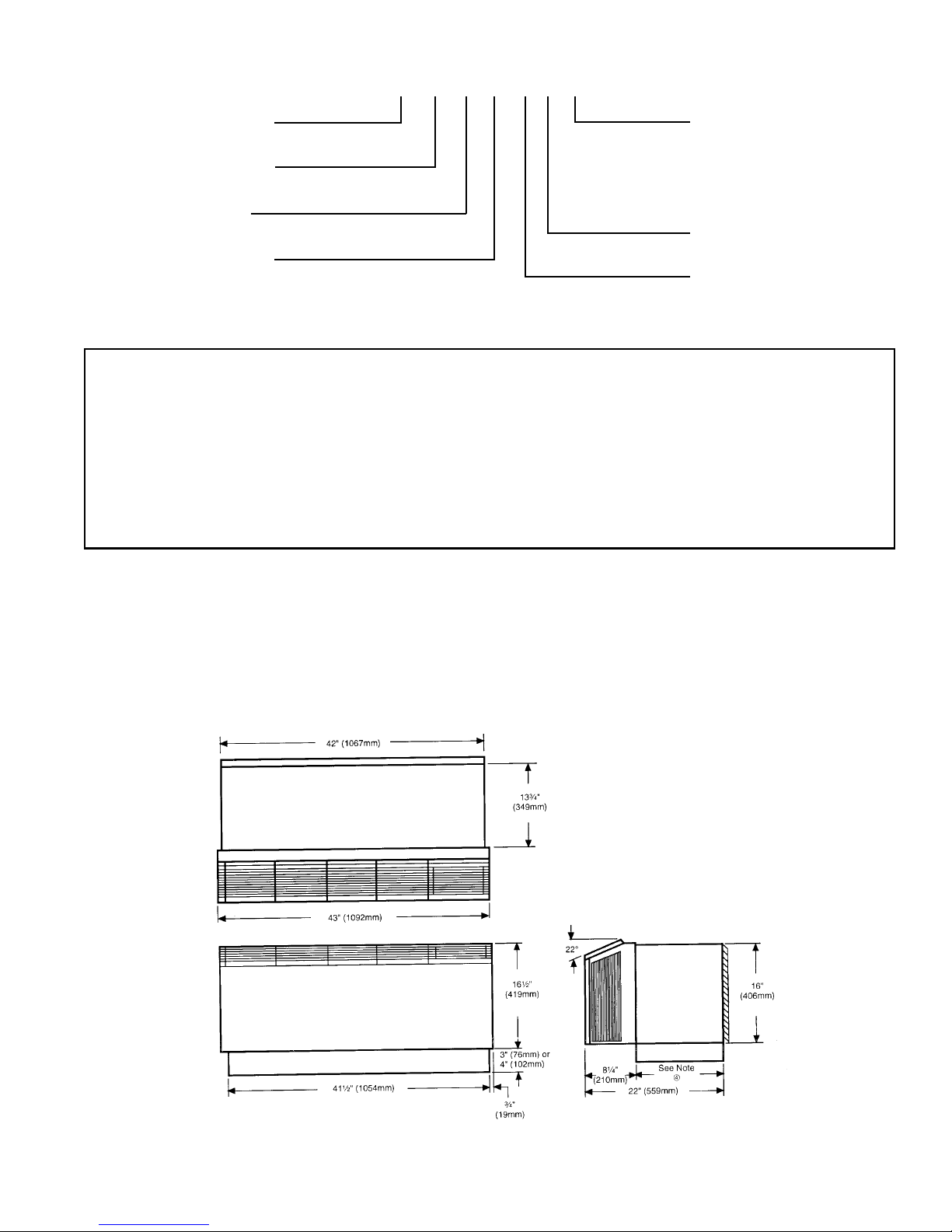

Wall Opening Requirement

Before installing the unit, check the wall opening to be sure the

cabinet/wall sleeve will slide into the opening unobstructed. For

masonry walls, a lintel must be used to provide support over each

opening. The rough opening should measure 16

1

42

/4" (1073mm) wide (see note ➂). When no subbase is used,

the opening should be a minimum of 3" (76mm) off the floor . This

Figure 2. Suite Unit with Electric Subbase

1

/4" (413mm) X

distance may vary when a subbase is supplied. The standard

subbase is available in 3" (76mm) or 4" (102mm) heights. For

units with hydronic heat, the subbase is 81/4" (210mm). Each

subbase has leveling legs providing for up to 1" (25.4mm)

additional height.

Notes:

➀ Unit pictured with subbase installed. Subbase is optional on 208V and 230V units. Subbase is standard on all 265V units and units with hydronic heat.

➁ Subbase extends to front edge of unit when furnished with hydronic heat.

➂ Opening needs to be 16

④ Subbase side channels are adjustable from 43/8" to 133/4" (111mm to 349mm).

5

/8" (422mm) x 425/8" (1083mm) when using a louver frame. See page 7.

IM 368 / Page 3 of 20 (Rev. 11/03)

Page 4

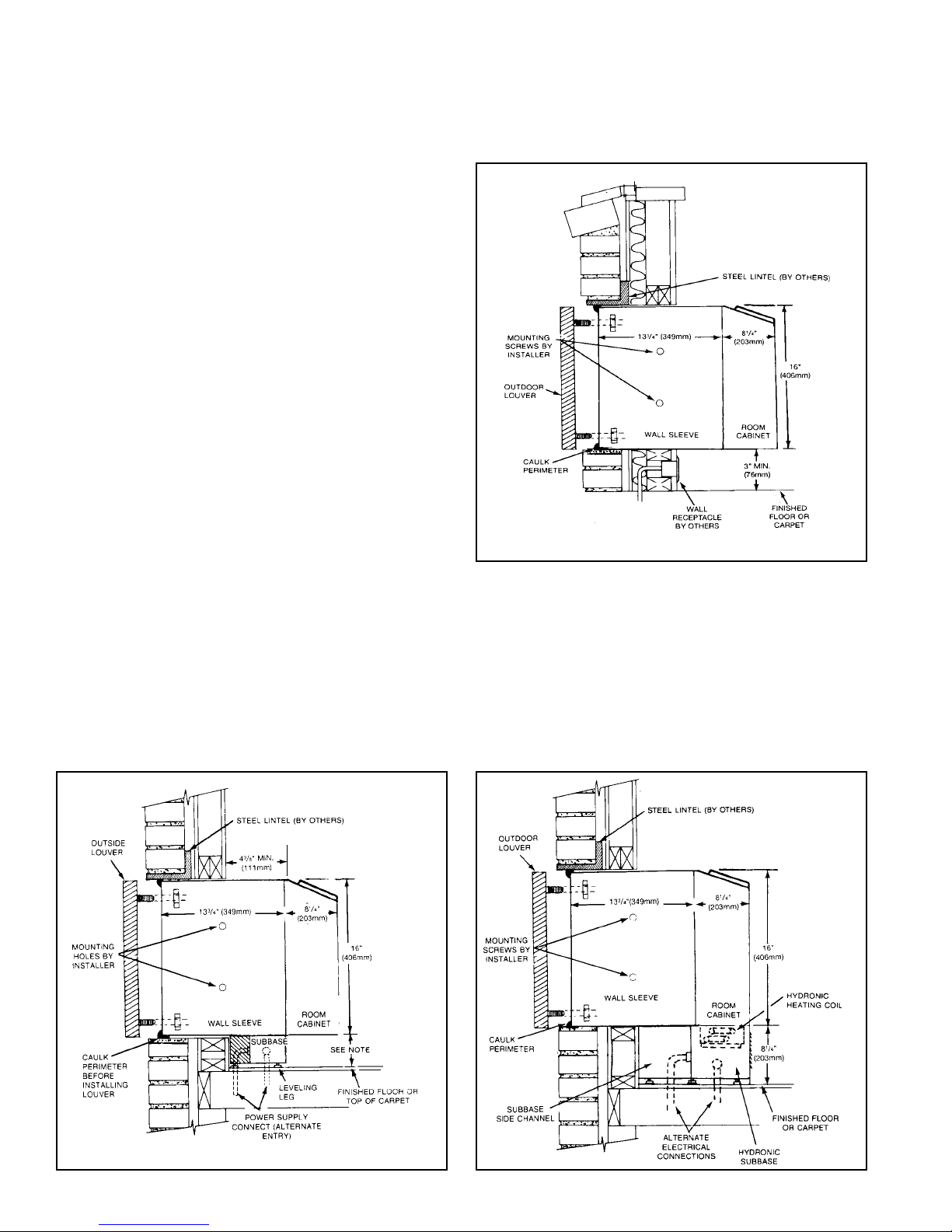

Wall Slee ve Installation — Frame and Brick

A heavy-gauge, corrosion resistant cabinet/wall sleeve is provided for each unit. The cabinet/wall sleeve is either shipped in a separate

carton, shipped in a multi-pack of 15 or in a single carton with the heating/cooling chassis.

The standard cabinet/wall sleeve is designed to be easily installed

in a variety of wall constructions. Note: The center of gravity is

1

10

/4" (260mm) from the rear face of the wall sleeve. The wall

sleeve must be inserted into the wall at least 101/4" (260mm) or

other support must be employed. Support can be from a factory

supplied subbase or from other field supplied materials.

Recommended installation procedures are described below.

1. Clean the opening of all debris that may interfere with

installation.

2. If the unit is to be supplied with a subbase, refer to page 8 for

installation procedures. Install subbase before installing

cabinet/wall sleeve.

3. If the optional drain kit is to be employed (heat pump only),

refer to page 8 before proceeding.

4. Place a thin pad of soft mortar on the bottom of the opening

and slide in the cabinet/wall sleeve. Be sure to recess the wall

sleeve enough to accommodate outside louver. This recess

3

is

/8" (9.5mm) for stamped louvers and 11/4" (32mm) for

architectural louver. Louver should be flush to exterior

surface when complete. Note: The wall sleeve is not intended

to replace the lintel.

5. Level cabinet/wall sleeve in both directions and secure by

anchoring with appropriate fasteners (as shown in Figure C,

page 7). A

5

/16" (8mm) hole is provided on each side, 2" (51mm)

down from the top and 2" (51mm) in from the rear of the

cabinet/wall sleeve. Additional holes may be required to firmly

secure the cabinet/wall sleeve. Caution: Do not drill holes

in the base of the cabinet/wall sleeve. Where a subbase is

used, secure wall sleeve to subbase with clips provided.

6. Caulk the cabinet/wall sleeve to the wall opening on both the

inside and outside perimeter. Be careful not to plug the weep

holes. Caulking should be resilient, non hardening type such

as silicone.

Figure 3. Frame & Brick with Cord Connection

Figure 4. Frame & Brick with Standard Electrical Subbase

IM 368 / Page 4 of 20 (Rev 11/03)

Figure 5. Frame & Brick with Hydronic Subbase

Page 5

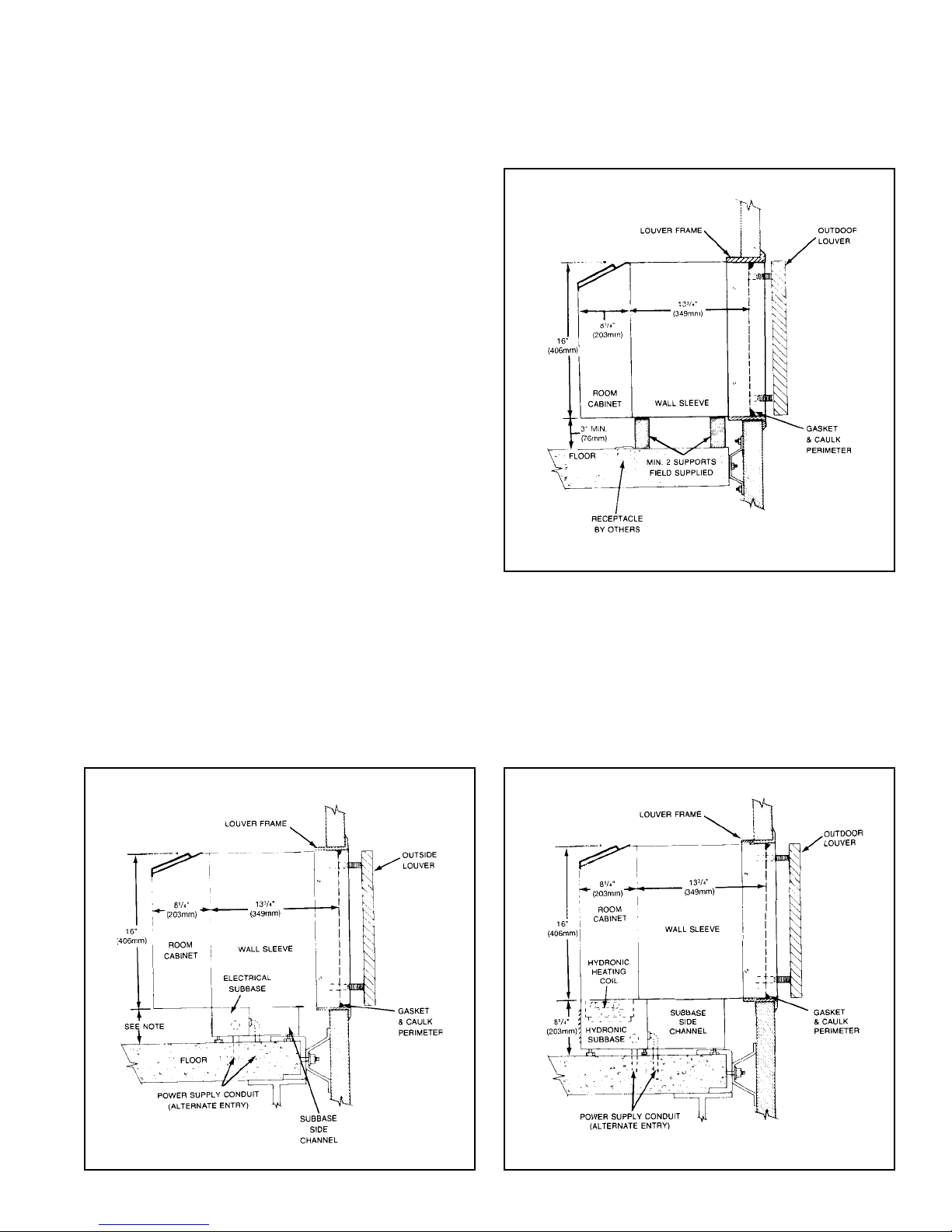

Wall Sleeve Installation — Panel Wall Construction

For panel wall and thin wall construction, it is recommended that a louver frame be used. Refer to page 7 for installaton of louver frame

before continuing.

Panel wall and thin wall construction varies only slightly from frame

and brick construction. Note: The center of gravity is 10

1

/4"

(260mm) from the rear face of the wall sleeve. The wall sleeve

must be inserted into the wall at least 10

1

/4" (260mm) or other

support must be employed. Support can be from a factory supplied subbase or from other field supplied materials. Installation

for this application is as follows:

1. Clean the opening of all debris that may interfere with in-

stallation.

2. If the unit is to be supplied with a subbase, refer to page 8 for

installation procedures. Install subbase before installing cabinet/wall sleeve.

3. If the optional drain kit is to be employed (heat pump only),

refer to page 9 before proceeding.

4. Be sure the cabinet/wall sleeve is mechanically attached to

the wall and caulked to assure a proper seal. It is recommended that the louver frame be used for this purpose. (See

Figure B, page 7.)

5. Recess the wall sleeve so that the louver is flush with the

exterior of the building.

6. Level cabinet/wall sleeve in both directions and secure by

anchoring with appropriate fasteners (as shown in Figure C,

page 7) or drill additional holes as required to secure firmly.

Caution: Do not drill holes in the base of the cabinet/wall

sleeve. Where a subbase is used, secure wall sleeve to sub-

base with clips provided.

7. If no subbase is employed, proper support by installer must

be provided under wall sleeve, as shown in Figure 6.

8. Caulk the cabinet/wall sleeve to the wall opening on both the

inside and outside perimeter. Be careful not to plug the weep

holes. Caulking should be resilient, non-hardening type such

as silicon.

Figure 6. Panel Wall Construction with Cord Connection

Figure 7. Panel Wall Construction with Standard Electrical

Subbase

Figure 8. Panel Wall Installation with Hydronic Subbase

IM 368 / Page 5 of 20 (Rev. 11/03)

Page 6

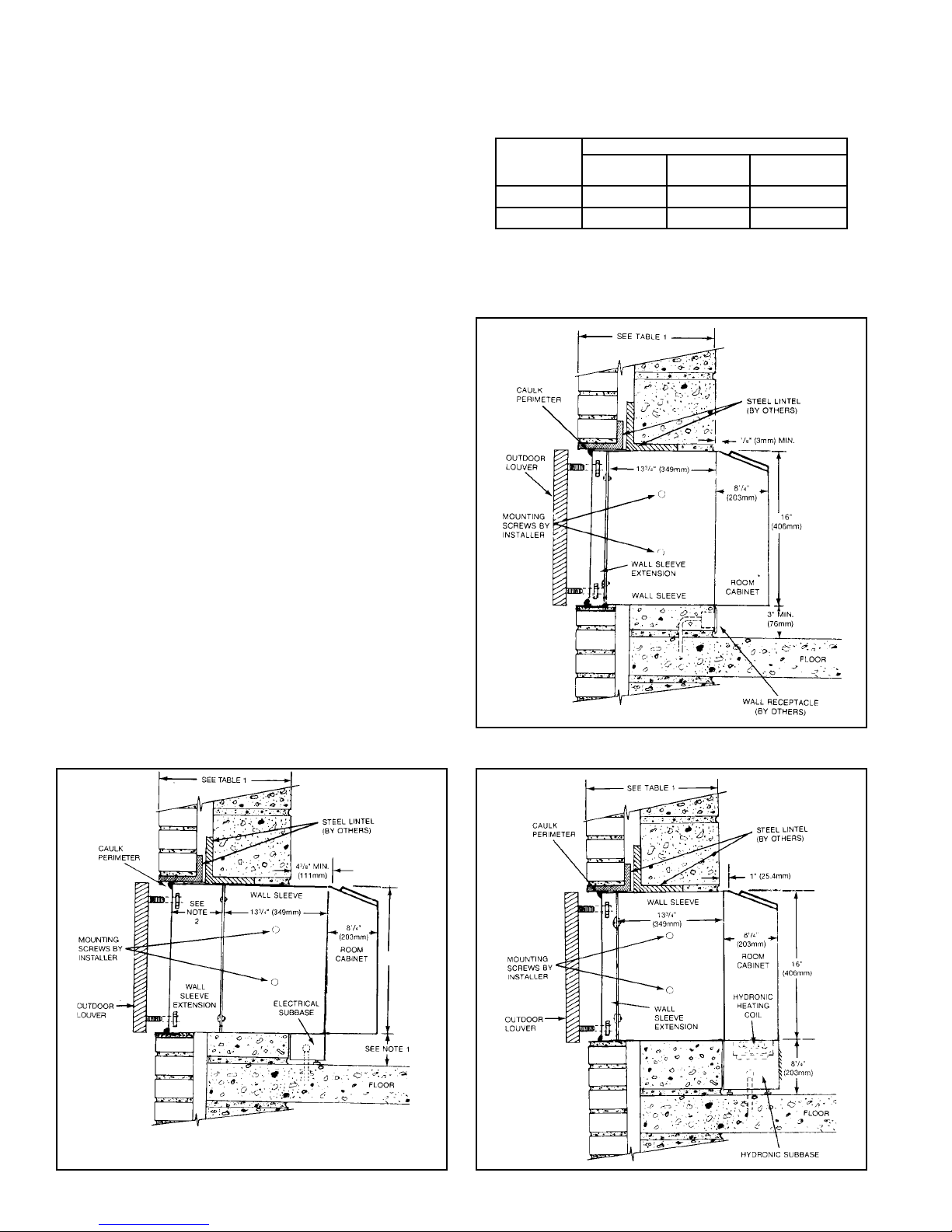

Wall Sleeve Installation — Thick Wall Construction

Installation of cabinet/wall sleeves for thick walls requires special

consideration. Table 1 should be used to determine the

maximum wall thickness allowed for the standard cabinet/wall

sleeve. For thicker walls, cabinet/wall sleeve extensions are

available from your representative. Refer to page 7 for proper

installation of cabinet/wall sleeve extensions.

Cabinet/wall sleeve installation in thick walls is similar to frame

and brick installation. Install as follows:

1. Clean the opening of all debris that may interfere with

installation.

2. If the unit is to be supplied with a subbase, refer to page 8 for

installation procedures. Install subbase before installing

cabinet/wall sleeve.

3. If the optional drain kit is to be employed (heat pump only),

refer to page 9 before proceeding.

4. If wall thickness exceeds dimensions shown in Table 1, a

cabinet/wall sleeve extension must be used. Install the

extension as described on page 7. Once the extension is

attached to the cabinet/wall sleeve, place a thin pad of soft

mortar on the bottom of the opening and slide in the wall

sleeve/extension assembly . Be sure to recess the wall sleeve

3

enough to accommodate outside louver. This recess is

/8"

(9.5mm) for stamped louvers and 11/4" (32mm) for architectural louvers. Louver should be flush to exterior surface when

completed. Note: The wall sleeve is not intended to replace

the lintel.

5. Level cabinet/wall sleeve in both directions and secure by

anchoring with appropriate fasteners (as shown in Figure C,

page 7) or drill additional holes as required to secure firmly.

Caution: Do not drill holes in the base of the cabinet/wall

sleeve. Where a subbase is used, secure wall sleeve to sub-

base with clips provided.

6. Caulk the cabinet/wall sleeve to the wall opening on both the

inside and outside perimeter. Be careful not to plug the weep

holes. Caulking should be resilient, non-hardening type such

as silicone.

Table 1. Maximum Wall Thickness without Sleeve Extensions

Maximum Wall Thickness

Louver Type

Stamped

Architectural

No

Subbase

14" (356mm)

147/8" (378mm)

Standard

Subbase

1

/2" (241mm)

9

3

10

/8" (264mm)

Hydronic

Subbase

1

/8" (333mm)

13

14" (356mm)

Figure 9. Thick Wall Construction with Cord Connection

Figure 10. Thick Wall Construction with Standard Electric

Subbase

Note: 1. Subbase is available in 3" (76mm) or 4" (102mm) height. Leveling legs provide for

adjustment of 1" (25.4mm).

2. Wall sleeve extension is available in various depths and supplied as required.

IM 368 / Page 6 of 20 (Rev 11/03)

Figure 11. Thick Wall Installation with Hydronic Subbase

Page 7

Wall Slee ve Extensions

The standard cabinet/wall sleeve will accommodate a maximum

wall thickness described in T able 1. For thicker walls, cabinet/wall

sleeve extensions are available from your local representative.

When it is supplied by the representative, it is treated for

maximum corrosion resistance and matched to the exact size of

the standard wall sleeve. Field fabricated wall sleeve extensions

should also be treated and matched to the standard wall sleeve.

Be sure to provide air splitters to prevent recirculation of

condenser air. Air splitters should be placed in the wall sleeve as

shown in Figure A. It is important that spacing of the air splitters

match exactly those dimensions shown in Figure A.

Installation

Wall sleeve extensions are shipped in a separate carton and

tagged to match the proper unit. Be sure to check tagging of the

extension against that of the unit. Install the wall sleeve

extension as follows:

1. Position the extension with standard cabinet/wall sleeve so

proper alignment with drain and mounting holes is achieved.

2. Place a bead of caulk around the perimeter of the wall sleeve

and another bead around the mating side of the wall sleeve

extension so that the joint is watertight. Be sure to use a

resilient caulking such as silicone.

3. Assemble the wall sleeve extension to the wall sleeve. Clean

out weep holes to assure proper drainage.

4. Attach indoor drain kit (if used) according to the instructions

on page 9. Outdoor drain kits must be installed after wall sleeve

is in place.

5. Continue wall sleeve installation according to instruction #4

on page 6.

Figure A. Wall Sleeve Extension

Figure B. Louver Frame

Louver Frame

Louver frames should be used for panel wall and thin wall

applications to assure positive anchoring to the wall. Recess the

cabinet/wall sleeve so that the louver is flush with the outside of

the building. Place louver frame around cabinet/wall sleeve as

shown in Figure B. Be careful not to drill holes in the bottom of

the wall sleeve. Secure angles at sides and top of walls.

Anchoring

Anchoring the cabinet/wall sleeve in the opening is accomplished

as shown in Figure C. Be sure not to drill holes in the bottom as it

will cause leaks. It is recommended that rubber isolation washers

be used with the fasteners to minimize sound transmission from

the equipment to the wall, at the point of contact.

Figure C. Anchoring Methods

IM 368 / Page 7 of 20 (Rev. 11/03)

Page 8

Subbase Installation

Electric Subbase

An electrical subbase is optional for all 208V and 230V units. A

subbase is standard for all 265V units. The standard subbase is

available with 3" (76mm) or 4" (102mm) heights. The subbase

contains leveling legs for adjustment of up to 1" (25mm)

additional height. All subbases are factory supplied.

Installation

Install the subbase as follows:

1. If the minimum depth subbase is required, discard the side

extension pieces.

2. If more than the minimum depth is required, determine the

depth of the side extension pieces desired and break at the

Figure 12. Standard (Electric) Subbase

proper score line. Insert the extension pieces into the front

assembly and secure with two short black screws at

each side.

3. Insert leveling bolts into subbase bottom flange. Four (4) bolts

will be needed if side extensions are used. Only two (2) bolts

are required if side extensions are not used.

4. Place the subbase on the floor and align its center line with

the center line of the wall opening. Do not fasten the subbase

to the floor. Attach the subbase to the cabinet wall sleeve

using clips provided with the subbase.

5. The wiring should be roughed in and the conduit connected

to the subbase junction box. Complete the installation by

wiring the receptacle to the incoming power supply .

Electrical

3" x 5"

(76 to 127mm)

Opening for

Electrical and/or

Drain Rough-In

Knockouts for

Opitonal Fuse &

Disconnect Switch

Junction

Box for Main

Power Connection

Receptacle (Req’d

on 265V Units)

Plug/Cord Cover

(Req’d on 265V

Units)

Hydronic Subbase

A subbase is supplied as standard with all hydronic units. This

subbase measures 8" (203mm) in height and includes the

hydronic heating coil. Refer to IM Bulletin 419 for installation

Figure 13. Hydronic Subbase

Receptacle (Factory installed

As Req'd

1

8

3/4"

21/2"

/4"

3" x 5" Opening for Electrical

and/or Piping Rough-in

15"

5

/8" O.D. Copper Sweat

Top View

when fuse & disconnect are

furnished)

21/2"

7

⁄8"

5

⁄8"

3"

21⁄2"

5"

Leveling Screw (4 Places)

Front Elevation (Three Front Panels in Place)

Electrical Knockouts

17"

Plan

411⁄2"

0" to 93⁄8"

43⁄8"

12"

11⁄2"

3"or 4"

0" to 1"

details. In addition, rough in supply and return piping. Electrical

and plumbing rough-in can be done through the back of the

hydronic heat section or through the openings provided in the

bottom of the subbase. The finished piping can be done now or later .

NOTES:

1. Side channels are adjustable from 0"–93/8" in

Fuse

Optional Fuse

Disconnect

length by inverting them. Side channels are

predrilled to allow infinite adjustment.

2. Subbase shown with louvered front panel

removed. Front panel is hinged to allow

access to valve, coil, filter & electrical

junction box.

3. Leveling legs are adjustable from 1/4"–11/4".

71/4"

3/4"

Permanent

Mesh Filter

411/2"

Front View

IM 368 / Page 8 of 20 (Rev 11/03)

63/4"

71/2"

11/2"

51/2"

31/4"

Electrical

Knockout

1/4" – 11/4"

8"

Leveling Legs

End View

Page 9

Installation of Optional Condensate Drain Kit

Note: Heat pump models will generate condensate during

the heating season. To insure that no condensate will run

down the building, always use a drain kit with the heat pump.

Condensate drain kits can be supplied for internal or external

applications. Figure 14 illustrates the installation of the indoor

drain kit. The indoor drain kit should be installed before placing

the cabinet/wall sleeve into the opening. Install as follows:

1. Locate the drain so that it will be on the room side of the wall

when the cabinet/wall sleeve is installed.

Figure 14. Internal Drain Kit

2. Drill a

1

/2" (13mm) diameter hole in the base of the cabinet/

wall sleeve for the drain line.

3. Drill two (2)

5

/32" (4mm) pilot holes for the mounting screws.

These holes can be located using the drain kit as a pattern.

4. Assemble the drain kit as shown in Figure 14 and securely

fasten it to the cabinet/wall sleeve with screws provided.

5. Slide the cabinet/wall sleeve into the opening and anchor it

into place.

Contractor To Drill Three (3) Holes

To Accept Drain Kit

Square Drain Holes

Neoprene Sponge Gasket

Steel Mounting Plate

Assembly of the external drain kit should be completed after the

cabinet/wall sleeve has been installed. Install the external drain

kit as follows:

1. Assemble the drain kit as shown in Figure 15.

2. Choose which side of the cabinet/wall sleeve the drain kit is

to be installed.

Room Side

See Detail

Gasket

Cabinet Bottom

1/2" (13mm) O.D.

Cover Plate

Screws

Tube

Cover Plate

3. There are weep holes and pilot holes provided in the cabinet/

wall sleeve from the factory. Place the drain kit against the

chosen weep hole and fasten securely with screws provided.

4. Cover the unused weep holes with the block off plate

supplied with the drain kit.

Figure 15. External Drain Kit

Note: Use of 6" straight drain tube will require modification of

architectural louver.

Neoprene Sponge Gasket

Steel Mounting Plate

Square Drain Holes

Room Side

1

/2" (13mm) O.D. Drain Tube

Alternate 6" Long, 1/2" O.D. Straight

Copper Tube

IM 368 / Page 9 of 20 (Rev. 11/03)

Page 10

Installation of Louvers

1. Remove louver and mounting hardware from the shipping

carton.

2. Remove temporary cardboard weather panel from cabinet/

wall sleeve.

3. Make a temporary handle by looping a piece of flexible wire

or heavy cord through the louver. This enables the installer to

keep a firm grasp on the louver when installing from inside

the room.

Installation of Chassis

Proper installation of the heating/cooling chassis is extremely

important to the proper operation of the unit. Whether the wall

sleeve has been separately shipped or shipped with the chassis,

proper installation is as follows:

1. Remove shipping carton and inspect for any shipping

damage. Report any found to the carrier.

2. Save shipping carton to cover installed conditioner until

construction is complete.

3. Check nameplate data on chassis to insure that the correct

jobsite distribution has been made with respect to heating/

cooling capacities. Generally, corner rooms require larger

capacities.

4. Set front panel aside and remove air filter.

5. Remove chassis from carton by pulling evenly on substantial

portion of unit. Caution: Do not pull on evaporator fan housing

or control box.

6. If wall sleeve has been previously installed, remove temporary

cardboard weather panel.

7. If louver has not been previously installed, connect to wall

sleeve as described earlier.

8. Place Tinnerman clips on wall sleeve. Clips and mounting

screws are enclosed in a bag attached to the inside chassis

side panel.

9. Rotate fans to be sure they are free of obstruction.

10.Check all fasteners to make certain they did not loosen

during shipment. Do not loosen nuts holding down compressor;

they are factory installed.

11. Do not lubricate motors before startup. Motors are factory

lubricated. Consult “Scheduled Maintenance” section on page

12 for lubrication instructions.

12.Slide chassis into wall sleeve until firmly seated against

weather seals. Caution: Do not push on coil surface, control

box cover or fan scroll. Make sure tubing does not catch when

inserting chassis.

13. Secure the chassis in the cabinet/wall sleeve with four (4)

screws packaged with the Tinnerman clips.

14.Plug electrical cord into receptacle. Excess cord for 208V and

230V units should be coiled neatly and stored in the conditioner. Attach plug/cord cover to front face of subbase on 265V .

15. Set the manual damper operator in open or closed position

as desired. On units equipped with the optional electric fresh

air damper, set the “auto/off” switch to the desired position. In

“auto,” the damper is open whenever the indoor fan motor is

running. The “auto/off” switch is located on the bottom front

face of the control box.

4. Push the louver through the opening at the rear of the wall

box, then pull the louver back to the wall sleeve flange so that

the louver studs pass through the holes in the flange.

5. Attach washers and nuts and secure louver in place.

6. If the heating/cooling chassis is not to be immediately installed,

replace the weather panel.

16. Check the “Override/Normal” dial (heat pump only) located

on the front face of the control box. For normal heat pump

operation, position the dial to “Normal.” Only the electric heater

will operate when dial is in “Override” position.

17. Set fan cycle switch (located on the lower front face of the

control box) for constant or cycling indoor fan. With the switch

in the “cycle” position, the indoor fan will shut off when the

thermostat shuts off heating or cooling.

18. Set the temperature limiting feature to the desired range of

thermostat operation.

19.Replace the air filter and front panel.

20. For hydronic units, place the disconnect switch to the “On”

position.

a. Punch the two low voltage valve wires, with Molex

connections, through the opening provided in the subbase

and connect to valve.

b. Connect short power cord from the chassis to the receptacle

in the subbase heat section.

c. Replace filter and louvered subbase front panel.

d. Relocate thermostat bulb to bracket located in the subbase.

Refer to IM 419 which is provided with the hydronic subbase.

Figure 16. Chassis Installation

IM 368 / Page 10 of 20 (Rev 11/03)

Page 11

Adjusting Temperature Limiting (Optional)

A temperature limiting device may be furnished as an option

to allow the owner to set the minimum and/or maximum

temperature selections. Adjust this device as follows:

1. Remove the two screws that secure the lower corners of the

front panel and remove the front panel.

2. Pull off the control knob and remove screws that hold down

polycarbonate membrane overlay.

3. Pull back overlay to gain access to the temperature limiting

device adjusting screw.

4. Loosen hold-down screw with Phillips screwdriver.

Electrical Service

All wiring should should be done in accordance with all local and

National Electrical Code requirements. The conditioners are

supplied as follows:

Electrical Heating Unit

1. 208V and 230V models are supplied with an attachment cord

and plug which exit from beneath the conditioner on the

control side. The cord has a usable length of 72" (1829mm)

from where it exits the conditioner. The use of an extension

cord is not recommended. The attachment plug size should

be used to determine circuit ampacity and overcurrent

protection. Time delay fuses are recommended to avoid

nuisance tripping. The receptacle is generally mounted

beneath the conditioner, on or recessed in the wall so that it

is concealed by the conditioner overhang. The space under

the conditioner must be at least 3" (76mm) high.

2. An electrical subbase is available for 208V and 230V units

and contains a junction box for a field mounted receptacle.

All electrical connections are made within the subbase, thus

5. Adjust cams to attain desired rotation limit.

6. Tighten hold-down screw.

7. Replace overlay and secure with screws removed in step #2.

8. Once unit is in operation, rotate knob to maximum heat and/

or maximum cool to check temperature limits. Repeat

procedure listed above until desired temperature limitations

are achieved.

9. Replace front panel and tamper resistant front panel screws

removed in step #1.

eliminating the need for a wall mounted receptacle. The

subbase is available in 3" (76mm) or 4" (102mm) height and

can be furnished with factory mounted fused disconnect option.

3. On all 265V models, an electrical subbase is required. The

chassis is supplied with a “short cord” which is just long enough

to plug into the subbase. A plug/cord cover is also furnished

with the subbase to make the interconnecting cord inaccessible,

as required by the National Electrical Code. The conditioner is

marked with the minimum circuit ampacity and maximum fuse size.

Hydronic Heating Unit

1. All hydronic units are supplied with a subbase. The subbase is

8" (203mm) high and houses both the hydronic heating coil

and the electrical connections.

2. A short cord is furnished to be plugged into the top of the subbase. A plug/cord cover is not furnished with these units.

3. A fused disconnect option is available and comes furnished

factory mounted.

Equipment Startup

Initial startup of the Incremental® conditioners by experienced

personnel is usually the responsibility of the installing contractor.

This startup consists of inspecting and operating the equipment

for all functions at the time of initial installation, and making

necessary adjustments. It also includes demonstrating its proper

operation to the owner or his agent. Note that unless otherwise

specifically agreed to in writing, AAF–McQuay Incorporated

includes no field labor, startup service or the like in the price of

its equipment. After the equipment leaves the McQuay factory, it

may become damaged or maladjusted during transportation or

on the job. Sometimes wires are disconnected accidentally, or

fan motors move on their bases due to rough handling, causing

fans to strike. The correction of such conditions is part of the

startup.

Before Starting Equipment, Make Certain That:

1. Correct voltage has been supplied to the equipment.

2. The electrical plug from the control box has been inserted

into the receptacle.

During Startup (applies only to standard equipment):

1. Set manual ventilation damper to OPEN or CLOSED position

as required by owner. Set “auto-of f” switch as required if unit

is equipped with electric fresh air damper.

2. Select HIGH on the fan speed rocker switch; push HEAT

button. Move thermostat to the extreme heating position

(counterclockwise). If the “CYCLE/CONSTANT” switch is

placed in the “CYCLE” position, Heat and indoor fan motor

should cycle on and off as the thermostat requires. Select

LOW on the fan speed rocker switch; fan should change to

low speed. If it is a heat pump unit, electric resistance neat

will be delivered at outdoor temperatures less than 30°F

(-1°C) to 35°F (1.6°C). Outdoor fan should be on whenever

compressor operates.

3. Select HIGH fan speed; push COOL button. Move thermostat

to the extreme cooling position (clockwise). Compressor and

indoor fan motor should cycle on and off as the thermostat

requires. Select LOW fan speed; fan should change to lower

speed. Outdoor fan should be on whenever compressor

operates.

4. Push FAN button. Indoor fan should operate at high or low

speed as selected. Neither heater nor compressor should

continue to operate.

5. Push STOP button. Fan should stop, and neither heater nor

compressor should continue to operate.

Note: Direction of conditioned air may be adjusted by

repositioning the discharge grille to change airflow pattern in a

room. The building superintendent or assistant manager should

be requested to make any changes.

IM 368 / Page 11 of 20 (Rev. 11/03)

Page 12

Installing Remote Mounted Thermostat Scheduled Maintenance

Units that are furnished with remote mounted thermostats should

be wired as shown in Figure 17. Other considerations for this

arrangement are as follows:

1. When wiring the low voltage plug and receptacle disconnect,

provide enough wire to move harness out of the way for

chassis removal.

2. If subbase is used, a small hole must be drilled and grommeted

in the subbase front to allow passage of the low voltage wires.

3. If slave units are to be employed, connect as shown in Figure

17. With this arrangement, the loop between terminals N2

and N4 of the slave unit must be severed. The standard

master transformer handles 10 VA power draw and each slave

unit draws 5 VA. If more than one slave unit is used, the

master transformer must be replaced with a larger one. The

number of slave units that can be connected is limited to the

maximum amperage rating of the thermostat contacts.

4. When using a programmable wall thermostat, splice into the

jumper going from N2 to N4 of the master unit and connect it

to the common terminal of the thermostat. Refer to the

instructions furnished with the chosen thermostat to locate

the common terminal. Note: It may be necessary to place a

larger VA transformer in the unit when using certain

programmable thermostats. Check the VA draw of the

chosen thermostat, plus a V A dra w of the slave unit to be

sure it does not exceed 10 VA power draw. Slave units are

connected as described in #3 above.

Figure 17.

Optional Wall Plate

Temperature

Fall

System

Switch

Heat

Off

Cool

On

Auto

Fan

Switch

Incremental conditioners are built to last. With proper care, the

unit should provide uninterrupted service for many years.

Scheduled maintenance of this equipment, as described below,

is the key to the equipment’s longevity .

A. Air filters must be cleaned at regular intervals. Twice annually

may be adequate in some areas while twice monthly may be

required in others. Areas with high dirt and lint content or heavy

usage of units require more frequent filter maintenance than

those areas of relatively clean operating or low usage

conditions. Unit malfunction may occur if air filters are not kept

clean. Rinse filters with hot water and a mild detergent. Let

dry and oil lightly to enhance dust collecting ability.

B. McQuay recommends that every year the chassis be removed

for a thorough checkup. This should be completed as follows:

1. Unplug unit from power source.

2. Remove front panel.

3. Remove chassis from cabinet and move it to the

maintenance department. Replace with spare chassis or

weather plate.

4. Check all seals and insulation and repair as required.

5. Check all wiring and controls for hazardous conditions.

6. Thoroughly clean discharge grilles.

7. Cover motors and control module with watertight

material and wash evaporator coil, condenser coil and base

pan using hot water and a mild soap.

WARNING

Residential and institutional cleaning compounds can

cause permanent damage to the packaged terminal unit.

To avoid damage to unit controls and heat transfer

surfaces, do not spray cleaning compounds onto the

discharge grille, return air opening, or unit controls.

Normal cleaning can be accomplished by wiping the unit

surface with a damp cloth. When using cleaning

compounds on carpets, floors or walls, turn the unit off to

avoid drawing potentially damaging vapors into the

package terminal unit.

Low

Voltage

Plug &

Receptacle

Disconnect

Wires from Control

Master Unit

IM 368 / Page 12 of 20 (Rev 11/03)

Wires from Control

Slave Unit

See Note

3 Above

8. Clean condensate drain and clear weep holes.

9. Dry equipment thoroughly, especially electric parts and

insulation.

10.Clean any rust spots with steel wool and paint with rust

inhibiting paint.

11.Clean insulation or replace if necessary.

12.Check insulation on suction tube and replace if necessary.

13.Check all fasteners and tighten as required.

14.Clean and oil damper door and linkage.

15.Test run chassis before reinstalling or returning to spare

parts stock.

Page 13

Recommended Spare Parts

An inherent advantage of the incremental system is that failure

of any part affects only one incremental conditioner and does not

interrupt the operation of the rest of the system. A further

advantage is that a failed part can be quickly and easily replaced,

thus minimizing the inoperative time of the equipment. This is so,

however, only if a replacement part is quickly available. In order

to replace a failed part quickly and keep all incremental

conditioners in good operating condition, McQuay International

recommends that at the time incremental conditioners are

purchased, owners arrange for a small stock of replacement parts.

Where an owner carries such a stock, immediate replacement

of a defective part is possible. The defective part can then be

returned to McQuay International or one of its authorized service

stations. So long as it is still in warranty , it is repaired or replaced

and returned to the owner without cost for shop labor and

material. Thus, the stock of replacement parts is constantly

replenished. T o the right is listed the kinds of parts which McQuay

International recommends to be carried in stock, together with

the quantity of parts recommended per 100 incremental

conditioners installed.

Refrigeration Cycle

Every motor-driven refrigeration system operates on the Carnot

cycle. A practical understanding of what goes on at the various

steps in this cycle can be a big help to the troubleshooting

mechanic. Figure 18 illustrates the refrigeration cycle. The

diagram shows what occurs in each component of a hermetically

Qty Per

Part Name

Cooling Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compressor Overload Device . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compressor Running Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . .

Conditioned Air Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condenser Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Condenser Fan Motor Capacitor . . . . . . . . . . . . . . . . . . . . . . . . . .

Pushbutton Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Damper Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Knob for Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Relay (if used) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Damper Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electric Resistance Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Touch-up Paint (1 pt. spray can) . . . . . . . . . . . . . . . . . . . . . . . . . .

For the current spare parts list, and applicable prices, see your

McQuay representative or write McQuay Service, P .O. Box 1551,

Minneapolis, MN 55440.

sealed system, as used in all AAF–McQuay Incorporated

equipment. The temperatures shown are typical of what they might

be when the air entering the condenser (outdoor temperature) is

95°F (35°C) and the temperature of the conditioned space is 75°F

(24°C) to 80°F (27°C).

100 Units

1

1

1

1

1

1

2

2

2

6

1

2

1

1

Figure 18. Refrigeration Cycle

IM 368 / Page 13 of 20 (Rev. 11/03)

Page 14

Troubleshooting Chart

These items should be checked by a qualified service techician only.

1. Blowers won’t operate on

2. Blowers operate on COOL

3. Blowers run on COOL and

4. Blowers run on COOL and

5. Compressor starts and

6. Compressor starts and

7. Equipment gives electrical

8. Insufficient cooling

TROUBLE CAUSE CURE

COOL.

but compressor doesn’t

start.

compressor starts but

stops after a short

interval.

compressor starts and

runs, but compressor

occasionally stops (on

overload device).

runs on COOL but blowers

do not run.

runs on COOL but blowers

do not run.

shock.

capacity.

a. No power.

b. Faulty pushbutton switch.

c. Loose connections at pushbutton switch.

a. Thermostat set too high.

b. Heat valve is open and heat is on.

c. Low voltage.

d. Fault pushbutton switch.

e. Faulty connection at pushbutton switch.

f. Defective wiring to thermostat.

g. Loose connections at compressor terminals.

h. Wiring to compressor terminals defective.

i. Loose connections in compressor overload device.

j. Starting capacitor malfunctions (open circuited, short

circuited or loss of capacity.

k. Defective compressor motor (short circuited, open

circuited, grounded).

a. Operation of overload device due to overloading

compressor motor.

a. Low voltage due to overloaded circuits within building or

throughout the local power system. Due to varying

power demands, this condition might exist only at

certain times during the day or on very hot days.

b. High voltage due to fluctuations in local power system;

usually occurs at low load periods of the day.

c. Partial short circuit in compressor motor. Under normal

loading a compressor with a partial short circuit might

appear to be operating all right; increased condensing

air temperature might then cause a short.

a. Faulty pushbutton switch.

b. Open circuited blower motor.

c. Blower rubbing against its housing.

d. Bearings on blower motor seized.

e. Loose connection at pushbutton switch.

a. Operation of the internally connected overload device

due to a short circuit in blower motor.

b. Windings, rubbing of blower wheel or lack of lubrication

in blower motor bearings.

a. Grounded electrical circuit.

a. Equipment standing too long without being run.

b. Insufficient airflow through condenser due to:

1) Dirty condenser.

2) Obstructed louvers on outer cabinet or wall box.

3) Condenser blower/fan not running.

4) Condenser blower/fan not up to speed.

5) Condenser blower/fan slipping on motor shaft.

6) Recirculation of condenser air.

c. Insufficient airflow through evaporator due to:

1) Dirty evaporator.

2) Ice on evaporator coils.

3) Dirty air filter.

4) Obstructed discharge grilles.

5) Evaporator blower motor not running.

6) Evaporator blower motor not up to speed.

7) Evaporator blower slipping on motor shaft.

d. Heat load in room exceeds capacity of equipment.

e. Windows and doors in room are open.

f. Compressor not pumping, indicated by:

1) Low wattage.

2) Condenser not warm, evaporator only partially cool

or not at all.

a. Check supply line fuses, circuit breakers, and be sure the

power is on. Blown fuses would indicate circuit overloading, a short circuit, or a grounded condition in the circuit.

Voltage supply to the equipment should be checked.

Voltage must be within 10% of voltage given on data

plate.

b. Replace.

c. Tighten.

a. Adjust. Rotate control knob to “Cooler.”

b. Close heat valve.

c. Check as above.

d. Replace.

e. Tighten.

f. Replace.

g. Tighten.

h. Replace.

i. Tighten.

j. Replace.

k. *Ship cooling chassis prepaid to nearest McQuay authorized

warranty station.

a. Check voltage supply. Clean condenser inside and out. Check

at outside face of condenser for recirculation of condenser air.

Put air “splitters” in, if missing. Check to make sure condenser

blower/fan is operating properly. Check compressor for short

circuit. If defective, *ship cooling chassis to nearest McQuay

authorized warranty station.

a. Run separate electric line to equipment. Consult local power

company.

b. Consult local power company.

c. If confirmed, ship cooling chassis prepaid to nearest McQuay

authorized warranty station.

a. Replace.

b. Replace.

c. Adjust blower motor or blower wheel position.

d. Replace motor

e. Tighten.

a. Adjust blower/fan wheel on shaft or blower motor mounting.

b. Adjust blower wheel or motor or replace wheel.

a. Eliminate ground.

a. If the air conditioner is allowed to stand for an extended

length of time without being run on COOL, it is possible for all

the refrigerant to become absorbed in the oil inside the

compressor and refrigeration circuit. If this should happen,

there will be no cooling until the necessary working pressures

have been established. This will take about 5 minutes of

continuous running.

b.

1) Clean.

2) Remove obstructions.

3) Check same as in the case of malfunctioning con-

ditioner air blower.

4) Check for correct voltage. Oil blower motor if nec-

essary.

5) Adjust blower position and tighten setscrew.

6) Correct as in No. 3 above.

c.

1) Clean.

2) Turn equipment off to let ice melt.

3) Clean or replace.

4) Remove obstructions. In case of top discharge equipment,

make sure books, magazines, etc., are kept off the

equipment.

5) Check as in No. 1.

6) Check for correct voltage.

7) Adjust motor wheel position and tighten setscrew.

d. Refer to original load calculations; recalculate heat load.

e. Close therm.

f. *Ship prepaid to nearest McQuay authorized warranty station.

IM 368 / Page 14 of 20 (Rev 11/03)

Continued on next page

Page 15

Troubleshooting Chart

These items should be checked by a qualified service techician only.

TROUBLE CAUSE CURE

8. Insufficient cooling

capacity (continued).

9. Too much cooling.

10. “Sweating”

11. Blowers won’t operate on

HEAT.

12. **Equipment is noisy.

13. Insufficient or no heat.

Notes:

† This guide was prepared with standard equipment in mind. If equipment is special, it may not be entirely applicable.

* If equipment is still in warranty.

** Note: Before trying to correct the noise, determine its cause: conditioned air blower, compressor or condenser blower. Operate the conditioned air blowers only. If

this doesn’t cause the noise, operate on cooling. Then disconnect one compressor lead. If the noise stops, the compressor is the source. If not, it is caused by the

condenser blower.

g. Restricted capillary tube or strainer, indicated by:

1) Frost on capillary or strainer.

2) Low wattage.

3) Condenser not warm.

4) Evaporator partially frosted, only partially cool or not

at all.

a. Thermostat set too low.

b. Defective thermostat.

a. Condensate drain from evaporator to condenser plugged.

b. Insulating seals on equipment damaged.

c. Evaporator blower motor not up to speed.

d. Evaporator blower incorrectly positioned.

a. No power.

b. Heat is off (equipment with heat fan lockout).

c. Faulty pushbutton switch.

d. Loose connections at pushbutton switch.

e. Thermostat set too low.

a. Blower rubbing against enclosure.

b. Blower motor bearings are dry.

c. Loose blower hold-down nuts on motor-bracket assembly.

d. Refrigerant absorbed in compressor oil after extended

shutdown.

e. Equipment improperly installed.

f. Damper solenoid hums.

g. Loose terminal box cover on side of compressor.

h. Loose electrical components.

i. Copper tubing vibrating.

j. Harmonics.

k. Loose sheet metal parts.

a. No steam or hot water being applied.

b. No power.

c. Faulty pushbutton switch.

d. Loose connection at pushbutton switch.

e. Thermostat set too high.

f. Thermostat faulty.

g. No power output on transformer secondary.

h. Inoperative valve.

1) Steam valve N/C.

2) Hot water valve N/C.

g. *Ship prepaid to nearest McQuay warranty station.

a. Adjust.

b. Replace.

a. See No. 1.

b. Open heat valve or turn on heating system.

c. Check for correct voltage.

d. Adjust.

a. See No. 1.

b. Open heat valve or turn on heating system.

c. Replace.

d. Tighten.

e. Adjust. Rotate control knob to “Warmer.”

a. Adjust fan position on motor shaft or reposition fan motor

bracket assembly.

b. Replace motor.

c. Align blower assembly and tighten nuts.

d. Noise will disappear after equipment runs awhile.

e. Make necessary adjustments to components.

f. Check for proper adjustment. Apply silicone oil or grease

to gap between solenoid and armature.

g. Tighten.

h. Fasten securely.

i. Adjust by bending or applying tape.

j. Occasionally equipment will have noisy operation for no

apparent reason. Inspection has revealed no loose

components that might be the source of the noise. Due to

the action of the compressor, it is possible to have internal

noise develop if the refrigerant tubing has become bent

even slightly. To distinguish this condition from the simple

rattle producing vibration caused by loose screws, nuts

and other components, grasp the refrigerant tubing at

various points throughout the system until a point is found

where the noise is eliminated or reduced. Bend the copper

tubing very gently until the noise disappears.

k. Tighten.

a. Contact building management.

b. Check power supply line fuses, circuit breakers. Blown

fuses would indicate circuit overloading, a short circuit, or

a grounded condition in the circuit.

c. Replace.

d. Replace wire or tighten.

e. Adjust. Rotate knob to “Warm.”

f. Replace.

g. Replace.

h.

1) Temporary lock valve open; replace.

2) Replace.

Chassis:

Size 007141 lbs. (64 kg) . . . . . . . . . . . . . . . . . .

Size 009145 lbs. (66 kg) . . . . . . . . . . . . . . . . . .

Size 012149 lbs. (68 kg) . . . . . . . . . . . . . . . . . .

Size 015153 lbs. (69 kg) . . . . . . . . . . . . . . . . . .

Wall Sleeve:

Uninsulated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Insulated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Room Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Louvers:

Flush-stamped . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Architectural . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appro ximate Shipping Weights

Subbase:

139 lbs. (63 kg)

143 lbs. (65 kg)

147 lbs. (67 kg)

151 lbs. (69 kg)

36 lbs. (16 kg)

37 lbs. (16 kg)

10 lbs. (4.5 kg)

6 lbs. (3 kg)

8 lbs. (4 kg)

3" (76mm) High Electrical . . . . . . . . . . . . . . . . . .

4" (102mm) High Electrical . . . . . . . . . . . . . . . . . .

8" (203mm) High Hydronic . . . . . . . . . . . . . . . . . .

Extendaire:

Primary Discharge Section . . . . . . . . . . . . . . . . .

36" (914mm) Duct Section . . . . . . . . . . . . . . . . .

10 lbs. (4.5 kg)

12 lbs. (5 kg)

20 lbs. (9 kg)

10 lbs. (4.5 kg)

22 lbs. (10 kg)

IM 368 / Page 15 of 20 (Rev. 11/03)

Page 16

Wiring Diagram – Electric Heat

Standard Manual Changeover Control

SUITE II 2 MOTOR

DES

MODEL––––––––––– AIR CONDITIONER

IM 368 / Page 16 of 20 (Rev 11/03)

THERMOSTAT––––––UNIT

HEAT–––––––––––––ELECTRIC

CHANGEOVER–––––MANUAL

Page 17

Wiring Diagram – Heat Pump

Standard Manual Changeover Control

SUITE II 2 MOTOR

DHS

MODEL––––––––––– HEAT PUMP

THERMOSTAT––––––UNIT

HEA T–––––––––––––ELECTRIC

CHANGEOVER–––––MANUAL

IM 368 / Page 17 of 20 (Rev. 11/03)

Page 18

Standard Manual Changeover Control

Wiring Diagram – Hot Water Heat with Normally Open Valve

SUITE II 2 MOTOR HYD

DES, DNS

MODEL––––––––––– AIR CONDITIONER

IM 368 / Page 18 of 20 (Rev 11/03)

THERMOSTAT––––––UNIT

HEAT–––––––––––––WATER

CHANGEOVER–––––MANUAL

Page 19

Standard Manual Changeover Control

Wiring Diagram – Steam Heat with Normally Closed Valve

SUITE II 2 MOTOR HYD

DES, DNS

MODEL––––––––––– AIR CONDITIONER

THERMOSTAT––––––UNIT

HEAT–––––––––––––STEAM

CHANGEOVER–––––MANUAL

IM 368 / Page 19 of 20 (Rev. 11/03)

Page 20

®

© 2003 McQuay International • www.mcquay.com • 800-432-1342 Page 20 of 20 / IM 368-7 / (Rev 11/03)

Loading...

Loading...