Page 1

Suite II™ Wall S leeves

Installation & Maintenance Data

IM 420-1

Group: PTAC

Part No.: 106018541

Date: May 1999

Wall opening requirement

Before installing the unit, check the wall opening to be sure the

cabinet/wall sleeve will slide into the opening unobstructed. For

masonry walls, a lintel must be used to provide support over each

1

opening. The rough opening should measure 16

/4" x 42 1/4"

(413mm x 1023mm) wide (see note 3, Figure 2). When no

subbase is used, the opening should be a minimum of 3"

(76mm) off the floor. This distance is available in 3" (76mm)

or 4" (102mm) heights. For units with hydronic heat, the

subbase is 8

1

/4" (210mm). Each subbase has leveling legs

providing for up to 1" (25mm) additional height.

Attaching cabinet wall sleeve to subbase

After the electrical or hydronic subbase has been set in place

and the rough-in for plumbing and/or electrical is complete, the

cabinet/wall sleeve can be installed.

1. Install cabinet/wall sleeve as described on pages 2 through 4.

2. Attach the subbase to the cabinet/wall sleeve using the clips

provided.

3. Secure the two sections by installing the clip screws supplied

with the hardware bag.

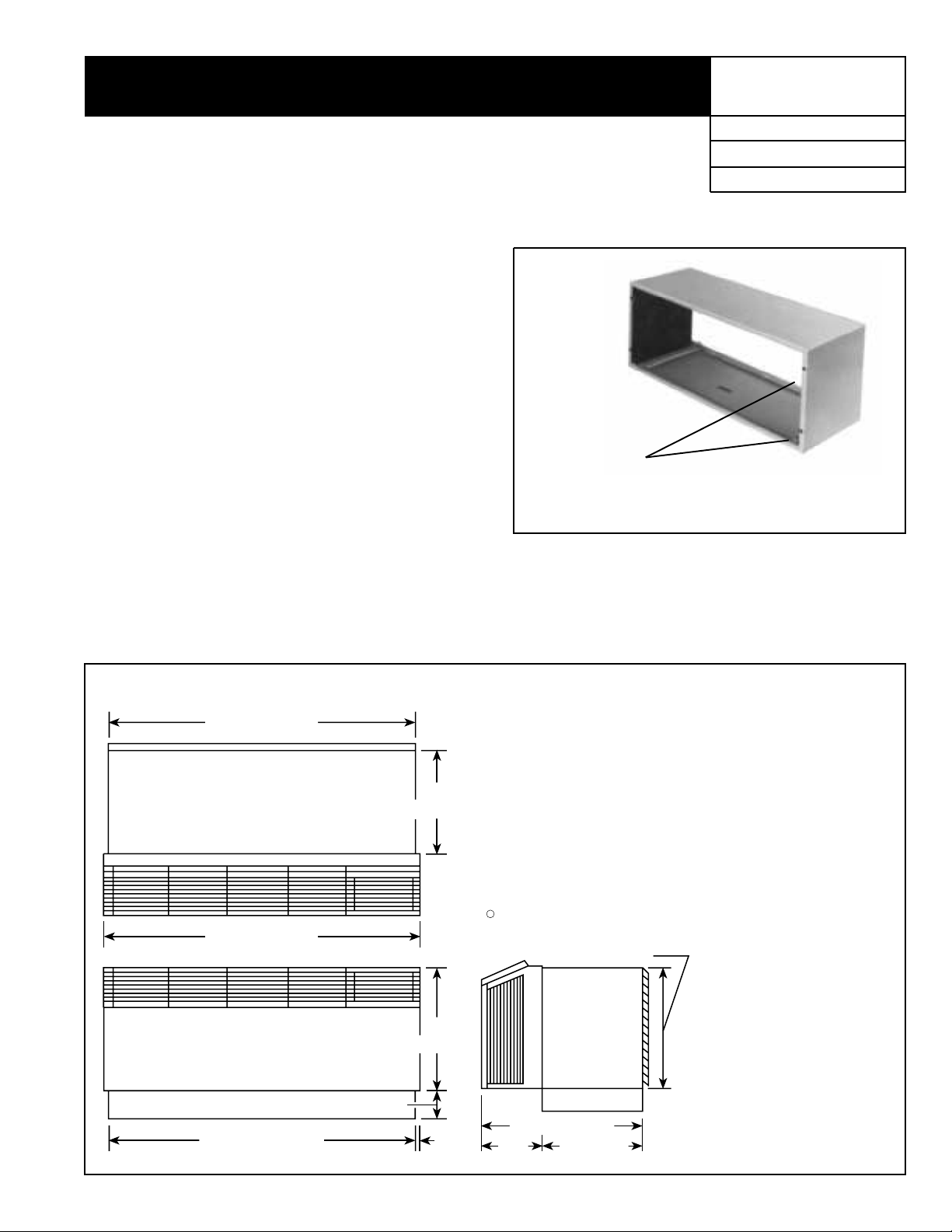

Figure 2. Unit with Subbase

42"

(1067 mm)

3

/4"

13

(349 mm)

43"

(1092 mm)

Figure 1. Wall Sleeve

➤

➤

Tinnerman

Clips

Note: Wall sleeve shown with optional insulation installed.

4. Caulk indoor/outdoor perimeter of cabinet/wall sleeve with

resilient caulk such as silicone.

5. Finish any uncompleted electrical and/or plumbing

connections.

Notes:

*Subbase Side Dimension:

**Subbase Height Dimension:

➀ Unit pictured with subbase installed. Subbase is optional on 208V and 230V units .

➁ Subbase extends to front edge of unit when furnished with hydronic heat.

➂ Opening needs to be 16

4

Electric: 4

Hydronic: 0" to 13

Electric: 3" to 4" (76mm to 102mm) with 0" to 1" (0mm to 25m) leveling

Hydronic: 8" (203mm) with

Subbase is standard on all 265V units and units with hydronic heat. Hydronic

subbase is flush with the front of the cabinet. Electric subbase is flush with w all

sleeve.

frame.

Subbase side channels are adiustable from 4

3

/8" to 133/4" (111mm to 349mm)

3

/4" (0mm to 349mm)

screw

5

16" (406 mm)

1

/4" (6mm) to 11/4" (32mm) leveling bolts

/8" x 425/8" (422mm x 1083mm) when using a louver

3

/8" to 133/4" (111mm to 349mm).

1

/2"

41

(1054 mm)

1

/2"

16

(419 mm)

**

©1999 AAF–McQuay Incorporated IM 420-1 / Page 1 (Rev. 5/99)

➀

1

/4"

8

(210 mm)

22" (559 mm)

*

Page 2

Wall sleeve installation — frame and brick

A heavy-gauge, corrosion resistant cabinet/wall sleeve is

provided for each unit. The cabinet/wall sleeve is either shipped

in a separate carton, shipped in a multipack of 15 or in a single

carton with the heating/cooling chassis.

The standard cabinet/wall sleeve is designed to be easily

installed in a variety of wall constructions. Note: The center of grav-

1

ity is 10

sleeve must be inserted into the wall at least 10

support must be employed. Support can be from a factory supplied

subbase or from other field supplied materials. Recommended

installation procedures are described below.

1.

2. If the unit is to be supplied with a subbase, install subbase

3. lf the optional drain kit is to be employed (heat pump only),

4. Place a thin pad of soft mortar on the bottom of the opening

5. Level cabinet/w all sleev e in both directions and secure by an-

6. Caulk the cabinet/wall sleev e to the wall opening on both the

/4" (260mm) from the rear face of the wall sleeve. The wall

1

/4" (260mm) or other

Clean the opening of all debris that may interfere with installation.

before installing cabinet/wall sleeve (see IM 419 or IM 420).

see IM 430-2.

and slide in the cabinet/wall sleev e. Be sure to recess the wall

sleeve enough to accommodate outside louver. This recess

3

is

/8" (9.5mm) for stamped louvers and 11/4" (32mm) for architectural louvers. Louver should be flush to exterior surface

with complete. Note: The wall sleeve is not intended to replace the lintel.

choring with appropriate fasteners. A

5

/16" (8mm) hole is provided on each side, 2" (51 mm) down from the top and 2"

(51mm) in from the rear of the cabinet/wall sleev e . Additional

holes may be required to firmly secure the cabinet/wall sleeve.

Caution:

sleeve.

Do not drill holes in the base of the cabinet/wall

Where a subbase is used, secure wall sleeve to sub-

base with clips provided.

inside and outside perimeter. Be careful not to plug the weep

holes. Caulking should be resilient, nonhardening type such

as silicone.

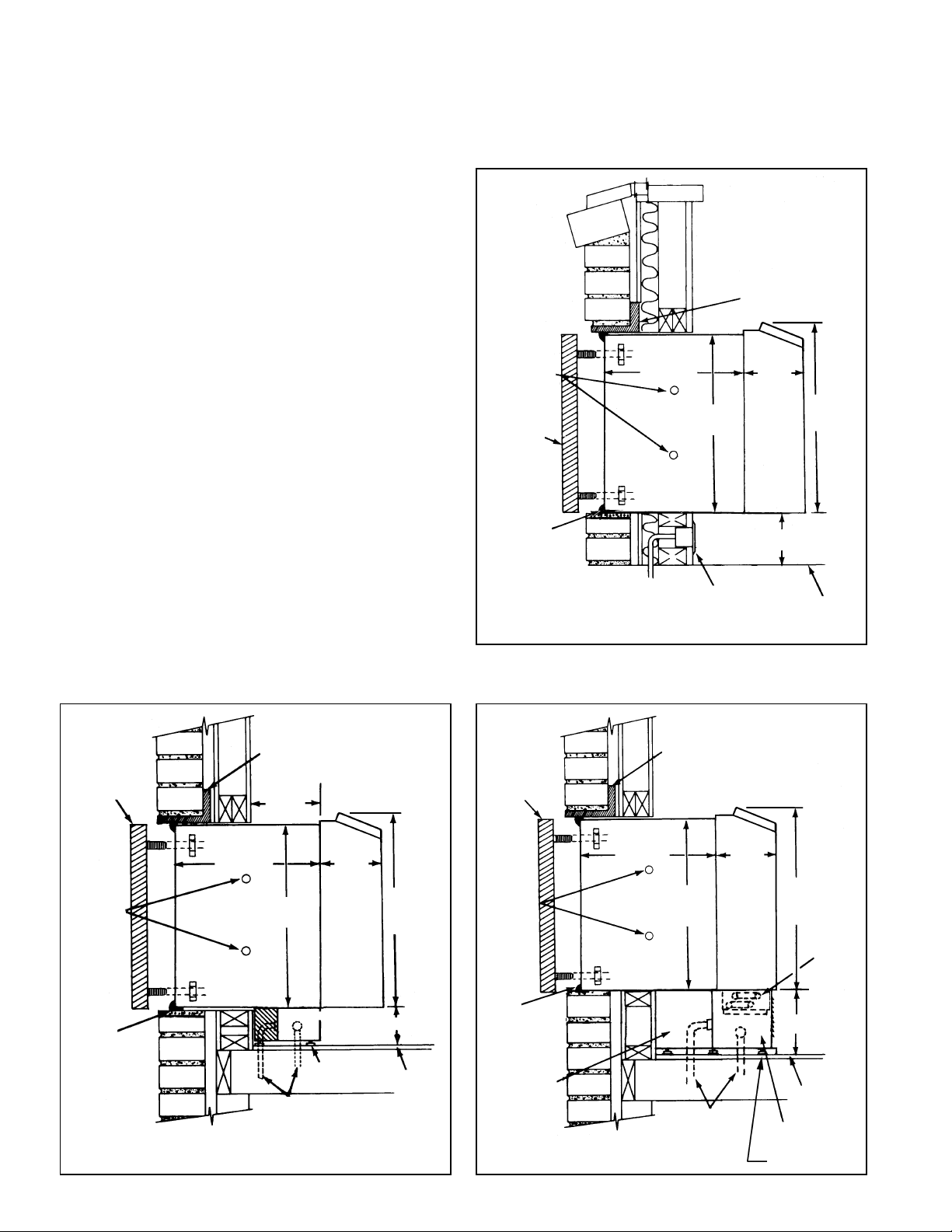

Figure 3. Frame and brick with cord connection

STEEL LINTEL (BY

OTHERS)

MOUNTING

SCREWS BY

INSTALLER

OUTDOOR

LOUVER

CAULK

PERIMETER

133/4"

(349mm)

WALL SLEEVE

16"

(406mm)

WALL

RECEPTACLE

BY OTHERS

81/4"

(209mm)

ROOM

CABINET

3" MIN.

(76mm)

17"

(432mm)

FINISHED

FLOOR OR

CARPET

Figure 4. Frame and brick with standard electrical subbase

STEEL LINTEL

BY OTHERS

OUTSIDE

LOUVER

133/4"

(349mm)

MOUNTING

HOLES BY

INSTALLER

CAULK

PERIMETER

BOTH

INDOORS &

OUTDOORS

BEFORE

INSTALLING

LOUVER

WALL SLEEVE

Note: Standard subbase is available in 3" or 4" (76 mm or 102 mm) height.

Leveling legs provide adjustment of 1" (25 mm).

IM 420-1 / Page 2 (Rev.5/99)

43/8"

(111mm)

81/4"

(209mm)

16"

(406mm)

ROOM

CABINET

SUBBASE

LEVELING LEG

POWER SUPPLY CONNECT

(ALTERNATE ENTRY)

17"

(432mm)

SEE NOTE

FINISHED

FLOOR OR

TOP OF

CARPET

Figure 5. Frame and brick with hydronic subbase

STEEL LINTEL

(BY OTHERS)

OUTDOOR

LOUVER

MOUNTING

SCREWS BY

INSTALLER

CAULK

PERIMETER

BOTH

INDOORS &

OUTDOORS

BEFORE

INSTALLING

LOUVER

SUBBASE

CHANNEL

SIDE

133/4"

(349mm)

WALL

SLEEVE

16"

(406mm)

ALTERNATE

ELECTRICAL

CONNECTIONS

81/4"

(209mm)

ROOM

CABINET

17"

(432mm)

81/4"

(209mm)

HYDRONIC

SUBBASE

HYDRONIC

HEATING

COIL

FINISHED

FLOOR OR

CARPET

Page 3

Wall slee ve installation–

panel wall construction

For panel wall and thin wall construction, it is recommended that

a louver frame be used.

Panel wall and thin w all construction varies only slightly from

frame and brick construction. Note: The center of gravity is 10"

(260mm) from the rear face of the wall sleeve. The wall sleeve

must be inserted into the wall at least 10" (260mm) or other

support must be employed. Suppor t can be from a factory

supplied subbase or from other field supplied materials.

Installation for this application is as follows:

1. Clean the opening of all debris that may interfere with

installation.

2. If the unit is to be supplied with a subbase, install subbase

before installing cabinet/wall sleeve (see IM 419 or IM 420).

3. If the optional drain kit is to be employed, see IM 430-3.

4. Be sure the cabinet/wall sleeve is mechanically attached to

the wall and caulked to assure a proper seat. It is

recommended that the louver frame be used for this purpose.

5. Recess the wall sleeve so that the louver is flush with the

exterior of the building.

6. Level cabinet/wall sleeve in both directions and secure by

anchoring with appropriate fasteners or drill additional holes

as required to secure firmly . Caution:

base of the cabinet/wall sleeve.

secure wall sleeve to subbase with clips provided.

7. Caulk the cabinet/wall sleev e to the w all opening on both the

inside and outside perimeter. Be careful not to plug the weep

holes. Caulking should be resilient, nonhardening type such

as silicone.

Do not drill holes in the

Where a subbase is used,

Certified Drawing

Figure 6. Panel wall construction with cord connection

LOUVER

FRAME

17"

(432mm)

3"MIN. (76mm)

FLOOR

RECEPTACLES

BY OTHERS

81/4"

(209mm)

ROOM

CABINET

CONDUIT

(349mm)

16"

(406mm)

SUPPORTS FIELD

133/4"

WALL

SLEEVE

PERIMETER

OUTDOORS

MINIMUM 2

SUPPLIED

OUTDOOR

LOUVER

CAULK

BOTH

INDOORS &

Figure 7. Panel wall construction with

standard electrical subbase

LOUVER

FRAME

OUTSIDE

81/4"

(209mm)

17"

(432mm)

SEE NOTE

ROOM

CABINET

POWER SUPPLY

(ALTERNATE ENTRY)

(406mm)

CONDUIT

Note: Standard subbase is available in 3" or 4" (76 mm or 102 mm) height.

Leveling legs provide adjustment of 1" (25 mm).

16"

ELECTRICAL

133/4"

(349mm)

WALL SLEEVE

SUBBASE

GASKET &

PERIMETER

SUBBASE SIDE

CHANNEL

LOUVER

CAULK

Figure 8. Panel wall installation with hydronic subbase

LOUVER

FRAME

16"

(406mm)

SUBBASE

CHANNEL

133/4"

(349mm)

WALL

SLEEVE

SIDE

PERIMETER

BOTH INDOORS

& OUTDOORS

IM 420-1 / Page 3 (Rev. 5/99)

81/4"

(209mm)

17"

(432mm)

81/4"

(209mm)

ROOM

CABINET

HYDRONIC

HEATING

COIL

POWER SUPPLY CONDUIT

(ALTERNATE ENTRY)

LEVELING LEGS

W/1" ADJUSTMENT

OUTDOOR

LOUVER

CAULK

Page 4

Wall sleeve installation– thick wall construction

Installation of cabinet/wall sleeves f or thick w alls requires special

consideration. Table 1 should be used to determine the

maximum wall thickness allowed for the standard cabinet/wall

sleeve. For thicker walls, cabinet/wall sleeve extensions are

available from your representative.

Wall sleeve installation in thick walls is similar to frame and

brick installation. Install as follows:

1. Clean the opening of all debris that may interfere with

installation.

2. If the unit is to be supplied with a subbase, install subbase

before installing cabinet/wall sleeve (see IM 419 or IM 420).

3. If the optional drain kit is to be employed (heat pump only),

see IM 430-3.

4. If wall thickness exceeds dimensions shown in Table 1, a

cabinet/wall sleeve extension must be used. Once the

extension is attached to the cabinet/wall sleeve, place a thin

pad of soft mortar on the bottom of the opening and slide in

the wall sleev e/extension assembly. Be sure to recess the wall

sleeve enough to accommodate outside louver. This recess

3

/8" (9.5mm) for stamped louvers and 11/4" (32mm) for ar-

is

chitectural louvers. Louver should be flush to exterior surface

when completed. Note: The wall sleeve is not intended to replace the lintel.

5. Level cabinet/wall sleeve in both directions and secure by

anchoring with appropriate fasteners or drill additional holes

as required to secure firmly . Caution:

base of the cabinet/wall sleeve.

secure wall sleeve to subbase with clips provided.

6. Caulk the cabinet/wall sleev e to the w all opening on both the

inside and outside perimeter. Be careful not to plug the weep

holes. Caulking should be resilient, nonhardening type such

as silicone.

Figure 10. Thick wall construction with

standard electrical subbase

SEE

TABLE 1

CAULK

PERIMETER

Do not drill holes in the

Where a subbase is used,

STEEL

LINTEL

(BY OTHERS)

43/8"MIN.

(111mm)

MAXIMUM WALL THICKNESS

LOUVER

TYPE

Stamped

Architectural

NO

SUBBASE

14"(356mm)

7

14

/8"(378mm)

STANDARD

SUBBASE

91/2"(241mm)

3

10

/8"(264mm)

HYDRONIC

SUBBASE

131/8"(333mm)

14"(356mm)

Figure 9. Thick wall construction with cord connection

CAULK

PERIMETER

OUTDOOR

LOUVER

MOUNTING

SCREWS BY

INSTALLER

SEE

TABLE 1

13

(349mm)

WALL

SLEEVE

WALL

SLEEVE

EXTENSION

3

/4"

16"

(406mm)

1

/8"(3mm)

MIN.

LINTEL (BY

OTHERS)

81/4"

(209mm)

ROOM

CABINET

3"MIN.(76mm)

STEEL

17"

(432mm)

WALL

RECEPTACLE

BY OTHERS

Figure 11. Thick wall installation with hydronic subbase

SEE T ABLE 1

CAULK

PERIMETER

STEEL

LINTEL BY

OTHERS

1" (25mm)

FLOOR

SEE

NOTE

MOUNTING

SCREWS BY

INSTALLER

OUTDOOR

LOUVER

Note: ➀ Standard subbase is available in 3" or 4" (76 mm or 102 mm) height.

Leveling legs provide adjustment of 1" (25 mm).

2

WALL

SLEEVE

EXTENSION

3

13

/4"

(349mm)

(406mm)

ELECTRICAL

SUBBASE

16"

81/4"

(209mm)

ROOM

CABINET

SEE NOTE 1

17"

(432mm)

FLOOR

➁ Wall sleeve extension is available in various depths and supplied as

required.

AAF–McQuay Incorporated

4900 Technology Park Boulevard, Auburn, New York 13021-9030 USA (315) 253-2771

Printed on recycled paper containing at least 10% post-consumer recycled material.

IM 420-1 / Page 4 (Rev. 5/99)

MOUNTING

SCREWS BY

INSTALLER

OUTDOOR

LOUVER

WALL SLEEVE

133/4"

(349mm)

WALL

SLEEVE

EXTENSION

16"

(406mm)

81/4"

(209mm)

ROOM

CABINET

HYDRONIC

HEATING

COIL

17"

(432mm)

8

(209mm)

HYDRONIC

SUBBASE

1

/4"

FLOOR

Loading...

Loading...