Page 1

Page 2

GENERAL

The Model ST air cooled condensing units are complete assemblies, factory tested and shipped with a

Refrigerant 22 holding charge. They have been designed to operate in conjunction with remote direct

expansion evaporator(s) and are available for operation

on three phase power supplies (see the published

catalog data for power ratings available). All units have

115 volt control circuits with provision for connection

of a remote mounted 24 volt thermostat. Additional

information on the units is covered on the pages

following.

McQUAY

RESPONSIBILITIES

The Model ST condensing units when applied within

the performance and application limits specified on the

sales and installation data will provide safe and

dependable service.

Details on the Model ST product warranty are included

in the information envelope packed with the unit.

RECEIVING EQUIPMENT

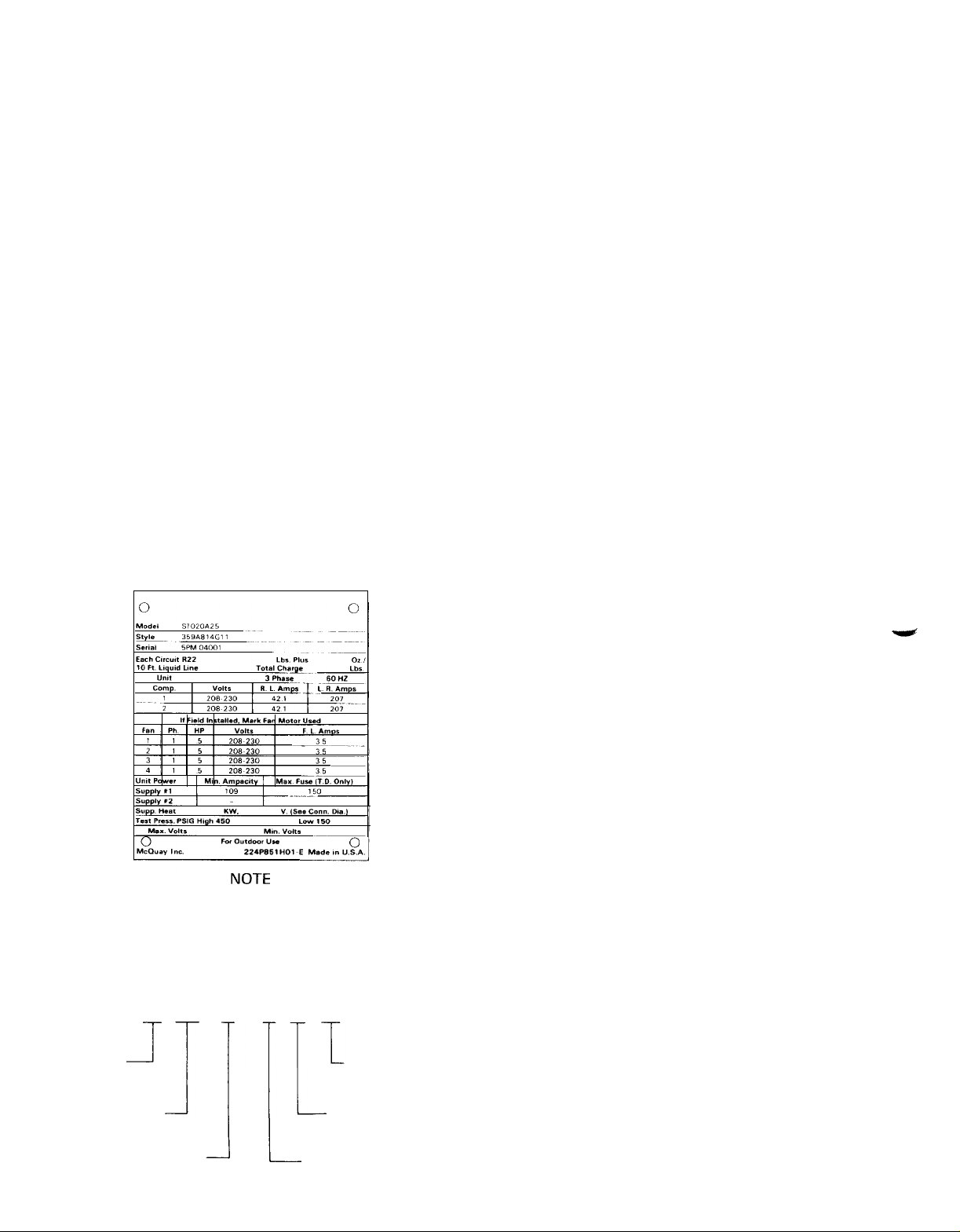

1. CHECK EQUIPMENT before removing it from the

delivery vehicle. The unit nameplate (shown below)

indicates the unit model number, power characteristics, serial number, etc. Be sure to check the

nameplate data against the shipping papers and pay

particular attention to the unit model number (size)

and power characteristics.

2.3.INSPECT the unit while it is still on the delivery

vehicle, make a note of any damage on the delivery

receipt. Be sure to carefully check for hidden

damage. If damage is found, have it checked and

noted by the representative of the transportation

company before accepting or removing the unit

from the vehicle.

NOTE

All equipment furnished by McQuay is

shipped F.O.B. the factory and all claims

for handling and shipping damage are the

responsibility of the consignee.

If an item is missing from the shipment notify your

nearest McQuay Sales office.

RIGGING - The STO08, 010, 013, and 015 should

be lifted by the skid, the ST020, 025, and 030 from

the lifting holes at the base corners. When lifting

use a spreader bar to prevent damage. If the unit is

to be skidded, be sure an adequate number of

rollers are used and be careful when moving the

unit not to drop it. Under no circumstances should

the unit be dragged with or without the skid.

NOTE

Unit mounting legs are shipped in a separate carton and are located in the compressor compartment. Before setting the unit at

its final location, attach the support legs at

each corner with the bolts provided.

5/8”

anchor holes are provided in the legs for

securing the unit to its base.

When requesting information about this

unit please forward the unit model number,

style and serial numbers with your inquiry.

UNIT MODEL NUMBER INTERPRETATION

ST 020 A

PRODUCT

FAMILY

NOMINAL

CAPACITY-TONS

CONDENSING MEDIUM

A = AIR

J

2 s 00

SPECIAL

MODIFICATIONS

UNIT POWER

CHARACTERISTICS

DESIGN MODIFICATION

CLEARANCES

The unit has been designed to permit slab or roof

mounting and care must be taken to provide adequate

clearance for air flow in and out of the unit.

TOP CLEARANCE - The unit has a draw through air

circuit with vertical air discharge from the top of the

unit. It is important that the areas above and below are

clear of any obstructions that could impede or divert

the air flow and cause recirculation back to the air

inlet.

SIDE CLEARANCE - A minimum clearance of 36

inches is required with the exception of the compres-

sor access end of the unit, where 42 inches is

recommended.

VIBRATION ISOLATION

Internal

isolation of the fan motors generally make it unneces-

sary to provide additional vribration isolation for the

unit. However, additional isolation could be required

depending on the installation location and building

construction.

Wherever possible locate the unit away from or over

occupied areas and provide adequate piping isolation.

Be

where it passes through walls, roof or floors.

spring

mounting of the compressor and

careful

not to allow piping to touch the structure

2

Page 3

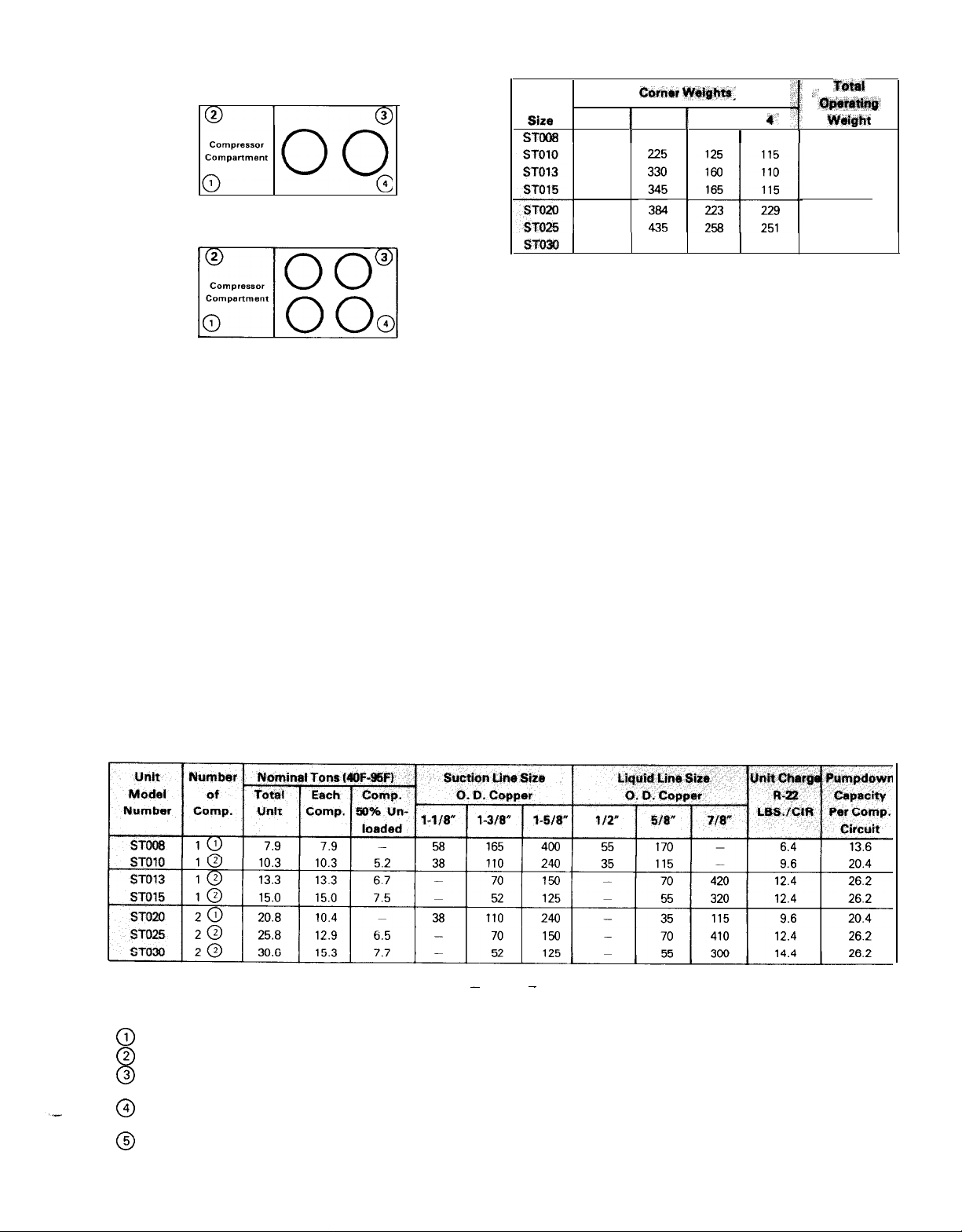

TABLE 1

ST008,010,013

ST020,025,030

m]

AND 015

REFRIGERANT PIPING

Piping between the condensing unit and the cooling

coil must be designed and installed to minimize

pressure drop, prevent liquid refrigerant carryover to

the compressor and to assure a continuous return of

compressor oil from the system. Piping sketches and

tables are not intended to provide information on all of

the possible arrangements. For example, when dual

circuit evaporators are used with an unloading com-

UNIT WEIGHT

Unit

Size

ST008

STDlO

ST013

ST015

ST020

ST025

-4

ST630 453

1

180

190

145

150

394

421

Gorn*r

1

2 f

I

210

465 277 270

aide.

I

-

POUNDS

3

I

115

0

4’

110

W&&t

I

Tti

615

645

745

775

1230

1365

1465

pressor, two liquid line solenoid valves may be used to

reduce coil capacity with compressor unloading. Note

especially that dual circuit evaporators should not be

piped with common liquid and suction lines to more

than one compressor. Separate evaporators, evaporator circuits and piping must be run for each compressor.

TABLE 2

SUCTION AND LIQUID LINE SIZES FOR EACH COMPRESSOR

MAXIMUM EQUIVALENT FEET OF COPPER TUBING

-

NOTES

Equivalent line lengths shown in above table are suitable for unit operating

condenser entering air temperature of 95F. When design conditions vary the table values should be rechecked.

0

Compressors used in the ST008 and 020 have no capacity reduction.

@

The compressors used in the

@

When refrigerant required to charge a circuit exceeds the pump down capacity of that circuit the use of a separate refrigerant storage

receiver will be required. The pump down capacity is based on the condenser 80% full at

@

Wherever vertical rise occurs in the piping, the minimum tonnage for oil entrainment should be checked and where necessary double

suction risers should be utilized. See Table 4, page 4.

@

Total equivalent feet for a given piping layout must include the equivalent length of straight pipe for fittings, valves and specialties added

to the total run of straight pipe.

ST010,

013, 015,025 and 030 have a single 50% capacity reduction step.

-

conditions

between 40 and 45F saturated suction temperature and

8OF.

3

Page 4

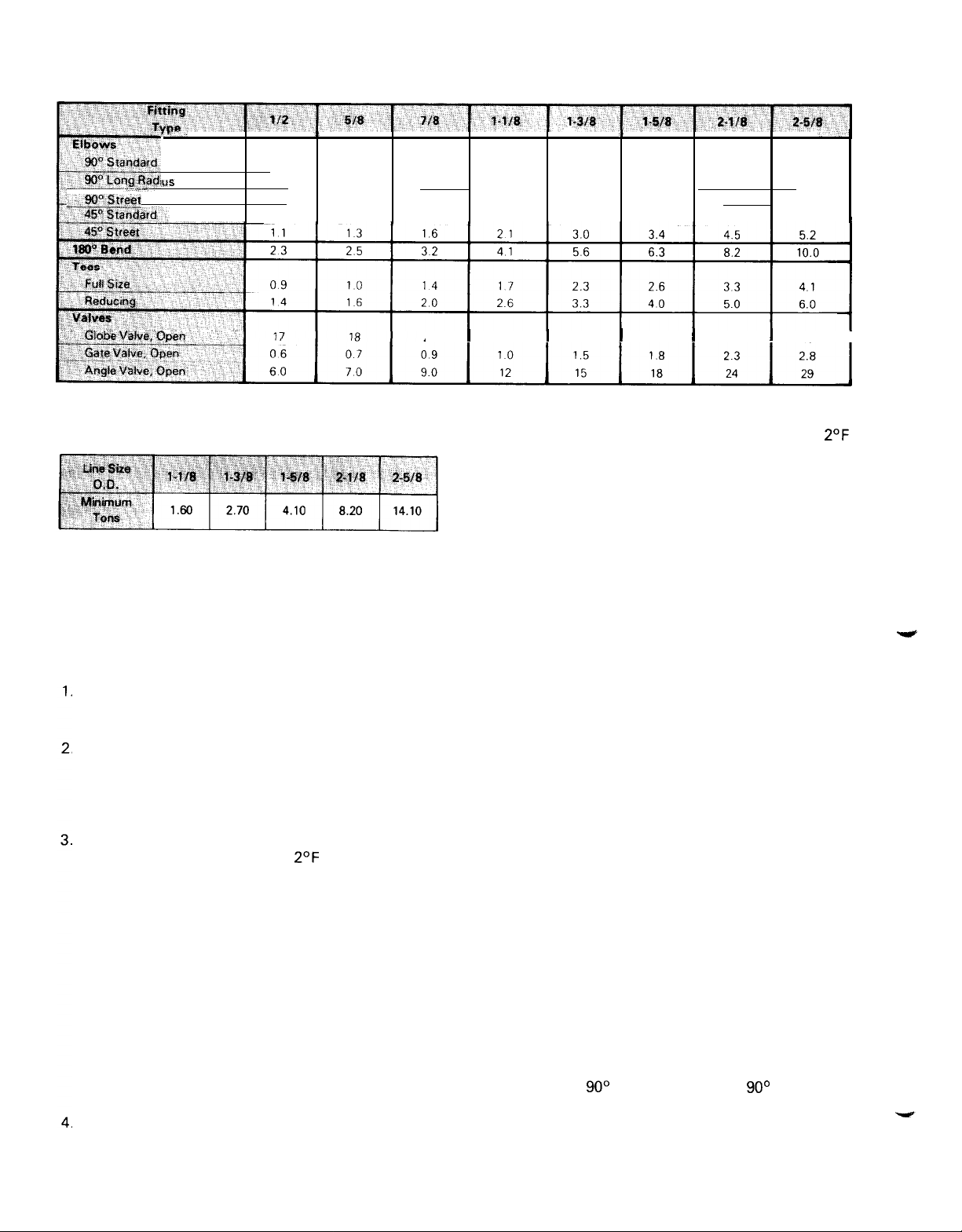

TABLE 3

EQUIVALENT FEET OF STRAIGHT TUBING FOR COPPER

16 20

10 14

25 32

08 09

22

ws

_.qQtq":?&qt

14

0.9

23

07

TABLE 4

Minimum Tonnage (R-22)

To Carry Oil Up Suction Riser

NOTE. When compressor minimum tonnage is less than shown in the

above table for a given line size, double suction risers will be

required.

To preclude potential problems that could be traced to

piping,

standard accepted piping practices as de-

scribed below and in the ASHRAE handbooks are

recommended.

Piping recommendations include:

The use of type K or L clean copper tubing. All

joints should be thoroughly cleaned and brazed

with high temperature solder.

Piping sizes should be based on temperature/

pressure limitations as recommended in the following paragraphs. Under no circumstances should

pipe size be based upon the coil or condensing unit

piping connection size.

Suction line piping pressure drop should not exceed

the pressure equivalent of

2’F

per 100 feet of

equivalent pipe length. After the suction line size

has been determined, the vertical suction risers

should be checked to verify that oil will be carried

up the riser and back to the compressor. The

suction

line(s)

should be pitched in the direction of

refrigerant flow and adequately supported. Lines

should be free draining and fully insulated between

the evaporator(s) and the compressor. Table 2,

page 3 shows piping information for units operating

at suction temperatures between 40 and 45 and a

condenser entering air temperature of 95. If operating conditions are expected to vary substantially

from these operating levels, the pipe sizing should

be rechecked.

Vertical suction risers should be checked using

Table 4, page 4 to determine the minimum tonnage

required to carry oil up suction risers of various

sizes.

I

26 33

17

41

13

I 29

2.3

5.6

1.7

I

38

FlTTlNGS AND

I

4.0

2.6

63

2.1

I

43

VALVES

5.0 6.0

3.3

82

2.6 3.2

55

I

I

69

5. The liquid line should be sized for a pressure drop

not to exceed the pressure equivalent of

saturated temperature. The liquid

line(s)

on all units

must include a liquid solenoid valve wired into the

circuit as shown on the applicable unit wiring

diagrams. The valve must be connected as follows:

1.

On model ST008, 010, 013, and 015 the solenoid

must be wired between terminals “P and N.”

2. Models ST020, 025, and 030 will require two sole

noid

valves, one in each liquid line. Make wiring

connections between terminals “P and N” for

circuit number 1 and “PI and N1" for circuit

number 2.

The unit control circuit for all compressors has been

designed to include a one time pump down cycle.

The use of a liquid line solenoid is required for

proper unit operation. In addition, a filter/drier

should be located between the liquid line service

valve and the solenoid valve and a combination

moisture indicator/sight glass should be located in

the liquid line ahead of the expansion valve.

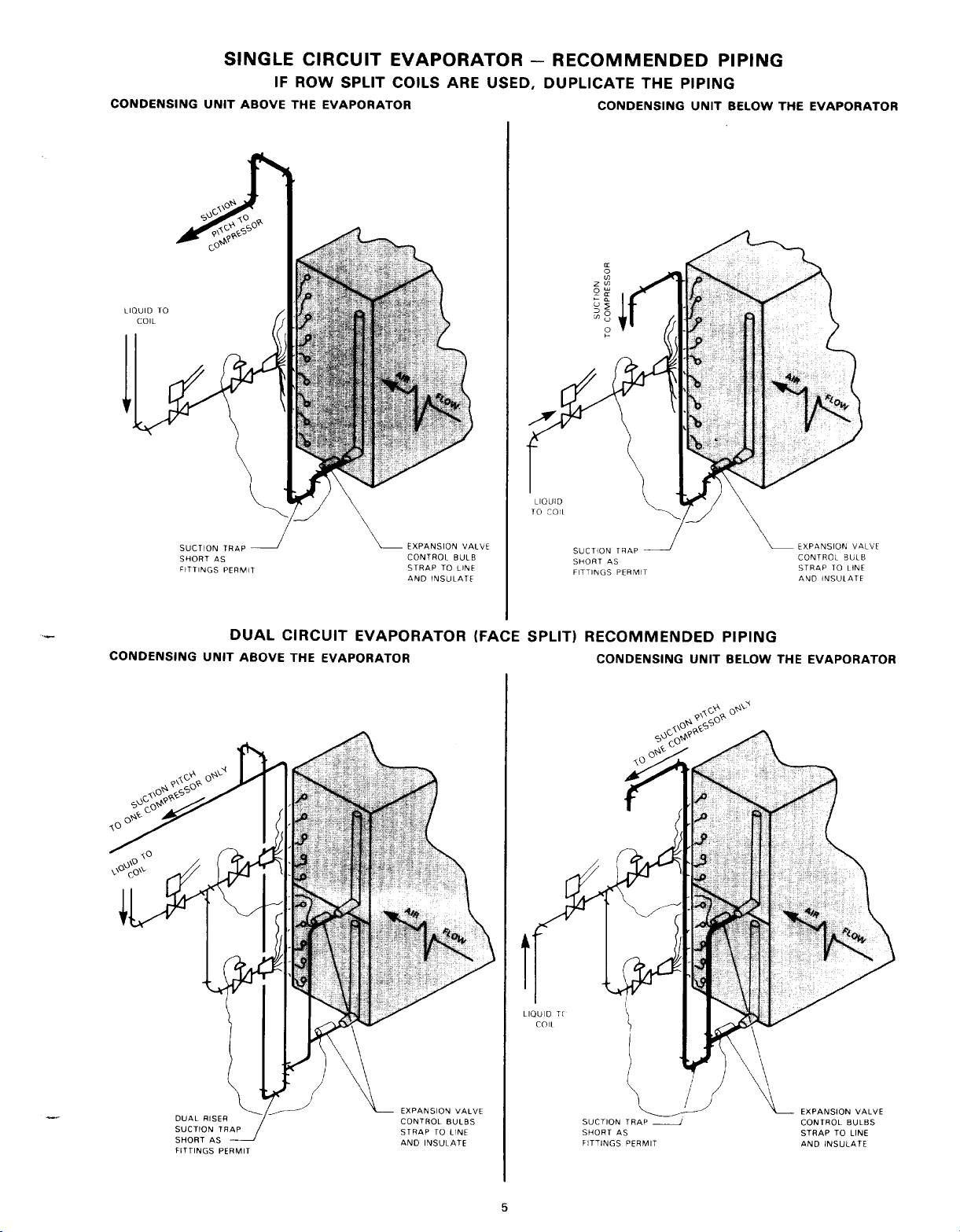

6. Suggested piping arrangements are shown on page

5.

All

multiple compressor units require a separate

refrigerant circuit for each compressor.

7. If Dual Suction Risers are Used:

A.

The combined cross sectional areas of the two

risers must be capable of maintaining adequate

refrigerant velocity for oil return at full unit

tonnage.

B.

The extra risers should be of a smaller diameter

than the main riser. The extra riser must

include its own trap at the bottom and should

enter the main suction header at twelve o’clock.

C.

The trap serving the extra riser must be as short

as fittings permit. A “U” fitting or the combination of a

90’

standard

ell

and a

90’

street

recommended.

D.

The suction line leaving the coil should also

include a trap if the expansion valve control bulb

is to be on the horizontal section leaving the coil

outlet. See the piping sketches on page 5.

4

4.1

10.0

ell

I

2’F

is

Page 5

Page 6

LEAK TESTING

All model ST condensing units are evacuated leak

tested and provided with a holding charge of R-22 at

the factory. Check the unit when it arrives at the job

site for damage or leaks in the refrigerant circuit. If the

refrigerant charge has been lost, locate and repair the

leak at the same time the connecting system is

checked. When you are ready to leak test, charge

enough R-22 into the system to raise the pressure to

about 30 psig; then add dry nitrogen and bring the

pressure up to a maximum of 150 psig. The system can

now be checked for leaks. Before attempting to repair

any leaks that may have been found, be sure to relieve

the test pressure from the system.

IMPORTANT CAUTION

Always use a pressure regulating valve on

the nitrogen drum and be sure to

nect the drum from the system after the

maximum of 150 psig test pressure is

reached. Under no circumstances should

you exceed the maximum leak test pressure

of 150 psig. DO NOT USE OXYGEN TO

BUILD UP PRESSURE, A SERIOUS EXPLOSION COULD RESULT.

discon-

EVACUATION

After all leaks have been repaired the system can be

evacuated, proceed as follows:

Connect a good quality manometer or gauge

(capable of measuring one millimeter of vacuum)

into the system and locate it as far away as possible

from the vacuum pump.

The triple evacuation method is recommended.

Evacuate the system to 29” vacuum, then add enough

R-22 to break the vacuum and bring the system up to

10 psig pressure. Repeat this evacuation ‘two more

times and on the third evacuation break the vacuum by

feeding R-22 into the system through the gauge port

on the condenser liquid shut off valve. With the

refrigerant cylinder up ended, it should be possible to

install close to 75% of the required charge into the

system in this manner without starting the com-

pressor. Do not start the compressor until the

following checks have been made.

PRELIMINARY CHECKS BEFORE

STARTING COMPRESSOR(S)

1.

With the unit disconnect switch off, check to be

sure that the starter contacts meet evenly and that

all operating starter parts move freely. Check that

the time delay fuses

are of the proper size.

2.

Open all refrigerant

charge, and liquid).

3.

With the thermostat

room thermostat below the design temperature.

Check that the air handling unit fans are rotating in

the proper direction.

in the unit disconnect switch

service valves (suction, dis-

in the “off” position, set the

Close the disconnect switch which energizes the

4.

crankcase heaters. These heaters must be ener-

gized 8 hours before attempting to start the

compressor(s).

Check that line voltage is within

5.

compressor nameplate voltage rating.

+ 10 percent of the

CHARGING

With the cylinder still up ended, charge as much

1.

refrigerant as possible into the system. When the

system will no longer accept refrigerant in this

manner, disconnect the drum from the liquid valve

and reconnect it to the gauge port on the suction

service valve.

Check the compressor oil level. If the oil level is

2.

over the top of the glass, be prepared when the

compressor starts to shut it down if sounds of liquid

pumping are evident.

Recheck that the suction, liquid and discharge line

3.

shut off valves are open. Close the unit disconnect

switch and set the room thermostat to call for

cooling.

With the compressor operating, continue to allow

4.

refrigerant to enter until the estimated charge has

been weighed in and/or the sight glass clears. At

this point, check the liquid line temperature leaving

the condenser, it should indicate 10 to 12 degrees

of subcooling.

Another method of checking the refrigerant charge

after the initial 75% has been added to the unit

would be to block the condenser coil until the head

pressure is built up to about 300 psig. Continue to

add refrigerant until the sight glass clears and 10 to

12 degrees subcooling is obtained.

Regardless of the method used to charge the unit,

refer to the charging and operating curves applicable to the unit involved and check operating

pressures against the curve values.

After about one hour of operation, check the compressor amperage being drawn. It should not exceed the

Full Load Amperes listed on the unit nameplate.

Also check that the combination sight glass/moisture

indicator is showing a dry condition. If moisture is

indicated, a refrigerant drier will have to be added into

the system.

TABLE 5

APPROXIMATE OPERATING CHARGE

FOR COMPRESSOR CIRCUIT

NOTE: Approximate charge includes evaporator coil, condensing

unit, liquid line drier and approximately 25 ft. of

liquid line per circuit. Refrigerant charging should be

performed as described under “Charging” on Page 6.

-

R-22, LBS

suction

and

6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

TYPICAL SCHEMATIC WIRING FOR MODELS

ST 025 AND

030

FUSE ~

115V.

BUSSMAN

FUSE PRIMARY CON

TRANSFORMER BUSS

4AMP

TYPE

NEC CLASS 2

MDX

COB WkllNG

-

X2 SYS

ONLY.

ON~OFF

FUSE

2.5A

SEE NOTES, PAGE 13

schematic diagram

shown on page 16

BEHIND TERM

HOUSING

BLOCK

TYPE S

UNIT LAYOUT

REFERENCE DRAWING

Xl COMPRESSOR

598C686-SUB

6

OPTIONAL

EQUIPMENT

ACCESSORY ITEMS

LOW AMBIENT FAN SPEED CONTROL - By

adding an accessory fan speed control to the last

operating fan motor on all model ST008 through 015

units, the minimum operating ambient temperature as

shown on Table 6, page 7 can be reduced to

O’F for all

unit operating capacities. This control is a standard

accessory available from McQuay for field installation.

TIME DELAY RELAY - On two compressor units

(models ST020 through

030),

it may be desirable to

prevent simultaneous starting of both compressors on

a call for cooling. An accessory time delay relay is

available for field installation in the unit operating

control circuit. This relay will add a short time delay

and only allow one compressor to start at a time.

SUCTION LINE ACCUMULATOR - Some systems,

depending on line length, solenoid valve leakage, etc.,

may require the use of a suction line accumulator to

prevent damage to the compressor from liquid

carry-

CONTROL CIRCUIT OPERATION

Refer to the schematic diagram shown on page 16. A

single line voltage fused disconnect switch must be

field supplied in the wiring supplying power to the unit.

With the disconnect switch closed, power is supplied

to the primary of the control transformer located on

over when the compressor first starts. A standard

accessory accumulator with a liquid capacity of 31

pounds is available for field installation in the suction

line of each compressor circuit.

PRESSURE GAUGES - Are available in kit form for

field installation.

HOT GAS BYPASS - This accessory option is

available for field installation on units where the

minimum capacity step does not reduce sufficiently to

meet the minimum load requirement. The use of hot

gas bypass is recommended on systems where evaporator air flow is varied or where the load at standard

air flow reduces sufficiently to cause a low suction

pressure condition. The kit contains all parts required

to adapt model ST units to hot gas bypass. It must be

used on systems with side outlet distributors on the

coil or on systems where it is permissible to introduce

hot gas between the expansion valve and evaporator

unit.

line 47, a secondary control voltage of 115 volts is

generated by the transformer.

A second transformer (115 to 24V) is located on line

74. On a call for cooling by either or both of the room

thermostats “1TC” or

relays

“1CR”

and “2CR”

2TC,”

on lines 78 and 80 are energized through the indoor

unit fan coil unit interlock contacts

(5MA).

15

Page 16

Page 17

Assume thermostat contacts

cooling, relay coil “ICR” contacts on lines 56 and 59

will be closed. Closing the

energize the compressor starter holding coil

through the high pressure cutout

switch

pressure cutout

gized, the contacts on lines I, 3 and 5 and auxiliary

contacts

sor number 1 and auxiliary contacts 1MA line 54 provide an interlock circuit parallel to the

on line 56. A second set of

close and energize liquid line solenoid valve “1 LS”.

In addition, the closing of relay “1CR” contacts on line

56 also provides voltage to the

(line 53).

After

actuated contacts

necessary to load the compressor.

When either the first or second stage of the thermostat

calls for cooling the compressor starter auxiliary

contacts

the condenser fan motor

Contactors

through outdoor ambient thermostats

as the outdoor temperature changes. See table 7 on

page 8 for details on the action of the head pressure

control.

To insure that the indoor fan starter is energized,

before the condensing unit can be started, indoor fan

starter auxiliary contacts must be installed in the open

section of the control circuit between terminals Yl-Sl

and

identified on the schedmtic diagram as

5MA2.”

The unit control circuit incorporates a one time

down control. For example, when the second step on

(SWS1),

1CR

Y2-S2

overload contacts

(1

LP). With holding coil

“1MA”

contacts have closed the suction pressure

1MA or

on line 54 close. This starts compres-

“1CC”

2MA

on lines 70 and 72 will energize

“4M”

and

on lines 78 and 80. These contacts are

“1TC”

are calling for

1CR

contacts on line 56 will

“1M”

(1HP),

the system

(1OL

and the low

“1M”

ener-

“1CR”

contacts

1CR

contacts on line 59

“1OL”

overload module

on line 53 can open when

contactors 3M,

“5M”

can also be cycled

4M and 5M.

“1TA

and

“5MA1”

pump-

2TA”

and

the two-stage thermostat is satisfied and opens contacts 2TC on line 80, cooling relay 2CR is de-energized

opening relay contacts on lines 64 and 67. The circuit

on line 65 is maintained by the 2MA starter auxiliary

contacts on line 62. The liquid line solenoid valve on

line 67 is de-energized when the 2CR relay contacts

ahead of it are opened. De-energizing the solenoid

valve cuts off the flow of refrigerant to the number 2

expansion valve. The compressor continues to run because the circuit to compressor starter holding coil 2M

is maintained by the 2MA auxiliary contacts on line 62.

The compressor continues to run and pump refrigerant

from the system until the setting of low pressure

cutout “2LP” on line 65 is reached and the contacts of

this control are opened. When this occurs the compressor starter holding coil 2M is de-energized, opening the starter contacts on lines 7, 9 and 11 and

auxiliary contacts 2MA on line 62. Suction pressure

switch “2LP” is automatic reset and when it does

reset, the compressor will not restart because both

relay contacts 2CR (Line 64) and starter auxiliary

contacts 2MA (Line

sor cannot be restarted until the 2TC thermostat again

calls for cooling and relay coil 2CR is energized again

closing 2CR contacts on lines 64 and 67. A similar

sequence will occur when thermostat contacts

open.

Also built into the compressor control circuit is a timed

off provision to prevent the compressor from restarting

after it has cycled off. A period of 3 to 5 minutes must

elapse before the compressor can restart. This function

is built into all model ST condensing units. On all units

except models ST010 and 020, this time delay is built

into the solid state control, on the ST010 and 020 it

is provided by separate time delay relays

“2TD.”

62)

are both open. The compres-

“1TD”

1TC

and

MAINTENANCE AND SERVICE

CRANKCASE HEATERS - The unit power supply

must be kept on at all times during the operating

season to keep the compressor crankcase heaters

energized. If the power is disconnected the compressor(s) could be damaged.

-

COMPRESSOR LUBRICATION

sealed compressors used in the model ST unit assem-

bly will not require additional lubrication once the

unit has been checked out and placed in operation.

In the event a large quantity of oil is lost as the

result of refrigerant leak, the system may require the

addition of oil.

CONDENSER FAN MOTORS

used on model ST008, 010, 013, 015 and 020 are

supplied with

ings. These motor bearings should be checked annually and lubricated with 20 weight non-detergent

oil.

The model ST025 and 030 units utilize permanently

lubricated ball bearing type motors.

CONDENSER COIL - The condenser coil should be

inspected and cleaned on a regular basis. Accumulation of leaves, paper and surface dirt should be

brushed from the finned surface. Annually the finned

prelubricated

sealed sleeve type bear-

The hermetically

-

The fan motors

surface should be cleaned using a fin cleaner. A dirty

condenser coil can increase unit power consumption

by as much as twenty percent.

INDOOR FAN AND EVAPORATOR COIL

indoor air handling system must be inspected and

serviced on a regular basis. Filters should be clean,

“V” belt tension adjusted and the evaporator coil

surface clean. In addition, the drain pan should be

clear of algea and the condensate should drain freely.

-

SEASONAL SHUTDOWN

need be made for end of season shutdown.

SEASONAL STARTUP

The crankcase heater circuit must be energized at

least eight hours before attempting to start the

compressor.

The air handling

serviced.

The unit condenser coil should be clean and free

of any debris that mav have accumulated during the

shutdown period.

Check and tighten all electrical connections.

Refer to section

Starting,” (page 6).

17

unit(s)

No special provisions

-

should be inspected and

“Preliminary Checks

-

The

before

Page 18

TROUBLE SHOOTING GUIDE

Possible

Cause

FUSE

BLOWN

COMPRESSOR

STARTER

OVERLOAD

RELAY

TRIPPED

LOW

PRESSURE

CUTOUT

TRIPPED

T

HIGH

PRESSURE

CUTOUT

TRIPPED

Possible

Reasons

Motor or Winding

Grounded.

Fuse or Wire

Too Small

Compressor seized

Compressor

Drawing

Excessive

Current

Low Indoor

Refrigerant

Expansion Valve

not Opening

Refrigerant Charge

inoperative

Non-Condensables

in the Condenser

Overcharge

Refrigerant

Airflow

Restricted

Flow

Loss of

Evaporator

Fan

of

Checking

Procedure

Test for grounds, loose

wire connections, starter

contact adjustment

Check Table 9,

Megger motor

Check wiring for size

and/or loose connections

Check whether phase

unbalance exceeds 3%

Reset compressor lockout

Run compressor, check

starting, noises, and

for amperge drawn

Operate condensing unit,

check evaporator coil for

slow even frosting

Check liquid line strainer,

liquid line, suction line

for temperature change.

frost or ice will generally

indicate restriction.

Remove bulb, hold in

hand. Feel distributor

to see if valve opened

Check liquid line

temperature and

sight glass

Verify voltage at motor,

remove belt, spin

motor by hand.

Check air temperature

rise across condenser,

purge condenser,

observe effect on

condensing pressure

Purge refrigerant, check

for reduction in head

pressure

Page 10

Possible

Remedy

Replace wire, tighen connections of if

is grounded, replace it.

Replace as required

Replace compressor

if required

Replace wire if necessary,

tighten

Consult with

power company

Replace compressor

Clean or replace filters,

clean evaporator coil,

increase fan speed, correct

indoor fan rotation

Remove restriction

Adjust or replace

power element.

Leaktest system, repair

leak, evacuate when

necessary, recharge

Replace or repair motor

Evacuate system

Remove refrigerant until

operating pressures are

normal.

compressor

connections.

CONTROL

CIRCUIT

OPEN

MOTOR

TEMPERATURE

SENSOR OPEN

Air Cooled Condenser

Fan(s) Inoperative

Thermostat

Contacts

Open

Protective

Control

Defective

Defective

Starter

Coil

Motor

Temperature

too High

Verify voltage at motor,

check bearings.

Adjust to lowest setting,

check for voltage across

compressor starter

operating coil

Check switch operation

Check voltage at coil. If

burned will generally have

burned odor and dark

appearance

Check motor for failure,

check voltage, check

running current, check

refrigerant charge

Megger Motor

18

Replace motor or repair

defective bearing

If thermostat is defective,

replace

If defective, replace

If defective replace coil

Correct operating

conditions or if motor

is defective, replace.

Page 19

TROUBLE SHOOTING GUIDE

NOISY

COM

PRESSOR

Low Refrigerant

Charge

Low

Air

Deliverv

Compressor

Not

Pumping

Compressor

Running

Unloaded

I

_iquid

refrigerani

flooding back

to compressor

Defective

Compressor

Head

Valves

System Leak

Coil and or Filter Dirty

Fan Speed too Low

Evaporator

Fan

Problem

Head Valves

Broken or

Head Gaskets

Blown

Unloading solenoid

Valve Stuck in

Unloaded Position

Faulty Expansion

Valve or Improper

Suoerheat Settinq

Liquid Refrigerant

Returning to Compressor

Expansion Valve and

Liquid Line Problems

Excess Oil in Svstem

Normal Wear

Check operating pressures Leak test, repair

and liquid line recharge

temperatures

Inspect filters and coil

Check fan speed and duct.Adjust fan speed, if

resistance against design

specifications

Start and stop fan,

observe rotation of

blades.

Check temperatures by

hand. Discharge and

suction lines warm cylinder Replace compressor

hot. Check suction and

discharge pressure

Check unloading solenoid Replace coil or valve

valve for defect

Check super heat

Try to pump system

down. Check how fast

discharge and suction

pressures equalize

Clean or replace filters,

clean coil

restriction is in duct may

require laraer motor

If fan rotation is wrong

correct by fan interchanging motor

connections

Readjust or replace valve

If compressor will not

pump or pressures equalize

too fast, replace

compressor.

OIL

PRESSURE

PR0BLEMS -

Liquid

Refrigerant

Returning to

Compressor

Oil Trapping

Expansion Valve Not

Set Properly, Leaking

Liquid Solenoid Valve

Piping Problem

Check valves Adjust or replace

as necessary

Check piping arrangement

and size. Check for

Check for possible traps.

Modify as necessary

valve(s)

19

Loading...

Loading...