Page 1

Installation and Maintenance Manual IM 1014

MT 155 Thermostat

Installation

DANGER

READ THESE INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE OR SERVICE THIS

THERMOSTAT.

Failure to observe safety information and comply with

instructions could result in PERSONAL INJURY, DEATH AND/

OR PROPERTY DAMAGE.

To avoid electrical shock or damage to equipment, disconnect

power before installing or servicing. Use only wiring with

insulation rated for full thermostat operating voltage. Use

copper wire only. Insulate or wirenut all un-used leads. Any

wiring, including the remote probe,may carry the full operating

voltage of the thermostat.

To avoid potential fire and/ or explosion do not use in

potentially flammable or explosive atmospheres.

Retain these instructions for future reference. You must review

your application and national and local codes to ensure that

your installation will be functional and safe.

1 Install the thermostat with the two furnished mounting

screws to a standard 2" x 4" electrical box, 4-11/16" x 21/8" square device box with a 2" x 4" adapter ring or to a

4" x 4" box with accessory adapter plate.

2 For wall installations, mount the thermostat on an inside

wall approximately 5 feet above the floor. The location

should provide circulation at average room temperature.

Avoid direct sunlight or sources of hot or cold air in the

room or wall.

3 Remove the knob and then the cover. Mount thermostat

base assembly to the outlet box using the screws

provided, tighten the screws evenly but do not over

tighten. Make wiring connections as noted.

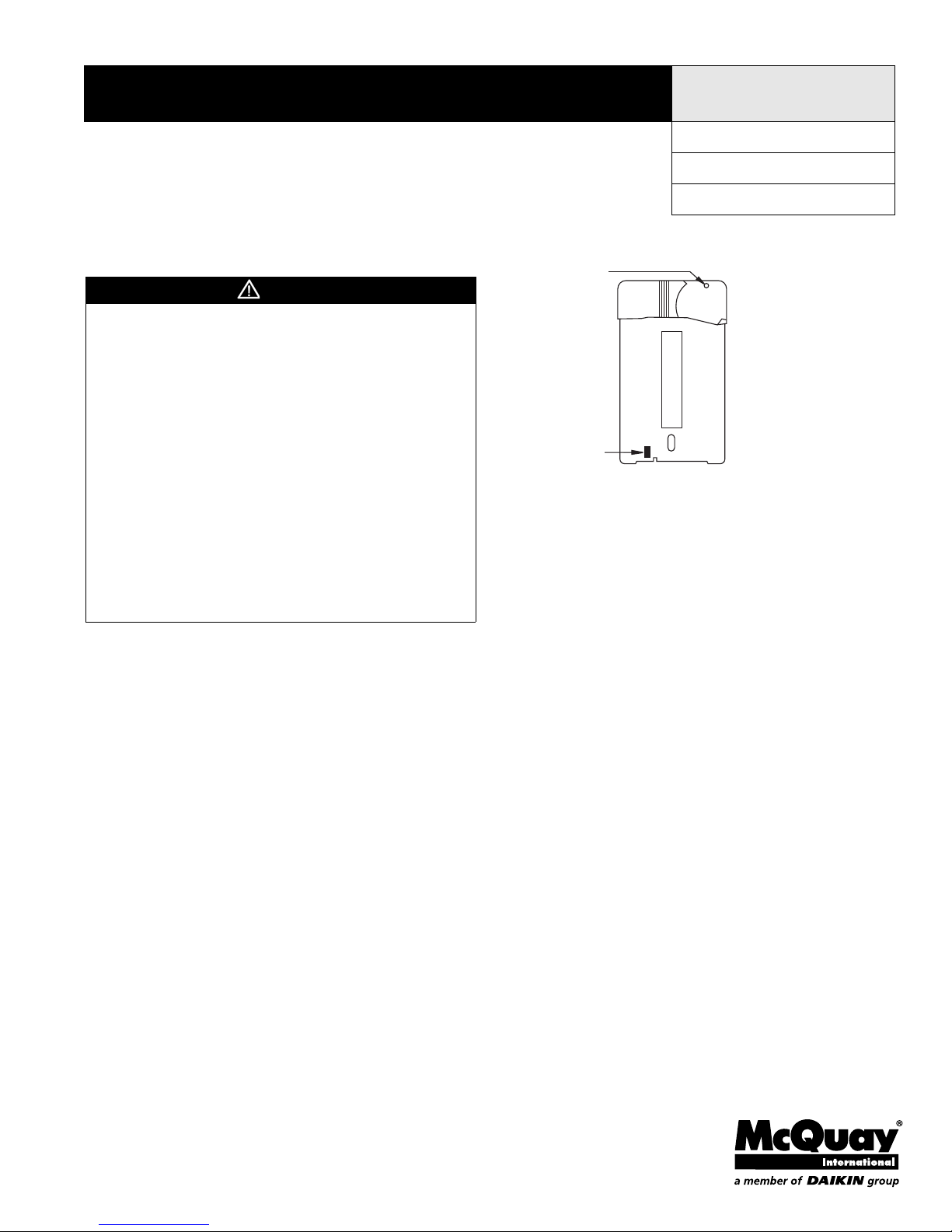

4 To use a remote sensor, remove jumper JP-1 to disable

local sensing. See Figure 1. Failure to remove JP-1 when

using a remote sensor will cause improper operation of

the thermostat. Some units do not have remote sensing

capability . See Application Notes.

Group: Applied Air Systems

Part Number: 910102989

Date: August 2009

Figure 1: Removing Jumper JP-1

INSTALL COVER

LOCKING SCREW

REMOVE JP1

WHEN USING A

REMOTE SENSOR

5 Reinstall the cover assembly. Install cover locking screw

JP1

provided. Reinstall the knob.

6 Checkout: After wiring and installation are complete,

energize the system and check the operation. Adjust the

thermostat as necessary to complete at least one cycle.

Be sure the thermostat and all other equipment are

functioning correctly.

Thermostat Operation

Temperature Range: 50°F - 90°F (10°C - 32°C)

TA155: A HEAT-OFF-COOL system switch manually selects

heating or cooling mode. In the HEAT position, only the heat

output cycles with demand. In the COOL position, only the

cool output cycles with demand. In the OFF position, heating

and cooling outputs are off. Units with a two position system

switch or without a system switch must use a load transfer

switch when both heating and cooling outputs are used. This

prevents control failure and equipment damage caused by

direct cycling between loads.

TB155: An ON-OFF system switch enables auto-changeover

of heating and cooling modes. In the ON position the

thermostat activates heating or cooling outputs dependant

upon the relationship between set point and ambient

temperature. Heat on to cool on dead band is 4°F. In the OFF

position, heating and cooling outputs are off. Units without a

system switch cycle between heating and cooling with a 4°F

dead band.

IM 1014 / Page 1 of 2 © 2009 McQuay International 800-432-1342 www.mcquay.com

FAN: Some units have a switch for manual selection of fan

speed. On these units fan operation is either internally wired

Page 2

for fan continuous operation or is dependant upon connection

1

2

3

1

2

5

1

2

3

4

TB1

TB2

TB3

NO CONNECTION

L2 or NEUTRAL

TB1-3

TB1-4

FAN

COOL

OUTPUT

HEAT

OUTPUT

TB2-3

FAN HIGH

FAN LOW

FAN MED

L1

FAN SUPPLY

TB2-2

TB2-1

TB2-4

TB2-5

TB3-3

CONNECT

FOR FAN

CONTINUOUS

TB3-2

TB3-1

SWITCHED POWER

COOL

OUTPUT

HEAT

OUTPUT

1

2

3

1

2

TB1

TB3

L1

TB3-3

TB3-2

TB3-1

NO CONNECTION

L2 or NEUTRAL

TB1-3

TB1-4

to the fan supply input . When internally wired for fan

continuous operation, the fan will be off when the system

switch is off. When dependant upon external connections the

fan may not be off with the system switch in the off position.

The fan supply input is switched to fan speed outputs (HI MED - LO).

SWITCHED POWER: L1 power is switched to this output any

time the system switch is out of the OFF position.

Ratings

Table 1: Fan and system switches

Voltage

Rating

Inductive

FLA LRA

24 VAC N.A. N.A. N.A. 24 VA 10 VA

120 5.8 34.8 6.0 125 VA 20 VA

240 2.9 17.4 5.0 125 VA 20 VA

277

2.4 14.4 4.2 125 VA 20 VA

Resistive

Amps

Pilot

Duty

Wire Lead Colors (if applicable)

White with Orange Stripe Fan High

White with Red Stripe Fan Med.

White with Brown Stripe Fan Low

Red Heat

Blue Cool

Black L1

Yellow L2 or Neutral

Orange Switched Power

Violet Fan Supply

Brown Remote Probe

Brown Remote Probe

Application Notes

1 To use a remote sensor, remove jumper JP-1 to disable

local sensing. See Figure 1. Failure to remove JP-1 when

using a remote sensor will cause improper operation of

the thermostat. Some units do not have remote sensing

capability.

2 Units with remote sensing capability have a four-position

terminal block at TB1. If TB1 is two position the unit is

local sensing only.

3 Remote probe wiring should be located away from any

electrical motors or power wiring

4 Some units are internally wired for permanent fan

continuous operation.

5 On units with a Fan Supply input, the operation of the

fan is determined by wiring connection. For fan

continuous, jumper the Fan Supply input (TB2-5) to the

Switched Power output (TB3-3).

6 For fan cycling operation with a call for heat or cool, a

fan relay must be used.

© 2009 McQuay International 800-432-1342 www.mcquay.com IM 1014 / Page 2 of 2

Thermostatic

Switching

7 Observe electrical ratings. Thermostatic outputs are pilot

duty only.

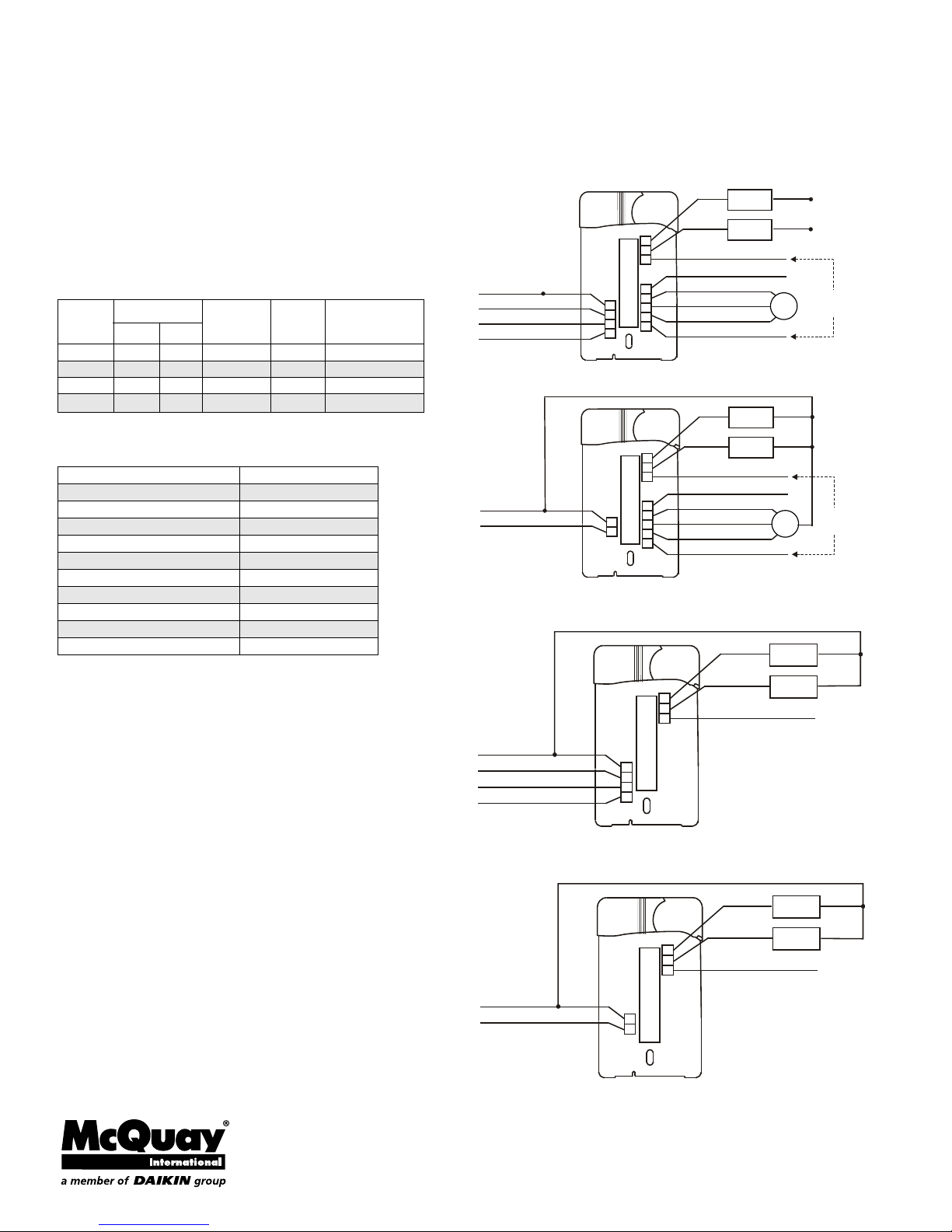

Wiring Diagrams

Figure 2: Units with remote sensing capability

TB3-1

HEAT

OUTPUT

TB3-2

TB3

1

2

TB3-3

3

TB2-1

TB2

1

L2 or NEUTRAL

NO CONNECTION

REMOTE PROBE 1

REMOTE PROBE 2

TB1-4

TB1-3

TB1-2

TB1-1

4

3

2

1

TB1

TB2-2

2

TB2-3

3

4

TB2-4

5

TB2-5

Figure 3: Units with switches used for local sensing only

Figure 4: Units with no switches with local/remote sensing

capability

TB3

1

2

3

L2 or NEUTRAL

NO CONNECTION

REMOTE PROBE 1

REMOTE PROBE 2

TB1-4

TB1-3

TB1-2

TB1-1

4

3

2

1

TB1

Figure 5: Units with no switches used for local sensing

only

COOL

OUTPUT

SWITCHED POWER

L1

FAN H IGH

FAN MED

FAN L OW

FAN SUPPLY

TB3-1

TB3-2

TB3-3

FAN

HEAT

OUTPUT

COOL

OUTPUT

CONNECT

FOR FAN

CONTINUOUS

L1

5

Loading...

Loading...