Page 1

Installation and Maintenance Manual IM 842-1

Maverick II™

Commercial Packaged Rooftop Systems

Heating & Cooling

Models MPS030A – 050A

30 to 50 Tons

R–410A Refrigerant

Group: Applied Systems

Part Number: IM 842-1

Date: January 2008

© 2008 McQuay International

Page 2

Contents

Introduction .............................................................. 3

General Information................................................ 3

Unit Nameplate ................................................... 3

Hazard Identification Information ........................ 3

Mechanical Installation ............................................ 4

Installer Responsibilities ......................................... 4

Receiving Inspection........................................... 4

Service Clearance .............................................. 4

Ventilation Clearance.......................................... 5

Overhead Clearance........................................... 5

Roof Curb Assembly and Installation.................. 5

Rigging and Handling ......................................... 9

Unit Piping for Condensate Drain Connection.. 10

Damper Assemblies.......................................... 10

Cabinet Weather Protection.............................. 10

Installing Ductwork............................................ 11

Installing Duct Static Pressure Sensor Taps .... 11

Installing Building Static Pressure Sensor Taps 12

Electrical Installation ............................................. 13

Field Power Wiring............................................ 13

Field Control Wiring .......................................... 14

Preparing Unit for Operation ................................. 15

Spring Isolated Fans......................................... 15

Optional Gas Heat .................................................. 16

Gas Furnace Design............................................. 16

Gas Heating Capacity Data .............................. 16

Installation ........................................................ 18

Gas Piping Routing Into Unit ............................ 20

Sequence of Operation..................................... 21

Start-Up Procedures ......................................... 21

Operating Procedures....................................... 22

Service.............................................................. 22

Maintenance ..................................................... 22

Ignition Control Module Information.................. 23

Optional Electric Heat ............................................ 24

Electric Heater Design.......................................... 24

Electric Heating Capacity Data ......................... 25

Electric Heater Data.......................................... 25

Wiring Diagrams ..................................................... 26

Unit Options ............................................................ 42

Economizer Enthalpy Control ........................... 42

External Time Clock.......................................... 42

Duct High Pressure Limit .................................. 42

Convenience Receptacle/Section Lights.......... 42

Exhaust Fan Option ......................................... 42

Sequence of Operation.......................................... 43

Operating States .................................................. 43

Start Up ............................................................ 43

Recirculation .................................................... 43

Fan Only........................................................... 43

Heating............................................................. 43

Minimum DAT .................................................. 43

Mechanical Cooling.......................................... 44

Economizer ...................................................... 44

Check, Test, and Start Procedures ...................... 45

Pre-Start of Unit ................................................... 45

Servicing Control Panel Components .............. 45

Before Start-Up ................................................ 45

Power-Up ......................................................... 45

Fan Start-Up..................................................... 45

Economizer Start-Up........................................ 45

Compressor Start-Up ....................................... 46

Sheave Alignment ............................................ 47

Drive Belt Tension Adjustment......................... 47

Air Balancing .................................................... 47

Final Control Settings............................................ 48

Controller Settings for Normal Operation ............. 48

Maintenance ........................................................... 49

Performing Service Maintenance ......................... 49

Servicing Control Panel Components .............. 49

Planned Maintenance ...................................... 49

All-Aluminum Condenser Coils ........................ 49

Unit Storage ..................................................... 50

Bearing Lubrication .......................................... 51

Setscrews......................................................... 52

Supply Fan Wheel-to-Funnel Alignment .......... 52

Refrigerant Charge........................................... 52

Servicing Refrigerant Sensors or Switches...... 52

Servicing Optional Electric Heater ................... 52

Service and Warranty Procedure ......................... 53

Replacement Parts........................................... 53

Scroll Compressor............................................ 53

All Compressors............................................... 53

In-Warranty Return Material Procedure ........... 53

Commercial Rooftop Equipment Warranty

Registration Form............................................. 54

Page 3

Introduction

General Information

Introduction

This manual provides general information about the “A”

vintage McQuay Commercial Packaged Rooftop Unit model

MPS. In addition to an overall description of the unit, it

includes mechanical and electrical installation procedures,

commissioning procedures, sequence of operation information,

and maintenance instructions.

The MicroTech II

®

rooftop unit controller is available on “A”

vintage rooftop units. For a detailed description of the

MicroTech II components, input/output configurations, field

wiring options and requirements, and service procedures, see

OM 843. For operation and information on using and

programming the MicroTech II unit controller, refer to the

appropriate operation manual (see Table 1).

For a description of operation and information on using the

keypad to view data and set parameters, refer to the

appropriate program-specific operation manual (see Table 1)

Table 1: Program Specific Rooftop Unit Operation

Literature

Rooftop unit control configuration

VFDs OM 844 - MD2

MPS Unit Controller

Discharge Air Control (VAV or CAV)

Space Comfort Control (SCC)

Operation manual bulletin

number

OM895 - MD3

OM847 - MD6

OM 843

.

Unit Nameplate

The unit nameplate is located on the outside of the main

control box door. It includes the unit model number, serial

number, electrical characteristics, and refrigerant charge.

Hazard Identification Information

DANGER

Dangers indicate a hazardous situation which will result in

death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which can

result in property damage, severe personal injury, or death if

not avoided.

CAUTION

Cautions indicate potentially hazardous situations, which can

result in personal injury or equipment damage if not avoided.

Figure 1: Nomenclature

McQuay Packaged System

(030, 035, 040, 050 tons)

Nominal capacity

M P S – 030 – A G

Heat medium

Y = None (cooling only)

G = Natural gas

E = Electric

Design vintage

McQuay IM 842-1 3

Page 4

Mechanical Installation

Mechanical Installation

Installer Responsibilities

The installation of this equipment shall be in accordance with

the regulations of authorities having jurisdiction and all

applicable codes. It is the responsibility of the installer to

determine and follow the applicable codes.

CAUTION

Sharp edges on sheet metal and fasteners can cause

personal injury. This equipment must be installed, operated,

and serviced only by an experienced installation company and

fully trained personnel.

Receiving Inspection

When the equipment is received, all items should be carefully

checked against the bill of lading to be sure all crates and

cartons have been received. If the unit has become dirty

during shipment (winter road chemicals are of particular

concern), clean it when received.

Figure 2: Service Clearances

All units should be carefully inspected for damage when

received. Report all shipping damage to the carrier and file a

claim. In most cases, equipment is shipped F.O.B. factory and

claims for freight damage should be filed by the consignee.

Before unloading the unit, check the unit nameplate to make

sure the voltage complies with the power supply available.

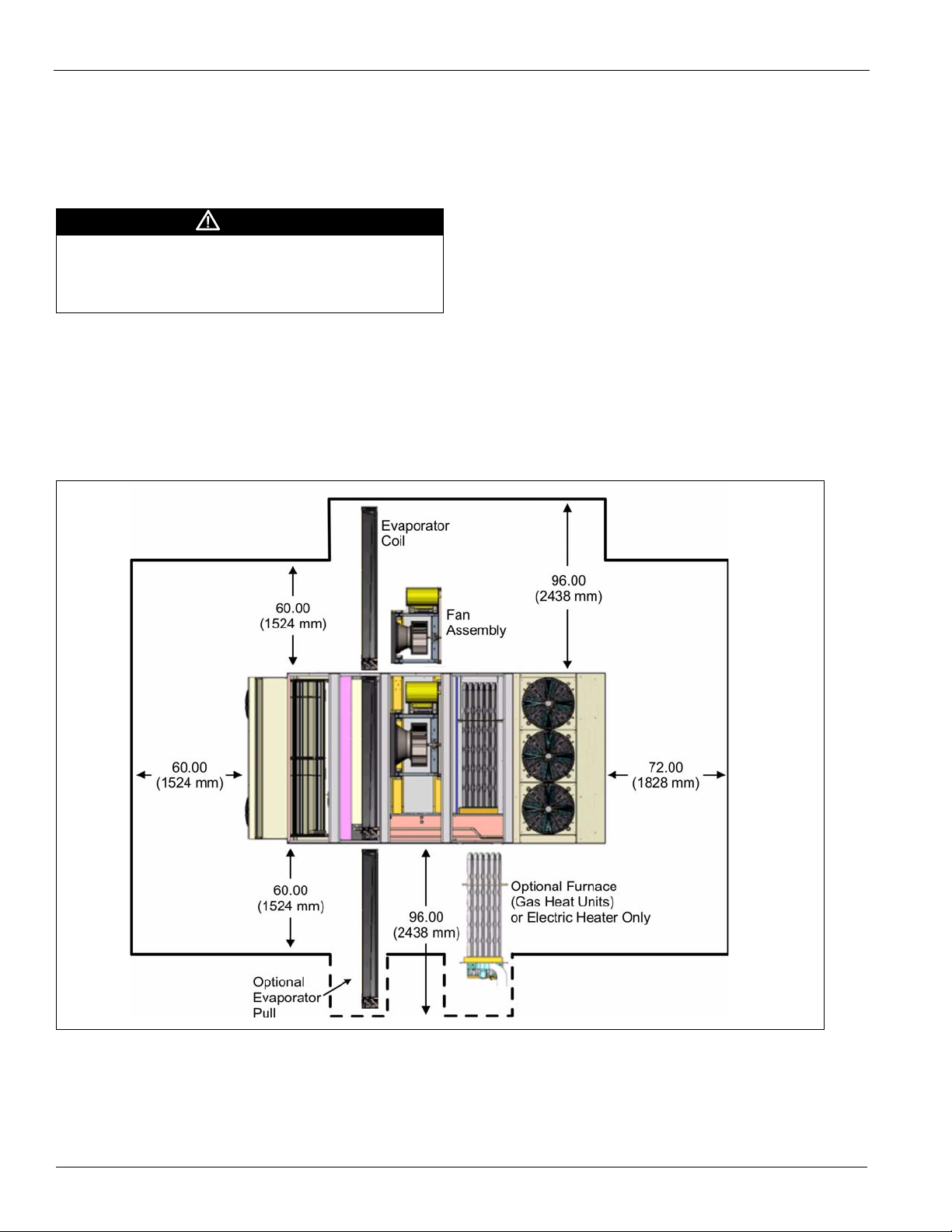

Service Clearance

Allow service clearances as approximately indicated in

Figure 2. Also, McQuay recommends providing a roof

walkway to the rooftop unit as well as along each side of the

unit that provides access to most controls and serviceable

components.

4 McQuay IM 842-1

Page 5

Mechanical Installation

Ventilation Clearance

Below are minimum ventilation clearance recommendations.

The system designer must consider each application and

provide adequate ventilation. If this is not done, the unit may

not perform properly.

Unit(s) Surrounded by a Screen or a Fence:

1 The bottom of the screen or fence should be at least 1 ft.

(305 mm) above the roof surface.

2 The distance between the unit and a screen or fence should

be as described in Figure 2 on page 4.

3 The distance between any two units within a screen or

fence should be at least 120" (3048 mm).

Unit(s) Surrounded by Solid Walls:

1 If there are walls on one or two adjacent sides of the unit,

the walls may be any height. If there are walls on more than

two adjacent sides of the unit, the walls should not be

higher than the unit.

2 The distance between the unit and the wall should be at

least 96" (2438 mm) on all sides of the unit.

3 The distance between any two units within the walls should

be at least 120" (3048 mm).

Do not locate outside air intakes near sources of contaminated

air.

If the unit is installed where windy conditions are common,

install wind screens around the unit, maintaining the

clearances specified (see Figure 2). This is particularly

important to maintain adequate head pressure control when

mechanical cooling is required at low outdoor air

temperatures.

Note: Low head pressure may lead to poor and erratic

refrigerant feed control at the thermostatic expansion

valve. The unit has automatic control of the condenser

fans which should provide adequate head pressure

control down to 20°F provided the unit is not exposed to

windy conditions. The system designer is responsible

for assuring the condensing section is not exposed to

excessive wind or air recirculation.

Overhead Clearance

1 Unit(s) surrounded by screens or solid walls must have no

overhead obstructions over any part of the unit.

2 The area above the condenser must be unobstructed in all

installations to allow vertical air discharge.

3 The following restrictions must be observed for overhead

obstructions above the air handler section:

a There must be no overhead obstructions above the

furnace flue, or within 9" (229 mm) of the flue box.

b Overhead obstructions must be no less than 96"

(2438 mm) above the top of the unit.

c There must be no overhead obstructions in the areas

above the outside air and exhaust dampers that are

farther than 24" (610 mm) from the side of the unit.

Roof Curb Assembly and Installation

Locate the roof curb and unit on a portion of the roof that can

support the weight of the unit. The unit must be supported to

prevent bending or twisting of the machine.

If building construction allows sound and vibration into

the occupied space, locate the unit over a non-critical area.

It is the responsibility of the system designer to make

adequate provisions for noise and vibration in the occupied

space.

WARNING

Mold can cause personal injury. Some materials such as

gypsum wall board can promote mold growth when damp.

Such materials must be protected from moisture that can enter

units during maintenance or normal operation.

Install the curb and unit level to allow the condensate drain to

flow properly and allow service access doors to open and close

without binding.

The gasketed top surface of the curb seals against the unit

when it is set on the curb. These flanges must not support the

total weight of the duct work. See “Installing Ductwork” on

page 11 for details on duct connections. It is critical that the

condensate drain side of the unit be no higher than the opposite

side.

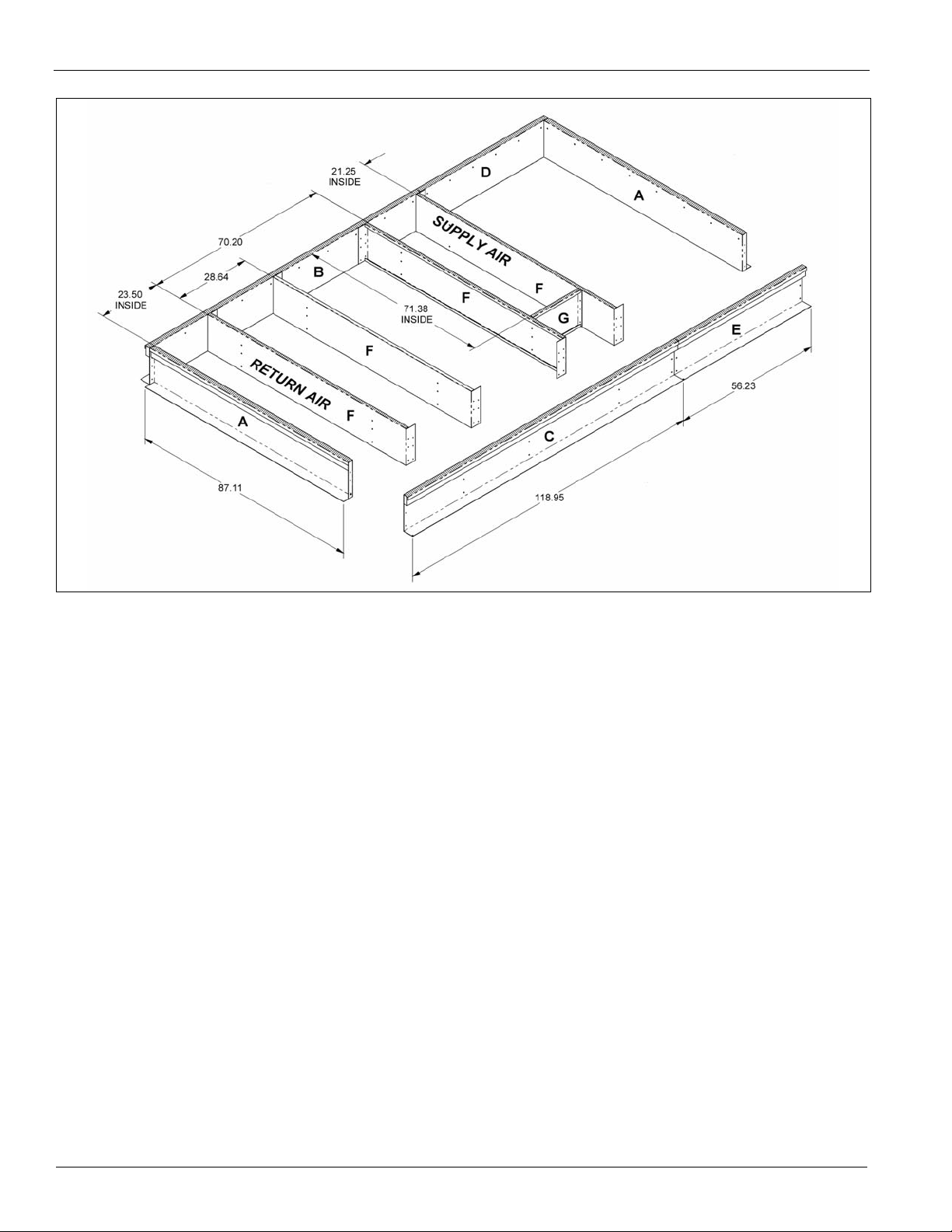

Assembly Instructions

Assembly of a typical roof curb is shown in Figure 3.

1 Set curbing parts A thru G per dimensions shown over roof

opening or on a level surface. Note location of supply air

opening. Check alignment of all mating screw holes.

2 Screw curbing parts together using fasteners provided.

Leave all screws loose until curb is checked to be square.

3 Square entire curbing assembly and securely tighten all

screws.

4 Position curb assembly over roof openings. Curb must be

level within .25 inches from side to side and 1.50 inches

over its length. Check that top surface of curb is flat with

no bowing or sagging.

5 Weld curb assembly in place. Caulk all seams watertight.

Remove backing from .25 x 1.50 wide gasket and apply to

surfaces shown by crosshatching.

6 Check that electrical connections are coordinated.

McQuay IM 842-1 5

Page 6

Mechanical Installation

Figure 3: Roof Curb Assembly—MPS 030A – 035A

6 McQuay IM 842-1

Page 7

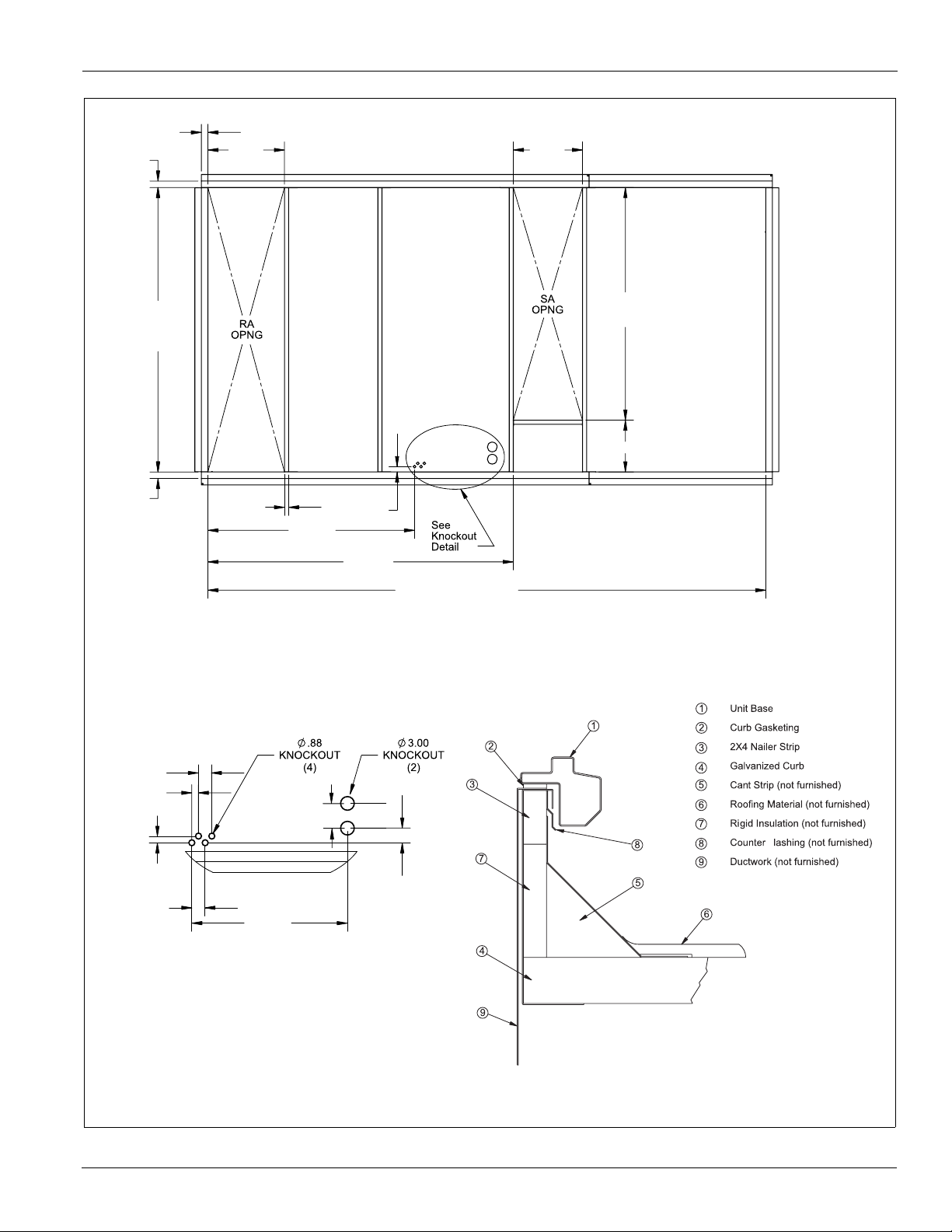

Figure 4: Roof Curb Layout—MPS 030A – 035A

2.00

[51 mm]

2.00

[51 mm]

23.50

[597 mm]

Mechanical Installation

21.25

[540 mm]

87.25

[2216 mm]

(INSIDE CURB)

2.00

[51 mm]

1.25

[32 mm] TYP

63.69

[1610 mm]

71.38

[1813 mm]

15.87

[403 mm]

1.63

[41 mm]

93.70

[2380 mm]

171.18 (INSIDE CURB)

[4348 mm]

PLAN VIEW

2.00

[51 mm]

1.00

[26 mm]

1.00

[26 mm]

2.00

[51 mm]

23.86

[606 mm]

3.75

[95 mm]

2.38

[58 mm]

F

KNOCKOUT DETAIL

CURB CROSS SECTION

McQuay IM 842-1 7

Page 8

Mechanical Installation

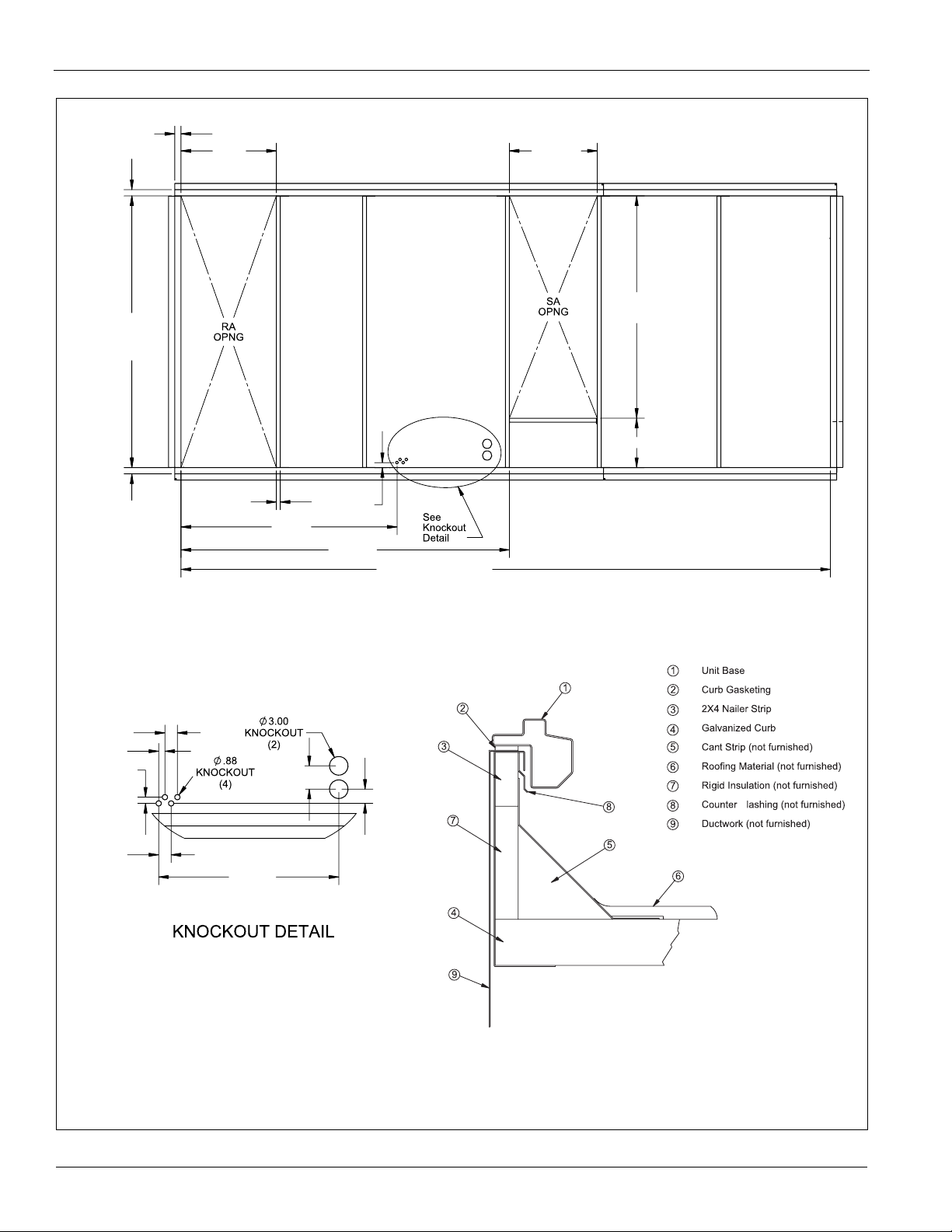

Figure 5: Roof Curb Layout—MPS 040A – 050A

2.00

[51 mm]

2.00

[51 mm]

87.25

[2216 mm]

(INSIDE CURB)

2.00

[51 mm]

30.63

[778 mm]

1.25 TYP

[32 mm]

69.39

[1763 mm]

1.63

[41 mm]

105.45

[2678 mm]

28.25

[718 mm]

71.38

[1813 mm]

15.87

[403 mm]

208.57 (INSIDE CURB)

[5298 mm]

1.00

[25 mm]

2.00

[51 mm]

2.00

[51 mm]

28.92

[735 mm]

3.75

[95 mm]

PLAN VIEW

2.28

[58 mm]

F

CURB CROSS SECTION

8 McQuay IM 842-1

Page 9

Mechanical Installation

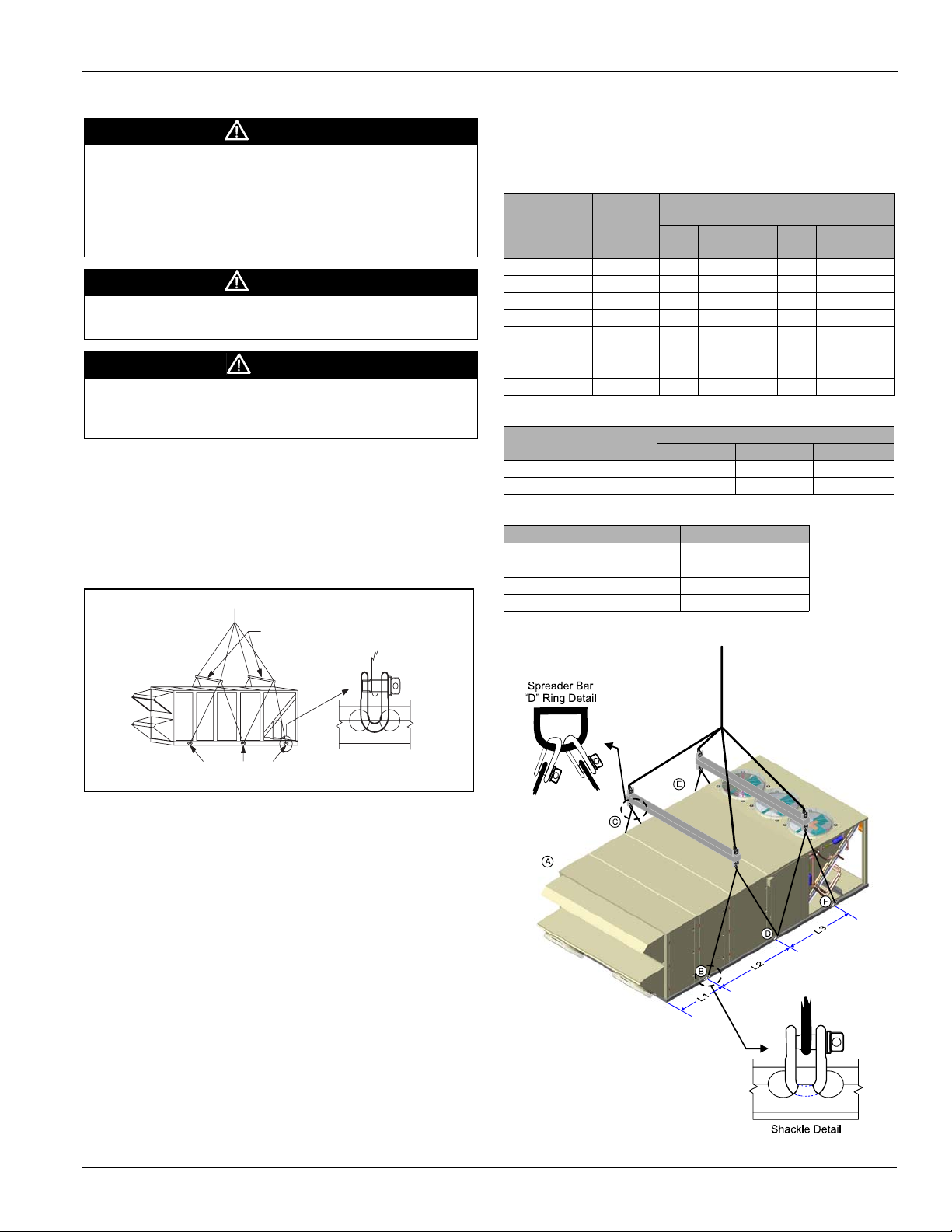

Rigging and Handling

WARNING

Only trained and qualified personnel should be allowed to

rig loads or operate load rated cranes and/or hoist

assemblies. Do not use a forklift to lift or maneuver the

unit. Failure to use a load rated crane or hoist assembly to

lift or maneuver the unit can cause severe personal injury

and property damage.

WARNING

Use all lifting points. Improper lifting can cause property

damage, severe personal injury, or death.

CAUTION

Lifting points may not be symmetrical to the center of

gravity of the unit. Ballast or unequal cable lengths may be

required.

Rigging holes for shackles are integral on the unit base. All six

lifting points must be used for rigging the equipment. Use

four independent lines, securing one end of a line to a unit

base lifting point and the other end of the line to an

associated spreader bar lifting point (see Figure 7). Figure 6

is an example of an instruction label shipped with each unit.

Figure 6: Rigging Label

LIFT UNIT ONLY AS SHOWN

Table 2 lists the weight distribution at each of the six lifting

points on the unit (also refer to Figure 7). Table 3 details lifting

point locations (also refer to Figure 7).

Table 4 lists the

weights of accompanying curbs.

Table 2: Percentage of Load and Weight Points

Tot al

Unit (Tons)

030A Cooling 3525 388 388 705 846 564 635

030A Heating 3625 399 399 725 870 580 653

035A Cooling 3680 405 405 736 883 589 662

035A Heating 3780 416 416 756 907 605 680

040A Cooling 4160 458 458 832 998 666 749

040A Heating 4410 485 485 882 1058 706 794

050A Cooling 4560 502 502 912 1094 730 821

050A Heating 4870 536 536 974 1169 779 877

Weight

(lbs)

A

11%B11%C20%D24%E16%F18%

Table 3: Location of Lifting Points

Unit (tons)

030A – 035A 35.5 62.0 52.0

–

050A 40.0 69.0 89.0

040A

L1 L2 L3

Table 4: Curb Weights

Unit (Tons) / Curb Height Weight (lbs)

030A – 035A / 14" Curb 341

030A

–

035A / 24" Curb 501

–

050A / 14" Curb 481

040A

040A

–

050A / 24" Curb 708

Point

% of Total Load

Distance (inches)

SPREADER BARS REQUIRED

MUST USE ALL OF THESE

LIFTING LUGS FOR LIFTING UNIT.

Use spreader bars, 96" to 100" (2438 to 2540 mm) wide to

prevent damage to the unit cabinet. Avoid twisting or uneven

lifting of the unit. The cable length from the bracket to the

hook should always be longer than the distance between the

outer lifting points.

If the unit is stored at the construction site for an intermediate

period, take these additional precautions:

1 Support the unit well along the length of the base rail.

2 Level the unit (no twists or uneven ground surface).

3 Provide proper drainage around the unit to prevent flooding

of the equipment.

4 Provide adequate protection from vandalism, mechanical

contact, etc.

5 Securely close the doors.

6 Cover the supply and return air openings.

Figure 7: Rigging the Unit (MPS 030A – 035A Example)

McQuay IM 842-1 9

Page 10

Mechanical Installation

Unit Piping for Condensate Drain Connection

The unit is provided with a 1" female NPT condensate drain

connection. For proper drainage, level the unit and drain pan

side to side and install a P-trap.

Figure 8 shows the layout of the condensate drain connection.

The distance from the drain pan outlet to the horizontal run of

the P-trap should be a distance of twice the static pressure in

the drain pan.

Example: If the static pressure as measured in the drain pan is

1.5", then the distance between the drain outlet and the

horizontal run should be 3".

Draining condensate directly onto the roof may be acceptable;

refer to local codes. Provide a small drip pad of stone, mortar,

wood, or metal to protect the roof against possible damage.

If condensate is piped into the building drainage system, pitch the

drain line away from the unit a minimum of 1/8" per foot. The

drain line must penetrate the roof external to the unit. Refer to

local codes for additional requirements. Sealed drain lines require

venting to provide proper condensate flow.

Where the cooling coils have intermediate condensate pans on

the face of the evaporator coil, copper tubes near both ends of

the coil provide drainage to the main drain pan. Verify that the

copper tubes are in place and open before the unit is put into

operation.

Periodically clean to prevent microbial growth/algae buildup

from plugging the drain and causing the drain pan to overflow.

Clean drain pans to prevent the spread of disease. Cleaning

should be performed by qualified personnel

WARNING

Drain pans must be cleaned periodically. Material in

uncleaned drain pans can cause disease.

Cleaning should be performed by qualified personnel.

.

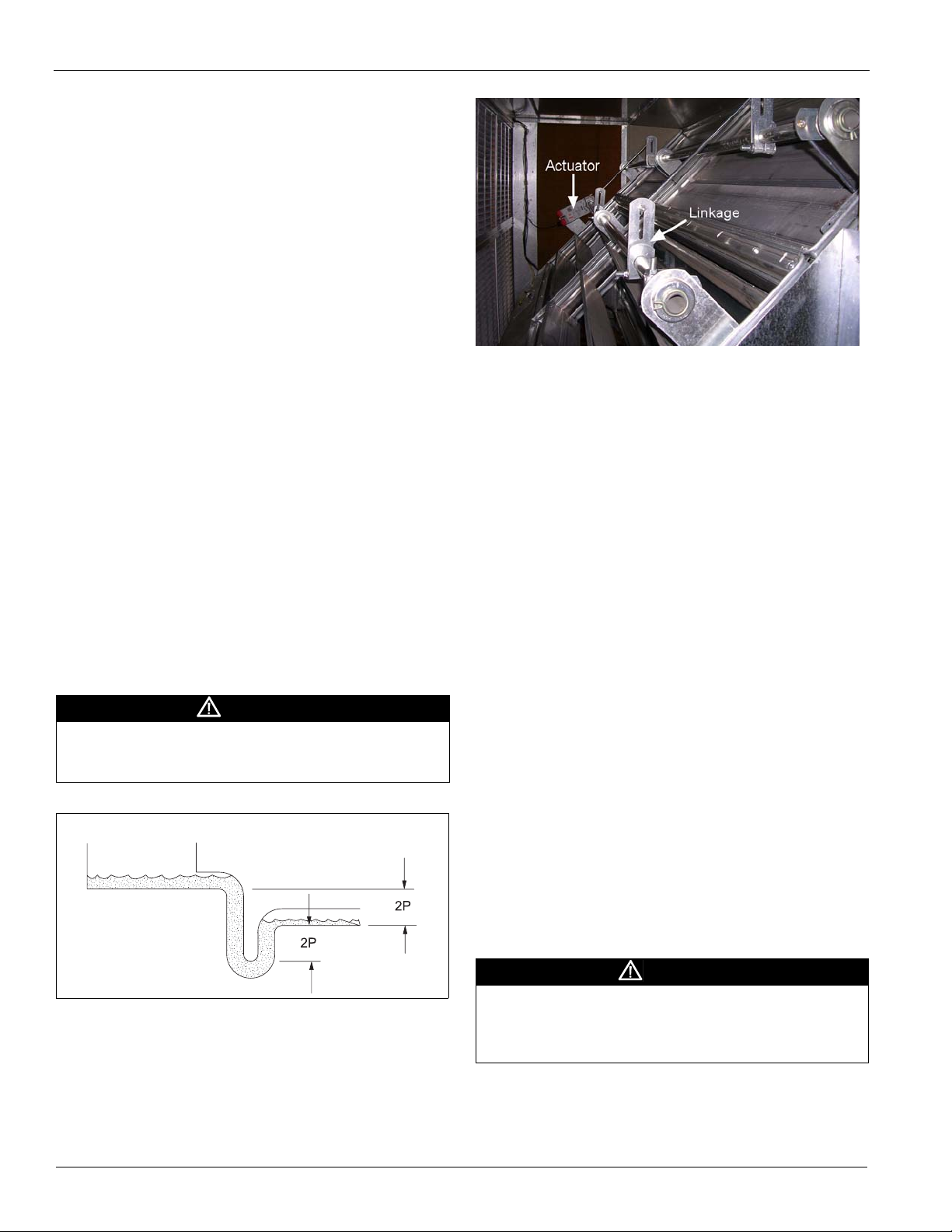

Figure 9: Damper Assembly

Economizer Dampers

As the single actuator modulates, the outside air dampers open,

the return air dampers close, and the exhaust air exits the unit

through the gravity relief dampers.

The economizer comes with manually adjustable linkage

(Figure 9). The damper is set so that the crankarm moves

through a 90-degree angle to bring the economizer dampers

from full open to full close. Mechanical stops are placed in the

crankarm mounting bracket. Do not remove stops. Driving the

crankarm past the stops results in damage to the linkage or

damper.

Outdoor Air Dampers (0% to 30%)

These dampers are intended to remain at a fixed position

during unit operation, providing fresh air quantities from 0 to

30% of the total system airflow, depending on the damper

setting.

The damper position may be set at the unit controller keypad

(refer to OM 843 for further detail). During unit operation, the

damper is driven to the position set at the unit controller.

During the off cycle, the damper is automatically closed.

Figure 8: Condensate Drain Connection

Static Pressure (P)

at the Drain Pan

Damper Assemblies

The optional damper assemblies described in this section are

ordered with factory-installed actuators and linkages. The

following sections describe the operation and linkage

adjustment of the factory option.

10 McQuay IM 842-1

Cabinet Weather Protection

This unit ships from the factory with fully gasketed access

doors and cabinet caulking to provide weather resistant

operation. After the unit is set in place, inspect all door gaskets

for shipping damage and replace if necessary.

Protect the unit from overhead runoff from overhangs or other

such structures.

CAUTION

Transportation, rigging, or maintenance can damage the

unit’s weather seal. Periodically inspect the unit for leakage.

Standing moisture can promote microbial growth, disease, or

damage to the equipment and building.

Page 11

Mechanical Installation

Installing Ductwork

On vertical-supply/vertical-return units, if a McQuay roof curb

is not used, the installing contractor should make an airtight

connection by attaching field fabricated duct collars to the

bottom surface of the unit’s duct opening. Do not support the

total weight of the duct work from the unit. See Figure 4 on

page 7 or Figure 5 on page 8.

Use flexible connections between the unit and ductwork to

avoid transmission of vibration from the unit to the structure.

To minimize losses and sound transmission, design duct work

per ASHRAE and SMACNA recommendations.

Where return air ducts are not required, connect a sound

absorbing T or L section to the unit return to reduce noise

transmission to the occupied space.

WARNING

Mold can cause personal injury. Materials such as gypsum

wall board can promote mold growth when damp. Such

materials must be protected from moisture that can enter units

during maintenance or normal operation.

Ductwork exposed to outdoor conditions must be built in

accordance with ASHRAE and SMACNA recommendations

and local building codes

.

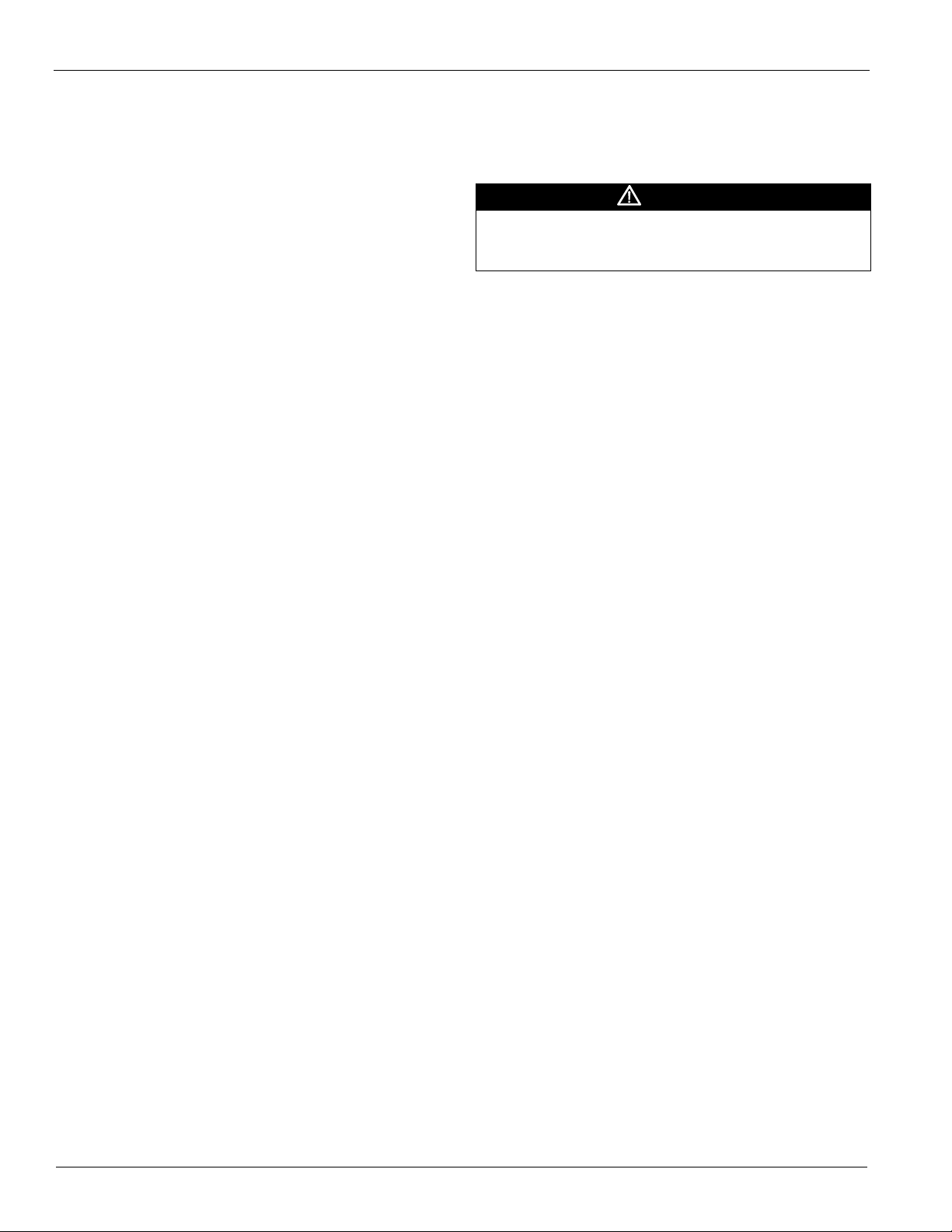

6 Install the duct tap so that it senses only static pressure (not

velocity pressure). If a bare tube end is used, it must be

smooth, square (not cut at an angle) and perpendicular to

the airstream (see Figure 11).

7 Locate the reference pressure (LO) tap near the duct

pressure tap within the building. If the tap is not connected

to the sensor, unsatisfactory operation will result.

8 Route the tubes through the curb and feed them into the

unit through the knockout in the bottom of the control panel

(see Figure 10). Connect the tubes to appropriate barbed

fittings (on SPS1) in the control panel. (Fittings are sized to

accept 1/8" ID tubing.)

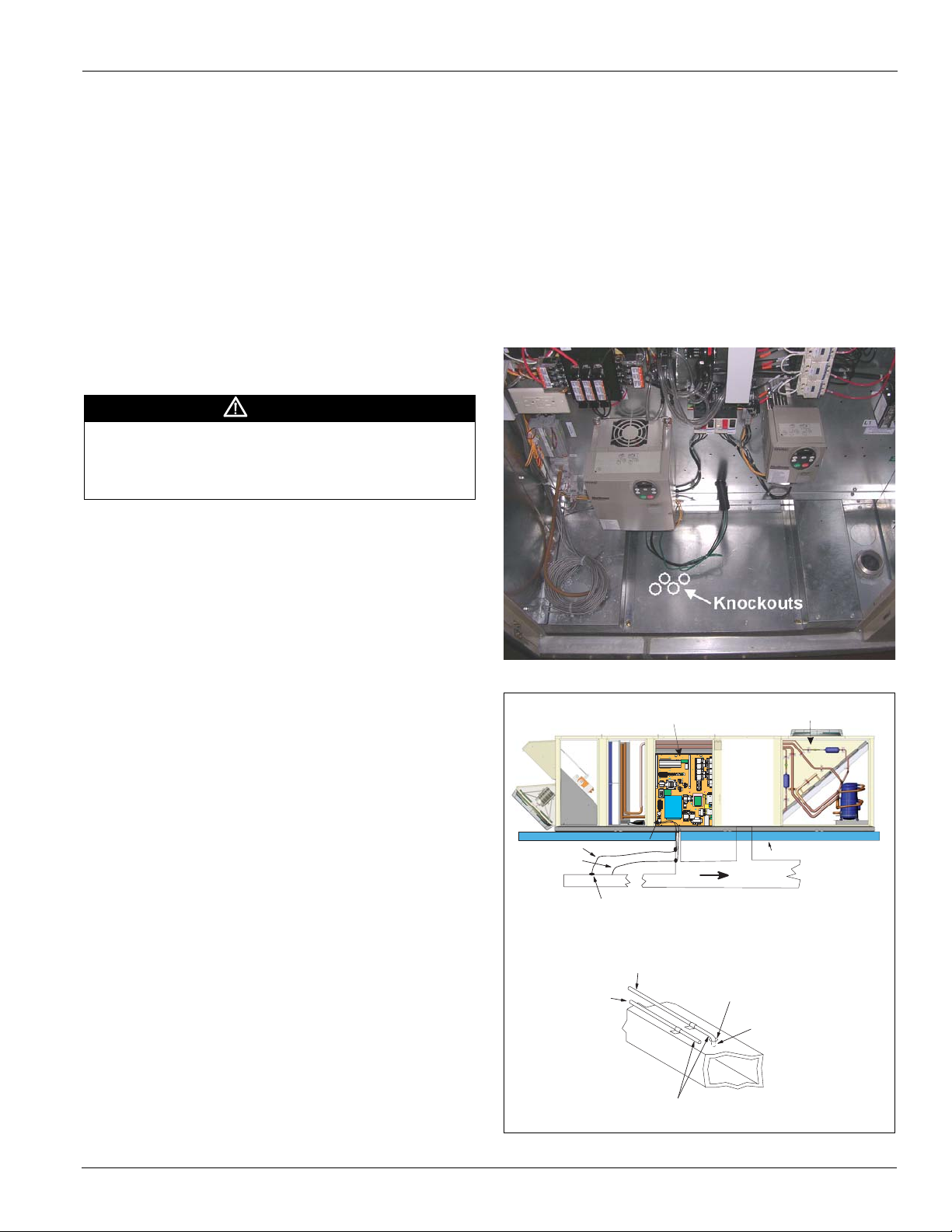

Figure 10: Static Pressure Tubing Knockout Location

Installing Duct Static Pressure Sensor Taps

For all VAV units, duct static pressure taps must be field

installed and connected to the static pressure sensor 1 (SPS1)

in the unit. Sensor SPS1 is standard on VAV units and is

located in the main control panel.

Carefully locate and install the duct static pressure sensing tap.

Improperly locating or installing the sensing tap causes

unsatisfactory operation of the entire variable air volume

system. Below are pressure tap location and installation

recommendations.The installation must comply with local

code requirements.

1 Install a tee fitting with a leak-tight removable cap in each

tube near the sensor fitting. This facilitates connecting a

manometer or pressure gauge if testing is required.

2 Use different colored tubing for the duct pressure (HI) and

reference pressure (LO) taps, or tag the tubes. McQuay

recommends 1/8" ID tubing.

3 Locate the duct pressure (HI) tap near the end of a long

duct to ensure that all terminal box take-offs along the run

have adequate static pressure.

4 Locate the duct tap in a nonturbulent flow area of the duct.

Keep it several duct diameters away from take-off points,

bends, neckdowns, attenuators, vanes, or other

irregularities.

5 Use a static pressure tip (Dwyer A302 or equivalent) or the

bare end of the plastic tubing for the duct tap. (If the duct is

lined inside, use a static pressure tip device.)

Figure 11: Duct Static Pressure Sensing Tubing Installation

Condenser Section

Roof

Ductwork

(Remote Location)

Tubing Extends

Through Approx. 1/8”

HI Line

LO Line

Remote Sense Point

To Sensor

LO Input

Main Control Panel

SPS1

To Sensor

HI Input

Rubber

Grommet

Pressure Sensing

Tubing

McQuay IM 842-1 11

Page 12

Mechanical Installation

Installing Building Static Pressure Sensor Taps

If a unit has building static pressure control capability, you

must field install and connect static pressure taps to the static

pressure sensor SPS2 in the unit. This sensor is located at the

bottom of the main control panel next to SPS1.

Carefully locate and install the two static pressure sensing

taps. Improper location or installation of the sensor taps causes

unsatisfactory operation. Below are pressure tap location and

installation recommendations for both building envelope and

lab, or “space within a space” pressure control applications.

The installation must comply with local code requirements.

CAUTION

Fragile sensor fittings. If you must remove tubing from a

pressure sensor fitting, use care. Do not use excessive force or

wrench the tubing back and forth to remove or the fitting can

break off and damage sensor.

Building Pressurization Applications

1 Install a tee fitting with a leak-tight removable cap in each

tube near the sensor fitting. This facilitates connecting a

manometer or pressure gauge if testing is required.

2 Locate the building pressure (HI) tap in the area that

requires the closest control. Typically, this is a ground level

floor that has doors to the outside.

3 Locate the building tap so it is not influenced by any source

of moving air (velocity pressure). These sources may

include air diffusers or outside doors.

4 Route the building tap tube through the curb and feed it into

the unit through the knockout in the bottom of the control

panel (refer to Figure 10). Connect the 1/8" ID tube to the

HI fitting for sensor SPS2.

5 Locate the reference pressure (LO) tap on the roof. Keep it

away from the condenser fans, walls, or anything else that

may cause air turbulence. Mount it high enough above the

roof so it is not affected by snow. Not connecting the

reference tap to the sensor results in unsatisfactory

operation.

6 Use an outdoor static pressure tip (Dwyer A306 or

equivalent) to minimize the adverse effects of wind. Place

some type of screen over the sensor to keep out insects.

Loosely packed cotton works well.

7 Route the outdoor tap tube out of the main control panel

through a small field-cut opening in the upright. Seal the

penetration to prevent water from entering. Connect the

1/8" ID tube to the LO fitting for sensor SPS2.

Figure 12: Outdoor Static Pressure Tubing Installation

Lab Pressurization Applications

1 Install a “T” fitting with a leak-tight removable cap in each

tube near the sensor fitting. This facilitates connecting a

manometer or pressure gauge if testing is required.

2 Use different colored tubing for the controlled space

pressure (HI) and reference pressure (LO) taps, or tag the

tubes.

3 Regardless whether the controlled space is positive or

negative with respect to its reference, locate the HI pressure

tap in the controlled space. (The setpoint can be set

between -0.2" and 0.2" wc)

4 Locate the reference pressure (LO) tap in the area

surrounding the controlled space. Not locating the

reference tap to the sensor results in unsatisfactory

operation.

5 Locate both taps so they are not influenced by any source

of moving air (velocity pressure). These sources may

include air diffusers or doors between the high and low

pressure areas.

6 Route the building tap tube between the curb and the

supply duct and feed it into the unit through the knockout in

the bottom of the control panel.

7 Connect the tube to the HI fitting for sensor SPS2.

12 McQuay IM 842-1

Page 13

Electrical Installation

Electrical Installation

Field Power Wiring

Wiring must comply with all applicable codes and ordinances.

The warranty is voided if wiring is not in accordance with

these specifications.

According to the National Electrical Code, a disconnecting

means shall be located within sight of and readily accessible

from the air conditioning equipment. The unit can be ordered

with an optional factory mounted disconnect switch. This

switch is not fused. Power leads must be over-current

protected at the point of distribution. The maximum rated

overcurrent protection device (MROPD) value appears on the

unit nameplate.

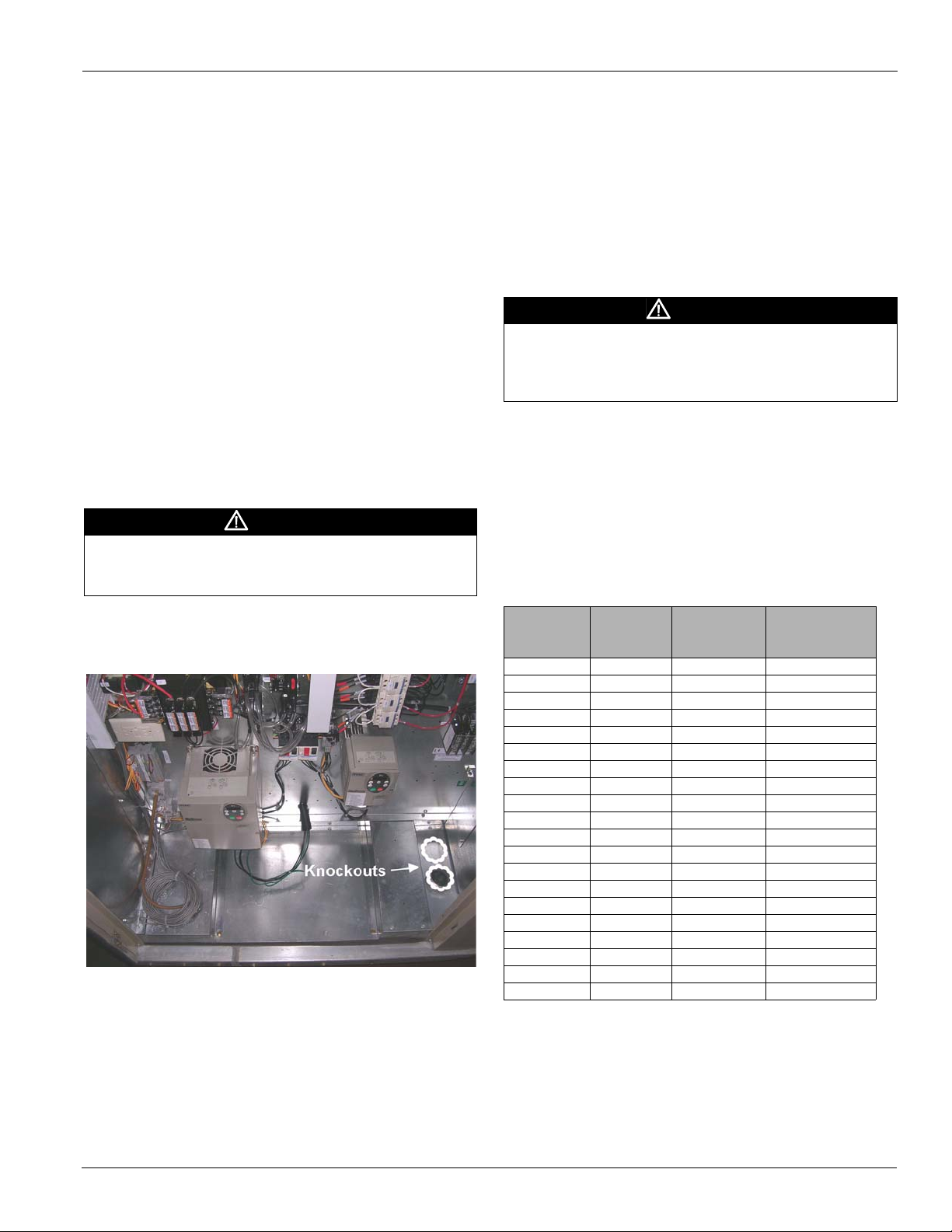

All Units

All units are provided with internal power wiring for single

point power connection. The power block or an optional

disconnect switch is located within the main control panel.

Field power leads are brought into the unit through knockouts

in the bottom of the main control panel (see Figure 13 and also

Table 5). Refer to the unit nameplate to determine the number

of power connections.

WARNING

Hazardous voltage. Can cause severe injury or death.

Disconnect electric power before servicing equipment. More

than one disconnect may be required to de-energize the unit.

Note: To wire entry points, refer to certified drawings for

dimensions.

Figure 13: MPS Power Wiring Knockout Locations

The preferred entrance for power cables is through the bottom

knockouts provided on the unit. If a side entrance is the only

option, a hole may be drilled in the stationary upright.

The minimum circuit ampacity (MCA) is shown on the unit

nameplate. Refer to Table 5 for the recommended number of

power wires.

Copper wire is required for all conductors. Size wires in

accordance with the ampacity tables in Article 310 of the

National Electrical Code. If long wires are required, it may be

necessary to increase the wire size to prevent excessive voltage

drop. Wires should be sized for a maximum of 3% voltage

drop. Supply voltage must not vary by more than 10% of

nameplate. Phase voltage imbalance must not exceed 2%.

(Calculate the average voltage of the three legs. The leg with

voltage deviating the farthest from the average value must not

be more than 2% away.) Contact the local power company for

correction of improper voltage or phase imbalance.

CAUTION

Provide proper line voltage and phase balance.

Improper line voltage or excessive phase imbalance constitutes

product abuse. It can cause severe damage to the unit's

electrical components.

A ground lug is provided in the control panel. Size the

grounding conductor in accordance with Table 250-95 of the

National Electrical Code.

In compliance with the National Electrical Code, a 115 V

factory mounted service receptacle outlet is provided. This

outlet must be powered by a field connected 15 A, 115 V

power supply. Leads are brought into the unit through a 7/8"

knockout in the bottom of the main control panel.

Table 5: Recommended Field Power Wiring

Ampacity

(MCA)

30 1 10 75

40 1 8 75

55 1 6 75

70 1 4 75

85 1 3 75

95 1 2 75

130 1 1 75

150 1 1/0 75

175 1 2/0 75

200 1 3/0 75

230 1 4/0 75

255 1 250 75

300 2 1/0 75

350 2 2/0 75

400 2 3/0 75

460 2 4/0 75

510 2 250 75

600 3 3/0 75

690 3 4/0 75

765 3 250 75

Notes:

1. All wire sizes assume separate conduit for each set of parallel conductors.

2. All wire sizes based on NEC Table 310-16 for 75°C THW wire (copper).

Canadian electrical code wire ampacities may vary.

3. All wire sizes assume no voltage drop for short power leads.

# of Power

Wires Per

Phase

Wire Gauge

Insulation

Temperature

Rating (°C)

McQuay IM 842-1 13

Page 14

Electrical Installation

Field Control Wiring

The Maverick rooftop units are available with the following

field control connections:

• Space sensor.

• Space sensor with setpoint adjustment.

• Fan operation output.

• VAV box output.

• Remote alarm output.

• External discharge air temperature reset.

• Outdoor air damper minimum position adjustment.

Descriptions of these field connections are included in the

MicroTech II Unit Controls manual (OM 843).

WARNING

Electrical shock hazard. Can cause severe injury or death.

Connect only low voltage NEC Class II circuits to terminal block

TB2.

14 McQuay IM 842-1

Page 15

Preparing Unit for Operation

Preparing Unit for Operation

Spring Isolated Fans

WARNING

Moving machinery hazard. Can cause severe injury or

death. Before servicing equipment, disconnect power and lock

off. More than one disconnect may be required to de-energize

unit. Prior to operating the fans for the first time, refer to “Check,

Test, and Start Procedures” on page 45.

Releasing Spring Mounts

The spring-mounted supply fan is locked down with four

shipping bolts for shipment. Remove each shipping bolt before

operating the fans. Figure 14 shows a typical spring mount

with a height adjustment nut and a shipping bolt.

After removing the shipping bolts, rock the fan assembly by

hand to check for freedom of movement.

Figure 14: Spring Mounts

Adjusting Spring Mounts

During operation all fans should ride level. Level the fan

assembly by performing the following:

1 Loosen the 3/8" cap screw (do not remove).

2 Loosen the spring cap nut.

3 Rotate the 5/8" adjustment nut counter-clockwise to raise

the fan assembly, or clockwise to lower the fan assembly.

4 Tighten the 3/8" cap screw.

5 Tighten the spring cap nut.

McQuay IM 842-1 15

Page 16

Optional Gas Heat

Optional Gas Heat

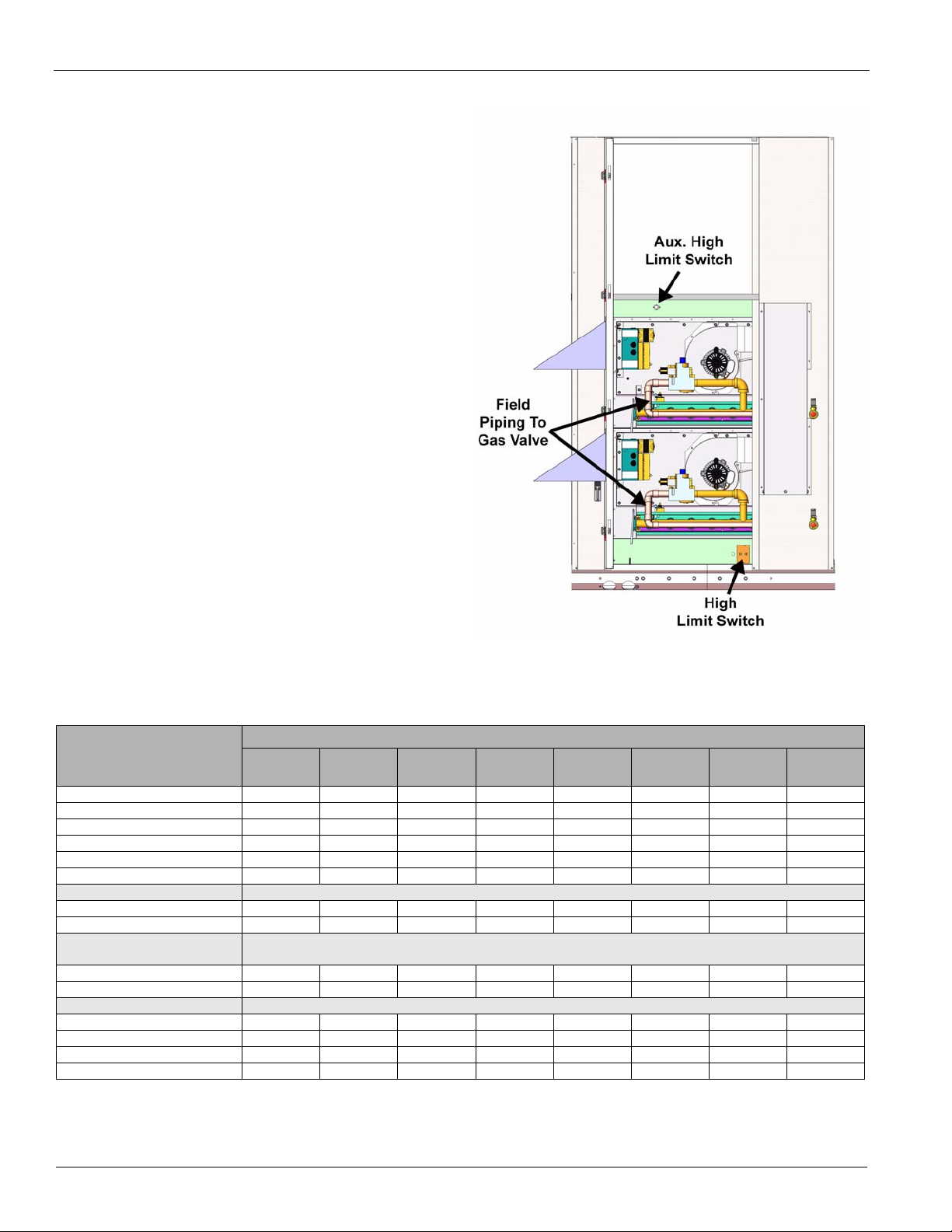

Gas Furnace Design

This section of the manual covers the optional furnace

(Figure 15). If the 8th digit in the model number is a “G”, the

rooftop unit was furnished with a factory installed furnace

(Example, MPS035AG). The Maverick commercial rooftop

units are available with either the low heat input or the high

heat input furnace (see capacities in Table 6). This packaged

gas heat rooftop unit is designed for outdoor non-residential

installations only.

The gas heat furnace design consists of a tubular heat

exchanger, in-shot burner manifold with gas valve, induced

combustion blower, gas heat DDC control module and all

operational safeties. The tubular heat exchanger can come with

the standard aluminized steel construction or the optional

stainless steel construction. The safety switches include a highlimit temperature switch (Figure 15), an auxiliary high-limit

switch (Figure 15), a combustion blower proof of airflow (see

Figure 16), and the flame roll-out switch (see Figure 16).

The high limit switch is an automatic reset switch and it opens

up at 160°F to shut the furnace down and closes at 130°F. The

auxiliary limit switch is a manual reset and opens up at 180°F

to shut the furnace down.

Figure 15: Gas Heat Section

Gas Heating Capacity Data

Table 6: MPS 030A – 050A Gas Heating Capacities

Unit Size

Data

Heating Input (MBh) 300 600

Heating Output (MBh)

Steady State Efficiency

Number of Stages

Minimum Airflow 3800 7400

Maximum Temperature Rise

Gas Main Pressure

Natural Gas (in. wc) 7-147-147-147-147-147-147-147-14

Liquid Propane (in. wc) 12-14 12-14 12-14 12-14 12-14 12-14 12-14 12-14

Manifold Pressure

Natural Gas (per gas valve)

Stage 1 (in. wc) 1.2 1.2 1.2 1.2 1.2 1.2 1.2 1.2

Stage 2 (in. wc) 3.2 3.2 3.2 3.2 3.2 3.2 3.2 3.2

Propane

Stage 1 (in. wc) 2.3 2.3 2.3 2.3 2.3 2.3 2.3 2.3

Stage 2 (in. wc) 10.0 10.0 10.0 10.0 10.0 10.0 10.0 10.0

Connection Size 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4" 3/4"

Quantity 12121212

030A

(Lo Heat)

240 480

80% 80% 80% 80% 80% 80% 80% 80%

24

60°F 60°F 60°F 60°F 60°F 60°F 60°F 60°F

030A

(High Heat)

035A

(Lo Heat)

300 600 400 800 400 800

240 480 320 640 320 640

242424

3800 7400 4900 9800 4900 9800

035A

(High Heat)

040A

(Lo Heat)

040A

(High Heat)

050A

(Lo Heat)

(High Heat)

050A

16 McQuay IM 842-1

Page 17

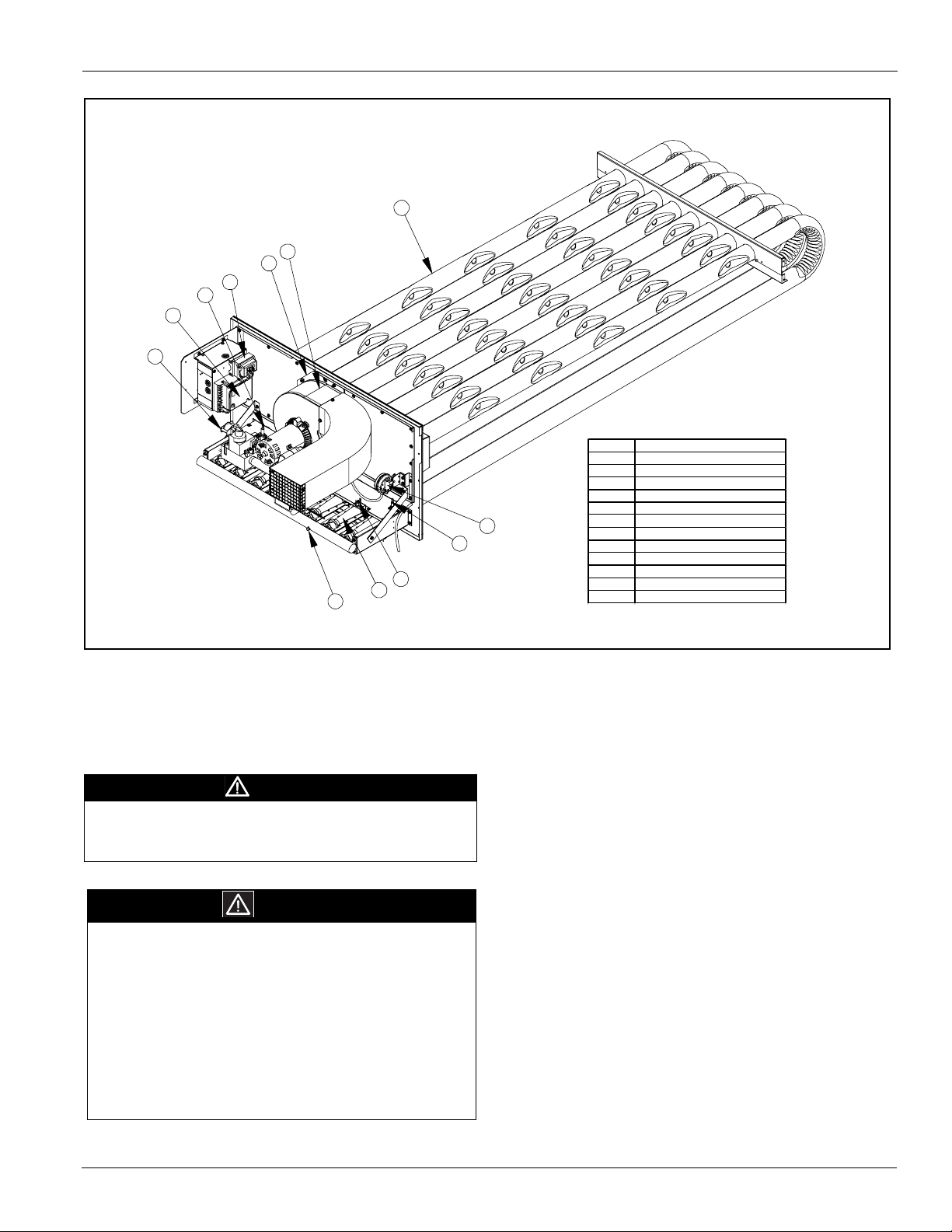

Figure 16: Burner Assembly

4

5

6

7

Optional Gas Heat

1

2

3

Item # D escr ip ti on

1Furnace

2 I nduced Co mbus tion Bl ower

3 P late-Induc er Orifice

4 T rans forme r-40VA

5 S park I gnito r

12

11

10

9

8

6IgnitionControl

7 G as Val ve-2 S tage

8 M anifold A ss embly Test Port

9 B urner Ins hot

10 Fl ame R ollout Switc h

11 Fl ame S ensor

12 Pr oof of A irflow S witch

Warranty Exclusion

Warranty is void if the furnace is operated in the presence of

chlorinated vapors, if the airflow through the furnace is not in

accordance with rating plate, or if the wiring or controls have

been modified or tampered with.

WARNING

Hot surface hazard. Can cause severe equipment damage,

personal injury, or death. Allow burner assembly to cool

before servicing equipment.

WARNING

Units equipped with gas heating must not be operated in

an atmosphere contaminated with chemicals which will

corrode the unit such as halogenated hydrocarbons,

chlorine, cleaning solvents, refrigerants, swimming pool

exhaust, etc. Exposure to these compounds may cause

severe damage to the gas furnace and result in improper

or dangerous operation. Operation of the gas furnace in such

a contaminated atmosphere constitutes product abuse and will

void all warranty coverage by the manufacturer. Questions

regarding specific contaminants should be referred to your

local gas utility.

Ventilation & Flue Pipe Requirements

The McQuay rooftop unit is equipped with an outdoor air hood

to supply adequate combustion air. The unit also has a flue

outlet assembly and requires no additional chimney, flue pipe,

Breidert cap, draft inducer, etc.

Factory Checkout

This complete furnace was fired and tested at the factory. The

unit was fired through several complete sequences of start-up

through shutoff to check operation. A check was made of the

air switch, gas pressure switch, high limit operation.

This checkout normally eliminates on-the-job start-up

problems; however, the equipment is subject to variable job

conditions and shipping shocks can change adjustments, cause

damage, and loosen connections and fasteners. Therefore, it is

necessary to go through the complete start-up procedure even

though the unit may appear to be operating properly.

McQuay IM 842-1 17

Page 18

Optional Gas Heat

Installation

IMPORTANT

This furnace must be installed by an experienced

professional installation company that employs fully

trained and experienced technicians. Install the furnace in

accordance with the manufacturer's instructions and local

codes. In the absence of local codes, follow the National

Fuel Gas Code, ANSI Z223.1/NFPA 54, or the CSA B149.1,

Natural Gas and Propane Installation Code.

WARNING

Sharp edges hazard. Can cause personal injury or death.

Sheet metal parts, self-tapping screws, clips, and similar items

inherently have sharp edges, and it is necessary that the

installer exercise caution when handling these items.

Flue Box

The flue box (Figure 17) is not installed at the factory because

it would increase the width of the unit beyond the allowable

shipping width.

Figure 17: Flue Box Installation

3 Line assembly holes up.

4 Install screws to fasten the flue box to the side of the unit.

Outdoor Air (OA) Hood

The OA hood (Figure 18) is not installed at the factory because

it would increase the width of the unit beyond the allowable

shipping width. The hood is shipped in a box in the fan

section.

Figure 18: Outdoor Air (OA) Hood Installation

The OA hoods must be installed over the outdoor air openings

as shown in Figure 18.

1 Remove and discard the shipping covers.

2 Position the hood over the OA openings.

3 Line assembly holes up.

4 Install screws to fasten the OA hood.

The OA hoods must be installed before the furnace is operated.

The flue box must be installed over the combustion exhaust

openings shown in Figure 17. All holes are prepunched, the

fasteners are furnished and everything is shipped inside the fan

section.

1 Remove and discard the shipping covers.

2 Position the flue box over the exhaust openings.

18 McQuay IM 842-1

Page 19

Optional Gas Heat

Electrical

The McQuay burner receives its electrical power from the

main unit control panel. No additional power wiring must be

routed to the burner. The sequencing of the burner is also

controlled through this panel and therefore is factory wired.

No additional wiring will be required.

DANGER

If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal

injury, or loss of life.

A. This appliance does not have a pilot. It is equipped with an

ignition device which automatically lights the burner. Do not try

to light the burner by hand.

B. Before operating, smell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch, do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand,

don't try to repair it, call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

Gas Piping

Gas piping must be sized to provide the minimum required

pressure at the burner when the burner is operating at

maximum input. Consult your local utility on any questions on

gas pressure available, allowing piping pressure drops, and

local piping requirements.

Install all piping in accordance with the National Fuel Gas

Code (ANSI Z223.1), (NFPA 54-1999) and any applicable

local codes.

The proper size piping must be run from the meter to the gas

burner without reductions. Undersized piping will result in

inadequate pressure at the burner. The pressure will be at its

lowest when it is needed the most, at times of maximum

demand. Therefore, it can cause intermittent hard-to-find

problems because the problem may have left before the service

technician has arrived. Avoid the use of bushings wherever

possible.

Remove all burrs and obstructions from pipe. Do not bend

pipe; use elbows or other pipe fittings to properly locate pipe.

A drip leg and a manual shut-off must be installed in the

vertical line before each burner such that it will not freeze.

Install unions so gas train components can be removed for

service. All pipe threads must have a pipe dope which is

resistant to the action of LP gas. After installation, pressurize

the piping as required and test all joints for tightness with a

rich soap solution. Any bubbling is considered a leak and must

be eliminated. Do not use a match or flame to locate leaks.

Gas Pressure Requirements

The pressure furnished to the main gas valve must not exceed

13.9" wc. When the supply pressure is above 13.9" wc, a high

pressure regulator must precede the appliance gas pressure

regulator. The inlet gas pressure must not exceed the

maximum pressure rating of the high pressure regulator, and

the outlet pressure must furnish gas to the appliance pressure

regulator within the pressure range mentioned above.

McQuay IM 842-1 19

Page 20

Optional Gas Heat

Table 7: Capacity of Pipe Natural Gas (CFH)

WITH PRESSURE DROP OF 0.3" WC & SPECIFIC GRAVITY OF 0.60

PIPE

LENGTH (FT.)

10 132 278 520 1050 1600 2050 4800 8500 17500

20 92 190 350 730 1100 2100 3300 5900 12000

30 73 152 285 590 890 1650 2700 4700 9700

40 63 130 245 500 760 1450 2300 4100 8300

50 56 115 215 440 670 1270 2000 3600 7400

60 50 105 195 400 610 1150 1850 3250 6800

70 46 96 180 370 560 1050 1700 3000 6200

80 53 90 170 350 530 990 1600 2800 5800

90 40 84 160 320 490 930 1500 2600 5400

100 38 79 150 305 460 870 1400 2500 5100

125 34 72 130 275 410 780 1250 2200 4500

150 31 64 120 250 380 710 1130 2000 4100

175 28 59 110 225 350 650 1050 1850 3800

200 26 55 100 210 320 610 980 1700 3500

NOTE: Use multiplier below for other gravities and pressure drops.

½ ¾ 1 1¼ 1½ 2 2½ 3 4

PIPE SIZE-INCHES (IPS)

Table 8: Specific Gravity Other Than 0.60

SPECIFIC GRAVITY MULTIPLIER

0.50 1.100

0.60 1.000

0.70 0.936

0.80 0.867

0.90 0.816

1.00 0.775

PROPANE-AIR

1.10 0.740

PROPANE

1.55 0.622

BUTANE

2.00 0.547

Table 9: Pressure Drop Other Than 0.3"

PRESSURE DROP MULTIPLIER PRESSURE MULTIPLIER

0.1 0.577 1.0 1.83

0.2 0.815 2.0 2.58

0.3 1.000 3.0 3.16

0.4 1.16 4.0 3.65

0.6 1.42 6.0 4.47

0.8 1.64 8.0 5.15

Gas Piping Routing Into Unit

On-The-Roof Piping

1 Remove knockout on upright (refer to Figure 19).

2 Route gas supply pipe through hole. Carefully plan pipe

route and fitting locations to avoid interference with

swinging of doors, etc.

Figure 19: Piping Schematic

20 McQuay IM 842-1

Page 21

Optional Gas Heat

Sequence of Operation

Low Heat Option (2 Stage Control)

The following details the sequence of operation for the low

heat option.

1 Unit DDC control calls for heat.

2 Furnace DDC control module receives a call for heat.

3 High limit switch is checked for safe condition.

4 Proof of airflow switch is check for combustion airflow.

5 60 second prepurge cycle starts.

6 Spark ignitor is activated for 3 seconds.

7 Gas valve receives a command for stage 1 of heat.

8 Burner is ignited.

9 Unit DDC controller calls for stage 2 of heat.

10 Furnace DDC controller receives a stage 2 heat command.

11 Gas valve receives a command for stage 2 of heat.

High Heat Option (4 Stage Control)

For a unit with the optional high heat the above sequence is

followed for the first two stages.

For the remaining 2 stages the above procedure is repeated on

the second furnace module.

Start-Up Procedures

Start-Up Responsibility

The start-up organization is responsible for determining that

the furnace, as installed and as applied, will operate within the

limits specified on the furnace rating plate.

1 The furnace must not operate at an airflow below the

specified Minimum Airflow CFM (refer to Table 6 on

page 16). On variable air volume systems it must be

determined that the furnace will not be operated if or when

system cfm is reduced below the specified minimum

airflow cfm.

2 It must be established that the gas supply is within the

proper pressure range (refer to Table 6 on page 16).

Start-up and service of this equipment must be performed

by trained and experienced technicians. It is highly

recommended that the initial start-up and future service be

performed by McQuay trained technicians who are familiar

with working on live equipment. A representative of the owner

or the operator of the equipment should be present during startup to receive instructions in the operation, care and adjustment

of the unit.

WARNING

Overheating or failure of the gas supply to shut off can

cause equipment damage, severe personal injury or

death. Turn off the manual gas valve to the appliance before

shutting off the electrical supply.

Before Start-Up

1 Notify inspectors or representatives who may be required

to be present during start-up of gas fuel equipment. These

could include the gas utility company, city gas inspectors,

heating inspectors, etc.

2 Review the equipment and service literature and become

familiar with the location and purpose of the furnace

controls. Determine where the gas and power can be turned

off at the unit, and before the unit.

3 Determine that power is connected to the unit and

available.

4 Determine that the gas piping, meter, and service regulator

have been installed, tested, and meet the equipment

requirements.

5 Determine that proper instruments will be available for the

start-up. A proper start-up requires the following:

voltmeter, manometer or gauges with ranges for both

manifold pressure and inlet gas pressure.

Start-Up Preliminary

Close gas main.

1 Check the burner fan wheel for binding, rubbing, or loose

setscrews.

2 Check power.

3 Purge the gas lines.

4 Leak check. Using a rich soap-water mixture and a brush,

check the gas lines for leaks. Correct all leaks before

starting furnace.

McQuay IM 842-1 21

Page 22

Optional Gas Heat

Operating Procedures

DANGER

If you do not follow these instructions exactly, a fire or

explosion may result causing property damage, personal

injury, or loss of life.

A. This appliance does not have a pilot. It is equipped with an

ignition device which automatically lights the burner. Do not try

to light the burner by hand.

B. Before operating, smell all around the appliance area for

gas. Be sure to smell next to the floor because some gas is

heavier than air and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch, do not use any phone in

your building.

• Immediately call your gas supplier from a neighbor's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to push in or turn the gas control knob.

Never use tools. If the knob will not push in or turn by hand,

don't try to repair it, call a qualified service technician. Force or

attempted repair may result in a fire or explosion.

D. Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and to replace any part of the control system and

any gas control which has been under water.

1 Set the thermostat to the lowest setting.

2 Turn off all electric power to the appliance.

3 This appliance is equipped with an ignition device which

automatically lights the burner. Do NOT try to light the

pilot by hand.

4 Open the control access panel.

5 Turn the gas control clockwise to “OFF”.

6 Wait five (5) minutes to clear out any gas. Then, smell for

gas, including near the floor. If you smell gas, STOP!

Follow step “B” in the DANGER label on this page. If you

don't smell gas, proceed to the next step.

7 Turn the gas control counter-clockwise to “ON”.

8 Close the control access panel.

9 Turn on all electric power to the appliance.

10 Set thermostat to desired setting.

11 If the appliance will not operate, refer to “Turning Off Gas

to the Appliance”, and call your service technician or gas

supplier.

Turning Off Gas to the Appliance

1 Set the thermostat to the lowest setting.

2 Turn off all electrical power to the appliance if service is to

be performed.

3 Open the control access panel.

4 Turn the gas control knob clockwise to “OFF”. Do not

force.

5 Close the control access panel.

Service

The furnace DDC controller has diagnostic information for

troubleshooting the furnace operation. The ignition control

module has a LED light that will flash when an abnormal

condition occurs. See Figure 20 for an explanation of the

diagnostic information.

Maintenance

Planned maintenance is the best way to avoid unnecessary

expense and inconvenience. Have this system inspected at

regular intervals by a trained and experienced service

technician. The following service intervals are typical for

average situations but will have to be adjusted to suit your

particular circumstances.

Fuel pressure settings and control settings should be made only

by persons thoroughly experienced with the burner and control

system, and must not be tampered with by persons without

such experience.

Always replace covers on burner controls and boxes as the

electrical contacts are sensitive to dust and dirt. Perform

maintenance of controls, gas valves, and other components in

accordance with instructions contained in the manufacturer's

bulletins.

Monthly

Check air filters and replace if dirty.

Twice Yearly

1 Burner Air - Check burner fan wheel for dirt buildup and

lint. Check combustion air intake louver and flue box for

dirt buildup and accumulation of windborne debris.

2 Cleaning - Inspect flue tubes and combustion chamber,

cleaning as required. Keep burner vestibule clean. Dirt and

debris can result in burner air blockages.

Yearly

Gas Train - Check all valves, piping and connections for

leakage. Inspect and clean flame rod, ignition electrode,

and burner manifold.

Condensate Pan/Drain/P-Trap - Check pan, drain, and ptraps for accumulation of debris. Check that p-traps are

filled with water at the start of each cooling season.

22 McQuay IM 842-1

Page 23

Ignition Control Module Information

Figure 20: Typical Gas Furnace Electrical Schematic with Sensor

Optional Gas Heat

L1 L2

B

1

B

BL

W

W

BL

1016-427

Ignition Module

X

L1 IND

COM

MV

PS2

PS1

HV

FS

G

ROS1

B

Y

C

ROS2

APS

Flame Sensor

2 Stage Gas

1

R

Igniter

Comb Fan

Motor

Valve

HIMV

Y

2

115VAC

40VA

24VAC

Y

C

W

R

Y

BL

OR

OR

Y

Y

OR

W

BW

Gnd

W

W

Gr

2

APS Airflow Proving Switch

ROS1 Roll Out Switch #1

ROS2 Roll Out Switch #2

Ignition Control Module LED Diagnostics

The following LED indicators can be used to diagnose faults

associated with the gas furnace.

Table 10: Indicator and Fault Conditions

Indicator Fault Condition

Steady Off No power or control hardware fault

Steady On Power applied, control OK

1 Flash

2 Flashes

3 Flashes Ignition lockout from too many trials

4 Flashes

5 Flashes Control hardware fault detected

Combustion fan motor energized, pressure

switch open

Combustion fan motor off, pressure switch

closed

Ignition lockout from too many flame losses

within single call for heat

1/4" quick connect termination to harness

from main control panel

Terminal Block

McQuay IM 842-1 23

Page 24

Optional Electric Heat

Optional Electric Heat

Electric Heater Design

This section of the manual covers the optional heater

(Figure 21). If the 8th digit in the model number is an “E”, the

rooftop unit was furnished with a factory installed electric

furnace (Example, MPS035AE). The Maverick commercial

rooftop units are available with low, medium, or high heat

output (see capacities in Table 11). This packaged electric heat

rooftop unit is designed for outdoor non-residential

installations only.

The electric heat design consists of a heating coil, DDC

staging control, and all operational safeties. The safety

switches include high-limit temperature switches and

individual coil fusing.

The high limit switch is an automatic reset switch. The switch

opens the control circuit and shuts the heater down when the

temperature reaches 160°F. The high limit switch closes again

allows the heater to run when the temperature gets to 130°F.

There is a second level of protection with an auxiliary high

limit switch. This switch opens up and shuts the heater down

when the temperature reaches 250°F. The auxiliary switch

automatically resets again at 220°F. The third level of

protection is the secondary auxiliary high limit switch which

shut the heater down at 285°F. This switch requires a manual

reset.

Figure 21: Electric Heat Section

24 McQuay IM 842-1

Page 25

Optional Electric Heat

Electric Heating Capacity Data

Table 11: MPS 030A – 050A Electric Heating Capacities

Ton s

* Temperature rise is calculated at nominal cfm

Nom

30 12,000 4

35 14,000 4 54 2900 184 12.2 72 3800 246 16.3 90 4800 307 20.3

40 16,000 4 72 3800 246 14.2 90 4800 307 17.8 108 5700 369 21.3

50 20,000 4 72 3800 246 11 .4 90 4800 307 14.2 108 5700 369 17.1

cfm

Stages

kW

54 2900 184 14.2 72 3800 246 19.0 90 4800 307 23.7

Electric Heater Data

Table 12: MPS 030A – 050A Electric Heater Data

kW Volt age Amps

54 208 150

54 230 130

54 460 65

54 575 52

72 208 200

72 230 173

72 460 86

72 575 70

90 208 250

90 230 217

90 460 108

90 575 87

108 460 130

108 575 104

Low Medium High

Min

cfm

MBh

Delta T*

kW

Min

cfm

MBh

Delta T*

kW

Min

cfm

MBh

Delta T

McQuay IM 842-1 25

Page 26

Wiring Diagrams

Wiring Diagrams

Figure 22: VAV Power

26 McQuay IM 842-1

Page 27

Wiring Diagrams

McQuay IM 842-1 27

Page 28

Wiring Diagrams

Figure 23: VAV Control—Inputs

28 McQuay IM 842-1

Page 29

Wiring Diagrams

McQuay IM 842-1 29

Page 30

Wiring Diagrams

Figure 24: VAV Control—Outputs

30 McQuay IM 842-1

Page 31

Wiring Diagrams

McQuay IM 842-1 31

Page 32

Wiring Diagrams

Figure 25: CAV Power

32 McQuay IM 842-1

Page 33

Wiring Diagrams

McQuay IM 842-1 33

Page 34

Wiring Diagrams

Figure 26: CAV Control—Inputs

34 McQuay IM 842-1

Page 35

Wiring Diagrams

McQuay IM 842-1 35

Page 36

Wiring Diagrams

Figure 27: CAV Control—Outputs

36 McQuay IM 842-1

Page 37

Wiring Diagrams

McQuay IM 842-1 37

Page 38

Wiring Diagrams

Figure 28: Electric Heat Option Power

38 McQuay IM 842-1

Page 39

Wiring Diagrams

McQuay IM 842-1 39

Page 40

Wiring Diagrams

Figure 29: Electric Heat Option—Outputs

40 McQuay IM 842-1

Page 41

Wiring Diagrams

McQuay IM 842-1 41

Page 42

Unit Options

Unit Options

Economizer Enthalpy Control

The economizer can be ordered with the optional differential

enthalpy control. With this option a solid-state humidity and

temperature sensing device is located in the return and outdoor

airstreams. These devices are labeled RAE and OAE

respectively. When the outdoor enthalpy is lower than the

return air enthalpy, the economizer operation will be initiated.

If the outdoor air enthalpy is higher than the return air, the

outdoor air damper position will be at the minimum setpoint.

See OM 843 for further information on the economizer

operation.

External Time Clock

You can use an external time clock as an alternative to (or in

addition to) the MicroTech II controller’s internal scheduling

function. The external timing mechanism is set up to open and

close the circuit between field terminals 101 and 102. When

the circuit is open, power is not supplied to binary input ID1.

This is the normal condition where the controller follows the

programmable internal schedule. When the circuit is closed,

power is fed to ID1. The MicroTech II controller responds by

placing the unit in the occupied mode, overriding any set

internal schedule.

Duct High Pressure Limit

The duct high pressure limit control (DHL) is provided on all

VAV units. The DHL protects the duct work, the terminal

boxes, and the unit from over pressurization, which could be

caused by, for example, tripped fire dampers or control failure.

The DHL control opens when the discharge plenum pressure

rises to 3.5" wc (872 Pa). This setting should be correct for

most applications and should not be adjusted.

If the DHL switch opens, digital input ID9 on the Unit Control

Board will be de-energized. The MicroTech II controller then

shuts down the unit and enters the Off-Alarm state. The alarm

must be manually cleared before the unit can start again. Refer

to the operation manual supplied with your unit for more

information on clearing alarms (refer to OM 843).

Convenience Receptacle/Section Lights

A Ground Fault Circuit Interrupter (GFCI) convenience

receptacle is provided in the main control box on all units. To

use this receptacle, connect a separate field-supplied 115 V

power wiring circuit to the outlet.

Exhaust Fan Option

Economizer units may include exhaust fan options. For units

with CAV applications, the exhaust fans can be ordered as

staged control or they may be ordered with building pressure

control. The building pressure control option has a VFD that

runs the exhaust fan motors and is controlled by the static

pressure sensor number 2 (SPS2). Refer to OM 843 for setting

up the unit controller with these two options. The units are

only available with building pressure control on VAV units.

The exhaust fan motors are permanently lubricated and do not

require any additional periodic lubrication.

42 McQuay IM 842-1

Page 43

Sequence of Operation

r

Operating States

Sequence of Operation

The transition from any operating state to another is

graphically represented in Figure 30.

Figure 30: State Diagram

Any Othe r Stat e

Off

Start Up

Economize

Mechanical

Coolling

Recirculation

Fan Only

Heating

Minimum DAT

Fan Only

The outside air damper will modulate to the minimum position

and based upon the sensor inputs, the unit will go into one of

the four running states - “Heating,” “Cooling,”

“Economizing,” or “Minimum DAT.” If the control

temperature is between its setpoint and its dead band, the unit

will remain in the “Fan Only” state.

Heating

The unit's heating mode of operation is controlled by the

control temperature and the heating setpoint temperature. The

unit goes into the heating mode of operation by analyzing the

control temperature.

The control temperature can be either the return temperature or

the space temperature.

The return temperature is typically used for VAV units and the

space temperature is typically used for CAV units.

The unit goes into the heating mode of operation when the

control temperature (return or space temperature) is below the

heating setpoint by more than ½ the deadband.

Example - If the heating setpoint is 68.0°F and the deadband

is 1.0°F, the unit will not go into the heating mode of operation until the control temperature reaches 67.4°F.

Start Up

With a “start up” command from the “Off” State the unit will

default into the "Start Up" state of operation for 3 minutes.

During this time, the fan is off.

Recirculation

Next, the unit will transition into the “Recirculation” state of

operation for another 3 minutes. During this time, the outside

air damper will close and the fan will turn on, thereby mixing

the air in the ductwork and the space.

When this takes place, the heating mode of operation will

begin and the 1st stage of heating operation will start.

The next stage, up or down, will take place after 4 minutes.

This “4 minutes” is called the stage timer. The gas or electric

heat module will continue to stage up as long as the control

temperature is below the heating setpoint by more than ½ the

heating setpoint deadband. The unit will stage down if the

maximum discharge air temperature of 120°F is reached. Gas

units with one gas valve have 2 stages of heating and units

with two gas valves have 4 stages of heating.

Minimum DAT

This control mode is designed to temper the air in the

ductwork when in heating mode. When the unit is in the “Fan

Only” state and the Discharge Air Temperature is less than the

minimum discharge air temperature limit, “Minimum DAT”

control is initiated. The unit will turn on minimum heat until

the discharge air temperature exceeds the limit.

McQuay IM 842-1 43

Page 44

Sequence of Operation

Mechanical Cooling

Constant Volume (Space Comfort Controller)

The control temperature for a CAV unit is typically the space

temperature. A space temperature sensor must be field

installed into the occupied space and connected to the unit

controller.

The unit goes into the cooling mode of operation when the

control temperature (space temperature) is above the cooling

setpoint by more than ½ the deadband.

Example - the cooling setpoint is set to 70.0°F and the dead-

band is 1.0°F, the unit will not go into the cooling mode of

operation until the space sensor reaches 70.6°F.

When this takes place, the cooling mode of operation will

begin and the 1st stage of compressor operation will start.

The unit controller will turn on the next stage of compressor

operation, or turn off a stage of compressor operation, to

maintain the cooling setpoint temperature within the deadband.

When a compressor stage turns on, the next compressor stage,

up or down, will not take place for the next 4 minutes. This “4

minutes” is called the stage time. Reference the “Cooling

Setup” menu for the adjustable stage time value.

When a cooling stage is initiated no further operation will take

place within the stage timer limit. In the above example, the

unit will stage down or turn off the cooling mode of operation

when the cooling setpoint reaches 69.4°F.

Variable Air Volume (Discharge Air Controller)

The unit's cooling mode of operation is controlled by the

control temperature, the change-over temperature, and the

discharge air temperature. The unit goes into the cooling mode

of operation by analyzing the control temperature. The control

temperature for a VAV system is the return temperature.

The unit goes into the cooling mode of operation when the

control temperature (return temperature) is above the changeover setpoint by more than ½ the deadband.

Example - If the change over temperature is 70.0°F and the

deadband is 1.0°F, the unit will not go into the cooling

mode of operation until the return temperature reaches

70.6°F.

When this takes place, the cooling mode of operation will

begin and the 1st stage of compressor operation will start.

The unit controller will turn on the next stage of compressor

operation, or turn off a stage of compressor operation, to

maintain the discharge air temperature setpoint within the

deadband. When a compressor stage turns on, the next

compressor stage up or down will not take place for the next 4

minutes. This “4 minutes” is called the stage timer.

When a cooling stage is initiated no further operation will take

place within the stage timer limit. Reference the Cooling Setup

menu for the adjustable stage time value. In the above

example, the unit will stage down or turn off the cooling mode

of operation when the return temperature reaches 69.4°F.

Economizer

When the economizer is enabled, the outside air temperature is

below the changeover setpoint, and the differential enthalpy

switch (if installed) is made, the economizer becomes the first

stage of cooling. It will modulate to control to either the

discharge air temperature (VAV) or space temperature (CV).

Every 4 minutes, the unit can then either add mechanical

cooling if the economizer is at 100% open, continue

economizing, or if the control temperature is satisfied, return

to minimum position and transition back to “Fan Only” mode.

If the enthalpy switch breaks or the outside air warms, the unit

will exit economizing and continue to mechanically cool while

returning to the minimum position for ventilation.

44 McQuay IM 842-1

Page 45

Check, Test, and Start Procedures

Pre-Start of Unit

All units are completely run tested at the factory to promote

proper operation in the field. However, to ensure proper

operation once the unit is installed, the following check, test,

and start procedures must be performed to properly start the

unit. To obtain full warranty coverage, complete and sign the

check, test, and start form supplied with the unit and return it

to McQuay International.

WARNING

Electric shock and moving machinery hazard. Can cause

severe equipment damage, personal injury, or death.

Disconnect and tag out all electrical power before servicing this

equipment.

All start-up and service work must be performed only by trained,

experienced technicians familiar with the hazards of working on

this type of equipment.

Read and follow this manual: “MicroTech II Unit Controls”

(OM 843) before operating or servicing.

Bond the equipment frame to the building electrical ground

through grounding terminal or other approved means.

A representative of the owner or the operator of the equipment

should be present during start-up to receive instructions in the

operation, care, and maintenance of the unit.

Servicing Control Panel Components

WARNING

Hazardous voltage. May cause severe injury or death.

Disconnect electric power before servicing equipment.

Before Start-Up

1 Remove shipping bolt form fan spring.

2 Verify that the unit is completely and properly installed

with ductwork connected.

3 Verify that all construction debris is removed, and that the

filters are clean.

4 Verify that all electrical work is complete and properly

terminated.

5 Verify that all electrical connections in the unit control

panel are tight, and that the proper voltage is connected.

6 Verify all nameplate electrical data is compatible with the

power supply.

7 Verify the phase voltage imbalance is no greater than 2%.

8 Verify that gas piping is complete and leak tight.

9 Verify that the shutoff cock is installed ahead of the

furnace, and that all air has been bled from the gas lines.

10 Verify installation of gas flue and outside air vents.

Check, Test, and Start Procedures

11 Manually rotate all fans and verify that they rotate freely.

12 Verify that the belts are tight and the sheaves are aligned.

13 Verify that all setscrews and fasteners on the fan assemblies

are still tight. “See “Setscrews” on page 52.”

14 Verify that the evaporator condensate drain is trapped and

that the drain pan is level.

15 If unit is curb mounted, verify that the curb is properly

flashed to prevent water leakage.

16 Review the equipment and service literature, the sequences

of operation, and the wiring diagrams to become familiar

with the functions and purposes of the controls and devices.