Page 1

Operation and Maintenance Manual OM 844-1

Group: Rooftop Systems

Part Number: OM 844

Date: January 2007

MD2 Variable Speed Drive Controllers

Packaged Rooftop Units RPS, RFS, RDT, RPE, and RDE

Rooftop Air Handler Units RDS and RAH

Vertical Self-Contained Units SWP and SWT

Commercial Packaged Rooftop Units MPS 030 to 050 Tons

© 2007 McQuay International

Page 2

Introduction.................................................................... 3

Applications With MicroTech II Control (A1a, A2, B1a,

B2, C, and D)............................................................ 4

Applications Without MicroTech II Controls (A1b and

B1b).......................................................................... 4

Replacement VFD .................................................... 4

Hazard Categories and Special Symbols ...................... 5

Before You Begin .......................................................... 6

Bus Voltage Measurement Procedure ..................... 7

Initial Start-Up........................................................... 8

Control Terminals .......................................................... 9

Switch Settings and Terminal Designations ................ 12

Integrated Display Terminal......................................... 13

Programming ............................................................... 15

Mode Access.......................................................... 15

Parameter Groups.................................................. 15

Access to Menus and Parameters ......................... 16

AUF Quick Menu....................................................... 17

AUF Quick Menu Parameters .............................. 18

Setting the Acceleration/Deceleration

Ramp Times ........................................................... 19

Setting the Macro Function .................................... 20

Setting the Mode of Operation ............................... 20

Command Mode Selection ..................................... 21

Frequency Mode Selection..................................... 21

Default Setting........................................................ 22

Forward/Reverse Run Selection ............................ 22

Maximum Frequency.............................................. 23

High Speed and Low Speed................................... 24

Nominal Motor Frequency and Voltage

Settings .................................................................. 24

V/Hz Control Mode Selection ................................. 25

Voltage Boost (Energy Recovery

Application Only) .................................................... 25

Electronic Motor Overload Protection..................... 26

Input Signal Selection ............................................ 28

Terminal Function Selection................................... 28

Jump Frequency (Jumping

Resonant Frequencies).......................................... 29

Switching Frequency.............................................. 30

Auto Restart ........................................................... 31

Drive Controller Fault Retention............................. 33

Output Phase Loss Detection ................................ 33

Input Phase Loss Detection ................................... 34

Avoiding Overvoltage Tripping ............................... 34

Undervoltage Fault................................................. 35

Changing the Display Parameter ........................... 36

Troubleshooting Fault and Alarm Codes..................... 37

Resetting the Drive Controller After a

Fault Condition ....................................................... 44

Appendix A—Input Terminal Functions....................... 45

Appendix B—Output Terminal Functions .................... 49

Appendix C—Receiving and Preliminary Inspection... 53

Storing and Shipping.............................................. 53

Lifting and Handling ............................................... 54

Precautions ............................................................ 54

Appendix D—Wiring Recommendations ..................... 60

Power Terminals .................................................... 63

Appendix E—Wiring Diagrams and

Parameter Settings...................................................... 65

LL (Lower Limit Frequency) ................................... 65

MODE KEY (LOCAL or REMOTE Keypad) ........... 65

MPS Rooftop with MicroTech II Controls for SAF and

EAF Applications.................................................... 66

Rooftop and Self-Contained with MicroTech II Controls

for SAF, RAF, and EAF Applications ..................... 69

Rooftop Controls by Others for SAF, RAF, and EAF

Applications............................................................ 72

Rooftop Energy Recovery Wheel Speed Control... 74

Page 3

Introduction

Introduction

This manual provides information about the McQuay MD2 variable speed drive (VFD)

that was originally factory installed within a McQuay HVAC unit. The manual

describes operation of the VFD along with descriptions and functions of the VFD

parameters for the models and applications listed below.

Specific packaged equipment wiring schematics and parameter settings can be found

in Appendix E—Wiring Diagrams and Parameter Settings on page 65. Please refer to

the rooftop or self-contained installation manual and/or operation manual for

information on the unit controller and its control of the variable speed drive.

A. Packaged Rooftop models RPS, RFS, RDT, RPE, and RDE

1. VFDs for supply, return and exhaust air fan speed control

a. Units with Mircotech II control

b. Units without Microtech II control

2. VFDs for energy recovery wheel speed control

B. Rooftop Air Handler models RDS and RAH

1. VFDs for supply, return and exhaust air fan speed control

a. Units with Mircotech II control

b. Units without Microtech II control

2. VFDs for energy recovery wheel speed control

C. Vertical Self-Contained models SWP and SWT, supply fan speed control

D. Commercial Packaged Rooftop Model MPS

1. For supply and exhaust air fan speed control

WARNING

UNINTENDED EQUIPMENT OPERATION

• Modifying or changing parameters whose function is not

described in this manual will affect drive controller operation.

Some register changes will take effect as soon as they are

entered.

• Do not modify or change parameters whose function is not

described in this instruction bulletin.

Failure to follow this instruction can result in death, serious

injury, or equipment damage.

McQuay OM 844-1 3

Page 4

Introduction

Applications With MicroTech II Control (A1a, A2, B1a, B2, C, and D)

The variable speed drive has been selected and coordinated with the McQuay air

conditioning equipment’s unit controller. The drive that is installed on the McQuay

packaged equipment has the parameters modified for the HVAC application. For the

standard HVAC system design, no further modifications should need to be made to

the drive.

Applications Without MicroTech II Controls (A1b and B1b)

The McQuay variable speed drive parameters must be changed to coordinate the

drive with the unit controls and the system it is being installed on. This manual

describes the parameters that should be reviewed and adjusted. Other parameters

should not be adjusted.

Replacement VFD

When replacing a VFD, the owner/installer must determine which of the above listed

applications applies and follow the appropriate procedures within this manual.

4 McQuay OM 844-1

Page 5

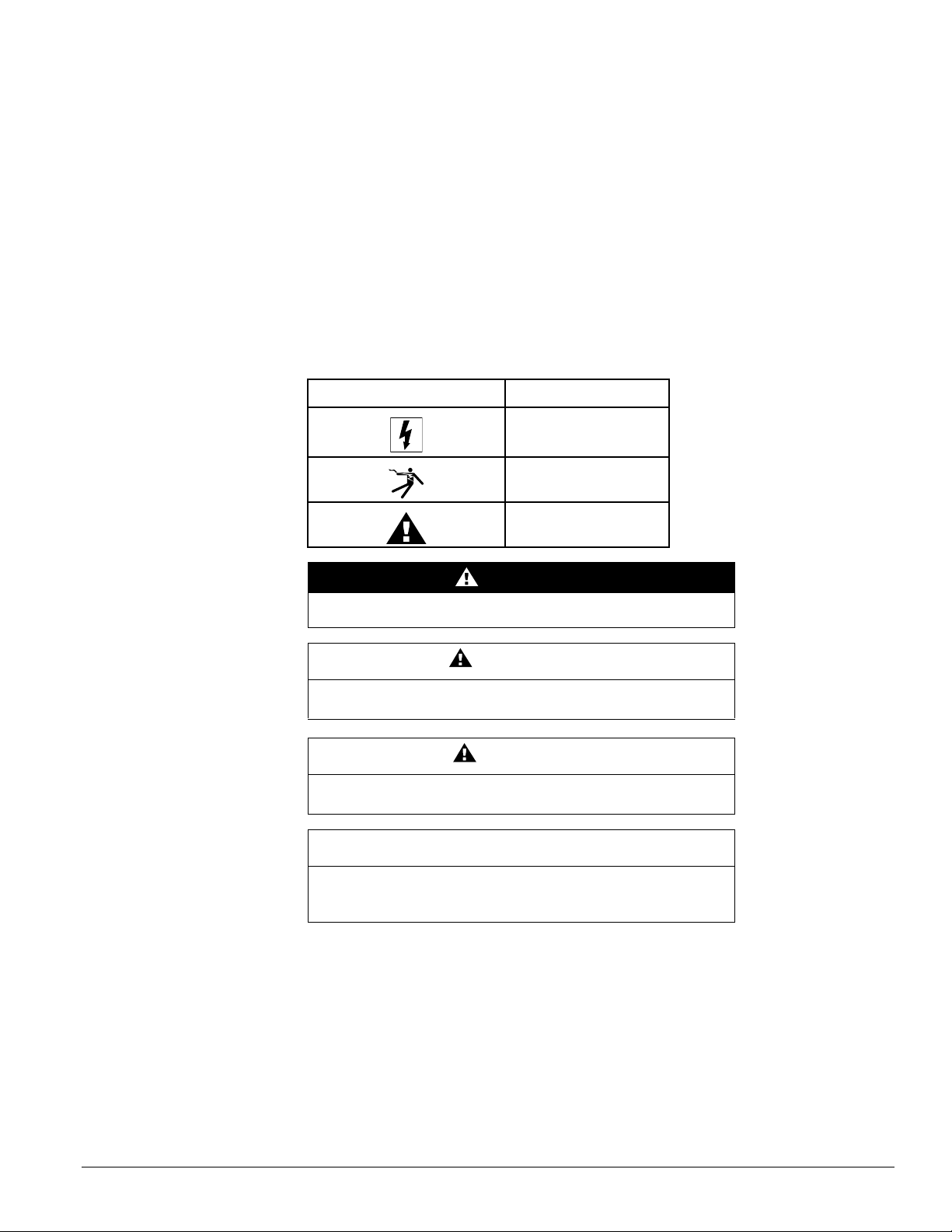

Hazard Categories and Special Symbols

Hazard Categories and Special Symbols

Read these instructions carefully and look at the equipment to become familiar with

the device before trying to install, operate, service, or maintain it. The following special

messages may appear throughout this bulletin or on the equipment to warn of

potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of a lightning bolt or ANSI man symbol to a “Danger” or “Warning” safety

label indicates that an electrical hazard exists which will result in personal injury if the

instructions are not followed.

The exclamation point symbol is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

Symbol Name

Lightning Bolt

ANSI Man

Exclamation Point

DANGER

DANGER indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not

avoided, can result in death, serious injury, or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not

avoided, can result in minor or moderate injury.

CAUTION

CAUTION, used without the safety alert symbol, indicates a

potentially hazardous situation which, if not avoided, can result in

property damage.

McQuay OM 844-1 5

Page 6

Before You Begin

Before You Begin

Read and understand these instructions before performing any procedure on this

drive controller.

DANGER

HAZARDOUS VOLTAGE

• Read and understand this manual before installing or operating

the MD2 drive controller. Installation, adjustment, repair, and

maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and

national electrical code requirements with respect to grounding of

all equipment.

• Many parts of this drive controller, including the printed circuit

boards, operate at the line voltage. DO NOT TOUCH. Use only

electrically insulated tools.

• Before servicing the drive controller:

— Disconnect all power.

— Place a “DO NOT TURN ON” label on all power disconnects.

— Lock all power disconnects in the open/off position.

• DO NOT touch unshielded components or terminal strip screw

connections with voltage present.

• DO NOT short across terminals PA/+ and PC/- or across the DC

bus capacitors.

• Install and close all covers before applying power or starting and

stopping the drive controller.

• Disconnect all power, including external control power that may

be present, before servicing the drive controller. WAIT

10 MINUTES to allow the DC bus capacitors to discharge. Then

follow the DC bus voltage measurement procedure on page 7 to

verify that the DC voltage is less than 45 V. The drive LEDs are

not accurate indicators of the absence of DC bus voltage.

Failure to follow these instructions will result in death or

serious injury.

CAUTION

IMPROPER DRIVE CONTROLLER OPERATION

• If the drive controller is de-energized for a prolonged period, the

performance of the electrolytic capacitors will be reduced.

• Once a year, apply power to the drive controller for at least

5 hours to restore the performance of the capacitors, then check

its operation.

• If the drive has not been powered for more than a year, do not

connect the drive controller to the line voltage. Gradually

increase the voltage using an adjustable AC source.

Failure to follow these instructions can result in injury and

equipment damage.

6 McQuay OM 844-1

Page 7

Before You Begin

DANGER

AUTOMATIC RESTART ENABLED

• This drive controller can restart under fault conditions.

• Equipment must be shut down, locked out and tagged out to

perform servicing or maintenance.

Failure to follow this instruction will result in death or serious

injury.

Bus Voltage Measurement Procedure

Before working on the drive controller, turn it off and wait 10 minutes to allow the DC

bus to discharge and then measure the DC bus voltage.

DANGER

HAZARDOUS VOLTAGE

Read and understand the precautions in “Before You Begin” on

page 6 before performing this procedure.

Failure to follow this instruction will result in death or serious

injury.

The DC bus voltage can exceed 1,000 Vdc. Use a properly rated voltage-sensing

device when performing this procedure. To measure the DC bus voltage:

1. Disconnect all power and wait 10 minutes to allow the DC bus to discharge.

2. Measure the voltage of the DC bus between the PA/+ and PC/– terminals to

ensure that the voltage is less than 45 Vdc.

3. If the DC bus capacitors do not discharge completely, contact your local McQuay

representative. Do not repair or operate the drive controller.

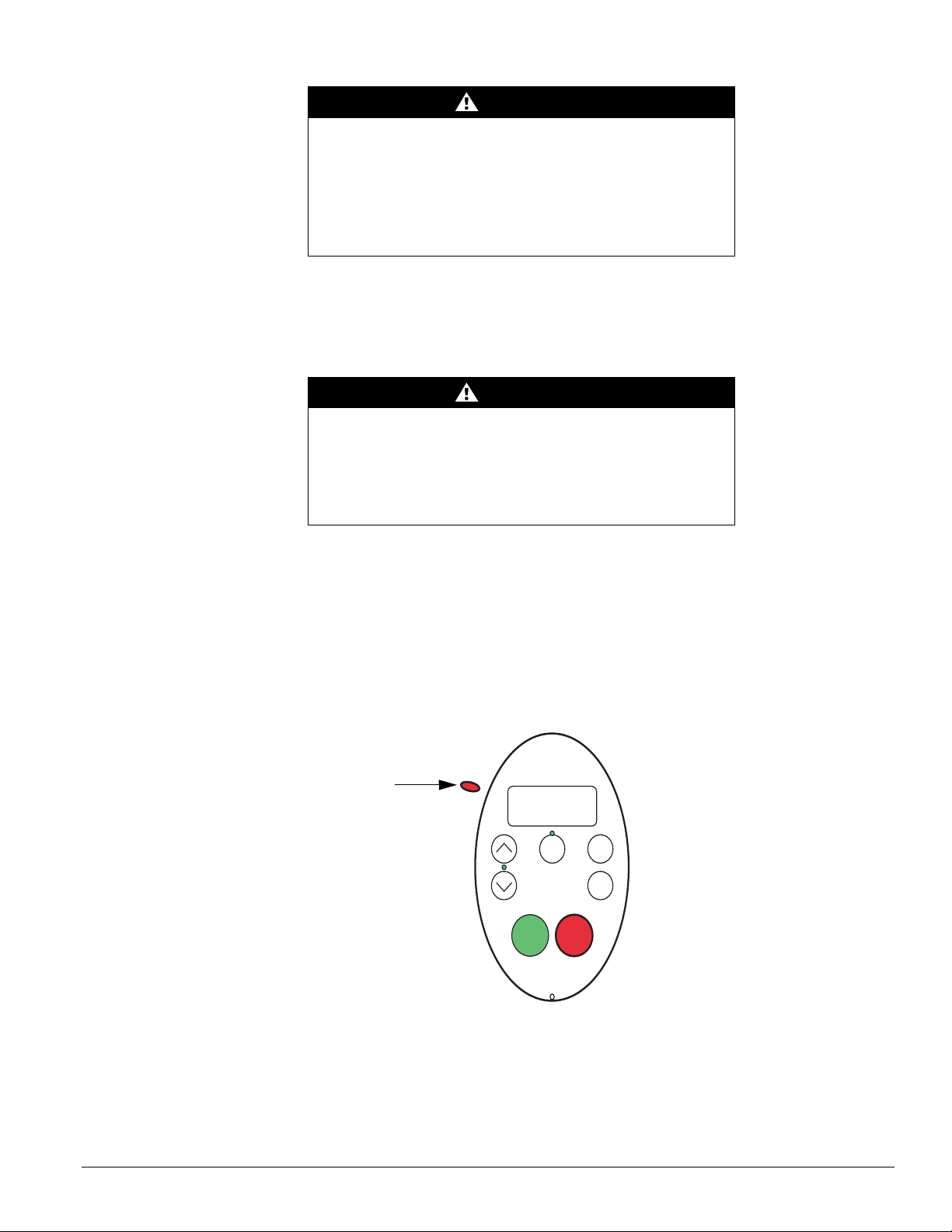

Figure 1: Capacitor Charging LED

Capacitor

charging LED

RUN

PRG

MON

RUN STOP

Loc

Rem

%

Hz

MODE

ENT

McQuay OM 844-1 7

Page 8

Before You Begin

Initial Start-Up

Before providing power to the VFD, refer to the appropriate unit

installation/maintenance manual(s) listed below:

• IM 738 for packaged rooftops with air-cooled condensers (RPS, RFS, and RDT)

• IM 487 for rooftop air handlers (RDS and RAH)

• IM 791 for packaged rooftops with evaporative condensers (RPE and RDE)

• IM 708 for one-piece self-contained units

• IM 709 for modular self-contained units

Perform the following (RPS/RDT example) general procedures on the specific unit

purchased (yours may differ slightly depending on the unit)

1. Before closing (connecting) the power disconnect switch, open (disconnect) the

following unit control circuit switches:

a. Turn system switch S1 to OFF

b. Turn system switch S7 to OFF

2. Confirm duct static pressure sensor SPS1 is connected to the ductwork.

3. Confirm the VFD lugs for the line voltage are tight.

4. Confirm the horsepower (hp) of the drive matches that of the motor.

Before starting the fan and VFD

1. Close the unit disconnect switch. With the control system switch S1 in the OFF

position, power should be available only to the control circuit transformer (TI) and

the compressor crankcase heaters.

2. Turn the Switch S1 to ON. Power should now be supplied to the control panel, and

the LEDs on MCB1 should follow the normal startup sequence (refer to the “MCB

LED Power-Up Sequence” of IM 696).

3. Verify all duct isolation dampers are open. Unit mounted isolation dampers may be

mounted in the supply or return sections.

4. Place the unit into the “Fan Only” mode through the keypad menu System

Summary\System\Ctrl Mode= Fan Only.

5. Confirm the power supply matches the setting of the J7J parameter.

6. Confirm the power supply frequency matches that of the J7 parameter.

7. Confirm the thermal protection level, tHr (or amps), matches that of the motor.

NOTE: All of the above parameters can be quickly found in the AUF Quick menu.

Start the fan and VFD

1. Turn Switch S7 to ON. The controller should enter the “Startup Initial” operating

state. If the fan does not run:

a. Check fuses F1 and F3.

b. Check that the manual motor protectors or circuit breakers have not tripped.

c. Check the optional phase monitor.

2. If the fans are equipped with optional spring isolators, check the fan spring mount

adjustment. When the fans are running they should be level.

3. Verify the rotation is correct.

4. Verify the DHL safety is opening at a pressure compatible with duct working

pressure limits.

NOTE: Refer to the unit IMs for additional non-VFD instructions.

8 McQuay OM 844-1

Page 9

Control Terminals

Control Terminals

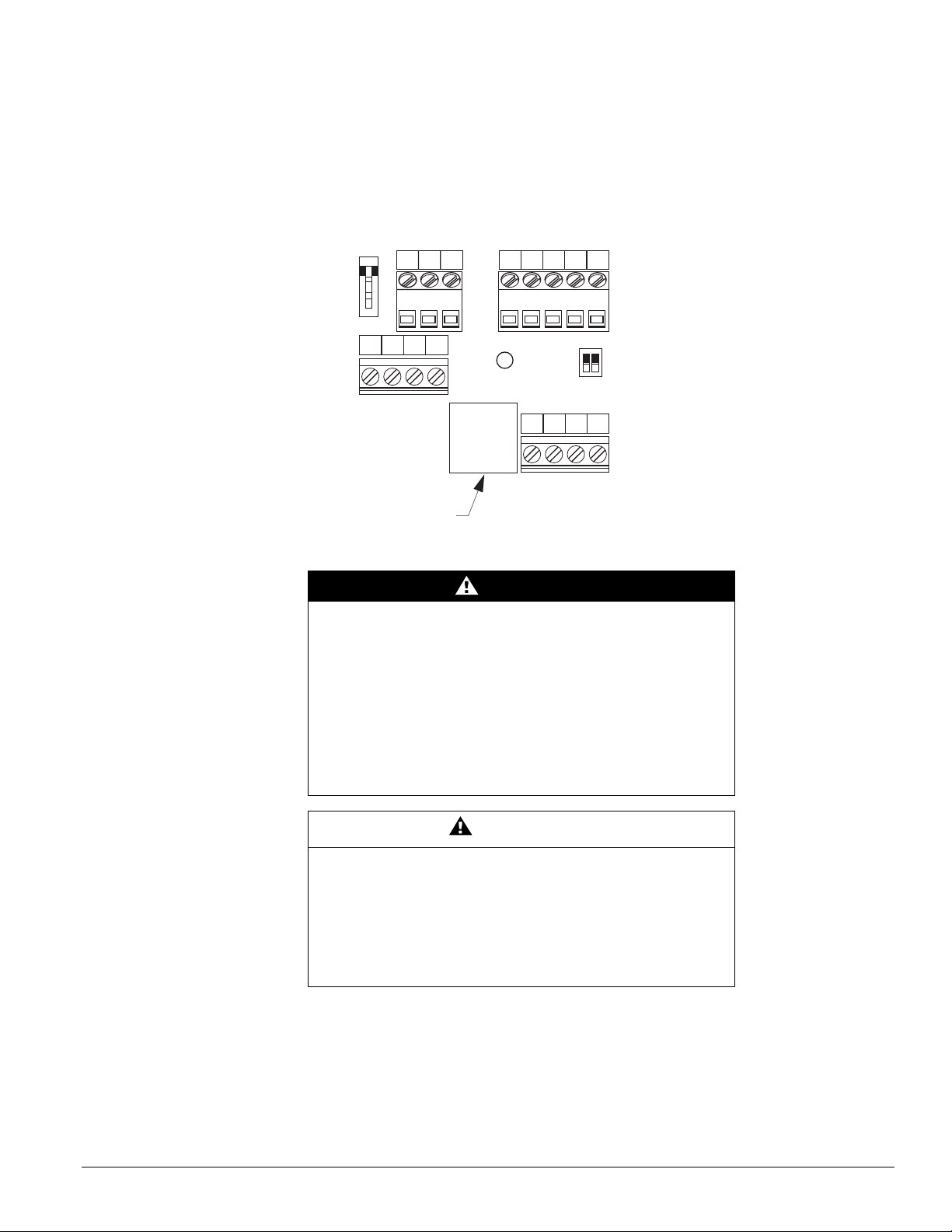

The control terminals are illustrated in Figure 2 (refer to Appendix E—Wiring

Diagrams and Parameter Settings for more details).

Figure 2: Control Terminals

SOURCE

PLC

SINK

SW4

PLC

P24 CC

SW4

F R RES FM

Connector (RJ45)

FLA FLB FLC R Y RC

FM VIA

VIV

SW2 SW3

PP VIA VIB CC

Factory settings:

SW4:

FM: V side

VIA: V side

•

I

• Tightening torque: 0.6 Nm

SOURCE side

(positive)

Maximum wire size: 2.5 mm²

(AWG 14)

(5.3 lb.in)

DANGER

UNINTENDED EQUIPMENT OPERATION

• The accidental grounding of logic inputs configured for Sink Logic

can result in unintended activation of drive controller functions.

• Protect the signal conductors against damage that could result in

unintentional conductor grounding.

• Follow NFPA 79 and EN 60204 guidelines for proper control

circuit grounding practices.

Failure to follow these instructions will result in death or

serious injury.

WARNING

RISK OF IMPROPER OPERATION

The MD2 logic input selector switch (SW4) is factory-set to the

source position. The switch should never be moved to the PLC or

sink position.

Failure to follow this instruction can result in death or serious

injury.

McQuay OM 844-1 9

Page 10

Control Terminals

Table 1: Control Terminal Characteristics

Terminals Function Characteristics

External

PLC

power supply

input

P24

Internal

supply

CC Common 0 V common (2 terminals)

FLA,

FLB,

FLC

Configurable

relay outputs

RY, RC

F

R

Logic inputs

RES

FM

Analog

output

Internal

PP

supply

available

+24 Vdc input for external power supply for logic inputs

Max. permissible voltage: 50 Vac

Short-circuit and overload protection:

24 Vdc supply (min. 21 V, max. 27 V), maximum current:

200 mA

One relay logic output, one N/C contact, and one N/O contact

with common point

Minimum switching capacity: 3 mA for 24

Maximum switching capacity:

• On resistive load: 5 A for 250 Vac or 30

• On inductive load: 2 A for 250 Vac or 30

Max. response time: 7ms ± 0.5ms

Electrical service life: 100,000 operations

One relay logic output, one N/O contact

Minimum switching capacity: 3 mA for 24

Maximum switching capacity:

• On resistive load: 5 A for 250 Vac or 30

• On inductive load: 2 A for 250 Vac or 30

Max. response time: 7ms ± 0.5ms

Electrical service life: 100,000 operations

Three programmable logic inputs, 24

level 1 PLC, IEC 65A-68 standard

Impedance: 3.5 kΩ

Maximum voltage: 30 V

Max. sampling time: 2 ms ± 0.5 ms

Multiple assignment makes it possible to configure several

functions on one input

Positive logic (Source): State 0 if ≤ 5 V or logic input not wired,

state 1 if ≥ 11 V

Negative logic (Sink): State 0 if ≥ 16 V or logic input not wired,

state 1 if ≤ 10 V

One switch-configurable voltage or current analog output:

• Voltage analog output 0–10 Vdc, minimum load impedance 470 Ω

• Current analog output X–Y mA by programming X and Y from 0 to

20 mA, maximum load impedance: 500 Ω

Max. sampling time: 2 ms ± 0.5 ms

Resolution: 10 bits

Accuracy: ± 1% for a temperature variation of 60°C

Linearity: ± 0.2%

Short-circuit and overload protection:

One 10.5 Vdc ± 5% supply for the reference potentiometer (1

to 10 kΩ), maximum current: 10 mA

Vdc

Vdc

Vdc

Vdc

Vdc

Vdc

Vdc

, compatible with

10 McQuay OM 844-1

Page 11

Table 1: Control Terminal Characteristics (continued)

Terminals Function Characteristics

Switch-configurable voltage or current analog input:

• Voltage analog input 0–10 Vdc, impedance 30 kΩ (max. safe

voltage: 27 Vdc +/- 3 Vdc)

• Analog current input X–Y mA by programming X and Y from 0 to

20 mA, with impedance 242 Ω

Max. sampling time: 2 ms ± 0.5 ms

Resolution: 11 bits

Accuracy: ± 0.6% for a temperature variation of 60°C

Linearity: ± 0.15% of the maximum value

•

0–10

Vdc

, impedance 30 kΩ (max. safe voltage 27 Vdc)

• Max. sampling time: 2 ms ± 0.5 ms

• Resolution: 11 bits

• Accuracy: ± 0.6% for a temperature variation of 60°C

• Linearity: ± 0.15% of the maximum value

VIA

VIB

Analog/logic

input

Analog input Voltage analog input:

Control Terminals

McQuay OM 844-1 11

Page 12

Switch Settings and Terminal Designations

Switch Settings and Terminal Designations

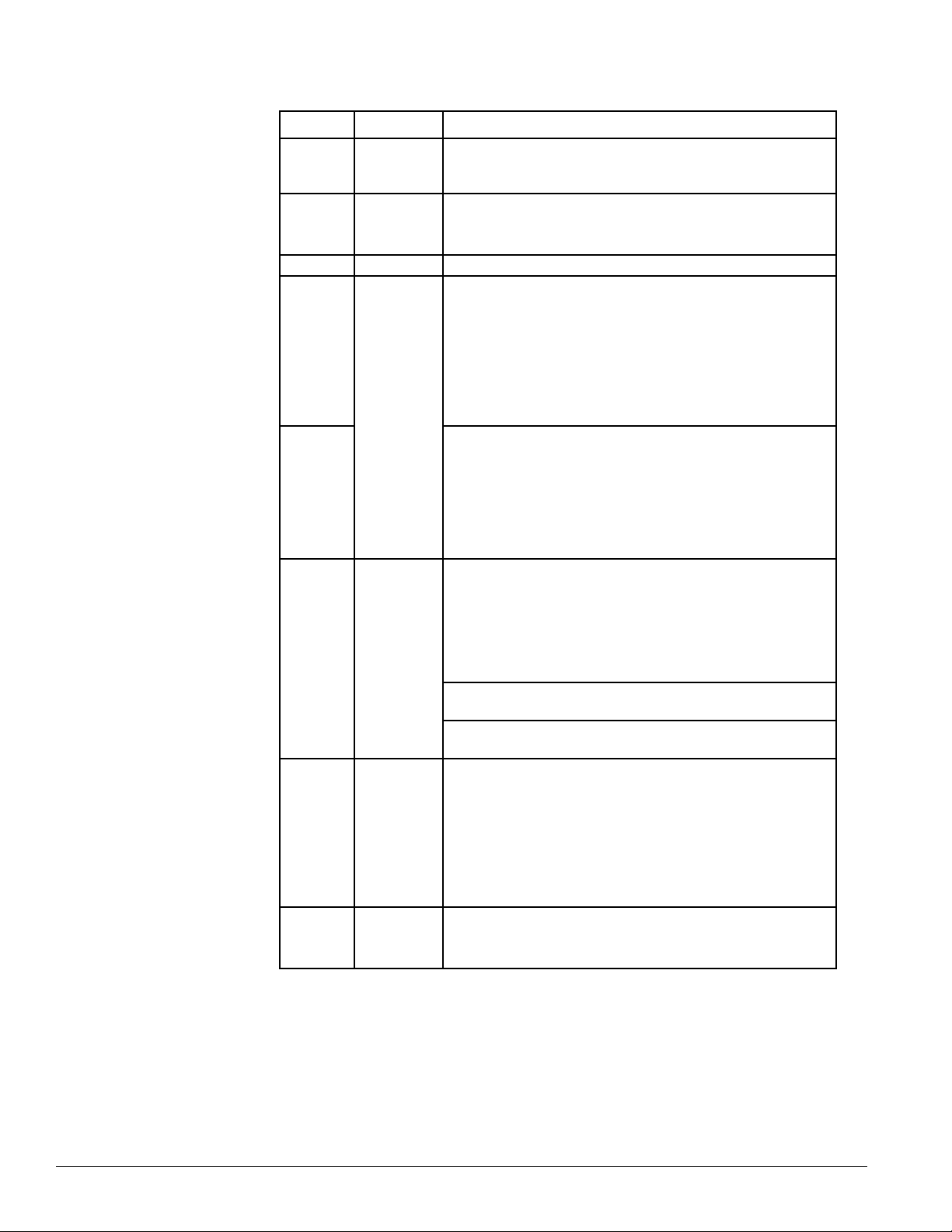

Figure 3: Switches

Voltage/current selection for

analog I/O (FM and VIA)

SW4

Source

(positive logic)

PLC

Sink

(negative logic)

SW4

V (voltage)

Selection of logic

type

FM VIA

V (voltage)

I (current)I (current)

SW2 SW3

NOTE: Refer to Appendix E—Wiring Diagrams and Parameter Settings on page 65 for your

specific HVAC application and switch settings.

NOTE: The logic input switch SW4 is set to the source position. The switch should never be

moved to the PLC or sink position.

DANGER

UNINTENDED EQUIPMENT OPERATION

• The accidental grounding of logic inputs configured for Sink Logic

can result in unintended activation of drive controller functions.

• Protect the signal conductors against damage that could result in

unintentional conductor grounding.

• Follow NFPA 79 and EN 60204 guidelines for proper control

circuit grounding practices.

Failure to follow these instructions will result in death or

serious injury.

Table 2: Drive Controller Default Terminal Function Assignments

Terminal Function

FLA-FLB-FLC relay

RY-RC relay

F Forward (2-wire control)

R Preset speed

RES Fault reset

VIA Speed reference 0-10 Vdc

VIB Not assigned

FM Output frequency

De-energized in the event of a fault or when the power supply

is disconnected

Energized when the speed is greater than or equal to low

speed (LL)

12 McQuay OM 844-1

Page 13

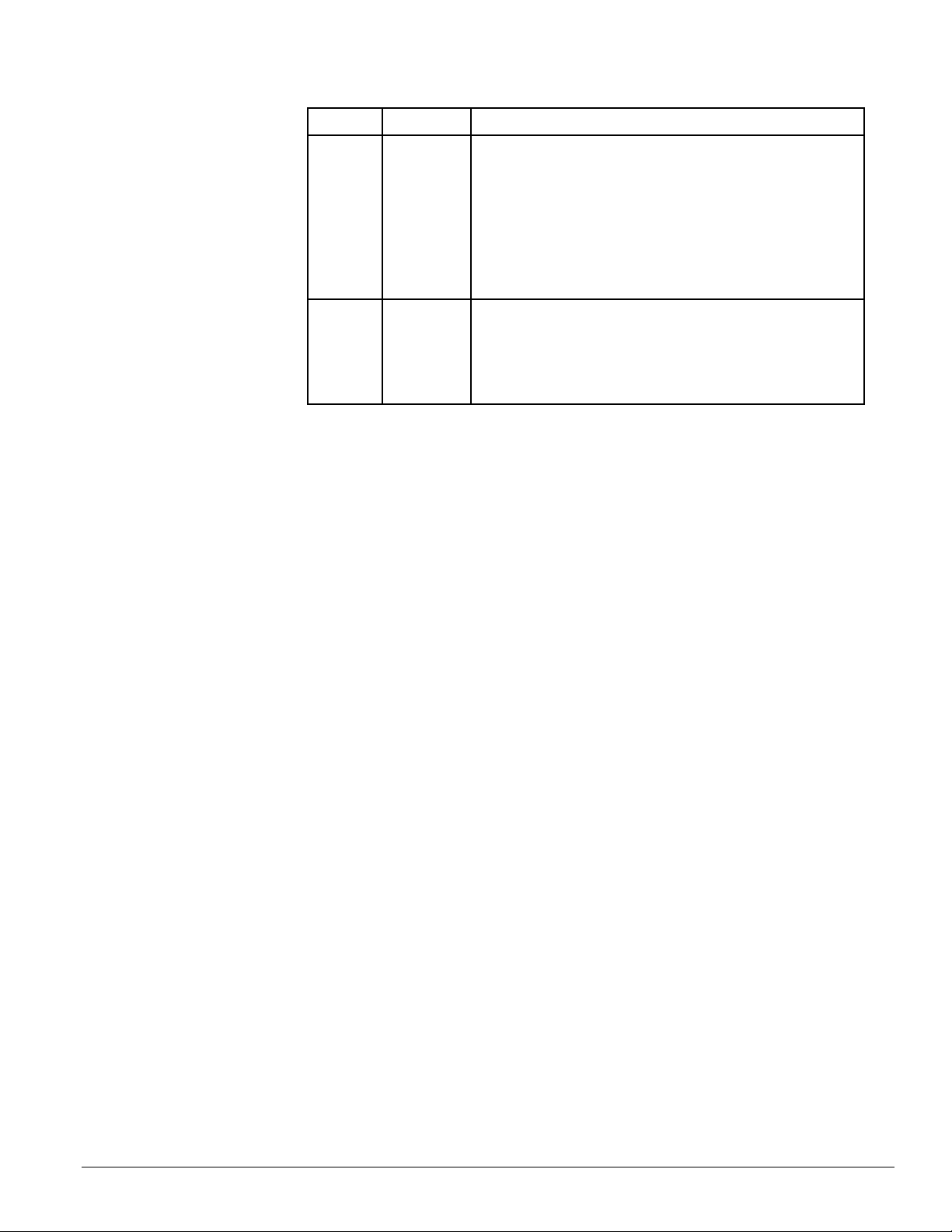

Integrated Display Terminal

Integrated Display Terminal

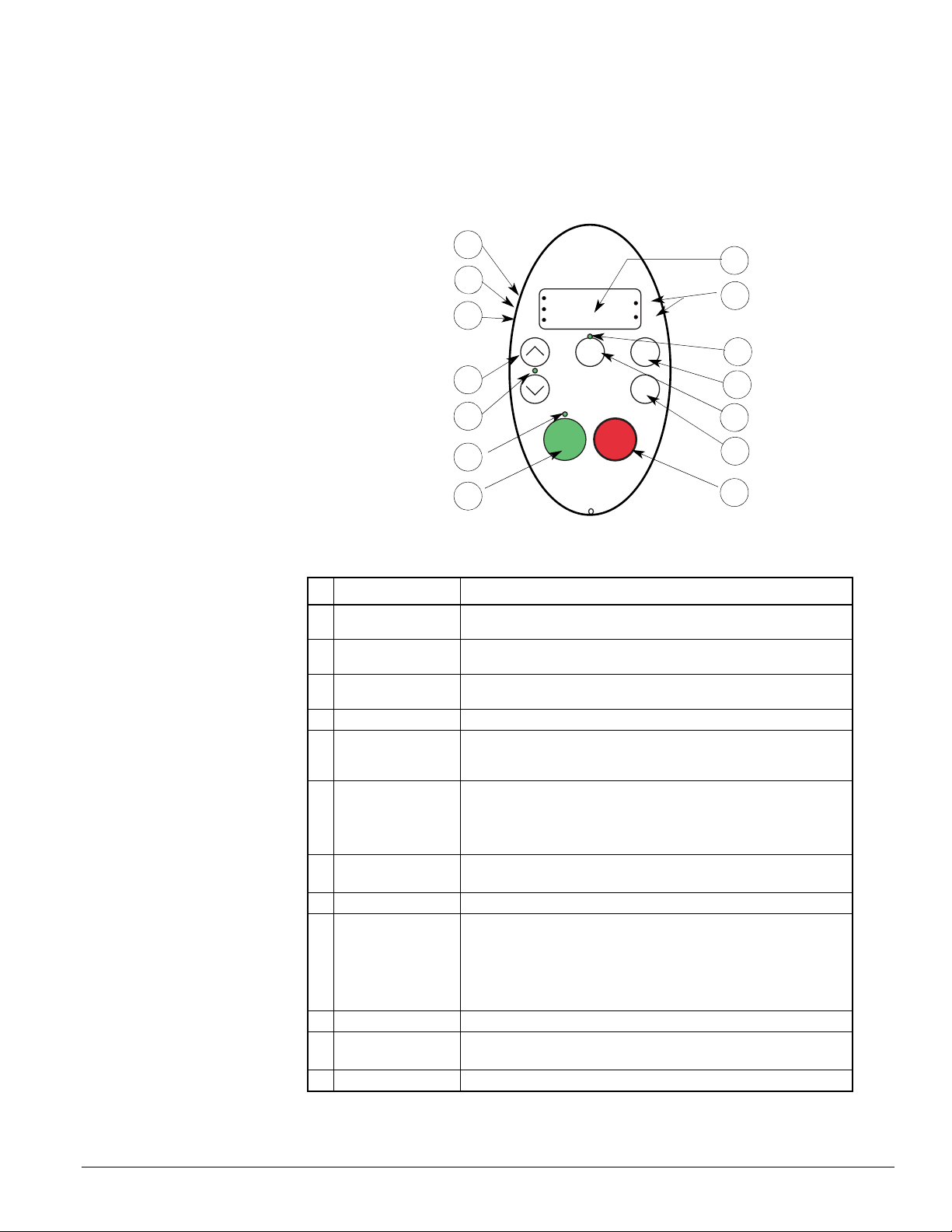

The LEDs and keys on the integrated display terminal are illustrated in Figure 4.

Figure 4: Description of Display Terminal

1

4

2

RUN

3

PRG

MON

%

Hz

5

12

13

Loc

Rem

6

7

RUN STOP

MODE

ENT

8

9

10

11

14

NOTE: Display terminal functions described above reflect VFD default settings.

Table 3: Display Terminal Features

LED/Key Characteristics

1 Display RUN LED

2 Display PRG LED

3 Display MON LED

4 Display unit Four digits, seven segments

5 Display unit LED

6 Navigation arrows

7 Arrow LED

8 Loc/Rem LED Illuminates when Local mode is selected

9Mode

10 Loc/Rem key Switches between Local and Remote modes

11 ENT

12 RUN LED Illuminates when the Run key is enabled

• Illuminates when a run command is applied to the drive controller

• Flashes when there is a speed reference present

• Illuminates when Adjustment mode is active

• Flashes in AUF–Gr.U modes

• Illuminates when Monitoring mode is active

• Flashes in fault record display mode

• The % LED illuminates when a displayed numeric value is a

percentage

• The Hz LED illuminates when a displayed numeric value is in hertz

Depending on the mode, you can use the arrows to:

• Navigate between the menus

• Change a value

• Change the speed reference when the Arrow LED (7) is lit

Illuminates when the navigation arrows are controlling the

speed reference

Press to select the Mode (see Figure 5)

• Display mode (default)

• Adjustment mode

• Monitoring mode

Can also be used to go back to the previous menu

Press to display a parameter’s value or to save a changed

value

McQuay OM 844-1 13

Page 14

Integrated Display Terminal

Table 3: Display Terminal Features (continued)

LED/Key Characteristics

13 RUN

14 STOP

Pressing this key when the RUN LED is illuminated starts the

drive controller

Stop/reset key

In Local mode (see table item #10), pressing the STOP key

decelerates the drive to a stop

In Remote mode (see table item #10), while the VFD is being

controlled by the unit controller, pressing the STOP key will

allow the drive to freewheel stop (drive display will indicate a

flashing “E”)

If F735 is set to 0 (default setting), pressing the stop key

twice will reset the flashing “E” fault and other resettable faults

if the fault condition has been resolved

DANGER

STOP BUTTON CAN CAUSE MOTOR RESTART

• The Stop Button on this drive controller can reset faults and

restart the motor if an active run command is present.

• Disable all run commands and inspect the drive system for the

cause of the fault before activating a fault reset.

• Disable the panel reset operation (F735) to remove this

hazard.

Failure to follow these instructions will result in death or

serious injury.

14 McQuay OM 844-1

Page 15

Programming

Programming

Mode Access

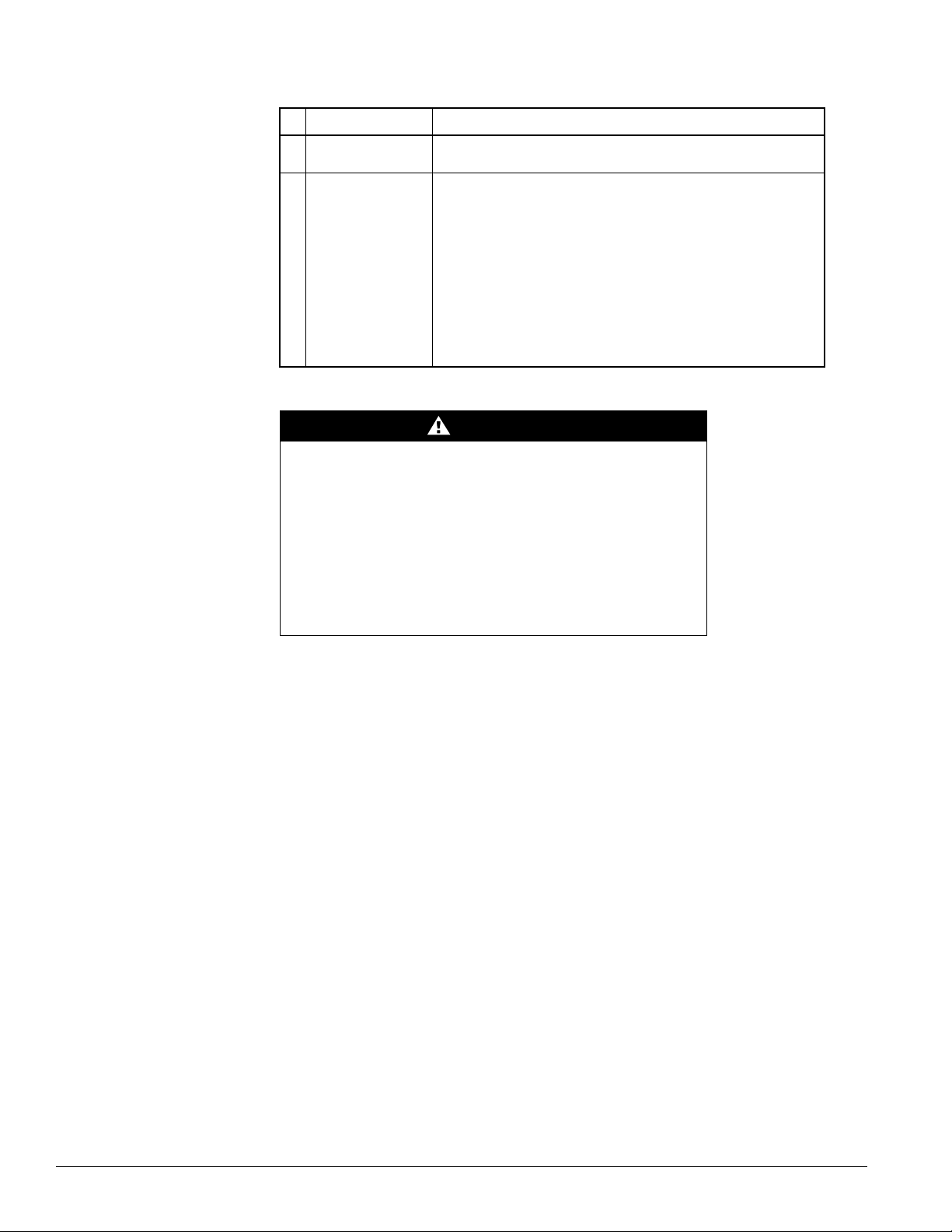

MD2 drive controllers have three modes of operation described in Table 4.

Table 4: Mode Descriptions

Display mode

(default)

Adjustment mode

Monitoring mode

• Active when power is applied to the drive controller

• Use to display drive controller parameters, alarms, and faults

• Use to modify drive controller parameters

• Use to monitor drive controller status

Figure 5 illustrates how to access the modes with the display terminal MODE key.

Figure 5: Mode Access

RUN

Display mode

(default)

60.0

MODE

PROG

Adjustment

mode

AUF

Monitoring

MODE MODE

mode

Fr-F

MON

Parameter Groups

MD2 drive controllers are factory programmed per your HVAC application (refer to

Appendix E—Wiring Diagrams and Parameter Settings for your application options

and settings).To restore McQuay factory settings, use parameter “tYp” (see Default

Setting on page 22).

WARNING

UNINTENDED EQUIPMENT OPERATION

• Any parameter values altered from the VFD control panel will

affect the operation of the drive.

• If parameter “

parameters will be transferred into the VFD memory and may

affect safe operation of the equipment.

Failure to follow this instruction can result in death, serious

injury, or equipment damage.

tYp” is selected and changed, altered

Table 5: MD2 Parameter Groups

Parameter Type Description

Basic parameters Parameters that need validation before using the drive controller.

Extended Parameters

(menu F---)

User Parameters (menu

Gr.U.)

Quick menu (menu AUF) Subset of Basic and Extended parameters frequently used.

History Parameters (menu

AUH)

McQuay OM 844-1 15

Parameters for special settings and applications.

Subset of Basic and Extended parameters whose values have

changed from the VFD default settings.

Subset of Basic and Extended parameters displaying the five

parameters that were last changed, displayed in reverse

chronological order.

Page 16

Programming

Access to Menus and Parameters

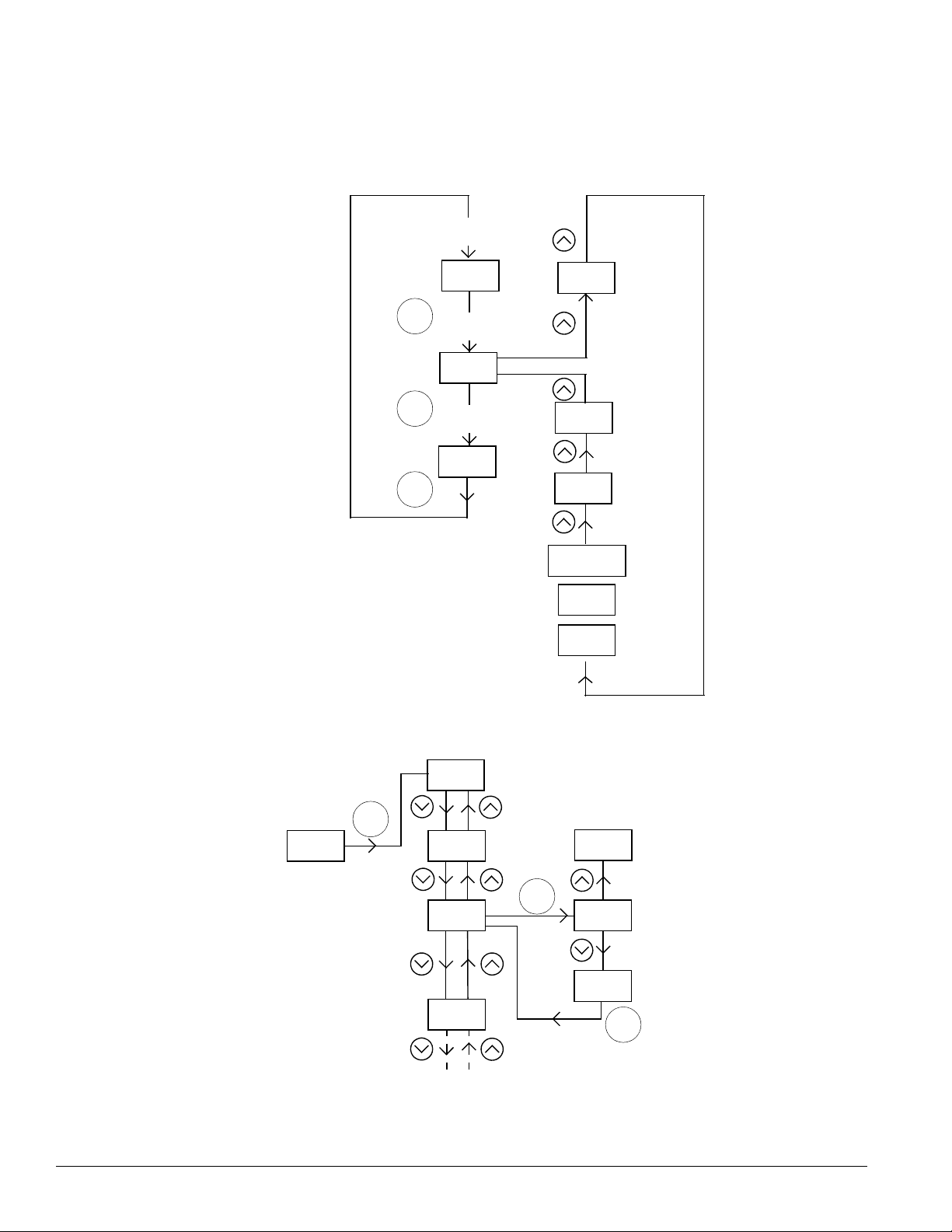

Figure 6 illustrates how to access menus.

Figure 6: Menu Access

Display

Mode

RUN

MOD

60.0

Adjustment

Mode

AUH

PROG

MOD

MOD

AUF

Monitoring

Mode

Fr-F

Figure 7: Access to Parameters

AU1

ENT

ACCAUF

GrU

F---

Basic

Parameters

AUF

AU1

10.1

NOTE: Press the MODE key to

go back to the previous level.

For example:

— To go from 9.9 to

dEC

— To go from

AUF

dEC

to

ENT

dEC

LL

10

9.9

ENT

Confirm value

16 McQuay OM 844-1

Page 17

AUF Quick Menu

AUF Quick Menu

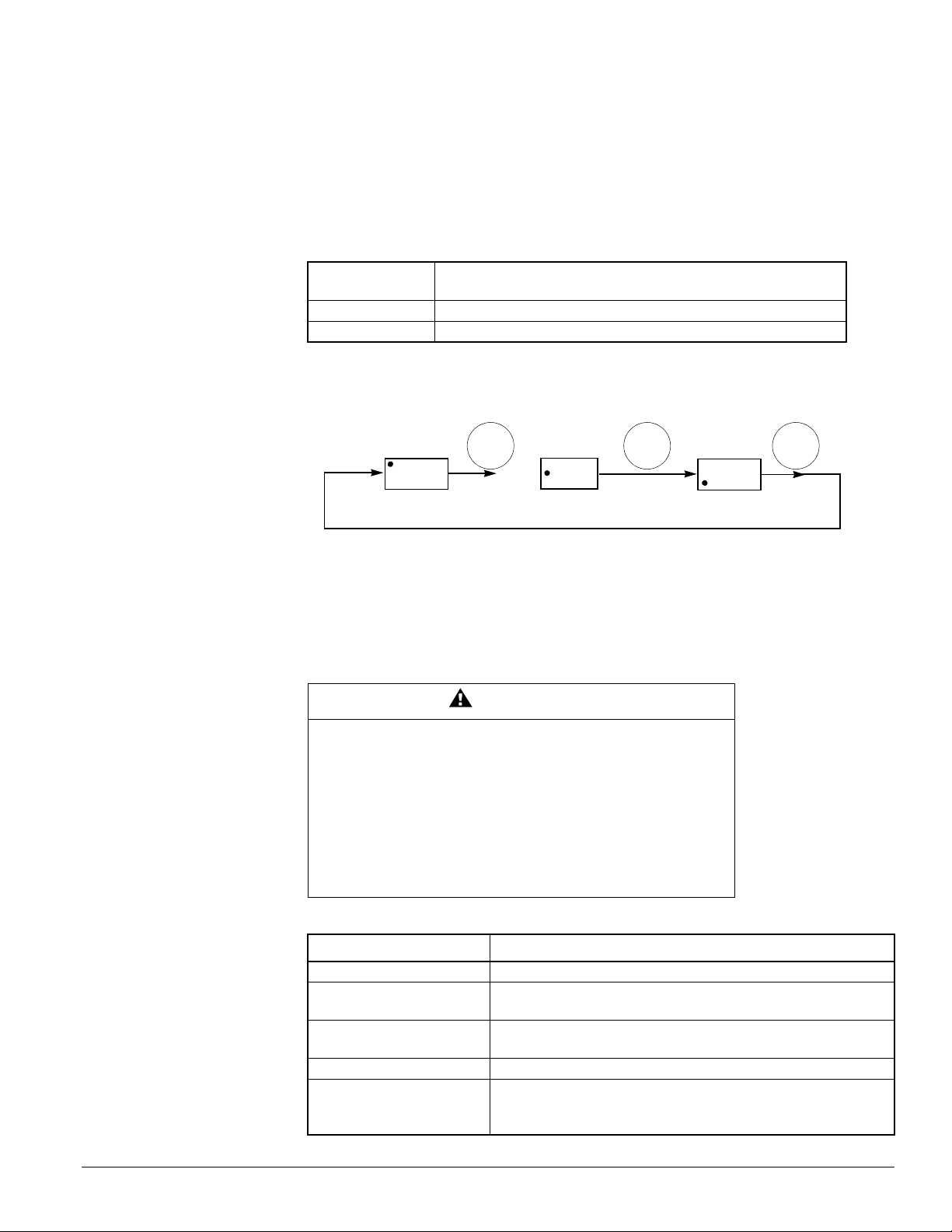

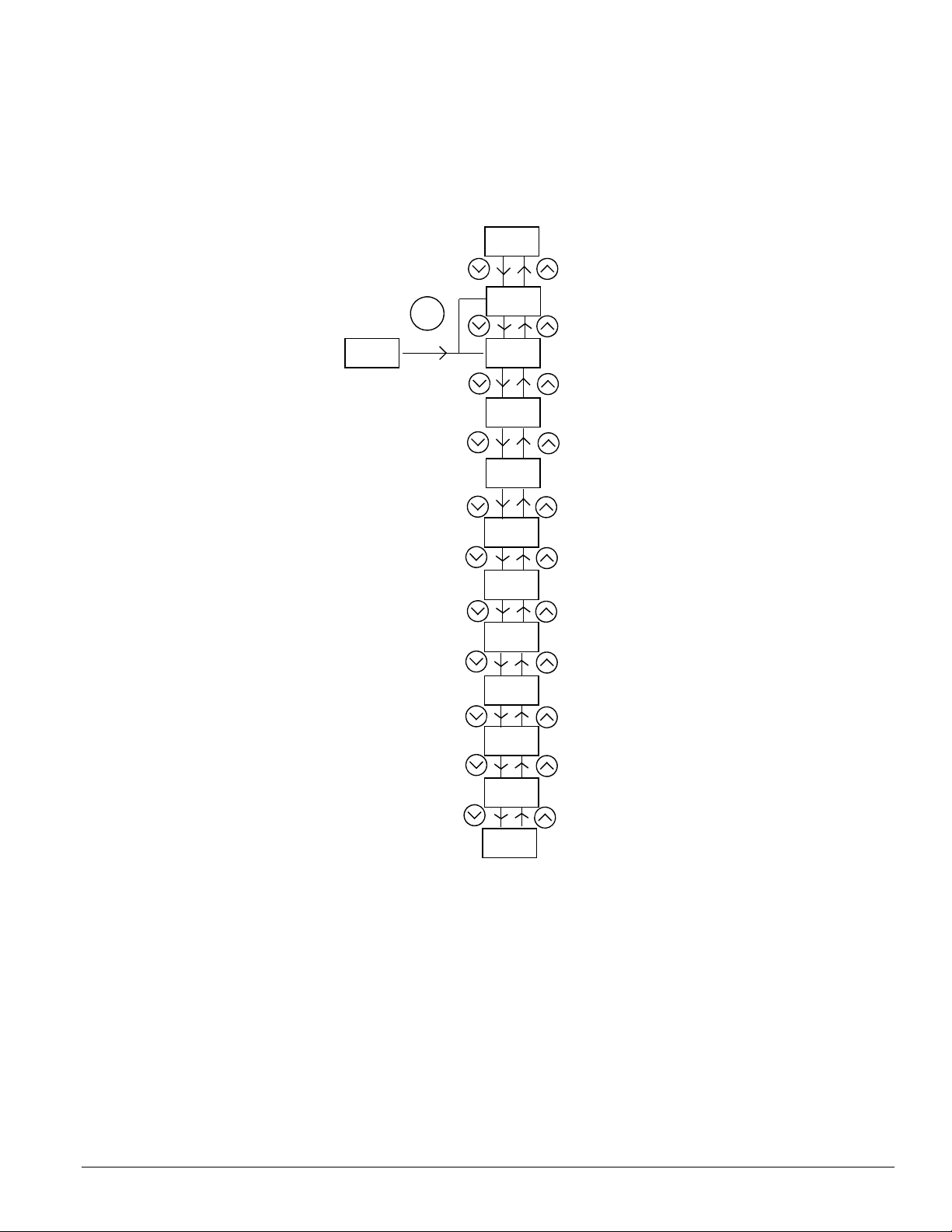

Figure 8 illustrates the parameters accessible from the AUF Quick menu.

Figure 8: AUF Quick Menu Parameters

ENT

HEAD

AU1

ACCAUF

dEC

LL

UL

tHr

FN

Pt

Top of list

Automatic ramp adaptation

Acceleration ramp times

Deceleration ramp times

Minimum motor frequency

Maximum motor frequency

Motor thermal protection

Analog output scaling

Motor control profile

uL

uLu

END

Nominal motor frequency

Nominal motor voltage

End of list

McQuay OM 844-1 17

Page 18

AUF Quick Menu

AUF Quick Menu Parameters

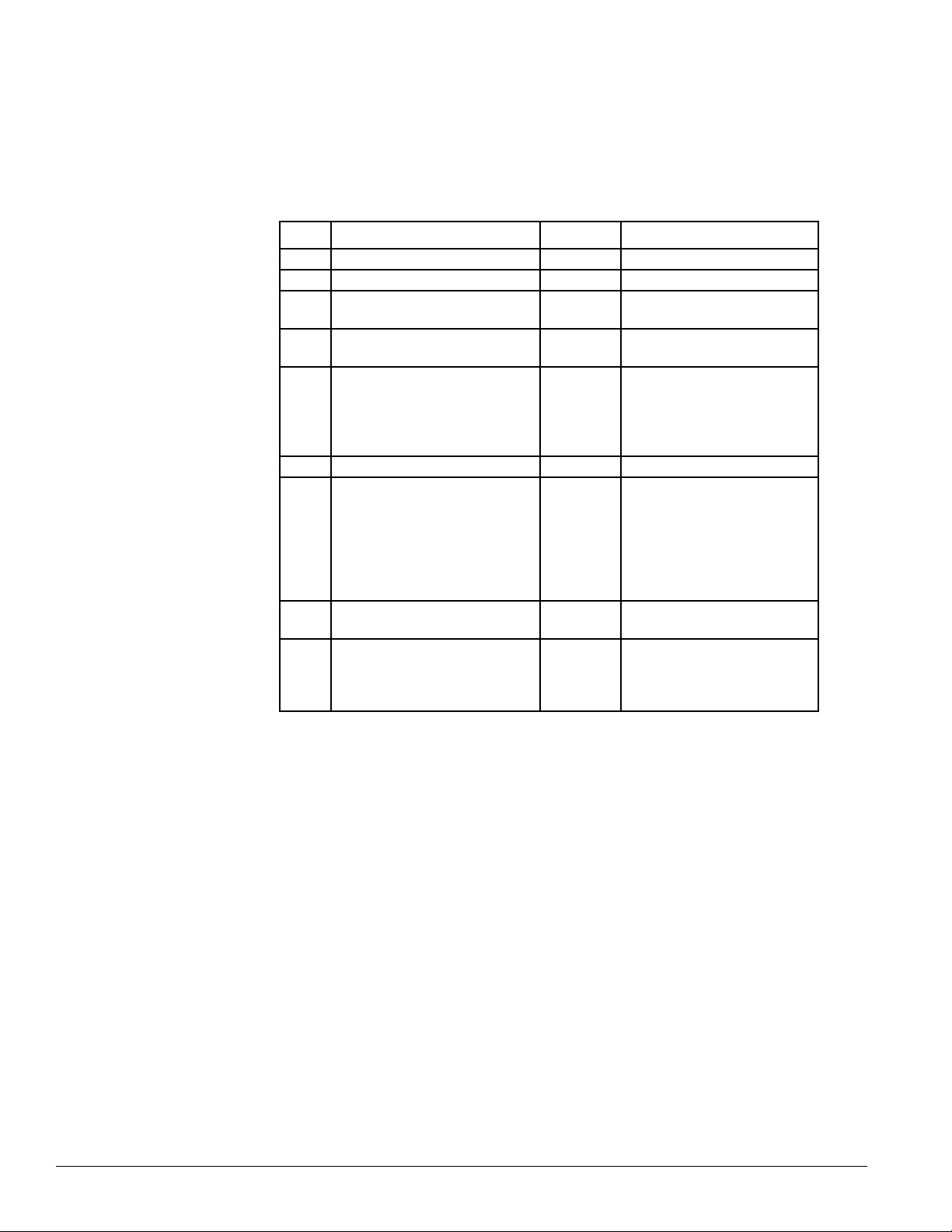

Table 6 describes the parameters that can be accessed from the AUF Quick menu.

With the exception of ACC and dEC, the parameters cannot be modified while the

drive controller is running.

Table 6: AUF Quick Menu Parameters

Code Description Unit Adjustment Range

ACC Acceleration time Seconds 0.0 to 3200

dEC Deceleration time Seconds 0.0 to 3200

LL

UL

tHr

FN Analog output scaling — Do not use

Pt

uL

uLu

1

Frequency lower limit (minimum

motor frequency)

Frequency upper limit (maximum

motor frequency)

Motor electronic thermal

protection level in amperes.

Adjust tHr to the nominal

current value which appears on

the motor nameplate.

Selection of Volts/Hz control

mode (motor control profile)

Base frequency (nominal motor

frequency)

Voltage at base frequency

(nominal motor voltage)

In is the nominal drive current shown on the drive controller nameplate.

Hz 0.0 to uL

Hz 0.5 to 200.0

A 0.1 to 1 times In

0: V/Hz profile constant torque

1: V/Hz profile variable torque

2: Automatic voltage boost

—

Hz 25 to 200.0

V

3: Flux vector control

4: Energy saving

6: Permanent magnet

synchronous motor

50 to 330 (230 V drive

controllers)

50 to 660 (460 V drive

controllers)

1

NOTE: With the exception of

drive controller is running.

18 McQuay OM 844-1

ACC

and

dEC

, the parameters cannot be modified while the

Page 19

Setting the Acceleration/Deceleration

O

f

Output

s)

Ramp Times

AUF Quick Menu

-<$

Acceleration/deceleration ramp adaptation. Automatically adjusts the

acceleration/deceleration ramp times to match the inertia of the load.

-//

Programs the time it takes for the drive controller output frequency to go from

0 Hz to the maximum frequency (parameter FH).

@1/

Programs the time it takes for drive controller output frequency to go from

maximum frequency (parameter FH), to 0 Hz.

Table 7: Setting Ramp Time Parameters

Parameter Name Range

AU1

Automatic

Acceleration/

Deceleration Ramp

Adaptation

0: Disabled

1: Automatic

2: Automatic acceleration only

(Do not use)

ACC Acceleration Time 1 0.0 to 3200 s

dEC Deceleration Time 1 0.0 to 3200 s

See Appendix E—Wiring Diagrams and Parameter Settings on page 65 for McQuay

settings.

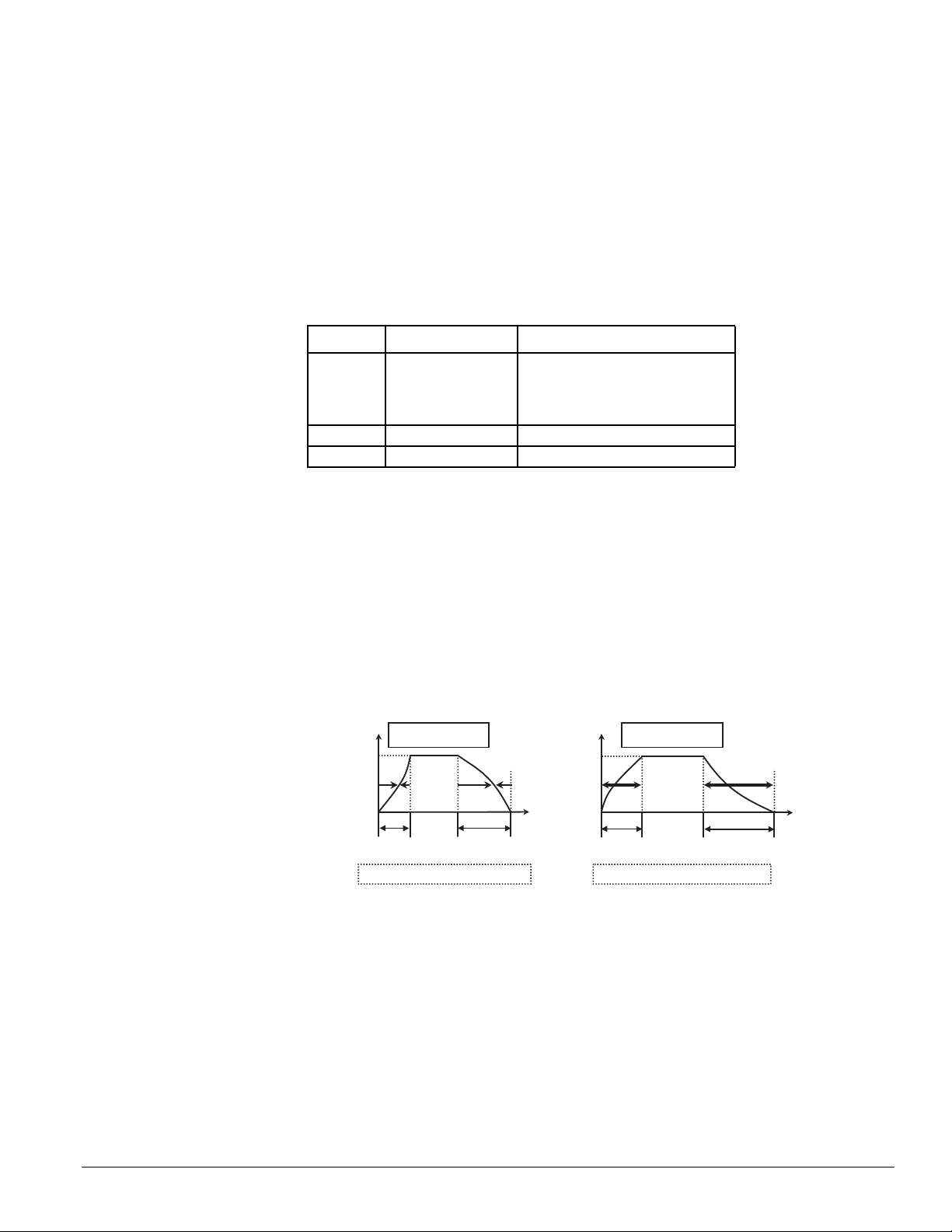

Acceleration/Deceleration Ramp Adaptation

• AU1 = 0: Function is disabled.

• AUI = 1: Automatically adjusts the acceleration and deceleration ramp times

from 1/8–8 times the value set in the ACC or dEC parameters, depending on the

current rating of the drive controller.

• AUI = 2: Do not use.

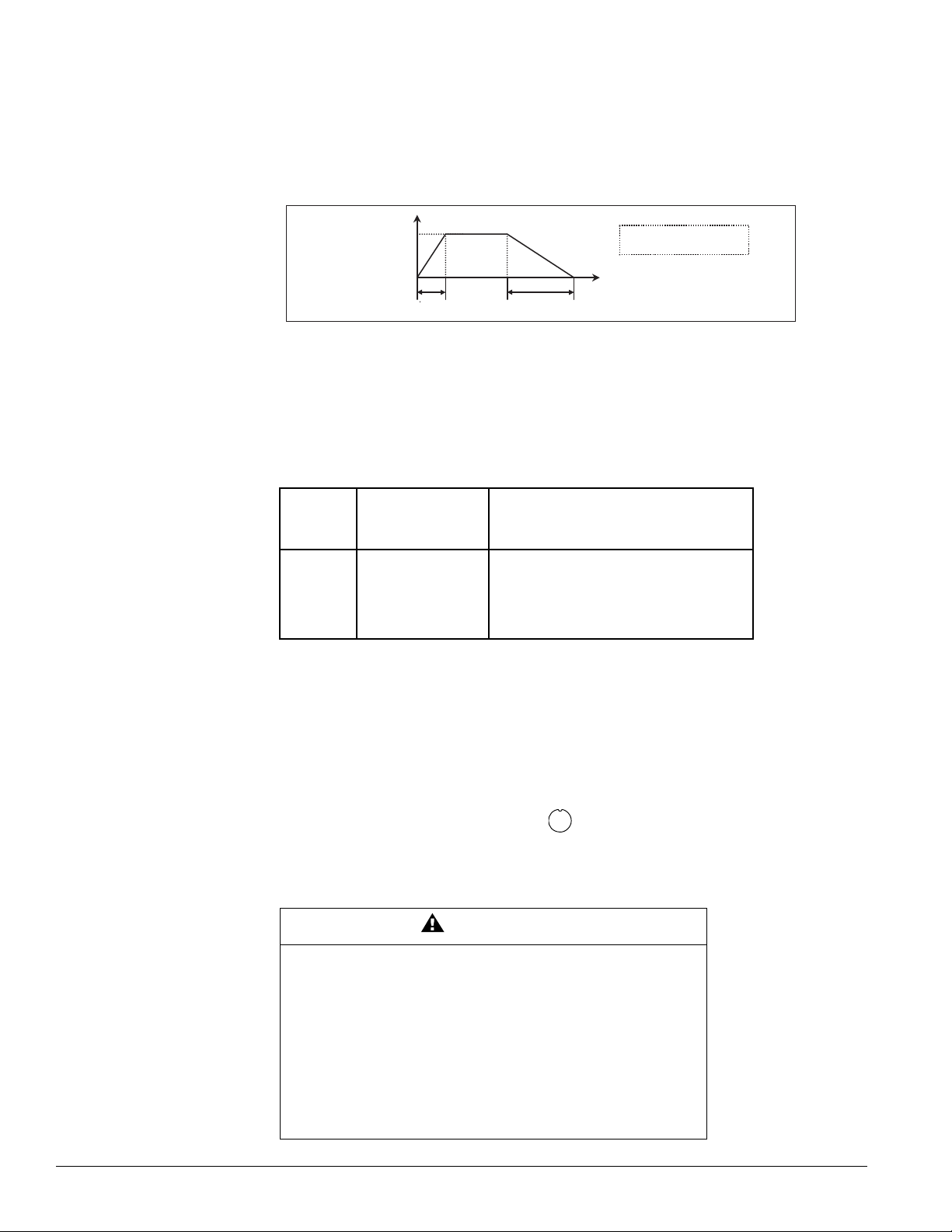

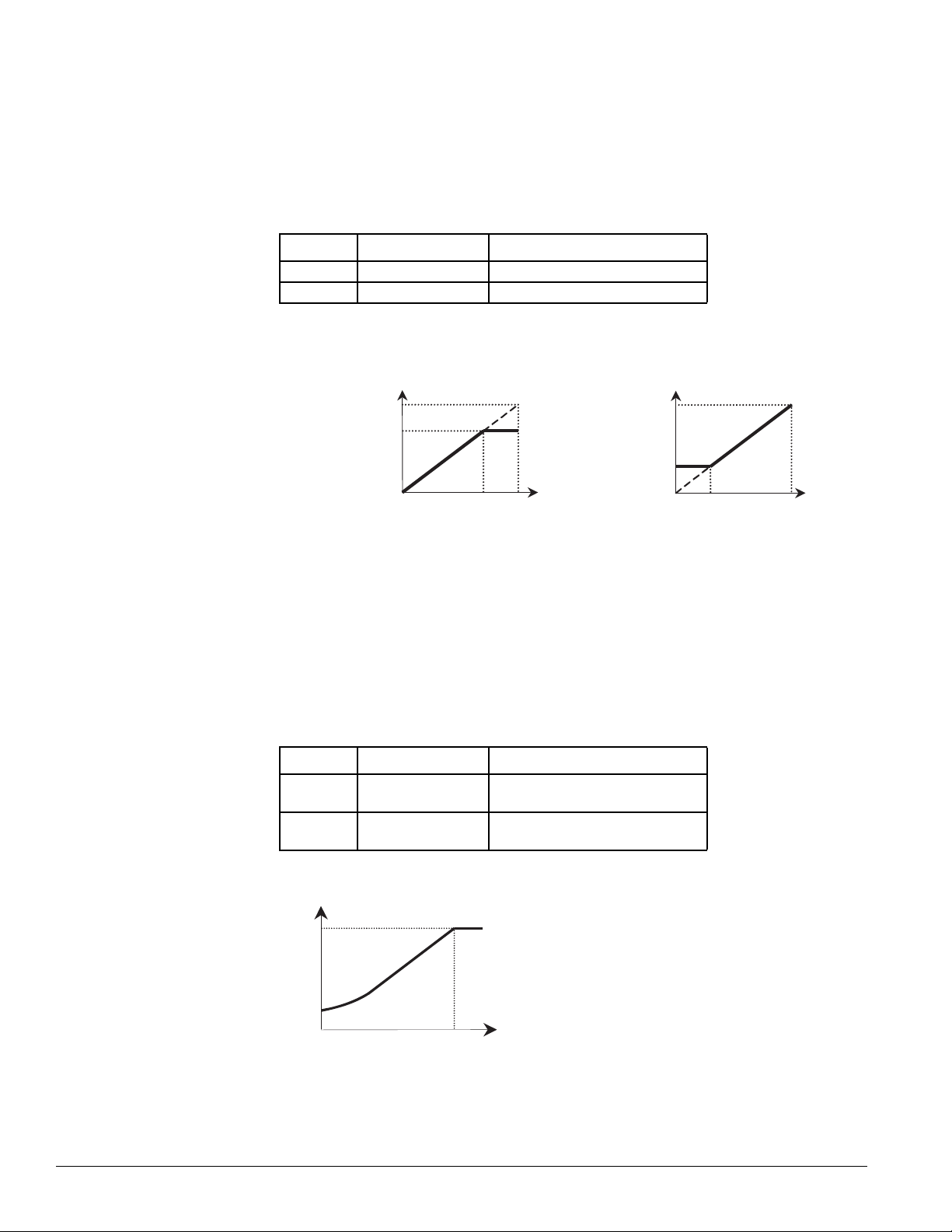

Figure 9: Automatic Ramp Adaptation

utput

requency (Hz)

When load is small ... When load is large ...

FH

0

Acceleration

Time

shorten acceleration/deceleration time. lengthen acceleration/deceleration time.

Deceleration

Time

frequency (Hz)

Time

(seconds)

FH

0

Acceleration

Time

Deceleration

Time

Time

(second

McQuay OM 844-1 19

Page 20

AUF Quick Menu

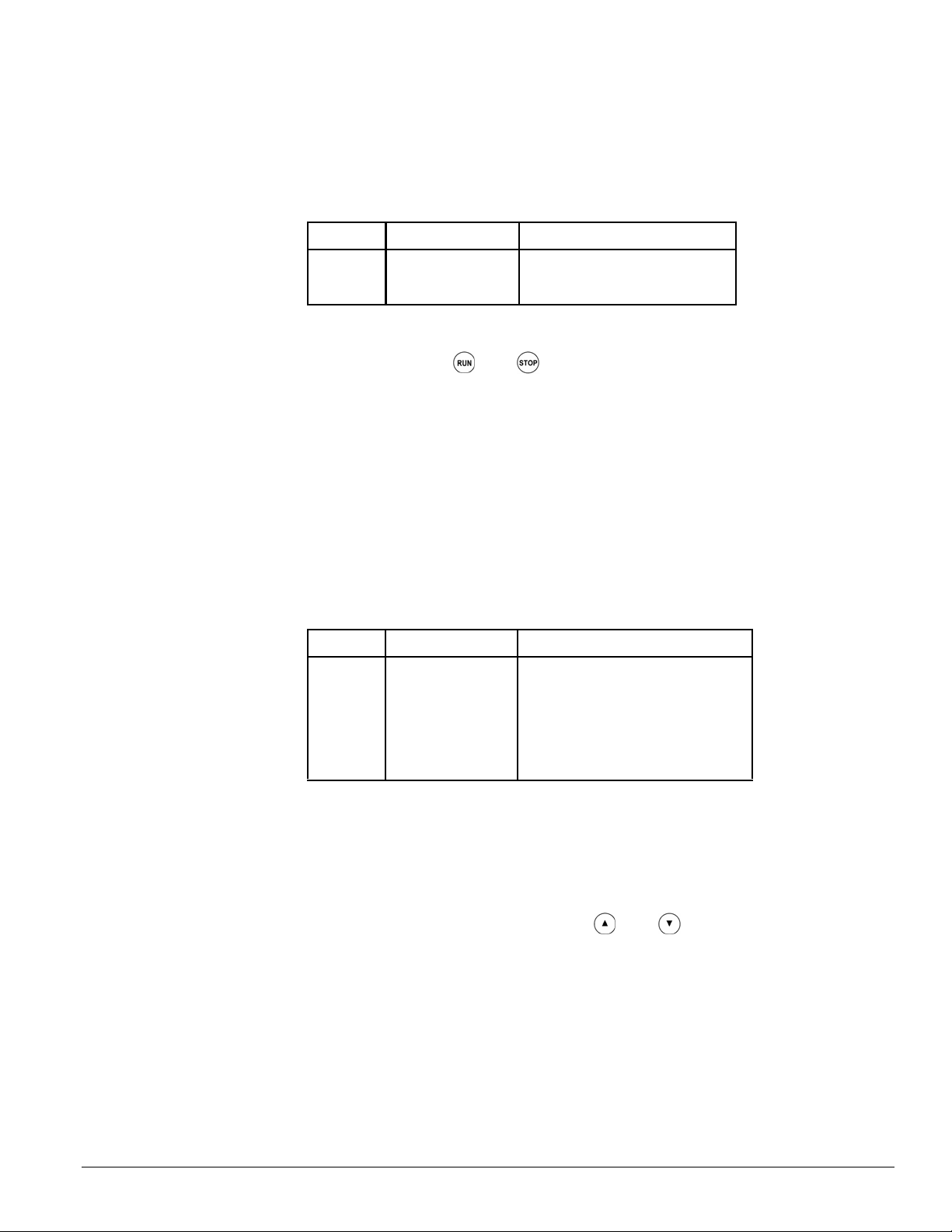

Manually Setting Acceleration/Deceleration Ramp Times

During startup, confirm parameters ACC and dEC match the parameters in

Appendix E—Wiring Diagrams and Parameter Settings.

Figure 10: Manually Setting the Acceleration/Deceleration Ramp Times

Output frequency (Hz)

FH

0

ACC dEC

AUI=0 (Manual)

Time (seconds)

Setting the Macro Function

-<'

Table 8: Parameter AU4

Parameter Name

AU4 Macro Function

NOTE: The current setting of this parameter is shown on the left side of the display. The number

0 is always displayed on the right. For example, indicates that the freewheel stop

setting is enabled.

Sets the drive controller to one of four macro configurations. The macro

configuration selection automatically determines the settings of the following

parameters: CMOd, FMOd, F110–F113, and F201.

Range (refer to Appendix E—Wiring

Diagrams and Parameter Settings for

values)

0: Disabled

1: Freewheel stop

2: 3-wire operation

3: + - speed from logic input(s)

4: 4–20 mA current input operation

$#

Setting the Mode of Operation

In Remote mode, start and stop commands and the frequency are determined by the

settings of CMOd (Command mode) and FMOd (Frequency Setting mode).

LOC

When Local mode is selected with the key, start/stop commands and frequency

settings can only be made from the display terminal. The Local LED illuminates while

Local mode is selected. See page 13 for Local/Remote key operation and Local LED.

When service is complete, return the VFD to the remote mode.

WARNING

UNINTENDED EQUIPMENT OPERATION

• Modifying or changing parameters whose function is not

described in this manual will affect drive controller operation.

Some register changes will take effect as soon as they are

entered.

• Do not modify or change parameters whose function is not

described in this instruction bulletin.

Failure to follow this instruction can result in death or serious

injury.

20 McQuay OM 844-1

REM

Page 21

Command Mode Selection

AUF Quick Menu

CNOd

Specifies which command source has priority in issuing Start and stop

commands.

NOTE: You must stop the drive controller before changing the setting of

CMOd

.

Table 9: Parameter CMOd

Parameter Name Range

0: Terminal board

1: Display terminal

2: Serial communication

CNOd

Command Mode

Selection

• CMOd = 0: Start and stop commands via the logic inputs on the control terminal

board.

• CMOd = 1: The and keys on the display terminal start and stop the drive

controller.

• CMOd = 2: The serial link sends start and stop commands to the drive controller.

Some functions, when assigned to an input terminal, are commanded by the input

terminal even if CMOd is set to 1 (display terminal).

Priority commands via a serial link can take precedence over the setting of CMOd.

Frequency Mode Selection

289@

command.

Table 10: Parameter FMOd

Specifies which input device has priority in issuing a speed reference

Parameter Name Range

1: VIA

2: VIB (not used with McQuay

FNOd

NOTE: You must stop the drive controller before changing the setting of

operation is allowed with all settings of

Frequency Mode

Selection

controls)

3: Display terminal

4: Serial communication (not used

with McQuay controls)

5: +/- speed from logic input(s)

FMOd

.

FMOd

. Preset speed

• FMOd = 1: Speed Reference command via analog input terminal VIA (0-10 Vdc

or 4-20 mAdc).

• FMOd = 2: Speed Reference command via analog input terminal VIB (0-10 Vdc)

- not used with McQuay controls.

• FMOd = 3: Speed reference via the and arrow keys on the display

terminal or the optional remote keypad.

• FMOd = 4: Speed reference via serial communication link - not used with

McQuay controls.

• FMOd = 5: Speed reference from +/- speed from logic input(s)

McQuay OM 844-1 21

Page 22

AUF Quick Menu

Default Setting

tYp

This parameter provides a variety of functions to reset, restore and save

parameter settings.

WARNING

UNINTENDED EQUIPMENT OPERATION

• Drive controller default parameter settings will be substituted for

the present settings when value 3 (standard default settings) of

thetYP parameter is selected.

• Drive controller default parameter settings may not be compatible

with the application.

• Contact McQuay product support before initiating standard

default settings.

Failure to follow these instructions can result in death, serious

injury, or equipment damage

Table 11: Parameter tYP

Parameter Name Range

0:

1: 50 Hz default

2: 60 Hz default

3: Standard default settings (Initialization)

tYp Default Setting

4: Clear the fault record

5: Clear the cumulative operation time

6: Initialize the type information

7: Save the user-defined parameters (do not use)*

8: Recalls your McQuay defined parameters

9: Clear the cumulative fan operation time

* You may replace McQuay parameters if this is used.

NOTE: You must stop the drive controller before changing the setting of

NOTE: The following parameters are not affected by settings 1, 2,

and 3:

FN, FNSL, F109, F470F473

NOTE: The setting display of this parameter contains two numbers. The left-most number

displays the last operation performed. The right-most number indicates the pending operation

and should be adjusted for the action desired.

, and

F880

.

tYP

.

Forward/Reverse Run Selection

Fr

keypad display.

Table 12: Parameter 2H

Parameter Name Range

Fr

NOTE: For more information, contact your McQuay representative.

22 McQuay OM 844-1

Programs the direction of motor rotation when starting the drive from the

Forward/

Reverse Run

Selection

0: Forward run

1: Reverse run (do not use)

2: Forward run with forward/ reverse switching (do not use)

3: Reverse run with forward/reverse switching (do not use)

Page 23

Maximum Frequency

AUF Quick Menu

FH

Programs the maximum output frequency of the drive controller. This value is

used as the maximum frequency reference for the acceleration and

deceleration ramps.

CAUTION

UNINTENDED EQUIPMENT OPERATION

• Do not use above 60Hz.

Failure to follow this instruction can result in equipment

damage.

Table 13: Parameter FH

Parameter Name Range

FH

NOTE: You must stop the drive controller before changing the

setting of FH.

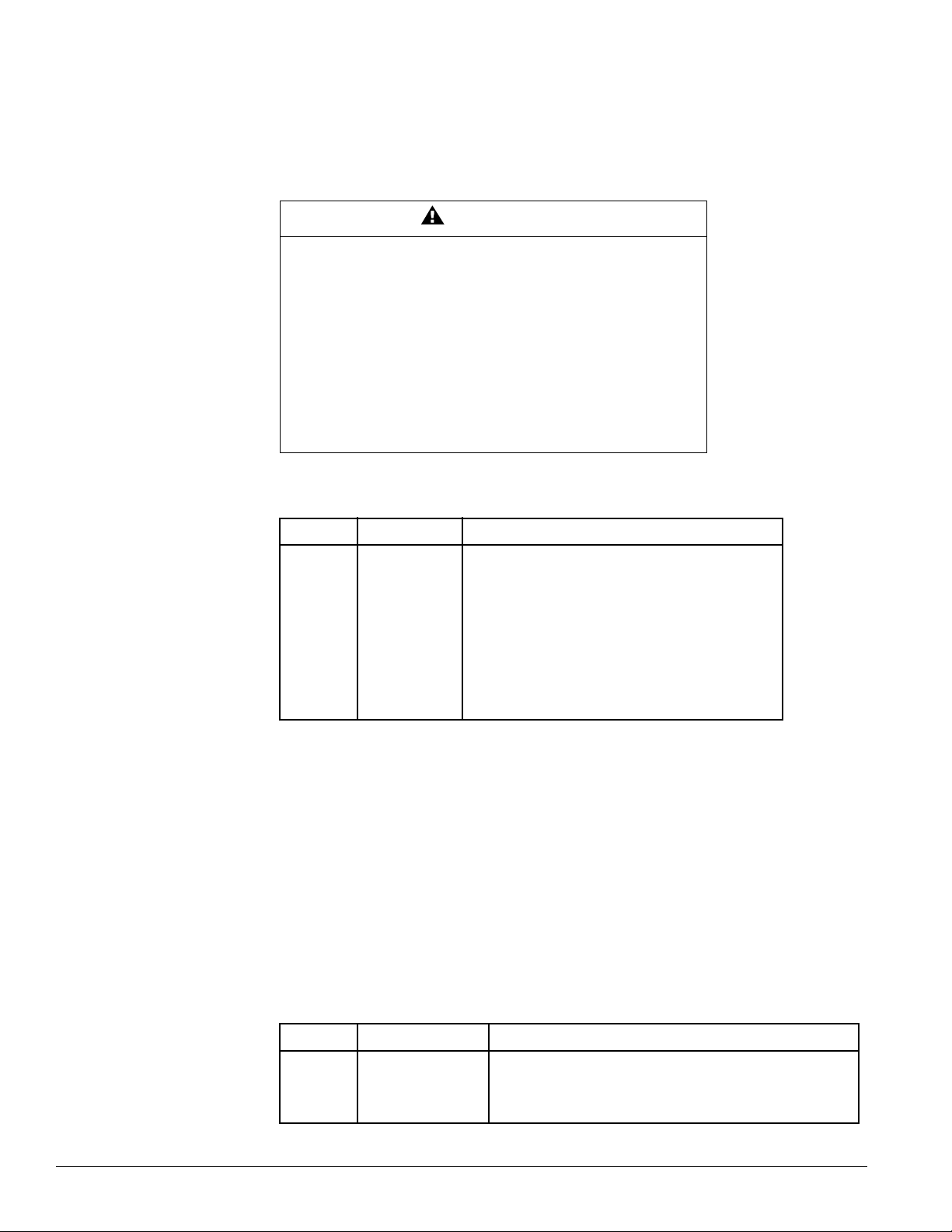

Figure 11: Maximum Frequency

Output frequency (Hz)

Maximum

Frequency

80 Hz

60 Hz

30–200 (Hz)

When FH = 80 Hz

When FH = 60 Hz

NOTE:

NOTE:

0

FH

can not be adjusted during operation

UL

value can not exceed FH value.

100 % Frequency setting signal (%)

McQuay OM 844-1 23

Page 24

AUF Quick Menu

High Speed and Low Speed

UL

LL

Programs the high speed.

Programs the low speed.

Table 14: Parameters UL and LL

Parameter Name Range

UL High Speed 0.5–FH (Hz)

LL Low Speed 0.0–UL (Hz)

Figure 12: High speed and low speed

High Speed Low Speed

Output frequency (Hz) Output frequency (Hz)

uL

0 100 %

Speed Reference signal Speed Reference signal

LL

0

100 %

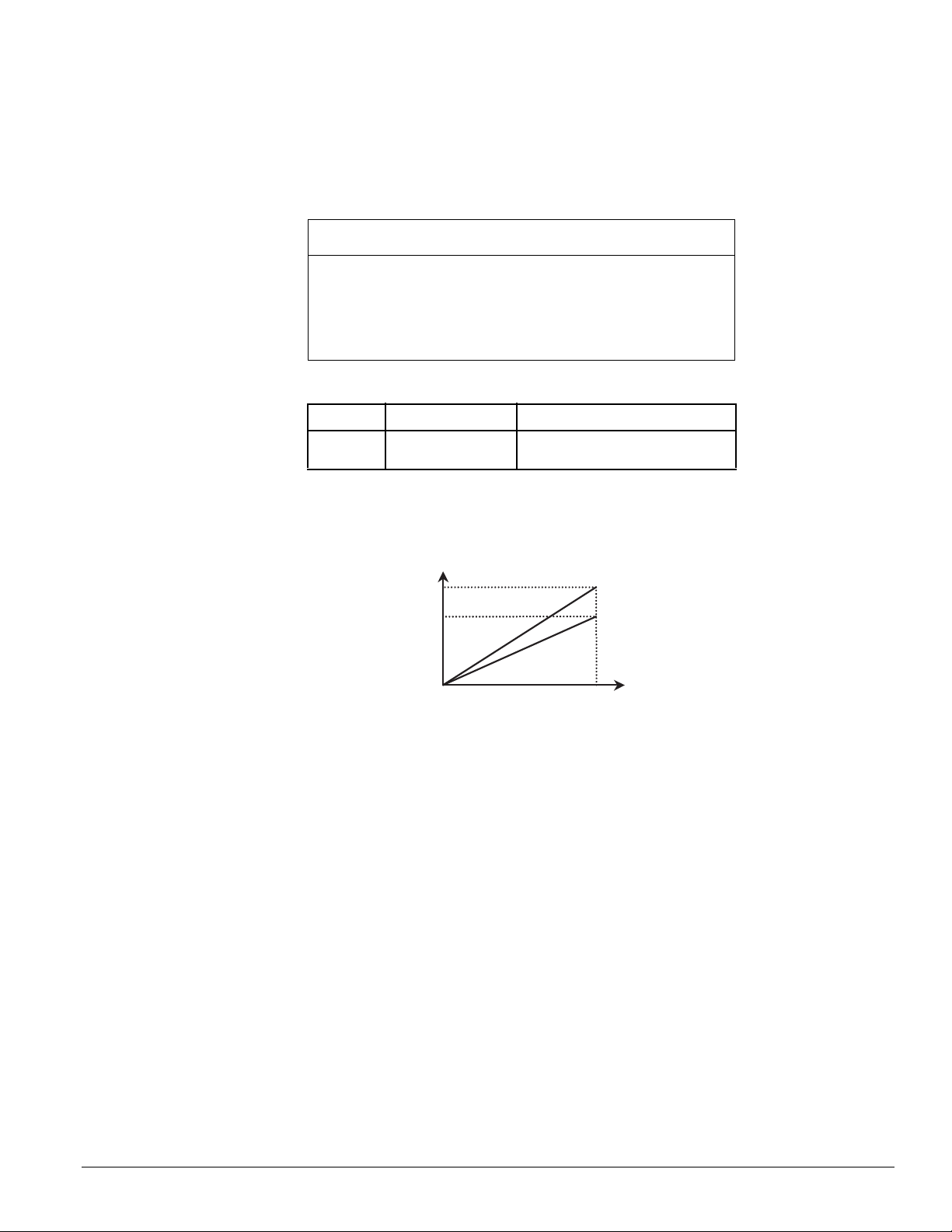

Nominal Motor Frequency and Voltage Settings

J7, J7J

Table 15: Parameters J7 and J7u

Parameter Name Range

uL

uLu Voltage Setting

Figure 13: Nominal motor frequency and voltage settings

uLu

Output voltage (V)

0

Use these parameters to set the nominal motor frequency (uL) and

voltage settings (uLu) to the motor nameplate values.

Nominal Motor

Frequency

Output frequency

25.0–200.0 Hz

50.0–330 V: 200 V Class

50.0–660 V: 400 V Class

uL

24 McQuay OM 844-1

Page 25

V/Hz Control Mode Selection

AUF Quick Menu

Pt

Use this parameter to set the V/Hz control mode.

Table 16: Parameter Pt

Parameter Name Range

0: V/Hz constant (do not use)

1: Variable torque

2: Automatic voltage boost control

3: Vector control (do not use)

4: Energy saving (do not use)

5: No assignment (do not use)

6: PM motor control (do not use)

:I

V/Hz Control Mode

Selection

Voltage Boost (Energy Recovery Application Only)

ub

Table 17: Parameter ub

Parameter Name Range

ub Voltage Boost 0.0–30.0%

Use this parameter to increases the voltage boost rate. This function is useful

for applications where the torque is not adequate at low speeds.

Figure 14: Voltage Boost

uLu

(V)/(%)

Output voltage

ub

0

Output frequency (Hz)

uL

V/Hz Control Mode (Pt) must be set to 0 (V/Hz constant) or 1 (variable torque) to

use this function.

The optimum setting for Voltage Boost depends on the drive controller capacity.

Increasing Voltage Boost too much can cause the drive controller to fault on an

overcurrent at start up.

McQuay OM 844-1 25

Page 26

AUF Quick Menu

OLN

Electronic Motor Overload Protection

tHr

Motor rated current value (FLA)

Electronic motor overload characteristics

F632

Electronic motor overload memory

These parameters must be set to match the rating and characteristics of the motor

(refer to the motor nameplate, full load amps).

Table 18: Electronic Thermal Protection Parameter Settings

Parameter Name Adjustment Range

tHr

OLN

F632

1

“In.” corresponds to the drive rated current indicated on the drive controller nameplate.

Motor Electronic

Thermal Protection

Electronic Thermal

Protection

Characteristic

Electronic Motor

Thermal State

Memory

0.1–1.0 In.1 Set to the rated current indicated on

the motor nameplate.

Setting Value

0

1 Enabled Enabled

2 Disabled Disabled

3 Disabled Enabled

4

(do not use)

5

(do not use)

6

(do not use)

7

(do not use)

Cooled

Motor

Forced

Cooled

Motor

0: Disabled

1: Enabled

Overload

Protection

Enabled Disabled

Self

Enabled Disabled

Enabled Enabled

Disabled Disabled

Disabled Enabled

Overload

Stall

CAUTION

MOTOR OVERHEATING

This drive controller does not provide direct thermal protection for

the motor. Use of a thermal sensor in the motor may be required for

protection at all speeds and load conditions. Consult the motor

manufacturer for thermal capability of the motor when operated

over the desired speed range.

Failure to follow this instruction can result in injury or

equipment damage.

26 McQuay OM 844-1

Page 27

AUF Quick Menu

Setting tHr, and OLM

Use electronic thermal protection characteristics (OLM) to enable or disable the

motor overload fault function (97%) and the overload stall function.

While the drive controller overload fault (OL1, see page 26) is always enabled,

motor overload fault (97%) can be selected using parameter OLM.

Overload stall is used with variable torque loads such as fans, pumps, and blowers, in

which the load current decreases as the operating speed decreases. When the drive

controller detects an overload, overload stall automatically lowers the output

frequency before the motor overload fault, OL2, is activated. This function maintains

the motor at frequencies that allow the load current to remain balanced so that the

drive controller can continue operation without tripping.

NOTE: Do not use overload stall with constant torque loads such as conveyor belts in which

load current is fixed with no relation to speed.

Self Cooled Motors

To set electronic thermal protection characteristics, OLM, for a self-cooled motor,

refer to Table 18.

If the capacity of the motor is smaller than the capacity of the drive controller, or the

rated current of the motor is smaller than the rated current of the drive controller, set

the electronic thermal protection level, tHr, to the motor's nominal rated current

value.

Figure 15: Motor Electronic Thermal Protection:

Self-cooled motor

Output current factor

(%)/(A)

tHr

x 1.0

tHr

x 0.55

0

Output frequency (Hz)30 Hz

Motor Electric Thermal Protection Retention, 2)&%

The setting of this parameter determines whether electric thermal calculation values

are retained when power is removed. Enabling the parameter (F632 = 1) causes

the electric thermal calculation values to be retained when power is removed.

NOTE: For installations to meet Article 430 of the National Electric Code, parameter F632 must

be set to 1.

McQuay OM 844-1 27

Page 28

AUF Quick Menu

Input Signal Selection

2$#,

VIA terminal function selection

This parameter allows you to select an analog or digital input for the VIA terminal.

Table 19: Parameter F109

Parameter Name Range

0: Analog input

1: Do not use (sinking input

assignment)

2: Digital (sourcing) input

F109

Analog/Digital Input

Function Selection

(VIA Terminal)

When using the VIA terminal as a digital input terminal, set the VIA slide switch to the

V position. For switch location see Figure 2.

DANGER

UNINTENDED EQUIPMENT OPERATION

• The accidental grounding of logic inputs configured for Sink Logic

can result in unintended activation of drive controller functions.

• Protect the signal conductors against damage that could result in

unintentional conductor grounding.

• Follow NFPA 79 and EN 60204 guidelines for proper control

circuit grounding practices.

Failure to follow these instructions will result in death or

serious injury.

Terminal Function Selection

Modifying Input Terminal Functions

Table 20: Parameters F110, F111, F112, F113, and F118

Terminal

Symbol

— F110

F F111 Logic Input

R F112 Logic Input

RES F113 Logic Input

VIA F118 Input Terminal

The functions selected with parameters F110 are always active.

Parameter Name Range

Always-Active Function (the

control input function assigned to

this parameter will always be

active).

(refer to Appendix E—

Wiring Diagrams and

0–71

Parameter Settings)

28 McQuay OM 844-1

Page 29

Modifying Output Terminal Functions

Jumping width 1 (

F271

)

Jumping width 2 (

F273

)

Jumping width 3 (

F275

)

Jump frequency 3 (

F274

)

Jump frequency 1 (

F270

)

Jump frequency 2 (

F272

)

Output command frequency

(Hz)

Frequenc y setting si gnal

0

AUF Quick Menu

2$&#

Output terminal selection 1A (RY-RC)

Figure 16: Application Example

RY

Function of RY-RC:

Can be set using parameter F130

RC

RY

Table 21: Assigning One Function to an Output Terminal

Terminal

Symbol

RY-RC F130

Parameter Name Range

0–255

(Refer to Appendix

Output Terminal

Selection 1A

E—Wiring Diagrams

and Parameter

Settings on page 65,

for McQuay settings)

Jump Frequency (Jumping Resonant Frequencies)

2%*#

2%*$

2%*%

2%*&

2%*'

2%*(

Resonance due to the natural frequency of the mechanical system can be avoided by

jumping the resonant frequency during operation.

Figure 17: Jump Frequency Timing Diagram

Jump Frequency 1

Jumping Width 1

Jump Frequency 2

Jumping Width 2

Jump Frequency 3

Jumping Width 3

McQuay OM 844-1 29

Page 30

AUF Quick Menu

Table 22: Jump Frequency Parameter Setting

Parameter Name Range

F270 Jump Frequency 1 0.0–FH (Hz)

F271 Jump Width 1 0.0–30.0 (Hz)

F272 Jump Frequency 2 0.0–FH (Hz)

F273 Jump Width 2 0.0–30.0 (Hz)

F274 Jump Frequency 3 0.0–FH (Hz)

F275 Jump Width 3 0.0–30.0 (Hz)

NOTE: The jump frequency plus jump width may not overlap another jump frequency plus jump

width.

NOTE: During acceleration or deceleration, the jumping function is disabled for the operation

frequency.

Switching Frequency

2&##

2&$%

Switching Frequency

Random Mode

The F300 parameter allows the audible noise from the motor to be changed by

altering the switching frequency.

In addition, the F300 parameter reduces the electromagnetic noise generated by

the drive controller. Decrease the switching frequency to reduce electromagnetic

noise.

NOTE: Although the electromagnetic noise level is reduced when decreasing switching

frequency, the acoustic noise of the motor is increased.

The F312 parameter (random mode) reduces motor electromagnetic and acoustic

noise by changing the pattern of the switching frequency.

Table 23: Parameters F300, F312

Parameter Name Range

F300 Switching Frequency 6.0–16.0 (kHz)

F312 Random Mode

0: Disabled

1: Enabled

30 McQuay OM 844-1

Page 31

Auto Restart

AUF Quick Menu

2&#&

Select the number of restarts

DANGER

AUTOMATIC RESTART ENABLED

• This drive controller can restart under fault conditions.

• Equipment must be shut down, locked out and tagged out to

perform servicing or maintenance.

Failure to follow these instructions will result in death or

serious injury.

This parameter resets the drive controller automatically if it is in an alarm state.

Table 24: Parameter F303

Parameter Name Range

F303 Number of Restarts

Table 25: Causes of Tripping and Corresponding Restart Processes

Cause of

Tripping

Momentary

power failure

Overcurrent

Overvoltage

Overload

Overheating

Restart Process Canceling Conditions

Up to 10 restarts in

succession

1st restart: 1 second

after tripping

2nd restart: 2 seconds

after tripping

3rd restart: 3 seconds

after tripping

10th restart: About 10

seconds after tripping

0: Disabled

1–10: 1 to 10 restarts

Auto restart is possible

only after the following

faults: momentary

power failure,

overcurrent,

overvoltage, or

overload.

The restart function will

be canceled if restarting

is not successful within

the specified number of

times.

Restart is disabled when the faults or errors listed in Table 26 occur.

Table 26: Faults Which Cannot Be Automatically Reset

OCA Motor overcurrent at start up

OCL Overcurrent on load side at start up

EPHO Output phase loss

OH2 External thermal fault

Ot Overtorque fault

E External fault stop

UC Low-current operation fault

UPI Undervoltage fault (main circuit)

EF2 Ground fault

EPH1 Input phase loss

EtYP Drive controller error

Err2 Main unit RAM fault

Err3 Main unit ROM fault

Err4 CPU fault

McQuay OM 844-1 31

Page 32

AUF Quick Menu

Table 26: Faults Which Cannot Be Automatically Reset

OCA Motor overcurrent at start up

OCL Overcurrent on load side at start up

EPHO Output phase loss

OH2 External thermal fault

Ot Overtorque fault

E External fault stop

UC Low-current operation fault

UPI Undervoltage fault (main circuit)

EF2 Ground fault

EPH1 Input phase loss

EtYP Drive controller error

Err2 Main unit RAM fault

Err5 Remote control error

Err7 Current detector fault

Err8 Control circuit board format error

EEP1 EEPROM fault 1

EEP2 EEPROM fault 2

EEP3 EEPROM fault 3

Etn1 Auto-tuning error

E-18 VIA input detection error

E-19 Main unit CPU communication error

E-20 Excessive voltage boost

E-21 CPU fault 2

CAUTION

MOTOR OVERHEATING

• Repeated reset of the thermal overload can result in thermal

stress to the motor.

• When faults occur, promptly inspect the motor and driven

equipment for problems such as locked shaft and mechanical

overload before restarting. Also check the power supplied to the

motor for abnormal conditions such as phase loss and phase

imbalance.

Failure to follow these instructions can result in equipment

damage.

When using Auto Restart, observe the following:

• By default, protective operation detection relay signals (FLA-FLB-FLC terminal

signals) are not sent during an auto restart process. To allow a signal to be sent to

the protective operation detection relay (FLA-FLB-FLC terminals) during an auto

restart process, assign value 36 or 37 to parameter F132.

• A calculated cooling time is provided for overload tripping (OL1, OL2, OLr). In

this case, the auto restart function operates after the calculated cooling time and

the restart time.

• In the event of an overvoltage fault (OP1–OP3), the auto restart function is not

activated until the voltage in the DC section comes down to a normal level.

• In the event of an overheating fault (OH), the auto restart function is not activated

until the drive controller temperature is low enough to restart operation.

32 McQuay OM 844-1

Page 33

AUF Quick Menu

• When F602 is set to 1 (fault retained), the restart function is not performed,

regardless of the setting of F303.

• During an auto restart process, the display alternates between “rtry” and the

setting specified by display mode selection parameter F710.

• The number of auto restarts is cleared if the drive controller does not fault for the

specified period of time after a successful restart. A successful restart means that

the drive controller output frequency reaches the command frequency without

causing the drive controller to fault again.

Drive Controller Fault Retention

2)#%

Drive controller fault retention

This parameter can be set to retain fault information for display after power has been

cycled.

Table 27: Parameter F602

Parameter Name Range

0: Clear the fault information when power

F602

Drive Controller Fault

Retention Selection

is removed

1: Retain the fault information when the

power is removed

The causes of up to four trips can be displayed in status monitor mode.

Output Phase Loss Detection

2)#(

The setting of this parameter determines how the drive controller responds after

detecting an output phase loss. If the phase loss status persists for one second or

more, the drive controller will fault, the FL relay will be activated, and fault code

EPHO will be displayed.

Output phase loss detection mode

Table 28: Parameter F605

Parameter Name Range

0: Disabled

1: At start-up (only one time after power is

Output Phase Loss

F605

NOTE: If the drive controller detects an all-phase loss (i.e. contactor opening), it will restart on

completion of recondition. The drive controller does not check for output phase loss when

restarting after a momentary power loss.

McQuay OM 844-1 33

Detection (one

second or greater).

turned on)

2: At start-up (each time)

3: During operation

4: At start-up and during operation

5: Detection of cutoff on output side

Page 34

AUF Quick Menu

DC Voltage

Output

Frequency

F626

:

Over-voltage stall protection level

Input Phase Loss Detection

2)#+

Input phase loss detection mode selection

Setting this parameter to 1 (default) enables Input Phase Loss Detection. During a

complete input phase loss event the drive controller will fault (code EPHI) and the

FL relay will be activated.

NOTE: The drive controller may not fault on all input phase imbalance conditions.

Input phase loss nuisance tripping on low source impedance power systems may

indicate the need to install an AC input line reactor.

Table 29: Parameter F608

Parameter Name Range

F608 Input Phase Loss Detection

0: Disabled

1: Enabled

Setting F608 to 0 (input phase loss detection disabled) may result in damage to the

drive controller if operation is continued under a heavy load during an input phase

loss.

Avoiding Overvoltage Tripping

2&#(

2)%)

Overvoltage limit operation

Overvoltage stall protection level

Use these parameters to keep the output frequency constant, or to increase it to

prevent overvoltage tripping should the voltage in the DC section rise during

deceleration or varying speed operation. The deceleration time during overvoltage

limit operation may increase above the designated time. Overvoltage stall protection

level sets the percentage of the nominal DC bus level where the drive will modify the

output frequency to prevent an Overvoltage fault.

Figure 18: Overvoltage Limit Operation Level

CAUTION

MOTOR OVERHEATING

• Repetitive braking can cause motor overheating and damage if

the Quick Deceleration or Dynamic Quick Deceleration features

are active.

• Use of a thermal sensor in the motor is recommended to protect

the motor during repetitive braking.

Failure to follow these instructions can result in injury or

equipment damage.

34 McQuay OM 844-1

Page 35

AUF Quick Menu

Table 30: Parameters F305, F626

Parameter Name Range

0: Enabled

F305

F626

* McQuay setting = 140%. If power transients are more common than normal, increase toward

150%.

Overvoltage Limit

Operation

Overvoltage Stall

Protection Level

1: Disabled

2: Enabled (quick deceleration - do not use)

3: Enabled (dynamic quick deceleration - do

not use)

100–150%*

If F305 is set to 2 (quick deceleration), the drive controller will increase the voltage

to the motor (over-excitation control) to increase the amount of energy consumed by

the motor when the voltage reaches the overvoltage protection level. The motor can

therefore be decelerated more quickly than with normal deceleration.

If F305 is set to 3 (dynamic quick deceleration), the drive controller will increase the

voltage to the motor (over-excitation control) to increase the amount of energy

consumed by the motor as soon as the motor begins to slow down. The motor can

therefore be decelerated even more quickly than with quick deceleration.

Undervoltage Fault

2)%*

The setting of this parameter determines how the drive controller responds when it

detects an undervoltage. The fault code displayed is UPI.

Table 31: Parameter F627

Parameter Name Range

F627

Undervoltage fault/alarm selection

0: Alarm only (input voltage level below 60%)

The drive controller stops but does not fault

(the FL relay is not activated).

1: Fault (detection level below 60%)

The drive controller stops and faults when

Undervoltage

Fault/Alarm

Selection

the input voltage is less than 60% of it's

rating.

2: Alarm only (input voltage level below 50%,

input reactor needed)

The drive controller stops but does not fault

when the input voltage is less than 50% of it's

rating. A line reactor must be used with this

setting.

McQuay OM 844-1 35

Page 36

AUF Quick Menu

Changing the Display Parameter

2*$#

Display selection

When power is applied to the drive controller, it is in display mode. The display

terminal shows operation frequency as the default setting.

Table 32: Parameter F710

Parameter Name Range

0: Operation frequency (Hz/free unit/step)

1: Frequency command (Hz/free unit/step)

2: Output current (%/A)

3: Drive controller rated current (A)

4: Drive controller load factor (%)

5: Output power

6: Frequency command after PID control (Hz/free

unit/step)

7: Optional item specified from an external control

unit

8: Output speed of fan motor

9: Communication counter

10: Normal state communication counter

F710

Display

Selection

36 McQuay OM 844-1

Page 37

Troubleshooting Fault and Alarm Codes

Troubleshooting Fault and Alarm Codes

When an alarm or fault occurs, use Tables 33 and 34 to diagnose and resolve the

problem.

If the problem cannot be resolved by any of the actions described in the tables, refer

to the programming guide or contact your McQuay representative.

Drive Controller Fault Conditions

Table 33: Fault Codes

Error

Code

OC1

OC1p

OC2

OC2P

OC3

OC3P

0C1p

0C2p

0C3p

Failure

Code

0001

0025

0002

0026

0003

0027

0025

0026

0027

Problem Possible Causes Remedies

• Increase the acceleration

time, ACC.

Overcurrent

during

acceleration

Transistor

overcurrent

Overcurrent

during

deceleration

Transistor

overcurrent

Overcurrent

during constant

speed operation

Transistor

overcurrent

Ground fault

Motor

overcurrent at

start-up

(for 15 and 20

hp models only)

• The acceleration time

ACC is too short.

• The V/Hz setting is

improper.

• A restart signal is input to

the rotating motor after a

momentary stop, etc.

• A special motor (e.g.

motor with a small

impedance) is used.

• Possible ground fault.

• The deceleration time

dECis too short.

• Possible ground fault.

• The load fluctuates

abruptly.

• Mechanical blockage

• A current leaked from an

output cable or the motor

to ground.

• A main circuit elements

is defective.

• Check the V/Hz

parameter.

• Use F301 (auto-

restart) and F302(ride-

through control).

• Adjust the switching

frequency F300.

• Set the switching

frequency control mode

selection parameter

F316 to 1 or 3

(switching frequency

decreased automatically).

• Increase the deceleration

time dEC.

• Set the switching

frequency control mode

selection parameter

F316 to 1 or 3

(switching frequency

decreased automatically).

• Reduce the load

fluctuation.

• Check the load (operated

machine).

• Set the switching

frequency control mode

selection parameter

F316 to 1 or 3

(switching frequency

decreased automatically).

• Contact your Mcquay

representative.

• Check the cables

connecting the drive

controller to the motor,

and check the motor

insulation.

• Reduce the switching

frequency.

• Connect output filters in

series with the motor.

McQuay OM 844-1 37

Page 38

Troubleshooting Fault and Alarm Codes

Table 33: Fault Codes (continued)

Error

Code

Failure

Code

Problem Possible Causes Remedies

Overcurrent (an

OCL 0004

overcurrent on

the load side at

start-up)

Motor

OCA 0005

overcurrent at

start-up

EpH1* 0008 Input phase loss

EPH0* 0009

Output phase

loss

Overvoltage

Op1 000A

during

acceleration

Overvoltage

Op2 000B

during

deceleration

• The insulation of the

output main circuit or

motor is defective.

• Motor impedance is too

low

• Current is leaked from an

output cable or the motor

to ground.

• A main circuit elements

is defective.

• Possible ground fault

• Input phase loss, blown

fuse

• Three-phase drive

controller used on a

single phase line supply

• Input phase imbalance

• Transient phase fault

• Loss of phase at drive

controller output

• Downstream contactor

open

• Motor not connected

• Instability in the motor

current

• Drive controller

oversized for motor

• Line voltage too high

• Line supply transients

• A restart signal is input to

the rotating motor after a

momentary stop, etc.

• There is possibility of

output phase loss.

• The deceleration time

dEC is too short.

(regenerative energy is

too large.)

• F305 (overvoltage

limit operation) is off.

• The input voltage

fluctuates abnormally:

• Overhauling load

• There is possibility of

output phase loss.

• Check the cables and

wires for defective

insulation.

• Check cables,

connectors, and so on for

ground faults.

• Check the cables

connecting the drive

controller to the motor,

and check the motor

insulation.

• Reduce the switching

frequency.

• Connect output filters in

series with the motor.

• Contact your McQuay

representative.

• Check the main circuit

input line for phase loss.

• Enable F608 (input

phase loss detection).

• Check the main circuit

output line, motor, etc. for

phase loss.

• Enable F605 (output

phase loss detection).

• Check the line voltage.

Compare with the drive

controller nameplate

rating.

• Reset the drive controller.

• Install a line reactor

• Use F301 (auto-

restart) and F302 (ridethrough control).

• Check the main circuit

output line, motor, etc. for

phase loss.

• Increase the deceleration

time dEC.

• Enable F305

(overvoltage limit

operation).

• Check the main circuit

output line, motor, etc. for

phase loss.

38 McQuay OM 844-1

Page 39

Table 33: Fault Codes (continued)

Troubleshooting Fault and Alarm Codes

Error

Code

Failure

Code

Problem Possible Causes Remedies

Overvoltage

Op3 000C

during constantspeed operation

OL1 000D

Drive controller

overload

OL2 000E Motor overload

Ot*

0020

Over-torque

fault

OH

Drive controller

0010

over

temperature

OH2

002E

External thermal

fault

E 0011 Emergency stop

• The input voltage

fluctuates abnormally.

• The motor is in a

regenerative state

because the load causes

the motor to run at a

frequency higher than

the drive controller

output frequency.

• There is possibility of

output phase loss.

• The acceleration time

ACC is too short.

• The DC braking level is

too large.

• The V/Hz setting is

improper.

• A restart signal is input to

the rotating motor after a

momentary stop, etc.

• The load is too large.

• The V/Hz setting is

improper.

• The motor is locked.

• Low-speed operation is

performed continuously.

• An excessive load is

applied to the motor

during operation.

• Over-torque during

operation.

• The cooling fan does not

rotate.

• The ambient

temperature is too high.

• The vent is blocked.

• A heat generating device

is installed close to the

drive controller.

• The thermistor in the unit

is broken.

• External thermal fault.

• External PTC probe

fault.

• During automatic

operation or remote

operation, a stop

command is entered

from the operation panel

or a remote input device.

• Check the main circuit

output line, motor, etc. for

phase loss.

• Increase the acceleration

time ACC.

• Reduce the DC braking

amount F251 and the

DC braking timeF252.

• Check the V/Hz

parameter setting.

• Use F301 (auto-

restart) and F302 (ridethrough control).

• Use an drive controller

with a larger rating.

• Check the V/Hz

parameter setting.

• Check the load (operated

machine).

• Adjust OLN to the

overload that the motor

can withstand during

operation in a low speed

range.

• Enable F615 (over-

torque fault selection).

• Check system error.

• Restart the operation by

resetting the drive

controller after it has

cooled down.

• The fan requires

replacement if it does not

rotate during operation.

• Ensure sufficient space

around the drive

controller.

• Do not place any heat

generating device near

the drive controller.

• Contact your McQuay

representative.

• Check the external

thermal input.

• Check the PTC in the

motor.

• Reset the drive controller.

McQuay OM 844-1 39

Page 40

Troubleshooting Fault and Alarm Codes

Table 33: Fault Codes (continued)

Error

Code

Failure

Code

Problem Possible Causes Remedies

EEp1 0012 EEPROM fault 1

EEp2 0013 EEPROM fault 2

EEp3 0014 EEPROM fault 3

Err2 0015

Err3 0016

Main unit RAM

fault

Main unit ROM

fault

Err4 0017 CPU fault 1

Err5*

0018

Err7 001A

Communication

error

Current detector

fault

Err8 001B Network error

UC* 001D

Low-current

operation fault

Undervoltage

Up1* 001E

fault

(main circuit)

EF2 0022 Ground fault

Etn* 0054

EtYp 0029

Auto-tuning

error

Drive controller

type error

• Turn off the drive

controller, then turn it

• Data writing error.

• Power supply is cut off

during tYp operation

and data writing is

aborted.

• A data reading error

occurred.

• The control RAM is

defective.

• The control ROM is

defective.

• The control CPU is

defective.

• An error arises during

serial communication.

• The current detector is

defective.

• The error has occurred

during Network

communication.

• The output current

decreased to a lowcurrent detection level

during operation.

• The input voltage (in the

main circuit) is too low.

• A ground fault occurs in

the output cable or the

motor.

• Check the motor parameter F401 to F494.

• The motor with the capacity of 2 classes or less than

the drive controller is used.

• The output cable is improperly sized.

• The motor is rotating.

• The drive controller is used for loads other than those of

three-phase induction motors.

• Circuit board is changed.

(or main circuit/drive

circuit board)

again. If it does not

recover from the error,

contact your McQuay

representative.

• Turn the power off

temporarily and turn it

back on, and then try

tYp operation again.

• Turn off the drive

controller, then turn it

again. If it does not

recover from the error,

contact your McQuay

representative.

• Contact your McQuay

representative.

• Contact your McQuay

representative.

• Contact your McQuay

representative.

• Check the remote control

device, cables, etc.

• Contact your McQuay

representative.

• Check the Network

device and wiring.

• Enable F610 (low-

current detection).

• Check the suitable

detection level for the

system (F611,

F612).

• Check the input voltage.

• Enable F627

(undervoltage fault

selection).

• To cope with a

momentary stop due to

undervoltage, enable

F302 (ride-through

control) and F301

(auto-restart).

• Check the cable and the

motor for ground faults.

• Contact your McQuay

representative.

40 McQuay OM 844-1

Page 41

Table 33: Fault Codes (continued)

Troubleshooting Fault and Alarm Codes

Error

Code

E-18* 0032

E-19 0033

E-20 0034

E-21 0035 CPU fault 2

SOUt 002F

Failure

Code

Problem Possible Causes Remedies

Break in analog

signal cable

CPU

communication

error

Excessive

voltage boost

Step-out (for PM

motor only)

• The signal input via VIA

is below the analog

signal detection level set

with F633.

• A communications error

occurs between control

CPUs.

• The voltage boost

parameter F402 is set

too high.

• Impedance of the motor

is too low

• The control CPU is

defective.

• The motor shaft is

locked.

• One output phase is

open.

• An impact load is

applied.

* You can select a trip ON/OFF by parameters.

• Check the cables for

breaks. And check the

setting of input signal or

setting value of F633.

• Contact your McQuay

representative.

• Decrease the setting of

the voltage boost

parameter F402.

• Contact your McQuay

representative.

• Unlock the motor shaft.

• Check the interconnect

cables between the drive

controller and the motor.

McQuay OM 844-1 41

Page 42

Troubleshooting Fault and Alarm Codes

Drive Controller Alarm Conditions

Alarms do not cause the drive controller to fault.

Table 34: Alarm Codes

Error

Code

OFF

Problem Possible Causes Remedies

ST terminal

OFF

Undervoltage

NOFF

in main

circuit

rtrY

Restart in

process

Frequency

Err1

point setting

error alarm

Clear

CLr

command

acceptable

Emergency

EOFF

stop

command

acceptable

Setting error

alarm /

H1

LO

An error code

and data are

displayed

alternately

twice each.

HEAd

End

Display of

first/last data

items

db DC braking

Flowing out

EI

of excess

number of

digits

Momentary

power failure

slowdown

StOp

stop

prohibition

function

activated.

Auto-stop

because of

continuous

LStp

operation at

the lowerlimit

frequency

• The ST-CC circuit is opened. • Close the ST-CC circuit.

• Measure the main circuit supply

• The supply voltage between R,

S and T is under voltage.

• The drive controller is in the

process of restart.

• A momentary stop occurred.