Page 1

Operation Manual OM 1077

DDC Rooftop Unit Controller

Heating & Cooling, Gas/Electric & Electric/Electric

Models MPS 003B – 025B

3 to 25 Tons [10.6 to 87.9 kW]

R-410A Refrigerant

Group: Applied Air Systems

Part Number: OM 1077

Date: August 2010

© 2010 McQuay International

®

Page 2

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . 3

Third party Building Management System . . . 3

Programmable 24 Volt Thermostat. . . . . . . . . 4

Control Inputs and Outputs . . . . . . . . . . . . . . . . . . 6

Control Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Control Input Descriptions. . . . . . . . . . . . . . . . 6

Control Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control Output Descriptions . . . . . . . . . . . . . . 8

Unit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sequence of Operation. . . . . . . . . . . . . . . . . . . . . 12

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Heat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Integrated Furnace Control. . . . . . . . . . . . . . 12

Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . 14

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Keypad 15

General information Screen . . . . . . . . . . . . . 16

Unit Status Screen . . . . . . . . . . . . . . . . . . . . 17

Effective Occupancy Screen . . . . . . . . . . . . 17

Temperature Screen. . . . . . . . . . . . . . . . . . . 18

Set points Screen. . . . . . . . . . . . . . . . . . . . . 18

Economizer. . . . . . . . . . . . . . . . . . . . . . . . . . 19

Integrated Furnace Control Screen . . . . . . . 21

Time Delays Screen . . . . . . . . . . . . . . . . . . . 21

Initial Test Sequence . . . . . . . . . . . . . . . . . . 22

Alarm List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

QUICK START - Units with Thermostat Control. 28

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Page 3

Introduction

General

Read this manual and any instructions packaged with separate

equipment prior to installation. Give this manual to the owner

and explain its provisions. The owner should retain this

manual for future reference.

Unit Manual

Rooftop unit control configuration OM 1077

BACnet Communication Module IM 1000

LonWorks Communication Module IM 999

Field Installed Accessories IM 921

Maverick I, 3 to 5 ton Installation and Maintenance IM 970

Maverick I, 6 to 12 ton Installation and Maintenance IM 971

Maverick I, 15 to 25 ton Installation and Maintenance IM 972

Safety Information

DANGER

These instructions are intended as an aid to qualified service

personnel for proper installation, adjustment, and operation of

this unit. Read these instructions thoroughly before

attempting installation, adjustment, or operation. Failure to

follow these instructions can result in improper installation,

adjustment, service or maintenance, possibly resulting in fire,

electrical shock, property damage, personal injury, or death.

DANGER

Introduction

NOTICE

This equipment generates, uses, and can radiate radio

frequency energy and; if not installed and used in accordance

with this instruction manual, may cause interference to radio

communications. It has been tested and found to comply with

the limits for a Class A digital device, pursuant to part 15 of

the FCC rules. These limits are designed to prov i d e

reasonable protection against harmful interference when the

equipment is operated in a commercial envi ro nment.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at their own expense.

The Maverick I 3 to 25 ton Package has a Rooftop Unit

Controller factory mounted and wired in their respective

control panel. The DDC Controller is a solid-state

microprocessor-based control board that provides flexible

control and extensive diagnostics for all unit functions. The

DDC Controller through proportional/integral control

algorithms perform specific unit functions that govern unit

operation in response to; zone conditions, system

temperatures, ambient conditions and electrical inputs. The

DDC Controller features an LCD display and a five-button

keypad for local configuration and direct diagnosis of the

system.

The Maverick I 3 to 25 ton Package Air Conditioner with

integral Rooftop Unit Controller (DDC Controller) is

specifically designed to be applied in three distinct

applications:

Third party Building Management System

Before beginning any modification, be sure main disconnect

switch is in the “off” position. Failure to do so can cause

electrical shock resulting in property damage, personal injury

or death. Tag disconnect with a suitable warning label.

CAUTION

Static sensitive components. Discharge any static electrical

charge by touching the bare metal inside the control panel

before performing any service work. Never unplug cables,

circuit board terminal blocks, or power plugs while power is

applied to the panel.

In an application where a third party building management is

in use or will be incorporated the Maverick I is communication

compatible with the system that supports the BACnet

Application Specific Controller device profile, LonMark

Space Comfort Controller functional profile. This is

accomplished with a field installed BACnet or LonMark

communication module. The BAS system provides the

schedule functions for the DDC controller.

BACnet Communication Module

The BACnet Communication Module allows communication

between the DDC Controller and the BACnet network. The

communication module translates input and output variables

between the DDC Controller protocol and the BACnet

protocol.

The BACnet Communication Module is compatible with

MSTP EIA-485 daisy chain networks communicating at 38.4

bps. It is compatible with twisted pair, shielded cables.

See IM 1000 for full documentation

LonMark Communication Module

The LonMark Communication Module allows communication

between the DDC Controller and a Lon Works Network. The

McQuay OM 1077 3

Page 4

Introduction

Communication module translates input and output variables

between the DDC Controller protocol and the Lon Talk

protocol. The Lon Talk Communication Module has been

developed to communicate with building automation systems

that support the Lon Mark Space Comfort Controller (SCC).

The LonMark Communication Module utilizes an FTT-10A

free topology transceiver communicating at 78.8 kbps. It is

compatible with Echelon qualified twisted pair cable, Belden

8471 or NEMA Level 4 cables. The Module can communicate

up to 1640 ft. with no repeater. The LonWorks limit of 64

nodes per segment applies to this device.

See IM 999 for full documentation

Programmable 24 Volt Thermostat

The Maverick with integral DDC Controller is compatible

with programmable 24 volt thermostats. The programmable

thermostat can supply the time schedule functions when the

DDC controller is not connected to a BAS system.

Connections are made via conventional thermostat connection

screw terminals on terminal T81. Extensive unit status and

diagnostics are displayed on the LCD screen.

Zone sensor with time clock

The Maverick I with integral DDC Controller is compatible

with a zone sensor and mechanical or solid state time clock.

The DDC Controller in each Maverick I 3 to 25 ton Package

Air Conditioner has many design features that optimize

operation, installation and service. Each unit with the DDC

Controller has the following features:

Blower On/Off Delay. Adjustable time delay between blower

on and off mode

economizer. The DDC Controller communicates with the ELM

for control, setpoint, and diagnostics. The DDC Controller has

several choices for controlling the economizer. See

Economizer Menu Screen. The ELM monitors the mixed air

temperature, return air enthalpy (optional), minimum position

set point (local or remote), power exhaust set point, CO2 set

point, CO2, and outdoor enthalpy sensor, if selected, to control

dampers to an accuracy of ±5% of stroke. The actuator is

spring returned to the closed position any time that power is

lost to the unit. It is capable of delivering up to 44 inch pounds

of torque and is powered by 24VAC.

Unit Diagnostics. The DDC Controller monitors all sensors

and functions related to unit operation to provide critical

information and maintain diagnostic code information even if

a power failure occurs.

Exhaust Fan Control Modes. Exhaust fans are controlled by

fresh air damper position. Setpoint is adjustable through the

unit display and keypad.

Field Changeable Control Parameters. Over 50 different

control parameters allow customization of the unit operation

by changing delays, cooling stages, dead bands, and set points.

Minimum Compressor Run Time. Ensures proper oil return

to the compressor.

Comfort Alert. The DDC Controller has two inputs to monitor

optional Copeland Comfort Alerts. The inputs can provide the

following information: Locked rotor, Open Circuits, Missing

Phase, Reverse Phase, and Welded Contactor.

Smoke Alarm Mode. The input will shutdown the unit and

requires a manual reset. The sensor is used to detect smoke due

to fire in the air conditioning or ventilation ducts.

Built-in Control Parameter Defaults. No programming

required.

Compressor Time-off Delay. Adjustable time delay between

compressor shutoff and start up

Dirty Filter Switch Input. The DDC Controller will signal an

increase in static pressure across the air filter, indicating a dirty

filter condition.

On Board User Interface Display/Keypad. Displays control

parameters, diagnostic codes, and sensor readings. The keypad

allows scrolling through display menu and field configurable

changes to be made.

Economizer Control. The economizer is controlled by the

Economizer Logic Module (ELM) that comes with the

Lead Lag Compressor Operation. Stage 1 compressor

operation based on compressor accumulated run time.

Staging. Depending on the unit controls up to 2 stages of

cooling, 2 stages of gas heat, and 2 stages of electric heat.

Active Protection. Provides active unit protection when any

of the following occurs three times within a thermostat cycle:

low pressure trip, high pressure trip, gas heat limit trip.

Thermostat Bounce Delay. Protects compressor from short

cycling when mechanical thermostat is used

Warm-up Mode Delay. Adjustable time that the economizer

dampers are kept in the closed position during morning warmup input

4 McQuay OM 1077

Page 5

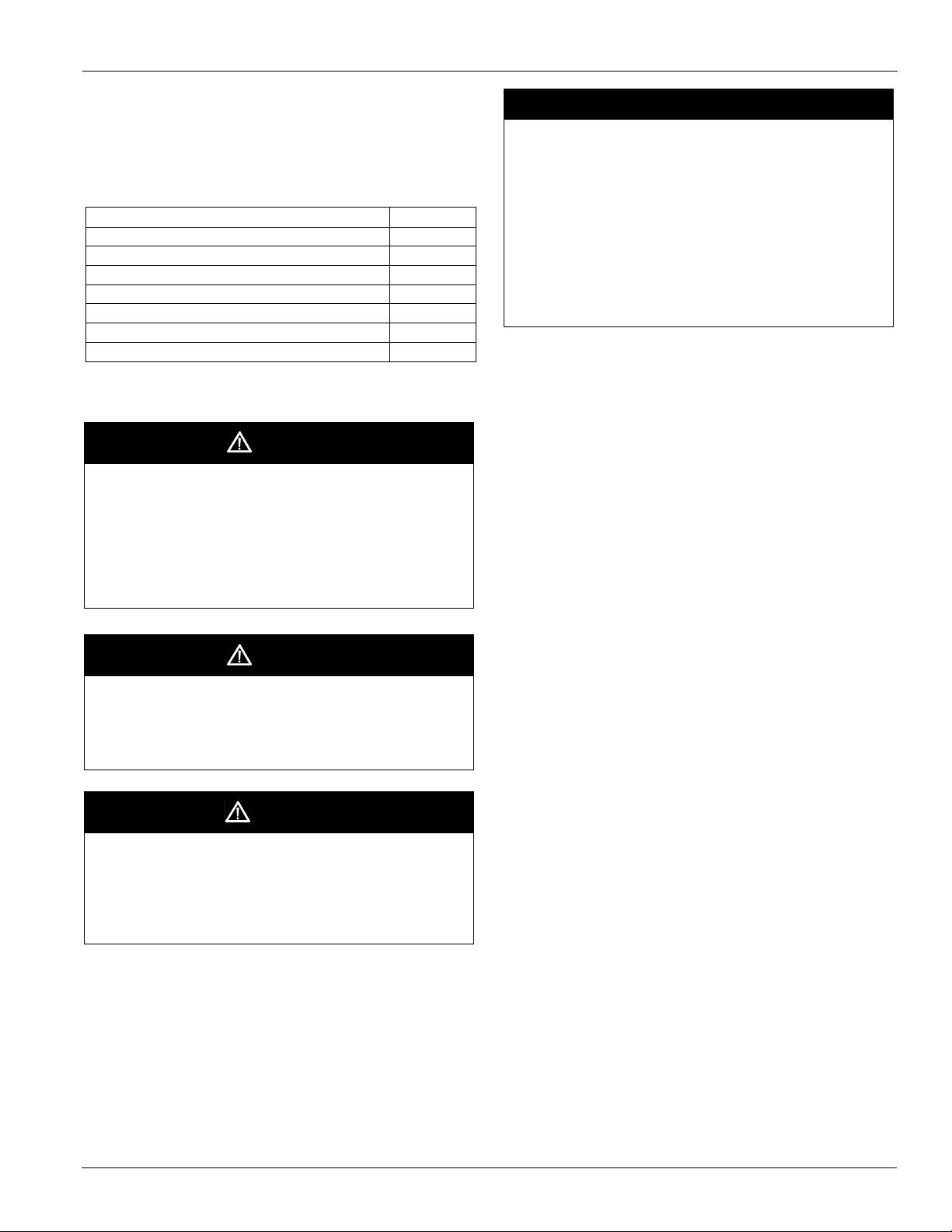

Figure 1: Controller Component Locations

Introduction

P4

P5

P11

LED 4

Keypad

MOD1

P10

P13

P6

Comfort Alert

LCD Display

Fan, CC1, CC2,

Common

P1

P3

24 VAC

Common

T14

T7

P12

Item Description

P1 Electric heat connector

Fan Indoor blower motor connector

CC1 Compressor1 connector

CC2 Compressor 2 connector

Reversing valve 1, Reversing valve 2, Outdoor

P3

P4

P5

P6

P10 RJ11 connector for factory run test

P11 Configurable pins used to set unit type

P12 Test Pins to force defrost for heat pump models

Coil temperature sensor 1, Outdoor Coil

temperature sensor 2, Outdoor Fan 1, and

Outdoor Fan 2 connector

Motorized Fresh Air Damper, Economizer Logic

Module (ELM), and Smoke Detector connector

Return air temperature sensor, Fan proving

switch, Clogged filter switch, and Discharge air

temperature sensor connector

Freeze sensor 1, Freeze sensor 2, Outside air

temperature sensor, High pressure switch 1, High

pressure switch 2, Low pressure switch 1, and

Low pressure switch 2 connector

MOD2

T81

Item Description

Connector to Integrated Furnace Control (IFC) –

P13

T7

T14 Not supported

T81 Thermostat screw terminals

Common

terminals

24 Volt

terminals

Comfort

Alert

LED4

MOD1

LED

MOD2

LED

provides power and communication between

DDC Controller and IFC

Field Installed Space Temperature Sensor with

Setpoint and Override, Field configurable 1, and

Field configurable 2 terminal block

T erminals used for 24 volt common connections &

power supply

Terminals used for 24 volt hot connections &

power supply

T erminals used to connect a Comfort Alert module

LED4 is blinking when the control has an ALARM

present, solid when power is applied.

MOD1 LED blinks when the control is

communicating on the internal network between

the IFC and/or economizer

MOD2 LED blinks when the control is

communicating between the DDC Controller and

field installed communication card

McQuay OM 1077 5

Page 6

Control Inputs and Outputs

Control Inputs and Outputs

Control Inputs

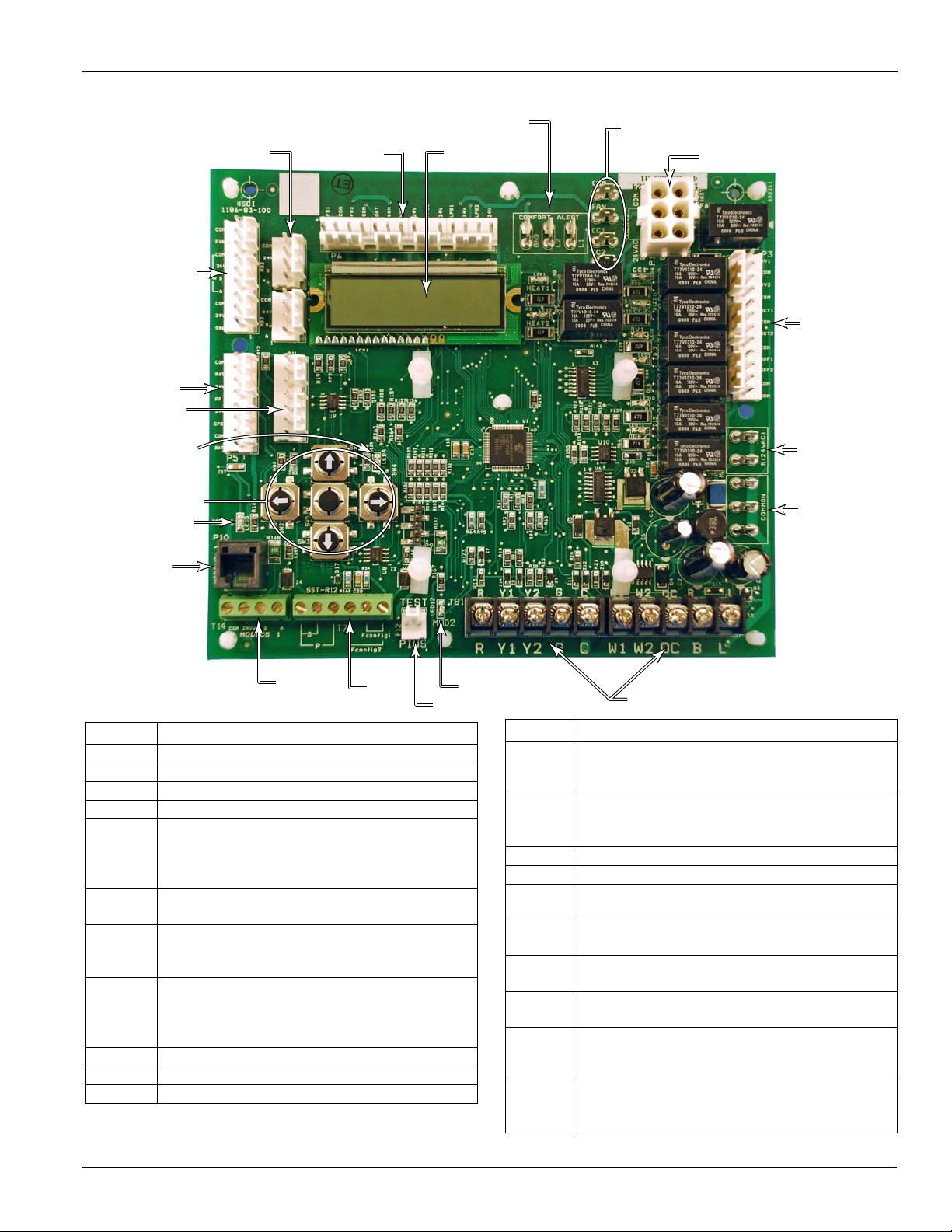

Table 1: ControlInputs

Item Description Type Option

1 ST - Space temperature Thermistor 10k? Field Installed (optional)

2 RAT - Return Air Temperature Thermistor 10k? Factory Installed

3 SAT - Supply Air Temperature Thermistor 10k? Factory Installed

4 OAT - Outside Air Temperature Thermistor 10k? Factory Installed

5 FS1 - Freeze Stat Thermistor 10k? Factory Installed

6 FS2 - Freeze Stat Thermistor 10k? Factory Installed

7 Field Configurable input #1 Thermistor 10k? Field Installed (optional)

8 Field Configurable input #2 Analog input Field Installed (optional)

9 SPA - Set point Adjustment Resistance input Field Installed (optional)

a

G - Thermostat fan input 24VAC Field Installed (optional)

10

†

Y1 - Thermostat 1st stage compressor 24VAC Field Installed (optional)

11

12 Y2 - Thermostat 2nd stage compressor 24VAC Field Installed (optional)

13 W1 - Thermostat heating demand 24VAC Field Installed (optional)

14 W2 - Thermostat heating demand 24VAC Field Installed (optional)

15 HP1 - High Pressure Switch 1 24VAC Factory Installed

16 LP1 - Low Pressure Switch 1 24VAC Factory Installed

†

HP2 - High Pressure Switch 2 24VAC Factory Installed

17

18 LP2 - Low Pressure Switch 2 24VAC Factory Installed

19 Smoke Detector 24VAC Factory or Field Installed

20 FP - Fan proving 24VAC Factory Installed

21 CFS - Clogged Filter Switch 24VAC Factory Installed

22 Occupied input 24VAC Field Installed (optional)

23 L1 - Comfort Alert 1 Pulsed 24VDC Factory or Field Installed (optional)

24 L2 - Comfort Alert 2 Pulsed 24VDC Factory or Field Installed (optional)

25 Configuration pins Polarized Plug P11 Factory Installed

a.Heat Pump Only

Control Input Descriptions

(1) ST - Space temperature. The space temperature sensor is

used to measure the building zone temperature. Sensors should

be located on an interior building wall.

(2) RAT - Return Air Temperature. The DDC Controller has a

return air temperature input. This input is used to monitor

system functionality and to provide diagnostics on how the

system is operating. This sensor input can be used in place of

the space temperature input. It also acts as a backup in case of

a space temperature sensor failure.

(3) SAT - Supply Air Temperature. The DDC Controller has a

supply air temperature input. This input is used to monitor

system functionality and to provide diagnostics on how the

system is operating.

(4) OAT - Outside Air Temperature. The outdoor air

temperature sensor is factory installed in the unit to monitor

the outside temperature. This temperature is used to control the

economizer.

(5) FS1 - Freeze Stat. When the thermistor reads a

temperature below 37°F continuously for 15 minutes, the

control will shutdown compressor #1 and continue to run the

indoor blower. The system will return to normal operation

when the thermistor reads a temperature above 42°F for 15

minutes.

(6) FS2 - Freeze Stat. When the thermistor reads a

temperature below 37°F continuously for 15 minutes, the

control will shutdown compressor #2 and continue to run the

indoor blower. The system will return to normal operation

when the thermistor reads a temperature above 42°F for 15

minutes.

(7) Field Configurable input #1. Used for custom installation

of a 10K ohm temperature sensor (e.g. discharge air

temperature sensor installed in supply duct).

(8) Field Configurable input #2. Used for custom installation

of an analog input (e.g. 0-10VDC input from outdoor airflow

monitoring station).

(9) SPA - Set point Adjustment. If the set point adjustment is

enabled, then the control will consider the hard wired

potentiometer input to determine occupied set points only. If

the remote set point adjustment is enabled but the input reads

6 McQuay OM 1077

Page 7

Control Inputs and Outputs

an invalid number, the control will default back to the

occupied set point selection.

(10) G - Thermostat fan input. This is a 24 volt input that is

used to control the indoor fan when the DDC Controller is

used in conjunction with a thermostat.

(11) Y1 - Thermostat 1st stage compressor. This is a 24 volt

input that is used to control the first stage of mechanical

cooling when the DDC Controller is used in conjunction with a

thermostat.

(12) Y2 - Thermostat 2nd stage compressor. This is a 24

volt input that is used to control the second stage of

mechanical cooling when the DDC Controller is used in

conjunction with a thermostat.

(13) W1 - Thermostat heating demand. This is a 24 volt

input that is used to control the first stage of heating (electric

heat or gas heat) when the DDC Controller is used in

conjunction with a thermostat.

(14) W2 - Thermostat heating demand. This is a 24 volt

input that is used to control the second stage of heating

(electric heat or gas heat) when the DDC Controller is used in

conjunction with a thermostat.

(15 &17) HP1, HP2 - High Pressure Switch 1 & 2. When the

HPC is opened, the compressor for that circuit is turned off.

The compressor will not be allowed to restart for a minimum

of 3 minutes. If three consecutive open conditions occur

during an active call for operation, the compressor will be

locked out, a diagnostic will appear on the LCD display and

communicated to the network if applicable. Cycling the call

for operation will restart the compressor. On dual compressor

units only the affected compressor circuit is locked out.

(16 & 18) LP1, LP2 - Low Pressure Switch 1 & 2. When the

LPC is opened, the compressor for that circuit is turned off.

The compressor will not be allowed to restart for a minimum

of 3 minutes. The low pressure switch is ignored during

defrost and for the first 90 seconds of compressor run time. If

three consecutive open conditions occur during an active call

for operation, the compressor will be locked out, a diagnostic

will appear on the LCD display and communicated to the

Network if applicable. Cycling the call for operation will

restart the compressor. On dual compressor units only the

affected compressor circuit is locked out.

(19) Smoke Detector. The sensor is only applicable on units

equipped with a smoke detector. The input will shutdown the

unit and requires a manual reset. The sensor is used to detect

smoke due to fire in the air condition or ventilation ducts.

(20)FP - Fan proving. The unit mounted fan proving switch

monitors the pressure differential across the unit blower to

detect when the indoor fan is blowing air. A diagnostic signal

is sent to the LCD display if the pressure differential indicates

that the indoor blower is not operating. The control will also

monitor the system and if the blower is running and is not

required a fault will be sent to the DDC Controller.

(21) CFS - Clogged Filter Switch. The unit mounted clogged

filter switch monitors the pressure differential across the return

air filters. It is mounted in the filter section and is connected to

the DDC Controller. A diagnostic signal is sent to the LCD

display if the pressure differential across the filters is at least

0.5" w.c. The contacts will automatically open when the

pressure differential across the filters decreases to

approximately 0.4" w.c., the clogged filter output is operating,

and the clogged filter switch has been closed for at least 2

minutes. The system will continue to operate regardless of the

status of the filter switch.

(22) Occupied input (OC). This is a 24 volt input that is used

to control the occupancy (occupied or unoccupied mode) when

the DDC Controller is used in conjunction with a zone sensor

and solid state time clock.

(23 & 24) L1, L2 - Comfort Alert. The DDC Controller has

two inputs to monitor up to two compressor circuits using

optional Copeland Comfort Alerts. The inputs can provide the

following information: Locked rotor, Open Circuits, Missing

Phase, Reverse Phase, and Welded Contactor. Note: The

Comfort Alert sends the Open Circuit Alarm (code 5) only

after the fault has been sensed for a minimum of 4 hours.

(25) Configuration pins (P11). The DDC Controller features a

7 pin header (P11) on board for the connection of a

configuration key. This 7-position connector allows the

controller to determine the unit application mode without a

menu entry. Table 2 describes the connections necessary for

each one of the possible options. The configuration connector

provides a quick and safe way of replacing boards while

keeping the proper configuration of the unit.

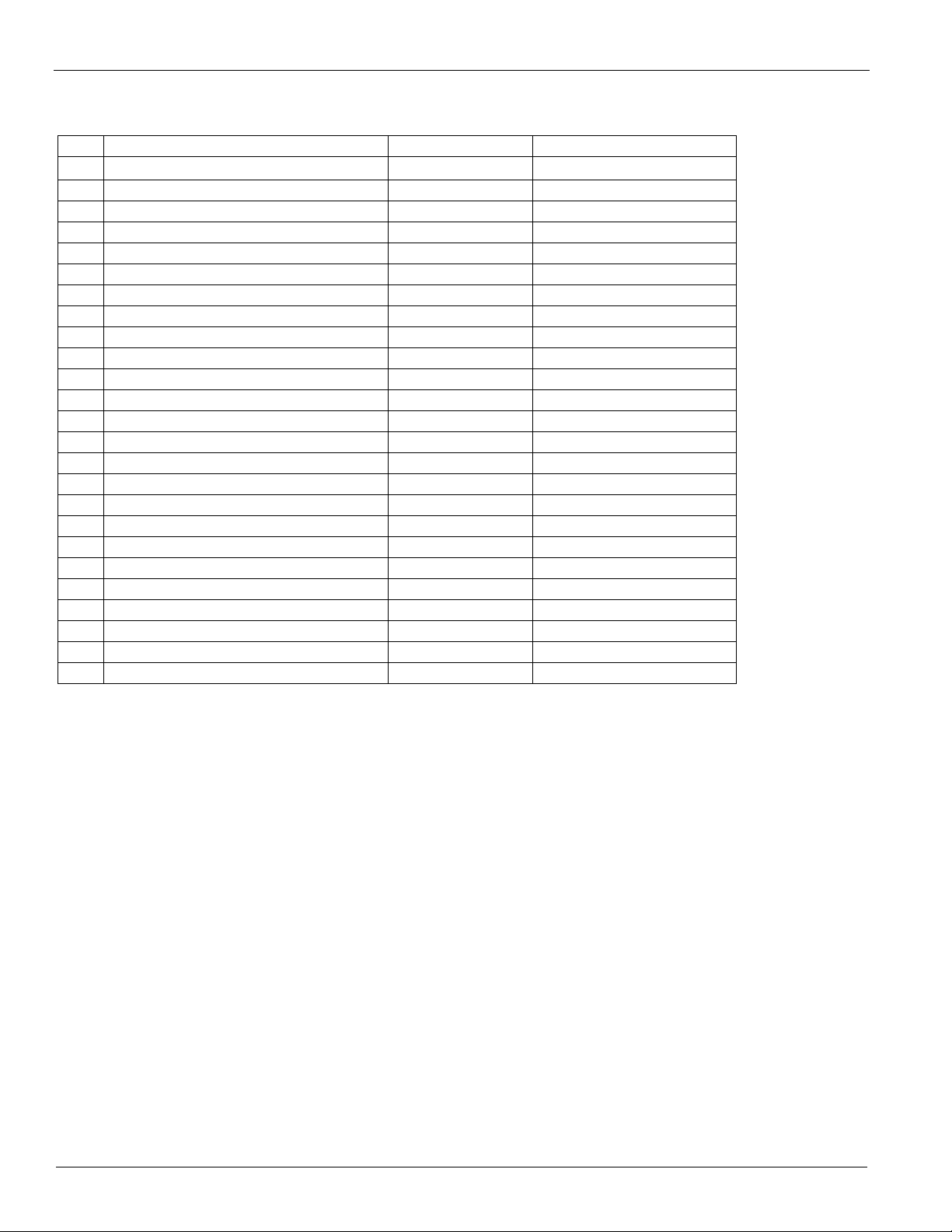

Table 2: Configuration Connector Parameters

P11 – Unit configuration 1 2 3 4 5 6 7

Cooling only (default for 3-25T) – default

Single stage Cooling with 2 stages EH x x

Single stage G/E(cool) with 1 stage GH x x

Single stage G/E(cool) with 2 stages GH x x

2 stages cool with 2 stages EH x x

2 stages G/E(cool) with 2 stages GH x x

Selection is made through the display x x x x

McQuay OM 1077 7

Page 8

Control Inputs and Outputs

Control Outputs

Table 3: Control Outputs

1 CC1 - Compressor output 1 24VAC 1.5A @ 24VAC, pilot duty

2 CC2 - Compressor output 2 24VAC 1.5A @ 24VAC, pilot duty

3 W1 - Heat output 24VAC 1.5A @ 24VAC, pilot duty

4 W2 - Heat Output 24VAC 1.5A @ 24VAC, pilot duty

5 G - Fan Output 24VAC 1.5A @ 24VAC, pilot duty

6 L - thermostat signal 24VAC 25mA loading

Control Output Descriptions

(3) W1 - Heat output. The DDC Controller has two outputs to

control resistance electric heat.

(1) CC1 - Compressor output 1. The DDC Controller can

control the compressor contactors. The DDC Controller can

monitor the system and respond to system faults and comfort

alert inputs to shut down the compressors in the event of a

failure.

(2) CC2 - Compressor output 2. The DDC Controller can

control the compressor contactors. The DDC Controller can

monitor the system and respond to system faults and comfort

alert inputs to shut down the compressors in the event of a

(4) W2 - Heat Output. The DDC Controller has two outputs to

control resistance electric heat.

(5) G - Fan Output. The DDC Controller can control the

indoor fan by use of a fan relay.

(6) L - Thermostat signal. The “L” terminal will output a

flash code to an indoor 24 V thermostat equipped with an “L”

terminal.

failure.

Table 4: Thermo stat Options

Device Part Number Description

Stand alone 24V thermostat / touch screen 113129801 Up to 2-heat / 2-cool

Stand alone 24V thermostat 113129901 Up to 2-heat / 2-cool

Table 5: Zone Sensor Module Wire Guide

Device

Wall mounted sensor w/ tenant override 113117701 18 3 Solid 18 AWG 3/C CL2P Thermostat

Wall mounted sensor w/ space point adjustment 113117701 18 3 Solid 18 AWG 3/C CL2P Thermostat

Part

Number

Wire

Gauge

Conductors Type Listings

8 McQuay OM 1077

Page 9

Unit Installation

Important - The DDC Controller is shipped with the control

disabled so units do not accidentally energize during

installation. The commissioning of the rooftop unit therefore

requires the configuration of the Occupied Mode menu prior to

initial startup. See Effective Occupancy‚ page 17.

DANGER

Before beginning any modification, be sure main disconnect

switch is in the “off” position. Disconnect all electric power,

including remote disconnect before servicing. Fai lure to do so

can cause electrical shock resulting in property damage,

personal injury or death. Follow proper lockout/tag out

procedures to ensure the power cannot be inadvertently

energized.

The unit DDC Controller must have a thermostat or zone

sensor input in order to operate the unit. If the zone sensor is

not present, or has failed, the unit will use the return air

temperature sensor to maintain the occupied setpoint. The

flexibility of the unit mode capabilities depends upon the type

of zone sensor or thermostat selected to interface with the

DDC controller.

The descriptions of the following basic Input Devices used

within the DDC controller network are to acquaint the operator

with their function as they interface with the various modules.

Refer to the unit's electrical schematic for the specific module

connection.

Unit Installation

Controls using DC Analog Input/Outputs (Standard

Low Voltage Multi-conductor Wire)

Before installing any connecting wiring between the unit and

components utilizing a DC analog input/output signal, refer to

the unit installation manual for the electrical access locations

provided on the unit.

• Use shielded cable for high EMI environments.

Note: Resistance in excess of 2.5 ohms per conductor can

cause deviations in the accuracy of the control s.

• Ensure that the wiring between controls and the unit's

termination point does not exceed two and a half (2.5) ohms

per conductor for the length of the run.

• Do not run the electrical wires transporting DC signals in or

around conduit housing high voltage wires.

• Most sensor wire insulation has a voltage rating less than the

line voltage. Route Zone Sensor and Network Cable behind

low voltage shield during unit installation per Figure 2. This

is necessary to meet NEC and UL 1995 requirements for

separation of high and low voltage circuits.

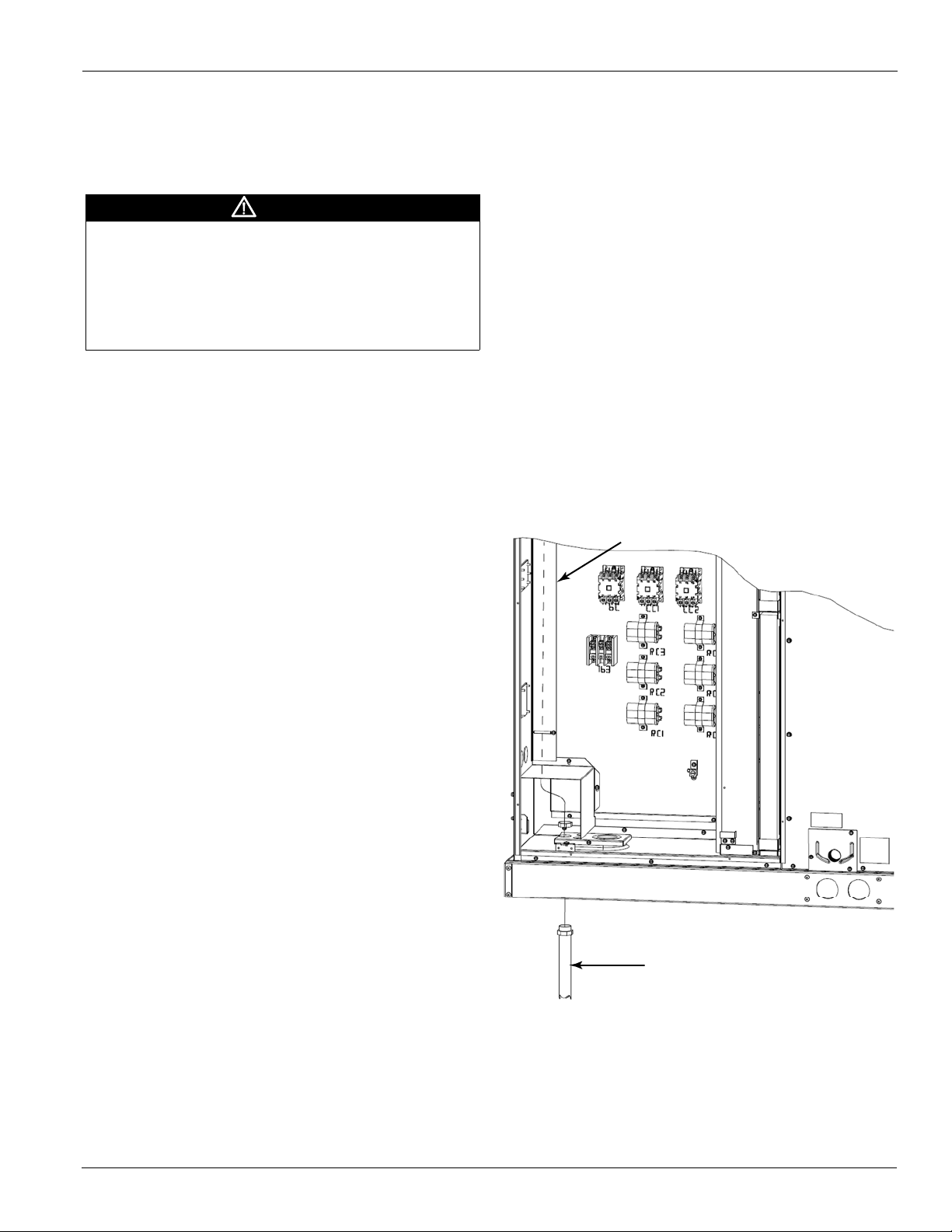

Figure 2: Low Voltage Shielding

Sheilding for Low

Voltage Conductors

The following controls are available from the factory for field

installation:

Controls using 24 VAC

Before installing any connecting wiring, refer to the unit

installation manual for AC conductor sizing guidelines “Field

Wire Size For 24 Volt Thermostat Circuits”, for the electrical

access locations provided on the unit, and;

• Use copper conductors unless otherwise specified.

• Ensure that the AC control wiring between the controls and

the unit's termination point does not exceed three (3) ohms

per conductor for the length of the run.

Note: Resistance in excess of 3 ohms per conductor may

cause component failure due to insufficient AC voltage

supply.

• Be sure to check all loads and conductors for grounds,

shorts, and mis-wirings.

• Do not run the AC low voltage wiring in the same conduit

with the high voltage power wiring.

• Some thermostat wire insulation has a voltage rating less

than the line voltage. Route Thermostat Wire behind low

voltage shield during unit installation per Figure 2. This is

necessary to meet National Electrical Code (NEC) and UL

1995 requirements for separation of high and low voltage

circuits.

Conduit for Low

Voltage Conductors

Stand Alone with Thermostat

Once Occupied Mode is set to “Control by Thermostat” the

DDC Controller will follow the commands from a regular

24VAC thermostat, according to the following convention:

• G - Indoor fan

• Y1 - First stage of compressor

McQuay OM 1077 9

Page 10

Unit Installation

• Y2 - Second Stage of compressor

• B - Not Used

• W1 - First Stage Auxiliary heat (electric or gas)

• W2 - Second Stage Auxiliary heat (electric or gas)

• L - Comfort Alert signal (output)

• R & C - 24VAC

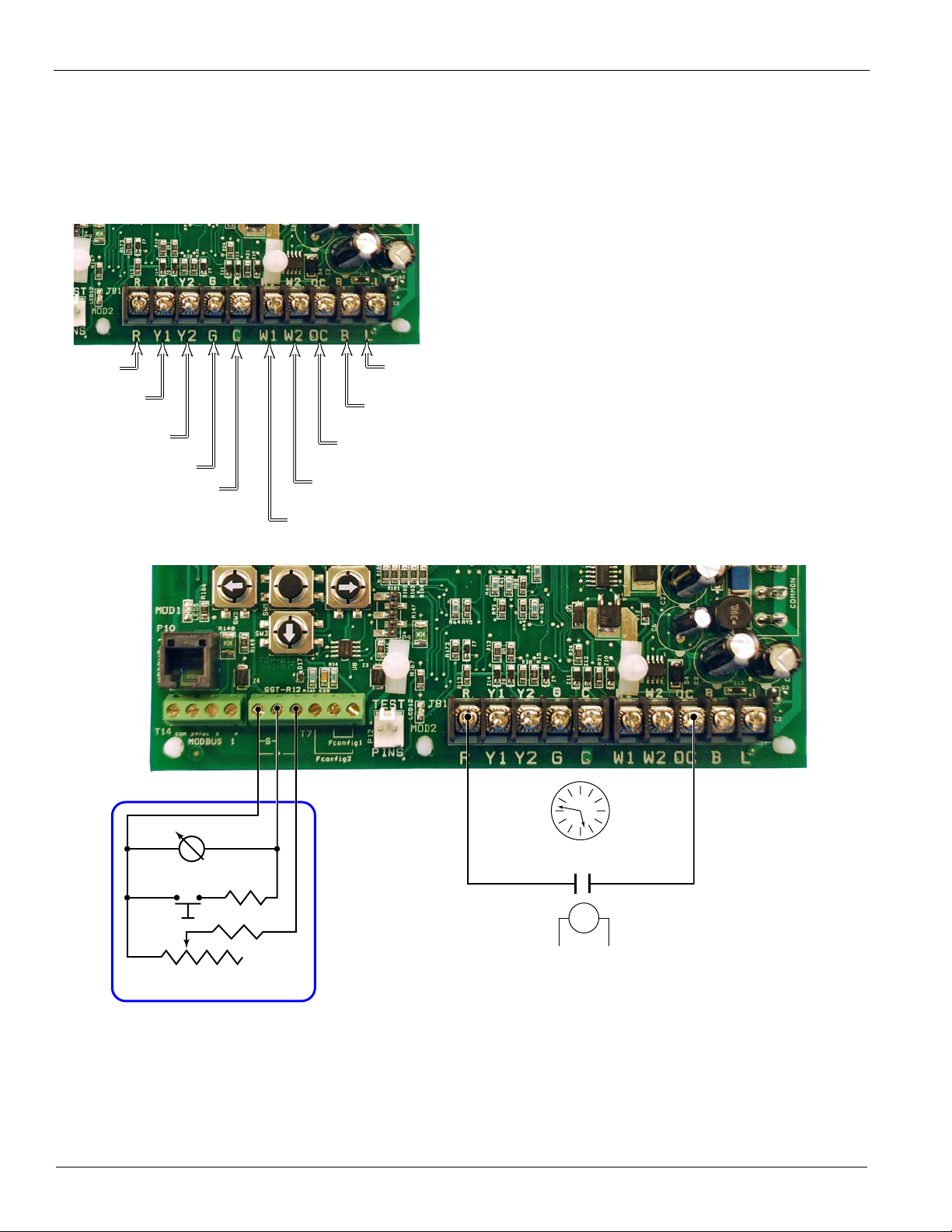

Figure 3: Thermostat Inputs and Outputs

+24VAC

1st Stage

Compressor

2nd Stage

Compressor

Occupancy

Signal

Comfort

Alert

Not Used

Indoor Fan

24V Common

2nd Stage Heat

1st Stage Heat

Figure 4: Standalone with Zone Sensor and Time Clock

Standalone with Zone Sensor and Time Clock

If Occupied Mode is set to any of the options other than “Off”

and “Control By Thermostat”, the control will operate in Stand

Alone mode or network using its local temperature sensors to

determine demand. The system can be set up with a zone

sensor to determine heat or cool demand and a solid state time

clock to determine occupancy . (See Occupied Mode‚ page

17)

Zone Sensor

10k Thermistor

Time Clock

Override

Button

10k Pot

Setpoint Adj.

10 McQuay OM 1077

2k

5k

Page 11

Unit Installation

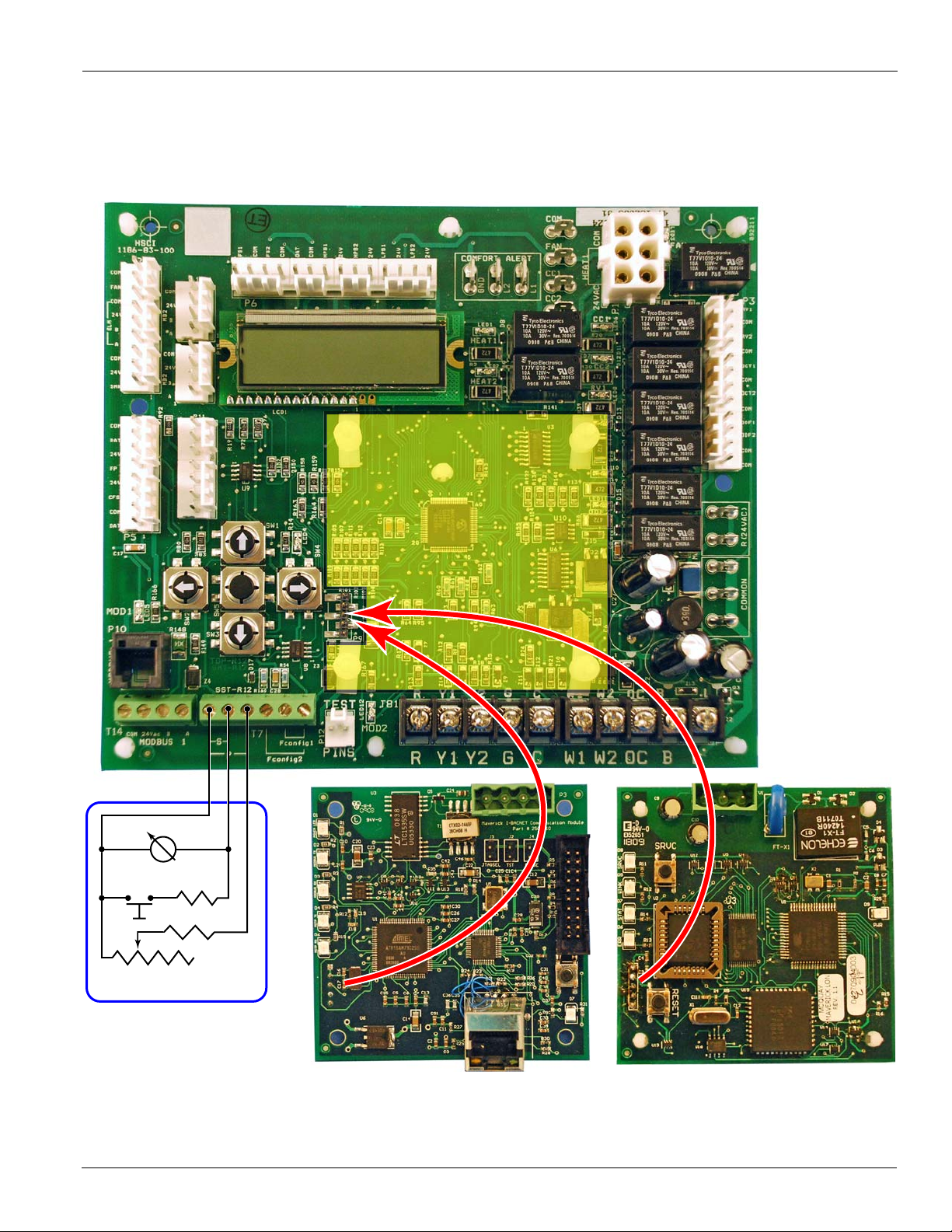

Standalone with Building Automation System

If Occupied Mode is set to any of the options other than “Off”

and “Control By Thermostat”, the control will operate in Stand

Alone mode or network using its local temperature sensors to

Figure 5: Zone Sensor with Building Automation System

determine demand. The system can be set up with a zone

sensor, 910108514 or 910108214 communication card, and

2nd party building automation system that will be controlled

from a central location.

Zone Sensor

10k Thermistor

Override

Button

10k Pot

Setpoint Adj.

2k

5k

LONWorks Daughter BoardBACnet Daughter Board

McQuay OM 1077 11

Page 12

Sequence of Operation

Sequence of Operation

Important - The DDC Controller is shipped with the control

disabled so units do not accidentally energize during

installation. The commissioning of the rooftop unit therefore

requires the configuration of the Occupied Mode menu prior to

initial startup. See Occupied Mode‚ page 17.

Cooling

When the DDC Controller receives a call for cooling via

thermostat or zone sensor compressor 1 energizes. After the

indoor fan on delay (1-180 sec / default 10 sec) the indoor fan

energizes. The indoor fan on delay starts when the call for

cooling is initiated.

When used in local zone sensor mode of operation, the DDC

Controller satisfies the set point using all or a partial number

of stages available. When cooling demand exists, the DDC

Controller will stage up in the following order: Economizer,

First Stage Cooling, and Second Stage Cooling based on

demand.

When used in local thermostat mode of operation, the DDC

Controller allows the thermostat to control the demand for

cooling. When cooling demand exists, the DDC Controller

will stage up in the following order: Economizer, First Stage

Cooling. Only two stages will be allowed to energize, so if the

economizer is active then the first stage mechanical cooling

will become second stage and second stage mechanical

cooling will not be used.

Heat

When in heating mode of operation, the DDC Controller

satisfies the set point using all or a partial number of stages

available. When heating demand exists, the DDC Controller

will utilize heat sources in the following order of priority as

available: Gas Heat and Electric.

When the heat demand requires multiple heating outputs at the

same time, a minimum staging delay of 5 seconds between

energizing and de-energizing heating outputs is necessary to

prevent the inrush current startup of multiple loads. The inter

stage is adjustable between 5 and 50 seconds.

The source of demand, like the other modes of operation, is a

result of one of either thermostat or remote sensors.

Integrated Furnace Control

The Integrated Furnace Control (IFC) is external to the DDC

Controller, and on units so equipped, controls the furnace and

gas valve operation based on signals from the DDC controller.

The IFC also provides furnace troubleshooting information via

LED flashing fault codes. When a fault condition exists, the

LED (see Figure 6) flashes the number of times indicated by

the code number, pauses, and repeats.

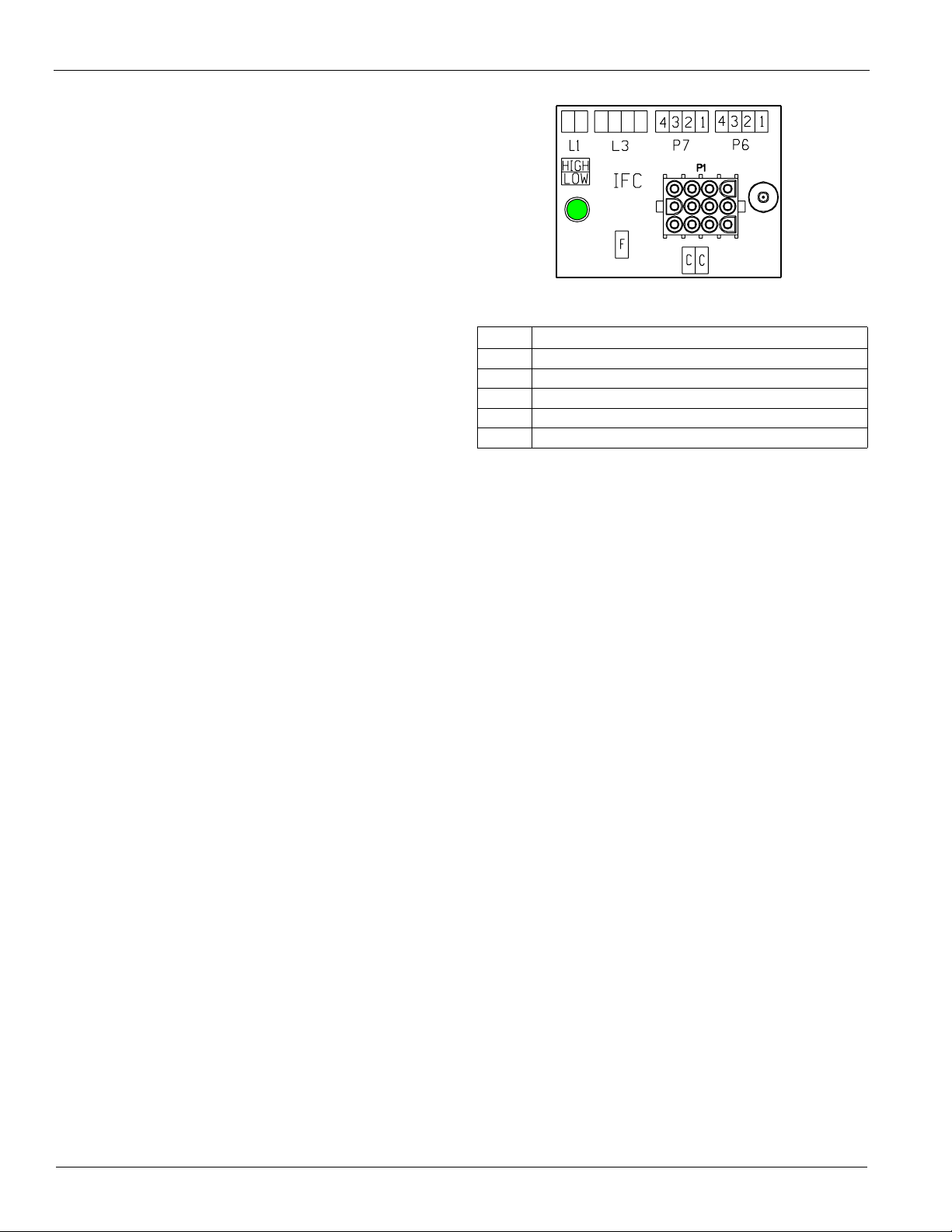

Figure 6: Integrated Furnace Control Status LED

LED

Table 6: Integrated Furnace Control Fault Codes

Code Meaning

1 Failure To Detect Or Sustain Flame

2 Pressure Switch Or Inducer Problem Detected

3 High Limit Protection Deice Open

4 Gas Valve Not Energized Or No “W” Signal

5 Flame Toll Out Switch Open

Call for Heat

After a call for heat the IFC checks to ensure the high

temperature limit and rollout switches are closed. If either is

open, the IFC responds with a fault code. If high limit and

rollout switches are closed, the IFC checks that both pressure

switches are open. If either pressure switch is closed, the IFC

will respond with a fault code and it will flash code “2” on the

LED, waiting indefinitely for both pressure switches to open.

If both pressure switches are open, the IFC proceeds to prepurge.

Pre-Purge

The IFC energizes the low inducer motor, flashes code “2” on

LED, and waits for the low pressure switch to close. If the low

pressure switch does not close within 3 minutes, the control

will energize the high inducer and wait for both pressure

switches to close. The IFC will light on high fire and remain

on high fire for the remainder of the heat cycle.

When the low pressure switch has closed, the IFC stops

flashing the LED and begins timing the 30 second pre-purge

period. If flame is sensed as present during pre-purge, the IFC

restarts the pre-purge time to require a full pre-purge after

flame is removed. When pre-purge time has expired, the IFC

begins the ignition trial.

Ignition Trial

The IFC energizes the gas valve and spark. The IFC ignores

flame sense for the first 2 seconds of the ignition trial. If flame

is not established within 7 seconds, the gas valve and spark is

de-energized and the IFC goes to an inter-purge. If flame is

established, the spark is de-energized, the IFC energizes the

high inducer (low inducer remains energized) and begins heat

blower on delay.

12 McQuay OM 1077

Page 13

Sequence of Operation

Heat Blower On-Delay

The control waits for 45 second heat fan on delay and then

energizes the indoor blower heat speed. If the blower is already

energized by a call for cooling or continuous fan, or in a

blower off delay per iod, t he on dela y is ski pped and t he blower

remains energized. After the blower on delay time is complete,

the control goes to high fire warm-up mode.

The high pressure switch is ignored during the heat blower on

delay to give time for the high pressure switch to close if

lighting on low fire.

High-fire Warm-up

The IFC remains on high fire for 120 seconds after flame is

established. If the DDC Controller is calling for 2 nd stage heat,

the IFC remains in high heat. If the IFC lit on high fire because

the low pressure switch did not close within 3 minutes, then th e

IFC remains on high fire for the entire call for heat regardless

of 2nd stage thermostat call. If there is no DDC Controller

demand for 2nd stage heat when the 120 second time has

expired, the IFC transitions from high heat to low h eat.

Low Heat

IFC inputs are continuously monitored to ensure limit, rollout,

and pressure switches are closed, flame is established, and the

thermostat call for heat remains. Low gas, low inducer, and

blower remain energized. If the DDC Controller calls for 2nd

stage heat (Hi Heat), the IFC transitions to high heat.

High Heat

IFC inputs are continuously monitored to ensure limit, rollout,

and pressure switches are closed, flame is established, and the

DDC Controller calls for heat remain. Low gas, high gas, low

inducer, high inducer, and blower remain energized. If the

DDC Controller terminates the call for 2nd stage heat and the

first stage call remains, the IFC transitions to low heat.

Low Heat to High Heat Transition

When the DDC Controller calls for 2nd stage heat after low

heat is established, the IFC checks the high pressure switch. If

the high pressure switch is closed, the IFC flashes “2” on the

LED and waits indefinitely for the high pressu re sw itch to

open. When the high pressure switch is proven open, the IFC

energizes the high inducer motor and waits for the pressure

switch to close. If the high pressure switch does not close

within 60 seconds, the control flashes “2” on the LED and deenergizes the high inducer motor for 5 minutes. The high

inducer is re-energized after the 5 minute period for 60 seconds

and the cycle repeats indefinitely until the high pressure switch

closes. When the high pressure switch closes, the IFC energizes

the high gas output and proceeds to high heat.

High Heat to Low Heat Transition

When the DDC Controller ends the call for 2nd stage heat and

the first stage call remains, the IFC de-energizes the high gas

output. The high inducer remains energized for 60 seconds

after the high gas de-energizes. The IFC proceeds to low heat.

Post Purge

When the DDC Controller demand for heat is satisfied, the

IFC immediately de-energizes the gas valve(s). The Inducer

output(s) remains on for a 5 second post-purge period. The

IFC continues the heat blower off delay.

Heat Blower Off Delay

The IFC de-energizes the Indoor blower motor 90 seconds

after the call for heat terminated

Interrupted Call For Heat

If the DDC Controller demand for heat is removed before the

ignition period, the IFC will immediately de-energize the inducer.

If the DDC Controller demand for heat is removed after

ignition has begun, the induced draft motor will run through a

post purge and the indoor blower motor will run on heat speed

for the delay off time.

Ignition Retry

If flame is not established on the first trial for ignition period,

the induced draft motor remains energized and the IFC deenergizes the low gas valve. The IFC waits for a 60 second

inter-purge period then attempts an ignition re-try. If the

second ignition trial is unsuccessful, the IFC energizes the high

inducer and waits indefinitely for the high pressure switch to

close. When the high pressure switch closes, the IFC energizes

the high gas output, interpurges 60 seconds and tries the 3rd

and 4th ignition attempts on high fire.

If flame is not established on the fourth trial for ignition, the

IFC de-energizes the high and low gas outputs and goes into

lockout. The IFC indicates a fault by flashing the status LED 1

time to indicate lockout is due to failed ignition.

Ignition Recycle

If flame is established and maintained during the trial for

ignition period and then flame is lost, the gas valve is deenergized, the induced draft motor continues to run, and the

control begins timing the pre-purge delay. The indoor blower

motor will be energized and/or remain energized on heat speed

for the delay off time.

When the pre-purge delay is over, the control energizes the

spark and gas valve for an ignition attempt. If ignition is

unsuccessful, the IFC will attempt up to 3 more retries as

described above. The IFC will recycle up to 17 flame losses (16

recycles) within a single call for heat before going to lockout.

The IFC status LED will flash 1 time if lockout is due to too

many flame loses. (This is same flash code as failed ignition.).

Open Limit switch

The limit switch is ignored unless a call for heat is present. If

the limit switch opens while a call for heat is present, the

indoor fan is energized on heat speed and both inducers are

energized. The gas valve is de-energized if it was energized.

The status LED will flash 3 times indicating the Limit switch

McQuay OM 1077 13

Page 14

Sequence of Operation

is open. The blower and inducers will remain energized as long

as the limit is open and there is a call for heat.

If the call for heat goes away while the limit switch is open,

the induced draft motor will run through post purge and the

indoor blower will run through the heat fan off delay. The

status LED will return to steady on.

If the limit switch re-closes and the call for heat remains, the

status LED will return to steady on and the IFC will begin a

pre-purge time with high gas output energized to begin a reignition attempt. The indoor blower remains on (for the delay

off time) through the re-ignition attempt.

Open Rollout switch

The rollout switch is ignored unless a call for heat is present and

the limit switch is closed. If the rollout switch opens for more

than 1 second, the indoor fan is energized on heat speed for a

heat blower off delay period and the inducer motor is energized

for a post-purge time period. The gas valve is de-energized if it

was energized. The status LED will flash 5 times indicating the

rollout switch is open and the IFC is in lockout.

If the rollout switch re-closes before the call for heat goes away,

the IFC will remain in lockout with the LED flashes 5 times.

Note: Rollout switch open for less than 1 second will cause

interrupted heat cycle from open PS, however it will not

lock out.

Pressure switch

The pressure switches are ignored unless a call for heat is

present and the limit and rollout switches are closed. When a

call for heat occurs and either pressure switch is closed before

the inducer is energized, the inducer will remain off and the

LED will flash 2 times until both pressure switches open.

If either pressure switch opens before the ignition period, both

induced draft motor will remain on, the high gas output will be

de-energized, and the LED will flash 2 times. When both

pressure switches are closed, the LED flash code is cleared, the

high gas output is energized, and the control re-starts the prepurge period.

If the low pressure switch opens after the gas valve has been

energized, the control will de-energize both gas outputs and run

the indoor blower on heat speed through the fan off delay. The

low inducer remains energized and the high inducer energizes if it

was not already energized. When both pressure switches re-close,

the control begins the pre-purge period and re-ignites. If the call

for heat goes away before the pressure switches close, both

inducer motors are de-energized and the control goes to standby.

If the high pressure switch opens while in high heat and the

low pressure switch remains closed, the control de-energizes

the high gas output and attempts to reestablish high heat.

Call for Fan

When the DDC Controller calls for continuous fan (Cont Fan)

without a call for heat, the indoor fan is immediately

energized. The fan remains energized as long as the call for fan

remains without a call for heat.

The continuous fan operation continues to function while the

control is in heat mode lockout.

Undesired Flame

If flame is sensed longer than 2 seconds while the gas valve is

de-energized, the IFC will energize both induced draft motors

and indoor blower motor. When flame is no longer sensed, the

induced draft motors and indoor blower motor will deenergize. The IFC will do a soft lockout, but will still respond

to open limit and flame. The status LED will flash 4 times

when lockout is due to undesired flame. If there is no call for

heat, or the call for heat is removed, lockout will reset.

Gas Valve relay fault

If the IFC senses the gas valve is energized for more than 1

second when the control is not attempti ng to energize the gas

valve, or if the gas valve is sensed as not energized when it is

supposed to be energized, then the IFC will lockout with the

LED off. The IFC assumes either the contacts of the relay

driving the gas valve have welded shut, or the sensing circuit

has failed. The inducer is forced off to open the pressure

switch to stop gas flow unless flame is present.

If the gas valve was sensed as closed when it should be open,

and has not de-energized after the inducer was shut off for 15

seconds, then both inducers are re-energized to vent the

unburned gas.

Soft Lockout

The IFC shall not initiate a call for heat while in lockout. A

call for continuous fan operates as normal. The IFC will still

respond to an open limit and undesired flame.

Lockout shall automatically reset after 1 hour. Lockout may be

manually reset by removing the thermostat call for heat for

more than 3 seconds or removing power from the control for

more than 5 seconds.

Hard lockout

If the IFC detects a fault, the status LED will be de energized

and the IFC will lockout as long as the fault remains. Hard

lockout may be reset by removing power to the control for

more than 5 seconds. Faults detected within the

microcontroller continually re-test to see if they are hard

failures. Failures detected within the flame sensor or gas valve

drive circuits re-test every 1 hour.

Electric Heat

The DDC Controller will always consider two available stages

of electric heat, although installation may have only one.

The electric heat is energized whenever the demand for heat is

not satisfied. The heat source it will be staged on based on

demand.

During electric heat operation the control does not delay

energizing the indoor fan.

14 McQuay OM 1077

Page 15

User Interface

User Interface

Keypad

The keypad consists of Up, Down, Left, Right arrow keys, and

an Enter key. The Right and Left keys allow the user to select

among the different groups of menus. The Up and Down keys

allow the user to scroll vertically through sub-menus within

the menu group. Up and Down keys also allow the input of

certain parameters, such as set points and time delays. Before

changing any parameter please see the appropriate sections

and have a full understanding of what you are changing.

Adjustment are possible only when a blinking cursor is over or

next to the parameter to be adjusted. The blinking cursor is

available for adjustable parameters after the user presses the

Enter key (center key) while the value in question is shown on

the display. Once the adjustment is made, the user must press

the Enter key again for the change to take effect. During the

adjustment, either left or right keys work as “escape” so the

parameter reverts back to its original value and the cursor is no

longer visible.

Figure 7: Keypad and Display

Up

Left

Right

Down

Display

Enter

McQuay OM 1077 15

Page 16

User Interface

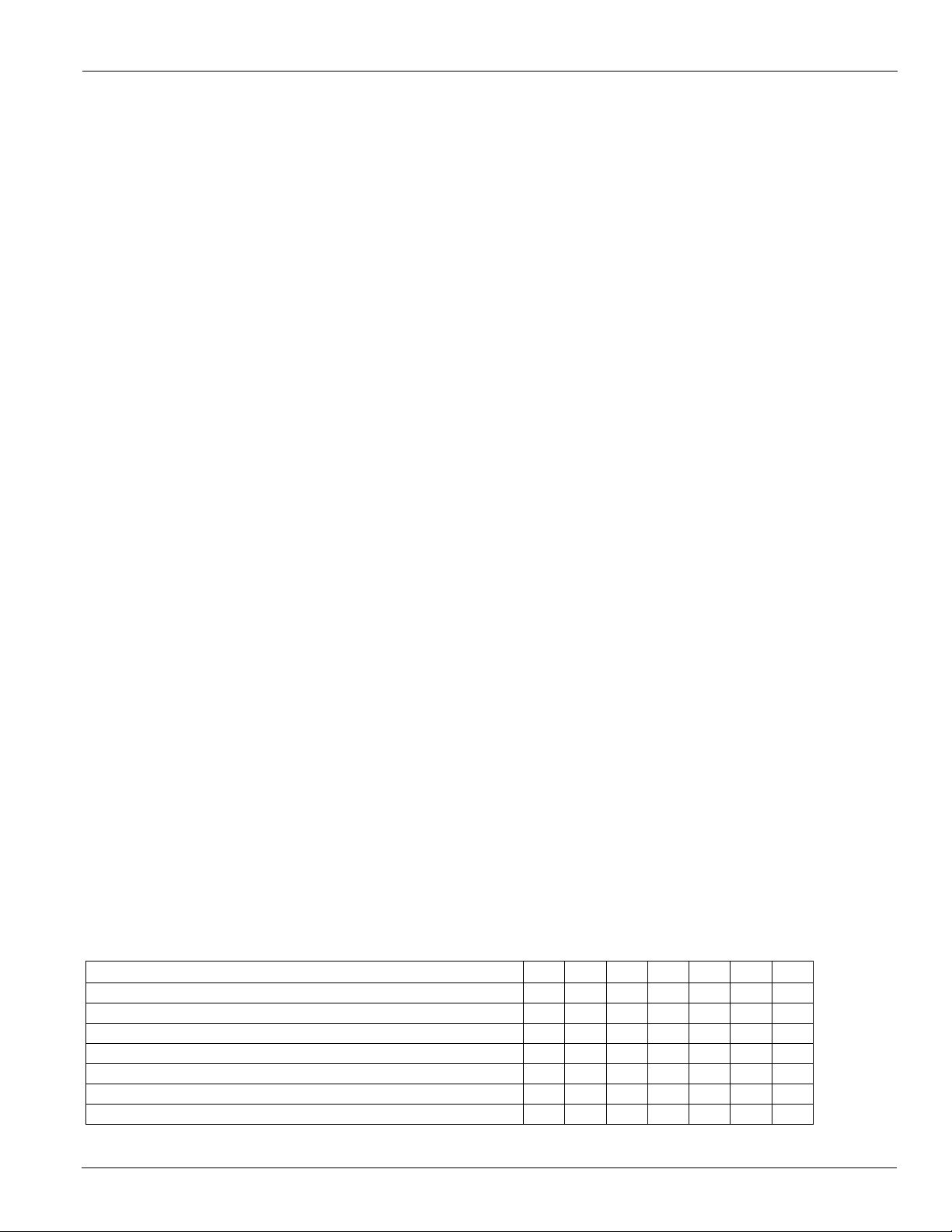

Figure 8: Menu Structure

General

Info

Software

Version

Alarms

System

Configuration

Unit Status

Mode

Inputs

Outputs

Capacity %

Effect

Occupancy

Occupied

Mode

Ind Fan

Occpcy

Temperature

Space Temp

Eff Space Temp

Return Air Temp

Outside Air Temp

Eff Outside Air

Temp

Disch. Air Temp

Out Coil Temp 1

Out Coil Temp 2

Freeze sensor 1

Freeze sensor 2

Set points

Occ Cool/Heat

Unc Cool/Heat

Eff. Temp. SP

Cool Diff

Heat Diff

Min DAT spt

Max DAT spt

Sptnt Adj Enable

Setpoint Adjust

Hi balance point

Economizer

Free Cooling

Econ. Status

Econ. Status

Enthalpy Setpt.

Eff. Mix. Air Temp

Mixed Air Setpt.

Ext. Mix. Air Temp

Econ. Vent. Lim

Econ. Exh. On/Off

Econ. DCV Limit

Furnace Ctrl.

Device ID

IFC Fault

IFC Inputs

IFC Outputs

Time Delays

Demand Delay

Indr FanOn Dly

Indr Fan Off Dly

Keypad Tmr Lim

Compressors

ASCD

Comp. Min run

Tm.

Staging Time Dly

LPS Bypass Delay

HPS Bypass

Delay

Fan Proving SW

INITIAL TEST SEQ

Pwd Required

ENTER PASSWORD

????

ACCESS DENIED/

GRANTED

Please see I&O

Section 6.10 for field

test sequence

History

of Alarms

Alarm # 1

Alarm # 2

Alarm # 3

Alarm # 4

Alarm # 5

Alarm 3 6

Alarm # 7

Alarm # 8

Alarm # 9

Alarm # 10

Active

Alarms

Active

Alarms

Field Config 1

Field Config 2

All Sub-Menus highlighted gray

are user adjustable

Low balance point

Tmp Lockout Cool

Tmp Lockout Heat

Defrost Mode

Acc defrost time

Defrost SCT lim.

Defrost Comp. Off

General information Screen

This is the home page of the system. At power up or after a

period of time of 5 minutes (display delay) without the

selection of any buttons, the system returns to this screen and

resumes scrolling through the items of this group.

The general information screen automatically scrolls through

the different menu items at 2-second intervals. When the user

DCV Control

DCV Level Setpt.

Ext. DCV Level

Eff. DCV Level

Dff. Eco Position

Eff. Min. Position

Local Min. Pos.

Econ. Faults

Econ Firm Vrsn

Clogged FilterSW

Smoke Alm

Switch

Ten. Over Time

Clear

Alarms?

presses any button, the changing of screens stops until the

display delay expires.

The software is programmed in the factory and cannot be

changed. The item “Alarms” is dependent upon the existence

of an alarm and it may display either “No Active Alarm” or

“Check Alarms!” Another screen outside this group shows the

details of existing alarms. The option for system configuration

is set with a configuration key from the factory.

16 McQuay OM 1077

Page 17

User Interface

Unit Status Screen

The status screen shows basic information about the operation

of the unit, such as mode of operation, inputs, outputs, and

capacity of cooling or heating.

Table 7: Unit Status Screen

Item Range

STANDBY

Fan Only

COOL STG1 ECON

COOL STG2 CC/ECO

COOL STG1 COMP

COOL STG2 COMP

HEAT STG1 COMP

HEAT STG2 COMP

Mode

Inputs

Outputs

CAPACITY

Heating: / Cooling:

HEAT STG1 ELEC

HEAT STG2 ELEC

HEAT STG1 GAS

HEAT STG2 GAS

HEAT STG2 CC/ELE

HEAT STG3 CC/ELE

HEAT STG4 CC/ELE

Defrost 1

Defrost 2

24VAC Inputs

Y1 – ON/OFF

Y2 – ON/OFF

W1 – ON/OFF

W2 – ON/OFF

B – ON/OFF

G – ON/OFF

OCC – ON/OFF

LPS1 – ON/OFF

LPS2 – ON/OFF

HPS1 – ON/OFF

HPS2 – ON/OFF

CFS – ON/OFF

SMKS – ON/OFF

FPS – ON/OFF

OUTPUTS

Compressor 1 – ON/OFF

Compressor 2 – ON/OFF

Rev Vlv 1 – ON/OFF

Rev Vlv 2 – ON/OFF

Heat 1 – ON/OFF

Heat 2 – ON/OFF

Outdr Fan 1 – ON/OFF

Outdr Fan 2 – ON/OFF

Indoor Fan – ON/OFF

– 100%

Effective Occupancy Screen

The Occupancy screen determines whether the unit is

operating in occupied mode, unoccupied mode, or tenant

override. It also displays whether the control is connected to a

network, regular thermostat, or if it is just using its local

sensors for controlling the temperatures.

Table 8: Effe ctive Occupancy Screen

Item Range

Effective Occupancy Occupied / Unoccupied / TntOverr XXX min

OFF

AUTO

Occupied Mode

Ind Fan Occupcy

FAN O NLY

HEAT ONLY

COOL ONLY

Ctrl by Tstat

Continuous

Auto

Cont when occup.

Effective Occupancy

Tenant Override, Occupied, or Unoccupied will be displayed

depending on the mode. The DDC Controller allows separate

adjustment of temperature set points and fan operation

according to the building occupancy. This feature is only

available when a thermostat is not controlling the ambient.

For the following sections, Occupied Mode implies that the

calculation for demand utilizes occupied set points, which are

used to satisfy the comfort in the ambient. Unoccupied mode

utilizes unoccupied set points and is normally set to save

energy during periods in which buildings are closed and

unoccupied. Tenant Override Mode is a state in which the

control utilizes occupied set points for a limited amount of

time, after which it returns to unoccupied mode. To start

Tenant Override, the user presses a button on the space sensor

for more than 2 seconds. The Tenant Override period is

adjustable between 2 and 6 hours and it has priority over any

other settings.

All set points are available via network and local human

interface.

Occupied Mode

The Occupied Mode is available through network and user

interface. The possible selections are:

• Off

• Auto

• Cooling only

• Heating only

• Fan Only

• Control by thermostat: not available through network. This

is exclusive to the human interface.

Off mode is the default factory selection, so units do not

accidentally energize during installation. The commissioning

of the rooftop unit therefore requires the configuration of the

Occupied Mode register prior to initial startup.

Auto mode is used with a zone sensor and solid state time

clock.

McQuay OM 1077 17

Page 18

User Interface

Ind Fan Occupcy

The Ind Fan Occupcy is the option that decides the indoor fan

function. It includes the following options.

• Continuous

• Auto

• Cont. when occup.

Continuous is used if it is desired that the fan runs all the time

regardless of Effective Occupancy . The Auto option allows the

fan to cycle with the heat or cool call regardless of Effective

Occupancy. The “Cont. when occup” option lets the indoor fan

run continuous when Effective Occupancy is occupied.

Temperature Screen

The temperature screen shows all available temperature

readings in the system. If any sensors are not available, the

control will either show “Sensor shorted” or “Sensor open”

messages.

Table 9: Temperature Screen

Item Range

Space Temp XXX °F

Eff Space Temp XXX °F

Return Air Temp XXX °F

Outside Air Temp XXX °F

Eff Out Air Temp XXX °F

Disch. Air temp XXX °F

Outdoor Coil temp 1 XXX °F

Outdoor Coil temp 2 XXX °F

Freeze Sensor 1 XXX °F

Freeze Sensor 2 XXX °F

Field Config 1 XXX °F

Field Config 2 XXX V

Item Range

Hi Balance Point

XXX °F

Lo Balance Point

XXX °F

Tmp Lockout Cool

XXX °F

Tmp Lockout Heat

XXX °F

0 to 120°F, default 40°F

0 to 120°F, default 35°F

30 to 50°F, default 35°F

70 to 95°F, default 90°F

Set Points

Set point is the desired temperature of comfort. The user has

two ways to adjust the set point: (a) using the User interface, or

(b) sending a command through the network. The set point

selection will only be valid when the board is not connected to

a thermostat.

The user can select occupied and unoccupied set points for

both heating and cooling through either the display or the

network. The selection through display does not allow the user

to choose set points closer than the value of the dead band plus

differential, so the control automatically changes the value of

the set point not being adjusted. As an example, if the

differential plus dead band equals to three degrees and the user

is adjusting cooling set point at 72°F, the control will lower the

heating set point to 69°F if the difference between the two is

less than three.

If the remote set point adjustment is enabled, then the control

will consider the hardwired potentiometer input to determine

occupied set points only. If the remote set point adjustment is

enabled but the input reads an invalid number, the control will

default back to the occupied set point selection.

Network data takes precedence over local selections. In other

words the control will follow a valid remote set point

adjustment from the network, even if the remote set point

adjustment is enabled and the hardwired input reading is valid.

Set points Screen

These screens allow the input of desired cooling, heating, and

defrost set points.

Table 10: Set Points Screen\

Item Range

Occ Cool Spt XXX °F

Occ Heat Spt XXX °F

Unc Cool Spt XXX °F

Unc Cool Spt XXX °F

Cool. Diff.

X.X °F

Heat Diff.

X.X °F

Min DAT Spt

XXX °F

Max DAT Spt

XXX °F

Stpnt Adj Enable Enable / Disable

Setpoint Adjust.

XXX °F

18 McQuay OM 1077

Cooling: 40 to 100°F, default 76°F

Heating: 36 to 96°F, default 68°F

Cooling: 40 to 100°F, default 76°F

Heating: 36 to 96°F, default 68°F

0.5 to 9.9°F, default 1.0°F

0.5 to 9.9°F, default 1.0°F

10 to 90°F, default 55°F

50 to 120°F, default 55°F

36 to 100°F, default 76°F

The DDC Controller will consider the hardwired

potentiometer reading or the network remote set point

adjustment as the cooling set point. It calculates the heating set

point by subtracting dead band (2.0°F) and differential from

the cooling set point.

Cooling Differential, Heating Differential, and De ad

Band

Differential is the maximum difference allowed between the

temperature reading and set point before the control considers

a valid demand for cooling or heating. The differential is also

valid for determining that the unit has satisfied demand.

Depending of the mode of operation, the differential will either

be added or subtracted from the set point to determine those

points.

Dead band is the difference between cooling set point minus

cooling differential and heating set point plus heating

differential.

Page 19

User Interface

Min DAT Spt

The Minimum DAT set point is used to create warnings in the

system.

Max DAT Spt

The Maximum DAT set point is used to create warnings in the

system.

Stpnt Adj Enabl e

If the set point adjustment is enabled, then the control will

consider the hardwired potentiometer input to determine

occupied set points only. If the remote set point adjustment is

enabled but the input reads an invalid number, the control will

default back to the occupied set point selection.

Setpoint Adjust

This is the actual reading of the potentiometer set point “Stpnt

Adj Enable”.

Cooling Lockout Temperature

If the outdoor air temperature is below the cooling lockout

temperature the control will prevent the operation of

mechanical cooling. The default cooling lockout temperature

is 35°F with a range of adjustment from 30°F to 50°F and the

cooling lockout resets at 5°F above the set point. As an

example, if the setting is 40°F and the compressors are not

operating due to low outdoor air temperature, then the DDC

Controller will only allow the operation of mechanical cooling

again once the OAT reading exceeds 45°F.

Heating Lockout Temperature

If the outdoor air temperature is above the heating lockout

temperature the control will prevent the operation of heating.

The default heating lockout temperature is 90°F with a range

of adjustment from 70°F to 90°F and the heating lockout resets

at 5°F below the set point.

Economizer

This screen shows the information available from the

Economizer. When this device is not connected, the control

will show the word “Unavailable” on the second line of the

display.

The Economizer uses controllable dampers to increase the

amount of outside-air intake into the building whenever

enabled and whenever outside air enthalpy is favorable for

conditioning the ambient.

The DDC Controller board communicates to the Economizer

Logic Module (ELM) via RS485. Once the ELM receives

communication from the main control indicating a cooling

demand, the ELM will calculate the outdoor air enthalpy and

determine if the economizer operation is favorable for

conditioning the ambient. The main control will read the status

of the economizer and determine whether it is a valid stage for

cooling or not.

If mechanical cooling is active and the enthalpy is favorable

for ELM operation, the DDC Controller will override the

Economizer opening the damper 100%. ELM will regain

control of the damper whenever mechanical cooling is no

longer necessary.

If operating from a thermostat, the Economizer is the first

stage of cooling. If the unit has two compressors available, the

second stage will never be active as long as free cooling is

available.

When the DDC Controller is operating from its local

temperature sensors, the Economizer is also a first stage of

cooling, if free cooling is available. First and second stages of

mechanical cooling may be necessary for satisfying the

demand in case the temperature trend towards the set point is

not large enough. Whenever mechanical cooling is active,

DDC Controller overrides the Economizer, opening the

damper 100%.

Table 11: Demand Control Ventil ati on

Economizer Adjustable Range

Econ. Status Economizer OK / Economizer Not OK

Econ. Status Diff Enthalpy / Single Enthalpy

Econ. Status Exh. Fan is ON/OFF

* Enthalpy Setpt. A/B/C/D/E A

Eff.Mix.Air Temp XXX.X °F

* Mixed Air Setpt. 0 - 99 45

Ext.Mix.Air Temp

* Econ. Vent. Limit 0 - 100 0

* Econ.Exh. On/off 0 - 100 50

* Econ. DCV Limit 0 - 100 0

DCV Control Enabled / Disabled Disabled

* DCV Level Setpt. 500 - 2000 ppm 700

Ext. DCV Level

Eff. DCV Level

Eff.Eco.Position

Eff.Min.Position

Local. Min. Pos.

DCV Sensor Fault

Econ. Faults

Econ Firm Vrsn 0103

OAE Sensor Fault

RAE Sensor Fault

MAT Sensor Fault

Default

setting

* Menus that are user adjustable

Economizer Status

This screen confirms if the enthalpy is acceptable for

economization.

Economizer Status

This screen indicates if the system is using single or

differential enthalpy.

McQuay OM 1077 19

Page 20

User Interface

Economizer Status

This screen gives the status of the exhaust fan.

Enthalpy Setpoint

The user has five levels to choose for the enthalpy set point.

Figure 9 indicates what each of those levels represents in the

psychometric chart. This setting determines the level at which

economization is allowed. This setting is only adjustable at

economizer potentiometer.

Figure 9: Demand Control Ventilation

codes, ASHRAE standards, or standard practice. It is usually

expressed in terms of volumetric flow-rate (cfm) per occupant

or per unit floor area. The use of a CO2 sensor can lower the

ventilation limit by verifying that the indoor air quality is

suitable for human occupancy, as described in the next section

for Demand Control Ventilation (DCV).

The system allows the adjustment of the ventilation limit

through four different methods, listed below in order of

priority:

1 Network interface (BACnet, BAS, or LonWorks)

2 Human Systems Interface (HSI)

3 Remote potentiometer

4 Direct adjustment through a potentiometer on ELM

control.

Economizer Exhaust ON/OFF

This screen allows the user to change the set point of what

percentage the exhaust fan is energized.

Economizer DCV Limit

The economizer will allow the dampers to close more than the

minimum position if the indoor air quality is not contaminated.

The Econ. DCV Limit can be set from 0 to 100% but must be

lower than the minimum position.

Effective Mixed Air Temperature

This is the current value of mixed air temperature.

Mixed Air Setpoint

When the mixed air temperature falls below this set point, the

freeze protection control will disable the mixed air control and

close the outdoor damper to the effective minimum position.

External Mixed Air Temperature

This screen corresponds to the discharge air temperature

reading from the DDC Controller.

Economizer Ventilation Limit

The ventilation limit corresponds to a minimum position of the

Economizer that complies with the minimum acceptable

outside-air ventilation rate. The volumetric flow-rate of

outside air required to provide healthful, comfortable

conditions for occupants can be determined from building

Economizer DCV Control

If connected to a CO2 sensor, the ELM measures and regulates

the amount of outdoor air supplied to the space in order to

maintain the levels of carbon dioxide below the recommended

700ppm above the outdoor levels. In this case, CO2 levels

serve as a proxy for building occupancy and the rate of humangenerated indoor pollutants.

Once the DCV is operating, the minimum damper position can

then be lowered to the DCV ventilation limit. By default, this

value is 50% of the ventilation limit, but the user has the

option to adjust it through network or human system interface.

The user also has the option to disable DCV altogether .

DCV Level Setpoint

The DCV level setpt is a selectable level of carbon dioxide that

the system does not allow to be exceeded. The set point is

communicated to the economizer and the minimum ventilation

position is changed in order to prevent the increase of CO2.

External DCV Level

This is the value DDC Controller sends to the Economizer.

Effective DCV Level

This is the actual DCV Level in ppm.

Effective Economizer Position

This is the actual position of the economizer.

20 McQuay OM 1077

Page 21

User Interface

Effective Minimum Position

This displays current value of the effective minimum damper

position.

Local Minimum Position

This displays the local minimum position that is set at the

ELM.

Economizer Faults

This screen displays any ELM sensor or actuator faults. Check

for proper installation of the sensor or actuator, or replace the

sensor or actuator so the alarm is cleared. Note: The actuator

fault must be present for at least 2 minutes with the unit

powered, the indoor fan running, and the outside damper

commanded to open more than 0% before the alarm is set.

Integrated Furnace Control Screen

This screen shows the information available from the IFC

board. When this device is not connected the control will show

the word “Unavailable” on the second line of the display.

Device ID

This screen displays the IFC software version.

IFC Fault

This screen displays any IFC faults. The faults will also be

displayed on the main DDC Controller fault screen.

IFC Inputs

Status of IFC Inputs

IFC Outputs

Status of IFC outputs

Time Delays Screen

This screen allows the input of time constants of the system.

Table 12: Time Delays Screen

Time Settings

Demand Delay 30– 1800 sec 300 sec

Indoor Fan On Delay 1sec – 180sec 10 sec

Indoor Fan Off Delay 1sec – 180sec 45 sec

Keypad auto scroll timeout 30sec – 10min 5 min

Compressors ASCD (Anti Short Cycle Delay) 10sec – 30 min 3 min

CMRT (Compressor Minimum Run Time) 1 – 20min 2 min

Stage Delay 5 – 300 sec 5 sec

LPS (low pressure switch) bypass timer 10 – 90 sec 30 sec

HPS (high pressure switch) bypass timer 1 – 5 sec 2 sec

Fan Proving Switch 1sec – 180sec 20 sec

Clogged Filter Switch 1sec – 180sec 20 sec

Smoke Alarm Switch 1sec – 180sec 20 sec

Tenant Override 2h – 6h 2h

Adjustable

Range

Default

Demand Delay

The demand delay is the time period in which the control

compares set point to zone temperature readings and

determines whether the current stage of either cooling or

heating is sufficient to satisfy the set point. The demand delay

is set by default at 5 minutes, and it can be configured between

30 seconds and 30 minutes.

Indoor Fan On Delay

The indoor fan on delay is the time delay before the fan is

allowed to energize after a call for cool, heat, or fan only. This

delay is ignored if the indoor fan is in continuous mode. In the

heating mode, for electric heat models, there is not a delay; for

gas heat models the delay is handled by the integrated furnace

control (IFC).

Indoor Fan Off Delay

The indoor fan off delay is the time delay after a call for cool

or heat is terminated. This delay is ignored for gas heat units or

if the indoor fan is in continuous mode. For gas heat units, the

indoor fan off delay is handled by the integrated furnace

control (IFC).

Keypad auto scroll timeout

The keypad auto scroll timeout will keep the User Interface

from returning to the general information screen for the

selected time.

ASCD (Anti Short Cycle Delay)

The anti short cycle delay is an adjustable delay used to keep

the compressor from re-energizing too quickly after a cycle.

The delay time starts after the compressor de-energizes.

CMRT (Compressor Minimum Run Time)

The compressor minimum run time is an adjustable time used

to ensure proper compressor oil return.

Stage Delay

The stage delay is an adjustable time that keeps the next stage

of cooling or heat pump from energizing.

LPS (low pressure switch) bypass timer

The low pressure switch bypass timer is an adjustable time that

the DDC Controller ignores the refrigerant low pressure switch

after a call for cooling or heat pump.

HPS (high pressure switch) bypass timer

The high pressure switch bypass timer is an adjustable time

that the DDC Controller ignores the refrigerant high pressure

switch after a call for cooling or heat pump.

Fan Proving Switch

The fan proving switch bypass timer is an adjustable time that

starts after the indoor fan is energized. The purpose of the

timer is to give the indoor fan time to come up to speed.

McQuay OM 1077 21

Page 22

User Interface

Clogged Filter Switch

The clogged filter switch bypass timer is an adjustable time

that can only be activated if the indoor fan is energized. If the

clogged filter switch input is continuously closed until the time

expires, the clogged filter alarm is tripped. The purpose of the

delay is to prevent nuisance trips when the indoor fan is started

or other pulsations in the airflow.

Smoke Alarm Switch

The smoke alarm switch is an input that will lock out the

system when an open switch is detected for 2 seconds. T o reset

the system power must be cycled to the unit or an “all clear”

signal must be communicated through the network.

Tenant Override

The DDC Controller allows separate adjustment of

temperature set points and fan operation according to the

building occupancy. This feature is only available when a

thermostat is not controlling the space temperature. For the

following sections, Occupied Mode implies that the

calculation for demand utilizes occupied set points, which are

used to satisfy the comfort in the space. Unoccupied mode

utilizes unoccupied set points and is normally set to save

energy during periods in whi c h buildings are closed and

unoccupied. Tenant Override Mode is a state in which the

control utilizes occupied set points for a limited amount of

time, after which it returns to unoccupied mode. To start

Tenant Override, the user presses a button on the space sensor

for more than 2 seconds.

Initial Test Sequence

The DDC Control allows a technician to Field Commission a

new or existing installation of a package unit with the DDC

control. By entering a password (5555), the technician can

select a cooling test or a heating test. If a cooling test was

selected, the first stage of cooling is now energized for 5

minutes to check for alarms. At the end of the test, the

temperature sensor readings are displayed. If the technician

connected refrigerant gauges to the unit, the technician can

record their gauge readings along with the sensor temperature

readings for future reference or to calculate refrigerant

superheat. If the unit has two stages of cooling, the next stage

of cooling is now energized for 5 minutes to check for alarms.

At the end of the test, the temperature sensor readings are

displayed. If the technician connected refrigerant gauges to the

unit, the technician can record their gauge readings along with

the sensor temperature readings for future reference or to

calculate refrigerant superheat for the second stage of cooling.

Using the reading from the outdoor air temperature sensor and

the refrigerant pressure and temperature readings, the

technician can verify unit operation obeys the refrigerant

charge chart. The DDC then de-energizes the second stage

compressor, the first stage compressor, and finally the indoor

fan. The test is then terminated. Temporarily shorting across

the “TEST PINS” (P12) on the DDC board during the heating

test will cause the gas valves to energize and de-energize

instead of the compressors. No temperature display is provided

at the end of the gas heat test.

History of alarms

This screen shows the last 10 alarm occurrences of the system.

A new alarm enters in position 1, shifting the other

occurrences one position down.