Page 1

Maverick I™

Commercial Packaged Rooftop System

Cooling Only or Heating & Cooling

Electric/Electric

Models MPS007AY – 012AY

7 to 12 Tons

Installat

ion and Maintenance Manual

IM 866

Group: Applied Systems

Part Number: 92-102421-05-00

Date: March 2007

© 2007 McQuay International

ARI Standard

210/240 UAC

™

Page 2

2 IM 866

Table of Contents

Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Checking Product Received . . . . . . . . . . . . . . . . . . . . 3

Equipment Protection . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pre-Installation Check Points . . . . . . . . . . . . . . . . . . . . . . . 15

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Outside Slab Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Rooftop Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ductwork. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Conversion Procedure . . . . . . . . . . . . . . . . . . . . . . . 17

Downflow to Horizontal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Electrical Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Control Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Internal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

208 Volt Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Indoor Air Flow Data . . . . . . . . . . . . . . . . . . . . . . . . . 20

Crankcase Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pre-Start Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cooling Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Heating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Airflow Data Tables . . . . . . . . . . . . . . . . . . . . . . . 22-25

Heater Kit Characteristics . . . . . . . . . . . . . . . . . . 26-29

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . 31-32

Charging Charts . . . . . . . . . . . . . . . . . . . . . . . . . . 33-36

Page 3

IM 866

3

Introduction

This manual contains the installation and operating instructions for your packaged rooftop system. There are a few precautions that should be taken to derive maximum satisfaction

from it. Improper installation can result in unsatisfactory operation or dangerous conditions.

Read this manual and any instructions packaged with separate

equipment required to make up the system prior to installation.

Give this manual to the owner and explain its provisions. The

owner should retain this manual for future reference.

Checking Product Received

Upon receiving the unit, inspect it for any damage from shipment. Claims for damage, either shipping or concealed, should

be filed immediately with the shipping company. Check the

unit model number, heating size, electrical characteristics, and

accessories to determine if they are correct.

Equipment Protection From The

Environment

The metal parts of this unit may be subject to rust or deterioration in adverse environmental conditions. This oxidation could

shorten the equipment’s useful life. Salt spray, fog or mist in

seacoast areas, sulphur or chlorine from lawn watering systems, and various chemical contaminants from industries such

as paper mills and petroleum refineries are especially corrosive.

If the unit is to be installed in an area where contaminants

are likely to be a problem, special attention should be

given to the equipment location and exposure.

1 Avoid having lawn sprinkler heads spray directly on the

unit cabinet.

2 In coastal areas, locate the unit on the side of the building

away from the waterfront.

3 Shielding provided by a fence or shrubs may give some

protection.

Regular maintenance will reduce the buildup of contaminants and help to protect the unit’s finish.

1 Frequent washing of the cabinet, fan blade and coil with

fresh water will remove most of the salt or other contaminants that build up on the unit.

2 Regular cleaning and waxing of the cabinet with a good

automobile polish will provide some protection.

3 A good liquid cleaner may be used several times a year to

remove matter that will not wash off with water.

Several different types of protective coatings are offered in

some areas. These coatings may provide some benefit, but the

effectiveness of such coating materials cannot be verified by

the equipment manufacturer.

The best protection is frequent cleaning, maintenance and

minimal exposure to contaminants.

Recognize this symbol as an indication of

Important Safety Information!

!

The manufacturer’s warranty does not cover any damage or

defect to the air conditioner caused by the attachment or

use of any components, accessories or devices (other than

those authorized by the manufacturer) into, onto or in conjunction with the air conditioner. You should be aware that

the use of unauthorized components, accessories or

devices may adversely affect the operation of the air conditioner and may also endanger life and property. The manufacturer disclaims any responsibility for such loss or injury

resulting from the use of such unauthorized components,

accessories or devices.

▲▲

DANGER

!

Disconnect all power to the unit before starting maintenance. Failure to do so can result in severe electrical shock

or death.

▲▲

DANGER

!

Page 4

4 IM 866

Figure 1: Unit Dimensions

Figure 2: Unit Dimensions – Bottom View

A0734-03

A0715-03

40.19”

[1020.7 mm]

3.81”

[96.8 mm]

93.69”

[2379.6 mm]

COMPRESSOR

ACCESS

SUPPLY COVER

RETURN COVER

58.75”

[1492.2 mm]

6.81”

[173 mm]

11.69”

[296.9 mm]

4.13”

[104.8 mm]

6.63”

[168.3 mm]

5”

[127 mm]

CONTROL

ENTRY

.88” [22.2 mm]

DIA.

POWER

ENTRY

7.75” [44.5 mm]

DIA.

2”

[50.8 mm]

2”

[50.8 mm]

2”

[50.8 mm]

2”

[50.8 mm]

4.44”

[112.7 mm]

14”

[355.6 mm]

23”

[584.2 mm]

8.99”

[2278 mm]

*ACTUAL OPENING

DIMENSIONS

2”

[50.8 mm]

54.75”

[1390.6 mm]

10.44”

[265.1 mm]

25”

[635 mm]

15.13”

[384.2 mm]

34”

[863.6 mm]

BOTTOM VIEW

[ ] Designates Metric Conversions

Page 5

IM 866

5

Figure 3: Unit Dimensions

Figure 4: Unit Dimensions – Front View

A0737-03

A0735-03

58.75”

[1487.7 mm]

44”

[1117.6 mm]

5.625”

[142.9 mm]

7.02”

[178.3 mm]

CONTROL/FILTER

ACCESS

ELECTRIC HEAT

ACCESS

POWER ENTRY

CONTROL

ENTRY

CONDENSATE DRAIN

1” [25.4 mm] FNPT

93.69”

[2379.7 mm]

5.56”

[2141.2 mm]

27.25”

[692.1 mm]

93.69”

[2379.6 mm]

27.27”

[692.6 mm]

33.725”

[805.5 mm]

OPTIONAL OUTDOOR

AIR HOOD LOCATION

OPTIONAL EXHAUST

HOOD LOCATION

BLOWER ACCESS

COMPRESSOR

ACCESS

(BOTH SIDE SAME MODELS:

44"

[1117.6 mm]

Page 6

6 IM 866

Figure 5: Bottom View

Figure 6: Back View

A0712-02

A0714-03

*RECOMMENDED DUCT DIMENSIONS ARE 26”

93.69”

[2379.4 mm]

4.44”

[112.7 mm]

15.13”

[384.1 mm]

4.44”

[112.7 mm]

10.44”

[265.1 mm]

2.13”

[54 mm]

6.5”

[165.1 mm]

27.5”

[698.5 mm]

2.13”

[54 mm]

88.94”

[2259 mm]

2.38”

[60.3 mm]

58.75”

[1492.2 mm]

93.69”

[2379.6 mm]

13.63”

[346 mm]

4.44”

[112.7 mm]

7.22”

[183.3 mm]

SUPPLY RETURN DIMENSIONS FOR DOWNFLOW APPLICATIONS

54"

[1371.6 mm]

[635 mm]

25"

23"

[585.5 mm]

14"

[355.6 mm]

34"

[863.6 mm]

SUPPLY AND RETURN DIMENSIONS FOR HORIZONTAL APPLICATION

8"

[203.2 mm]

THRU THE BASE ELECTRIC

SUPPLY DUCT MAY EXTEND UP TO THIS LEVEL

*26"

[660.4 mm]

[1117.6 mm]

34"

[863.6 mm]

44"

12"

[304.8 mm]

[711.2 mm]

28"

14"

[355.6 mm]

Page 7

IM 866

7

NOM. SIZES 7.5-12.5 TON [26.4 & 44.0 kW] ASHRAE 90.1-2004 COMPLIANT MODELS

General Data

McQuay MPS Series 007AYCL 007AYCM 007AYDL 007AYDM

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 93,000 [27.25] 93,000 [27.25] 93,000 [27.25] 93,000 [27.2]

EER/SEER

2

10.3/NA 10.3/NA 10.3/NA

Nominal CFM/ARI Rated CFM [L/s] 3000/3200 [1416/1510] 3000/3200 [1416/1510] 3000/3200 [1416/1510] 3000/3200 [1416/1510]

ARI Net Cooling Capacity Btu [kW] 90,000 [26.37] 90,000 [26.37] 90,000 [26.37] 90,000 [26.37]

Net Sensible Capacity Btu [kW] 68,000 [19.92] 68,000 [19.92] 68,000 [19.92] 68,000 [19.92]

Net System Power kW 8.74 8.74 8.74 8.74

Net Weight lbs. [kg] 1048 [475] 1056 [479] 1048 [475] 1056 [479]

Integrated Part Load Value

3

11 11 11 11

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

4

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Smooth Smooth Smooth Smooth

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 11.25 [1.05] 11.25 [1.05] 11.25 [1.05] 11.25 [1.05]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Net Latent Capacity Btu [kW] 22,000 [6.45] 22,000 [6.45] 22,000 [6.45] 22,000 [6.45]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 2 2 2 3

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 69/69 [1956/1956] 69/69 [1956/1956] 69/69 [1956/1956] 69/69 [1956/1956]

Weights

Ship Weight lbs. [kg] 1085 [492] 1093 [496] 1085 [492] 1093 [496]

10.3/NA

CONTINUED

[] Designates Metric Conversions

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does

not include the effect of fan motor heat. ARI capacity is net and includes the effect of fan motor heat. Units are suitable

for operation to

20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner Equipment

certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Integrated Part Load Value is rated in accordance with ARI Standard 210/240 or 360. Units are rated at 80° F ambient,

80° F entering dry bulb, and 67° F entering wet bulb at ARI rated cfm.

4. Heating Performance limit settings and rating data were established and approved under laboratory test conditions

using American National Standard Institute standards. Ratings shown are for elevations up to 2000 feet. For elevations

above 2000 feet, ratings should be reduced at the rate of 4% for each 1000 feet above se

a level.

5. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

Page 8

8 IM 866

NOM. SIZES 7.5-12.5 TON [26.4 & 44.0 kW] ASHRAE 90.1-2004 COMPLIANT MODELS

General Data

McQuay MPS Series 007AYYL 007AYYM 008AYCL 008AYCM

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 93,000 [27.25] 93,000 [27.25] 104,000 [30.47] 104,000 [30.47]

EER/SEER

2

10.3/NA 10.3/NA 10.3/NA

Nominal CFM/ARI Rated CFM [L/s] 3000/3200 [1416/1510] 3000/3200 [1416/1510] 3400/3400 [1604/1604] 3400/3400 [1604/1604]

ARI Net Cooling Capacity Btu [kW] 90,000 [26.37] 90,000 [26.37] 100,000 [29.3] 100,000 [29.3]

Net Sensible Capacity Btu [kW] 68,000 [19.92] 68,000 [19.92] 76,000 [22.27] 76,000 [22.27]

Net System Power kW 8.74 8.74 9.71 9.71

Net Weight lbs. [kg] 1048 [475] 1056 [479] 917 [416] 928 [421]

Integrated Part Load Value

3

11 11 11 11

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

4

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Smooth Smooth Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 11.25 [1.05] 11.25 [1.05] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Net Latent Capacity Btu [kW] 22,000 [6.45] 22,000 [6.45] 24,000 [7.03] 24,000 [7.03]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 2 2 2 3

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 69/69 [1956/1956] 69/69 [1956/1956] 86/86 [2438/2438] 86/86 [2438/2438]

Weights

Ship Weight lbs. [kg] 1085 [492] 1093 [496] 980 [445] 988 [448]

10.3/NA

CONTINUED

[] Designates Metric Conversions

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does

not include the effect of fan motor heat. ARI capacity is net and includes the effect of fan motor heat. Units are suitable

for operation to

20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner Equipment

certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Integrated Part Load Value is rated in accordance with ARI Standard 210/240 or 360. Units are rated at 80° F ambient,

80° F entering dry bulb, and 67° F entering wet bulb at ARI rated cfm.

4. Heating Performance limit settings and rating data were established and approved under laboratory test conditions

using American National Standard Institute standards. Ratings shown are for elevations up to 2000 feet. For elevations

above 2000 feet, ratings should be reduced at the rate of 4% for each 1000 feet above se

a level.

5. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

Page 9

IM 866

9

NOM. SIZES 7.5-12.5 TON [26.4 & 44.0 kW] ASHRAE 90.1-2004 COMPLIANT MODELS

General Data

[] Designates Metric Conversions

McQuay MPS Series 008AYDL 008AYDM 008AYYL 008AYYM

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 104,000 [30.47] 104,000 [30.47] 104,000 [30.47] 104,000 [30.47]

EER/SEER

2

10.3/NA 10.3/NA 10.3/NA

Nominal CFM/ARI Rated CFM [L/s] 3400/3400 [1604/1604] 3400/3400 [1604/1604] 3400/3400 [1604/1604] 3400/3400 [1604/1604]

ARI Net Cooling Capacity Btu [kW] 100,000 [29.3] 100,000 [29.3] 100,000 [29.3] 100,000 [29.3]

Net Sensible Capacity Btu [kW] 76,000 [22.27] 76,000 [22.27] 76,000 [22.27] 76,000 [22.27]

Net System Power kW 9.71 9.71 9.71 9.71

Net Weight lbs. [kg] 917 [416] 925 [420] 917 [416] 925 [420]

Integrated Part Load Value

3

11 11 11 11

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

4

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Net Latent Capacity Btu [kW] 24,000 [7.03] 24,000 [7.03] 24,000 [7.03] 24,000 [7.03]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 2 3 2 3

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 86/86 [2438/2438] 86/86 [2438/2438] 86/86 [2438/2438] 86/86 [2438/2438]

Weights

Ship Weight lbs. [kg] 980 [445] 988 [448] 980 [445] 988 [448]

10.3/NA

CONTINUED

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does

not include the effect of fan motor heat. ARI capacity is net and includes the effect of fan motor heat. Units are suitable

for operation to

20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner Equipment

certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Integrated Part Load Value is rated in accordance with ARI Standard 210/240 or 360. Units are rated at 80° F ambient,

80° F entering dry bulb, and 67° F entering wet bulb at ARI rated cfm.

4. Heating Performance limit settings and rating data were established and approved under laboratory test conditions

using American National Standard Institute standards. Ratings shown are for elevations up to 2000 feet. For elevations

above 2000 feet, ratings should be reduced at the rate of 4% for each 1000 feet above se

a level.

5. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

Page 10

10 IM 866

NOM. SIZES 7.5-12.5 TON [26.4 & 44.0 kW] ASHRAE 90.1-2004 COMPLIANT MODELS

General Data

[] Designates Metric Conversions

McQuay MPS Series 010AYCL 010AYCM 010AYDL 010AYDM

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 126,000 [36.92] 126,000 [36.92] 126,000 [36.92] 126,000 [36.92]

EER/SEER

2

10.3/NA 10.3/NA 10.3/NA

Nominal CFM/ARI Rated CFM [L/s] 4000/4000 [1888/1888] 4000/4000 [1888/1888] 4000/4000 [1888/1888] 4000/4000 [1888/1888]

ARI Net Cooling Capacity Btu [kW] 120,000 [35.16] 120,000 [35.16] 120,000 [35.16] 120,000 [35.16]

Net Sensible Capacity Btu [kW] 88,000 [25.78] 88,000 [25.78] 88,000 [25.78] 88,000 [25.78]

Net System Power kW 11.65 11.65 11.65 11.65

Net Weight lbs. [kg] 1125 [510] 1151 [522] 1125 [510] 1151 [522]

Integrated Part Load Value

3

10.6 10.6 10.6 10.6

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

4

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Net Latent Capacity Btu [kW] 32,000 [9.38] 32,000 [9.38] 32,000 [9.38] 32,000 [9.38]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 3 / 18 [7] 3 / 18 [7] 3 / 18 [7] 3 / 18 [7]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 2 3 2 3

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 173/173 [4905/4905] 173/173 [4905/4905] 173/173 [4905/4905] 173/173 [4905/4905]

Weights

Ship Weight lbs. [kg] 1162 [527] 1188 [539] 1162 [527] 1188 [539]

10.3/NA

CONTINUED

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does

not include the effect of fan motor heat. ARI capacity is net and includes the effect of fan motor heat. Units are suitable

for operation to

20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner Equipment

certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Integrated Part Load Value is rated in accordance with ARI Standard 210/240 or 360. Units are rated at 80° F ambient,

80° F entering dry bulb, and 67° F entering wet bulb at ARI rated cfm.

4. Heating Performance limit settings and rating data were established and approved under laboratory test conditions

using American National Standard Institute standards. Ratings shown are for elevations up to 2000 feet. For elevations

above 2000 feet, ratings should be reduced at the rate of 4% for each 1000 feet above se

a level.

5. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

Page 11

IM 866

11

NOM. SIZES 7.5-12.5 TON [26.4 & 44.0 kW] ASHRAE 90.1-2004 COMPLIANT MODELS

General Data

[] Designates Metric Conversions

McQuay MPS Series 010AYYL 010AYYM 012AYCL 012AYCM

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 126,000 [36.92] 154,000 [45.12] 154,000 [45.12] 154,000 [45.12]

EER/SEER

2

10.3/NA 10.3/NA 9.7/NA

Nominal CFM/ARI Rated CFM [L/s] 4000/4000 [1888/1888] 4000/4000 [1888/1888] 5000/4300 [2360/2029] 5000/4300 [2360/2029]

ARI Net Cooling Capacity Btu [kW] 120,000 [35.16] 120,000 [35.16] 146,000 [42.78] 146,000 [42.78]

Net Sensible Capacity Btu [kW] 88,000 [25.78] 88,000 [25.78] 104,000 [30.47] 104,000 [30.47]

Net System Power kW 11.65 11.65 15.05 15.05

Net Weight lbs. [kg] 1125 [510] 1151 [522] 1047 [475] 1073 [487]

Integrated Part Load Value

3

10.6 10.6 10 10

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

4

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 22 [9] 2 / 22 [9]

Net Latent Capacity Btu [kW] 32,000 [9.38] 32,000 [9.38] 42,000 [12.31] 42,000 [12.31]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 3 / 18 [7] 3 / 18 [7] 4 / 15 [6] 4 / 15 [6]

Refrigerant Control Capillary Tubes Capillary Tubes Orifices Orifices

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 2 3 3 5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 184

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 173/173 [4905/4905] 173/173 [4905/4905] 192/192 [5443/5443] 192/192 [5443/5443]

Weights

Ship Weight lbs. [kg] 1162 [527] 1188 [539] 1084 [492] 1119 [508]

9.7/NA

CONTINUED

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does

not include the effect of fan motor heat. ARI capacity is net and includes the effect of fan motor heat. Units are suitable

for operation to

20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner Equipment

certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Integrated Part Load Value is rated in accordance with ARI Standard 210/240 or 360. Units are rated at 80° F ambient,

80° F entering dry bulb, and 67° F entering wet bulb at ARI rated cfm.

4. Heating Performance limit settings and rating data were established and approved under laboratory test conditions

using American National Standard Institute standards. Ratings shown are for elevations up to 2000 feet. For elevations

above 2000 feet, ratings should be reduced at the rate of 4% for each 1000 feet above se

a level.

5. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

Page 12

12 IM 866

NOM. SIZES 7.5-12.5 TON [26.4 & 44.0 kW] ASHRAE 90.1-2004 COMPLIANT MODELS

General Data

[] Designates Metric Conversions

McQuay MPS Series 012AYDL 012AYDM 012AYYL 012AYYM

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 154,000 [45.12] 154,000 [45.12] 154,000 [45.12] 154,000 [45.12]

EER/SEER

2

9.7/NA 9.7/NA 9.7/NA

Nominal CFM/ARI Rated CFM [L/s] 5000/4300 [2360/2029] 5000/4300 [2360/2029] 5000/4300 [2360/2029] 5000/4300 [2360/2029]

ARI Net Cooling Capacity Btu [kW] 146,000 [42.78] 146,000 [42.78] 146,000 [42.78] 146,000 [42.78]

Net Sensible Capacity Btu [kW] 104,000 [30.47] 104,000 [30.47] 104,000 [30.47] 104,000 [30.47]

Net System Power kW 15.05 15.05 15.05 15.05

Net Weight lbs. [kg] 1047 [475] 1073 [487] 1047 [475] 1073 [487]

Integrated Part Load Value

3

10 10 10 10

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

4

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Net Latent Capacity Btu [kW] 42,000 [12.31] 42,000 [12.31] 42,000 [12.31] 42,000 [12.31]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 4 / 15 [6] 4 / 15 [6] 4 / 15 [6] 4 / 15 [6]

Refrigerant Control Orifices Orifices Orifices Orifices

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3 5 3 5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 184 56 184

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 192/192 [5443/5443] 192/192 [5443/5443] 192/192 [5443/5443] 192/192 [5443/5443]

Weights

Ship Weight lbs. [kg] 1084 [492] 1119 [508] 1084 [492] 1119 [508]

9.7/NA

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does

not include the effect of fan motor heat. ARI capacity is net and includes the effect of fan motor heat. Units are suitable

for operation to

20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner Equipment

certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Integrated Part Load Value is rated in accordance with ARI Standard 210/240 or 360. Units are rated at 80° F ambient,

80° F entering dry bulb, and 67° F entering wet bulb at ARI rated cfm.

4. Heating Performance limit settings and rating data were established and approved under laboratory test conditions

using American National Standard Institute standards. Ratings shown are for elevations up to 2000 feet. For elevations

above 2000 feet, ratings should be reduced at the rate of 4% for each 1000 feet above se

a level.

5. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

Page 13

IM 866

13

Electrical Data

ELECTRICAL DATA

Minimum Circuit Ampacity 44/44

Unit Information

Unit Operating

Voltage Range

187-253

Minimum Overcurrent

Protection Device Size

50/50

Maximum Overcurrent

Protection Device Size

50/50

Compressor Motor

No. 2

Volts 200/240

Phase 3

HP 3 1/3

RPM 3450

Amps (RLA) 13/13

Amps (LRA) 88/88

Condenser Motor

No. 2

Volts 208/230

Phase 1

HP 1/3

Amps (FLA) 6

Amps (LRA) 4.7

Evaporator Fan

No. 1

Volts 208/230

Phase 3

HP 2

Amps (FLA) 8

Amps (LRA) 56 56

13

2

3

208/230

1

4.7

6

1/3

1

208/230

2

88/88

13/13

3450

3 1/3

3

200/240

2

60/60

60/60

49/49

187-253

28

4

2

3

460

1

2.4

4

1/3

1

460

2

44

7

3450

3 1/2

3

480

2

30

30

24

414-506

38.1

7

3

3

460

1

2.4

4

1/3

1

460

2

44

7

3450

3 1/2

3

480

2

30

30

27

414-506

19

4

2

3

575

1

1.5

2

1/3

1

575

2

34

5

3450

3 1/2

3

600

2

20

20

18

518-632

19

8

2

3

575

1

1.5

2

1/3

1

575

2

34

5

3450

3 1/2

3

600

2

30

25

22

518-632

007AYCL 007AYCM 007AYDL 007AYDM 007AYYL 007AYYM

1. Horsepower Per Compressor.

2. Amp Draw Per Motor. Multiply Value By Number of Motors to Determine Total Amps.

ELECTRICAL DATA

Minimum Circuit Ampacity 44/44

Unit Information

Unit Operating

Voltage Range

187-253

Minimum Overcurrent

Protection Device Size

50/50

Maximum Overcurrent

Protection Device Size

50/50

Compressor Motor

No. 2

Volts 200/230

Phase 3

HP 4

RPM 3450

Amps (RLA) 13.3/13.3

Amps (LRA) 91/91

Condenser Motor

No. 2

Volts 208/230

Phase 1

HP 1/3

Amps (FLA) 6

Amps (LRA) 4.7

Evaporator Fan

No. 1

Volts 208/230

Phase 3

HP 2

Amps (FLA) 8

Amps (LRA) 56 74.5

13

3

3

208/230

1

4.7

6

1/3

1

208/230

2

91/91

13.3/13.3

3450

4

3

200/230

2

60/60

60/60

49/49

187-253

28

4

2

3

460

1

2.4

4

1/3

1

460

2

50

7.1

3450

4

3

460

2

30

30

24

414-506

38.1

7

3

3

460

1

2.4

4

1/3

1

460

2

50

7.1

3450

4

3

460

2

30

30

27

414-506

19

4

2

3

575

1

1.5

2

1/3

1

575

2

37

5.5

3450

4

3

575

2

20

20

19

518-632

20

8

3

3

575

1

1.5

2

1/3

1

575

2

37

5.5

3450

4

3

575

2

30

25

23

518-632

008AYCL 008AYCM 008AYDL 008AYDM 008AYYL 008AYYM

1. Horsepower Per Compressor.

2. Amp Draw Per Motor. Multiply Value By Number of Motors to Determine Total Amps.

Page 14

14 IM 866

Electrical Data

ELECTRICAL DATA

Minimum Circuit Ampacity 53/53

Unit Information

Unit Operating

Voltage Range

187-253

Minimum Overcurrent

Protection Device Size

60/60

Maximum Overcurrent

Protection Device Size

60/60

Compressor Motor

No. 2

Volts 200/240

Phase 3

HP 5

RPM 3450

Amps (RLA) 17/17

Amps (LRA) 124/124

Condenser Motor

No. 2

Volts 208/230

Phase 1

HP 1/3

Amps (FLA) 6

Amps (LRA) 4.7

Evaporator Fan

No. 1

Volts 208/230

Phase 3

HP 2

Amps (FLA) 8

Amps (LRA) 56 74.5

13

3

3

208/230

1

4.7

6

1/3

1

208/230

2

124/124

17/17

3450

5

3

200/240

2

70/70

70/70

58/58

187-253

28

4

2

3

460

1

2.4

4

1/3

1

460

2

59.6

9

3450

5

3

480

2

35

35

29

414-506

38.1

7

3

3

460

1

2.4

4

1/3

1

460

2

59.6

9

3450

5

3

480

2

40

40

32

414-506

19

4

2

3

575

1

1.5

2

1/3

1

575

2

49.4

7

3450

5

3

600

2

25

25

22

518-632

20

8

3

3

575

1

1.5

2

1/3

1

575

2

49.4

7

3450

5

3

600

2

30

30

26

518-632

010AYCL 010AYCM 010AYDL 010AYDM 010AYYL 010AYYM

1. Horsepower Per Compressor.

2. Amp Draw Per Motor. Multiply Value By Number of Motors to Determine Total Amps.

ELECTRICAL DATA

Minimum Circuit Ampacity 71/71

Unit Information

Unit Operating

Voltage Range

187-253

Minimum Overcurrent

Protection Device Size

80/80

Maximum Overcurrent

Protection Device Size

90/90

Compressor Motor

No. 2

Volts 208/230

Phase 3

HP 6

RPM 3450

Amps (RLA) 21.9/21.9

Amps (LRA) 156/156

Condenser Motor

No. 2

Volts 208/230

Phase 1

HP 1/3

Amps (FLA) 6

Amps (LRA) 4.7

Evaporator Fan

No. 1

Volts 208/230

Phase 3

HP 3

Amps (FLA) 15

Amps (LRA) 74.5 82.6

15

5

3

208/230

1

4.7

6

1/3

1

208/230

2

156/156

21.9/21.9

3450

6

3

208/230

2

90/90

80/80

71/71

187-253

38.1

7

3

3

460

1

2.4

4

1/3

1

460

2

75

10.9

3450

6

3

460

2

45

40

36

414-506

41.3

10

5

3

460

1

2.4

4

1/3

1

460

2

75

10.9

3450

6

3

460

2

45

45

39

414-506

20

8

3

3

575

1

1.5

2

1/3

1

575

2

54

8.9

3450

6

3

575

2

35

35

31

518-632

33

8

5

3

575

1

1.5

2

1/3

1

575

2

54

8.9

3450

6

3

575

2

35

35

31

518-632

012AYCL 012AYCM 012AYDL 012AYDM 012AYYL 012AYYM

1. Horsepower Per Compressor.

2. Amp Draw Per Motor. Multiply Value By Number of Motors to Determine Total Amps.

Page 15

IM 866

15

Installation

General

1 PRE-INSTALLATION CHECK-POINTS

Before attempting any installation, the following points

should be carefully considered:

a Structural strength of supporting members.

(rooftop installation)

b Clearances and provision for servicing.

c Power supply and wiring.

d Air duct connections.

e Drain facilities and connections.

f Location for minimum noise.

2 LOCATION

These units are designed for outdoor installations. They

can be mounted on a slab or rooftop. They are not to be

installed within any part of a structure such as an attic,

crawl space, closet, or any other place where condenser

air flow is restricted or other than outdoor ambient conditions prevail. Since the application of the units is of the

outdoor type, it is important to consult your local code

authorities at the time the first installation is made.

Outside Slab Installation

(Typical outdoor slab installations are shown in Figures 7 and 8.)

1 Select a location where external water drainage cannot

collect around the unit.

2 Provide a level concrete slab extending 3" [76.2 mm]

beyond all four sides of the unit. The slab should be sufficient above grade to prevent ground water from entering

the unit. IMPORTANT: To prevent transmission of noise or

vibration, slab should not be connected to building structure.

3 The location of the unit should be such as to provide

proper access for inspection and servicing.

4 Locate unit where operating sounds will not disturb

owner or neighbors.

5 Locate unit so roof runoff water does not pour directly on

the unit. Provide gutter or other shielding at roof level.

Do not locate unit in an area where excessive snow drifting may occur or accumulate.

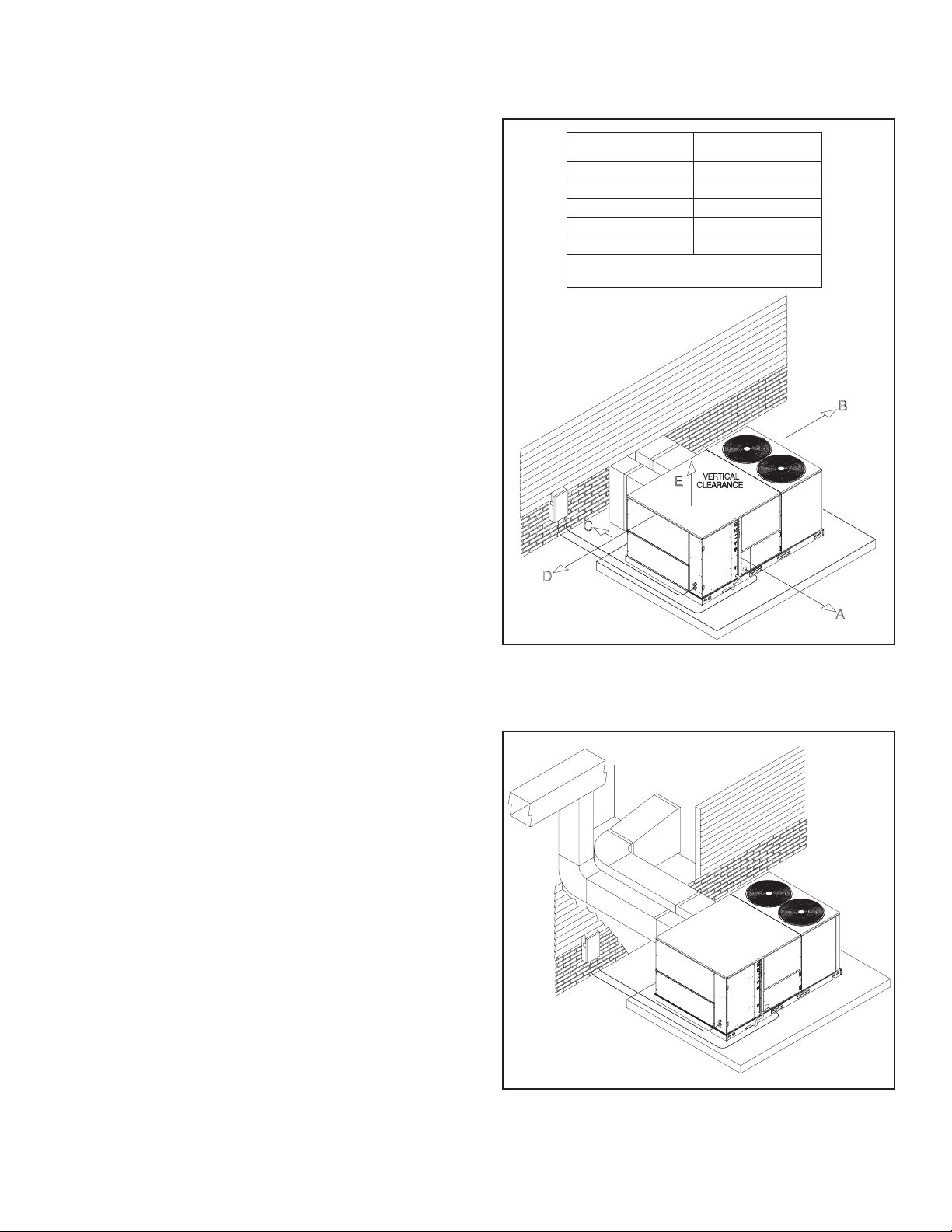

Clearances

The following minimum clearances must be observed for

proper unit performance and serviceability.

1 Provide 48" [1219.2 mm] minimum clearance at the front

of the unit. Provide 18" [457.2 mm] minimum clearance

at all other sides of the unit.

2 Provide 60" [1524 mm] minimum clearance between top

of unit and maximum 3 foot [.91 m] overhang.

3 Unit is design certified for application on combustible

flooring with 0" [0 mm] minimum clearance.

4 See Figure 7 for illustration of minimum installation-ser-

vice clearances.

Figure 7: Outside Slab Installation, Basement or Crawl

Space Distribution System

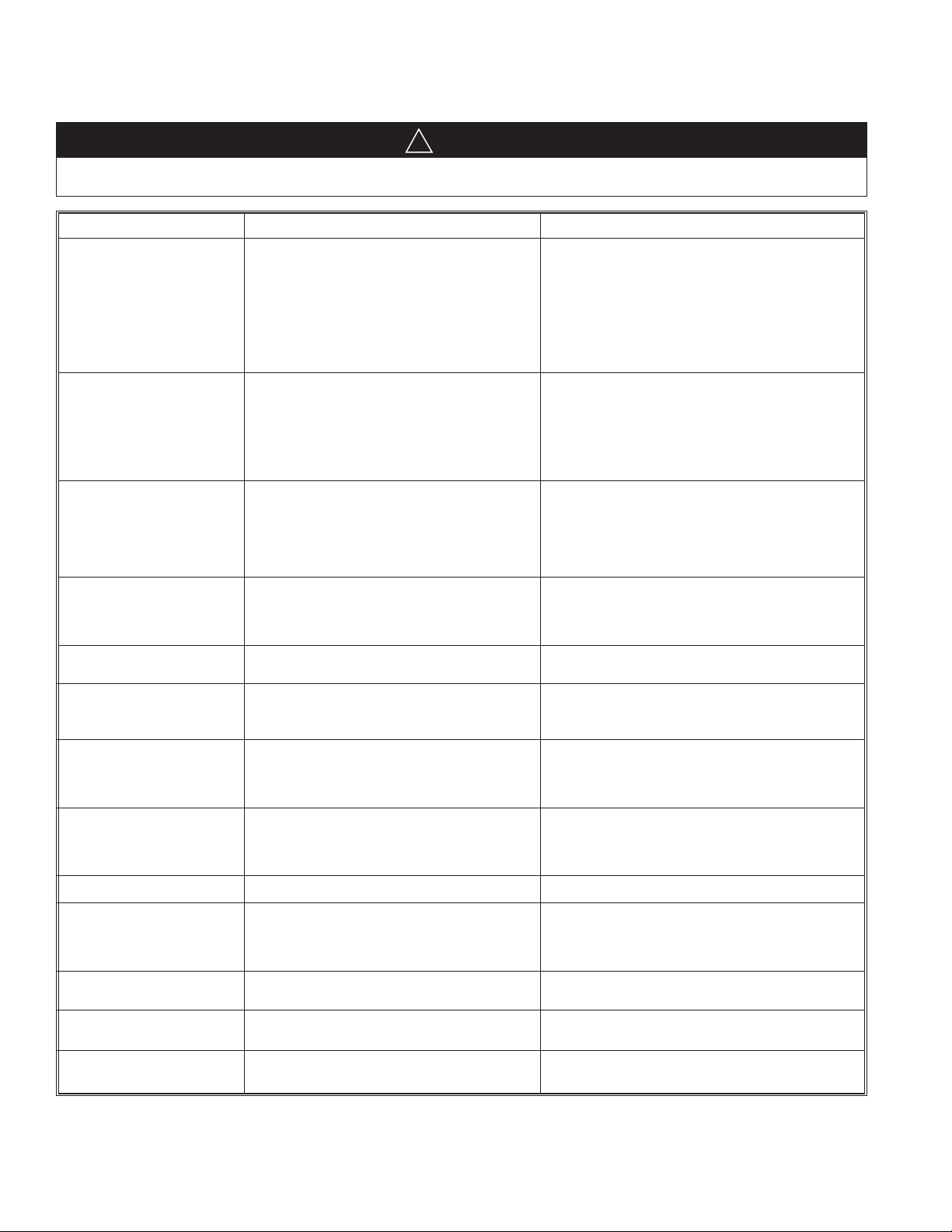

Figure 8: Outside Slab Installation, Closet Distribution

System. Slab Floor Construction

A0739-03

A0741-03

Recommended

Clearance

Location

48” [1219.2 mm] A - Front

18” [457.2 mm] B - Condenser Coil

18” [457.2 mm] C - Duct Side

18”* [457.2 mm] D - Evaporator End

60” [1524 mm] E - Above

*Without Economizer. 48” [1219.2 mm] With

*Economizer

Page 16

16 IM 866

Rooftop Installation

1 Before locating the unit on the roof, make sure that the

strength of the roof and beams is adequate at that point to

support the weight involved. This is very important and

user’s responsibility.

2 For rigging and roofcurb details, see Figures 9 and 10.

Use field-furnished spreaders.

3 For roofcurb assembly, see Roofcurb Installation Instruc-

tions.

4 If the roofcurb is not used, provisions for disposing of

condensate water runoff must be provided.

5 The unit should be placed on a solid and level roofcurb or

platform of adequate strength. See Figure 11.

6 The location of the unit on the roof should be such as to

provide proper access for inspection and servicing.

IMPORTANT: If unit will not be put into service immediately,

cover supply and return openings to prevent excessive condensation.

Figure 9: Rigging For Lifting

A0719-02

A0719-03

CORNER WEIGHTS BY PERCENTAGE

ABCD

33% 27% 17% 23%

Figure 10: Roofcurb Installation

A0744-03

.63” [14.9 mm] SHACKLE

(EACH CORNER)

41.19”

[1046.4 mm]

35.31”

[896.6 mm]

CENTER OF

GRAVITY

INSTALL GASKET

NAILING STRIP

DUCT FLANGE NOT

TO EXCEED 1" [25.4 mm]

UNIT

ROOFCURB

SUPPLY DUCT

CAULK ALL JOINTS

RETURN DUCT

WATERTIGHT

Page 17

IM 866

17

Ductwork

Ductwork should be fabricated by the installing contractor in

accordance with local codes and NFPA90A. Industry manuals

may be used as a guide when sizing and designing the duct

system - contact Air Conditioning Contractors of America,

1513 16th St. N.W., Washington, D.C. 20036.

The unit should be placed as close to the space to be air conditioned as possible allowing clearance dimensions as indicated.

Ducts should be run as directly as possible to supply and

return outlets. Use of non-flammable waterproof flexible connectors on both supply and return connections at the unit to

reduce noise transmission is recommended.

It is preferable to install the unit on the roof of the structure if

the registers or diffusers are located on the wall or in the ceiling. A slab installation could be considered when the registers

are low on a wall or in the floor.

On ductwork exposed to outside air conditions of temperature

and humidity, use a minimum of 2" [50.8 mm] of insulation

and a vapor barrier. Distribution system in attic, furred space

or crawl space should be insulated with at least 2" [50.8 mm]

of insulation with vapor barrier. One-half to 1" [25.4 mm]

thickness of insulation is usually sufficient for ductwork inside

the air conditioned space.

Balancing dampers should be provided for each branch duct in

the supply system. Ductwork should be properly supported

from the structure.

When installing ductwork, consider the following items:

1 Noncombustible flexible connectors should be used

between ductwork and unit to reduce noise and vibration

transmission into the ductwork.

2 When auxiliary heaters are installed, use noncombustible

flexible connectors and clearance to combustible material

of 0" [0 mm] for the first 3 feet [.91 m] of discharge duct.

Clearance to unit top and side is 0" [0 mm].

Filters

This unit is provided with 6 - 2" x 18" x 18" [51mm x 457 mm

x 457 mm] disposable filters. When replacing filters, ensure

they are inserted fully to the back to prevent bypass.

Conversion Procedure

Downflow To Horizontal

1 Remove the screws and covers from the outside of the

supply and return sections.

2 Install the covers over the bottom supply and return open-

ings, painted side up inserting the leading flange under the

bracket provided. Place the back flange to the top of the

front bracket provided. See Figure 12.

3 Secure the return and supply cover to the front bracket

with one (1) screw.

Condensate Drain

The condensate drain connection of the evaporator is

1" [25.4 mm] nominal female pipe thread. IMPORTANT:

Install a condensate trap to ensure proper condensate drainage.

See Figure 13.

FIGURE 11: Flat Rooftop Installation, Attic or Drop Ceiling

Distribution System. Mounted on Roofcurb. Curb Must Be

Level

A0742-04

Figure 12: Cover Gasket Detail

A0725-01

REAR PANEL

FRONT BRACKET

SUPPLY OR RETURN COVER

INSULATION

BACK

BRACKET

INSULATION

BASE PAN

BASE RAIL

NOTE: COVER SLIDES

UNDER BACK

BRACKET FLANGE.

NOTE: COVER FITS ON

TOP OF FRONT

BRACKET FLANGE.

Do not, under any circumstances, connect return ductwork

to any other heat producing device such as a fireplace

insert, stove, etc. Unauthorized use of such devices may

result in fire, carbon monoxide poisoning, explosion, property damage, severe personal injury or death.

▲▲

DANGER

!

Page 18

18 IM 866

Electrical Wiring

Field wiring must comply with the National Electrical Code

(CEC in Canada) and local ordinances that may apply.

Power Wiring

1 This unit incorporates single-point electrical connections

for the unit and electric heat accessory.

2 It is important that proper electrical power is available to

the unit. Voltage should not vary more than 10% from the

values marked on the unit rating plate. Phase voltages must

be balanced within 3%.

3 For branch circuit wiring (main power supply to unit dis-

connect), the minimum wire size can be determined from

Table 1 using the circuit ampacity found on the unit

nameplate or from Tables 3, 4, 5 and 6.

4 The branch circuit wire must be sized in accordance with

the National Electrical Code (C.E.C. in Canada) and local

ordinances that may apply using the minimum circuit

ampacity found on the unit rating plate.

5 Field-installed power wiring must be run through grounded

rain-tight conduit attached to the unit power entry panel

and connected as follows:

UNITS WITHOUT ELECTRIC HEAT - Connect

power wiring to the power terminal block located on the

left side of the electric heat compartment. Connect the

ground wire to the adjacent ground lug.

UNITS WITH FACTORY INSTALLED ELECTRIC

HEAT - Connect power wiring to the power terminal

block located on the electric heater kit. Connect the ground

wire to the adjacent ground lug. DO NOT connect aluminum wiring directly to the electric heater terminal block.

Wiring to the unit contactors is factory-connected.

6 For field installation of an electric heater kit, follow the

instructions below. Refer to the information supplied with

the kit.

a Removing screws as required, open heater access door

and detach adjacent power entry panel.

b Remove wires to unit contactor (1L1, 1L2, 1L3) from

unit terminal block on the left side of the electric heat

compartment. Remove and discard the terminal block

and the adjacent ground lug.

c Remove the heater kit block-off panel and install the

heater kit in its place using 9 of the 12 screws previously

removed.

d Connect the unit contactor wires (1L1, 1L2, 1L3) to the

compressor fuse block on the heater kit.

e Re-install the power entry panel & run conduit and the

proper size field wiring through the opening in the

panel.

f Connect field wiring to the power terminal block located

on the electric heater kit. Connect ground wire to the

adjacent ground lug.

Figure 14:Branch Circuit Disconnect Location

A0742-04

Figure 13: Condensate Drain

3”

[76 mm]

3”

[76 mm]

TABLE 1: COPPER WIRE SIZE — AWG (1% VOLTAGE DROP)

300

250

200

150

100

50

Supply

Wire

Length

Feet

4

4

6

8

10

14

15

3

4

4

6

8

12

20

2

3

4

6

8

10

25

2

3

4

4

6

10

30

1

2

3

4

6

8

35

1/0

1

2

4

6

8

40

1/0

1

2

3

4

6

45

2/0

1/0

1

3

4

6

50

2/0

1/0

1

2

4

6

55

3/0

2/0

1/0

2

3

4

60

3/0

2/0

1/0

1

3

4

65

3/0

2/0

1/0

1

2

4

70

4/0

3/0

2/0

1/0

2

3

75

4/0

3/0

2/0

1/0

2

3

80

4/0

3/0

2/0

1/0

1

3

85

4/0

4/0

3/0

1/0

1

2

90

250

4/0

3/0

2/0

1

2

95

250

4/0

3/0

2/0

1

2

100

250

4/0

3/0

2/0

1

2

105

250

4/0

3/0

2/0

1/0

2

110

300

250

4/0

2/0

1/0

1

115

300

250

4/0

3/0

1/0

1

120

300

250

4/0

3/0

1/0

1

125

Circuit Ampacity

NOTE:

1. Wire size based on 60ºC type copper conductors below 100 ampacity. 2. Wire size based on 75ºC type copper conductors for 100 ampacity and above.

Page 19

IM 866

19

g Connect heater kit control plug to the receptacle on the

control wiring harness.

h Close heater access door and secure with screws previ-

ously removed.

Control Wiring (Class II)

1 Low voltage wiring should not be run in conduit with

power wiring.

2 Control wiring is routed through the 7/8" [22 mm] hole in

the unit side panel. See Figures 1 & 15. Use a minimum

#18 AWG thermostat wire. For wire lengths exceeding

50' [15.24 m] use #16 AWG thermostat wire. Connect the

control wiring to the low voltage terminal block located

below the unit control box.

3 It is necessary that only approved thermostats be used.

Please contact your McQuay Representative.

4 Figure 17 shows representative low voltage connection

diagrams. Read your thermostat installation instructions

for any special requirements for your specific thermostat.

Internal Wiring

1 A diagram of the internal wiring of this unit is located on

the inside of the control access panel and in this manual. If

any of the original wiring must be replaced, the wire gauge

and insulation must be the same as original wiring.

208 Volt Applications

Transformer is factory-wired for 220 volts on 200/220 volt

models and must be changed for 200-volt applications. See unit

wiring diagram for 200-volt wiring.

Grounding

GROUNDING MAY ALSO BE ACCOMPLISHED BY

GROUNDING THE POWER LINE CONDUIT TO THE

UNIT. MAKE SURE THE CONDUIT NUT LOCKING

TEETH HAVE PIERCED THE INSULATING PAINT FILM

OF THE SIDE PANEL.

Thermostat

The thermostat should be mounted on an inside wall about

five feet above the floor in a location where it will not be

affected by unconditioned air, sun, or drafts from open doors

or other sources. READ installation instructions in air conditioner thermostat package CAREFULLY because each has

some different wiring requirements.

The low voltage wiring should be sized as shown in Table 2.

Install the room thermostat in accordance with the instruction

sheet packed in the box with the thermostat.

A0728-02

A0728-03

Figure 15: Base Entry Locations

(2) CAP

PLUGS

SIDE

CONTROL

ENTRY

BASE

CONTROL

ENTRY

SIDE

POWER

ENTRY

BASE

POWER

ENTRY

Figure 16

The unit must be permanently grounded. A grounding lug is

provided in the electric heat access area for a ground wire.

Failure to ground this unit can result in fire or electrical

shock causing property damage, severe personal injury or

death.

▲▲

DANGER

!

Table 2

FIELD WIRE SIZE FOR 24 VOLT THERMOSTAT CIRCUITS

SOLID COPPER WIRE - AWG.

3.0 16 14 12 10 10 10

2.5 16 14 12 12 12 10

2.0 18 16 14 12 12 10

50 100 150 200 250 300

Length of Run – Feet (1)

Thermostat Load -

Amps

(1) The total wire length is the distance from the furnace to the thermostat and back to the furnace.

NOTE: DO NOT USE CONTROL WIRING SMALLER THAN NO. 18

AWG.

Page 20

20 IM 866

Indoor Air Flow Data

Belt-drive blower models have motor sheaves set for proper

CFM at a typical external static. See Tables C through G for

blower performance.

Crankcase Heat (Optional)

Crankcase heat is not required on scroll type compressors, but

may be desirable under certain conditions.

Pre-Start Check

1 Is unit properly located and slightly slanted toward indoor

condensate drain?

2 Is ductwork insulated, weatherproofed, with proper spac-

ing to combustible materials?

3 Is air free to travel to and from outdoor coil? (See Figure

5.)

4 Is the wiring correct, tight, and according to unit wiring

diagram?

5 Is unit grounded?

6 Are field supplied air filters in place and clean?

7 Do the outdoor fan and indoor blower turn freely without

rubbing, and are they tight on the motor shafts?

Startup

1 Turn thermostat to “OFF,” turn “on” power supply at

disconnect switch.

2 Turn temperature setting as high as it will go.

3 Turn fan switch to “ON.”

4 Indoor blower should run. Be sure it is running in the

right direction.

5 Turn fan switch to “AUTO.” Turn system switch to

“COOL” and turn temperature setting below room temperature. Unit should run in cooling mode.

6 Is outdoor fan operating correctly in the right direction?

7 Is compressor running correctly.

Record the following after the unit has run some time.

a Operating Mode _____________________________

b Discharge Pressures (High) ___________PSIG [kPa]

c Vapor Pressure at Compressors (Low)___PSIG [kPa]

d Vapor Line Temperature at Compressors ___°F [C°].

e Indoor Dry Bulb_______________________°F [C°].

f Indoor Wet Bulb ______________________°F [C°].

g Outdoor Dry Bulb _____________________°F [C°].

h Outdoor Wet Bulb _____________________°F [C°].

i Voltage at Contactor _____________________Volts

j Current at Contactors ____________________ Amps

k Model Number ______________________________

A0823-01

Figure 17: Thermostat Connections Diagram

Page 21

IM 866

21

l Serial Number_______________________________

m Location ___________________________________

n Owner _____________________________________

o Date_______________________________________

8 Turn thermostat system switch to “HEAT.” Unit com-

pressors should stop. Raise temperature setting to above

room temperature. Unit should run in heating mode and

auxiliary heaters, if installed, should come on.

9 Check the refrigerant charge using the instructions

located on unit charging chart. Replace service port

caps. Service port cores are for system access only and

will leak if not tightly capped.

10 Adjust discharge air grilles and balance system.

11 Check ducts for condensation and air leaks.

12 Check unit for tubing and sheet metal rattles.

13 Instruct the owner on operation and maintenance.

14 Leave “INSTALLATION” and ”USE AND CARE“

instructions with owner

Operation

Cooling Mode

With thermostat in the cool mode, fan auto and the room temperature higher than the thermostat setting:

1 Indoor blower contactor is energized through thermostat

contact (G).

2 Compressor contactors are energized through thermostat

contacts (Y1) & (Y2) and high pressure controls.

3 Economizer enthalpy control (if installed) controls opera-

tion of first-stage cooling and positions fresh air damper

to maintain mixed air temperature. Second-stage cooling

operates normally as required by second stage of thermostats.

4 The system will continue in cooling operation as long as

all safety controls are closed, until the thermostat is satisfied.

Heating Mode

With the thermostat in heat mode, fan on auto, and the room

temperature lower than the thermostat setting, the Indoor

blower contactor is energized through thermostat contact (G).

In the heating mode, the thermostat will energize one or more

supplementary heaters.

Miscellaneous

Replacement Parts

To find your local McQuay Certified Parts Distributor, go to

www.mcquay.com and select Parts Locator.

Only electric heater kits supplied by this manufacturer as

described in this publication have been designed, tested,

and evaluated for use with this unit. Use of any other manufactured electric heaters installed within this unit may cause

hazardous conditions resulting in property damage, fire,

bodily injury or death.

▲▲

DANGER

!

Page 22

22 IM 866

AIR-FLOW DATA 7.5 TON [26.4 kW] MODELS

AIRFLOW DATA TABLES

Page 23

IM 866

23

AIR-FLOW DATA 8.5 TON [29.9 kW] MODELS

Page 24

24 IM 866

AIR-FLOW DATA 10 TON [35.2 kW] MODELS

Page 25

IM 866

25

AIR-FLOW DATA 12.5 TON [44 kW] MODELS

COMPONENT AIR RESISTANCE

IWC 12.5 TON [44 kW]

AIRFLOW CORRECTION FACTORS

12.5 TON [44 kW]

Page 26

26 IM 866

Heater Kit Characteristics

Table 3: Auxiliary Heater Kits Characteristics and Application (7.5 Ton [26.4 kW] Models)

UNIT MODEL

NUMBER

MPS

007AYCL

007AYCM

007AYDL

007AYDM

007AYYL

007AYYM

REBMUN

-BMLR

LC090A

MC090A

LD090A

LEDOMTINU

TIKRETAEH

.ONLEDOM

-JJXR

ENON

C01CC

C51CC

C02CC

C03CC

C13CC

C04CC

C14CC

ENON

C01CC

C51CC

C02CC

C03CC

C13CC

C04CC

4CC

C1

ENON

D01CC

D51CC

D02CC

D03CC

D13CC

D04CC

D14CC

—

—

—

WkRETAEH

V042/802@

—

6.9/2.7

4.41/8.01

2.91/4.41

8.82/6.12

8.82/6.12

4.83/8.82

4.83/8.82

—

6.9/2.7

4.41/8.01

2.91/4.41

8.82/6.12

8.82/6.12

4.83/8.82

4.83/8.82

V084@

6.9

4.41

2.91

8.82

8.82

4.83

4.83

6

—

ALFTIKRETAEH

1.32/0.02

6.43/0.03

2.64/0.04

3.96/0.06

3.96/0.06

4.29/1.08

4.29/1.08

1.32/0.02

6.43/0.03

2.64/0.04

3.96/0.0

3.96/0.06

4.29/1.08

4.29/1.08

42

5

.11

3.71

1.32

6.43

6.43

2.64

2.64

42

72

43

94

94

36

36

.TKC.NIMTINU

YTICAPMA

34/34

34/34

45/84

86/16

79/68

79/68

621/111

621/111

94/94

94/94

06/45

47/76

301/29

301/29

231/711

231/711

ROESUF.XAM

EZIS.RKB.TKC

TSUM.RKB.TKC(

EPYTRCAHEB

)ASUROF

05/05

05/05

06/05

07/07

001/09

001/09

051/521

051/521

06/06

06/06

06/06

08/07

011/001

011/001

051/521

051/521

03

03

03

53

05

05

07

07

MD090A

0A

MY090A

ENON

D01CC

D51CC

D02CC

D03CC

D13CC

D04CC

4CC

D1

ENON

Y01CC

LY09

Y51CC

Y02CC

Y03CC

Y04CC

ENON

Y01CC

Y51CC

Y02CC

Y03CC

Y04CC

—

6.9

4.41

2.91

8.82

8.82

4.83

4.83

V006@

—

6.9

4.41

2.91

8.82

4.83

—

6.9

4.41

2.91

8.82

4.83

—

—

—

72

5.11

3.71

1.32

6.43

6.43

2.64

2.64

2.9

9.31

5.81

7.72

0.73

2.9

9.31

5.81

7.72

0.73

72

13

83

25

25

76

76

81

81

32

92

04

25

22

22

82

43

54

75

03

03

53

04

06

06

07

07

02

02

52

03

04

06

52

52

03

53

54

06

Page 27

IM 866

27

Heater Kit Characteristics (continued)

Table 4: Auxiliary Heater Kits Characteristics and Application (8.5 Ton [29.9 kW] Models)

008AYCL

008AYCM

008AYDL

008AYDM

008AYYL

008AYYM

UNIT MODEL

NUMBER

MPS

REBMUN

-BMLR

LC201A

MC201A

LD201A

LEDOMTINU

TIKRETAEH

.ONLEDOM

-JJXR

ENON

C01CC

C51CC

C02CC

C03CC

C13CC

C04CC

C14CC

ENON

C01CC

C51CC

C02CC

C03CC

C13CC

C04CC

4CC

C1

ENON

D01CC

D51CC

D02CC

D03CC

D13CC

D04CC

D14CC

—

—

—

WkRETAEH

V042/802@

—

6.9/2.7

4.41/8.01

2.91/4.41

8.82/6.12

8.82/6.12

4.83/8.82

4.83/8.82

—

6.9/2.7

4.41/8.01

2.91/4.41

8.82/6.12

8.82/6.12

4.83/8.82

4.83/8.82

V084@

6.9

4.41

2.91

8.82

8.82

4.83

4.83

6

—

ALFTIKRETAEH

1.32/0.02

6.43/0.03

2.64/0.04

3.96/0.06

3.96/0.06

4.29/1.08

4.29/1.08

1.32/0.02

6.43/0.03

2.64/0.04

3.96/0.0

3.96/0.06

4.29/1.08

4.29/1.08

5

.11

3.71

1.32

6.43

6.43

2.64

2.64

.TKC.NIMTINU

YTICAPMA

44/44

44/44

45/84

86/06

79/58

79/58

621/111

621/111

94/94

94/94

06/45

47/76

301/29

301/29

231/711

231/711

42

42

72

43

94

94

36

36

ROESUF.XAM

EZIS.RKB.TKC

TSUM.RKB.TKC(

EPYTRCAHEB

)ASUROF

05/05

05/05

06/05

07/06

001/09

001/09

051/521

051/521

06/06

06/06

06/06

08/07

011/001

011/001

051/521

051/521

03

03

03

53

05

05

07

07

MD201A

1A

LY20

MY201A

ENON

D01CC

D51CC

D02CC

D03CC

D13CC

D04CC

4CC

D1

ENON

Y01CC

Y51CC

Y02CC

Y03CC

Y04CC

ENON

Y01CC

Y51CC

Y02CC

Y03CC

Y04CC

—

6.9

4.41

2.91

8.82

8.82

4.83

4.83

V006@

—

6.9

4.41

2.91

8.82

4.83

—

6.9

4.41

2.91

8.82

4.83

—

—

—

72

5.11

3.71

1.32

6.43

6.43

2.64

2.64

2.9

9.31

5.81

7.72

0.73

2.9

9.31

5.81

7.72

0.73

72

13

83

25

25

76

76

91

91

32

92

04

25

32

32

82

43

54

75

03

03

53

04

06

06

07

07

02

02

52

03

04

06

52

52

03

53

54

06

Page 28

28 IM 866

Heater Kit Characteristics (continued)

Table 5: Auxiliary Heater Kits Characteristics and Application (10 Ton [35.2 kW] Models)

010AYCL

010AYCM

010AYDL

010AYDM

010AYYL

010AYYM

UNIT MODEL

NUMBER

MPS

REBMUN

-BMLR

LC021A

MC021A

LD021A

MD021A

LY021A

MY021A

LEDOMTINU

TIKRETAEH

.ONLEDOM

-JJXR

ENON

C01CC

C51CC

C02CC

C03CC

C13CC

C04CC

C14CC

C05CC

C15CC

ENON

C01CC

C51CC

C02CC

C03CC

C13CC

C04CC

C14CC

C05CC

C15CC

ENON

D01CC

D51CC

C

D02C

D03CC

D13CC

D04CC

D14CC

D05CC

D15CC

ENON

D01CC

D51CC

D02CC

D03CC

D13CC

D04CC

D14CC

D05CC

D15CC

ENON

Y01CC

Y51CC

Y02CC

Y03CC

Y04CC

Y05CC

ENON

Y01CC

Y51CC

Y02CC

Y03CC

Y04CC

Y05CC

WkRETAEH

V042/802@

—

6.9/2.7

4.41/8.01

2.91/4.41

8.82/6.12

8.82/6.12

4.83/8.82

4.83/8.82

0.84/1.63

0.84/1.63

—

6.9/2.7

4.41/8.01

2.91/4.41

8.82/6.12

8.82/6.12

4.83/8.82

4.83/8.82

0.84/1.63

0.84/1.63

V084@

—

6.9

4.41

2.91

8.82

8.82

4.83

4.83

0.84

0.84

—

6.9

4.41

2.91

8.82

8.82

4.83

4.83

0.84

0.84

V006@

—

6.9

4.41

2.91

8.82

4.83

0.84

—

6.9

4.41

2.91

8.82

4.83

0.84

4

ALFTIKRETAEH

—

1.32/0.02

6.43/0.03

2.64/0.04

3.96/0.06

3.96/0.06

4.29/1.08

4.29/1.08

5.511/0.001

5.511/1.001

—

1.32/0.02

6.43/0.03

2.64/0.04

3.9

6/0.06

3.96/0.06

4.29/1.08

4.29/1.08

5.511/0.001

5.511/1.001

—

5.11

3.71

1.32

6.43

6.43

2.64

2.64

7.75

7

.75

—

5.11

3.71

1.32

6.43

6.43

2.64

2.64

7.75

7.75

—

2.9

9.31

5.81

7.72

0.73

2.6

—

2.9

9.31

5.81

7.72

0.73

2.64

.TKC.NIMTINU

YTICAPMA

95/95

95/95

95/95

86/16

79/68

79/68

621/111

621/111

551/631

551/631

35/35

35/35

45/35

86/06

79/58

79/58

621/111

621/111

1/631

55

551/631

92

92

92

43

94

94

36

36

87

87

23

23

23

83

25

25

76

76

18

18

22

22

32

92

04

25

36

62

62

82

43

54

75

86

ROESUF.XAM

EZIS.RKB.TKC

TSUM.RKB.TKC(

EPYTRCAHEB

)ASUROF

07/07

07/07

07/07

07/07

001/09

001/09

051/521

051/521

571/051

571/051

06/06

06/06

06/06

07/06

001/09

001/09

051/521

051/521

571/051

571/051

53

53

53

53

05

05

07

07

08

08

04

04

04

04

06

6

0

07

07

09

09

52

52

52

03

04

06

07

03

03

03

53

54

06

07

Page 29

IM 866

29

Heater Kit Characteristics (continued)

Table 6: Auxiliary Heater Kits Characteristics and Application (12.5 Ton [44 kW] Models)

012AYCL

012AYCM

012AYDL

012AYDM

012AYYL

012AYYM

UNIT MODEL

NUMBER

MPS

REBMUN

-BMLR

LC051A

MC051A

LD051A

MD051A

LY051A

MY051A

LEDOMTINU

TIKRETAEH

.ONLEDOM

-JJXR

ENON

C01CC

C51CC

C02CC

C03CC

C13CC

C04CC

C14CC

C05CC

C15CC

ENON

C01CC

C51CC

C02CC

C03CC

C13CC

C04CC

C14CC

C05CC

C15CC

ENON

D01CC

51CC

D

D02CC

D03CC

D13CC

D04CC

D14CC

D05CC

D15CC

ENON

D01CC

D51CC

D02CC

D03CC

D13CC

D04CC

D14CC

D05CC

D15CC

ENON

Y01CC

Y51CC

Y02CC

Y03CC

Y13CC

Y04CC

Y14CC

Y05CC

ENON

Y01CC

Y51CC

Y02CC

Y03CC

Y13CC

Y04CC

Y14CC

Y05CC

WkRETAEH

V042/802@

—

6.9/2.7

4.41/8.01

2.91/4.41

8.82/6.12

8.82/6.12

4.

83/8.82

4.83/8.82

0.84/1.63

0.84/1.63

—

6.9/2

.7

4.41/8.01

2.91/4.41

8.82/6.12

8.82/6.12

4.83/8.82

4.83/8.82

0.84/1.63

0.84/1.63

V084@

—

6.9

4.41

2.91

8.82

8.82

4.83

4.83