Page 1

Installation and Maintenance Manual IM 921-1

Accessories for Maverick™ I

Commercial Packaged Rooftop Systems

Models MPS003 – 025

3 to 25 Tons

R-410A Refrigerant

Group: Applied Systems

Part Number: IM 921-1

Date: May 2010

Note: This manual is a collection of various installation manuals for accessories that may be purchased separately. To print this manual with

page numbers showing, choose “Documents and Markups” from the Adobe

© 2010 McQuay International

®

Reader® print option settings.

Page 2

INSTALLATION INSTRUCTIONS

MODELS (-)XRX-BGF03 & (-)XRX-BGF04/BGF06

ECONOMIZER POWER EXHAUST

WARN ING

This installation shall be carried out by a manufacturer's authorized representative, in accordance with the

requirements of the manufacturer. Failure to follow instructions can result in fire or explosion, causing property

damage, severe personal injury, or death. The qualified service personnel performing this work assumes

responsibility for this installation.

IM POR TANT

Damage to the product, resulting from failure to follow instructions or use of unauthorized parts, may be exclude from

the manufacturer's product warranty coverage.

WARN ING

Turn off electrical power and turn off main gas supply before beginning modification. Failure to do so can

cause electrical shock, explosion, or fire, resulting in property damage, personal injury, or death.

TOOLS RE QUIRED FOR IN STAL LA TION:

3

" electric drill with

8

1

" diameter drill bit for sheet metal.

8

5

" socket

16

(-)XRX-BGF04

PACK AGE CON TENTS

ITEM DE SCRIP TION PART No. PART No.

1 Power Exhaust Assembly 6046520 / PEA 6046508 / PEA

2 Fan Blade 6046520 / 3464 6046508 / 3464

3 Fan Motor 208-230 volt / 1 phase (C) 6046520 / 3675 6046508 / 3675

4 Fan Motor 460 volt / 1 phase (D) 6046520 / 3675 6046508 / 3675

5 Fan Motor 575 volt / 1 phase (Y) 6046520 / 3698 6046508 / 3968

6 Relay (R1) 6046520 / 3400 6046508 / 3400

7 Fuse Block 6046520 / 3370 6046508 / 3370

8 Barometric Relief Adaptor 6046520 / ADP 6046508 / ADP

(-)XRX-BGF06

Power Exhaust

C, D, Y Voltage

(-)XRX-BGF03

Power Exhaust

C, D, Y Voltage

Page 3

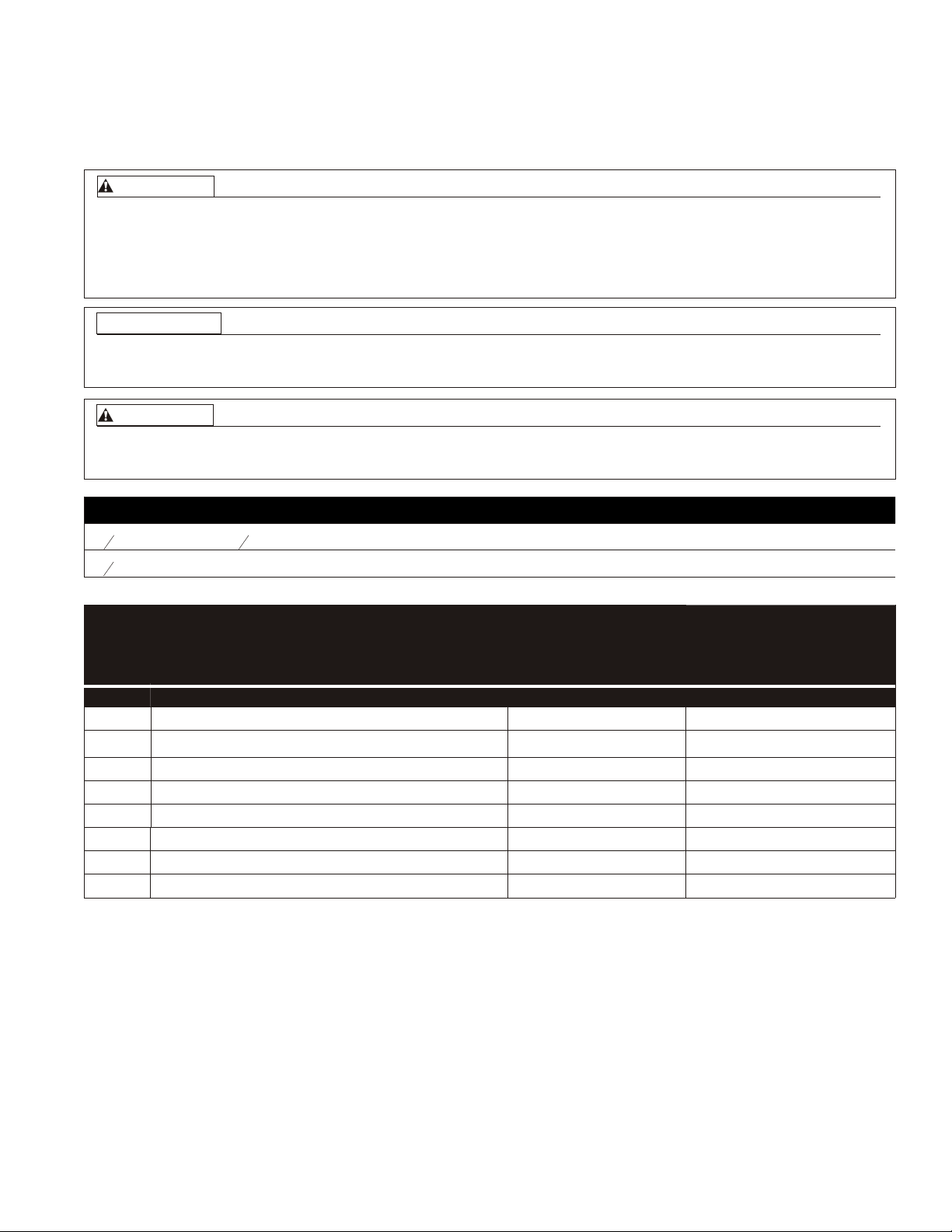

Step 1:

Remove lower barometric relief hood. Remove relief damper section from economizer or duct work.

Step 2:

Place relief damper section onto barometric relief damper adapter and secure with screws provided with power exhaust.

Step 3:

Place relief damper assembly into lower hood assembly where prepunched holes are in hood sides with screws from Step

1.

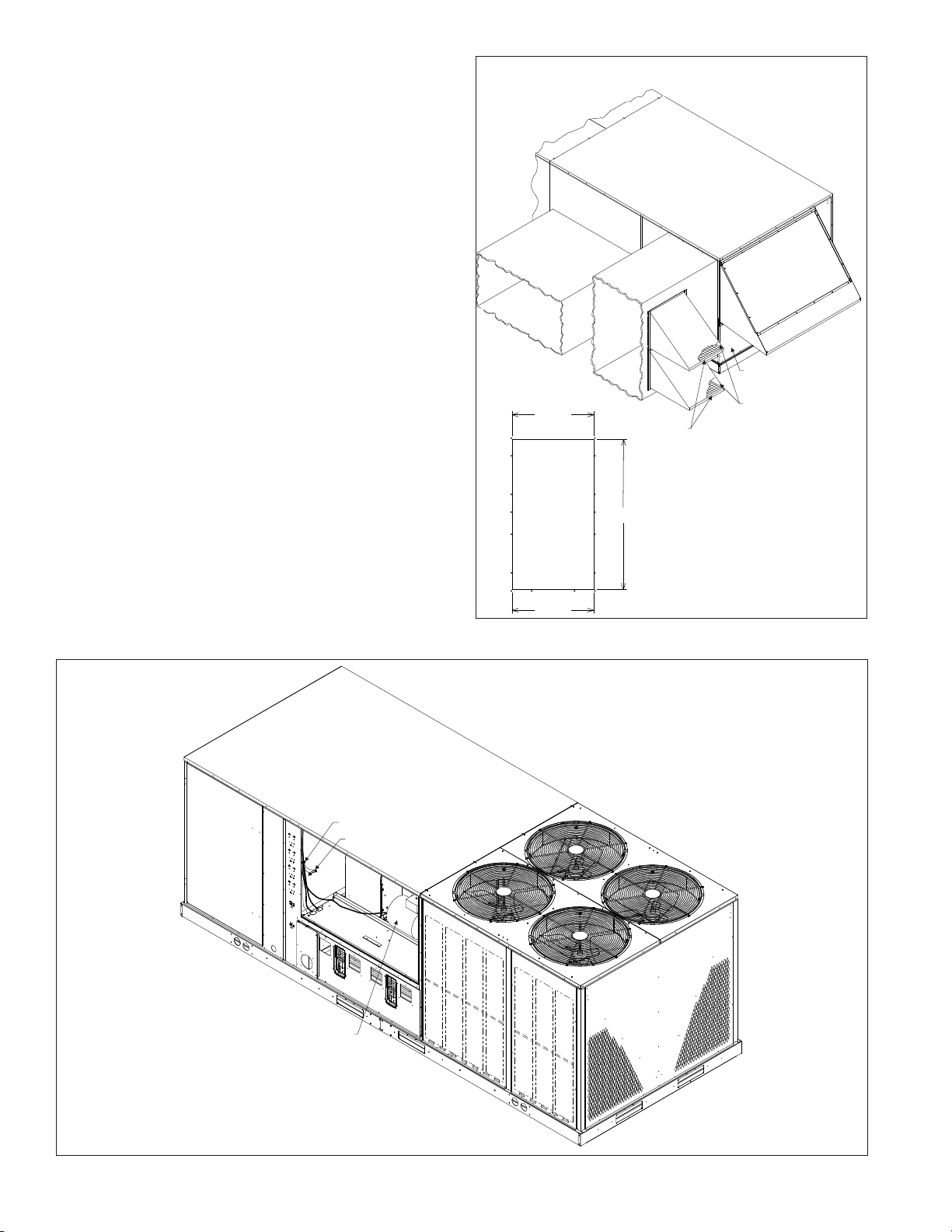

Horizontal Application:

Step 4:

Place power exhaust over hole in duct work and secure to duct work. Adjust support legs to level power exhaust. See

Figure 1.

Vertical Application:

Step 5:

Place over hole where hood was located and secure. See Figure 2.

MODEL "A"

3 - 6 TON 23.750 REF

7 ½ TON 29.750 REF.

RETURN DUCT TO BE

PROPERLY SIZED FOR

AIRFLOW OF SPECIFIC

INSTALLATION

A

FIGURE1

2

SECURE TO DUCT WORK

PREPUNCHED HOLE FOR

RELIEF DAMPER

BAROMETRIC RELIEF DAMPER &

HOOD TO BE RELOCATED FROM

ECONOMIZER TO POWER

EXHAUST

Page 4

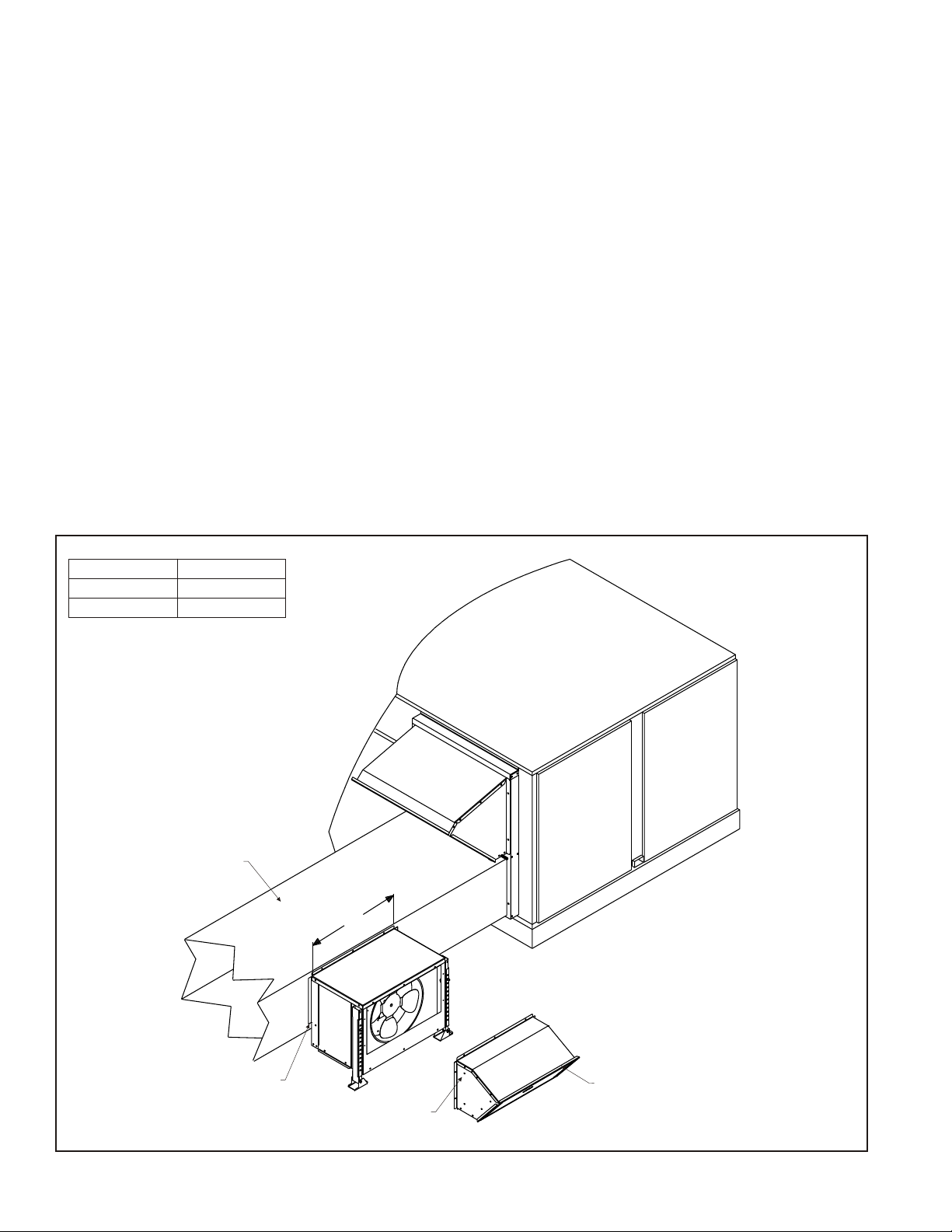

SECURE TO HOOD EXTENSION

PREPUNCHED HOLE FOR RELIEF DAMPER

NOTE:

COIL NOT SHOWN

FOR CLARITY

FIGURE 2

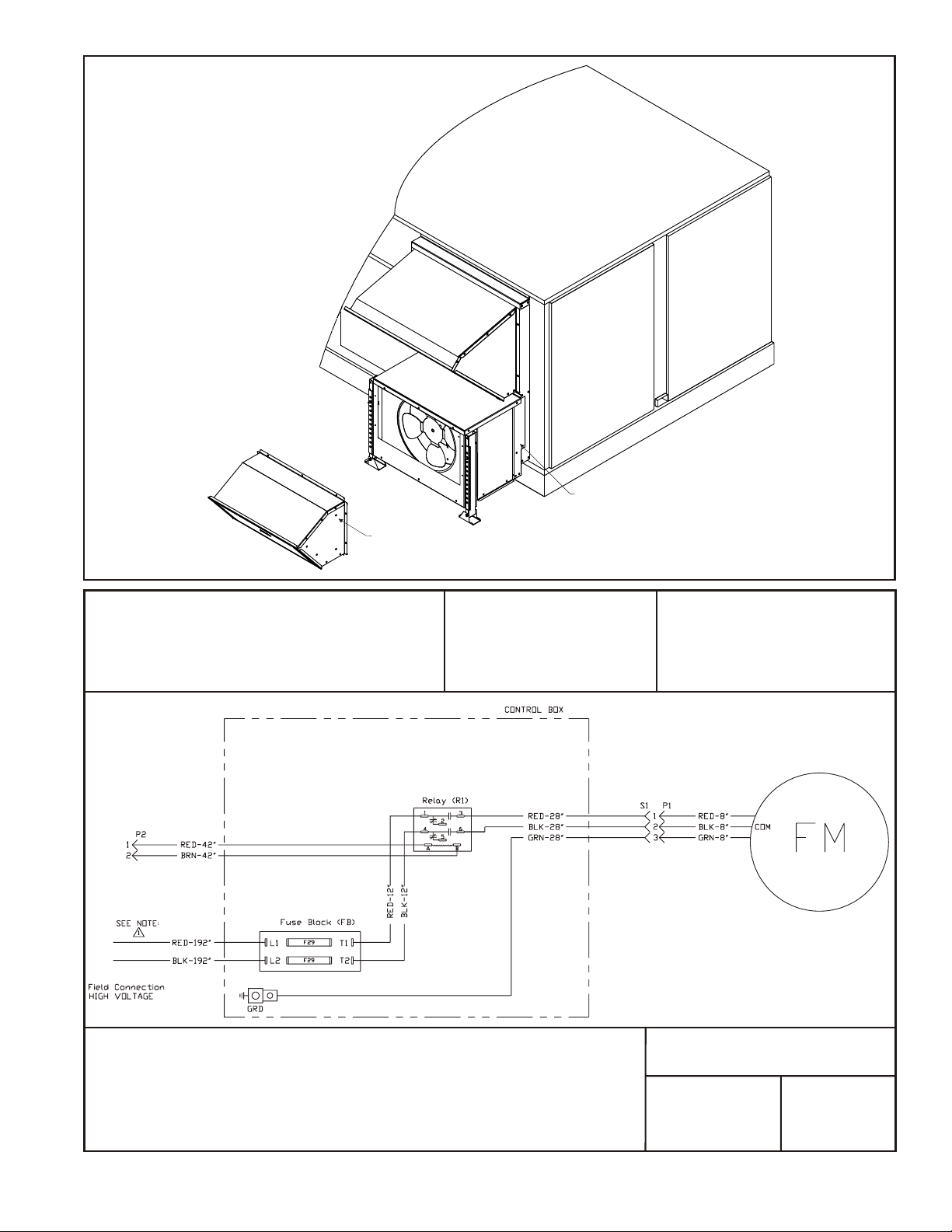

HARNESS DETAIL

COMPONENT CODE WIRE COLOR CODE

BLK Black BLU Blue

BRN Brown GRN Green

GRY Gray ORG Orange

RED Red VIO Violet

YEL Yellow

Notes:

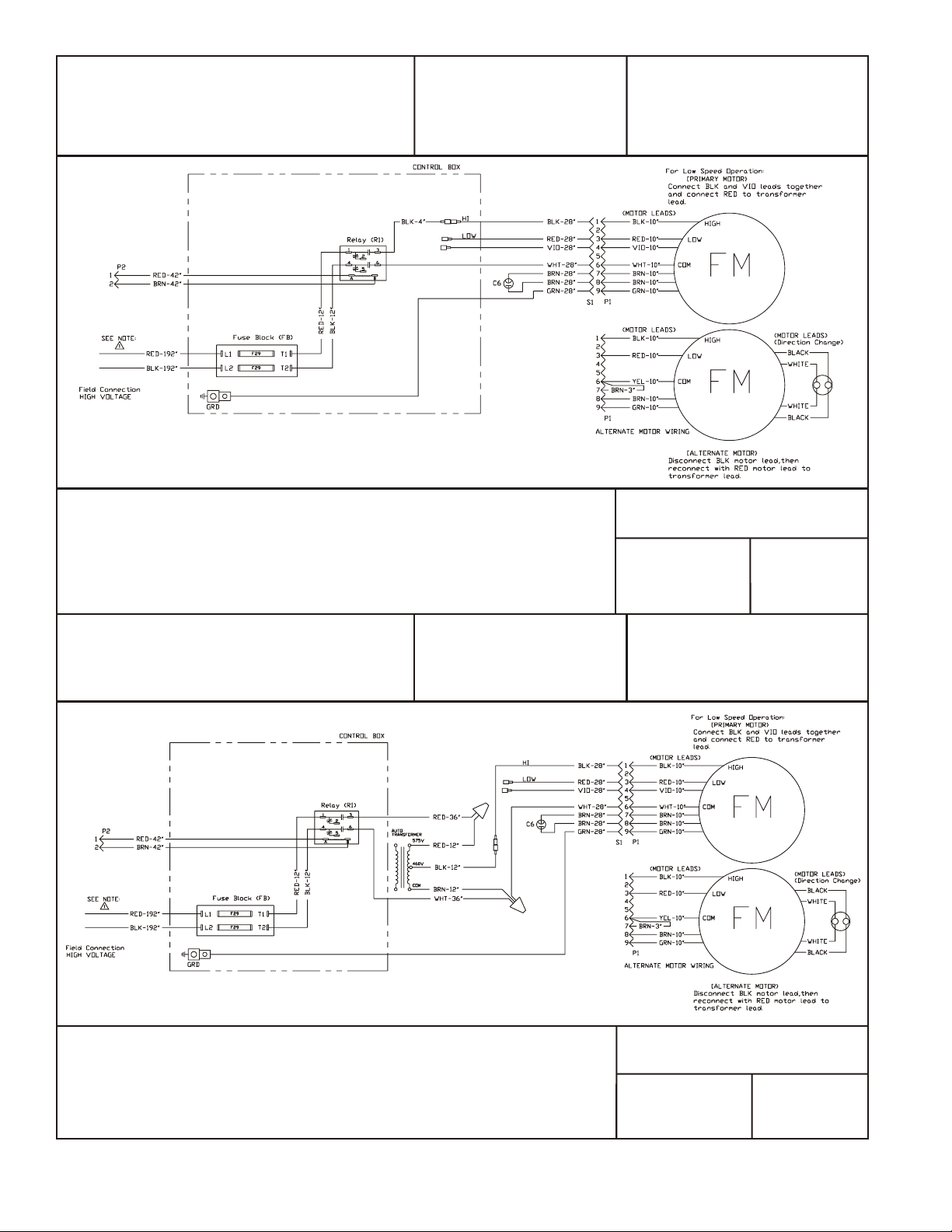

230 Volt 1-Phase Power Ex haust for

RXRX-BGF03C / RXRX-BGF04C

RKKA/JKA/LKA/KMA/JMA/LMA/KNL/LNL/JNL 036-072

Roof top Sys tems, Inc.

2405 McIver Lane

Car roll ton, Texas 75006

Phone(972) 247- 7447

Fax (972) 243- 0940

RKNA/LNA/JNA 036-060

Date: June 17, 2009

Supersedes: 05-17-06

Drawn by: MGL

Unit #:60-465-20/08-21

Di a gram#: 4652021W

Ap proved by:

3

Page 5

HARNESS DETAIL

COMPONENT CODE

WIRE COLOR CODE

BLK Black BLU Blue

BRN Brown GRN Green

GRY Gray ORG Orange

RED Red VIO Violet

WHT White YEL Yellow

Notes:

HARNESS DETAIL

COMPONENT CODE

460 Volt 1-Phase Power Ex haust for

(-)XRX-BGF03D / (-)XRX-BGF04D/BGF06

RKKA/JKA/LKA/KMA/JMA/LMA/KNL/LNL/JNL 036-072

Roof top Sys tems, Inc.

2405 McIver Lane

Car roll ton, Texas 75006

Phone(972) 247- 7447

Fax (972) 243- 0940

BLK Black BLU Blue

BRN Brown GRN Green

GRY Gray ORG Orange

RED Red VIO Violet

WHT White YEL Yellow

RKNA/LNA/JNA 036-060

Date: June 17, 2009

Supersedes: 05-17-06

Drawn by: MGL

Unit #:60-465-20/08-31

Di a gram#: 4652031W

Ap proved by:

WIRE COLOR CODE

Notes:

SUPERSEDES 05-28-09

JUNE 17, 2009

575 Volt 1-Phase Power Ex haust for

(-)XRX-BGF03Y / (-)XRX-BGF04Y/BGF06

RKKA/JKA/LKA/KMA/JMA/LMA/KNL/LNL/JNL 036-072

Roof top Sys tems, Inc.

2405 McIver Lane

Car roll ton, Texas 75006

Phone(972) 247- 7447

Fax (972) 243- 0940

RKNA/LNA/JNA 036-060

Date: June 17, 2009

Supersedes: 05-17-06

Drawn by: MGL

Unit #:60-465-20/08-41

Di a gram#: 4652041W

Ap proved by:

RMIPE20

Page 6

INSTALLATION INSTRUCTIONS

MODELS (-)XRX-BGF05

ECONOMIZER POWER EXHAUST

WARN ING

This installation shall be carried out by a manufacturer's authorized representative, in accordance with the

requirements of the manufacturer. Failure to follow instructions can result in fire or explosion, causing property

damage, severe personal injury, or death. The qualified service personnel performing this work assumes

responsibility for this installation.

IM POR TANT

Damage to the product, resulting from failure to follow instructions or use of unauthorized parts, may be exclude from

the manufacturer's product warranty coverage.

WARN ING

Turn off electrical power and turn off main gas supply before beginning modification. Failure to do so can

cause electrical shock, explosion, or fire, resulting in property damage, personal injury, or death.

TOOLS RE QUIRED FOR IN STAL LA TION:

3

" electric drill with

8

1

" diameter drill bit for sheet metal.

8

5

" socket

16

(-)XRX-BGF05

PACK AGE CON TENTS

ITEM DE SCRIP TION PART No.

1 Power Exhaust Assembly 6046516 / PEA

2 Fan Blade 6046516 / 3465

3 Fan Motor 208-230 volt / 1 phase(C) 6046516 / 3677

4 Fan Motor 460 volt / 1 phase (D) 6046516 / 3694

5 Fan Motor 575 volt / 1 phase (Y) 6046516 / 3690

6 Relay (R1) 6046516 / 3400

7 Fuse Block 6046516 / 3370

8 Barometric Relief Adaptor 6046516 / ADP

Power Exhaust

C, D, Y Voltage

Page 7

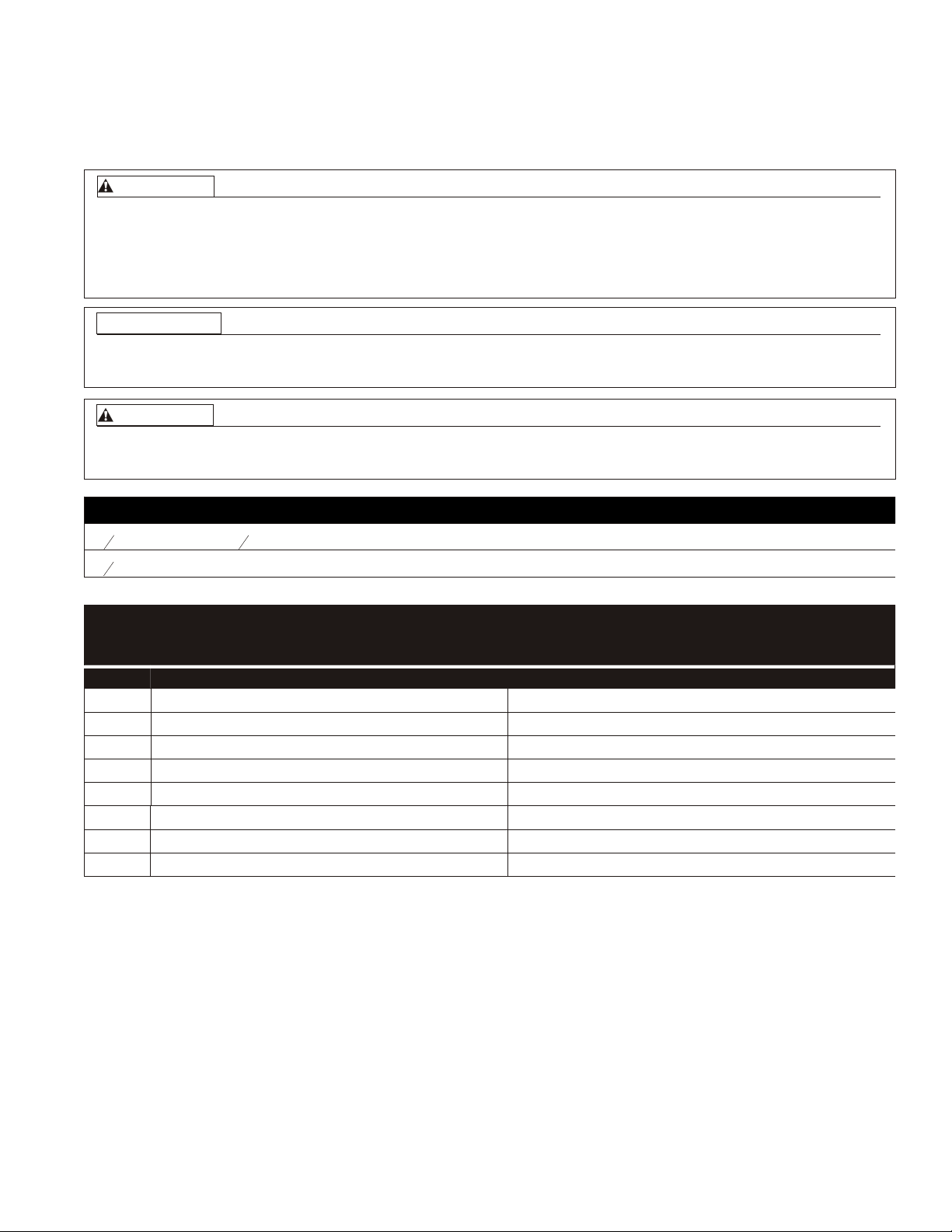

INSTALLATION

1. Remove return cover. See Figure 1.

2. Connect new wire harness in control box back (View A) and route above economizer. See Figure 2.

FILTERS

EXISTING WIRE HARNESS

VIEW A

NEW WIRE HARNESS

ECONOMIZER

RETURN COVER

FIGURE 1

REMOVE PLUG IN BULKHEAD BEFORE

INSTALLING NEW WIRE HARNESS

INSTALL FUSES IN

FUSEHOLDERS

VIEW A

CONNECT WIRE HARNESS TERMINALS

TO ANY TWO OF THE THREE SUPPLY

FAN CONTACTOR TERMINALS.

FIGURE 2

2

Page 8

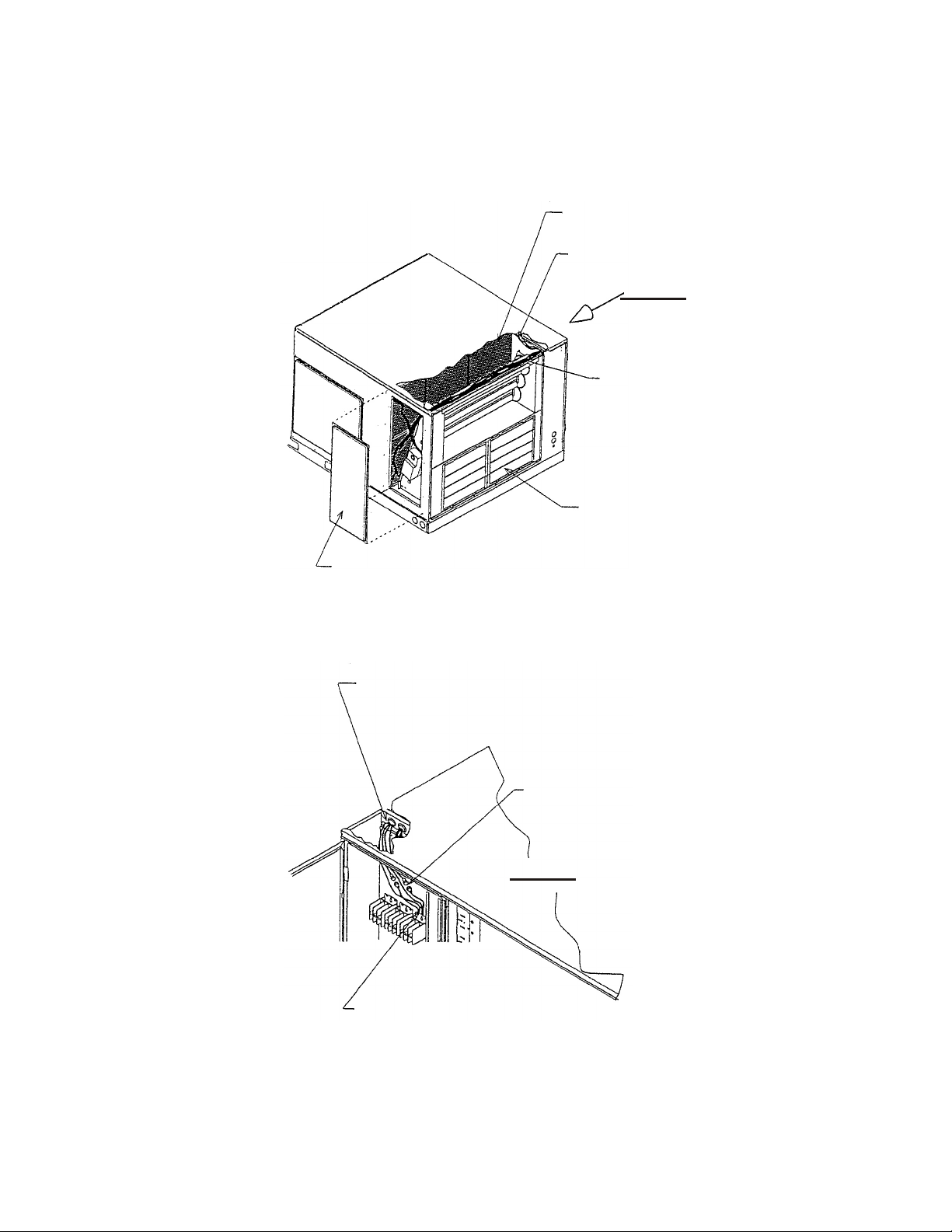

3. Remove relief dampers from economizer. See

Figure 3.

4. Connect power exhaust wiring:

Plug in control connections from power

exhausts to existing connections provided on

economizer.

Remove small rectangular cover beside control

connections on economizer and discard

(Figure 2).

Use screw that was removed in previous step to

attach ground terminals on wire harness.

Plug in power connections through the

rectangular holes revealed when the cover was

removed.

5. Route power and control connections under

divider panel using line clamps provided to take

up excess slack in wiring harness and avoid

contact between fan blades and wiring harness

during operation (Figure 4). secure each

power exhaust with (4) screws (2 in top flange

and 2 in bottom flange).

POWER EXHAUST

RELIEF DAMPERS

6. Connect ends of new wire harness to power

connections. See Figure 4.

7. Reinstall relief dampers.

8. Reinstall return cover.

9. All units are factory shipped for high speed. for

changing to low speed, see notes section on

wiring diagram.

POWER CONNECTIONS

FIGURE 3

(5) LINE CLAMPS

DIVIDER PANEL

CONTROL CONNECTIONS

FIGURE 4

SUPERSEDES 08-19-09

AUGUST 25, 2009

RMIPE16

Page 9

E# = WIRE END DESIGNATION

E2 STUD #6 18 Ga. Wire

E3 Female ¼ Quick Disc.

E4 Male ¼ Quick Disc. Insul

E6 Wire Nut Size 73B

HAR NESS LEADS

ARE 14 GA. WIRE

WITH NO END

DES IG NA TION

COMPONENT CODE

WIRE COLOR CODE

BLK Black

BLU Blue

BRN Brown

GRN Green

GRY Gray

ORG Orange

RED Red

VIO Violet

YEL Yellow

Re vi sion Change Date

ECN 3032 Changed wir ing diagram 08-18-09

CON NEC TOR & CON TACT CON FIG U RA TION

P1 (303903) PLUG - (303912) PIN

S1 (303904) CAP - (303913) SOCKET

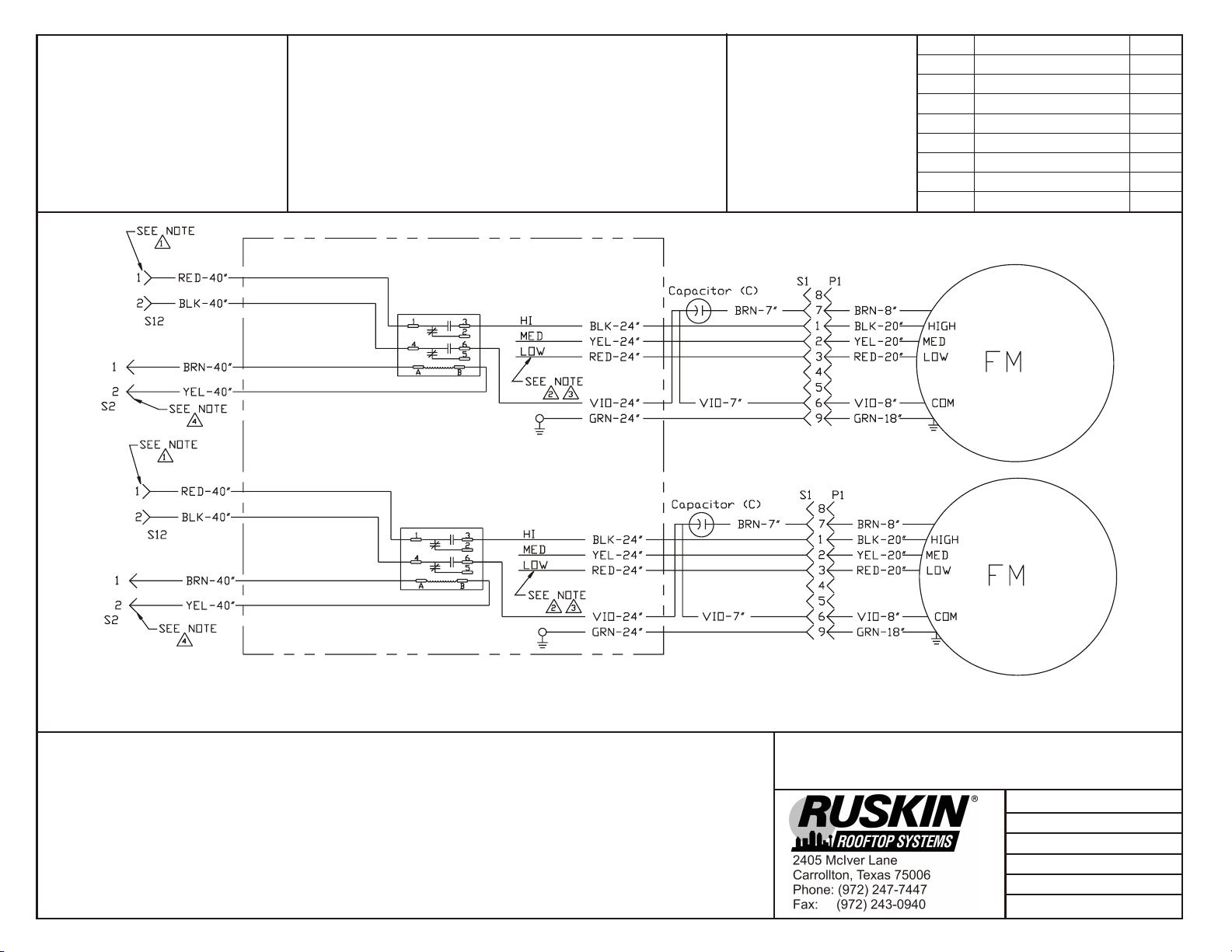

Notes:

1. Con nect J12 to S12 at economizer. High volt age har ness.

2. A. Power Ex haust wired for High speed.

B. For Med speed dis con nect BLK at re lay (3).

C. For Low speed dis con nect BLK at re lay (3).

3. Be sure all leads from mo tor have been cov ered with tape.

4. Con nect J2 to S2 at economizer. Low volt age har ness.

208-230/460/575 Volt 1 Phase Power Ex haust for

RKNL / RLNL 180-300

Date: August 18, 2009

Supercedes: 06-29-09

Drawn by: MGL

Unit #: 60-465-16-21/31/41

Di a gram#: 604651641w

Ap proved by:

Page 10

INSTALLATION INSTRUCTIONS

MODELS (-)XRD-RGCM3

HORIZONTAL AIRFLOW ECONOMIZERS

WARN ING

THIS ACCESSORY IS TO BE INSTALLED BY A QUALIFIED, LICENSED SERVICE PERSON. TO AVOID

UNSATISFACTORY OPERATION OR DAMAGE TO THE PRODUCT AND POSSIBLE UNSAFE CONDITIONS,

INCLUDING ELECTRICAL SHOCK, REFRIGERANT LEAKAGE AND FIRE, THE INSTALLATION

INSTRUCTIONS PROVIDED WITH THIS ACCESSORY MUST BE STRICTLY FOLLOWED AND THE PARTS

SUPPLIED USED WITHOUT SUBSTITUTION. DAMAGE TO THE PRODUCT RESULTING FROM NOT

FOLLOWING THE INSTRUCTIONS OR USING UNAUTHORIZED PARTS MAY BE EXCLUDED FROM THE

MANUFACTURER’S WARRANTY COVERAGE.

WARN ING

DISCONNECT ELECTRICAL POWER TO THE UNI T. FAILURE TO DO S O CAN CAUSE ELE CTRICAL SHOCK

RESULTING IN PERSONAL INJURY OR DEATH.

TOOLS RE QUIRED FOR IN STAL LA TION:

3

" elec tric drill with

8

Wa ter proof ex te rior duct seal ant Sheet metal tools (e.g. shears)

5

" socket Small flat blade (0.125" wide) screw driver

16

TABLE 1

PACK AGE CON TENTS

ITEM DE SCRIP TION PART No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Discharge Air Sensor (Hardware Bag)

(2) Permanent Filters

(2) Spotweld Assy - Bird Screen

(2) Exhaust Air Rainhood - Top

OA Rainhood Assy - Left Side

OA Rainhood Assy - Right Side

(2) Exhaust Air Rainhood - Left Side

(2) Exhaust Air Rainhood – Right Side

OA Rainhood Assy - Filter Bracket Strip

OA Rainhood Assy – Top

OA Rainhood - Front Filter Support

OA Filter Rail

Hardware Bag

Exhaust Air Rain Hood Spacer

(-)XRD-RGCM3 economizer with controller,

actuator, and outside enthalpy sensor attached

6039416 / 3112

6039416 / 8568 (23.875" X 23.875")

6039416 / BSWA

6039416 / EHT2

6039416 / EHSL

6039416 / EHSR

6039416 / EHS3L

6039416 / EHS3R

6039416 / ADP

6039416 / EHT

6039416 / EHB

6039416 / FCH

6039416 / HDW

6039416 / ADP2

Page 11

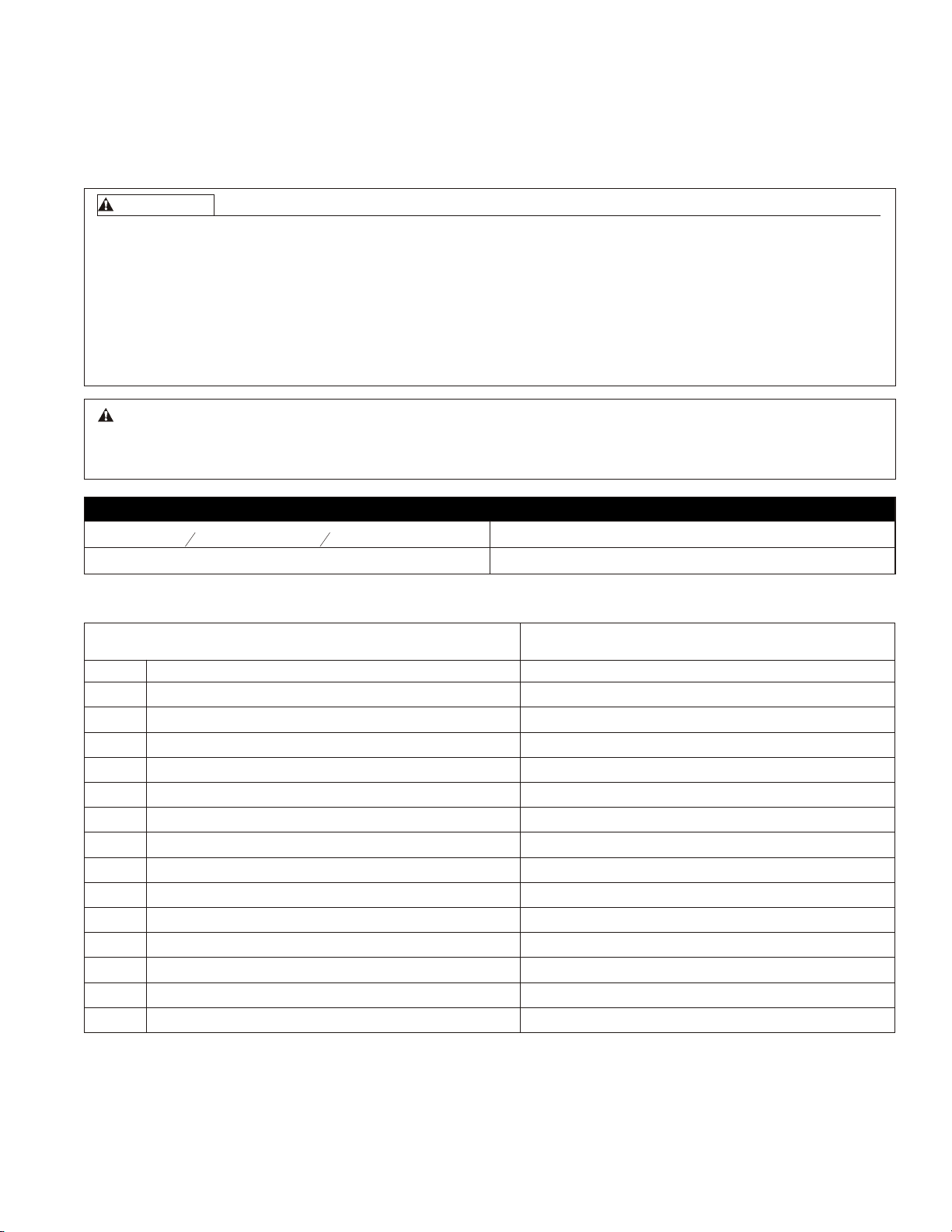

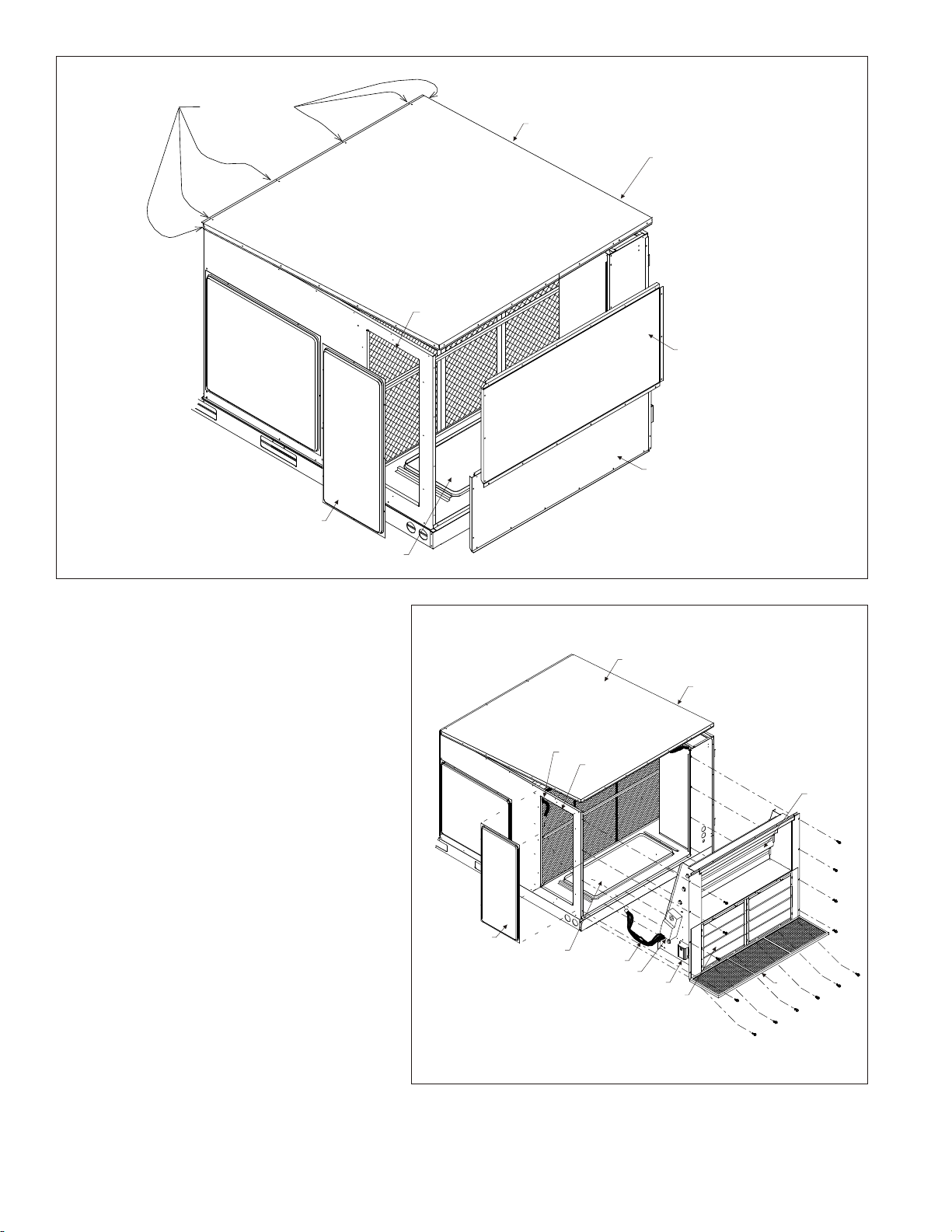

FIGURE 1

PANEL - TOP LEFT

PANEL - LEFT BOTTOM SECTION

RETURN COVER

STEP 1:

Immediately upon receipt, all cartons and contents

should be inspected for transit damage. Units with

damaged cartons should be opened immediately.

If damage is found, it should be noted on the

delivery papers and a damage claim filed with the

last carrier.

STEP 2:

Remove RETURN COVER, PANEL – TOP LEFT,

and PANEL – LEFT BOTTOM SECTION from the

unit and retain for reuse (SEE FIGURE 1). Retain

screws.

STEP 3:

Fasten RETURN COVER (SEE FIGURE 2) over

bottom return opening using 4 retained screws.

STEP 4:

Remove screws from 3 sides of ROOF PANEL so

that it can be raised during economizer insertion.

STEP 5:

Remove jumper plug PL7 and connect unit

ECONOMIZER PLUG to economizer mating plug

and slide economizer into unit. Reinstall jumper

plug PL7to PL21 located on economizer.

FIGURE 2

RE TURN COVER

ECONOMIZER

(SEE BILL OF MA TE RIAL)

A1005-01

ROOF PANEL

ECONOMIZER PLUG

A1005-01

2

Page 12

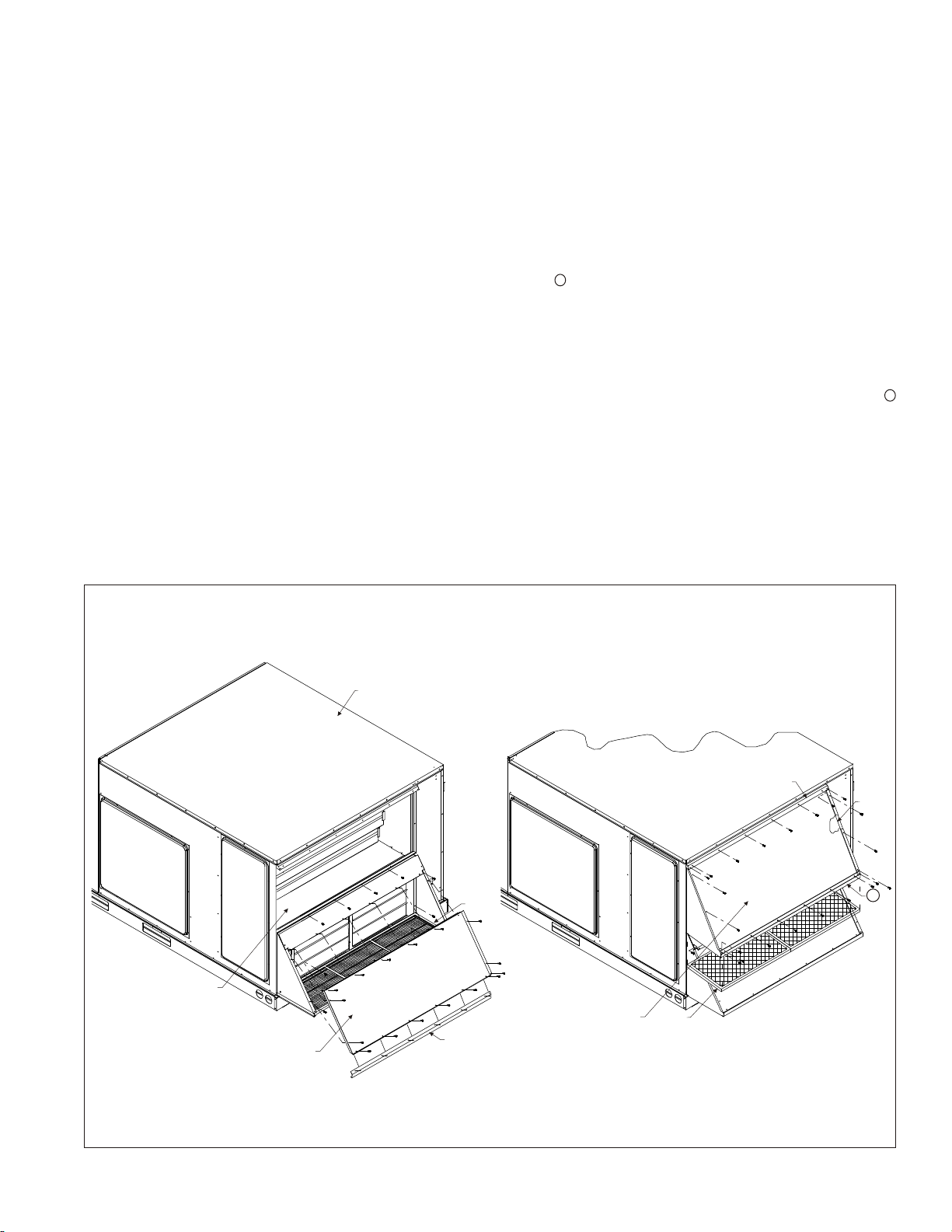

STEP 6:

Mount PANEL – LEFT BOTTOM SECTION to unit (SEE

FIGURE 3). Use only 2 screws (one on each side) for easy

removal during calibration.

STEP 11:

Fasten 11 OA RA INHOOD - FRONT FILTER SUPPORT to

PANEL – TOP LEFT. The bottom lip should support the

PERMANENT FILTERS.

STEP 7:

Fasten FILTER BRACKET STRIP to unit using 2 screws

(one on each side). See Table 1 for identification.

STEP 8:

Fasten 12 OA FILTER RAIL to FILTER BRACKET STRIP

with 4 screws. Fasten FILTER BRACKET STRIP to

economizer with 4 neoprene washer head screws

provided.

STEP 9:

Fasten OA RAINHOOD - LEFT SIDE and OA

RAINHOOD - RIGHT SIDE to unit using 3 screws

provided.

STEP 10:

Slide PERMANENT FILTERS between OA

RAINHOOD - LEFT SIDE and OA RAINHOOD - RI GHT

SIDE back into the 12 OA FILTER RAIL.

STEP 12:

Fasten PANEL – TOP LEFT to OA RAINHOOD - LEFT

SIDE and OA RAINHOOD - RIGHT SIDE and 11 OA

RAINHOOD - FRONT FILTER SUPPORT using 16

screws.

STEP 13:

Position the OA RAINHOOD ASSY – TOP under edge

of ROOF PANEL.

STEP 14:

Re-secure ROOF PANEL using existing screws.

FIGURE 3

PANEL - LEFT BOTTOM SECTION

ROOF PANEL (REF.)

12

PANEL - TOP LEFT

11

A1012-01

3

Page 13

STEP 15:

Provide opening in return air duct to mount the two

barometric relief dampers and hoods (SEE FIGURE 4).

Locate a convenient distance from unit.

STEP 16:

Using self-drilling screws provided, assemble exhaust air

rain hoods ( EXHAUST AIR RAINHOOD – TOP,

EXHAUST AIR RAINHOOD - LEFT SIDE, EXHAUST

AIR RAINHOOD - RIGHT SIDE, SPOTWELD ASSY BIRD SCREEN) and install in return air duct. Use sealant

(not provided) as required.

STEP 17:

Remove the blower motor access panel (SEE FIGURE 5).

STEP 18:

Connect the DISCHARGE AIR SENSOR to wires 51

and 52 located in the blower motor compartment.

NOTE:

Mixed air sensor should be secured with the included wire

tie to avoid entanglement with the blower and direct

contact with any sheet metal surfaces.

STEP 19:

Replace the blower motor access panel.

FIGURE 4

SUPPLY AIR

25.250

RETURN AIR

DUCT

PANEL - LEFT

BOTTOM SECTION

STEP 20:

Upon start-up check the economizer sequence of

operation using the steps provided in these instructions.

After testing unit operation and setting outside air damper

minimum position, secure PANEL – LEFT BOTTOM

SECTION (SEE FIGURE 3) with remaining screws.

FIGURE 5

WIRE TIE

25.250

47.250

A1005-01

INDOOR MOTOR

A1006-01

4

Page 14

DI RECT MOUNT ECONOMIZER SE QUENCE OF OP ER A TION

GEN ERAL

This accessory economizer package is designed to save

energy costs by using outdoor air for cooling and

ventilation in place of mechanical cooling whenever

possible. The economizer continuously monitors indoor

and outdoor air conditions and compares them to a

user-selected setpoint to determine if free cooling is

available.

AC CES SO RIES

RXRX-AV02 — Dual Enthalpy Up grade Kit

For maximum energy savings, this upgrade kit will allow

the economizer to compare the outdoor air enthalpy to the

return air enthalpy, instead of a user-selected setpoint to

determine if "free cooling" is available.

RXRX-AR02 - Wall-Mounted Car bon Di ox ide Sen sor

For installations requiring Demand Control Ventilation

(DCV) based upon indoor air levels of carbon dioxide

(CO2). When the unit supply fan is running, the CO2 sensor

modulates the outside air damper to maintain a

user-selected CO2 level inside the occupied space.

Energy savings are achieved by not bringing in excessive

amounts of outdoor air when the indoor air conditions are

suitable. Energy savings can be substantial on buildings

with highly variable occupancy rates.

Wall-Mounted Remote Potentiometer

For installations requiring remote adjustment of damper

minimum position by the occupants, a remote

potentiometer, such as the Honeywell S963B1128 can be

used.

RXRX-BFF02C, RXRX-BFF02D, RXRX-BFF02Y —

Power Exhaust Kit

For installations requiring more space static pressure relief

than can be obtained with the standard barometric relief

damper included with the economizer, a power exhaust kit

can be added.

B. Range of adjustment is from 0-100% (2-10V); in

most applications the minimum position is

adjusted to allow 10% to 25% outside air to enter

the system.

C. The Outside Air Damper Minimum Position

potentiometer can be adjusted at any time.

D. Whenever the "G" (supply fan) signal is present,

the damper will open to this minimum position

unless:

a. It may modulate to a greater position if

overridden by the CO2 sensor (DCV).

b. It may not open if overridden by the discharge

air temperature sensor (Freeze Protect

Mode).

3. DCV Max — Demand Control Ventilation (DCV)

Maximum Setpoint

A. The DCV maximum position potentiometer allows

the installer to limit the amount of outdoor air flow

into the building when the DCV overrides the

mixed air sensor.

B. Setting the DCV maximum position of the damper

prevents the introduction of large amounts of hot

or cold air into the space.

C. Note: If the DCV maximum position is set below

the outside air damper minimum position, the

minimum position overrides the DCV maximum

position (negating the function of the DCV).

4. DCV Set — Demand Control Ventilation (DCV)

Setpoint

A. The DCV can be any sensor that provides a

2-10Vdc output. The DCV modulates the outdoor

damper to provide ventilation based on

occupancy. Typically, a carbon dioxide (CO2)

sensor is used to indirectly monitor occupancy

level.

B. No cooling signal (e.g.Y1, Y2) is required for the

DCV to override the outdoor air damper when

ventilation requires outdoor air.

C. The controller must receive a "G" (supply fan)

signal to open the damper.

D. Range of adjustment is from 2 Volts to 10 Volts.

E. The DCV setpoint can be adjusted at any time.

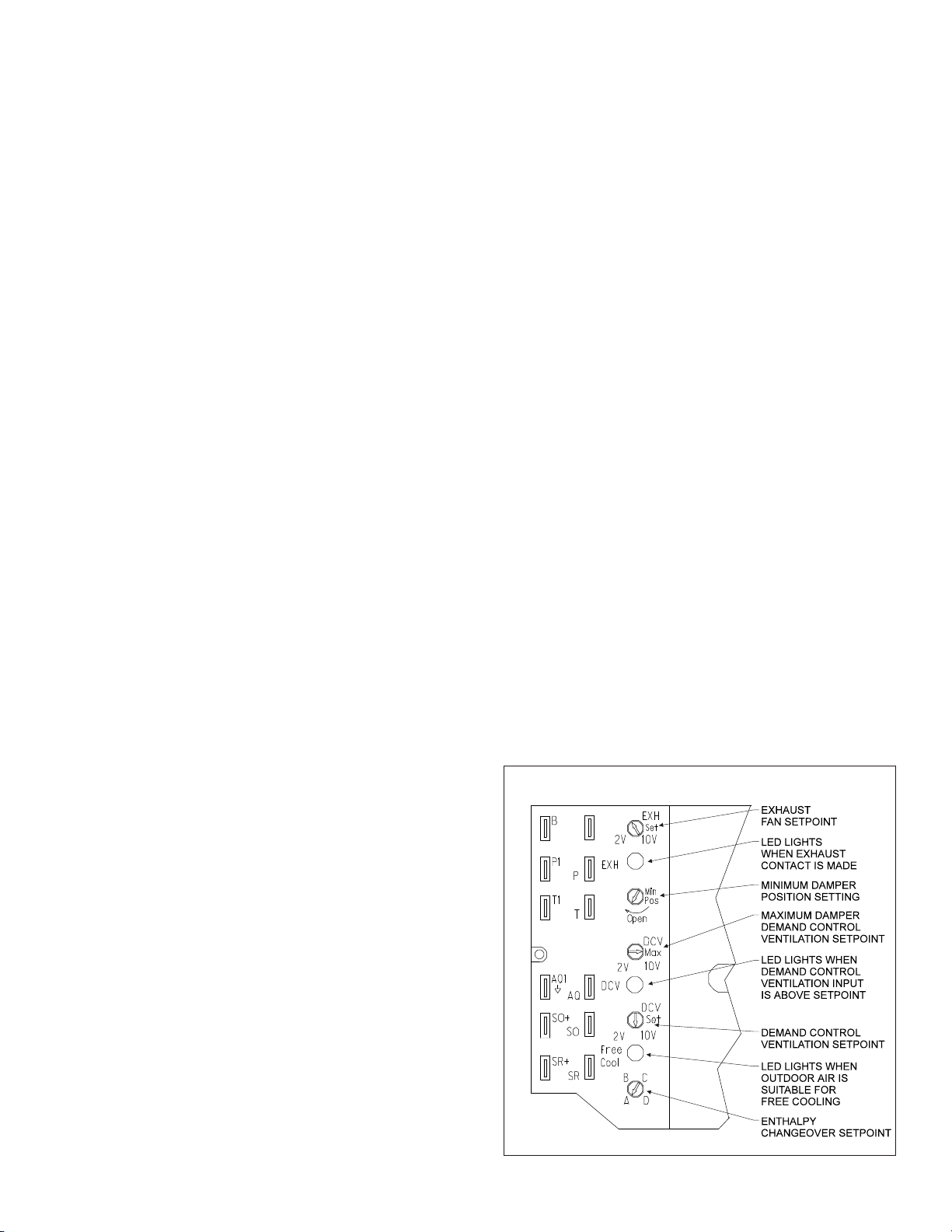

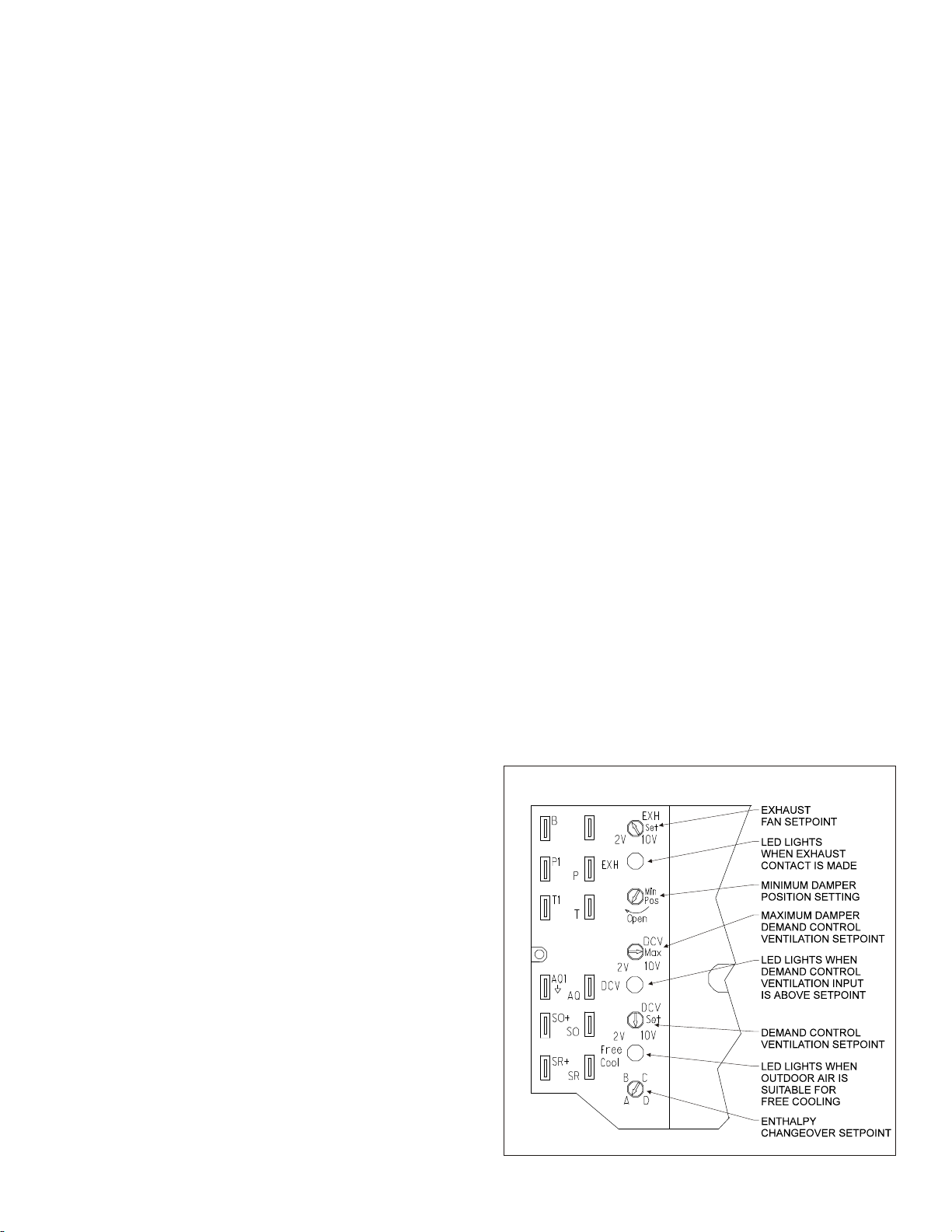

FIGURE 6

STARTUP

Attach connector from Economizer Controller to Rooftop

Control Panel Connector and install discharge/mixed air

temperature sensor per installation guide.

AD JUST MENTS

5 po ten ti om eters with screw driver ad just ment slots,

start ing from top of con trol ler

1. EXH Set — Adjustments for (optional) power ex haust

A. The outside air damper position at which the

power exhaust fan(s) will engage. The LED

labeled EXH below the potentiometer adjustment

will indicate when power exhaust is available.

When the power exhaust call is made, the

controller provides a 60 ±30 second delay before

exhaust fan activation to allow the damper to

reach the appropriate position.

B. Range of adjustment is from 0-100% (2-10V); in

most applications the power exhaust is set to

engage at about 70% outside air.

5

Page 15

F. The controller compares the CO2 sensor input to

the setpoint setting to determine the damper

minimum position.

a. If the actual CO2 level is below the setpoint,

then the damper minimum position is

determined by the damper minimum position

potentiometer setting.

b. If the actual CO2 level rises above the

setpoint, then the damper minimum position is

overridden proportionally more open.

c. If the discharge air temperature drops below

48°F (Freeze Protect Mode), the DCV input

will be overridden and the damper may not

open.

G. Compatible CO2 sensors will have a 2-10Vdc

output for a 0-1500 ppm CO2 input.

H. Ensure proper polarity of the sensor wires when

connecting to the economizer controller. Incorrect

polarity negates the sensor signal.

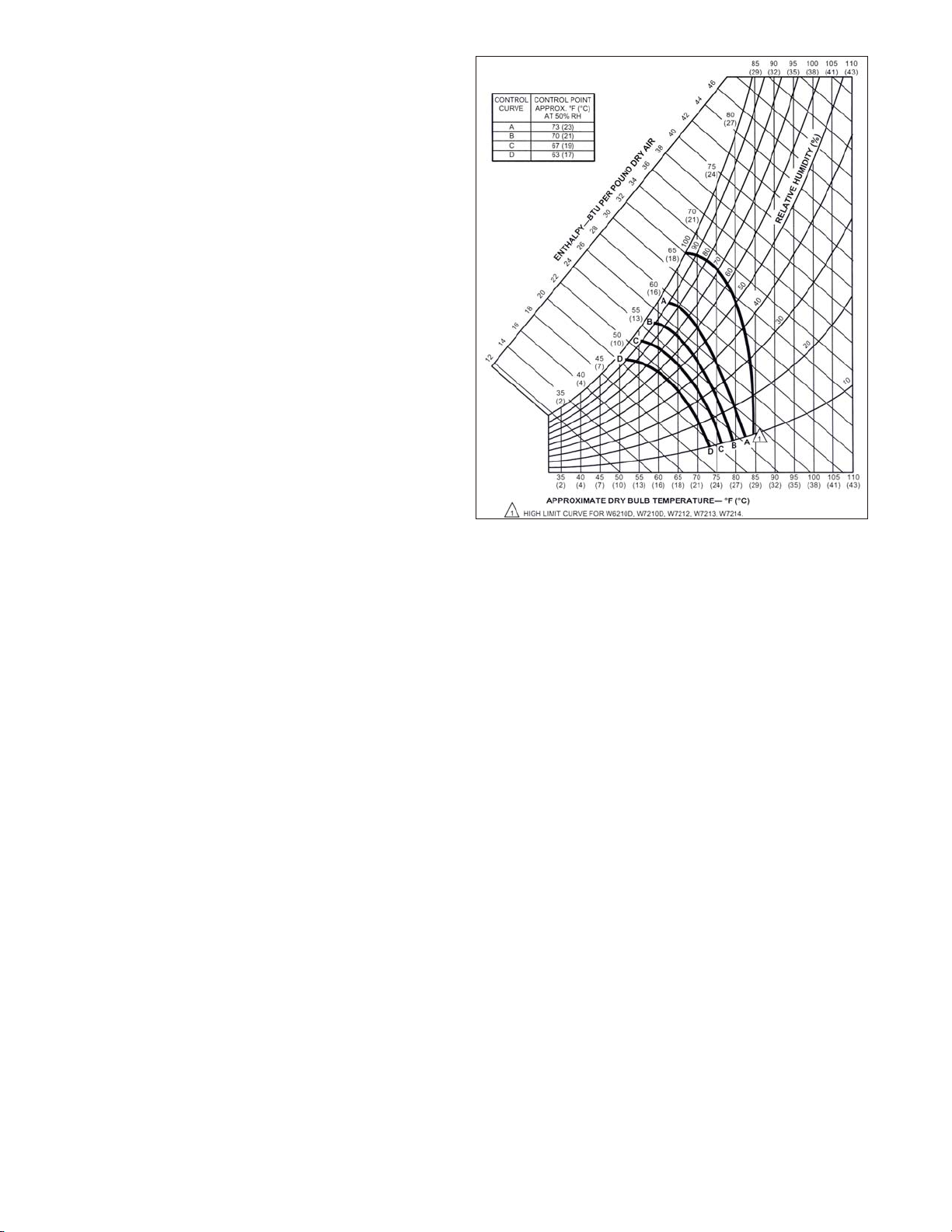

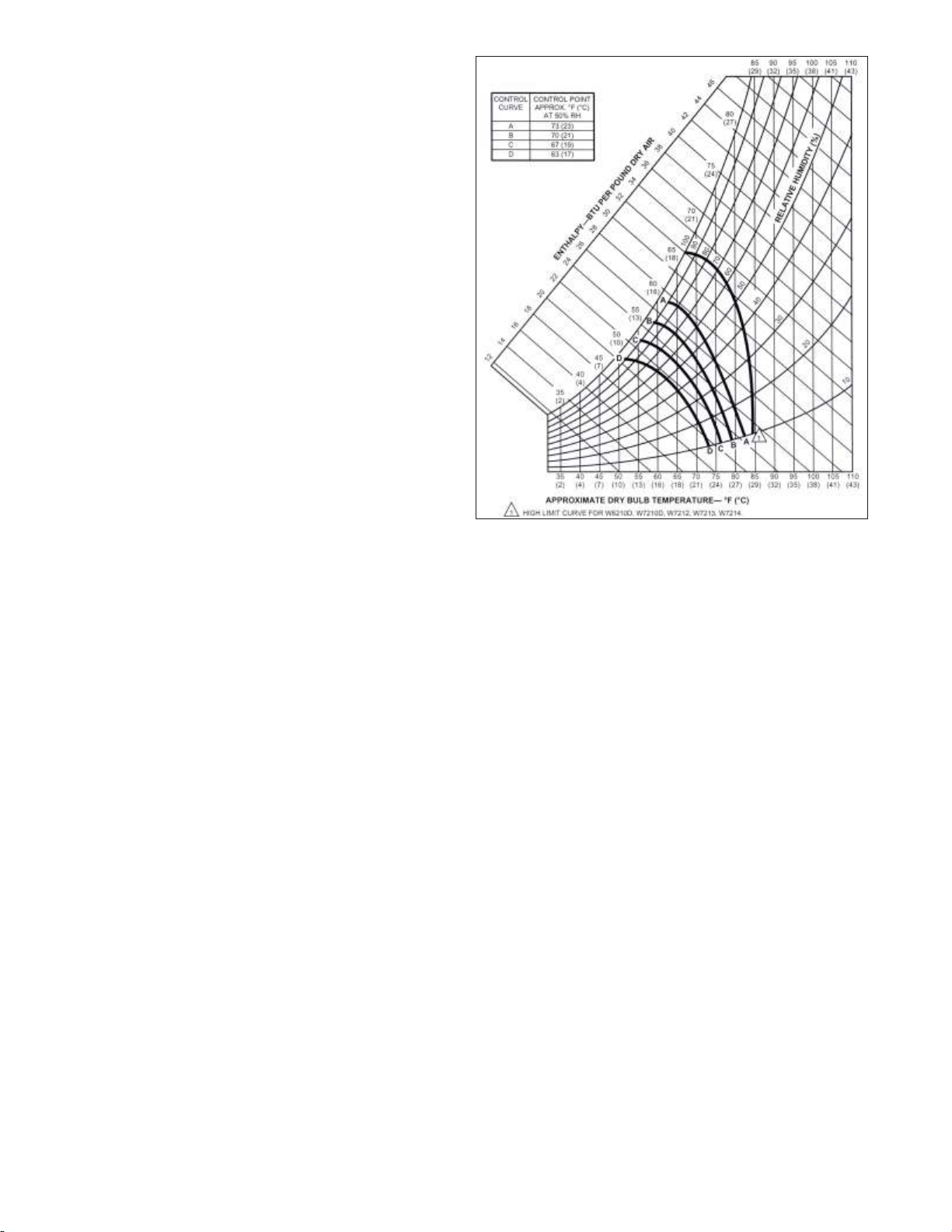

5. Economizer Setpoint

A. Only the coolest, driest outside air is used for

economizer operation when the potentiometer is

on setting "D". For greatest energy savings, the

potentiometer is on setting "A".

B. Adjustment range is A, B, C, or D

a. Setting "A" = 73F db or 27 Btu/lbm @ 50% RH

b. Setting "B" = 70F db or 25 Btu/lbm @ 50% RH

c. Setting "C" = 67F db or 23 Btu/lbm @ 50% RH

d. Setting "D" = 63F db or 22 Btu/lbm @ 50% RH

C. Economizer Setpoint potentiometer can be

adjusted at any time.

D. The controller compares the enthalpy sensor input

with the economizer setpoint to determine if free

cooling is available.

a. Single enthalpy strategy: If outdoor air

enthalpy is lower than the setpoint, then free

cooling is available. Note: The

factory-installed 620-ohm resistor must be in

place across terminals SR and SR+.

b. Dual enthalpy strategy: If outdoor air enthalpy

is lower than return air enthalpy, then free

cooling is available.

1. Note: If using dual enthalpy, the Economizer

Setpoint must be at the "D" setting.

2. The factory-installed 620-ohm jumper must

be removed to install the dual enthalpy

upgrade kit.

NOR MAL OP ER A TION

1. Fan Only (G)

A. Damper will go to minimum position (in 90

seconds or less) whenever the "G" (supply fan)

signal is present.

B. When "G" signal is removed, the outside air

damper closes against blade seals for tight shutoff

of outside air.

C. If the discharge air temperature drops below 48ºF,

then the control will override the minimum position

setting and will modulate the outside air damper

closed.

2. Call for First Stage of Cooling (Y1)

A. Economizer Unavailable (warm outdoor air).

Compressor 1 is commanded on without delay.

B. Economizer Available (free cooling). The

controller tries to maintain a discharge air

temperature of 53ºF ± 5 by modulating the outside

air damper position.

FIGURE 7

3. Call for Second Stage of Cooling (Y2)

A. Economizer Unavailable (warm outdoor air).

Compressor 2 is commanded on without delay.

B. Economizer Available (free cooling). Compressor

1 is commanded on without delay. The controller

tries to maintain a discharge air temperature of

53ºF ± 5 by modulating the outside air damper

position. Compressor 2 is not activated in the

economizer mode.

4. Call for Heat

A. Standard Air Conditioner with electric or gas heat.

(W1 & W2)

a. The Thermostat controls the stages of heating

directly.

b. If the control detects that the supply fan is on

(through its "G" input), then the control will

open the damper to minimum position.

c. If the discharge air temperature drops below

48ºF, then the control will override the

minimum position setting and will modulate

the outdoor damper closed.

B. Heat Pump Operation (B)

a. The "B" signal from the Thermostat allows

operation of the compressors to provide

heating without delay.

b If the control detects that the supply fan is on

(through its "G" input), then the control can

open the damper to minimum position.

c. If the discharge air temperature drops below

48ºF, then the control will override the

minimum position setting and will modulate

the outdoor damper closed.

5. Low Ambient Compressor Lockout – None present.

6

Page 16

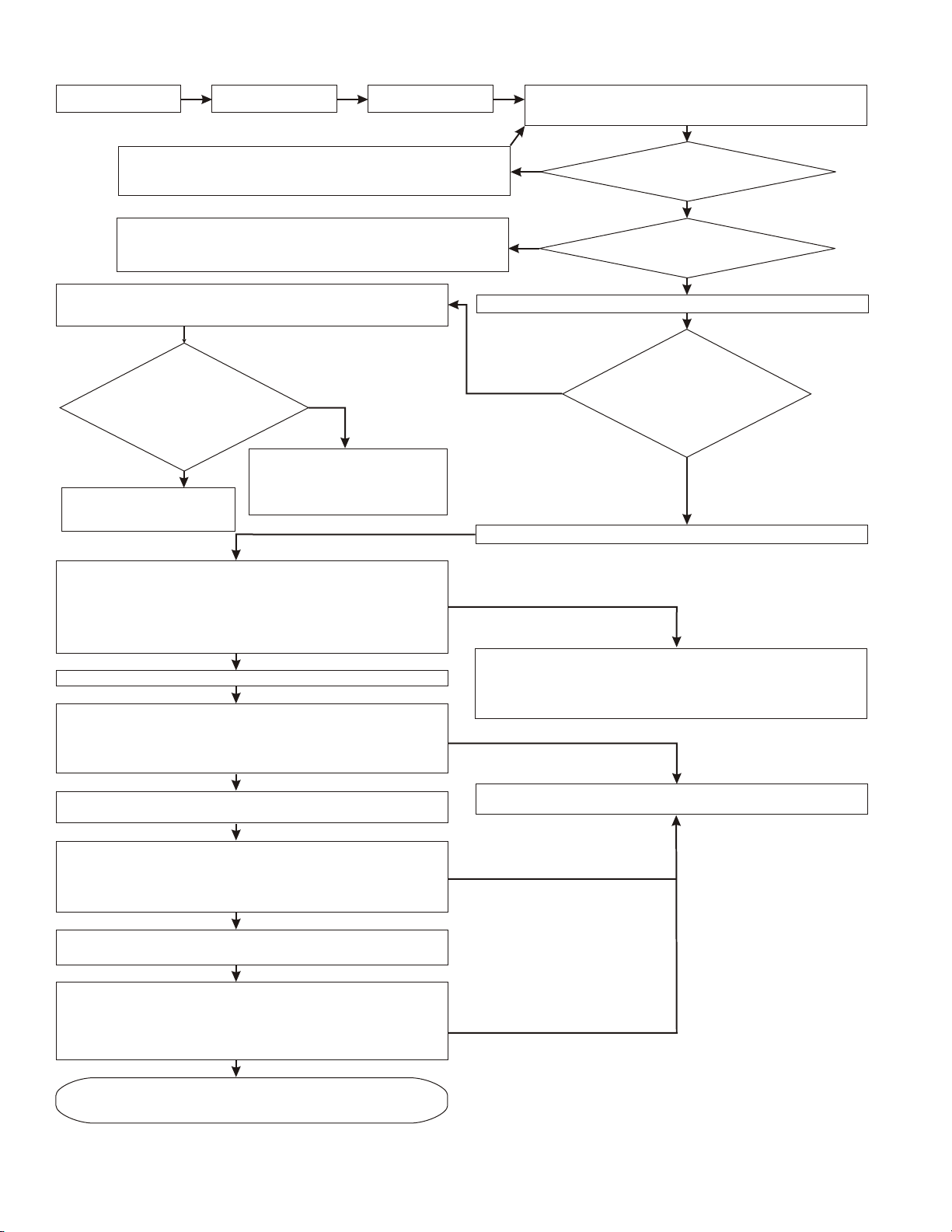

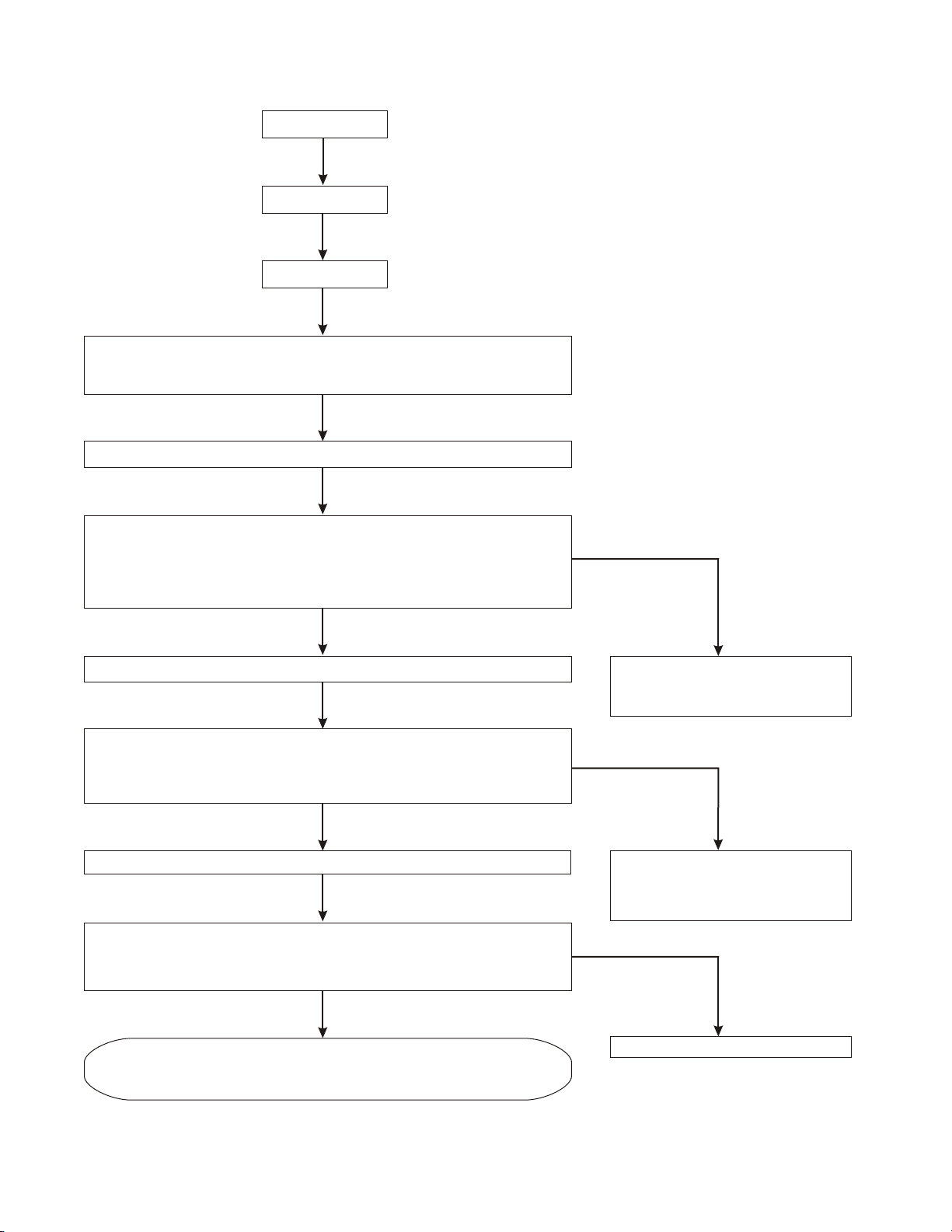

TROU BLE SHOOT ING

1. Checkout requires a handheld multimeter, 9V battery,

a 5.6k ohm .25 watt resistor, a 1.2k ohm .25 watt

resistor, a jumper wire with .25" quick connect

terminals, and the 620 ohm resistor that is

factory-installed across terminals SR+ and SR. The

terminal names below reference the economizer

controller. Use the following flowcharts for to diagnose

unit.

2.

a. Disconnect power to the unit.

b. Jumper P to P1 (factory installed jumper is

normally present).

c. Remove outdoor air enthalpy sensor from

terminals SO+ and SO and install the 1.2k ohm

resistor.

d. Put 620 ohm resistor across terminals SR+ and

SR (factory installed 620 ohm resistor is normally

present and can be used).

e. Put 5.6k ohm resistor across T and T1.

3.

a. Turn (EXH Set) Exhaust fan Setpoint

potentiometer fully CCW.

b. Turn (Min Pos) Minimum Outside Air Damper

potentiometer fully CCW.

c. Turn (DCV Max) Demand Control Ventilation

Maximum potentiometer fully CW.

d. Turn (DCV Set) Demand Control Ventilation

Setpoint potentiometer fully CCW.

e. Turn enthalpy potentiometer to "D".

7

Page 17

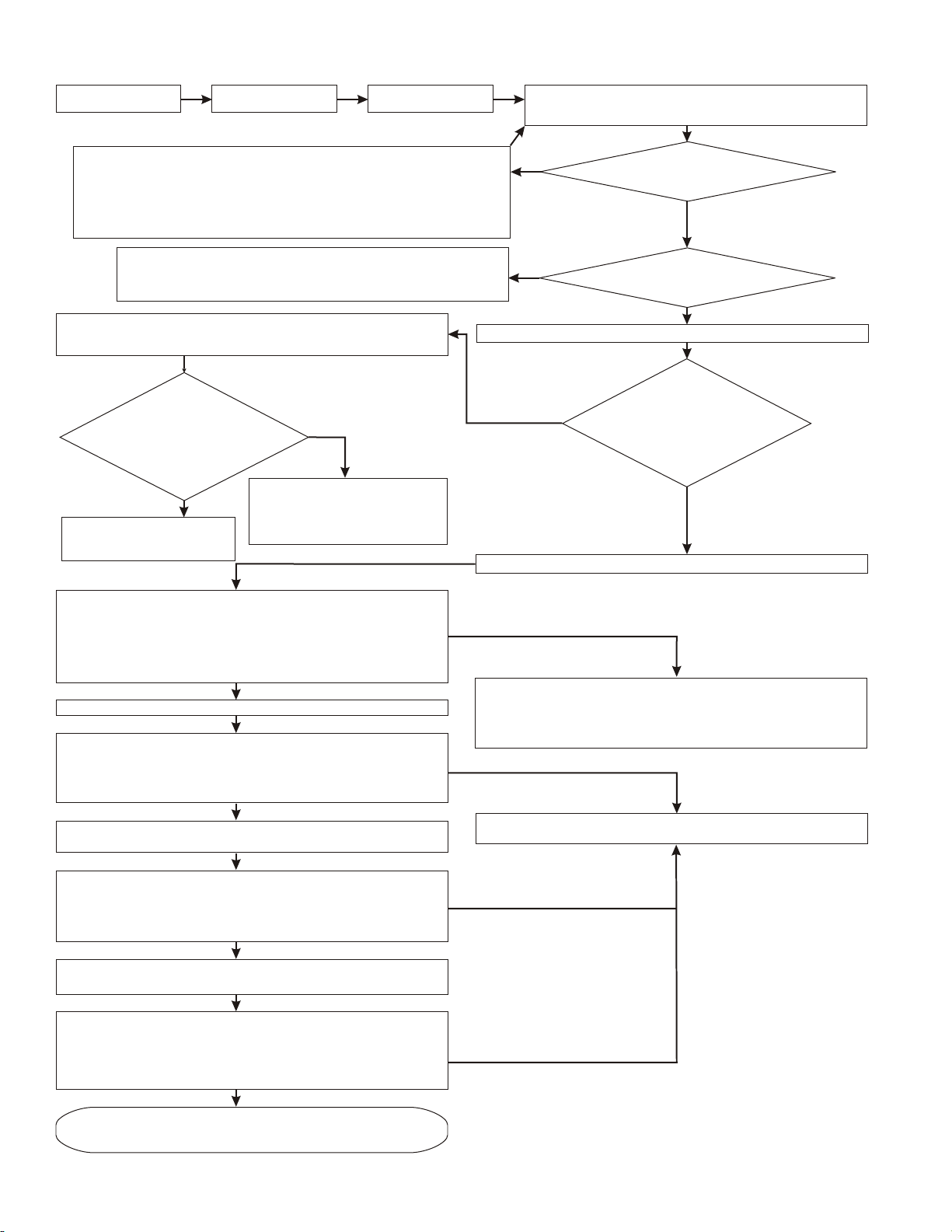

BASIC ECONOMIZER OPERATION

START Perform STEP 2 Perform STEP 3

Put thermostat fan setting to "CONTINUOUS FAN"

Reapply Power to the Unit

Set thermostat so neither heating or cooling is called

Connect Economizer Wire Harness to Unit

Check Thermostat Connections

Check for 24 VAC at Unit Transformer

Check Unit Wire Harness

Check Economizer Controller Model Number

Perform STEP 2 & STEP 3 again.

If problem continues, replace controller

Unplug Economizer Wire Harness from Unit Wire harness and Install

Jumper Plug (Jumpers Y1 Thermostat to Y1 Compressor and Jumpers

Y2 Thermostat to Y2 Compressor)

If one

stage of cooling

is called by the

thermostat, do first stage

compressor(s) run? If both stages

are called, do both stages

of compressors

run?

NO

Check Thermostat Wiring

Check Unit Wiring Harness

The "Free Cooling" LED turns on & the EXH LED turns on.

If only one stage of cooling is called by the thermostat, then that stage

will turn off. If two stages are called by the thermostat, then only the

second stage will turn off. The power exhaust (optional) contacts will

close after 60 +/- 30 seconds. The outside air damper opens

approximately 50% (this position is determined by the actual resistance

of the 5.6k ohm resistor placed across terminals T and T1).

Set enthalpy potentiometer to D (fully CW).

The "Free Cooling" LED turns off & the EXH LED turns off.

If only one stage of cooling is called by the thermostat, then that stage

will turn back on. If two stages are called by the thermostat, then both

stages will turn on. The power exhaust (optional) contacts open & the

outside air damper fully closes.

Set enthalpy potentiometer back to A (fully CCW).

Remove 5.6k ohm resistor and jumper terminals T to T1.

(W7213A1016)

YES

Check Economizer Wiring

Harness. Check Unit wiring

harness at economizer

connection for proper terminal

location

YES

YES

NO

NO

Turn down thermostat setting so that a call for cooling is present.

NO

Set enthalpy potentiometer on economizer controller to A (fully CCW).

NO

Recheck STEP 2 and STEP 3. If LED’s turn on and damper motor

does not operate, measure voltage between terminals 24V COM and

(+ (white wire)). If approximately 6 VDC is present, replace damper

actuator. If voltage not present, or LED’s do not light replace controller.

NO

Recheck STEP 2 and STEP 3.

If problem continues replace controller

24 VAC power

available between terminal TR and

TR1?

YES

Are all LED's off &

outside air damper fully closed?

YES

If one

stage of cooling

is called by the

thermostat, do first stage

compressor(s) run? If both stages

are called, do both stages

of compressors

run?

YES

The "Free Cooling" LED turns on & the EXH LED turns on. If only one

stage of cooling is called by the thermostat, then that stage will turn off.

If two stages of cooling are called by the thermostat, then only the

second stage will turn off. The power exhaust (optional) contacts will

close after 60 +/- 30 seconds. The outside air damper fully opens

YES

Remove jumper from terminals T to T1 and leave open (simulates the

The "Free Cooling" LED remains on & the EXH LED turns off.

If only one stage of cooling is called by the thermostat, then that stage

will remain off. If two stages of cooling are called by the thermostat,

then only the second stage will remain off. The power exhaust

(optional) contacts opens & the outside air damper fully closes

Economizer Controller, Actuator, Wiring are correct.

Remove resistors, reconnect wires, and set up

Freeze Protect mode).

YES

potentiometers per jobsite requirements.

8

NO

NO

Page 18

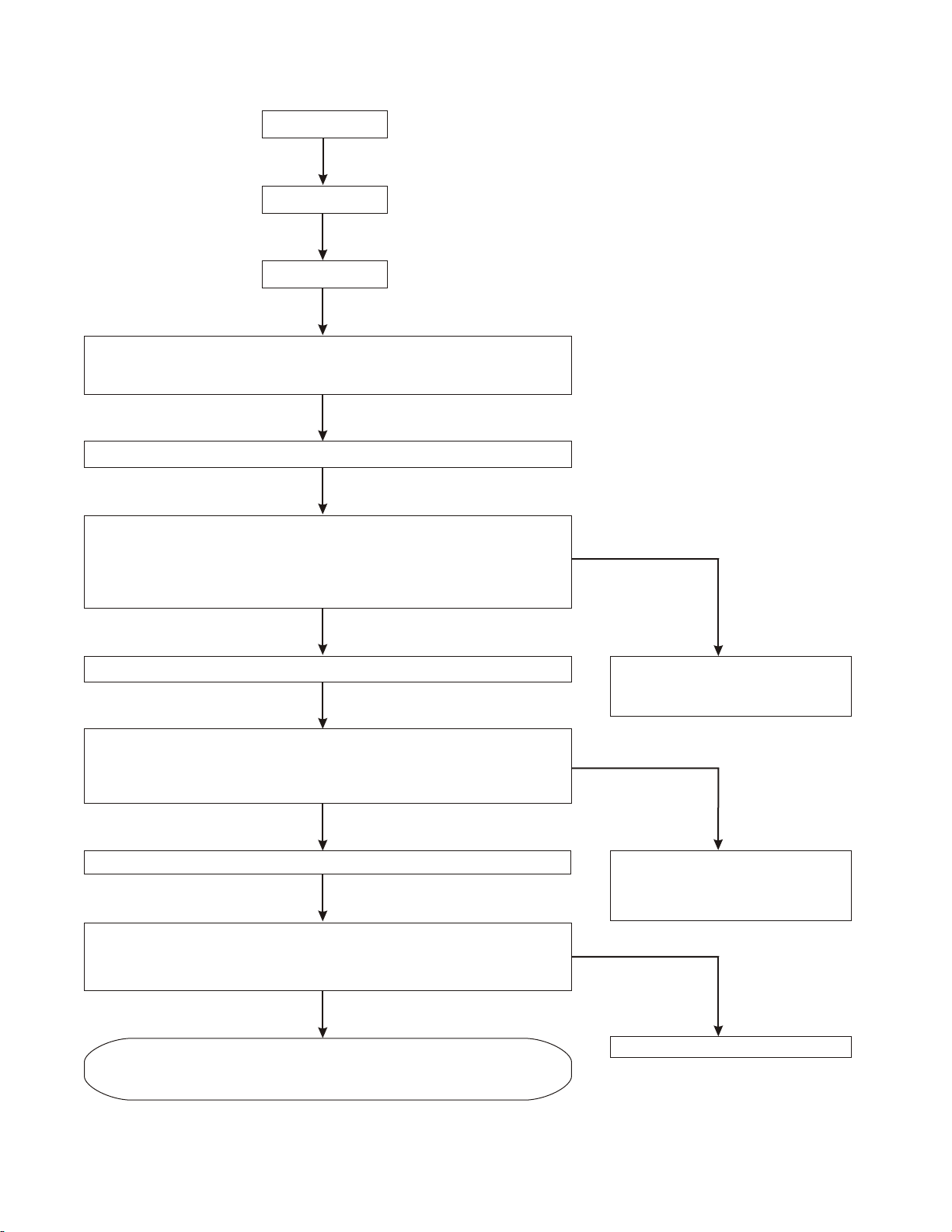

HEAT PUMP OPERATION

(Perform BASIC ECONOMIZER OPERATI ON check first)

START

Perform STEP 2

Perform STEP 3

Put thermostat fan setting to "CONTINUOUS FAN"

Reapply Power to the Unit

Turn down thermostat setting so that a call for cooling is present.

Set enthalpy potentiometer on economizer controller to A (fully CCW).

The "Free Cooling" LED turns on & the EXH LED turns on.

If only one stage of cooling is called by the thermostat, then that stage will turn off.

If two stages are called by the thermostat, then only the second stage will turn off.

The power exhaust (optional) contacts will close after 60 +/- 30 seconds.

The outside air damper opens approximately 50% (this position is determined by

the actual resistance of the 5.6k ohm resistor placed across terminals T and T1).

YES

Reset the thermostat setting so that a call for heating is present.

The "Free Cooling" LED turns off & the EXH LED turns off.

If only one stage of heating is called by the thermostat, then that stage will turn on.

If two stages are called by the thermostat, then both stages will turn on.

The power exhaust (optional) contacts will open The outside air damper fully

closes.

NO

Perform Basic Economizer Operation

check first. Recheck STEP 2 and

STEP 3

NO

YES

Turn Min Pos potentiometer fully CW.

The outside air damper drives fully open.

The EXH LED turns on.

The power exhaust (optional) contacts will close after

approximately 60 +/- 30 seconds.

YES

Heat Pump Operation is Correct.

Remove resistors, reconnect wires, and set up

potentiometers per jobsite requirements.

Check for 24 VAC at B terminal.

Check for B signal at thermostat.

Check Unit wire harness.

Check Economizer Wire harness.

NO

Replace controller.

9

Page 19

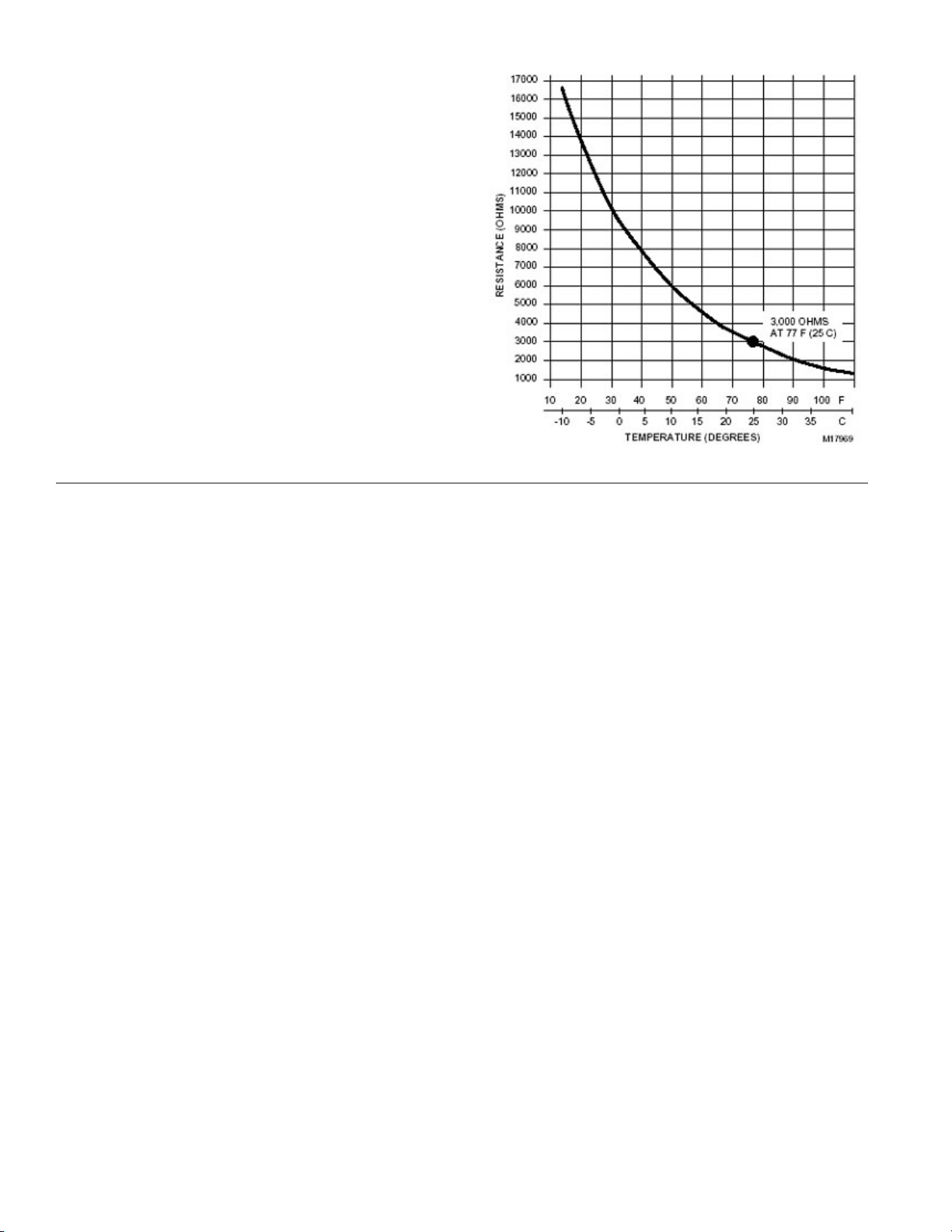

Use the following graph and the multimeter to verify proper

operation of the mixed air / discharge air temperature

sensor.

Measure the resistance (ohms) of the mixed air / discharge

air temperature sensor with the multimeter. Look up the

equivalent temperature on the graph. This should be the

same as temperature the mixed air / discharge air sensor is

detecting. If it is not, replace the mixed air /discharge air

sensor.

NOTES

1. The mist eliminator (Permanent Outdoor Air Filter), is

of aluminum mesh construction and should be

cleaned by flushing regularly with warm soapy water.

The replacement mist eliminator size is listed on the

first page of these instructions.

2. When diagnosing the system, the best results are

obtained by first putting the fan setting on the

Thermostat to the "Continuous Fan" mode.

3. Operation of the optional power exhaust only depends

upon the supply fan running and the damper position

(it is possible to set the minimum position high enough

to engage the power exhaust in the heating mode).

4. This economizer requires a two-stage thermostat.

5. Upon loss of power to the unit or economizer, the

outside air damper will spring close shut in about 5

seconds.

6. Compressor Time Delays, Compressor Interstage

Delays, Compressor Low Ambient Lockouts, etc. are

not provided by the economizer controller.

10

Page 20

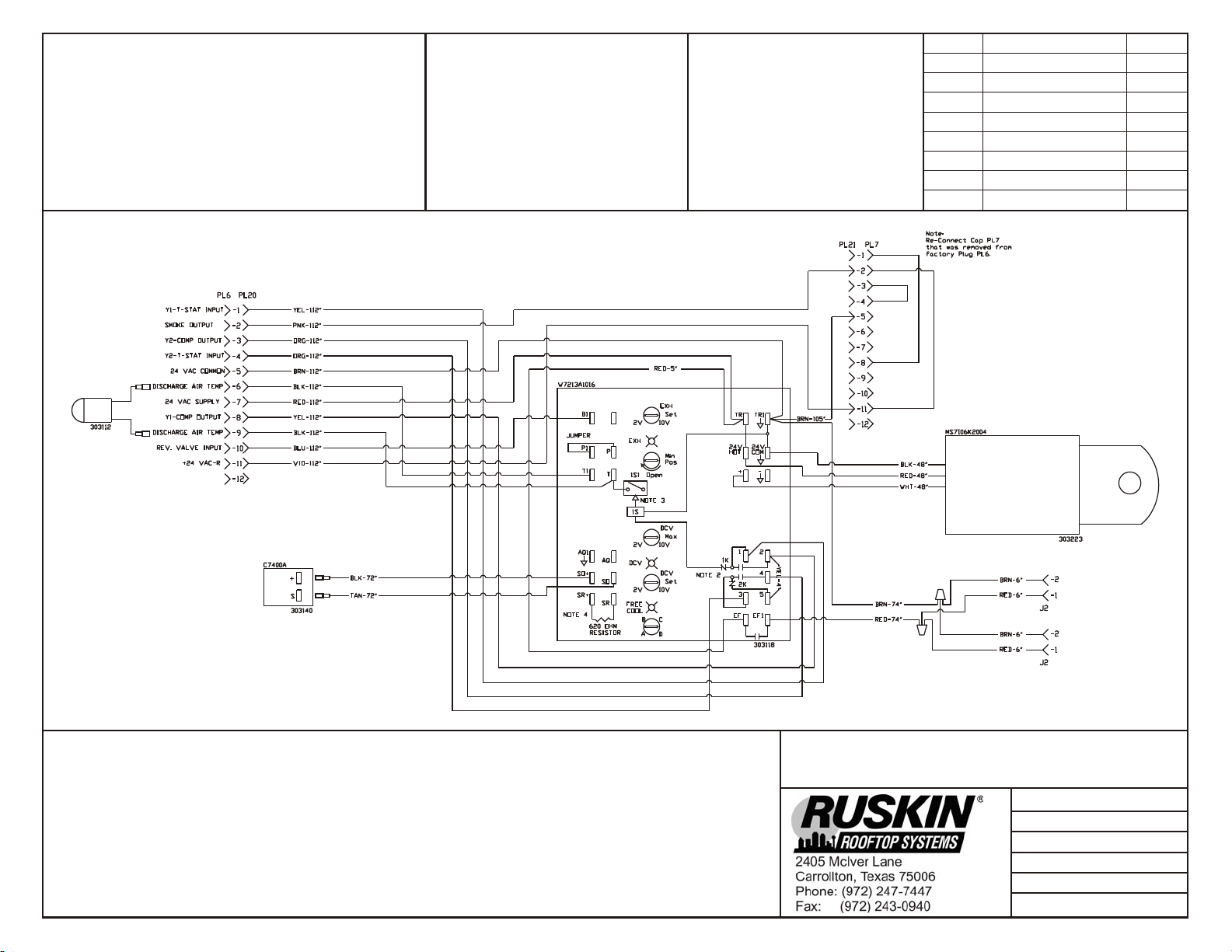

HARNESS ENDS AT PL6 & PL7

COMPONENT CODE

C7400A Fresh Air Sensor

9RT1H Mixed Air Sensor

J2 Power Exhaust Cap

MS7106K Damper Actuator 24v

PL6 Male A/C Unit Plug

PL7 Female A/C Unit Plug

PL20 Female Economizer Cap

PL21 Male Smoke Plug

W7213A Logic Module

WIRE COLOR CODE

BLK Black BLU Blue

BRN Brown GRN Green

GRY Gray ORG Orange

PNK Pink RED Red

TAN Tan VIO Violet

WHT White YEL Yellow

Re vi sion Change Date

ECN 2259 Change brown wire length 07/09/09

CONNECTOR & CONTACT CONFIGURATION

PL7 (303917) CAP - (303902) SOCKET

J2 (303909) CAP - (303902) SOCKET

Notes:

1. Unit wir ing shown as ref er ence only. Check unit wir ing for ac tual unit wir ing.

2. Re lays 1K and 2K ac tu ate when the Out door Air Enthalpy is lower than the Re turn Air Enthalpy.

3. 1S is an elec tronic switch which closes when pow ered by a 24 VAC in put.

4. Fac tory in stalled re sis tor should be re moved only if C7400 Dif fer en tial Enthalpy Sen sor is added.

5. Y2 must be en er gized for the com pres sor to op er ate.

Hor i zon tal Mod u lat ing Gear Economizer

RKNL / RLNL 180-300

Date: July 9, 2009

Supercedes: 03-19-09

Drawn by: MGL

Unit #: 60-394-16

Di a gram#: 6039416W

Ap proved by:

Page 21

SUPERSEDES 06-04-09

JULY 15, 2009

RMIHE16

Page 22

INSTALLATION INSTRUCTIONS

MODELS (-)XRD-PDCM3 & (-)XRD-SDCM3

VERTICAL AIRFLOW ECONOMIZERS

WARN ING

THIS ACCESSORY IS TO BE INSTA LLED BY A QUA LIFIED, LICENSED SERVICE PERSON. TO A VOID UNSATISFA CTORY

OPERATION OR DA MAGE TO THE PRODUCT A ND POSSIBLE UNSAFE CONDITIONS, INC LUDING ELECTRICAL SHOCK,

REFRIGERANT LEAKAGE AND FIRE, THE INSTALLATION INSTRUCTIONS PROVIDED WITH THIS ACCESSORY MUST

BE STRICTLY FOLLOWED AND THE PARTS SUPPLIED USED WITHOUT SUBSTITUTION. DAMAGE TO THE PRODUCT

RESULTING FROM NOT FOLLOWING THE INSTRUCTIONS OR USING UNAUTHORIZED PARTS MAY BE EXCLUDED

FROM THE MANUFACTURER’S WARRANTY COVERAGE.

WARN ING

DISCONNECT ELECTRICAL POWER TO TH E UNIT. FA ILURE TO DO SO CA N CA USE ELECTRIC A L SHOCK RESULTING

IN PERSONAL INJURY OR DEATH.

WARN ING

THE SMOKE DETECTOR MUST NOT BE RELIED UPON AS THE PRIMARY SMOKE DETECTION IN BUILDING SAFETY.

THE ECONOMIZER SMOKE DETECTOR DE-ENERGIZES THE SUPPLY FAN AND CLOSES THE OUTSIDE AIR DAMPER

WHEN SMOKE IS DETECTED. REFER TO ENCLOSED SMOKE DETECTOR INSTRUCTIONS (SECTION 7) FOR TESTING

OF ADEQUATE SMOKE SENSOR AIRFLOW UPON INSTALLATION OF (-)XRD-SDCM3 ECONOMIZER WITH SMOKE

DETECTOR CAPA BILITIES. SUFFICIENT DUCTED AIR VELOC ITY MUST BE PRESENT ACROSS THE SMOKE DETEC TOR

SAMPLING TUBE TO ENSURE PROPER OPERATION. ADDING POWERED EXHAUST MAY BE REQUIRED IN BUILDINGS

WITH EXCESSIVE ENVELOPE AIR LOSSES AND/OR RESTRICTIVE RETURN AIR CONDITIONS TO THE UNIT

PREVENTING ADEQUATE RETURN AIR TO THE UNIT WHEN ECONOMIZER IS OPEN TO OUTSIDE AIR.

TOOLS RE QUIRED FOR IN STAL LA TION:

3

" electric drill with

8

5

" socket Small flat blade (0.125" wide) screwdriver

16

TABLE 1

(-)XRD-SDCM3

economizer with smoke

detector, con trol ler,

ac tu a tor, and out side

enthalpy sen sor at tached

PACK AGE CON TENTS

(-)XRD-PDCM3

economizer with con trol ler,

ac tu a tor, and out side

enthalpy sen sor at tached

ITEM DE SCRIP TION PART No. PART No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Dis charge Air Sen sor (Hardware Bag)

(2) Per ma nent Fil ters

Spotweld Assy - Bird Screen

Ex haust Air Rainhood Assy – Birdscreen

Front Sup port

OA Rainhood Assy - Left Side

OA Rainhood Assy - Right Side

Ex haust Air Rainhood - Left Side

Ex haust Air Rainhood – Right Side

OA Fil ter Rail Assy

OA Rainhood Assy – Top

OA Rainhood - Front Fil ter Sup port

Hardware Bag

Smoke Detector w/ Harness

Sampling Tube

Sampling Tube Bracket

6036413B / 3112 6036413S / 3112

6036413B / 8567

(11.875" X 23.875")

6036413S / 8567

(11.875" X 23.875")

6036413B / BSWA 6036413S / BSWA

6036413B / EHB2 6036413S / EHB2

6036413B / EHSL 6036413S / EHSL

6036413B / EHSR 6036413S / EHSR

6036413B / EHS2L 6036413S / EHS2L

6036413B / EHS2R 6036413S / EHS2R

6036413B / EHT2 6036413S / EHT2

6036413B / EHT 6036413S / EHT

6036413B / EHB 6036413S / EHB

6036413B / HDW 6036413S / HDW

------ 6036413S / 3528

------ 6036413S / 3532

------ 6036413S / BRKT

Page 23

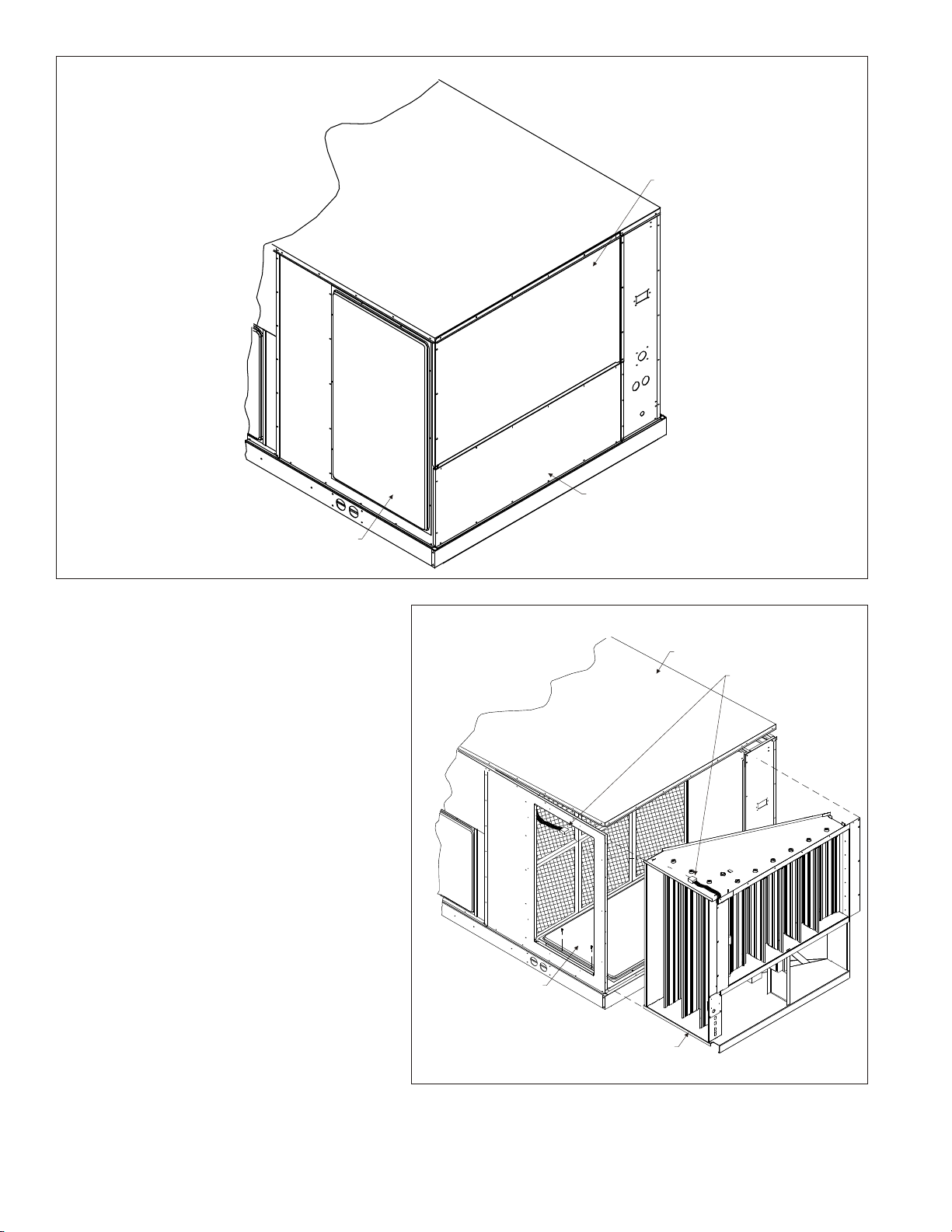

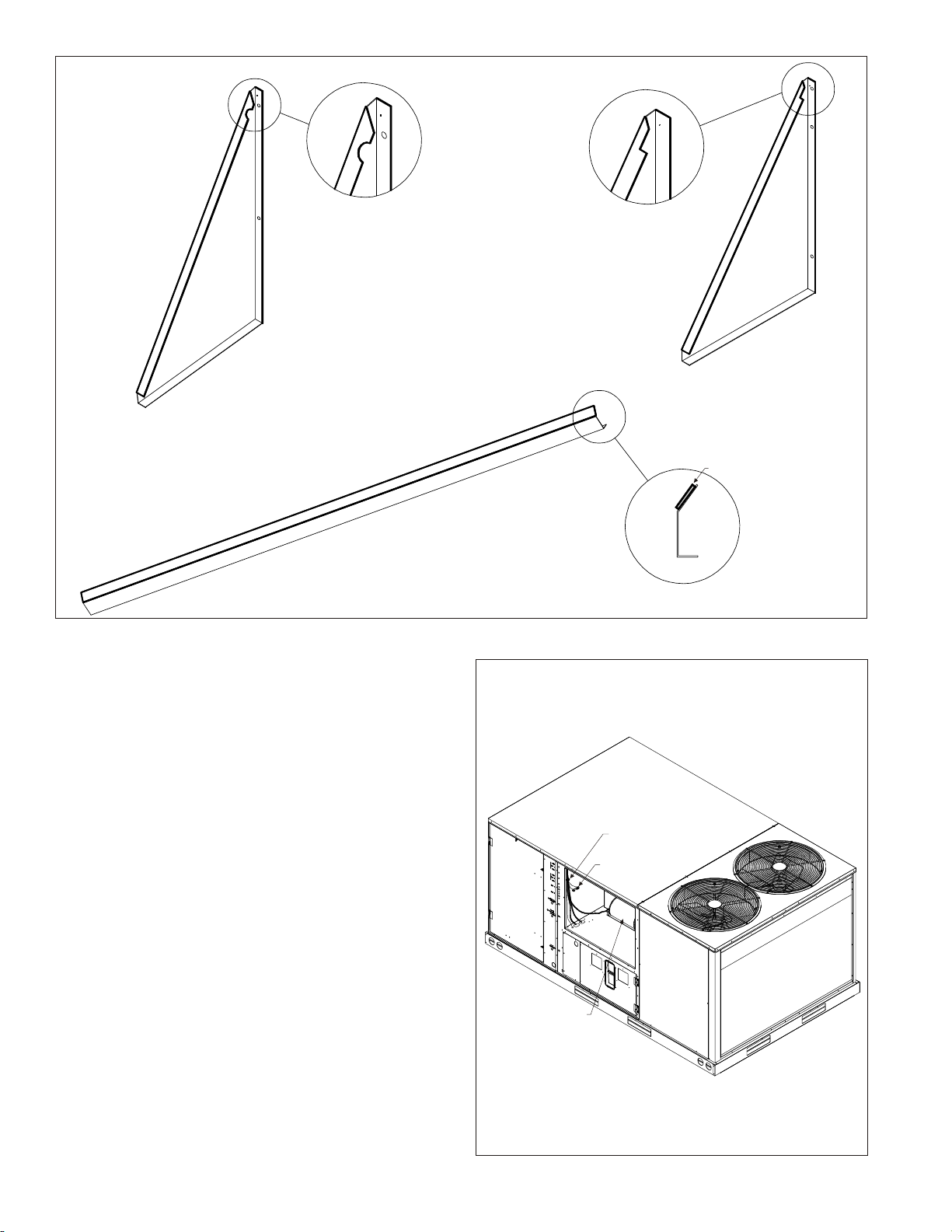

FIGURE 1

(-)XRD-PDCM3 Shown - (-)XRD-SDCM3 Similar

LEAVE THESE

SCREWS ENGAGED

RETURN COVER

FRONT SIDE

ROOF PANEL REMOVE

SCREWS FROM THREE

SIDES (FRONT, LEFT AND

BACK) EXCEPT AS NOTED

FILTERS

LEFT PANEL - UPPER

(REMOVE TO BE REUSED

IN RAIN HOOD ASSEMBLY

LEFT PANEL - LOWER

(REMOVE TO BE REUSED

IN RAIN HOOD ASSEMBLY

DOWNFLOW RETURN OPENING

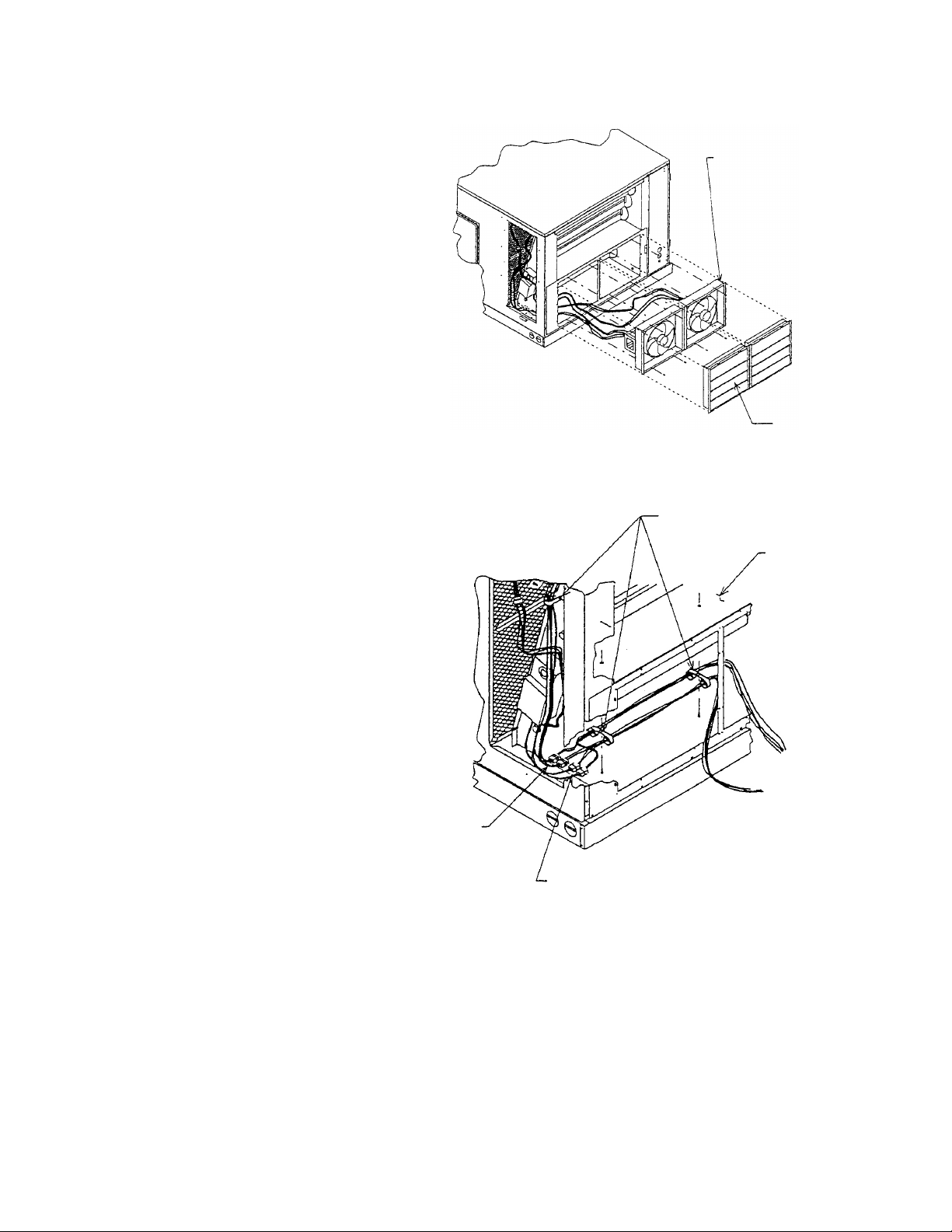

STEP 1:

Immediately upon receipt, all cartons and contents

should be inspected for transit damage. Units with

damaged cartons should be opened immediately.

If damage is found, it should be noted on the

delivery papers and a damage claim filed with the

last carrier. Compare carton(s) contents to

PACKAGE CONTENTS List (TABLE 1) above to

note any missing items.

STEP 2:

Remove RETURN COVER, LEFT PANEL –

UPPER and LOWER PANELS – LEFT BOTTOM

SECTION from the unit and retain for reuse (SEE

FIGURE 1). Retain screws.

STEP 3:

Remove screws from 3 sides of ROOF PANEL so

that it can be raised during economizer insertion.

NOTE 1:

Remove shipping bracket, PERMANENT

FILTERS, OA RAINHOOD - LEFT SIDE, OA

RAINHOOD - RIGHT SIDE, EXHAUST AIR

RAINHOOD - LEFT SIDE and EXHAUST AIR

RAINHOOD – RIGHT SIDE from fresh air opening.

(SEE FIGURE 2).

STEP 4:

Remove jumper plug and slide economizer into unit

return air section (SEE FIGURE 2). After the

economizer is installed, connect unit

ECONOMIZER PLUG to economizer mating plug.

PDCM3 - Reinstall jumper plug PL7 to PL21

(located on economizer). SDCM3 - Save jumper

plug PL7 in this compartment for diagnostic

purposes.

FIGURE 2

RE TURN COVER

DOWNFLOW RE TURN OPEN ING

ROOF PANEL

PLUG

FIL TERS

WIRE HARNESS

ACTUATOR

CONTROLLER

ECONOMIZER ASSEMBLY

A1010-01

FRONT SIDE

NOTE 1

A1011-01

2

Page 24

STEP 5:

Secure economizer and SPOTWELD ASSY - BIRD

SCREEN along bottom with six screws as shown (SEE

FIGURE 2). See TABLE 1 for identification.

STEP 6:

Fasten EXHAUST AIR RAINHOOD - LEFT SIDE and

EXHAUST AIR RAINHOOD – RIGHT SIDE to barometric

relief opening (lower opening) on the economizer (SEE

FIGURE 3). Fasten with six screws. See FIGURE 4 for

identification of EXHAUST AIR RAINHOODS.

STEP 7:

Fasten EXHAUST AIR RAINHOOD ASSY –

BIRDSCREEN FRONT SUPPORT under edge of LEFT

PANEL – LOWER using six screws. Do not install a screw

in the rightmost hole in the panels at this time.

STEP 8:

Fasten LEFT PANEL – LOWER and EXHAUST AIR

RAINHOOD ASSY – BIRDSCREEN FRON T SUPPORT

to the top of the EXHAUST AIR RAINHOOD - LEFT

SIDE and EXHAUST AIR RAINHOOD – RIG HT SIDE

which was previously installed on the unit (SEE STEP 7).

STEP 9:

Attach OA FILTER RAIL ASSY to economiz er center

support, EXHAUST AIR RAINHOOD - LEFT SIDE and

EXHAUST AIR RAINHOOD – RIGHT SIDE and L EFT

PANEL – LOWER using screws provided.

STEP 10:

Position the OA RAINHOOD ASSY – TOP under edge

of ROOF PANEL. Do not install screws at this time.

STEP 11:

Fasten OA RAINHOOD - LEFT SIDE and OA

RAINHOOD - RIGHT SIDE to unit using screws provided

(2 each on (-)XRD-PDCM3, and on (-)XRD-SDCM3).

STEP 12:

Slide PERMANENT FILTERS between OA

RAINHOOD - LEFT SIDE and OA RAINHOOD - RI GHT

SIDE back into the OA FILTER RAIL ASSY.

STEP 13:

Fasten 11 OA RA INHOOD - FRONT FILTER SUPPORT to

LEFT PANEL – UPPER with six screw s. The bottom lip

should support the PERMANENT FILTERS. Do not

install a screw in the rightmost hole in the panels at this

time.

STEP 14:

Fasten LEFT PANEL – UPPER to OA RAINHOOD LEFT SIDE and OA RAINHOOD - RIGHT SIDE and 11

OA RAINHOOD - FRONT FILTER SUPPORT using

screws (12 on (-)XRD-PDCM3, and on (-)XRD-SDCM3).

STEP 15:

Re-secure ROOF PANEL using the washer head screws

that were removed in STEP 3 from the ROOF PANEL.

FIGURE 3

(-)XRD-PDCM3 Shown - (-)XRD-SDCM3 Similar

(See Table 1 for identification of parts)

ECON. CENTER

SUPPORT (REF.)

LEFT PANEL - LOWER

ROOF PANEL (REF.)

LEFT PANEL - UPPER

11

A1012-01

3

Page 25

FIGURE 4

EXHAUST AIR RAIN HOOD

(LOWER LEFT SIDE)

OUTSIDE AIR RAIN HOOD

(UPPER LEFT SIDE)

SEAL STRIP

EXHAUST AIR RAIN HOOD ASSEMBLY

(BIRDSCREEN FRONT SUPPORT)

STEP 16:

Remove the BLOWER MOTOR ACCESS PANEL (SEE

FIGURE 5).

STEP 17:

Connect the j DISCHARGE AIR SENSOR to wires 51

and 52 located in the blower motor compartment.

NOTE:

Mixed air sensor should be secured with the included wire

tie to avoid entanglement with the blower and direct

contact with any sheet metal surfaces.

STEP 18:

Replace the BLOWER MOTOR ACCESS PANEL.

STEP 19:

Upon start-up check the economizer sequence of

operation using the steps provided in these instructions.

After testing unit operation and setting outside air damper

minimum position, replace RETURN COVER with

remaining screws.

END VIEW

A1005-01

FIGURE 5

WIRE TIE

INDOOR MOTOR

A1006-01

4

Page 26

DI RECT MOUNT ECONOMIZER SE QUENCE OF OP ER A TION

GEN ERAL

This accessory economizer package is designed to save

energy costs by using outdoor air for cooling and

ventilation in place of mechanical cooling whenever

possible. The economizer continuously monitors indoor

and outdoor air conditions and compares them to a

user-selected setpoint to determine if free cooling is

available.

AC CES SO RIES

(-)XRX-AV02 — Dual Enthalpy Up grade Kit

For maximum energy savings, this upgrade kit will allow

the economizer to compare the outdoor air enthalpy to the

return air enthalpy, instead of a user-selected setpoint to

determine if "free cooling" is available.

(-)XRX-AR02 - Wall-Mounted Car bon Di ox ide Sen sor

For installations requiring Demand Control Ventilation

(DCV) based upon indoor air levels of carbon dioxide

(CO2). When the unit supply fan is running, the CO2 sensor

modulates the outside air damper to maintain a

user-selected CO2 level inside the occupied space.

Energy savings are achieved by not bringing in excessive

amounts of outdoor air when the indoor air conditions are

suitable. Energy savings can be substantial on buildings

with highly variable occupancy rates.

Wall-Mounted Remote Potentiometer

For installations requiring remote adjustment of damper

minimum position by the occupants, a remote

potentiometer, such as the Honeywell S963B1128 can be

used.

(-)XRX-BFF02C, (-)XRX-BFF02D, (-)XRX-BFF02Y —

Power Exhaust Kit

For installations requiring more space static pressure relief

than can be obtained with the standard barometric relief

damper included with the economizer, a power exhaust kit

can be added.

B. Range of adjustment is from 0-100% (2-10V); in

most applications the power exhaust is set to

engage at about 70% outside air.

2. Min Pos — Outside Air Damper minimum position

A. Adjust the minimum position potentiometer to

allow the minimum amount of outdoor air, as

required by local codes, to enter the building.

B. Range of adjustment is from 0-100% (2-10V); in

most applications the minimum position is

adjusted to allow 10% to 25% outside air to enter

the system.

C. The Outside Air Damper Minimum Position

potentiometer can be adjusted at any time.

D. Whenever the "G" (supply fan) signal is present,

the damper will open to this minimum position

unless:

a. It may modulate to a greater position if

overridden by the CO2 sensor (DCV).

b. It may not open if overridden by the discharge

air temperature sensor (Freeze Protect

Mode).

3. DCV Max — Demand Control Ventilation (DCV)

Maximum Setpoint

A. The DCV maximum position potentiometer allows

the installer to limit the amount of outdoor air flow

into the building when the DCV overrides the

mixed air sensor.

B. Setting the DCV maximum position of the damper

prevents the introduction of large amounts of hot

or cold air into the space.

C. Note: If the DCV maximum position is set below

the outside air damper minimum position, the

minimum position overrides the DCV maximum

position (negating the function of the DCV).

STARTUP

Operational Note

For (-) XRD-SDCM3 economizer. After these startup

adjustments have been completed, perform airflow

measurement tests on the smoke detector to ensure

adequate smoke detector sensing air. Refer to enclosed

smoke detector instructions (section 7).

Attach connector from Economizer Controller to Rooftop

Control Panel Connector and install discharge/mixed air

temperature sensor per installation guide.

AD JUST MENTS

5 po ten ti om eters with screw driver ad just ment slots,

start ing from top of con trol ler

1. EXH Set — Adjustments for (optional) power ex haust

A. The outside air damper position at which the

power exhaust fan(s) will engage. The LED

labeled EXH below the potentiometer adjustment

will indicate when power exhaust is available.

When the power exhaust call is made, the

controller provides a 60 ±30 second delay before

exhaust fan activation to allow the damper to

reach the appropriate position.

FIGURE 6

5

Page 27

4. DCV Set — Demand Control Ventilation (DCV)

Setpoint

A. The DCV can be any sensor that provides a

2-10Vdc output. The DCV modulates the outdoor

damper to provide ventilation based on

occupancy. Typically, a carbon dioxide (CO2)

sensor is used to indirectly monitor occupancy

level.

B. No cooling signal (e.g.Y1, Y2) is required for the

DCV to override the outdoor air damper when

ventilation requires outdoor air.

C. The controller must receive a "G" (supply fan)

signal to open the damper.

D. Range of adjustment is from 2 Volts to 10 Volts.

E. The DCV setpoint can be adjusted at any time.

F. The controller compares the CO2 sensor input to

the setpoint setting to determine the damper

minimum position.

a. If the actual CO2 level is below the setpoint,

then the damper minimum position is

determined by the damper minimum position

potentiometer setting.

b. If the actual CO2 level rises above the

setpoint, then the damper minimum position is

overridden proportionally more open.

c. If the discharge air temperature drops below

48°F (Freeze Protect Mode), the DCV input

will be overridden and the damper may not

open.

G. Compatible CO2 sensors will have a 2-10Vdc

output for a 0-1500 ppm CO2 input.

H. Ensure proper polarity of the sensor wires when

connecting to the economizer controller. Incorrect

polarity negates the sensor signal.

5. Economizer Setpoint

A. Only the coolest, driest outside air is used for

economizer operation when the potentiometer is

on setting "D". For greatest energy savings, the

potentiometer is on setting "A".

B. Adjustment range is A, B, C, or D

a. Setting "A" = 73F db or 27 Btu/lbm @ 50% RH

b. Setting "B" = 70F db or 25 Btu/lbm @ 50% RH

c. Setting "C" = 67F db or 23 Btu/lbm @ 50% RH

d. Setting "D" = 63F db or 22 Btu/lbm @ 50% RH

C. Economizer Setpoint potentiometer can be

adjusted at any time.

D. The controller compares the enthalpy sensor input

with the economizer setpoint to determine if free

cooling is available.

a. Single enthalpy strategy: If outdoor air

enthalpy is lower than the setpoint, then free

cooling is available. Note: The

factory-installed 620-ohm resistor must be in

place across terminals SR and SR+.

b. Dual enthalpy strategy: If outdoor air enthalpy

is lower than return air enthalpy, then free

cooling is available.

FIGURE 7

1. Note: If using dual enthalpy, the Economizer

Setpoint must be at the "D" setting.

2. The factory-installed 620-ohm jumper must

be removed to install the dual enthalpy

upgrade kit.

NOR MAL OP ER A TION

1. Fan Only (G)

A. Damper will go to minimum position (in 90

seconds or less) whenever the "G" (supply fan)

signal is present.

B. When "G" signal is removed, the outside air

damper closes against blade seals for tight shutoff

of outside air.

C. If the discharge air temperature drops below 48ºF,

then the control will override the minimum position

setting and will modulate the outside air damper

closed.

2. Call for First Stage of Cooling (Y1)

A. Economizer Unavailable (warm outdoor air).

Compressor 1 is commanded on without delay.

B. Economizer Available (free cooling). The

controller tries to maintain a discharge air

temperature of 53ºF ± 5 by modulating the outside

air damper position.

3. Call for Second Stage of Cooling (Y2)

A. Economizer Unavailable (warm outdoor air).

Compressor 2 is commanded on without delay.

B. Economizer Available (free cooling). Compressor

1 is commanded on without delay. The controller

tries to maintain a discharge air temperature of

53ºF ± 5 by modulating the outside air damper

position. Compressor 2 is not activated in the

economizer mode.

6

Page 28

4. Call for Heat

A. Standard Air Conditioner with electric or gas heat.

(W1 & W2)

a. The Thermostat controls the stages of heating

directly.

b. If the control detects that the supply fan is on

(through its "G" input), then the control will

open the damper to minimum position.

c. If the discharge air temperature drops below

48ºF, then the control will override the

minimum position setting and will modulate

the outdoor damper closed.

B. Heat Pump Operation (B)

a. The "B" signal from the Thermostat allows

operation of the compressors to provide

heating without delay.

b If the control detects that the supply fan is on

(through its "G" input), then the control can

open the damper to minimum position.

c. If the discharge air temperature drops below

48ºF, then the control will override the

minimum position setting and will modulate

the outdoor damper closed.

5. Low Ambient Compressor Lockout – None

present.

TROU BLE SHOOT ING

1. Checkout requires a handheld multimeter, 9V battery,

a 5.6k ohm .25 watt resistor, a 1.2k ohm .25 watt

resistor, a jumper wire with .25" quick connect

terminals, and the 620 ohm resistor that is

factory-installed across terminals SR+ and SR. The

terminal names below reference the economizer

controller. Use the following flowcharts for to diagnose

unit.

2.

a. Disconnect power to the unit.

b. Jumper P to P1 (factory installed jumper is

normally present).

c. Remove outdoor air enthalpy sensor from

terminals SO+ and SO and install the 1.2k ohm

resistor.

d. Put 620 ohm resistor across terminals SR+ and

SR (factory installed 620 ohm resistor is normally

present and can be used).

e. Put 5.6k ohm resistor across T and T1.

3.

a. Turn (EXH Set) Exhaust fan Setpoint

potentiometer fully CCW.

b. Turn (Min Pos) Minimum Outside Air Damper

potentiometer fully CCW.

c. Turn (DCV Max) Demand Control Ventilation

Maximum potentiometer fully CW.

d. Turn (DCV Set) Demand Control Ventilation

Setpoint potentiometer fully CCW.

e. Turn enthalpy potentiometer to "D".

7

Page 29

BASIC ECONOMIZER OPERATION

START Perform STEP 2 Perform STEP 3

Put thermostat fan setting to "CONTINUOUS FAN"

Set thermostat so neither heating or cooling is called

Reapply Power to the Unit

Connect Economizer Wire Harness to Unit

Check Thermostat Connections

Check for 24 VAC at Unit Transformer

Ensure power is available from smoke detector (-)XRD-SSDCM3 at PL20-2 with

harness connected. Push reset at the smoke detector if power is not present

(refer to smoke detector instructions if smoke detector is suspect).

Unplug Economizer Wire Harness from Unit Wire harness and Install

Jumper Plug (Jumpers Y1 Thermostat to Y1 Compressor and Jumpers

compressor(s) run? If both stages

Check Thermostat Wiring

Check Unit Wiring Harness

The "Free Cooling" LED turns on & the EXH LED turns on.

If only one stage of cooling is called by the thermostat, then that stage

will turn off. If two stages are called by the thermostat, then only the

second stage will turn off. The power exhaust (optional) contacts will

close after 60 +/- 30 seconds. The outside air damper opens

approximately 50% (this position is determined by the actual resistance

of the 5.6k ohm resistor placed across terminals T and T1).

The "Free Cooling" LED turns off & the EXH LED turns off.

If only one stage of cooling is called by the thermostat, then that stage

will turn back on. If two stages are called by the thermostat, then both

stages will turn on. The power exhaust (optional) contacts open & the

Remove 5.6k ohm resistor and jumper terminals T to T1.

Y2 Thermostat to Y2 Compressor)

If one

stage of cooling

is called by the

thermostat, do first stage

are called, do both stages

of compressors

Set enthalpy potentiometer to D (fully CW).

outside air damper fully closes.

Set enthalpy potentiometer back to A (fully CCW).

Check Unit Wire Harness

Check Economizer Controller Model Number

Perform STEP 2 & STEP 3 again.

If problem continues, replace controller

run?

NO

(W7213A1016)

YES

Check Economizer Wiring

Harness. Check Unit wiring

harness at economizer

connection for proper terminal

YES

YES

location

NO

NO

NO

available between terminal TR and TR1?

NO

Turn down thermostat setting so that a call for cooling is present.

NO

Set enthalpy potentiometer on economizer controller to A (fully CCW).

Recheck STEP 2 and STEP 3. If LED’s turn on and damper motor

does not operate, measure voltage between terminals 24V COM and

(+ (white wire)). If approximately 6 VDC is present, replace damper

actuator. If voltage not present, or LED’s do not light replace controller.

Recheck STEP 2 and STEP 3.

If problem continues replace controller

24 VAC power

YES

Are all LED's off &

outside air damper fully closed?

YES

If one

stage of cooling

is called by the

thermostat, do first stage

compressor(s) run? If both stages

are called, do both stages

of compressors

run?

YES

The "Free Cooling" LED turns on & the EXH LED turns on. If only one

stage of cooling is called by the thermostat, then that stage will turn off.

If two stages of cooling are called by the thermostat, then only the

second stage will turn off. The power exhaust (optional) contacts will

close after 60 +/- 30 seconds. The outside air damper fully opens

YES

Remove jumper from terminals T to T1 and leave open (simulates the

The "Free Cooling" LED remains on & the EXH LED turns off.

If only one stage of cooling is called by the thermostat, then that stage

will remain off. If two stages of cooling are called by the thermostat,

then only the second stage will remain off. The power exhaust

(optional) contacts opens & the outside air damper fully closes

Economizer Controller, Actuator, Wiring are correct.

Remove resistors, reconnect wires, and set up

Freeze Protect mode).

YES

potentiometers per jobsite requirements.

8

NO

NO

Page 30

HEAT PUMP OPERATION

(Perform BASIC ECONOMIZER OPERATI ON check first)

START

Perform STEP 2

Perform STEP 3

Put thermostat fan setting to "CONTINUOUS FAN"

Reapply Power to the Unit

Turn down thermostat setting so that a call for cooling is present.

Set enthalpy potentiometer on economizer controller to A (fully CCW).

The "Free Cooling" LED turns on & the EXH LED turns on.

If only one stage of cooling is called by the thermostat, then that stage will turn off.

If two stages are called by the thermostat, then only the second stage will turn off.

The power exhaust (optional) contacts will close after 60 +/- 30 seconds.

The outside air damper opens approximately 50% (this position is determined by

the actual resistance of the 5.6k ohm resistor placed across terminals T and T1).

YES

Reset the thermostat setting so that a call for heating is present.

The "Free Cooling" LED turns off & the EXH LED turns off.

If only one stage of heating is called by the thermostat, then that stage will turn on.

If two stages are called by the thermostat, then both stages will turn on.

The power exhaust (optional) contacts will open The outside air damper fully

closes.

NO

Perform Basic Economizer Operation

check first. Recheck STEP 2 and

STEP 3

NO

YES

Turn Min Pos potentiometer fully CW.

The outside air damper drives fully open.

The EXH LED turns on.

The power exhaust (optional) contacts will close after

approximately 60 +/- 30 seconds.

YES

Heat Pump Operation is Correct.

Remove resistors, reconnect wires, and set up

potentiometers per jobsite requirements.

Check for 24 VAC at B terminal.

Check for B signal at thermostat.

Check Unit wire harness.

Check Economizer Wire harness.

NO

Replace controller.

9

Page 31

Use the following graph and the multimeter to verify proper

operation of the mixed air / discharge air temperature

sensor.

Measure the resistance (ohms) of the mixed air / discharge

air temperature sensor with the multimeter. Look up the

equivalent temperature on the graph. This should be the

same as temperature the mixed air / discharge air sensor is

detecting. If it is not, replace the mixed air /discharge air

sensor.

NOTES

1. The mist eliminator (Permanent Outdoor Air Filter), is

of aluminum mesh construction and should be

cleaned by flushing regularly with warm soapy water.

The replacement mist eliminator size is listed on the

first page of these instructions.

2. When diagnosing the system, the best results are

obtained by first putting the fan setting on the

Thermostat to the "Continuous Fan" mode.

3. Operation of the optional power exhaust only depends

upon the supply fan running and the damper position

(it is possible to set the minimum position high enough

to engage the power exhaust in the heating mode).

4. This economizer requires a two-stage thermostat.

5. Upon loss of power to the unit or economizer, the

outside air damper will spring close shut in about 5

seconds.

6. Compressor Time Delays, Compressor Interstage

Delays, Compressor Low Ambient Lockouts, etc. are

not provided by the economizer controller.

SUPERSEDES 07-15-09

0CTOBER 1, 2009

10

RMIGE13B

Page 32

HARNESS ENDS AT PL6

COMPONENT CODE

C7400A Fresh Air Sensor

9RT1H Mixed Air Sensor

J2 Power Exhaust Cap

MS7106K Damper Actuator 24v

PL6 Male A/C Unit Plug

PL7 Female A/C Unit Plug

PL20 Female Economizer Cap

PL21 Male Smoke Plug

W7213A Logic Module

WIRE COLOR CODE

BLK Black BLU Blue

BRN Brown GRN Green

GRY Gray ORG Orange

PNK Pink RED Red

TAN Tan VIO Violet

WHT White YEL Yellow

Re vi sion Change Date

CONNECTOR & CONTACT CONFIGURATION

PL7 (303917) CAP - (303902) SOCKET

J2 (303909) CAP - (303902) SOCKET

Notes:

1. Unit wir ing shown as ref er ence only. Check unit wir ing for ac tual unit wir ing.

2. Re lays 1K and 2K ac tu ate when the Out door Air Enthalpy is lower than the Re turn Air Enthalpy.

3. 1S is an elec tronic switch which closes when pow ered by a 24 VAC in put.

4. Fac tory in stalled re sis tor should be re moved only if C7400 Dif fer en tial Enthalpy Sen sor is added.

5. Y2 must be en er gized for the com pres sor to op er ate.

Modulating Gear Economizer

(-)XRD-PDCM3

RKNL/RLNL 072 - 150 Without Smoke Detector

Date: June 8, 2009

Supersedes: 03-19-09

Drawn by: MGL

Unit #: 60-364-13C

Di a gram#: 6036413CW

Ap proved by:

Page 33

HARNESS ENDS AT PL6

COMPONENT CODE

C7400A Fresh Air Sensor

9RT1H Mixed Air Sensor

J2 Power Exhaust Cap

MS7106K Damper Actuator 24v

PL6 Male A/C Unit Plug

PL20 Female Economizer Cap

PL21 Male Smoke Plug

PL22 Female Smoke Cap

W7213A Logic Module

WIRE COLOR CODE

BLK Black BLU Blue

BRN Brown GRN Green

GRY Gray ORG Orange

PNK Pink RED Red

TAN Tan VIO Violet

WHT White YEL Yellow

Re vi sion Change Date

A Changed 303530 to 303528 09-30-09

CONNECTOR & CONTACT CONFIGURATION

PL7 (303917) CAP - (303902) SOCKET

J2 (303909) CAP - (303902) SOCKET

Notes:

1. Unit wir ing shown as ref er ence only. Check unit wir ing for ac tual unit wir ing.

2. Re lays 1K and 2K ac tu ate when the Out door Air Enthalpy is lower than the Re turn Air Enthalpy.

3. 1S is an elec tronic switch which closes when pow ered by a 24 VAC in put.

4. Fac tory in stalled re sis tor should be re moved only if C7400 Dif fer en tial Enthalpy Sen sor is added.

5. Y2 must be en er gized for the com pres sor to op er ate.

Modulating Gear Economizer

(-)XRD-SDCM3

RKNL/RLNL 072 - 150 With Smoke Detector

Date: Sep tem ber 30, 2009

Supersedes: 03-19-09

Drawn by: MGL

Unit #: 60-364-13S

Di a gram#: 6036413SW

Ap proved by:

Page 34

INSTALLATION INSTRUCTIONS

MODELS (-)XRD-PGCM3 & (-)XRD-SGCM3

VERTICAL AIRFLOW ECONOMIZERS

WARN ING

THIS ACCESSORY IS TO BE INSTA LLED BY A QUA LIFIED, LICENSED SERVICE PERSON. TO A VOID UNSATISFA CTORY

OPERATION OR DA MAGE TO THE PRODUCT A ND POSSIBLE UNSAFE CONDITIONS, INC LUDING ELECTRICAL SHOCK,

REFRIGERANT LEAKAGE AND FIRE, THE INSTALLATION INSTRUCTIONS PROVIDED WITH THIS ACCESSORY MUST

BE STRICTLY FOLLOWED AND THE PARTS SUPPLIED USED WITHOUT SUBSTITUTION. DAMAGE TO THE PRODUCT

RESULTING FROM NOT FOLLOWING THE INSTRUCTIONS OR USING UNAUTHORIZED PARTS MAY BE EXCLUDED

FROM THE MANUFACTURER’S WARRANTY COVERAGE.

WARN ING

DISCONNECT ELECTRICAL POWER TO TH E UNIT. FA ILURE TO DO SO CA N CA USE ELECTRIC A L SHOCK RESULTING

IN PERSONAL INJURY OR DEATH.

WARN ING

THE SMOKE DETECTOR MUST NOT BE RELIED UPON AS THE PRIMARY SMOKE DETECTION IN BUILDING SAFETY.

THE ECONOMIZER SMOKE DETECTOR DE-ENERGIZES THE SUPPLY FAN AND CLOSES THE OUTSIDE AIR DAMPER

WHEN SMOKE IS DETECTED. REFER TO ENCLOSED SMOKE DETECTOR INSTRUCTIONS (SECTION 7) FOR TESTING

OF ADEQUATE SMOKE SENSOR AIRFLOW UPON INSTALLATION OF (-)XRD-SDCM3 ECONOMIZER WITH SMOKE

DETECTOR CAPA BILITIES. SUFFICIENT DUCTED AIR VELOC ITY MUST BE PRESENT ACROSS THE SMOKE DETEC TOR

SAMPLING TUBE TO ENSURE PROPER OPERATION. ADDING POWERED EXHAUST MAY BE REQUIRED IN BUILDINGS

WITH EXCESSIVE ENVELOPE AIR LOSSES AND/OR RESTRICTIVE RETURN AIR CONDITIONS TO THE UNIT

PREVENTING ADEQUATE RETURN AIR TO THE UNIT WHEN ECONOMIZER IS OPEN TO OUTSIDE AIR.

TOOLS RE QUIRED FOR IN STAL LA TION:

3

" electric drill with

8

5

" socket Small flat blade (0.125" wide) screwdriver

16

TABLE 1

PACK AGE CON TENTS

(-)XRD-PGCM3

economizer with

con trol ler, ac tu a tor, and

out side enthalpy sen sor

at tached

(-)XRD-SGCM3

economizer with smoke

detector, con trol ler,

ac tu a tor, and out side

enthalpy sen sor at tached

ITEM DE SCRIP TION PART No. PART No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Dis charge Air Sen sor (Hardware Bag)

(2) Per ma nent Fil ters

Spotweld Assy - Bird Screen

Ex haust Air Rainhood Assy – Birdscreen

Front Sup port

OA Rainhood Assy - Left Side

OA Rainhood Assy - Right Side

Ex haust Air Rainhood - Left Side

Ex haust Air Rainhood – Right Side

OA Fil ter Rail Assy

OA Rainhood Assy – Top

OA Rainhood - Front Fil ter Sup port

Adaptor Panel

Hardware Bag

Smoke Detector w/ Harness

Sampling Tube

Sampling Tube Bracket

6036416 / 3112 6036416S / 3112

6036416 / 8567

(11.875" X 23.875")

6036416S / 8568

(23.875" X 23.875")

6036416 / BSWA 6036416S / BSWA

6036416 / EHB2 6036416S / EHB2

6036416 / EHSL 6036416S / EHSL

6036416 / EHSR 6036416S / EHSR

6036416 / EHS2L 6036416S / EHS2L

6036416 / EHS2R 6036416S / EHS2R

6036416 / EHT2 6036416S / EHT2

6036416 / EHT 6036416S / EHT

6036416 / EHB 6036416S / EHB

6036416 / ADP 6036416S / ADP

6036416 / HDW 6036416S / HDW

------ 6036416S / 3528

------ 6036416S / 3527

------ 6036416S / BRKT

Page 35

FIGURE 1

(-)XRD-PGCM3 Shown - (-)XRD-SGCM3 Similar

LEAVE THESE

SCREWS ENGAGED

RETURN COVER

DOWNFLOW RETURN OPENING

FRONT SIDE

ROOF PANEL REMOVE

SCREWS FROM THREE

SIDES (FRONT, LEFT AND

BACK) EXCEPT AS NOTED

FILTERS

LEFT PANEL - UPPER

(REMOVE TO BE REUSED

IN RAIN HOOD ASSEMBLY

LEFT PANEL - LOWER

(REMOVE TO BE REUSED

IN RAIN HOOD ASSEMBLY

A1010-01

STEP 1:

Immediately upon receipt, all cartons and contents

should be inspected for transit damage. Units with

damaged cartons should be opened immediately.

If damage is found, it should be noted on the

delivery papers and a damage claim filed with the

last carrier. Compare carton(s) contents to

PACKAGE CONTENTS List (TABLE 1) above to

note any missing items.

STEP 2:

Remove RETURN COVER, LEFT PANEL –

UPPER and LOWER PANELS – LEFT BOTTOM

SECTION from the unit and retain for reuse (SEE

FIGURE 1). Retain screws.

STEP 3:

Remove screws from 3 sides of ROOF PANEL so

that it can be raised during economizer insertion.

NOTE 1:

Remove shipping bracket, PERMANENT

FILTERS, OA RAINHOOD - LEFT SIDE, OA

RAINHOOD - RIGHT SIDE, EXHAUST AIR

RAINHOOD - LEFT SIDE and EXHAUST AIR

RAINHOOD – RIGHT SIDE from fresh air opening.

(SEE FIGURE 2).

STEP 4:

Remove jumper plug and slide economizer into unit

return air section (SEE FIGURE 2). After the

economizer is installed, connect unit

ECONOMIZER PLUG to economizer mating plug.

PGCM3 - Reinstall jumper plug PL7 to PL21

(located on economizer). SGCM3 - Save jumper

plug PL7 in this compartment for diagnostic

purposes.

2

FIGURE 2

RE TURN COVER

DOWNFLOW RE TURN OPEN ING

ROOF PANEL

PLUG

FIL TERS

WIRE HARNESS

ACTUATOR

CONTROLLER

ECONOMIZER ASSEMBLY

FRONT SIDE

NOTE 1

A1011-01

Page 36

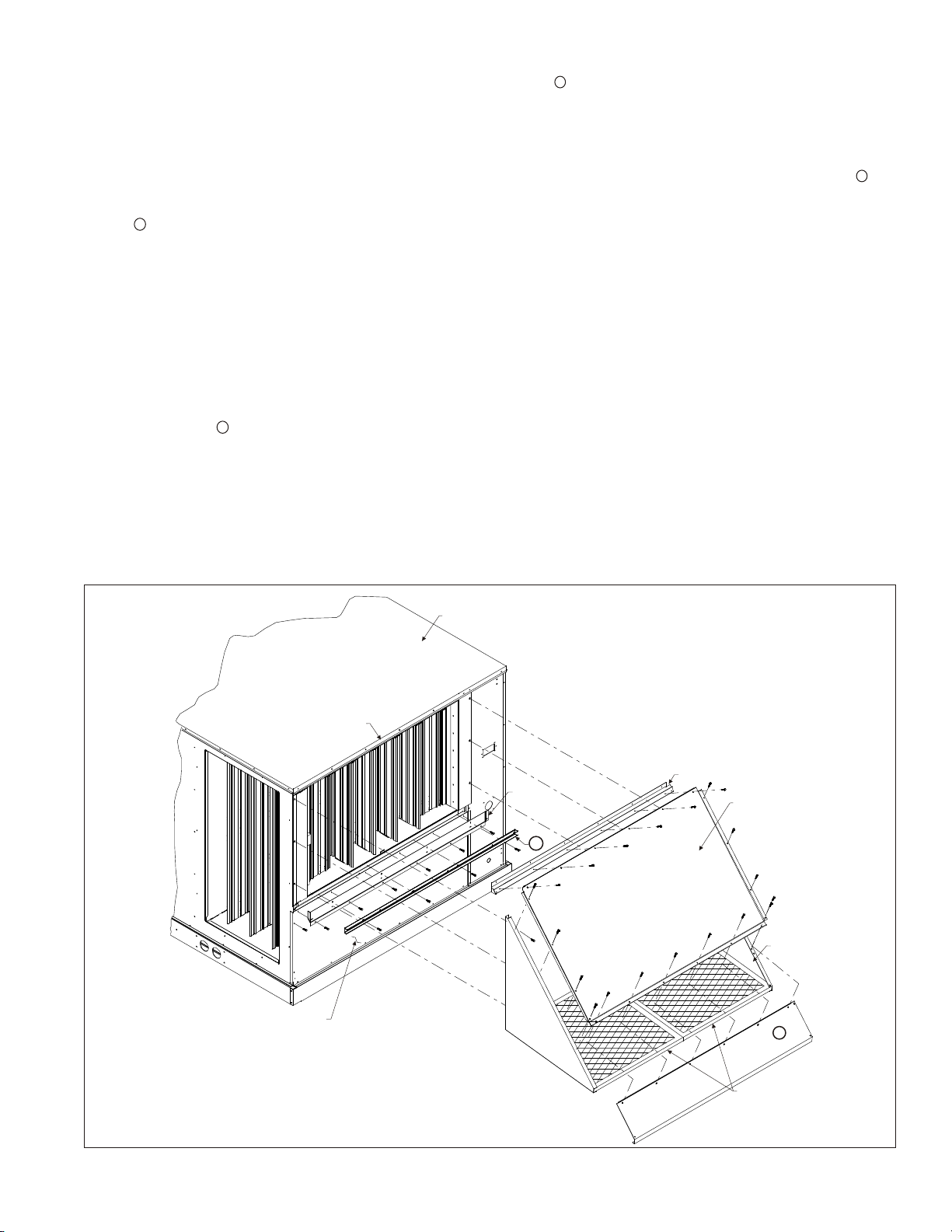

STEP 5:

Secure economizer and SPOTWELD ASSY - BIRD

SCREEN along bottom with six screws as shown (SEE

FIGURE 2). See TABLE 1 for identification.

STEP 6:

Fasten EXHAUST AIR RAINHOOD - LEFT SIDE and

EXHAUST AIR RAINHOOD – RIGHT SIDE to barometric

relief opening (lower opening) on the economizer (SEE

FIGURE 3). Fasten with six screws. See FIGURE 4 for

identification of EXHAUST AIR RAINHOODS.

STEP 7:

Fasten EXHAUST AIR RAINHOOD ASSY –

BIRDSCREEN FRONT SUPPORT under edge of LEFT

PANEL – LOWER using six screws. Do not install a screw

in the rightmost hole in the panels at this time.

STEP 8:

Fasten LEFT PANEL – LOWER and EXHAUST AIR

RAINHOOD ASSY – BIRDSCREEN FRON T SUPPORT

to the top of the EXHAUST AIR RAINHOOD - LEFT

SIDE and EXHAUST AIR RAINHOOD – RIG HT SIDE

which was previously installed on the unit (SEE STEP 7).

STEP 9:

Attach OA FILTER RAIL ASSY to economiz er center

support, EXHAUST AIR RAINHOOD - LEFT SIDE and

EXHAUST AIR RAINHOOD – RIGHT SIDE and L EFT

PANEL – LOWER using screws provided.

STEP 10:

Position the OA RAINHOOD ASSY – TOP under edge

of ROOF PANEL. Do not install screws at this time.

STEP 11:

Fasten OA RAINHOOD - LEFT SIDE and OA

RAINHOOD - RIGHT SIDE to unit using screws provided

(3 each on (-)XRD-PGCM3, and on (-)XRD-SGCM3).

STEP 12:

Slide PERMANENT FILTERS between OA

RAINHOOD - LEFT SIDE and OA RAINHOOD - RI GHT

SIDE back into the OA FILTER RAIL ASSY.

STEP 13:

Fasten 11 OA RA INHOOD - FRONT FILTER SUPPORT to

LEFT PANEL – UPPER with six screw s. The bottom lip

should support the PERMANENT FILTERS. Do not

install a screw in the rightmost hole in the panels at this

time.

STEP 14:

Fasten LEFT PANEL – UPPER to OA RAINHOOD LEFT SIDE and OA RAINHOOD - RIGHT SIDE and 11

OA RAINHOOD - FRONT FILTER SUPPORT using

screws (16 on (-)XRD-PGCM3, and on (-)XRD-SGCM3).

STEP 15:

Re-secure ROOF PANEL using the washer head screws

that were removed in STEP 3 from the ROOF PANEL.

FIGURE 3

(-)XRD-PGCM3 Shown - RRDX-MFCM3 Similar

(See Table 1 for identification of parts)

ECON. CENTER

SUPPORT (REF.)

LEFT PANEL - LOWER

ROOF PANEL (REF.)

12

ADAPTOR PANEL

LEFT PANEL - UPPER

11

A1012-01

3

Page 37

FIGURE 4

EXHAUST AIR RAIN HOOD

(LOWER LEFT SIDE)

OUTSIDE AIR RAIN HOOD

(UPPER LEFT SIDE)

SEAL STRIP

EXHAUST AIR RAIN HOOD ASSEMBLY

(BIRDSCREEN FRONT SUPPORT)

STEP 16:

Remove the BLOWER MOTOR ACCESS PANEL (SEE

FIGURE 5).

STEP 17:

Connect the j DISCHARGE AIR SENSOR to wires 51

and 52 located in the blower motor compartment.

NOTE:

Mixed air sensor should be secured with the included wire

tie to avoid entanglement with the blower and direct

contact with any sheet metal surfaces.

STEP 18:

Replace the BLOWER MOTOR ACCESS PANEL.

END VIEW

A1005-01

FIGURE 5

WIRE TIE

STEP 19:

Upon start-up check the economizer sequence of

operation using the steps provided in these instructions.

After testing unit operation and setting outside air damper

minimum position, replace RETURN COVER with

remaining screws.

4

INDOOR MOTOR

A1006-01

Page 38

DI RECT MOUNT ECONOMIZER SE QUENCE OF OP ER A TION

GEN ERAL

This accessory economizer package is designed to save

energy costs by using outdoor air for cooling and

ventilation in place of mechanical cooling whenever

possible. The economizer continuously monitors indoor

and outdoor air conditions and compares them to a

user-selected setpoint to determine if free cooling is

available.

AC CES SO RIES

RXRX-AV02 — Dual Enthalpy Up grade Kit

For maximum energy savings, this upgrade kit will allow

the economizer to compare the outdoor air enthalpy to the

return air enthalpy, instead of a user-selected setpoint to

determine if "free cooling" is available.

RXRX-AR02 - Wall-Mounted Car bon Di ox ide Sen sor

For installations requiring Demand Control Ventilation

(DCV) based upon indoor air levels of carbon dioxide

(CO2). When the unit supply fan is running, the CO2 sensor

modulates the outside air damper to maintain a

user-selected CO2 level inside the occupied space.

Energy savings are achieved by not bringing in excessive

amounts of outdoor air when the indoor air conditions are

suitable. Energy savings can be substantial on buildings

with highly variable occupancy rates.

Wall-Mounted Remote Potentiometer

For installations requiring remote adjustment of damper

minimum position by the occupants, a remote

potentiometer, such as the Honeywell S963B1128 can be

used.

RXRX-BGF05C, RXRX-BGF05D, RXRX-BGF05Y —

Power Exhaust Kit

For installations requiring more space static pressure relief

than can be obtained with the standard barometric relief

damper included with the economizer, a power exhaust kit

can be added.

1. EXH Set — Adjustments for (optional) power ex haust

A. The outside air damper position at which the

power exhaust fan(s) will engage. The LED

labeled EXH below the potentiometer adjustment

will indicate when power exhaust is available.

When the power exhaust call is made, the

controller provides a 60 ±30 second delay before

exhaust fan activation to allow the damper to

reach the appropriate position.

B. Range of adjustment is from 0-100% (2-10V); in

most applications the power exhaust is set to

engage at about 70% outside air.

2. Min Pos — Outside Air Damper minimum position

A. Adjust the minimum position potentiometer to

allow the minimum amount of outdoor air, as

required by local codes, to enter the building.

B. Range of adjustment is from 0-100% (2-10V); in

most applications the minimum position is

adjusted to allow 10% to 25% outside air to enter

the system.