Page 1

Installation and Maintenance Manual

Group: McQuay Controls

Date: July 2002

MicroTech II™

AAF®HermanNelson® Unit Ventilator Controller

N2 Open Communication Modules

IM 730-0

© 2002 McQuay International

Page 2

Contents

GENERAL INFORMATION ............................................................................................................ 4

DESCRIPTION ..................................................................................................................................... 4

APPLICATION .....................................................................................................................................5

COMPONENT DATA ............................................................................................................................ 5

N2 Network Connection ................................................................................................................ 5

Address Switch .............................................................................................................................. 6

Dip switch settings and how they work .................................................................................................... 6

12-Pin Header............................................................................................................................... 6

INTEGRATION.................................................................................................................................. 7

CONFIGURING THE UNIT CONTROLLER .............................................................................................. 7

NETWORK CONNECTION ....................................................................................................................7

N2 Open Addressing ..................................................................................................................... 7

N2 Bus Information....................................................................................................................... 7

Selecting the Right Cable.............................................................................................................. 7

N2 Bus Rules ................................................................................................................................. 8

Number of Devices........................................................................................................................ 8

Line Length and Type.................................................................................................................... 8

INSTALLATION................................................................................................................................ 9

To mount a new MicroTech II N2 communication module onto the Unit Controller board,

follow these steps: ......................................................................................................................... 9

To replace a MicroTech II N2 communication module on a MicroTech II Unit Controller board,

follow these steps: ....................................................................................................................... 10

Figures

SERVICE INFORMATION ............................................................................................................ 12

TEST PROCEDURES........................................................................................................................... 12

LIST OF REPLACEABLE PARTS.......................................................................................................... 12

Network Connection Plug ........................................................................................................... 12

Generic Replacement Parts ..................................................................................................................... 12

Direct Replacement Parts........................................................................................................................ 12

Kit................................................................................................................................................ 12

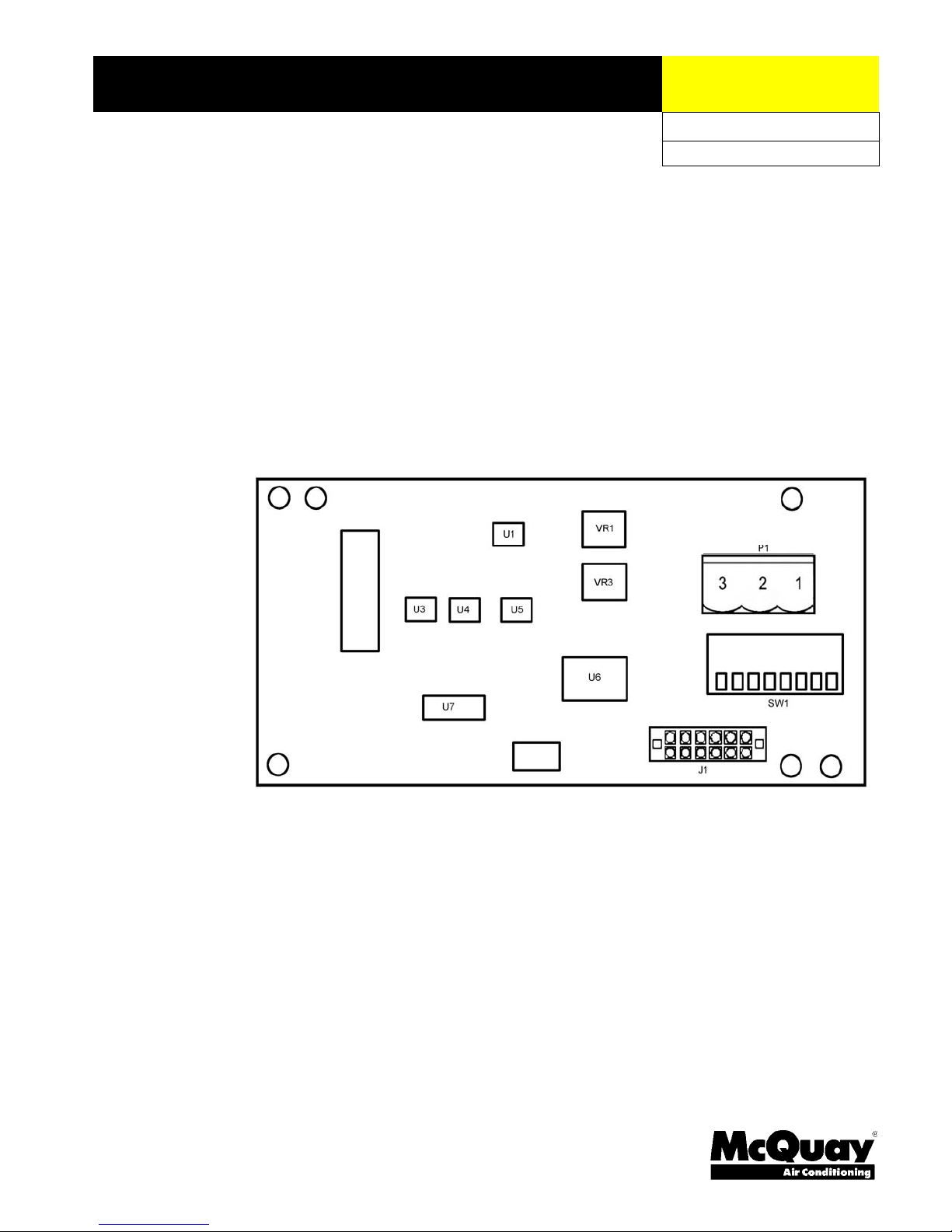

FIGURE 1: N2 COMMUNICATION MODULE.............................................................................................. 5

FIGURE 2. MICROTECH II N2 COMMUNICATION MODULE MAJOR COMPONENTS.................................... 5

FIGURE 3. ADDRESS SWITCH (S1) .......................................................................................................... 6

FIGURE 4. DIP SWITCH VALUES (WHEN CLOSED).................................................................................... 6

FIGURE 5. ADDRESS SWITCH (S1) SET TO EXAMPLE............................................................................... 6

FIGURE 6. N2 BUS RULES...................................................................................................................... 8

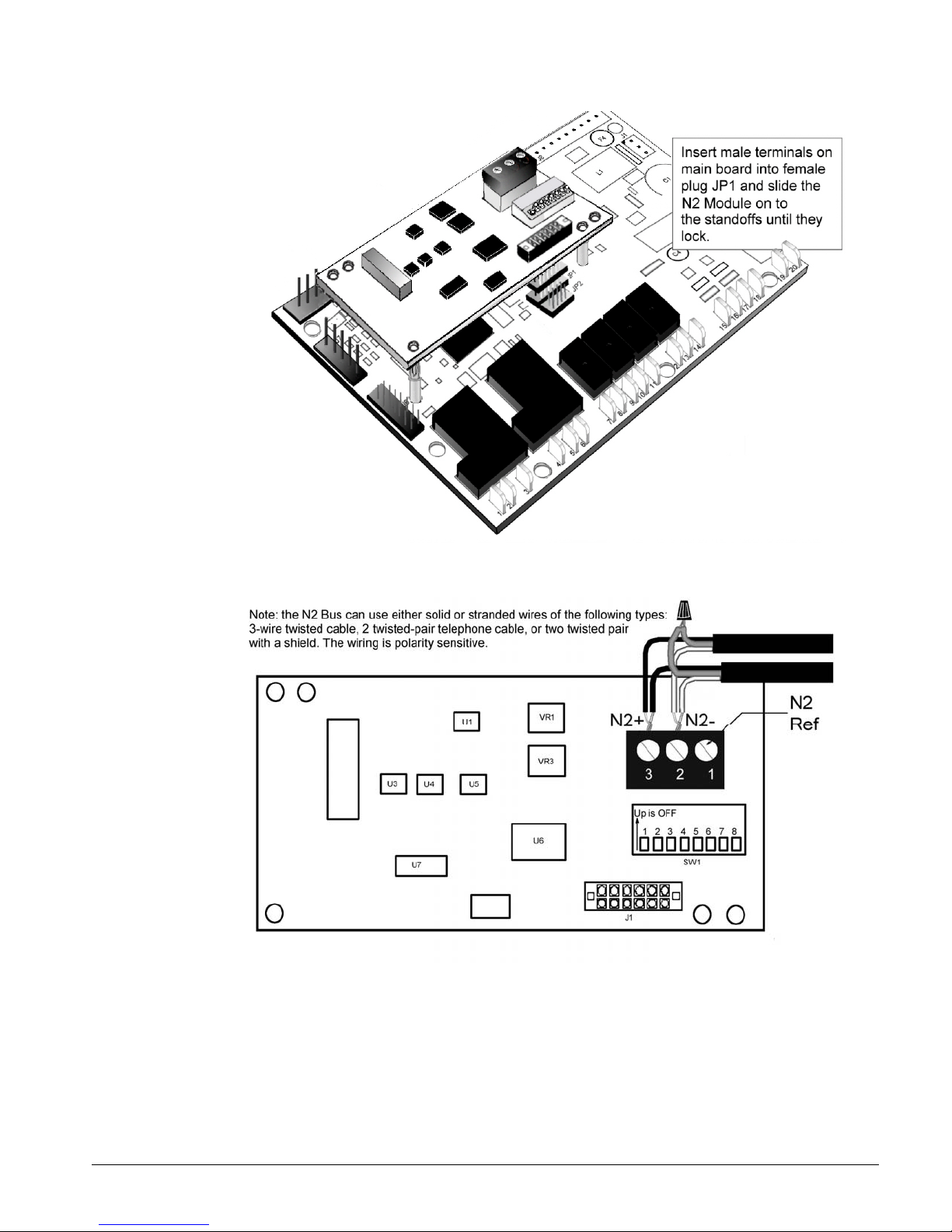

FIGURE 7. COMMUNICATION MODULE MOUNTED ON THE UNIT CONTROLLER BOARD ......................... 10

FIGURE 8. COMMUNICATION MODULE MOUNTING DETAIL ...................................................................11

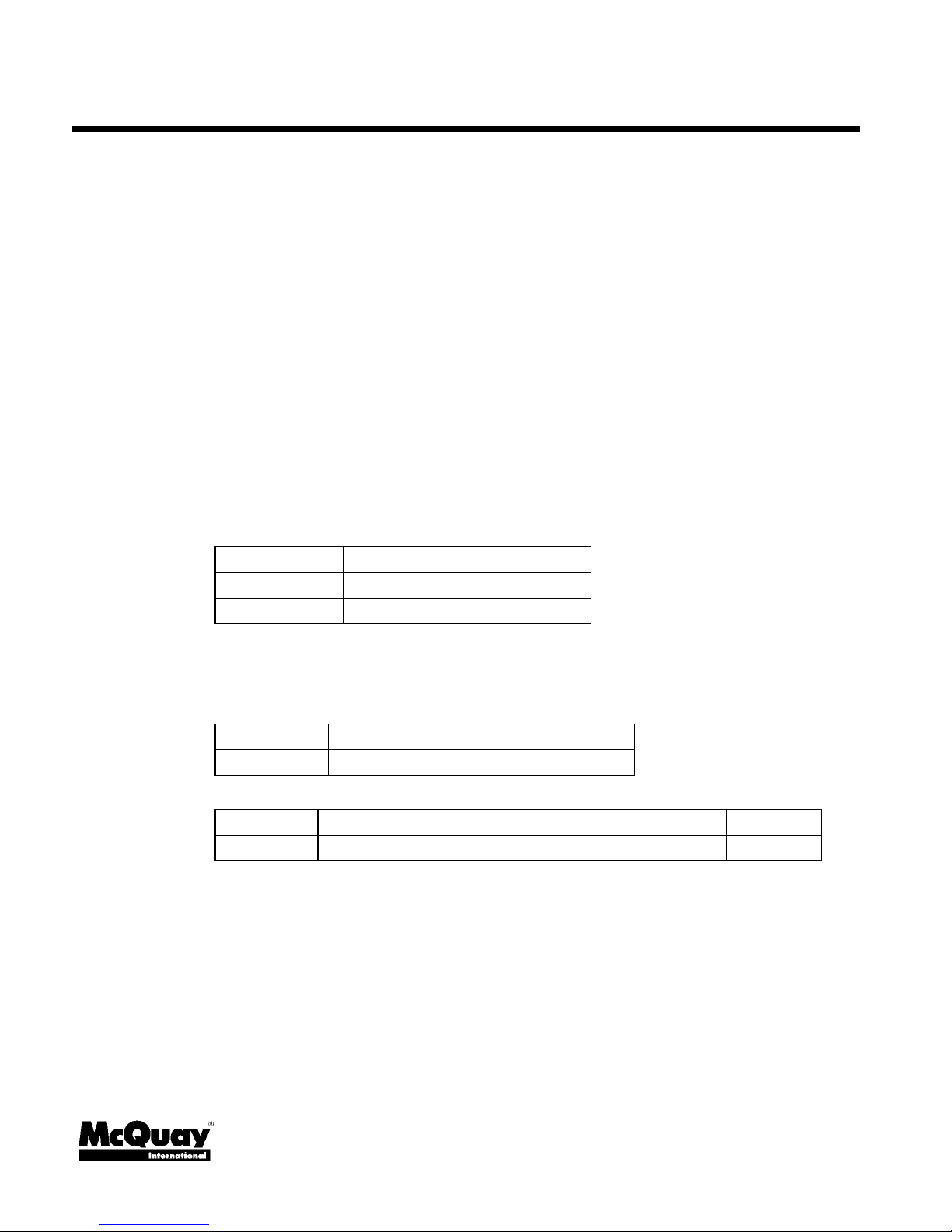

FIGURE 9. N2 MODULE TYPICAL WIRING.............................................................................................. 11

2 IM 730-0

Page 3

Limited Warranty

Consult your local McQuay Representative for warranty details. Refer to Form 933-43285Y. To find

your local McQuay Representative, go to www.mcquay.com.

Revision History

IM 732 August 1, 2002 Initial Release

Reference Documents

Number Source Title

OM748 www.McQuay.com Air Source Heat Pump with Electric Heat (Software Model 00)

OM749 www.McQuay.com Water Source Heat Pump with Electric Heat (Software Model 02)

OM750 www.McQuay.com DX Cooling with Electric Heat (Software Model 04)

OM751 www.McQuay.com DX Cooling Only (Software Model 05)

OM752 www.McQuay.com Electric Heat Only (Software Model 06)

OM753 www.McQuay.com DX Cooling with Wet Heat - Valve Control (Software Model 07)

OM754 www.McQuay.com 2-pipe Wet Heat Only - Valve Control (Software Model 09)

OM755 www.McQuay.com 2-pipe Heat/Cool - Valve Control (Software Model 11)

OM756 www.McQuay.com 4-pipe Heat/Cool - Valve Control (Software Model 13)

OM757 www.McQuay.com 2-pipe Cooling Only - Valve Control (Software Model 15)

OM758 www.McQuay.com 2-pipe Cooling with Electric Heat - Valve Control (Software Model 17)

ED 15069 www.McQuay.com MicroTech II™ Unit Ventilator Unit Controller

ED 15065 www.McQuay.com MicroTech II™ AAF®-HermanNelson® Unit Ventilator Unit Controller Protocol

IM731 www.McQuay.com MicroTech II™ AAF®HermanNelson® Unit Ventilator Controller BACnet®

IM747 www.McQuay.com MicroTech II™ Unit Ventilator Unit Controls Installation Manual

www.johnsoncontrols.com/Metasys/n2open.htm N2 -- A Data Communication Protocol for Building Automation and

Water Source Heat Pump without Electric Heat (Software Model 03)

DX Cooling with Wet Heat - F&BP Damper Control (Software Model 08)

2-pipe Wet Heat Only - F&BP Damper Control (Software Model 10)

2-pipe Heat/Cool - F&BP Damper Control (Software Model 12)

4-pipe Heat/Cool - F&BP Damper Control (Software Model 14)

2-pipe Cooling Only - F&BP Damper Control (Software Model 16)

2-pipe Cooling with Electric Heat - F&BP Damper Control (Software Model 18)

Protocol Implementation Conformance Statement

Information

Communication modules

Control Networks

Notice

Copyright © 2002 McQuay International, Minneapolis MN All rights reserved throughout the world

™ The following are trademarks or registered trademarks of their respective companies: N2 Open from Johnson Controls

Corporation, Protocol Selectability, MicroTech II, and AAF-HermanNelson from McQuay International.

IM 730-0 3

Page 4

General Information

Use this manual to physically install the communication module onto the Unit Ventilator Unit

Controller board and to make the wiring connections to your network. You also need the appropriate

McQuay Engineering Data Sheet known as the Protocol Information to integrate the unit into your

network. The Protocol Information contains addressing details, N2 Open protocol information, and a

list of the data points available to the network. See the Reference Documents section of this

document for part numbers of Protocol Information manuals. These documents are available from

your local McQuay International representative and for downloading at the McQuay International

web site: www.mcquay.com.

Electric shock hazard. Can cause personal injury or equipment damage.

This equipment must be properly grounded. Only personnel that are knowledgeable in the

operation of the equipment being controlled must perform connections and service to the

MicroTech II control panel.

Static sensitive components. Can cause equipment damage.

!

WARNING

!

CAUTION

Description

Discharge any static electrical charge by touching the bare metal inside the control panel

before performing any service work. Never unplug cables, circuit board terminal blocks, or

power plugs while power is applied to the panel.

NOTICE

This equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with this instruction manual, may cause interference to radio

communications. It has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his or her own

expense. McQuay International disclaims any liability resulting from any interference or

for the correction thereof.

A MicroTech II N2 Open communication module incorporates a MicroTech II Unit Controller into

an N2 Open Local Area Network (LAN). This combination provides an interface to the buildingautomation network.

The MicroTech II N2 communication module is a printed-circuit board that plugs onto the

MicroTech II Unit Controller board. Figure 1 shows an outline drawing of the N2 communication

module with reference dimensions.

4 IM 730-0

Page 5

Application

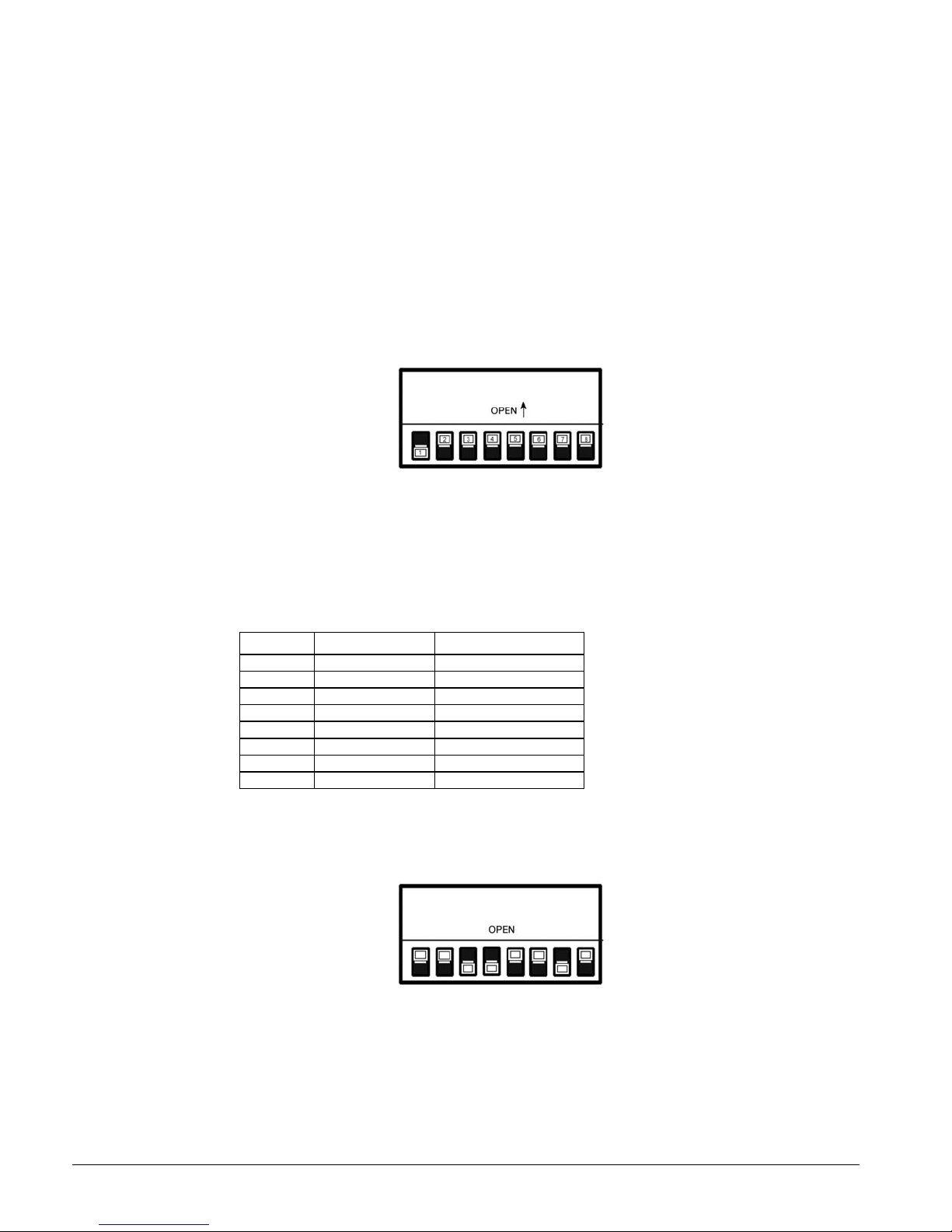

Figure 1: N2 communication module

The MicroTech II N2 communication module connects the MicroTech II Unit Controller to the

Building Automation System (BAS) on a N2 Local Area Network. It is the interface for the

exchange of N2 points between the network and the Unit Controller.

Component Data

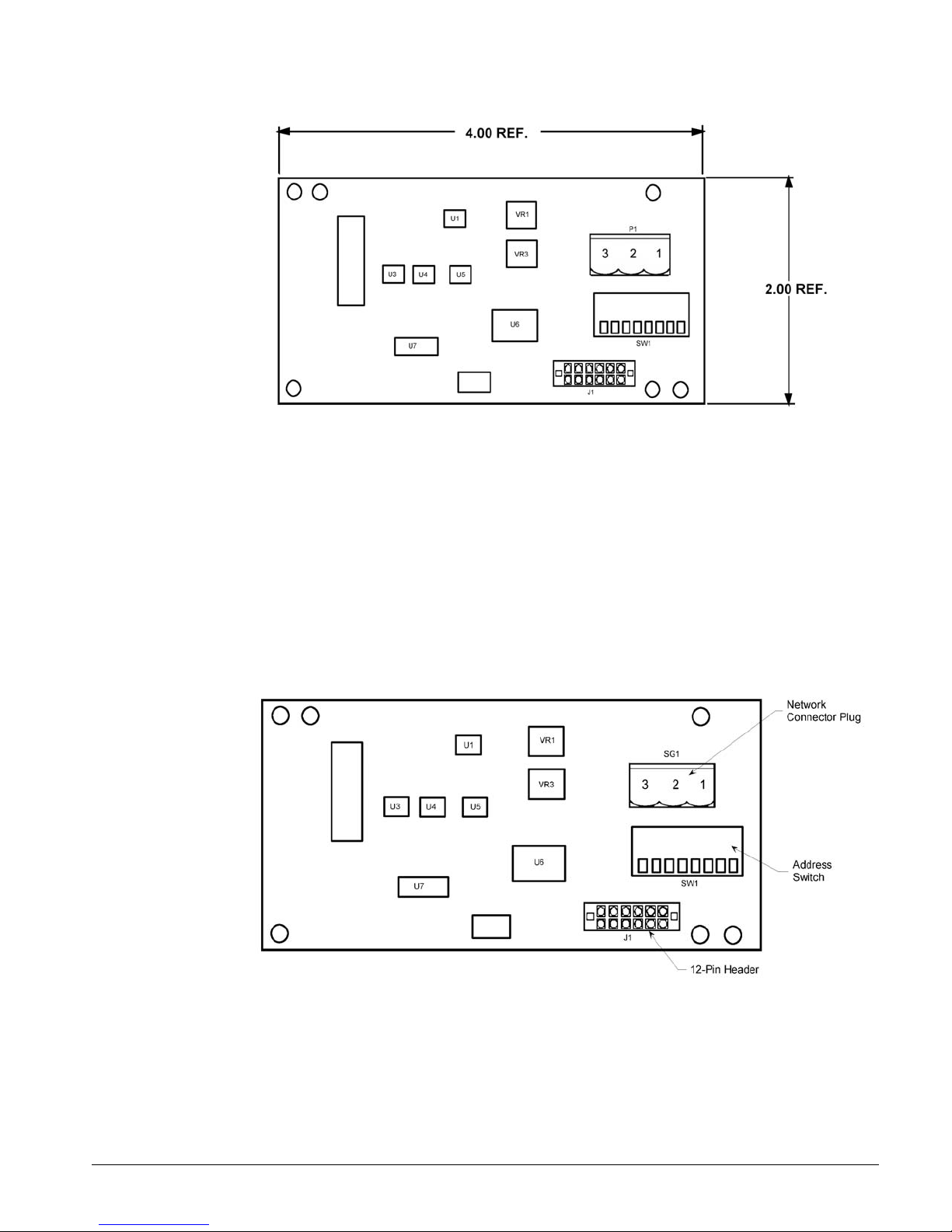

Figure 2 shows the major components of the communication module.

Figure 2. MicroTech II N2 communication module major components

N2 Network Connection

N2 network wiring connections are made to SG1 (Network Connector Plug). This connector is

physically made in two parts, a board-mounted (3-terminal) male plug and a (3-terminal) female plug

with screw-type wiring connections.

IM 730-0 5

Page 6

The two portions come plugged together and look like a single part. However, they can be

separated at the middle by gently pulling them apart. Connect the wiring (that has been

stripped of insulation by about 1/3-inch) to the SG1 female plug portion. Insert the wires into

the proper screw-terminals and tighten the connections with a small flat-blade screwdriver

(see

Figure 9). Make sure that the wiring connections aren't shorted and that they are tight.

Address Switch

The Address Switch (S1) must be field-configured on each MicroTech II N2 communication module

to a unique address, so that it can be located and addressed when wired into the network. The system

integrator usually pre-assigns an address to each module. The available range of possible addresses

using the binary switches is 1 through 253.

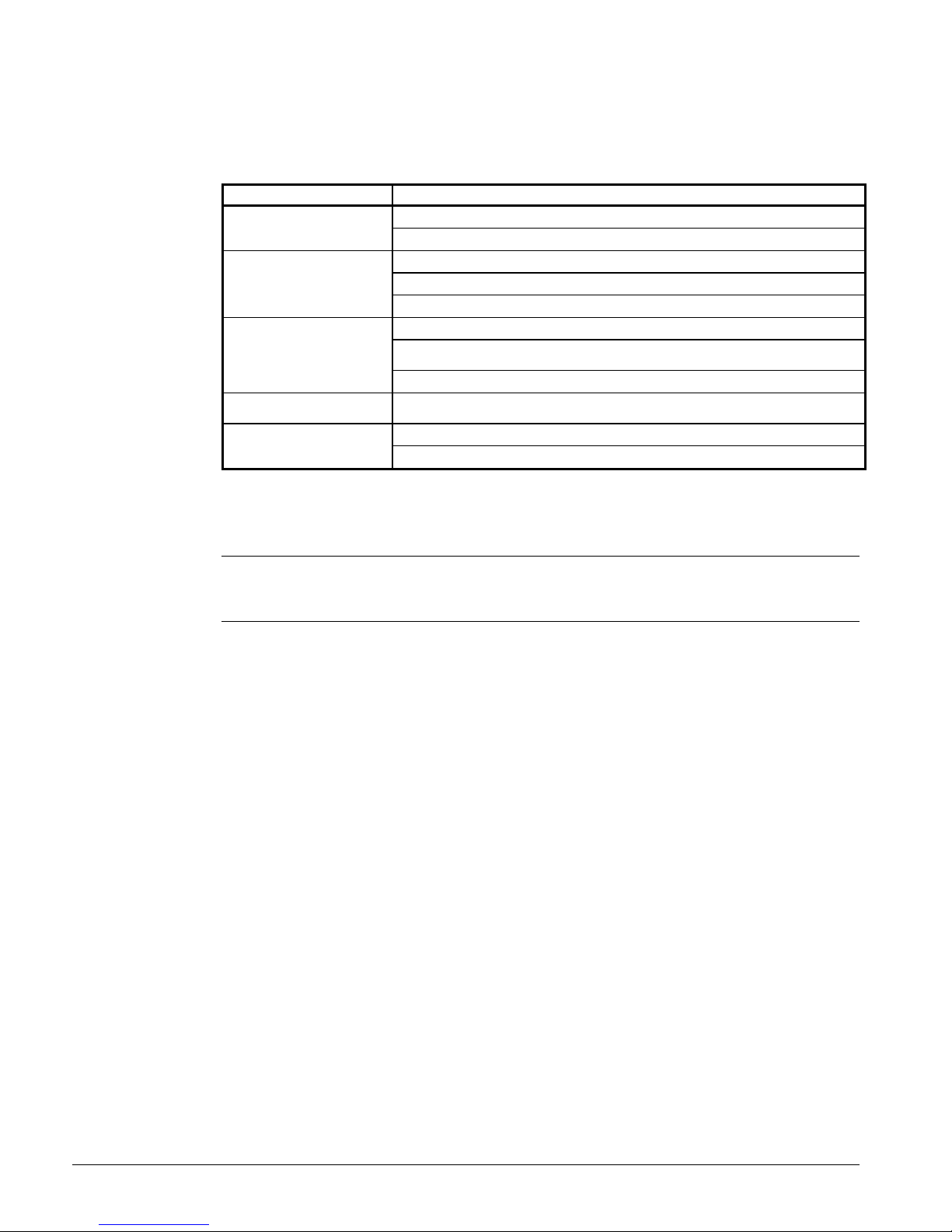

Figure 3. Address switch (S1)

Dip switch settings and how they work

When a switch is in the up (open) position, its value is 0. So when all the switches are in the up there

is no module address. When switches are set in the down (closed) position, their individual values

are shown in Figure 4 below.

Figure 4. Dip switch values (when closed)

Switch # Value Number when closed

1 2 to the zero power 1

2 2 to the 1st power 2

3 2 to the 2nd power 4

4 2 to the 3rd power 8

5 2 to the 4th power 16

6 2 to the 5th power 32

7 2 to the 6th power 64

8 2 to the 7th power 128

Figure 5 shows an example of a typical address setting. The digital switch positions as read from left

to right are 00110010. This provides an address of 76 as illustrated below.

Figure 5. Address switch (S1) set to example

12-Pin Header

The 12-pin header, J1, connects the unit-controller Unit Controller board to the MicroTech II N2

Open communication module through the bottom side of the printed-circuit board.

6 IM 730-0

(0 + 0 + 4 + 8 + 0 +0 +64 +0 =76)

Page 7

Integration

Configuring the Unit Controller

Each MicroTech II Unit Controller board and N2 communication module is preprogrammed and

configured at the factory to be a single Unit Controller, whether the boards are assembled together at

the factory or field assembled. Each unit is also ready to operate using the default values. These

default values may be changed via the unit’s keypad, using ServiceTools™, or via the network. See

the appropriate operation manual for default values and keypad operating instructions, and refer to

the appropriate MicroTech II Protocol Information for descriptions of the network variables. See

Reference Documents for part numbers.

Network Connection

N2 Open Addressing

The N2 Open device address of the MicroTech II controller in a Local Area Network (LAN) is set by

using the eight-position DIP switch on the N2 communication module (see the heading: Address

Switch). The address is physically set using the binary switches. An open switch (switch up) is a 0,

and the value of a closed switch (switch down) is shown in Figure 4. The address naming starts with

switch 1. Each address must be unique and set during installation. After setting the address with the

switches, you must cycle power to the controller (turn the controller off and then on again) for the

new address to take effect.

The data transmission rate is 9600-bps (baud)..

N2 Bus Information

The N2 communication Bus is a local network that links controllers and point interfaces to the

Network Control module (NCM). The N2 Bus uses a master/slave protocol in which the master

device (the NCM) initiates all communication with the N2 Bus devices. These N2 Bus devices

include the Digital Control modules (DCMs), Point Multiplex modules (XBN, XRE, XRL, XRM),

and all Application Specific Controllers (ASCs).

The N2 Bus is wired in a daisy-chain fashion and the devices are connected in series. The N2 Bus

can use solid or stranded wire, or optical fiber when special fiber modems are used. So the choices

include:

• 3-wire twisted cable

• 2-wire twisted-pair telephone cable

• 2-wire twisted-pair cable with a shield

• Duplex optical fiber (requires a pair of fiber modems).

Selecting the Right Cable

For most N2 Bus installations, the most practical choice is solid, 2-wire twisted-pair, unshielded,

telephone cables. If you have existing stranded cable, you can use it, but you may find that the

strands become a nuisance when wiring the cable.

For N2 Bus installations where there is a lot of electrical noise (e.g., gas ignition systems, radar or

magnetic-resonance imaging equipment, on a factory floor, or outdoors), shielded wire or optical

fiber is the best choice. Of the two, fiber is by far the better option, but it is more expensive. It offers

extended N2 distances and excellent immunity to electrical noise, lightning, and various other

building noises. It can also be buried underground between two buildings so that the N2 Bus can be

extended in a campus-type installation.

IM 730-0 7

Page 8

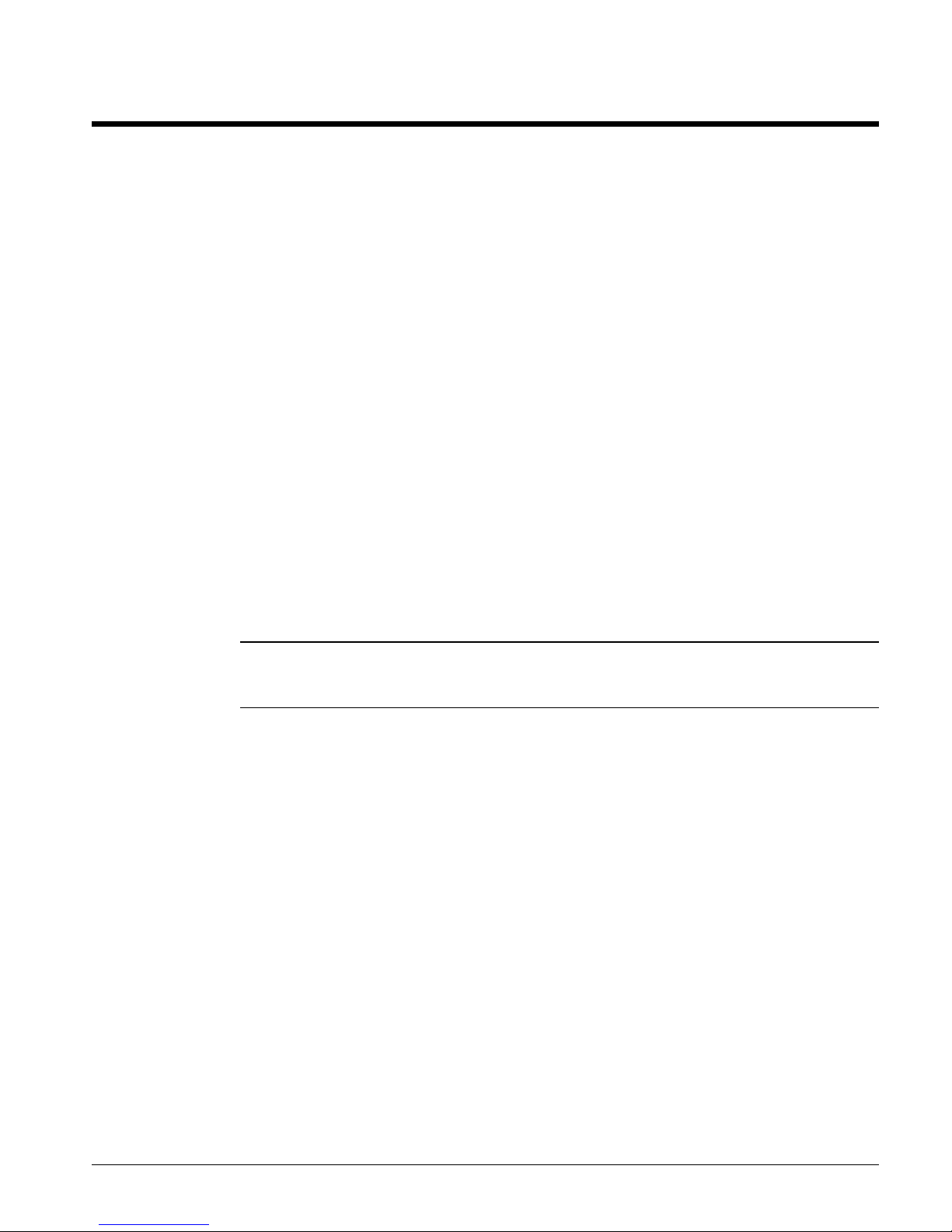

N2 Bus Rules

Figure 6 summarizes the rules and maximums allowed for installing the N2 Bus. You may wish to

print this table and keep it handy.

Figure 6. N2 Bus Rules

Category Rules/Maximums Allowed

General

Number of Devices

Line Length and Type

Cable

Terminations

One or two N2 Bus per NCM

Only daisy-chained devices

100 devices per NCM (60 to 200 TC-9100s)

50 devices per repeater

Two repeaters cascaded

1524 m (5000 ft) between NCM to farthest N2 device before repeater is needed

4572 m (15,000 ft) from NCM to farthest N2 device (three segments of 1524 m [5000 ft]

each)

2012 m (6600 ft) between two fiber modems

26 AWG twisted pair or larger

(solid or stranded 22 AWG or heavier recommended)

Two switched EOL per segment (preferred)

One switched EOL per segment (required)

Number of Devices

• Currently, up to 100 devices can be connected to an NCM, including repeaters. The actual

number of devices is dependent on the features and point count used in the NCM.

Note: The number of devices varies because both the number of software objects and JC-BASIC

processes influence the Network Controller’s (NC’s) performance (see Guidelines for

Efficient Operation Technical Bulletin [LIT-636341]).

• Up to 50 daisy-chained devices are allowed before a repeater is needed. Add a repeater to the

bus when you reach 49 devices. Count each repeater as one device.

• Any path from the NCM to an N2 device cannot go through more than two repeaters or two

pairs of fiber modems (i.e., cascaded repeaters/modems). This is because the repeater/modem

delays the N2 Bus signal between Sides A and B. The N2 Bus can compensate for only two of

these delays; therefore, up to two repeaters or two pairs of fiber modems can be cascaded in

series. Note that the signal from the NCM only passes through two repeaters or two pairs of

modems to any N2 device.

• For additional information on the maximum number of devices and priority assignments, be sure

to read Guidelines for Efficient Operation Technical Bulletin (LIT-636341).

Line Length and Type

• A repeater is required for every 1524 m (5000 ft) of daisy-chained cable.

• The maximum distance between an NCM and the farthest device (even through repeaters) is

4572 m (15,000 ft).

• You may use 18 through 26 AWG twisted pair wire; however, Johnson Controls recommends

22 AWG or heavier, because lighter wire breaks easily when stripped and installed.

• The maximum distance between two fiber modems is 2,012 m (6,600 ft). If your application

requires lengths beyond that, contact S.I. Tech for information about their “high power” option.

You may also use optical fiber on the N2 Bus (a pair of fiber modems is required for conversion).

Duplex optical fiber is needed, either 50 (3.0 dB/km), 62.5 (4.0 dB/km), or 100 (5.0 dB/km)

micrometers. The 62.5 size is preferred.

8 IM 730-0

Page 9

Installation

The MicroTech II N2 Open communication module may either be installed in the factory or field

installed. The module mounts on connector pins and is held in place with three plastic locking

standoffs. The N2 Open network connects to the MicroTech II N2 Open communication module at

the network connector plug (SG1).

The MicroTech II N2 Open communication module is included in a kit (part number 107293125).

You need to know the N2 address that is assigned to the communication module. The network

administrator can supply this information.

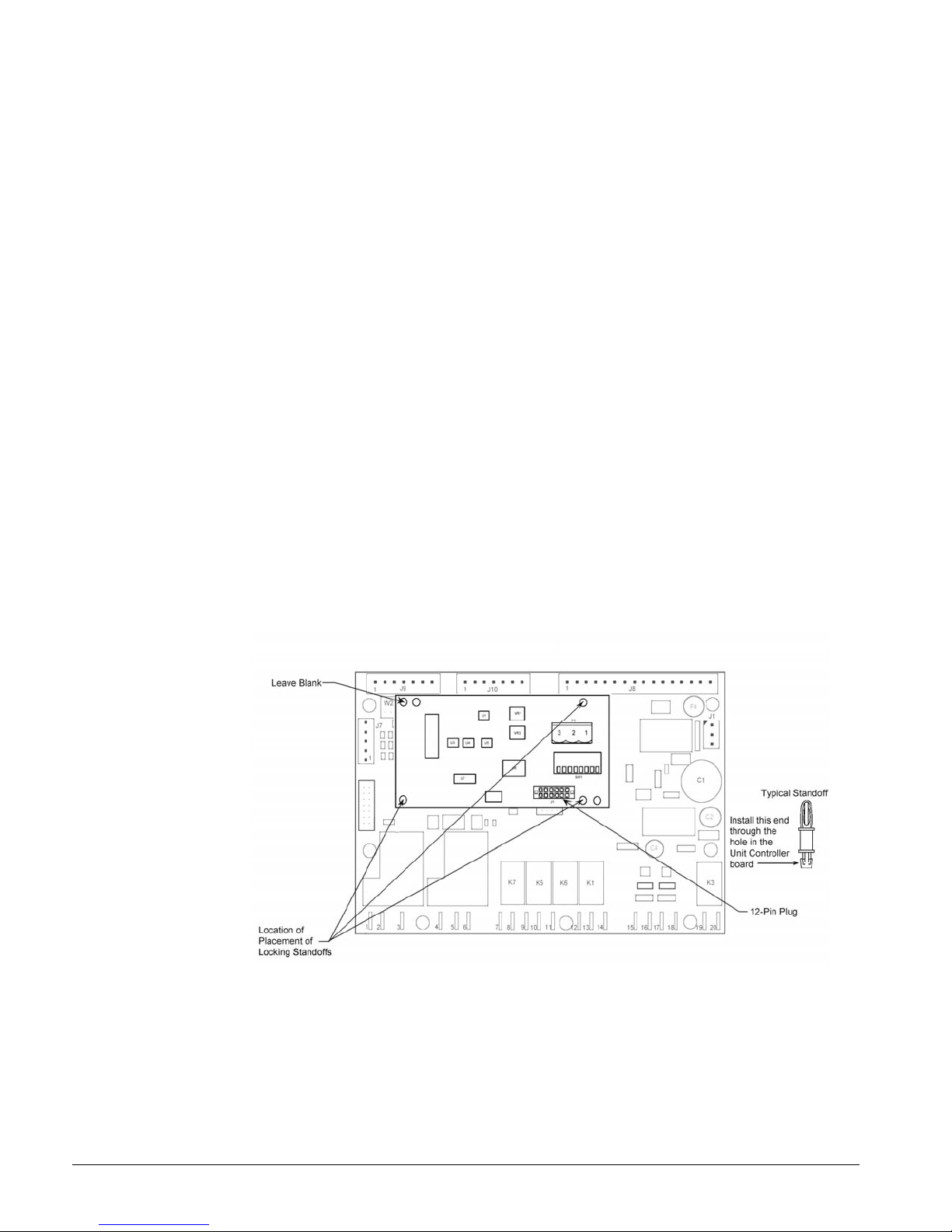

To mount a new MicroTech II N2 communication module onto the Unit

Controller board, follow these steps:

1. Disconnect power from the Unit Controller board.

2. Unplug the unwired network cable connector from the terminal block SG1 (see Figure 2).

3. Install the three standoffs on the Unit Controller board at the locations shown in Figure 7 Simply

press the locking standoffs into the holes on the board. Then locate the empty connector for the

MicroTech II N2 communication module on the Unit Controller board (see Figure 8).

4. Orient the communication module printed-circuit board so that the component side faces

outward and the connector pins can penetrate the 12-pin header on the communication module.

5. Push the communication module onto the connector pins and standoffs until you hear the faint

click of the locking standoffs securing the board in place.

6. Connect the network wiring to the network cable connector and plug it into the terminal block,

SG1, on the MicroTech II communication module (see Figure 9).

7. Set the N2 address (supplied by the network administrator) using the Address Switch (SW1).

The valid range is 1 to 253 (see Figure 4).

8. Reapply power to the MicroTech II Unit Controller board.

Note: You must maintain the polarity of the signal throughout the network. Always connect + to

+ and – to –. Also, the network cable shield or third-wire connection must be continuous

throughout the network and must be connected to earth ground at one (and only one) point.

IM 730-0 9

Page 10

To replace a MicroTech II N2 communication module on a MicroTech II

Unit Controller board, follow these steps:

1. Disconnect power from the Unit Controller board.

2. Record the N2 address on the Address Switch (SW1).

3. Remove the network cable plug-in connector from the SG1 terminal block (see Figure 2).

4. Locate the three standoffs for the MicroTech II N2 communication module on the Unit

Controller board (Figure 7 and Figure 8).

5. Using a pliers or screwdriver to depress the barb on one standoff, gently pull the corner of the

communication module over the barb. Be careful to not bend the communication module or

misalign the connector pins.

6. Proceeding to the other two corners, remove the communication module from each standoff, and

pull the module over the standoffs.

7. Gently lift the MicroTech II N2 communication module from the Unit Controller board.

8. Locate the empty connector pins and three standoffs for the MicroTech II N2 communication

module on the Unit Controller board.

9. Orient the communication module printed-circuit board so that the component side faces

outward and the connector pins can penetrate the 12-pin header on the communication module.

10. Push the communication module onto the connector pins and standoffs until you hear the faint

click of the locking standoffs securing the board in place.

11. Connect the communication module to the network by reinserting the network-cable plug into

SG1 (see Figure 9).

12. Set the N2 Address in Address Switch SW1 (see Figure 4).

13. Reapply power to the MicroTech II Unit Controller board.

Figure 7. Communication module mounted on the Unit Controller board

10 IM 730-0

Page 11

Figure 8. Communication module mounting detail

Figure 9. N2 module typical wiring

IM 730-0 11

Page 12

Service Information

Test Procedures

If you can control the unit from the keypad but are unable to communicate with it via the network,

try the following:

• Verify the network (bus) wiring

• Check the integrity of the cable harness to the network terminals

• Verify that the N2 address (SW1) is set to a unique binary number between 1 and 253.

If the MicroTech II N2 Open communication module still doesn’t respond, replace the

communication module.

List of Replaceable Parts

Network Connection Plug

Generic Replacement Parts

The three-contact network connector plug has custom markings, but if you lose this terminal block

you can replace it with a standard block without the markings from a manufacturer. The list below

contains manufacturers part numbers for equivalent parts without the custom markings.

Manufacturer Telephone Order Number

Phoenix Contact (800) 888-7388 17 57 02 2

Altech Corp (908) 806-9400 37.003

Direct Replacement Parts

You can order direct replacement parts for these connector plugs from McQuay International

(1-800-37-PARTS).

Part Number Description

AS-TBKIT-0 5 terminal blocks marked REF, N2- and N2+

Kit

Component Description Part No.

Kit N2 communication module for unit ventilators with standoffs 107293125

13600 Industrial Park Boulevard, Minneapolis, MN 55440 USA (763) 553-5330 (www.mcquay.com)

Loading...

Loading...