Page 1

Installation, Operating and Maintenance Manual

Field Installation Procedure for MicroTech II

Centrifugal Chiller Control Panel Retrofit Kit

Description Kit Part Number

WSC 50/60 Hz, All Models with Touch Screen Panel 300042762

WSC 50/60 Hz, All Models without Touch Screen Panel 300042763

WDC 50/60 Hz, All Models with Touch Screen Panel 300042764

WDC 50/60 Hz, All Models without Touch Screen Panel 300042765

Operator Interface Upgrade kit 50/60 Hz 300040547

IM 786

Group: Aftermarket Products

Part Number: 331357301

Effective: October 2005

Supersedes: January 2004

Page 2

2004 McQuay International

2 Field Installation Procedure IM 786

Page 3

Table of Contents

Introduction...................................................................................................... 5

Building Automation Systems (BAS) Interface .....................................................................5

Disassembly....................................................................................................... 6

Important Note on Downloading Settings..............................................................................6

Existing MicroTech Control Panel.......................................................................................10

Lube Box (MT 100 with PSC oil pump motor shown)........................................................11

Installing the MT II Control Elements......................................................... 13

Install New Panels...............................................................................................................13

Enhanced Surge Protection..................................................................................................18

Install New Components......................................................................................................20

Sensor Locations..................................................................................................................22

Control Panel Connections..................................................................................................26

Check Out and Startup.................................................................................. 31

Table of Figures

Figure 1, MicroTech 200 Panel .............................................................................................6

Figure 2, Existing Data Record: MicroTech 200...................................................................7

Figure 3, Existing Data Record: MicroTech 100...................................................................9

Figure 4, Unit Control Panel, brackets and optional Touch Screen Panel ...........................15

Figure 5, Unit Control Panel, brackets and optional Touch Screen Panel ...........................16

Figure 6, Unit Control Panel and optional Touch Screen Panel mounting locations ...........17

Figure 7, Suction temperature sensor location.....................................................................18

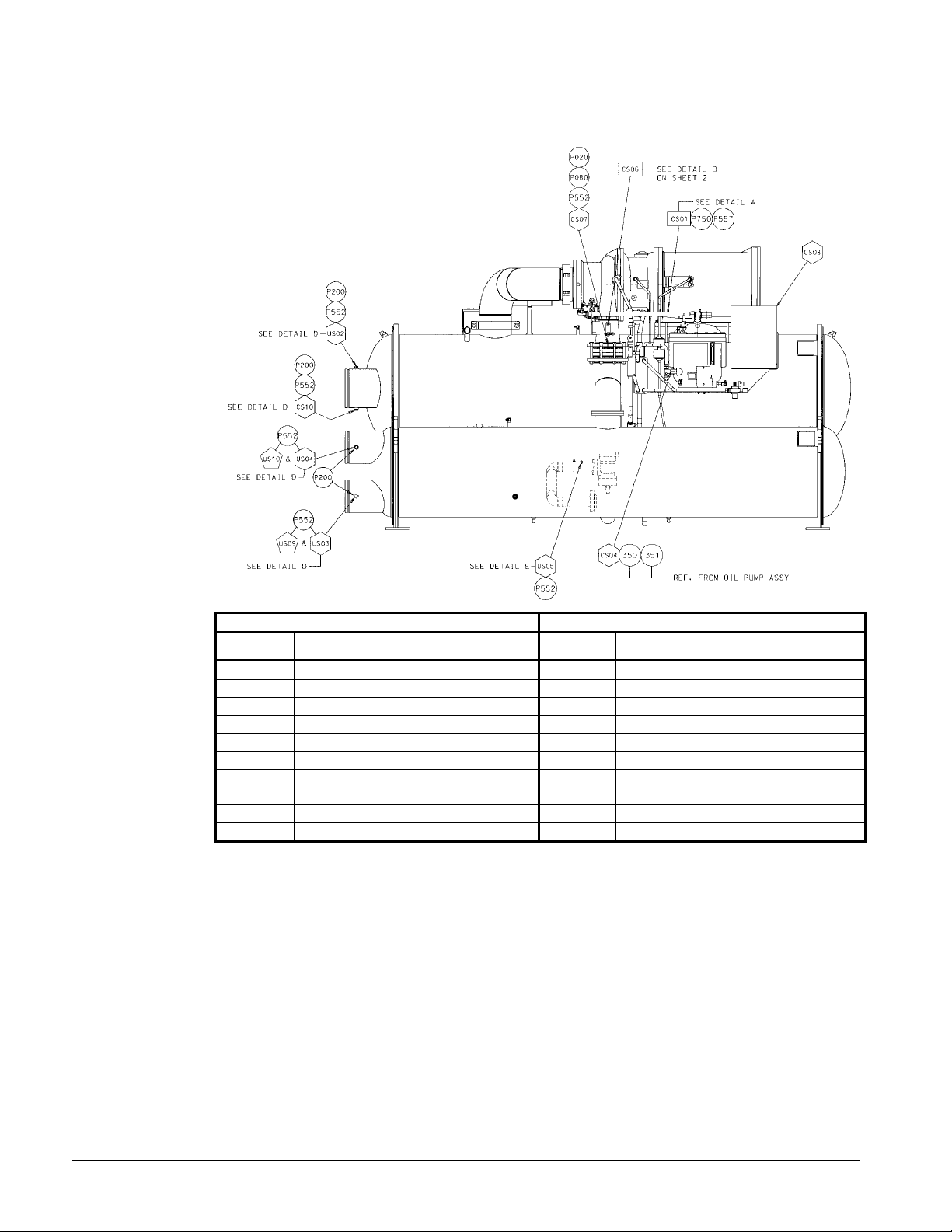

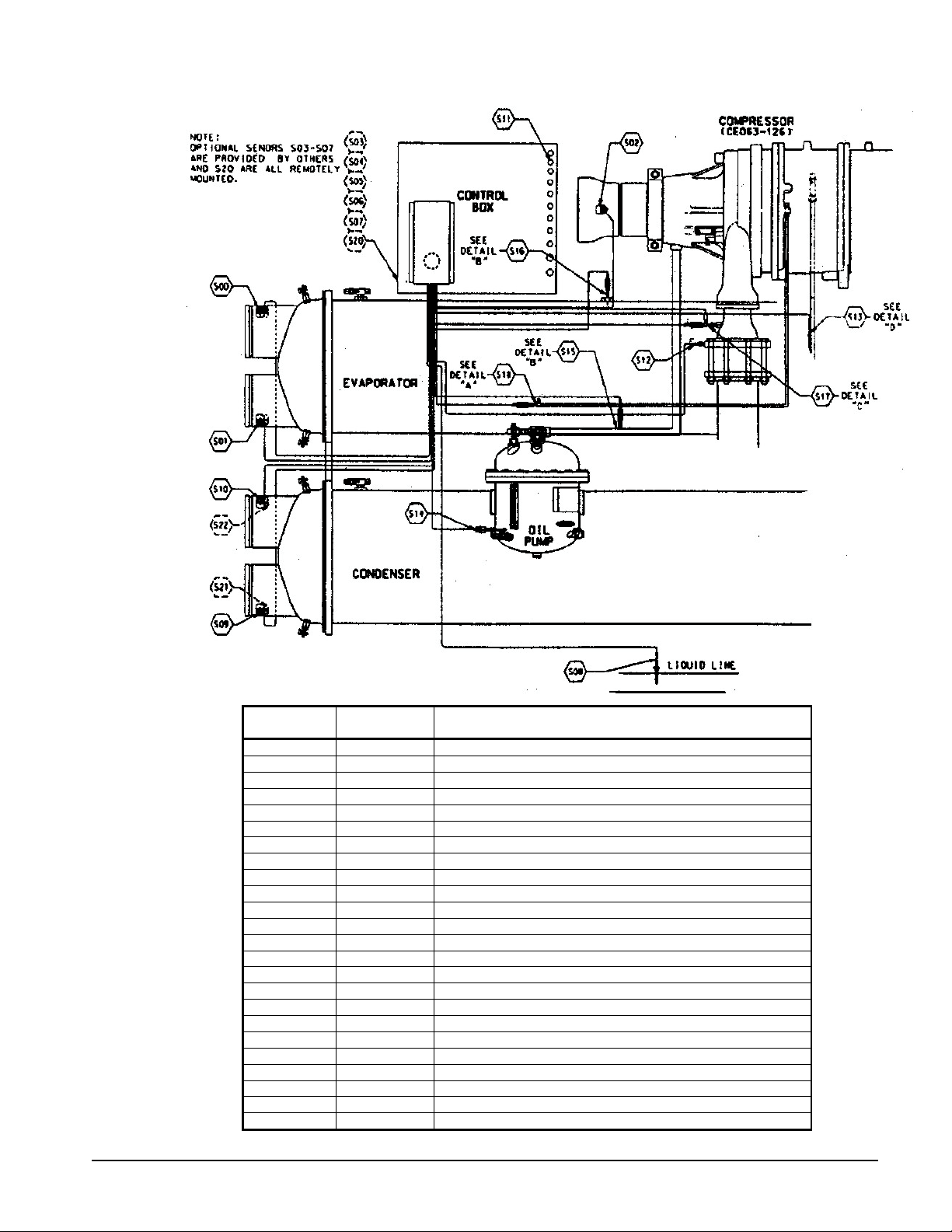

Figure 8, Sensor Locations on unit (Models WSC/WDC)...................................................22

Figure 9, Partial front view of unit.......................................................................................23

Figure 10, Detail of sensor locations...................................................................................23

Figure 11, Sensor locations (Models PEH/PFH) .................................................................25

Figure 12, Unit Control Panel detail....................................................................................26

Figure 13, Unit Control Panel connections..........................................................................27

Figure 14, Compressor Control Panel detail........................................................................28

Figure 15, Compressor Control Panel connections..............................................................29

Manufactured in an ISO Certified Facility

Illustrations and information cover McQuay International products at the time of publication and we reserve the right

to make changes in design and construction at anytime without notice.

IM 786 Field Installation Procedure 3

2003 McQuay International

Page 4

4 Field Installation Procedure IM 786

Page 5

Introduction

These procedures must be performed only by technicians with training and experience on

Westinghouse/McQuay centrifugal water chillers including, but not limited to, MicroTech Series

100 and 200 controllers and MicroTech II (MT II) controllers.

Before commencing any actual replacement work, review the entire procedure, step by step, for the

unit being considered. Also, study the unit to pinpoint the location of the new control components.

This should help prevent difficulties during the procedure.

The procedure consists of:

1. Disassembling of the old control components

2. Installing the MT II control panels

3. Installing new sensors and rewiring.

4. Installing and configuring new software and checking unit operation.

Building Automation Systems (BAS) Interface

Determine if the new chiller controls will be required to tie into the building’s BAS. If so, verify

that the communication protocol is BACnet, L

for these protocols can be obtained separately and field installed on the controller. MicroTech II

cannot talk to an existing BAS through McQuay Open Protocol Master Panels (OPM, CVPC,

CSC, and direct connections) that may be on the job. Communication module part numbers are:

ONTALK, or Modbus. Communication modules

L

ONMARK: 350147401

BACnet: 350147404

Modbus: 350147402

IMPORTANT: Because the new MicroTech II controllers utilizes open, standard protocols listed

above, they are not compatible with legacy MicroTech system controls which utilize legacy,

proprietary McQuay Open Protocol. Therefore, the new MicroTech II chiller unit control panel is

not compatible with the existing MicroTech Chiller System Controller (CSC), Chiller Plant

Controller (CPC), MicroTech Monitor software, MicroTech Network Master Panels (NMP), or

MicroTech Remote Monitoring and Sequencing (RMS) panels. Your McQuay Representative can

help you plan the efficient management of your MicroTech and MicroTech II chiller equipment with

your building’s chiller plant or overall building automation system as your building needs change.

IM 786 Field Installation Procedure 5

Page 6

Disassembly

Important Note on Transferring Settings

Record all settings from the existing MicroTech 100 or 200 controller before de-energizing the panel

and removing it. Many of the settings will have to be changed from default later in the MT II

controller to configure the unit correctly. Forms are included on pages 6 and 7 to record settings.

MicroTech 200

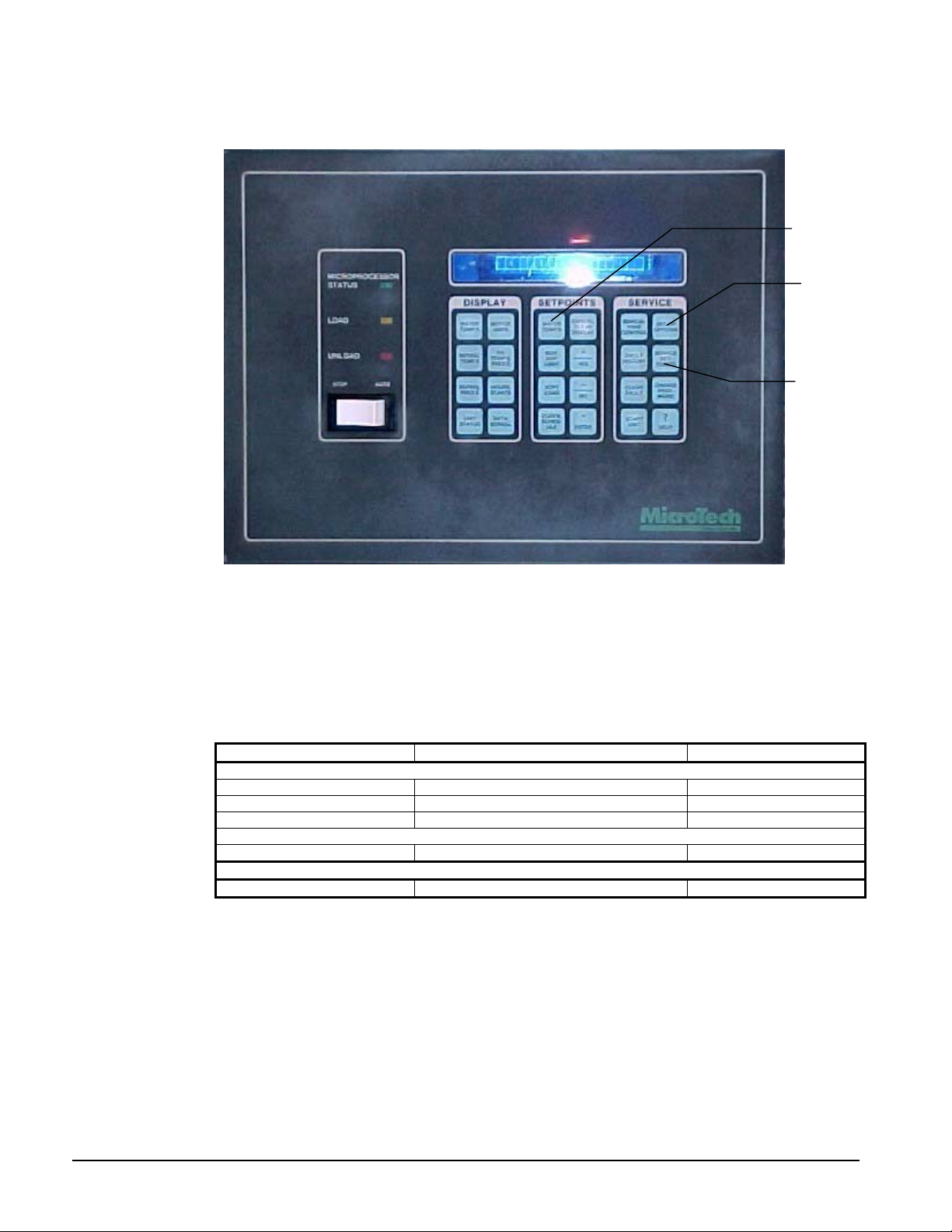

Figure 1, MicroTech 200 Panel

Perform the following steps to record setpoint data from the existing MicroTech 200 control. See

manual OM 200 for detailed information.

Action View Record/Ignore

Press Water Setpoints Screen 12, Water Setpoints Record

Press Next Menu Screen 13, Motor Setpoints Record

Press Next Menu Screen 14, Time/Date Ignore*

Press Next Menu Screen 15, Schedule Ignore*

Press Next Menu Screen 16, Schedule Ignore*

Press Next Menu Screen 17, Timers Setpoints Record

Press Next Menu Screen 18-20, Tower Setpoints Record

Press Next Menu Screen 21, Oil Setpoints Record

Press Next Menu Screen 22, Alarms Setpoint Record

Press Next Menu Screen 23, Lead/Lag, dual compressors Ignore

*The schedule function is not avaliable in the MTII

6 Field Installation Procedure IM 786

Page 7

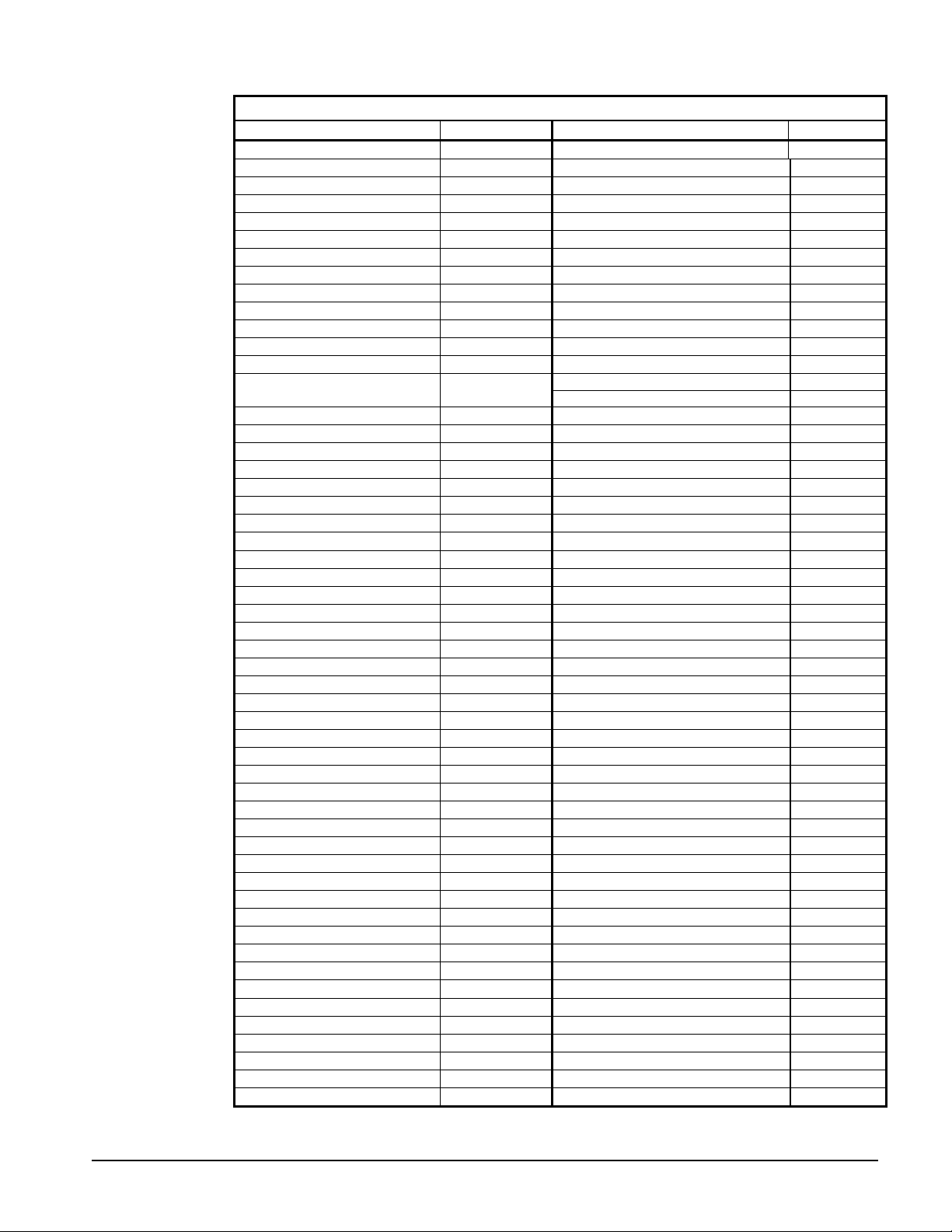

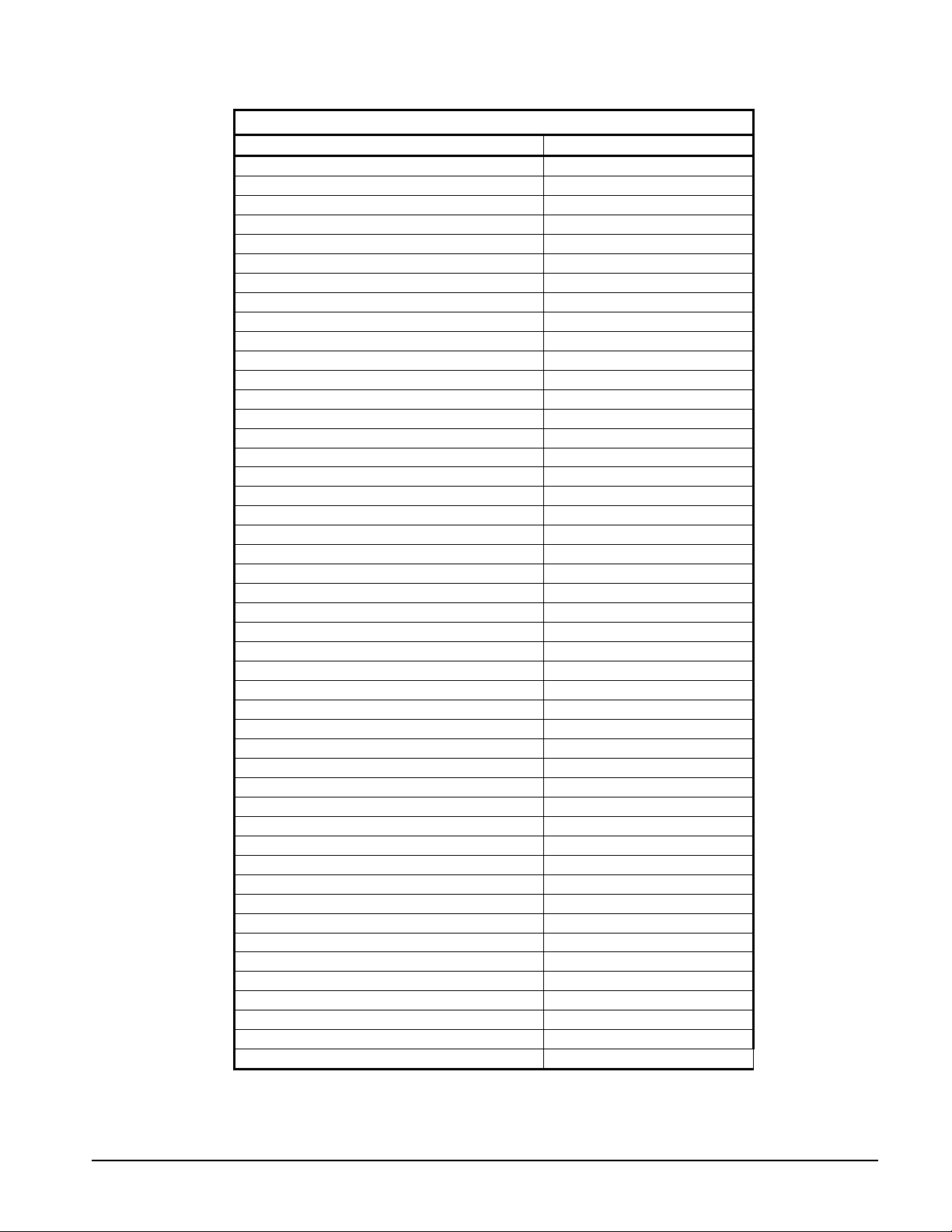

Figure 2, Existing Data Record: MicroTech 200

MicroTech 200

Setting Value Setting Value

Menu 12, Water Setpoints S creen 2

Screen 1 Stage 1 On

Spt Source Stage 4 on

Local Spt Stage 2 On

Startup DT Stage 3 On

Shutdn DT Menu 20 Tower Valve Control

Screen 2 Screen1

Chw Reset Valve control

Max lvg Spt Valve Spt

Return Spt Valve Deadb

No Reset at 70°F

Reset Signal Max position

Max reset

Screen 3

Pulldn Rate Sample Time

Amb Lockout

Menu 13, Motor Setpoints PA Time

Screen 1 Screen 3

Amp Reset Min Start Position

Active Spt Max Start Position

Reset Signal

Min Amp Spt Max Pos At

Network Spt

Max Amp Spt Screen 1

Screen 2 Feed Spt

Soft load No Start Diff

Begin Amp Lim Htr On Diff

Ramp Time Menu 22, Alarms Setpoint

Menu 14, Time/Date

Screen 1 Low Evap Press Shutdown

Hh;mm;ss

Day

mm-dd-yy

Menu 15, Schedule High Discharge Temp Shutdown

Start-stop schedule

Menu 16, Schedule High Condenser Press Shutdown

Start-stop schedule

Menu 17, Timers Setpoints Motor Current Thres hol d

Screen 1 High Oil Feed Temp

Start to Start Low Oil Delta Temp

Evap recirc Screen 4

Stop to Start Low Net Oil Pressure

Menu 18 Pump Setpoints Low Disch Superht at Min RLA

Screen 1 High Disch Superht at Min RLA

Evap Pmp Screen 5

Cond Pmp Low Disch Superht at Max RLA

Menu 19 Cooling Tower Control High Disch Superht at Max RLA

Screen 1 Surge-High Suct Superht-St artinf

Tower Control Screen 6

Tower Stages Surge-High Suct Superht-Running

Stageup Time Evap Water Freeze

Stage Dn Time Cond Water Freeze

Stage Differential

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

Min position

Screen 2

Valve Type

Mod Limit

Max Change

Min Pos At

Menu 21, Oil Setpoints

Screen 1

Low Evap Press Unload

Low Evap Press Hold

Screen 2

High Discharge Temp Load

Screen 3

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

IM 786 Field Installation Procedure 7

Page 8

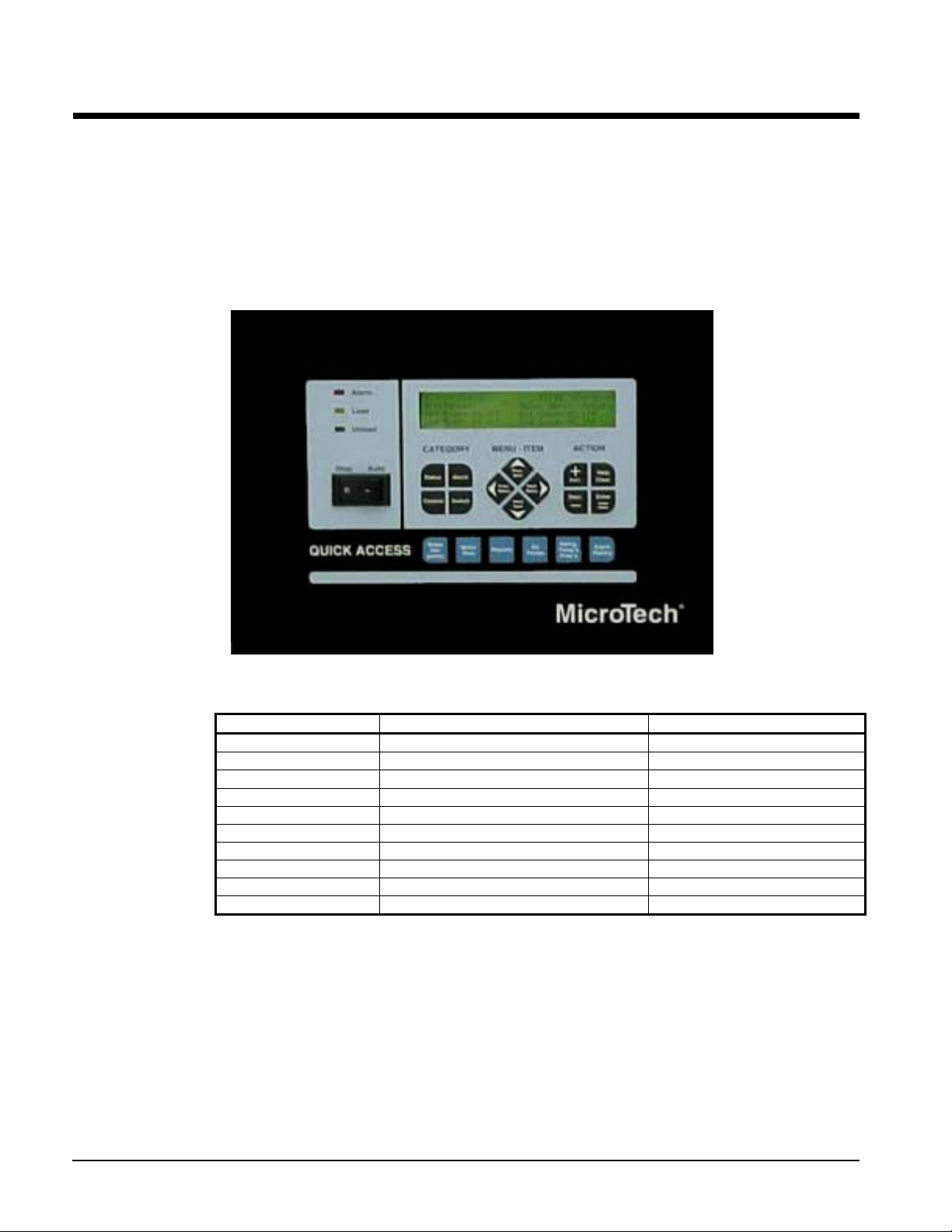

MicroTech 100

Setpoints reside in three locations on the MicroTech control. There are eight buttons under

the “SETPOINT” heading, only three of which have information to be recorded as shown

below. The buttons are pressed three times to access three different sets of data. Refer to

manual IM 403.

Setpoint

Menus

Set-up

Options

Service

Setpoint

Menus

1. There are thirteen settings under the Service Setpoint button, accessed by repeatedly

pressing the button.

2. There are 18 settings under the Set-up Options button.

Action View Action

SETPOINTS

Press WATE R TEMPERATURE View LWT, Reset, Res et Record Data

Press MAXIMUM AMP LIMIT View Amp Limit, Remote Limit, Si gnal Record Data

Press SOFT LOAD View Soft Load, Beginning Amps , Ramp Time Record Data

SERVICE SETPOINTS

Press 13 times View Setpoints Rec ord 2-13

SET-UP O PTIONS

Press 18 times View setpoint s Record 1-18

8 Field Installation Procedure IM 786

Page 9

Figure 3, Existing Data Record: MicroTech 100

MicroTech 100

Setting Value

SETPOINTS, Password Required

Press WATER TEMPERATURE

LLVG EVAP SPT

RESET LVG SIG This is a Read Only Value

RMT RESET SIG This is a Read Only Value

Press MA XI MU M AMP LIMIT

MAX AMP LIM

REMOT AMP LIN This is a Read Only Value

REMOT AMP SIG

Press SOFT LOAD

SOFT LOAD AMP

BEG AMP LIMIT

RAMP UP TIME

SET-UP OPTIONS, Password Required

RESET OPTIONS

MAX CHW RESET

ENT EVAP SPT

ENT EVAP TIMER

START MODE

START UP DELTA –T

SHUTDOWN DELTA -T

STARTTO START TIME

STOP TO START TIME

LOAD DELAY

COND PUMP TMR

TWR STG 1 ON

TWR STG 1 OFF

TWR STG 2 ON

TWR STG 2 OFF

ENABLE LAG

DISABLE LAG

DELAY TIMER

SERVICE SET-POINTS, Service Password Req’d

LOW MTR CURR

HOT GAS SPT

LOW OIL DELTA

CALC OIL STP

HIGH OIL FEED

LOW EVAP PRESS

LP OVERRIDE

HI DISCHARGE

HIGH SUCT RUN

HIGH SUCT OFF

HI COND PRESS

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

N/A on MTII

IM 786 Field Installation Procedure 9

Page 10

WARNING

Electric shock hazard. Disconnect all power sources to the control box.

Existing MicroTech Control Panel

Chiller may need to be pumped down to allow installation of new pressure transducers and new

mechanical high pressure switch before removal of old control panel. As in every case, make sure

there is water flow during pumpdown.

CAUTION

1. Service on this equipment must be performed by trained, experienced refriger ation

personnel familiar with equipment operat ion, maintenance, correct servicing

preocdedures, and the safety hazards inherent in this work.

2. Anyone servicing this equipment must comply with EPA requirements reg arding

refrigerant r eclaim a t ion and venting.

1. De-energize power to existing MicroTech (MT) panel (lock and tag out).

2. Check with VOM for presence of voltage in the MT panel. Isolate and de-energize if present.

3. Check for and disconnect any BAS communication from motherboard or display board.

4. Identify all external wiring to and from the MT panel. Mark as necessary. Factory wiring

should be labeled with wire numbers.

5. Remove all external wiring and conduit.

6. Remove all temperature sensors and discard. MT II uses all new sensors, 10k versus 3k on the

older units.

7. Isolate refrigerant and oil lines connected to MT panel. Remove and cap to prevent loss of

refrigerant and oil. Isolate the oil sump while there is still some pressure in the system to

prevent moisture from entering the tank. This is particularly important on R-134a systems.

8. Remove solenoid coil, wires, and conduit from oil cooler valve, liquid injection valve (if

present), and motor cooling valve (if present). Any valves that are not Sporlan brand will have

to be replaced. Older controllers used 115V solenoids coils, MT II use 24V solenoids coils.

Alternately, 115V to 24V interposing relays can be added to operate the existing valves.

9. Remove old control panel from chiller.

10. In most cases it is easier to leave the existing lube box on the unit and mount the new

compressor control panel adjacent to it. Two pieces of angle iron can be installed on the existing

lube box supports, extending out to provide a mounting location for the new panel.

10 Field Installation Procedure IM 786

Page 11

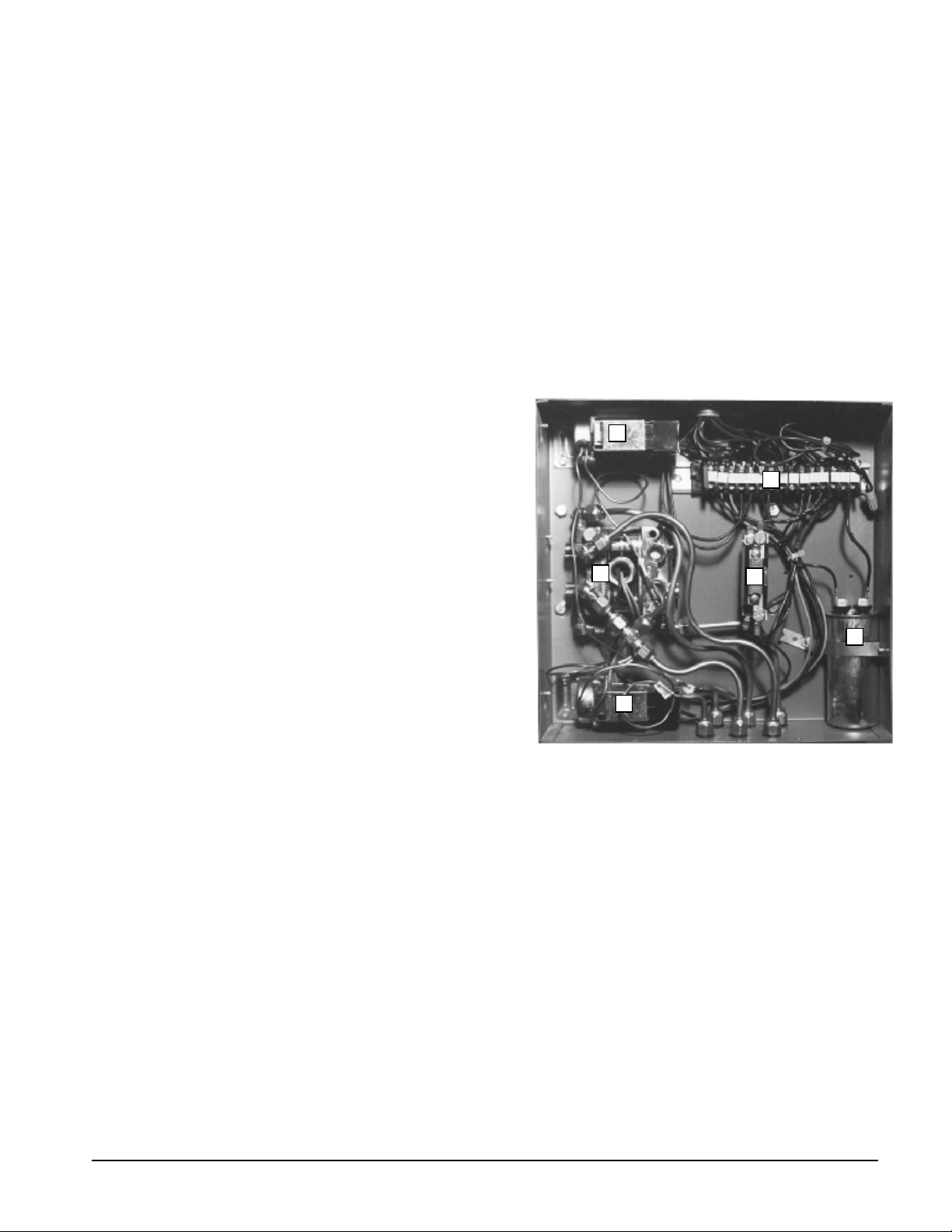

Lube Box (MT 100 with PSC oil pump motor shown)

There are two basic types of oil pump motors used on Westinghouse/McQuay centrifugal chillers.

Many early design chillers with all size compressors, and all chillers (including current production)

with compressor sizes CE050 and smaller use a Capacitor Start oil pump motor that has uses a

voltage relay. Chillers from approximately 1981 onward with compressor size CE063 and larger

use a Permanent Split Capacitor (PSC) oil pump motor which does not use the voltage relay. In

addition to the presence or absence of the voltage relay the two style motors use different overload

heaters and different capacitors. The same style oil pump motor will use slightly different value

capacitors when used in a 50 Hz application as opposed to a 60 Hz application.

To account for these differences some changes to the factory assembled compressor control panel

may be necessary as the kit is set up for a 60Hz PSC oil pump motor, and the chiller which the

upgrade kit is being installed in may be different. Details on the necessary changes are documented

in the following section.

1. Remove and discard oil pump contactor

(not shown). MT 200 has the pump

contactor in lube box, . MT 100 has

contactor in the control panel.

2. Remove Voltage Relay (not shown) if

present and discard. This is used only on

Capacitor Start oil pump motors, and not

on PSC oil pump motors. A new one is

included in the kit for mounting in the

compressor control panel.

3

4

6

5

3. Re-use Vane Close (VC) pressure switch.

4. Rewire terminal block as required and

document.

5. Remove and discard oil pump overload A

new overload is included in the

8

compressor control panel. This may need

to have its heater replaced with the

alternate. See following instructions.

6. Re-use SA/SB solenoid valve

7. Remove and discard oil pump capacitor(s) . A new capacitor is included in the compressor

control panel. This may need to be changed for one of the alternate capacitors, depending upon

the oil pump motor type and Hz. See following instructions.

8. Existing Oil Pressure (OP) switch can be re-used if desired. Wire NO contacts in starter MCR

circuit. MT 200 does not have this switch, the microprocessor senses the pressures and performs

this function.

7

IM 786 Field Installation Procedure 11

Page 12

If the chiller is a 60 Hz unit with a PSC oil pump then no changes to the compressor control panel are

necessary.

If the chiller is not a 60 Hz unit with a PSC oil pump, open the compressor control panel(s) and

make the following changes:

A. If the chiller is a 50 Hz unit with a PSC oil pump motor (unit will not have a voltage relay

in the lube box):

1. Remove and discard the p/n 7350767401 capacitor (35 MFD) in the panel and replace

with the included p/n 735067403 capacitor (60 MFD).

B. If the chiller is a 60 Hz unit with a Capacitor Start oil pump motor (Used on CE050

compressor which will have a voltage relay in the lube box):

1. Remove and discard the p/n 7350767401 capacitor (35 MFD) in the panel and replace

with the included p/n 330261502 capacitor (161 MFD).

2. Remove and discard the overload heater from the overload and replace with the

included p/n 735021578

3. Install the included voltage relay p/n 735020118.

C. If the chiller is a 50 Hz unit with a Capacitor Start oil pump motor (Used on CE050

compressor which will have a voltage relay in the lube box):

1. Remove and discard the p/n 7350767401 capacitor (35 MFD) in the panel and replace

with the included p/n 330261501 capacitor (200 MFD).

2. Remove and discard the overload heater from the overload and replace with the

included p/n 735021578

3. Install the included voltage relay p/n 735020118.

12 Field Installation Procedure IM 786

Page 13

Installing the MT II Control Elements

Install New Panels

Whenever possible, mount the MT II control panels in the same location as current production

WSC/WDC units. Mount the unit control panel on the evaporator where the old control panel was

and mount the compressor control panel adjacent to the existing (and remaining) lube box as shown

below.

MT II compressor control panel mounted to the

right of the existing lube box on angle-iron

extensions.

End view looking at the new compressor control

panel. The two angle-iron supports are visible on

the rear of the panel

MT II unit control panel and Touch Screen Panel

mounted on existing evaporator shelf. A small junction

box has been added to the top to facilitate connections.

View of the existing lube box with the angle-iron just

visible, inserted between the box and the box support.

Some chillers will not accommodate the compressor control panel mounted adjacent to the lube box,

so both MT II panels must be mounted on the evaporator.

Mount compressor control panel (on left) and unit control panel (on right) on the plate where the

Series 100 control panel was mounted. The plate will have to be re-drilled for mounting if both

panels are mounted next to each other (see picture on the following page). Fabricate brackets where

needed for vertical support of compressor control panel. If kit was purchased with an optional

Touch Screen Panel, drill and mount arm for display screen. See Figure 5 on page 16 for mounting

location on unit.

IM 786 Field Installation Procedure 13

Page 14

Note: The unit control panel has the

emergency stop/start switch located

on the left side, between the two

panels. The switch must be easily

accessible, so it must be moved,

ample space left between the panels

to access the switch, or the position

of the panels must be reversed.

Exploded views of the mounting of

the unit control panel and Touch

Screen Panel (TS) for WSC and

WDC vintage units can be found as

follows:

Touch Screen Compressor Box Unit Box

• Figure 3, WSC 050 - 126, WDC 050 – 126, except WDC 079-087 E36/C30 and E36/C36

• Figure 4, WDC 079-087 E36/C30 and E36/C36

Various mounting locations for the unit control panel are shown on Figure 5 on page 16.

Use existing MT Series 100/200 wiring diagrams, MT II wiring diagrams, and wiring details

enclosed in the kit for termination of wiring.

14 Field Installation Procedure IM 786

Page 15

Figure 4, Unit Control Panel, brackets and opt ional Touch Screen Panel

For WSC 050 - 126, WDC 050 – 126

Except WDC 079-087 E36/C30 and E36/C36

IM 786 Field Installation Procedure 15

Page 16

Figure 5, Unit Control Panel, brackets and opt ional Touch Screen Panel

WDC 079-087 E36/C30 and E36/C36

16 Field Installation Procedure IM 786

Page 17

Figure 6, Unit Control Panel and optional Touch Screen Panel mounting locati ons

IM 786 Field Installation Procedure 17

Page 18

Enhanced Surge Protection

Current software (late 2003 and after) supports “Enhanced Surge Protection”, which provides

improved protection against possible damage resulting from the compressor going into a surge

condition. The suction sensor is used to transmit temperature conditions to the controller. It is

important that the sensor be located in the correct position. If not, it must be relocated.

Figure 7, Suction temperature sensor location

18 Field Installation Procedure IM 786

Page 19

If the suction sensor is not in the correct location, complete the following steps.

WARNING

Refrigerant can cause asphyxiation, environmental damage, severe personal injury or death. Follow

EPA procedures for removing charge before continuing installation.

1. Be sure that the charge from the compressor has been removed following EPA or related

government regulations. The system pressure must be 0 psig to perform this modification.

2. Remove the existing temperature sensor and well. Discard the sensor.

3. Remove the suction elbow from the chiller unit.

4. Locate the center of the new port approximately 1 inch (2.5 cm) from the Victaulic coupling and

at the five o’clock position as viewed looking into the inlet cone.

5. Drill a 1.44 inch hole as shown.

6. Weld the ¾ NPT pipe coupling(p/n 735031434) in the new location.

7. Insert the suction temperature well (p/n047441511, use Loctite sealant*).

8. Install a new 10K temperature sensor (p/n 073007303) into the well.

9. Plug the original hole with the ¾ inch plug provided (p/n 735031649, use Loctite sealant*).

10. Clean and replace Victaulic gaskets if needed.

*Loctite 277 is recommended. 50ml part number 300040885, 250ml 300040884.

IM 786 Field Installation Procedure 19

Page 20

Install New Components

1. Chiller may need to be pumped down to allow installation of new pressure transducers and new

mechanical high pressure switch (steps 3 and 5, below) before removal of old control panel. As

in every case, make sure there is water flow during pumpdown.

2. Install new temperature sensors and connect to appropriate controller (compressor or unit).

Sensor p/n 073007203 are 90°

Sensor p/n 073007303 are straight

Extra temperature sensors are included to allow for various installation needs.

Oil sump temperature sensor may be p/n 0730007303 (straight) or p/n 330198003 (requires

well), depending upon the vintage of the oil pump. One of each is included for each compressor

control panel.

Unit Controller Temp Sensors

• Evap entering water temp

• Cond entering water temp

• Cond leaving water temp

• Liquid line temp

Compressor Controller Temp Sensors (one

set for each compressor on a chiller)

• Oil sump temp

• Compressor suction temp

• Compressor discharge temp

• Oil feed temp

• Evap leaving water temp

3. MT 200 units will have the correct high pressure and low pressure transducers for refrigerant

pressure and oil pressure sensing. New transducers are included for use on MT 100 units (blue

dot low-pressure range; red dot high-pressure range). Install transducers and terminate in

compressor control box. Oil pressure transducer will be installed on existing 1/4" line that fed

the old oil pressure transducer. This line may be shortened with 1/4" male flare fitting with

Schraeder valve brazed on the end.

4. Install new 24 VAC solenoid valve and cable on liquid injection solenoid valve (if present),

motor cooling solenoid valve (if present) and oil cooler solenoid valve. Terminate at compressor

control panel. If compressor has hot gas bypass purchase and install coils for solenoid

valves on HGBP assembly (solenoid coils not included in kit).

5. MT 200 units will have the correct mechanical high pressure switch (MHP) on discharge line.

New MHP switches are included for use on MT 100 units. Install switch if not already present,

run wiring in flexible conduit, and terminate at compressor control box. See “High Pressure

Switch Use” section to determine which switch you should use.

6. Install pLAN communications cables between unit controller and compressor controllers.

Sixteen feet of 3-conductor cable (074608901) is enclosed with each compressor control panel

for this purpose.

7. Re-install all conduits from lube box, motor starter, motor temperature (Guardistor)

protection, and water flow protection into compressor control panel and terminate wiring.

8. Ensure that correct components have been installed into compressor control panel (see

lube box section, pages 10 and 11). Re-wire lube box as required.

9. If applicable, re-install conduits from pump and /or tower controls, external start/stop or alarm

circuit into unit controller and terminate wiring.

10. If purchased, install Touch Screen Panel (TS) flexible arm and TS. Attach cable from TS to unit

control panel.

20 Field Installation Procedure IM 786

Page 21

Unit Controller External Inputs/Outputs

For Optional Functions

• External start/stop contacts (D.I.)

• Water Pumps start/stop contacts (D.O.)

• Tower Fans start/stop contacts (D.O.)

• External Chilled water temperature reset (A.I.)

• External Motor Amps reset (A.I.)

• Alarm contacts (D.O.)

• Tower fan VFD and/or bypass valve (A.O.)

Compressor Controller Wiring Connections

• Oil pump and oil heaters

• Motor starter wiring

• Oil cooler, liquid injection, and motor cooling

solenoid valves

• Motor temperature thermistors

• SA/SB solenoid valves

• Vane close switch

• Evap and cond water flow (pressure) switches

• Refrigerant pressure transducers

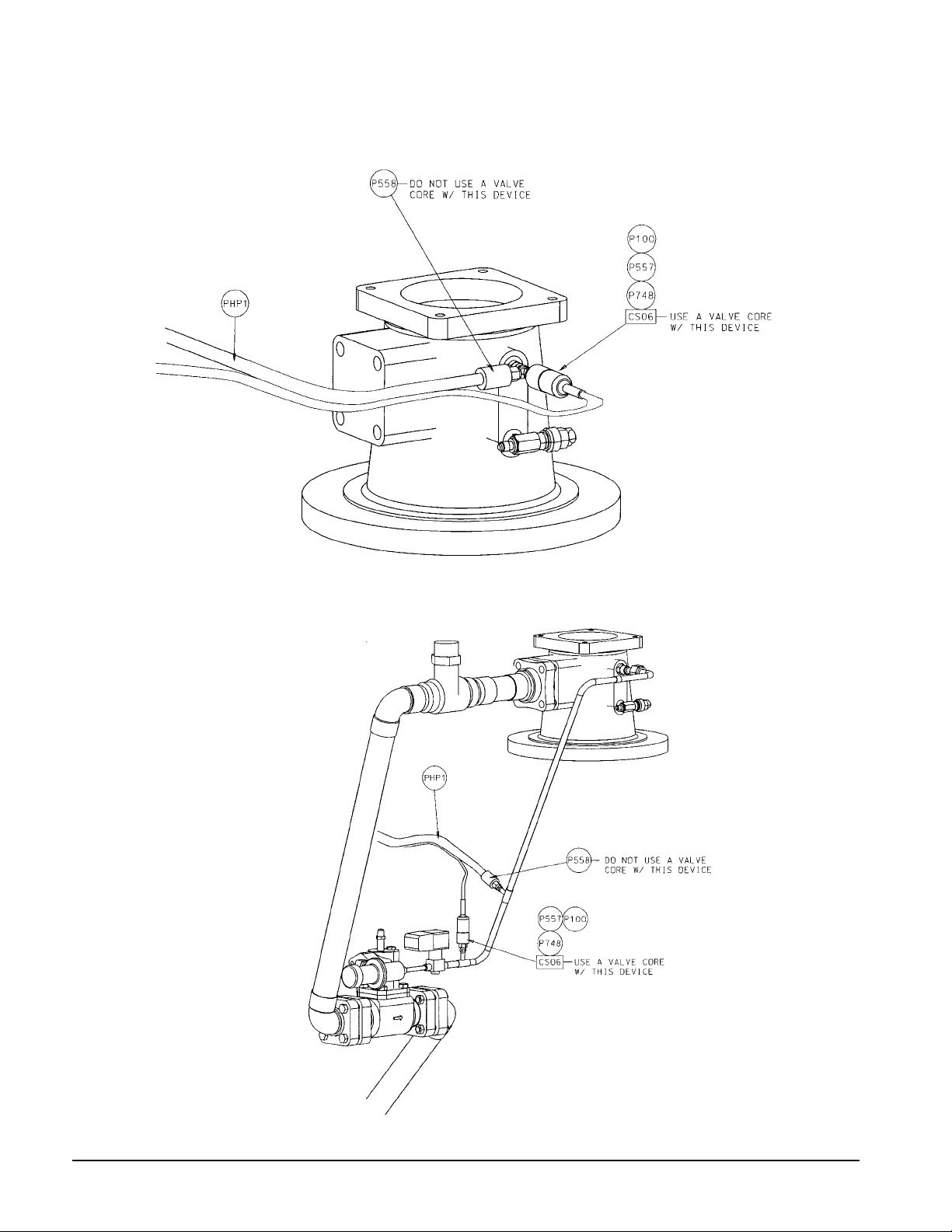

CAUTION

Mechanical high-pressure switch (MHP) and transducers must be installed on unit with MT II

upgrade. Mechanical high-pressure switch must be installed on high side (discharge pressure) above

the check valve and may not be installed on a valve that can be isolated from system per pressure

vessel per A.S.M.E. code.

IM 786 Field Installation Procedure 21

Page 22

Sensor Locations

Figure 8, Sensor Locations on unit (Models WSC/ WDC)

UNIT CONTROL LER SENSOR LOCATION COMPRESSOR CONTROLLER SENSOR LOCATION

SENSOR

NUMBER

US02 EVAP. ENTERING WATER TEMP. CS01 OIL SUMP PRESSURE

US03 COND. ENTERING WATER TEMP. CS02 OIL FEED GAUGE PRESSURE

US04 COND. LEAVING WATER TEMP. CS03 EVAP. REFRIGERANT PRESSURE

US05 LIQUID LINE TEMPERATURE CS04 OIL SUMP TEMPERATURE

US09 Not used (Heat Recovery applications only). CS05 COMP. SUCTION TEMPERATURE

US10 Not used (Heat Recovery applications only) CS06 COND. REFRIGERANT PRESSURE

DESCRIPTION

SENSOR

NUMBER

CS07 COMP. DISCHARGE TEMPERATURE

CS08 % COMPRESSOR AMPS (STARTER)

CS09 OIL FEED TEMPERATURE

CS10 EVAP. LEAVING WATER TEMP.

DESCRIPTION

The illustration above is for a single compressor chiller. On dual compressor chillers the

two compressor controllers have identical sensor call-outs.

22 Field Installation Procedure IM 786

Page 23

Figure 9, Partial front view of unit

Figure 10, Detail of sensor locations

Detail A

OIL PUMP VENT LINE,

CENTER-TOP OF SUMP

TO COMPRESSOR

Detail D

LINE FROM OIL COOLER

TO COMPRESSOR

FILTER

Detail C

Detail E

IM 786 Field Installation Procedure 23

Page 24

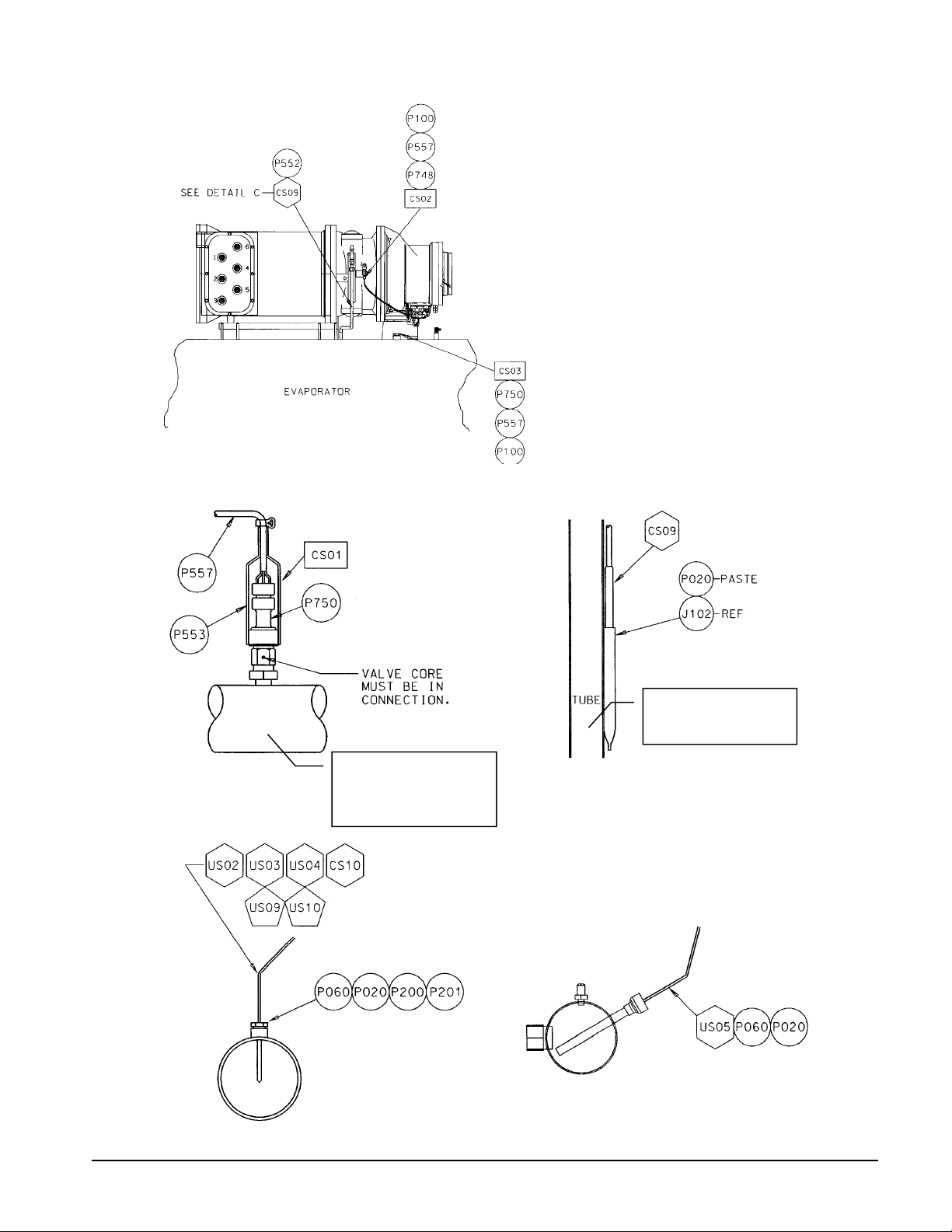

Detail of sensor locations, conti nued

Detail B1 for MT 100/200 CS06, cond refrigerant pressure sensor & M HP l ocat i on

Detail B2 for MT 100/200 CS06, cond refrigerant pressure sensor location & MHP with

HGBP

24 Field Installation Procedure IM 786

Page 25

Figure 11, MT200 Sensor l ocat ions (Models PEH/PFH)

MT200

Sensor No.

S00 CS10 Evaporator Leaving W ater Temperature

S01 US02 Evaporator Entering Water Temperature

S02 CS05 Compressor Suct i on Temperature

S03 - External Chilled Water Reset (By Others)

S04 - External Motor Current Reset (By Others)

S05 - Refrigerant Leak Monitor Signal (By Ot hers)

S06 - Evaporator Water Flow Transm i tter Signal (By Others)

S07 - Condenser Water Flow Transm i t ter Signal (By Others)

S08 US05 Condenser Liquid Line Temperature

S09 US03 Condenser Entering Water Temperature

S10 US04 Condenser Leaving Wat er Temperature

S11 CS08 Percent Unit Amps

S12 CS07 Compressor Disc harge Temperature

S13 CS09 Oil Feed Temperature

S14 CS04 Oil Sump Temperat ure

S15 CS01 Oil Vent Pressure

S16 CS03 Evaporator Refrigerant Pres sure

S17 CS06 Condenser Refrigerant Press ure

S18 CS02 Oil Feed Gauge Pressure

S19 - Transducer Power Voltage Ratio

S20 - Outdoor Air Temperature

S21 US09 Not used (Heat Recovery Enteri ng Water Temperature)

S22 US10 Not used (Heat Recovery Leaving Water Temperature)

MT II Sensor

No

- Spare

Description

IM 786 Field Installation Procedure 25

Page 26

Control Panel Connections

The following figures give details of the control panels and how their input and output

connections are made.

Figure 12, Unit Control Panel detail

26 Field Installation Procedure IM 786

Page 27

Figure 13, Unit Control Panel connections

IM 786 Field Installation Procedure 27

Page 28

Figure 14, Compressor Control Panel detail

28 Field Installation Procedure IM 786

Page 29

Figure 15, Compressor Control Panel connections

IM 786 Field Installation Procedure 29

Page 30

High Pressure Switch Use

Included in the MicroTech II Retrofit Kit are two different model high pressure switches.

074796301 - SPST-NC switch that trips(opens) at 180psi +/-7psi and resets at 125psi +/- 10psi.

074796302 - SPST-NC switch that trips(opens) at 190psi +/-7psi and resets at 135psi +/- 10psi.

The use of either component should be determined by the rating of the relief valve on the condenser.

It is required that the pressure switch trips at a maximum pressure of 90% of the rated relief valve

setting that is installed on the chiller. It is desirable to select the lower rated pressure switch if it is

suitable to your application.

For the use of the 190psi pressure switch, the relief valve must be rated at 212psi or greater. For the

use of the 180psi pressure switch the relief valve must be rated at 200psi or greater relief pressure.

The 190psi pressure switch allows a little more operating room in the case of running higher saturated

condenser temperatures.

30 Field Installation Procedure IM 786

Page 31

Check Out and Startup

Disconnect motor leads from compressor before beginning check, test, and start to prevent

compressor from starting during start-up. Failure to do so can cause equipment damage.

1. Set dip switches on controllers.

CAUTION

Chiller Comp 1 Comp 2

A

Six Binary Switches: Up is ‘On’, indicated by ‘1’. Down is ‘Off’, indicated by ‘0’.

125678

100000 010000 101000 011000 111000 000100

Unit

Controller

Reserved

Operator

Interface

Reserved

2. Re-check all wire terminations to verify they are landed correctly.

3. Power up 115 volt circuit.

4. Check for proper voltages.

5. If the unit controller and compressor controller(s) have not been pre-loaded with software

contact Parts Tech Group @ 763-553-5403 for assistance in obtaining the necessary equipment

to load software into the controllers. This will also involve loading software into the optional

Touch Screen Panel. Input the specific chiller operating and equipment protection parameters

previously recorded from the old controller, after reviewing and checking against factory

defaults and current system design conditions.(See instructions in OM CentrifMicro II for

procedure).

CAUTION

Each of the MicroTech controllers must have compatible software versions(the latest version is

always recommended), including the Touch Screen software and UCM module. Controllers trying to

communicate with mixed software versions will result in corrupt data and may cause unexpected

events, such as random output energizing and possible compressor damage. Always follow proper

download procedures and check software versions on all controller devices and Touch Screen before

attempting to operate the chiller.

6. Check operation of all safety and operating controls.

7. Dry run starter.

8. Re-commission chiller.

The following are trademarks or registered trademarks of their respective companies: BACnet

from ASHRAE; L

ONMARK and LONWORKS from Echelon Corporation; Loctite from Loctite

Corporation, Sporlan from Sporlan Valve Company, Victaulic from Vitaulic Company, and

Guardistor, MicroTech, MicroTech II, Open Protocol, and Protocol Selectability from McQuay

International.

IM 786 Field Installation Procedure 31

Page 32

32 Field Installation Procedure IM 786

Page 33

Page 34

This document contains the most current product information as of this printing. For the most current product

information, please go to www.mcquay.com.

(800) 432-1342 • www.mcquay.com IM 786 (01/04)

Loading...

Loading...