Page 1

Installation Manual

Digital Variable Multi Air Conditioner

MDS 30 – 70A(R)

MDS 80 – 320B(R)

5MDS 50 – 500B(R)

Page 2

Page 3

Installation Manual IM-MDS_(i) i

The data and suggestions in this document are believed current and accurate at the time of publication, but they

are not a substitute for trained, experienced and professional service. Individual applications and site variations

can significantly affect the results and effectiveness of any information, the reader must satisfy him/herself

regarding the applicability of any article and seek professional evaluation of all materials. McQuay disclaims any

responsibility for actions based on this document.

This installation manual is intended for and should only be used by qualified engineers/service

personnel. Installation and maintenance are to be performed only by qualified personnel who are familiar

with local codes and regulations, and experienced with this type of equipment.

Caution: Sharp edges and coil surfaces are a potential injury hazard. Avoid contact with them.

Warning: Moving machinery and electrical power hazard. May cause severe personnel injury

or death. Disconnect and lock off power before servicing equipment.

Page 4

ii Installation Manual IM-MDS_(i)

1.0 Safety Precautions...……………………………………………………………………………....1

1.1 Precautions before installation………………………………………………..………..1

1.2 Safety reminder on installation process...……………………………………………..1

1.3 Precautions on commissioning..………………………………………………………….1

1.4 Precautions for devices that use R410A refrigerant……………………………….....1

1.5 Other precautions……...…………………………………………………………………..2

2.0 Electrical Parameter……………………………………………………………………………..2

3.0 Installation Instruction……………………………………………………………….…………..4

4.0 Outdoor Unit Installation...………………………………………………………………………...4

4.1 Location and space of installation….…………………………………………………….4

4.2 Unit handling…………….………………………………………………………………….6

4.3 Unit installation…………..…………………………………………………………………6

4.4 Installation of master and slave unit……………………………………………………..6

5.0 Indoor Unit Installation…………………………………………………………………………7

5.1 Location and space of installation...……………………………………………………..7

5.2 Installation of MEX box………………………………….………………………………...7

5.3 Installation of MCCD series indoor unit………………………………………………….8

5.4 Installation of MCKD series indoor unit …………………………...…………………….8

5.5 Installation of MCMD series indoor unit ……………………………………………….10

5.6 Installation of MWMD series indoor unit ………………………………………………12

6.0 Piping Installation…………………………………………………………………………………13

6.1 Precautions for piping installation……………………………………………………....13

6.2 Refrigerant piping system………..………………………………………………..........14

6.3 Piping size, refnet and distributor selection….………………………………………15

6.4 Installation of refrigerant piping…………………………………………………...........18

6.5 Ball valve installation and operation.…………………………………………………19

7.0 Wiring Connection……………………………………………………………………………..…20

7.1 General wiring precautions……………………………………………………………20

7.2 Wire specification…………………………………………………………………………21

7.3 Electrical wiring connection……………………………………………………………21

7.4 Communication wiring connection……………………………………………………22

7.5 Dip switch setting……………………….………………………………………………..23

7.6 Auto restart setting……………………………………….............................................24

8.0 Air Leakage Test, Vacuum and Refrigerant Charge….…………………………………..….25

8.1 Air leakage test………………………...…………………………………………………25

8.2 Vacuum……………………………………………………………………………………25

8.3 Refrigerant charge…………..……………………………………………………………25

9.0 Commissioning………………………………………...….…………………………………..….25

9.1 Checking list before commissioning....…………………………………………………25

9.2 Commissioning record table.……………………………………………………………25

9.3 Common problems during commissioning.……………………………………………25

10.0 Unit Outlines and Dimensions….…………………………………..…………………………27

Table of Content

Page 5

Installation Manual IM-MDS_(i) 1

1.0 Safety Precautions

Please take note of the safety item stated below before and after the installation process:

1.1 Preparation before installation

Check the electrical power supply condition. Power supply shall meet the requirement of local rule and

regulation.

The tolerance of voltage shall be less than ±10% based on nominal voltage. It is not allowed to share the

same power cable through soldering as it will cause fluctuation of power supply.

Professional technician or engineer is needed to conduct the installation.

Follow the installation instruction in this manual. Improper installation may cause damage to the unit which

will then cause other accident to happen.

A solid base shall be built on the ground before installation of outdoor unit. The base shall be strong enough

to support the weight of the outdoor units. Counter measure should be taken against possible natural

disaster such as earthquake and typhoon.

Installation kits and protection kits shall be used to prevent injury.

1.2 Safety reminder on installation process

Do not touch the fins of heat exchanger. It may cause injury. Besides that, any damage on the heat

exchanger will reduce the heat exchange performance.

Secure the outdoor unit to avoid any vibration. The service panel and control box cover shall be closed

tightly to avoid any dirt and water from damaging the components.

Only air filter and heater provided/approved by factory shall be installed on the indoor units.

Action shall be taken to avoid refrigerant leakage during the installation process.

In case of any refrigerant leakage occur, open the window and door to improve ventilation and prevent fire

hazard.

Any electrical cable shall be kept away from water and humidity.

Do not change any settings of the protection devices unless instructed by factory.

Do not pull the electrical cable too tight, as it may cause the cable to break without notice.

Ensure the cable size is correct and sufficient to support the current and power consumption.

Unit must be earthed properly. Do not connect earth line with telephone line.

Indoor condensing water shall be drained away properly to avoid overflow. Insulation is needed for piping

connecting to the drain pan.

All units shall be handled and carried carefully during transportation.

After installation completed, the unit should undergo leakage test.

1.3 Precautions on commissioning

Power is to be supplied to the units for 12 hours before running them for the first time. This is to prevent any

damage of electrical components.

Avoid contact with power switch when hand is wet.

Do not remove the front panel or protection guard when the unit is in operation. The components running in

high speed may cause injury and damage.

Do not touch the refrigerant piping when the unit is running or just stop to avoid any injury.

Do not switch off the power supply immediately after the unit is off. Please wait for 5 minutes before shutting

down the power supply.

1.4 Precautions for devices that use R410A refrigerant

R410A is high pressure refrigerant. Do not use refrigerant piping of other type of refrigerant to prevent burst.

Do not use old refrigerator oil as it may contains large amount of chlorine that can cause the refrigerator oil in

R410A unit to deteriorate.

Use refrigerant piping that is made of phosphorus deoxidized copper and copper alloy seamless pipe.

Ensure the inner and outer surfaces of the pipes are clean and free of sulphur, oxide, dust, shaving particles,

oils, moisture and other contaminant.

Store the piping properly and keep both ends sealed until it is used to prevent dust and moisture.

Ensure that only liquid refrigerant is charged into the system as the composition of refrigerant is different in

gaseous phase.

Use ester oils, ether oil or small amount of alkylbenzene as the refrigerator oil to coat flares and flange

connection. Do not use mineral oil.

Use a vacuum pump with a reverse flow check valve. The vacuum pump oil may flow back into the

refrigerant cycle and cause the refrigerator oil to deteriorate.

Do not use refrigerant other than R410A.

Do not use tools such as gauge manifold, charge hose and etc which are not designed for R410A refrigerant.

Page 6

2 Installation Manual IM-MDS_(i)

1.5 Other precautions

Contact local distributor/manufacturer for assistance when there’s doubt on the installation process.

Do not charge in other type of refrigerant to the unit as this will damage the unit.

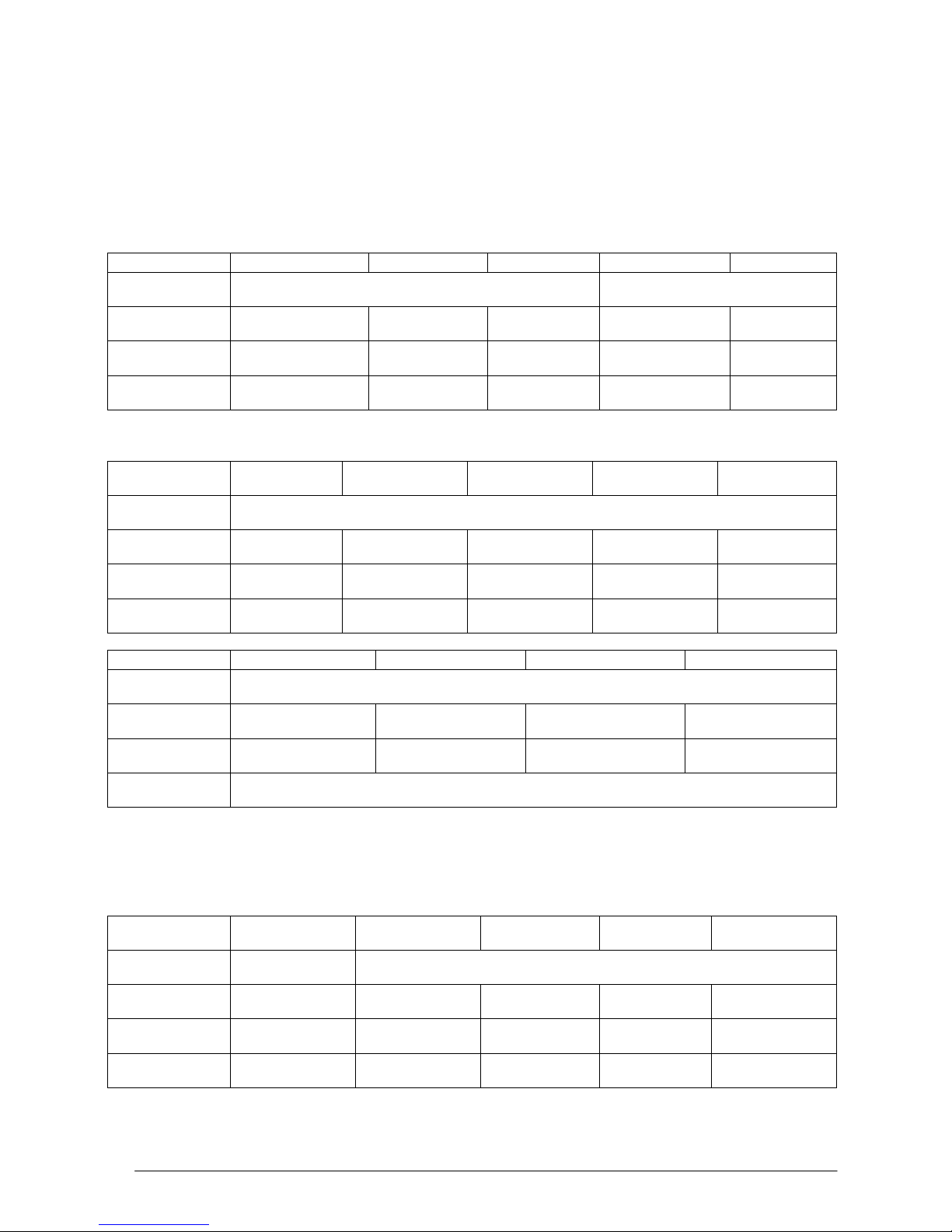

2.0 Electrical Parameter

All values given are for reference only. They shall be checked and selected to comply with local standards and

regulations.

MDS-A Series Outdoor

Model

MDS30-40A(R)

MDS50A(R)

MDS60A(R)

MDS50-60A(R)

MDS70A(R)

Power supply

(V/Ph/Hz)

220-240/1/50

380-415/3/50

Max. Breaker

Size (A)

25

30

40

15

20

Number of

Wires

3 3 3 5 5

Power Cable

Size (mm2)

6 6 6 4 4

MDS-B Series Outdoor

Model

MDS80B(R)

MDS100-

120B(R)

MDS150-

180B(R)

MDS200-

220B(R)

MDS240B(R)

Power supply

(V/Ph/Hz)

380-415/3/50

Max. Breaker

Size (A)

25

30

50

50

60

Number of

Wires

5 5 5 5 5

Power Cable

Size (mm2)

6 6 10

16

16

Model

MDS260B(R)

MDS280B(R)

MDS300B(R)

MDS320B(R)

Power supply

(V/Ph/Hz)

380-415/3/50

Max. Breaker

Size (A)

60

70

80

80

Number of

Wires

5 5 5

5

Power Cable

Size (mm2)

16 (Master) 10 (Slave)

Note: MDS 260-320B(R) is combined unit, consist of master unit and slave unit. There are two ways to connect the cable, either separate

connection or serial connection. For MDS 320, only separate connection can be used. For other combined units, it is recommended to use

serial connection.

5MDS-B Series Outdoor

Model

5MDS60B(R)

5MDS50B(R)

5MDS60-

70B(R)

5MDS80-

100B(R)

5MDS120B(R)

Power supply

(V/Ph/Hz)

220-240/1/50

380-415/3/50

Max. Breaker

Size (A)

40

15

20

25

30

Number of

Wires

3 5 5 5 5

Power Cable

Size (mm2)

6 4 4 6 6

Page 7

Installation Manual IM-MDS_(i) 3

Model

5MDS140-160B(R)

5MDS180-200B(R)

5MDS220B(R)

5MDS240B(R)

Power supply

(V/Ph/Hz)

380-415/3/50

Max. Breaker

Size (A)

40

50

60

60

Number of

Wires

5 5 5

5

Power Cable

Size (mm2)

10

10

10

16

Model

5MDS260-

280B(R)

5MDS300B(R)

5MDS320B(R)

5MDS340-360B(R)

Power supply (V/Ph/Hz)

380-415/3/50

Max. Breaker Size (A)

70

80

80

90

Number of Wires

5 5 5

5

Power Cable

Size (mm2)

Separate

6 (Master) 10 (Slave)

10 (Master) 10 (Slave)

Serial

16 (Master) 10 (Slave)

-

Model

5MDS380B(R)

5MDS400B(R)

5MDS420-

460B(R)

5MDS480-500B(R)

Power supply (V/Ph/Hz)

380-415/3/50

Max. Breaker Size (A)

100

100

125

125

Number of Wires

5 5 5

5

Power Cable

Size (mm2)

Separate

16 (Master) 10 (Slave)

16 (Master) 16 (Slave)

Serial

25 (Master) 10 (Slave)

25 (Master) 16 (Slave)

Note: 5MDS 260-500B(R) is combined unit, consist of master unit and slave unit. There are two ways to connect the cable, either separate

connection or serial connection. For 5MDS 320-360B(R), only separate connection can be used. For other combined units, it is

recommended to use serial connection.

MCCD/M5CCD Series Indoor

Model

10-15C

20-25C

28-30C

38-40C

50-60C

Power supply (V/Ph/Hz)

220-240/1/50

Number of Wires

3

Power Cable Size (mm2)

1.5

2.5

4.0

1.5

2.5

MCKD/M5CKD Series Indoor

Model

20-25A

30A

40A

50A

10-15C

20C

Power supply (V/Ph/Hz)

220-240/1/50

Number of Wires

3

Power Cable Size (mm2)

2.5

4.0

1.5

2.5

1.5

2.5

MCMD/M5CMD/MCMD/M5CMD Series Indoor

Model

15-25E

28E

40D

50D

62C

Power supply (V/Ph/Hz)

220-240/1/50

Number of Wires

3

Power Cable Size (mm2)

2.5

4.0

1.5

2.5

2.5

MWMD/M5WMD Series Indoor

Model

09-15G

20-25G

Power supply (V/Ph/Hz)

220-240/1/50

Number of Wires

3

Power Cable Size (mm2)

1.5

2.5

Page 8

4 Installation Manual IM-MDS_(i)

3.0 Installation Instruction

Kindly follow the installation steps shown below:

1. Choose the installation place

2. Install the outdoor and indoor unit

3. Install the piping and cable line

4. Perform leakage test

5. Vacuum the system and charge in refrigerant

6. Test run/commissioning

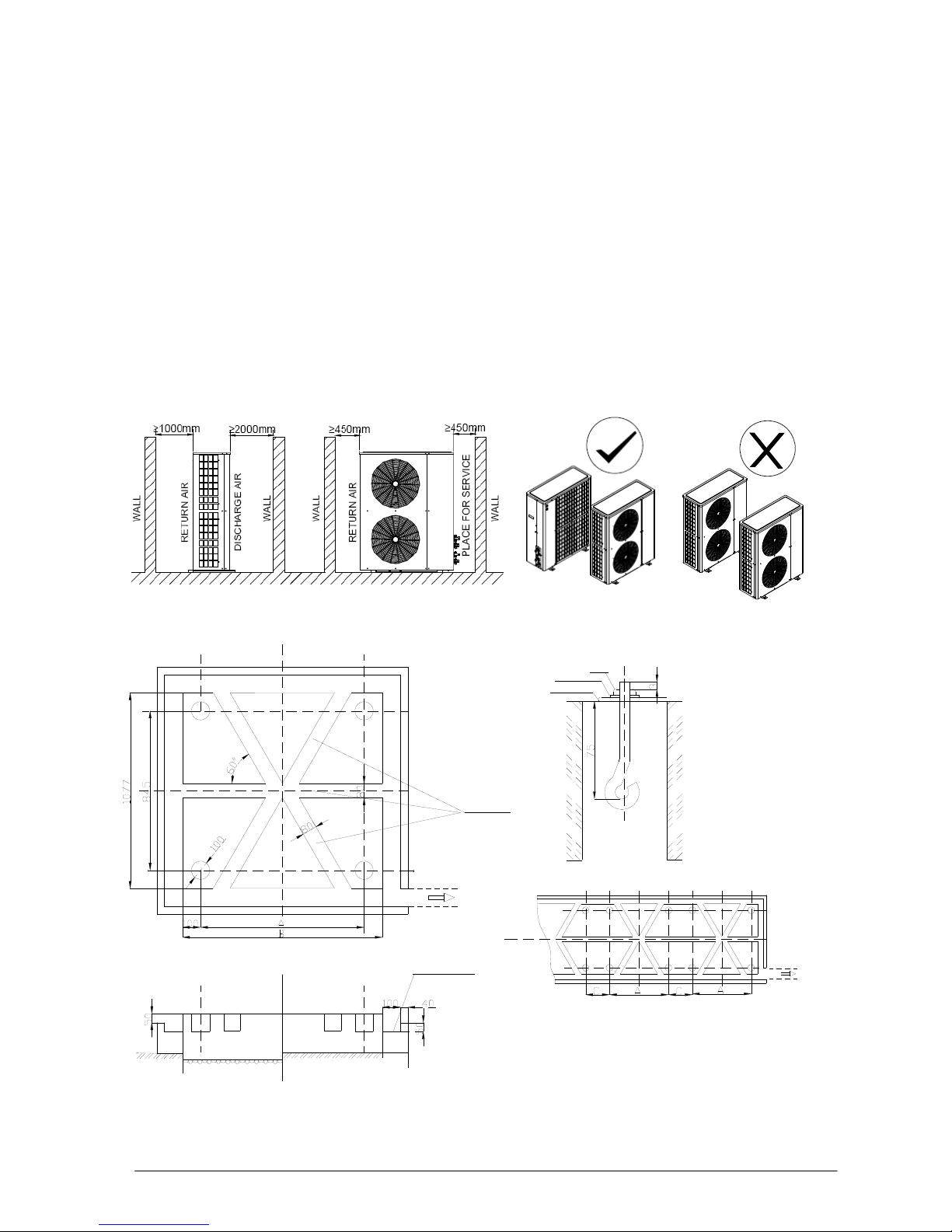

4.0 Outdoor Unit Installation

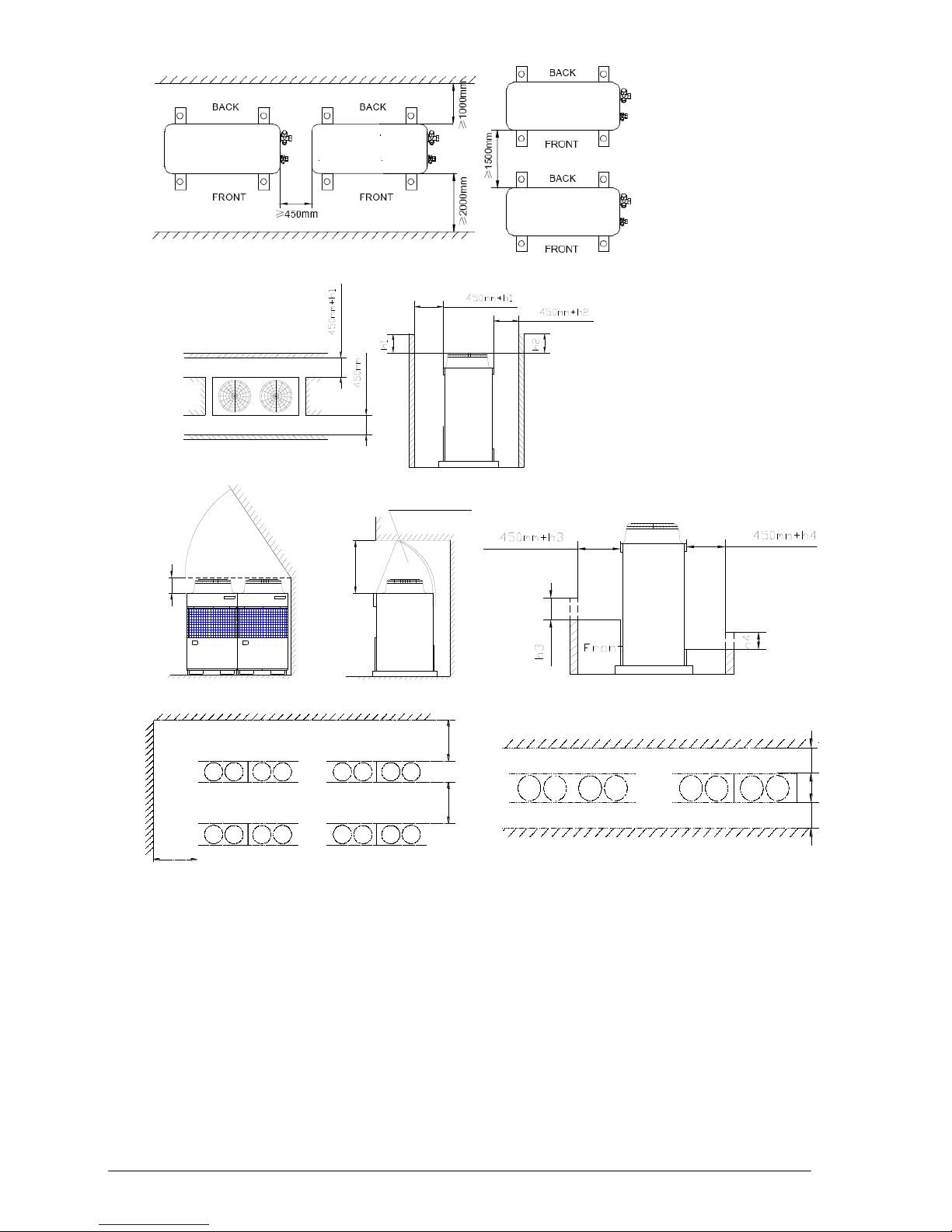

4.1 Location and space of installation

Avoid the discharge air from circulating back to air inlet.

Remove any barrier to improve the air ventilation.

Ensure enough space for maintenance.

Avoid installation of unit under corrosive environment.

Avoid installation of unit at places with flammable gas.

Follow the clearance when more than one outdoor unit is installed at the same location.

Constructing on the ground

x

Foundation nut installing

Many units concentrated installing

Constructing on the floor

AMDS200~240BR5

Mode

AMDS080~120BR5

AMDS140~180BR5

Drain ditch

Gradient is 1/40

x

Drain ditch

1900

2100

900

1200

A

1100

1400

B

Nut

Y Trough

Undercarriage

Spring washer

Bolt mode: JA

Dimension:M12

Quantity:4

MDS 30-70A(R)

5MDS 50-70B(R)

MDS 80-320B(R)

5MDS 80-500B(R)

Page 9

Installation Manual IM-MDS_(i) 5

≥

≥

≥

≥

≥

≥

≥ 45°

Front

Air Outlet Guide

≥

300mm

≥

1000mm

FRONT

BACK

FRONT

BACK

≥

450mm

≥

450mm

BACK

FRONT

FRONT

BACK BACK

FRONT

FRONT

BACK

≥600mm

≥

450mm

≥

900mm

MDS 30-70A(R)

5MDS 50-70B(R)

MDS 80-320B(R)

5MDS 80-500B(R)

Page 10

6 Installation Manual IM-MDS_(i)

4.2 Unit handling

Use 4 supporting points to move the units (refer to diagram).

Avoid unstable move to prevent unit drop off.

Do use special rope to tie the units for transportation.

Do not touch the fin to avoid injury.

Keep the plastic bag from reach of children.

4.3 Unit installation

Ensure the base is solid to support the unit.

Consider the location for drainage and piping installation.

Screw bolt to secure the 4 corners of the unit.

Use rubber absorber to prevent transfer of vibration.

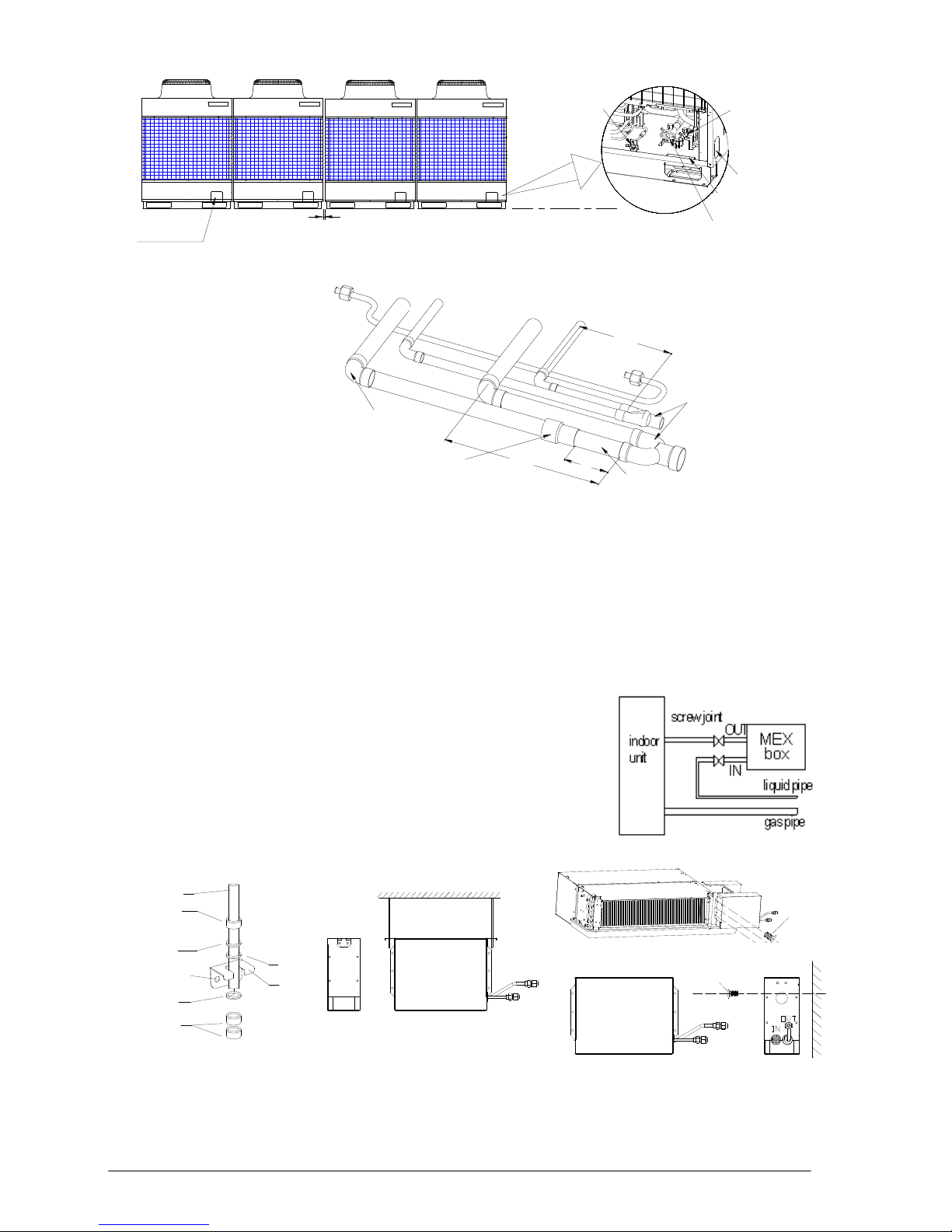

4.4 Installation of Master and Slave unit

Both master and slave unit must be positioned side by side and installed in the same level.

The distance between master and slave unit shall be more than 10mm.

Copper part accessories are packed with the outdoor units.

All piping should be insulated.

Gas and liquid piping should be connected paralleled to each other.

Balance piping must be installed. It should be connected through the hole of side panel, base panel or the

piping connection position with the other outdoor unit.

Balance piping shall be installed horizontally and it must be lower than the access valve of balance piping.

Balance piping shall not be touching any other parts.

Page 11

Installation Manual IM-MDS_(i) 7

5.0 Indoor Unit Installation

5.1 Location and space of installation

Ensure adequate air flow for the indoor unit and no obstacle around it.

Ensure enough space for maintenance and servicing.

Wall or ceiling shall be strong enough to support the indoor units.

Do not expose the unit under direct sunlight.

Do not install the indoor unit near to places with oil, steam or flammable gas.

Do not install the indoor unit at places with high frequency.

5.2 Installation of MEX Box

All indoor units need to connect to MEX Box.

It should be installed away from quiets such as bedroom.

Ensure the MEX box is vertical when installed. The distance between

MEX box and indoor unit could not exceed the maximum length limit

of the expansion valve cable. The cable needs to be plugged on the

control board of indoor unit.

MEX Box can be installed in any of the method shown below.

Remove the panel

C

For φ28.6mm gas pipe, directly

connect to Tri-joint; For φ34.9mm

gas pipe, add a reducer and a

transition pipe

Elbow

To units ball valve

Balance pipe

Liquid pipe

Gas pipe

A

Knock-out-hole

Piping connection position

To balance pipe

access valve

Tri-jiont

φ28.6mm a transiton pipe

(only for φ34.9mm gas pipe)

Connect pipe to

indoor units

D

A >10mm

B >200mm

C >500mm

D>100mm

B

To units ball valve

Ball valve (gas side)

Knock-out-hole

(for connecting balance pipe)

Access valve for

balance piping (φ9.52)

Knock-out-hole

Ball valve

(liquid side)

Master and slave must be

installed in the same level

steeve

nut

washer

hole for screw

washer

nut

washer

hook

SUSPENDING BY STEEVES

SCREW SETTING ON INDOOR UNIT

SCREW

SCREW SETTING ON WALL

SCREW

Page 12

8 Installation Manual IM-MDS_(i)

5.3 Installation of MCCD series indoor units

Use the hanger supplied with the unit.

Install the unit horizontally and ensure the slope for drainage is sufficient.

Ensure the distance between return air inlet and heat exchanger shall be at least 1m.

Do not open the valves, connector, copper cup and cover before installation.

Install the piping and drainage properly.

Use selected air distributor or diffuser to meet the design requirement.

Connect the return air inlet of indoor units with return air inlet on the ceiling.

Both air supply and return duct shall be insulated with aluminium foil.

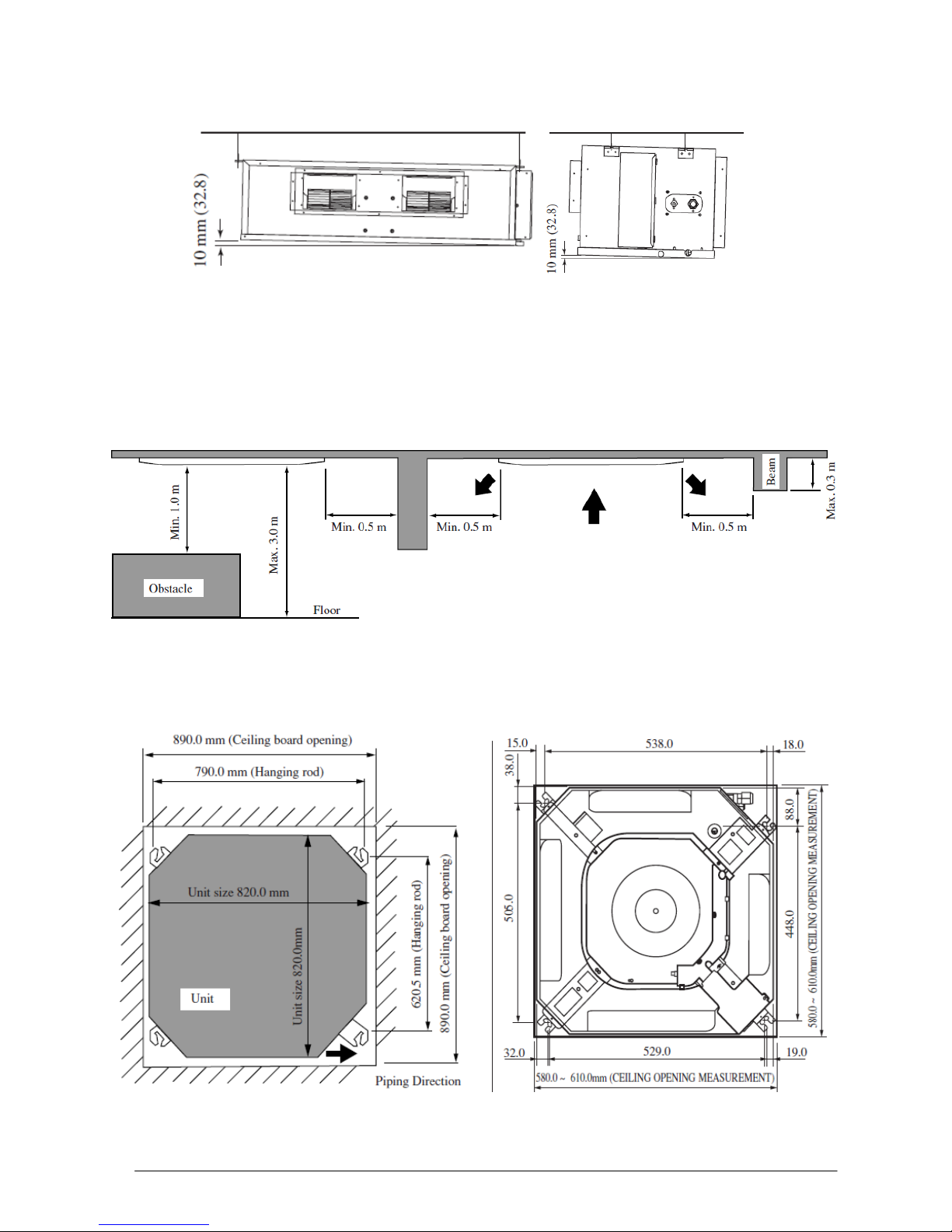

5.4 Installation of MCKD series indoor units

Ensure sufficient space for ventilation and no obstacle around the indoor unit.

The support shall carry weight 4 times larger than the indoor units to avoid unnecessary vibration and noise.

Keep the indoor units away from source of heat and vapour.

Use the installation template on the carton box to measure position for hanging rod. Drill the hole for the

angle nut on the ceiling and fix the hanging rod.

Confirm the pitch of the hanging rod as per figure below.

MCKD/M5CKD-A MCKD/M5CKD-C

Use nut and washer to fix the indoor units securely to prevent unit falling and vibration.

Page 13

Installation Manual IM-MDS_(i) 9

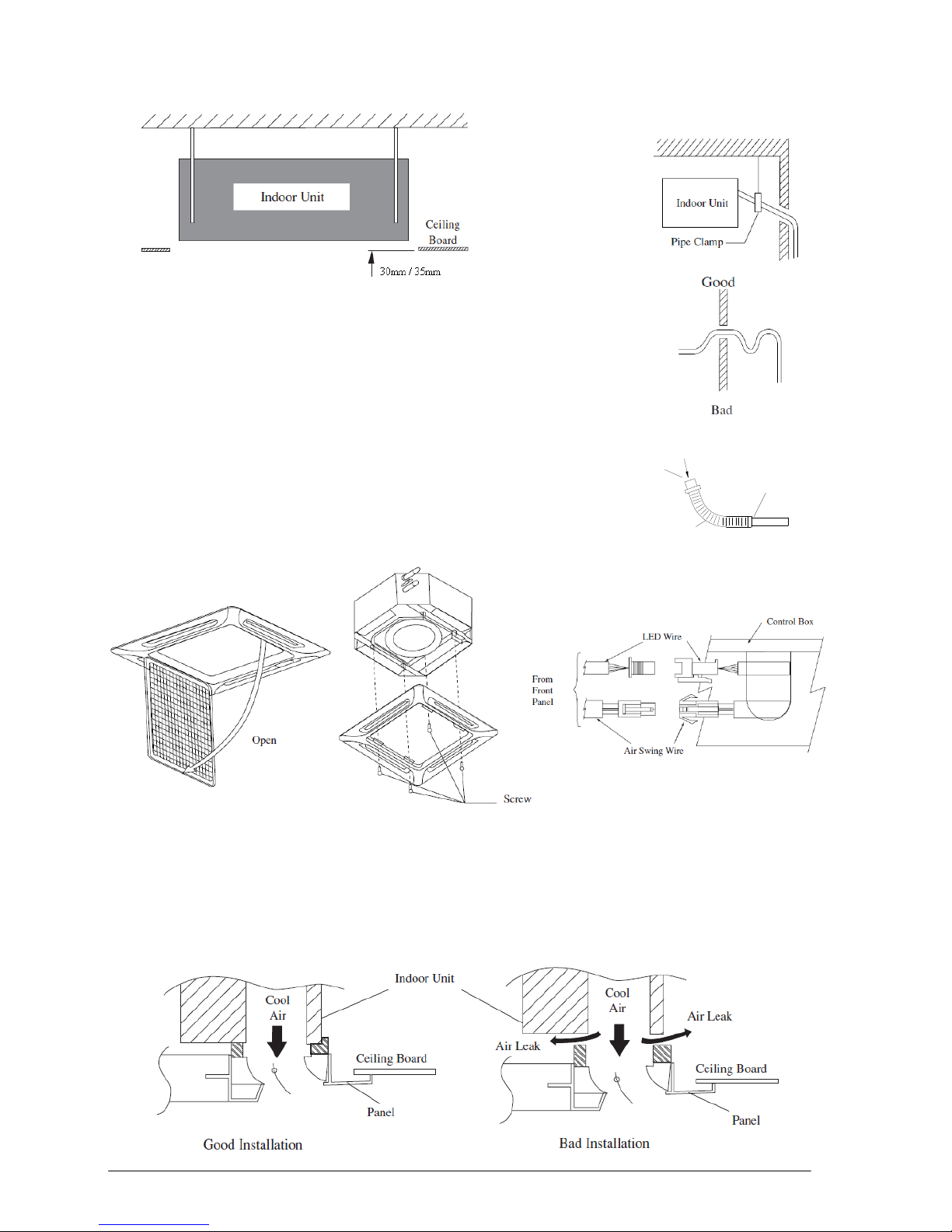

Adjust the unit height to 35mm (for MCKD-A) or 30mm (for MCKD-C) between the indoor unit bottom surface

and the ceiling surface.

Confirm with a level gauge that the unit is installed horizontally.

Open the ceiling board along the outer edge of the installation template.

Drain pipe must be in downward gradient for smooth drainage to

prevent reversed water flow.

When connecting the drain pipe, be careful not to exert extra force

on the drain connector at indoor unit.

The outer diameter of the drain connection at the flexible drain hose

is 20mm.

Ensure to apply insulation (polyethylene foam with thickness more

than 8mm) on the drain piping to avoid the condensed water dripping

inside the room.

Connect the main drain pipe to the flexible drain hose.

Feed water from flexible drain hose to check the piping for leakage.

When the test is completed, connect the flexible drain hose to the drain

connector on the indoor unit.

The front panel can only be fitted in one direction, following the piping direction. (Follow piping arrow sticker

on front panel).

Be sure to remove the installation template before installing the front panel.

Open the air intake grille by pulling back the catchers and removing it together with filter from panel.

Install the front frame panel onto the indoor unit by 4 screws and tighten it completely to prevent cool air

leakage.

Connect the LED wire and air swing wire to the indoor unit.

Install the front panel firmly to prevent cool air leakage which will cause condensation and water dripping.

drain pipe

drain & leakage test

fill water

flexible pipe

Drain pipe installation

Front panel installation

Wire connection between unit and panel

Drainage leak test

Page 14

10 Installation Manual IM-MDS_(i)

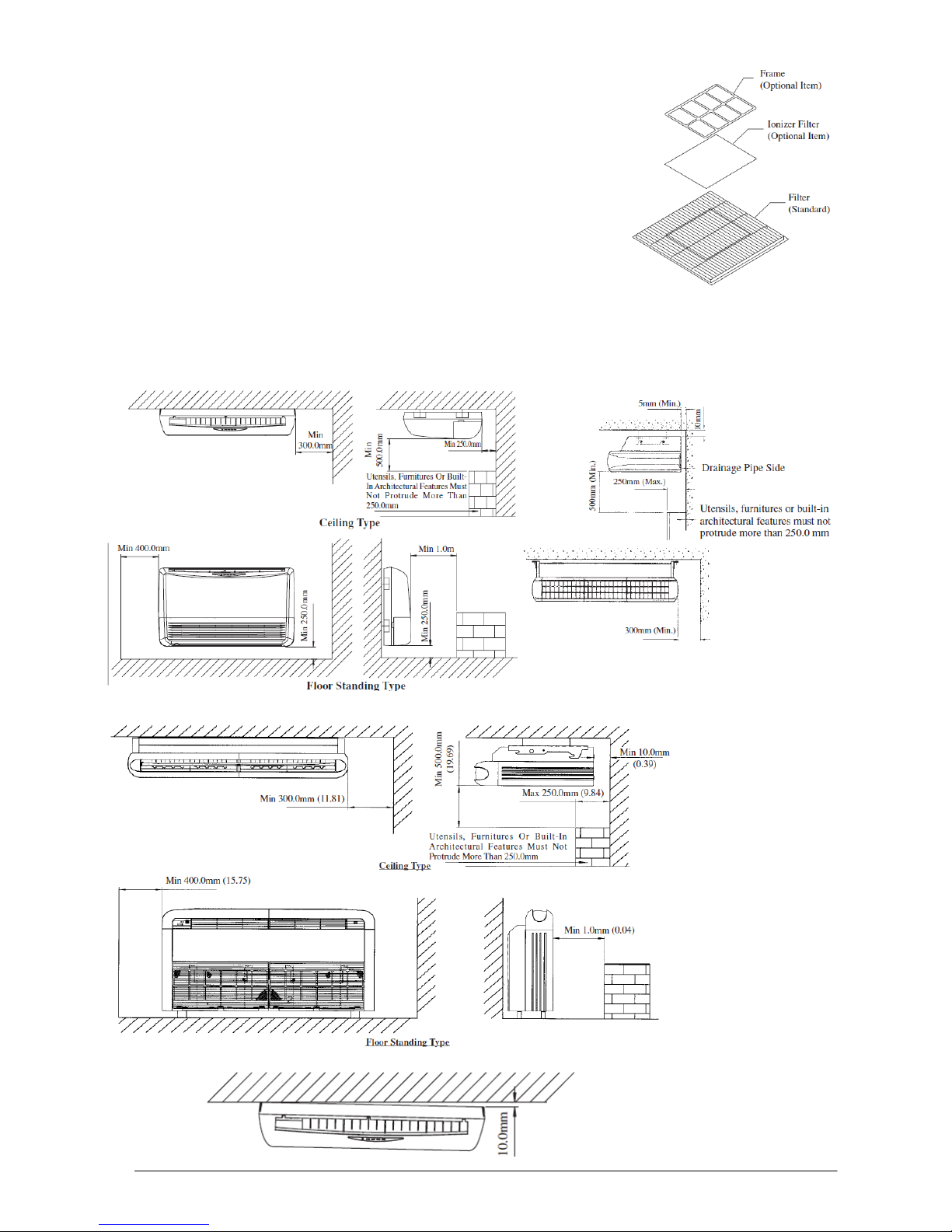

Install the air intake grille together with the air filter to the front panel.

The grille can be fit in any direction, when selecting direction, the ceiling

design and grille operability should be considered.

If the unit comes with ionizer filter (optional item), make sure to fix the

ionizer filter to the air filter before installing the air intake grille.

Fix the ionizer filter to the air filter with the black side on top and white

side at bottom. Carefully clip on the ionizer filter frame.

Note that water pump is installed in this type of indoor unit.

5.5 Installation of MCMD series indoor units

Ensure sufficient space for ventilation and no obstacle around the indoor unit.

Install the unit horizontally and ensure the slope for drainage is sufficient.

Note that MCMD/M5CMD62C is unable to be installed in floor standing position.

MCMD/M5CMD-E Series

MCMD/M5CMD-C Series

MCMD/M5CMD-D Series

Slope for drainage

Page 15

Installation Manual IM-MDS_(i) 11

Ensure the overhead supports are strong enough to hold the weight of the unit.

Position the hanger rods and check for its alignment with the unit. Also check that the hangers are secured

and the base of the indoor unit is levelled in both horizontal directions.

Provide clearance for easy serviceability and optimal air flow.

The unit must be installed a large distance away from the door to avoid direct sunlight.

The location of indoor unit should be suitable for piping and drainage installation.

The indoor unit must be installed such that there is no short circuit of cool discharge air with the warm return

air.

Air return grill

Frame

Suspending

panel

Panel side

Installation of MCMD/M5CMD-C/D Series

Installation of MCMD/M5CMD-E Series

Ceiling Type Installation

Page 16

12 Installation Manual IM-MDS_(i)

5.6 Installation of MWMD series indoor units

Ensure sufficient space for ventilation and no obstacle around the indoor unit.

The indoor unit must be installed in such a way so as to prevent short circuit of cool discharged air with the

hot return air. Please follow the installation clearance shown below.

Do not expose the indoor unit to direct sunlight and away from doors and windows.

Consider the location of piping and drainage when selecting the installation space.

The refrigerant piping can be routed to the unit in a number of ways by using the cut-out holes on the casing

of the unit.

Floor Type Installation

Page 17

Installation Manual IM-MDS_(i) 13

Ensure that the wall is strong enough to withstand the weight of the unit. Otherwise, it is necessary to

reinforce the wall with plates, beams or pillars.

Use the level gauge for horizontal mounting and fix it with 4 suitable screws.

In case the rear piping draws out, drill a hole 65mm in diameter with a cone drill, slightly lower on the outside

wall.

The indoor drain pipe must be in a downward gradient for smooth drainage. Avoid situations that are likely to

cause water to leak.

Hook the indoor unit onto the upper portion of the installation plate (engage the two hooks at the rear top of

the indoor unit with the upper edge of the installation plate).

Ensure that the hooks are properly seated on the installation plate by moving it to the left and right.

6.0 Piping Installation

MDS system is a “one outdoor unit coupled with many indoor units” system. For piping connection, there are gas

pipe and liquid pipe connection with flare joint.

6.1 Precautions for piping installation

Check and ensure the thickness, diameter and cleanliness of the copper tube is within specification.

It is not allowed to vacuum the system with refrigerant.

Do not use any detergent to clean the refrigerant piping.

Seal the outlet of the copper tube to avoid dust, dirt or water from entering.

Do not install the copper pipe during rainy day.

Avoid bending and turning of piping. Special tools must be used to bend the piping.

Use the right equipment for brazing the copper tube.

All copper tube must be insulated to ensure heat exchange efficiency and to avoid water from condensing.

The outdoor ball valve should remain closed until the completion of leakage test and vacuum process.

Ensure the unit is properly charged with the correct amount of refrigerant.

Page 18

14 Installation Manual IM-MDS_(i)

6.2 Refrigerant piping system

The below 3 piping structure designs are recommended.

It is not allowed to connect any refnet after the distributor.

balance pipe

Tee joint

Bifurcation

Indoor unit

Distributor

Indoor unit

Balance pipe

Tee joint

Distributor

Bifucation

Balance pipe

Tee joint

Indoor unit

Distributor

Distributor

balance pipe

Tee joint

Indoor uint

Wrong connection

Bifurcation

Wrong connection

Page 19

Installation Manual IM-MDS_(i) 15

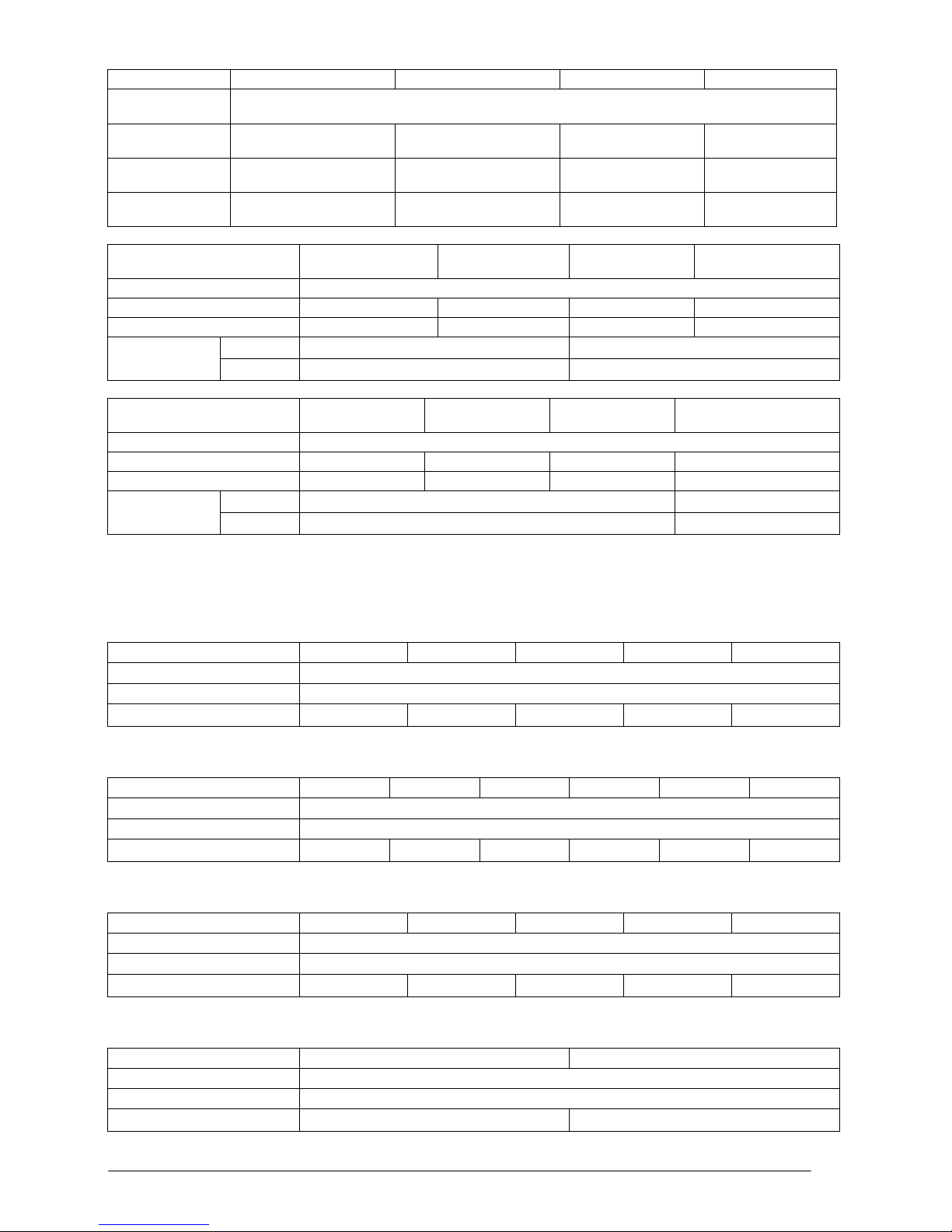

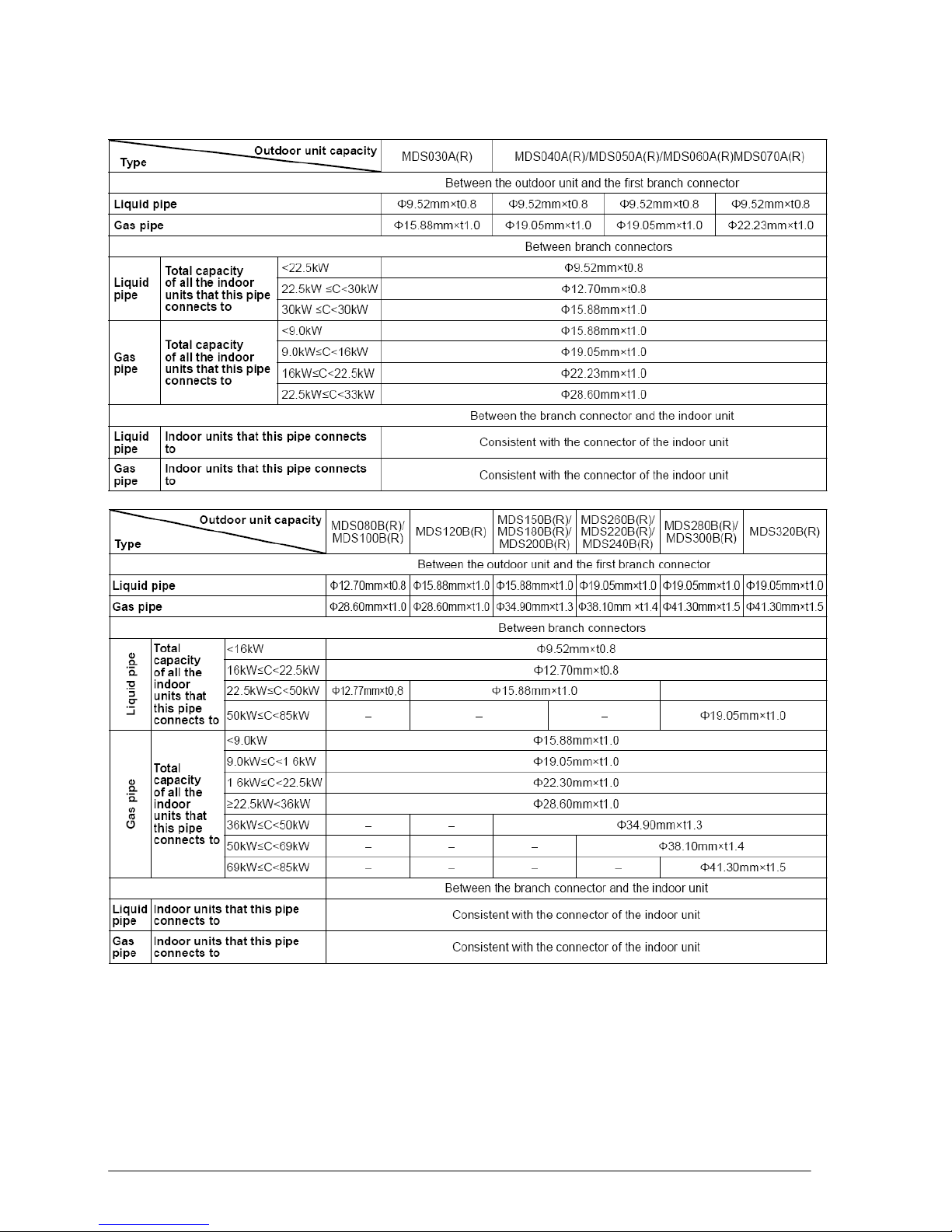

6.3 Piping size, refnet and distributor selection

Select the piping, refnet and distributor base on the tables and diagrams below.

Refrigerant piping

Page 20

16 Installation Manual IM-MDS_(i)

R410A Piping Materials/Radial Thickness

Type

TP2M

TP2Y2

Diameter (mm)

6.4

9.5

12.7

15.9

19.1

22.2

25.4

28.6

31.8

34.9

38.1

41.3

Diameter (inch)

1/4

3/8

1/2

5/8

3/4

7/8 1 1-1/8

1-1/4

1-3/8

1-1/2

1-5/8

Minimum

Thickness

(mm)

0.8

0.8

0.8

1.0

1.0

1.0

1.0

1.0

1.1

1.3

1.4

1.5

The minimum thickness of the pipe in the chart is based on the PRC Standard Specification for Drawn Tube

of Copper and Copper Alloys (GB/T1527-1997), TP2M and TP2Y2 are the marks of the material brand and

state. Using this table as reference, choose the pipe that meets the local standards and the maximum

operation pressure reaches 4.15MPa.

If the unit is used in the environment which is eroded seriously, it should be thickened by 0.2mm.

The table shows the minimum thickness. If the pipe needs to be bent or drawn, please add the extra

thickness appropriately.

Page 21

Installation Manual IM-MDS_(i) 17

Refnet

Page 22

18 Installation Manual IM-MDS_(i)

Horizontal

Vertical

installation

<30°

Direction A

view

Horizontal

installation

Direction A

Outdoor

Oil trap

(every 6~8m fall of the

gas pipe set a oil trap)

Indoor

Installation of refnet and distributor should be within the allowable tolerance as shown in diagrams below.

Installation of the system should within the piping length limitation as shown below.

MDS

5MDS

Length (m)

30-50

60-70

80-320

50

60-70

80-500

Piping

Total equivalent length

100

150

350

100

150

500

Maximum length of

longest branch

Actual piping length

50

70

125

50

70

150

Equivalent length

60

80

150

60

80

175

Maximum equivalent length from first

branch to furthest unit

25

30

40

25

30

65

Height

Between further

indoor and outdoor

outdoor above

20

30

50

20

30

50

indoor above

20

30

40

20

30

40

Maximum height between indoor unit

15

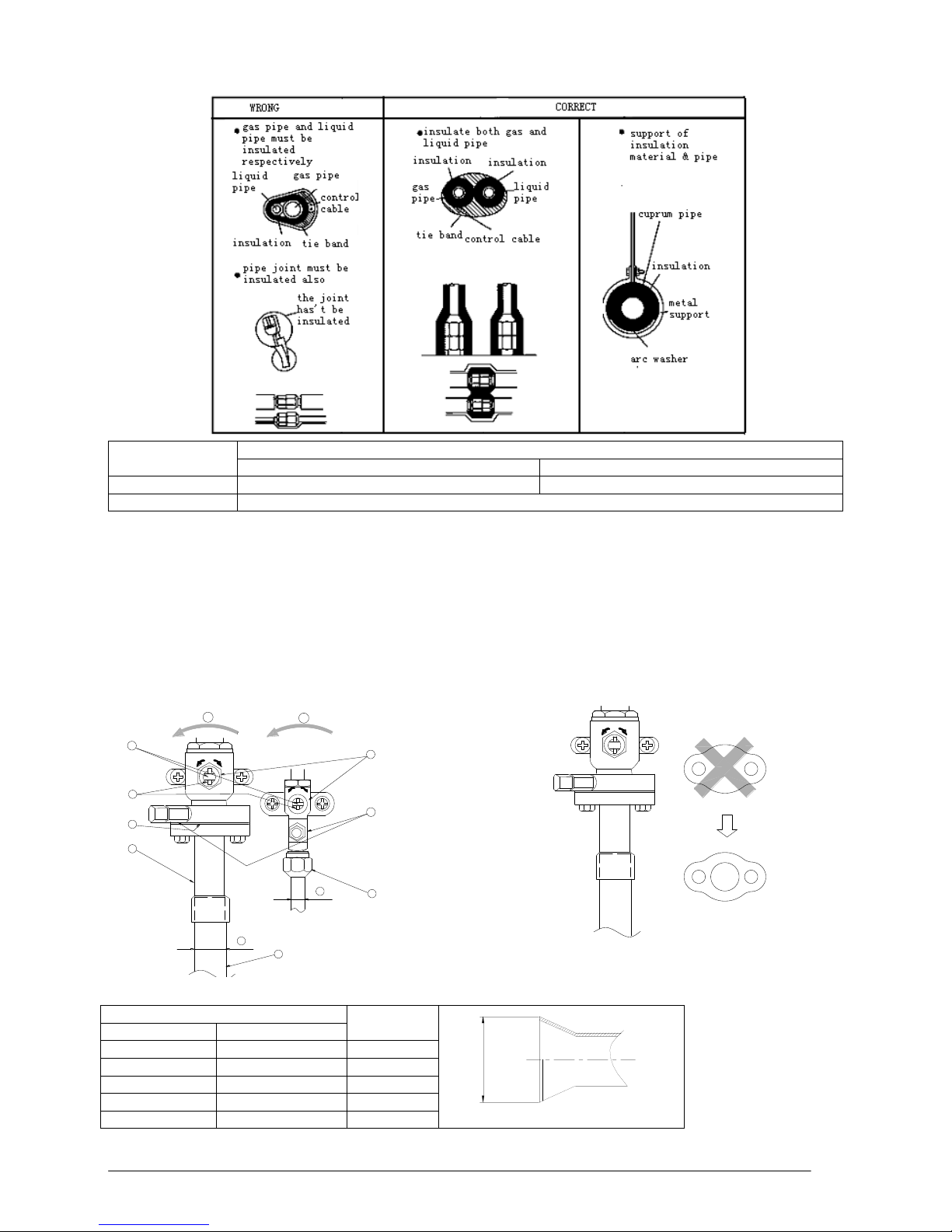

6.4 Insulation of refrigerant piping

All refrigerant piping must be insulated to ensure heat exchange efficiency and prevent water condensing.

Specification of insulation material is as below.

Insulation Material

Fiberglass+Steel

Adhering material+Chloroethylene foam+adhering strip

Layer

Indoor

Chloroethylene insulation strip

Bare floor

Water proof flax+Bronze Pitch

outdoor

Water proof flax+galvanized panel+painting

Maximum height

between indoor units

Height between further

indoor and outdoor

Maximum length of

longest branch

Page 23

Installation Manual IM-MDS_(i) 19

so

Close-packed

packing

Hollow

packing

ball valve

(gas side)

A Valve stem

B Stopper pin

C Packing(accessory)

D Connecting pipe(accessory)

E Open

F Cap, copper packing

G Service port

H Flare nut

I Liquid pipe diameter

J Gas pipe diameter

K Field piping

ball valve

(liquid side)

o s

o s

A

B

C

D

J

K

H

G

I

F

E

E

diameter

The proper steps to insulate the refrigerant piping are shown below.

Pipe Specification

Diameter 6.35 - 25.4mm

Diameter 28.58 - 41.3mm

Thickness

Min 10mm

Min 12mm

Heat resistance

Min100℃

6.5 Ball valve installation and operation

Operate the gas side ball valve

o Uninstall the flange connector: remove the flange connector from the piping

o Stick the seal material to cover the inlet of the ball valve flange to avoid the dirt entry

o Change the hollow seal pad

o Fix the flange connector and hollow seal pad and fixed ball valve of gas side with screw bolt.

Liquid side ball valve connecting: expand the copper tube outlet and connect the ball valve connector

Vacuum and charge in refrigerant, ensure to open the valve completely

Calculate the additional refrigerant and charge into units accordingly

Check the looseness to avoid leakage of refrigerant

Copper tube expanded connector dimension. (unit: mm)

External Diameter

Diameter

mm

inch

Ф6.35

1/4”

9.0

Ф9.52

3/8”

13.0

Ф12.7

1/2”

16.2

Ф15.88

5/8”

19.4

Ф19.05

3/4”

23.3

Page 24

20 Installation Manual IM-MDS_(i)

diameter

Matching screw specification. (unit: mm)

Diameter

Diameter

mm

inch

Ф6.35

1/4”

17.0

Ф9.52

3/8”

22.0

Ф12.7

1/2”

24.0

Ф15.88

5/8”

27.0

Ф19.05

3/4”

36.0

When connecting the liquid piping and liquid ball valve, use wrench to fix tightly and ensure they are in the

same axial.

Outside diameter(mm)

Moment(N.m)

angle (˚ ) Ф6.35

14~18

60~90

Ф9.52

35~42

60~90

Ф12.7

50~57.5

30~60

Ф15.88

75~80

30~60

Ф19.05

100~140

20~35

7.0 Wiring Connection

7.1 General wiring precautions

Power of indoor and outdoor units must be supplied simultaneously.

Cable for power and communication should be designed in parallel and maintain a distance of more than

20cm between them.

Communication cable should be screened to avoid interference of strong signal. Total wire length should be

less than 1000m.

Signal wire has two poles of A and B the same pole must be connected in one connection (A to A, B to B).

Screened layer of signal wires should be earthed.

Outdoor units use either 3 phase or single phase supply (depends on model) while indoor units use only

single phase power cable.

Wiring diagram can be obtained within the units.

7.2 Wire specification

For communication wire, please use below standard.

A: conducting wiring (copper, intersection surface is more than 0.5mm2 or 20AWG)

B: Insulation material

C: Screen layer (efficiency shall be higher than 95%)

D: outside layer protector (PVC)

For wiring cable, please refer to UL2547 and UL2791 standard

Wiring cable

Page 25

Installation Manual IM-MDS_(i) 21

7.3 Electrical wiring connection

For single unit connection.

For master and slave units connection.

Fuse

Switch

Two-core cable

(power circuit)

Two-core cable

(power circuit)

Switch

Fuse

Indoor unit

Fuse

Switch

L1

Switch

Fuse

L2L1

L3

N

Power

Outdoor unit

N

L2

L3

Indoor unit

Switch

Fuse

Fuse

Switch

Power

L1

L2

Fuse

Switch

L1

L2

L3L2N

Fuse

Switch

L1

L3

N

L3

N

Two-core cable

(power circuit)

Switch

Fuse

Outdoor unit

Master

Slave

Two-core cable

(power circuit)

Indoor unit

Master

Outdoor unit

Two-core cable

(power circuit)

Two-core cable

(power circuit)

Fuse

Switch

L1

N

Switch

Fuse

L1

N

Power

L3

L1 L2

N

Fuse

Switch

L2

L1

L3

N

Switch

Fuse

L1

N

Slave

Separate Connection

Serial Connection

Page 26

22 Installation Manual IM-MDS_(i)

Indoor unit 1

To network or central

control (optional)

Communication cable

Screen

layer

Detail for

Terminal

A

pc

Outdoor unit

Control box

Main PCB

Connection

port

B

pc

A

pc

A

in

B

in

B

pc

B

in

A

in

Control box

A B

PCB

Control box

Indoor unit 2

B

Communication cable

Control box

A

PCB

Communication cable

JP1 of last unit on

main bus should be on

Indoor unit i

A B

PCB

JP1

A

B

A

B

A

B

Connection port

com1

com2

com2

com1

Connection port

Connection port

com2

com1

Master unit

Outdoor unit

To network or central

control (optional)

A

in

B

in

B

pc

A

pc

Main PCB

Connection

port

Screen

layer

Communication cable

Connection

port

Slave unit

Main PCB

A

in

B

pc

A

pc

B

in

Indoor unit 2

Communication cable

Indoor unit 1

Control box

PCB

Connection port

A B

Control box

PCB

A B

JP1 of last unit on

main bus should be on

Indoor unit i

B

Communication cable

Control box

A

PCB

JP1

A

B

A

B

A

B

com2

Connection port

Connection port

com1

com2

com2

com1

com1

PCB

BA

A B

PCB

Connect A with B, wrong

A

B

A

B

com2

Connection port

Connection port

com2

com1

7.4 Communication wiring connection

For single unit connection.

For master and slave units connection.

Example of wrong connection.

not bus structrue,connection cable

should be layed as bus structure

Bpc

AinApc

Bin

Outdoor unit

Control box

Main PCB

Connection

port

Screen

layer

BA

A B

PCB

Control box

Indoor unit 1

Indoor unit 2

Communication cable

Communication cable

PCB

Control box

A

B

A

B

Connection port

Connection port

com1

com2

com2

com1

B

pc

A

in

A

pc

B

in

Screen layer must be

grounded with outdoor unit

Control box

Connection

port

Main PCB

PCB

A

B

Neglect to

connect

A

B

Connection port

com1

com2

Page 27

Installation Manual IM-MDS_(i) 23

7.5 Dip switch setting

Indoor unit address setting for all indoor (dip switch SW2).

S2.1 S2.2 S2.3 S2.4 S2.5 S2.6 Indoor Address S2.1 S2.2 S2.3 S2.4 S2.5 S2.6 Indoor Address

0 0 0 0 0 0 0 0 1 1 0 0 0 24

0 0 0 0 0 1 1 0 1 1 0 0 1 25

0 0 0 0 1 0 2 0 1 1 0 1 0 26

0 0 0 0 1 1 3 0 1 1 0 1 1 27

0 0 0 1 0 0 4 0 1 1 1 0 0 28

0 0 0 1 0 1 5 0 1 1 1 0 1 29

0 0 0 1 1 0 6 0 1 1 1 1 0 30

0 0 0 1 1 1 7 0 1 1 1 1 1 31

0 0 1 0 0 0 8 1 0 0 0 0 0 32

0 0 1 0 0 1 9 1 0 0 0 0 1 33

0 0 1 0 1 0 10 1 0 0 0 1 0 34

0 0 1 0 1 1 11 1 0 0 0 1 1 35

0 0 1 1 0 0 12 1 0 0 1 0 0 36

0 0 1 1 0 1 13 1 0 0 1 0 1 37

0 0 1 1 1 0 14 1 0 0 1 1 0 38

0 0 1 1 1 1 15 1 0 0 1 1 1 39

0 1 0 0 0 0 16 1 0 1 0 0 0 40

0 1 0 0 0 1 17 1 0 1 0 0 1 41

0 1 0 0 1 0 18 1 0 1 0 1 0 42

0 1 0 0 1 1 19 1 0 1 0 1 1 43

0 1 0 1 0 0 20 1 0 1 1 0 0 44

0 1 0 1 0 1 21 1 0 1 1 0 1 45

0 1 0 1 1 0 22 1 0 1 1 1 0 46

0 1 0 1 1 1 23 1 0 1 1 1 1 47

Indoor unit capacity setting for all indoor (dip switch SW3).

Outdoor unit address setting for MDS30-70A(R) and 5MDS50-70B(R) (dip switch J2).

J2.1 J2.2 J2.3 J2.4 J2.5 Outdoor Address

0 0 0 0 0 0

1 0 0 0 0 1

0 1 0 0 0 2

1 1 0 0 0 3

0 0 1 0 0 4

1 0 1 0 0 5

0 1 1 0 0 6

1 1 1 0 0 7

0 0 0 1 0 8

1 0 0 1 0 9

0 1 0 1 0 10

1 1 0 1 0 11

0 0 1 1 0 12

1 0 1 1 0 13

0 1 1 1 0 14

1 1 1 1 0 15

S3.1 S3.2 S3.3 S3.4 S3.5 Capacity (kW) Model Name

0 0 0 1 0 2.5 09

1 0 1 1 0 2.8 10

0 0 1 0 0 3.6 15

0 1 0 0 0 5.6 20

0 1 0 1 0 6.5 25

1 1 0 1 0 8.0 28

1 1 1 0 0 9.0 30

0 1 1 1 0 10.0 38

1 1 1 1 0 11.2 40

1 0 0 1 0 14.0 50

0 1 0 1 1 16.4 60/62

0 0 0 0 1 22.4 80

0 0 0 1 1 28.0 100

S3.6 S3.7 S3.8 Indoor Type

0 0 0 Ceiling Concealed

0 0 1 Ceiling Cassette

0 1 0 Ceiling Convertible

0 1 1 Wall Mounted

1 0 0 Ducted Blower

Page 28

24 Installation Manual IM-MDS_(i)

Outdoor unit address setting for MDS/5MDS80-500B(R) (dip switch S2).

S2.4 S2.5 S2.6 S2.7 S2.8 Outdoor Address S2.4 S2.5 S2.6 S2.7 S2.8 Outdoor Address

0 0 0 0 0 0 1 0 0 0 0 16

0 0 0 0 1 1 1 0 0 0 1 17

0 0 0 1 0 2 1 0 0 1 0 18

0 0 0 1 1 3 1 0 0 1 1 19

0 0 1 0 0 4 1 0 1 0 0 20

0 0 1 0 1 5 1 0 1 0 1 21

0 0 1 1 0 6 1 0 1 1 0 22

0 0 1 1 1 7 1 0 1 1 1 23

0 1 0 0 0 8 1 1 0 0 0 24

0 1 0 0 1 9 1 1 0 0 1 25

0 1 0 1 0 10 1 1 0 1 0 26

0 1 0 1 1 11 1 1 0 1 1 27

0 1 1 0 0 12 1 1 1 0 0 28

0 1 1 0 1 13 1 1 1 0 1 29

0 1 1 1 0 14 1 1 1 1 0 30

0 1 1 1 1 15 1 1 1 1 1 31

Outdoor unit indoor quantity setting for MDS/5MDS80-500B(R) (dip switch S1).

S1.3 S1.4 S1.5 S1.6 S1.7 S1.8 Indoor Quantity S1.3 S1.4 S1.5 S1.6 S1.7 S1.8 Indoor Quantity

0 0 0 0 0 0 1 0 1 1 0 0 0 25

0 0 0 0 0 1 2 0 1 1 0 0 1 26

0 0 0 0 1 0 3 0 1 1 0 1 0 27

0 0 0 0 1 1 4 0 1 1 0 1 1 28

0 0 0 1 0 0 5 0 1 1 1 0 0 29

0 0 0 1 0 1 6 0 1 1 1 0 1 30

0 0 0 1 1 0 7 0 1 1 1 1 0 31

0 0 0 1 1 1 8 0 1 1 1 1 1 32

0 0 1 0 0 0 9 1 0 0 0 0 0 33

0 0 1 0 0 1 10 1 0 0 0 0 1 34

0 0 1 0 1 0 11 1 0 0 0 1 0 35

0 0 1 0 1 1 12 1 0 0 0 1 1 36

0 0 1 1 0 0 13 1 0 0 1 0 0 37

0 0 1 1 0 1 14 1 0 0 1 0 1 38

0 0 1 1 1 0 15 1 0 0 1 1 0 39

0 0 1 1 1 1 16 1 0 0 1 1 1 40

0 1 0 0 0 0 17 1 0 1 0 0 0 41

0 1 0 0 0 1 18 1 0 1 0 0 1 42

0 1 0 0 1 0 19 1 0 1 0 1 0 43

0 1 0 0 1 1 20 1 0 1 0 1 1 44

0 1 0 1 0 0 21 1 0 1 1 0 0 45

0 1 0 1 0 1 22 1 0 1 1 0 1 46

0 1 0 1 1 0 23 1 0 1 1 1 0 47

0 1 0 1 1 1 24 1 0 1 1 1 1 48

For master and slave unit, set the master unit’s S2.1 as 1, and set the slave unit’s S2.1 as 0.

Address cannot be duplicated and must be continuous without skipping any address in between.

The address of first unit must be 0. Address and indoor quantity code of the slave unit need not to be set.

Start up the unit after the address setting has been completed.

1 stands for On while 0 stands for Off.

7.6 Auto restart setting

To allow indoor unit to auto restart once power resume from failure, apply the setting as below.

For wireless controller, to enable auto restart, the steps are as follow:

1. Press the indoor PCB emergency ON/OFF button for 5 seconds to go into setting mode. When the unit

are in setting mode, all the LED of the indoor will be light up.

2. Use the wireless handset, select “Fan” mode.

3. Select “High Fan” speed.

4. Press the “ON/OFF” button on the wireless handset to complete the setting. Once the setting is

complete, all the indoor LED will be turned off and the unit will remain in standby mode.

To disable auto restart, the steps are as follow:

1. Press the indoor PCB emergency ON/OFF button for 5 seconds to go into setting mode. When the unit

are in setting mode, all the LED of the indoor will be light up

2. Use the wireless handset, select “Fan” mode.

3. Select “Medium Fan” speed

4. Press the “ON/OFF” button on the wireless handset to complete the setting. Once the setting is

complete, all the indoor LED will be turned off and the unit will remain in standby mode.

For wired controller, turn On dip switch 2 at the back of the controller to enable auto restart function. To

disable it, turn Off dip switch 2.

Page 29

Installation Manual IM-MDS_(i) 25

LEAKAGE TEST SKETCH

to indoor unit

to indoor unit

nitrogen

LO

outdoor

unit

ball valve

ball valve

liquid pipe

gas pipe

HI

service port

pressure gauge

8.0 Air Leakage Test, Vacuum and Refrigerant Charge

8.1 Air leakage test

To conduct air leakage test, ensure the ball valve is off.

Refer to the procedure below to avoid polluting the lubricating

oil during the leakage test.

Air leakage testing procedure

Remark

Charging Nitrogen gas

Nitrogen gas (For R410A units: 4.15MPa, R22 units: 2.94MPa),

wait for 24 hours. If the pressure is not drop, the units pass the

air tightness testing; if pressure decrease, use soap water to

detect the leakage point.

After charging the nitrogen gas, use soap water on the part of

brazing, flange and connection position to see if there is any

bubble occurred.

After air leakage testing, wipe off the bubbling agent.

Do not use oxygen and other flammable

air to increase the pressure to avoid

explosion

8.2 Vacuum

Ensure the ball valve is off before conducting vacuum.

Vacuum pressure is 650Pa and the time of vacuum is

24 hours.

Do not use refrigerant to vacuum.

8.3 Charging the refrigerant

Charge in additional refrigerant based on the piping length connection.

Additional charge required can be obtained from selection report or calculated manually with the steps as

shown below.

Additional charge amount:

= ∑ Li* Gi

= (Piping Length for 15.88mm X Additional Charge Amount)

+ (Piping Length for 12.7mm X Additional Charge Amount)

+ (Piping Length for 9.52mm X Additional Charge Amount)

+ (Piping Length for 6.35mm X Additional Charge Amount)

Caution that the additional charge amount of different pipe diameter varies base on type of refrigerant.

Pipe Diamater (mm) 6.35 9.52 12.70 15.88 19.05

R22 Additional Charge (g/m) 50 80 120 180 290

Pipe Diamater (mm) 6.35 9.52 12.70 15.88 19.05

R41A additional Charge (g/m) 45 70 120 180 260

Before charging, open the all ball valve.

vacuum

pump

check valve

service port

ball valve

liquid pipe

gas pipe

ball valve

outdoor

unit

compound

pressure gauge

HI

LO

to indoor unit

to indoor unit

VACUUM SKETCH

Page 30

26 Installation Manual IM-MDS_(i)

REFRIGERANT CHARGING SKETCH

weighbridge

refrigerant

tank

compound

pressure gauge

HI

LO

to indoor unit

to indoor unit

service port

ball valve

liquid pipe

gas pipe

ball valve

outdoor

unit

refrigerant

tank

weighbridge

LO

HI

compound

pressure gauge

outdoor

unit

ball valve

gas pipe

liquid pipe

ball valve

service port

to indoor unit

to indoor unit

When charging R410A with cylinder which is without the siphon pipe, turn the cylinder upside down when

charging to ensure only liquid refrigerant is charged into the system.

9.0 Commissioning

9.1 Checking list before commissioning

Ampere of indoor & outdoor units is normal and under protection value?

Power supply for indoor and outdoor units is normal?

Dip switch address setting up for indoor units are ok?

Indoor unit is power on?

Communication wiring is ok?

Refnet is well installed?

Condensing water drainage system is ok?

Earthing is ok?

Insulation testing (10Mega Ω)

Power supply check (220-240V/380-415V)

System has been vacuumed and charged with additional refrigerant?

How many indoor units are controlled by outdoor unit controller?

Outdoor unit ball valve is opened?

9.2 Commissioning record table

Before commissioning, power on the system 24 hours in advance to preheat the crankcase heater.

No.

Suction

pressure(bar)

Discharge

pressure

(bar)

Voltage

(V)

Ampere

(A)

Suction

temperature

(℃ )

Ambient

Temp.(

℃ )

Checking person

/ Time

1 2 3 4 5 6

9.3 Common problems during commissioning

Symptoms

Wiring controller

Possible reason

No heating or cooling

Cannot select cooling or heating

When one indoors units in heating, all

indoors in heating mode

Fan stop when heating

Defrost

Fan stop running when defrosting

Pump keep running

No indication

Pump keep running to drain the water

The cylinder had Syphon pipe

Syphon pipe

Page 31

Installation Manual IM-MDS_(i) 27

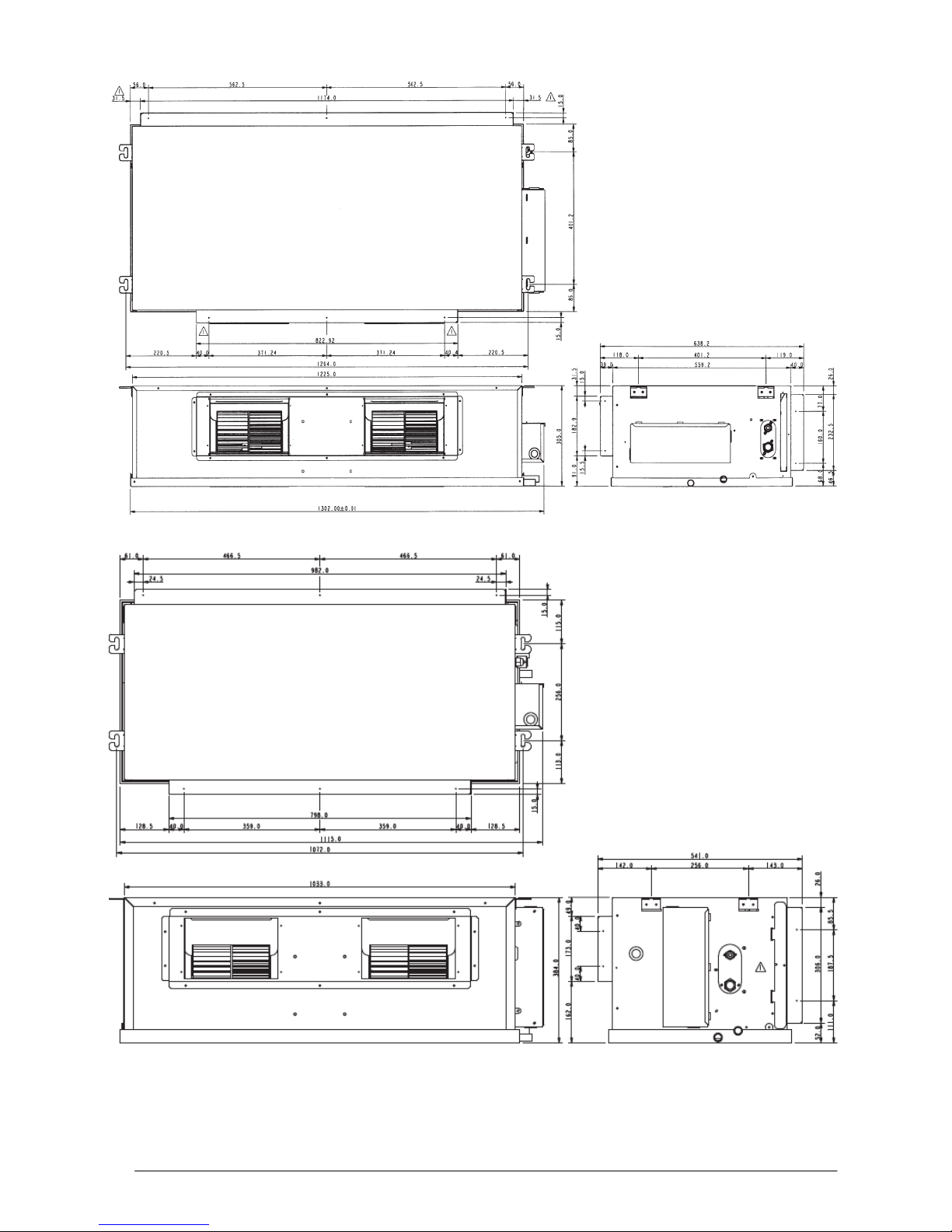

10.0 Unit Outlines and Dimensions

MWMD/M5WMD 009/010/015G

MWMD/M5WMD 020/025G

Page 32

28 Installation Manual IM-MDS_(i)

MCKD/M5CKD 020/025/030/040/050A

MCKD/M5CKD 010/015/020C

MCMD 020/025/028E

M5CMD 015/020/025/028E

Page 33

Installation Manual IM-MDS_(i) 29

MCMD/M5CMD 040/050D

MCMD/M5CMD 062C

Page 34

30 Installation Manual IM-MDS_(i)

MCCD/M5CCD 010C

MCCD/M5CCD 015/020/025C

Page 35

Installation Manual IM-MDS_(i) 31

MCCD/M5CCD 028C

MCCD/M5CCD 030C

Page 36

32 Installation Manual IM-MDS_(i)

MCCD/M5CCD 038C

MCCD/M5CCD 040C

Page 37

Installation Manual IM-MDS_(i) 33

MCCD/M5CCD 050C

MCCD/M5CCD 060C

Page 38

34 Installation Manual IM-MDS_(i)

MDS 030A(R)

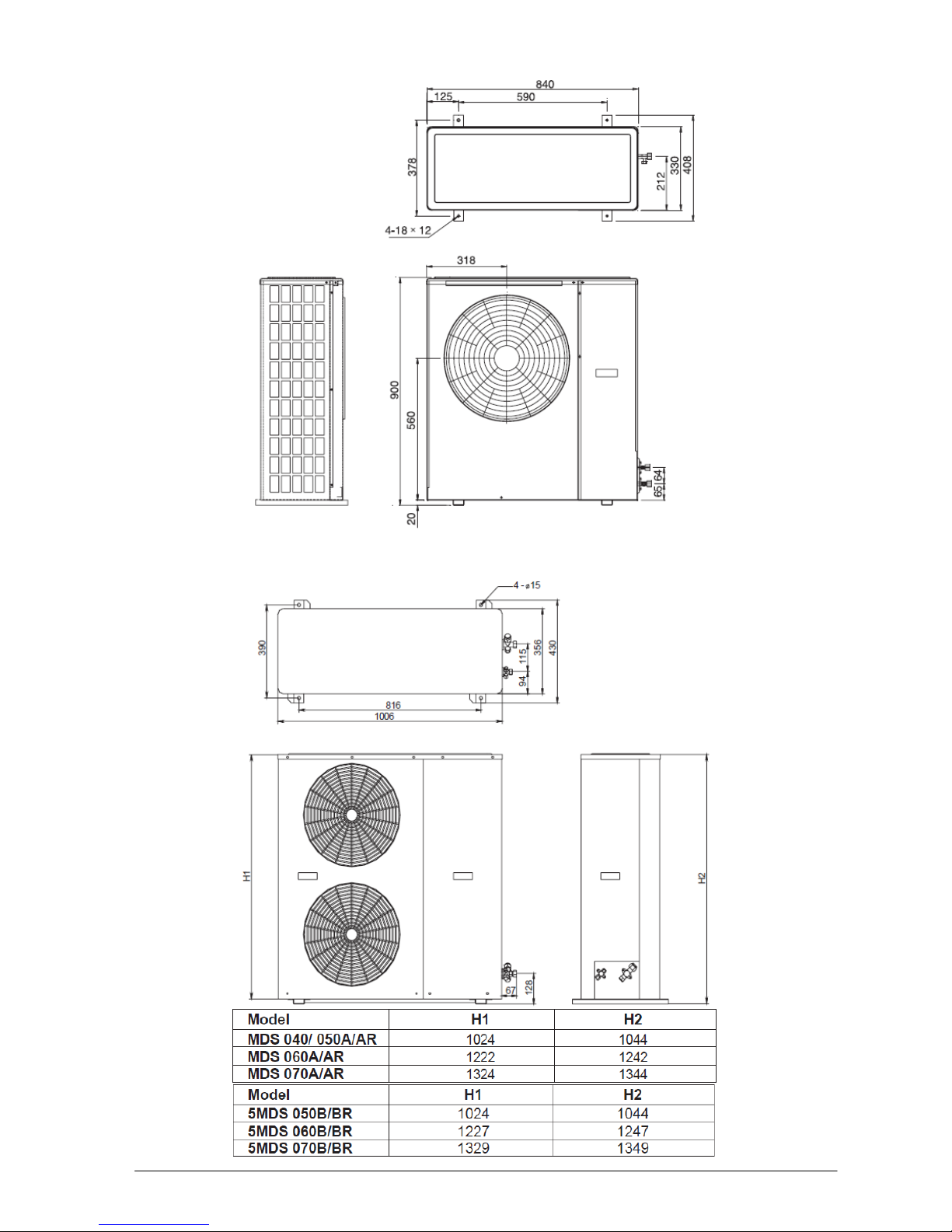

MDS 040/050/060/070A(R)

5MDS 050/060/070B(R)

Page 39

Installation Manual IM-MDS_(i) 35

MDS 080/100/120/150B(R)

5MDS 080/100/120/140/160/180B(R)

MDS 180/200/220/240B(R)

5MDS 200/220/240B(R)

Page 40

36 Installation Manual IM-MDS_(i)

MDS 260/280/300/320B(R)

5MDS 260/280/300/320/340/360B(R)

5MDS 380/400/420B(R)

Page 41

Installation Manual IM-MDS_(i) 37

5MDS 440/460/480/500B(R)

Page 42

Page 43

Page 44

Products manufactured in an ISO certified facility.

This document contains the most current product information as of this printing. For the

most up-to-date product information, please go to www.mcquayup.com

www.mcquayup.com

Loading...

Loading...