Page 1

Design & Installation Guide For McQuay MDS Multi System

Engineered for flexibility and performance.

TM

Page 2

© 2004 McQuay International. All Rights Reserved.

is a registered trademark of McQuay in the United States and other countries, licensed and recognized

all over the world. Without prior written consent of McQuay, use of the above-named trademark for business

purposes may constitute a violation of the federal and state laws in the Unites states and laws of related countries,

and remain subject to a charge of trademark infringement and unfair competition.

This manual is prepared by the Market Department of McQuay ’s Shenzhen-based factory. Pursuant to the

copyright law, this manual may not be reproduced or otherwise distributed in whole or in part without prior

written permission of McQuay.

We have used our best endeavor to make sure the information contained in this manual is accurate. As we are

always committed to technological improvement, any change in the units and specifications is subject to further

notice. In addition, to meet local criteria and customer requirements, we may modify the units and specifications.

Please also take notice that not all the models suit every market.

Discussed in this manual is a product made in China in compliance with the national standard – GB/T18837-2002.

Page 3

CONTENTS

Foreword

1. Overview

1.1 General Information………………………………………………………………………………4

1.2 Working Principle & System Principle…………………………………………………………4

1.3 Main Features……………………………………………………………………………………11

1.4 Nomenclature……………………………………………………………………………………13

1.5 Products Series…………………………………………………………………………………15

1.6 Performance Parameter…………………………………………………………………………16

1.7 Operating Range…………………………………………………………………………………20

1.8 Refnet………………………………………………………………………………………………20

1.9 Outline of Indoor Units…………………………………………………………………………22

1.10 Outline of Outdoor Units………………………………………………………………………28

2. Unit Control

2.1 Introduction of the Controller……………………………………………………………………34

2.2 Main Functions……………………………………………………………………………………34

2.3 Operation of the Controller………………………………………………………………………35

2.4 Software Management System…………………………………………………………………39

2.5 Network Central Control…………………………………………………………………………41

2.6 Wiring Diagram……………………………………………………………………………………42

2.7 Electric Connection………………………………………………………………………………56

2.8 Electric Data……………………………………………………………………………………58

3. Selection

3.1 Load Calculation…………………………………………………………………………………59

3.2 Selection of Indoor Units………………………………………………………………………61

3.3 Selection of Outdoor Units……………………………………………………………………63

3.4 Design of Air System……………………………………………………………………………66

3.5 Selection of Refnet Joint………………………………………………………………………71

4. Installation

4.1 Installation of Indoor Units………………………………………………………………………75

4.2 Installation of Outdoor Units……………………………………………………………………82

4.3 Refrigerant Pipe & Installation…………………………………………………………………87

4.4 Design, Processing and Installation of Condensate Pipe…………………………………102

5. Testing

5.1Hardware Diagram and Equipment………………………………………………… 106

5.2 Running……………………………………………………………………………………………113

6. Servicing and Maintenance

6.1 Notice to the Customer…………………………………………………………………………114

6.2 Maintenance………………………………………………………………………………………115

7. Troubleshooting…………………………………………………………………………………119

Annexes…………………………………………………………………………………………………121

Page 4

-4-

Design & installation Guide For McQuay MDS Multi System

The MDS(Multi Digital Scroll) air conditioning system is operated by a digital compressor and is

accommodated by multiple evaporators (indoor units). It is touted as the next-generation modular

system in the world of high-efficiency air conditioning. lt has undoubtedly changed the face of cooling

associated with high-storied buildings. It provides a broad range of different applications for settings

such as offices, hotels and schools. With its easy installation and simple controlling system, the MDS

will more than meet the demands of the air conditioning market.

C H A P T E R

1

Overview

1.1 General information

1.2 Working principle & system principle

1.2.1Working principle

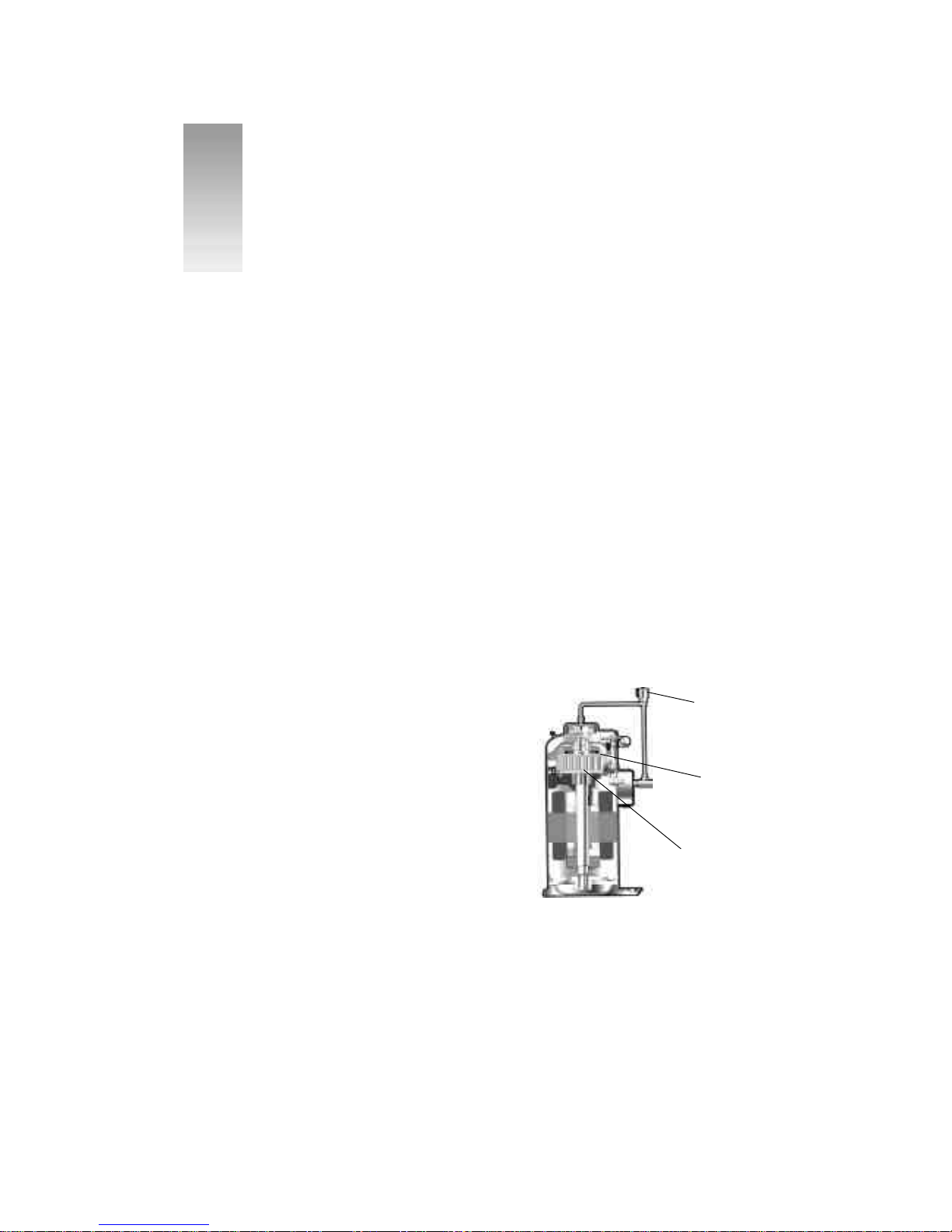

The beauty of this technology is its inherent simplicity. The standard digital scroll compressor has

a unique feature called axial compliance. This allows the fixed scroll to move in the axial direction, by

very small amounts, to ensure that the fixed and orbiting scrolls are always loaded together with the

optimal force.

This optimal force holding the 2 scrolls to-

gether at all operating condi tions ensure the

high efficiency of Copeland scrolls. The Digital

Scroll operation builds on this principle.

The Digital Scroll operates in two stages -

the "loaded state", when the solenoid valve is

normally closed and "unloaded state", when

the solenoid valve is open. During the loaded

state the compressor operates like a standard

scroll and delivers full capacity and mass flow.

However, during the unloaded state, there is no capacity and no mass flow through the compressor.

At this stage, let us introduce the concept of a cycle time. A cycle time consists of a "Loaded State"

time and "Unloaded State" time. The duration of these 2-time segments determine the capacity

modulation of the compressor. Example: In a 20 seconds cycle time, if the loaded state time is 10 seconds

and the unloaded state time is 10 seconds, the compressor modulation is (10 seconds x 100% + 10

seconds x 0%)/ 20 = 50% (Figure 3). If for the same cycle time, the loaded state time is 15 seconds

and the unloaded state time is 5 seconds, the compressor modulation is 75%. The capacity is a time

averaged summation of the loaded state and unloaded state. By varying the loaded state time and

unloaded state time, any capacity (10%-100%) can be delivered by the compressor.

fixed scroll

(movable in axial direction)

PWM vale

Orbiting scroll

(Rotatable in radial direction)

Page 5

-5-

Design & installation Guide For McQuay MDS Multi System

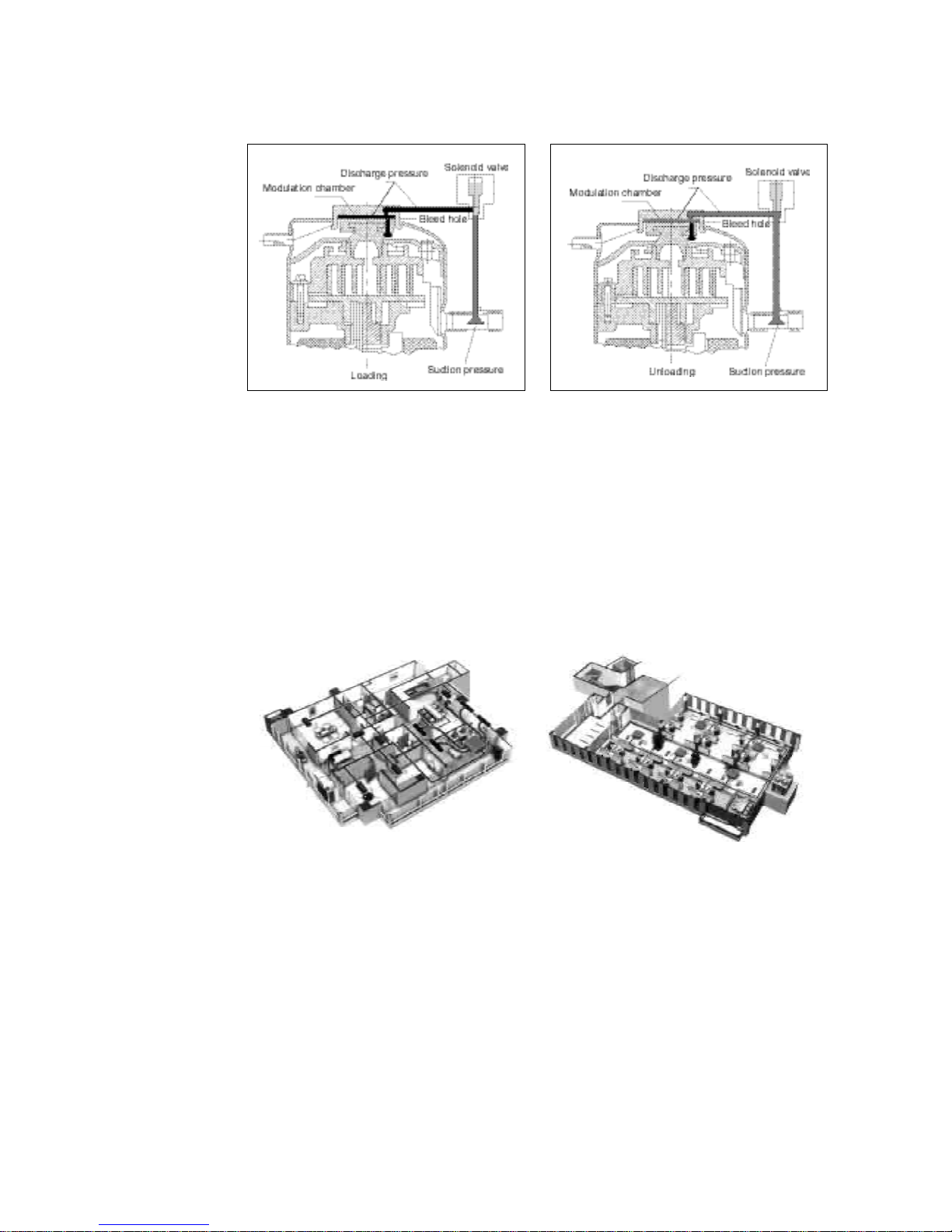

■ PWM valve power off

■ Valve close

■ Fixed scroll move downwards

■ Two scrolls gather together

■ Loading

■ PWM valve power on

■ Valve open

■ Fixed scroll moves upwards

■ Two scrolls separate

■ Unloading

Resident system Commerce system

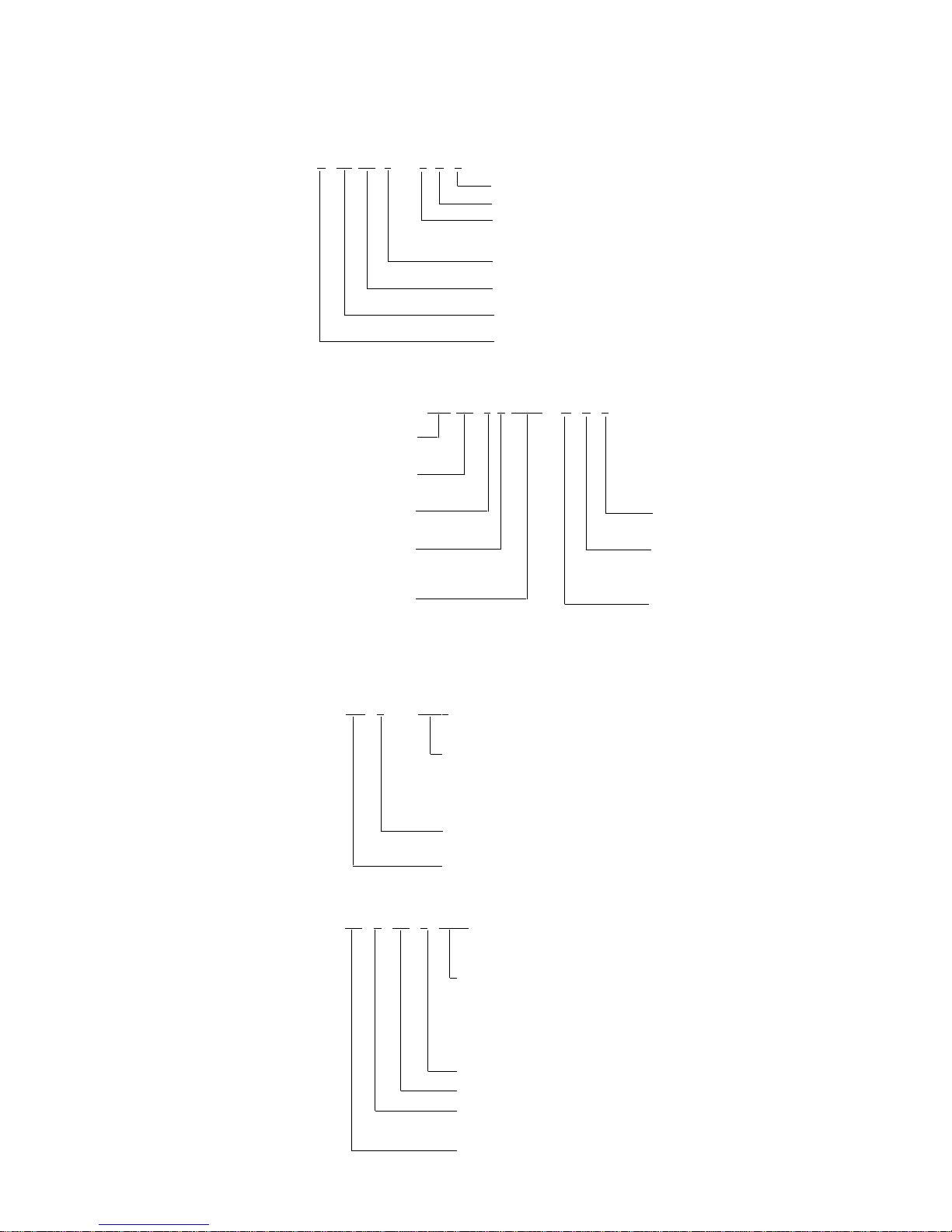

1.2.2 Installation sketch map

Page 6

-6-

Design & installation Guide For McQuay MDS Multi System

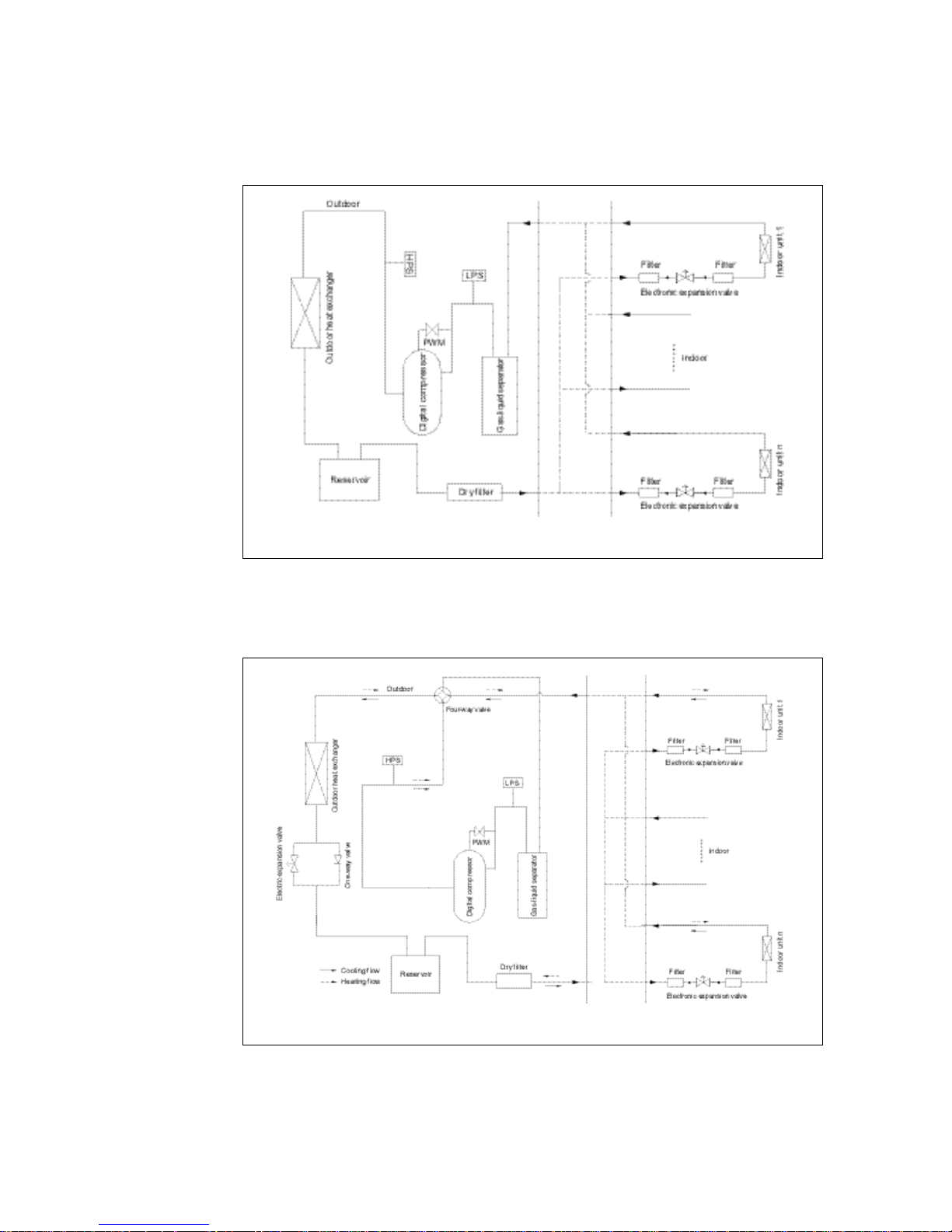

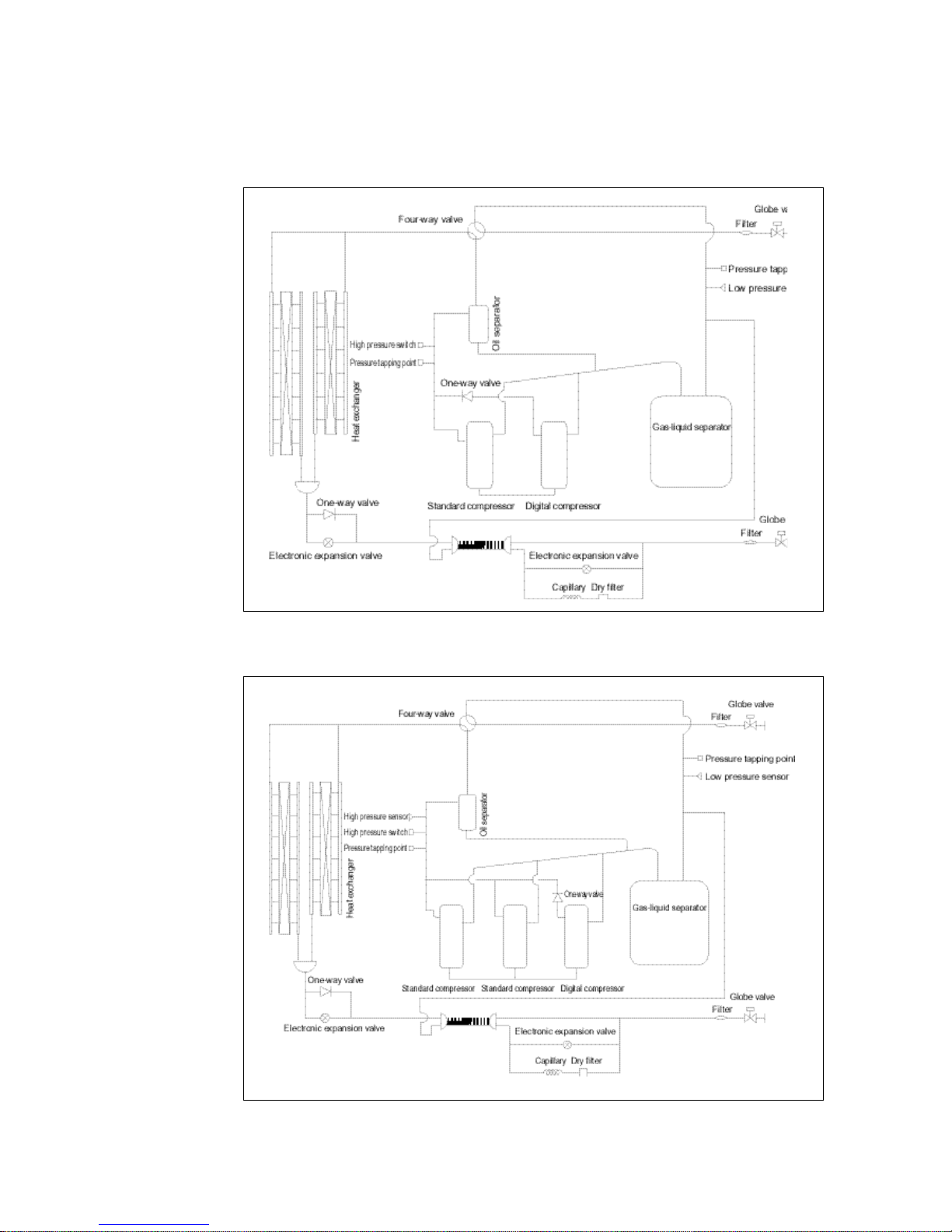

MDS030AR、MDS040AR、MDS050AR、MDS060AR

1.2.3 System principle

MDS030A、MDS040A、MDS050A、MDS060A

Note: MDS030AR unit excludes the reservoir.

Note: MDS030A unit excludes the reservoir.

Page 7

-7-

Design & installation Guide For McQuay MDS Multi System

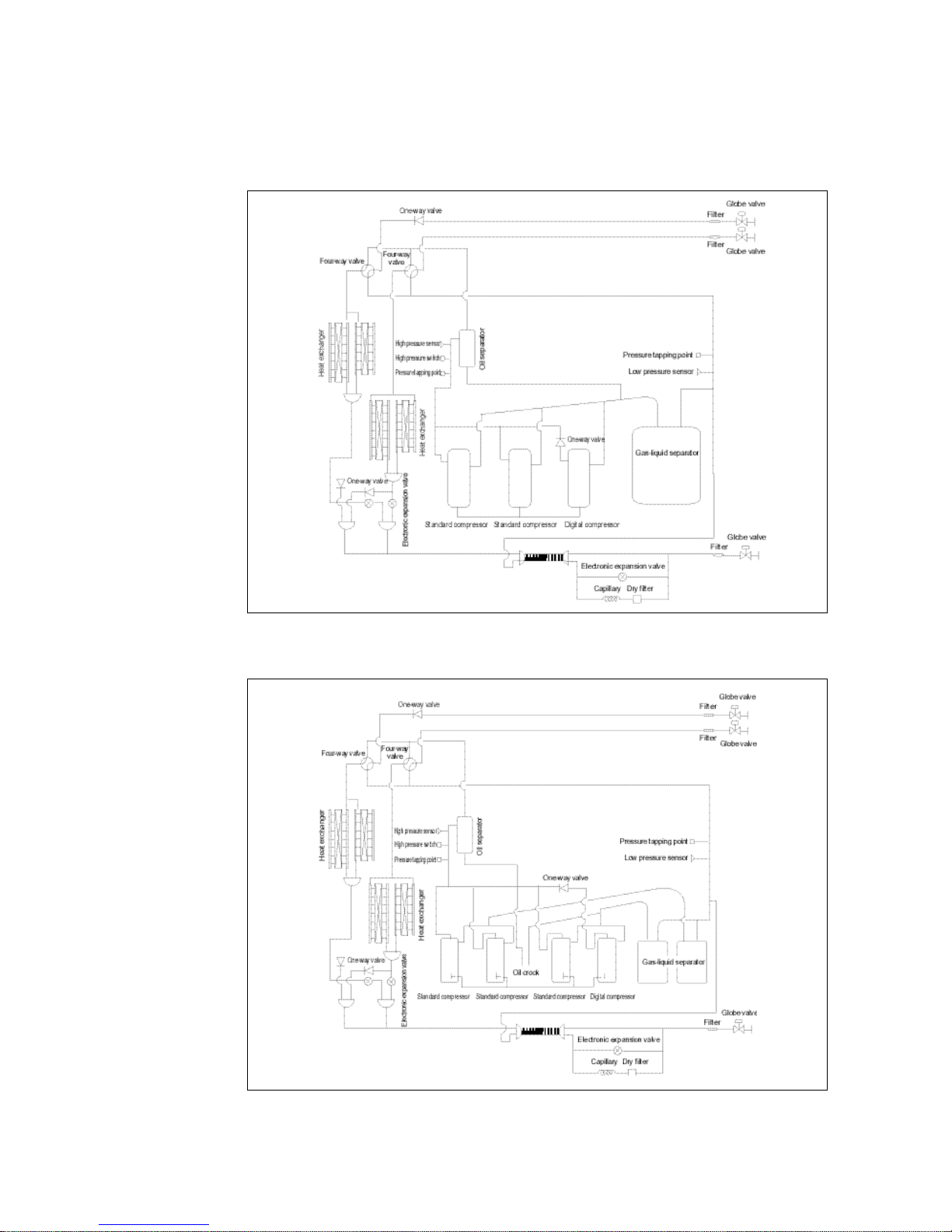

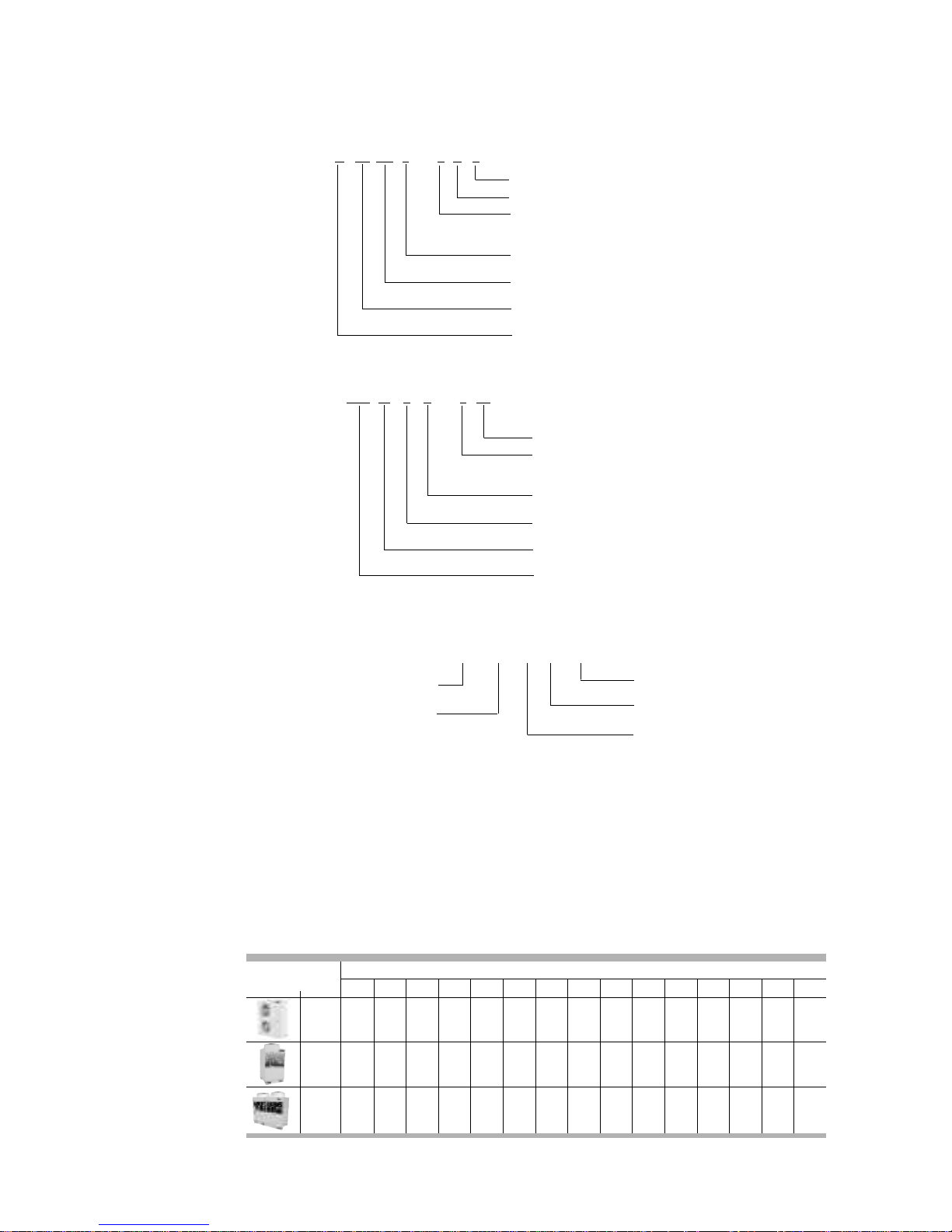

MDS080R、 MDS100BR、MDS120BR

MDS150BR

Page 8

-8-

Design & installation Guide For McQuay MDS Multi System

MDS200BR、MDS220BR、MDS240BR

MDS180BR

Page 9

-9-

Design & installation Guide For McQuay MDS Multi System

MDS280BR、MDS300BR

MDS260BR

Page 10

-10-

Design & installation Guide For McQuay MDS Multi System

1.3 Main features

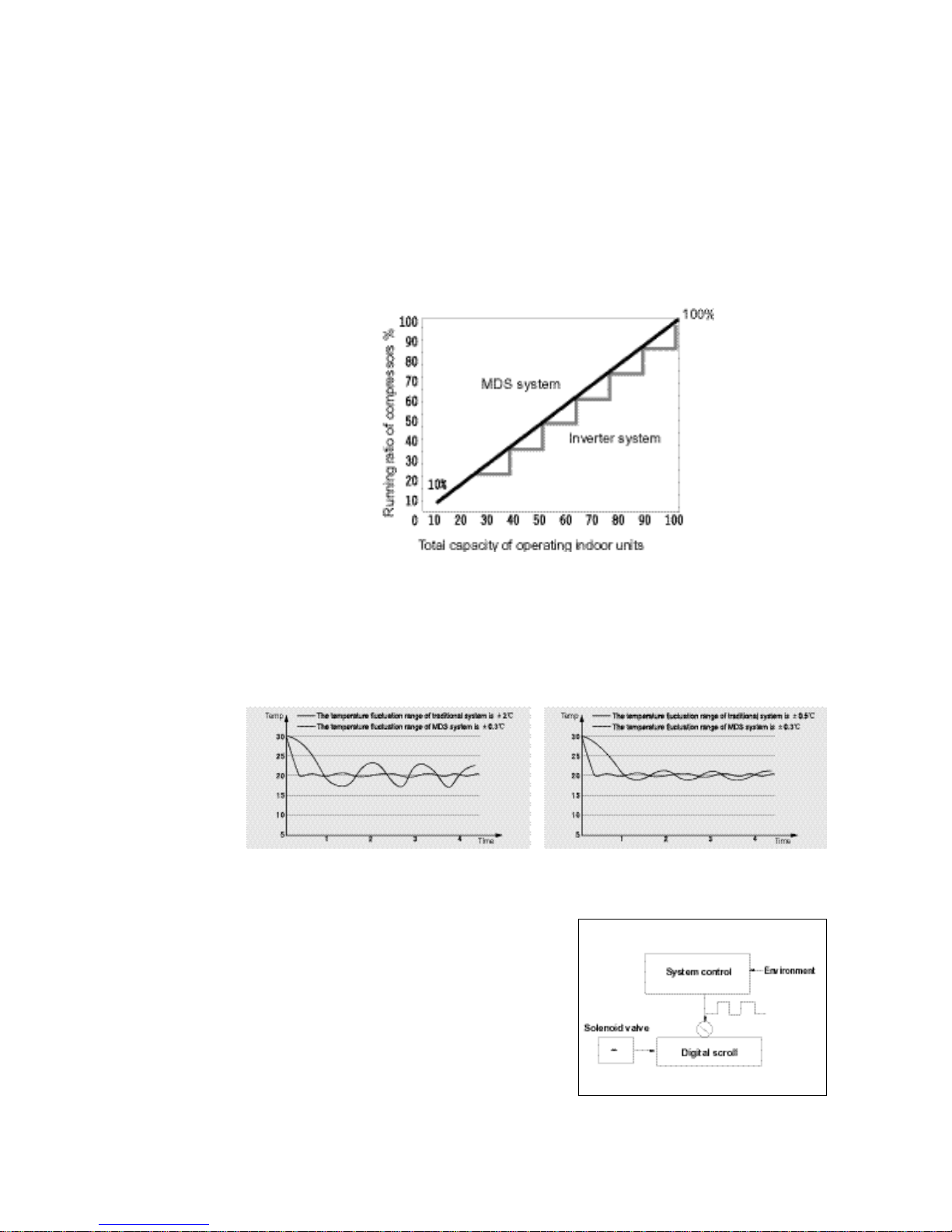

1.3.1 Wide range and stepless capacity modulation

■ Wide capacity modulation range(10%-100%) ;

■ According to changing the ratio of “loading time”and “unloading time, MDS can modulate

the capacity steplessly;

■ Lower the energy consumption and running cost.

1.3.2 Accurate temperature control and quick response.

■ The cooling/heating capacity of the indoor units is controlled by the EXV,

which ensure the low temperature fluctuation of ± 0.3℃;

■ Stepless capacity modulation;

■ Quick response to output the capacity (40s).

1.3.3 Simple, reliable and long life

■ The PWM valve has the longevity of 40 million times

■ Wide range of capacity modulation makes sure

the start/stop times reduces

■ Less components

■ No complicate inverter controller

■ The compressor has an excellent oil return

performance, there is no need for the oil return

circuit

■ Even the units run in 10% part load, the MDS

system can be in good stage.

Page 11

-11-

Design & installation Guide For McQuay MDS Multi System

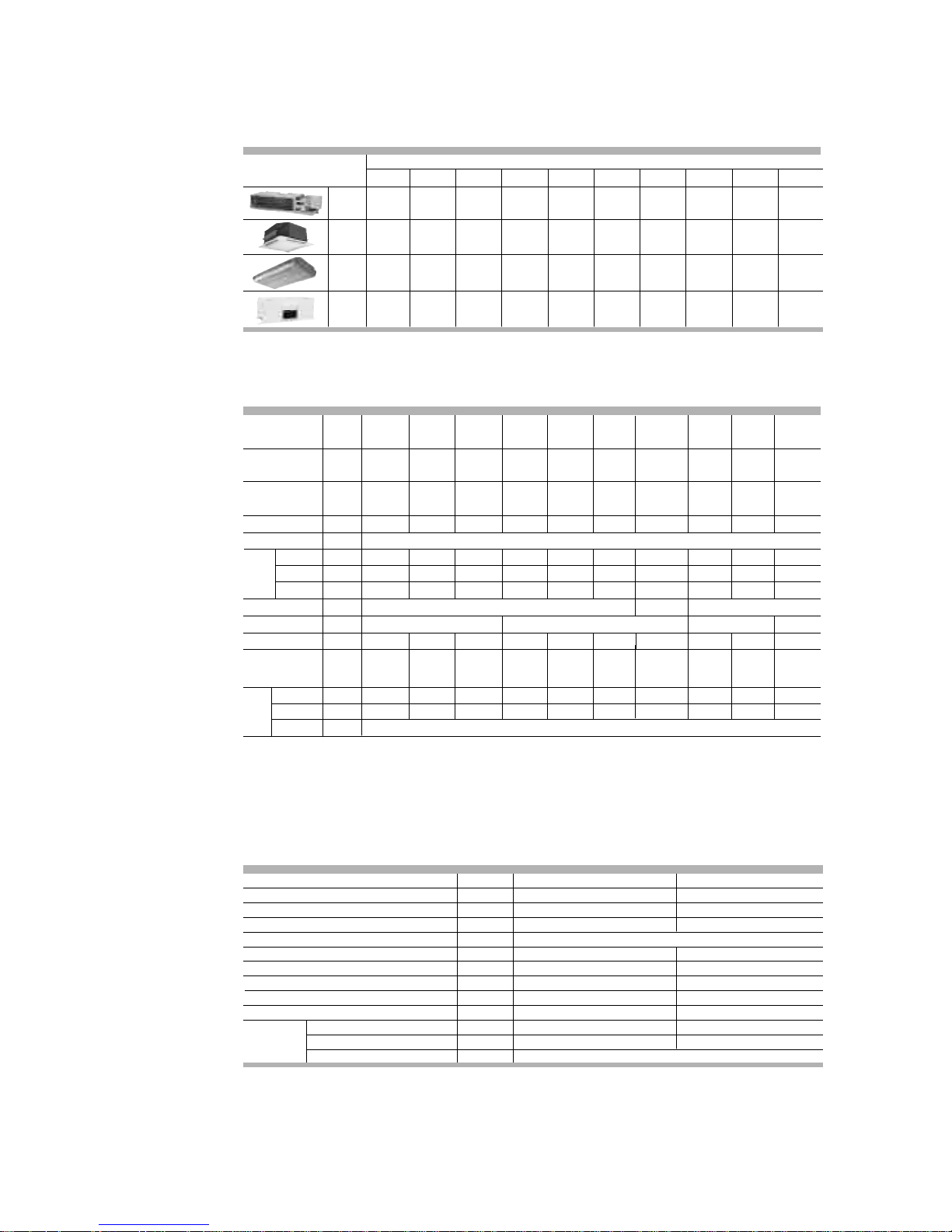

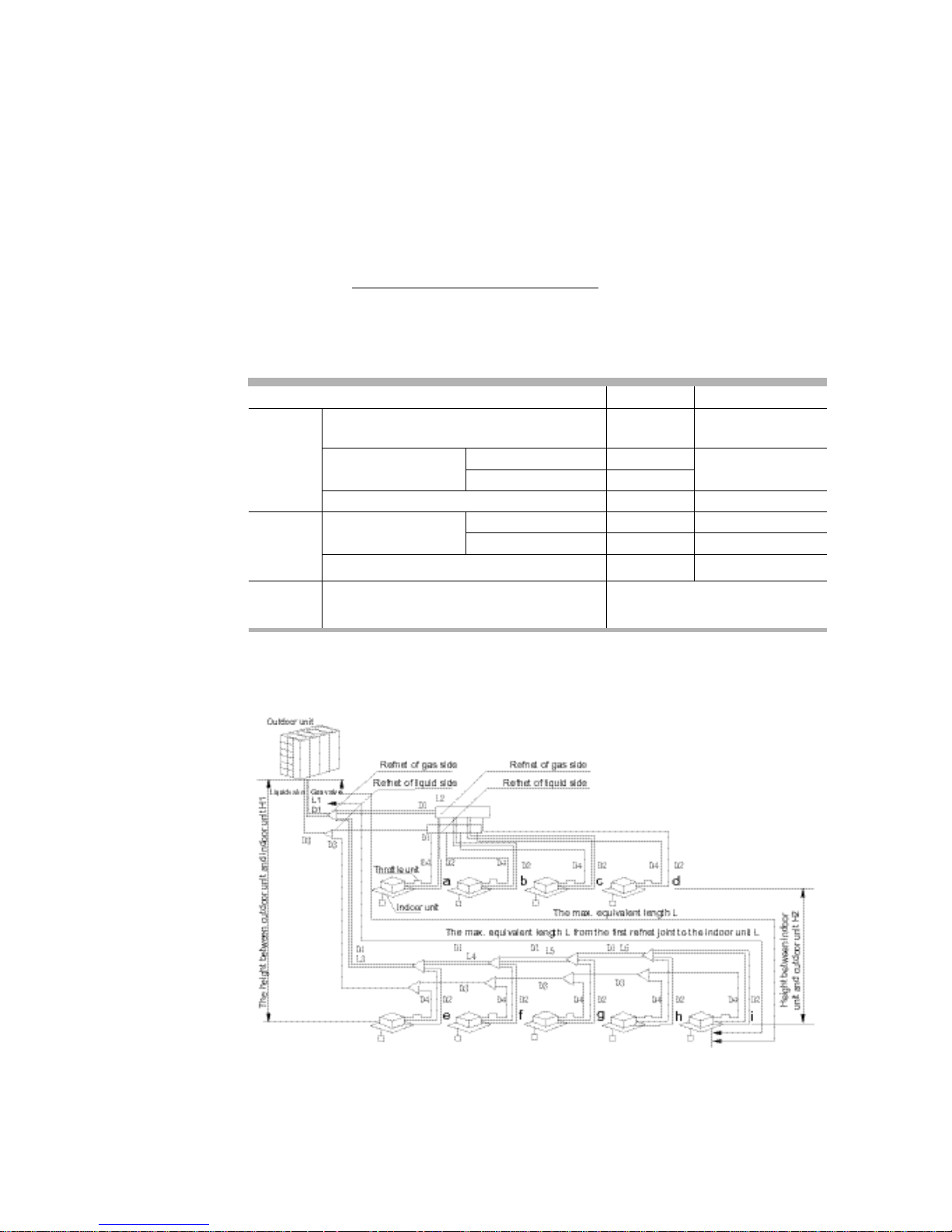

【Note】OT: outdoor unit is above indoor unit; IT: Indoor unit is above outdoor unit

Height Max. accessory Max. accessory

Height

pipe length pipe length

OT IT

12~30HP 350 150 50 40

10HP 250 125 50 40

8HP 250 125 50 40

6HP 150 70 30 30

5HP 150 70 30 30

4HP 150 70 20 20

3HP 100 50 20 20

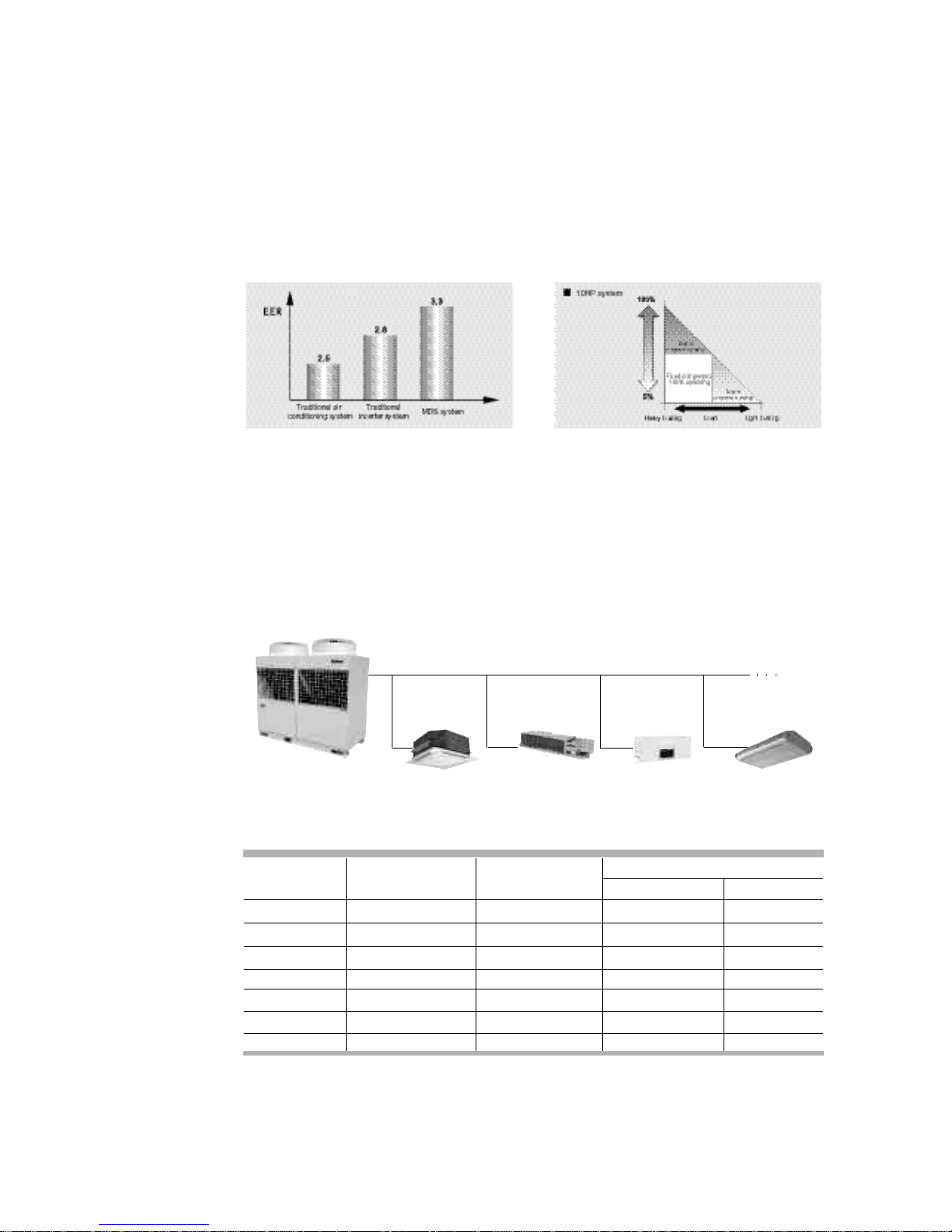

1.3.4 Energy saving

■ The inverter system’s capacity modulation range is from 30% to 100%, while MDS system ’s

capacity modulation range is from 10% to 100%;

■ Quick response to the capacity modulation;

■ Min. power consumption is only 10% of the full load power consumption;

■ Compared to t he inverter system, there is no power consumption of transducer;

■ Compared to the nominal capacity scroll system, it can save 20% energy consumption.

1.3.5 Flexible combination of indoor units

■ The max. capacity of the indoor units is as 130% as the outdoor units capacity;

■ The outdoor unit can connect different numbers of indoor units according to the outdoor unit

capacity;

■ One outdoor unit can be connected up to 48 indoor units;

■ Various types of indoor units are available;

■ There are various indoor units for option: concealed exposed, ceiling concealed, high static

pressure fan coil and ceiling exposed/floor standing.

1.3.6 Long accessory pipe connection design

■ Max. accessory pipe length is 15m (12HP-30HP), max. height is 50m (8HP— 0HP).

Page 12

-12-

Design & installation Guide For McQuay MDS Multi System

1.3.7 Space saving

■ Compared to large size central air conditioning, MDS system is high centralized, no need for special

equipment room to save more space, and bring more benefits.

1.3.8 Easy to install and simple to maintain

■ Easy installation

● With simple structure, clear piping diagram, little work amount at field installation, MDS system

is equipped with simple indoor and outdoor units and pipe connection, and it is complete with

refrigerant piping system to ease the maintain.

■ Independent system, stage installation

● The easy installation makes the users to choose the suitable time to install MDS system

within longer time, which reduces the limits of period to install air conditioning at the installation.

● For new projects, the step installation can decrease the disposal investment.

● For renovation projects, the users can install the units easily.

■ No need for special maintenance

● It has only simple refrigerant piping system, no complex maintenance;

● Compared to the chilled water system, MDS system is with no water system, no piping cleaning,

no maintenance for water system control design; and MDS system is much simple so there is no

need for expert people to manage and maintain it.

Traditional central air conditioning MDS system

1.4 Nomenclature

■ Indoor unit: ceiling cassette

CK 030 T -- A M A

Design serial No

Cooling capacity No.

Indoor unit: ceiling cassette

McQuay

Design alternation No.

Matching outdoor units:MDS series

Power supply features:220V~/50Hz

M

Page 13

-13-

Design & installation Guide For McQuay MDS Multi System

■ Indoor unit: ceiling concealed unit

■ Indoor unit: Ceiling exposed/floor standing unit

M CM 050 T - A M A

Design serial No

Cooling capacity No.

Indoor unit: Ceiling exposed/floor standing unit

McQuay

Design serial No.

Matching outdoor units: MDS series

Power supply features: A:220V~/50Hz

MCC 050 T R (B)/(D) - -A M A

McQuay

Concealed exposed indoor unit

Cooling capacity No.

Design serial No.

Pipe mode:

R-right connecting pipe

L-left connecting pipe

Air return mode:

B-rear air return box

D-lower air return box

Omitted-no air return box

Design serial No.

Matching outdoor units:

MDS series

Power supply features:

A:220V~/50Hz

■ Hot water heater box

■ Electric heater box

08-15 means it can be used in MCC008/010/015T

18-30 means it can be used in MCC018/020/025/030T

40-50 means it can be used in MCC040/050T

60 means it can be used in MCC060T

T means that unit can be used

in MCC“T”series

Hot water heater box

HW T 08-15

HD P 1.2 T 08-15

18-15 means it can be used in MCC008/010/015T

18-30 means it can be used in MCC018/020/025/030T

40-50 means it can be used in MCC040~050T

60 means it can be used in MCC060T

T means the unit can be used in MCC“T”seres

Heating capacity (kW)

Heating unit: P means the heating unit is PTC Omitted means the

heating unit is electric heating pipe

Electric heater box

Page 14

-14-

Design & installation Guide For McQuay MDS Multi System

■ Air-cooled cooling duct indoor unit

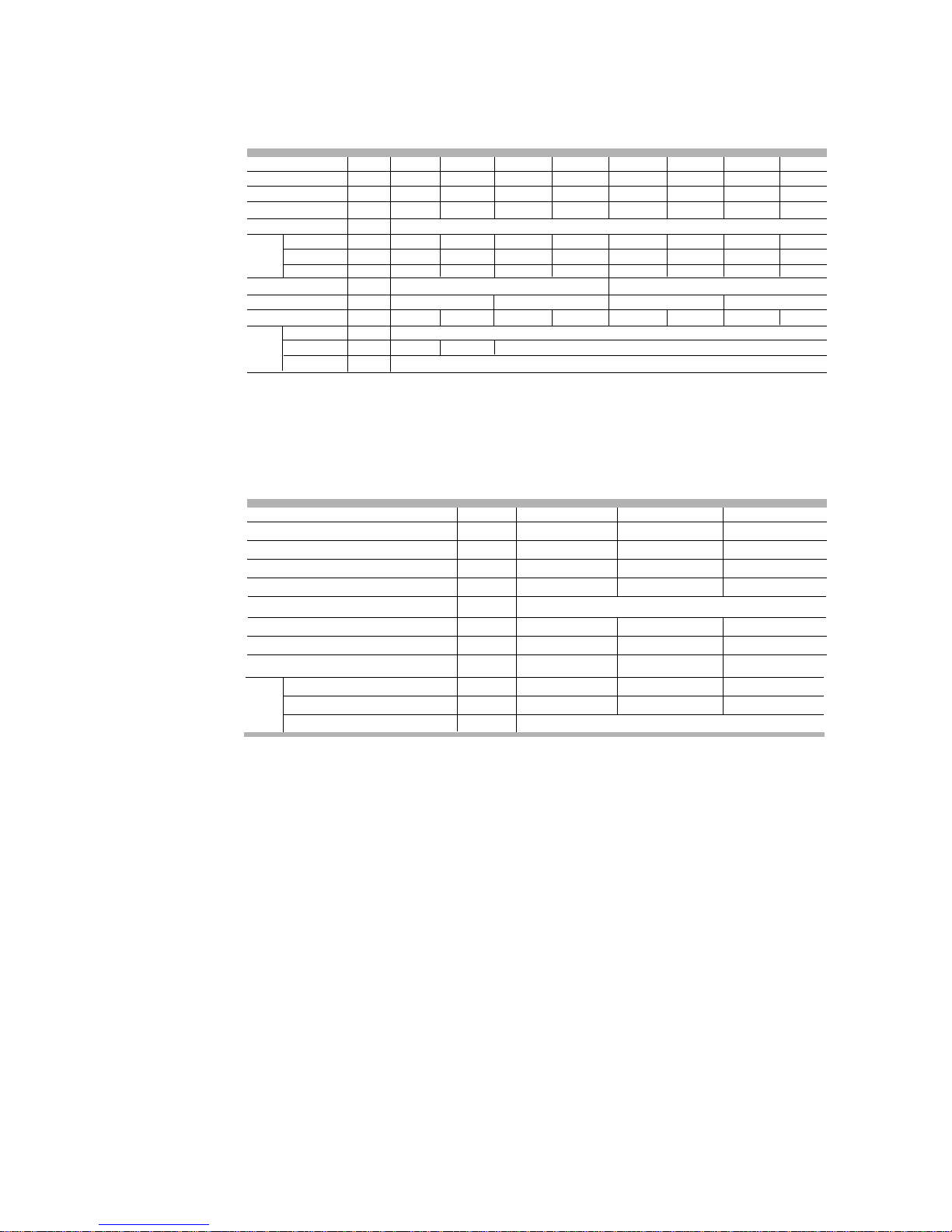

1.5 Products Series

1.5.1 Outdoor unit

Capacity range

3HP 4HP 5HP 6HP 8HP 10HP12HP 15HP 18HP 20HP 22HP 24HP 26HP 28HP 30HP

● ● ● ●

● ● ● ●

● ● ● ● ● ● ●

Model

MDS-A

MDS-B

MDS-B

M DB 050 T - A M A

Design serial No

Cooling capacity No.

Air-cooled cooling duct indoor unit

McQuay

Design serial No.

Matching outdoor units:MDS series

Power supply features: A:220V~/50Hz

■ Outdoor unit: MDS unit

MDS 60 A R - F AA

Design serial No

Cooling capacity No

McQuay multi digital scroll unit

Description of the unit

Power supply:

A:220V~/50Hz B:380V/3N~/50Hz

Heat pump (omitted if cooling only)

_________

MEX:Throttle box (one expansion valve)

_________

ominal opening diameter value× 10

_________

2:1/4 inch

_________

3:3/8 inch

_________

4:1/2 inch

_________

Flare fitting & nipple joint

_________

Primary design

McQuay

Valve opening size No.

Pipe size:

Pipe mode:

Design serial No.

■ MEX throttle box

Design serial No.

Pipe mode

Pipe size:

MEX - 14 - 3 SA - A

McQuay

Valve opening size No.

Page 15

-15-

Design & installation Guide For McQuay MDS Multi System

1.6 Performance Parameter

1.6.1 Ceiling concealed

Model

Indoor MCC MCC MCC MCC MCC MCC MCC MCC MCC MCC

unit

008T 010T 015T 018T 020T 025T 030T 040T 050T 060T

Cooling

W

2000 2500 3650 4500 5600 6500 7800 10600 12400 14400

capacity

Heating

W

2200 2600 3700 4700 6100 7400 8900 11600 14500 17300

capacity

Nominal input W 47 47 81 82 82 123 158 276 276 280

Power supply 220V~/50Hz

Air

High m3/h 450 450 580 800 800 960 1200 1900 1900 2100

flow Medium m3/h 370 370 470 650 650 780 950 1520 1520 1750

Low m3/h 280 280 380 540 540 600 800 1300 1300 1460

ESP Pa 15(0/30/50)

30(15/50/70)

50(15/30/70)

Dimension mm 1030x469x220 1290x490x250 1640x490x250

1900x490x250

Weight kg 22 22 22 25 25 27 28 39 39 45

Sound(High/

dB (A)

31/29/27 31/29/27 34/32/30 35/32/29 35/32/29 37/36/35 42/40/38 47/45/43 47/45/43 48/46/44

medium/Low)

Piping

Liquid pipe Φ

mm(in)

6.35 (1/4) 6.35 (1/4) 6.35 (1/4) 9.52 (3/8) 9.52 (3/8) 9.52(3/8) 9.52(3/8) 9.52(3/8) 9.52(3/8) 9.52(3/8)

size

Gas pipe Φ

mm(in)

9.52 (3/8) 9.52 (3/8) 12.7 (1/2) 15.88(5/8) 15.88(5/8) 15.88(5/8) 15.88(5/8) 19.05(3/4) 19.05(3/4) 19.05(3/4)

Drainage pipe

inch R3/4

Capacity range

0.8HP 1.0HP 1.5HP 1.8HP 2.0HP 2.5HP 3.0HP 4.0HP 5.0HP 6.0HP

MCC ● ● ● ● ● ● ● ● ● ●

MCK ● ● ● ● ● ● ● ●

MCM ● ● ●

MDB ● ●

Model

1.5.2 Indoor products

Notes:

◆ The nominal cooling cap acity is gotten in the return air temperature of 27℃ /19℃ , and the ambient temperature of 35℃ /24℃ .

◆ The nominal heating capacity is gotten in the return air temperature of 20 ℃/15℃ , and the ambient temperature of 7℃ /6℃ .

◆ The sound level is gotten from the test room, it may differ in actual use due to the ambient temperature or other causes.

◆ The above parameters are of heat pump parameters.

Notes:

◆ The nominal cooling cap acity is gotten in the return air temperature of 27℃ /19℃ , and the ambient temperature of 35℃ /24℃ .

◆ The nominal heating capacit y is gotten in the return air temperature of 20℃ /15℃ , and the ambient temperature of 7℃ /6℃ .

◆ The sound level is gotten from the test room, it may differ in actual use due to the ambient temperature or other causes.

1.6.2 High static pressure duct unit

Model Indoor unit Indoor unit MDB050T MDB060T

Nominal cooling capacity W 12500 14000

Nominal heating capacity W 14000 16500

Nominal input W 615 789

Power supply 220V~/50Hz

Air flow(High/Medium/Low) m3/h 2550/2040/1650 3000/2540/1920

ESP Pa 100 100

Dimension mm 1230 × 910 × 350 1430 × 910 × 350

Weight kg 69 75

Sound Level(High/Medium/Low) dB(A) 58/55/52 60/56/53

Liquid pipe outside diameterΦ

mm(in) 9.52(3/8) 9.52(3/8)

pipe size Gas pipe outside diameterΦ mm(in) 19.05(3/4) 19.05(3/4)

Drainage pipe inch R3/4

Page 16

-16-

Design & installation Guide For McQuay MDS Multi System

Notes:

◆ The nominal cooling capacity is gotten in the return air temperature of 27℃ /19℃ , and the ambient temperature of 35℃ /24℃

◆ The nominal heating capacity is gotten in the return air temperature of 20℃ /15℃ , and the ambient temperature of 7℃ /6℃ .

◆ The sound level is gotten from the test room, it may differ in actual use due to the ambient temperature or other causes.

1.6.4 Ceiling exposed/floor standing

Model Indoor unit MCM020T MCM030T MCM050T

Cooling capacity W 5800 7500 12500

Heating capacity W 5800 8000 13500

Air flow(High/Medium/Low) m3/h 1100/970/750 1300/1100/870 1850/1550/1200

Rated power input W 81 116 161

Power supply 220V~/50Hz

Dimension mm 1214x670x214 1214x670x249 1714x670x249

Weight kg 39 44 44

Sound(High/medium/Low) dB(A) 48/45/42 50/46/43 52/48/44

Liquid pipe outside diameterΦ mm(in) 9.52(3/8) 9.52(3/8) 9.52(3/8)

PiPing

Gas pipe outside diameterΦ mm(in) 15.88(5/8) 15.88(5/8) 19.05(3/4)

Size

Drain pipe mm φ 20.5

Notes:

◆ The nominal cooling cap acity is gotten in the return air temperature of 27℃ /19℃ , and the ambient temperature of 35℃ /24℃ .

◆ The nominal heating capacity is gotten in the return air temperature of 20℃/15℃ , and the ambient temperature of 7℃ /6℃ .

◆ The sound level is gotten from the test room, it may differ in actual use due to the ambient temperature or other causes.

1.6.3 Ceiling cassette

Model

Indoor unit

MCK010T MCK015T MCK018T MCK020T MCK025T MCK030T MCK040T MCK050T

Nominal cooling capacity

W 2800 3600 4500 5400 6500 7500 10000 12500

Nominal heating capacity

W 3200 3900 5000 5900 7200 8000 11000 13500

Nominal input W 26 34 36 42 75 84 110 140

Power supply 220V~/50Hz

High m3/h 520 600 650 700 1200 1300 1360 1650

Air flow Medium m3/h 430 520 550 600 1100 1060 1200 1450

Low m3/h 380 430 400 530 960 850 1110 1350

Dimension mm 930X930X278 930X930X363

Weight kg 26 30 39.5 39.5

Sound(High/medium/Low)

dB(A) 29/28/26 32/30/27 38/34/30 39/35/31 42/40/38 45/43/41 46/44/42 48/45/42

Piping

Liquid pipeΦmm(in) 6.35(1/4) 9.52(3/8) 9.52(3/8)

Size

Gas pipeΦmm(in) 9.52(3/8) 12.7(1/2) 15.8(5/8) 19.05(3/4)

Drainage pipe mm φ 20.5

Page 17

-17-

Design & installation Guide For McQuay MDS Multi System

1.6.5 Specification

Model Unit MDS030A MDS030AR MDS040A MDS040AR MDS050A MDS050AR MDS060A MDS060AR

Nominal cooling capacity kW 8.5 8.5 10 10 12.5 12.5 14.5 14.5

Nominal heating capacity kW - 9.0 - 11.5 - 13.5 - 16.5

Power supply 220V~/50Hz

Dimension Lx W x H mm

Weight

kg 82 85 112 115 117 120 123 130

Cooling rated power input

kW 3.0 3.0 3.5 3.6 4.4 4.4 5.0 5.0

Cooling rated current

A 13.6 13.6 15.9 15.9 20 20 22.8 22.8

Heating rated power input

kW - 2.5 - 3.4 - 4.2 - 4.2

Heating rated current

A - 11.4 - 15.5 - 19 - 20.3

Refrigerant

R22

Type of connecting pipe

copper f lare fitting & nipple joint

Liquid pipeф

(mm/in)

Gas pipeф

(mm/in)

Notes:

◆ The nominal cooling cap acity is gotten in the return air temperature of 27℃ /19℃ , and the ambient temperature of 35 ℃/24℃.

◆ The nominal heating capacity is gotten in the return air temperature of 20℃ /15℃ , and the ambient temperature of 7℃ /6℃.

◆ The specifications may be undated as we are trying to update the units at the time, please regard the nameplate of the unit as

standard.

840x408x900 1058x430x1044 1058x4230x1247

9.52(3/8″) 9.52(3/8″) 9.52(3/8″) 9.52(3/8″)

15.88(5/8″) 19.05(3/4″) 19.05(3/4″) 19.05(3/4″)

Notes:

◆ The nominal cooling cap acity is gotten in the return air temperature of 27℃/19℃ , and the ambient temperature of 35℃ /24℃

◆ The nominal heating capacity is gotten in the return air temperature of 20℃ /15℃ , and the ambient temperature of 7℃ /6℃ .

◆ The specifications may be undated as we are trying to update the units at the time, please regard the nameplate of the unit as

standard.

Connecting

accessory

pipe size

Model Unit MDS050A MDS050AR MDS060A MDS060AR

Nominal cooling capacity kW 12.5 12.5 15 15

Nominal heating capacity kW - 13.5 - 17

Power supply 380V/3N~/50Hz

Dimension L x W x H mm

Weight

kg 117 120 123 130

Cooling rated power input

kW 4.4 4.4 5.0 5.0

Cooling rated current

A 8.4 8.4 9.6 9.6

Heating rated power input

kW - 4.2 - 4.23

Heating rated current

A - 8.0 - 8.8

Refrigerant

R22

Liquid pipe

Gas pipe

Liquid pipeф (mm/in)

Gas pipe ф (mm/in)

1

058x430x1044 1058x430x1247

Copper flare fitting & nipple joint

Copper flare fitting & nipple joint

9.52(3/8″)

19.05(3/4″)

Connecting

accessory

pipe size

Type of

connecting

pipe

Page 18

-18-

Design & installation Guide For McQuay MDS Multi System

Notes:

◆ The nominal cooling cap acity is gotten in the return air temperature of 27℃ /19℃ , and the ambient temperature of 35℃ /24 ℃

◆ The nominal heating capacity is gotten in the return air temperature of 20℃ /15℃ , and the ambient temperature of 7℃ /6℃.

◆ The sound level is gotten from the test room, it may differ in actual use due to the ambient temperature or

1.6.6 Specification

Model

MDS080B MDS080BR MDS100B MDS100BR MDS120B MDS120BR MDS150B MDS150BR MDS180B MDS180BR MDS200B MDS200BR

Nominal cooling

kW 24.5 24.5 28.0 28.0 32.5 32.5 40.0 40.0 47.5 47.5 50.0 50.0

capacity

Nominal heating

kW - 26.0 - 30.0 - 34.0 - 43.0 - 50.0 - 53.0

capacity

Power supply 380V/3N~/50Hz

Sound leveldB(A) 62 62 64 64 66 66 67 67 66 66 66 66

Dimension Lx W x H mm 990x840x1840 1290x840x1840 1990x840x1840

Weight kg 275 290 285 300 290 305 355 370 520 550 560 590

Cooling rated

kW 7.5 7.5 8.5 8.5 9.8 9.8 12.9 12.9 14.1 14.1 15.2 15.2

power input

Cooling rated current A 14.6 14.6 16.8 16.8 18.8 18.8 23.1 23.1 28.2 28.2 31.1 31.1

Heating rated

kW - 7.2 - 8.3 - 9.0 - 11.1 - 13.2 - 14.7

power input

Heating rated current A - 13.6 - 15.7 - 16.7 - 22.6 - 27.1 - 29.4

Refrigerant R22

Gas side

Welding & flange

Liquid side

Flare fitting &nipple joint

Liquid pipeф

mm(in)

12.7(1/2) 15.88(5/8)

Gas pipe ф

mm(in)

28.6(11/8) 34.9(13/8)

Model

MDS220B MDS220BR MDS240B MDS240BR MDS260B MDS260BR MDS280B MDS280BR MDS300B MDS300BR

Nominal coolingcapacity

kW 55.0 55.0 65.0 65.0 70.0 70.0 75.0 75.0 80.0 80.0

Nominal heating capacity kW - 58.0 - 68.0 - 75.0 - 80.0 - 85.0

Power supply 380V/3N~/50Hz

Sound level dB(A) 66 66 68 68 68 68 69 69 69 69

Dimension Lx W x H mm 1990x840x1840 2280x840x1840 2580x840x1840

Weight kg 560 590 570 600 645 675 710 740 710 740

Cooling rated power input kW 16.7 16.7 19.8 19.8 21.3 21.3 22.8 22.8 26.2 26.2

Cooling rated current A 32.7 32.7 38.5 38.5 40.0 40.0 42.5 42.5 46.5 46.5

Heating rated power input kW - 16.2 - 18.5 - 20.9 - 22.0 - 23.6

Heating rated current A - 31.0 - 33.8 - 37.2 - 41.0 - 43.1

Refrigerant R22

Gas side

Welding & flange

Liquid side

Flare fitting &nipple joint

Liquid pipe ф mm(in) 19.05(3/4) 19.05(3/4)

Gas pipe ф mm(in) 38.1(11/2) 41.3(15/8)

Connecting

accessory

pipe size

pipe

size

Page 19

-19-

Design & installation Guide For McQuay MDS Multi System

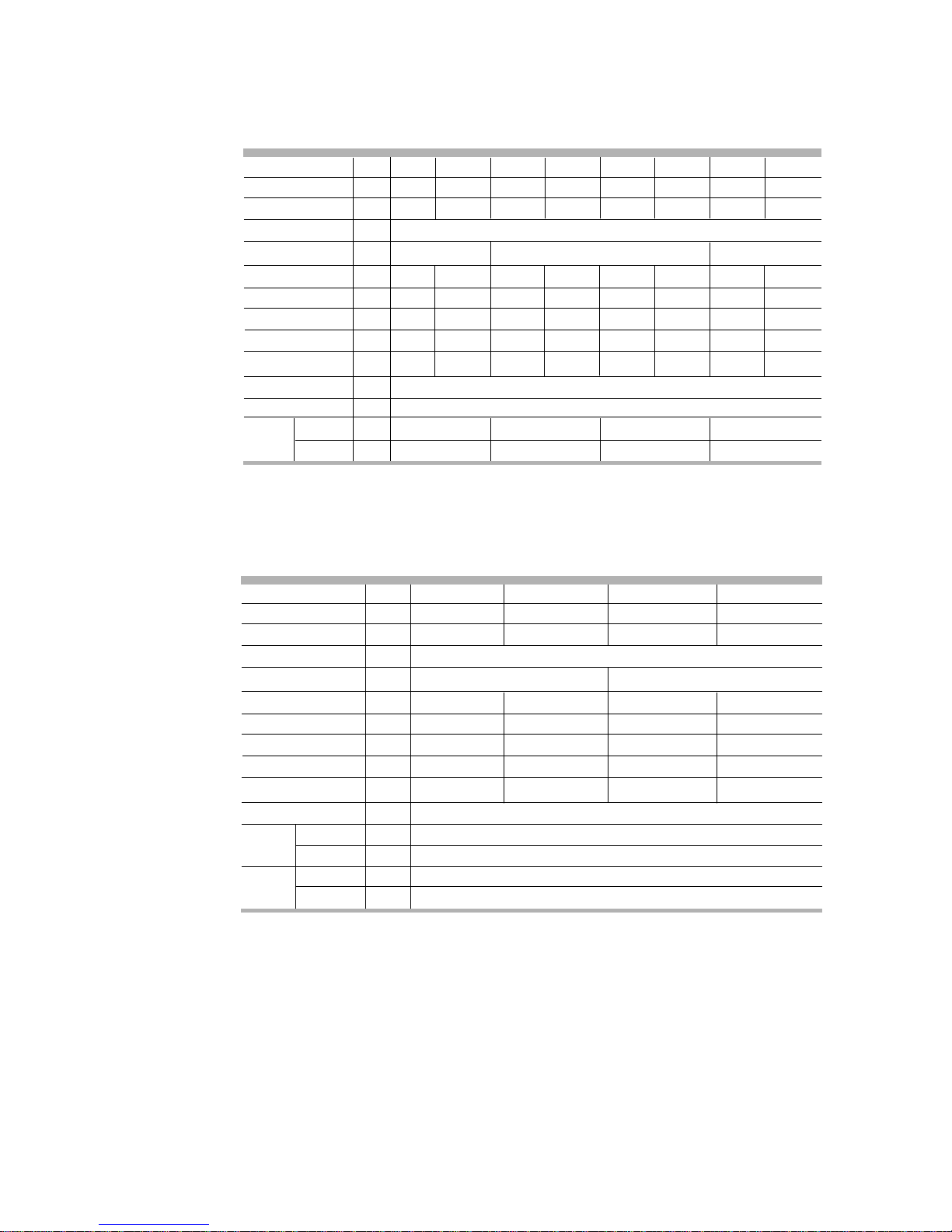

1.7 Operating Range

【Note】The t able is gotten based on the equivalent length of 16m and the height is 0 m.

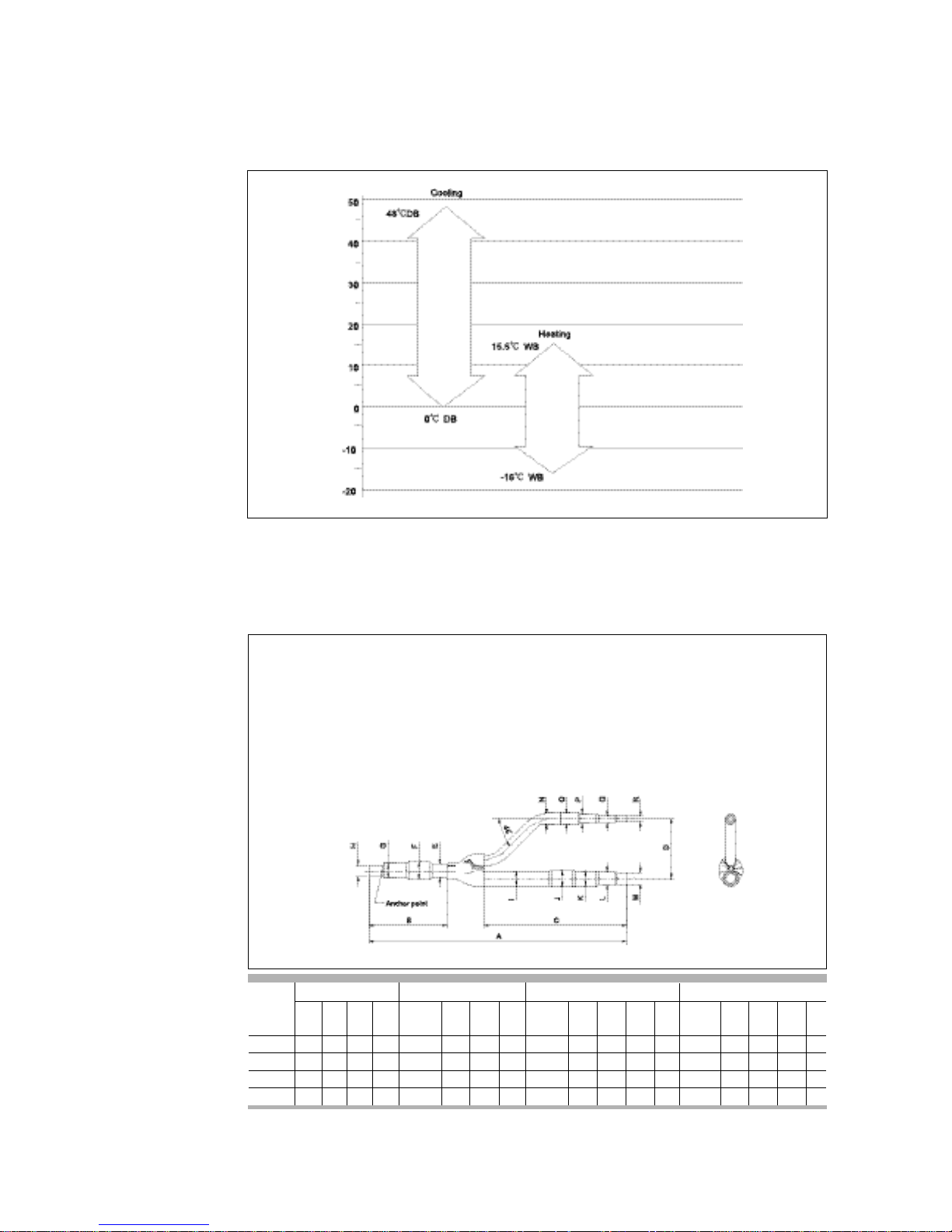

1.8 Refnet

1.8.1“Y” type

unit:mm

Length(mm) Diameter(mm) Diameter(mm) Diameter(mm)

Refnet

A B C D

E(outer

F G H

I(outer

J K L M

N(outer

O P Q R

model

diamenter diamenter diamenter

MDS-Y1 553 172 293 120 28.6 28.9 25.7 22.5 28.6 28.9 25.7 22.5 19.3 22.2 19.3 16.1 12.9 9.7

MDS-Y2 420 142 223 80 15.88 16.1 12.9 9.7 12.7 12.9 9.7 6.5 12.7 12.9 9.7 6.5

MDS-Y3 420 142 223 80 15.88 16.1 12.9 9.7 12.7 12.9 9.7 6.5 15.88 16.1 12.9 9.7

MDS-Y4 493 142 223 80 22.2 22.5 19.3 16.1 19.1 19.3 16.1 12.9 9.7 19.1 19.3 16.1 12.9

Page 20

-20-

Design & installation Guide For McQuay MDS Multi System

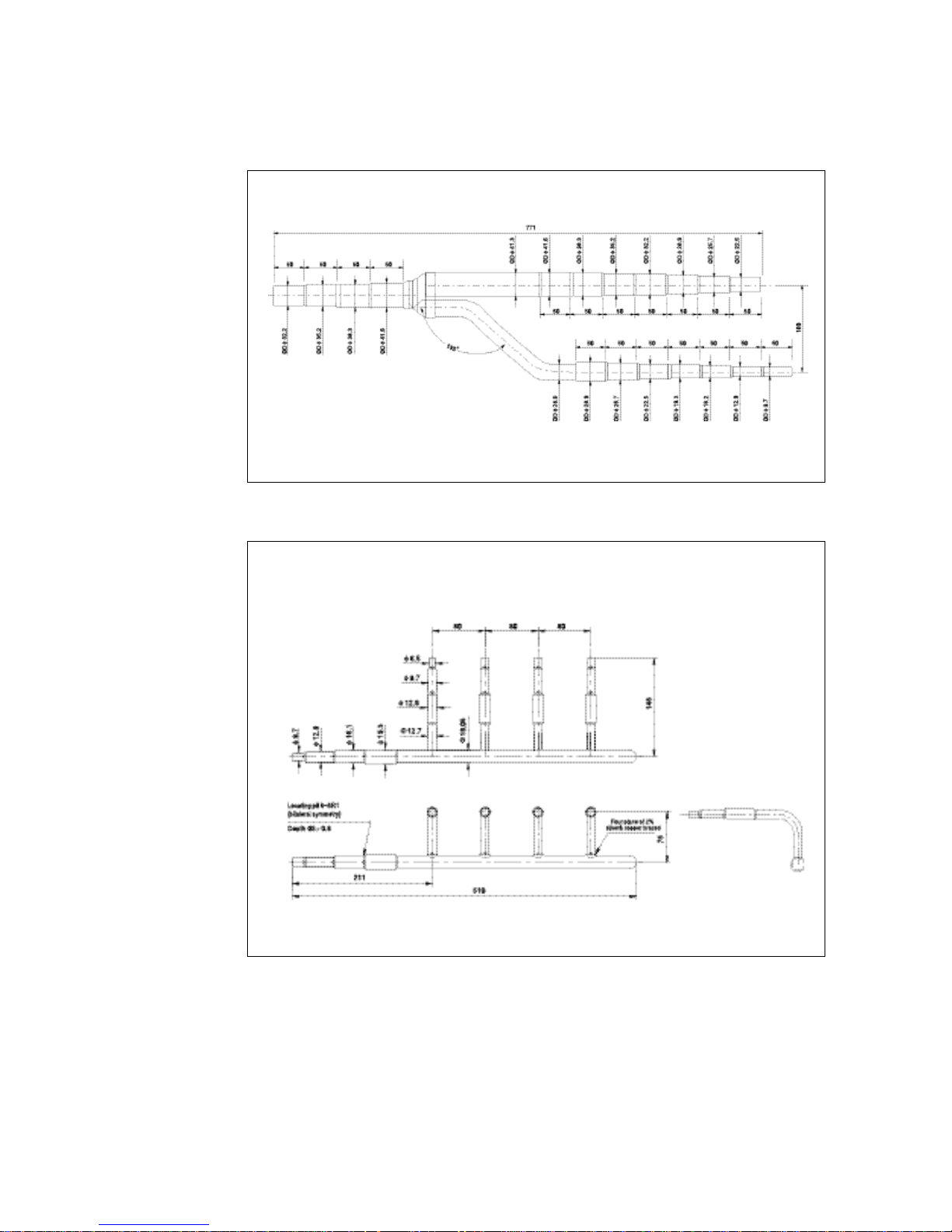

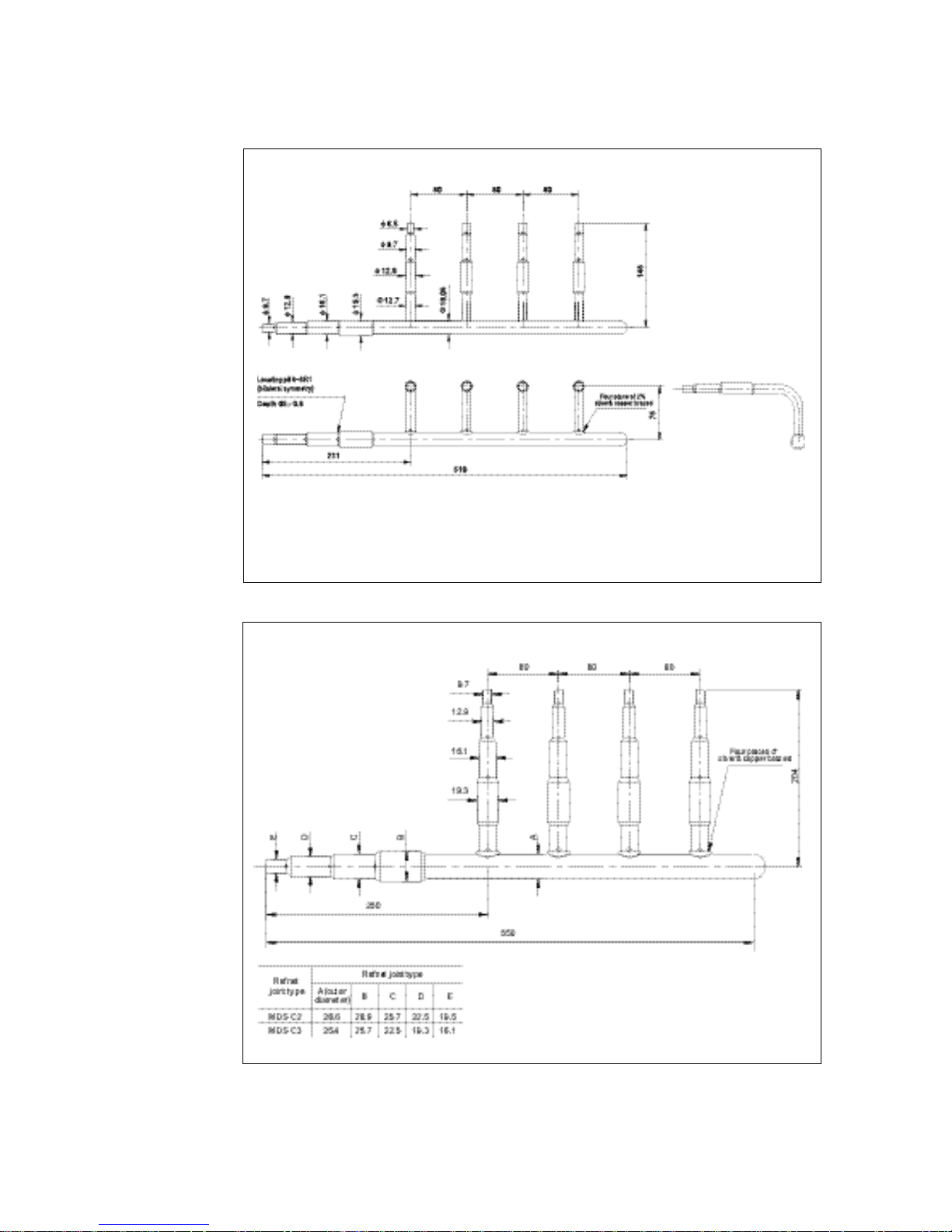

1.8.2 Distributor kit

unit: mm

Type: MDS-C1

Type: MDS-Y5

unit: mm

Page 21

-21-

Design & installation Guide For McQuay MDS Multi System

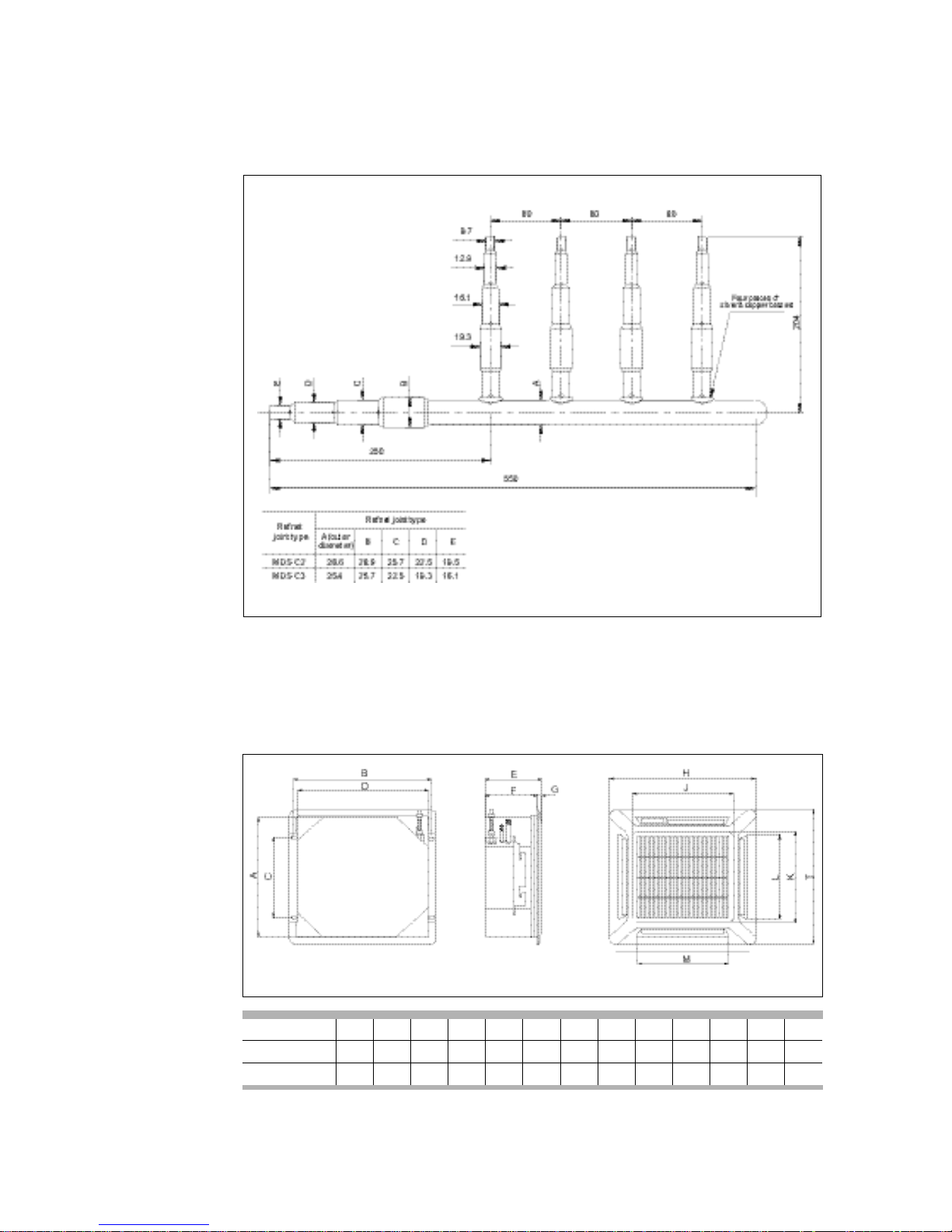

1.9 Outline of Indoor Units

1.9.1 MCK010~050T

Model A B C D E F G H I J K L M

MCK010~020T

820 875 548 820 278 250 28 930 930 642 622 555 555

MCK025~050T

820 875 548 820 363 335 28 930 930 642 622 555 555

unit: mm

unit: mm

Page 22

-22-

Design & installation Guide For McQuay MDS Multi System

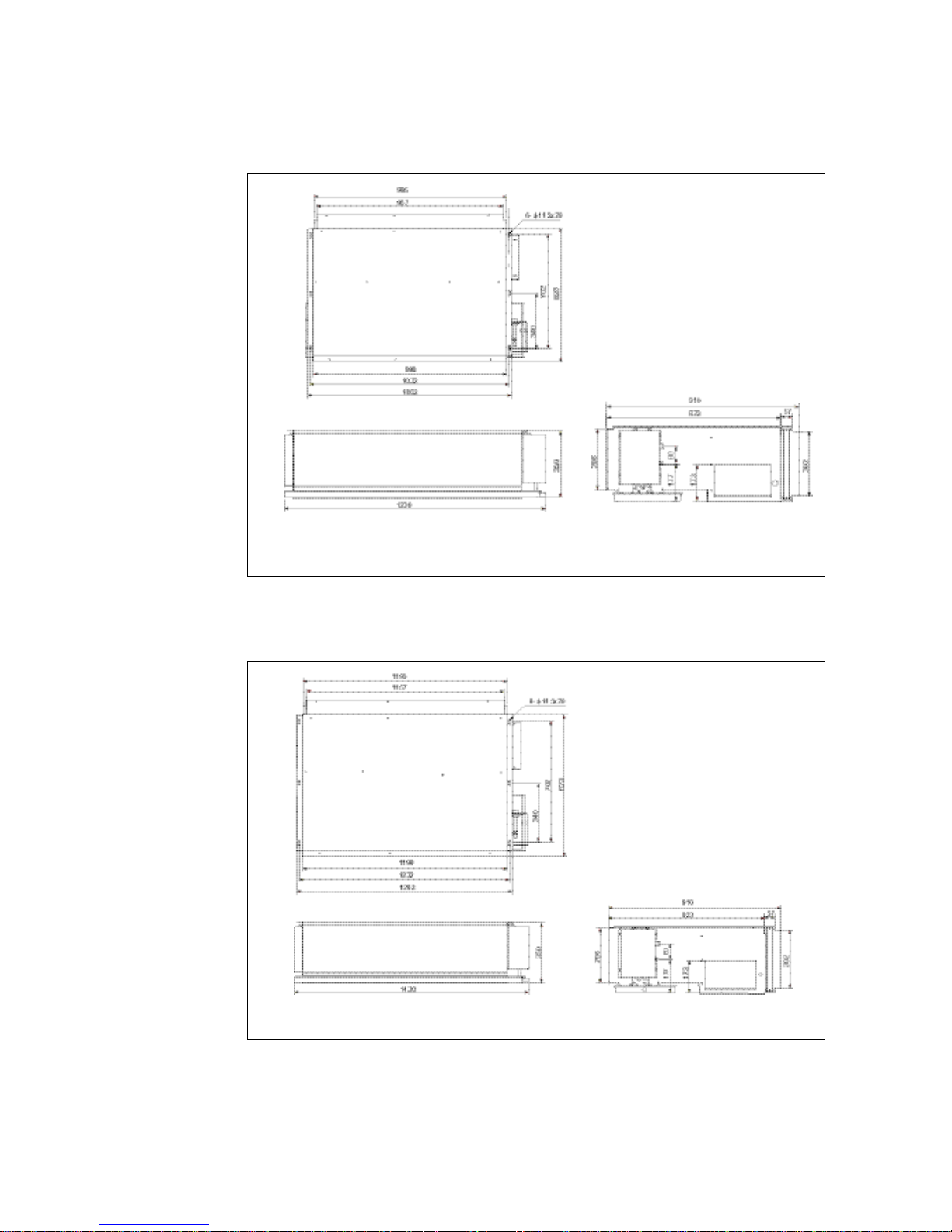

1.9.2 MDB050T

1.9.3 MDB060T

unit: mm

unit: mm

Page 23

-23-

Design & installation Guide For McQuay MDS Multi System

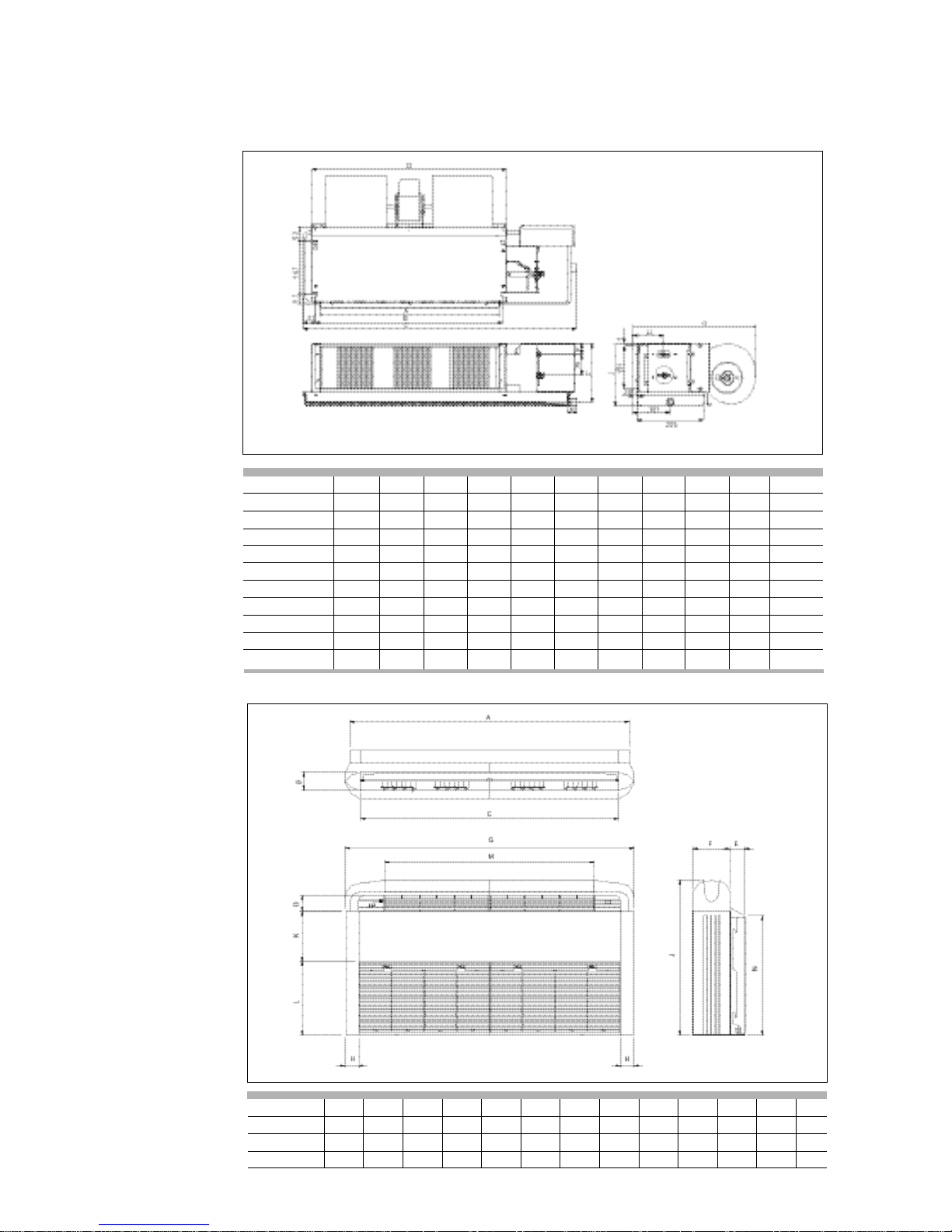

1.9.4 MCC008、010、015、018、020、025、030、040、050、060T

1.9.5 MCM020T、MCM030T、MCM050T

unit: mm

unit: mm

Model A B C D E F G H I J

No.of fans

MCC008T 690 722 1054 751 39 210 469 118 9 220 2

MCC010T 690 722 1054 751 39 210 469 118 9 220 2

MCC015T 690 722 1054 751 39 210 469 118 9 220 2

MCC018T 950 981 1314 1005 32 248 490 81 14 251 2

MCC020T 950 981 1314 1005 32 248 490 81 14 251 2

MCC025T 950 981 1314 1005 32 248 490 81 14 251 2

MCC030T 950 981 1314 1005 32 248 490 81 14 251 2

MCC040T 1300 1331 1664 1355 32 248 490 81 14 251 3

MCC050T 1300 1331 1664 1355 32 248 490 81 14 251 3

MCC060T 1560 1591 1924 1615 32 248 490 81 14 251 4

Model A B C D E F G H J K L M N

MCM020T 1174 75 1082 68 58 156 1214 57 670 216 319 879 517

MCM030T 1174 75 1082 68 93 156 1214 57 670 216 319 879 517

MCM050T 1674 75 1582 68 93 156 1714 57 670 216 319 1379 517

Page 24

-24-

Design & installation Guide For McQuay MDS Multi System

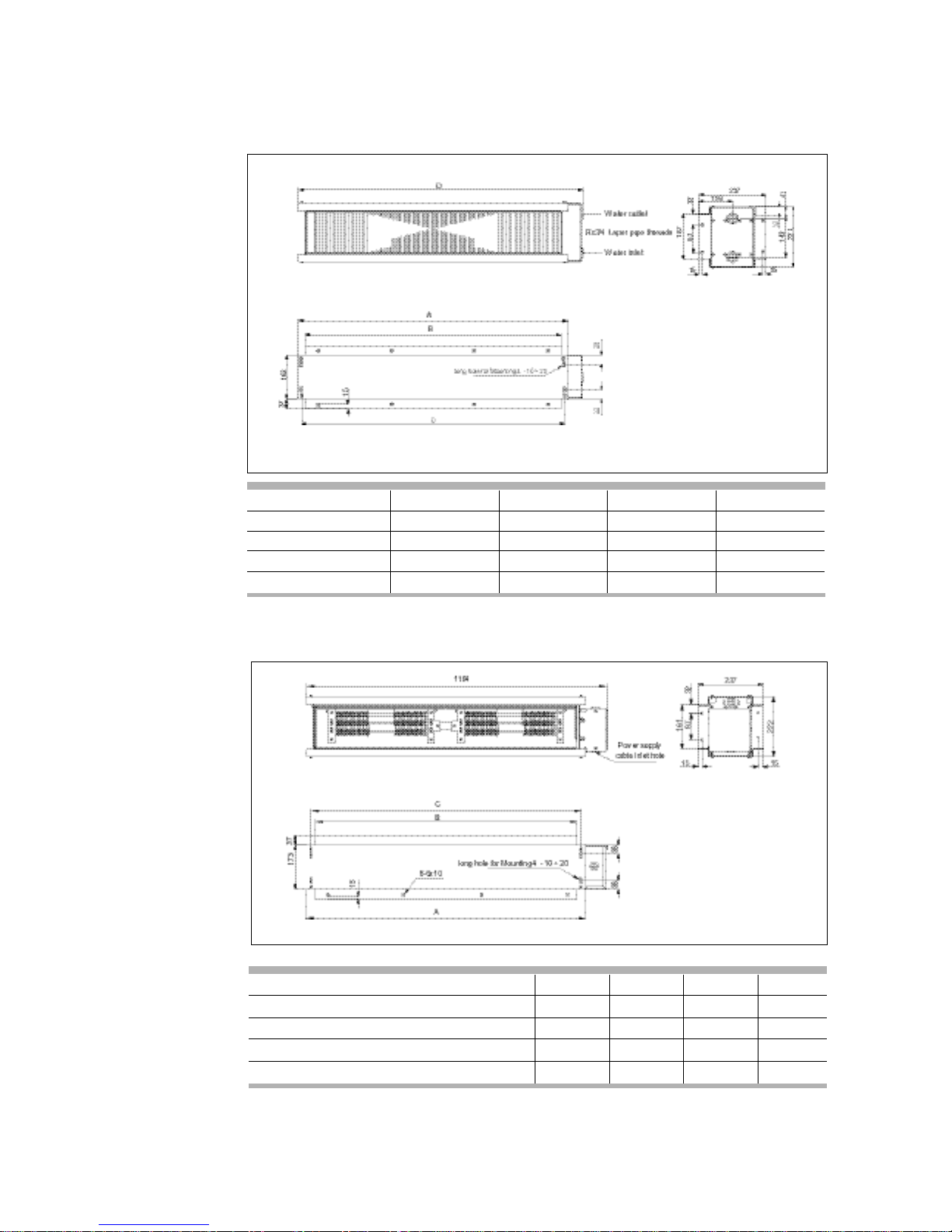

1.9.6 Auxiliary heating coil

Model A B C D

HWT08-15 762 704 732 818

HWT18-30 1022 964 992 1078

HWT40-50 1372 1314 1342 1438

HWT60 1632 1574 1602 1688

unit: mm

1.9.7 Auxiliary electric heating box

unit: mm

Model A B C D

HDP1.2T08-15/HDP2.4T08-15 762 704 732 844

HDP2.4T18-30/HDP3.6T18-30 1022 964 992 1104

HDP2.4T40/HDP3.6T40/HDP4.8T40-50/HDP7.2T40-50 1372 1314 1342 1454

HDP5.4T60/HDP7.2T60/HDP10.8T60 1632 1574 1602 1714

Page 25

-25-

Design & installation Guide For McQuay MDS Multi System

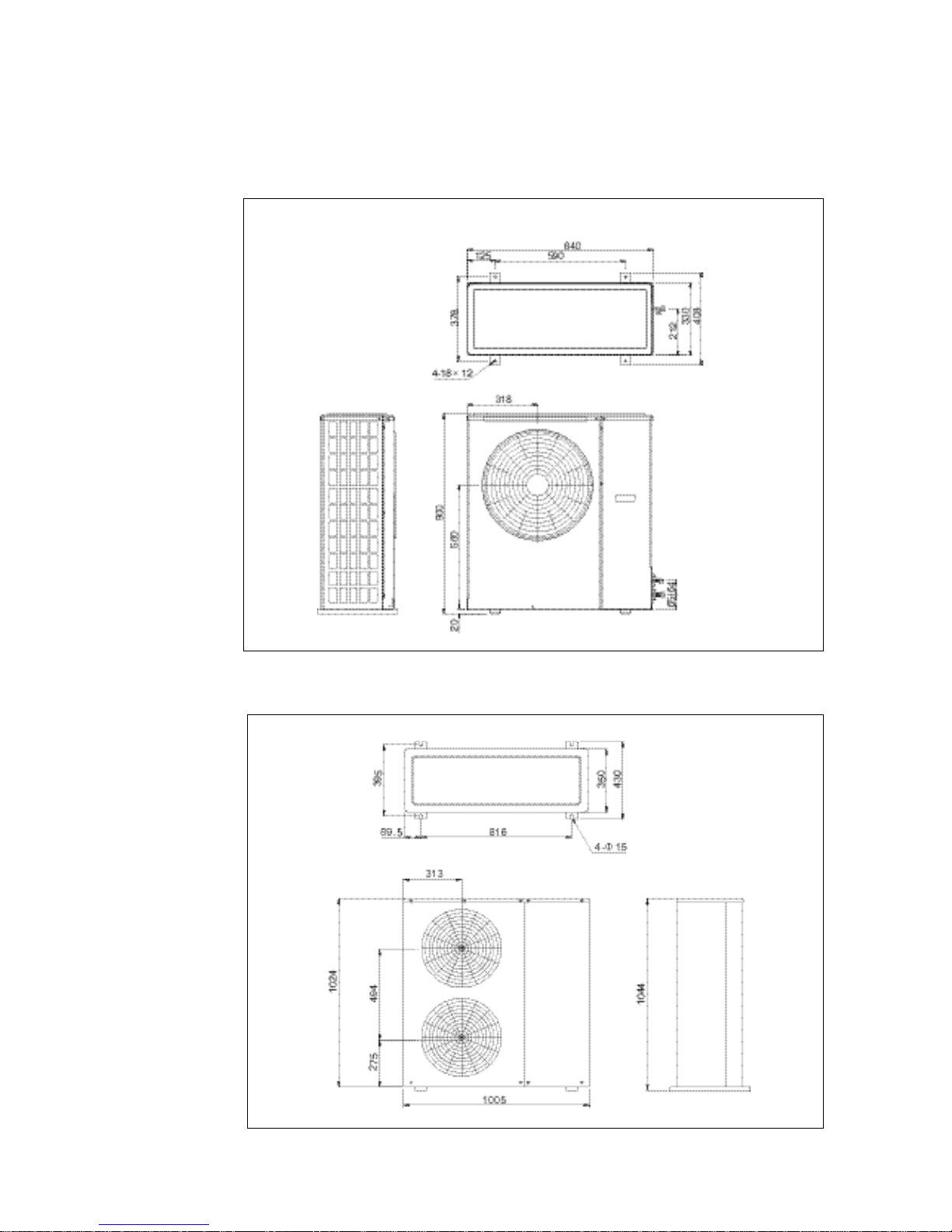

1.10 Outline of Outdoor Units

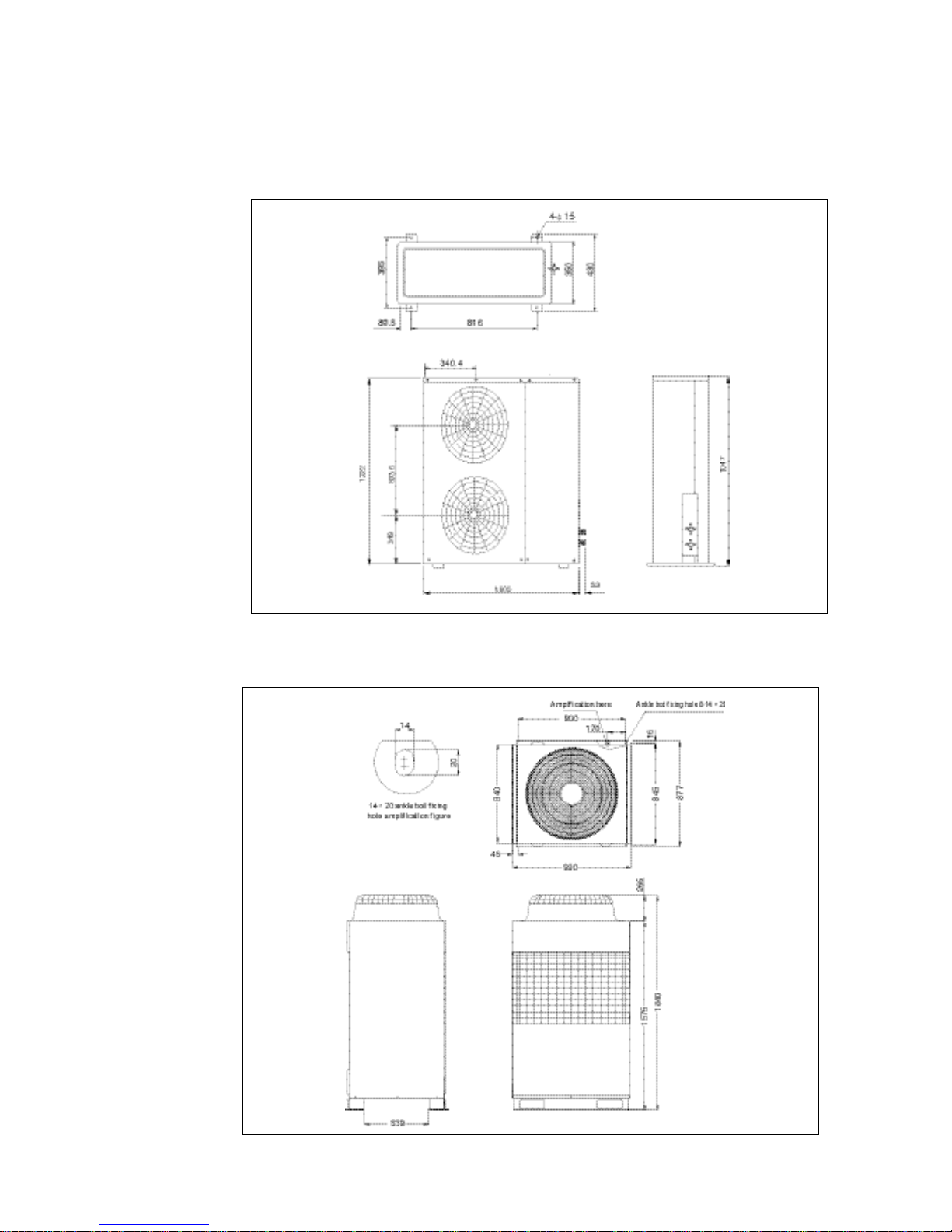

1.10.1 MDS030A(R)

1.10.2 MDS040A(R)、MDS050A(R)

unit: mm

unit: mm

Page 26

-26-

Design & installation Guide For McQuay MDS Multi System

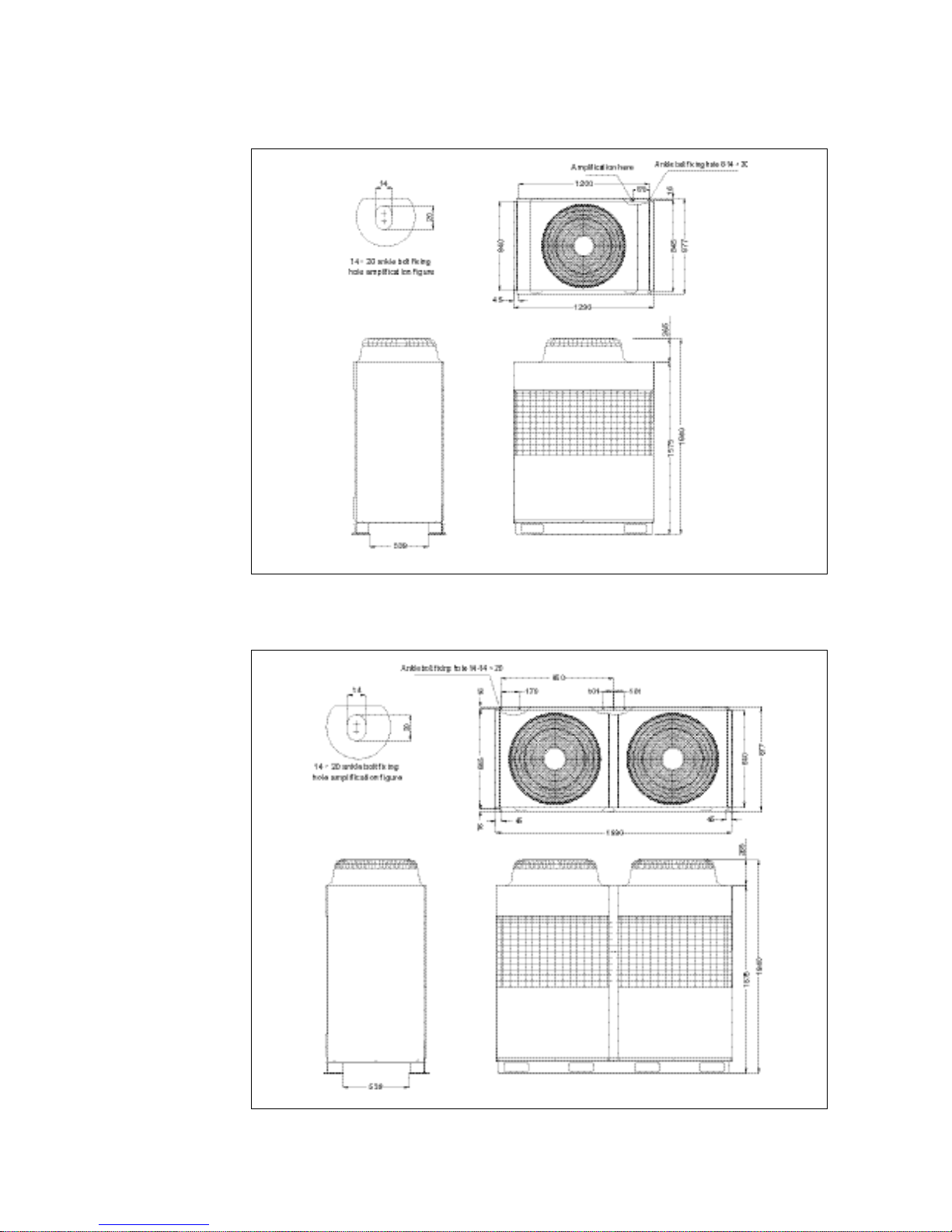

1.10.4 MDS080B(R)、MDS100B(R)、MDS120B(R)

unit: mm

1.10.3 MDS060A(R)

unit: mm

Page 27

-27-

Design & installation Guide For McQuay MDS Multi System

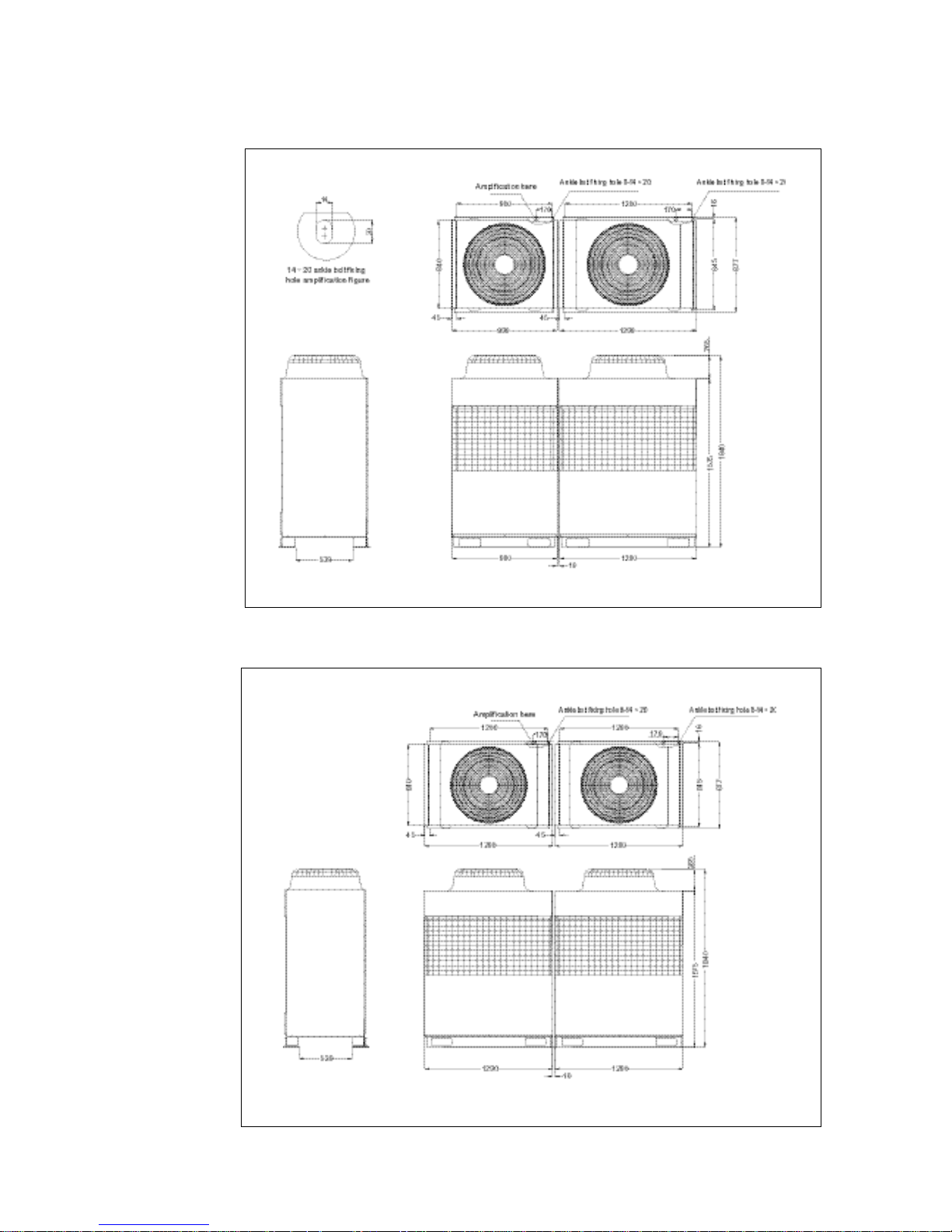

1.10.5 MDS150B(R)

unit: mm

1.10.6 MDS180B(R)、MDS200B(R)、MDS220B(R)、MDS240B(R)

unit: mm

Page 28

-28-

Design & installation Guide For McQuay MDS Multi System

1.10.8 MDS280B(R)、MDS300B(R)

1.10.7 MDS260B(R)

unit: mm

unit: mm

Page 29

-29-

Design & installation Guide For McQuay MDS Multi System

C H A P T E R

2

Units Control

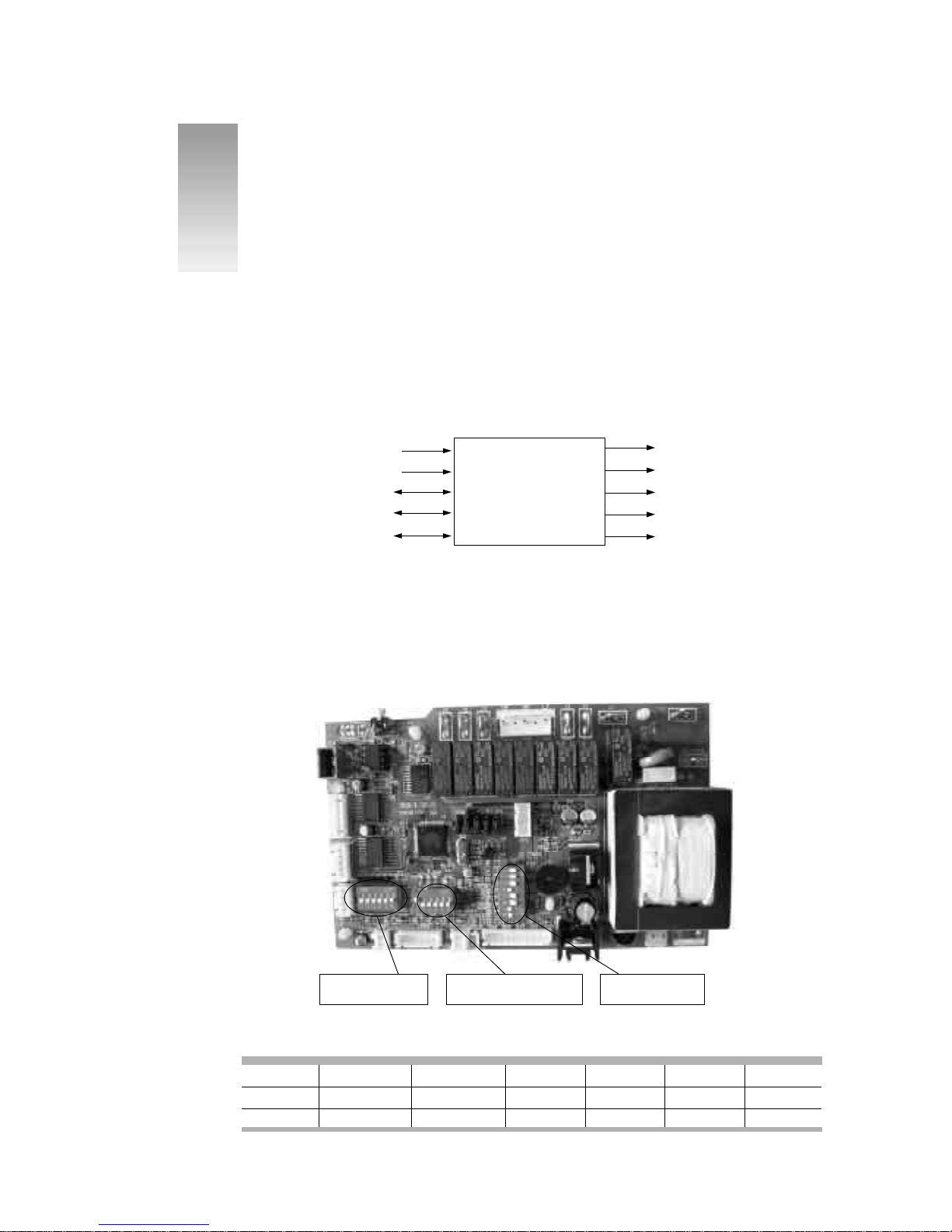

2.1 Introduction of Controller

MDS system is controlled by the micro-computer. Several types of controller are available, including

wireless controller, wire controller, wire controller +remote controller and central controller. One wireless

controller can control one unit, one wire controller can control one unit or up to 48 units, while central

controller can control up to 512 units (32groups).

2.2 Main Functions

■ Cooling./heating/auto/air supply/dehumidity mode are available

■ LCD wire controller and remote controller are available

■ Digital scroll compressor is used to reduce the start/stop times

■ Electronic expansion valve is used to control the refrigerant flow

■ One outdoor unit can connect up to 48 indoor units

■ Central control is available

■ Both the indoor and outdoor units have two speeds

■ Timer for ON/OFF

■ Energy saving can be setting when the unit is running in cooling or heating condition

■ High/low pressure protection for the compressor

■ Overload protection for the fan motor in indoor unit and outdoor unit

■ Anti-icing function for the coil of indoor unit

■ Function of auto restart after power

■ Auto defrost and manual defrost can be set

■ Auto check function for the sensor malfunction

■ Overheat protection for the coil of indoor unit

■ Three minutes delayed protection when auto restart after power failure

■ Malfunction indicating

■ Temperature unit can be ℃or F .

Page 30

-30-

Design & installation Guide For McQuay MDS Multi System

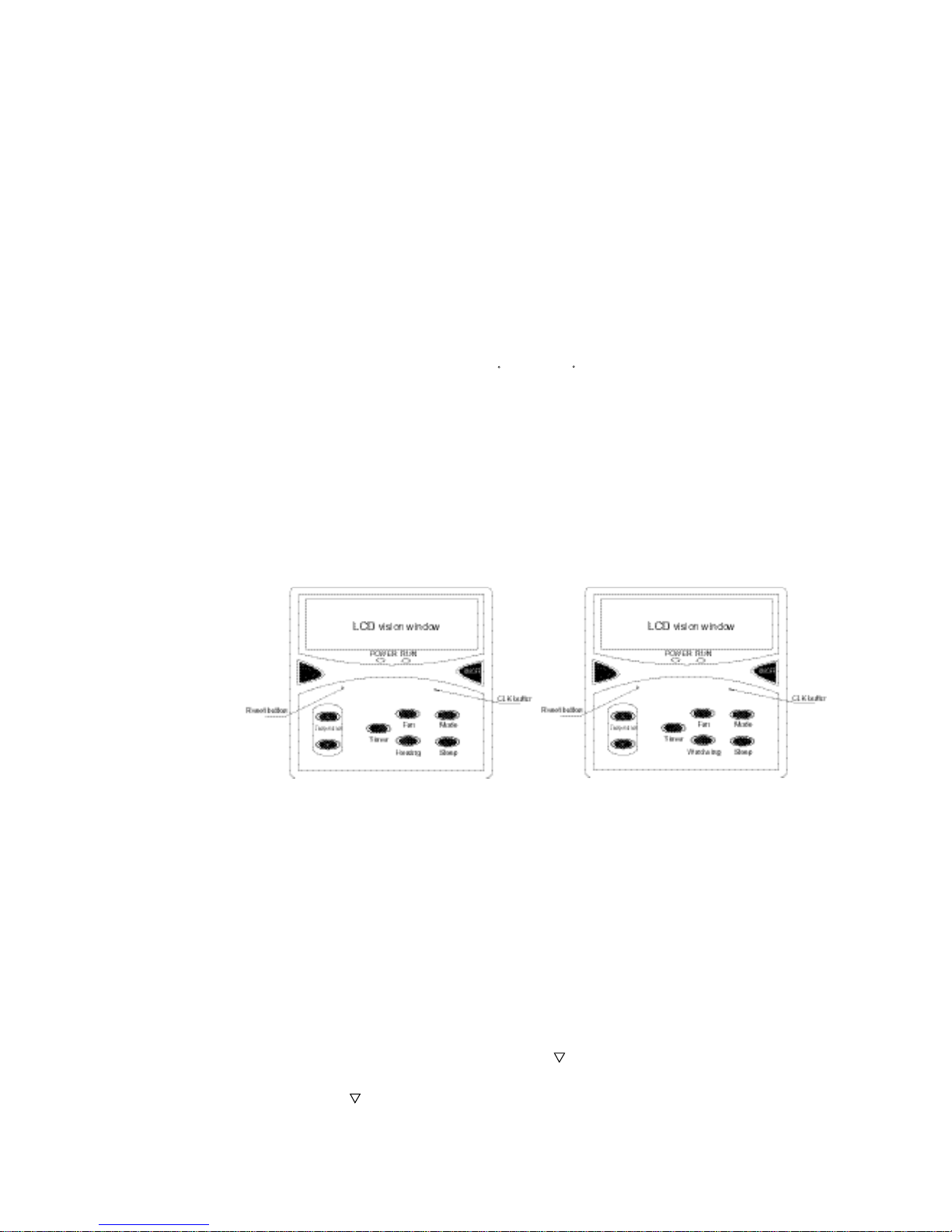

2.3 Operation of the Controller

2.3.1 Main features

Both wire controller (using the key on board) and remote controller (equipped with infrared receiver to

receive the order from the remote controller ) to control the unit, and to perform such functions as

parameter setting , working mode setting, status display and malfunction indicating.

Features:

■ Working mode Cooling only unit: Cooling/air supply/dehumidity; Heat pump unit: Cooling/heating

/air supply/dehumidity

■ Indoor units have several speed: auto/low/medium/high.

■ Temperature setting range: 16℃ /61 F~30℃ /78 F.

■ Timer for ON/OFF. Max. time is 24 hours

■ Sleep

■ Auxiliary electric heater & hot water heater control and the wind wing function.

■ LCD indicator is available to slow the setting temperature, working mode, real time, week, and

status of the units.

2.3.2 Operation of the line controller

■ Wire controller panel button

For the unit without wind wing For the unit with wind wing

■ Operation manual

● The omitted parameter

When the function of auto restart after power failure is not active: The unit is OFF and the

temp is 24℃/75 ,cooling mode, high speed, No sleep function, no defrost, no wind wing,

no electric heater.

When the function of auto restart after power failure is active: the unit is the same as that

before power failure.

● Temp setting

In normal mode condition, press“△”or “ ”to increase the temp by 1 ℃ or 1 Temp

adjustment range is 16-30℃ (or 61-86 When the temp reach the upper limit or floor limit, the

“△”or “ ”is invalid.

Page 31

-31-

Design & installation Guide For McQuay MDS Multi System

● Temp unit setting

There is a switch on the PCB board. When switch OP1 is ON, the unit is ℃; when it is

OFF, the unit is Alternate method is as follows: Press“fan”key and last for 5 seconds in

the normal condition, the temp unit setting will be successful and there will be a buzzer to

indicate.

● Real time setting

Press“CLK”to enter, the first time is week setting and indicate its icon, press “△”or

“ ” to adjust the week from Sunday to Saturday while the real time does not change. If

there is no press on any key within 5 seconds, the unit will exit from the real time setting

and back to the normal status. If you press“CLK”one more time within 5 seconds, the

setting will be OK and it is the real time setting icon, as well as the light is twinkling. At this

time, you can press “△” to increase the hour while press “ ” to increase the minute.

If there is no press on any key within 5 seconds, the unit will exit from the real time setting

and the time setting is valid. If you want to confirm the setting, you need to press“CLK”

one more time. If any other key is press during the setting, the system will exit and back

to the normal condition without saving

● Mode setting

When the unit is in off status, you can press “mode”to enter and the current mode is

twinkling. The mode will be changed when you press “mode” one more time. The mode

changing sequence is as follows:

When outdoor unit is OFF:

Heat pump: Cooling ,heating, air supply, dehumidifying, cooling

Cooling only: Cooling, air supply, dehumidifying, cooling

When outdoor is in cooling condition: Cooling, air supply, dehumidifying, cooling

When outdoor is in heating condition: Heating, air supply, heating

Note: In one system, the follows are not available: some units are in cooling condition while the

other is in heating condition.

● Air flow setting

In normal condition, when the“fan”key is pressed, the air flow will be changed as the

following sequence: High, auto, low, medium, high. When the unit is in air supply condition,

there is no “auto”function.

● Sleep

Press “sleep” key, the icon will be ON or OFF.

● Setting of auto restart after power failure

There is a switch on the PCB board to fulfill the setting of auto restart after power failure.

When OP2 is set “ON”, then this function is active and the icon is shown on the LCD.

● Manual defrost

When the unit runs in heating mode condition, press “Heater” key and last for 5 seconds,

you will enter “manual defrost mode” and “Defrost mode” is shown on the LCD. When

it is auto defrost, “Defrost mode” is also shown on the LCD and it will disappear when the

defrost finishes.

Page 32

-32-

Design & installation Guide For McQuay MDS Multi System

● Timer setting

Press “Timer ” to enter timer setting (When the unit is ON, it can only be set to OFF;

When the unit is OFF, it can only be set to ON) and last timer will be shown on the LCD.

If there is no press on any key within 5 seconds, it will exit and cancel the timer setting at

the same time. During this 5 seconds, press“△”or “ ”to increase the hour while

press“△”or “ ”to increase the minutes, please press “Timer ” within 5 seconds

to confirm the setting.When it is timer setting, the system will show the real time and the

setting time on the LCD.When the setting time is reaching, the unit will be Power on or off,

and the timer settingfunction is cancel. When you need the timer setting function, you

need to reset.

● Keyboard locked and unlocked setting

Press “Sleep” and last for 5 seconds, the keyboard will be alter between locked and

unlocked. When it is locked, a icon will be shown on the LCD. During the locked stage, only

the ON/OFF keyboard is valid.

● ON/OFF setting

Press “ON/OFF”keyboard, the unit will be alter between ON and OFF, and a relative

icon will be shown on the LCD.

● Reset

This keyboard is used to restart the unit because of some uncertain factors.

● Remote controller

The remote controller can be used with the wire controller and it and it has the same

keyboard as the wire controller, But the keyboard “fan”, “sleep”, “ heater”do not

have the second function.

● Central control

The units can be central controlled by the computer or centralized controller. When it is

locked, the keyboard on the wire controller is invalid and the key icon is twinkling. It can only

be unlocked by the computer or by the centralized controller. When it is central control, the

wire controller can communicate with the computer and the centralized controller.

Page 33

-33-

Design & installation Guide For McQuay MDS Multi System

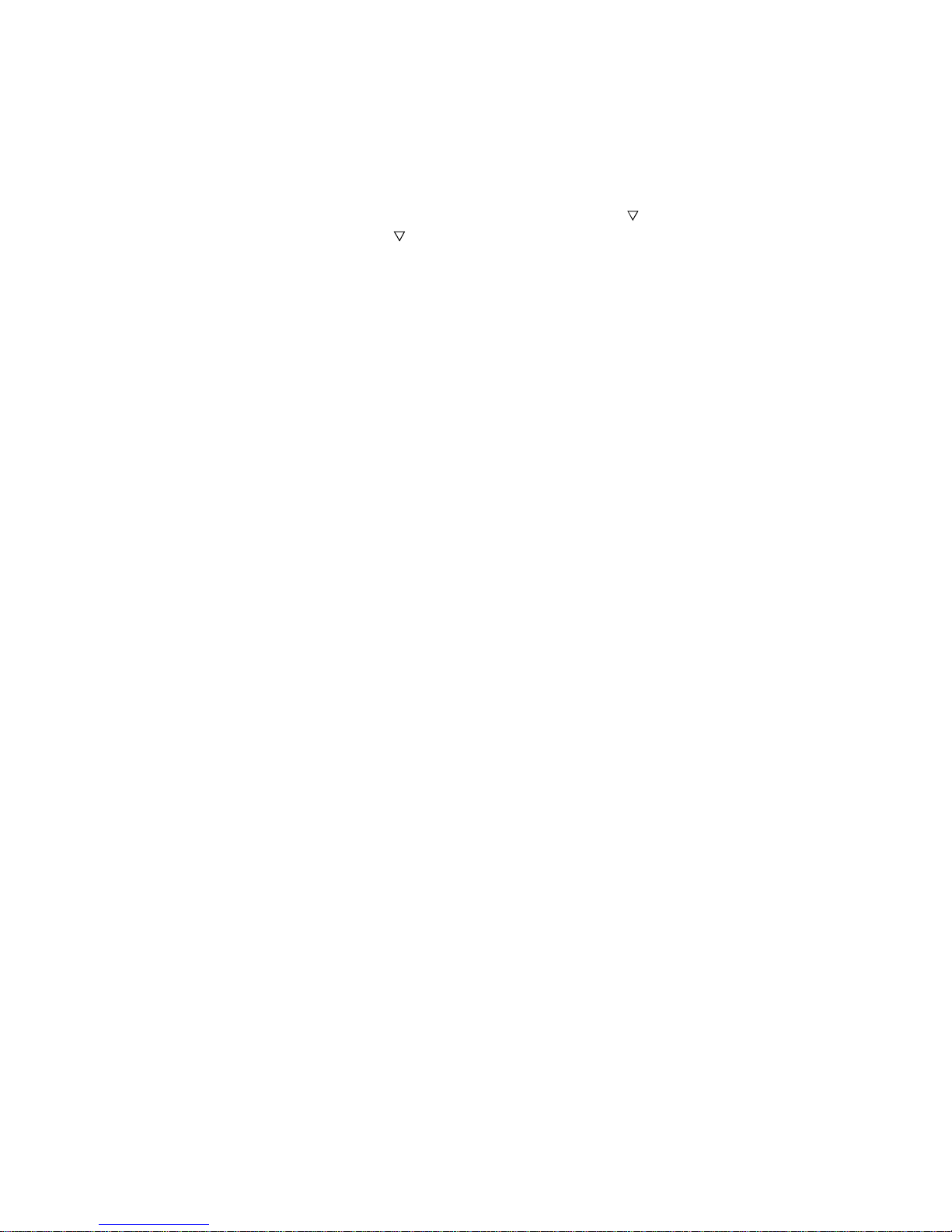

2.3.3 Wire control panel

2.3.4 Outline dimension

2.3.5 Installation type

■ concealed installation

Unit:mm

For three speed

unit with auxiliary

heater

For single speed

unit with auxiliary

heater

For three-speed unit

with wind wing

For the cooling and

heat pump unit with

three-speed

For the cooling and

heat pump unit with

single-speed

Page 34

-34-

Design & installation Guide For McQuay MDS Multi System

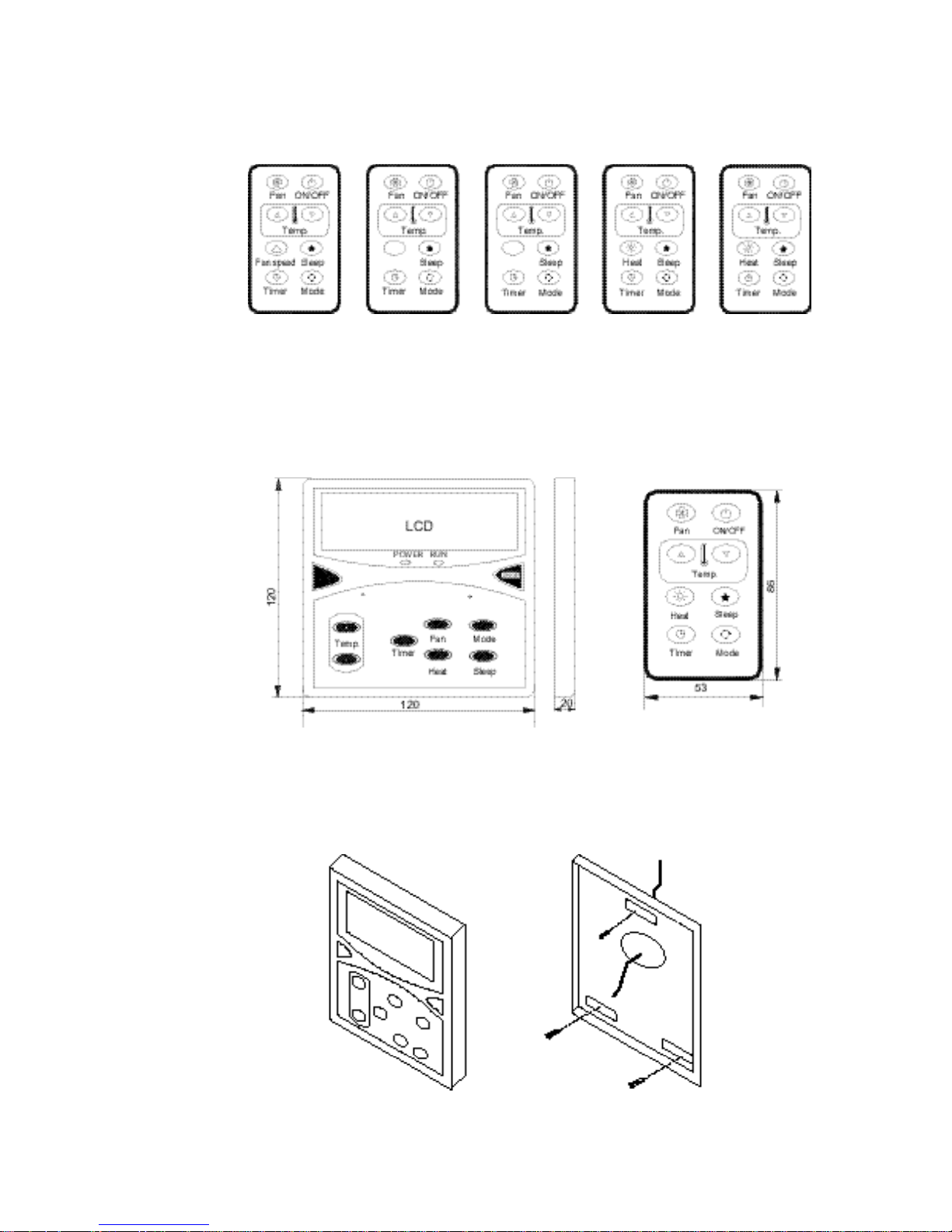

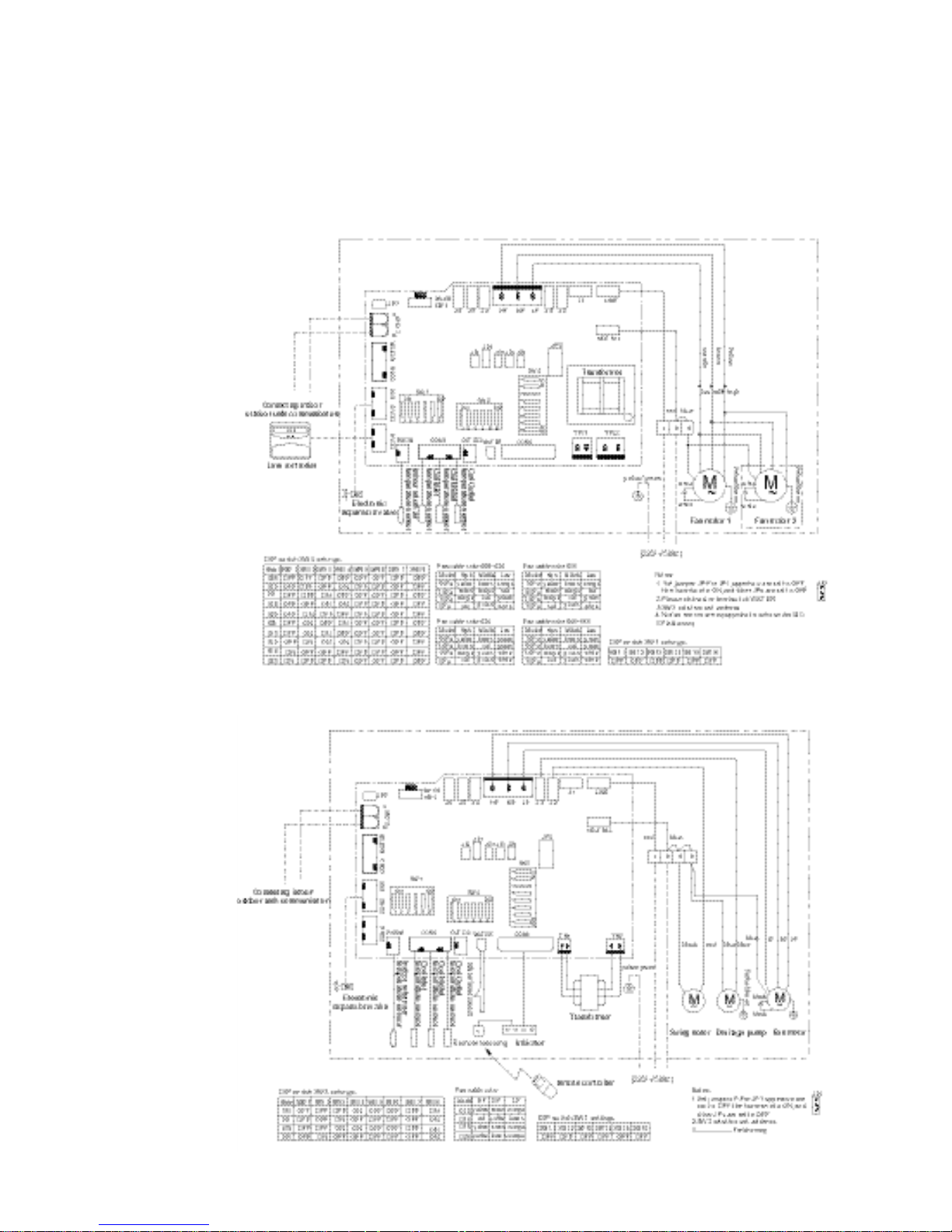

2.4 Software Management System

2.4.1 Real-time monitor software

■ System monitor software: The real time monitor software of MDS unit can perform such

functions as indoor monitor, system monitor and service monitor, for the purpose of making

the user or service test personnel see the detailed parameters and know the operation of

the unit.

Main control function:

2.4.1 Real-time monitor software

Indoor monitor

■ Set indoor mode/wind speed/auxiliary setting/temperat ure

and ON/OFF (they can be set in many units or the units in

groups at the same time).

■ Both indoor and outdoor units can be set in different groups

by self-defining. (The default group is set according to

outdoor unit)

■ Alarm display and alarm information query (you can choose

outdoor unit No. or indoor unit No. to query the corresponding

malfunction.)

■ Set timer mode and indoor unit timer mode. (The timer mode

can be set without limit and can be stored.)

■ System monitor

Display the model and status of all indoor units in the system (such as alarm and timer)

Indoor icon instruction

Small icon

Introduction

Introduction of the units

Indoor

Icon

unit model

Stop: Cooling Heating Dehumidity Air vent

MCC

MCK

MCM

MDB

The timer function

has been started.

The line controller has

been locked, we can not

use it to control the indoor units at this time.

There is malfunction in this

indoor unit, double-click the

icon to know the details.

Page 35

-35-

Design & installation Guide For McQuay MDS Multi System

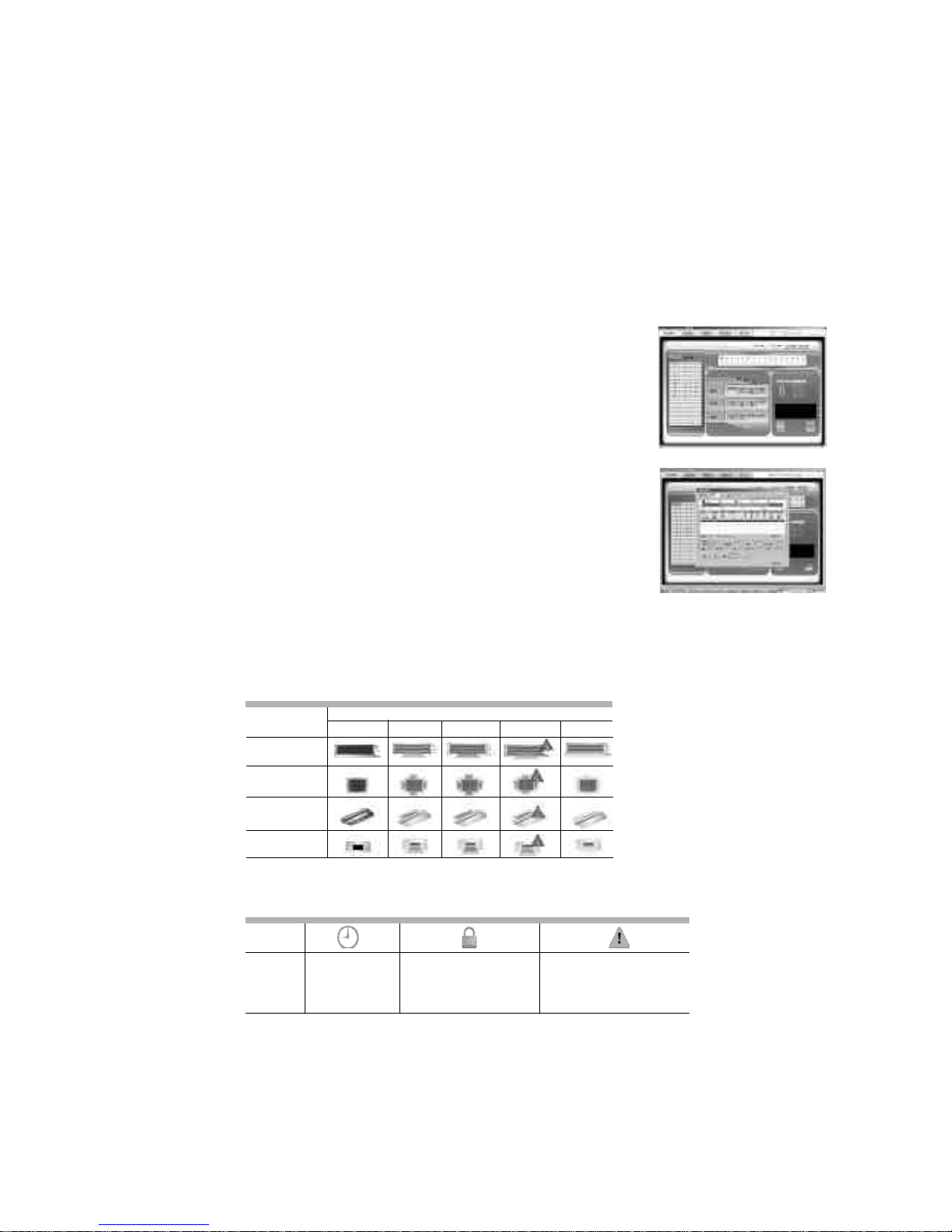

2.4.2 User-specific biller

■ Based on real-time monitoring, McQuay has created

user-specific billing software. With the technology of

accurate flow control, this software makes the calculation of power consumption more reasonable. It also

enables users to group up to 1536 indoor units at random,

and to calculate the electricity charge accurately in real

time. It features great flexibility, allowing you to easily

change and group devices and statistics. This software

is also capable of charging power consumption at wave

crests and wave troughs on a time-specific basis. Whenever a user becomes delinquent, the real -time monitoring software is capable of blocking the user without

affecting other users. In this way, it helps ease your

management.

2.4.3 Unit type selection software

■ The type selection software developed depending on different unit models allows you to select

and verify the unit model as required by customers, and collect statistics on the models of indoor/

outdoor units as well as the quantity of refnet and copper pipes. In this way, unit design and type

selection are as easy as a single click.

■ Loop monitor*

Select and see the outdoor unit system

figure, operation parameters and operation

parameters of all indoor

■ Service monitor*

Display the current operation parameters

and history record curve of indoor outdoor

unit inthe system.

Note: the interface can be used by the authorized maintenance personnel.

Page 36

-36-

Design & installation Guide For McQuay MDS Multi System

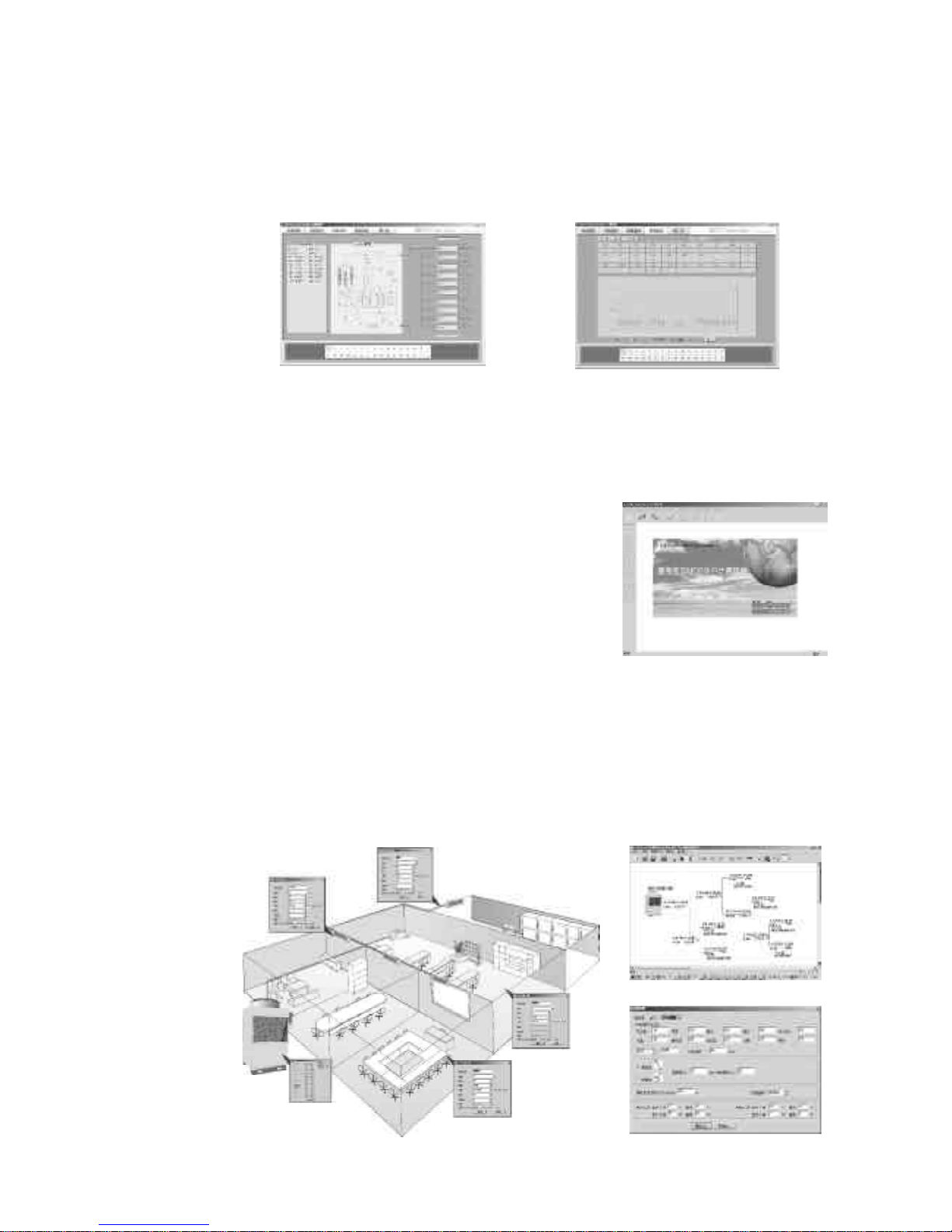

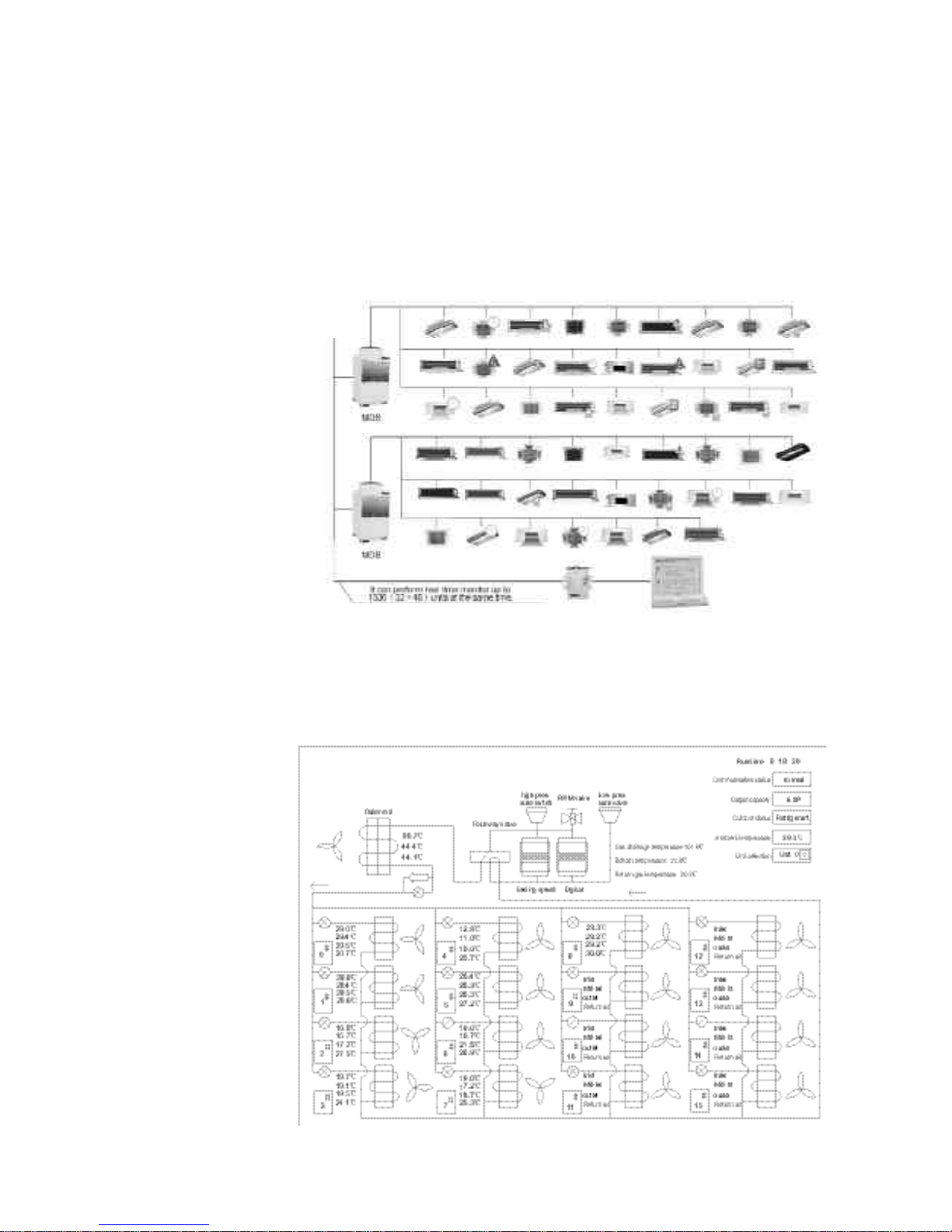

2.5 Network Central Control

■ One outdoor unit can control up to 48 indoor units, and the central controller can control up

to 32 outdoor units. The monitor software can perform the real time control up to 1536 (32*48)

units at the same time. The connection cables for outdoor and indoor units are very simple.

MDS system is equipped with strong alarm display and inquiry function to save the time and

cost of maintenance.

■ The real time monitor software of MDS is developed by McQuay and has huge performance.

It can monitor each unit in the system and set the parameter in accordance with the

requirement. It can also show the malfunction information, which can save the customer a lot

of time and money.

Page 37

-37-

Design & installation Guide For McQuay MDS Multi System

2.6 Wiring Diagram

2.6.1 Wiring diagram of the indoor unit

■ Model MCC008/010/015/018/020/025/030/040/050/060T

■ Model MCK010/015/018/020T

Page 38

-38-

Design & installation Guide For McQuay MDS Multi System

■ Model MCK025/030/040/050T

■ MCM020/030T

Page 39

-39-

Design & installation Guide For McQuay MDS Multi System

■ Model MCM050T

■ Model MDB050/060T

Page 40

-40-

Design & installation Guide For McQuay MDS Multi System

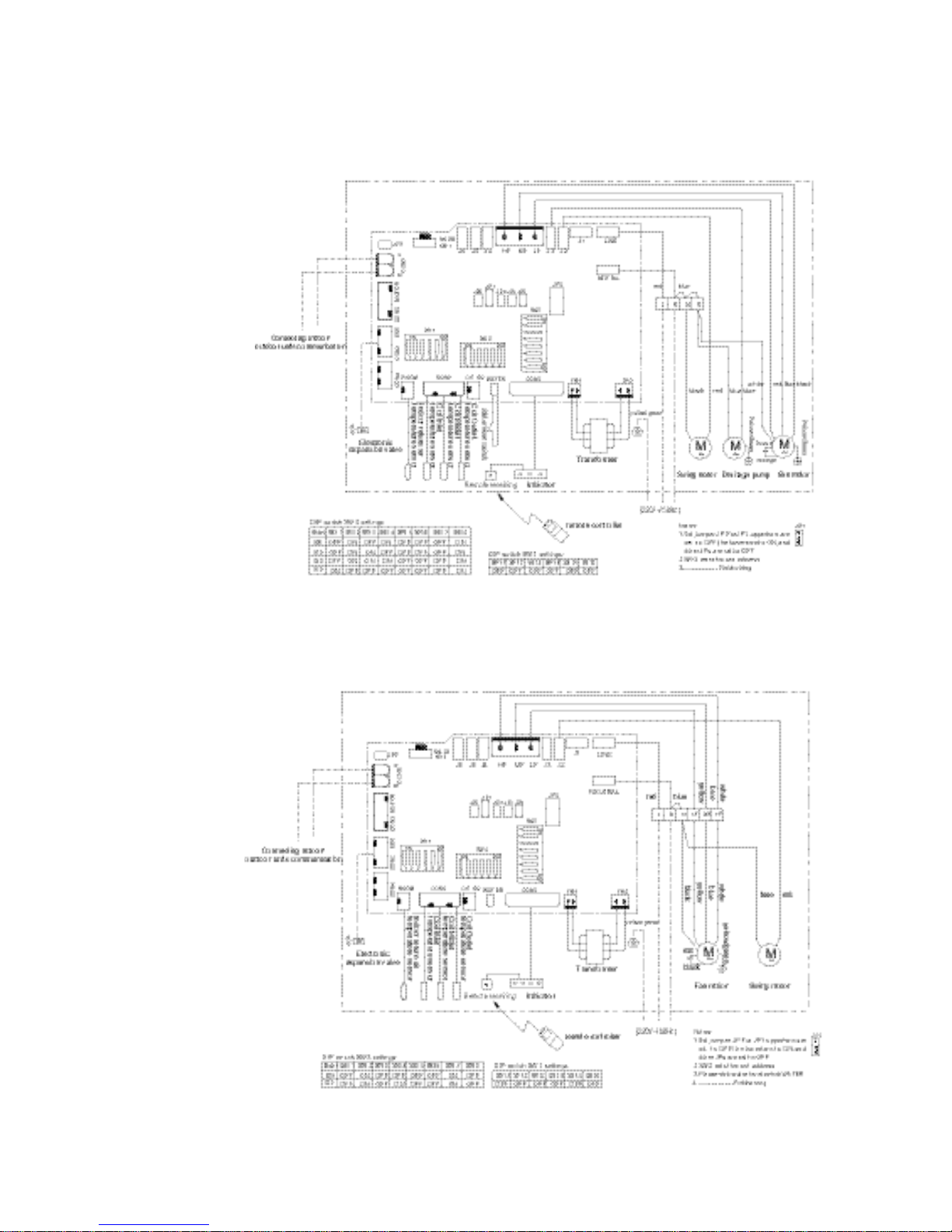

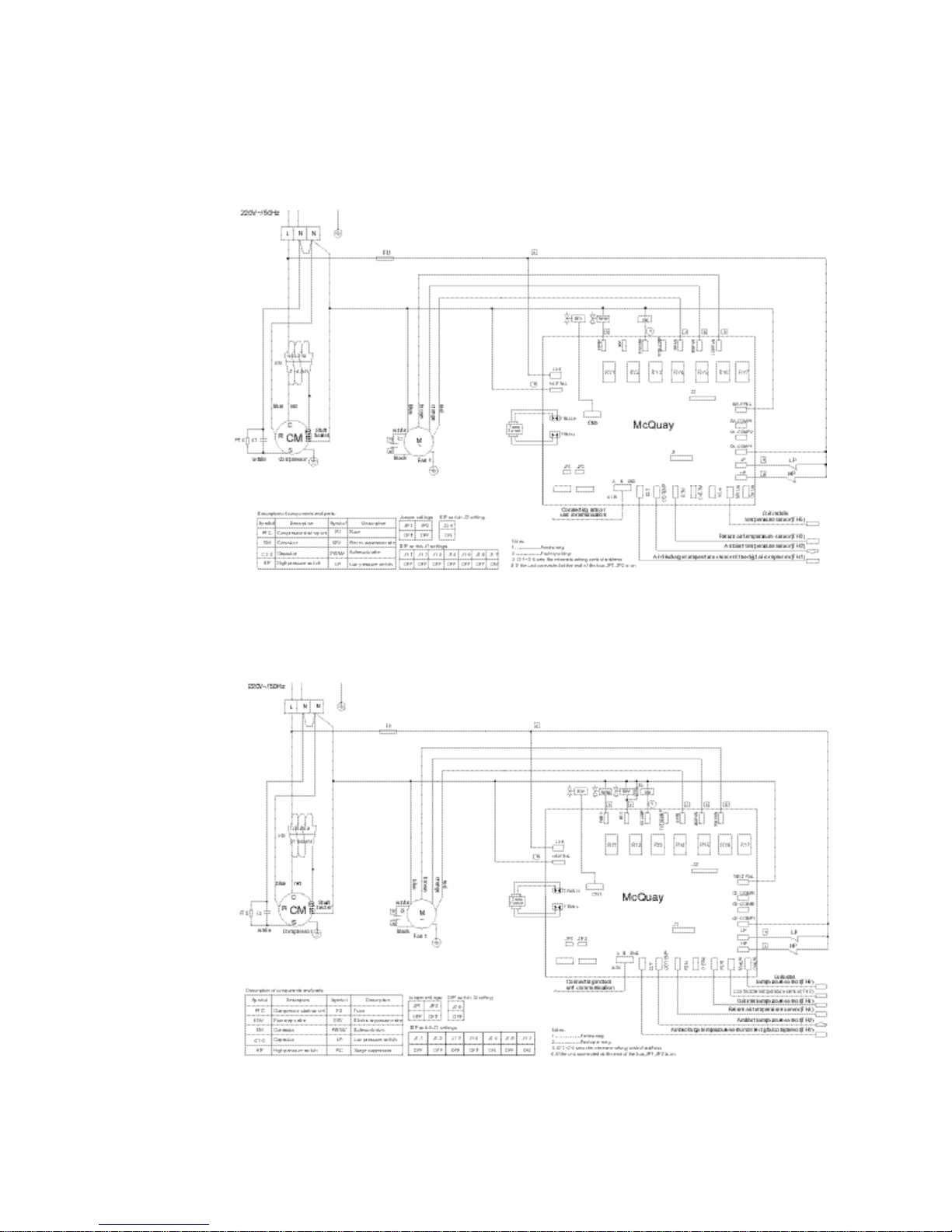

2.6.2 Wiring diagram of outdoor units

■ Model MDS030A

■ Model MDS030AR

Page 41

-41-

Design & installation Guide For McQuay MDS Multi System

■ Model MDS040AR

■ Model MDS040A

Page 42

-42-

Design & installation Guide For McQuay MDS Multi System

■ Model MDS050A

■ Model MDS050AR

Page 43

-43-

Design & installation Guide For McQuay MDS Multi System

■ Model MDS050AR

■ Model MDS060A

Page 44

-44-

Design & installation Guide For McQuay MDS Multi System

■ Model MDS060AR

■ Model MDS060AR

Page 45

-45-

Design & installation Guide For McQuay MDS Multi System

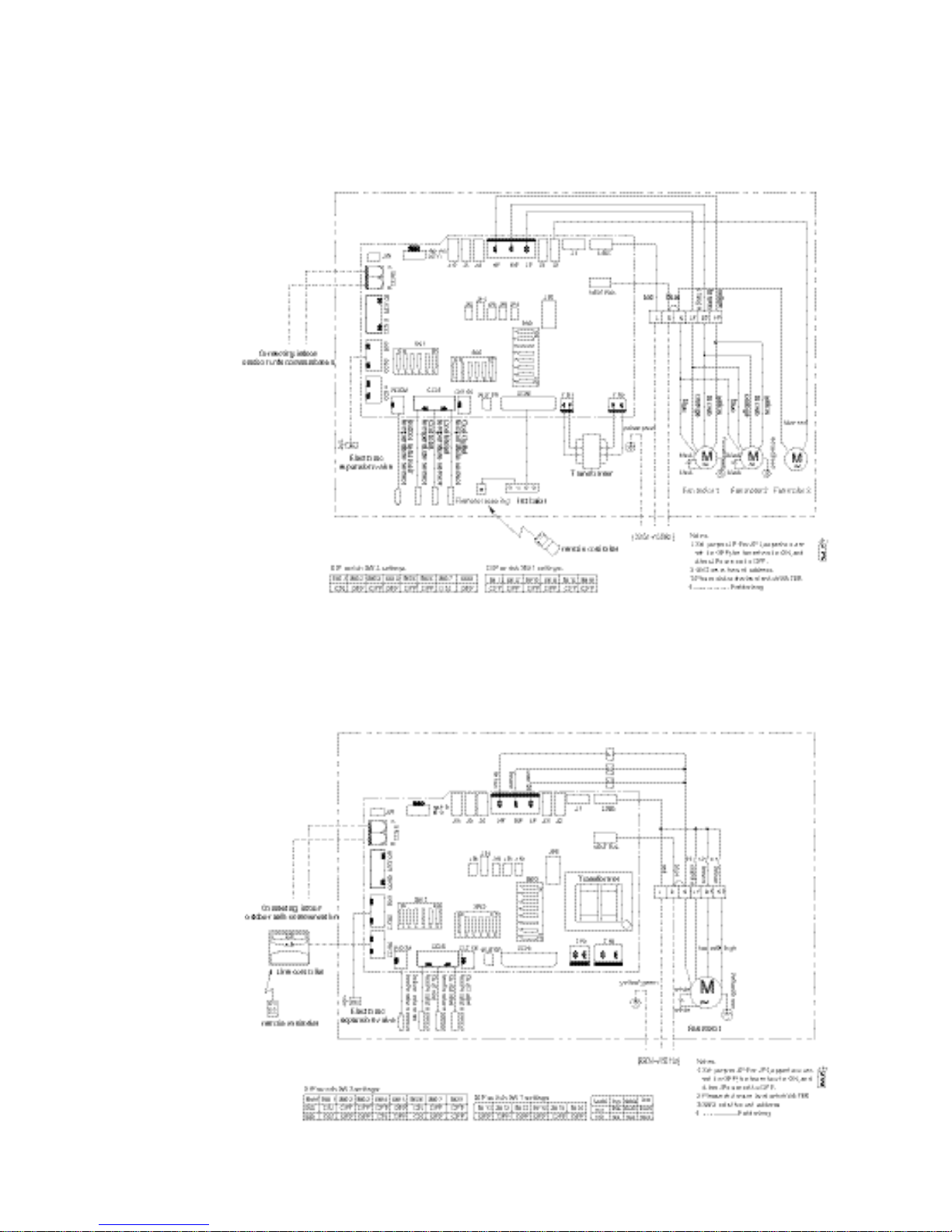

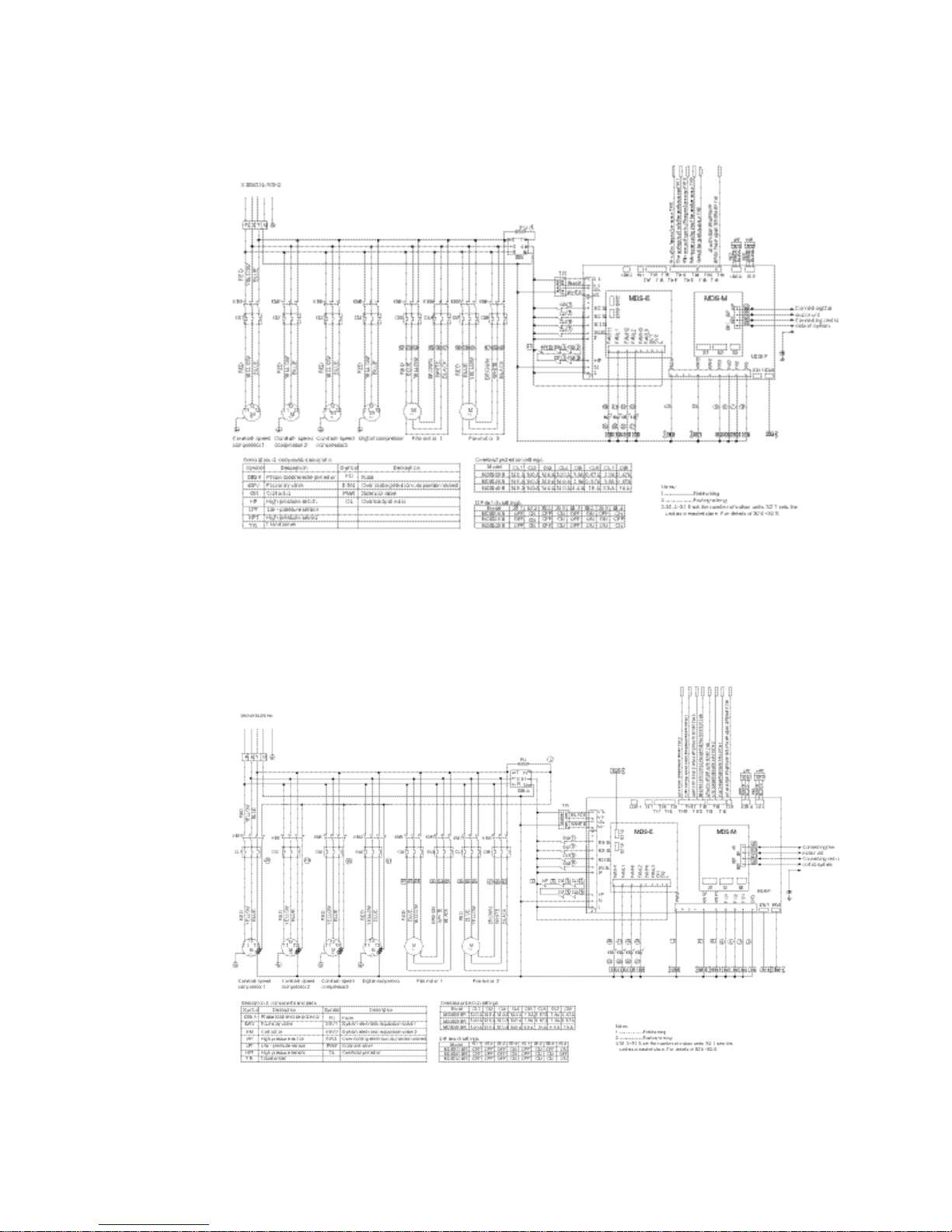

■ Model MDS080/100/120B

■ Model MDS080/100/120BR

Page 46

-46-

Design & installation Guide For McQuay MDS Multi System

■ Model MDS150B

■ Model MDS150BR

Page 47

-47-

Design & installation Guide For McQuay MDS Multi System

■ Model MDS180B

■ Model MDS180BR

Page 48

-48-

Design & installation Guide For McQuay MDS Multi System

■ Model MDS200/220/240B

■ MDS200/220/240BR

Page 49

-49-

Design & installation Guide For McQuay MDS Multi System

■ Model MDS260BR

■ Model MDS260/280/300BR

Page 50

-50-

Design & installation Guide For McQuay MDS Multi System

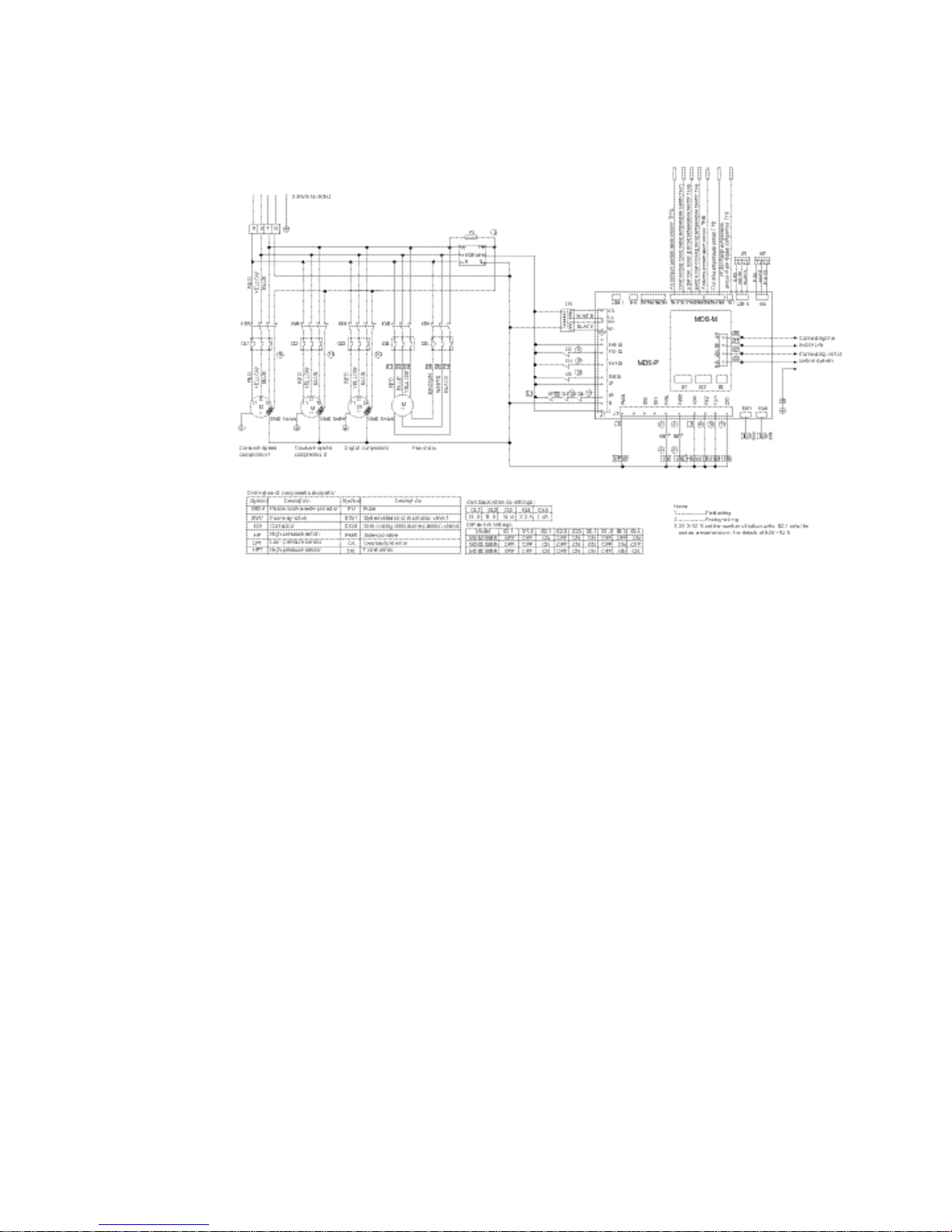

■ Model MDS280/300BR

Page 51

-51-

Design & installation Guide For McQuay MDS Multi System

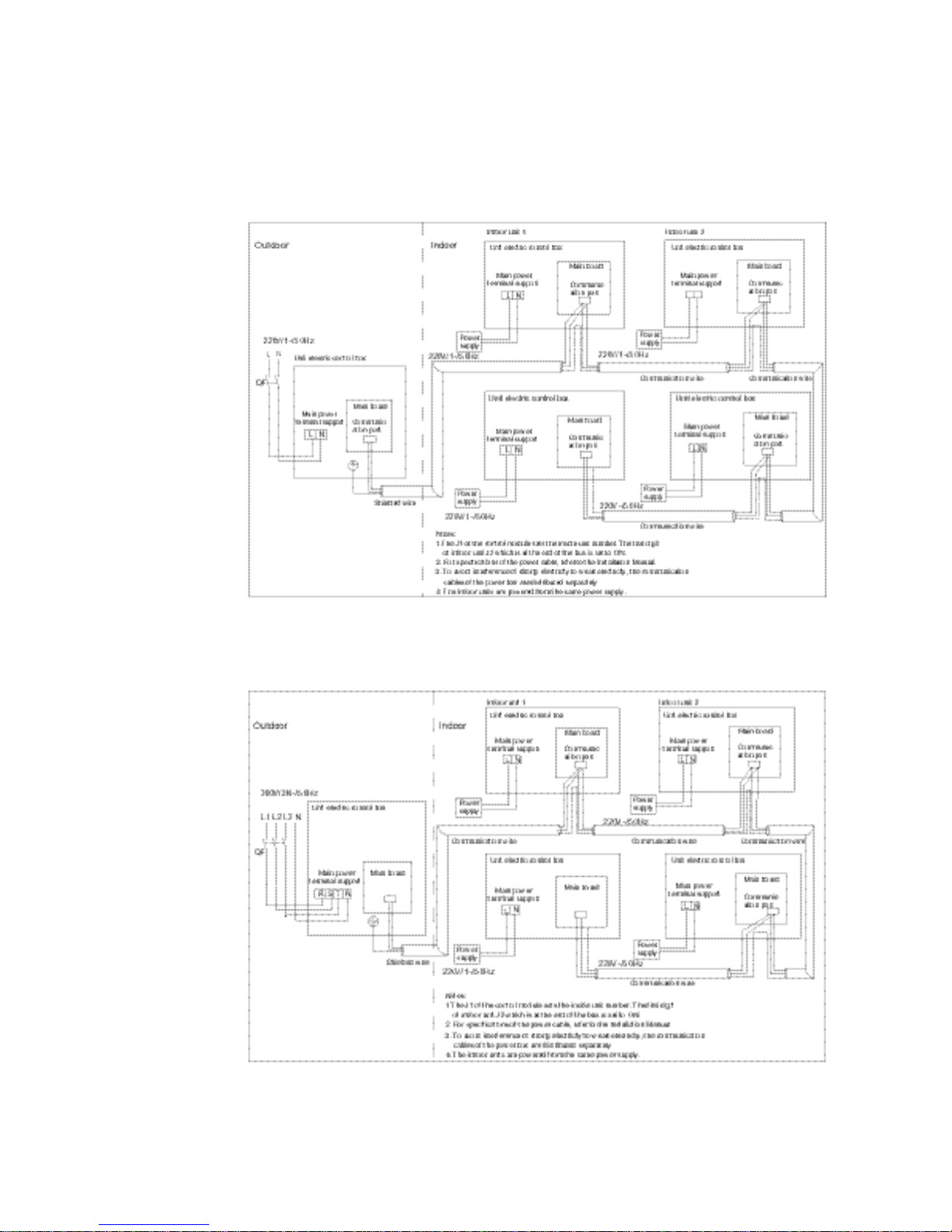

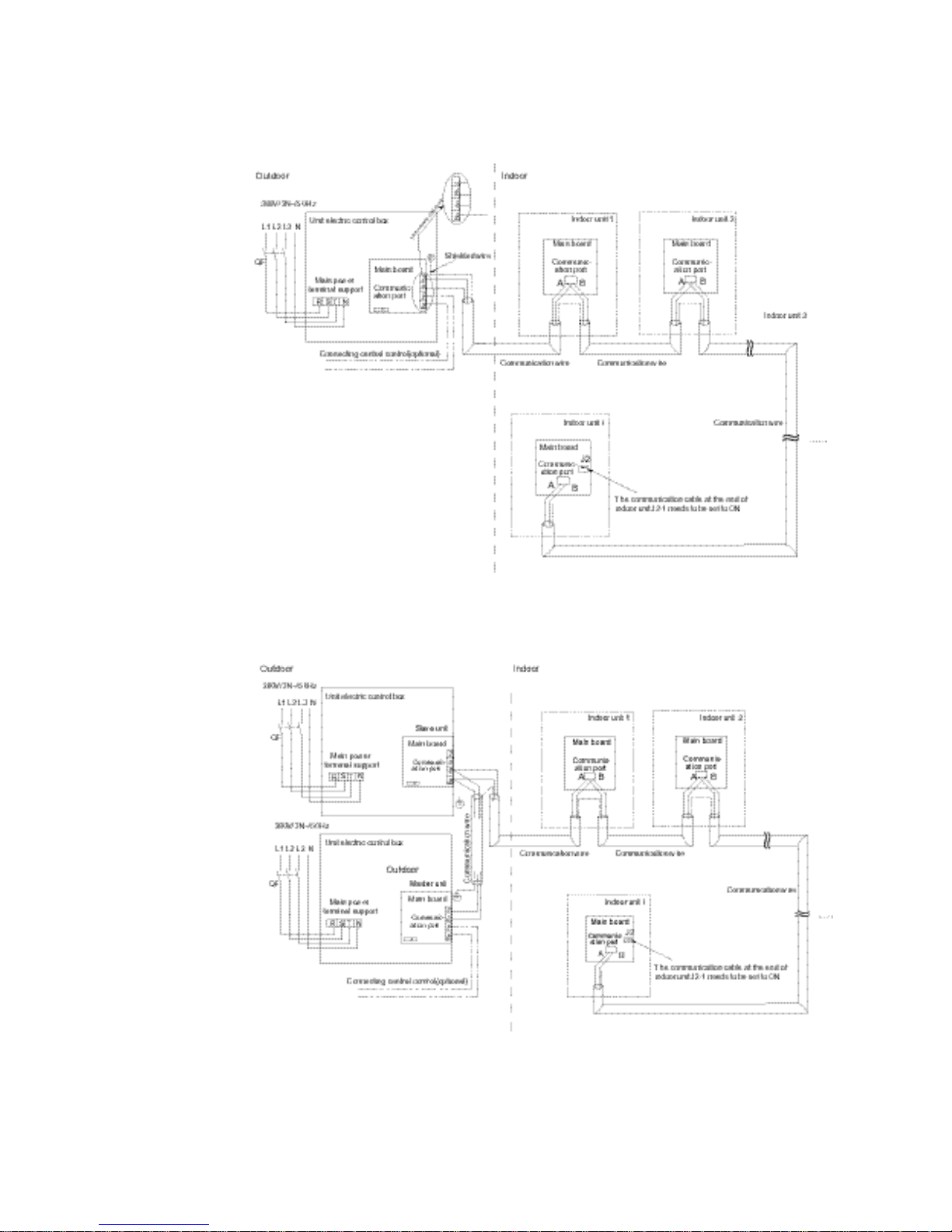

2.7.2 MDS050A/AR、MDS060A/AR

2.7 Wiring Diagram

2.7.1 MDS030A/AR、MDS040A/AR、MDS050A/AR

Page 52

-52-

Design & installation Guide For McQuay MDS Multi System

2.7.3 MDS080~240B/BR

2.7.4 MDS260~300B/BR

Page 53

-53-

Design & installation Guide For McQuay MDS Multi System

Note:

■ All the wiring should be fixed;

■ Electric wiring must not touch the refrigerant pipe, compressor and moving parts of the fan motor;

■ All wiring between indoor unit and outdoor unit should be neoprene copper core, and section area

of cable should be in accordance with above requirements.

Model MCM020T MCM030T MCM050T

Power supply 220V~/50Hz

Cross section area(mm2) 2.5

Q.T.Y 3

Power

cable

2.8.5 Indoor unit(MCM)

2.8.4 Indoor unit(MDB)

Model MDB050T MDB060T

Power supply 220V~/50Hz

Power

Cross section area(mm2) 2.5

Q.T.Y 3

cable

Model MCC025T MCC030T MCC040T MCC050T MCC060T

Power supply 220V~/50Hz

Cross section area(mm2)

2.5

Q.T.Y 3

Power

cable

Model MCC008T MCC010T MCC015T MCC018T MCC020T

Power supply 220V~/50Hz

Cross section area(mm2)

1.5 2.5

Q.T.Y 3

2.8.2 Indoor unit(MCC)

Power

cable

2.8 Electrical Date

2.8.1 Outdoor unit(MDS)

Model

MCK010T MCK150T MCK180T MCK020T MCK025T MCK030T MCK040T MCK050T

Power supply 220V~/50Hz

Power

Cross sectionarea(mm2)

1.5 2.5

Q.T.Y 3

2.8.3 Indoor unit(MCK)

cable

Model

MDS220B/ MDS240B/ MDS260B/ MDS280B/ MDS300B/

MDS220BR MDS240BR MDS260BR MDS280BR MDS300BR

Power supply 380V /3N~/50Hz

Cross section area(mm2)

10 16

Q.T.Y 5

Power

Model

MDS080B/ MDS100B/ MDS120B/ MDS150B/ MDS180B/ MDS200B/

MDS080BR MDS100BR MDS120BR MDS150BR MDS180BR MDS200BR

Power supply 380V /3N~/50Hz

Cross section area(mm2)

6 10

Q.T.Y 5

Power

cable

Model

MDS050A/MDS050AR MDS060A/MDS060AR

Power supply 380V /3N~/50Hz

Cross section area(mm2) 4(2.5)

Q.T.Y 4(1)

Power

cable

Model

MDS030A/MDS030AR MDS040A/MDS040AR MDS050A/MDS050AR MDS060A/MDS060AR

Power supply 220V~/50Hz

Cross section area(mm2)

6(2.5)

Q.T.Y 2(1)

Power

Page 54

-54-

Design & installation Guide For McQuay MDS Multi System

Selection

C H A P T E R

3

3.1 Load Calculation

3.1.1 Planning and cooperation

McQuay recommends you to estimate and plan the following information before engineering.

■ Based on the air conditional area function, calculate out the cooling/heating load (depending

on the temperature,humidity, and ventilation).

■ Query related meteorologic information, especially the sun light, wind direction in winter and

summer, the ambient cooling/heating sources, and other external factors that may affect the

running of the units. Then decide the place and azimuth to place the units based on the

environmental factors favoring the normal running of the units. For the outdoor meteorologic

parameters of each city in China, see “Appendix 1 Outdoor meteorologic parameters of major

cities in China”. However, the description about selection in this manual is only for your reference;

for actual engineering, please consult with a professional design institute or construction organ in

this area.

■ Make the project schedule, plan the installation space of the unit, and adjust the engineering

associated with the constructional engineering and inside finishing.

■ Through field survey, ascertain the size of the entrance for the air conditioner, the weight

capacity of the place to put or hang the equipment, the range of the auxiliary engineering, and

the location of the power supply.

■ Check and verify the figures of the design. Confirm or decide the specifications and the unit model.

3.1.2 Cooling load calculation

■ The cooling load of the air conditioning area is decided by the real-time maximum cooling load

or accumulated calculated cooling load of each room based on the area, height, and usage of

the room serviced. It is also affected by the additional cooling load caused by the ventilator

blower, the exhauster, and the air pipe system. In practice, it is calculated as follows:

Q

total

= F1q1 + F2q2+… + Fnq

n

Where,

F1 is the air conditioning area of each calculated unit. Its unit is m2.

q1 is the cooling load per unit area of each calculated unit. Its unit is W/m

2

■ Appendix 2 lists out the estimated indexes and design parameters for different buildings for

your reference.

3.1.3 Heating load calculation

■ The heating load of the air conditioning system is closely related with the heat insulation performance

of the walls, doors and windows, and roof. It is also affected by the penetration of cool wind from

outdoors, open frequency of the outside door, and the use of the indoor appliances. It is calculated

basically in the same way as the cooling load. If the heating load per unit area of the

building qF is known (see Appendix 2), the heating load of the building is as follows:

Q = Fq

F

Where,

F is the construction area. Its unit is m

2

Page 55

-55-

Design & installation Guide For McQuay MDS Multi System

■ If we know the heat performance index qv[W/(m3 . ℃)] and outside volume V (m3), we can calculate the

heating load

as follows:

Q

total

= aqvV( tn– tw)

Where,

a is the correction factor. For details, see the table.

qv is the heat performance index of the building. It is the heating load when the difference between the

indoor temperature and the outdoor temperature is 1℃. For details, see the table.

V is the outside volume of the building. Its unit is m2.

(tn – tw) is the calculated difference between the indoor and outdoor temperatures. Its unit is℃.

Heating correction factor a:

Heating outdoor temperature(℃) a Heating outdoor temperature(℃) a

0 2.05 -25 1.08

-5 1.67 -30 1.00

-10 1.45 -35 0.95

-15 1.29 -40 0.9

-20 1.17

【Notes】

■ During selection, you must consider the attenuation of the following factors to the cooling and heating effects: 1)

the length of the pipe connecting the indoor unit and outdoor unit; 2) the difference between the actual

temperatures of the indoor and outdoor units and the rated working temperatures of the MDS for cooling/heating.

■ If the heating pump system is selected according to the cooling load, you must verify its heating capacity. Especially

for areas north to Yellow River, inadequate heating capacity must be compensated

with a model with an auxiliary electric heater or hot-water heater.

■ The MDS unit is designed following GB/T 18837-2002. There is a negative difference between the actual cooling

capacity and the rated capacity, about 5%. Therefore, you must pay enough attention to this factor and keep the cooling

capacity a certain security level.

Heat performance index of the building

Building type V (103 m3) qvW/m3℃ tn(℃)

Building type

V(103 m3) qv W/m3℃ tn(℃)

≤5 0.6 5~10 3.38

Office 5~10 0.53 18 Workshop 11~20 2.73 14

building 11~15 0.49 21~30 2.04

>15 0.56 > 31 1.45

≤5 0.72 ≤ 0.5 2.30

Club 5~10 0.65 16 Equipment 0.6~1.0 0.82 12

>11 0.58 room 1.1~2.0 0.71

>2.1 0.50

≤5 0.81 ≤ 0.5 0.83

Hospital 6~10 0.75 20 0.6~1.0 0.72 18

11~15 0.67

Auxiliary room

1.1~2.0 0.56

>16 0.64 > 2.1 0.51

≤5 0.92

6

~10 0.82 ≤ 2.0 0.72

Cinema 11~15 0.79 14 Engine 2.1~5.1 0.63 15

16~20 0.70 house

>5.1 0.60

21~30 0.65

>31 0.61

≤5 1.22 ≤ 5.0 1.49

Public area 6~10 1.14 14 Bathroom 5.1~10.0 1.38 25

>11 1.05 > 10 1.25

Page 56

-56-

Design & installation Guide For McQuay MDS Multi System

3.2 Indoor unit selection

■ The selection of indoor unit should be based on the several factors, including customer ’s

requirement, indoor air distribution, indoor decoration, etc. Ceiling concealed, ceiling cassette,

high pressure duct unit and ceiling exposed are available now.

■ The indoor unit should be selected to meet the actual indoor load demand. The nominal

cooling capacity should be is more than or equal to the actual indoor load demand.

■ As the indoor total capacity is different from the outdoor total capacity, the actual indoor

cooling capacity may be different from the nominal capacity, and it should be calculated in

accordance with the outdoor capacity table.

3.2.1 The selection of ceiling concealed and duct unit

For ceiling concealed and duct unit, McQuay has several types such as standard unit, auxiliary

electric heater, auxiliary hot water heater, etc.

■ The selection is based on the following factors:

● Cooling capacity/ heating capacity

● Auxiliary heater capacity ( optional )

● Air flow

● External static pressure

● Dimension

● Power supply and others.

■ Selection step

● Select the type of the indoor unit:

1. Are the units Ceiling concealed, ceiling cassette, high pressure duct unit or ceiling

exposed ?

2. Are the units cooling only, heat pump, auxiliary electric heater or auxiliary hot water heater?

● Calculate the cooling capacity and heating capacity

● Confirm the model and the quantity

● According to the cooling capacity, heating capacity, return air temp, ambient temp, humidify

and air flow, we can choose the model and confirm the quantity.

● The ESP of the unit can be confirmed according to the air flow and the duct parameter.

● Confirm the heating capacity. If the unit selected can meet the heating requirement, then it

is OK, but if can not, then we should select auxiliary hot water heater or auxiliary electric

heater.

● For the cooling only unit, the actual total cooling capacity can be gotten through the following

formula: Actual total cooling capacity = actual capacity x QTY

● For the heating only unit, the actual total heating capacity can be gotten through the

following formula: Actual total heating capacity = actual capacity x QTY + ( auxiliary heating capacity )

● The best selection is that both the cooling capacity and the cooling capacity can meet the

requirement. Please note that the nominal cooling capacity and the nominal heating capacity

is obtained in the standard condition. When the units run in nonstandard condition, the actual

cooling capacity and the actual heating capacity are different from the nominal cooling

capacity and the nominal heating capacity.

Page 57

-57-

Design & installation Guide For McQuay MDS Multi System

3.3 Selection of Outdoor Units

For the combinations allowed, please refer to the "Indoor unit total capacity indexes” table.

The standard combination is the one with which the total indoor unit capacity is most proximate

to but less than 100% of the capacity of the outdoor unit combination.

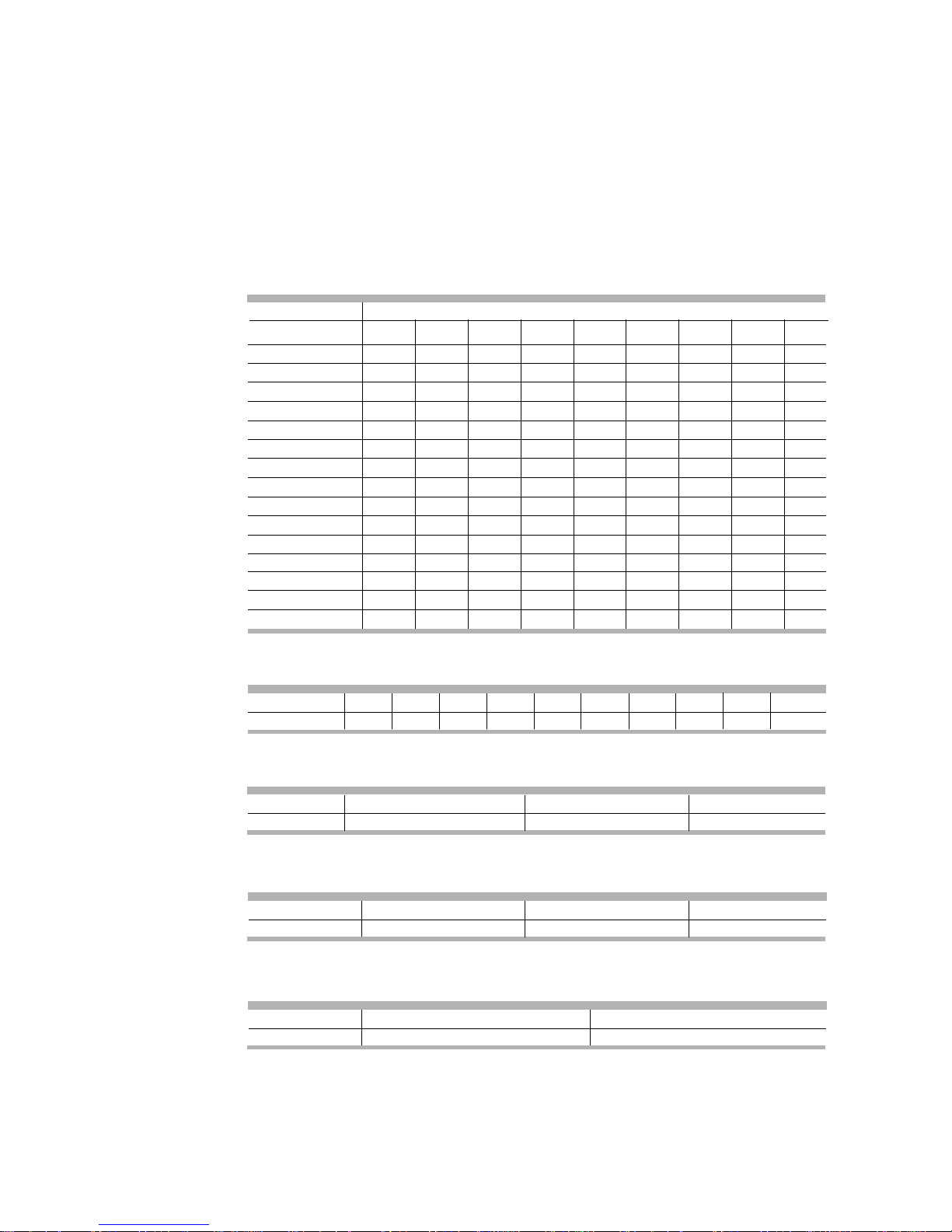

3.3.1 Capacity indexes of outdoor units

3.3.5 Capacity indexes of indoor unit (MDB)

Unit spec 050 060

Capacity index 125 140

3.3.3 Capacity indexes of indoor unit (MCK)

Unit spec 010 015 018 020 025 030 040 050

Capacity index 28 36 45 54 65 75 100 125

3.3.4 Capacity indexes of indoor unit (MCM)

Unit spec 020 030 050

Capacity index 58 75 125

130% 120% 110% 100% 90% 80% 70% 60% 50%

MDS030A(R) 111 102 94 85 77 68 60 51 43

MDS040A(R) 130 120 110 100 90 80 70 60 50

MDS050A(R) 163 150 138 125 113 100 88 75 63

MDS060A(R) 195 180 165 150 135 120 105 90 75

MDS080B(R) 319 294 270 245 221 196 172 147 123

MDS100B(R) 364 336 308 280 252 224 196 168 140

MDS120B(R) 423 390 358 325 293 260 228 195 163

MDS150B(R) 520 480 440 400 360 320 280 240 200

MDS180B(R) 618 570 523 475 428 380 333 285 238

MDS200B(R) 650 600 550 500 450 400 350 300 250

MDS220B(R) 715 660 605 550 495 440 385 330 275

MDS240B(R) 845 780 715 650 585 520 455 390 325

MDS260B(R) 910 840 770 700 630 560 490 420 350

MDS280B(R) 975 900 825 750 675 600 525 450 375

MDS300B(R) 1040 960 880 800 720 640 560 480 400

Indoor unit combination rate

Outdoor unit

3.3.2 Capacity indexes of indoor unit (MCC)

Unit spec 008 010 015 018 020 025 030 040 050 060

Capacity index 20 25 37 45 56 65 78 106 124 144

Page 58

-58-

Design & installation Guide For McQuay MDS Multi System

3.3.6 Actual capacity calculation

■ Based on the model and combination rate of the outdoor unit, select an appropriate door unit

capacity table. Then find out the capacity of the outdoor unit (kW) and that of each indoor unit

(kW) according to the rated temperatures of the indoor and outdoor units. The formula is as

follows:

IUC=OUC x (INX/TNX)

Where,

IUC is the actual capacity of each indoor unit.

OUC is the capacity of the outdoor unit. Its unit is kW.

INX is the capacity index of each indoor unit.

TNX is the total capacity index.

■ The capacity of indoor units changes with the length of the refrigerant pipe. If the capacity after

change is less than the load, replace the unit with one with larger capacity and calculate

and select the model again.

3.3.7 Change of cooling capacity (3-30HP)

■ Read the performance correction factor of the refrigerant pipe length and height drop from the

figure. When the height drop is negative, the outdoor unit is installed below the indoor unit.

■ If there is snow on the heat exchanger or the outdoor temperature drops to 7℃~-5℃ when the

air conditioning system is heating, frosting occurs. As this will reduce the heating performance,

the air conditioner will automatically defrost once every 40 min to 70 min. During the defrosting,

the air conditioner will stop heating and the fan of the indoor unit will also stop for three to

ten minutes.

■ The heating capacity tables of outdoor and indoor units do not reflect the reduction of performance

caused by defrosting.

3.3.8 Change of heating capacity (3-30HP)

Page 59

-59-

Design & installation Guide For McQuay MDS Multi System

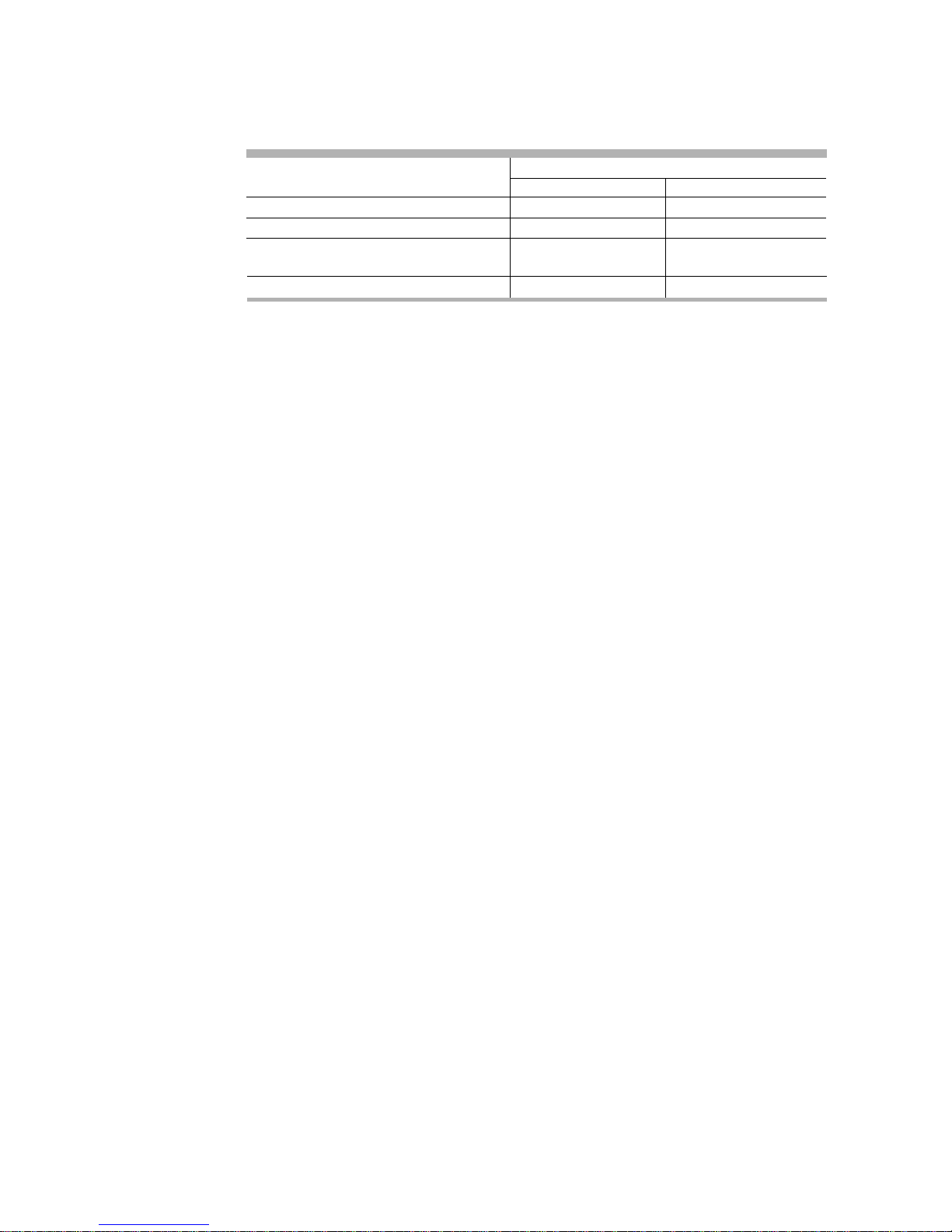

3.3.10 Temperature-related heating capacity correction factors

3.3.9 Temperature-related cooling capacity correction factors

Page 60

-60-

Design & installation Guide For McQuay MDS Multi System

3.4 Design of Air System

The air cooled pipeline unit is an important and complex part of the air system. The air system

must be designed in compliance with Design Code for Heating, Ventilation and Air Conditioning and

Code of Design on Building Fire Protection.

The air pipe diameter, processing, air outlet, muffling static pressure box, fire protection valve,

insulation and indoor airflow layout must be designed professionally and well implemented, so as to

achieve an ideal effect of comfortableness and energy saving. The following information or data is a

reference for users to design.

3.4.1 Design of the input air, air pipe and air outlet

The air should be supplied to the indoor space in a volume corresponding to the load at a most

comfortable speed, so as to achieve comfort air conditioning.

■ Air outlet design & calculation

● Air supply is to supply cool/hot air to a room or specified air conditioning area, and to mix the

indoor air and supply airflow to the room temperature.

● The direction and guiding force of the air outlet vary with the outlet shape and type. Select

according to the use purpose.

● Determine the volume and arrival distance of air supply from a single outlet according to the

para-meters in the product catalog. Select the air outlet and return outlet type that matches

the ceiling pattern according to the room shape. In addition, the relationship between air

speed and noise should be considered to determine the outlet air speed. Annex 3 is for your

reference only.

■ Air outlet selection

In the designing of the air-flow pattern, determine the type of the air outlet according to air

conditioning accuracy, air-flow type, air outlet installation position and construction fit-up art.

● Common types of the air outlet

◆ Side air outlet

The shutter air outlet is generally used. The shutter can be louver shutter through which the air flow

and direction can be adjusted. Besides, grille air outlet and slotted air outlet are also used. These

two outlets can well match with the construction decoration.

◆ Air diffuser

The air diffuser is the air outlet installed in the ceiling, supplying air flow from top to bottom.

◆ Orifice plate air outlet

The orifice plate air outlet features even air supply and fast air flow attenuation. It applies to the

room where even air flow and little temperature difference are needed.

◆ Jet air outlet

The jet air outlet features long range and low noise. It applies to large public buildings, such as

gymnasium and cinema.

◆ Whirl air outlet

The whirl air outlet features good mixture of supplied air and indoor air and fast speed attenuation.

It applies to the floor air supply in the electronic computer room.

■ Air flow pattern

No. Range Advantages and disadvantages

Return air flow pattern

Side air supply

upper air return

Upper air supply

upper air return

Side air supply

side air return

The room with low floor height

The room with low floor

height or large depth

The room with high floor height

and only for cooling in Summer

Staffs are in the return air flow area, the fan coil of the unit does

occupy the indoor space in the corridor, and the air vent can be

adjusted freely.But, short-flow may occur easily.

Staffs are in the return air flow area, need for little or no space, and

the air vent can be adjusted freely. But, the exposed ceiling in the

room has two difference heights or there are two exposed ceilings.

The fan coil of air pipe in the exposed ceiling makes the fit-up

easy. But, higher floor height is required and certain exposed

ceiling space is occupied.

1

2

3

Page 61

-61-

Design & installation Guide For McQuay MDS Multi System

3.4.2 Calculation of the air pipe resistance

The air resistance in the air outlet and return air inlet cause pressure loss when the air pipe is

being used, and the unit can supply air only when it overcomes the resistance. It is equal to the air

pressure of the unit with pressure loss, that is, exterior static pressure (ESP).

The pipe resistance must be equal to the ESP. Otherwise, or the air volume will be too large or

small causing the unit faulty.

To determine the ESP of the unit, get the whole-static pressure of the air pipe. In this case, it is

generally required to calculate the static pressure loss at the farthest point of the air pipe or the

maximum static pressure.

■ Calculation method of the air pipe resistance

● Preliminary determination of the air pipe resistance:

Air pipe resistance=RmL(1+K) (Pa)

Rm=0.8~1.5Pa/m

L: Total length of the air pipe with the loop of most resistance, m

K: Ratio of local resistance loss to frictional resistance. If there are few local components,

k=1~2; if there are many local components, k=3~5

● Draw the ventilation system diagram, mark the air flow by segment and number each pipe

segment.

● Assume the air speed (refer to annex 4), and calculate the cross-section dimension and the

pipe diameter.

The conflux of the return air inlet brings little affect on the air flow pattern in the room. So, its structure

is simple. Some only have a metal mesh in the orifice, or a shutter or grille.

● The return air inlet location and shape depend on the air flow pattern. If it is installed in the lower area

of the room, the lower edge of the inlet must be at least 0.15 m away from the ground.

● The return air inlet structure may be simple, but should be equipped with air volume adjustment device.

■ Size of the air outlet

Determine the air volume and type of a single air outlet according to the number of air outlets to be

installed and the volume requirements in the room where the air conditioner will be installed. Make sure

there is no overlapping between the set air volume and the minimum diffusion radius, and the maximum

diffusion radius covers the whole room. In addition, check whether the vertical arrival distance is

adequate, and determine the air speed in the air outlet at the acceptable noise level.

Air flow pattern diagram

Air flow pattern diagram

Page 62

-62-

Design & installation Guide For McQuay MDS Multi System

● Check the air speed according to the actual pipe diameter, and calculate the actual speed, which

should not larger than the recommended value in the design manual.

● Select the loop of most resistance and that of minimum resistance, and then calculate the

frictional resistance and local resistance loss of each pipe segment.

● Check the unbalance ratio of the loop of most resistance to that of minimum resistance must be

less than 15%. Otherwise, redesign the air pipe system, or satisfy the balance ratio requirements by adjusting with the valve.

3.4.3 Air pipe design

To improve the operational efficiency of air conditioning, carefully consider and fully install such

fittings as material, adjustment valve and fire protection valve.

■ Material of the air pipe

The air pipe is always made from metal material, such as sheet steel, galvanized sheet or aluminum

sheet. It also can be made from non-metal material, such as hard polyvinyl chloride, glass reinforced

plastic or other composite materials. The air pipe in the construction space or duct channel also can

be used according to the actual conditions. The air pipe surface should be polished, straight and

smooth. Some air pipes should even be painted. The air duct channel should be waterproofed. The

air pipe in the room with corros ive gas may be made from glass reinforced plastic or plastics and

tightly sealed.

■ Air pipe shape

● The cross-section of the air pipe is generally rectangle or round. It also can be designed to ellipse,

semicircle or spiral.

● The round air pipe has the advantages of high strength and low material loss, but it occupies large

useful space and its elbow and tee should be of long distance. Generally, the flexible round air pipe

is used for the new air pipe, small volume air refnet joint (such as in toilet with small area).

● The rectangle air pipe occupies small space, and is easy to install and neat for surface mounting. It

has been widely applied.

● For the convenience of mechanical processing of the air pipe and flange and configuring

standard valves, try to improve the utilization of the air pipe cross section. The air pipe

dimension should be designed according to Calculation Form of National Universal Air pipe.

The ratio of the height of the rectangle air pipe to its width should be less than 4, based on the

outer diameter or length of external sides. The following table shows the standard specifications of the air pipe.

Specifications of the round air pipe

Diameter of the air pipe

Basic series Auxiliary series Basic series Auxiliary series Basic series Auxiliary series

100 80/90 320 300 900 850

120 110 360 340 1000 950

140 130 400 380 1120 1060

160 150 450 420 1250 1180

180 170 500 480 1400 1320

200 190 560 530 1600 1500

220 210 630 600 1800 1700

250 240 700 670 2000 1900

280 260 800 750

The high-speed air pipe is generally round spiral pipe with a larger thickness.

unit: mm

Side size of the air pipe

120 320 800 2000 3000

160 400 1000 2200 3500

200 500 1250 2500 4000

250 630 1600 2800

Specifications of the rectangle air pipe

unit: mm

Page 63

-63-

Design & installation Guide For McQuay MDS Multi System

■ Reinforcement of the air pipe

Generally, the air pipe is reinforced through using the ridge web and ridge lines, or adding flanges

or reinforcing frames. Strictly follow the newest national standard Ventilation and Air Condition-

ing Engineering and Acceptance Standard when making and installing the pipes.

■ Accessories of the air system

The air system has following accessories: air outlet/return air inlet, outside rainproof shutter, air

flow adjusting valve, smoke discharge & fireproof valve, and air deflector. The smoke discharge

& fireproof valve must be tested before installed. The surface of the air outlet and the return air

inlet must be smooth and even. The size of the neck part must be within the allowed deviation

range so that it can engage with the air pipe tightly. The entire air conditioning system, including

all the accessories, should be firm and tight, and, after installed, it should be pass the light

leakage or air leakage acceptance check for a low-pressure air pipe system.

■ Heat insulation of the air system

The heat insulating layer of the air pipe system should also be non-flammable. Generally, it is 25

mm thick if it is PE materials, or at least 35 mm when consisting of common glass cotton. This

layer should be even, dense, closely attached to the air pipe and its accessories, and without cold

bridges. It should also be well protected against scratch.

■ Design and calculation of fresh air flow

The fresh air volume mainly depends on the health requirements, the supplementary local air exhaust

volume, and therequirement to guarantee the air conditioned room in “positive pressure”.

■ Health requirements

Generally, in both the country and the city, the content of carbon dioxide outdoor is 0.5–0.75 g/

kg. According to the allowed density of this gas (see the following table), you can use the overall

ventilation volume defined in the Industrial Ventilation to calculate the volume of fresh air needed

to eliminate it.

■ Elbow

The rectangular air pipe can be inner-arc or inner-slanting, as shown in Figure 4-2. When the

longest side is 500 mm or longer, a flow deflector must be used.

■ Wall thickness of the air pipe

The wall thickness directly relates to the effect and life of the pipe. A too thin wall will cause

unstable installation, and thus the pipe will sway within a large range to increase the noise. Even

worse, the friction might compound the problem, shortening the service life of the air pipe or even

the entire air conditioning system.

Air pipe elbow

≤320 340~450 480~630 670~1000 1120~1250 1320~2000

Low-speed air pipe 0.5 0.6 0.8 1.0 1.2

High-speed air pipe 0.8 0.8 0.8 1.0 1.2

Round air pipe 0.5 0.6 0.8 1.0 1.2

Connection mode Insertion Flange

Unit: mmRecommended thickness of steel air pipes and accessories

Diameter of round air pipe or

length of the longest side of rectangular air pipe

Rectangular

air pipe

Page 64

-64-

Design & installation Guide For McQuay MDS Multi System

Acceptable (CO2) density

Room type

Acceptable CO2 density

L/m

3

g/kg

Place where people stay for a long time 1 1.5

Place where children and patients stay 0.7 1.0

Place where people stay

1.25 1.75

regularly (governmentagency)

Place where people stay for a short time

2 3.0

In actual practice, the fresh air volume is generally 30 m2/h person or more, no matter how much

room space a person occupies.

For densely populated buildings, such as air conditioned gymnasiums and meeting rooms, as the

room space per capita is less and every one stays shorter, the fresh air volume can be calculated on

a basis of 7–15 m2/h.person. However, as the fresh air volume got by this way will count for 30% to

40% of the total air volume and it will greatly affect the cooling capacity, you need to be careful in

deciding it.

● Supplementary of air discharge

When the air conditioned room has an exhaust system, the air conditioning system must have

corresponding fresh air volume to complement the exhaust volume. Generally, it is recommended to use an exhaust volume that is 80% of the fresh air volume for comfortable air

conditioning.

● Keeping the air conditioned room in “positive pressure”

To prevent outside air (those from outdoor and adjacent rooms with less strict air conditioning

requirements) from penetrating the room and affecting the temperature/humidity or the

cleanness of the air conditioned room, the air conditioning system needs to use a certain

volume of fresh air to keep the room in “positive pressure”, that is, the atmospheric pressure

of the room is higher than that of outside). Generally, the indoor positive pressure is 5–10 Pa.

Too high positive pressure not only is a waste, but also makes the system run less costeffectively. In actual engineering design, the fresh air flow should count for 10% or more of the

total inlet to guarantee the air is healthy and comfortable.

■ Introduction of fresh air

● The inlet of fresh air should be at a clean place outdoor. It should be away from the air discharge

outlet and leeward to smoke, dust, and other harmful and toxic sources.

● To keep out dust, the fresh air inlet should be at least 2m above the ground, or 1m above the

ground if it is placed in a green belt.

● To introduce less hot air from outdoor in the summer, the inlet should be placed at the shade side

of the building.Generally, it is placed on the northern wall, not at the roof or on the west wall.

● Configure waterproof shutters, metal web, and air flow adjustment valves to fresh air inlet if

necessary.

● To guarantee the quality and of the introduced fresh air and the ambient temperature, do not place

the fresh air inlet near to the outdoor unit which has a condenser or put it near to the exhaust

outlet.

● Generally, the size of the fresh air inlet depends on the air volume and air speed. For the air speed,

refer to Appendix 4.

【Note】

For heat pump unit, you should consider the effects of layer height to the air conditioning effects. When the layer

height is 3m or more, you should select an appropriate air inlet to improve the air flow organization and the blownin air flow.

Page 65

-65-

Design & installation Guide For McQuay MDS Multi System

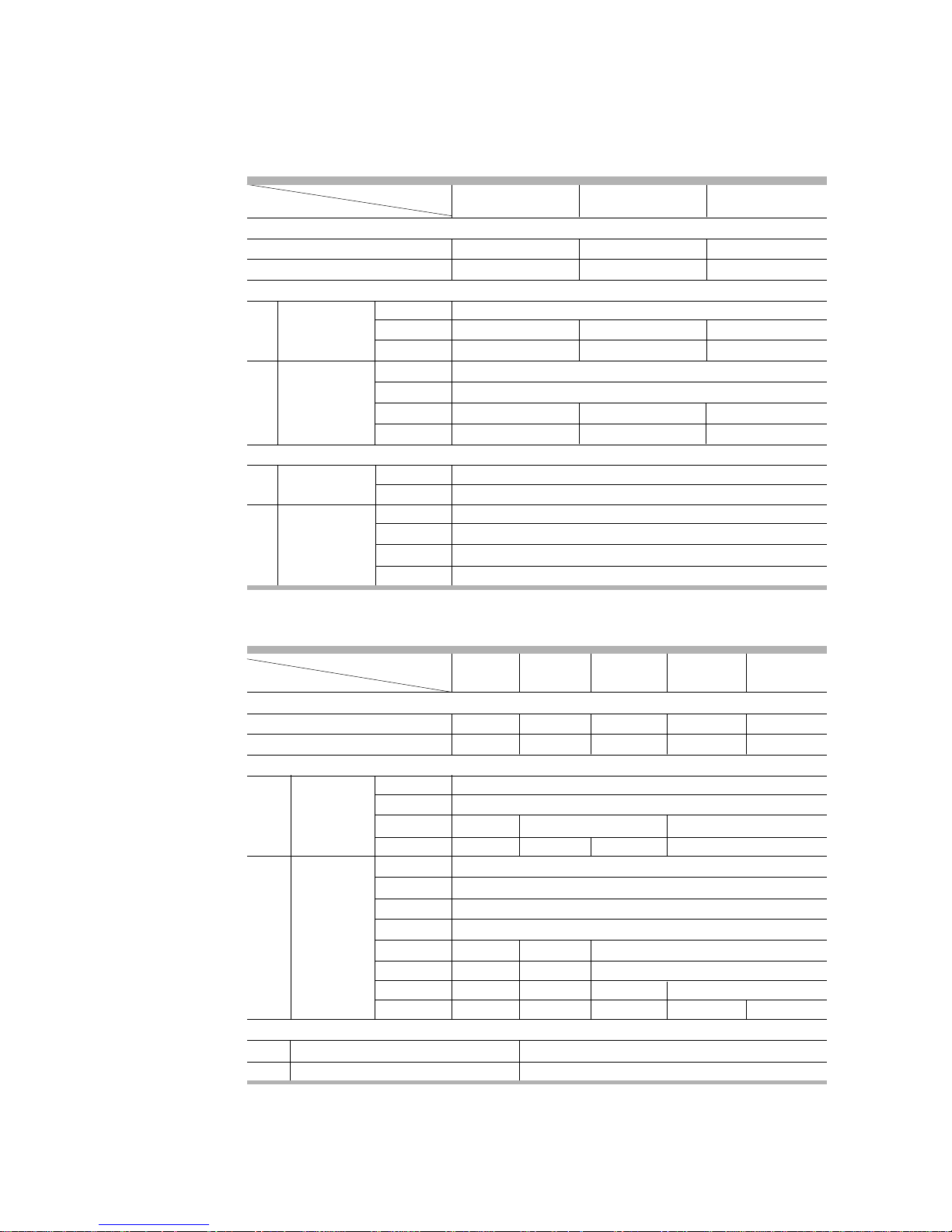

3.5 Refnet joint selection

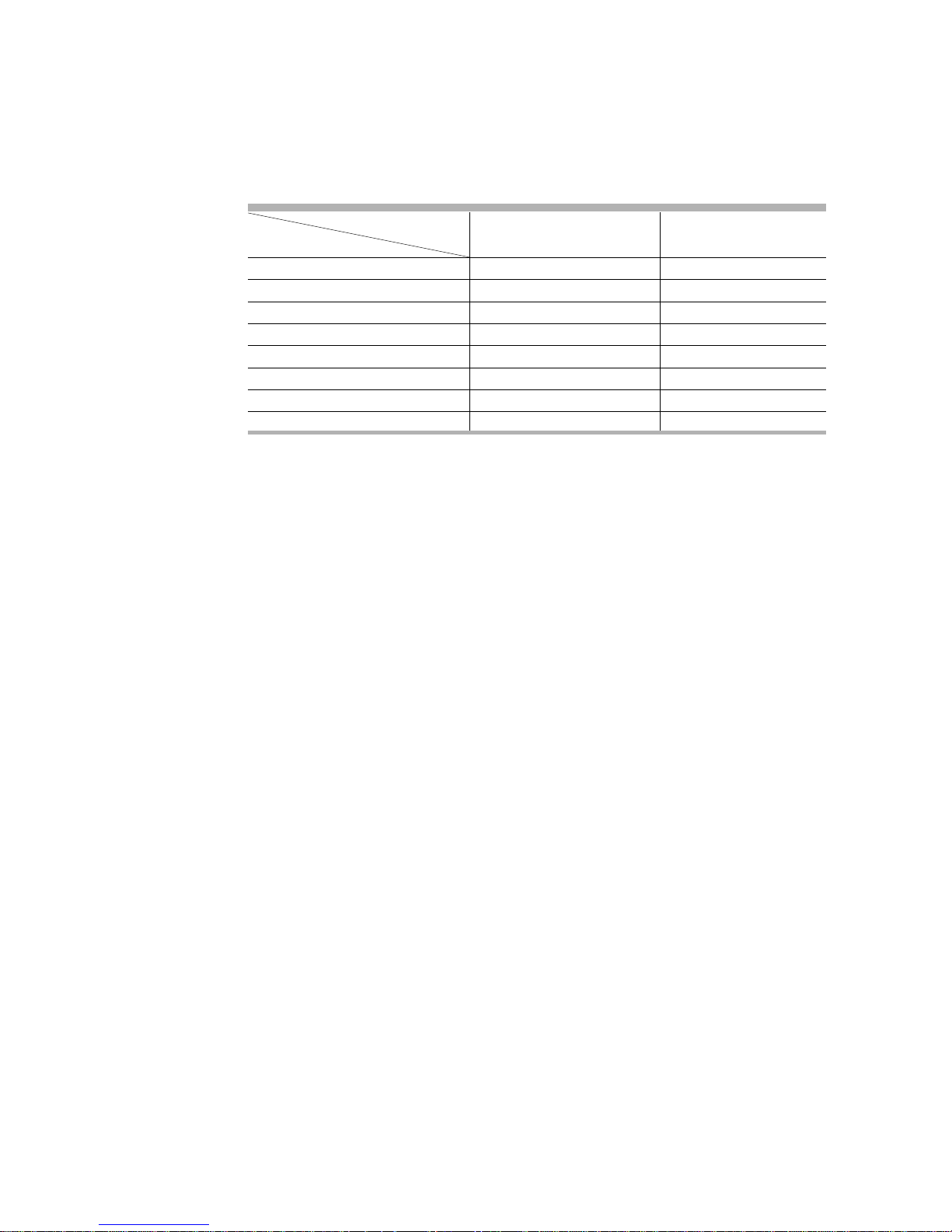

3.5.1 Copper pipe selection ( MDS100BR )

■ Diameter of the main pipe and that of the remotest pipe(equivalent length<90m)

Main pipe:φ 12.7/ φ 28.6(the same as the outdoor unit)

The remotest pipe: the same as the indoor unit

■ Refer to the refrigerant pipe to calculate the cooling capacity of downstream A

A-B-C: 17.4 KW

A-D-E: 11.8 KW

■ Select the pipe diameter of downstream A

Diameter of A-B: φ 12.7/ φ 25.4

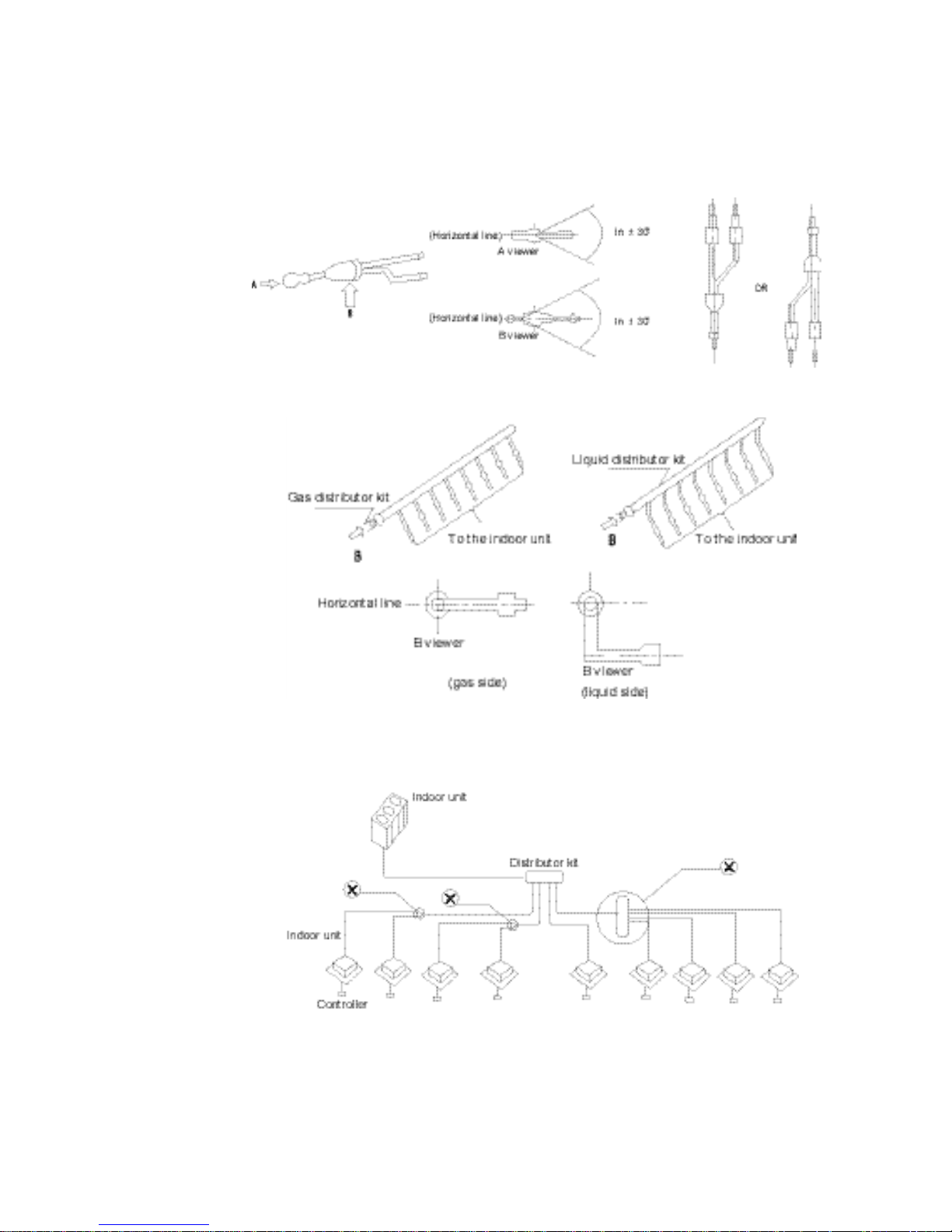

Diameter of A-D: φ 9.52/ φ 19.05

■ We can use the same method to select the pipe diameter of downstream B and D.

Diameter of B-C: φ 9.52/ φ 19.05

Diameter of D-E: φ 9.52/ φ 15.88

3.5.2 Refnet joint selection

■ Refer to the refnet joint specification to select the refnet joint for Point A.

A: Refnet joint to liquid pipe: MDS-Y2

A: Refnet joint to gas pipe: MDS-Y1

■ We can adopt the same method to select the refnet joint for point B to D.

B: Refnet joint to liquid pipe: MDS-Y2 B: Refnet joint to gas pipe: MDS-Y1

C: Refnet joint to liquid pipe: MDS-Y2 C: Refnet joint to gas pipe: MDS-Y4

D: Refnet joint to liquid pipe: MDS-Y2 D: Refnet joint to gas pipe: MDS-Y4

E: Refnet joint to liquid pipe: MDS-Y2 E: Refnet joint to gas pipe: MDS-Y2

Page 66

-66-

Design & installation Guide For McQuay MDS Multi System

The following tables show the refrigerant copper pipe dimension specifications.

8.0HP

12.0HP

15.0HP/18.0HP 22.0HP 26.0HP/28.0HP

Specification 10.0HP 20.0HP 24.0HP 30.0HP

Between the outdoor unit and the first tap joint

Liquid pipe

φ12.7mmxt1.0 φ 15.88mmxt1.2 φ 15.88mmxt1.2 φ 19.05mmxt1.2 φ 19.05mmxt1.2

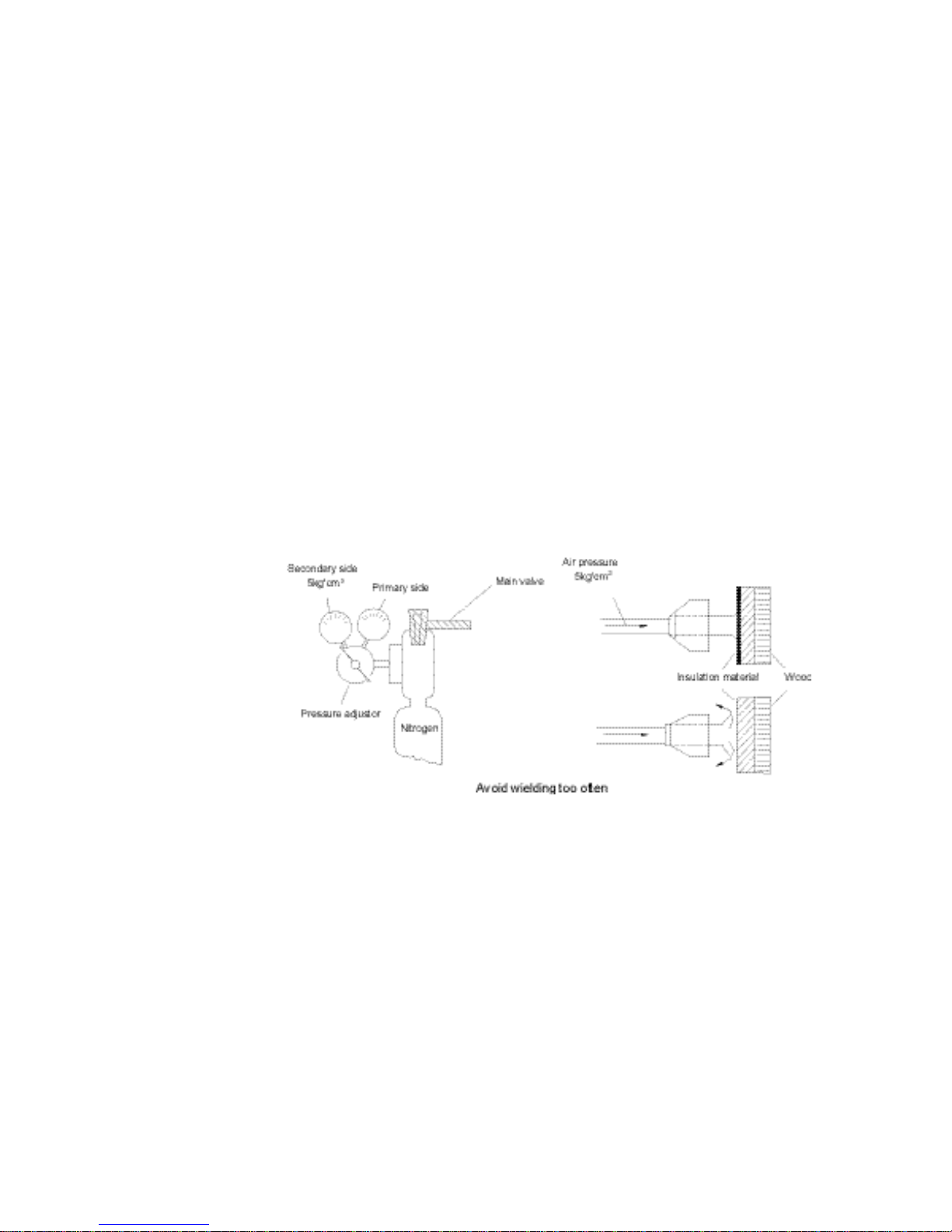

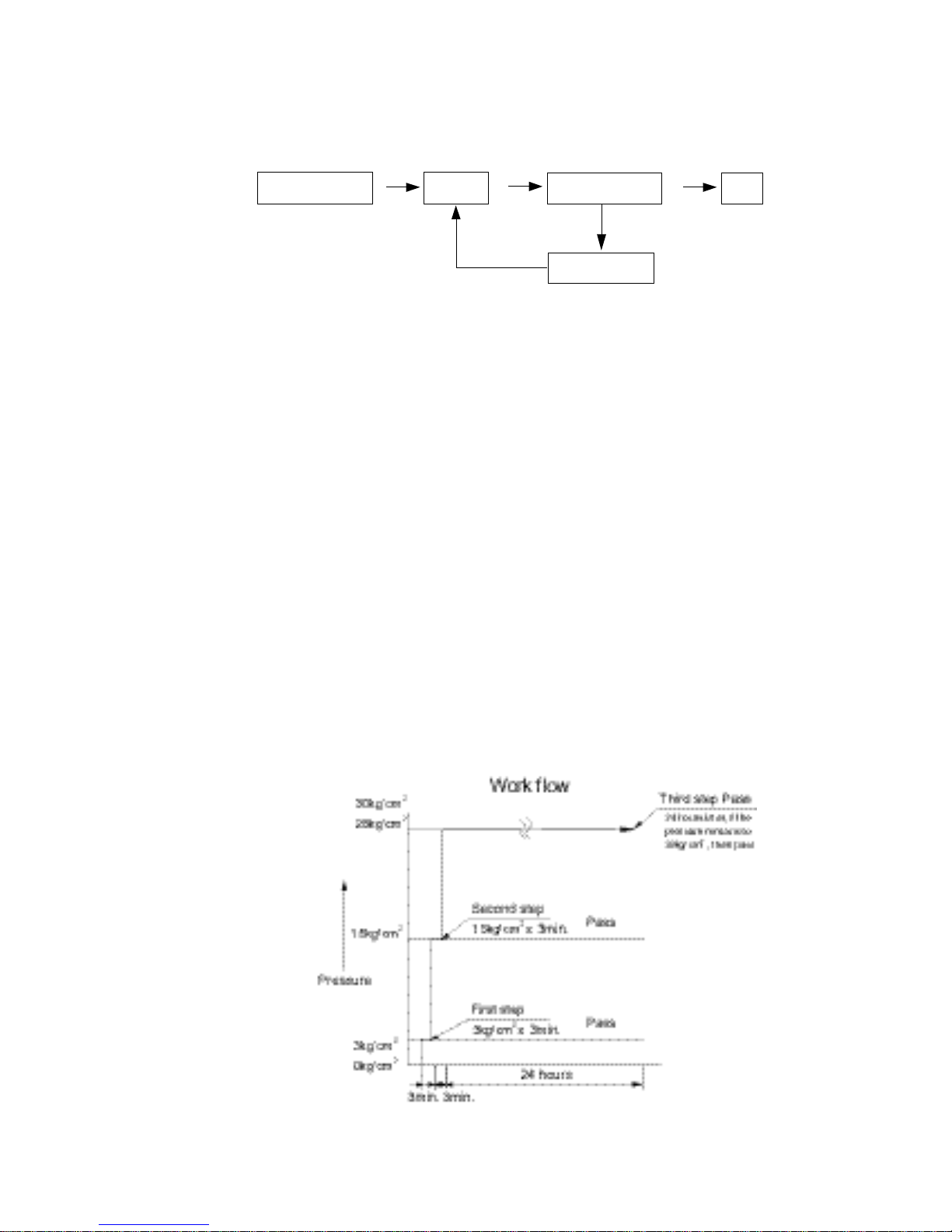

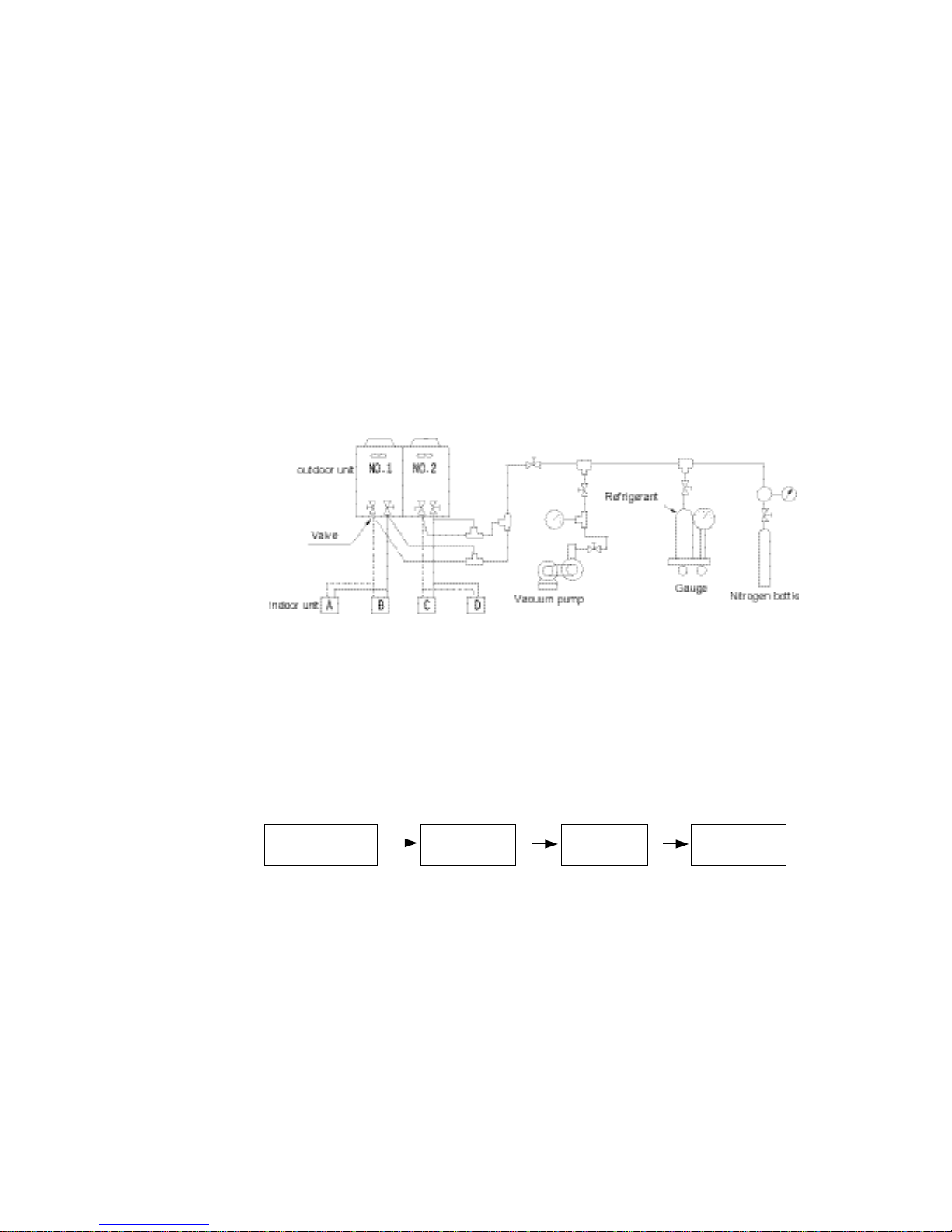

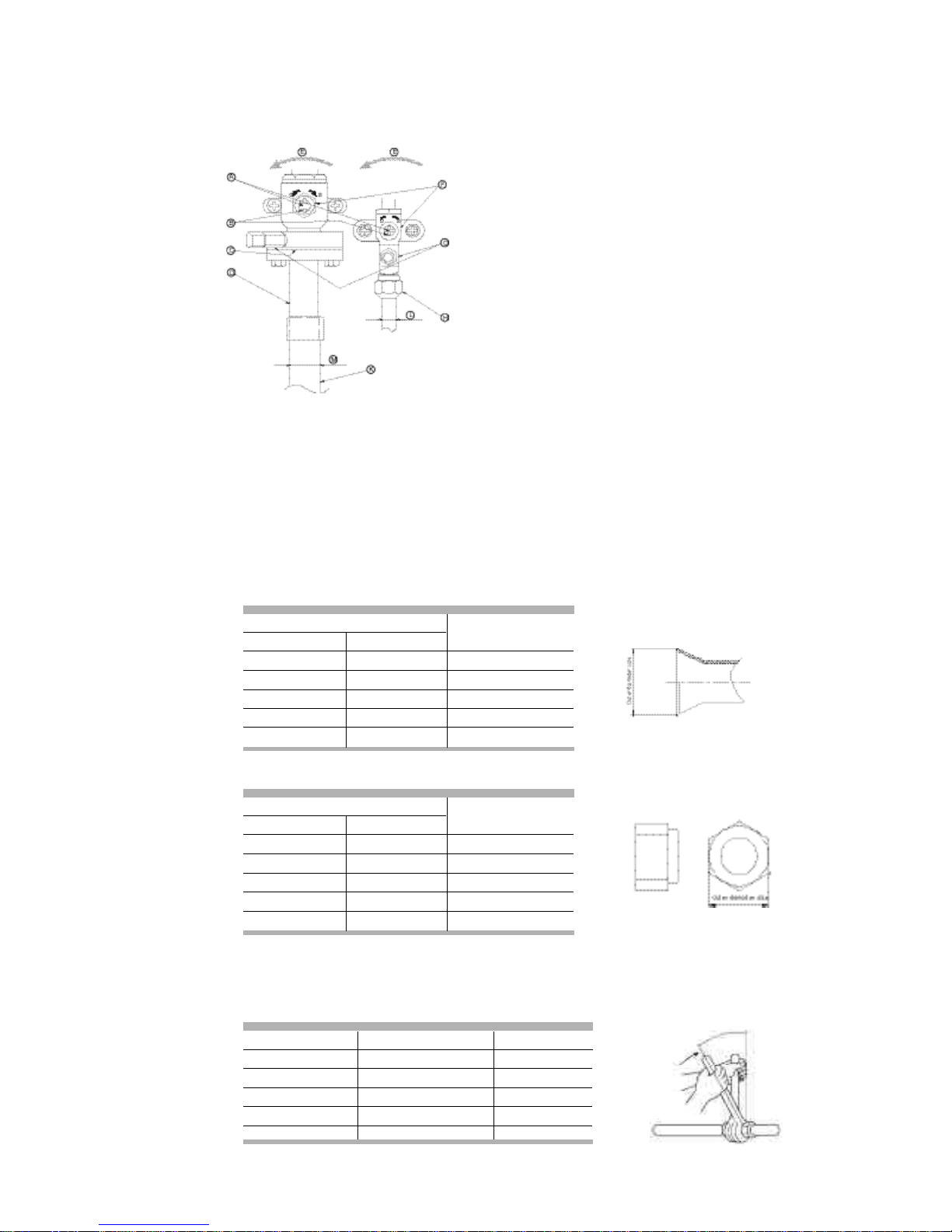

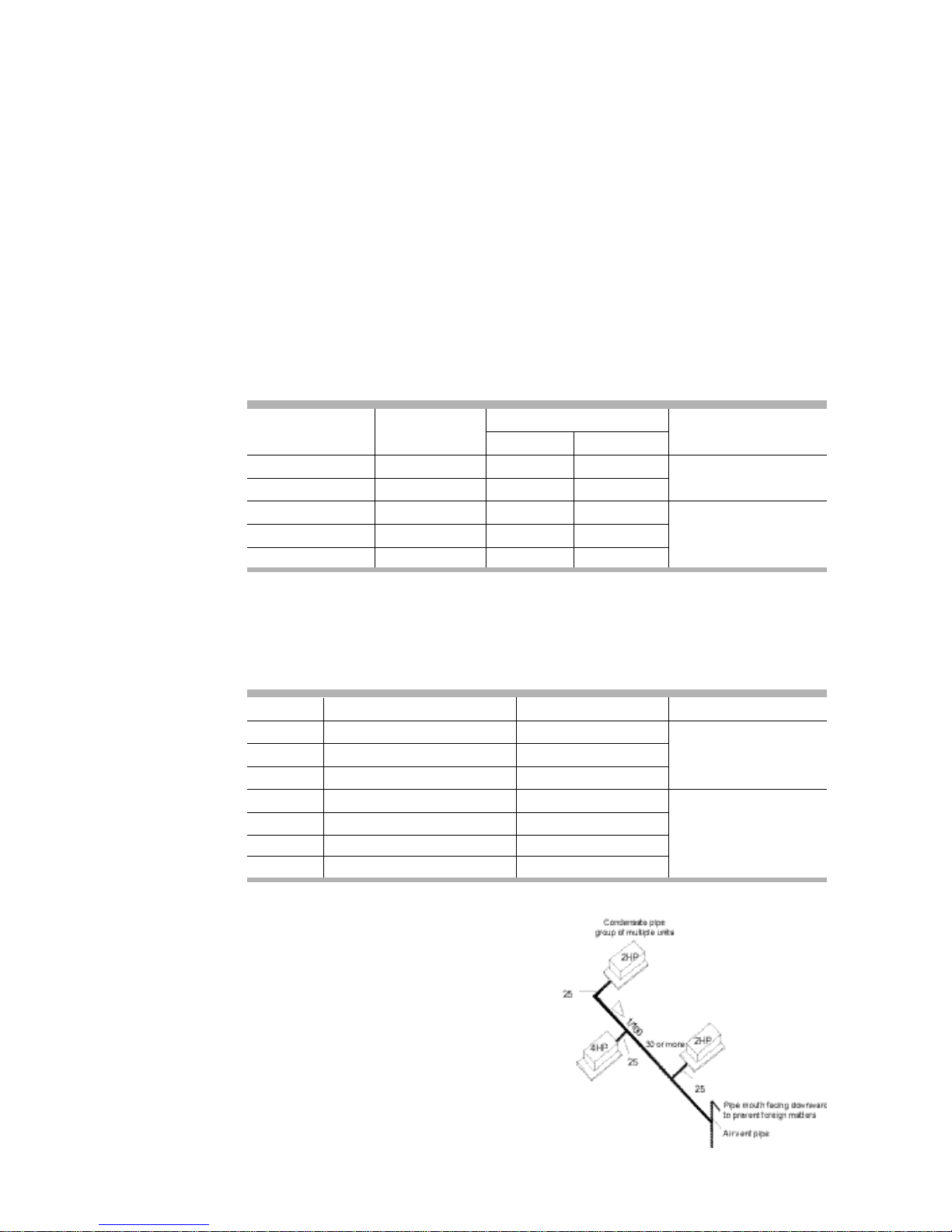

Gas pipe