Page 1

Ceiling Concealed

Chilled Water Fan Coil Unit

Models: MCW200DA MCW900DA

MCW300DA MCW1000DA

MCW400DA MCW1200DA

MCW500DA MCW1400DA

MCW600DA MCW1600DA

MCW800DA

Technical Manual

Engineered for flexibility and performance.

TM

MCW-DA-2009

Page 2

1

Nomenclature..............................................................................................................................2

Main Features .............................................................................................................................3

Specication ...............................................................................................................................4

Sound Pressure Level ................................................................................................................6

Performance Data .......................................................................................................................7

Air Flow vs ESP Table ................................................................................................................8

Operating Limit ........................................................................................................................... 9

Water Flow vs Pressure Drop Chart .......................................................................................10

Outline and Dimension ............................................................................................................11

Wiring Diagram ......................................................................................................................... 12

Installation .................................................................................................................................13

Exploded-view & Part List .......................................................................................................15

Optional ..................................................................................................................................... 17

Guide Specications ................................................................................................................ 18

Contents

“McQuay” is a registered trademark of McQuay International. All rights reserved throughout the world.

© 2009 McQuay International.

Bulletin illustrations cover the general appearance of McQuay International products at the time of publication. We reserve the right to change

design and construction specications at any time without notice.

Note: Installation and maintenance are to be performed only by qualied personnel who are familiar with

local codes and regulations, and experienced with this type of equipment.

Caution: Sharp edges and coil surfaces are a potential injury hazard. Avoid contact with them.

Warning: Moving machinery and electrical power hazard may cause severe personal injury or death.

Disconnect and lock off power before servicing equipment.

Literature No.:

TM-MCWDA-0901A

Supersedes: TM-MCWDA-0708A

Part No.: M08039110019

Page 3

2

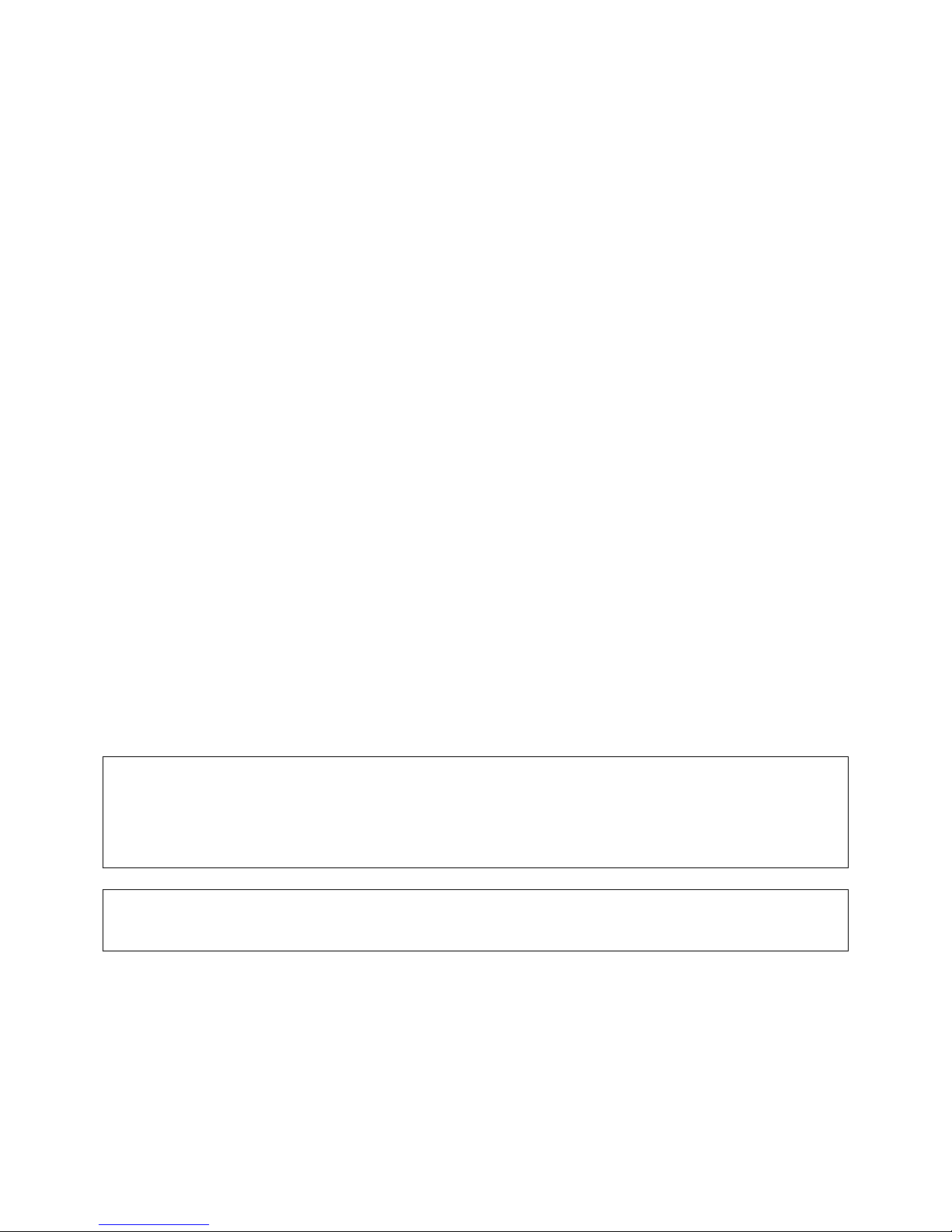

Nomenclature

MCW 200 DA 8 R X F A A F1 E

Export

1-100mm Extended Drain Pan

2-200mm Extended Drain Pan

Omitted for Standard Drain Pan

Description of Products:

A-Standard Drain Pan

F-Extended Drain Pan

Material of Drain Pan

A-Coated Cold Rolled Steel

S-Stainless Steel

Power Supply: A-220-240V/1PH/50Hz

F 8mm Nylon Filter

G 25mm Nylon Filter

H 25mm Aluminium Filter

Back Rerurn Air Plenum With Bottom Removal Filter

Pipe Connection: R-Right Hand

L-Left Hand(Facing Air Flow)

75Pa External Static Pressure

Design Series: DA-4 Rows and 2 Pipes

Nominal Air Flow(CFM)

McQuay Horizontal Ceiling Concealed Fan Coil Unit

Page 4

3

Main Features

General

The new MCW-DA FCUs are specically designed to satisfy high cooling capacity application requirement. They

represent one of the most cost effective solutions to provide a comfortable environment for both commercial and

residential applications. Their quiet operation, compact dimensions and particularly low height, make units ideal

for ceiling concealed installation even in buildings with narrow ceiling spaces. Units are standard supplied with

soundproofed suction plenum and air lter. Centrifugal fans, with forward-curved blades, are statically and dynamically

balanced and driven by single-phase motors with three speeds.They feature elegant design, advanced structure,

high efciency, low noise, convenient installation and low maintenance. They are widely used in houses, shopping

malls, hospitals and ofce etc.

Higher Cooling Capacity in High Delta T Application

These units are particularly suitable for high External Static Pressure and high Delta T(chilled water temperature

difference) applications. They can delivery more cooling capacity in high Delta T conditions with the specially designed

fans & motors, coils and excellent combination of them.

Low Chilled Water Pressure Drop

In order to meet even the most demanding customer requirements, the new FCUs adopt the most reasonable and

optimized water circuit design and utilize the National accredited thermal test room to guarantee both the perfect

performance and a low chilled water pressure drop.

Extra High Air Flow Volume at High ESP

These units can supply more air ow at high ESP. 11 models of MCW-DA cover an air ow range from 200 to 1600

CFM at medium speed with ESP of 75Pa.

High Efciency and Energy Saving

A boundary layer lm of air adhering to the n surface will insulate the n surface and severely reduces the heat

exchange efciency. McQuay slit designed and HYDROPHILIC BLUE FIN eliminates this boundary layer of air and

creates continuous turbulence for best heat exchange efciency.

Flexibility

Units are available with left or right hand water connections, which can be easily switched in the eld by changing the

positions of the fan-motor assembly and the supply air ange assembly if required.

Compact Design

The low height design makes this fan coil unit series ideally suited for the tight ceiling concealed installation

Low Noise Design

Enlarged fan wheels design allows lower fan speed selection for the same external static pressure and airow

requirement. Thereby noise level is signicantly reduced.

Powerful Selection Software

Powerful select software makes various conditions selection precise and cost saving.

Page 5

4

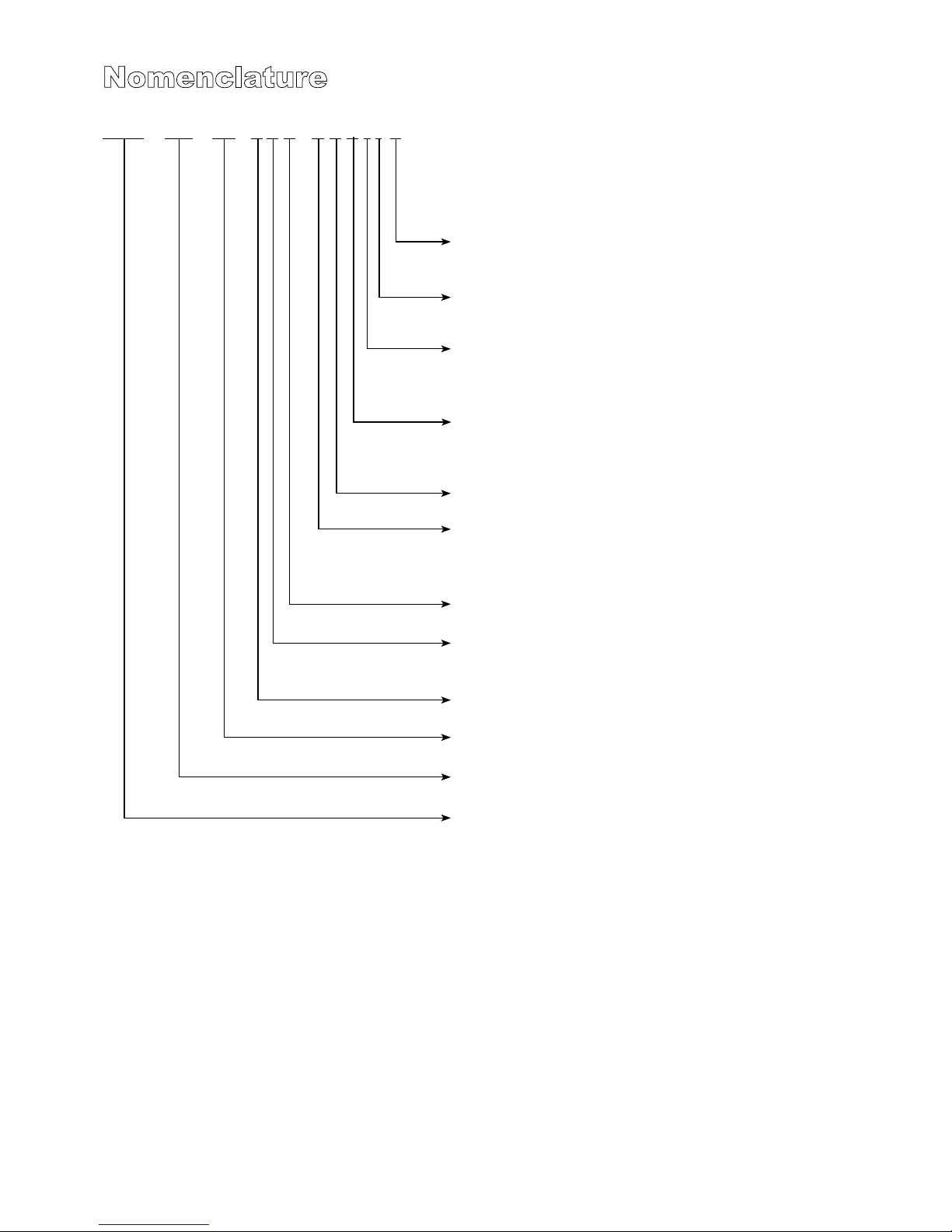

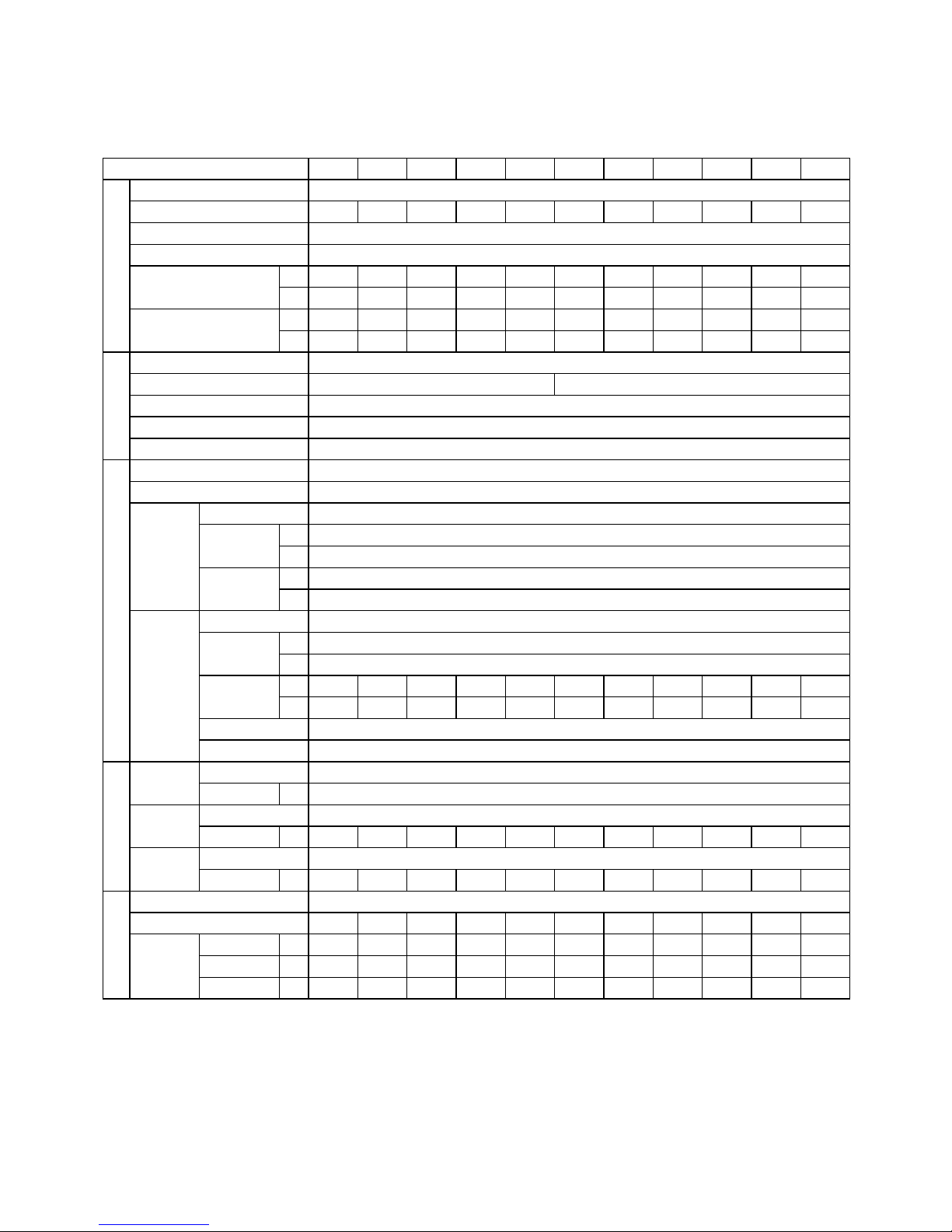

Specication

General Data

NOTES:

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) THE PERFORMANCE DATA ARE BASED ON THE FOLLOWING CONDITIONS:

A) COOLING: 24°C DB/18°C WB INDOOR AND WATER INLET 5.5°C OUTLET 14.5°C.

B) MEDIUM SPEED,75PA ESP.

C) 220V/1PH/50HZ.

3) ALL THE DIMENSIONS ARE FOR THE UNITS WITH STANDARD DRAIN PAN. TO GET DIMENSIONS FOR UNITS

WITH EXTENDED DRAIN PAN, PLEASE INCREASE THE ABOVE LENGTH VALUES ACCORDINGLY.

4) WHEN THE WATER CONNECT DIRECTION IS CHANGED IN FIELD,THE CAPACITY SHOULD BE REDUCED BY 6%.

MODEL 200DA 300DA 400DA 500DA 600DA 800DA 900DA 1000DA 1200DA 1400DA 1600DA

NOMINAL

AIR FLOW

H

m3/h 348 446 665 831 923 1369 1564

1683

2375 2386 3163

cfm 205 262 391 489 543 805 920

990

1397 1404 1861

M

m3/h 304 399 611 794 868 1296 1514

1631

2208 2381 2974

cfm 179 235 359 467 511 762 891

959

1299 1401 1749

L

m3/h 200 270 446 631 694 1089 1294

1376

1668 1931 2312

cfm 118 159 262 371 408 641 761

809

981 1136 1360

COOLING

CAPACITY

TOTAL

W

1660 2300 3280 3750 4300 6570 7150 7910 9980 10490 12920

Btu/h

5664 7848 11191 12795 14672 22417 24396 26989 34052 35792 44083

SENSIBLE

W

980 1400 2040 2580 2850 4490 4870 5480 7360 7880 9960

Btu/h

3344 4777 6960 8803 9724 15320 16616 18698 25112 26887 33984

RATED

POWER

INPUT

H W 84 101 116 148 165 297 299

309

507 603 665

M W 78 92 108 133 154 273 277

290

475 523 607

L W 58 69 92 110 133 225 232

250

407 428 529

RATED

CURRENT

INPUT

H A 0.40 0.48 0.54 0.67 0.81 1.44 1.53

1.58

2.37 2.78 3.10

M A 0.36 0.42 0.49 0.62 0.71 1.25 1.28

1.34

2.17 2.46 2.78

L A 0.28 0.32 0.43 0.54 0.61 1.02 1.06

1.14

1.85 2.04 2.42

WATER FLOW RATE

m3/h

0.16 0.22 0.31 0.36 0.41 0.63 0.68

0.75

0.95 1.00 1.23

GPM

0.70 0.97 1.36 1.58 1.80 2.77 2.99

3.30

4.18 4.40 5.41

WATER PRESSURE

DROP

KPa

3 6 13 6 8 10 13

11

14 16 20

PSI

0.46 0.87 1.89 0.88 1.16 1.45 1.92

1.60

2.03 2.28 2.90

EXTERNAL STATIC

PRESSURE

Pa

75 75 75 75 75 75 75

75

75 75 75

in.wg 0.3 0.3 0.3 0.3 0.3 0.3 0.3

0.3

0.3 0.3 0.3

SOUND PRESSURE

LEVEL

dB(A) 42.6 45.6 45.3 46.7 49.2 48.7 48.2

50.3

50.9 50.9 52.9

CONDENSATE DRAIN PIPE Rc3/4

UNIT

DIMENSION

LENGTH mm 677 827 927 997 1097 1427 1537

1727

1427 1527 1827

WIDTH mm 530 530 530 530 530 530 530

530

600 600 600

HEIGHT mm 243 243 243 243 243 243 243

243

297 297 297

PACKING

DIMENSION

LENGTH mm 689 839 939 1009 1109 1439 1549

1739

1439 1539 1839

WIDTH mm 542 542 542 542 542 542 542

542

612 612 612

HEIGHT mm 255 255 255 255 255 255 255

255

309 309 309

NET WEIGHT

kg 16 21 22 24 28 39 44

48

51 52 62

lb 36 45 49 54 61 85 96

106

111 115 136

GROSS WEIGHT

kg 19 24 25 28 31 43 48

53

55 58 68

lb 41 52 56 61 69 95 106

117

122 127 149

OPERATING WEIGHT kg 17 22 24 26 30 41 47

50

54 54 66

Page 6

5

Components Data

NOTE:

ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

MODEL 200DA 300DA 400DA 500DA 600DA 800DA 900DA

1000DA

1200DA 1400DA 1600DA

FAN

TYPE Centrifugal (Blade: Forward-curved)

QUANTITY 1 2 2 2 2 3 4 4 3 3 4

MATERIAL Galvanized Steel

DRIVE Direct Drive

DIAMETER

mm 160 160 160 160 160 160 160

160 200

200 200

in 6.30 6.30 6.30 6.30 6.30 6.30 6.30

6.30 7.87

7.88 7.88

LENGTH

mm 200 160 200 200 200 200

160 200 190

190 190

in 7.87 6.30 7.87 7.87 7.87 7.87

6.30 7.87 7.48

7.48 7.48

MOTOR

TYPE Split-capacitor Motor With Ball Bearing

NUMBER OF MOTORS 1 2

POWER SUPPLY 220-240V/1ph/50Hz

IP/INSULATION CLASS IP20/Class B

POLES 4

COIL

TYPE Seamless Copper Tube Mechanically Bonded To Corrugated Aluminum Fin

TESTING PRESSURE Pressure Test:3.3mpa For 1 Minute; Leakage Test:1.6mpa For 5 Minutes

TUBE

MATERIAL Copper

DIAMETER

mm 9.52

in 3/8

THICKNESS

mm 0.3

in 0.012

FIN

MATERIAL Hydrophilic Aluminum

THICKNESS

mm 0.11

in 0.0043

FACE AREA

m

2

0.09 0.12 0.14 0.16 0.18 0.24 0.26 0.30 0.30 0.33 0.41

ft2141 185 217 242 273 377 409 472 472 511 629

ROW 4

FIN PER INCH 10

INSULATION

COIL TOP

PANEL

MATERIAL Fibre Glass

THICKNESS mm 8

OTHER

PANELS

MATERIAL PE Foam

THICKNESS mm 5 5 5 5 5 5 5 5 5 5 5

DRAIN

PAN

MATERIAL PE Foam

THICKNESS mm 7 7 7 7 7 7 7 7 7 7 7

AIR FILTER

MATERIAL Aluminium Frame Nylon Filter

NUMBER 1 1 2 2 3 3 3 3 3 3 3

SIZE

LENGTH mm 485 665 765 805 905 1235 1375 1535 1252 1337 1637

WIDTH mm 236 236 236 236 236 236 236 236 292 292 292

THICKNESS mm 8 8 8 8 8 8 8 8 8 8 8

Page 7

6

Sound Pressure Level

NOTES: TEST POINTS ARE AS BELOW:

1) TEST POINTS ARE AS BELOW:

Air Duct

Test Point

1 m

Test

Unit

Back

Return

Plenum

1 m

2) THE SOUND LEVEL IS TESTED UNDER 11.5DBA BACKGROUND NOISE IN A BAFFLE CHAMBER WITH ESP OF 50PA AND 75PA.

ESP 50 Pa 75 Pa

Unit Speed

1/1 Octave Sound pressure level [dB(A),ref 20 uPa]

Total

dB(A)

1/1 Octave Sound pressure level [dB(A),ref 20 uPa]

Total

dB(A)

125 250 500 1k 2k 4k 8k 125 250 500 1k 2k 4k 8k

200DA

H 26.1 34.3 37.6 40.4 33.1 22.8 14.1 43.4 24.9 33.9 37.4 40.2 33.6 24.4 15.0 43.3

M 27.0 33.4 36.9 39.6 32.1 21.6 13.7 42.7 26.2 33.8 36.4 39.5 32.9 23.5 14.6 42.6

L 27.8 29.2 33.5 35.9 28.1 18.1 13.0 39.2 26.6 30.6 34.2 37.2 30.0 20.8 13.7 40.2

300DA

H 27.7 35.0 36.5 44.3 36.4 25.4 16.1 46.0 29.2 35.5 37.0 44.7 37.1 26.9 17.5 46.5

M 28.3 34.3 35.4 43.1 35.6 24.6 15.5 45.0 29.7 34.5 36.2 43.8 36.1 25.9 16.7 45.6

L 27.9 31.2 32.8 40.1 32.2 20.9 14.3 42.0 25.0 32.6 34.2 41.5 34.0 23.6 15.4 43.4

400DA

H 26.9 36.7 38.8 42.6 37.8 25.7 14.6 45.7 28.7 36.5 39.2 42.8 38.3 26.2 15.2 46.0

M 27.9 35.3 38.2 41.8 36.8 24.6 13.7 44.9 28.2 36.5 38.3 42.1 37.5 25.9 15.0 45.3

L 27.3 32.3 35.8 38.4 33.8 20.8 11.4 41.9 27.4 34.3 37.0 40.3 36.3 24.3 14.0 43.7

500DA

H 29.7 39.1 40.4 43.9 38.1 29.0 18.3 47.1 30.3 39.3 40.4 43.7 38.3 29.2 18.1 47.1

M 28.9 38.7 39.7 43.6 37.9 28.3 17.6 46.8 29.7 38.7 39.9 43.3 37.7 28.7 17.5 46.7

L 27.3 36.7 37.8 41.3 35.6 26.2 15.8 44.6 27.3 36.5 38.0 41.5 36.3 27.1 16.2 44.8

600DA

H 30.5 40.9 41.8 46.6 42.7 29.8 18.5 49.7 33.2 40.7 42.3 45.8 43.4 29.9 20.5 49.6

M 30.8 40.0 41.6 46.1 42.1 29.2 18.3 49.2 30.2 40.5 41.7 46.0 42.1 29.0 17.5 49.2

L 31.5 37.5 39.3 43.5 38.8 25.4 15.1 46.6 29.9 38.1 39.8 44.2 40.3 26.9 15.6 47.4

800DA

H 34.7 41.1 42.2 45.9 39.8 29.1 19.7 49.1 33.2 40.7 42.3 46.0 40.2 29.9 20.5 49.2

M 33.6 40.5 41.9 45.4 39.5 28.8 19.3 48.6 33.4 40.5 41.9 45.5 39.6 29.6 20.0 48.7

L 31.7 38.5 40.3 43.9 37.5 26.6 16.8 47.0 32.5 39.0 40.7 44.3 38.3 27.6 18.0 47.5

900DA

H 34.1 40.9 42.3 45.7 40.3 29.9 20.6 49.1 35.1 40.9 41.2 45.4 40.0 30.1 20.8 48.7

M 34.6 39.8 41.3 45.3 39.8 29.5 20.1 48.5 34.5 40.2 40.9 44.8 39.5 30.0 20.5 48.2

L 33.2 38.7 39.9 43.8 38.0 27.7 18.3 47.0 33.4 38.4 39.8 43.8 38.3 28.4 18.9 47.0

1000DA

H

33.8 42.5 44.3 47.5 41.2 30.7 20.5 50.7 35.2 41.9 44.4 47.4 41.4 31.1 21.1 50.7

M

33.2 41.7 43.9 46.9 40.7 30.0 19.8 50.1 34.0 40.8 44.0 47.3 41.0 31.0 21.3 50.3

L

33.2 40.1 42.1 45.3 38.8 28.0 17.3 48.5 33.2 40.1 42.8 45.7 39.6 29.5 19.3 49.0

1200DA

H 37.2 44.7 44.1 47.7 42.6 34.0 26.2 51.5 37.4 44.8 44.4 47.9 42.2 33.7 25.6 51.6

M 36.1 43.0 43.1 47.2 41.1 32.5 24.6 50.5 37.0 43.7 43.8 47.3 41.5 32.8 24.6 50.9

L 34.3 39.9 40.8 43.3 37.2 28.0 19.2 47.1 35.1 41.7 42.0 44.5 38.7 29.6 20.3 48.5

1400DA

H 39.2 45.0 43.6 47.7 41.8 33.2 26.5 51.5 39.3 45.5 43.8 47.5 41.6 33.3 26.4 51.5

M 37.7 44.7 43.2 47.3 40.9 32.4 25.6 51.0 38.4 44.9 43.1 46.9 41.0 32.6 25.5 50.9

L 35.5 41.3 40.2 43.7 37.4 28.4 21.1 47.6 36.4 42.1 40.4 43.7 37.5 28.6 20.9 47.9

1600DA

H 41.3 46.1 46.4 51.2 44.1 34.6 27.9 54.1 45.3 45.8 46.0 50.4 43.6 33.7 27.0 54.0

M 40.5 45.1 45.7 50.2 42.7 33.2 26.2 53.1 41.6 44.7 45.4 49.8 42.5 32.4 25.5 52.9

L 38.2 40.3 42.2 46.0 37.8 27.6 19.8 49.0 43.6 41.2 42.4 46.2 38.4 27.9 20.4 50.1

Page 8

7

Performance Data

Cooling Capacity (The tables below are two examples)

NOTES:

1) THE FIRST TABLE IS UNDER MEDIUM SPEED,BUT THE SECOND TABLE IS BASED ON THE ARI STANDARD 440-2005 IN HIGH SPEED.

2) CAPACITY UNDER DIFFERENT CONDITIONS CAN BE DERIVED BY SELECTION SOFTWARE.

Model

ESP

Entering air

Temperature( )

Chilled water

Temperature( )

Cooling Capacity (kw) Water ow

Water Pressure

Drop

Pa DB WB In Out Total Sensible m3/h kPa

MCW200DA 75 24 18 5.5 14.5 1.65 0.98 0.16 3

MCW300DA 75 24 18 5.5 14.5 2.30 1.41 0.22 6

MCW400DA 75 24 18 5.5 14.5 3.30 2.04 0.31 13

MCW500DA 75 24 18 5.5 14.5 3.75 2.58 0.36 6

MCW600DA 75 24 18 5.5 14.5 4.30 2.86 0.41 8

MCW800DA 75 24 18 5.5 14.5 6.59 4.50 0.63 10

MCW900DA 75 24 18 5.5 14.5 7.17 4.88 0.68 13

MCW1000DA 75 24 18 5.5 14.5 7.91 5.48 0.75 11

MCW1200DA 75 24 18 5.5 14.5 9.96 6.77 0.83 11

MCW1400DA 75 24 18 5.5 14.5 10.43 7.84 0.98 15

MCW1600DA 75 24 18 5.5 14.5 13.00 9.97 1.23 20

Model

ESP

Entering air

Temperature(℃)

Water

Temperature(℃)

Cooling Capacity (kw) Water ow

Water Pressure

Drop

Pa DB WB In Out Total Sensible m3/h kPa

MCW200DA 50 26.7 19.4 7.2 15.6 2.33 1.47 0.24 6

MCW300DA 50 26.7 19.4 7.2 15.6 3.16 2.08 0.32 12

MCW400DA 50 26.7 19.4 7.2 15.6 4.20 2.81 0.43 23

MCW500DA 50 26.7 19.4 7.2 15.6 4.64 3.40 0.47 10

MCW600DA 50 26.7 19.4 7.2 15.6 5.38 3.83 0.55 14

MCW800DA 50 26.7 19.4 7.2 15.6 8.10 5.89 0.83 17

MCW900DA 50 26.7 19.4 7.2 15.6 8.76 6.34 0.89 20

MCW1000DA 50 26.7 19.4 7.2 15.6 9.51 7.03 0.97 16

MCW1200DA 50 26.7 19.4 7.2 15.6 10.39 8.53 1.06 17

MCW1400DA 50 26.7 19.4 7.2 15.6 11.84 9.36 1.21 22

MCW1600DA 50 26.7 19.4 7.2 15.6 15.18 12.36 1.55 30

Page 9

8

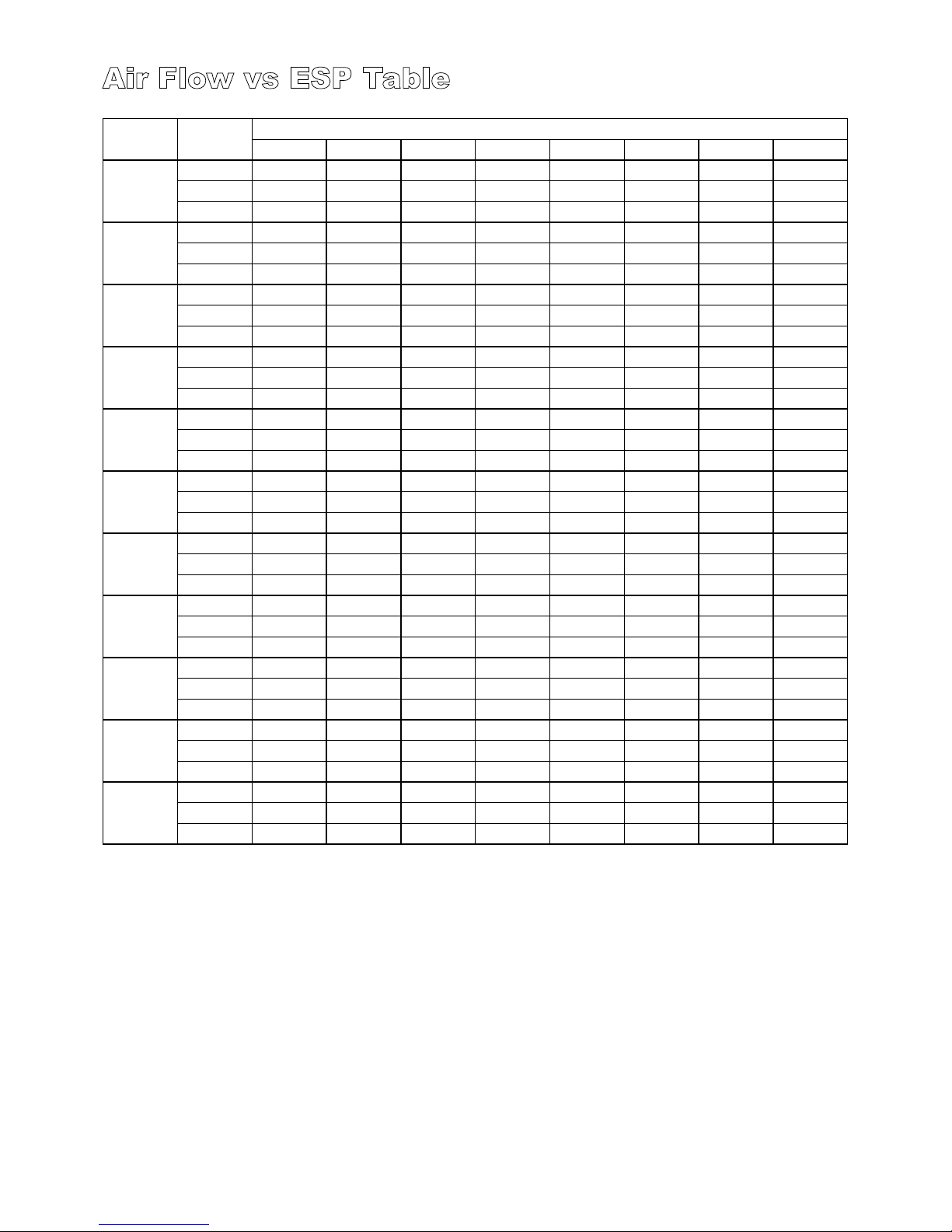

Air Flow vs ESP Table

NOTES:

1) AIR FLOW IS IN DRY COIL CONDITIONS.

2) ESP OUT OF THE RANGE 40-100PA APPLICATION IS NOT RECOMMENDED.

3) FOR MORE AIR FLOW UNDER DIFFERENT CONDITION,PLEASE REFER TO THE SELECTION PROGRAM.

Model fan speed

Air ow(m

3

/h) at ESP(Pa)

40 50 60 70 75 80 90 100

200DA

H 468 436 402 367 349 330 292 253

M 437 400 362 324 304 285 245 205

L 316 285 253 218 201 182 145 105

300DA

H 624 578 529 475 446 417 355 289

M 581 535 484 429 400 370 306 239

L 434 388 342 295 271 247 198 148

400DA

H 858 809 755 696 665 633 566 494

M 794 748 697 642 612 581 515 445

L 595 558 516 470 446 421 367 309

500DA

H 1018 970 918 861 831 800 734 664

M 977 931 880 824 795 764 700 631

L 774 742 703 657 632 605 546 480

600DA

H 1167 1106 1038 963 923 882 794 699

M 1104 1044 978 906 869 830 748 660

L 865 828 782 726 694 660 585 501

800DA

H 1662 1587 1506 1417 1369 1320 1216 1104

M 1592 1516 1433 1344 1296 1247 1144 1033

L 1318 1263 1200 1129 1090 1049 961 865

900DA

H 1916 1830 1733 1623 1564 1502 1369 1223

M 1863 1778 1681 1573 1515 1453 1321 1178

L 1611 1534 1447 1348 1294 1238 1118 986

1000DA

H

2047 1952 1850 1740 1683 1623 1498 1366

M

1995 1902 1800 1690 1631 1571 1443 1307

L

1677 1604 1520 1427 1376 1322 1207 1082

1200DA

H 2577 2522 2465 2406 2376 2345 2281 2215

M 2379 2334 2286 2235 2209 2182 2126 2066

L 1738 1723 1704 1681 1668 1655 1624 1590

1400DA

H

2637 2562 2490 2421 2387 2353 2288 2226

M

2594 2536 2475 2413 2381 2349 2284 2216

L 2059 2027 1992 1953 1932 1910 1863 1813

1600DA

H 3464 3384 3299 3210 3164 3116 3018 2916

M 3229 3162 3091 3014 2975 2934 2848 2758

L 2430 2407 2376 2336 2313 2288 2232 2168

Page 10

9

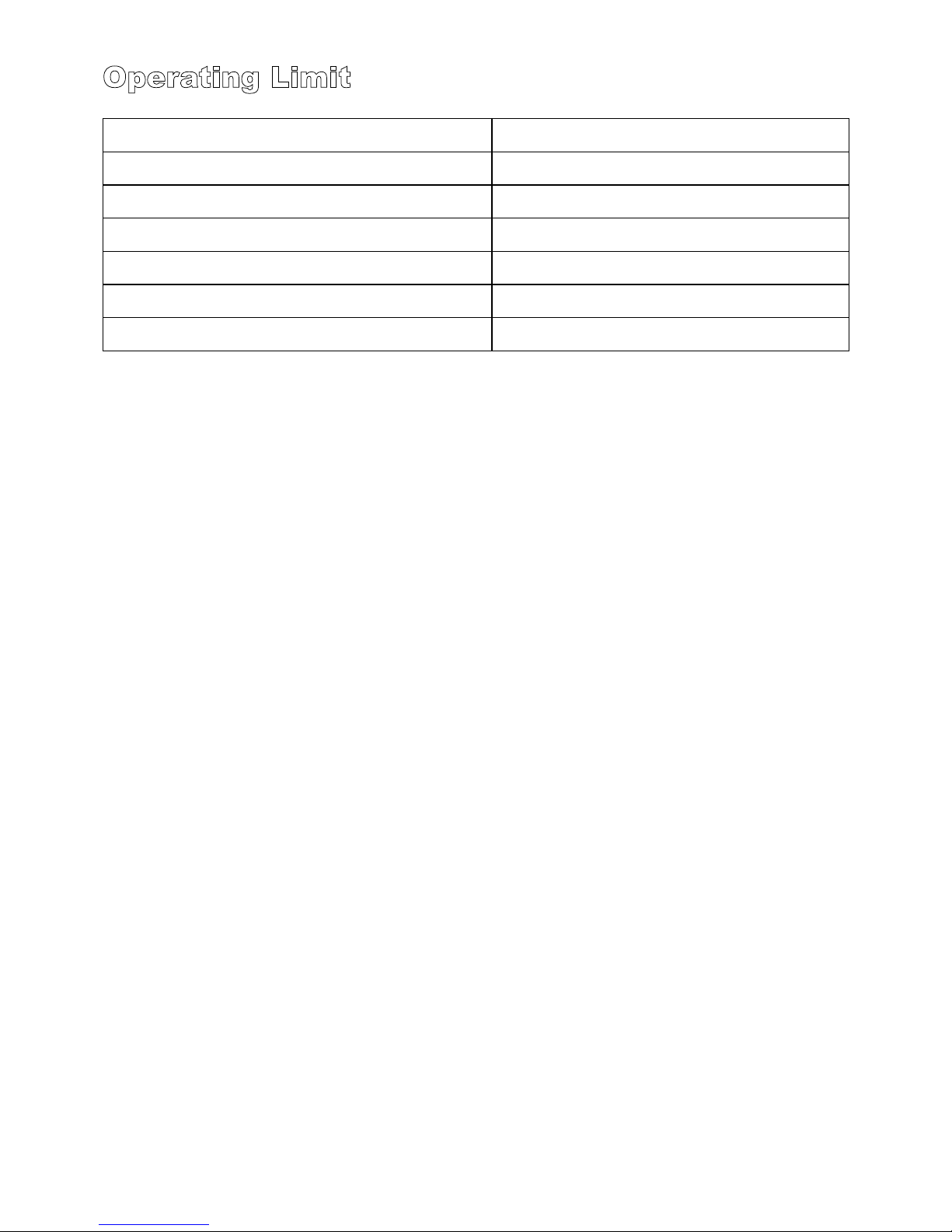

Operating Limit

OPERATING LIMITS

Maximum water side pressure 16 Bars

Minimum entering water temperature 3 ℃

Maximum entering water temperature 95 ℃

Minimum air inlet temperature 5 ℃

Maximum air inlet temperature 43 ℃

Power supply 220-240V/1Ph/50Hz

Page 11

10

Water Flow vs Pressure Drop Chart

NOTE:

ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

Page 12

11

Outline and Dimension

NOTES:

1) ALL DIMENSIONS ARE IN MM;

2) ALL STANDARD UNITS ARE WITH BACK AIR PLENUM AND BOTTOM REMOVAL FILTERS;

3) WHEN SELECT EXTENDED DRAIN PAN,PLEASE ADD THE INCREMENT TO THE LENGTH ACCORDINGLY.

4) RIGHT HAND COIL CONNECTION SHOWN;

5) WIRING CONNECTION SIDE IS THE SAME AS COIL AND DRAIN CONNECTIONS.

Model A B C D E F G H I J K L Fan number

MCW200DA 677 452 487 469 522 540 151 143 530 211 243

382

1

MCW300DA 827 592 627 649 702 820 151 143 530 211 243

382

2

MCW400DA 927 692 727 749 802 820 151 143 530 211 243

382

2

MCW500DA 997 772 807 789 842 860 151 143 530 211 243

382

2

MCW600DA 1097 872 907 889 942 960 151 143 530 211 243

382

2

MCW800DA 1427 1202 1237 1219 1272 1290 151 143 530 211 243

382

3

MCW900DA 1537 1302 1337 1359 1412 1420 151 143 530 211 243

382

4

MCW1000DA

1727 1502 1537 1519 1572 1580 151 143 530 211 243 382 4

MCW1200DA 1427 1202 1237 1219 1272 1290 201 194 600 266 297 413 3

MCW1400DA 1527 1302 1337 1319 1372 1390 201 194 600 266 297 413 3

MCW1600DA 1827 1602 1637 1619 1672 1690 201 194 600 266 297 413 4

242

262

131

I

104

14

20

20

16

J

G

28H

K

35

B

C

A

35

44 187

L

D

E

F

WATER SUPPLY Rc3/4

WATER RETURN Rc3/4

MOUNTING HOLES 4-10 x 16

CONDENSATE DRAIN R3/4

AIR VENT VALVE

TERMINAL BOX

Page 13

12

Electrical wiring connection must be done according to the following wiring diagram. The unit must be GROUNDED

to the earth system of the building. All eld wiring must be installed in accordance with the national wiring regulation

and Fire Department regulation.

Wiring Diagram

NOTE:

FOR MCW DA SERIES, (H. M. L.) ARE CONNECTED TO (SHF. HF. MF.) RESPECTIVELY.

MODEL: MCW 200-1600

POWER

SOURCE

ORANGE

N

L

MF

LF

SHF

HF

L

M

BROWN

H

YELLOW

FAN

BLACK

FAN SPEED

SWITCH

NOTE:

MOTOR

1

BLACK

FAN MOTOR

CAPACITOR

MOTOR

CAPACITOR

2

BLACK

FAN MOTOR

BLACK

FAN

RED

RED

YELLOW

BROWN

ORANGE

BLUE

BLUE

HF: HIGH SPEED

MF: MEDIUM SPEED

LF: LOW SPEED

SHF: SUPER HIGH SPEED

FIELD WIRING

FAN MOTOR2 APPLY TO 800~1600 UNITS

Page 14

13

Installation

Receiving

All units leaving the factory have been inspected to ensure the shipment of high quality products and reasonable

means are utilized to properly pack the fan coil units to protect them in transit.

Carefully inspect all shipments immediately upon delivery. When damage is visible, note this fact on the carrier’s

freight bill and request that the carrier send a representative to inspect the damage. This may be done by telephone

or in person, but should always be conrmed in writing.

The shipment should be unpacked in the presence of the agent so that the damage or loss can be determined. The

carrier’s agent will make an inspection report and a copy will be given to the consignee for forwarding to the carrier

with a formal claim.

Location

Before installation, please check the following:

1. There must be enough space for unit installation and maintenance. Please refer to the outline and dimensions and

g.1 for the minimum distance between the unit and obstacle.

2. In case of installation in free blow, the unit must be installed at a minimum height of 2.5m to avoid contact with the

appliance.

3. Please ensure enough space for piping connection and electrical wiring.

4. Please make sure that the hanging rods can support weight of the unit.

Installation

1. The unit is designed for concealed ceiling installation.

2. There are holes on the top of the unit for hanging. Please refer to Fig.1. Fig.2 and Fig.3.

3. Make sure that the top of the unit is level.

Insulation

1. The insulation design and materials should be complying with local and national codes and regulations.

2. Chilled water pipes and all parts on the pipes should be insulated.

3. It is also necessary to insulate the air duct.

B

CEILLING

OBSTACLE

A

OBSTACLE

≥400mm

≥200mm

DRAIN PIPE

The suggested slope of the

drain pipe is at least 1:50

Fig. 1

Page 15

14

Fig.3 DETAIL A:

FAN COIL UNIT

NUT

FLAT WASHER

HANGING ROD

EXPANSION SCREW

Detail A

Air Duct Connection

1. Circulatory air pressure drop should be within External Static Pressure.

2. Galvanized steel air ducts are suitable.

3. Make sure there is no leak of air.

4. Air duct should be re-proof, refer to concerned country national and local regulations.

Pipe Connection

1. Using suitable ttings as water pipe connections with reference to the outline and dimensions.

2. The water inlet is on the bottom while outlet on top.

3. The connection must be concealed with rubberized fabric to avoid leakage.

4. Drain pipe can be PVC or steel.

5. Tightening torque should not be too high when connecting water pipes, in order to avoid brass deformation or

water-leakage by torsion split.

6. The suggested slope of the drain pipe is at least 1:50.

Wiring

1. Wiring connection must be done according to the wiring diagram on the unit.

2. The unit must be GROUNDED well.

3. An appropriate strain relief device must be used to attach the power wires to the terminal box.

4. A 7/8” hole is designed on the terminal box for eld installation of the strain relief device.

5. Field wiring must be complied with the national security regulations.

6. A main switch or other means for disconnection, having a contact separation in all poles, must be incorporated in

the xed wiring in accordance with the relevant local and national legislation.

A

DISCHANGE AIR

RETRUN AIR

CEILING ACCESS PANEL

CEILLING

WITH AIR RETRUN

L

M

N

NOTE:

Dimension M and N was

determined by air duct design, air

duct should be fire-proof, refer to

concerned country national and

local regulations.

Circulatory air pressure drop should

be approximately equal to the

External Static Pressure.

≥300mm

:$7(5,1/(7

:$7(5287/(7

Fig. 2

WITH AND WITHOUT PLENUM FORM:

Page 16

15

Exploded-view & Part List

Item Description

1 Motor

2 Top Panel For Air Return Plenum

3 Blower Left

4 Flange top/bottom For Air Return Plenum

5 Filter

6 Flange left/right For Air Return Plenum

7 Filter Cover

8 Bottom Panel For Air Return Plenum

9 Side Panel Right For Air Return Plenum

10 Fan Deck

11 Terminal Box

12 Drain Guide

13 Drain Pan

14 Coil Assy

15 Top Panel

16 Blower Right

17 Side Panel Left For Air Return Plenum

Page 17

16

MODEL MCW200DA MCW300DA MCW400DA MCW500DA MCW600DA

MCW800DA

CLASS B

MOTOR

MOTOR 1

YDK36-4Be

M03034065200

YSK56-4B4

M03034065201

YSK71-4B4

M03034065202

YSK100-4B4

M03034065203

YSK150-4B6

M03034065204

YSK150-4B6

M03034065204

MOTOR 2 \ \ \ \ \

YDK71-4B4

M03034065205

DRAIN PAN M50014063363 M50014063364 M50014063365 M50014063366 M50014063367

M50014063368

BLOWER

LEFT M03029000980 M03024060001 M03029000980 M03029000980 M03029000980

M03029000980

RIGHT \ M03024060002 M03029000981 M03029000981 M03029000981

M03029000981

COIL

LEFT HAND M50024065190 M50024065191 M50024065192 M50024065193 M50024065194

M50024065195

RIGHT HAND M50024065180 M50024065181 M50024065182 M50024065183 M50024065184

M50024065185

FILTER

8mm NYLON M03084066197 M03084066198 M03084066199 M03084066200 M03084066201

M03084066202

25mm NYLON

M03084066187 M03084066188 M03084066189 M03084066190 M03084066191

M03084066192

MODEL

MCW900DA MCW1000DA

MCW1200DA MCW1400DA MCW1600DA

CLASS B

MOTOR

MOTOR 1

YSK150-4B6

M03034065204

YSK150-4B6

M03034065204

YSK240-4B8

M03034065206

YSK280-4B8

M03034065208

YSK240-4B8

M03034065206

MOTOR 2

YSK150-4B6

M03034065204

YSK150-4B6

M03034065204

YDK95-4B6

M03034065207

YDK125-4B6

M03034065209

YSK240-4B8

M03034065206

DRAIN PAN

M50014063369

M50014063370

M50014063368 M50014063369 M50014063797

BLOWER

LEFT

M03024060001

M03029000980

M03024060003 M03024060003 M03024060003

RIGHT

M03024060002

M03029000981

M03024060004 M03024060004 M03024060004

COIL

LEFT HAND

M50024065196

M50024065197

M50024065202 M50024065203 M50024065204

RIGHT HAND

M50024065186

M50024065187

M50024065199 M50024065200 M50024065201

FILTER

8mm NYLON

M03084066203

M03084066226

M03084066204 M03084066205 M03084066206

25mm NYLON

M03084066193

M03084066225

M03084066148 M03084066195 M03084066196

NOTE:

LEFT OR RIGHT HAND COIL IS CONSIDERED FACING THE AIR FLOW.

Page 18

17

1. Drain pan

100mm and 200mm extended cold-rolled steel drain pan and stainless steel drain pan available, meet various

application requirements.

2. Insulation

Aramex Class 0 insulation material ensure more effective thermal and sound insulation together with re-proof

safety.

3. Casing

Anti-corrosion powder coating, looks elegant and more endurable to erosive environment.

4. Filter

25mm nylon lter and 25mm aluminum lter optional.

Different material lter meet various customer requirements.

5. Motor

Class F insulation motor provides reliable operation and suits harder applications.

Optional

Page 19

18

Unit Description

Factory-assembled, horizontal, blow-thru type, galvanized casing, ceiling ducted fan coil unit is complete with water

coil, fans, motors, drain pan, lters and all required wiring, with full access to internal components.

Quality Assurance

Each coil is factory tested for leakage at 3.3MPa air pressure with coil submerged in water. Each unit and its moving

components (fans and motors) are factory computer-tested and recorded after unit is complete and before it is

packed.

Component Specications

1. Casing

Construction is of 0.8mm thickness galvanized steel, lined inside with 8mm bre glass and 5mm PE thermal and

acoustical insulation. Return air plenum is lined with 5mm PE foam and has a 20mm ange for return duct connection.

Supply duct connection also has a 20mm ange. Removable bottom panel is provided for access to the fan/motor

assembly.

2. Coil

Standard unit is equipped with a 4-row coil for installation in a 2-pipe system. Coil has 3/8 inch seamless copper

tubes, slit type aluminum blue ns bonded to the tubes by mechanical expansion. Each coil has a manual air vent

and two Rc3/4 water pipe connections with a working pressure of 1.6MPa.

3. Fan

Direct-driven centrifugal fan wheel has forward-curved blades which are statically and dynamically balanced. The fan

housing and blades are constructed of high quality hot-galvanizing steel.

4.Motor

Fan motor is 4-speed, 220V-240V, single-phase, 50Hz, permanent split-capacitor with ball type bearing and build-in

automatic reset thermal overload protection. The motor’s insulation is class B, class F optional.

5. Drain pan

The drain pan plate body is constructed of cold-rolled steel by way of integral cupping. Both its sides are sprayed

with plastic coating. And its outer wall is lined with 7mm heat insulating PE foam and high quality adhesive by way

of integral adhering and pressing. It extends under the full length and width of the coils and is pitched for positive

drainage with features of high anti-corrosion, anti-condensation and high re reluctance.

6. Filter

Filter is with washable type double-layer nylon media in 8mm or 25mm thickness aluminum frame or 25mm aluminum

lter.

Guide Specications

Page 20

©2009 McQuay International +1 (800) 432-1342 www .mcquay. com

While utmost care is taken in ensuring that all details in the publication are correct at the time of going

to press, we are constantly striving for improvement and therefore reserve the right to alter model

specications and equipment without notice.

Details of specications and equipment are also subject to change to suit local conditions and requirements

and not all models are available in every market.

Loading...

Loading...