Page 1

Fan Coil Units

Catalog

MFCU_(i)

Models:

MWM-G2W

MCM-DW/EW

MCK-AW/BW/CW

MCC-CW

MDB-BW

Page 2

TT

aa

bb

a

aa

b

bb

le ofle of

le of

le ofle of

T

TT

Nomenclature................................................................................................................. 1

Features ......................................................................................................................... 8

Application Information.................................................................................................. 10

Sound Data ................................................................................................................... 26

Selection Process ......................................................................................................... 29

Engineering and Physical Data ..................................................................................... 55

Performance Data ......................................................................................................... 96

Dimensional Data......................................................................................................... 148

Electrical Data .............................................................................................................. 166

Contents Contents

Contents

Contents Contents

Wiring Diagrams........................................................................................................... 171

Servicing and Maintenance .......................................................................................... 179

Troubleshooting............................................................................................................ 180

Eploded View and Parts List ........................................................................................ 181

This manual supercedes MFCU-2009

Note : Installation and maintenance are to be performed only by qualified personnel who are

familiar with local codes and regulations, and experienced with this type of equipment.

Caution: Sharp edges and coil surfaces are a potential injury hazard. Avoid contact with them.

Warning : Moving machinery and electrical power hazard. May cause severe personal

injury or death. Disconnect and lock off power before servicing equipment.

"McQuay" is a registered trademark of McQuay International. All rights reserved.

Bulletin illustrations cover the general appearance of McQuay International products at the time of publication.

We reserve the right to change design and construction specifications at any time without notice.

c 2010 McQuay International. All rights reserved throughout the world.

Page 3

NomencNomenc

Nomenc

NomencNomenc

Production spec variation

Type of ref. connection

X : Not applicable

Electrical

A : 220 - 240V/1Ph/50Hz

F : 380 - 415V/3Ph/50Hz

U : 220 - 240V/1Ph/50Hz/60Hz

lala

la

lala

turtur

tur

turtur

ee

e

ee

M

WM 025 G2

W AB

-

A

Piping

H : 4 pipes system

Model Type

W : Chilled water fan coil

Series

G2 : G+ series

Capacity

025 : 18,000 Btu/h (Cooling)

Model Name

X

WM : Wall mounted split type

CK : Ceiling cassette split type

CM : Ceiling exposed split type

CC : Ceiling concealed split type

DB : Ducted split type

Brand

M : McQuay

1

Page 4

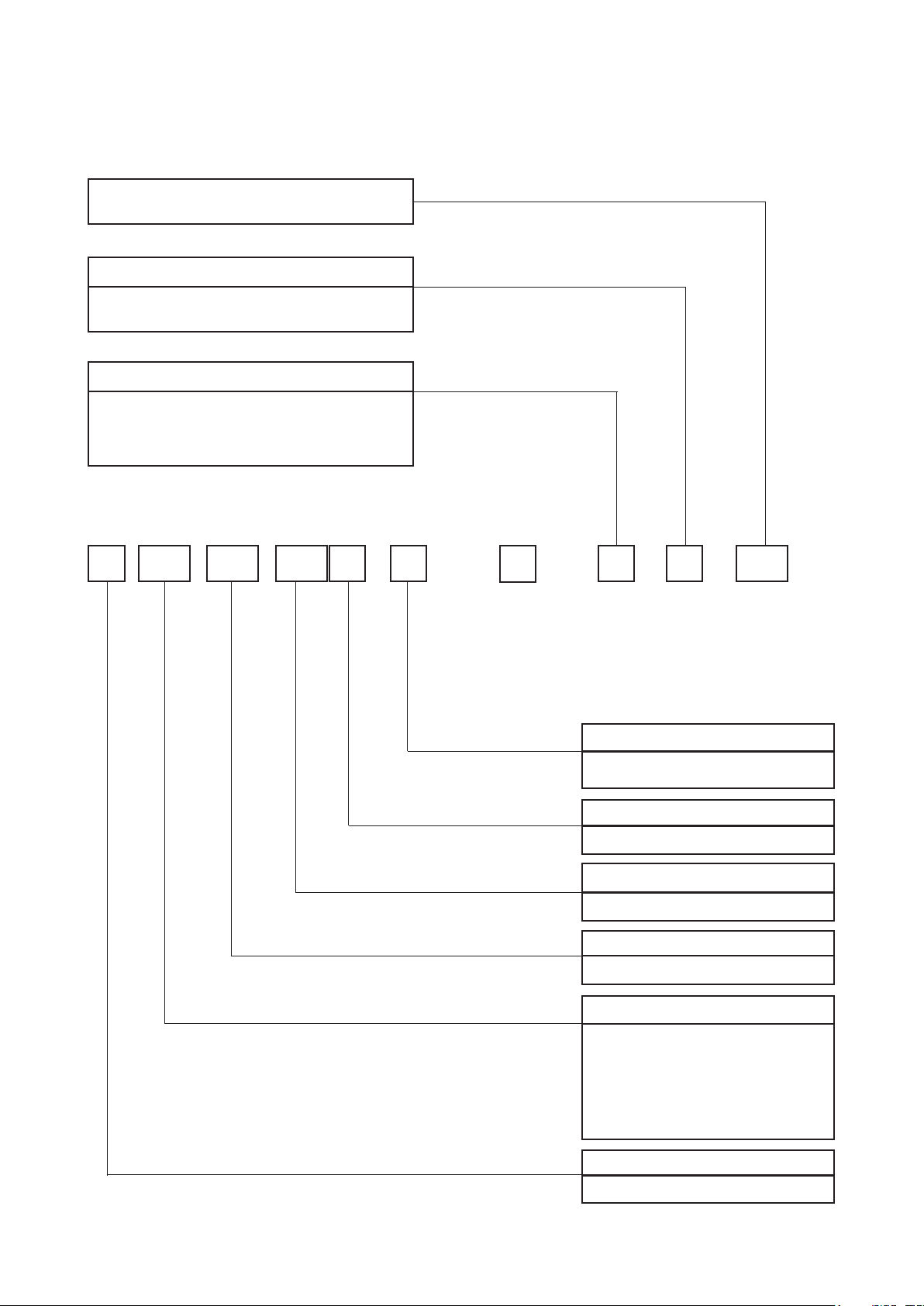

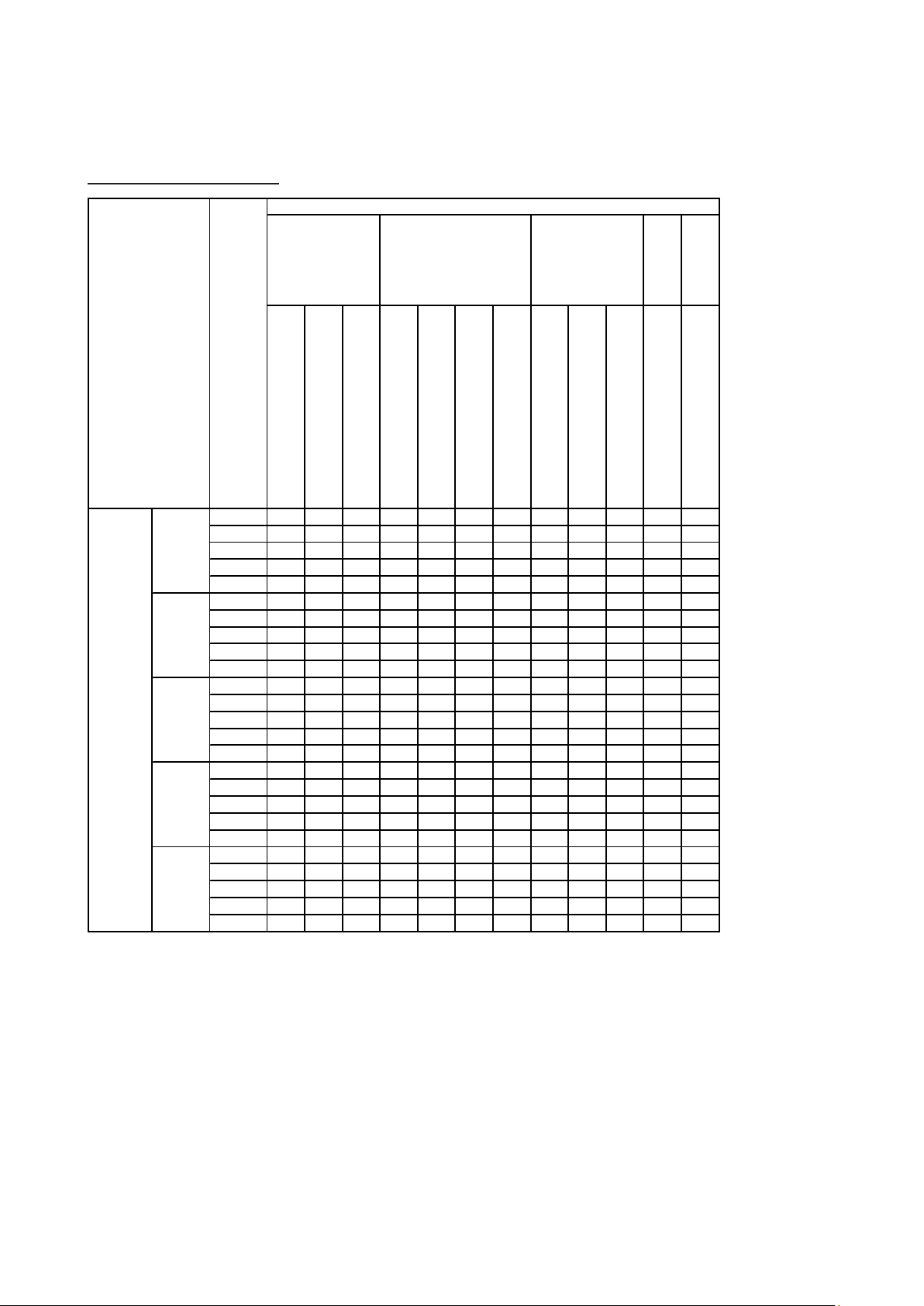

Product Line-Up

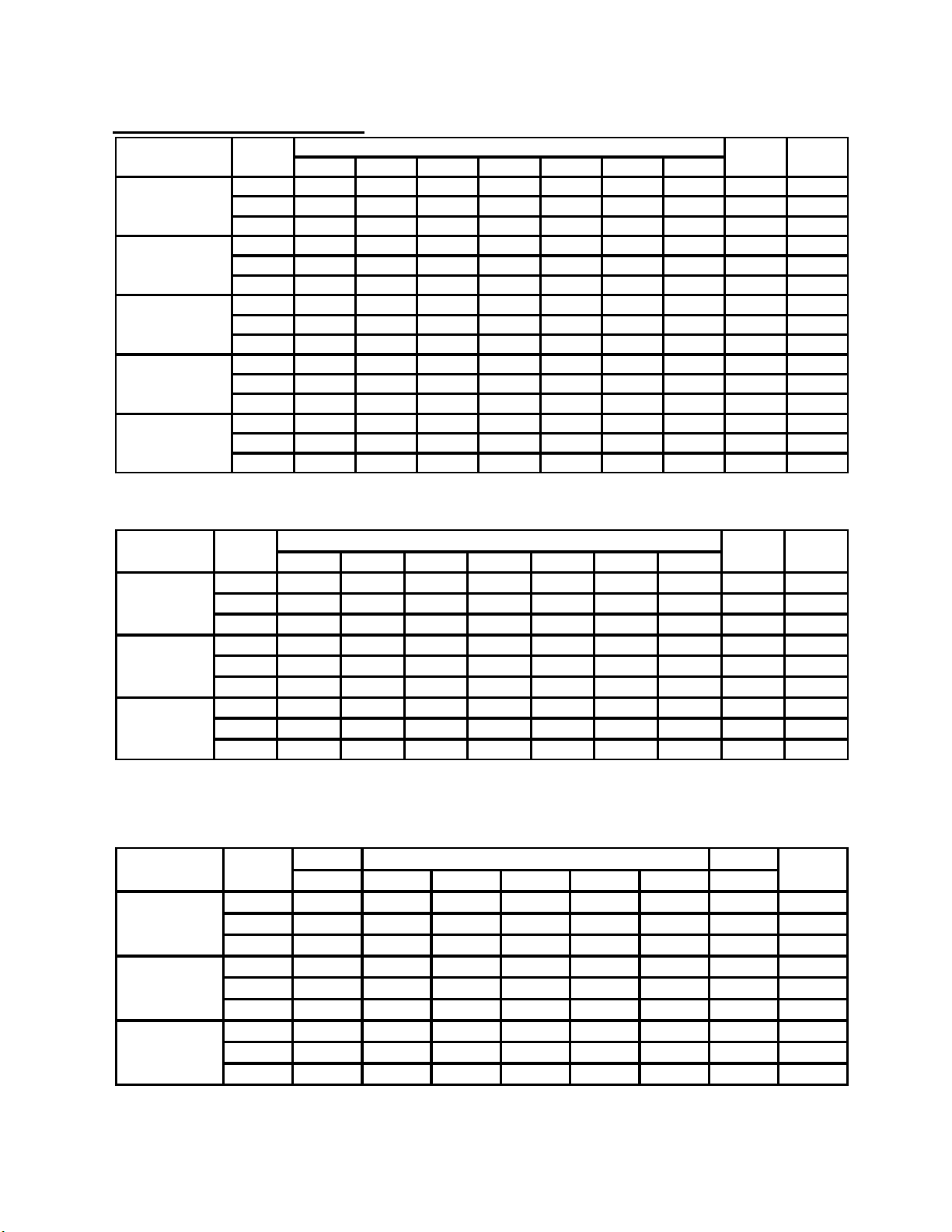

MWM-G2W Product Line-Up

CLASSIFICATION

MWM

MODEL NAME

007G2W

010G2W

015G2W

020G2W

025G2W

301W

Control

NOMENCLATURE

PCB W2_L

Valve Application only

AXALxxxx xxxxx x x

AXAKxxxxx xxxx x x

AXALxxxx xxxxx x x

AXAKxxxxx xxxx x x

AXALxxxx xxxxx x x

AXAKxxxxx xxxx x x

AXALxxxx xxxxx x x

AXAKxxxxx xxxx x x

AXALxxxx xxxxx x x

AXAKxxxxx xxxx x x

AXAExxx x xxx x x

AXADxxx xxxx x x

Turbo

Auto Air Swing

G17 Cooling

HANDSET

G17 Heat Pump

CONNECTION

Left piping

1/2" BSP (female) brass adaptor

FILTER

Ionizer

Nanosilver + Nanovis filter

PANEL

+

Light Grey Chasis

Pure White Chasis

MARKING

Std Marking (CE)

G2 silver coated facelift

2

Page 5

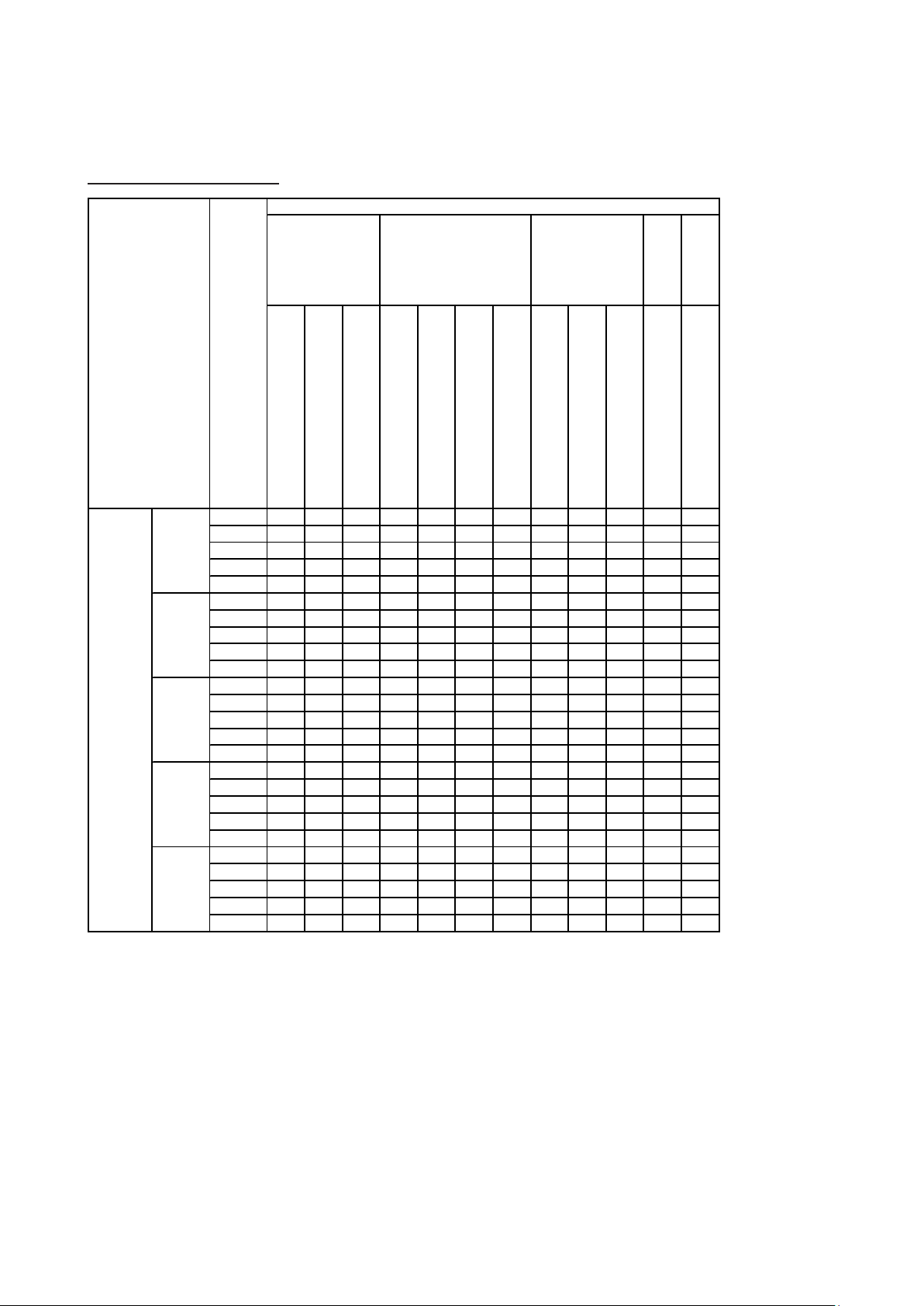

Product Line-Up

MCM-DW/CBW/EW Product Line-Up

CLASSIFICATION

MCM

MODEL NAME

020DW

025DW

030DW

040DW

050DW

007CBW

010CBW

015CBW

015EW

020EW

025EW

CONTROL

NOMENCLATURE

UCW - W2.0

Valve / Valveless Application

AXCExx x xxx

AXCFxx xxxxx

AXCG xx xxx

AXCHxx x xxx

AXCIxx x xxx

AXCExx x xxx

AXCFxx xxxxx

AXCG xx xxx

AXCHxx x xxx

AXCIxx x xxx

AXCExx x xxx

AXCFxx xxxxx

AXCG xx xxx

AXCHxx x xxx

AXCIxx x xxx

AXCExx x xxx

AXCFxx xxxxx

AXCG xx xxx

AXCHxx x xxx

AXCIxx x xxx

AXCExx x xxx

AXCFxx xxxxx

AXCG xx xxx

AXCHxx x xxx

AXCIxx x xxx

UXBFxxx xxx

UXBGxx x xxx

UXBHxx x xxx

UXBFxxx xxx

UXBGxx x xxx

UXBHxx x xxx

UXBFxxx xxx

UXBGxx x xxx

UXBHxx x xxx

AXAC x x

AXADxx x xxx

AXAC x x

AXADxx x xxx

AXAC x x

AXADxx x xxx

G17 Cooling

Without Controller

x

x

x

HANDSET

G17 Heat Pump

SLM 3 Cooling

Netware 3 (Cool/Heat)

SLM 3 Heat Pump

FILTER

CONNECTION

3/4" BSP (female) union

xxx

xxx

xxx

MARKING

Saranet filter

Std Marking (CE)

3

Page 6

Product Line-Up

AXBA

AXBA

AXBA

MCK-AW/AWH/CW Product Line-Up

MCK

CLASSIFICATION

CONTROL

MODELNAME

020AWAXBExxxx xxxxxx

025AWAXBExxxx xxxxxx

030AWAXBExxxx xxxxxx

040AWAXBExxxx xxxxxx

050AWAXBExxxx xxxxxx

020AWH AXAA xxxxxxx x

025AWH AXAA xxxxxxx x

030AWH AXAA xxxxxxx x

040AWH AXAA xxxxxxx x

050AWH AXAA xxxxxxx x

010CW AXAB xxxx xx xxx

015CW AXAB xxxx xx xxx

020CW AXAB xxxx xx xxx

NOMENCLATURE

UCW‐W2.0

Control(dependonpanel)

Autoairswing

Valve/ValvelessApplication

CONNECTION

4pipesystems

MARKING

PLCKAW‐NNET3

StdMarking(CE)

3/4"BSP(female)brassunion

MCK‐AW

PLCKAW‐NSLM3HP

PANEL

PLCKCW‐NSLM3HP

MCK‐CW

PLCKCW‐NG17Cooling

MCK‐AWH

PLCKAW‐NG17Cooling

PLCKAW‐NG17HeatPump

PLCKAWH‐NG17HeatPump

PLCKCW‐NG17HeatPump

4

Page 7

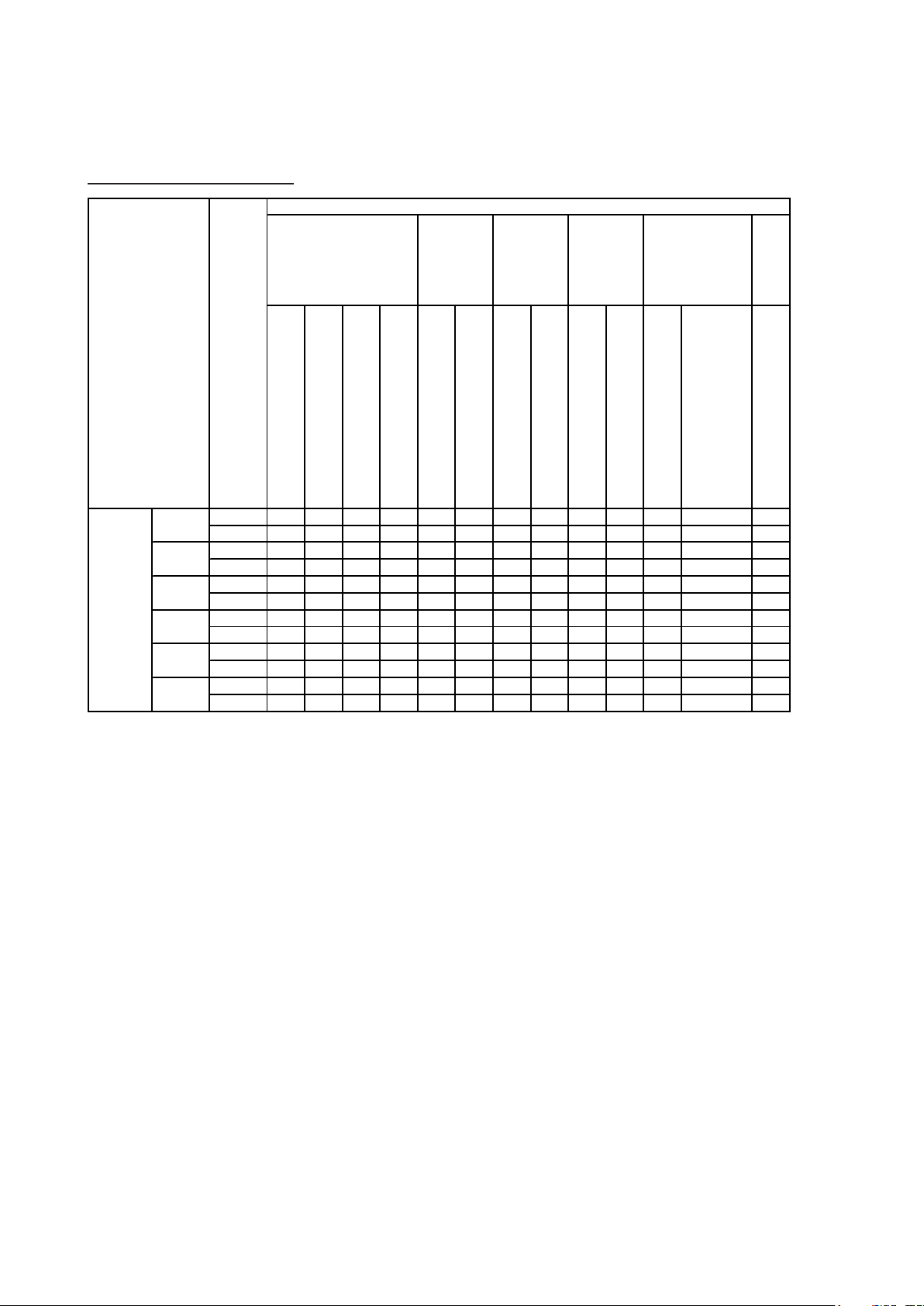

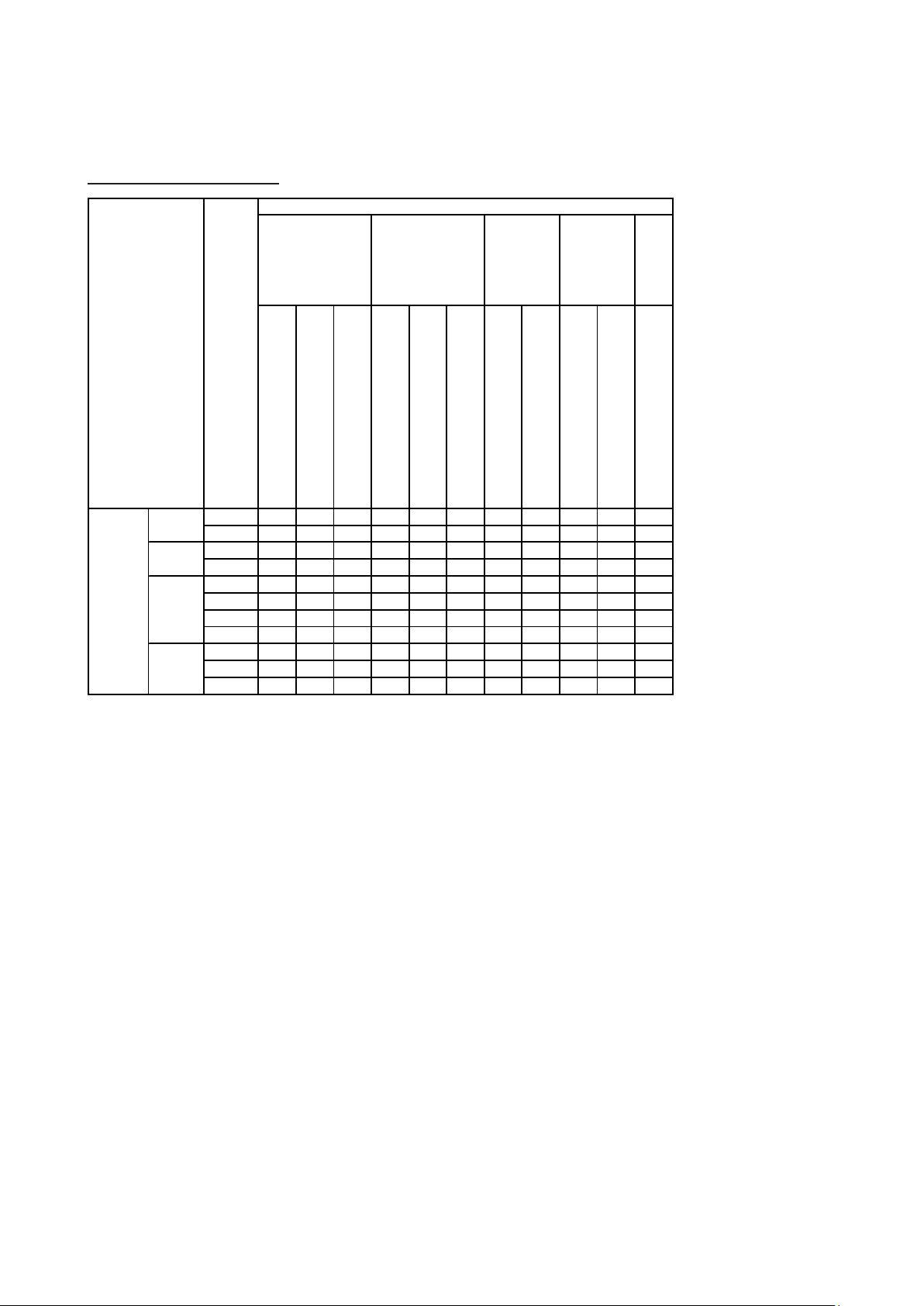

Product Line-Up

MCC-CW Product Line-Up

CLASSIFICATION

MCC

MODEL NAME

010CW

015CW

020CW

025CW

028CW

CONTROL

NOMENCLATURE

Cool/ Heat

UCW - W2.0

Without Controller

Valve / Valveless Application

AXAKx x xx xxxx

AXBCxxx xxx xxx

AXAJxxx x xxxx

AXACx xx xxxx

AXBAxxxx x xxx

AXAKx x xx xxxx

AXBCxxx xxx xxx

AXAJxxx x xxxx

AXACx xx xxxx

AXBAxxxx x xxx

AXAKx x xx xxxx

AXBCxxx xxx xxx

AXAJxxx x xxxx

AXACx xx xxxx

AXBAxxxx x xxx

AXAKx x xx xxxx

AXBCxxx xxx xxx

AXAJxxx x xxxx

AXACx xx xxxx

AXBAxxxx x xxx

AXAKx x xx xxxx

AXBCxxx xxx xxx

AXAJxxx x xxxx

AXAAx xx xxxx

AXBAxxxx x xxx

HANDSET

SLM 3 Cooling

Netware 3 (Coll/Heat)

SLM 3 Heat Pump

Left piping

CONNECTION

Right piping

FILTER

MARKING

Saranet Filter

Std Marking (CE)

3/4" BSP (female) adaptor

5

Page 8

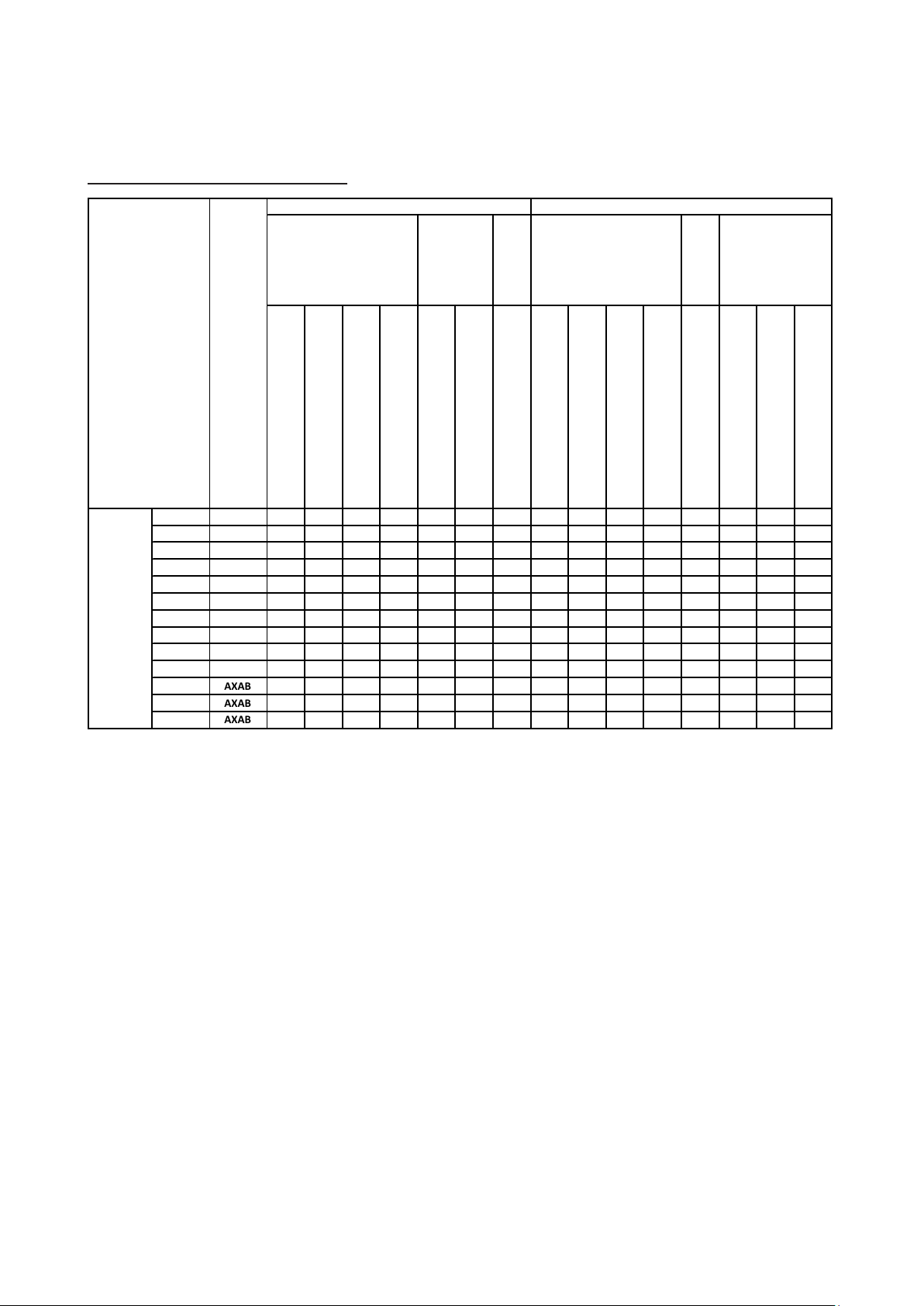

Product Line-Up

MCC-CW Product Line-Up

CLASSIFICATION

MCC

MODEL NAME

030CW

038CW

040CW

050CW

060CW

CONTROL

NOMENCLATURE

Cool/ Heat

UCW - W2.0

Without Controller

Valve / Valveless Application

AXAKx x xx xxxx

AXBCxxx xxx xxx

AXAJxxx x xxxx

AXAAx xx xxxx

AXBAxxxx x xxx

AXAKx x xx xxxx

AXBCxxx xxx xxx

AXAJxxx x xxxx

AXAAx xx xxxx

AXBAxxxx x xxx

AXAKx x xx xxxx

AXBCxxx xxx xxx

AXAJxxx x xxxx

AXAAx xx xxxx

AXBAxxxx x xxx

AXAKx x xx xxxx

AXBCxxx xxx xxx

AXAJxxx x xxxx

AXAAx xx xxxx

AXBAxxxx x xxx

AXAKx x xx xxxx

AXBCxxx xxx xxx

AXAJxxx x xxxx

AXAAx xx xxxx

AXBAxxxx x xxx

HANDSET

SLM 3 Cooling

Netware 3 (Coll/Heat)

SLM 3 Heat Pump

Left piping

CONNECTION

Right piping

FILTER

MARKING

Saranet Filter

Std Marking (CE)

3/4" BSP (female) adaptor

6

Page 9

Product Line-Up

MDB-BW Product Line-Up

CLASSIFICATION

MDB

MODEL NAME

075BW

100BW

125BW

150BW

CONTROL

NOMENCLATURE

UCW - W2.0

Without Controller

Valveless Application

AXAA x x x x x x x x

AXABxxxx xx x x

AXAA x x x x x x x x

AXABxxxx xx x x

FXAA x x x x x x x x

FXABxxxx x x xx

FXACxxxxx x xx

FXADxxxxx x xx

FXAA x x x x x x x x

FXABxxxx x x xx

FXACxxxxx x xx

Brazing (OD 28.6mm, 1 1/8")

CONNECTION

Left piping

Right piping

Horizontal flow

DISCHARGE

Vertical flow

FILTER

Saranet Filter

MARKING

R15/R29 Filter

Std Marking (CE)

7

Page 10

FF

eaea

ea

eaea

turtur

tur

turtur

F

FF

Space Saving

Different types of fan coil units are designed to be both versatile and space saving to suit every interior design. Ceiling

concealed type for the sophisticated, luxurious floor space saving, all kind of interior decoration; ceiling exposed type for

economical and space saving installation; etc.

Zone Control

These fan coil units can be installed in different zones as each unit operates independently. Zone control on energy

saving, different comfort requirement; better air distribution needs can therefore be easily achieved.

Standardisation Of Fan Coil Unit Control

The fan coil unit controller is standardized using W2 I.C, which enables the selection of valve / valveless and cooling /

heating applications. This allows the user to choose the desired application by just plugging in or removing the jumpers

at certain connectors on the PCB. The advantages of these units are lesser inventory for finished goods stock and spare

parts. For more details, please refer to General Installation guide.

Unique Features For MWM Series

Easy Installation

The wall mounted fan coil unit is easily installed because of its compact size, slimness and light weight. Slim and short

outdoor unit can be easily installed even in a narrow balcony and passageway and yet have a stable profile.

Space Saving

No space is required on either floor or ceiling. This newly developed super slim design for wall mounting maximises floor

space usage and enhance ceiling appearance where ceilings are low.

eses

es

eses

Quiet Operation

Cooling comfort is improved by whisper-quiet operation which is achieved by a tangential fan.

Excellent Air Distribution

Air discharge direction can be adjusted in four directions, manually or automatically by using LCD remote control, coupled

with good air flow, the unit provides excellent air distribution.

Facilitated Maintenance Ensured

The new design cassette filter is slide-out type which can be easily removed at the air inlet grille for cleaning. Maintenance

is easy for electrical components, piping and wiring as these are all easily accessible by merely removing front plastic

panel.

Wireless Remote Control

The compact LCD transmitter is able to operate the air conditioner unit within the distance of 9 meters. Fan motor speed

can be set at low/medium/high or automatic. Sleep mode automatically increase set temperature since room temperature

is lower at night thus achieving comfort surrounding. Air flow direction can be controlled automatically. Room temperature

is controlled by electronic thermostat. The unit can be preset to on and off automatically for maximum of 15 hours by using

timer on/off.

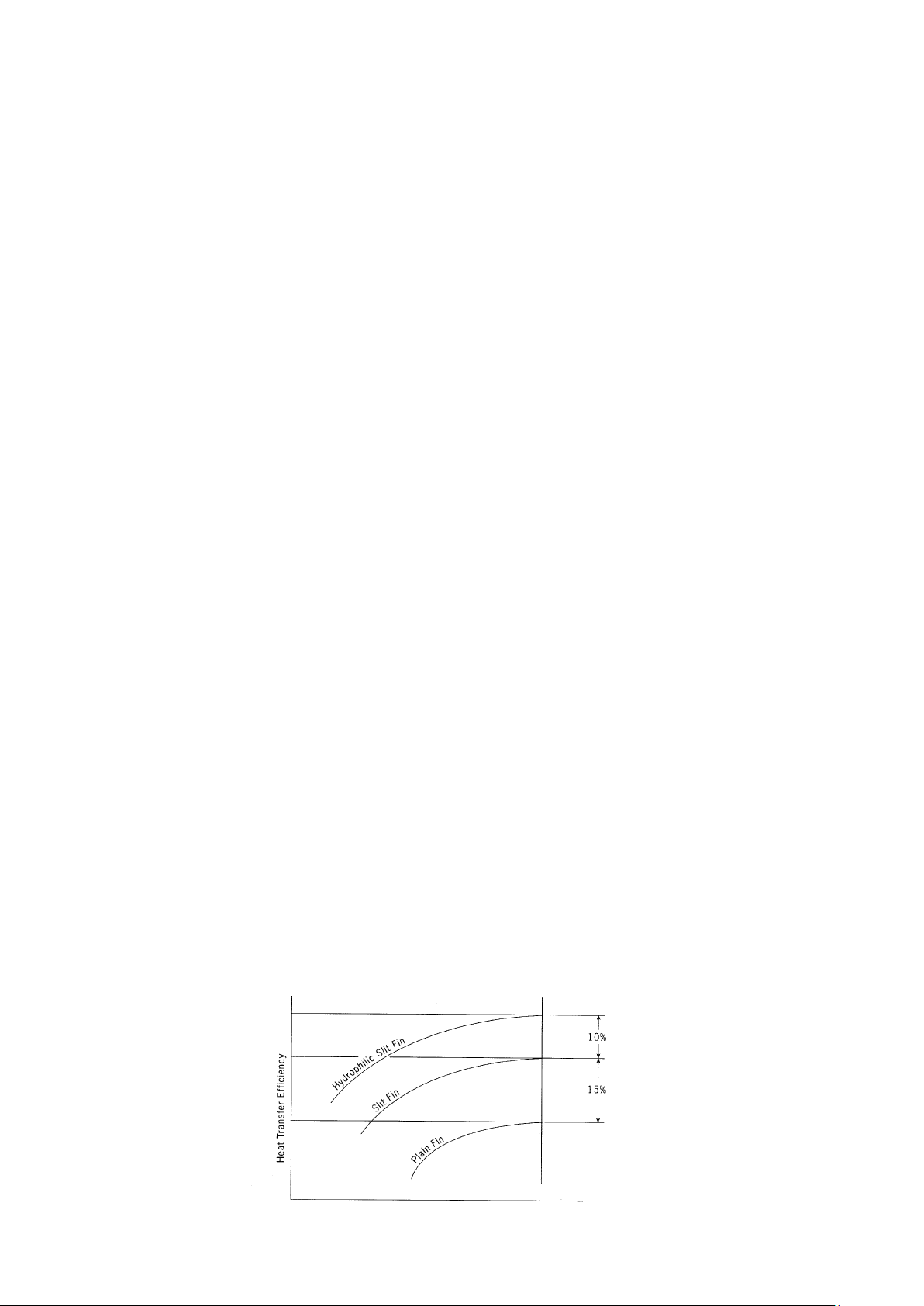

Slit Fin

The unique Hydrophilic slit fin has greatly improved the air flow and the contact surfaces with the air thus to boost the

cooling capacity.

8

Page 11

Unique Features For MCK Series

Built In High Head Drain Pump

The unit comes with a built in high head drain pump. Condensate water can be pumped up to 700mm and drain out

smoothly.

4-way Air Discharge And Air Swing

These features greatly improve the air distribution in the conditioned space.

Wireless And Wired Controller Option

Wireless Handset is the standard controller. However if wired controller required, Netware3 & SLM3 wired controller is a

wise choice(optional).

Unique Features For MCM-DW/EW Series

2-way Air Discharge And Air Swing

The 2-way air discharge couple with the air swing function, provide better air distribution in the conditioned space.

Easy Maintenance

The air filter and components can be easily accessed from the bottom of the unit. This make servicing and maintenance

become a simple task.

Wireless And Wired Controller Option

Wireless Handset is the standard controller. However if wired controller required, Netware3 & SLM3 wired controller is a

wise choice(optional).

Unique Features For MCC Series

Elegance And Prestige

As the unit is installed above the ceiling with only the supply and return air grille exposed to view, the air conditioned space

will appear as elegant and prestigious as a centralized air conditioned area.

Evergreen Design

This unit will never become obsolete as the unit is completely concealed away. Interior decoration for maximum aesthetic

beauty as well as interior design is easily achieved.

Superior Air Distribution

As the conditioned air can be distributed to every corner of the area by air duct, this will ensure more pleasant living

environment, thus provide extra comfort to the occupants.

Optional Duct Accessories

The optional duct accessories makes the ducting and installation work so easy.

Wired Controller

Netware3 & SLM3 wired controller offers simple and flexibility in controlling the unit.

Unique Features For MDB-BW Series

Superb Air Distribution

These units are designed with high air flow and static, enables adequate distribution of air to the desired space. Providing

comfort to every corner of the room.

Reliability

The structures are strong and robust to ensure the product operation life.

Versatile

Multiple rooms can be cooled together by just using one unit of MDB.

9

Page 12

√

AA

pplicapplica

A

pplica

AA

pplicapplica

General Installation Guide

System Configuration

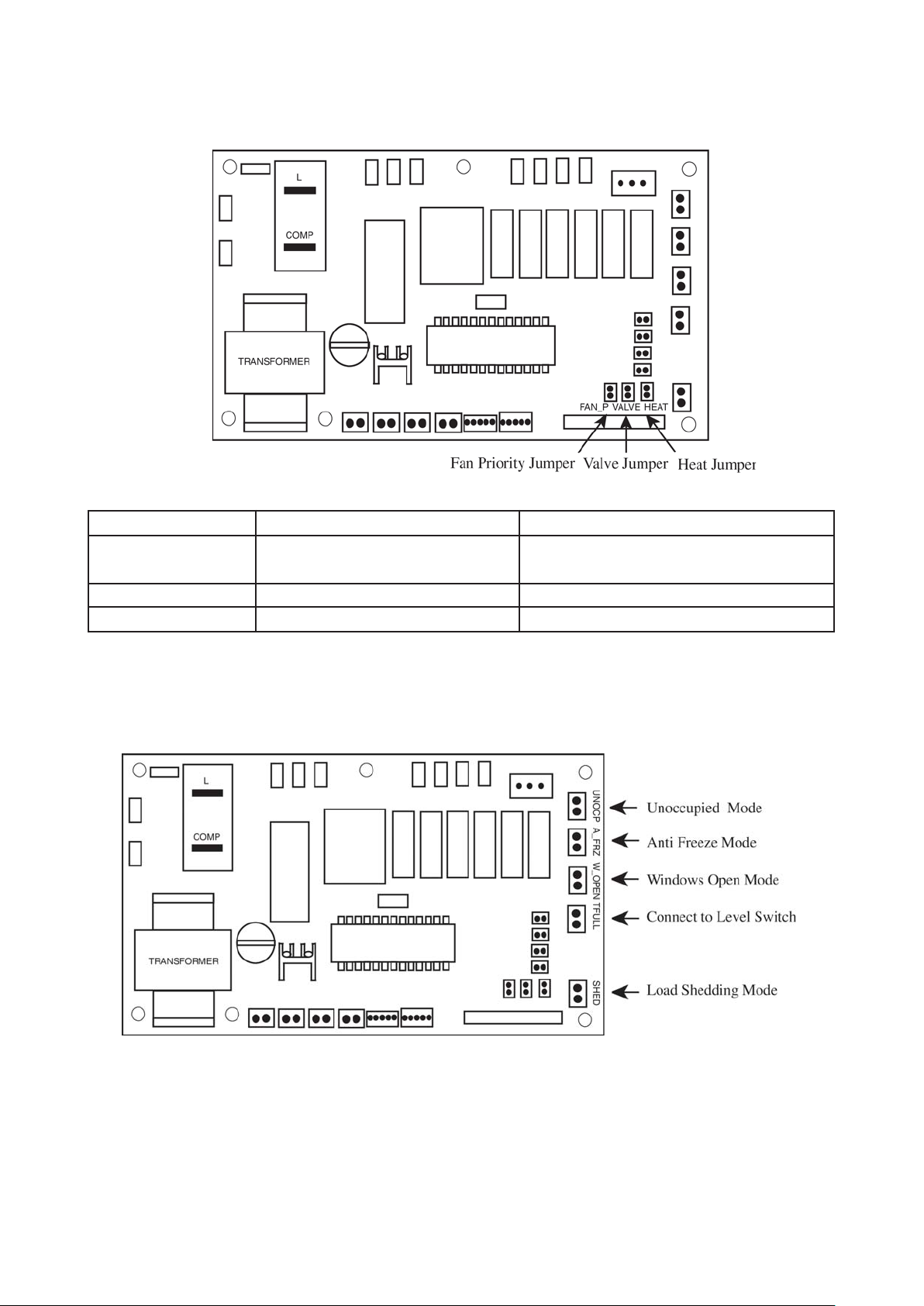

The standard controller board (W2) comes with a VALVE jumper and a HEAT jumper. The system can be

configured as the jumper selection listed below:

Heatpump Mode & Valve Application

Heatpump Mode & Valveless Application

Cooling Mode & Valve Application

Cooling Mode & Valveless Application

Jumper Remained X Jumper Removed

VALVE & HEAT Jumper Location

tion Inftion Inf

tion Inf

tion Inftion Inf

Disconnect the power supply to the unit before attempting to connect the wiring

oror

or

oror

mama

ma

mama

CACA

CA

CACA

tiontion

tion

tiontion

HEAT Jumper VALVE Jumper

UTION !UTION !

UTION !

UTION !UTION !

√√

√ X

X √

XX

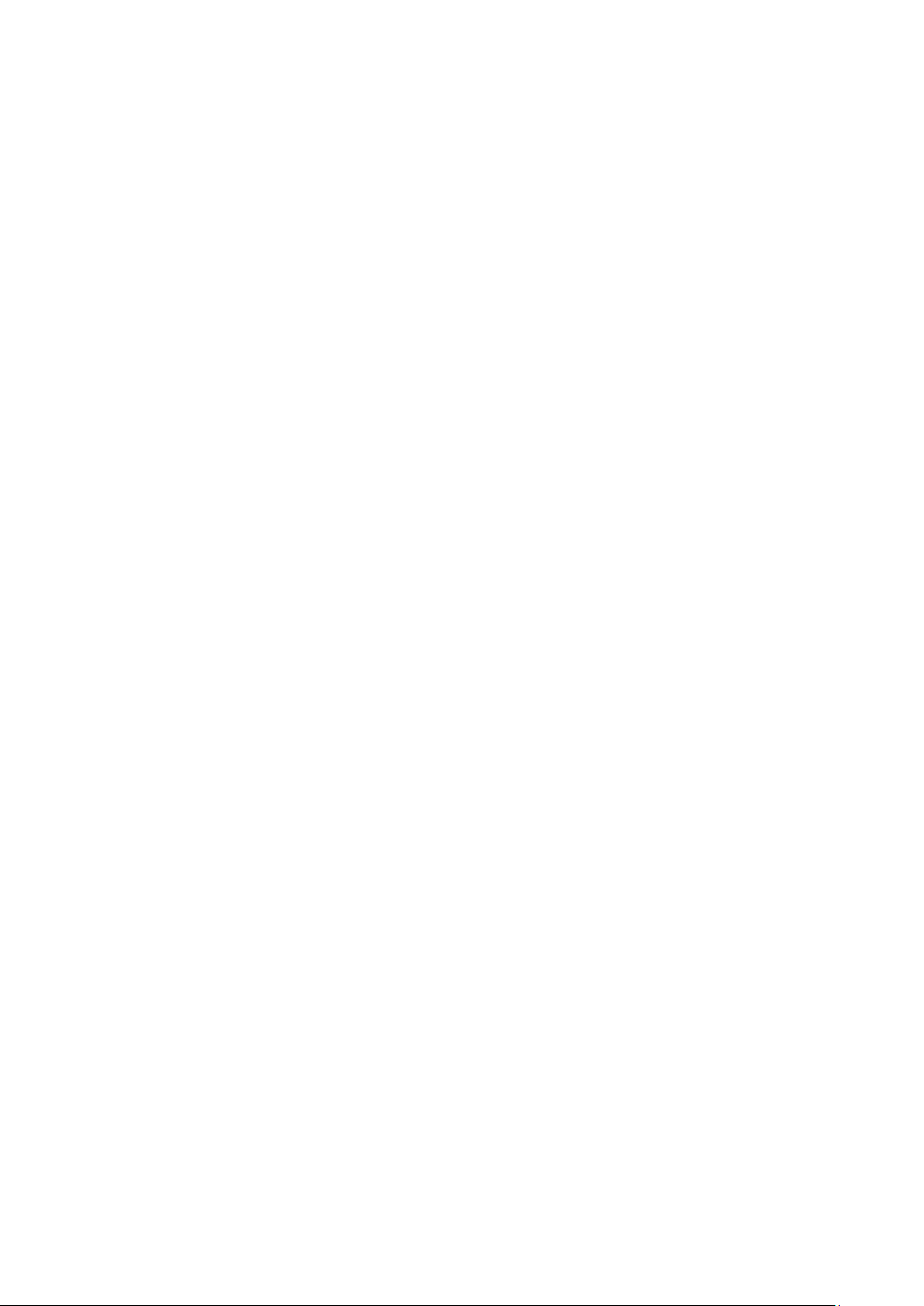

Model: MWM - G2W / 301W

1. VALVE jumper is plugged into JVLV connector on the emergency switch board.

2. HEAT jumper is plugged into JMODE connector on the emergency switch board.

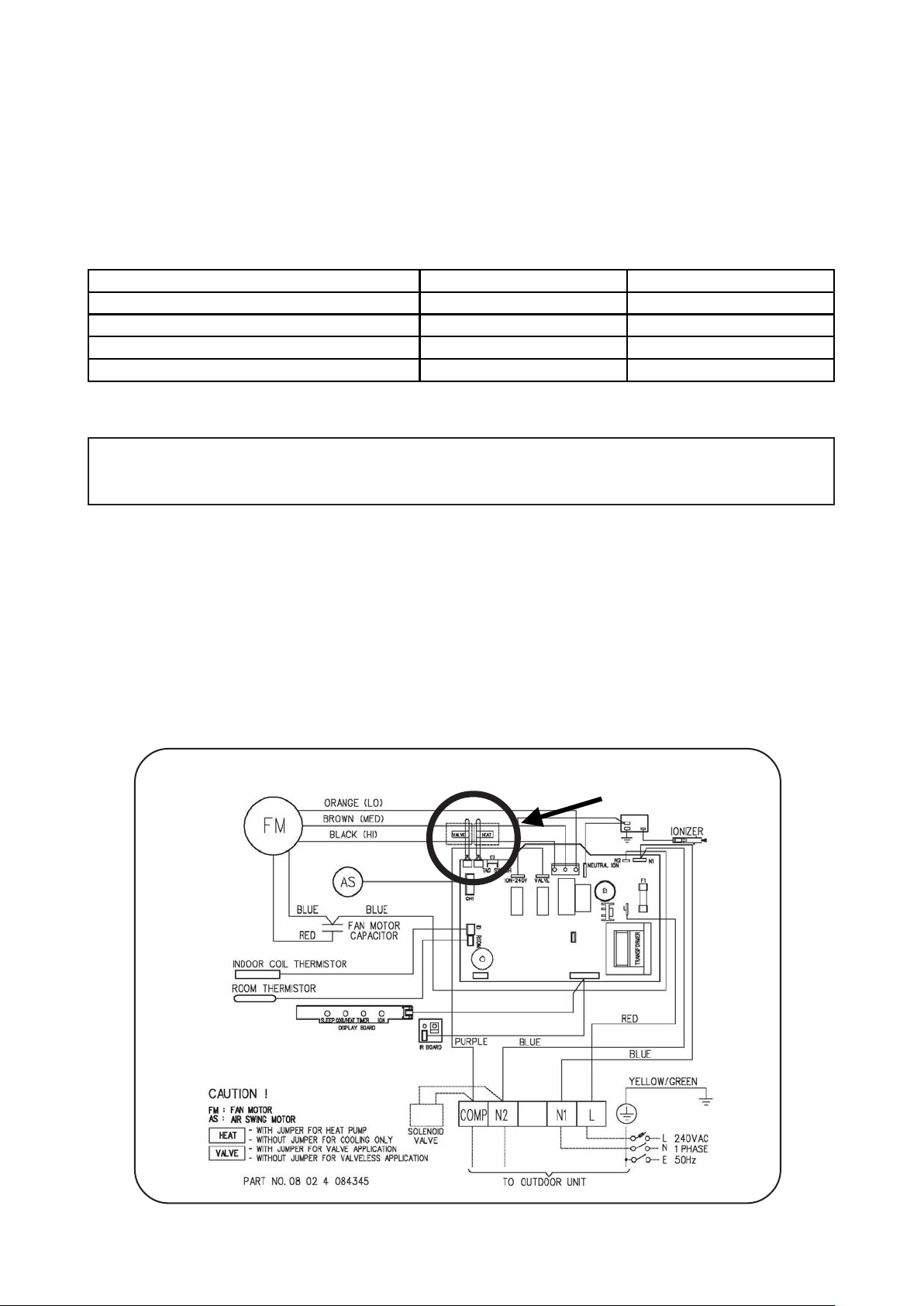

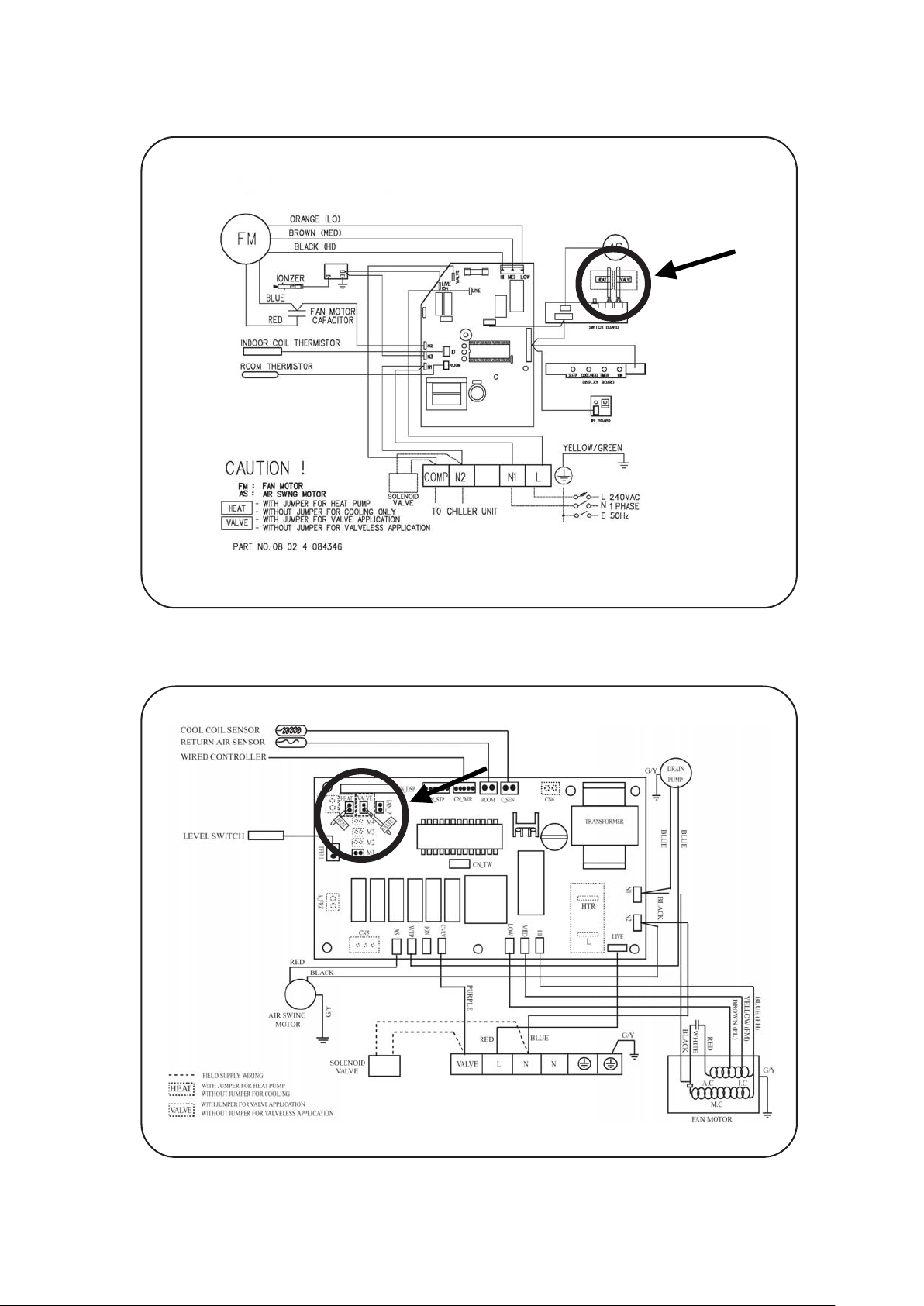

Model: MCK-AW/AWH/CW, MCM-DW/CBW/EW and MCC-CW

1. VALVE jumper is plugged into JVLV connector on the main board.

2. HEAT jumper is plugged into OD connector on the main board.

Model : MWM 007 / 010 / 015G2W (IONIZER)

10

Page 13

Model : MWM 020 / 025G2W (IONIZER)

Model : MCM Series / MCC Series / MCK-AW/CW

11

Page 14

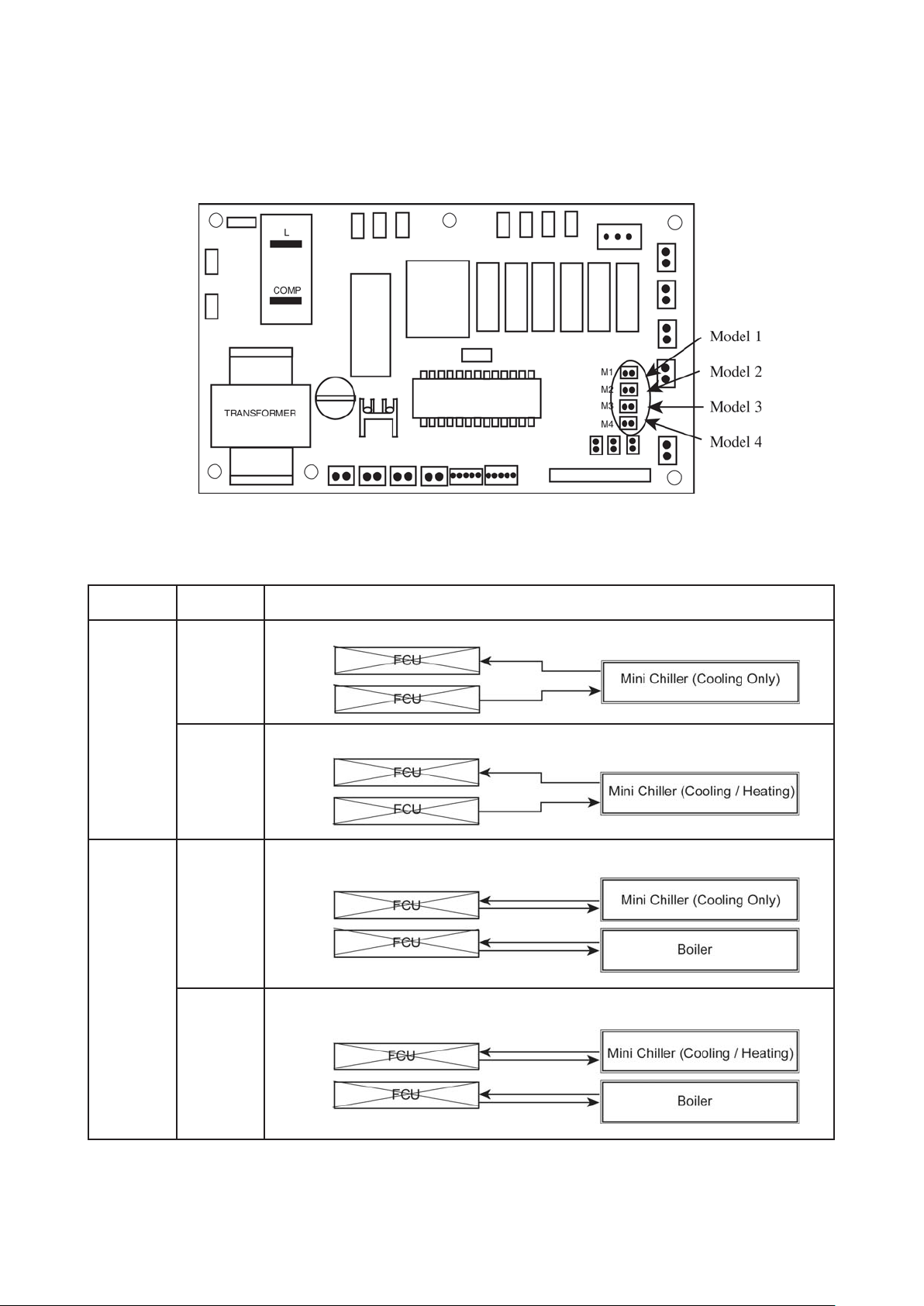

MCK-AWH 4 pipes system controller board setting

A) Model selection

The standard controller board (W2.0) comes with a default setting for model selection. Please select the model

accordingly by using jumper.

System Model Function

2 Pipe

System

4 Pipe

System

M1 Model 1

M2 Model 2

M2 Model 2

M4 Model 4

Cooling or Heating

Cooling or Heating with Auxiliary Heater

Cooling Only with Boiler

Cooling or Heating with Boiler

12

Page 15

B) Valve, Heat and Fan priority selection

Jumper With Jumper (Default) Without Jumper

Fan Priority Jumper User set speed or lower fan if auto Fan stop when thermostat cut off

mode is selected

Heat Jumper For Heat pump For cooling only

Valve Jumper For Valve control (Model 1,2,3 & 4) For valveless control (Model 1 & 2)

C) Others

The controller board comes with other option.

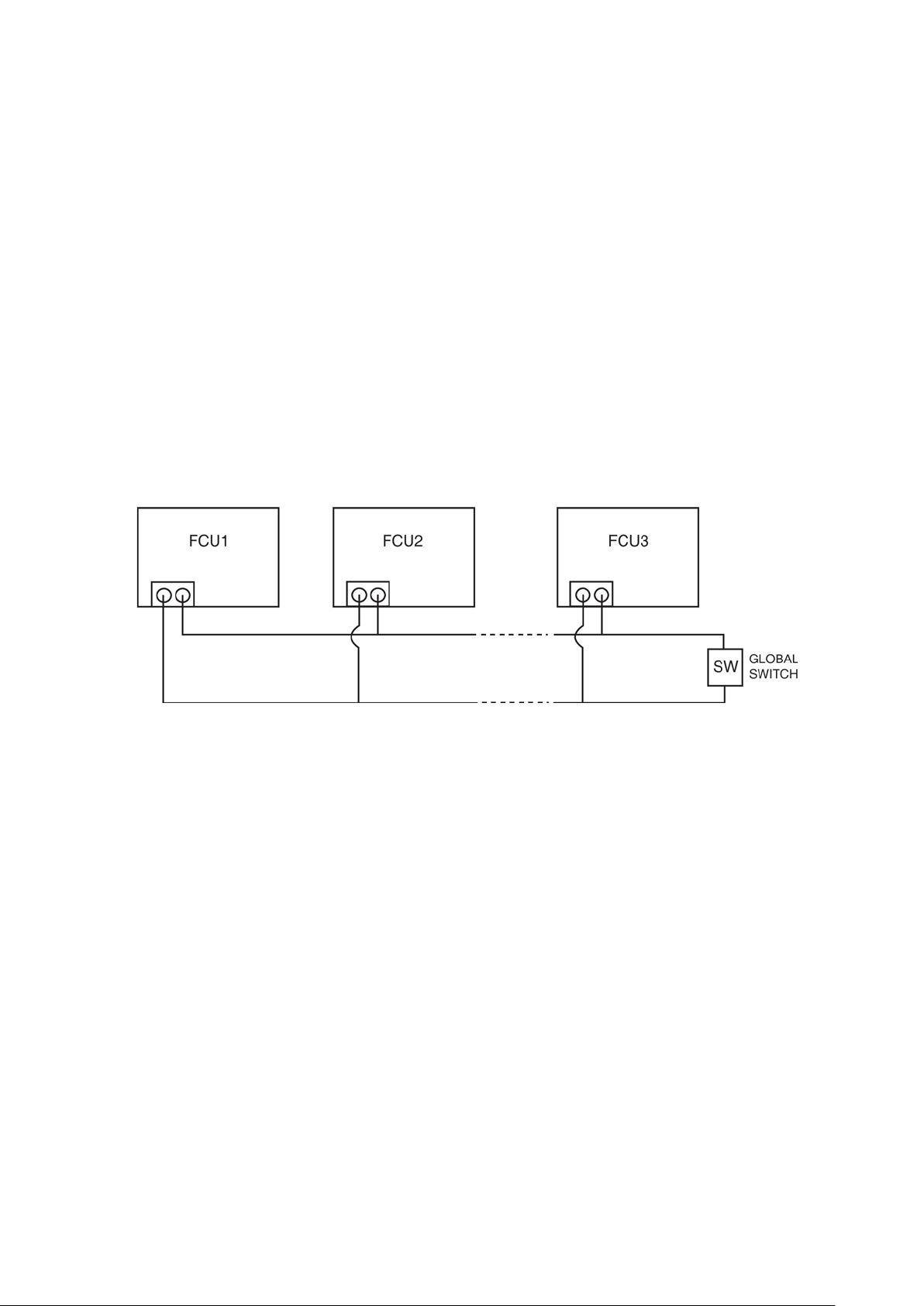

i) Unoccupied Mode

If the dry contact is closed, the Unoccupied mode is activated and vice versa. When Timer On is active, system

goes back to Occupied mode.

The dry contact connection points can be connected parallel with other fan coil unit (FCU) boards. If the dry

contact is closed, Unoccupied mode will be activated on all fan coil units that are connected parallel as shown in

figure below.

13

Page 16

ii) Anti Freeze Mode

Anti Freeze operation has the highest priority among all unit operation. Anti Freeze operation will be activated

only if dry contact is closed and vice versa.

iii) Window Open Mode

The dry contact connection points can be connected in parallel with other fan coil unit (FCU) boards. If the dry

contact is closed, Window open mode will be activated on all the fan coil units which are connected in parallel as

shown in figure below.

iv) Load Shedding

The dry contact connection points can be connected in parallel with other fan coil unit (FCU) boards. If the dry

contact is closed, Load shedding mode will be activated on all the fan coil units which are connected in parallel

as shown in figure below.

Global Unoccupied, Global Window Open and Global Load Shedding operation could also be activated via the

network communication bus line by master controller with or without the above connection.

NOTE :

i) Auto Fan Mode is only applicable in Model 3 only. ( Cooling only with Boiler)

ii) Fan mode is not available in valveless control.

iii) Wired handset (Netware and SLM) has an indoor room sensor. Avoid locating the wired handset at isolated

places where room temperature reading will be inaccurate.

14

Page 17

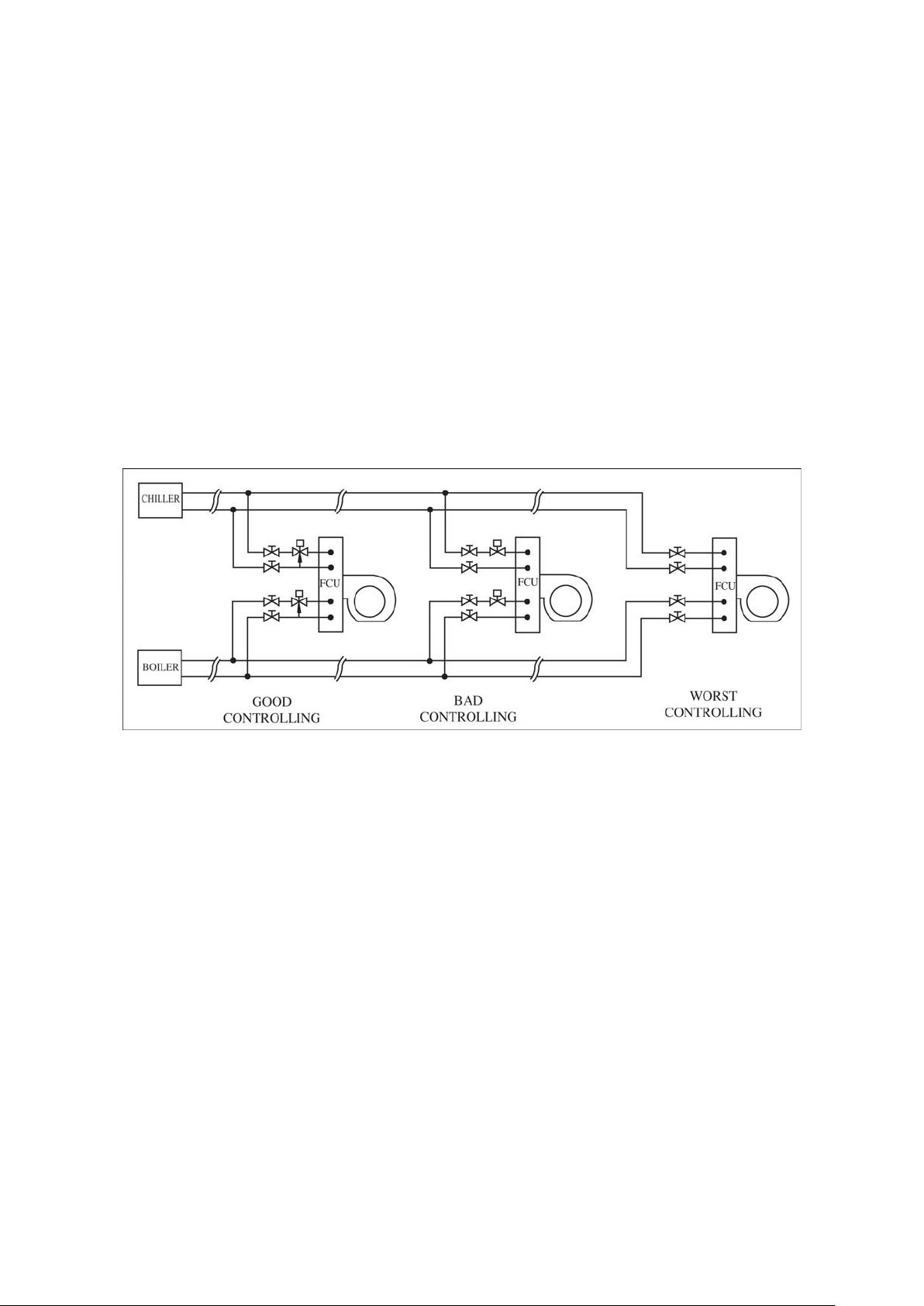

Water Piping Connection

The indoor unit is equipped with water outlet and inlet bare connection. There is an air-vent for air purging that is

fitted at the outlet water header.

3 ways solenoid valve is required for cycling off or bypass the chilled water.

Black steel pipe, polyethrene pipe, PVC pipe and copper tube recommended in field installation.

All types of piping and connection must be insulated by polyurethane (ARMAFLEX type or equivalent) to avoid

condensation.

Do not use contaminated or damaged pipe and fitting for installation.

Some main fitting components are needed in the system to enhance the capacity and ease of service, such as

gate valve, balancing valve, 2 ways or 3 ways solenoid valve, filter, strainer etc.

15

Page 18

Preliminary Site Survey

Electrical supply and installation is to conform to LOCAL AUTHORITY's (e.g. National Electricity Board) CODES

and REGULATIONS.

Voltage supply fluctuation must not exceed ± 10% of rated voltage. Electricity supply lines must be independent

of welding transformers which can cause supply fluctuation.

Ensure that the location is convenient for wiring and piping.

Mounting

For ceiling mounted models, locate a position where piping and ducting work can be kept to a minimum.

Ensure that overhead supports are strong enough to hold the unit's weight. Position hanger rods and check for

alignment with the unit. Check that hangers are secure and that the base of fan coil unit is level in two horizontal

positions.

Piping

Drain and water piping must be accurately connected.

Please refer to "Specification Sheet" for piping sizes.

Piping Support

All water mains must be adequately supported to carry the necessary weight involved, provisions must be

made by the installing contractor to allow for adequate free movement of all vertical and horizontal risers and

run outs. Due to the fact that cold water will be circulated through the water mains, a sizeable movement of the

water mains can be expected due to contraction. If for example, the piping is rigidly supported with no provision

for movement, it is very possible that the tubing of fitting may be broken causing water leakage in the conditioned spaces throughout the building.

Coil Venting

Each standard basic unit coil is equipped with a manually operated air vent which is installed at the end of a

small copper line leading into the highest point of the coil. By means of this valve, air may be vented manually,

from the coil to keep it operating at full capacity. When water is first introduced into a coil, air is sometimes

trapped in the coil tubing. This trapped air will reduce cooling capacity and create "Bubbling" or "Clanking"

noise within the units. To release air trapped in the coil, press the air vent head to allow air to flow out of the air

vent opening. Release when a steady stream of water appear.

Electrical Connection

As wiring regulations differ from country to country, please refer to your LOCAL ELECTRICAL CODES for field

wiring regulations and ensure that they are complied with. Besides, take note of the following general precaution:

1) Ensure that the rated voltage of the unit corresponds to the name plate before commencing wiring work.

2) Provide a power outlet to be used exclusively for each unit and a power supply disconnect and a circuitbreaker for over-current protection should be provided in the exclusive line.

3) The unit must be EARTH to prevent possible hazards due to insulation failure.

4) All wiring must be firmly connected.

16

Page 19

General Operation Guide

Start-Up

The following procedure must be completed before any attempts is made to put the entire system Into operation:

1) Piping connections completed.

2) Electrical connections completed.

3) Duct connections completed.

4) Auxiliary drain pans in position where required.

5) Drain line draining into drain pans.

6) Filters correctly installed and free of construction debris.

7) Motor-blower assembly rotates freely.

8) Unit Hydro-statically tested and air vented.

Starting The Fan Coil Unit

1) Turn on the switch of water pump.

2) Start water chiller.

3) Operate the fan coil unit by turning on the fan and set the control switch to get the desired speed.

4) Inspect the duct and piping condition and rectify problem (e.g. vibration, noise, etc.) if exist.

Servicing And Maintenance

Fan coil units are designed to operate continuously with minor routine maintenance. Since fan coil units cool

the discharging forced air, the efficiency with which the units operate is directly related to the amount of air

passing through the coil.

Air Filters

The function of the air filters is to remove foreign matter such as dirt, soot, pollen and certain other impurities

from the air passing through it. A clogged or dirty filter not only fails to do the job for which it is designed, but

restricts the flow of air over the coil.

The importance of cleaning the filter before it becomes clogged must be greatly stressed. The frequency with

which a filter should be cleaned will depend upon the amount of dust and foreign material that enters a unit, and

this depends upon location and situation.

The washable viledon or saranet filter may be cleaned by tapping the filter on a solid surface to dislodge heavy

particles. Wash under stream of warm water, with detergent if necessary. Dry it thoroughly before replacing.

Fan Motor

The fan motor is pre-lubricated and sealed at the factory. Therefore, no lubricating maintenance is required.

Coils

Clean coil unit by brushing between fins with a nylon brush. Brushing should be followed by cleaning with a

vacuum cleaner. The coil may also be cleaned by using a high pressure air hose and nozzle if a compressed air

source is available. It should be pointed out that if suitable air filter is used and taken care of properly, the coils

need no cleaning.

Drain Pipe

The drain pipe should be checked before operation of unit is begun. If it is clogged, steps should be taken to

clean the debris so that condensate will flow out easily.

Replacement Of Parts

Replacement of parts are available through your local dealers. When ordering parts, you must supply

1) Model name of the unit.

2) Serial number of the unit.

3) Part name and number.

17

Page 20

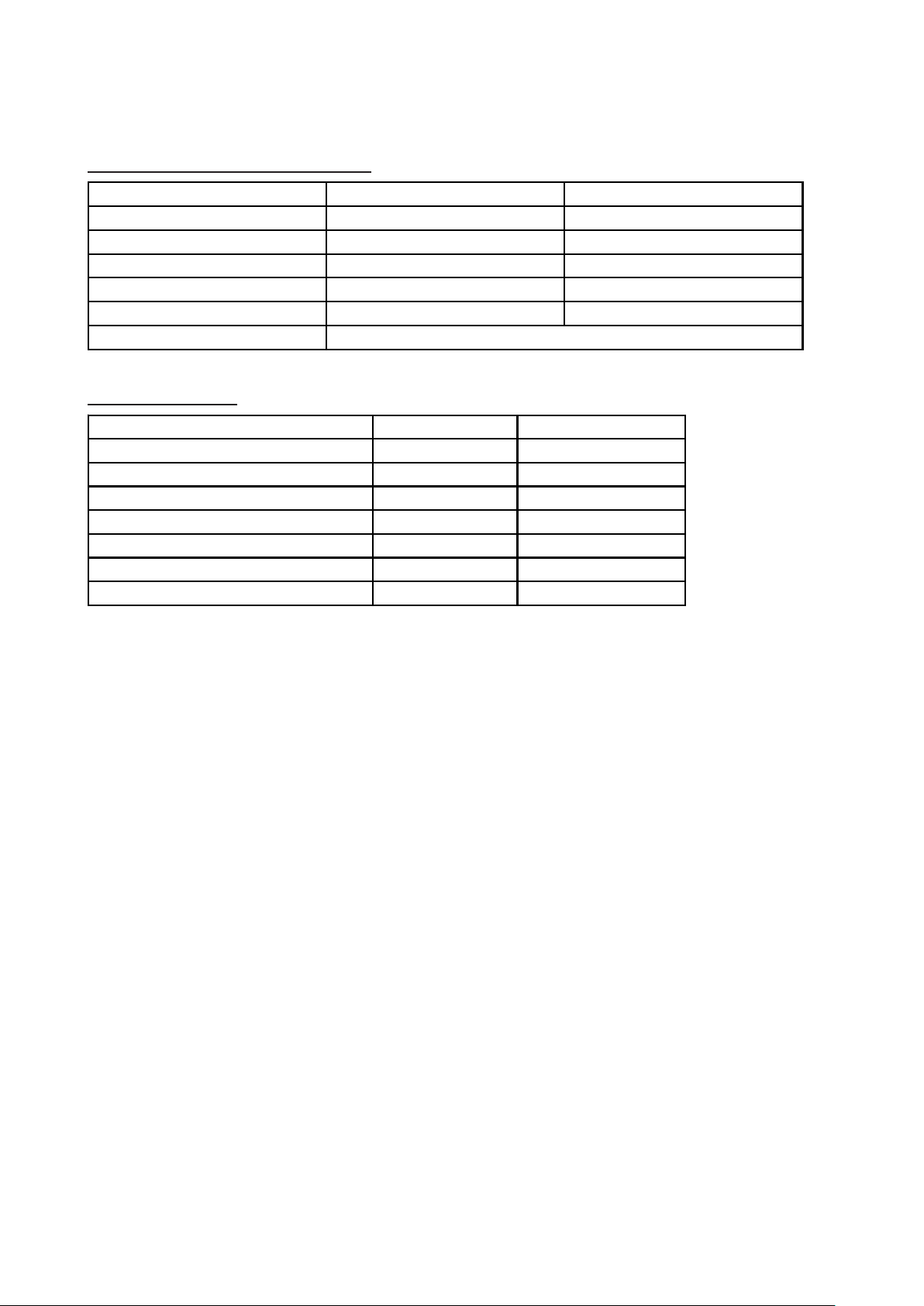

Controller

Type Of Controller Vs Type Of Fan Coil

MODELS STANDARD CONTROLLER OPTIONAL CONTROLLER

MWM - G2W G11 (Wireless) NETWARE3 / SLM3 (Wired)

MWM 301W G7 (Wireless) NETWARE3 / SLM3 (Wired)

MCK - AW / AWH / CW G7 (Wireless) NETWARE3 / SLM3 (Wired)

MCM - DW / CBW / EW G7 (Wireless) NETWARE3 / SLM3 (Wired)

MCC - CW NETW ARE3 / SLM3 (W ired) -

MDB - BW

Self Diagnosis Table

Error Indication Cool LED 7 Segment Display

Room Sensor error (short/open) Blinks 1 times E1

Pipe Water Sensor Error (short/open) Blinks 2 times E2

Water Pump Error Blinks 6 times E6

Pipe Water Temperature Fault Blinks 5 times E5

* Window Open Activated Blinks 3 times -

* Antifreeze Mode Activated Blinks 7 times -

* Load Shedding Activated Blinks 8 times -

Without Controller

* Only applicable for 4-pipe system

18

Page 21

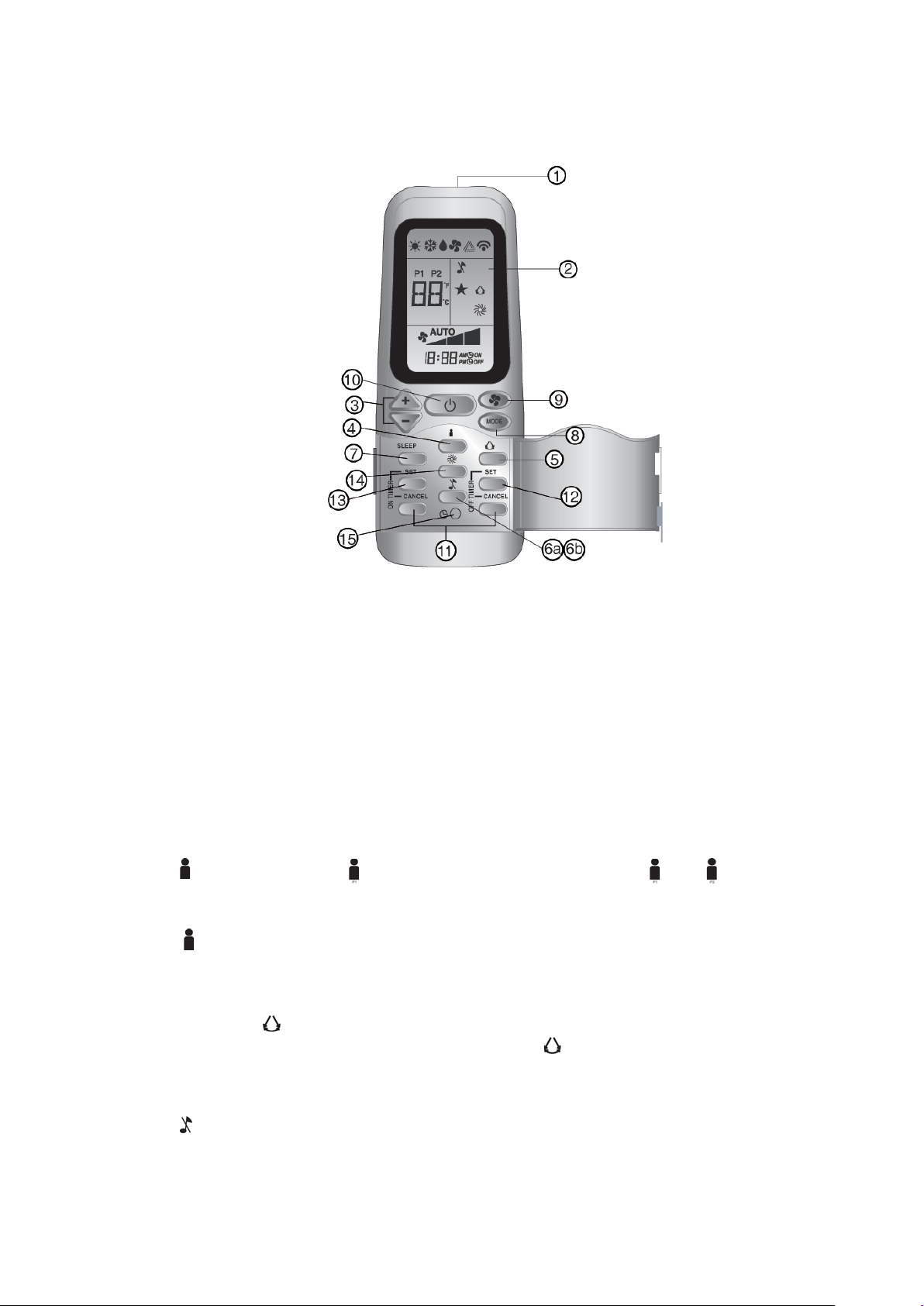

Operation Guide For G17

1. Transmission Source

• The source where the signal will be transmitted.

2. Signal Transmission Indication

• Blink to confirm that the last setting has been transmitted to the unit.

3. Temperature Setting

• To set the desired room temperature, press the S or T button to increase or decrease the set temperature.

• The temperature setting range is from 16°C to 30°C (optional setting 20°C to 30°C).

4. Personalize Setting

• Press and hold for 3s, then will blink. Press again to cycle between and .

• Set the desire setting, then leave the handset for 4s without pressing any key and it will save the setting

into the programme.

• Press once to activate the P1 setting, press again to cycle between P1 and P2.

• Press any key to deactivate the personalize setting.

5. Automatic Air Swing (optional)

• Press the SWING button to activate the automatic air swing function.

• To distribute the air to a specific direction, press the SWING button and wait until the louver move to

the desired direction and press the button once again.

6a. Silent Function

• Press for quiet operation.

• Fan speed turn to minimum speed.

• Press again to deactivate the function.

19

Page 22

6b. Ionizer Function

• Press button to activate the negative ion function, which will refresh the indoor air effectively.

7. Sleep Mode Setting

• Press the SLEEP button will activate the sleep mode function. This function is available under COOL,

HEAT and AUTO mode.

• When the unit is operating under cooling mode, the set temperature is increased by 0.5°C after 30

minutes, 1°C after an hour, and 2°C after 2 hours.

• When the unit is operating under heating mode, the set temperature is decreased by 1°C after 30

minutes, 2°C after an hour, and 3°C after 2 hours.

8. Operating Mode

• Press the MODE button to select the type of operating mode.

• For cooling only unit, the available modes are: COOL ( ), DRY ( ) and FAN ( ).

9. Fan Speed Selection

• Press the button continuously will toggle the fan speed in the following order:

Low → Med → High → Auto

• Stop pressing when the desired fan speed appears on the display screen.

10. “ON/OFF” Button

• Press one to start the air conditioner unit.

• Press again to stop the unit.

11. Timer Cancel

• Press the TIMER CANCEL button to cancel the on timer setting.

12. OFF Timer Setting

• Press the OFF TIMER button will activate the off timer function.

• Set the desired off time by pressing the OFF TIMER button continuously.

13. ON Timer Setting

• Press the ON TIMER button will activate the on timer function.

• Set the desired on time by pressing the ON TIMER button continuously. If the timer is set to 7.30am,

the air conditioner will turn on at 7.30am sharp.

14. Turbo Function

• Press for fast cooling.

• Fan speed turn to maximum speed.

• Press again to deactivate the function.

15. Clock Time Setting

• Press and hold to set the clock time.

20

Page 23

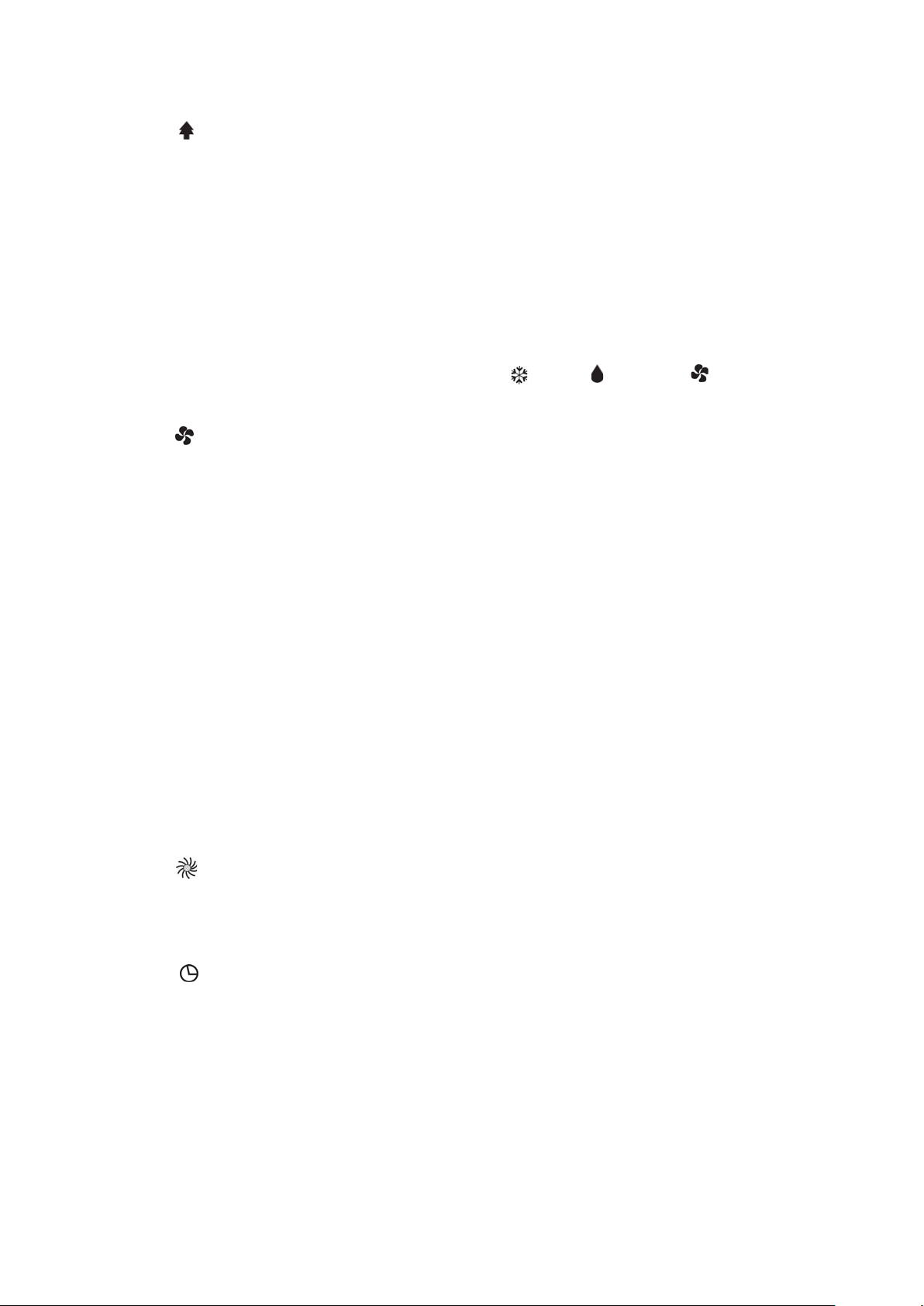

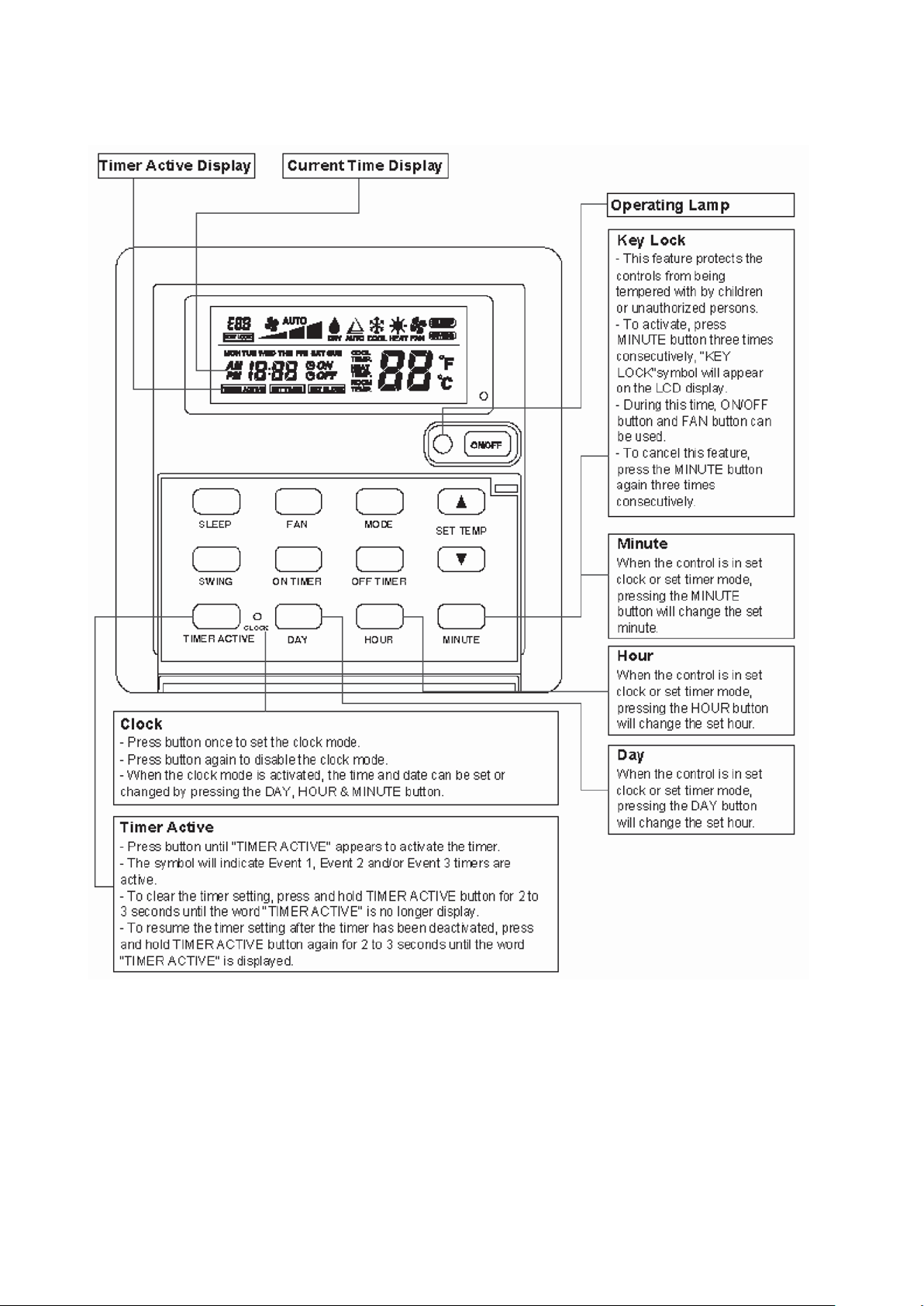

Netware3 Wired Controller

21

Page 24

222324

Page 25

Page 26

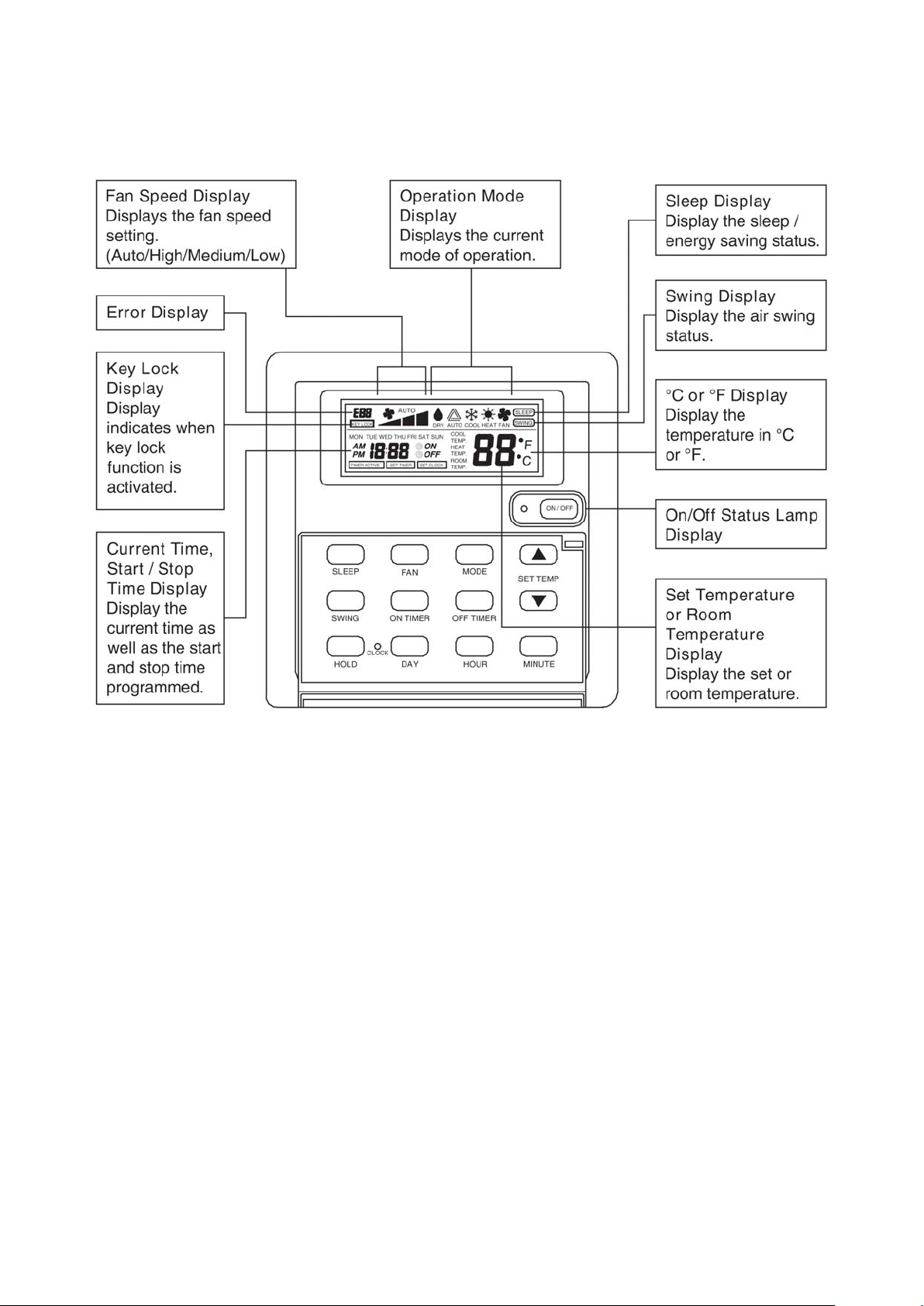

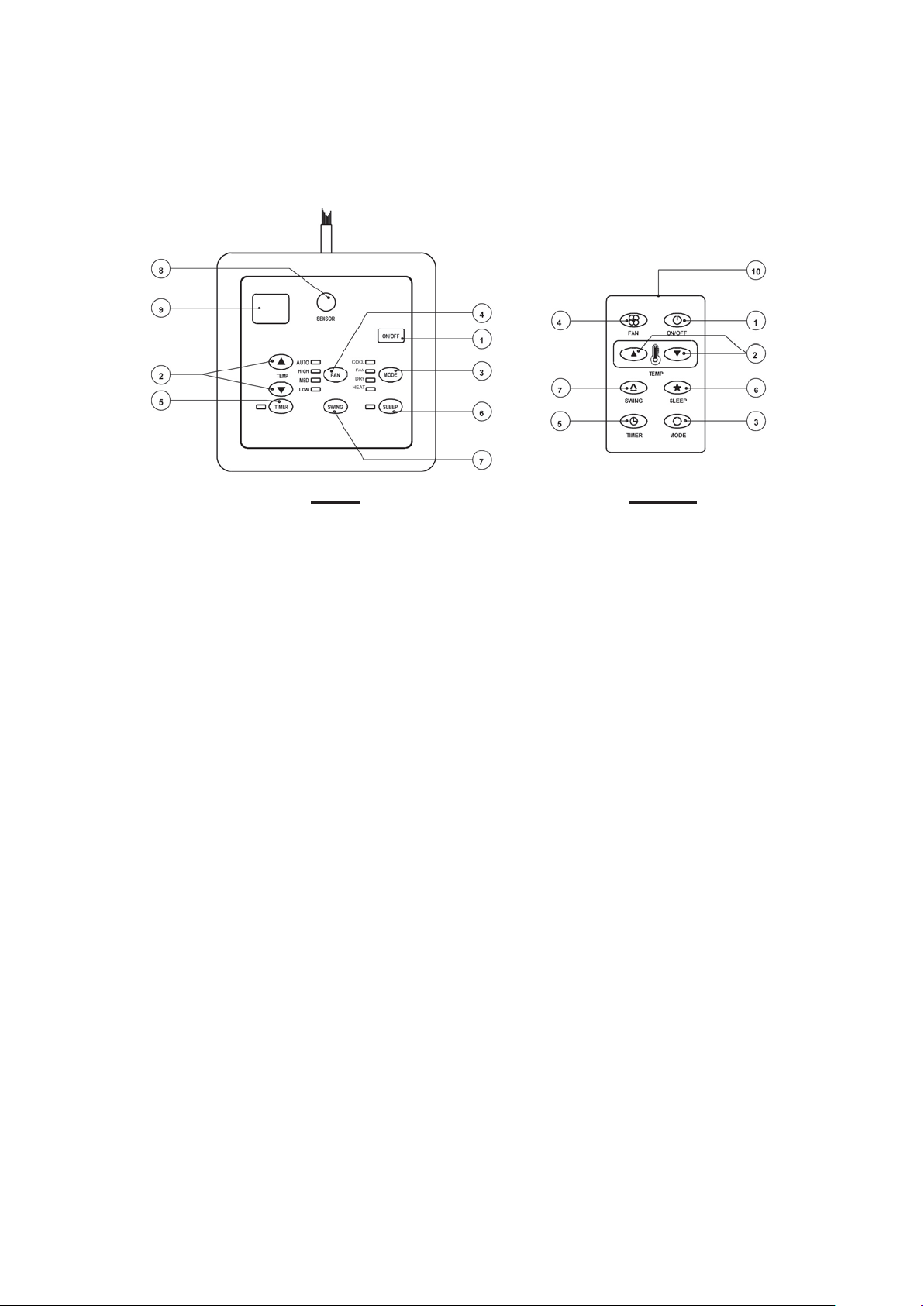

SLM3 WIRED CONTROLLER

SLM3 AC5300

1. "ON/OFF" switch

• Press to start the air conditioner unit.

• Press again to stop the unit.

2. Temperature setting

• Set the desired room temperature.

• Press button to increase or decrease the set tem-

perature. Setting range are between 16°C to 30°C

(60°F to 80°F).

3. Operation Modes

• Press the "mode" button for select the type of operating mode.

- Cooling Only :

COOL, FAN, DRY

- Heat Pump :

COOL, FAN, DRY, HEAT

4. Fan Speed selection

• Press the button until the desired fan speed is

achieved.

5. Timer

• Press the set button to select the switch timer of the

air conditioner unit (the setting range is between 1

to 15 hours).

6. "Sleep" mode

• Press button to activate the sleep function. This

function can only be activated under "cool" or

heating mode operation. When it is activated

under "cool" mode operation, the set temperature will increase 0.5°C after 30 minutes, 1°C

after 1 hour and 2°C after 2 hours. If it is activated under "HEAT" mode operation, the set

temperature will be decreased 0.5° C after 30

minutes, 1° C after 1 hour and 2° C after 2 hours.

7. Air Swing

• Press button to activate the automatic air swing

function.

8. Sensor

• Infra red sensor to receive signals from wireless

controller.

9. LED display

• To display the set temperature (in º C) and timer

delay setting (in hours).

10. Transmission source

• To transmit signals to the air conditioner.

Page 27

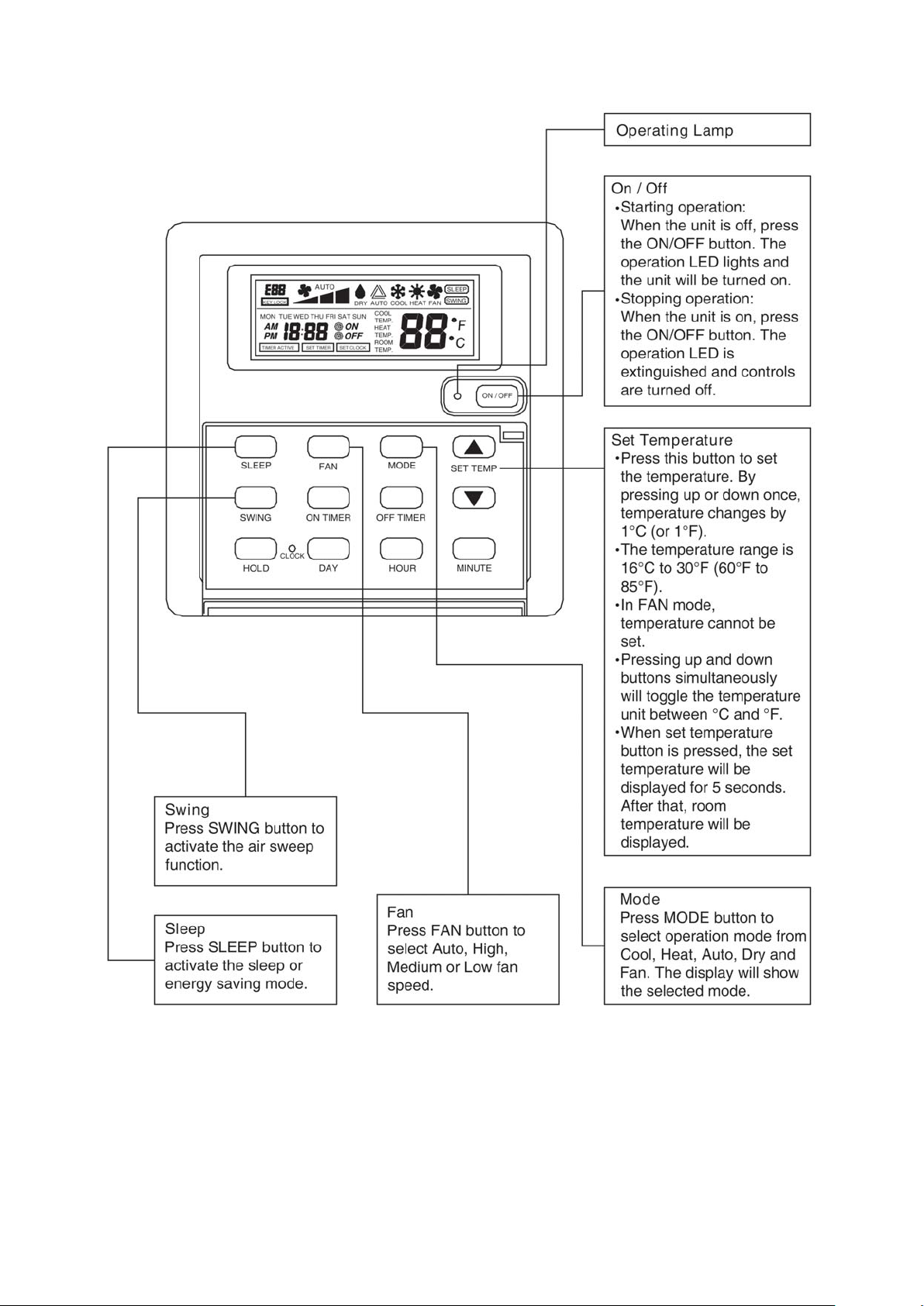

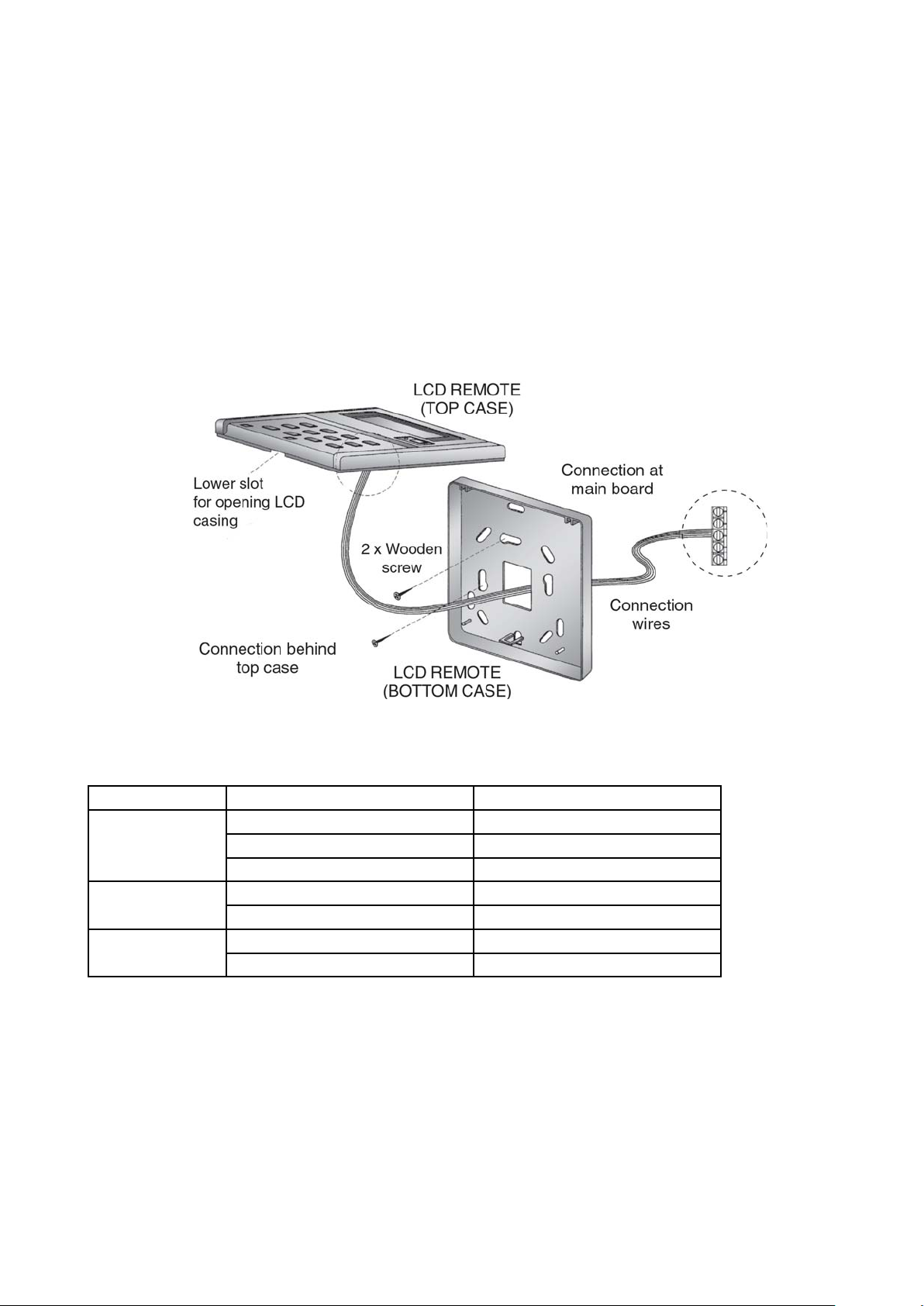

INSTALLATION OF LCD REMOTE CONTROLLER

STEP-BY-STEP GUIDE

i) First, open up the casing of the LCD remote controller into its top and bottom case using a screwdriver.

To do this, insert the screwdriver into the lower slot and slide it in the outward direction.

ii) Fix the bottom case onto the wall with the 2 wooden screws provided. Then, insert the 4 connecting

wires (from the main board) through the slot on the lower center of the case as shown below.

iii) Connect one end in each of the 3 wires to the terminal block behind the top case as illustrated.

iv) To select cooling only model or heatpump model, some adjustment required in the dip switch setting.

v) Fasten back the top and bottom case into place. Hook the two upper claws into their respective slots and

snap the lower part shut.

Dip switch setting for model selection

Pin Function Remarks

JH & JD RESERVE JH-OFF, JD-OFF

COOL, DRY, FAN JH-OFF, JD-ON

COOL, DRY, FAN, HEAT JH-ON, JD-OFF

RTC NO REAL TIME CLOCK RTC-OFF

REAL TIME CLOCK RTC-ON

NO DRY WITHOUT DRY FUNCTION NO DRY-ON

DRY FUNCTION NO DRY-OFF

25

Page 28

Sound DaSound Da

33

31

26

33

29

25

36

32

27

34

29

23

28

23

17

19

13

8

7

5

5

38

33

33

28

28

41

39

37

48

44

41

47

43

40

43

39

36

40

35

32

28

25

23

20

19

49

44

42

35

38

43

40

38

36

48

46

42

48

45

44

35

27

50

45

47

44

423942

38

33

29

25

23

48

45

43

Sound Da

Sound DaSound Da

tata

ta

tata

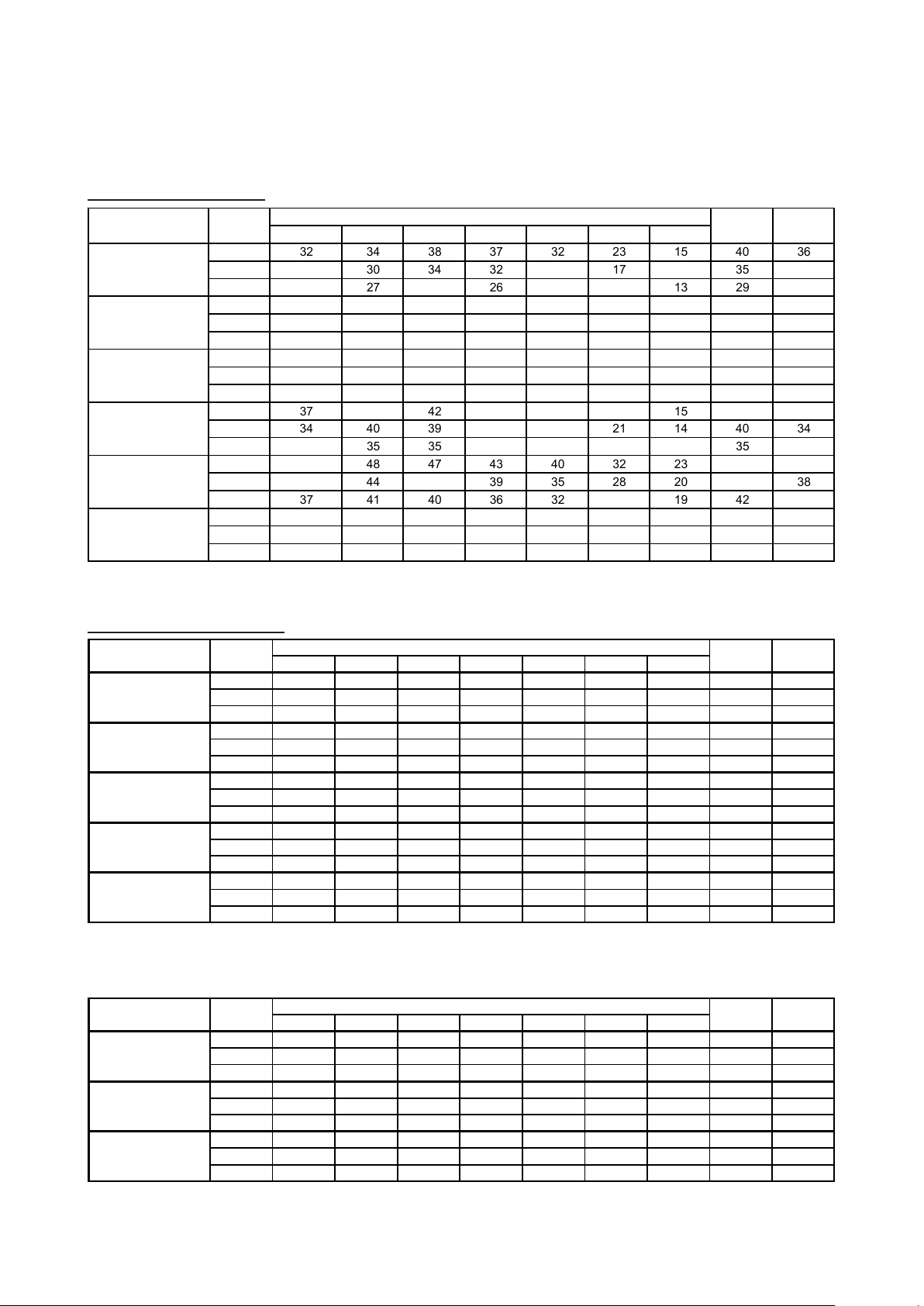

Sound Pressure Level

Wall Mounted Split Type

Model Speed

HIGH 32 34 38 37 32 23 15 40 36

MWM007G2W

MWM010G2W

MWM015G2W

MWM020G2W

MWM025G2W

MWM301W

Microphone position : MWM-G2W -- 1 m in front of the unit and 0.8 m below the vertical centre line of the unit. (JIS C 9612)

MEDIUM 27 30 34 32 26 17 14 35 31

LOW 24 27 29 26 20 13 13 29 24

HIGH 28 34 37 36 31 22 13 39 35

MEDIUM 27 30 33 31 25 17 12 34 30

LOW 24 26 28 25 19 12 11 28 23

HIGH 30 35 39 38 33 25 15 42 37

MEDIUM 28 31 34 33 26 18 13 36 32

LOW 24 26 28 26 20 13 12 29 24

HIGH 37 44 42 37 34 25 15 43 37

MEDIUM 34 40 39 34 30 21 14 40 34

LOW 30 35 35 30 26 18 13 35 30

HIGH 41 48 47 43 40 32 23 49 43

MEDIUM 39 44 43 39 35 28 20 44 38

LOW 37 41 40 36 32 25 19 42 35

HIGH 42 46 45 44 41 35 28 49 43

MEDIUM 40 45 44 43 35 33 27 47 42

LOW 37 43 43 40 35 30 26 45 39

MWM301W -- 1 m in front and 1 m below the air discharge opening of the unit (JIS B 8615)

125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

1/1 Octave Sound Pressure Level (dB, ref 20μPa)

Overall

(dBA)

Noise

Criteria

Ceiling Exposed Split Type

Model

MCM020DW

MCM025DW

MCM030DW

MCM040DW

MCM050DW

Microphone position : MCM 20/25DW -- 1 m in front of the unit and 0.8 m below the air discharge opening. (JIS C 9612)

Model Speed

MCM007CBW

MCM010CBW

MCM015CBW

Microphone position : 1m in front and 0.8m below the vertical centre line of the unit.

Speed

High 45 46 47 46 41 38 29 50 45

Medium 42 43 45 42 38 34 24 47 41

Low 36 37 39 35 31 24 15 40 34

High 48 51 51 50 45 41 33 54 49

Medium 47 50 50 49 44 40 32 53 48

Low 45 47 48 47 41 36 27 50 46

High 45 48 48 47 43 33 24 51 46

Medium 44 47 47 46 42 32 23 50 45

Low 43 45 45 44 39 29 20 48 43

High 51 53 51 50 47 37 30 54 49

Medium 48 51 50 49 46 36 28 53 48

Low 46 50 49 48 44 35 27 52 47

High 51 53 51 50 47 37 30 54 49

Medium 48 51 50 49 46 36 28 53 48

Low 46 50 49 48 44 35 27 52 47

MCM 30/40/50DW -- 1 m in front of the unit and 1 m below the air discharge opening. (JIS B 8615)

High 26 34 38 42 38 35 23 45 41

Medium 23 29 36 39 34 31 18 42 38

Low 19 26 33 34 31 23 12 37 33

High 27 35 39 43 39 36 24 46 42

Medium 24 30 37 40 35 32 19 43 39

Low 20 27 34 35 32 24 13 38 34

High 28 36 40 44 40 37 25 47 43

Medium 25 31 38 41 36 33 20 44 40

Low 21 28 35 36 33 25 13 39 35

125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz (dBA) Criteria

125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz A (dBA) Criteria

1/1 Octave Sound pressure level (dB, ref 20μPa)

1/1 Octave Sound pressure level (dB, ref 20μPa)

Overall Noise

Overall Noise

26

Page 29

27

Ceiling Cassette Split Types

Microphone position: MCK020/025AW/AWH – 1.4m below the facia (JIS C 9612)

MCK030/040/050AW/AWH – 1.5m below the facia (JIS B 8615

Microphone position: 1.4m below the facia. (JIS C 9612)

Sound Power Level

125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz

High

46 45 40 38 32 21 14 42 37

MCK020AW / AWH

Medium

44 43 37 33 28 18 12 39 32

Low

43 42 35 31 26 17 11 37 31

High

48 46 43 39 33 27 19 45 38

MCK025AW / AWH

Medium

45 43 40 35 29 21 15 42 35

Low

43 42 38 32 27 19 14 40 33

High

50 48 47 43 37 35 28 49 42

Medium

48 45 43 38 32 31 27 45 38

Low

46 43 41 35 30 30 26 43 36

High

50 49 49 46 39 38 31 51 45

MCK040AW / AWH

Medium

48 47 47 43 36 34 25 48 42

Low

46 45 46 41 34 30 23 46 41

High

54 52 51 48 43 42 34 53 47

MCK050AW / AWH

Medium

52 50 50 46 41 40 32 52 46

Low

51 49 49 45 39 39 31 50 45

Overall

(dBA)

Noise

Criteria

MCK030AW / AWH

Model

Speed

1/ 1 O cta ve So und p ressu re le ve l (dB , ref 20μP a)

125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz

High

44 45 40 36 26 19 10 42 35

MCK010CW

Medium

40 38 34 28 19 9 7 35 29

Low

37 32 27 20 14 6 7 29 21

High

48 48 44 39 31 27 15 45 39

MCK015CW

Medium

42 42 36 30 22 13 7 38 31

Low

39 36 28 20 15 6 6 30 23

High

52 51 46 41 34 31 19 48 41

Medium

44 43 39 33 26 18 8 40 33

Low

41 39 35 28 22 11 7 36 30

MCK020CW

1/1 O cta ve So und p ressu re level (dB, ref 20μ Pa)

Model

Speed

Overall

(dBA)

Noise

Criteria

125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz

High

53 56 49 43 35 28 21 52

MCK010CW

Medium

47 49 42 35 26 20 19 45

Low

43 44 36 27 19 14 19 39

High

52 55 53 46 41 33 24 54

MCK015CW

Medium

46 50 46 38 30 21 20 47

Low

46 48 40 30 22 12 19 41

High

56 58 55 50 42 38 29 56

Medium

50 51 48 41 32 26 20 49

Low

47 49 45 37 27 20 19 45

Model

Speed

1/1 Octave Sound Power level (dB, ref 1pW)

Overall

(dBA)

MCK020CW

Page 30

Ceiling Concealed Fan Coil Unit

Model

MCC010CW

MCC015CW

MCC020CW

MCC025CW

MCC028CW

MCC030CW

MCC038CW

MCC040CW

MCC050CW

MCC060CW

Ext. Static Overall Noise

(mmAq) 125Hz 250Hz 500Hz 1kHz 2kHz 4kHz 8kHz (dBA) Criteria

5 High333030292216103327

4 Medium 31 28 28 26 20 13 8 30 24

3 Low 28 25 24 22 16 10 7 26 20

5 High393634322718113731

4 Medium 35 34 32 29 23 14 9 34 27

3 Low 32 29 28 25 17 11 8 29 23

5 High423936342822173833

4 Medium 41 37 34 31 26 20 15 36 30

3 Low 40 36 32 29 23 18 13 34 27

5 High424137343129234033

4 Medium 41 40 36 33 29 28 22 39 32

3 Low 36 35 33 31 26 27 21 36 30

10 Super High 48 45 42 38 34 29 26 44 37

8 High454239353126224134

7 Medium 42 38 37 32 28 22 17 38 32

6 Low 36 33 33 27 23 16 11 34 27

21 Super High 54 50 46 45 40 34 30 49 44

17 High 50 45 43 42 37 31 26 46 41

13 Medium 45 40 40 38 32 26 20 42 37

9 Low 42 36 37 33 28 22 15 38 32

14 Super High 56 57 53 50 46 41 36 55 49

12 High 54 51 48 46 41 36 31 51 45

11 Medium 51 48 46 45 37 32 26 48 44

9 Low 47 45 44 41 34 28 22 45 40

21 Super High 56 49 49 46 41 37 32 51 45

18 High 54 47 47 45 39 35 29 49 44

13 Medium 49 42 43 41 35 31 24 45 40

9 Low 45 39 41 37 30 26 18 41 36

18 Super High 56 50 50 49 44 38 33 53 48

16 High 54 49 49 48 43 37 32 52 47

14 Medium 53 47 46 47 40 35 29 50 46

11 Low 51 45 44 44 36 32 26 47 43

18 Super High 57 50 51 51 46 39 35 55 50

16 High 55 49 49 50 44 37 33 53 49

14 Medium 53 46 47 47 39 34 28 50 46

10 Low 51 43 44 43 35 30 24 47 42

Speed

Microphone position : 1.4 m below the centre of the unit. (GB standard - GB/D17758 )

Tested with 2m length duct at the air discharge outlet and air return inlet.

1/1 Octave Sound pressure level (dB, ref 20μPa)

Ducted Split Fan Coil Unit

Model

125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

1/1 Octave Sound Pressure Level (dB, ref 20μPa)

MDB075BW 54504644413626 49 43

MDB100BW 53544848443931 52 47

MDB125BW 53515045443829 52 46

MDB150BW 58565754524739 59 54

Microphone Position: MDB075/100/125/150BW, 1.4m below the unit (free return and the discharge air was ducted to adjacent room )

Overall

(dBA)

Noise

Criteria

28

Page 31

Selection PrSelection Pr

Selection Pr

Selection PrSelection Pr

Fan Performance Curves

ocessocess

ocess

ocessocess

FAN PERFORMANCE CURVE

MCC 010CW

29

Page 32

FAN PERFORMANCE CURVE

MCC 015CW

30

Page 33

FAN PERFORMANCE CURVE

MCC 020CW

31

Page 34

FAN PERFORMANCE CURVE

MCC 025CW

32

Page 35

FAN PERFORMANCE CURVE

MCC 028CW

33

Page 36

FAN PERFORMANCE CURVE

MCC 030CW

34

Page 37

MCC038CW Blower Performance Curve

H

M

L

Page 38

FAN PERFORMANCE CURVE

MCC 040CW

36

Page 39

FAN PERFORMANCE CURVE

MCC 050CW

37

Page 40

FAN PERFORMANCE CURVE

MCC 060CW

38

Page 41

FAN PERFORMANCE CURVE

MDB 075BW

39

Page 42

FAN PERFORMANCE CURVE

MDB 100BW

40

Page 43

FAN PERFORMANCE CURVE

MDB 125BW

41

Page 44

FAN PERFORMANCE CURVE

MDB 150BW

42

Page 45

Water Flow Vs Pressure Drop

Wall Mounted Split Type

MODELS

MWM007G2W

MWM010G2W

MWM015G2W

MWM020G2W

MWM025G2W

MWM301W

Note :

a. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * ( EWT°C * 1.8 + 32 )

b. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * EWT°F

LITRES/M USGPM kPa PSI

FLOW RATE WATER PRESSURE DROP

4.00 1.06 20.23 2.93

5.33 1.41 27.04 3.92

6.66 1.76 33.88 4.91

7.99 2.11 40.75 5.91

9.32 2.46 47.65 6.91

4.79 1.27 26.96 3.91

6.39 1.69 36.00 5.22

7.99 2.11 45.06 6.54

9.59 2.53 54.15 7.85

11.19 2.96 63.26 9.18

5.50 1.45 33.20 4.82

7.33 1.94 44.27 6.42

9.16 2.42 55.34 8.03

10.99 2.90 66.41 9.63

12.82 3.39 77.47 11.24

7.79 2.06 17.71 2.57

10.38 2.74 24.09 3.49

12.98 3.43 30.71 4.45

15.58 4.11 37.56 5.45

18.17 4.80 44.65 6.48

9.08 2.40 19.88 2.88

12.11 3.20 26.91 3.90

15.14 4.00 34.13 4.95

18.17 4.80 41.56 6.03

21.20 5.60 49.20 7.14

11.13 2.94 26.21 3.80

14.84 3.92 34.90 5.06

18.55 4.90 43.66 6.33

22.26 5.88 52.51 7.62

25.97 6.86 61.44 8.91

43

Page 46

Water Flow Vs Pressure Drop

Ceiling Exposed Split Type

MODELS

MCM020DW

MCM025DW

MCM030DW

MCM040DW

MCM050DW

Note :

a. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * ( EWT°C * 1.8 + 32 )

b. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * EWT°F

LITRES/M USGPM kPa PSI

FLOW RATE WATER PRESSURE DROP

8.90 2.35 23.37 3.39

11.87 3.14 30.36 4.40

14.84 3.92 37.73 5.47

17.81 4.70 45.48 6.60

20.78 5.49 53.62 7.78

10.49 2.77 26.38 3.83

13.99 3.70 36.14 5.24

17.49 4.62 46.37 6.73

20.99 5.54 57.08 8.28

24.49 6.47 68.27 9.90

12.40 3.28 22.04 3.20

16.54 4.37 31.14 4.52

20.67 5.46 41.12 5.96

24.80 6.55 51.97 7.54

28.94 7.64 63.69 9.24

15.70 4.15 11.21 1.63

20.93 5.53 15.45 2.24

26.16 6.91 19.94 2.89

31.39 8.29 24.68 3.58

36.62 9.68 29.67 4.30

22.69 5.99 17.70 2.57

30.26 7.99 24.35 3.53

37.82 9.99 31.38 4.55

45.38 11.99 38.79 5.63

52.95 13.99 46.58 6.76

44

Page 47

Water Flow Vs Pressure Drop

Ceiling Exposed Split Type

MODELS

MCM007CBW

MCM010CBW

MCM015CBW

MCM015EW

MCM020EW

MCM025EW

LITRES/M USGPM kPa PSI

FLOW RATE WATER PRESSURE DROP

3.29 0.87 4.21 0.61

4.39 1.16 5.94 0.86

5.49 1.45 7.84 1.14

6.59 1.74 9.90 1.44

7.69 2.03 12.12 1.76

4.29 1.13 6.84 0.99

5.72 1.51 10.20 1.48

7.15 1.89 13.71 1.99

8.58 2.27 17.38 2.52

10.01 2.64 21.21 3.08

5.29 1.40 1.77 0.26

7.06 1.86 2.84 0.41

8.82 2.33 4.08 0.59

10.58 2.80 5.48 0.80

12.35 3.26 7.06 1.02

7.79 2.06 11.73 1.70

10.38 2.74 16.90 2.45

12.98 3.43 22.70 3.29

15.58 4.11 29.13 4.22

18.17 4.80 36.19 5.25

10.20 2.69 23.78 3.45

13.60 3.59 31.82 4.62

17.00 4.49 39.92 5.79

20.40 5.39 48.09 6.97

23.80 6.29 56.31 8.17

10.61 2.80 27.78 4.03

14.14 3.74 37.56 5.45

17.68 4.67 47.59 6.90

21.22 5.60 57.87 8.39

24.75 6.54 68.41 9.92

Note :

a. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * ( EWT°C * 1.8 + 32 )

b. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * EWT°F

45

Page 48

Water Flow Vs Pressure Drop

Ceiling Cassette Split Type

MODELS

MCK020AW

MCK025AW

MCK030AW

MCK040AW

MCK050AW

Note :

a. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * ( EWT°C * 1.8 + 32 )

b. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * EWT°F

LITRES/M USGPM kPa PSI

FLOW RATE WATER PRESSURE DROP

11.40 3.01 8.80 1.28

15.20 4.02 14.19 2.06

19.00 5.02 20.60 2.99

22.80 6.02 27.99 4.06

26.60 7.03 36.30 5.26

12.90 3.41 10.91 1.58

17.20 4.54 17.61 2.55

21.50 5.68 25.60 3.71

25.80 6.82 34.81 5.05

30.10 7.95 45.15 6.55

15.14 4.00 18.53 2.69

20.18 5.33 28.86 4.19

25.23 6.67 39.90 5.79

30.28 8.00 51.65 7.49

35.32 9.33 64.11 9.30

17.11 4.52 22.97 3.33

22.82 6.03 35.27 5.11

28.52 7.53 48.49 7.03

34.22 9.04 62.63 9.08

39.93 10.55 77.70 11.27

18.58 4.91 30.11 4.37

24.78 6.55 45.92 6.66

30.97 8.18 63.00 9.14

37.16 9.82 81.35 11.80

43.36 11.45 100.98 14.65

46

Page 49

Water Flow Vs Pressure Drop

Ceiling Cassette Split Type

LITRES/M USGPM kPa PSI

5.83 1.54

11.61 1.68

6.67 1.76

14.86 2.15

7.67 2.03

19.28 2.80

8.33 2.20

22.54 3.27

9.17 2.42

26.98 3.91

10.00 2.64 16.38

2.38

10.83 2.86 19.03

2.76

11.67 3.08 21.89

3.18

13.00 3.43 26.88

3.90

14.17 3.74 31.66

4.59

10.83 2.86

19.01

2.76

12.50 3.30

24.91

3.61

13.33 3.52

28.17

4.09

13.50 3.57

28.84

4.18

14.67 3.87

33.78

4.90

9.07 2.40

2.08 0.30

12.10 3.20

2.61 0.52

15.12 3.99

5.55 0.80

18.14 4.79

7.88 1.14

21.17 5.59

10.60 1.54

9.45 2.50 2.22

0.32

12.60 3.33 3.85

0.56

15.75 4.16 5.91

0.86

18.90 4.99 8.40

1.22

22.05 5.82 5.91

1.64

10.76 2.84

2.99

0.43

14.34 3.79

5.25

0.76

17.93 4.74

7.96

1.15

21.52 5.68

11.12

1.61

25.10 6.63

14.75

2.14

11.59 3.06

3.47 0.50

15.46 4.08

6.04 0.88

19.32 5.10

9.13 1.32

23.18 6.12

12.75 1.85

27.05 7.15

16.90 2.45

11.84 3.13

3.60 0.52

15.78 4.17

6.21 0.90

19.73 5.21

9.35 1.36

23.68 6.25

13.03 1.89

27.62 7.30

17.25 2.50

MCK050AWH

MCK020AWH

MCK025AWH

MCK030AWH

MCK040AWH

MODELS

FLOW RATE

WATER PRESSURE DROP

MCK010CW

MCK015CW

MCK020CW

Revised Table

Page 50

Water Flow Vs Pressure Drop

Ceiling Concealed Split Type

MODELS

MCC010CW

MCC015CW

MCC020CW

MCC025CW

MCC028CW

MCC030CW

MCC038CW

MCC040CW

MCC050CW

MCC060CW

LITRES/M USGPM kPa PSI

Note :

a. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * ( EWT°C * 1.8 + 32 )

b. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * EWT°F

FLOW RATE WATER PRESSURE DROP

5.00 1.32 5.23 0.76

6.66 1.76 7.00 1.02

8.33 2.20 8.79 1.28

10.00 2.64 10.60 1.54

11.66 3.08 12.42 1.80

5.79 1.53 11.82 1.71

7.72 2.04 15.79 2.29

9.65 2.55 19.76 2.87

11.58 3.06 23.75 3.44

13.51 3.57 27.74 4.02

9.08 2.40 9.50 1.38

12.11 3.20 13.04 1.89

15.14 4.00 16.78 2.43

18.17 4.80 20.71 3.00

21.20 5.60 24.83 3.60

11.31 2.99 15.62 2.26

15.08 3.98 21.17 3.07

18.85 4.98 26.89 3.90

22.62 5.98 32.78 4.75

26.39 6.97 38.85 5.63

13.10 3.46 11.94 1.73

17.47 4.62 15.99 2.32

21.84 5.77 20.09 2.91

26.21 6.92 24.22 3.51

30.58 8.08 28.39 4.12

17.81 4.70 23.26 3.37

23.74 6.27 31.87 4.62

29.68 7.84 40.91 5.93

35.62 9.41 50.37 7.31

41.55 10.98 60.27 8.74

14.11 3.73 6.71 0.97

18.81 4.97 9.31 1.35

23.51 6.21 12.10 1.76

28.21 7.45 15.08 2.19

32.91 8.69 18.23 2.64

19.19 5.07 11.16 1.62

25.59 6.76 14.04 2.04

31.99 8.45 17.23 2.50

38.39 10.14 20.71 3.00

44.79 11.83 24.49 3.55

23.62 6.24 19.53 2.83

31.50 8.32 26.56 3.85

39.37 10.40 33.85 4.91

47.24 12.48 41.41 6.01

55.12 14.56 49.23 7.14

27.21 7.19 3.54 0.51

36.28 9.58 4.88 0.71

45.35 11.98 6.32 0.92

54.42 14.38 7.83 1.14

63.49 16.77 9.43 1.37

48

Page 51

Water Flow Vs Pressure Drop

Ducted Split Type

MODELS

MDB075BW

MDB100BW

MDB125BW

MDB150BW

LITRES/M USGPM kPa PSI

FLOW RATE WATER PRESSURE DROP

38.11 10.07 22.00 3.19

50.82 13.42 27.65 4.01

63.52 16.78 33.37 4.84

76.22 20.14 39.16 5.68

88.93 23.49 45.01 6.53

47.90 12.65 24.69 3.58

63.86 16.87 29.58 4.29

79.83 21.09 34.87 5.06

95.80 25.31 40.56 5.88

111.76 29.52 46.64 6.76

63.01 16.64 28.03 4.07

84.01 22.19 34.14 4.95

105.01 27.74 40.69 5.90

126.01 33.29 47.67 6.91

147.01 38.84 55.09 7.99

75.61 19.97 31.97 4.64

100.82 26.63 38.04 5.52

126.02 33.29 44.59 6.47

151.22 39.95 51.62 7.49

176.43 46.61 59.12 8.58

Note :

a. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * ( EWT°C * 1.8 + 32 )

b. PRESSURE DROP CORRECTION FACTOR = 1.2947 - 0.0021 * EWT°F

49

Page 52

Correction Factors

Air Flow Correction Factors

MWM007G2W Low 0.74 0.90

MWM007G2W Medium 0.87 0.95

MWM007G2W High 1.00 1.00

MWM010G2W Low 0.79 0.92

MWM010G2W Medium 0.90 0.96

MWM010G2W High 1.00 1.00

MWM015G2W Low 0.74 0.78

MWM015G2W Medium 0.87 0.85

MWM015G2W High 1.00 1.00

MWM020G2W Low 0.82 0.92

MWM020G2W Medium 0.93 0.97

MWM020G2W High 1.00 1.00

MWM025G2W Low 0.79 0.87

MWM025G2W Medium 0.91 0.95

MWM025G2W High 1.00 1.00

MCM007CBW Low 0.85 0.85

MCM007CBW Medium 0.94 0.94

MCM007CBW High 1.00 1.00

MCM010CBW Low 0.85 0.85

MCM010CBW Medium 0.94 0.93

MCM010CBW High 1.00 1.00

MCM015CBW Low 0.77 0.77

MCM015CBW Medium 0.82 0.82

MCM015CBW High 1.00 1.00

MCM020DW Low 0.80 0.85

MCM020DW Medium 0.95 0.98

MCM020DW High 1.00 1.00

MCM025DW Low 0.80 0.85

MCM025DW Medium 0.95 0.98

MCM025DW High 1.00 1.00

MCM030DW Low 0.94 0.94

MCM030DW Medium 0.96 0.97

MCM030DW High 1.00 1.00

MCM040DW Low 0.93 0.95

MCM040DW Medium 0.96 0.96

MCM040DW High 1.00 1.00

MCM050DW Low 0.93 0.94

MCM050DW Medium 0.98 0.98

MCM050DW High 1.00 1.00

50

Page 53

Model Speed Air Flow Ratio (Sensible Capacity) Air Flow Ratio (Total Capacity)

0.75

0.88

0.64

0.83

0.72

0.83

0.74

0.84

0.68

0.86

0.76

0.88

MCM015EW Low 0.78 0.87

MCM015EW Medium 0.85 0.92

MCM015EW High 1.00 1.00

MCM020EW Low 0.85 0.90

MCM020EW Medium 0.89 0.94

MCM020EW High 1.00 1.00

MCM025EW Low 0.83 0.89

MCM025EW Medium 0.90 0.95

MCM025EW High 1.00 1.00

MCK020AW Low 0.74 0.77

MCK020AW Medium 0.90 0.91

MCK020AW High 1.00 1.00

MCK025AW Low 0.74 0.75

MCK025AW Medium 0.91 0.90

MCK025AW High 1.00 1.00

MCK030AW Low 0.72 0.75

MCK030AW Medium 0.88 0.89

MCK030AW High 1.00 1.00

MCK040AW Low 0.72 0.75

MCK040AW Medium 0.93 0.92

MCK040AW High 1.00 1.00

MCK050AW Low 0.78 0.80

MCK050AW Medium 0.95 0.94

MCK050AW High 1.00 1.00

MCK020WH Low 0.91 0.95

MCK020WH Medium 0.93 0.97

MCK020WH High 1.00 1.00

MCK025WH Low 0.89 0.94

MCK025WH Medium 0.93 0.96

MCK025WH High 1.00 1.00

MCK030WH Low 0.88 0.93

MCK030WH Medium 0.92 0.95

MCK030WH High 1.00 1.00

MCK040WH Low 0.88 0.92

MCK040WH Medium 0.93 0.96

MCK040WH High 1.00 1.00

MCK050WH Low 0.81 0.92

MCK050WH Medium 0.93 0.96

MCK050WH High 1.00 1.00

MCK010CW Low 0.89 0.87

MCK010CW Medium 0.95 0.93

MCK010CW High 1.00 1.00

MCK015CW Low 0.88 0.89

MCK015CW Medium 0.94 0.93

MCK015CW High 1.00 1.00

MCK020CW Low 0.90 0.93

MCK020CW Medium 0.96 0.96

MCK020CW High 1.00 1.00

51

Page 54

Model Speed Air Flow Ratio (Sensible Capacity) Air Flow Ratio (Total Capacity)

MCC010CW Low 0.82 0.82

MCC010CW Medium 0.92 0.92

MCC010CW High 1.00 1.00

MCC015CW Low 0.75 0.75

MCC015CW Medium 0.91 0.91

MCC015CW High 1.00 1.00

MCC020CW Low 0.93 0.93

MCC020CW Medium 0.98 0.98

MCC020CW High 1.00 1.00

MCC025CW Low 0.88 0.80

MCC025CW Medium 0.98 0.91

MCC025CW High 1.00 1.00

MCC028CW Low 0.86 0.86

MCC028CW Medium 0.94 0.95

MCC028CW High 1.00 1.00

MCC030CW Low 0.86 0.86

MCC030CW Medium 0.94 0.95

MCC030CW High 1.00 1.00

MCC038CW Low 0.74 0.74

MCC038CW Medium 0.98 0.79

MCC038CW High 1.00 1.00

MCC040CW Low 0.74 0.74

MCC040CW Medium 0.98 0.79

MCC040CW High 1.00 1.00

MCC050CW Low 0.88 0.88

MCC050CW Medium 0.95 0.95

MCC050CW High 1.00 1.00

MCC060CW Low 0.84 0.84

MCC060CW Medium 0.95 0.95

MCC060CW High 1.00 1.00

MDB075BW High 1.00 1.00

MDB100BW High 1.00 1.00

MDB125BW High 1.00 1.00

MDB150BW High 1.00 1.00

52

Page 55

Altitude Correction Factors

Elevation, m Total Capacity Sensible Capacity

0 1.00 1.00

300 0.99 0.96

600 0.98 0.93

900 0.97 0.90

1200 0.96 0.86

1500 0.94 0.83

1800 0.93 0.80

Heating Capacity Correction Factors

MCK020AWH - MCK050AWH

EAT

°C 37.8 43.3 45 48.8 50 54.4 60 65.5 70

4.4

7.2

10

12.7

15.5

18.3

20

21.1

22

23.9

26.7

1.112 1.143 1.153 1.175 1.182 1.207 1.239 1.271 1.296

1.044 1.078 1.088 1.112 1.119 1.146 1.181 1.214 1.244

0.977 1.014 1.026 1.051 1.060 1.089 1.127 1.164 1.191

0.908 0.947 0.959 0.986 0.995 1.026 1.066 1.106 1.138

0.839 0.882 0.895 0.924 0.934 0.968 1.011 1.053 1.085

0.796 0.830 0.841 0.868 0.876 0.910 0.955 0.996 1.032

0.729 0.775 0.790 0.822 0.831 0.869 0.917 0.963 1.000

0.685 0.740 0.756 0.792 0.802 0.843 0.892 0.942 0.979

0.680 0.729 0.743 0.777 0.786 0.826 0.876 0.924 0.962

0.630 0.681 0.697 0.732 0.743 0.783 0.835 0.886 0.927

0.562 0.616 0.632 0.669 0.681 0.724 0.778 0.832 0.874

ENT TEMP, °C

MCK020AW

EAT

°C 37.8 43.3 45 48.8 50 54.4 60 65.5 70

4.4

7.2

10

12.7

15.5

18.3

20

21.1

22

23.9

26.7

1.256 1.343 1.370 1.431 1.450 1.520 1.609 1.696 1.770

1.175 1.265 1.293 1.355 1.374 1.446 1.537 1.627 1.699

1.087 1.179 1.207 1.271 1.291 1.364 1.458 1.550 1.627

1.004 1.142 1.127 1.192 1.213 1.288 1.384 1.478 1.555

0.917 1.014 1.044 1.110 1.132 1.209 1.308 1.404 1.483

0.849 0.939 0.968 1.033 1.054 1.131 1.232 1.328 1.410

0.777 0.877 0.909 0.978 1.000 1.081 1.183 1.284 1.366

0.730 0.837 0.870 0.943 0.965 1.048 1.151 1.255 1.338

0.716 0.822 0.850 0.920 0.943 1.024 1.129 1.231 1.314

0.657 0.761 0.793 0.865 0.887 0.970 1.076 1.180 1.266

0.572 0.678 0.711 0.784 0.807 0.892 1.000 1.106 1.194

ENT TEMP, °C

MCK025AW

EAT

°C 37.8 43.3 45 48.8 50 54.4 60 65.5 70

4.4

7.2

10

12.7

15.5

18.3

20

21.1

22

23.9

26.7

1.311 1.366 1.383 1.421 1.433 1.477 1.533 1.588 1.633

1.231 1.289 1.307 1.347 1.359 1.406 1.464 1.522 1.567

1.145 1.205 1.224 1.266 1.279 1.327 1.389 1.449 1.501

1.062 1.126 1.145 1.189 1.203 1.253 1.318 1.381 1.434

0.977 1.044 1.064 1.110 1.125 1.178 1.246 1.312 1.368

0.920 0.977 0.997 1.040 1.054 1.107 1.177 1.243 1.300

0.842 0.913 0.935 0.985 1.000 1.057 1.130 1.202 1.2599

0.791 0.871 0.895 0.949 0.965 1.025 1.100 1.175 1.234

0.782 0.855 0.878 0.929 0.944 1.003 1.078 1.152 1.212

0.725 0.801 0.824 0.877 0.893 0.954 1.031 1.107 1.167

0.641 0.720 0.744 0.798 0.816 0.878 0.959 1.037 1.101

ENT TEMP, °C

53

Page 56

MCK030AW

EAT

°C 37.8 43.3 45 48.8 50 54.4 60 65.5 70

4.4

7.2

10

12.7

15.5

18.3

20

21.1

22

23.9

26.7

1.344 1.380 1.390 1.415 1.422 1.451 1.486 1.522 1.550

1.263 1.301 1.312 1.339 1.347 1.377 1.416 1.454 1.488

1.182 1.224 1.237 1.266 1.275 1.308 1.351 1.393 1.424

1.098 1.143 1.156 1.187 1.197 1.233 1.278 1.322 1.361

1.015 1.064 1.079 1.112 1.123 1.161 1.211 1.259 1.298

0.962 1.000 1.014 1.044 1.054 1.092 1.143 1.191 1.234

0.880 0.934 0.951 0.988 1.000 1.043 1.098 1.152 1.196

0.828 0.892 0.911 0.952 0.965 1.012 1.069 1.126 1.171

0.822 0.878 0.895 0.934 0.946 0.991 1.048 1.104 1.151

0.766 0.825 0.843 0.884 0.897 0.944 1.004 1.063 1.108

0.685 0.747 0.766 0.809 0.823 0.872 0.936 0.998 1.045

ENT TEMP, °C

MCK040AW

EAT

°C 37.8 43.3 45 48.8 50 54.4 60 65.5 70

4.4

7.2

10

12.7

15.5

18.3

20

21.1

22

23.9

26.7

1.330 1.373 1.386 1.416 1.425 1.459 1.503 1.546 1.580

1.249 1.295 1.309 1.340 1.350 1.387 1.433 1.479 1.517

1.165 1.214 1.229 1.263 1.274 1.313 1.363 1.412 1.452

1.086 1.138 1.154 1.190 1.202 1.244 1.297 1.349 1.388

1.000 1.055 1.073 1.111 1.123 1.168 1.224 1.280 1.324

0.948 0.993 1.008 1.043 1.054 1.099 1.157 1.212 1.258

0.867 0.928 0.946 0.988 1.000 1.050 1.111 1.172 1.2195

0.815 0.885 0.906 0.952 0.965 1.018 1.081 1.146 1.194

0.809 0.871 0.890 0.934 0.946 0.997 1.061 1.124 1.173

0.749 0.815 0.835 0.880 0.894 0.947 1.013 1.079 1.130

0.668 0.737 0.758 0.806 0.821 0.876 0.946 1.014 1.066

ENT TEMP, °C

MCK050AW

EAT

°C 37.8 43.3 45 48.8 50 54.4 60 65.5 70

4.4

7.2

10

12.7

15.5

18.3

20

21.1

22

23.9

26.7

1.321 1.370 1.385 1.419 1.430 1.469 1.519 1.568 1.607

1.241 1.293 1.309 1.344 1.356 1.397 1.450 1.501 1.542

1.158 1.213 1.230 1.268 1.280 1.324 1.380 1.435 1.477

1.075 1.132 1.150 1.190 1.203 1.249 1.308 1.366 1.411

0.989 1.050 1.069 1.111 1.125 1.173 1.236 1.297 1.346

0.933 0.985 1.002 1.041 1.054 1.103 1.167 1.227 1.279

0.854 0.920 0.941 0.986 1.000 1.053 1.121 1.187 1.2398

0.803 0.878 0.900 0.950 0.965 1.021 1.091 1.160 1.214

0.795 0.863 0.884 0.931 0.945 1.000 1.070 1.138 1.193

0.736 0.806 0.828 0.877 0.892 0.948 1.020 1.090 1.149

0.655 0.729 0.752 0.803 0.819 0.878 0.953 1.026 1.084

ENT TEMP, °C

All other models

EAT

°C 37.8 43.3 45 48.8 50 54.4 60 65.5 70

4.4

7.2

10

12.7

15.5

18.3

20

21.1

22

23.9

26.7

1.338 1.376 1.388 1.414 1.422 1.452 1.491 1.529 1.559

1.257 1.297 1.310 1.338 1.347 1.379 1.421 1.462 1.497

1.176 1.221 1.235 1.265 1.275 1.311 1.356 1.401 1.433

1.093 1.140 1.155 1.187 1.198 1.235 1.284 1.331 1.370

1.010 1.061 1.077 1.113 1.124 1.165 1.217 1.268 1.306

0.958 0.999 1.013 1.044 1.054 1.095 1.149 1.199 1.242

0.877 0.933 0.950 0.989 1.000 1.046 1.103 1.159 1.2035

0.824 0.890 0.910 0.953 0.965 1.014 1.074 1.134 1.179

0.819 0.877 0.895 0.935 0.947 0.994 1.054 1.112 1.158

0.758 0.819 0.838 0.880 0.894 0.943 1.005 1.066 1.115

0.677 0.741 0.761 0.806 0.820 0.871 0.937 1.001 1.052

ENT TEMP, °C

54

Page 57

Engineering and PhEngineering and Ph

Engineering and Ph

Engineering and PhEngineering and Ph

ysical Daysical Da

ysical Da

ysical Daysical Da

tata

ta

tata

General Data - MWM-G2W

MODEL

NOMINAL TOTAL COOLING CAPACITY

NOMINAL SENSIBLE COOLING CAPACITY

NOMINAL TOTAL HEATING CAPACITY (ENTERING

WATER TEMP. = 50°C)

HIGH l/s / CFM 130 / 275 142 / 300

NOMINAL AIR FLOW

UNIT DIMENSION

PACKING DIMENSION

UNIT WEIGHT

SOUND PRESSURE LEVEL ( H/M/L )

NOMINAL WATER FLOW RATE

HEAD LOSS (COOLING)

HEAD LOSS (HEATING) : 50°C

MAX. WORKING PRESSURE

SURFACE AIR VELOCITY

CONNECTION

CONTROL

CONDENSATE DRAIN SIZE

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 & ISO13253.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - ENTERING AIR TEMP. : 27°C (80.6°F) DB / 19°C (66.2°F) WB, ENTERING WATER TEMP. : 7°C (44.6°F), LEAVING WATER TEMP. : 12°C (53.6°F)

b) HEATING - ENTERING AIR TEMP.: 20°C (68°F) DB, ENTERING WATER TEMP. : 50°C (122°F), WATER FLOW RATE BASED ON COOLING CYCLE.

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS C 9612 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND

0.8m BELOW THE VERTICAL CENTRE LINE OF THE UNIT.

MEDIUM l/s / CFM

LOW l/s / CFM 83 / 17 5 94 / 200

HEIGHT mm/in 260 / 10.2 260 / 10.2

WIDTH mm/in

DEPTH mm/in 198 / 7.8 198 / 7.8

HEIGHT mm/in 330 / 13.0 330 / 13.0

WIDTH mm/in

DEPTH mm/in 265 / 10.4 265 / 10.4

ROOM TEMPERATURE

AIR DISCHARGE

OPERATION

Btu/h 8000 9500

W 2340 2780

Btu/h 5900 6900

W 1730 2030

Btu/h 10300 12800

W 3020 3750

kg/lb 10 / 22.1 12 / 26.5

dBA

USGPM 1.76 2.11

LITRES/M

kPa / psi 48 / 7 65 / 9.4

kPa / psi 42 / 6.1 59 / 8.5

kPa / psi

m/s 0.65 0.61

ft/min 127.8 121.0

mm/in

MWM07G2W MWM10G2W

106 / 225 118 / 250

799 / 31.5 899 / 35.4

827 / 32.6 827 / 32.6

38 / 33 / 28 39 / 34 / 28

6.66 7.99

1608 / 233

1/2" BSP FEMALE ADAPTOR

MICRO-COMPUTER CONTROLLED THERMOSTAT

AUTOMATIC LOUVER (UP& DOWN)

LCD WIRELESS MICRO-COMPUTER REMOTE CONTROL

12.7 / 0.5

55

Page 58

General Data - MWM-G2W

MODEL

NOMINAL TOTAL COOLING CAPACITY

NOMINAL SENSIBLE COOLING CAPACITY

NOMINAL TOTAL HEATING CAPACITY (ENTERING

WATER TEMP. = 50°C)

Btu/h 11000 15500

W 3220 4540

Btu/h 8010 12480

W 2350 3650

Btu/h 14000 20500

W 4100 6010

HIGH l/s / CFM 163 / 345 297 / 630

NOMINAL AIR FLOW

MEDIUM l/s / CFM

LOW l/s / CFM 104 / 220 208 / 440

HEIGHT mm/in 260 / 10.2 304 / 12.0

UNIT DIMENSION

WIDTH mm/in

DEPTH mm/in 198 / 7.8 222 / 8.7

HEIGHT mm/in 330 / 13.0 378 / 14.9

PACKING DIMENSION

WIDTH mm/in

DEPTH mm/in 265 / 10.4 292 / 11.5

UNIT WEIGHT

SOUND PRESSURE LEVEL ( H/M/L )

NOMINAL WATER FLOW RATE

HEAD LOSS (COOLING)

HEAD LOSS (HEATING) : 50°C

MAX. WORKING PRESSURE

SURFACE AIR VELOCITY

kg/lb 12 / 26.5 16 / 35.3

dBA

USGPM 2.42 3.43

LITRES/M

kPa / psi 77 / 11.1 50 / 7.3

kPa / psi 64 / 9.2 51 / 7.3

kPa / psi

m/s 0.71 0.90

ft/min 139.1 177.4

CONNECTION

ROOM TEMPERATURE

CONTROL

AIR DISCHARGE

OPERATION

CONDENSATE DRAIN SIZE

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 & ISO13253.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - ENTERING AIR TEMP. : 27°C (80.6°F) DB / 19°C (66.2°F) WB, ENTERING WATER TEMP. : 7°C (44.6°F), LEAVING WATER TEMP. : 12°C (53.6°F)

b) HEATING - ENTERING AIR TEMP.: 20°C (68°F) DB, ENTERING WATER TEMP. : 50°C (122°F), WATER FLOW RATE BASED ON COOLING CYCLE.

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS C 9612 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND

0.8m BELOW THE VERTICAL CENTRE LINE OF THE UNIT.

mm/in 12.7 / 0.5 19.05 / 0.75

MWM15G2W MWM20G2W

134 / 285 231 / 490

899 / 35.4 1062 / 41.8

827 / 32.6 1100 / 43.3

42 / 36 / 29 49 / 44 / 42

9.16 12.98

1608 / 233

1/2" BSP FEMALE ADAPTOR

MICRO-COMPUTER CONTROLLED THERMOSTAT

AUTOMATIC LOUVER (UP& DOWN)

LCD WIRELESS MICRO-COMPUTER REMOTE CONTROL

56

Page 59

General Data - MWM301W

360 / 14.2

1200 / 47.2

200 / 7.9

MODEL

NOMINAL TOTAL COOLING CAPACITY

NOMINAL SENSIBLE COOLING CAPACITY

NOMINAL TOTAL HEATING CAPACITY (ENTERING

WATER TEMP. = 50°C)

Btu/h

W 5280 6450

Btu/h 14750 16720

W

Btu/h 23000 23000

W 6740 6740

HIGH l/s / CFM

NOMINAL AIR FLOW

MEDIUM l/s / CFM 274 / 580 297 / 630

LOW l/s / CFM 222 / 470 236 / 500

HEIGHT mm/in

UNIT DIMENSION

WIDTH mm/in 1062 / 41.8 815 / 32.1

DEPTH mm/in 222 / 8.7 181 / 7.1

HEIGHT mm/in

PACKING DIMENSION

WIDTH mm/in 1100 / 43.3 1100 / 43.3

DEPTH mm/in 292 / 11.5 301 / 11.9

UNIT WEIGHT

SOUND PRESSURE LEVEL ( H/M/L )

NOMINAL WATER FLOW RATE

HEAD LOSS (COOLING)

HEAD LOSS (HEATING) : 50°C

MAX. WORKING PRESSURE

SURFACE AIR VELOCITY

kg/lb

dBA 50 / 48 / 45 49 / 47 / 45

USGPM 4.00 4.90

LITRES/M

kPa / psi 69 / 10 52 / 7.6

kPa / psi 71 / 10.2 19 / 2.7

kPa / psi

m/s 0.94 1.09

ft/min

CONNECTION 1/2" BSP FEMALE ADAPTOR

ROOM TEMPERATURE

CONTROL

AIR DISCHARGE

OPERATION

CONDENSATE DRAIN SIZE 19.05 / 0.75

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 & ISO13253.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - ENTERING AIR TEMP. : 27°C (80.6°F) DB / 19°C (66.2°F) WB, ENTERING WATER TEMP. : 7°C (44.6°F), LEAVING WATER TEMP. : 12°C (53.6°F)

b) HEATING - ENTERING AIR TEMP.: 20°C (68°F) DB, ENTERING WATER TEMP. : 50°C (122°F), WATER FLOW RATE BASED ON COOLING CYCLE.

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS C 9612 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND

0.8m BELOW THE VERTICAL CENTRE LINE OF THE UNIT.

mm/in

MWM25G2W MWM301W

18000 22000

4320 4900

311 / 660 316 / 670

304 / 12.0 291 / 11.4

378 / 14.9 760 / 30.0

16 / 35.3 20 / 44.2

15.14 18.55

1608 / 233

185.9 214.7

MICRO-COMPUTER CONTROLLED THERMOSTAT

AUTOMATIC LOUVER (UP& DOWN)

LCD WIRELESS MICRO-COMPUTER REMOTE CONTROL

57

Page 60

General Data - MCK-AW

MODEL

NOMINAL TOTAL COOLING CAPACITY

NOMINAL SENSIBLE COOLING CAPACITY

NOMINAL TOTAL HEATING CAPACITY (ENTERING

WATER TEMP. = 50°C)

Btu/h 22500 25500

W 6590 7470

Btu/h 16700 18400

W 4890 5390

Btu/h

W 8350 9380

HIGH l/s / CFM 364 / 771 383 / 812

NOMINAL AIR FLOW

MEDIUM l/s / CFM

LOW l/s / CFM 297 / 630 297 / 630

HEIGHT mm/in

UNIT DIMENSION - ( ) WITH PANEL

WIDTH mm/in

DEPTH mm/in

PMCK0ING DIMENSION

( ) - PANEL

HEIGHT mm/in

WIDTH mm/in

DEPTH mm/in

UNIT WEIGHT ( UNIT + PANEL )

SOUND PRESSURE LEVEL ( H/M/L )

NOMINAL WATER FLOW RATE

HEAD LOSS (COOLING)

HEAD LOSS (HEATING) : 50°C

MAX. WORKING PRESSURE

SURFACE AIR VELOCITY

FAN COIL WATER VOLUME & MASS

kg/lb ( 31+4 ) / ( 68.3+8.8 ) ( 32+4 ) / ( 70.5+8.8 )

dBA

USGPM 5.00 5.68

LITRES/M 19.00 21.50

kPa / psi

kPa / psi 21 / 3.1 27 / 3.9

kPa / psi

m/s

ft/min 153.6 161.8

kg 2.7 2.7

CONNECTION

ROOM TEMPERATURE

CONTROL

AIR DISCHARGE

OPERATION

CONDENSATE DRAIN SIZE

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 & ISO13253.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - ENTERING AIR TEMP. : 27°C (80.6°F) DB / 19°C (66.2°F) WB, ENTERING WATER TEMP. : 7°C (44.6°F), LEAVING WATER TEMP. : 12°C (53.6°F)

b) HEATING - ENTERING AIR TEMP.: 20°C (68°F) DB, ENTERING WATER TEMP. : 50°C (122°F), WATER FLOW RATE BASED ON COOLING CYCLE.

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS C 9612 STANDARD. MCK020/025AW : POSITION OF THE MEASUREMENT POINT IS 1.4m

BELOW THE FACIA. MCK030/040/050AW : 1.5m BELOW THE FACIA (JIS B 8615).

mm/in

MCK020AW MCK025AW

28500 32000

314 / 665 328 / 695

305 / 12 ( 355 / 14 )

824 / 32.4 ( 930 / 36.6 )

824 / 32.4 ( 930 / 36.6 )

371 /14.6 ( 121 / 4.8 )

916 / 36.1 (1000 / 39.4 )

916 / 36.1 (1016 / 40.0 )

42 / 39 / 37 45 / 42 / 40

25 / 3.6 31 / 4.5

1608 / 233

0.78 0.82

3/4" BSP FEMALE UNION

MICRO-COMPUTER CONTROLLED THERMOSTAT

AUTOMATIC LOUVER (UP& DOWN)

LCD WIRELESS MICRO-COMPUTER REMOTE CONTROL

19.05 / 3/4

58

Page 61

General Data - MCK-AW

MODEL

NOMINAL TOTAL COOLING CAPACITY

NOMINAL SENSIBLE COOLING CAPACITY

NOMINAL TOTAL HEATING CAPACITY (ENTERING

WATER TEMP. = 50°C)

Btu/h 30000 33500

W 8790 9820

Btu/h 21800 24200

W

Btu/h 37500 40500

W

HIGH l/s / CFM 433 / 918 483 / 1024

NOMINAL AIR FLOW

MEDIUM l/s / CFM

LOW l/s / CFM 336 / 712 372 / 789

HEIGHT mm/in

UNIT DIMENSION - ( ) WITH PANEL

WIDTH mm/in

DEPTH mm/in

PMCK0ING DIMENSION

( ) - PANEL

HEIGHT mm/in

WIDTH mm/in

DEPTH mm/in

UNIT WEIGHT ( UNIT + PANEL )

SOUND PRESSURE LEVEL ( H/M/L )

NOMINAL WATER FLOW RATE

HEAD LOSS (COOLING)

HEAD LOSS (HEATING) : 50°C

MAX. WORKING PRESSURE

SURFACE AIR VELOCITY

FAN COIL WATER VOLUME & MASS

kg/lb ( 35+4 ) / (77.2+8.8 ) ( 38+4 ) / ( 83.8+8.8 )

dBA

USGPM 6.65 7.53

LITRES/M

kPa / psi 42 / 6 52 / 7.6

kPa / psi 35 / 5.1 45 / 6.6

kPa / psi

m/s 0.93 1.04

ft/min

kg 2.7 2.7

CONNECTION

ROOM TEMPERATURE

CONTROL

AIR DISCHARGE

OPERATION

CONDENSATE DRAIN SIZE

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 & ISO13253.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - ENTERING AIR TEMP. : 27°C (80.6°F) DB / 19°C (66.2°F) WB, ENTERING WATER TEMP. : 7°C (44.6°F), LEAVING WATER TEMP. : 12°C (53.6°F)

b) HEATING - ENTERING AIR TEMP.: 20°C (68°F) DB, ENTERING WATER TEMP. : 50°C (122°F), WATER FLOW RATE BASED ON COOLING CYCLE.

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS C 9612 STANDARD. MCK020/025AW : POSITION OF THE MEASUREMENT POINT IS 1.4m

BELOW THE FACIA. MCK030/040/050AW : 1.5m BELOW THE FACIA (JIS B 8615).

mm/in

MCK030AW MCK040AW

6390 7100

11000 11870

367 / 777 425 / 900

305 / 12 ( 355 / 14 )

824 / 32.4 ( 930 / 36.6 )

824 / 32.4 ( 930 / 36.6 )

371 /14.6 ( 121 / 4.8 )

916 / 36.1 (1000 / 39.4 )

916 / 36.1 (1016 / 40.0 )

49 / 45 / 43 51 / 48 / 46

25.23 28.52

1608 / 233

182.9 204.0

3/4" BSP FEMALE UNION

MICRO-COMPUTER CONTROLLED THERMOSTAT

AUTOMATIC LOUVER (UP& DOWN)

LCD WIRELESS MICRO-COMPUTER REMOTE CONTROL

19.05 / 3/4

59

Page 62

General Data - MCK-AW

MODEL

NOMINAL TOTAL COOLING CAPACITY

NOMINAL SENSIBLE COOLING CAPACITY

NOMINAL TOTAL HEATING CAPACITY (ENTERING

WATER TEMP. = 50°C)

Btu/h

W

Btu/h

W

Btu/h

W

HIGH l/s / CFM

NOMINAL AIR FLOW

MEDIUM l/s / CFM

LOW l/s / CFM

HEIGHT mm/in

UNIT DIMENSION - ( ) WITH PANEL

WIDTH mm/in

DEPTH mm/in

PMCK0ING DIMENSION

( ) - PANEL

HEIGHT mm/in

WIDTH mm/in

DEPTH mm/in

UNIT WEIGHT ( UNIT + PANEL )

SOUND PRESSURE LEVEL ( H/M/L )

NOMINAL WATER FLOW RATE

HEAD LOSS (COOLING)

HEAD LOSS (HEATING) : 50°C

MAX. WORKING PRESSURE

SURFACE AIR VELOCITY

FAN COIL WATER VOLUME & MASS

kg/lb

dBA

USGPM

LITRES/M

kPa / psi

kPa / psi

kPa / psi

m/s

ft/min

kg

CONNECTION

ROOM TEMPERATURE

CONTROL

AIR DISCHARGE

OPERATION

CONDENSATE DRAIN SIZE

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151 & ISO13253.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - ENTERING AIR TEMP. : 27°C (80.6°F) DB / 19°C (66.2°F) WB, ENTERING WATER TEMP. : 7°C (44.6°F), LEAVING WATER TEMP. : 12°C (53.6°F)

b) HEATING - ENTERING AIR TEMP.: 20°C (68°F) DB, ENTERING WATER TEMP. : 50°C (122°F), WATER FLOW RATE BASED ON COOLING CYCLE.

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS C 9612 STANDARD. MCK020/025AW : POSITION OF THE MEASUREMENT POINT IS 1.4m

BELOW THE FACIA. MCK030/040/050AW : 1.5m BELOW THE FACIA (JIS B 8615).

mm/in

MICRO-COMPUTER CONTROLLED THERMOSTAT

AUTOMATIC LOUVER (UP& DOWN)

LCD WIRELESS MICRO-COMPUTER REMOTE CONTROL

MCK050AW

36500

10700

26280

7690

44000

12900

511 / 1083

467 / 989

428 / 906

305 / 12 ( 355 / 14 )

824 / 32.4 ( 930 / 36.6 )

824 / 32.4 ( 930 / 36.6 )

371 /14.6 ( 121 / 4.8 )

916 / 36.1 (1000 / 39.4 )

916 / 36.1 (1016 / 40.0 )

( 40+4 ) / ( 88.2+8.8 )

53 / 52 / 50

8.19

30.97

69 / 10

64 / 9.3

1608 / 233

1.10

215.7

2.7

3/4" BSP FEMALE UNION

19.05 / 3/4

60

Page 63

General Data - MCK-AWH

MODEL

NOMINAL TOTAL COOLING CAPACITY

NOMINAL SENSIBLE COOLING CAPACITY

NOMINAL TOTAL HEATING CAPACITY (ENTERING

WATER TEMP. = 70°C)

Btu/h 13000 13500

W 3810 3960

Btu/h 11600 12100

W 3400 3520

Btu/h

W 10550 10990

HIGH l/s / CFM 364 / 771 383 / 812

NOMINAL AIR FLOW

MEDIUM l/s / CFM 314 / 665 328 / 695

LOW l/s / CFM 297 / 630 297 / 630

HEIGHT mm/in

UNIT DIMENSION - ( ) WITH PANEL