Page 1

Operation & Maintenance Data OM 120-2

Mark IV/AC Controller For

Water Source Heat Pump Units

Group: WSHP

Part Number: 578993Y

Date: May 1999

Contents

Features of the Mark IV Controller ................................ 2

Initial Power Up................................................................2

General Use and Information ......................................... 2

Occupied Operation ........................................................ 3

Thermostat Inputs (G, Y1, W1, and W2)........................3

Control Inputs (HP, LT, COF, U, L, E, O) 3

Control Outputs (A and P)..............................................3

Fan Operation................................................................. 3

Cooling Mode ................................................................. 3

Heating Mode.................................................................3

Unoccupied Operation....................................................3

Thermostat Inputs (G, Y1, W1, and W2)........................3

Control Inputs (HP, LT, COF, U, L, E, O) 3

Control Outputs (A and P)..............................................3

Fan Operation................................................................. 4

Cooling Mode ................................................................. 4

Heating Mode.................................................................4

Additional Operating Modes .......................................... 4

Load Shed ......................................................................4

Brownout ........................................................................ 4

©1999 AAF-McQuay Incorporated OM 120-2 (Rev. 5/99)

Remote Shutdown.......................................................... 4

High/Low Pressure Faults..............................................4

Low Temperature Faults ................................................5

Condensate Overflow..................................................... 5

Tenant Override.............................................................. 5

Operation of the Fan during most Modes, Faults &

Shutdowns ..................................................................5

Operation with High Speed Jumper ..............................5

Priority of Faults and Modes..........................................5

LED Status and Fault Output Status .............................6

14-PositionTerminal Strip...............................................6

Trouble Shooting the Mark IV/AC Control Board ........ 6

Interfacing the Mark IV/AC Controller

to External Equipment .................................................7

Typical Mark IV/AC Unit Wiring Diagram...................... 8

Page 2

Features of the

Mark IV/AC Controller

The Mark IV/AC controller incorporates features which

improve the operation and safety of AAF-McQuay heat

pumps. These features include:

1. Compressor short cycle protection

2. Brownout protection with time delays for the fan and compressor to prevent damage due to low voltage conditions

3. Condensate overflow protection

4. Refrigerant high / low pressure protection

5. Low temperature protection with automatic condenser

defrost cycle

6. Random start delay compressor to prevent high building

electrical demands when multiple units are simultaneously

switched on during power-up, return from brownouts,

return from load shed, etc.

7. LED’s to indicate operational status and fault indication

8. Controlled delay of the reversing valve to reduce annoying “swish” noise

9. High speed test jumper (TP) used to reduce compressor short cycle and reversing valve delay times to

speed system check out and repair.

10. Load shed control input for energy management systems

11. Remote shutdown control input for remote shutdown

of unit

*

12. Unoccupied control input for night setback control

13. Inputs for both standard (W1) and night setback (W2)

thermostats

Initial Power Up

When power is first applied to the unit, the following events

occur:

1. The board executes a reset routine which sets up the

microcontroller for normal operation. During this routine

the following occurs:

a. The reversing valve may click on and off.

b. The A output goes low for a fraction of a second.

c. The GREEN LED will flash at

approximately 1

d. A new random start delay time between 0 and 32

seconds is generated. A new short-cycle timer is

also generated by adding 180 to the new start delay

time for a total time delay between 180 and 212

seconds. Once these numbers are generated, the

same time delays will be used until the next power

cycle.

2. The microcontroller then checks for the following conditions in the following order:

a. High pressure fault

b. Low temperature fault

c. Load shed signal on

d. Brownout or remote shutdown condition

e. Condensate fault

f. Unoccupied signal on

If any of these conditions are true, the microcontroller

executes the appropriate routine. For example, if the high

pressure switch is open upon power up, the compressor

will not start and the RED LED will flash.

3. If none of the above signals or faults are detected during

start up, the unit will go into normal operation.

1

⁄2 seconds.

1

⁄2 second intervals for

14. Fault output for remote fault indication

15. Operation of the fan during most faults and load shed to

increase comfort

16. Tenant override input to manually switch from unoccupied mode (U) to occupied mode (O)

17. Control board inputs U, L, E, Y1, W1, G, W2, and O have

been designed to operate by connecting to the units

24vac, 24vdc, or chassis ground

The remote shutdown input (E) should not be the sole

*

means of ensuring equipment status when used as a part of

a life-safety control system as the unit fan may operate

during some fault conditions.

CAUTION

The Mark IV/AC circuit board incorporates static sensitive

devices. A static charge from touching the device can

damage the electronic components. To prevent damage

during service, AAF-McQuay Incorporated recommends the

use of static discharge wrist straps which are grounded to the

heat pump chassis through a one mega ohm resistor.

For replacement of a Mark IV/AC circuit board:

1. Connect wrist strap to unit.

2. Remove faulty board and place on static protected surface.

3. Remove replacement board from static protected bag.

Do not touch circuit board; hold by edges.

4. Holding board in grounded hand, install board in unit.

5. Insert faulty board in empty static bag for return.

General Use and Information

The Mark IV/AC control board is provided with three drive

terminals, R (24vac), F (24vdc), and C (0vac) that can be used

by the end user to drive the thermostat inputs (G, Y1, W1, and

W2) and control inputs (U, L, E, and O). Any combination of

or single board drive terminal (R, F, or C) may be used to

operate the Mark IV/AC boards control or thermostat inputs.

However, only one drive terminal (R, F, or C) can be connected to any individual input terminal or damage will occur.

Some of the control inputs are used within the Water Source

Heat Pump and not accessible to the end user. For example

HP, LT, and COF are not available for use by the end user.

Typically the Mark IV/AC board’s R (24vac) terminal is used

to drive the board’s thermostat inputs and control inputs by

connecting it to the R terminal of an industry standard

thermostat. The control outputs of the standard thermostat

are then connected to the Mark IV/AC board thermostat

inputs and control inputs as needed. Any remaining board

input(s) may be operated by additional thermostat outputs or

remote relays (dry contacts only).

All Mark IV/AC board inputs must be operated by dry

contacts powered by the control board’s power terminals.

No solid state devices (Triacs) may be used to operate Mark

IV/AC board inputs. No outside power sources may be used

to operate Mark IV/AC board inputs.

Page 2 / OM 120-2

Page 3

Occupied Operation

Board LED Status

Yellow Green Red

Off On Off

Thermostat Inputs (G, Y1, W1, and W2)

Thermostat inputs used during occupied operation are G, Y1,

and W1, which when energized will activate the Fan Only,

Cooling Mode, and Heating Mode respectively. Input W2,

unoccupied Heating Mode has no effect during occupied

mode.

The Mark IV/AC board is configured so that when either the Y1

or W1 input is energized the unit fan will also be activated with

Cooling or Heating Modes. In other words, energizing Y1 and G

together will have the same effect as energizing just Y1.

The W1 input has priority over the Y1 input. In situations when

both inputs W1 and Y1 become energized (unlikely) in any order

the unit will go into the Heating Mode as described below:

1. For example, if the unit is in Cooling Mode, Y1 energized, and

W1 becomes energized and remains energized, the following will occur:

l The compressor will be de-energized

l The reversing valve will energize 1 minute later (Heating

Mode position)

l The compressor will restart between 180 and 212

seconds (short-cycle timer)

2. If the unit is in Cooling Mode, Y1 energized, and W1 becomes

energized momentarily the controller will de-energize the

compressor for 180 to 212 seconds (short-cycle timer) and

then return to the cooling mode.

3. However, if the unit is in Heating Mode, W1 energized, and

Y1 becomes energized the unit will remain in Heating Mode.

The board will be in occupied

mode if the unoccupied terminal

(U) is de-energized.

3. The P control output is de-energized when the compressor

is energized

When the Y1 terminal is then de-energized, the following

will occur:

1. The compressor is de-energized immediately

2. The fan is de-energized immediately, unless the G terminal

is energized

3. The P control output is energized when the compressor is

de-energized

Compressor time delays may be longer than indicated above as

the short-cycle timer (180 to 212 seconds) will be used as

needed to prevent adverse compressor cycling.

Heating Mode

The W1 terminal controls occupied Heating Mode operation.

When the W1 terminal is energized the following will occur:

1. The reversing valve will be energized immediately

2. The fan will be energized immediately

3. The compressor will be energized after 0 to 32 seconds (start

delay timer)

4. The P control output is de-energized when the compressor

is energized

When the W1 terminal is then de-energized the following will

occur:

1. The compressor will be de-energized immediately

2. The fan will be de-energized immediately, unless the G

terminal is energized

3. The reversing valve de-energizes after 1-minute

4. The P control output is energized when the compressor is

de-energized

Compressor time delays may be longer than indicated above as

the short-cycle timer (180 to 212 seconds) will be used as

needed to prevent adverse compressor cycling.

Control Inputs (HP, LT, COF, U, L, E, O)

The control inputs are High / Low Pressure (HP), Low Temperature (LT), Condensate Overflow (COF), Unoccupied (U), Load

Shed (L), and Remote Shutdown (E). The control inputs will all

be in their normal states during occupied mode. The state of

each control in occupied mode during normal operation is as

follows:

l High / Low Pressure (HP): energized, switch is closed (no

fault)

l Low Temperature (LT): energized, switch is closed (no fault)

l Condensate Overflow (COF): sensing no condensate water

(no fault)

l Unoccupied (U): de-energized (no signal)

l Load Shed (L): de-energized (no signal)

l Remote Shutdown (E): de-energized (no signal)

l Tenant Override (O): has no effect in occupied mode

Control Outputs (A and P)

The control outputs are Alarm Fault (A) and Pump Request (P).

The operation of the control outputs during occupied mode is

as follows:

l Alarm Fault (A): energized (no fault)

l Pump Request (P): energized when the compressor is off,

and de-energized when the compressor is on.

Fan Operation

The G terminal controls Fan Only operation. The fan will start

when the G terminal is energized. De-energizing the G terminal

will cause the fan to stop unless the W1 or Y1 terminals are

energized.

Unoccupied Operation

Board LED Status

Yellow Green Red

On On Off

Thermostat Inputs (G, Y1, W1, and W2)

The only thermostat input used during unoccupied operation is

W2, which when energized will activate Heating Mode. Inputs

G, Y1, and W1 have no effect during unoccupied mode.

Control Inputs (HP, LT, COF, U, L, E, O)

The control inputs are High / Low Pressure (HP), Low Temperature (LT), Condensate Overflow (COF), Unoccupied (U), Load

Shed (L), and Remote Shutdown (E). The state of each control

input during unoccupied mode during normal operation is as

follows:

l High / Low Pressure (HP): energized, switch is closed (no fault)

l Low Temperature (LT): energized, switch is closed (no fault)

l Condensate Overflow (COF): sensing no condensate water

(no fault)

l Unoccupied (U): energized (signal provided)

l Load Shed (L): de-energized (no signal)

l Remote Shutdown (E): de-energized (no signal)

l Tenant Override (O): see section “Tenant Override Mode”

The board will be in unoccupied

mode if the unoccupied terminal

(U) is energized.

Cooling Mode

The Y1 terminal controls Cooling Mode operation. When the Y1

terminal is energized, the following will occur:

1. The fan will be energized immediately

2. The compressor will be energized after 0 to 32 seconds (start

delay timer)

Control Outputs (A and P)

The control outputs provided by the Mark IV/AC board are

Alarm Fault (A) and Pump Request (P). The operation of the

control outputs during unoccupied mode is the same as in

occupied mode. See occupied operation.

OM 120-2 / Page 3

Page 4

Fan Operation

The G terminal has no effect during unoccupied mode. Operation of the fan is controlled by the W2 input.

Cooling Mode

Cooling operation is not provided during unoccupied mode.

Heating Mode

The W2 terminal controls unoccupied Heating Mode operation.

When the W2 terminal is energized the following occurs:

1. The reversing valve is energized immediately

2. The fan is energized immediately

3. The compressor will start after 0 to 32 seconds (start

delay timer)

4. The P control output is de-energized when the compressor

is energized

When the W2 terminal is then de-energized the following

occurs:

1. The compressor is de-energized immediately

2. The reversing valve de-energizes after 1-minute

3. The P control output is energized when the compressor is

de-energized

Compressor time delays may be longer than indicated above as

the short-cycle timer (180 to 212 seconds) will be used as

needed to prevent adverse compressor cycling.

Additional Operating Modes

Load Shed

Board LED Status

Yellow Green Red

Off Off On

or fault. Load shed is provided so that when properly connected

to a building automation system, remote switch, etc., the L

terminal can be used to deactivate the compressor. The load

shed input may also be used as part of a boiler-less system kit,

which will disable the compressor by energizing the L terminal

when loop water temperature drops. The fan will operate

normally during load shed mode.

Some faults and modes have higher priority than load shed

mode. See the section “Priority of Faults and Modes”.

When the L terminal is energized the following occurs:

1. The compressor is immediately de-energized

2. The reversing valve will be de-energized after 1-minute

When the L terminal is then de-energized, the controller will

automatically return to normal operation.

Brownout

Board LED Status

Yellow Green Red

Off Flash Off

source heat pump drops, the 24vac supply to the control board

will also drop. When the line voltage supplied to the unit drops

below approximately 80% of the unit nameplate rated value the

controller will go into brownout mode. The controller will then

remain in brownout mode until line voltage returns to approximately 90% of the unit nameplate value. Brownout mode is

provided to protect the water source heat pump’s motors from

low voltage conditions.

When in brownout mode all thermostat and control inputs have

no effect on unit operation. No faults or modes have higher

The Mark IV/AC board will be in

load shed mode when the L

terminal is energized unless over

ridden by a higher priority mode

The Mark IV/AC board is

designed to monitor the 24vac

supply to the board. If the line

voltage supplied to the water

priority than brownout mode. Remote shutdown and brownout

modes have the same level of priority. See the section “Priority

of Faults and Modes”.

When the unit is in brownout mode the following occurs:

1. The compressor is immediately de-energized

2. The reversing valve is immediately de-energized

3. The fan is immediately de-energized

4. Fault terminal (A) is de-energized (fault)

When the line voltage supplied to the unit returns to acceptable

levels (~90% of nameplate) the controller will return to the

current mode.

Remote Shutdown

Board LED Status

Yellow Green Red

Flash Off Off

when properly connected to a building automation system,

remote switch, etc., the E terminal can be used to shut down the

water source heat pump.

When in remote shutdown (E terminal energized) no other

thermostat or control inputs will have effect on unit operation.

No faults or modes have higher priority than remote shutdown.

Remote shutdown and brownout modes have the same level of

priority. See the section “Priority of Faults and Modes”.

When the unit is in remote shutdown mode the following

occurs:

1. The compressor is immediately de-energized

2. The reversing valve is immediately de-energized

3. The fan is immediately de-energized

4. Fault terminal (A) is de-energized (fault)

When the E terminal is de-energized the unit will automatically

return to normal operation.

The remote shutdown input (E) should not be the sole

*

means of ensuring equipment status when used as a part of

a life-safety control system as the unit fan may operate

during some fault conditions.

The Mark IV/AC board will be in

remote shutdown when the E

terminal is energized. Remote

shutdown is provided so that

High / Low Pressure Faults

Board LED Status

Yellow Green Red

Off Off Flash

tect from excessively high or low refrigerant pressures. The

Mark IV/AC board will monitor these switches connected in

series through the HP control input terminals on the board.

When the HP circuit is open the controller will go into the

pressure fault mode. The fan will operate normally during the

pressure fault mode.

Only brownout and remote shutdown modes have higher

priority than the pressure fault mode. See the section “Priority

of Faults and Modes”.

When the unit is in pressure fault mode the following occurs:

1. The compressor is immediately de-energized

2. The reversing valve is immediately de-energized

3. The fault terminal (A) is de-energized (fault)

After the HP circuit is then closed the unit will not return to

normal operation until the control board is reset. The unit is

locked out in this manner after a high / low pressure fault to help

insure that a service technician inspects it to verify no problems

exist. The control board is reset by a short interruption of unit

power.

Normally closed high and low

refrigerant pressure switches are

used as needed within the water

source heat pump to help pro-

Page 4 / OM 120-2

Page 5

Low Temperature Faults

Board LED Status

Yellow Green Red

Flash Off Off

cessively low water out temperatures. The Mark IV/AC board

will monitor this switch connected to the LT control input

terminals on the board. When the LT circuit is open the controller

will go into the low temperature fault mode. The controller is

programmed for different responses if a low temperature fault

is detected during heating or cooling modes. The control board

LED status shown below only occurs when a low temperature

fault is detected during heating mode. No LED status changes

occur if the fault is detected while in cooling mode. The fan will

operate normally during the low temperature fault mode.

Brownout, remote shutdown, and pressure fault modes have

higher priority than the low temperature fault mode. See the

section “Priority of Faults and Modes”.

When the unit senses a low temperature fault while in heating

mode the following occurs:

1. The reversing valve will be immediately de-energized

2. The compressor will run in cooling mode for 1-minute

(heating the unit’s water coil) and then be de-energized

3. The fault terminal (A) is de-energized (fault)

When the LT circuit is then closed after a fault during heating

mode the unit will not return to normal operation until the control

board is reset. The unit is locked out in this manner after a low

temperature fault to help insure that a service technician inspects it to verify no problems exist. The unit is reset by a short

interruption of unit power.

When the unit senses a low temperature fault while in the cooling

mode the following occurs:

1. The compressor is immediately de-energized

2. The fault terminal (A) remains energized (no fault)

When the LT circuit is then closed after a fault during cooling

mode the unit will automatically return to normal operation.

A normally closed low temperature switch is used as needed

within the water source heat

pump to help protect from ex-

Condensate Overflow

Board LED Status

Yellow Green Red

On Dim Off

high condensate water levels are detected during cooling mode

the controller will go into condensate fault mode. No condensate overflow fault will occur during heating modes, therefore

the unit will be allowed to heat with high condensate water

levels. The fan will operate normally during the condensate

overflow fault mode.

Some faults and modes have higher priority than condensate

overflow mode. See the section “Priority of Faults and Modes”.

When the unit senses a condensate overflow fault while in

cooling mode the following occurs:

1. The compressor is immediately de-energized

2. The fault terminal (A) is de-energized (fault)

When condensate levels return to normal, the controller will

automatically return to normal operation.

The Mark IV/AC board is designed to sense when condensate water levels in the drain pan

become excessively high. When

Tenant Override

Prior to reviewing this section, read “Occupied Operation” and

“Unoccupied Operation” sections. The Mark IV/AC board will

be in tenant override mode when the O terminal is momentarily

energized during a period when the water source heat pump is

in unoccupied mode (U terminal energized). Tenant override is

provided so that when the controller is placed into unoccupied

mode by a building automation system, timer, remote switch,

etc., a tenant returning to the controlled space during the

unoccupied period can activate the tenant override input (O)

forcing the unit into occupied mode. A tenant override option is

provided for this purpose on some AAF-McQuay thermostats.

Any remote button or switch with momentary dry contacts can

be used for this purpose. During the 2-hour tenant override

period the W2 input will be ignored and the G, Y1, and W1 inputs

will be used (see Occupied Operation) for unit operation. If after

the 2-hour time limit the U terminal is still energized the unit will

return to unoccupied mode. If after the 2-hours the U terminal

is de-energized the unit will remain in occupied mode.

Operation of the Fan during most Modes,

Faults, and Shutdowns

To increase the level of comfort the Mark IV/AC controller is

configured to allow fan operation during most modes, faults,

and shutdowns. However, the fan will not operate during

brownout mode. During most modes, faults, or shutdowns the

fan will operate under the following conditions:

1. In occupied modes, whenever the thermostat inputs G, Y1,

or W1 are energized

2. In unoccupied modes, whenever the thermostat input W2 is

energized

Operation with the High Speed Jumper

The Mark IV/AC board is provided with a high-speed jumper

terminal labeled TP to speed system check out and troubleshooting. This jumper is intended for AAF-McQuay factory unit

testing and should only be used by trained service technicians

as several timing functions are reduced to speed system check

out. When a jumper is placed on the TP terminal, operation of the

unit is normal except the following timing values are used:

1. Reversing valve delay time = 2 seconds

2. Compressor delay time = 6 seconds

Note: It is required that power be disconnected to the unit when

installing or removing the high-speed jumper.

Note: It is required that the high speed jumper only be used for

short periods of time and only to aid the testing of the

unit’s operation by a trained service technician. The

jumper must be removed for normal unit operation. If the

jumper is left on after system check out, the unit will be

damaged.

Priority of Faults and Modes

The Mark IV/AC control board is configured with mode and fault

priorities. The higher level priorities, lower numbers in the table

below, override lower level modes and faults under most

conditions. There are some exceptions to this priority list. For

example, tenant override has no affect on occupied modes.

Priority

Level

in heating mode only

*

Mode or Fault

1 Emergency Shutdown Mode + Brownout Fault

2 High / Low Pressure Fault

3 Low Temperature Fault

4 Load Shed Mode

5 Tenant Override Mode

6 Unoccupied Heating Mode

7 Occupied Heating Mode

8 Condensate Overflow Fault

9 Occupied Cooling Mode

*

OM 120-2 / Page 5

Page 6

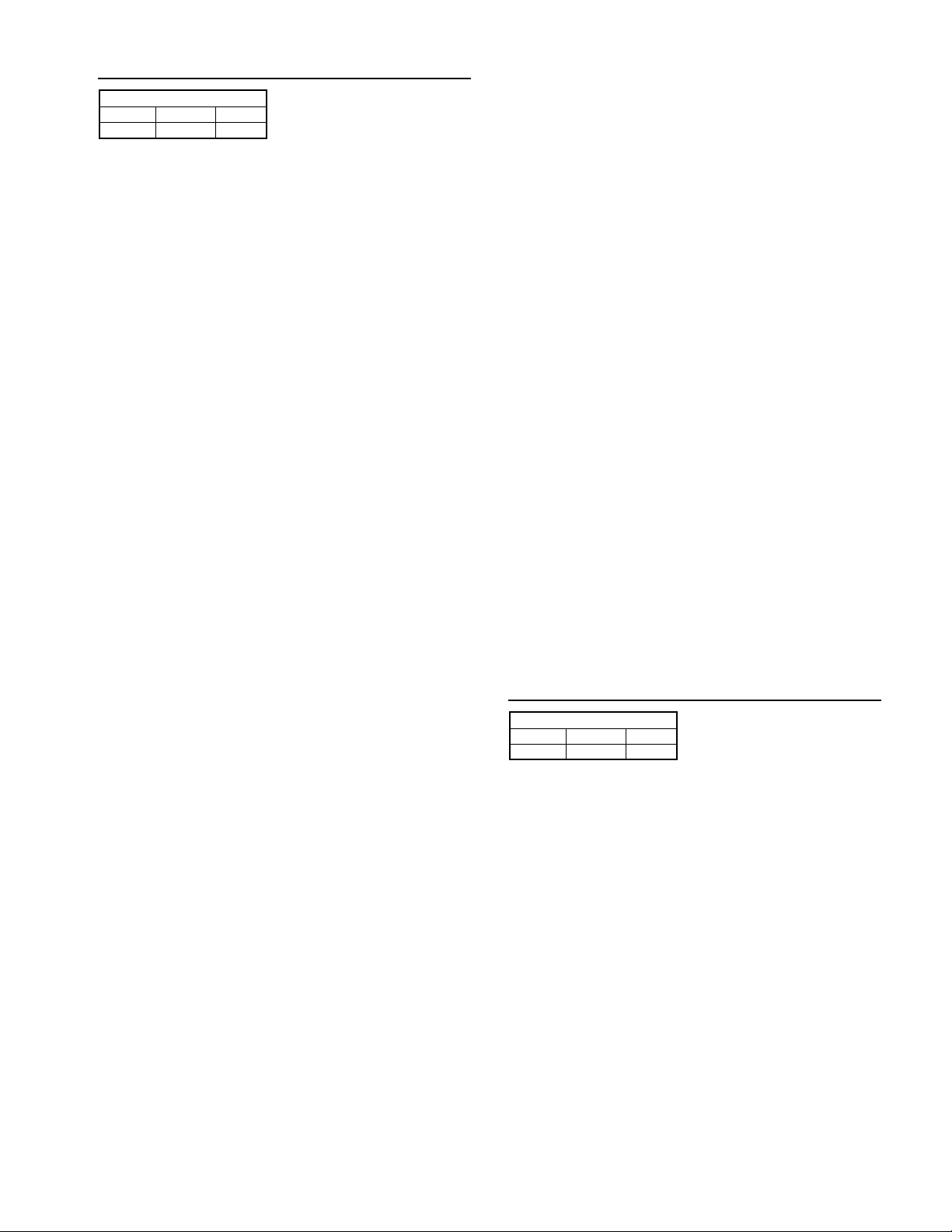

LED Status and

Fault Output Status

Board Status LED’s Fault Output

Mode Yellow Green Red Terminal A

Occupied Off On Off Energized

Unoccupied On On Off Energized

Load Shed Off Off On Energized

Condensate Overflow On Dim Off De-energized

High / Low Pressure Fault Off Off Flash De-energized

Low Temperature Fault*Flash Off Off De-energized

Brownout Off Flash Off De-energized

Emergency Shutdown Off Flash Off De-energized

in heating mode only

*

Note: The fault output is energized when no faults exist. The

fault output is de-energized during faults and when unit

power is off.

14-Position T erminal Strip

Pin Designation Description

1 C Transformer ground (0vac)

2 R Transformer supply (24vac)

3 V -DC power connection

4 P Pump request output

5 A Alarm fault output

6 U Unoccupied input

7 L Load shed input

8 E Remote shutdown input

9 F +DC power connection

10 Y1 Occupied cooling mode input

11 W1 Occupied heating mode input

12 G Fan only input

13 W2 Unoccupied heating mode input

14 O Tenant override input

Trouble Shooting the

Mark IV/AC Control Board

Note: Only trained and experienced service technicians may

perform the trouble-shooting techniques described below.

l How can I prove the water source heat pump is operating

properly?

Test the water source heat pump’s fan, cooling, and heating

operation. To do this first switch off unit power, remove and

safely secure all wires connected to the board’s 14-position

terminal strip, and then switch on unit power. Make sure no

faults exist. If no faults exist the green LED should be on solid

with the red and yellow LED’s off. If another LED pattern

appears try resetting the controller by temporarily

interrupting unit power. All faults must be eliminated prior to

performing this test. If the board is functioning properly the

only possible fault conditions with all wires removed from the

board’s 14-position terminal strip are high / low pressure, low

temperature, condensate overflow, or brownout. Remember

that while performing this test the compressor may take

more than 3-minutes to start due to the short cycle timer.

Return all wiring to original positions when testing is complete.

To test fan operation: connect a jumper from the R terminal to

the G terminal. The fan will start if the board and unit are

operating properly; disconnect the jumper when complete.

To test cooling operation: connect a jumper from the R

terminal to the Y1 terminal. The unit will go into cooling mode if

the board and unit are operating properly; disconnect the

jumper when complete.

To test heating operation: connect a jumper from the R

terminal to the W1 terminal. The unit will go into heating mode

if the board and unit are operating properly; disconnect the

jumper when complete.

l How can I prove the Mark IV/AC board is receiving 24vac and

that its DC power supply is operating correctly?

The Mark IV/AC board is provided 24vac by the water source

heat pump’s 24vac transformer. The board has a built-in DC

power supply that converts a portion of the 24vac into 24vdc.

A voltage meter set to read AC voltage can be used to verify

the 24vac supply to the board by placing the meter’s leads

onto board terminals C and R. You should read approximately 24vac if it is operating correctly. A voltage meter set

to read DC voltage can be used to verify the board’s DC

voltage supply by connecting the meter’s leads to board

terminals F (+) and V (-). You should read approximately

between +28 to +33vdc if the board is operating correctly.

l What voltages will I measure at the thermostat and control

inputs on the Mark IV/AC board when they are energized or deenergized?

The Mark IV/AC board is designed to be very flexible as to

how its thermostat (G, Y1, W1, and W2) and control inputs (U,

L, E, and O) are activated. The board inputs are capable of

being energized by 24vac, 24vdc, or a connection to ground.

Terminals R (24vac), F (24vdc), and C (ground) on the Mark

IV/AC board are the drive terminals that must be used to

energize the board’s thermostat and control inputs. A table

of voltages are provided below that will be measured for

each of the board’s drive terminals. Before measuring any

voltage, switch off unit power, remove and safely secure all

wires connected to the board’s 14-position terminal strip,

and then switch on unit power. Use a voltage meter to verify

the de-energized input voltages and compare with the table.

Then, using jumpers, energize the desired inputs (U, L, E, G,

Y1, W1, W2, and O) one at a time with the drive terminal of

choice. Use the voltage meter to verify the jumper-connected terminal voltage and compare with table results. This

is also a good method to test board function. The voltages

given in this table are approximations that will vary slightly

based upon unit options, present power consumption, etc.

Be sure that when testing is complete you remove any

jumpers and reconnect all wires to their proper location with

unit power off. The table below may also be used to determine if an input is energized or de-energized with wiring

connected to the 14-position thermal strip.

Using Using Using

Drive Terminal R Drive Terminal F Drive Terminal C

(24vac) (ground) (24vdc)

De-energized Energized De-energized Energized De-energized Energized

Place the

Meters

Red (+) Lead

on Input to

be checked

U, L, E, Y1, W1, 10 to 22 to

G, W2, O 14vac 26vac 33vdc 14vac 26vac

Place the Place the Place the

Meters on Meters Meters

Black (-) Lead Black (-) Lead Black (-) Lead

on C on V on R

0vdc

30 to 10 to 22 to

l Do I need to use the same drive terminal for all Mark IV/AC

board inputs?

No. You can use one, two, or all three of the drive terminals.

For example, you can use terminal R to drive inputs G, Y1,

W1, and W2; terminal C to drive inputs U, L, E; and then

terminal F to drive input O. The R terminal (24vac) is the

terminal most commonly used to drive the control board’s

thermostat and control inputs. You cannot connect two drive

terminals to one board input or board damage will result.

Page 6 / OM 120-2

Page 7

l Can I use 24vac or 24vdc power from the water source heat

pump to provide power to my programmable thermostat or

some other external devices that I need to power?

No. The water source heat pump is provided with a 24vac

transformer that is capable of providing power only to

devices supplied with the unit from the factory or to

approved add on options typically shipped with the unit or

purchased as accessories. The Mark IV/AC board cannot be

used to provide 24vdc power to external equipment.

If you need to power external devices you will need to

provide power from another location.

l How can I test the unit’s high / low pressure switch or the low

temperature switch?

The Mark IV/AC board uses its DC power supply as a source

for these normally closed safety switches. There are two HP

and two LT spade terminals located on the Mark IV/AC board

for this purpose. You can use a voltage meter to determine

if the switch is open or closed. Carefully placing the meter’s

probes, one on each of the control board’s HP terminals, you

will measure approximately 30vdc when the switch is open

(fault) or 0vdc when the switch is closed (no fault). The same

procedure can be applied to the LT terminals. To prove the

circuit operates you can pull one HP or LT spade connection

off the control board to cause the fault condition. Be sure to

replace these connections if removed.

l How can I test the condensate overflow circuit?

The condensate overflow circuit is designed to sense a

connection to chassis ground through the drain pan when

the drain pan is over full with condensate water. To test this

circuit, activate the fault when the unit is in cooling mode by

connecting a jumper between the COF spade terminal and

the C (ground) spade terminal. Be sure to remove this jumper

when testing is complete.

l Can I use a 24vac solenoid on the reversing valve?

No. The Mark IV/AC board is designed to drive a 24vdc

reversing valve solenoid. If you switch the 24vdc solenoid

provided with the water source heat pump with a 24vac

solenoid you will damage the Mark IV/AC control board. This

type of damage to the board may not occur immediately and

it can cause the fan and or compressor outputs to operate

erratically or not operate at all. If the compressor and or the

fan do not operate as expected, check the reversing valve

solenoid to ensure it is the proper voltage type.

Interfacing the Mark IV/AC

Controller to External Equipment

A 14-position terminal strip is provided on the control board to

interface to external equipment.

l The Mark IV/AC board’s thermostat input terminals may be

directly interfaced with any standard or night setback thermostat that uses mechanical dry contacts. Power cannot be

supplied from the water source heat pump for electronic

thermostats that require a separate power supply for their

internal operation except hose provided by AAF-McQuay.

Only the programmable and mercury bulb type thermostats

offered by AAF-McQuay are proven to operate properly with

the Mark IV/AC control board. AAF-McQuay makes no

guarantees about any other thermostat or control device

interfaced by the end user with the Mark IV/AC board.

l Care must be used to isolate all external power sources from

the Mark IV/AC board to prevent ground loops and other

unpredictable electrical problems. Only dry mechanical

contacts should be used to operate or interface with the

Mark IV/AC board’s thermostat and or control inputs.

If external equipment with its own power supply is used to

interface with or control the Mark IV/AC board’s thermostat

and or control inputs, you must use mechanical relays to

isolate the two power systems. For example, if you have a

building automation system, controller, etc., and you wish to

use a digital output from the building automation system or

controller that is internally powered, then you must use an

additional mechanical relay (not supplied by AAF-McQuay)

to isolate the Mark IV/AC board.

l If you need to connect multiple water source heat pumps

with Mark IV/AC control boards, use a connection to ground

(terminal C) to drive the thermostat (G, Y1, W1, and W2) and

control inputs (U, L, E, and O). For example, the load shed

input of multiple Mark IV/AC controllers may be daisychained together through one set of dry contacts to ground

(C). This is useful if you need to operate multiple units from

one thermostat or if you need to signal multiple units from one

location. However, care must be used to ensure that this type

of connection has very low resistance to ground for proper

operation. To keep resistance low, wire runs should be kept

short and wire gauges may need to be increased. AAFMcQuay also offers special control boards and relays for

operating two or three water source heat pumps from one

thermostat which should be used when multiple unit operation is required.

l Due to the nature of triacs and other solid state devices they

cannot be directly used to operate the Mark IV/AC board’s

thermostat or control inputs. To interface triacs or other solid

state switching devices to the Mark IV/AC board inputs, you

need to separate them from the board using mechanical

relays. To do this, use the triac or solid state device to drive

a mechanical relay (not supplied by AAF-McQuay), then use

the mechanical relay’s dry contacts to drive the desired

Mark IV/AC board input.

l Do not connect the coils of standard mechanical relays in

series or parallel with the Mark IV/AC board inputs as you

may introduce electrical noise causing unexpected water

source heat pump operation or board damage. AAF-McQuay

offers a special relay for this purpose when additional signaling is needed.

l The Mark IV/AC board’s fault terminal (A) is primarily de-

signed to operate a fault LED on the AAF-McQuay wall

thermostats. Terminal A is designed to maintain an equivalent DC voltage level with board terminal F (+30vdc) when no

faults exist. When a fault exists, the A terminal will be lowered

to 0vdc. To use this output to signal external equipment,

connect the coil of a 24vdc mechanical relay (not provided by

AAF-McQuay) between terminals F and A on the Mark IV/AC

board. Then use the dry contacts of this mechanical relay as

an alarm or fault signal to external equipment or systems.

When using this output to signal external equipment it cannot

be used to operate a thermostat fault LED and vice versa.

l The Mark IV/AC board’s pump request terminal (P) is de-

signed for use as a signal to external equipment that water

flow is required by the heat pump. The P terminal follows

compressor operation inversely and will equal approximately 30vdc when the compressor is off and 0vdc when the

compressor is on. The P terminal should only be used as a

signal to pump controls if the water loop can respond with

water flow fast enough (3-5 seconds) to prevent unit shutdown due to high refrigerant pressure from a lack of water

flow. If adequate water flow is a concern, and the load shed

terminal (L) is not used for other purposes, you may use the

L terminal to prevent compressor operation until water flow

is established by using a flow control device as a signal to

allow compressor operation when flow exists.

OM 120-2 / Page 7

Page 8

Typical Mark IV/AC Unit Wiring Diagram

L1

COMMON

L2 L3 GND

FC- FAN CONTACTOR

CC- COMPRESSOR CONTACTOR

HTR- CRANKCASE HEATER(CCW ONLY)

CAP- MOTOR CAPACITOR

43

LO TEMP

CONDENSATE

SENSOR

42

HI PRESS

2

CC

FC

16

BK

FC

15

13

30

COMPR

MOTOR

HTR

FAN

MOTOR

24 VAC

YE

BL

14

CC

32

3

RDRD

11

CAP

480 BK/RD

575V VI

XFORMER

44

34

1

1210

CC

37

41

45

LO PRESS

40

BK

BK

REVERSING

S

AAF-McQuay Incorporated

4900 Technology Park Boulevard, Auburn, NY 13201-9030 USA, (315) 253-2771

Printed on recycled paper containing at least 10% post-consumer material.

VALVE

SOLENOID

(HT PUMP ONLY)

HP

W

O G F E L U A P V R C

2

HP

LT

LT

W1Y

COMMON

COF

1

48

FAN

LI

RV

RV

MARK IV

BOARD

47

V

PC

COMP

R

C

©1999 AAF-McQuay Incorporated

OM 120-2 (Rev. 5/99)

Loading...

Loading...