McQuay MAC 070 C, MAC 035 C, MAC 050 C, MAC 065 C, MAC 040 C Installation And Maintenance Manual

...Page 1

CMAC - C - 2004

Air-Cooled Mini Chiller

Models: MAC 030 C/CR

MAC 035 C/CR

MAC 040 C/CR

MAC 050 C/CR

MAC 065 C/CR

MAC 070 C/CR

MAC 080 C/CR

MAC 100 C/CR

MAC 120 C/CR

MAC 150 C/CR

Page 2

Contents

Introduction ...................................................................................................................2

Nomenclature ................................................................................................................ 2

Features .................................................................................................................... 3 - 4

General Specification.................................................................................................... 5

Controller ...................................................................................................................... 6

Specifications ........................................................................................................ 7 - 15

Performance Characteristics ............................................................................. 16 - 19

Technical Data ............................................................................................................ 20

Outlines and Dimensions .................................................................................... 21 - 23

Wiring Diagrams .................................................................................................. 24 - 33

Installation ............................................................................................................ 34 - 42

Servicing and Maintenance ........................................................................................ 43

Troubleshooting .......................................................................................................... 44

Troubleshooting with Microprocessor ...................................................................... 45

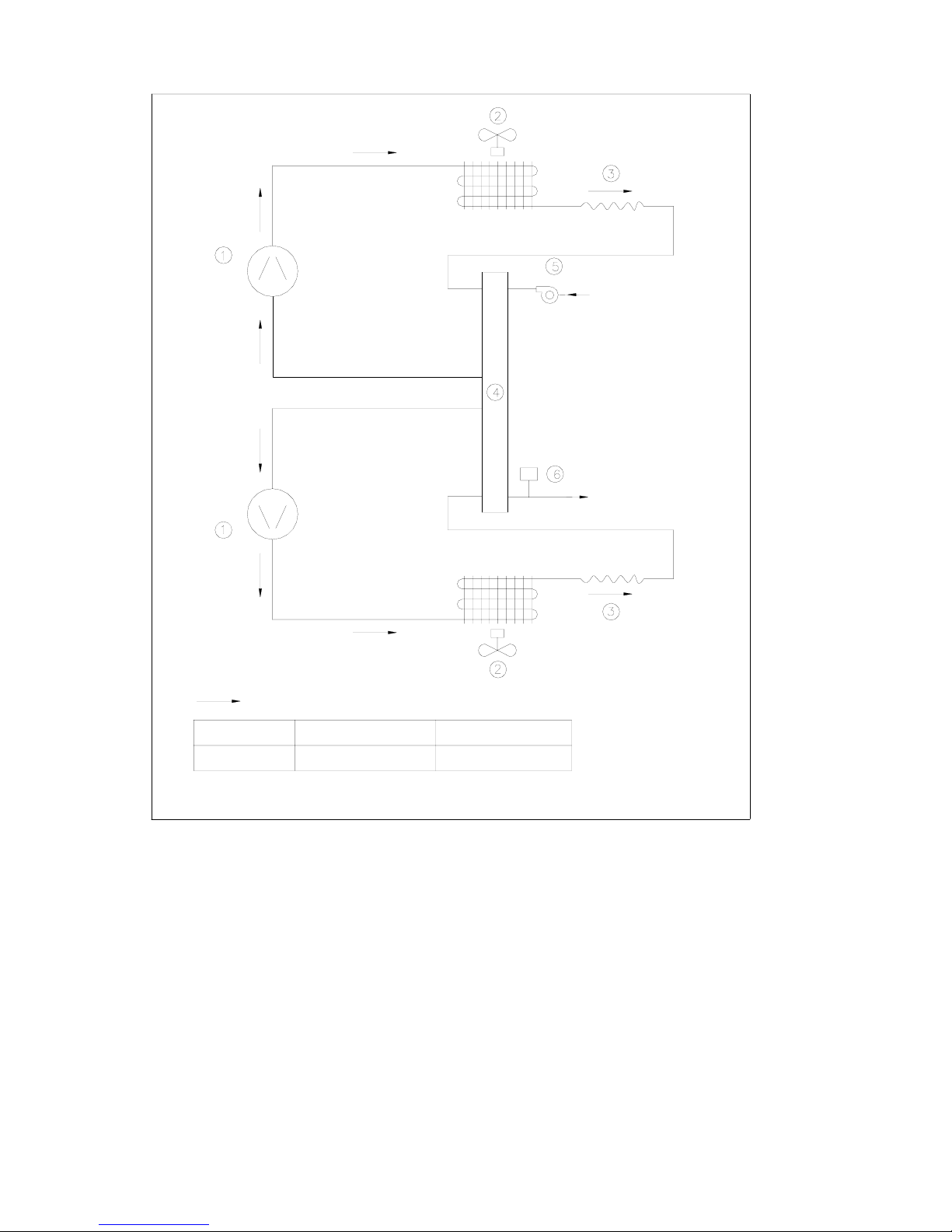

Schematic Diagram .............................................................................................. 46 - 49

Part List and Exploded View................................................................................ 50 - 51

Note: Installation and maintenance are to be performed only by qualified personnel who are

familiar with local codes and regulations, and experienced with this type of equipment,

Caution: Sharp edges and coil surfaces are a potential injury hazard. Avoid contact with them.

Warning: Moving machinery and electrical power hazards. May cause severe personal injury or death.

Disconnect and lock off power before servicing equipment.

"McQuay" is a registered trademark of McQuay International. All rights reserved throughout the world.

2003 McQuay International

"Bulletin illustrations cover the general appearance of McQuay International products at the time of publication

and we reserve the right to make changes in design and construction at any time without notice."

Page 1

Page 3

Introduction

For years, McQuay international has earned a reputation for providing the industry with various highest

qualities and most technologically advanced air conditioning systems. Now Shenzhen McQuay is proud to

introduce the new generation mini air-cooled chiller-MAC C series. Inherited from the advantage of the

earlier product experiences and introduced the most up-to-date technology, the new MAC C series are

designed with the always-in-mind concept - to satisfy customers’ requirements of high efficiency, comfort,

safety, intelligence to maximum extent. The unit can be flexibly coupled with multi fan coil units, easily

operated with artificial intelligence. Additionally combined with indoors top level decoration, this brings you to

enjoy the nobility coming from central air conditioning.

Providing the features such as high efficiency, low noise, compactness, simple operation, safety running,

easy installation and maintenance etc., the unit is widely equipped in plant, station, hotel, villa, office

building, top-level apartment as well as process cooling application.

Nomenclature

M AC 030 C R

Brand Name Nominal __ Cooling Only

(McQuay) Cooling Capacity R - Heat Pump

Water Source Generation

Heat Pump

Page 2

Page 4

Features

Superior Performance

• Extensive research work coupled with world leading manufacturing technology has caused the new

design with superb performance and high efficiency.

• Stringent quality control and component selection ensure performance and reliability. Major components

are rigorously tested and qualified prior to usage in the machine.

• Every machine design has passed many hours of rigorous testing to ensure the machine reliability,

durability and quality.

• Scroll compressor brings much higher energy efficiency. High efficiency heat exchanger ensures

strenuous exertion of equipment capacity. Dedicated water pump particularly designed for air

conditioning engineering is operating steadily with minimum vibration and noise.

For MAC080C/CR to MAC150C/CR

• These units are designed with double independent refrigerating system, greater energy saving is

achieved by only one compressor on duty under part load condition.

Simple To Operate

• The MAChine is complete with intelligent microprocessor controller and temperature sensor to

automatically control the operation to its optimum condition, making it very simple to operate. All

temperature settings are finished before shipment. The only thing for user to do is to start the unit by

pressing the ON/OFF button after ensuring unit proper function, then every operation can be

automatically performed by the unit itself.

• Either wireless remote controller or wired remote controller is ready for choosing to meet satisfactory

indoor unit control, both compatible with the unit.

Friendly Installation

• The machine has been designed with friendly installation in mind such that no refrigeration charging or

copper pipe brazing is required on site.

• Threaded fitting is provided for easy water piping connection on site.

• Water inlet and outlet are provided on both sides of the machine such that piping can be connected on

either side of the machine.

• Rust resistant PP-R composite water pipe with good insulation property and high durability is standard

parts in the machine.

• Stainless steel taper threaded fittings target convenient disassembly or assembly.

• For MAC080C/CR to MAC150C/CR, expansion chamber, water pump and water flow switches are

already equipped in this compact packaged unit with top air discharge. In addition, McQuay provides

accessory hydraulic kit with water storage tank, auto water fill valve, auto air vent valve, auto pressure

relief valve and strainer integrated in, aiming at ensuring high efficiency and safe operation. For

MAC030C/CR to MAC070C/CR, expansion chamber is equipped in the accessory hydraulic kit instead

of being incorporated in unit.

For MAC030C/CR to MAC070C/CR

• Both front and rear sides can be served as access to performing wiring and maintenance.

Safety Control

• Protection devices such as dual pressure protection and overload protection etc. is provided to ensure

unit operating within safety condition range. The microprocessor-based controller automatically directs

system on or off by processing the water temperature feedback. If the water temperature falls to

unacceptable low point, the controller automatically shut off the system to prevent hydraulic system

internal freeze for unit safety operation. Meanwhile, the microprocessor-based controller automatically

monitors every component operating status and malfunction, and feedback it to indoor controller to

greatly ease the work of status monitor and troubleshooting.

All Weather

• The cabinet is made of electro galvanized mild steel sheet, coated with baked polyester power to ensure

the units extra durability in all climates against sun, rain, wind corrosion.

• Space saving (small footprint) design of the machine eliminates large installation area requirement, no

need for equipment room.

• The machine uses high quality parts to ensure durability in various climate conditions.

Page 3

Page 5

Simple To Maintain

• The simple design of the machine allows for maximum serviceability. All components are with reach of

the maintenance personnel upon open up of the servicing panel. If emergency shutoff occurs, the

microprocessor-based controller will indicates the fault cause to quicken and ease troubleshooting.

Three Color Appearance Available (For MAC030C/CR to MAC070C/CR)

• There are three optional colors-blue, green and red available to be easily choose to meet customers’

requirements, so the unit can be harmonically blend into building overall look.

Page 4

Page 6

General Specification

Compressor

McQuay Mini Chillers are equipped with highly efficient, reliable and silence scroll compressor, double for

MAC080C(R) to MAC150C(R), one for MAC030C/CR to MAC070C/CR.

Air-Cooler Condenser

The air-cooled condenser coil consists of staggered rows of 3/8’’ O.D. seamless copper tube, mechanically

expanded into die formed aluminum fins to ensure optimum heat exchange capability.

Condenser Fan Motor

To achieve the high air change requirement, the unit is equip with the high air flow propeller fan. The fan is

direct driven by weatherproof motor to ensure reliable continuos operation.

Evaporator

The heat exchanger is made of stainless steel plates closely arranged and brazed together to ensure high

heat exchange efficiency. The complete heat exchanger is insulated with thermal insulation closed cell

rubber foam to give optimum thermal insulation.

Refrigerant Circuit

The refrigerant circuit is factory brazed and evacuated before accurately charged with R22 to ensure

optimum operating requirement. To ensure flawless continuous operation, each refrigerant circuit is

equipped with a carefully sized capillary tube.

Additional Safety Protection

The units are equipped with intelligently designed safety control to ensure continuous safe operation. High

and low pressure switch is provided to prevent the compressor damage resulting from both abnormally high

discharge head pressure or low pressure due to insufficient gas. The compressors are provided with crank

case heater to prevent liquid migration during the off cycle and also to ease the start up of the unit.

The standard electronic controller provides accurate water temperature control in the circuit by closely

monitoring and reacting to the input from the water entering temperature, water leaving temperature and

ambient air temperature.

Flow switch is provided in the unit to protect against damage to the water pump.

During abnormal condition, the electronic controller will turn the unit off and the then display the faulty of

operation. (See Troubleshooting sheet)

Page 5

Page 7

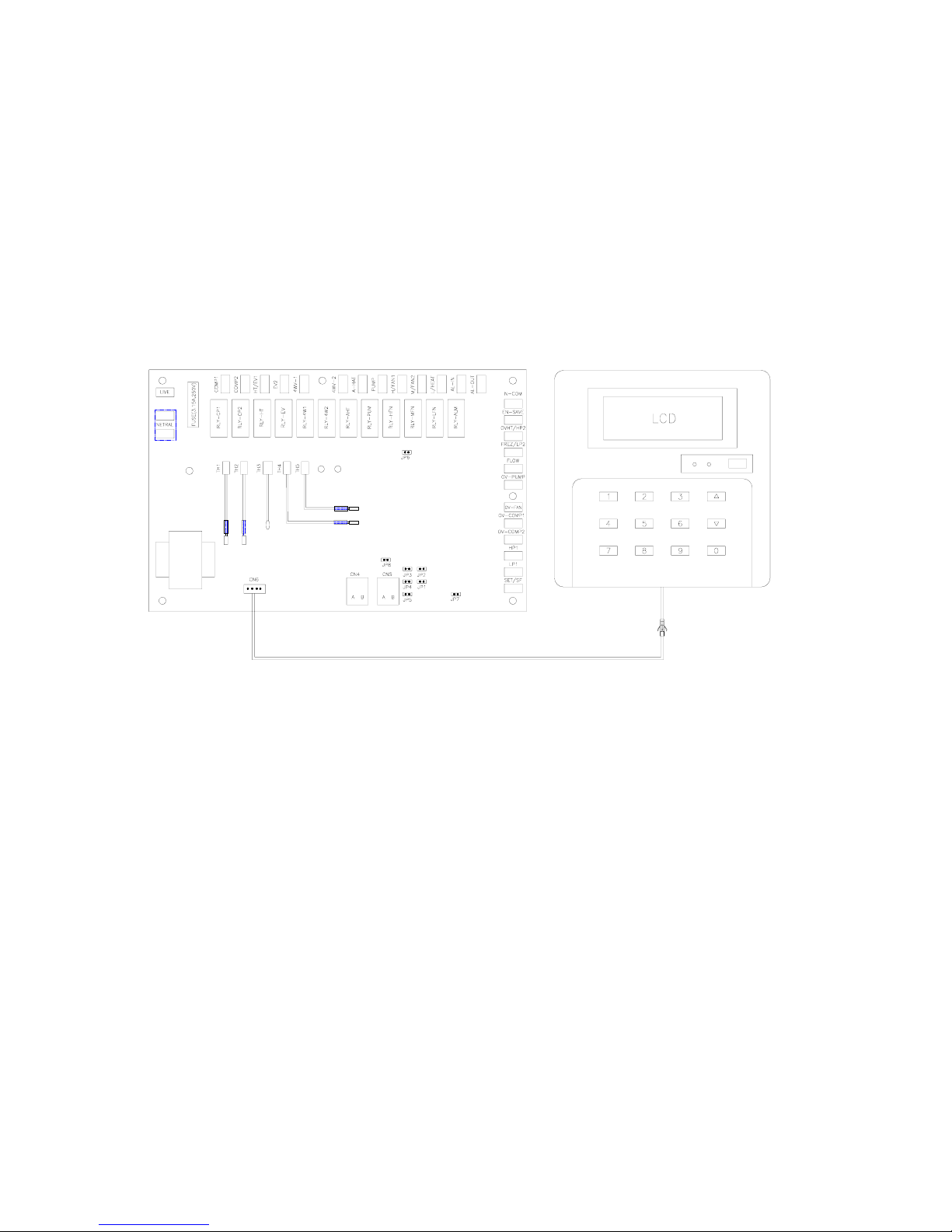

Controller

The controller accomplishes its control function with its built-in microprocessor. The two parameters,

temperature and water flow rate, have been factory set before shipment, no need for users to reset them.

The controller will display unit operation status to favor specialized personnel to monitor unit operating

condition for maintenance if necessary. When the system is cut off due to malfunction, the controller will

display the corresponding failure code for easy trouble shooting.

Installation and connection

After removing the terminal box cover, you will find the indoor controller, 20m long indoor connection wire,

and 1.5m long maintenance connection wire. Decide a suitable place for installing the indoor controller, you

can either mount it on wall or embed it in wall. Open the back cover of the indoor controller, plug one end of

the indoor connection wire to the CN3 connector located on controller, insert another end to the CN6

connector located on PCB, then assembly the terminal box cover back, now this work is finished.

Please ensure the 1.5m maintenance connection wire being in good keep for later maintenance by

specialized personnel.

Indoor LCD controller

PCB MAI N

BOARD

TRANSFORMER

R

E

T

U

R

N

W

A

T

E

R

T

E

M

P

.

S

E

N

S

O

R

HOUR

TIMER

MCH03A

PARAMETER

SET

GROUP

OPERATION

WEEK SET

EXIT WEEK

CLEAR

UNIT

No.

MODE

SC302A

CONTROLLER

OK

MINUTE

ROOM

TEMP.

ON/OFF

LED1

LED2

S

U

P

P

L

Y

W

A

T

E

R

T

E

M

P

.

S

E

N

S

O

R

R

E

T

U

R

N

A

I

R

T

E

M

P

.

S

E

N

S

O

R

D

E

F

R

O

S

T

I

N

G

T

E

M

P

.

S

E

N

S

O

R

1

D

E

F

R

O

S

T

I

N

G

T

E

M

P

.

S

E

N

S

O

R

2

After switching on power, the indoor controller will display system time, indoor temperature and unit status.

During normal operation, it will display the unit return water temperature.

When failure occurs, it will emit alarm, both audible and visual. Meanwhile show a corresponding error code.

Please see Troubleshooting With Microprocessor sheet.

a) On/off

Start an operation

First press [MODE] button, select “cooling” or “heating” mode, then press [ON/OFF] button, the yellow lamp

besides the [ON/OFF] button lights up and the system starts.

Stop an operation. Press the [ON/OFF] button again, the yellow lamp goes off and the system stops.

b) Indicating lamps on PCB

When the power supply is switched on, the red lamp lights up.

When the system is on operation, the green lamp lights up.

c) Below are the controllers’ protection functions and features, not its faults.

When restarting the unit after last start or stop, the unit automatically starts compressor and fan after the

lapse of approximately three minutes.

During defrosting cycle, the outdoor fan is stopped.

Page 6

Page 8

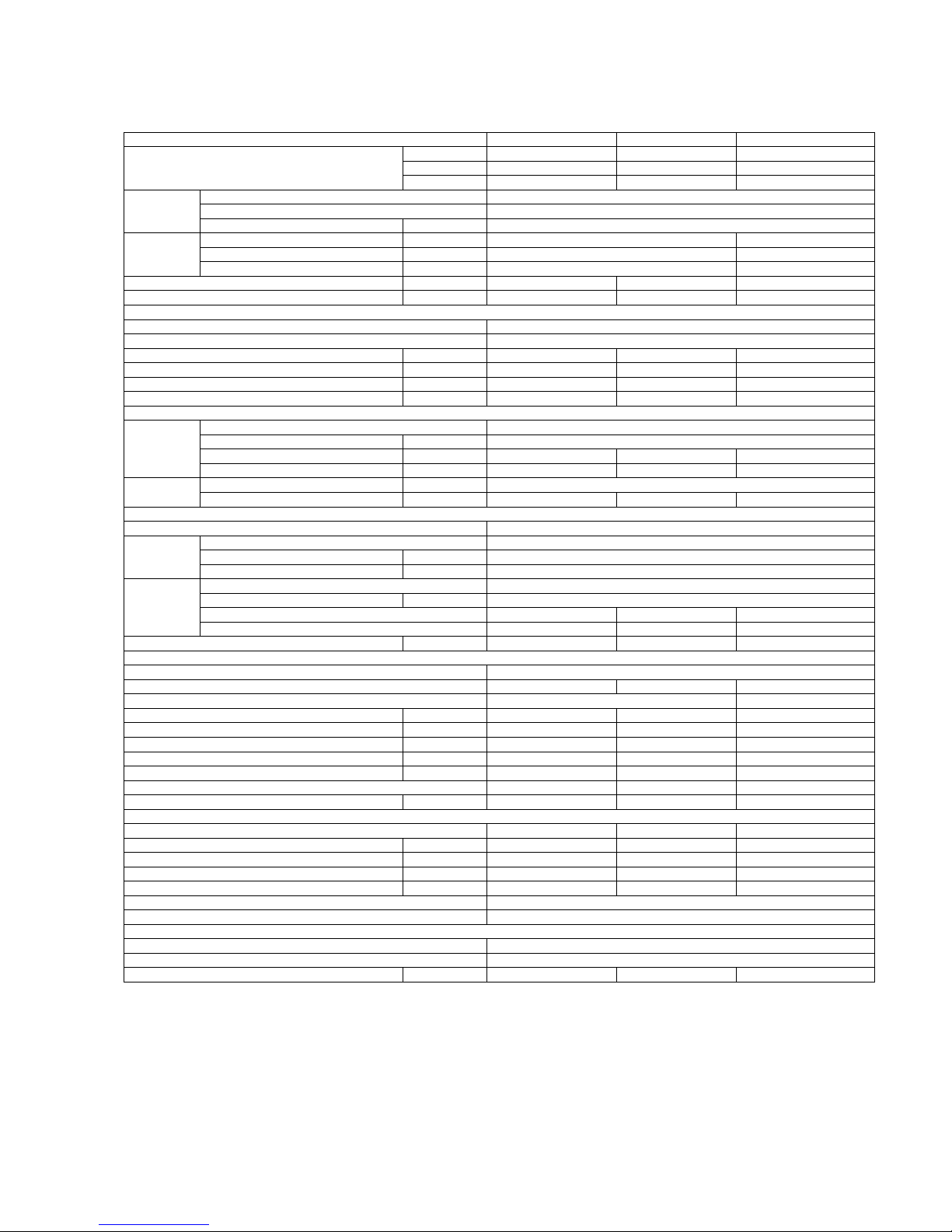

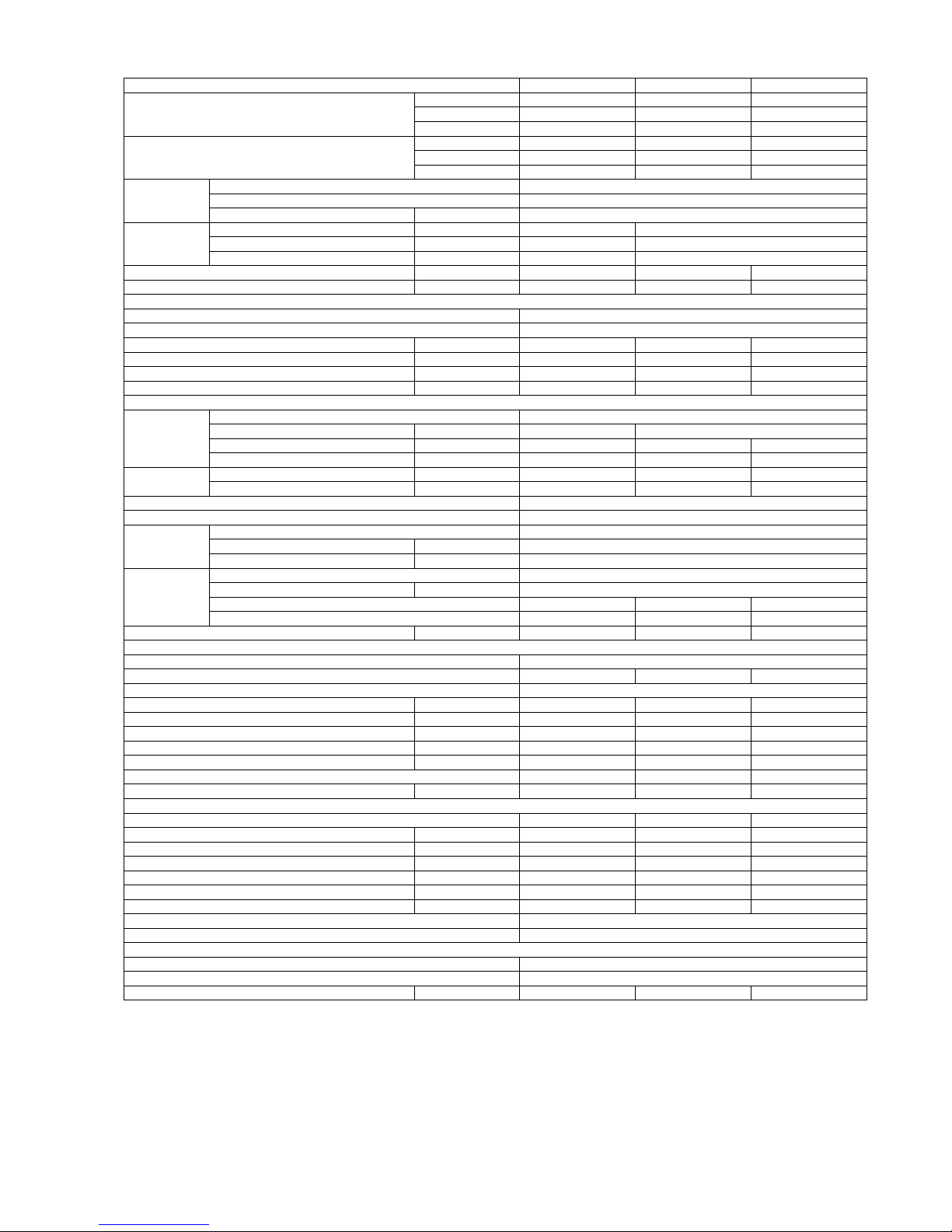

Specifications

Cooling Only Unit (50Hz)

MODEL MAC030C MAC035C MAC040C

Btu/hr 25,600 30,700 39,200

kcal/hr 6,450 7,740 9,890

NOMINAL COOLING CAPACITY

Watt 7,500 9,000 11,500

MATERIAL Electro-galvanised Mild Steel

FINISH Polyester Power

CASING

THICKNESS mm 1

HEIGHT (H) mm (in) 1250 (49.2) 1560 (61.4)

WIDTH (W) mm (in) 841 (33.1) 927 (36.5)

TOTAL

UNIT

DIMENSION

DEPTH (D) mm (in) 382 (15) 406 (16)

NET WEIGHT kg 115 138 145

NOISE LEVEL dB(A) 58 58 60

EVAPOR ATOR

TYPE Brazed Plate Heat Exchanger

PLATE MATERIAL Stainless Steel

HEAT EXCHANGE AREA m2 0.7 0.8 1.1

NOMINAL WATER FLOW l/s 0.36 0.42 0.55

BPHE PRESSURE DROP VS NOMINAL FLOW RATE kPa 6.0 5.7 5.2

UNIT PRESSURE DROP WS NOMINAL FLOW RATE kPa 50 58 67

WATER LINE(HYDRAULIC KIT)

TYPE Horizontal Multistage End-Suction

POWER SUPPLY V/Ph/Hz 220 / 1 / 50

RUNNING CURRENT Amp 2.2 2.2 2.5

PUMP

WATER FLOW RATE GPM U.S. (l/s) 5.72 (0.36) 6.78 (0.42) 8.71 (0.55)

INSTALLATION PIPE CONNECTION mm (in) 34 ( Rc 1)

PIPING

HEAD m 25 24 24

CONDENSER COIL

TYPE

Cross Finned Tubes

MATERIAL Seamless Copper

WALL THICKNESS mm (in) 0.35 (0.014)

TUBE

OUTER DIAMETER mm (in) 9.52 (3/8)

MATERIAL Aluminium

THICKNESS mm (in) 0.127 (0.0005)

ROWS 2 2 2

FIN

FINS PER INCH 12 14 14

FACE AREA

m

2

(ft2) 0.78 (8.40) 0.78 (8.40) 1.23 (13.24)

CONDENSER FAN

TYPE/DRIVE Propeller/Direct

QUANTITY 1 1 1

BLADE MATERIAL Plastic Aluminium Alloy

BLADE DIAMETER mm (in) 460 (18.1) 461 (18.1) 600 (24)

POWER SUPPLY V/Ph/Hz 220 / 1 / 50 220 / 1 / 50 220 / 1 / 50

RATED RUNNING CURRENT Amp 1.8 1.8 0.9

RATED INPUT Watt 182 182 200

RATED OUTPUT Watt 100 100 120

MOTOR POLES 6 6 8

AIR VOLUME cmm/cfm 75 / 2650 75 / 2650 100 / 3530

COMPRESSOR

TYPE Scroll Scroll Scroll

POWER SUPPLY V/Ph/Hz 220 / 1 / 50 220 / 1 / 50 380 / 3 / 50

RATED RUNNING CURRENT (COOLING) Amp 10.8 15.1 7.6

RATED INPUT (COOLING) Watt 2,200 3,300 3,910

MAXIMUM STARTING CURRENT Amp 82 114 65.5

PROTECTION DEVICES Overload and Discharge temp. Protection, Flow Switch and H/L Pressure Switch

STAGE OF CAPACITY CONTROL On/Off

REFRIGERANT

TYPE R22

CONTROL Capillary Tube

CHARGING MASS kg 2.1 2.1 3.6

Notes:

1. All specifications are subjected to change by manufacturer without prior notice.

2. Nominal cooling values are based on entering/leaving chilled water temperature 12ºC/7ºC and air ambient temperature 35ºC.

3. Nominal heating values are based on entering/leaving hot water temperature 40ºC/45ºC and air ambient temperature 7ºC.

Page 7

Page 9

Cooling Only Unit (50Hz)

MODEL MAC050C MAC065C MAC070C

Btu/hr 46,100 57,000 65,500

kcal/hr 11,610 14,360 16,510

NOMINAL COOLING CAPACITY

Watt 13,500 16,700 19,200

MATERIAL Electro-galvanised Mild Steel

FINISH Polyester Power

CASING

THICKNESS mm 1

HEIGHT (H) mm (in) 1560 (61.4) 1700 (66.9)

WIDTH (W) mm (in) 927 (36.5) 1135 (44.7)

TOTAL

UNIT

DIMENSION

DEPTH (D) mm (in) 406 (16) 502 (19.7)

NET WEIGHT kg 150 220 235

NOISE LEVEL dB(A) 60 64 64

EVAPOR ATOR

TYPE Brazed Plate Heat Exchanger

PLATE MATERIAL Stainless Steel

HEAT EXCHANGE AREA m2 1.3 1.4 1.7

NOMINAL WATER FLOW l/s 0.64 0.79 0.91

BPHE PRESSURE DROP VS NOMINAL FLOW RATE kPa 5 34 36.5

UNIT PRESSURE DROP WS NOMINAL FLOW RATE kPa 75 92 110

WATER LINE(HYDRAULIC KIT)

TYPE Horizontal Multistage End-Suction

POWER SUPPLY V/Ph/Hz 220 / 1 / 50 380 / 3 / 50

RUNNING CURRENT Amp 2.5 1.3 1.3

PUMP

WATER FLOW RATE

GPM U.S.

(l/s) 10.21 (0.64) 12.63 (0.79) 14.53 (0.91)

INSTALLATION PIPE CONNECTION mm (in) 34 ( Rc 1)

PIPING

HEAD m 23 24 23

CONDENSER COIL

TYPE

Cross Finned Tubes

MATERIAL Seamless Copper

WALL THICKNESS mm (in) 0.35 (0.014)

TUBE

OUTER DIAMETER mm (in) 9.52 (3/8)

MATERIAL Aluminium

THICKNESS mm (in) 0.127 (0.0005)

ROWS 2 2 2

FIN

FINS PER INCH 14 14 14

FACE AREA

m

2

(ft2) 1.23 (13.24) 1.74 (18.73) 1.74 (18.73)

CONDENSER FAN

TYPE/DRIVE Propeller/Direct

QUANTITY 1 1 1

BLADE MATERIAL Aluminium Alloy

BLADE DIAMETER mm (in) 600 (23.6) 710 (28) 710 (28)

POWER SUPPLY V/Ph/Hz 220 / 1 / 50 220 / 1 / 50 220 / 1 / 50

RATED RUNNING CURRENT Amp 0.9 1.2 1.2

RATED INPUT Watt 200 250 250

RATED OUTPUT Watt 120 130 130

MOTOR POLES 8 10 10

AIR VOLUME cmm/cfm 100 / 3530 133 / 4700 133 / 4700

COMPRESSOR

TYPE Scroll Scroll Scroll

POWER SUPPLY V/Ph/Hz 380 / 3 / 50 380 / 3 / 50 380 / 3 / 50

RATED RUNNING CURRENT (COOLING) Amp 8.0 10.4 11.9

RATED INPUT (COOLING) Watt 4,800 5,000 6,400

MAXIMUM STARTING CURRENT Amp 74 101 95

PROTECTION DEVICES Overload Protection, Flow Switch and H/L Pressure Switch

STAGE OF CAPACITY CONTROL On/Off

REFRIGERANT

TYPE R22

CONTROL Capillary Tube

CHARGING MASS kg 3.8 5.15 7

Notes:

1. All specifications are subjected to change by manufacturer without prior notice.

2. Nominal cooling values are based on entering/leaving chilled water temperature 12ºC/7ºC and air ambient temperature 35ºC.

3. Nominal heating values are based on entering/leaving hot water temperature 40ºC/45ºC and air ambient temperature 7ºC.

Page 8

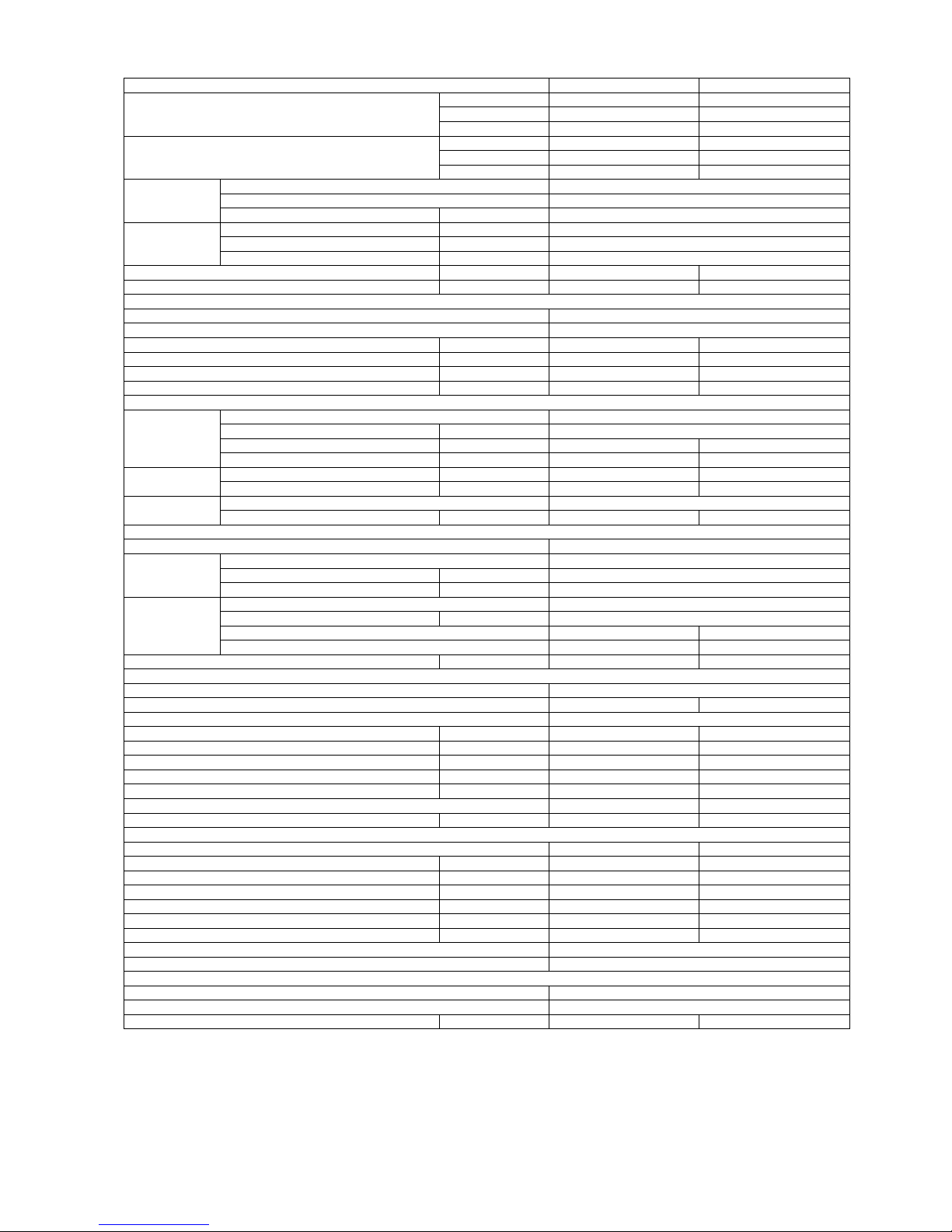

Page 10

Cooling Only Unit (50Hz)

MODEL MAC080C MAC100C MAC120C MAC150C

Btu/hr 76,800 92,100 112,600 129,700

kcal/hr 19,350 23,220 28,380 32,670

NOMINAL COOLING CAPACITY

Watt 22,500 27,000 33,000 38,000

MATERIAL Electro-galvanised Mild Steel Electro-galvanised Mild Steel

FINISH Polyester Power Polyester Power

CASING

THICKNESS mm 1.0 1

HEIGHT (H) mm (in) 1260 (49.6) 1260 (49.6)

WIDTH (W) mm (in) 1500 (59.1) 1800 (70.9)

TOTAL UNIT

DIMENSION

DEPTH (D) mm (in) 900 (35.4) 1150 (45.3)

NET WEIGHT kg 340 350 480 560

NOISE LEVEL dB(A) 62 64 67 70

EVAPORATOR

TYPE Brazed Plate Heat Exchanger Brazed Plate Heat Exchanger

PLATE MATERIAL Stainless Steel Stainless Steel

HEAT EXCHANGE AREA m

2

2.26 2.78

NOMINAL WATER FLOW l/s 1.08 1.31 1.67 2.0

BPHE PRESSURE DROP VS NOMINAL FLOW RATE kPa 74 82 76 75

UNIT PRESSURE DROP WS NOMINAL FLOW RATE kPa 104 121 138 155

WATER LINE(HYDRAULIC KIT)

TYPE Horizontal Multistage End-Suction Horizontal Multistage End-Suction

POWER SUPPLY V/Ph/Hz 380 / 3 / 50 380 / 3 / 50

RUNNING CURRENT Amp 1.1 1.1 2.5 2.5

PUMP

WATER FLOW RATE

GPM U.S.

(l/s)

17.17(1.08) 20.70(1.31) 26.42(1.67) 31.70(2.0)

INSTALLATION PIPE

CONNECTION

mm (in) 42 (Rc 1-1/4) 42 (Rc 1-1/4) 42 (Rc 1-1/4) 42 (Rc 1-1/4)

PIPING

HEAD m 26 23.5 31 28

MATERIAL Steel Steel

EXPANSION TANK

CAPACITY / VOLUME litres 8 8 8 8

CONDENSER COIL

TYPE Cross Finned Tubes Cross Finned Tubes

MATERIAL Seamless Coppe r Seamless Copper

WALL THICKNESS mm (in) 0.35 (0.014) 0.35 (0.014)

TUBE

OUTER DIAMETER mm (in) 9.52 (3/8) 9.52 (3/8)

MATERIAL Aluminium Aluminium

THICKNESS mm (in) 0.127 (0.0005) 0.127 (0.0005)

ROWS 2 2 2 2

FIN

FINS PER INCH 14 14 14 14

FACE AREA m2 (ft2) 2.5 (26.9) 2.5 (26.9) 2.5 (26.9) 2.5 (26.9)

CONDENSER FAN

TYPE/DRIVE Propeller/Direct Propeller/Direct

QUANTITY 2 2 2 2

BLADE MATERIAL Aluminium

BLADE DIAMETER mm (in) 600 (23.6) 600 (23.6) 660 (26) 660 (26)

POWER SUPPLY V/Ph/Hz 220 / 1 / 50 220 / 1 / 50 380 / 3 / 50

RATED RUNNING CURRENT Amp 0.9*2 0.9*2 0.86*2 4.5*2

RATED INPUT Watt 120*2 120*2 200*2 450*2

RATED OUTPUT Watt 200*2 200*2 470*2 820*2

MOTOR POLES 8 8 8 6

AIR VOLUME cmm/cfm 100*2 / 3530*2 100*2 / 3530*2 142*2 / 5000*2 142*2 / 5000*2

COMPRESSOR

TYPE Scroll Scroll S croll Scroll

POWER SUPPLY V/Ph/Hz 380 / 3 / 50 380 / 3 / 50 380 / 3 / 50 380 / 3 / 50

RATED RUNNING CURRENT Amp 7.3*2 8.6*2 10.3*2 11.5*2

RATED INPUT Watt 3,900*2 4,800*2 5,300*2 6,240*2

MAXIMUM STARTING CURRENT Amp 40 48

PROTECTION DEVICES Overload Protection, Flow Switch & H/L Pressure Switch Overload Protection, Flow Switch & H/L Pressure Switch

STAGE OF CAPACITY CONTROL (%) 0-50-100 0-50-100

REFRIGERANT

TYPE R22 R22

CONTROL Capillary Tube Capillary Tube

CHARGING MASS kg 3.5*2 3.3*2 6.3*2 5.7*2

Notes:

1. All specifications are subjected to change by manufacturer without prior notice.

2. Nominal cooling values are based on entering/leaving chilled water temperature 12ºC/7ºC and air ambient temperature 35ºC.

3. Nominal heating values are based on entering/leaving hot water temperature 40ºC/45ºC and air ambient temperature 7ºC.

Page 9

Page 11

Cooling Only Unit (50Hz)

MAC120C MAC150C

Btu/hr

112,600 129,700

kcal/hr

28,380 32,670

Watt

33,000 38,000

THICKNESS mm

HEIGHT (H) mm (in)

WIDTH (W) mm (in)

DEPTH (D) mm (in)

kg

470 550

dB(A)

67 70

EVAPORATOR

m

2

3.0 3.6

l/s

1.67 2.0

kPa

76 75

kPa

138 155

WATER LINE(HYDRAULIC KIT)

POWER SUPPLY V/Ph/Hz

RUNNING CURRENT Amp

2.5 2.5

WATER FLOW RATE GPM U.S. (l/s)

26.42(1.67) 31.70(2.0)

INSTALLATION PIPE CONNECTION mm (in)

42 (Rc 1-1/4) 42 (Rc 1-1/4)

HEAD m

31 28

CAP ACITY / VOL UME litres

88

CONDENSER COIL

WALL THICK NESS mm (in)

OUTER DIAMETER mm (in)

THICKNESS mm (in)

22

14 14

m

2

(ft2)

2.5 (26.9) 2.5 (26.9)

CONDENSER FAN

22

mm (in)

660 (26) 660 (26)

V/Ph/Hz

Amp

0.86*2 4.5*2

Watt

200*2 450*2

Watt

470*2 820*2

86

cmm/cfm

142*2 / 5000*2 142*2 / 5000*2

COMPRESSOR

Scroll Scroll

V/Ph/Hz

380 / 3 / 50 380 / 3 / 50

Amp

10.3*2 11.5*2

Watt

5,300*2 6,240*2

Amp

55 62

REFRIGERANT

kg

6.3*2 5.7*2

CHARGING MASS

Steel

TYPE

R22

CONTROL

Capillary Tube

Overload Protection, Flow Switch & H/L Pressure Switch

STAGE OF CAPACITY CONTROL (%)

0-50-100

MAXIMUM STARTING CURRENT

PROTECTION DEVICES

POWER SUPPLY

RATED RUNNING CURRENT

RATED INPUT

RATED OUTPUT

MOTOR POLES

AIR VOLUME

TYPE

POWER SUPPLY

380 / 3 / 50

RATED RUNNING CURRENT

RATED INPUT

QUANTITY

BLADE MATERIAL

BLADE DIAMETER

FACE AREA

TYPE/DRIVE

Propeller/Direc t

9.52 (3/8)

FIN

MATERIAL

Alum inium

0.127 (0.0005)

ROWS

FINS PER INCH

TYPE

Cross Finned Tubes

TUBE

MATERIAL

Seamless Copper

0.35 (0.014)

PIPING

EXPANSION

TANK

MATERIAL

PUMP

TYPE

Horizontal Multistage End-Suction

380 / 3 / 50

HEAT EXCHANGE AREA

NOMINAL WATER FLOW

BPHE PRESSURE DROP VS NOMINAL FLOW RATE

UNIT PRESSURE DROP VS NOMINAL FLOW RATE

Brazed Plate Heat Exchanger

PLATE MATERIAL

Stainless Steel

NET WEIGHT

NOISE LEVEL

TYPE

TOTAL

UNIT

DIMENSION

1260 (49.6)

1800 (70.9)

1150 (45.3)

Electro-galvanised Mild Steel

FINISH

Polyester Power

MODEL

NOMINAL COOLING CAPACITY

CASING

MATERIAL

1

Notes:

1. All specifications are subjected to change by manufacturer without prior notice.

2. Nominal cooling values are based on entering/leaving chilled water temperature 12ºC/7ºC and air ambient temperature 35ºC.

3. Nominal heating values are based on entering/leaving hot water temperature 40ºC/45ºC and air ambient temperature 7ºC.

Page 10

Page 12

Cooling Only Unit (60Hz)

MAC080C M AC100C MAC120C MAC150C

Btu/hr

87,000 95,200 120,100 132,700

kcal/hr

21,930 23,990 30,270 33,450

Watt

25,500 27,900 35,200 38,900

THICKNESS mm

HEIGHT (H) mm (in)

WIDTH (W) mm (in)

DEPTH (D) mm (in)

kg

340 350 470 550

dB(A)

62 64 67 70

EVAPORATOR

m

2

2.26 2.78 3.0 3.6

l/s

1.08 1.31 1.67 2

kPa

74 82 76 75

kPa

174 168 158 159

WATER LINE(HYDRAULIC KIT)

POWER SUPPLY V/Ph/Hz

RUNNING CURRENT Amp

1.1 1.1 2 .5 2.5

WATER FLOW RATE GPM U.S. (l/s)

17.17(1.08) 20.70(1.31) 26.42(1.67) 31.70(2.0)

INSTALLATION PIPE CONNECTION mm (in)

42 (Rc 1-1/4) 42 (Rc 1-1/4) 42 (Rc 1-1/4) 42 (Rc 1-1/4)

HEAD m

26 23.5 31 28

CAP ACITY / VOLU ME litres

CONDENSER COIL

WALL THICKNESS mm (in)

OUTER DIAMETER mm (in)

THICKNESS mm (in)

222 2

14 14 14 14

m

2

(ft2)

2.5 (26.9) 2.5 (26.9) 2.5 (26.9) 2.5 (26.9)

CONDENSER FAN

222 2

mm (in)

600 (24) 600 (24) 660 (26) 660 (26)

V/Ph/Hz

Amp

0.5*2 0.5*2 0.5*2 0.5*2

Watt

150*2 150*2 150*2 150*2

Watt

120*2 120*2 120*2 120*2

888 6

cmm/cfm

100*2 / 3530*2 100*2 / 3530*2 142*2 / 5000*2 142*2 / 5000*2

COMPRESSOR

Scroll Scroll Scroll Scroll

V/Ph/Hz

380 / 3 / 50 380 / 3 / 50 380 / 3 / 50 380 / 3 / 50

Amp

7.1*2 7.9*2 8.8*2 10.9*2

Watt

4,450*2 4,900*2 5,950*2 6,750*2

Amp

40 48 55 62

REFRIGERANT

kg

4.1*2 3.9*2 6.5*2 5.1*2

FINISH

MODEL

NOMINAL COOLING CAPACITY

CASING

MATERIAL

1.0 1.0

TOTAL

UNIT

DIMENSION

1260 (49.6) 1260 (49.6)

1500 (59.1) 1800 (70.9)

900 (35.4) 1150 (45.3)

PLATE MATERIAL

NET WEIGHT

NOISE LEVEL

TYPE

PUMP

TYPE

HEAT EXCHANGE AREA

NOMINAL WATER FLOW

BPHE PRESSURE DROP VS NOMINAL FLOW RATE

UNIT PRESSURE DROP VS NOMINAL FLOW RATE

TYPE

TUBE

MATERIAL

PIPING

EXPANSION

TANK

MATERIAL

FACE AREA

TYPE/DRIVE

Propeller/Direct

FIN

MATERIAL

ROWS

FINS PER INCH

0.127 (0.0005)

QUANTITY

BLADE MATERIAL

BLADE DIAMETER

Alum inium

POWER SUPPLY

RATED RUNNING CURRENT

RATED INPUT

460 / 3 / 60

POWER SUPPLY

RATED RUNNING CURRENT

RATED INPUT

RATED OUTPUT

MOTOR POLES

AIR VOLUME

TYPE

STAGE OF CAPACITY CONTROL (%)

Overload Protection, Flow Switch & H/L Pressure Switch

0-50-100

MAXIMUM STARTING CURRENT

PROTECTION DEVICES

TYPE

CONTROL

R22

Capillary Tube

CHARGING MASS

Electro-galvanised Mild Steel

Polyester Power

Brazed Plate Heat Exchanger

Stainless Steel

Horizontal Multistage End-Suction

460 / 3 / 60

Steel

8

Cross Finned Tubes

Seamless Copper

0.35 (0.014)

9.52 (3/8)

Alum inium

Notes:

1) All specifications are subjected to change by manufacturer without prior notice.

2) Nominal values are based on the condition complying with ARI standard.

Page 11

Page 13

Heat Pump Unit (50Hz)

MODEL MAC030CR MAC035CR MAC040CR

Btu/hr 25,600 30,700 39,200

kcal/hr 6,450 7,740 9,890

NOMINAL COOLING CAPACITY

Watt 7,500 9,000 11,500

Btu/hr 27,300 32,400 42,700

kcal/hr 6,880 8,170 10,750

NOMINAL HEATING CAPACITY

Watt 8,000 9,500 12,500

MATERIAL Electro-galvanised Mild Steel

FINISH Polyester Power

CASING

THICKNESS mm 1

HEIGHT (H) mm (in) 1250 (49.2) 1560 (61.4)

WIDTH (W) mm (in) 841 (33.1) 927 (36.5)

TOTAL

UNIT

DIMENSION

DEPTH (D) mm (in) 382 (15) 406 (16)

NET WEIGHT kg 125 148 155

NOISE LEVEL dB(A) 58 58 60

EVAPOR ATOR

TYPE Brazed Plate Heat Exchanger

PLATE MATERIAL Stainless Steel

HEAT EXCHANGE AREA m2 0.7 0.8 1.1

NOMINAL WATER FLOW l/s 0.36 0.42 0.55

BPHE PRESSURE DROP VS NOMINAL FLOW RATE kPa 6.0 5.7 5.2

UNIT PRESSURE DROP WS NOMINAL FLOW RATE kPa 50 58 67

WATER LINE(HYDRAULIC KIT)

TYPE Horizontal Multistage End-Suction

POWER SUPPLY V/Ph/Hz 220 / 1 / 50

RUNNING CURRENT Amp 2.2 2.2 2.5

PUMP

WATER FLOW RATE GPM U.S. (l/s) 5.72 (0.36) 6.78 (0.42) 8.71 (0.55)

INSTALLATION PIPE CONNECTION mm (in) 34 ( Rc 1) 34 ( Rc 1) 34 ( Rc 1)

PIPING

HEAD m 25 24 24

CONDENSER COIL

TYPE

Cross Finned Tubes

MATERIAL Seamless Copper

WALL THICKNESS mm (in) 0.35 (0.014)

TUBE

OUTER DIAMETER mm (in) 9.52 (3/8)

MATERIAL Aluminium

THICKNESS mm (in) 0.127 (0.0005)

ROWS 2 2 2

FIN

FINS PER INCH 12 14 14

FACE AREA

m

2

(ft2) 0.78 (8.40) 0.78 (8.40) 1.23 (13.24)

CONDENSER FAN

TYPE/DRIVE Propeller/Direct

QUANTITY 1 1 1

BLADE MATERIAL Plastic Aluminium Alloy

BLADE DIAMETER mm (in) 460 (18.1) 460 (18.1) 600 (23.6)

POWER SUPPLY V/Ph/Hz 220 / 1 / 50 220 / 1 / 50 220 / 1 / 50

RATED RUNNING CURRENT Amp 1.8 1.8 0.9

RATED INPUT Watt 182 182 200

RATED OUTPUT Watt 100 100 120

MOTOR POLES 6 6 8

AIR VOLUME cmm/cfm 75 / 2650 75 / 2650 100 / 3530

COMPRESSOR

TYPE Scroll Scroll Scroll

POWER SUPPLY V/Ph/Hz 220 / 1 / 50 220 / 1 / 50 380 / 3 / 50

RATED RUNNING CURRENT (COOLING) Amp 10.8 15.1 7.6

RATED RUNNING CURRENT (HEATING) Amp 12.8 14.7 7.8

RATED INPUT (COOLING) Watt 2,200 3,300 3,910

RATED INPUT (HEATING) Watt 2,670 3,200 4,050

MAXIMUM STARTING CURRENT Amp 82 114 65.5

PROTECTION DEVICES

Overload and Discharge temp. Protection, Flow Switch and H/L Pressure

Switch

STAGE OF CAPACITY CONTROL On/Off

REFRIGERANT

TYPE R22

CONTROL Capillary Tube

CHARGING MASS kg 2.1 2.1 3.6

Notes:

1. All specifications are subjected to change by manufacturer without prior notice.

2. Nominal cooling values are based on entering/leaving chilled water temperature 12ºC/7ºC and air ambient temperature 35ºC.

3. Nominal heating values are based on entering/leaving hot water temperature 40ºC/45ºC and air ambient temperature 7ºC.

Page 12

Page 14

Heat Pump Unit (50Hz)

MODEL MAC050CR MAC065CR MAC070CR

Btu/hr 46,100 57,000 65,500

kcal/hr 11,610 14,360 16,510

NOMINAL COOLING CAPACITY

Watt 13,500 16,700 19,200

Btu/hr 49,500 65,500 71,000

kcal/hr 12,470 16,510 17,880

NOMINAL HEATING CAPACITY

Watt 14,500 19,200 20,800

MATERIAL Electro-galvanised Mild Steel

FINISH Polyester Power

CASING

THICKNESS mm 1

HEIGHT (H) mm (in) 1560 (61.4) 1700 (66.9)

WIDTH (W) mm (in) 927 (36.5) 1135 (44.7)

TOTAL

UNIT

DIMENSION

DEPTH (D) mm (in) 406 (16) 502 (19.7)

NET WEIGHT kg 160 230 245

NOISE LEVEL dB(A) 60 64 64

EVAPOR ATOR

TYPE Brazed Plate Heat Exchanger

PLATE MATERIAL Stainless Steel

HEAT EXCHANGE AREA m2 1.3 1.4 1.7

NOMINAL WATER FLOW l/s 0.64 0.79 0.91

BPHE PRESSURE DROP VS NOMINAL FLOW RATE kPa 5 34 36.5

UNIT PRESSURE DROP WS NOMINAL FLOW RATE kPa 75 92 110

WATER LINE(HYDRAULIC KIT)

TYPE Horizontal Multistage End-Suction

POWER SUPPLY V/Ph/Hz 220 / 1 / 50 380 / 3 / 50

RUNNING CURRENT Amp 2.5 1.3 1.3

PUMP

WATER FLOW RATE GPM U.S. (l/s) 10.21 (0.64) 12.63 (0.79) 14.53 (0.91)

INSTALLATION PIPE CONNECTION mm (in) 34 ( Rc 1) 34 ( Rc 1) 34 ( Rc 1)

PIPING

HEAD m 23 24 23

CONDENSER COIL

TYPE

Cross Finned Tubes

MATERIAL Seamless Copper

WALL THICKNESS mm (in) 0.35 (0.014)

TUBE

OUTER DIAMETER mm (in) 9.52 (3/8)

MATERIAL Aluminium

THICKNESS mm (in) 0.127 (0.0005)

ROWS 2 2 2

FIN

FINS PER INCH 14 14 14

FACE AREA

m

2

(ft2) 1.23 (13.24) 1.74 (18.73) 1.74 (18.73)

CONDENSER FAN

TYPE/DRIVE Propeller/Direct

QUANTITY 1 1 1

BLADE MATERIAL Aluminium Alloy

BLADE DIAMETER mm (in) 600 (23.6) 710 (28) 710 (28)

POWER SUPPLY V/Ph/Hz 220 / 1 / 50 220 / 1 / 50 220 / 1 / 50

RATED RUNNING CURRENT Amp 0.9 1.2 1.2

RATED INPUT Watt 200 250 250

RATED OUTPUT Watt 120 130 130

MOTOR POLES 8 10 10

AIR VOLUME cmm/cfm 100 / 3530 133 / 4700 133 / 4700

COMPRESSOR

TYPE Scroll Scroll Scroll

POWER SUPPLY V/Ph/Hz 380 / 3 / 50 380 / 3 / 50 380 / 3 / 50

RATED RUNNING CURRENT (COOLING) Amp 8.0 10.4 11.9

RATED RUNNING CURRENT (HEATING) Amp 8.0 11.4 11.5

RATED INPUT (COOLING) Watt 4,800 5,000 6,400

RATED INPUT (HEATING) Watt 4,820 5,700 6,100

MAXIMUM STARTING CURRENT Amp 74 101 95

PROTECTION DEVICES Overload Protection, Flow Switch and H/L Pressure Switch

STAGE OF CAPACITY CONTROL On/Off

REFRIGERANT

TYPE R22

CONTROL Capillary Tube

CHARGING MASS kg 3.8 5.15 7

Notes:

1. All specifications are subjected to change by manufacturer without prior notice.

2. Nominal cooling values are based on entering/leaving chilled water temperature 12ºC/7ºC and air ambient temperature 35ºC.

3. Nominal heating values are based on entering/leaving hot water temperature 40ºC/45ºC and air ambient temperature 7ºC.

Page 13

Page 15

Heat Pump Unit (50Hz)

MODEL MAC080CR MAC100CR

Btu/hr 76,800 92,100

kcal/hr 19,350 23,220

NOMINAL COOLING CAPACITY

Watt 22,500 27,000

Btu/hr 81,900 97,200

kcal/hr 20,640 24,510

NOMINAL HEATING CAPACITY

Watt 24,000 28,500

MATERIAL Electro-galvanised Mild Steel

FINISH Polyester Power

CASING

THICKNESS mm 1.0

HEIGHT (H) mm (in) 1260 (49.6)

WIDTH (W) mm (in) 1500 (59.1)

TOTAL

UNIT

DIMENSION

DEPTH (D) mm (in) 900 (35.4)

NET WEIGHT kg 350 360

NOISE LEVEL dB(A) 62 64

EVAPOR ATOR

TYPE Brazed Plate Heat Exchanger

PLATE MATERIAL Stainless Steel

HEAT EXCHANGE AREA m2 2.26 2.78

NOMINAL WATER FLOW (COOLING/HEATING) l/s 1.08/1.14 1.31/1.39

BPHE PRESSURE DROP VS NOMINAL FLOW RATE (C/H) kPa 74/72 82/80

UNIT PRESSURE DROP VS NOMINAL FLOW RATE kPa 104 121

WATER LINE(HYDRAULIC KIT)

TYPE Horizontal Multistage End-Suction

POWER SUPPLY V/Ph/Hz 380 / 3 / 50

RUNNING CURRENT Amp 1.1 1.1

PUMP

WATER FLOW RATE ( C / H ) GPM U.S. (l/s) 17.17(1.08)/18.05(1.14) 20.70(1.31)/22.02(1.39)

INSTALLATION PIPE CONNECTION mm (in) 42 (Rc 1-1/4) 42 (Rc 1-1/4)

PIPING

HEAD (C / H) m 26/25 23.5/22.5

MATERIAL Steel EXPANSION

TANK

CAPACITY / VOLUME litres 8 8

CONDENSER COIL

TYPE

Cross Finned Tubes

MATERIAL Seamless Copper

WALL THICKNESS mm (in) 0.35 (0.014)

TUBE

OUTER DIAMETER mm (in) 9.52 (3/8)

MATERIAL Aluminium

THICKNESS mm (in) 0.127 (0.0005)

ROWS 2 2

FIN

FINS PER INCH 14 14

FACE AREA

m

2

(ft2) 2.5 (26.9) 2.5 (26.9)

CONDENSER FAN

TYPE/DRIVE Propeller/Direct

QUANTITY 2 2

BLADE MATERIAL Aluminium

BLADE DIAMETER mm (in) 600 (23.6) 600 (23.6)

POWER SUPPLY V/Ph/Hz 220 / 1 / 50 220 / 1 / 50

RATED RUNNING CURRENT Amp 0.9*2 0.9*2

RATED INPUT Watt 120*2 120*2

RATED OUTPUT Watt 200*2 200*2

MOTOR POLES 8 8

AIR VOLUME cmm/cfm 100*2 / 3530*2 100*2 / 3530*2

COMPRESSOR

TYPE Scroll Scroll

POWER SUPPLY V/Ph/Hz 380 / 3 / 50 380 / 3 / 50

RATED RUNNING CURRENT (COOLING) Amp 7.3*2 8.6*2

RATED RUNNING CURRENT (HEATING) Amp 7.3*2 8.6*2

RATED INPUT (COOLING) Watt 3,900*2 4,800*2

RATED INPUT (HEATING) Watt 3,900*2 4,800*2

MAXIMUM STARTING CURRENT Amp 40 48

PROTECTION DEVICES Overload Protection, Flow Switch & H/L Pressure Switch

STAGE OF CAPACITY CONTROL (%) 0-50-100

REFRIGERANT

TYPE R22

CONTROL Capillary Tube

CHARGING MASS kg 4.0*2 4.6*2

Notes:

1. All specifications are subjected to change by manufacturer without prior notice.

2. Nominal cooling values are based on entering/leaving chilled water temperature 12ºC/7ºC and air ambient temperature 35ºC.

3. Nominal heating values are based on entering/leaving hot water temperature 40ºC/45ºC and air ambient temperature 7ºC.

Page 14

Page 16

Heat Pump Unit (50Hz)

MODEL MAC120CR MAC150CR

Btu/hr 112,600 129,700

kcal/hr 28,380 32,670

NOMINAL COOLING CAPACITY

Watt 33,000 38,000

Btu/hr 119,400 136,500

kcal/hr 30,090 34,390

NOMINAL HEATING CAPACITY

Watt 35,000 40,000

MATERIAL Electro-galvanised Mild Steel

FINISH Polyester Power

CASING

THICKNESS mm 1

HEIGHT (H) mm (in) 1260 (49.6)

WIDTH (W) mm (in) 1800 (70.9)

TOTAL UNIT DIMENSION

DEPTH (D) mm (in) 1150 (45.3)

NET WEIGHT kg 480 560

NOISE LEVEL dB(A) 67 70

EVAPOR ATOR

TYPE Brazed Plate Heat Exchanger

PLATE MATERIAL Stainless Steel

HEAT EXCHANGE AREA m2 3.0 3.6

NOMINAL WATER FLOW (COOLING/HEATING) l/s 1.67/1.78 2.0/2.11

BPHE PRESSURE DROP VS NOMINAL FLOW RATE (C/H) kPa 76/74 75/73

UNIT PRESSURE DROP VS NOMINAL FLOW RATE kPa 138 155

WATER LINE(HYDRAULIC KIT)

TYPE Horizontal Multistage End-Suction

POWER SUPPLY V/Ph/Hz 380 / 3 / 50

RUNNING CURRENT Amp 2.5 2.5

PUMP

WATER FLOW RATE ( C / H ) GPM U.S. (l/s) 26.42(1.67)/28.18(1.78) 31.70(2.0)/33.47(2.11)

INSTALLATION PIPE

CONNECTION

mm (in) 42 (Rc 1-1/4) 42 (Rc 1-1/4)

PIPING

HEAD (C / H) m 31/29 28/26

MATERIAL Steel

EXPANSION

TANK

CAPACITY / VOLUME litres 8 8

CONDENSER COIL

TYPE Cross Finned Tubes

MATERIAL Seamless Copper

WALL THICKNESS mm (in) 0.35 (0.014)

TUBE

OUTER DIAMETER mm (in) 9.52 (3/8)

MATERIAL Aluminium

THICKNESS mm (in) 0.127 (0.0005)

ROWS 2 2

FIN

FINS PER INCH 14 14

FACE AREA m2 (ft2) 2.5 (26.9) 2.5 (26.9)

CONDENSER FAN

TYPE/DRIVE Propeller/Direct

QUANTITY 2 2

BLADE MATERIAL

BLADE DIAMETER mm (in) 660 (26) 660 (26)

POWER SUPPLY V/Ph/Hz 380 / 3 / 50

RATED RUNNING CURRENT Amp 0.86*2 4.5*2

RATED INPUT Watt 200*2 450*2

RATED OUTPUT Watt 470*2 820*2

MOTOR POLES 8 6

AIR VOLUME cmm/cfm 142*2 / 5000*2 142*2 / 5000*2

COMPRESSOR

TYPE Scroll Scroll

POWER SUPPLY V/Ph/Hz 380 / 3 / 50 380 / 3 / 50

RATED RUNNING CURRENT (COOLING) Amp 10.3*2 11.5*2

RATED RUNNING CURRENT (HEATING) Amp 10.3*2 11.5*2

RATED INPUT (COOLING) Watt 5,300*2 6,240*2

RATED INPUT (HEATING) Watt 5,300*2 6,240*2

MAXIMUM STARTING CURRENT Amp 55 62

PROTECTION DEVICES Overload Protection, Flow Switch & H/L Pressure Switch

STAGE OF CAPACITY CONTROL (%) 0-50-100

REFRIGERANT

TYPE R22

CONTROL Capillary Tube

CHARGING MASS kg 7.5*2 6.8*2

Notes:

1. All specifications are subjected to change by manufacturer without prior notice.

2. Nominal cooling values are based on entering/leaving chilled water temperature 12ºC/7ºC and air ambient temperature 35ºC.

3. Nominal heating values are based on entering/leaving hot water temperature 40ºC/45ºC and air ambient temperature 7ºC.

Page 15

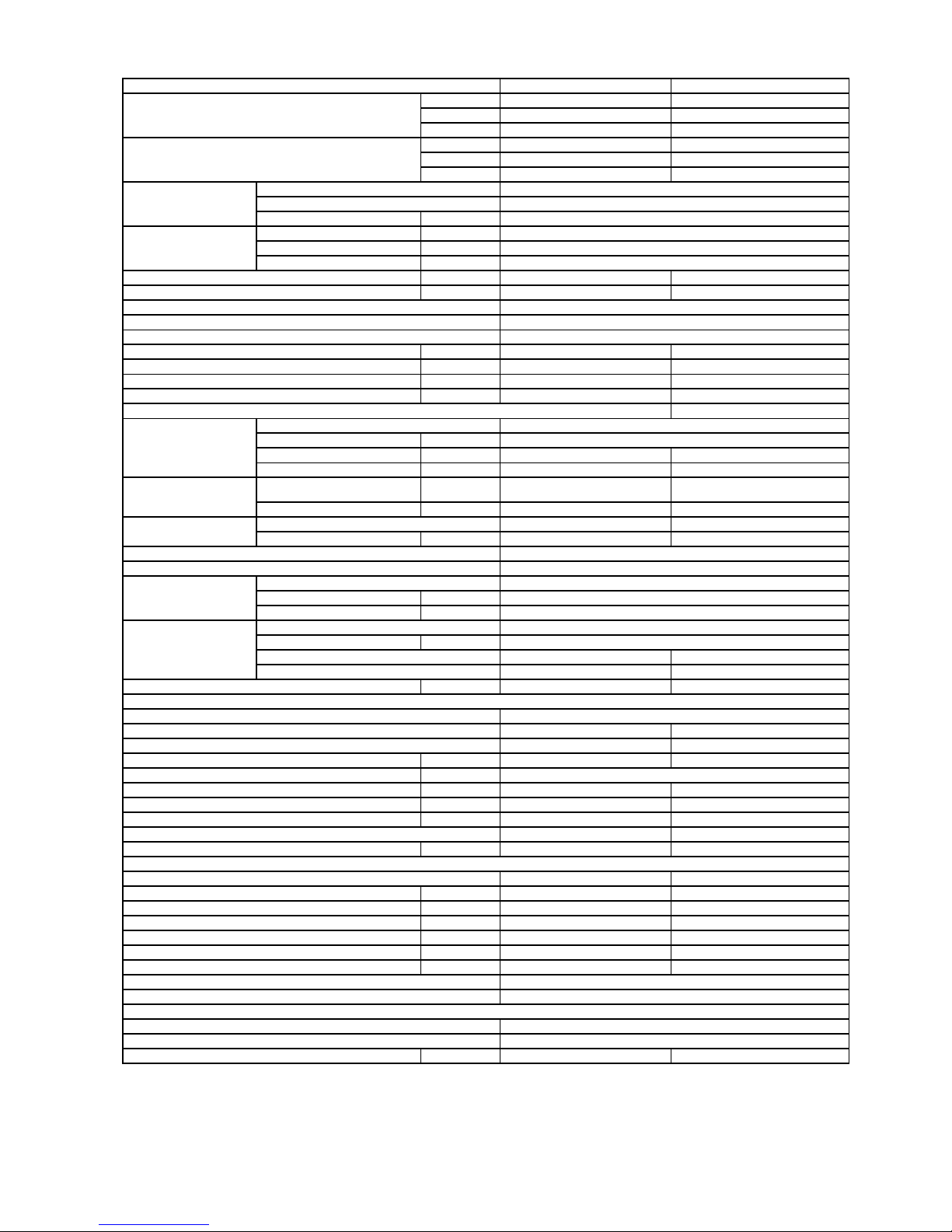

Page 17

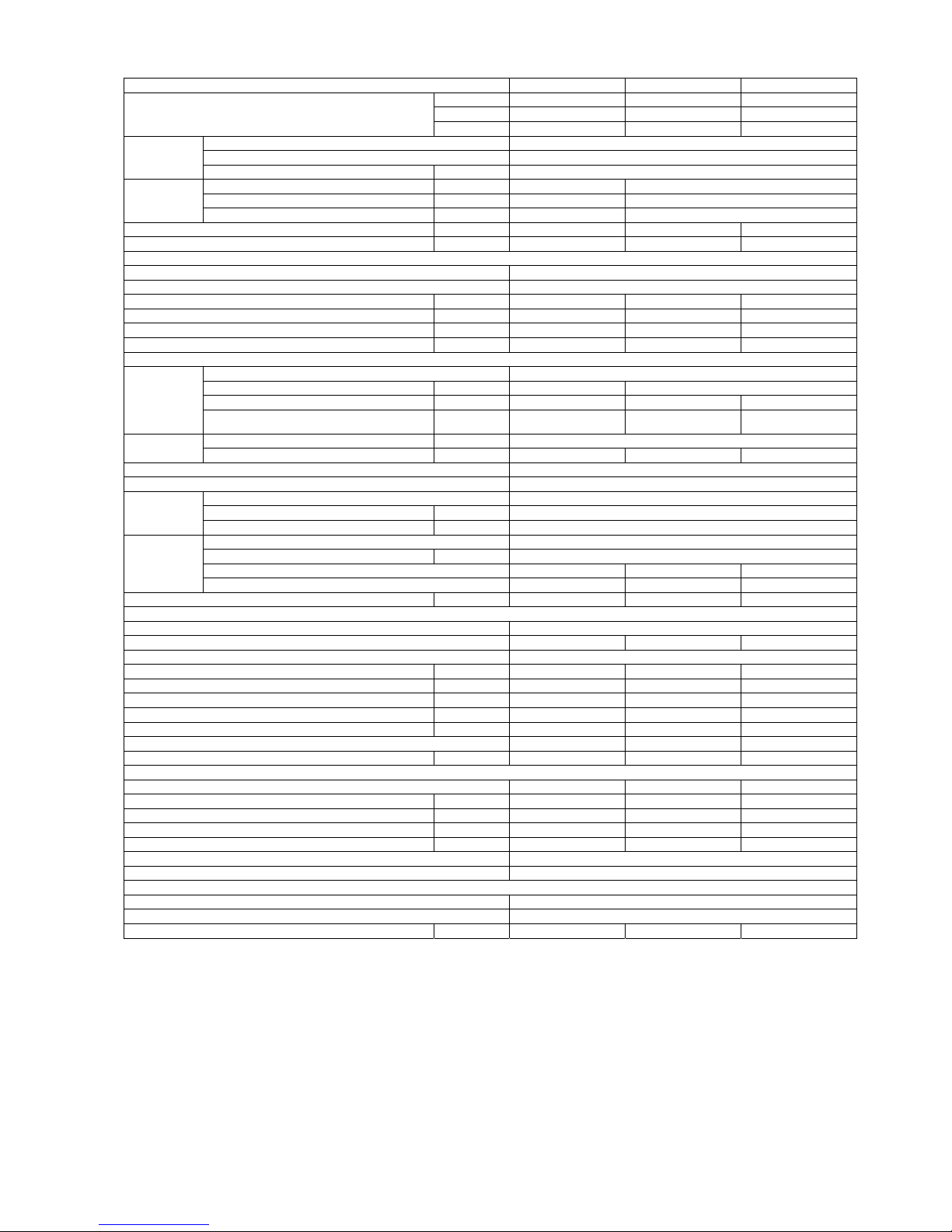

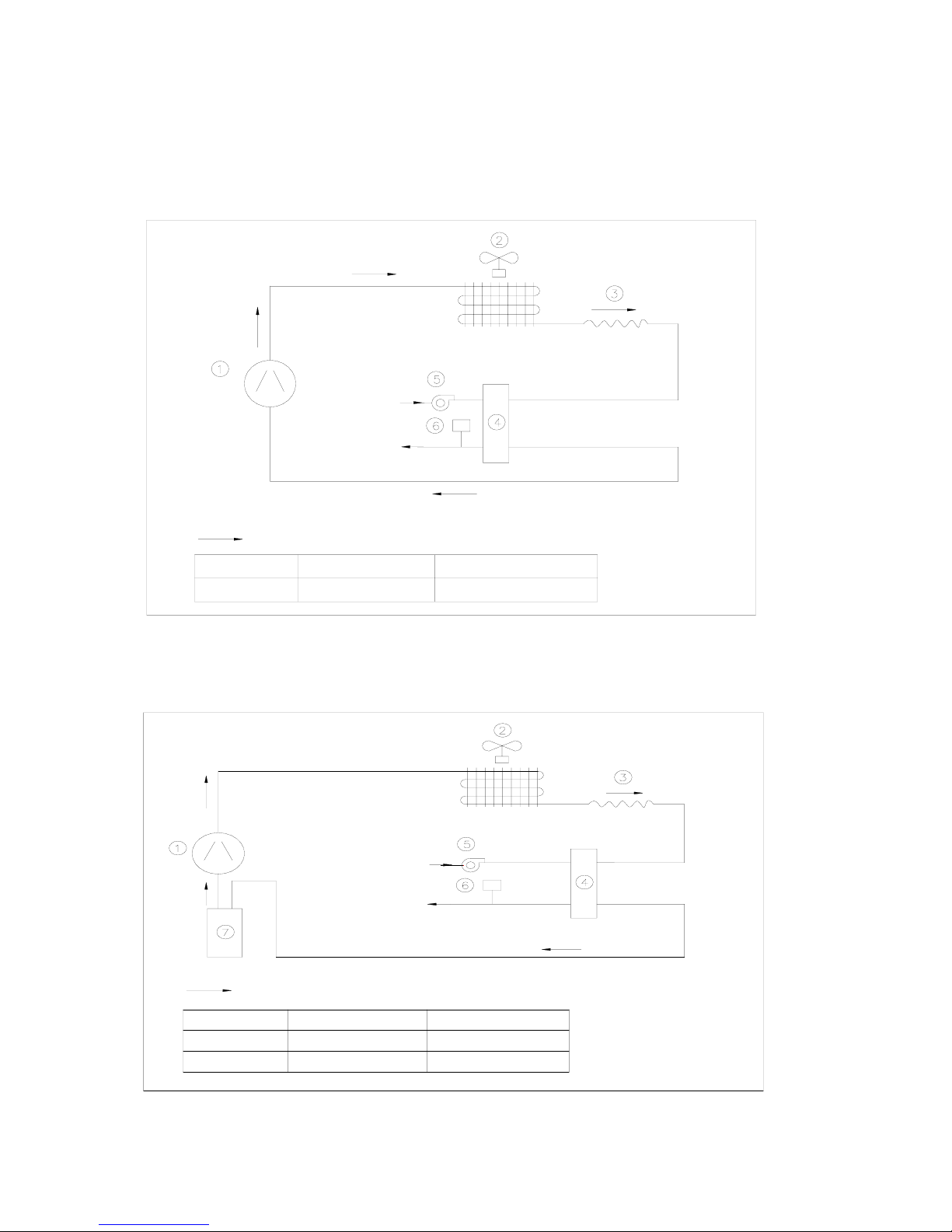

Performance Characteristic Charts

Actual performance can be determined by conducting correction after looking up the following charts.

Based on the ambient temperature and desired return water temperature, we can locate the corresponding

performance factor in these charts, then the corresponding actual cooling (heating) capacity and power input

can be determined by using the following formula.

Actual cooling (heating) capacity = nominal cooling (heating) capacity * cooling (heating) performance

correction factor

Actual power input = nominal power input * power input correction factor.

Page 16

Page 18

Cooling Only

Models: MAC 030 / 035 / 040 / 050 / 065 / 070 / 080 / 100 / 120 / 150 C

Cooling

Capacity W

Power

Input W

Cooling

Capacity W

Power

Input W

Cooling

Capacity W

Power

Input W

Cooling

Capacity W

Power

Input W

Cooling

Capacity W

Power

Input W

5 7313 1985 6915 2085 6773 2257 6353 2478 6113 2725

6 7553 2296 7260 2421 7200 2619 6930 2760 6758 3048

7 7793 2549 7605 2744 7500 3202 7245 3314 7088 3394

8 8298 2943 7898 3096 7763 3429 7403 3545 7260 3602

9 8348 3375 8168 3525 8040 3737 7628 3855 7485 4009

10 8648 3583 8505 3900 8288 4083 7770 4195 7628 4457

5 8775 2363 8298 2482 8127 2687 7623 2950 7335 3244

6 9063 2733 8712 2882 8640 3118 8316 3286 8109 3629

7 9351 3034 9126 3267 9000 3812 8694 3945 8505 4041

8 9958 3503 9477 3686 9315 4083 8883 4220 8712 4289

9 10017 4018 9801 4197 9648 4449 9153 4590 8982 4773

10 10377 4266 10206 4643 9945 4860 9324 4994 9153 5306

5 11213 2784 10603 2923 10385 3165 9741 3475 9373 3821

6 11581 3219 11132 3394 11040 3673 10626 3870 10362 4274

7 11949 3574 11661 3848 11500 4490 11109 4647 10868 4759

8 12724 4126 12110 4342 11903 4809 11351 4970 11132 5051

9 12800 4732 12524 4943 12328 5240 11696 5406 11477 5621

10 13260 5024 13041 5469 12708 5725 11914 5882 11696 6250

5 13163 3311 12447 3476 12191 3765 11435 4133 11003 4544

6 13595 3829 13068 4037 12960 4368 12474 4603 12164 5084

7 14027 4251 13689 4576 13500 5340 13041 5527 12758 5660

8 14937 4907 14216 5164 13973 5719 13325 5911 13068 6008

9 15026 5628 14702 5879 14472 6232 13730 6429 13473 6686

10 15566 5975 15309 6504 14918 6809 13986 6995 13730 7433

5 16283 4058 15397 4261 15080 4614 14145 5066 13611 5570

6 16817 4693 16166 4948 16032 5354 15431 5642 15047 6231

7 17351 5210 16934 5609 16700 6545 16132 6774 15782 6938

8 18477 6015 17585 6329 17285 7010 16483 7245 16166 7363

9 18587 6898 18186 7206 17902 7638 16984 7880 16667 8194

10 19255 7324 18938 7972 18454 8345 17301 8574 16984 9111

5 18720 4492 17702 4716 17338 5108 16262 5608 15648 6165

6 19334 5195 18586 5477 18432 5926 17741 6245 17299 6897

7 19949 5767 19469 6209 19200 7245 18547 7499 18144 7680

8 21243 6658 20218 7006 19872 7759 18950 8020 18586 8151

9 21370 7636 20909 7977 20582 8455 19526 8723 19162 9071

10 22138 8107 21773 8824 21216 9237 19891 9491 19526 10085

5 21938 5571 20745 5849 20318 6334 19058 6954 18338 7646

6 22658 6442 21780 6793 21600 7350 20790 7745 20273 8554

7 23378 7152 22815 7700 22500 8985 21735 9299 21263 9524

8 24894 8257 23693 8688 23288 9623 22208 9946 21780 10108

9 25043 9470 24503 9892 24120 10485 22883 10818 22455 11249

10 25943 10054 25515 10944 24863 11456 23310 11770 22883 12507

5 26325 6625 24894 6956 24381 7533 22869 8270 22005 9093

6 27189 7661 26136 8078 25920 8740 24948 9210 24327 10172

7 28053 8505 27378 9157 27000 10685 26082 11059 25515 11326

8 29873 9820 28431 10332 27945 11444 26649 11828 26136 12021

9 30051 11262 29403 11764 28944 12469 27459 12865 26946 13378

10 31131 11957 30618 13014 29835 13623 27972 13997 27459 14874

5 34125 7955 32270 8352 31605 9045 29645 9930 28525 10918

6 35245 9199 33880 9699 33600 10495 32340 11059 31535 12214

7 36365 10213 35490 10995 35000 12830 33810 13279 33075 13600

8 38725 11791 36855 12407 36225 13741 34545 14203 33880 14434

9 38955 13523 38115 14126 37520 14973 35595 15447 34930 16063

10 40355 14357 39690 15627 38675 16358 36260 16807 35595 17859

5 34125 9219 32270 9680 31605 10483 29645 11509 28525 12654

6 35245 10662 33880 11242 33600 12164 32340 12818 31535 14156

7 36365 11837 35490 12744 35000 14870 33810 15390 33075 15762

8 38725 13666 36855 14379 36225 15926 34545 16461 33880 16729

9 38955 15673 38115 16372 37520 17353 35595 17903 34930 18617

10 40355 16640 39690 18112 38675 18959 36260 19480 35595 20699

MAC120C

MAC150C

MAC065C

MAC070C

MAC080C

MAC100C

MAC030C

MAC035C

MAC040C

MAC050C

Model

Leaving

Water

Temp.

o

C

Environment Temperature

o

C

28

o

C

32

o

C

35

o

C

40

o

C

42

o

C

Page 17

Page 19

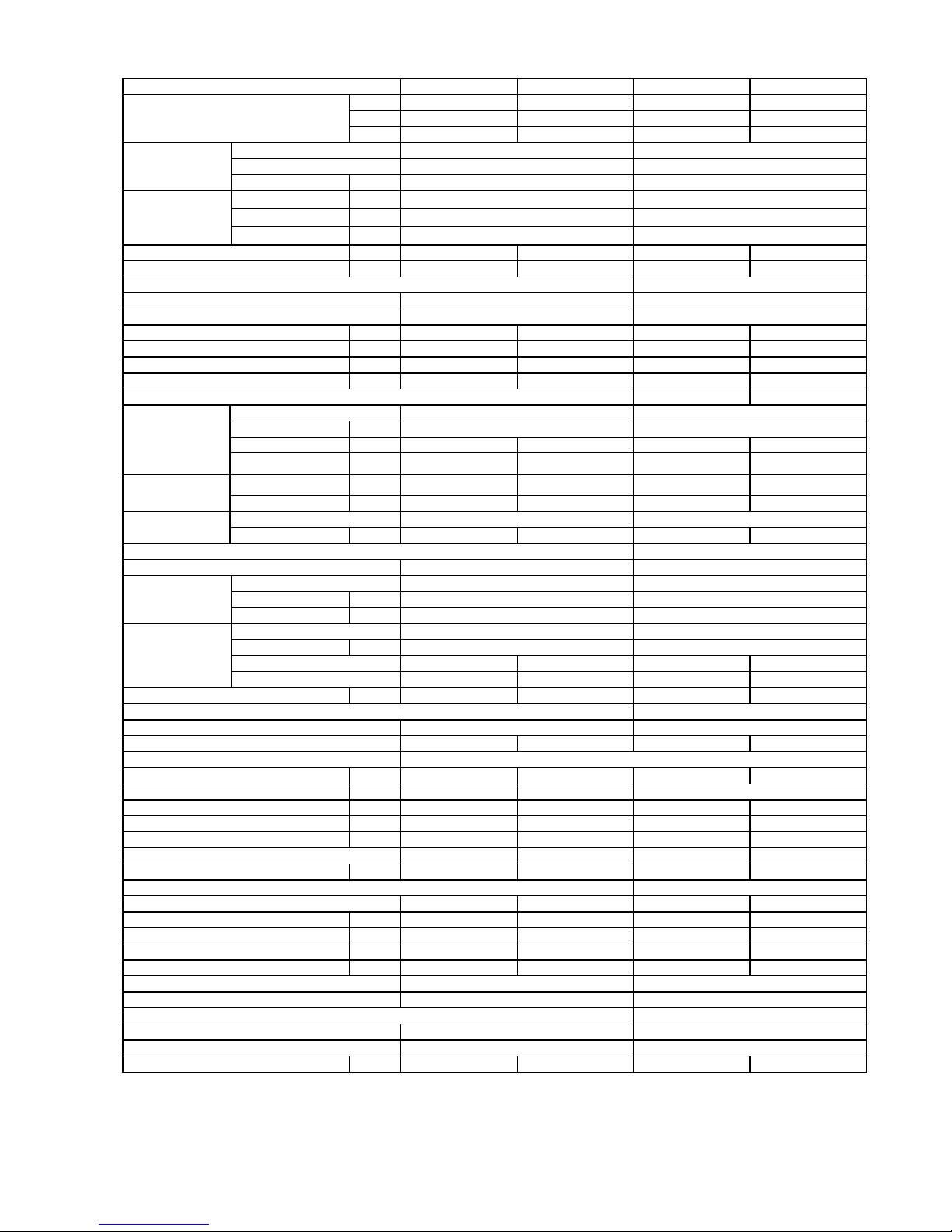

Heating Mode

Models: MAC 030 / 035 / 040 / 050 / 065 / 070 / 080 / 100 / 120 / 150 CR

Cooling

Capacity W

Power

Input W

Cooling

Capacity W

Power

Input W

Cooling

Capacity W

Power

Input W

Cooling

Capacity W

Power

Input W

Cooling

Capacity W

Power

Input W

5 7313 1953 6915 2261 6773 2632 6353 2690 6113 2831

6 7553 2101 7260 2389 7200 2968 6930 3026 6758 3336

7 7793 2171 7605 2469 7500 3202 7245 3340 7088 3653

8 8298 2498 7898 2686 7763 3369 7403 3481 7260 3874

9 8348 2770 8168 3026 8040 3509 7628 3650 7485 4191

10 8648 2975 8505 3180 8288 3653 7770 3794 7628 4502

5 8775 2325 8298 2691 8127 3133 7623 3202 7335 3370

6 9063 2501 8712 2844 8640 3534 8316 3602 8109 3972

7 9351 2585 9126 2939 9000 3812 8694 3976 8505 4349

8 9958 2973 9477 3198 9315 4010 8883 4144 8712 4613

9 10017 3297 9801 3602 9648 4178 9153 4346 8982 4990

10 10377 3541 10206 3785 9945 4349 9324 4517 9153 5360

5 11213 2739 10603 3170 10385 3691 9741 3772 9373 3969

6 11581 2945 11132 3350 11040 4162 10626 4243 10362 4679

7 11949 3044 11661 3462 11500 4490 11109 4683 10868 5123

8 12724 3502 12110 3767 11903 4723 11351 4881 11132 5433

9 12800 3884 12524 4243 12328 4921 11696 5119 11477 5877

10 13260 4171 13041 4459 12708 5123 11914 5321 11696 6313

5 13163 3257 12447 3770 12191 4389 11435 4486 11003 4721

6 13595 3503 13068 3984 12960 4950 12474 5046 12164 5564

7 14027 3621 13689 4117 13500 5340 13041 5570 12758 6093

8 14937 4165 14216 4480 13973 5618 13325 5805 13068 6461

9 15026 4619 14702 5046 14472 5853 13730 6088 13473 6990

10 15566 4961 15309 5303 14918 6093 13986 6328 13730 7508

5 16283 3992 15397 4621 15080 5380 14145 5498 13611 5786

6 16817 4294 16166 4883 16032 6067 15431 6185 15047 6820

7 17351 4438 16934 5046 16700 6545 16132 6826 15782 7468

8 18477 5105 17585 5491 17285 6885 16483 7114 16166 7919

9 18587 5661 18186 6185 17902 7173 16984 7461 16667 8567

10 19255 6080 18938 6499 18454 7468 17301 7756 16984 9202

5 18720 4419 17702 5115 17338 5955 16262 6086 15648 6405

6 19334 4753 18586 5405 18432 6716 17741 6847 17299 7549

7 19949 4912 19469 5586 19200 7245 18547 7557 18144 8267

8 21243 5651 20218 6079 19872 7622 18950 7875 18586 8766

9 21370 6267 20909 6847 20582 7941 19526 8259 19162 9484

10 22138 6731 21773 7194 21216 8267 19891 8585 19526 10186

5 21938 5481 20745 6343 20318 7386 19058 7547 18338 7943

6 22658 5894 21780 6703 21600 8329 20790 8491 20273 9362

7 23378 6092 22815 6927 22500 8985 21735 9371 21263 10252

8 24894 7008 23693 7538 23288 9452 22208 9767 21780 10872

9 25043 7772 24503 8491 24120 9848 22883 10243 22455 11761

10 25943 8347 25515 8922 24863 10252 23310 10647 22883 12633

5 26325 6518 24894 7544 24381 8783 22869 8975 22005 9446

6 27189 7009 26136 7971 25920 9905 24948 10097 24327 11134

7 28053 7244 27378 8238 27000 10685 26082 11144 25515 12192

8 29873 8334 28431 8965 27945 11241 26649 11615 26136 12929

9 30051 9243 29403 10097 28944 11711 27459 12181 26946 13987

10 31131 9926 30618 10610 29835 12192 27972 12662 27459 15023

5 34125 7826 32270 9058 31605 10546 29645 10777 28525 11342

6 35245 8416 33880 9571 33600 11893 32340 12124 31535 13369

7 36365 8699 35490 9892 35000 12830 33810 13382 33075 14639

8 38725 10007 36855 10764 36225 13497 34545 13946 33880 15524

9 38955 11098 38115 12124 37520 14062 35595 14626 34930 16794

10 40355 11919 39690 12740 38675 14639 36260 15204 35595 18039

5 34125 9071 32270 10498 31605 12223 29645 12491 28525 13145

6 35245 9755 33880 11093 33600 13784 32340 14052 31535 15495

7 36365 10082 35490 11465 35000 14870 33810 15509 33075 16967

8 38725 11599 36855 12476 36225 15643 34545 16164 33880 17993

9 38955 12863 38115 14052 37520 16298 35595 16952 34930 19465

10 40355 13814 39690 14766 38675 16967 36260 17621 35595 20907

MAC120CR

MAC150CR

Model

Leaving

Water

Temp.

o

C

42

o

C

MAC030CR

MAC035CR

MAC040CR

28

o

C

32

o

C

35

o

C

40

o

C

MAC050CR

MAC065CR

MAC070CR

MAC080CR

MAC100CR

Environment Temperature

o

C

Page 18

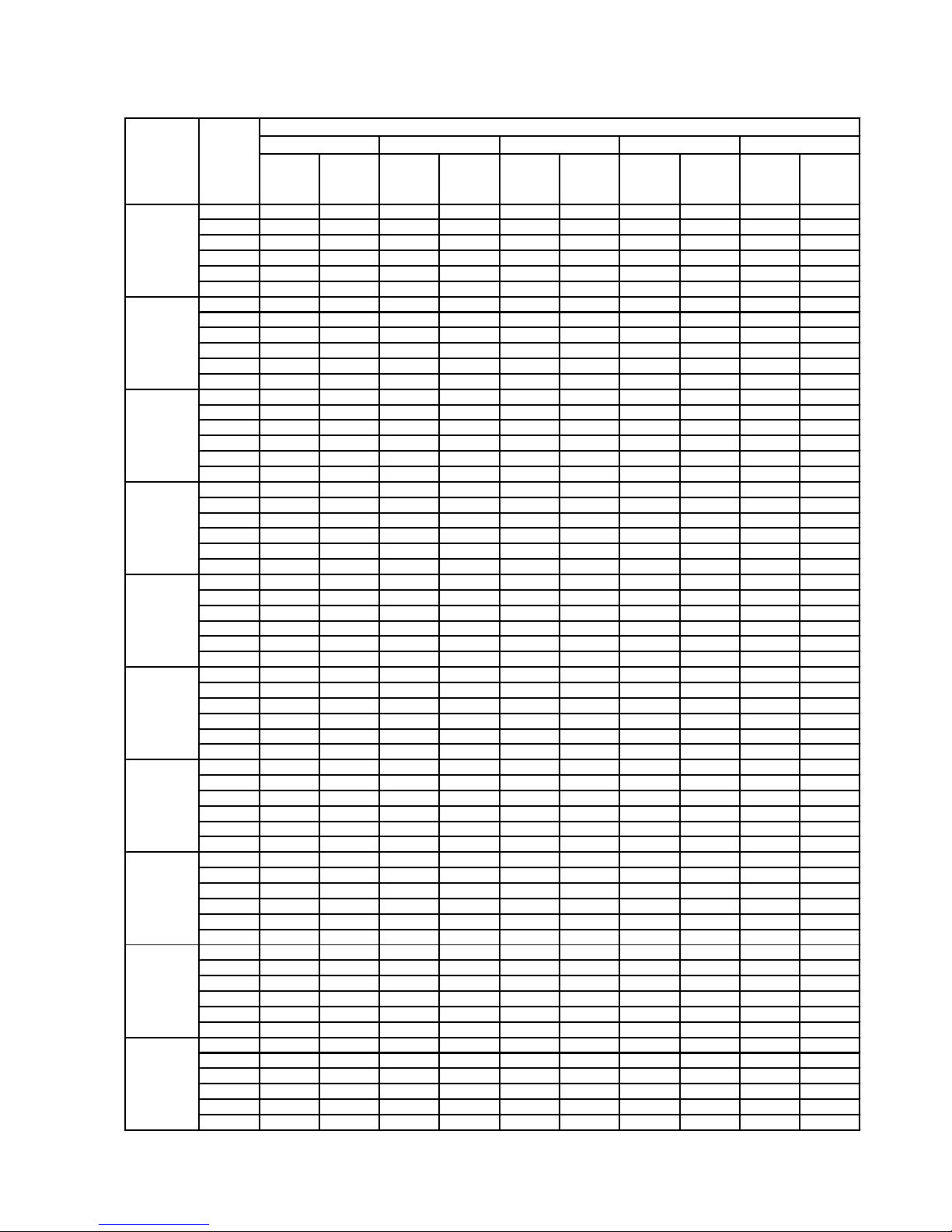

Page 20

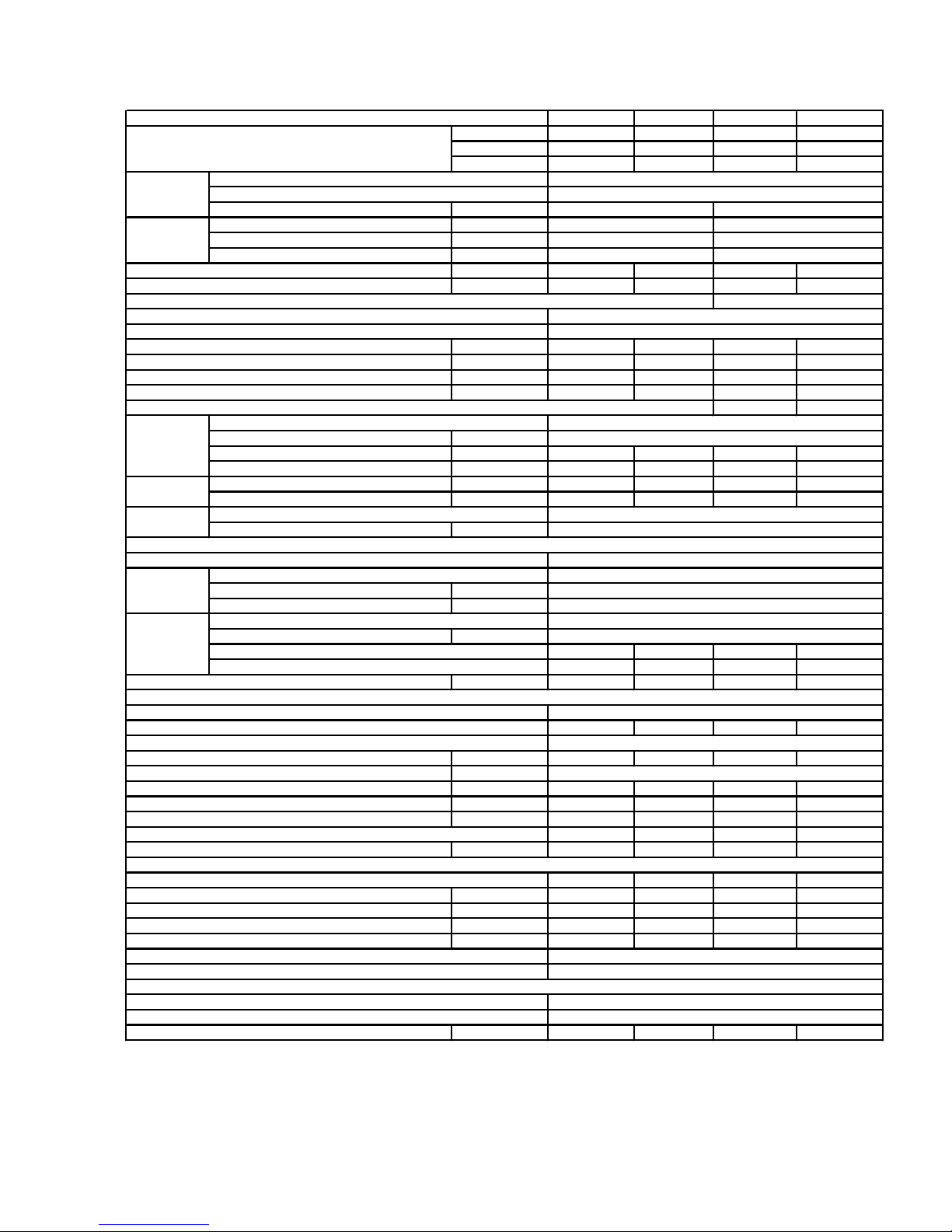

Heating Mode

Models: MAC 030 / 035 / 040 / 050 / 065 / 070 / 080 / 100 / 120 / 150 CR

Heating

Capacity W

Power Input WHeating

Capacity W

Power Input WHeating

Capacity W

Power Input WHeating

Capacity W

Power Input WHeating

Capacity W

Power Input WHeating

Capacity W

Power Input

W

35 6552 2350 7144 2459 7712 2690 8448 2859 8656 2943 8840 3023

40 6200 2478 6816 2651 7408 2815 8176 3048 8360 3074 8560 3228

45 5824 2645 6496 2779 7160 2930 8000 3202 8136 3269 8344 3340

50 5712 2693 6288 2805 6864 3071 7736 3269 7960 3295 8144 3394

55 5488 2738 6032 2872 6592 3196 7512 3394 7680 3433 7840 3487

35 7781 2798 8484 2928 9158 3202 10032 3404 10279 3503 10498 3599

40 7363 2950 8094 3156 8797 3351 9709 3629 9928 3660 10165 3842

45 6916 3149 7714 3309 8503 3488 9500 3812 9662 3891 9909 3976

50 6783 3206 7467 3339 8151 3656 9187 3892 9453 3923 9671 4041

55 6517 3259 7163 3419 7828 3804 8921 4041 9120 4086 9310 4151

35 10238 3296 11163 3448 12050 3772 13200 4010 13525 4126 13813 4239

40 9688 3475 10650 3718 11575 3947 12775 4274 13063 4310 13375 4526

45 9100 3709 10150 3897 11188 4108 12500 4490 12713 4583 13038 4683

50 8925 3776 9825 3933 10725 4306 12088 4584 12438 4620 12725 4759

55 8575 3839 9425 4028 10300 4481 11738 4759 12000 4813 12250 4890

35 11876 3920 12949 4101 13978 4486 15312 4769 15689 4907 16023 5041

40 11238 4133 12354 4422 13427 4694 14819 5084 15153 5126 15515 5383

45 10556 4411 11774 4635 12978 4886 14500 5340 14747 5451 15124 5570

50 10353 4491 11397 4678 12441 5121 14022 5452 14428 5495 14761 5660

55 9947 4566 10933 4790 11948 5329 13616 5660 13920 5724 14210 5815

35 14742 4804 16074 5027 17352 5498 19008 5845 19476 6015 19890 6178

40 13950 5066 15336 5419 16668 5753 18396 6231 18810 6283 19260 6597

45 13104 5406 14616 5681 16110 5989 18000 6545 18306 6681 18774 6826

50 12852 5504 14148 5733 15444 6277 17406 6682 17910 6735 18324 6938

55 12348 5596 13572 5871 14832 6532 16902 6938 17280 7016 17640 7128

35 17199 5318 18753 5564 20244 6086 22176 6470 22722 6658 23205 6839

40 16275 5608 17892 5999 19446 6368 21462 6897 21945 6955 22470 7303

45 15288 5984 17052 6289 18795 6629 21000 7245 21357 7396 21903 7557

50 14994 6093 16506 6347 18018 6948 20307 7397 20895 7455 21378 7680

55 14406 6194 15834 6499 17304 7231 19719 7680 20160 7767 20580 7890

35 19656 6595 21432 6900 23136 7547 25344 8024 25968 8257 26520 8482

40 18600 6954 20448 7440 22224 7898 24528 8554 25080 8626 25680 9057

45 17472 7422 19488 7799 21480 8221 24000 8985 24408 9172 25032 9371

50 17136 7556 18864 7871 20592 8617 23208 9174 23880 9246 24432 9524

55 16464 7682 18096 8060 19776 8967 22536 9524 23040 9632 23520 9785

35 23342 7843 25451 8206 27474 8975 30096 9542 30837 9820 31493 10087

40 22088 8270 24282 8847 26391 9392 29127 10172 29783 10258 30495 10770

45 20748 8826 23142 9275 25508 9777 28500 10685 28985 10907 29726 11144

50 20349 8986 22401 9360 24453 10247 27560 10909 28358 10995 29013 11326

55 19551 9136 21489 9584 23484 10664 26762 11326 27360 11454 27930 11636

35 30303 9417 33041 9853 35668 10777 39072 11457 40034 11791 40885 12112

40 28675 9930 31524 10623 34262 11278 37814 12214 38665 12317 39590 12933

45 26936 10598 30044 11136 33115 11739 37000 12830 37629 13097 38591 13382

50 26418 10790 29082 11239 31746 12304 35779 13099 36815 13202 37666 13600

55 25382 10970 27898 11509 30488 12804 34743 13600 35520 13754 36260 13972

35 30303 10915 33041 11420 35668 12491 39072 13279 40034 13666 40885 14037

40 28675 11509 31524 12312 34262 13071 37814 14156 38665 14275 39590 14989

45 26936 12283 30044 12907 33115 13606 37000 14870 37629 15179 38591 15509

50 26418 12506 29082 13026 31746 14260 35779 15182 36815 15301 37666 15762

55 25382 12714 27898 13338 30488 14840 34743 15762 35520 15941 36260 16193

0ºC-5ºC

Leaving

Water Temp.

o

C

Environment Temperature

o

C

15ºC10ºC7ºC4ºC

MAC050CR

MAC100CR

MAC120CR

MAC150CR

MAC065CR

MAC070CR

MAC080CR

MAC030CR

MAC035CR

MAC040CR

Model

Page 19

Page 21

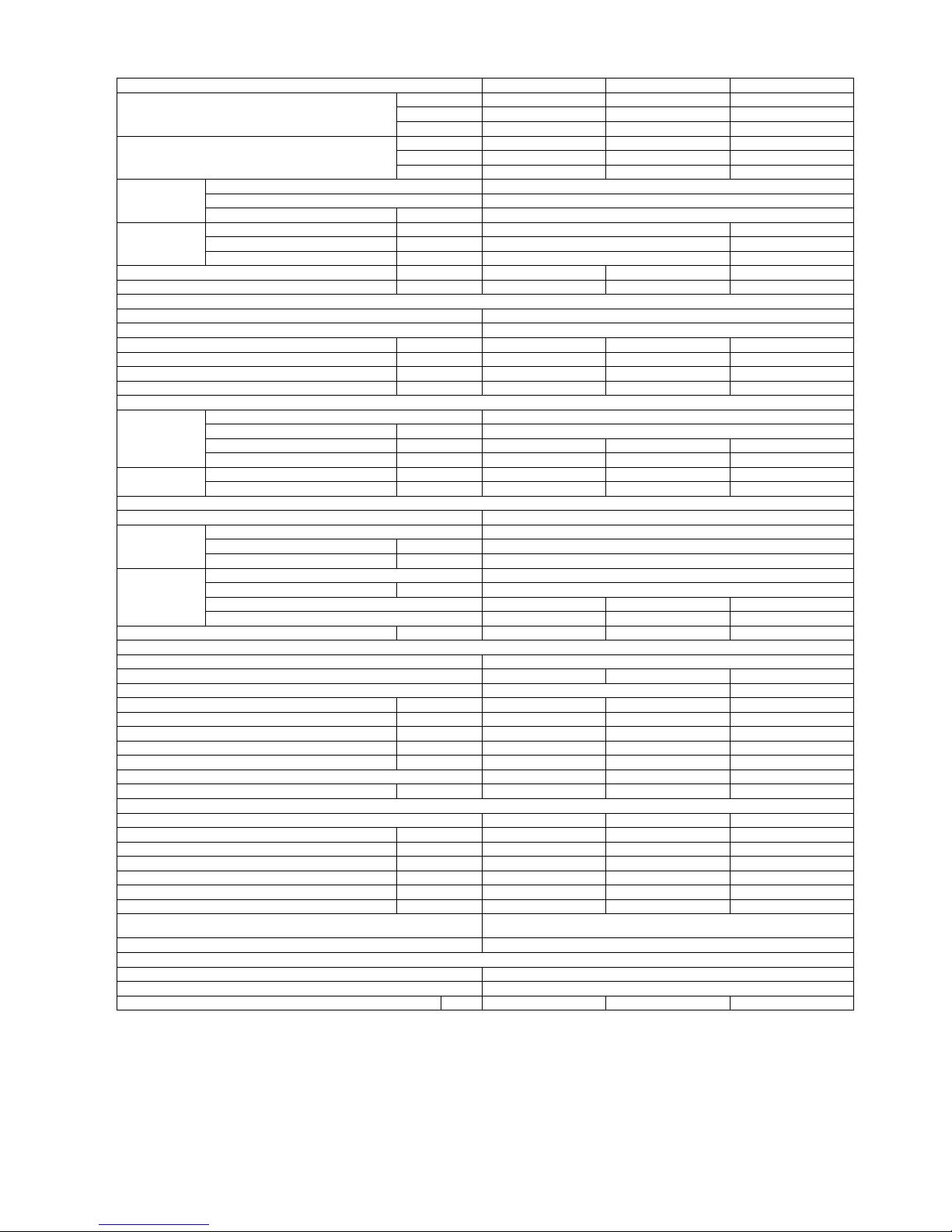

Technical Data

Correction Factors With Glycol Use

GLYCOL % COOLING CAPACITY WATER FLOW PRESSURE DROP

10 0.990 1.015 1.06

20 0.980 1.040 1.12

30 0.970 1.080 1.18

40 0.965 1.135 1.24

Water Pressure Drop And Flow Rate

Water Flow Rate Water Pressure Drop

MODEL

L/s m³/h kPa Bar

MAC080C

1.08 3.9 74 0.74

MAC100C

1.31 4.7 82 0.82

MAC120C

1.67 6.0 76 0.76

MAC150C

2.0 7.2 74 0.74

Cooling

1.08 3.9 74 0.74

MAC080CR

Heating

1.14 4.1 72 0.72

Cooling

1.31 4.7 82 0.82

MAC100CR

Heating

1.39 5.0 80 0.80

Cooling

1.67 6.0 76 0.76

MAC120CR

Heating

1.78 6.4 74 0.74

Cooling

2.0 7.2 75 0.45

MAC150CR

Heating

2.11 7.6 73 0.73

Page 20

Page 22

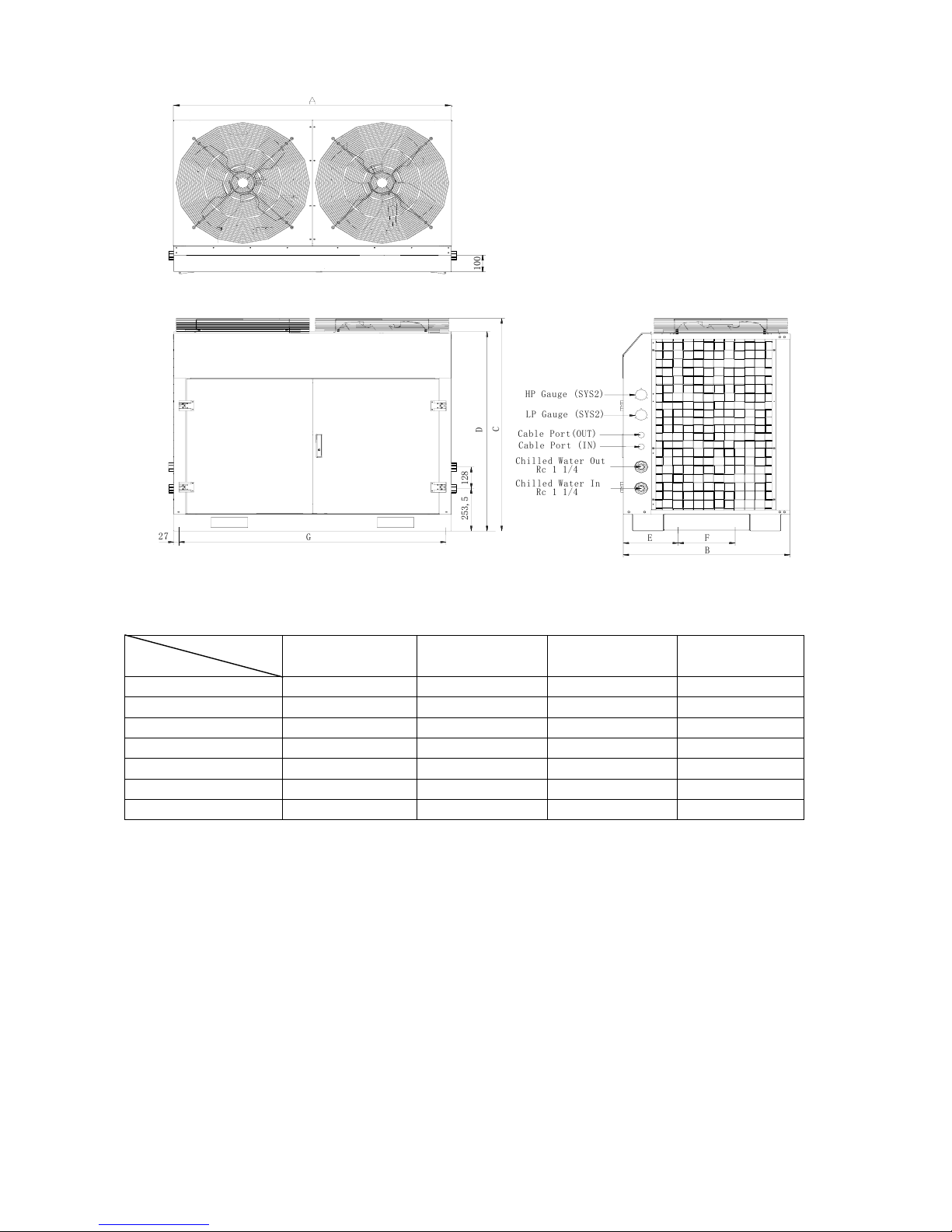

Outlines and Dimensions

Model: MAC 030C(R)/035C(R)/040C(R)/050C(R)/065C(R)/070C(R)

UNIT: mm

A B C D E

MAC030/035C(R)

922 382 1250 841 882

MAC040/050C(R)

1004 406 1560 927 970

MAC065/070C(R)

1212 502 1700 1135 1162

F G H I J

MAC030/035C(R)

86 231.5 90 75 531.5

MAC040/050C(R)

80 267 167.5 124.5 556

MAC065/070C(R)

132 254 235 80 604.5

2- Rc 1

4- 10X20

Page 21

Page 23

Model: MAC 080C(R)/100C(R)/120C(R)/150C(R)

2

7

G

E

2

5

3

,

5

1

2

8

D

C

HP Gauge (SYS2)

LP Gauge (SYS2)

Cable Port(OUT)

Chilled Water Out

Cable Port (IN)

F

B

1

0

0

Rc 1 1/

4

Chilled Water I

n

Rc 1 1/

4

UNIT: mm

Model

Dimension

MAC080C(R) MAC100C(R) MAC120C(R) MAC150C(R)

A

1500 1500 1800 1800

B

900 900 1150 1150

C

1260 1260 1260 1260

D

1190 1190 1190 1190

E

297.5 297.5 347.5 347.5

F(Mounting hole)

307.5 307.5 307.5 307.5

G(Mounting hole)

1446 1446 1546 1546

Page 22

Page 24

Accessory Hydraulic Kit

For MAC080C(R) to MAC150C(R), accessory hydraulic kit consists of 40L capacity stainless steel water

storage tank, safety valve, dirt drainage valve, and auto air vent valve etc. For MAC030C(R) to

MAC070C(R), with 8L volume water expansion chamber additionally.

Water Drainage Port DN2

5

Chilled Water Out R

1

Chilled Water In R

1

Dirt Drainage Port R1/

2

4-10x20

Page 23

Page 25

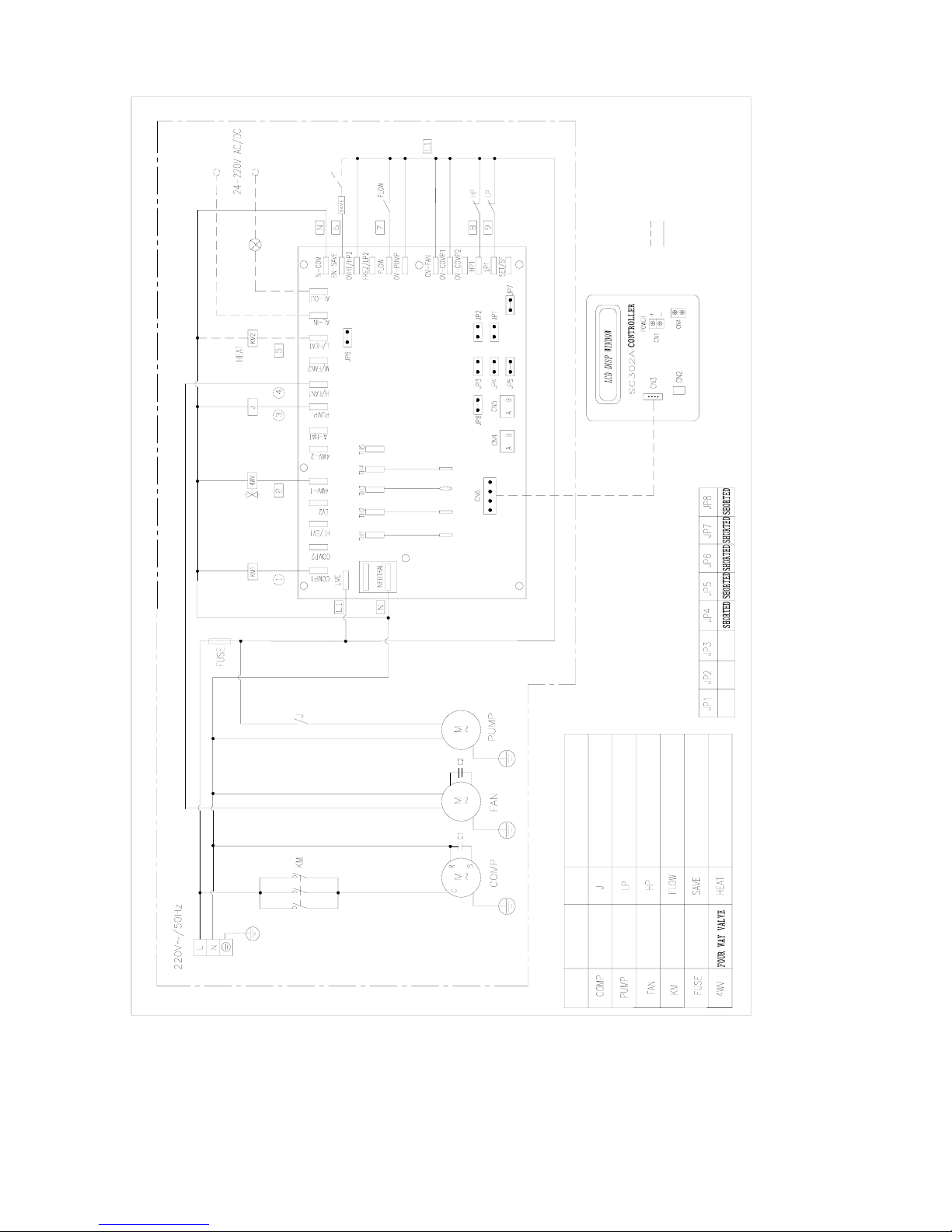

Wiring Diagrams

Model: MAC030/035C

W

A

T

E

R

F

L

O

W

S

W

I

T

C

H

T

W

O

W

A

Y

V

A

L

V

E

I

N

T

E

R

L

O

C

K

R

E

L

A

Y

C

O

M

P

.

L

O

W

P

R

E

S

S

U

R

E

S

W

I

T

C

H

W

H

I

T

E

C

O

M

P

.

H

I

G

H

P

R

E

S

S

U

R

E

S

W

I

T

C

H

S

Y

M

B

O

L

R

E

D

B

L

U

E

B

L

U

E

W

A

T

E

R

P

U

M

P

D

E

S

C

R

I

P

T

I

O

N

C

O

M

P

R

E

S

S

O

R

F

A

N

S

Y

M

B

O

L

F

U

S

E

(

1

0

A

)

C

O

N

T

A

C

T

O

R

J

U

M

P

E

R

S

S

E

T

T

I

N

G

:

W

H

I

T

E

B

L

A

C

K

B

L

U

E

R

E

D

B

L

U

E

R

E

D

D

E

S

C

R

I

P

T

I

O

N

R

E

TUR

N WAT

E

R

TE

M

P.

SENSO

R

S

U

P

PLY W

A

T

E

R T

E

MP.

SEN

S

O

R

A

L

A

R

M

I

N

D

I

C

A

T

O

R

C

O

N

T

R

O

L

M

O

D

U

L

E

R

E

TUR

N AIR

T

E

MP.

SENS

O

R

M

C

H

0

3

A

O

P

E

N

3

、

W

h

e

n

J

P

6

b

e

i

n

g

c

l

o

s

e

d

,

2

、

F

a

c

t

o

r

y

W

i

r

e

d

1

、

F

i

e

l

d

W

i

r

i

n

g

;

N

O

T

E

S

:

f

u

n

c

t

i

o

n

w

i

l

l

b

e

i

n

a

c

t

i

v

a

t

e

d

t

h

e

t

w

o

w

a

y

v

a

l

v

e

i

n

t

e

r

l

o

c

k

D

r

a

w

i

n

g

N

O

.

:

M

0

8

0

2

4

3

2

5

0

4

6

O

P

E

N

O

P

E

N

O

P

E

N

O

P

E

N

Page 24

Page 26

Model: MAC030/035CR

R

E

D

B

L

U

E

B

L

U

E

R

E

D

B

L

U

E

R

E

D

B

L

U

E

W

H

I

T

E

B

L

A

C

K

W

H

I

T

E

D

E

F

R

O

S

T

I

N

G

T

E

M

P

.

S

E

N

S

O

R

R

E

T

U

R

N

A

I

R

T

E

M

P

.

S

E

N

S

O

R

S

U

P

P

L

Y

W

A

T

E

R

T

E

M

P

.

S

E

N

S

O

R

R

E

T

U

R

N

W

A

T

E

R

T

E

M

P

.

S

E

N

S

O

R

A

L

A

R

M

I

N

D

I

C

A

T

O

R

C

O

N

T

R

O

L

M

O

D

U

L

E

M

C

H

0

3

A

R

E

L

A

Y

C

O

M

P

.

L

O

W

P

R

E

S

S

U

R

E

S

W

I

T

C

H

C

O

M

P

.

H

I

G

H

P

R

E

S

S

U

R

E

S

W

I

T

C

H

W

A

T

E

R

F

L

O

W

S

W

I

T

C

H

T

W

O

W

A

Y

V

A

L

V

E

I

N

T

E

R

L

O

C

K

S

Y

M

B

O

L

D

E

S

C

R

I

P

T

I

O

N

S

Y

M

B

O

L

D

E

S

C

R

I

P

T

I

O

N

C

O

M

P

R

E

S

S

O

R

W

A

T

E

R

P

U

M

P

F

A

N

C

O

N

T

A

C

T

O

R

F

U

S

E

(

1

0

A

)

J

U

M

P

E

R

S

S

E

T

T

I

N

G

:

A

U

X

I

L

I

A

R

Y

H

E

A

T

E

R

O

P

E

N

O

P

E

N

O

P

E

N

D

r

a

w

i

n

g

N

O

.

:

M

0

8

0

2

4

3

2

5

0

4

5

3

、

W

h

e

n

J

P

6

b

e

i

n

g

c

l

o

s

e

d

,

2

、

F

a

c

t

o

r

y

W

i

r

e

d

1

、

F

i

e

l

d

W

i

r

i

n

g

;

N

O

T

E

S

:

f

u

n

c

t

i

o

n

w

i

l

l

b

e

i

n

a

c

t

i

v

a

t

e

d

t

h

e

t

w

o

w

a

y

v

a

l

v

e

i

n

t

e

r

l

o

c

k

Page 25

Page 27

Model: MAC040/050C

R

E

T

U

R

N

A

I

R

T

E

M

P

.

S

E

N

S

O

R

S

U

P

P

L

Y

W

A

T

E

R

T

E

M

P

.

S

E

N

S

O

R

R

E

T

U

R

N

W

A

T

E

R

T

E

M

P

.

S

E

N

S

O

R

Y

E

L

.

R

E

D

B

L

A

C

K

R

E

D

B

L

A

C

K

B

L

U

E

Y

E

L

.

C

O

N

T

R

O

L

M

O

D

U

L

E

M

C

H

0

3

A

A

L

A

R

M

I

N

D

I

C

A

T

O

R

R

E

L

A

Y

A

M

P

S

T

H

E

R

M

A

L

O

V

E

R

L

O

A

D

1

0

.

5

A

S

Y

M

B

O

L

S

Y

M

B

O

L

D

E

S

C

R

I

P

T

I

O

N

C

O

M

P

R

E

S

S

O

R

W

H

I

T

E

S

Y

M

B

O

L

D

E

S

C

R

I

P

T

I

O

N

R

E

L

A

Y

D

E

S

C

R

I

P

T

I

O

N

C

A

P

A

C

I

T

O

R

F

A

N

M

O

T

O

R

W

A

T

E

R

P

U

M

P

C

O

N

T

A

C

T

O

R

W

A

T

E

R

F

L

O

W

S

W

I

T

C

H

M

A

C

0

5

0

C

F

U

S

E

(

1

0

A

)

M

A

C

0

4

0

C

M

O

D

E

L

N

O

T

E

S

:

O

P

E

N

J

U

M

P

E

R

S

S

E

T

T

I

N

G

:

9

.

6

A

D

r

a

w

i

n

g

N

O

.

:

M

0

8

0

2

4

3

2

5

0

7

6

f

u

n

c

t

i

o

n

w

i

l

l

b

e

i

n

v

a

l

i

d

a

t

e

d

1

、

F

i

e

l

d

W

i

r

i

n

g

;

2

、

F

a

c

t

o

r

y

W

i

r

e

d

3

、

W

h

e

n

J

P

6

b

e

i

n

g

c

l

o

s

e

d

,

t

h

e

t

w

o

w

a

y

v

a

l

v

e

i

n

t

e

r

l

o

c

k

O

P

E

N

O

P

E

N

O

P

E

N

O

P

E

N

Page 26

Page 28

Model: MAC040/050CR

D

E

F

R

O

S

T

I

N

G

T

E

M

P

.

S

E

N

S

O

R

R

E

T

U

R

N

A

I

R

T

E

M

P

.

S

E

N

S

O

R

S

U

P

P

L

Y

W

A

T

E

R

T

E

M

P

.

S

E

N

S

O

R

R

E

T

U

R

N

W

A

T

E

R

T

E

M

P

.

S

E

N

S

O

R

Y

E

L

.

R

E

D

B

L

A

C

K

R

E

D

B

L

U

E

B

L

A

C

K

Y

E

L

.

C

O

N

T

R

O

L

M

O

D

U

L

E

M

C

H

0

3

A

A

L

A

R

M

I

N

D

I

C

A

T

O

R

1

0

.

5

A

S

Y

M

B

O

L

D

E

S

C

R

I

P

T

I

O

N

S

Y

M

B

O

L

D

E

S

C

R

I

P

T

I

O

N

C

O

M

P

R

E

S

S

O

R

W

H

I

T

E

S

Y

M

B

O

L

R

E

L

A

Y

D

E

S

C

R

I

P

T

I

O

N

C

A

P

A

C

I

T

O

R

F

A

N

M

O

T

O

R

W

A

T

E

R

P

U

M

P

C

O

N

T

A

C

T

O

R

F

U

S

E

(

1

0

A

)

A

U

X

I

L

I

A

R

Y

H

E

A

T

E

R

M

A

C

0

5

0

C

R

C

O

M

P

.

H

I

G

H

P

R

E

S

S

U

R

E

S

W

I

T

C

H

C

O

M

P

.

L

O

W

P

R

E

S

S

U

R

E

S

W

I

T

C

H

M

O

D

E

L

M

A

C

0

4

0

C

R

N

O

T

E

S

:

O

P

E

N

O

P

E

N

O

P

E

N

O

P

E

N

O

P

E

N

J

U

M

P

E

R

S

S

E

T

T

I

N

G

:

9

.

6

A

D

r

a

w

i

n

g

N

O

.

:

M

0

8

0

2

4

3

2

5

0

7

2

f

u

n

c

t

i

o

n

w

i

l

l

b

e

i

n

a

c

t

i

v

a

t

e

d

t

h

e

t

w

o

w

a

y

v

a

l

v

e

i

n

t

e

r

l

o

c

k

1

、

F

i

e

l

d

W

i

r

i

n

g

;

2

、

F

a

c

t

o

r

y

W

i

r

e

d

3

、

W

h

e

n

J

P

6

b

e

i

n

g

c

l

o

s

e

d

,

T

H

E

R

M

A

L

O

V

E

R

L

O

A

D

R

E

L

A

Y

A

M

P

S

Page 27

Page 29

Model: MAC065C/070C

R

E

T

U

R

N

W

A

T

E

R

T

E

M

P

.

S

E

N

S

O

R

S

U

P

P

L

Y

W

A

T

E

R

T

E

M

P

.

S

E

N

S

O

R

R

E

T

U

R

N

A

I

R

T

E

M

P

.

S

E

N

S

O

R

Y

E

L

.

R

E

D

R

E

D

B

L

U

E

Y

E

L

.

B

L

U

E

Y

E

L

.

B

L

A

C

K

I

N

D

I

C

A

T

O

R

A

L

A

R

M

M

C

H

0

3

A

C

O