Page 1

MWM - G - 2009

Wall Mounted Split Systems

Models:

MWM007G/GR

MWM009G/GR

MWM010G/GR

MWM015G/GR

MWM020G/GR

MWM025G/GR

MWM301/301R

M5WM007G/GR

M5WM009G/GR

M5WM010G/GR

M5WM015G/GR

M5WM020G/GR

M5WM025G/GR

M5WM311/301R

Catalog

Catalog

MWM - G - 2007

Wall Mounted Split Systems

Catalog

MWM - G2 - 2010

Models: MWM 07G2 M5WM 07G2/G2R

MWM 09G2/G2R M5WM 09G2/G2R

MWM 10G2/G2R M5WM 10G2/G2R

MWM 152G/G2R M5WM 15G2/G2R

MWM 20G2/G2R M5WM 20G2/G2R

MWM 25G2/G2R M5WM 25G2/G2R

MWM 030F/FR M5WM 031F/030FR

Page 2

MWM-G2-2010 Table of Contents

Contents

Nomenclature......................................................................................................................1

Indoor Unit .....................................................................................................................1

Outdoor Unit ..................................................................................................................2

Product Line-Up ..................................................................................................................3

Features...............................................................................................................................9

Application Information ...................................................................................................10

Operating Range .........................................................................................................10

Refrigerant Circuit Diagram .........................................................................................11

Controller ....................................................................................................................19

Installation Guideline ...................................................................................................20

Sound Data ........................................................................................................................34

Sound Pressure Level .................................................................................................34

NC Curve .....................................................................................................................35

Engineering & Physical Data ........................................................................................... 38

General Data ...............................................................................................................38

Components Data ........................................................................................................55

Performance Data ............................................................................................................. 72

Calculation Steps .........................................................................................................72

Performance Data .......................................................................................................78

Outline and Dimension ..................................................................................................133

Electrical Data ................................................................................................................. 138

Wiring Diagram ...............................................................................................................146

Service and Maintenance...............................................................................................159

Troubleshooting .............................................................................................................161

Exploded View and Part List .........................................................................................171

“McQuay” is a registered trademark of McQuay International. All rights reserved.

© 2010 McQuay International. All rights reserved throughout the world.

Bulletin illustrations cover the general appearance of McQuay International products at the time of publication.

We reserve the right to change design and construction specifi cations at any time without notice.

2

Page 3

Nomenclature MWM-G2-2010

Nomenclature

Indoor Unit

M WM 10 G2 R

Brand

M

Refrigerant

“ “

4

5

Model Name

WM : Wall Mounted

: McQuay

: Omitted if R22

: R407C

: R410A

Capacity Index

10

20

Chassis

G2

Model Type

“ “

R

: 10,000 Btu/h

: 20,000 Btu/h

: G + Series

: Omitted if cooling only

: Heatpump

1

Page 4

MWM-G2-2010 Nomenclature

Outdoor Unit

M 5 LC 010 C R

Brand

M

Refrigerant

“ “

4

5

Model Name

LC : Single Split Condensing Unit

Capacity Index

010

020

: McQuay

: Omitted if R22

: R407C

: R410A

: 10,000 Btu/h

: 20,000 Btu/h

Chassis

C

Model Type

“ “

R

: C Series

: Omitted if cooling only

: Heatpump

2

Page 5

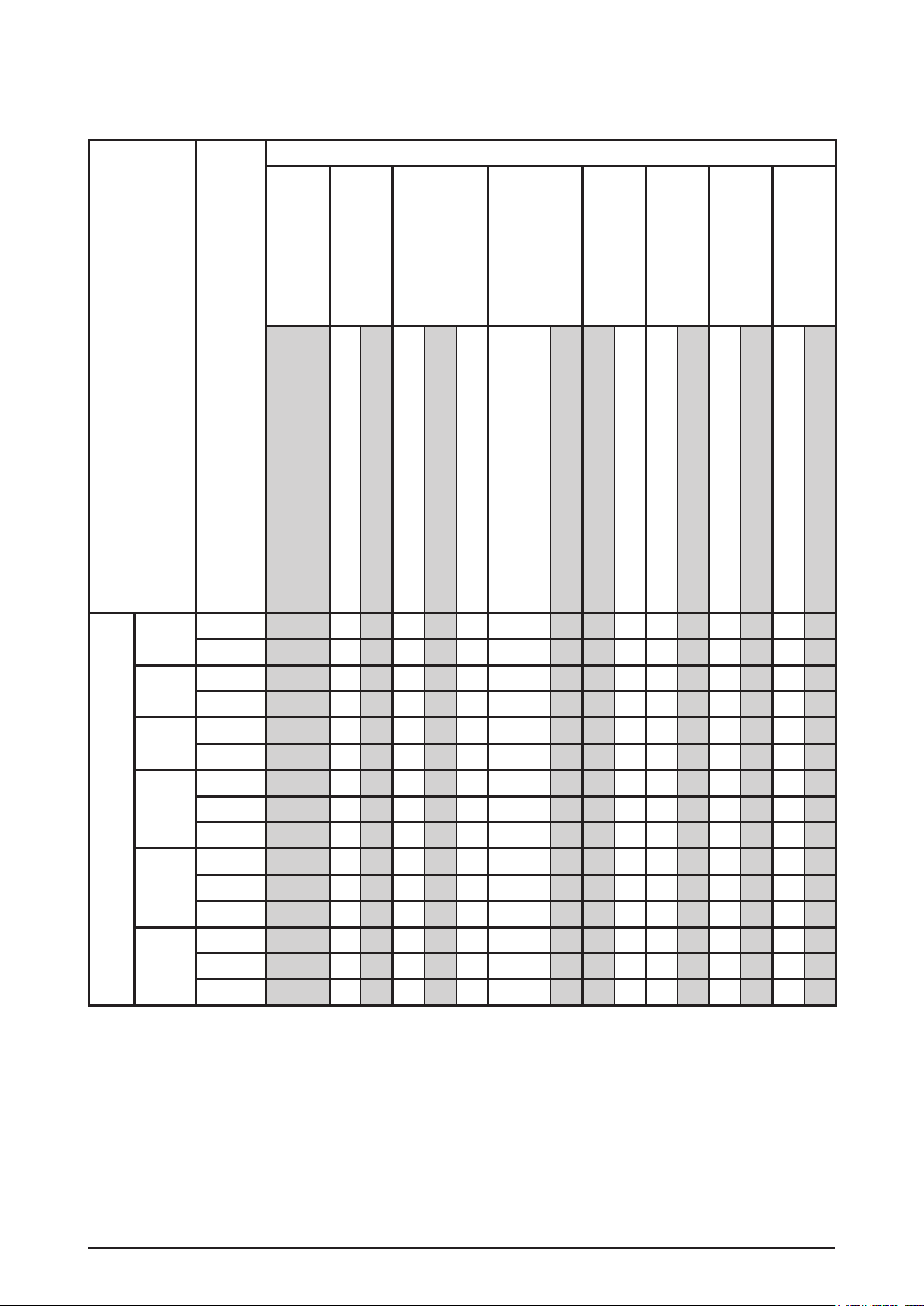

Product Line-Up MWM-G2-2010

Product Line-Up

Indoor Unit

MWM-G2 Series

Classication

PCB

MWM

Nomenclature

L2.0

07G2 ACICE X X X X X X X

09G2 ACICE X X X X X X X

10G2 ACICE X X X X X X X

15G2 ACICE X X X X X X X

20G2 ACICE X X X X X X X

COOLING

25G2 ACICE X X X X X X X

030F AFBF X X X X X X

Handset

G17

Ionizer Filter

Saranet Filter

Air Purication

Negative Ionizer

Nano Technology Air Filteration

C

Grille

CE

Marking

Others

Orice Kit

3

09G2R ACICE X X X X X X X

10G2R ACICE X X X X X X X

15G2R ACICE X X X X X X X

20G2R ACICE X X X X X X X

HEATPUMP

25G2R ACICE X X X X X X X

030FR AFAE X X X X X

Page 6

MWM-G2-2010 Product Line-Up

Indoor Unit

M5WM-G2 Series

Classication

PCB

M5WM

Nomenclature

L2.0

07G2 ACICE X X X X X X X

09G2 ACICE X X X X X X X

10G2 ACICE X X X X X X X

15G2 ACICE X X X X X X X

20G2 ACICE X X X X X X X

COOLING

25G2 ACICE X X X X X X X

031F AFCE X X X X X

Handset

G17

Filter

Ionizer

Saranet Filter

Air Purication

Negative Ionizer

Nano Technology Air Filteration

C

Grille

Marking

CE

Others

07G2R ACICE X X X X X X X

09G2R ACICE X X X X X X X

10G2R ACICE X X X X X X X

15G2R ACICE X X X X X X X

20G2R ACICE X X X X X X X

HEATPUMP

25G2R ACICE X X X X X X X

030FR AFCE X X X X X

4

Page 7

Product Line-Up MWM-G2-2010

Outdoor Unit

MLC-C Series

Classication

MLC

007C

009C

010C

015C

018C

COOLING

020C

025C

028C

030C

Nomenclature

ACPOE

ACPIE

ACPOD

ACPID

ACPOB

ACPIB

ACPOD

ACPID

ACPOD

ACPID

ACPBD

ACPOD

ACPID

ACPBD

ACPHB

ACPOD

ACPID

ACPBD

ACPHB

ACHOB

ACHIB

ACHBB

AFGE

PCB

Refrigerant Control

Cap Tube

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X X

X X X X

X X X X

X X X X X

X X X X X X

X X X X

X X X X

X X X X X

X X X X X X

FIN

Gold Coated

X X X

Bare

X X X

X X X X

X X X X X X

Safety Devices

Contactor

High Pressure Switch

Low Pressure Switch

Scroll

Compressor

Rotary

Marking

CE

Others

Back Panel Grille

Special

Super Tropical Specication

5

Page 8

MWM-G2-2010 Product Line-Up

Outdoor Unit

MLC-C Series

Classication

MLC

009CR

010CR

015CR

018CR

020CR

HEATPUMP

025CR

028CR

030CR

Nomenclature

ACPOD

ACPID

ACPOB

ACPIB

ACPOA

ACPIA

ACPOD

ACPID

ACPOD

ACPID

ACPHB

ACPOD

ACPID

ACHIB

ACHOB

ACHIB

AFFB

PCB

Refrigerant Control

Cap Tube

TXV

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X X

X X X X

X X X X

X X X X X

X X X X

X X X X

X X X X X X X

FIN

Gold Coated

Bare

Safety Devices

Contactor

High Prerssure Switch

Low Pressure Switch

Scroll

Compressor

Rotary

Marking

CE

Others

Drain Elbow

Special

Super Tropical Specication

6

Page 9

Product Line-Up MWM-G2-2010

Outdoor Unit

M5LC-C Series

Classication

M5LC

007C

009C

015C

020C

COOLING

025C

028C

Nomenclature

ACPOE

ACPIE

ACPOB

ACPIB

ACPOC

ACPIC

ACPOC

ACPIC

ACPGC

FCPOC

FCPGC

ACPOC

ACPIC

ACPGC

FCPOC

FCPGC

ACPOA

ACPIA

ACPGA

FCPOA

FCPGA

PCB

Refrigerant Control

Cap Tube

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X X

X X X X X X

X X X X X X X

X X X X

X X X X

X X X X X

X X X X X X

X X X X X X X

X X X X

X X X X

X X X X X

X X X X X X

X X X X X X X

FIN

Gold Coated

Bare

Safety Devices

Contactor

Phase Sequencer

Compressor

Rotary

Marking

CE

Others

Low Ambient Kit

Drain Elbow

Special

7

Page 10

MWM-G2-2010 Product Line-Up

Outdoor Unit

M5LC-C Series

Classication

M5LC

007CR

010CR

015CR

020CR

HEATPUMP

025CR

028CR

Nomenclature

ACPOE

ACPIE

ACPOB

ACPIB

ACPOC

ACPIC

ACPOC

ACPIC

FCPOC

ACPOC

ACPIC

FCPOC

ACPOA

ACPIA

FCPOA

PCB

Refrigerant Control

Cap Tube

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X

X X X X X X X

X X X X

X X X X

X X X X X X X

X X X X

X X X X

X X X X X X X

FIN

Gold Coated

Bare

Safety Devices

Contactor

Phase Sequencer

Compressor

Rotary

Marking

CE

Others

Low Ambient Kit

Drain Elbow

Special

8

Page 11

Features MWM-G2-2010

Features

Excellent Air Distribution

Air discharge direction can be adjusted in four directions, manually or automatically by using LCD remote

control. The new double louver design with automatic air swing function fully optimizes the room comfort by

distributing the air evenly to the room. The unique skew fan design with larger diameter creates better air ow

to the operating environment.

Self Diagnosis

This function is able to detect and to disgnose any faults occuring in the system by blinking of the LED lights.

Simplify and ease for troubleshooting.

Facilitated Maintenance Ensure

The new design of air discharge housing where by the fan blower can be easily accessed by just losing

two screws on the unit to provides a exible, faster and easier way to clean up the fan blower and ionizer.

Maintenance is easy for electrical components, piping and wiring as these are all easily accessible by merely

removing front plastic panel.

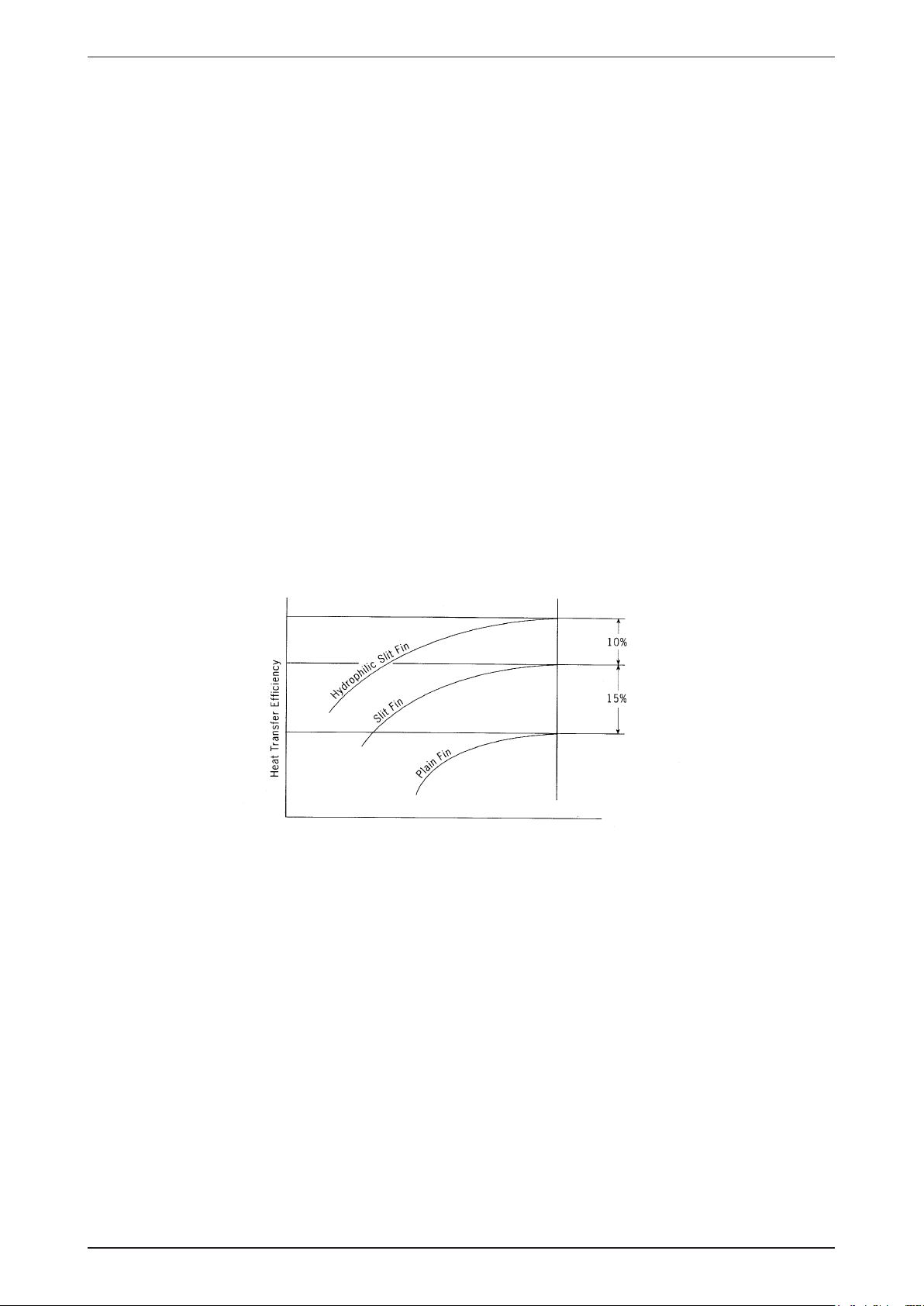

High Efciency Heat Exchanger

The compact design of the 3-fold structure heat exchanger provides a large surface are for better and efcient

heat exchange. The unique Hydrophilic slit n has greatly improved the air ow and the contact surfaces with

the air thus to boost the cooling capacity.

Wireless Remote Controller

The compact LCD transmitter is able to operate the air conditioner unit within the distance of 9 meters.

•

Fan motor speed can be set at low / medium / high or automatic.

•

Sleep mode auto control will gradually increase or decrease the setting temperature to provide a

•

comfortable surrounding for sleeping.

Air ow direction can be controlled automatically.

•

Room temperature is controlled by electronic thermostat.

•

The real time timer allows the air conditioner to be switched on and off automatically based on user

•

settings.

Turbo mode function is available to enables the required set temperature to be achieved in a short time

•

Personalized setting allows user to preset and store 2 groups of personal settings (including timer setting)

•

in the handset.

Auto random restart is a function where by when there is power failure occurred during operation, the unit

•

will automatically restart as the last setting condition once the power is resumed.

Rotary Compressors

The ever popular rotary compressor is more energy efcient and has a higher output to weight ratio.

9

Page 12

MWM-G2-2010 Application Information

Note :

Standard operating range.

With Low ambient kit. (Optional item)

Please refer to local dealer for unit of this specification.

Indoor temp. (°CDB)

Cooling

Outdoor temp. (°CDB)

Indoor temp. (°CWB)

Outdoor temp. (°CDB)

Indoor temp. (°CWB)

Heating

Outdoor temp. (°CWB)

-9

16 21

6

30

-5

19

35

14

46

23

Standard

point

Low ambient kit

18

-5

19

35

14

46

23

Low ambient kit

Standard

point

Standard

point

! Caution :

The use of your air conditioner

outside the range of working

temperature and humidity can

result in serious failure.

Application Information

Operating Range

Ensure the operating temperature is in allowable range.

Cooling only

Heatpump

10

Page 13

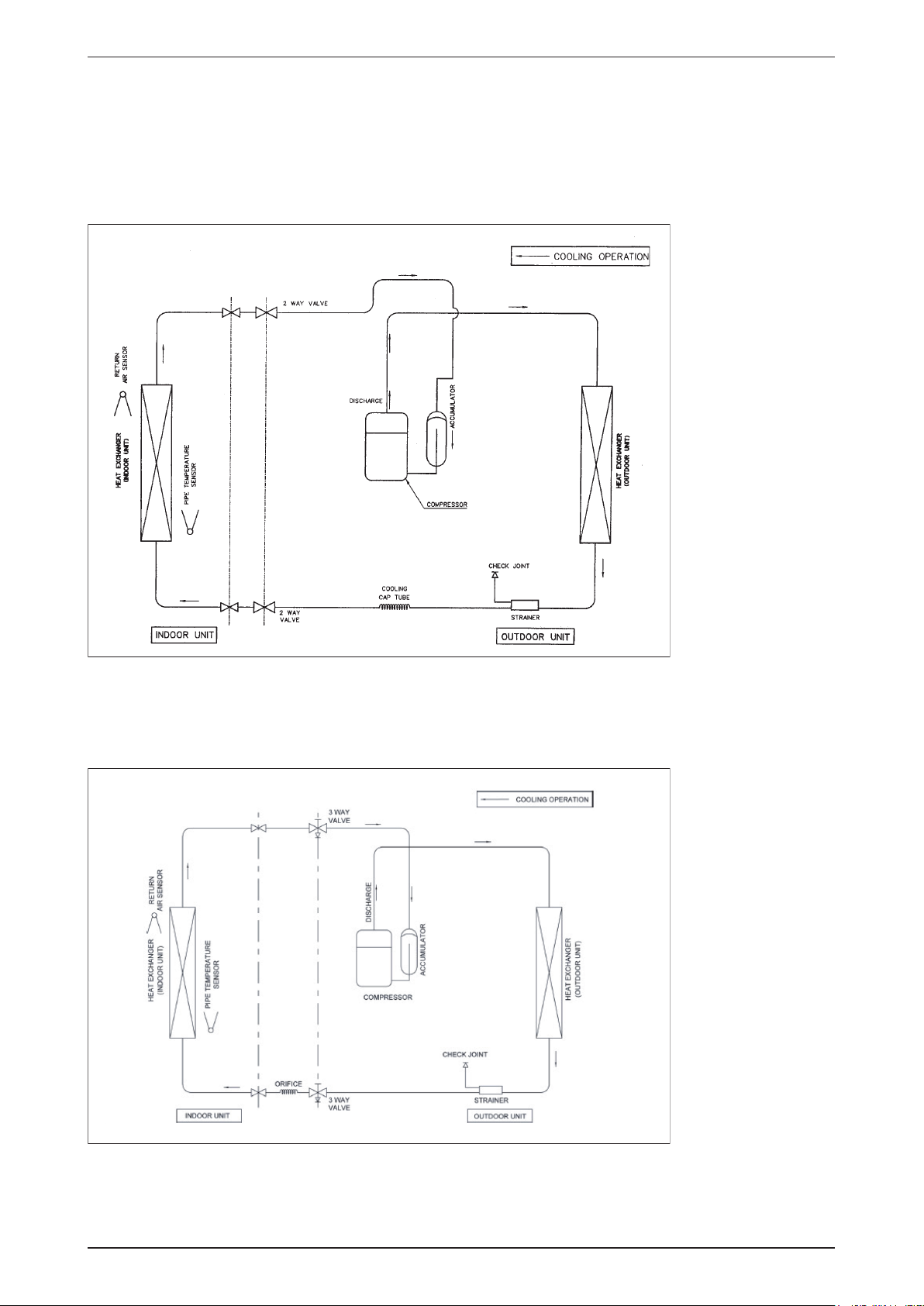

Application Information MWM-G2-2010

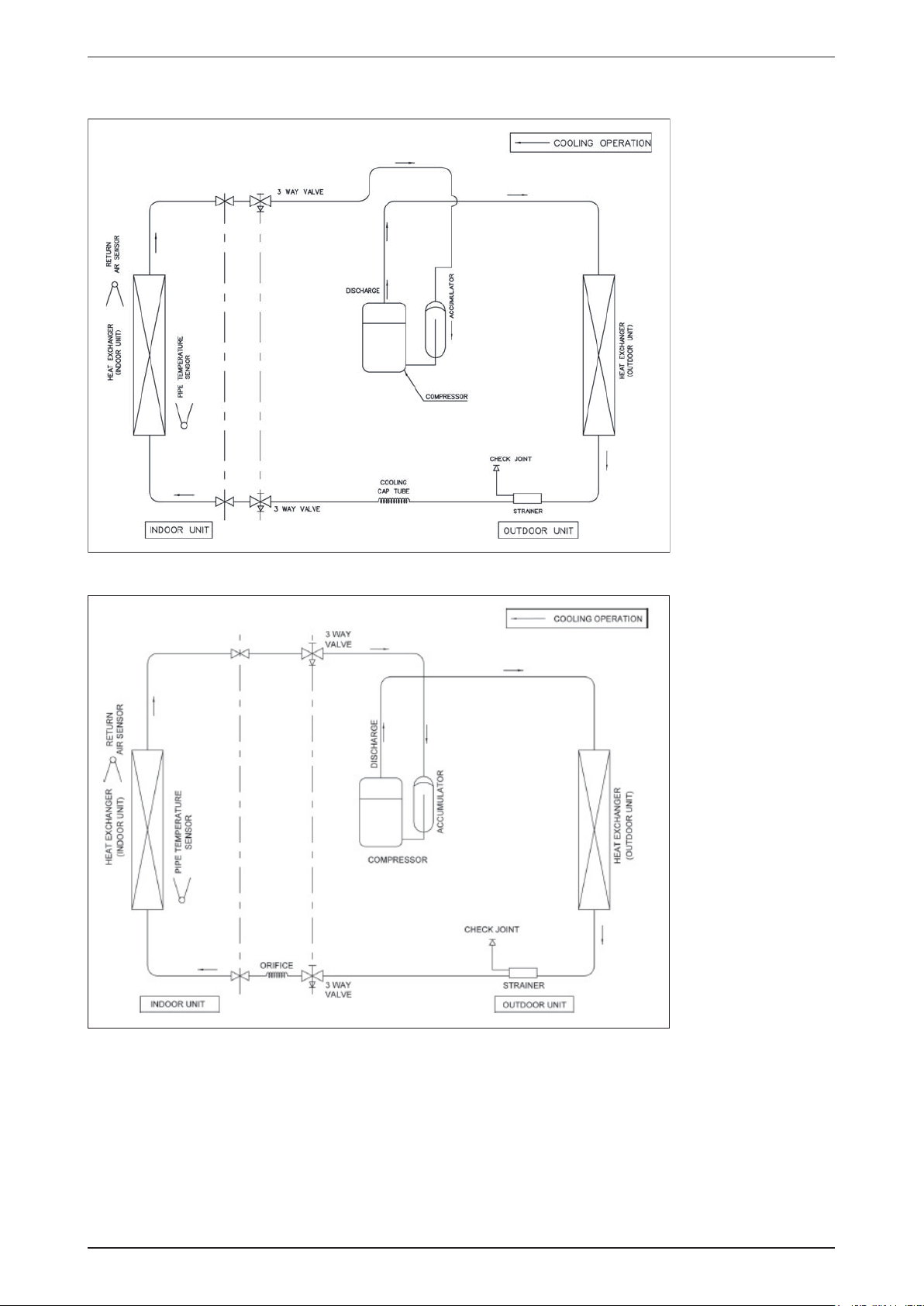

Refrigerant Circuit Diagram

Model: MWM07G2 - MLC007C M5WM07G2 - M5LC007C

MWM09G2 - MLC009C M5WM09G2 - M5LC009C

MWM10G2 - MLC010C M5WM10G2 - M5LC010C

MWM15G2 - MLC015C M5WM15G2 - M5LC015C

Model: MWM20G2 - MLC018C M5WM20G2 - M5LC020C

MWM20G2 - MLC020C M5WM25G2 - M5LC025C

11

Page 14

MWM-G2-2010 Application Information

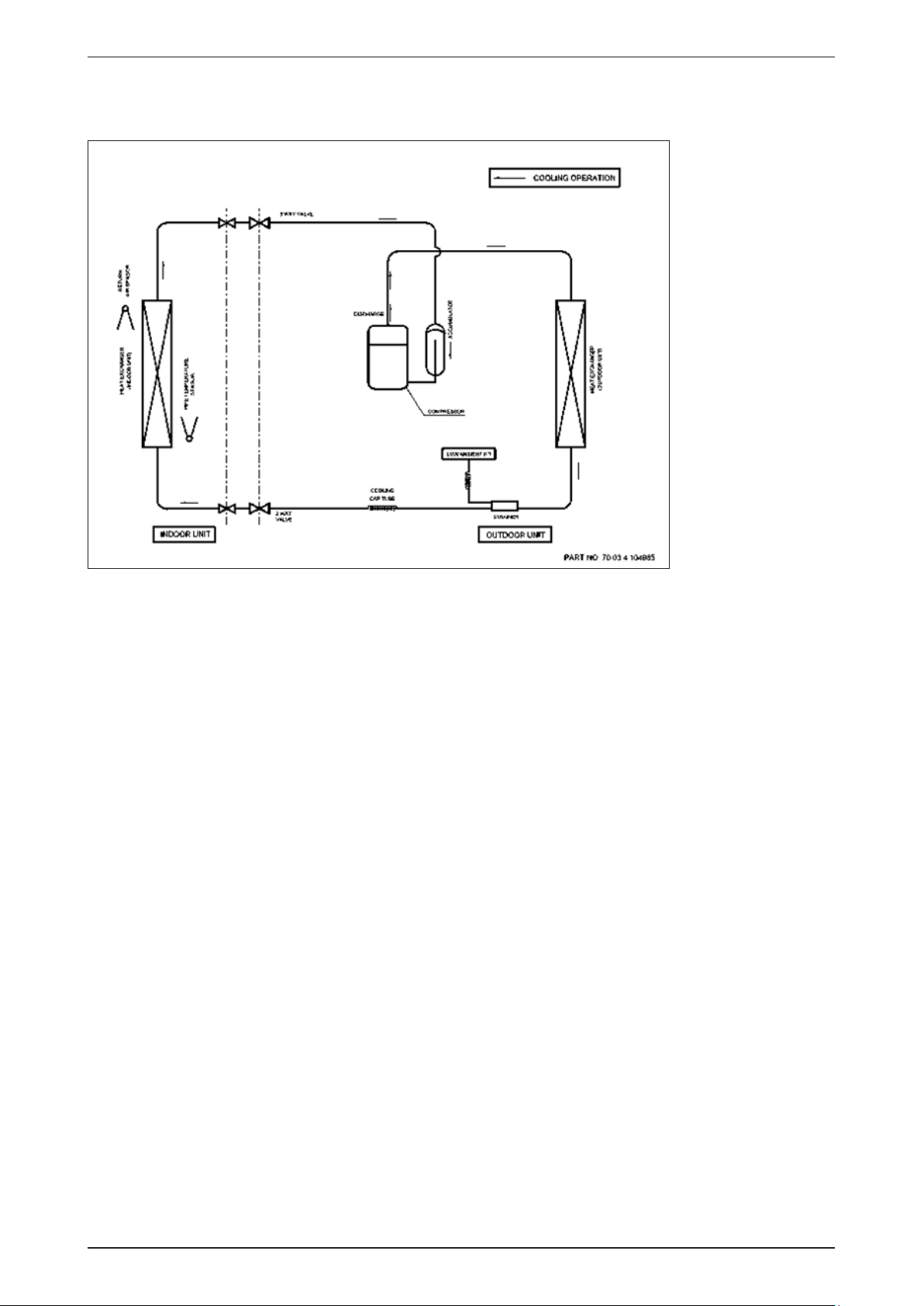

Model: MWM25G2 - MLC025C M5WM031F - M5LC028C

Model: MWM030F - MLC028C

12

Page 15

Application Information MWM-G2-2010

Model: MWM030F – MLC030C

13

Page 16

MWM-G2-2010 Application Information

Model: M5WM20/25G2 - M5LC020/025C (With Low Ambient Kit)

M5WM030F - M5LC028C (With Low Ambient Kit)

14

Page 17

Application Information MWM-G2-2010

Model: MWM09G2R - MLC009CR M5WM07G2R - M5LC007CR

Model: MWM10G2R - MLC010CR M5WM09G2R - M5LC010CR

M5WM10G2R - M5LC010CR

15

Page 18

MWM-G2-2010 Application Information

Model: MWM15G2R - MLC015CR M5WM15G2R - M5LC015CR

Model: MWM20G2R - MLC020CR M5WM20G2R - M5LC020CR

M5WM25G2R - M5LC025CR

16

Page 19

Application Information MWM-G2-2010

Model: MWM030FR - MLC028CR M5WM030FR - M5LC028CR

Model: MWM25G2R - MLC025CR

17

Page 20

MWM-G2-2010 Application Information

Model: MWM030FR – MLC030CR

18

Page 21

Application Information MWM-G2-2010

MODE

P1 P2

SLEEP

SET

CANCEL

ON TIMER

SET

CANCEL

OFF TIMER

6

12

15

11

13

14

7

4

3

10

9

2

1

8

5

Controller

G17

Operation Guide

1 Transmission Source

The source where the signal will be transmitted.•

Signal Transmission Indication

2

Blink to conrm that the last setting has been transmitted

•

to the unit.

Temperature Setting

3

To set the desired room temperature, press the v or V

•

button to increase orde crease the set temperature.

The temperature setting range is from 16°C to 30°C

•

(optional setting 20°C to 30°C).

Personalize Setting

4

Press and hold for 3s, then will blink. Press again to

•

cycle between and

Set the desire setting, then leave the hand set for 4s

•

without pressing any key and it will save the setting into the

programme.

Press once to activate the P1 setting, press again to

•

cycle between P1 and P2.

Press any key to deactivate the personalize setting.

•

5

Automatic Air Swing (optional)

Press the SWING button to activate the automatic air

•

swing function.

To distribute the air to a specic direction, press the

•

SWING button and wait until the louver move to the

desired direction and press the button once again.

Silent Function

6

Press for quiet operation.

•

Fan speed turn to minimum speed.

•

Press again to deactivate the function.

•

Sleep Mode Setting

7

Press the SLEEP button will activate the sleep mode

•

function. This function is available under COOL, HEAT and

AUTO mode.

When the unit is operating under cooling mode, the set

•

temperature is increased by 0.5°C after 30 minutes, 1°C

after an hour, and 2°C after 2 hours.

When the unit is operating under heating mode, the set

•

temperature is decreased by 1°C after 30 minutes, 2°C

after an hour, and 3°C after 2 hours.

19

8 Operating Mode

Press the MODE button to select the type of operating

•

mode.

For cooling only unit, the available modes are: COOL (),

•

DRY () and FAN ( ).

9

Fan Speed Selection

Press the button continuously will toggle the fan speed

•

in the following order:

Low p Med p High p Auto

Stop pressing when the desired fan speed appears on the

•

display screen.

10

“ON/OFF” Button

Press one to start the air conditioner unit.

•

Press again to stop the unit.

•

11

Timer Cancel

Press the TIMER CANCEL button to cancel the on timer

•

setting.

12

OFF Timer Setting

Press the OFF TIMER button will activate the off timer

•

function.

Set the desired off time by pressing the OFF TIMER button

•

continuously.

13

ON Timer Setting

Press the ON TIMER button will activate the on timer

•

function.

Set the desired on time by pressing the ON TIMER

•

button continuously. If the timer is set to 7.30am, the air

conditioner will turn on at 7.30am sharp.

14

Turbo Function

Press for fast cooling.

•

Fan speed turn to maximum speed.

•

Press again to deactivate the function.

•

Clock Time Setting

15

Press and hold to set the clock time.•

Page 22

MWM-G2-2010 Application Information

Installation Guideline

Safety Precautions

WARNING

•

Installation and maintenance should be performed by

qualified persons who are familiar with local code and

regulation, and experienced with this type of appliance.

•

All field wiring must be installed in accordance with the

national wiring regulation.

•

Ensure that the rated voltage of the unit corresponds

to that of the name plate before commencing wiring

work according to the wiring diagram.

•

The unit must be GROUNDED to prevent possible

hazard due to insulation failure.

•

All electrical wiring must not touch the refrigerant

piping or any moving parts of the fan motors.

•

Confirm that the unit has been switched OFF before

installing or servicing the unit.

•

Disconnect from the main power supply before

servicing the air conditioner unit.

•

DO NOT pull out the power cord when the power is

ON. This may cause serious electrical shocks which

may result in fire hazards.

•

Keep the indoor and outdoor units, power cable and

transmission wiring, at least 1m from TVs and radios,

to prevent distorted pictures and static. {Depending on

the type and source of the electrical waves, static may

be heard even when more than 1m away}.

CAUTION

Please take note of the following important points

when installing.

Do not install the unit where leakage of ammable

•

gas may occur.

If gas leaks and accumulates around the unit, it

may cause re ignition.

Ensure that drainage piping is connected properly.

•

If the drainage piping is not connected properly,

it may cause water leakage which will dampen

the furniture.

Do not overcharge the unit.

•

This unit is factory pre-charged. Overcharge will

cause over-current or damage to the compressor.

Ensure that the unit’s panel is closed after service

•

or installation.

Unsecured panels will cause the unit to operate

noisily.

Sharp edges and coil surfaces are potential

•

locations which may cause injury hazards. Avoid

from being in contact with these places.

Before turning off the power supply, set the remote

•

controller’s ON/OFF switch to the “OFF” position

to prevent the nuisance tripping of the unit. If this is

not done, the unit’s fans will start turning automatically

when power resumes, posing a hazard to service

personnel or the user.

Do not operate any heating apparatus too close to the

•

air conditioner unit. This may cause the plastic panel to

melt or deform as a result of the excessive heat.

Ensure the color of wires of the outdoor unit and

•

the terminal markings are same to the indoors

respectively.

IMPORTANT

•

AIR CONDITIONER UNIT IN A LAUNDRY ROOM.

•

Do not use joined and twisted wires for incoming

•

power supply.

: DO NOT INSTALL OR USE THE

NOTICE

Disposal requirements

Your air conditioning product is marked with this symbol. This means that electrical and electronic products

shall not be mixed with unsorted household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of

the refrigerant, of oil and of other parts must be done by a qualied installer in accordance with relevant

local and national legislation. Air conditioners must be treated at a specialized treatment facility for re-use,

recycling and recovery. By ensuring this product is disposed of correctly, you will help to prevent potential

negative consequences for the environment and human health. Please contact the installer or local authority

for more information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant

local and national legislation.

20

Page 23

Application Information MWM-G2-2010

Indoor Unit

Outdoor Unit

Refrigerant Piping

Air Discharge

Nozzle

Air Intake

Drain Hose

Signal Receiver

Indicator Light

Air Intake

Grille

Back Housing

ON/OFF Switch

Front Frame

Air Filter

Installation Diagram

Before installing the unit, ensure that the power supply matches the power requirement of the airconditioner.•

Caution

21

Page 24

MWM-G2-2010 Application Information

Maintenance &

Servicing Space

Air Flow

Direction

50.0 mm

50.0 mm

mm0.05

Higher Than

Eye Level

Selection of Location and Space

Indoor Unit

Install the fan coil (indoor) unit at a location with the following requirements

Location is suitable for wiring, piping and drainage.

•

No obstruction of air ow into and out of unit where cooler air can be evenly distributed.(See g. 1)

•

Ensure that air discharge is not short circuited with air intake.

•

Ensure that wall is sufciently strong, rigid, at, perpendicular and vibration free.

•

Where air lter cassette can be slided in or out easily.

•

Where there is no danger of ammable gases.

•

Where there is no direct sunlight on unit.

•

Also to take into consideration a place for the installation of the Wireless LCD Remote Controller.

•

Do not install unit near the door waybecause excessive fresh air may causepanel condensation on the unit.•

Caution

22

Page 25

Application Information MWM-G2-2010

Outdoor Unit

As condensing temperature rises, evaporating temperature rises and cooling capacity drops. In order to achieve

maximum cooling capacity, the location selected for outdoor unit should fulll the following requirements :

Install the condensing (outdoor) unit in a way such that hot air distributed by the outdoor condensing unit

•

cannot bedrawn in again (as in the case of short circuit of hot discharge air). Allow sufcient space for

maintenance around the unit.

•

Ensure that there is no obstruction of air ow into or out of the unit. Remove obstacles which block air

intake ordischarge.

•

The location must be well ventilated, so that the unit can draw in and distribute plenty of air thus lowering

the condensing temperature.

•

A place capable of bearing the weight of the outdoor unit and isolating noise and vibration.

•

A place protected from direct sunlight. Otherwise use an awning for protection, if necessary.

•

The location must not be susceptible to dust or oil mist.

Installation Clearance

•

Outdoor units must be installed such that there is no short circuit of the hot discharge air or obstruction to

smooth airow. Select the coolest possible place where intake air should not be hotter than the outside

temperature (max. 45°C)

ALL MODELS A B C D

Minimum Distance 300 mm 1000 mm 300 mm 500 mm

CAUTION : If the condensing unit is operated in an atmosphere containing oils (including machine oils), salt (coastal area),

sulphide gas (near hot spring, oil renery plant), such substances may lead to failure of the unit.

Caution

If the condensing unit is operated in an atmosphere containing oils(including machine oils),salt(coastal area), sulphide

•

gas(near hot spring, oil renery plant), such substances may lead to failure of theunit.

23

Page 26

MWM-G2-2010 Application Information

A

Installation of Outdoor Unit

Condensed Water Disposal of Outdoor Unit (Heat Pump Unit Only)

There are 2 holes on the base of outdoor unit for condensed water to ow out. Insert the drain elbow toone

•

of the holes.

To install the drain elbow, rst insert one portion of the hook to the base (portion A), then pull the

•

drainelbow in the direction shown by the arrow while inserting the other portion to the base. After

installation,check to ensure that the drain elbow clings to base rmly.

If the unit is installed in a snowy and chilly area, condensed water may freeze in the base. In such case,

•

please remove plug at the bottom of unit to smooth the drainage.

24

Page 27

Application Information MWM-G2-2010

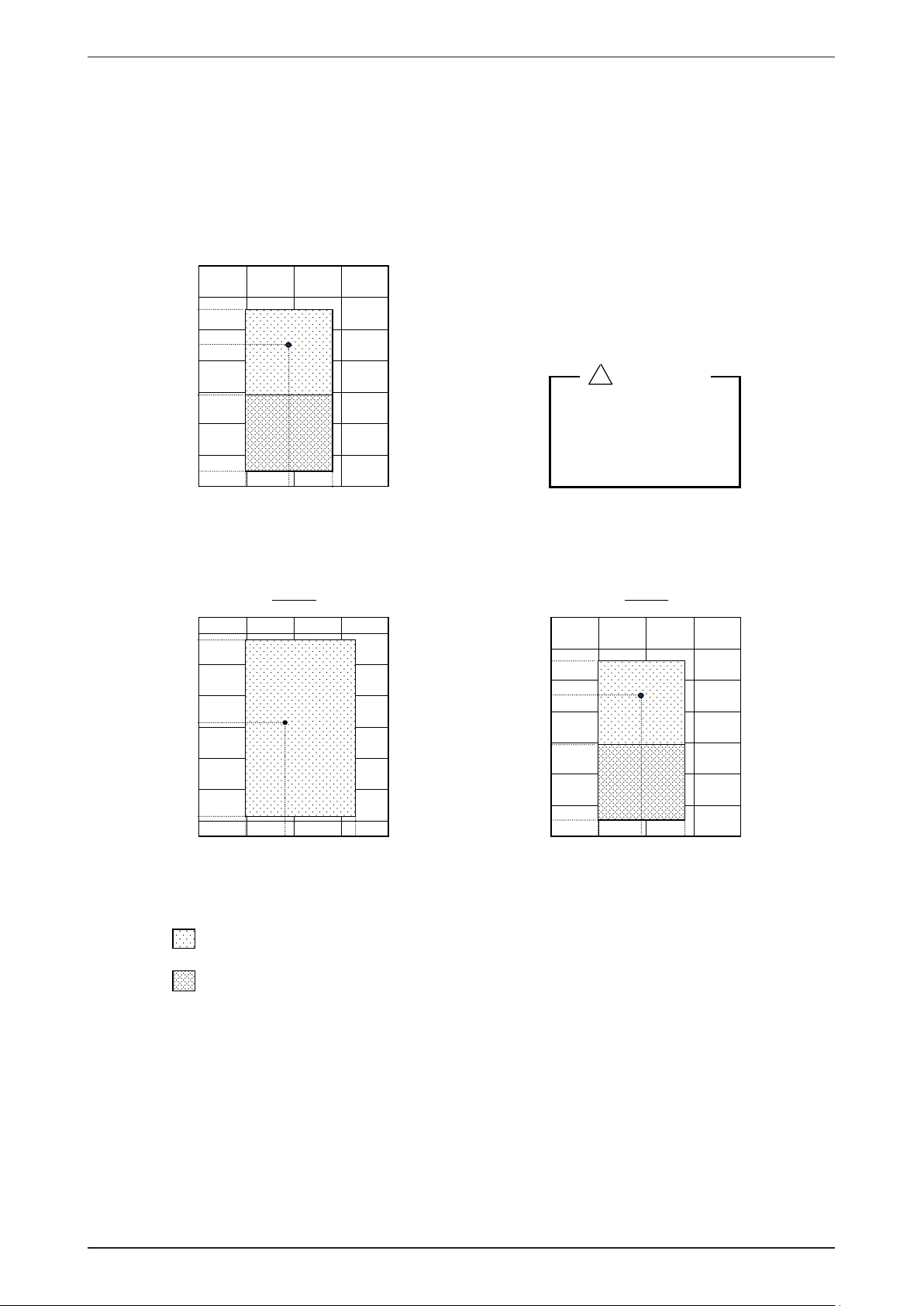

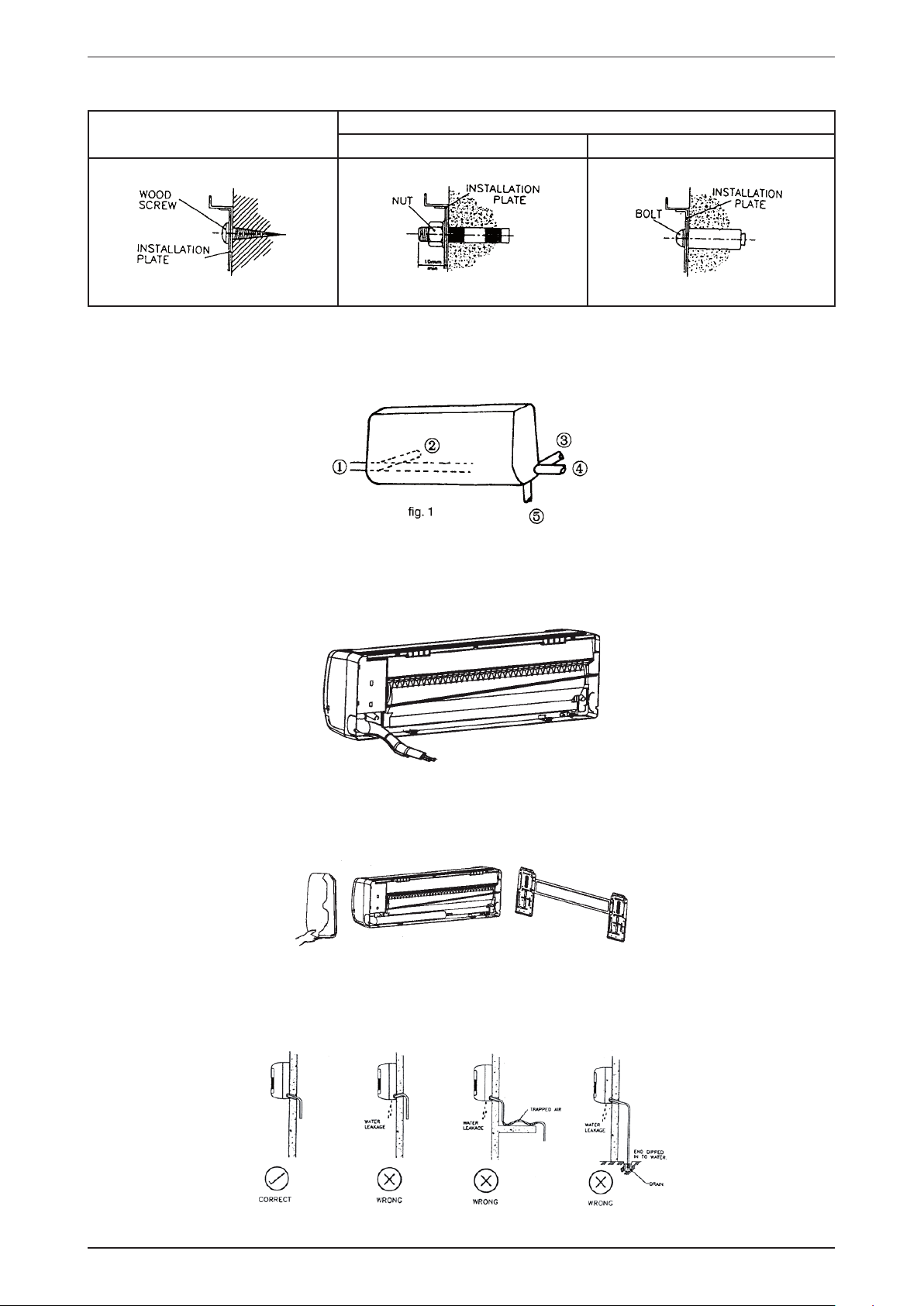

Drilling Holes and Mounting Installation Installation Plate

Caution

Please check the unit weight for each model. Always ensure that the wall is sufciently strong to withstandthe weight. If

•

not, it is necessary to reinforce the wall with plate, beams or pillars.

The unit cannot be directly xed onto the wall or the likes. In all cases, the installation plate provided MUST be used.

•

Paste the installation plan provided on the desired location on the wall and mark the holes location

•

accordingly.

Ensure that the minimum maintenance and servicing space at the top, left and right side of the unit

•

isreserved.

Ensure also the levelness of the installation plate.

•

Drill the screw mounting holes (minimum 4 screws are required).

•

Drill the pipe hole at the location as per plan. (This is only applicable for rear piping outlet installation).

•

Note: The hole should be drilled slightly lower at outdoor side as per gure below:--

Fix the installation plate rmly to wall, without tilting to left or right. Use a plumb line, if available.

•

Model DIMENSION “A”

MWM07/09G2/G2R

M5WM07/09G2/G2R

MWM10/15G2/G2R

M5WM10/15G2/G2R

350.0 mm

400.0 mm

MODEL

MWM20/25G2/G2R, M5WM20/25G2/G2R, MWM030F/030FR, M5WM031F/030FR

25

Page 28

MWM-G2-2010 Application Information

Fixing method:-

•

WOODENFRAME WALL

REINFORCED CONCRETE BUILDING

NUT ANCHOR BOLT ANCHOR

Indoor Unit Preparation

•

The refrigerant piping can be routed to the unit in 5 direction, by using the cut outs in the unit casing.

(See g. 1)

Carefully bend the pipes to the required position to align with the hole. For right hand and rear side

•

drawout, hold the bottom of the piping and x direction before shaping it to the desired position

(See g. 2). The condensation drain hose should be taped to the pipes with vinyl tape. The electrical cable

can also betaped to the pipes.

Mounting Indoor Unit

Hook the indoor unit onto the upper portion of installation plate. (Engage the 2 hooks of rear top of the indoor

unit withthe upper edge of the installation plate). Ensure the hooks are properly seated on the installation plate

by moving in left and right.

Water Drainage Piping

The indoor drain pipe must be downward gradient for smooth drainage. Avoid situation as shown in gure

below.

26

Page 29

Application Information MWM-G2-2010

Wiring

Electrical Connection

Wiring regulation on wire diameters differ from country to country. Please refer to your LOCAL

•

ELECTRICAL CODES for eld wiring rules. Be sure that installation comply with such rules and

regulations.

General Precautions

Ensure that the rated voltage of the unit corresponds to the name plate before carrying out proper wiring

•

according to the wiring diagram.

Provide a power outlet to be used exclusively for each unit. A power supply disconnect and a circuit

•

breaker for over current protection should be provided in the exclusive line.

The unit must be GROUNDED to prevent possible hazards due to insulation failures.

•

All wiring must be rmly connected.

•

All wiring must not touch the hot refrigerant piping, compressor or any moving parts of fan motors.

•

The eld wires from the indoor unit must be clamped on the wire clamp as per shown in the gure.

•

Refrigerant Piping

Maximum pipe Length and Maximum Number of Bends

Always choose the shortest path for refrigerant piping and follow the recommendations as tabulated below:

Model

Data

Max. Length, L (m) 12 12 12 12 15 15 15

Max. Elevation, H (m) 5 5 5 5 8 8 8

Max. No. of Bends 10 10 10 10 10 10 10

Flare Connection

Cut the pipe stages by stages, advancing the blade of pipe cutter slowly.

•

Remove burr with the burr remover. Hold the aring end down to prevent burrs from dropping inside pipe.

•

MWM/

M5WM

07G2/G2R

MWM

09G2/G2R

MWM/

M5WM

10G2/G2R

MWM/

M5WM

15G2/G2R

MWM/

M5WM

20G2/G2R

MWM/

M5WM

25G2/G2R

M5WM

031F/030FR

MWM030F/

R

27

Page 30

MWM-G2-2010 Application Information

Orifice Pipe

Liquid Pipe

The exact length of pipe protruding from the face of the are die is determined by the aring tool. The table

•

shows the use of an imperial die and riged die.

A(mm)

PIPE Ø, D (mm)

IMPERIAL DIE RIGED DIE

6.35 (1/4”) 1.3 0.7

9.52 (3/8”) 1.6 1

12.7 (1/2”) 1.9 1.3

15.88 (5/8”) 2.2 1.7

Fix the pipe rmly on the are die. Match the centers of both the are die and the aring punch, and tighten

aring punch fully.

INSTALLATION OF SEPARATE ORIFICE KIT AT OUTDOOR

i) Outdoor Unit Installation Space Is Wide Enough

Directly connect the “Female” nut of orice pipe to

•

the liquid pipe.

Flare the liquid pipe and connect it to the “Male”

•

joint of the orice pipe.

28

Page 31

Application Information MWM-G2-2010

Step 4

Step 3

Step 2

Step 1

Orifice Pipe

Liquid Pipe

Brazer

Liquid Pipe

Orifice Pipe

Liquid Pipe

Orifice Pipe

ii) Outdoor Installation Space Is Limited

If the orice pipe can not be connected directly to

•

the liquid valve due tolimitation space, it can be

connected between the liquid pipes.

Flare the liquid pipe and connect it to the liquid

•

valve.

Braze an addition “Male” joint to the liquid pipe.•

Connect the “Female” nut of the orice pipe to the

•

“Male” joint.

Flare another liquid pipe and connect it to the

•

“Male” joint of the orice pipe.

29

Page 32

MWM-G2-2010 Application Information

VACUUMING AND CHARGING

The precharged outdoor unit does not need any vacuuming or charging. However once it is connected, the

•

connecting pipe line and the indoor need to be vacuumed before releasing the R22/R407C/R410A from

the outdoor unit.

1) Open the service port core cap.

2) Connect pressure gauge to the service port.

3) Connect the line to vacuum pump. Open the charging manifold valve and turn the pump on. Vacuum

to–0.1 MPa (-760mmHg) or lower. (Evacuation time varies by the pump but averagely in 1 hour).

Note : R407C – Fix lter dryer

R22 - Nil

R410A - Nil

4) After evacuation, unscrew the spindle (diagram B) for the gas to run to indoor unit.

30

Page 33

Application Information MWM-G2-2010

4) Decision by low side pressure. Turn compressor on for 10 or 15 min.

Model

MWM07 G2 5.

09 G2

MWM

MWM10 G2 4.9 ~ 5.7 70.6 ~ 81.8 5.4 ~ 6.1 76.5 ~ 86.6

MWM15 G2 4.7 ~ 5.2 67.6 ~ 74.7 5.2 ~ 5.6 74.0 ~ 80.4

MWM20 G2

MWM25 G2 37~761.5~7.476~957.4~1.4

MWM030F 4.0 ~ 4.8 56.9 ~ 68.3 4.5 ~ 5.0 64.0 ~ 71.1

MWM07G 2R

MWM09G 2R 4.8 ~ 5.7 68.9 ~ 81.4 5.2 ~ 5.9 73.7 ~ 84.8

MWM10G 2R 4.9 ~ 5.9 70.5 ~ 83.7 5.4 ~ 6.3 76.5 ~ 90.7

MWM15G 2R

MWM20G 2R 77~074.5~9.427~660.5~6.4

MWM25G 2R

MWM030FR 4.0 ~ 4.8 56.9 ~ 68.3 4.5 ~ 5.0 64.0 ~ 71.1

2 ~ 5.7 74.3 ~ 81.0 5.7 ~ 6.2 81.9 ~ 89.1

4.7 ~ 5.5 66.6 ~ 78.6 5.0 ~ 5.8 71.2 ~ 83.1

5.2 ~ 5.8 74.8 ~ 82.3 5.6 ~ 6.1 79.3 ~ 87.7

4.9 ~ 6.3 69.4 ~ 89.3 5.0 ~ 6.6 71.7 ~ 93.8

noitidnoCdaoLyvaeHnoitidnoCdradnatS

C°34roodtuO/C°23roodnIC°53roodtuO/C°72roodnI

gisp²mc/gkgisp²mc/gk

47~072.5~9.496~668.4~6.4

37~761.5~7.486~068.4~2.4

M5WM07 G2

M5WM0 9G2/10 G2 9.4 ~ 9.9 134.9 ~ 141.8 10.2 ~ 10.6 145.4 ~ 152.1

M5WM15 G2 8.9 ~ 9.3 127.3 ~ 132.3 9.3 ~ 9.7 133.1 ~ 138.1

M5WM20 G2

M5WM25 G 8.0 ~ 8.3 114 ~ 118 9.0 ~ 9.2 128 ~ 132

M5WM031F 8.0 ~ 8.6 114 ~ 122 8.7 ~ 9.4 124 ~ 133m

M5W M07G 2R

M5WM09G 2R/10 G2R 9.4 ~ 9.9 134.4 ~ 141.9 9.9 ~ 10.5 141.4 ~ 149.7

M5WM15G 2R 9.0 ~ 9.4 128.0 ~ 134.2 9.4 ~ 9.9 134.6 ~ 142.0

M5WM20G 2R

M5WM25G 2R 7.7 ~ 8.3 110 ~ 118 8.4 ~ 9.0 120 ~ 129

M5WM030FR

9.6 ~ 10.0 137.5 ~ 143.2 10.4 ~ 10.7 148.4 ~ 153.1

8.5 ~ 8.8 121 ~ 125 9.3 ~ 9.6 133 ~ 137

9.6 ~ 9.9 136.6 ~ 141.0 10.8 ~ 11.1 154.1 ~ 159.1

8.3 ~ 8.8 119 ~ 125 8.8 ~ 9.2 125 ~ 132

8.0 ~ 8.6 114 ~ 122 8.7 ~ 9.4 124 ~ 133

Within the value refrigerant cycle normal.

Lower than value refrigerant cycle has some leaks check, amend and top up is necessary. Extremely low

(@ zero) needs evacuation and charge.

Additional Charge

The refrigerant gas is charged in the outdoor unit and, if the piping length is 7.6m, additional charge of

•

there frigerant after vacuuming is not necessary.

When the piping length is more than 7.6m, please use the table below :

•

Additional charge in gram.

10m 12m 15m 25m 35m

R22 MODELS

MWM07G2 / 09G2 / 10G2 / 15G2

MWM20G2

MWM25G2

MWM030F

MWM07G2R / 09G2R / 10G2R / 15G2R

MWM20G2R

MWM25G2R

MWM030FR

R410A MODELS

M5WM07G2 / 09G2 / 10G2 / 15G2

M5WM20G2

M5WM25G2

M5WM031F

M5WM07G2R / 09G2R / 10G2R / 15G2R

M5WM20G2R

M5WM25G2R

M5WM030FR

35 65 - - -

35 65 110 - -

90 165 280 - -

90 165 280 650 1030

50 90 - - -

60 110 185 - -

120 220 370 - -

120 220 370 870 1370

35 60 - - -

35 60 100 - -

80 150 255 - -

80 150 255 600 950

45 80 - - -

55 100 165 - -

110 200 335 - -

110 200 335 790 1250

31

Page 34

MWM-G2-2010 Application Information

Diagram shows typical charging method.

Caution For R410A

Avoid prolong exposure of an opened compressor, or the internal part of refrigerant piping to moist air. The POE oil in

•

the compressor and piping can absorb moisture from air.

Final Checking

Ensure that steps 1 to 8 are closely followed.

•

Ensure the following, in particular :

•

1) The unit is mounted solidly and rigidly in position.

2) Piping and connections are leak proof after charging.

3) Proper wiring has been done.

Trial run

•

1) Conduct a trial run after water drainage test and gas leakage test.

2) Watch out for the following :-

a) Is the electric plug rmly inserted into the socket?

b) Is there any abnormal sound from unit?

c) Is there any abnormal vibrations with regard to unit itself or pipings?

d) Is there smooth drainage of water?

Check that :

•

1) Condenser fan is running, with warm air blowing off the condensing unit.

2) Evaporator blower is running and discharging cool air.

3) Suction (Low side) pressure as per recommended.

4) The remote controller incorporate a 3 minute delay in their circuit. Thus, it requires about 3 minutes

uponcut off before the outdoor condensing unit can start up.

SPECIAL PRECAUTIONS WHEN DEALING WITH REFRIGERANT R410A UNIT

1) WHAT IS NEW REFRIGERANT R410A?

R410A is a new HFC refrigerant which does not damage the ozone layer. The working pressure of this

new refrigerant is 1.6 times higher than conventional refrigerant (R22), thus proper installation / servicing

is essential.

2) COMPONENTS

Mixture weight composition R32(50%) and R125(50%)

32

Page 35

Application Information MWM-G2-2010

Dip-pipe

Liquid

withdrawal

Invert cylinder

without dip-pipe

3) CHARACTERISTIC

•

R410A liquid and vapor components have different compositions when the uid evaporates or

condenses. Hence, when leak occurs and only vapor leaks out, the composition of the refrigerant

mixture left in the system will change and subsequently affect the system performance. DO NOT add

new refrigerant to leaked system. It is recommended that the system should be evacuated thoroughly

before recharging withR410A.

•

When refrigerant R410A is used, the composition will differ depending on whether it is in gaseous or

liquid phase. Hence when charging R410A, ensure that only liquid is being with drawn from the cylinder

or can.This is to make certain that only original composition of R410A is being charged into the system.

•

POE oil is used as lubricant for R410A compressor, which is different from the mineral oil used for R22

compressor. Extra precaution must be taken not to expose the R410A system too long to moist air.

4) CHECK LIST BEFORE INSTALLATION/SERVICING

•

Tubing

Refrigerant R410A is more easily affected by dust of moisture compared with R22, make sure to

temporarily cover the ends of the tubing prior to installation

•

Compressor oil

No additional charge of compressor oil is permitted.

•

Refrigerant

No other refrigerant other that R410A

•

Tools (size of service port is different from R22 system)

Tools specically for R410A only (must not be used for R22 or other refrigerant)

i) Manifold gauge and charging hose

ii) Gas leak detector

iii) Refrigerant cylinder/charging cylinder

iv) Vacuum pump c/w adapter

v) Flare tools

vi) Refrigerant recovery machine

5) HANDLING AND INSTALLATION GUIDELINES

Like R22 system, the handling and installation of R410A system are closely similar. All precautionary

measures;such as ensuring no moisture, no dirt or chips in the system, clean brazing using nitrogen, and

thorough leakcheck and vacuuming are equally important requirements. However, due to its hydroscopic

POE oil, additional precautions must be taken to ensure optimum and trouble free system operation.

a) During installation or servicing, avoid prolong exposure of the internal part of the refrigerant system tomoist

air. Residual POE oil in the piping and components can absorb moisture from the air.

b) Ensure that the compressor is not expose to open air for more than the recommended time specied byits

manufacturer (typically less than 10 minutes). Removed the seal plugs only when the compressor is about

to be brazed.

c) The system should be thoroughly vacuumed to 1.0 Pa ( 700mmHg) or lower. This vacuuming level is more

stringent than R22 system so as to ensure no incompressible gas and moisture in the system.

d) When charging R410A, ensure that only liquid is being with drawn from the cylinder or can. This is to ensure

that only the original composition of R410A is being delivered into the system. The liquid composition can

be different from the vapor composition.

f) Normally, the R410A cylinder or can is being equipped with a dip pipe for liquid with drawal. However,

if thedip pipe is not available, invert the cylinder or can so as to with draw liquid from the valve at the

bottom.

33

Page 36

MWM-G2-2010 Sound Data

Sound Data

Sound Pressure Level

Model

MWM07G2

MWM09G2/G2R

M5WM07G2/G2R

M5WM09G2/G2R

MWM10G2/G2R

M5WM10G2/G2R

MWM15G2/G2R

M5WM15G2/G2R

MWM20G2/G2R

M5WM20G2/G2R

MWM25G2/G2R

M5WM25G2/G2R

Speed

(RPM)

High 32 34 38 37 32 23 15 40 36

Medium 27 30 34 32 26 17 14 35 31

Low 24 27 29 26 20 13 13 29 24

High 28 34 37 36 31 22 13 39 35

Medium 27 30 33 31 25 17 12 34 30

Low 24 26 28 25 19 12 11 28 23

High 30 35 39 38 33 25 15 42 37

Medium 28 31 34 33 26 18 13 36 32

Low 24 26 28 26 20 13 12 29 24

High 37 44 42 37 34 25 15 43 37

Medium 34 40 39 34 30 21 14 40 34

Low 30 35 35 30 26 18 13 35 30

High 41 48 47 43 40 32 23 49 43

Medium 39 44 43 39 35 28 20 44 38

Low 37 41 40 36 32 25 19 42 35

1/1 Octave Sound Pressure Level (dB, ref 20µPa)

125 Hz 250 Hz 500 Hz 1k Hz 2k Hz 4k Hz 8k Hz

Overall

(dBA)

Noise

Criteria

High 42 46 45 44 41 35 28 49 43

MWM030F/030FR

M5WM031F/030FR

Microphone position - M5WM/MWM-G/GR : 1m in front and 0.8m below the vertical centre line of the unit. (JIS C 9612)

- M5WM/MWM030F/FR : 1m in front and 1m below the vertical centre line of the unit. (JIS B 8615)

MWM07G2 MWM20G2/G2R

MWM09G2/G2R MWM25G2/G2R

MWM10G2/G2R

MWM15G2/G2R

M5WM07G2/G2R M5WM20G2/G2R

M5WM09G2/G2R M5WM25G2/G2R

M5WM10G2/G2R

M5WM15G2/G2R

M5WM030F/030FR

M5WM031F/030FR

Medium 40 45 44 43 35 33 27 47 42

Low 37 43 43 40 35 30 26 45 39

Model Measuring location

Standard : JIS C 9612

Standard : JIS B 8615

34

Page 37

Sound Data MWM-G2-2010

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

MWM07/09G2/G2R , M5WM07/09G2/G2R

NC CURVES

60

50

NC-45

40

30

20

Sound pressure level (dB,ref 20µPa)

10

0

60

High Fan

Medium Fan

Low Fan

MWM10G2/G2R , M5WM10G2/G2R

NC CURVES

NC-40

NC-35

NC-30

NC-25

NC-20

50

40

30

20

Sound pressure level (dB,ref 20µPa)

10

0

Medium Fan

Low Fan

High Fan

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

35

Page 38

MWM-G2-2010 Sound Data

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

MWM15G2/G2R , M5WM15G2/G2R

NC CURVES

60

50

NC-45

40

30

20

Sound pressure level (dB,ref 20µPa)

10

0

60

High Fan

Medium Fan

MWM20G2/G2R , M5WM20G2/G2R

NC CURVES

NC-40

NC-35

NC-30

NC-25

NC-20

Low Fan

50

High Fan

40

Medium Fan

Low Fan

30

20

Sound pressure level (dB,ref 20µPa)

10

0

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

36

Page 39

Sound Data MWM-G2-2010

125 250 500 1000 2000 4000 8000

Octave-band frequency (Hz)

0

10

20

30

40

50

60

70

Octave-band frequency (Hz)

Sound pressure level (dB, ref20µPa)

NC-20

NC-25

NC-35

NC-40

NC-45

NC-50

High Fan

Medium Fan

Low Fan

MWM030F/030FR , M5WM031F/030FR

NC CURVES

125 250 500 1000 2000 4000 8000

MWM25G2/G2R , M5WM25G2/G2R

NC CURVES

60

50

High Fan

Medium Fan

Low Fan

40

30

20

Sound pressure level (dB,ref 20µPa)

10

0

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

37

Page 40

MWM-G2-2010 Engineering & Physical Data

Engineering & Physical Data

General Data - Cooling Only (R22)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER W 590 919

NOMINAL RUNNING CURRENT A 2.70 4.10

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 3.47 2.87

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 38 / 33 / 28 40 / 35 / 29

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 8.5 / 18.7 10 / 22.1

CONDENSATE DRAIN SIZE mm/in 16 / 0.6 16 / 0.6

AIR FLOW l/s / CFM 321 / 680 307 / 650

SOUND PRESSURE LEVEL dBA 45 46

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 28 / 61.7 28 / 61.7

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 0.50 / 1.10 0.53/ 1.16

INDOOR UNIT MWM07G2 MWM09G2

OUTDOOR UNIT MLC007C MLC009C

Btu/h 7000 9000

W 2050 2640

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

HIGH l/s / CFM 118 / 250 130 / 275

MEDIUM l/s / CFM 104 / 220 106 / 225

LOW l/s / CFM 85 / 180 83 / 175

HEIGHT mm/in 260 / 10.2 260 / 10.2

WIDTH mm/in 799 / 31.5 799 / 31.5

DEPTH mm/in 198 / 7.8 198 / 7.8

HEIGHT mm/in 337 / 13.3 337 / 13.3

WIDTH mm/in 857 / 33.7 857 / 33.7

DEPTH mm/in 270 / 10.6 270 / 10.6

HEIGHT mm/in 495 / 19.5 495 / 19.5

WIDTH mm/in 600 / 23.6 600 / 23.6

DEPTH mm/in 245 / 9.7 245 / 9.7

HEIGHT mm/in 575 / 22.6 575 / 22.6

WIDTH mm/in 715 / 28.1 715 / 28.1

DEPTH mm/in 330 / 13.0 330 / 13.0

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 9.52 / 3/8 9.52 / 3/8

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

6.35 / 1/4 6.35 / 1/4

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

38

Page 41

Engineering & Physical Data MWM-G2-2010

General Data - Cooling Only (R22)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER W 860 1200

NOMINAL RUNNING CURRENT A 3.80 5.40

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 3.23 2.93

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 39 / 34 / 28 42 / 36 / 29

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 12 / 26.5 12 / 26.5

CONDENSATE DRAIN SIZE mm/in 16 / 0.6 16 / 0.6

AIR FLOW l/s / CFM 396 / 840 453 / 960

SOUND PRESSURE LEVEL dBA 46 49

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 32 / 70.5 32 / 70.5

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 0.63 / 1.39 0.60 / 1.33

INDOOR UNIT MWM10G2 MWM15G2

OUTDOOR UNIT MLC010C MLC015C

Btu/h 9500 12000

W 2780 3520

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

HIGH l/s / CFM 142 / 300 163 / 345

MEDIUM l/s / CFM 118 / 250 135 / 285

LOW l/s / CFM 94 / 200 104 / 220

HEIGHT mm/in 260 / 10.2 260 / 10.2

WIDTH mm/in 799 / 31.5 799 / 31.5

DEPTH mm/in 198 / 7.8 198 / 7.8

HEIGHT mm/in 337 / 13.3 337 / 13.3

WIDTH mm/in 957 / 37.7 957 / 37.7

DEPTH mm/in 270 / 10.6 270 / 10.6

HEIGHT mm/in 540 / 21.3 540 / 21.3

WIDTH mm/in 700 / 27.6 700 / 27.6

DEPTH mm/in 250 / 9.8 250 / 9.8

HEIGHT mm/in 620 / 24.4 620 / 24.4

WIDTH mm/in 810 / 31.9 810 / 31.9

DEPTH mm/in 330 / 13.0 330 / 13.0

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 9.52 / 3/8 12.70 / 1/2

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

6.35 / 1/4 6.35 / 1/4

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

39

Page 42

MWM-G2-2010 Engineering & Physical Data

General Data - Cooling Only (R22)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER W 1820 1807

NOMINAL RUNNING CURRENT A 8.10 8.00

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 2.90 3.08

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 43 / 40 / 35 43 / 40 / 35

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 16 / 35.3 16 / 35.3

CONDENSATE DRAIN SIZE mm/in 20 / 0.8 20 / 0.8

AIR FLOW l/s / CFM 614 / 1300 614 / 1300

SOUND PRESSURE LEVEL dBA 51 51

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 58 / 127.9 59 / 130.1

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 0.80 / 1.76 1.35 / 2.98

INDOOR UNIT MWM20G2 MWM20G2

OUTDOOR UNIT MLC018C MLC020C

Btu/h 18000 19000

W 5280 5570

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

HIGH l/s / CFM 231 / 490 231 / 490

MEDIUM l/s / CFM 193 / 410 193 / 410

LOW l/s / CFM 160 / 340 160 / 340

HEIGHT mm/in 304 / 12.0 304 / 12.0

WIDTH mm/in 1062 / 41.8 1062 / 41.8

DEPTH mm/in 222 / 8.7 222 / 8.7

HEIGHT mm/in 378 / 14.9 378 / 14.9

WIDTH mm/in 1130 / 44.5 1130 / 44.5

DEPTH mm/in 292 / 11.5 292 / 11.5

HEIGHT mm/in 654 / 25.7 654 / 25.7

WIDTH mm/in 855 / 33.7 855 / 33.7

DEPTH mm/in 328 / 12.9 328 / 12.9

HEIGHT mm/in 710 / 28.0 710 / 28.0

WIDTH mm/in 990 / 39.0 990 / 39.0

DEPTH mm/in 415 / 16.3 415 / 16.3

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 15.88 / 5/8 15.88 / 5/8

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

6.35 / 1/4 6.35 / 1/4

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

40

Page 43

Engineering & Physical Data MWM-G2-2010

General Data - Cooling Only (R22)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER W 2530 2708

NOMINAL RUNNING CURRENT A 11.30 13.10

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 2.72 3.00

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE EXTERNAL ORIFICE

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 49 / 44 / 42 49 / 47 / 45

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 16 / 35.3 17 / 37.48

CONDENSATE DRAIN SIZE mm/in 20 / 0.8 20 / 0.8

AIR FLOW l/s / CFM 755 / 1600 741 / 1570

SOUND PRESSURE LEVEL dBA 52 54

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 62 / 136.7 65 / 143.3

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 1.5 / 3.30 1.75 / 3.86

INDOOR UNIT MWM25G2 MWM030F

OUTDOOR UNIT MLC025C MLC028C

Btu/h 23500 27000

W 6890 7913

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

HIGH l/s / CFM 297 / 630 316 / 670

MEDIUM l/s / CFM 231 / 490 297 / 630

LOW l/s / CFM 208 / 440 236 / 500

HEIGHT mm/in 304 / 12.0 360 / 14.2

WIDTH mm/in 1062 / 41.8 1200 / 47.2

DEPTH mm/in 222 / 8.7 200 / 7.9

HEIGHT mm/in 378 / 14.9 420 / 16.5

WIDTH mm/in 1130 / 44.5 1267 / 49.9

DEPTH mm/in 292 / 11.5 260 / 10.2

HEIGHT mm/in 756 / 29.8 756 / 29.8

WIDTH mm/in 855 / 33.7 855 / 33.7

DEPTH mm/in 328 / 12.9 328 / 12.9

HEIGHT mm/in 810 / 31.9 810 / 31.9

WIDTH mm/in 990 / 39.0 990 / 39.0

DEPTH mm/in 415 / 16.3 415 / 16.3

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 15.88 / 5/8 15.88 / 5/8

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

9.52 / 3/8 9.52 / 3/8

AUTO LOUVER (UP & DOWN) &

GRILLE (LEFT & RIGHT)

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

41

Page 44

MWM-G2-2010 Engineering & Physical Data

General Data - Cooling Only (R22)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER W 2944

NOMINAL RUNNING CURRENT A 12.60

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50

EER W/W 2.99

REFRIGERANT TYPE R22

REFRIGERANT CONTROL (EXPANSION DEVICE) EXTERNAL ORIFICE KIT

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 49 / 47 / 45

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 17 / 37.48

CONDENSATE DRAIN SIZE mm/in 20 / 0.8

AIR FLOW l/s / CFM 1605 / 3400

SOUND PRESSURE LEVEL dBA 58

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 95 / 209.4

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 1.60 / 3.53

INDOOR UNIT MWM030F

OUTDOOR UNIT MLC030C

Btu/h 30000

W 8790

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL

HIGH l/s / CFM 316 / 670

MEDIUM l/s / CFM 297 / 630

LOW l/s / CFM 236 / 500

HEIGHT mm/in 360 / 14.2

WIDTH mm/in 1200 / 47.2

DEPTH mm/in 200 / 7.9

HEIGHT mm/in 420 / 16.5

WIDTH mm/in 1267 / 49.9

DEPTH mm/in 260 / 10.2

HEIGHT mm/in 850 / 33.5

WIDTH mm/in 1030 / 40.6

DEPTH mm/in 400 / 15.6

HEIGHT mm/in 1000 / 39.4

WIDTH mm/in 1200 / 47.2

DEPTH mm/in 560 / 22.1

TYPE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 15.88 / 5/8

AUTO LOUVER (UP & DOWN) &

GRILLE (LEFT & RIGHT)

9.52 / 3/8

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

42

Page 45

Engineering & Physical Data MWM-G2-2010

General Data - Heat pump (R22)

MODEL

NOMINAL COOLING CAPACITY

NOMINAL HEATING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 910 860

NOMINAL TOTAL INPUT POWER (HEATING) W 750 750

NOMINAL RUNNING CURRENT (COOLING) A 4.00 3.80

NOMINAL RUNNING CURRENT (HEATING) A 3.40 3.40

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 2.84 3.23

COP W/W 3.36 3.71

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 40 / 35 / 29 39 / 34 / 28

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 10 / 22.5 12 / 26.5

CONDENSATE DRAIN SIZE mm/in 16 / 0.6 16 / 0.6

AIR FLOW l/s / CFM 307 / 650 396 / 840

SOUND PRESSURE LEVEL dBA 46 46

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 28 / 61.7 32 / 70.5

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 0.60 / 1.32 0.63 / 1.39

INDOOR UNIT MWM09G2R MWM10G2R

OUTDOOR UNIT MLC009CR MLC010CR

Btu/h 8800 9500

W 2580 2780

Btu/h 8600 9500

W 2520 2780

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

HIGH l/s / CFM 130 / 275 142 / 300

MEDIUM l/s / CFM 106 / 225 118 / 250

LOW l/s / CFM 83 / 175 94 / 200

HEIGHT mm/in 260 / 10.2 260 / 10.2

WIDTH mm/in 799 / 31.5 899 / 35.4

DEPTH mm/in 198 / 7.8 198 / 7.8

HEIGHT mm/in 337 / 13.3 337 / 13.3

WIDTH mm/in 857 / 33.7 957 / 37.7

DEPTH mm/in 270 / 10.6 270 / 10.6

HEIGHT mm/in 495 / 19.5 540 / 21.3

WIDTH mm/in 600 / 23.6 700 / 27.6

DEPTH mm/in 245 / 9.7 250 / 9.8

HEIGHT mm/in 575 / 22.6 620 / 24.4

WIDTH mm/in 715 / 28.1 810 / 31.9

DEPTH mm/in 330 / 13.0 330 / 13.0

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 9.52 / 3/8 9.52 / 3/8

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

6.35 / 1/4 6.35 / 1/4

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

b) HEATING - 20°C DB INDOOR AND 7°C DB / 6°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

43

Page 46

MWM-G2-2010 Engineering & Physical Data

General Data - Heat pump (R22)

MODEL

NOMINAL COOLING CAPACITY

NOMINAL HEATING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 1100 1820

NOMINAL TOTAL INPUT POWER (HEATING) W 980 1660

NOMINAL RUNNING CURRENT (COOLING) A 5.00 8.10

NOMINAL RUNNING CURRENT (HEATING) A 4.50 7.40

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 3.20 2.90

COP W/W 3.59 3.25

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 42 / 36 / 29 43 / 40 / 35

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 12 / 26.5 16 / 35.3

CONDENSATE DRAIN SIZE mm/in 16 / 0.6 20 / 0.8

AIR FLOW l/s / CFM 453 / 960 614 / 1300

SOUND PRESSURE LEVEL dBA 49 51

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 32 / 70.5 58 / 127.9

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 0.80 / 1.76 0.85 / 1.88

INDOOR UNIT MWM15G2R MWM20G2R

OUTDOOR UNIT MLC015CR MLC018CR

Btu/h 12000 18000

W 3520 5280

Btu/h 12000 18400

W 3520 5390

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

HIGH l/s / CFM 163 / 345 231 / 490

MEDIUM l/s / CFM 135 / 285 193 / 410

LOW l/s / CFM 104 / 220 160 / 340

HEIGHT mm/in 260 / 10.2 304 / 12.0

WIDTH mm/in 799 / 31.5 1062 / 41.8

DEPTH mm/in 198 / 7.8 222 / 8.7

HEIGHT mm/in 337 / 13.3 378 / 14.9

WIDTH mm/in 957 / 37.7 1130 / 44.5

DEPTH mm/in 270 / 10.6 292 / 11.5

HEIGHT mm/in 540 / 21.3 654 / 25.7

WIDTH mm/in 700 / 27.6 855 / 33.7

DEPTH mm/in 250 / 9.8 328 / 12.9

HEIGHT mm/in 620 / 24.4 710 / 28.0

WIDTH mm/in 810 / 31.9 990 / 39.0

DEPTH mm/in 330 / 13.0 415 / 16.3

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 12.7 / 1/2 15.88 / 5/8

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

6.35 / 1/4 6.35 / 1/4

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

b) HEATING - 20°C DB INDOOR AND 7°C DB / 6°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

44

Page 47

Engineering & Physical Data MWM-G2-2010

General Data - Heat pump (R22)

MODEL

NOMINAL COOLING CAPACITY

NOMINAL HEATING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 1807 2530

NOMINAL TOTAL INPUT POWER (HEATING) W 1757 2450

NOMINAL RUNNING CURRENT (COOLING) A 8.00 11.30

NOMINAL RUNNING CURRENT (HEATING) A 7.80 11.10

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 3.08 2.72

COP W/W 3.26 2.87

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 43 / 40 / 35 49 / 44 / 42

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 16 / 35.3 16 / 35.3

CONDENSATE DRAIN SIZE mm/in 20 / 0.8 20 / 0.8

AIR FLOW l/s / CFM 614 / 1300 755 / 1600

SOUND PRESSURE LEVEL dBA 51 52

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 59 / 130.1 62 / 136.7

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 1.35 / 2.99 1.50 / 3.30

INDOOR UNIT MWM20G2R MWM25G2R

OUTDOOR UNIT MLC020CR MLC025CR

Btu/h 19000 23500

W 5570 6890

Btu/h 19500 24000

W 5720 7030

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

HIGH l/s / CFM 231 / 490 297 / 630

MEDIUM l/s / CFM 193 / 410 231 / 490

LOW l/s / CFM 160 / 340 208 / 440

HEIGHT mm/in 304 / 12.0 304 / 12.0

WIDTH mm/in 1062 / 41.8 1062 / 41.8

DEPTH mm/in 222 / 8.7 222 / 8.7

HEIGHT mm/in 378 / 14.9 378 / 14.9

WIDTH mm/in 1130 / 44.5 1130 / 44.5

DEPTH mm/in 292 / 11.5 292 / 11.5

HEIGHT mm/in 654 / 25.7 756 / 29.8

WIDTH mm/in 855 / 33.7 855 / 33.7

DEPTH mm/in 328 / 12.9 328 / 12.9

HEIGHT mm/in 710 / 28.0 810 / 31.9

WIDTH mm/in 990 / 39.0 990 / 39.0

DEPTH mm/in 415 / 16.3 415 / 16.3

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 15.88 / 5/8 15.88 / 5/8

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

6.35 / 1/4 9.52 / 3/8

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

b) HEATING - 20°C DB INDOOR AND 7°C DB / 6°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

45

Page 48

MWM-G2-2010 Engineering & Physical Data

General Data - Heat pump (R22)

MODEL

NOMINAL COOLING CAPACITY

NOMINAL HEATING CAPACITY

NOMINAL TOTAL INPUT POWER (COOLING) W 2708 2944

NOMINAL TOTAL INPUT POWER (HEATING) W 2273 2864

NOMINAL RUNNING CURRENT (COOLING) A 13.20 14.30

NOMINAL RUNNING CURRENT (HEATING) A 13.30 13.70

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 2.92 2.99

COP W/W 3.48 3.07

REFRIGERANT TYPE R22 R22

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 49 / 47 / 45 49 / 47 / 45

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 17 / 37.48 17 / 37.48

CONDENSATE DRAIN SIZE mm/in 20 / 0.8 20 / 0.8

AIR FLOW l/s / CFM 741 / 1570 1605 / 3400

SOUND PRESSURE LEVEL dBA 54 58

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 68 / 150 95 / 209

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 1.83 / 4.03 2.15 / 4.74

INDOOR UNIT MWM030FR MWM 030FR

OUTDOOR UNIT MLC028CR MLC 030CR

Btu/h 27000 30000

W 7913 8790

Btu/h 27000 30000

W 7913 8790

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

HIGH l/s / CFM 316 / 670 316 / 670

MEDIUM l/s / CFM 297 / 630 297 / 630

LOW l/s / CFM 236 / 500 236 / 500

HEIGHT mm/in 360 / 14.2 360 / 14.2

WIDTH mm/in 1200 / 47.2 1200 / 47.2

DEPTH mm/in 200 / 7.9 200 / 7.9

HEIGHT mm/in 420 / 16.5 420 / 16.5

WIDTH mm/in 1267 / 49.9 1267 / 49.9

DEPTH mm/in 260 / 10.2 260 / 10.2

HEIGHT mm/in 756 / 29.8 850 / 33.5

WIDTH mm/in 855 / 33.7 1030 / 40.6

DEPTH mm/in 328 / 12.9 400 / 15.8

HEIGHT mm/in 810 / 31.9 1000 / 39.4

WIDTH mm/in 990 / 39.0 1200 / 47.2

DEPTH mm/in 415 / 16.3 560 / 22.1

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 15.88 / 5/8 15.88 / 5/8

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

9.52 / 3/8 9.52 / 3/8

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

a) COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

b) HEATING - 20°C DB INDOOR AND 7°C DB / 6°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

46

Page 49

Engineering & Physical Data MWM-G2-2010

General Data - Cooling Only (R22)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER W 620 860

NOMINAL RUNNING CURRENT A 2.90 3.90

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 3.55 3.07

REFRIGERANT TYPE R410A R410A

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 40 / 35 / 29 40 / 35 / 29

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 10 / 22.0 10 / 22.0

CONDENSATE DRAIN SIZE mm/in 16 / 0.6 16 / 0.6

AIR FLOW l/s / CFM 307 / 650 396 / 840

SOUND PRESSURE LEVEL dBA 44 46

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 26 / 57.3 32 / 70.5

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 0.48 / 1.06 0.73 / 1.61

INDOOR UNIT M5WM07G2 M5WM09G2

OUTDOOR UNIT M5LC007C M5LC010C

Btu/h 7500 9000

W 2200 2640

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

HIGH l/s / CFM 130 / 275 130 / 275

MEDIUM l/s / CFM 106 / 225 106 / 225

LOW l/s / CFM 83 / 175 83 / 175

HEIGHT mm/in 260 / 10.2 260 / 10.2

WIDTH mm/in 799 / 31.5 799 / 31.5

DEPTH mm/in 198 / 7.8 198 / 7.8

HEIGHT mm/in 337 / 13.3 337 / 13.3

WIDTH mm/in 857 / 33.7 857 / 33.7

DEPTH mm/in 270 / 10.6 270 / 10.6

HEIGHT mm/in 495 / 19.5 540 / 21.3

WIDTH mm/in 600 / 23.6 700 / 27.6

DEPTH mm/in 245 / 9.7 250 / 9.8

HEIGHT mm/in 575 / 22.6 620 / 24.4

WIDTH mm/in 715 / 28.1 810 / 31.9

DEPTH mm/in 330 / 13.0 330 / 13.0

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 9.52 / 3/8 9.52 / 3/8

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

6.35 / 1/4 6.35 / 1/4

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

47

Page 50

MWM-G2-2010 Engineering & Physical Data

General Data - Cooling Only (R410A)

MODEL

NOMINAL CAPACITY

NOMINAL TOTAL INPUT POWER W 910 1230

NOMINAL RUNNING CURRENT A 3.90 5.40

POWER SOURCE V/Ph/Hz 220 - 240 / 1 / 50 220 - 240 / 1 / 50

EER W/W 3.05 2.86

REFRIGERANT TYPE R410A R410A

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 39 / 34 / 28 42 / 36 / 29

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 12 / 26.5 12 / 26.5

CONDENSATE DRAIN SIZE mm/in 16 / 0.6 16 / 0.6

AIR FLOW l/s / CFM 396 / 840 453 / 960

SOUND PRESSURE LEVEL dBA 46 49

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 33 / 70.5 32 / 70.5

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 0.73 / 1.61 0.83 / 1.83

INDOOR UNIT M5WM10G2 M5WM15G2

OUTDOOR UNIT M5LC010C M5LC015C

Btu/h 9500 12000

W 2780 3520

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

HIGH l/s / CFM 142 / 300 163 / 345

MEDIUM l/s / CFM 118 / 250 135 / 285

LOW l/s / CFM 94 / 200 104 / 220

HEIGHT mm/in 260 / 10.2 260 / 10.2

WIDTH mm/in 899 / 35.4 899 / 35.4

DEPTH mm/in 198 / 7.8 198 / 7.8

HEIGHT mm/in 337 / 13.3 337 / 13.3

WIDTH mm/in 957 / 37.7 957 / 37.7

DEPTH mm/in 270 / 10.6 270 / 10.6

HEIGHT mm/in 540 / 21.3 540 / 21.3

WIDTH mm/in 700 / 27.6 700 / 27.6

DEPTH mm/in 250 / 9.8 250 / 9.8

HEIGHT mm/in 620 / 24.4 620 / 24.4

WIDTH mm/in 810 / 31.9 810 / 31.9

DEPTH mm/in 330 / 13.0 330 / 13.0

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 9.52 / 3/8 12.70 / 1/2

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

6.35 / 1/4 6.35 / 1/4

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR

4) SOUND PRESSURE LEVEL ARE ACCORDING TO JIS B 8615 STANDARD. POSITION OF THE MEASUREMENT POINT IS 1m IN FRONT AND 1m

BELOW THE UNIT.

48

Page 51

Engineering & Physical Data MWM-G2-2010

General Data - Cooling Only (R410A)

MODEL

NOMINAL CAPACITY-1Ø/ <3Ø>

NOMINAL TOTAL INPUT POWER-1Ø/ <3Ø> W 1630 / <1663> 1860 / <2195>

NOMINAL RUNNING CURRENT-1Ø/ <3Ø> A 7.3 / <3.2> 8.4 / <4.2>

POWER SOURCE-1Ø/ <3Ø> V/Ph/Hz 220-240/ 1/ 50 / <380-415/ 3/ 50> 220-240/ 1/ 50 / <380-415/ 3/ 50>

EER-1Ø/ <3Ø> W/W 3.21 / <3.17> 3.21 / <3.00>

REFRIGERANT TYPE R410A R410A

REFRIGERANT CONTROL (EXPANSION DEVICE) OUTDOOR CAP. TUBE OUTDOOR CAP. TUBE

CONTROL

AIR FLOW

SOUND PRESSURE LEVEL (H/M/L) dBA 43 / 40 / 35 49 / 44 / 42

UNIT DIMENSION

INDOOR UNIT

PACKING DIMENSION

UNIT WEIGHT kg/lb 16 / 35.3 16 / 35.3

CONDENSATE DRAIN SIZE mm/in 20 / 0.8 20 / 0.8

AIR FLOW l/s / CFM 614 / 1300 689 / 1460

SOUND PRESSURE LEVEL dBA 52 52

UNIT DIMENSION

PACKING DIMENSION

OUTDOOR UNIT

UNIT WEIGHT kg/lb 59 / 130.1 62 / 136.7

PIPE CONNECTION

REFRIGERANT CHARGE kg/lb 1.38 / 3.03 1.54 / 3.40

INDOOR UNIT M5WM20G2 M5WM25G2

OUTDOOR UNIT M5LC020C M5LC025C

Btu/h 17850 / <18000> 20350 / <22500>

W 5230 / <5280> 5960 / <6590>

AIR DISCHARGE

OPERATION LCD REMOTE CONTROL LCD REMOTE CONTROL

HIGH l/s / CFM 231 / 490 297 / 630

MEDIUM l/s / CFM 193 / 410 231 / 490

LOW l/s / CFM 160 / 340 208 / 440

HEIGHT mm/in 304 / 12.0 304 / 12.0

WIDTH mm/in 1062 / 41.8 1062 / 41.8

DEPTH mm/in 222 / 8.7 222 / 8.7

HEIGHT mm/in 378 / 14.9 378 / 14.9

WIDTH mm/in 1130 / 44.5 1130 / 44.5

DEPTH mm/in 292 / 11.5 292 / 11.5

HEIGHT mm/in 654 / 25.7 756 / 29.8

WIDTH mm/in 855 / 33.7 855 / 33.7

DEPTH mm/in 328 / 12.9 328 / 12.9

HEIGHT mm/in 710 / 28.0 810 / 31.9

WIDTH mm/in 990 / 39.0 990 / 39.0

DEPTH mm/in 415 / 16.3 415 / 16.3

TYPE FLARE VALVE FLARE VALVE

SIZE

LIQUID mm/in

GAS mm/in 12.70 / 1/2 15.88 / 5/8

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

6.35 / 1/4 6.35 / 1/4

DOUBLE LOUVER (UP & DOWN)

& GRILLE (LEFT & RIGHT)

1) ALL SPECIFICATIONS ARE SUBJECTED TO CHANGE BY THE MANUFACTURER WITHOUT PRIOR NOTICE.

2) ALL UNITS ARE BEING TESTED AND COMPLY TO ISO 5151.

3) NOMINAL COOLING AND HEATING CAPACITY ARE BASED ON THE CONDITIONS BELOW :

COOLING - 27°C DB / 19°C WB INDOOR AND 35°C DB / 24°C WB OUTDOOR