Page 1

Air-Cooled Mini Chiller

MAC-C-2004

Models: MAC 080 C/CR

MAC 100 C/CR

MAC 120 C/CR

MAC 150 C/CR

M4AC 080 C/CR

M4AC 100 C/CR

M4AC 120 C/CR

M4AC 150 C/CR

Page 2

Contents

Nomenclature.................................................................................................................. 2

General Features and Specifications...................................................................... 2 - 3

Chiller Panel Controller .......................................................................................... 4 - 35

Specifications ........................................................................................................ 36 - 39

Performance Table ................................................................................................ 40 - 45

Technical Data ....................................................................................................... 46 - 47

Outlines and Dimensions...................................................................................... 48 - 50

Wiring Diagrams .................................................................................................... 51 - 54

Special Precautions for R407C............................................................................. 55 - 56

Installation ............................................................................................................. 57 - 61

Servicing and Maintenance ......................................................................................... 62

Troubleshooting ........................................................................................................... 63

Schematic Diagram ...................................................................................................... 64

Parts List and Exploded View............................................................................... 65 - 66

Note: Installation and maintenance are to be performed only by qualified personnel who are

familiar with local codes and regulations, and experienced with this type of equipment,

Caution: Sharp edges and coil surfaces are a potential injury hazard. Avoid contact with them.

Warning: Moving machinery and electrical power hazards. May cause severe personal injury or death.

Disconnect and lock off power before servicing equipment.

"McQuay" is a registered trademark of McQuay International. All rights reserved throughout the world.

2003 McQuay International

"Bulletin illustrations cover the general appearance of McQuay International products at the time of publication

and we reserve the right to make changes in design and construction at any time without notice."

1

Page 3

Nomenclature

M 4AC080 C R

Brand Name _ R22 Equipment Air Cooled Norminal Generation

(McQuay) 4 R407C Equipment Chiller Cooling _ Cooling

Capacity R Heating

General Features and Specifications

Refrigerant circuit

The unit has been designed with two separate refrigerant circuits, i.e. it has two compressors. By doing so,

the unit has part loading capabilities, i.e. 0-50-100% of rated capacity. This will improve the reliability and

energy efficiency of the unit, especially during low loading operations. Each circuit is factory brazed and

evacuated before accurately charged with refrigerant to ensure optimum performance. Because each circuit

is separated, there is no danger of crosscontamination should either one of the compressors experiences a

burnt-up. Each circuit is also equipped with a carefully sized thermostatic expansion valve (for cooling only

units) to give optimum performance characteristics. For the heat pump versions, the expansion process is

done with capillary tubes.

Scroll compressors are used in the unit to give quiet and reliable performance over a wide operating

temperature range. However, in order to protect the compressors from damage, a phase protector is

provided to prevent the compressors from rotating in the wrong direction.

Condenser Fan Motor

The unit is equipped with two high air flow propeller fan blades which are made of metal. The fans are

directly driven by weather proof motors, the motors are of single phase type.

Evaporator

The heat exchanger is made of stainless steel plates closely arranged and brazed together (BPHE) to

ensure high heat exchange efficiency. The water flows through the BPHE in a channel on its own, while

because of the two compressors, the refrigerant flows through another two separate channels. The

refrigerant will either be in a counter-flow or parallel-flow with respect to the water, depending on the mode

of operation (cooling or heating).

Safety Protection

The safety protections provided for in the chiller unit are:

a) High and low pressure switches

b) Differential water flow switch

c) Compressor, water pump and fan motor overload protectors

d) Anti-freeze protection sensor

During abnormal condition, the electronic controller will turn off the unit and then display the fault of

operation.

Other than that, the unit also has pressure gauges (analog) for each compressor suction and discharge

pipes. These are useful for detecting abnormal operating conditions, especially during maintenance

services.

2

Page 4

Water buffer tank & pipe connection

The unit does not come with a water buffer tank. However, the unit does come with an 8 liters expansion

tank.

(A 135L water tank is available as optional item)

The external water piping connection can be made either from the left or right side of the unit. Connection is

done with I1-1/4” female thread couplings for both supply and return pipes.

Anti-freeze protection

The chiller unit has several anti-freeze protection features:

1. Brazed plate heat exchanger anti-freeze

The BPHE has a strip heater around it to prevent water freezing inside.

2. Auto mode

The chiller controller will force-on the unit to the heat mode if the outdoor ambient air temperature

becomes too cold.

Maintenance

In order to facilitate maintenance of the controller, a rocker switch is provided to power-off the supply to the

PCB. However, switching off this switch will not disconnect the main incoming power supply to the chiller

unit.

Coil Guard

The unit also comes with two sets of coil guards (i.e. on the left and right side coils). Each guard is basically

a metal mesh which protects the coil from damage due to a side impact on the coil surface itself.

Fin Coating

The finned tube heat exchanger coil used on the chiller unit is made of staggered rows of 3/8” seamless

copper tubes, mechanically expanded into die-formed louvered fins. The slit openings on the fins enhance

the heat transfer coefficient between the fin surfaces and air.

In order to protect these fins from corrosion, a special fin coating (gold fin) is applied on the surface. This

coating is standard on the heat pump version, whereas it is an option on the cooling only model.

3

Page 5

Chiller Panel Controller

1. SAFETY CONSIDERATION

Only specially trained and qualified technicians and installers are authorized to install and service this equipment.

1.1 General Installation Recommendations

x Only supply DC voltage (9-17V, typically 12V, maximum current 200mA) as a power source to the device.

x Input contact voltage supply should limit to 12VDC or 24VAC.

x Isolated all the low voltage wiring (communication bus, etc.) from high voltage power supply wiring.

2. GENERAL DESCRIPTION

2.1 General

The Chiller Panel Controller is designed to control the Chiller operation. This device allows the user to have

customized control for each connected unit.

2.2 Features

The requirements of user friendly and easy to use have been taken into account in designing this Chiller

Panel Controller. It can do the task as follow:

x Whole system configuration

x Unique parameter settings

x Operation status display

x Tracing fault record (easy in hardware troubleshooting)

The display is shown in an 8-line graphical LCD display. There are 8 dedicated keys available in the panel,

which allow user to do the following task:

x Menu selection

x Navigation on the screen

x Modification of the selected value

During first start-up, the panel will have a default configuration (timer schedule, set point, miscellaneous

settings, etc). User can do the changes on that particular configuration later.

2.3 Panel Position

The Chiller Panel Controller can be installed anywhere, as long as it is easy to accessed by authorized

personnel.

The requirements of installation are:

x Avoid exposure to shocks

x Avoid any source of electromagnetic pollution

x Avoid installation on uneven vertical surface

2.4 Operation Environmental Condition

x Temperature:

-10ºC to 65ºC Operating Temperature

-20ºC to 85ºC Storage Temperature

x Relative Humidity:

0 to 95% Non - Condensing

4

Page 6

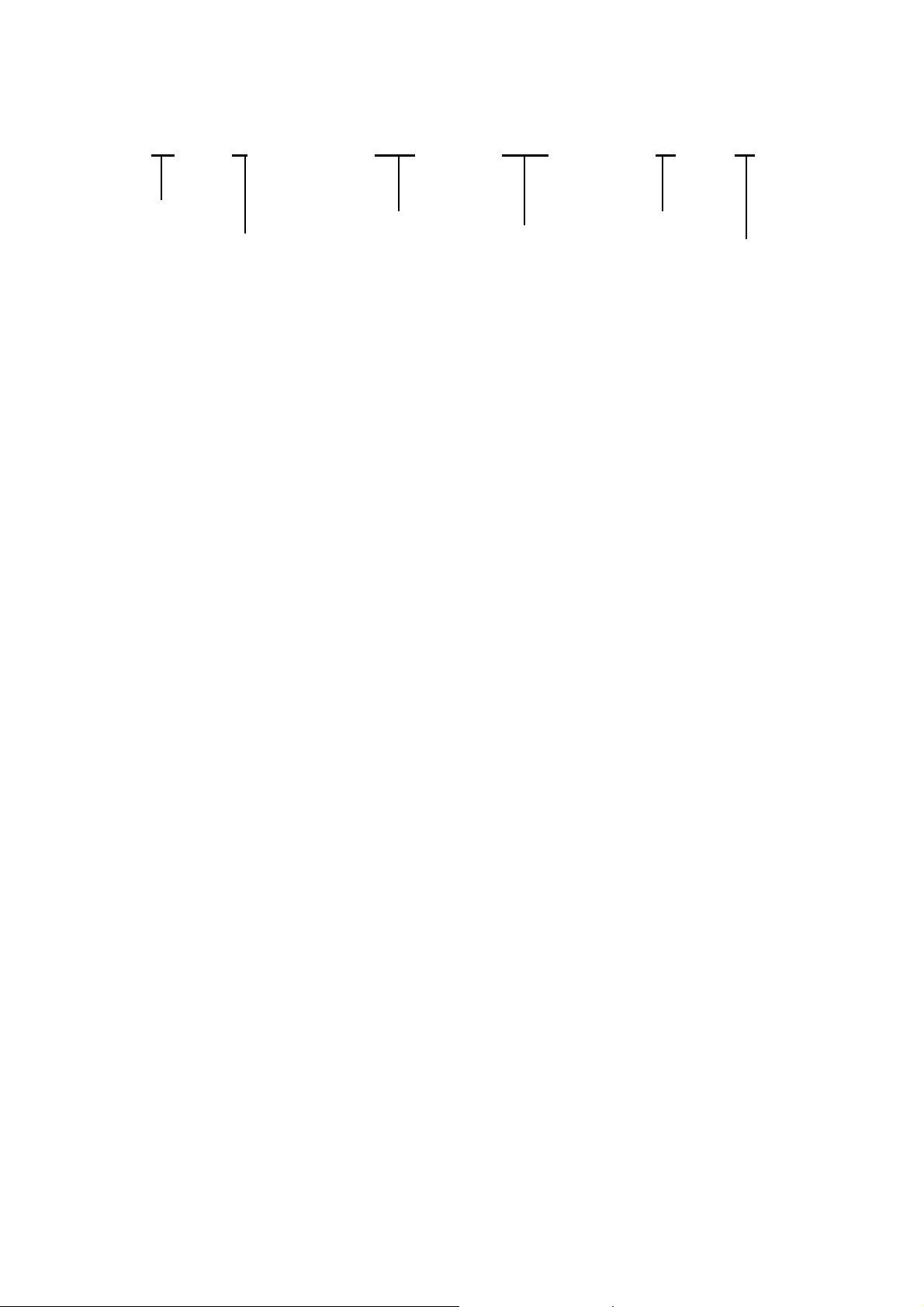

3. HARDWARE DESCRIPTION

9

Legend

5

7

8

6

Front View

Back View

3

2

4

1

10

1 & 2 Navigation key

3 Execute instruction key

4 Cancel instruction key

5 Switching to Heat mode shortcut key

6 Switching to Cool mode shortcut key

7 Toggle ON/OFF shortcut key

8 Show alarm key

9 Graphical LCD display

10 ON/OFF indicator

Legend

Chiller terminal unit connection

1 & 2

3

Not available

CMOS reset jumper (JH2)

4

5

Chiller bus resistor configuration (JH3)

Not available

6

Not available

7

Not available

8

Backup battery

9

3.1 Key Explanation

The 2 navigation keys permit item selection and modifying the selected value.

ENTER key is used to execute the navigation instruction

ESC key is used to cancel the navigation instruction

Shortcut key to switch the operation mode in the Summary Pages

Shortcut key to trigger ON/OFF in the Summary Pages

Shortcut key to show fault / alarm in the Summary Pages

5

Page 7

4. INSTALLATION

pp

r

r

r

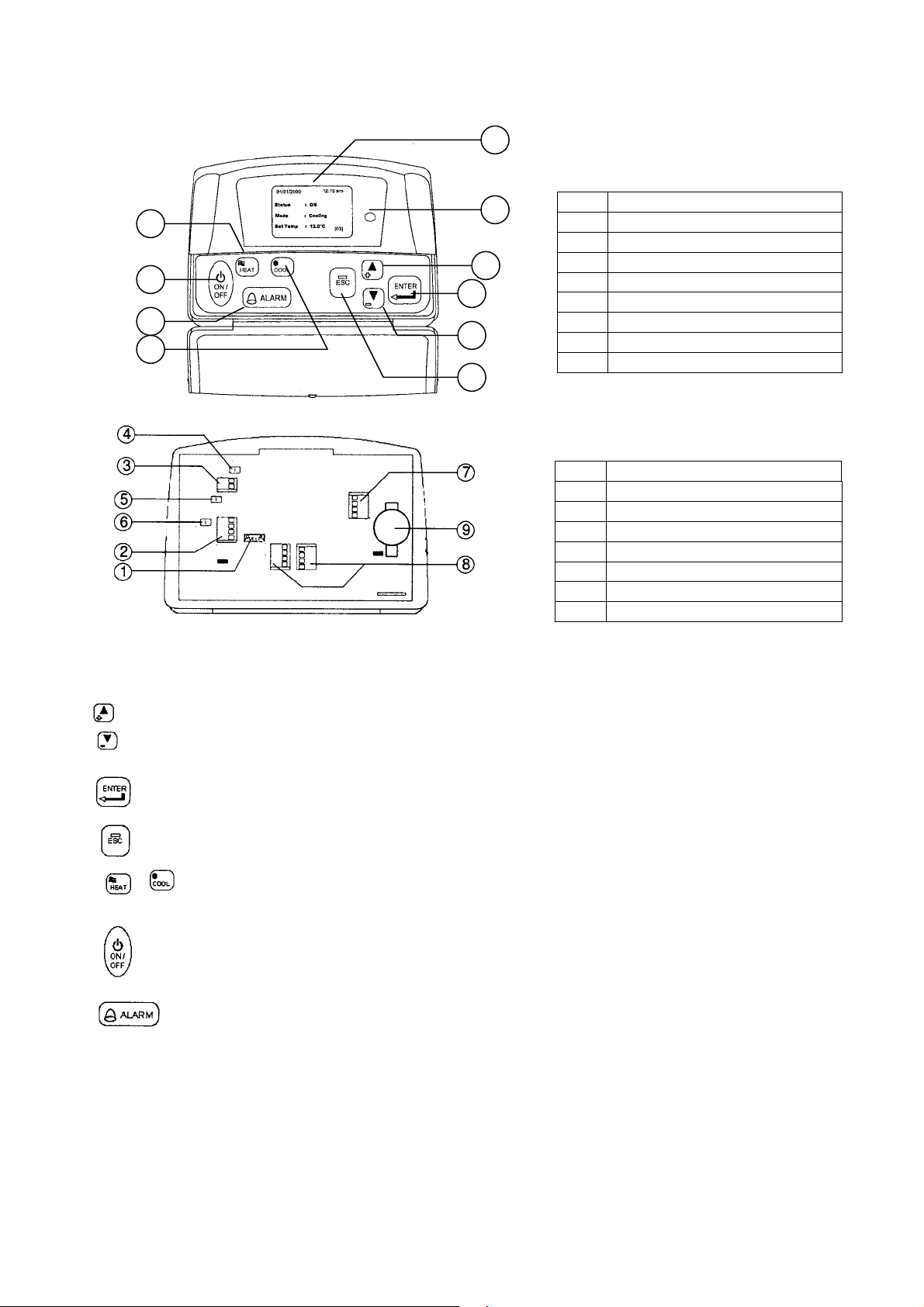

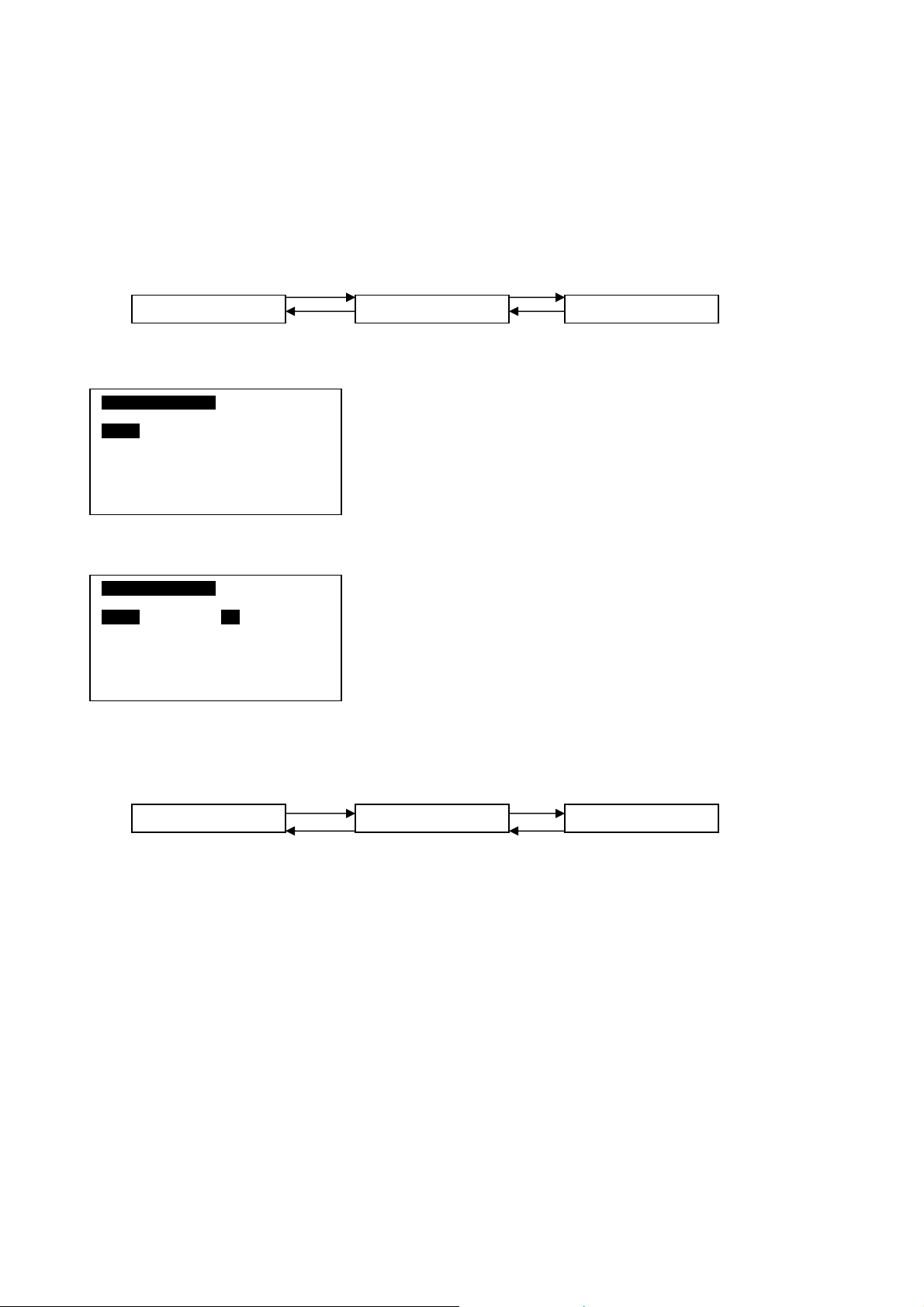

4.1 Chiller Bus

Su

orted up to 50 units of Chille

Chiller 0 Chiller 1 Chiller 2

Chiller Panel 0

(Master)

Chille

(Slave)

Panel 1

5 way wire (CN8)

Chille

Communication bus

CHILLER NETWORK

Chiller panel needs to be energized with +12Vdc. The 5 way wires that provided is once on the easiest solution to

establish a communication between the panel and chiller main board (CN8-CN8). If the 5-way wires socket has been

occupied in main board, just using 2 insulation wires connected to the +12Vdc and GND terminal block from main

board to panel can still energize a panel. Beside that, another 2 insulation wired are needed to establish a

communication between panel and chiller main board.

Chiller panel can support maximum up to 50 units of chiller. In the chiller network, duplication of main board unit

address is not allowed. Each chiller main board should have their unique unit address (0 – 50).

For first time running, user need to assign a unique unit address to each main board in the chiller network. User

should follow the procedure below:

x Only power ON one main board at once time. Make sure not others main boards are energized.

x By using the panel connected to the main board.

<ENTER> <ENTER>

Summary Pages Main Menu Settings Menu

<ENTER>

1. General Set ParameterG7 Unit No

<ENTER>

Key in a unique unit address and press ENTER to execute.

x

x De-energized the main board and repeat the procedures again until all the main boards have been assigned a unique unit

<ENTER>

Key in “0001” as

password

address

IMP ORT A NT : Do not assign a same unit address to more than one chiller main board.

RECOMMENDATION: Please select a coherent model (G1 Model) to all the chiller main boards in the same

network

6

Page 8

4.2 Others Configuration

x JH2 in Chiller panel should let it open (put the jumper header on one pin only) all the time unless user need to

do CMOS reset to that particular panel.

x JH3 should let it open (put the jumper header on one pin only) all the time as well.

x Remember to put in the coin cell battery on the panel. Without the backup battery, the panel will always reset

the time to 12:00am, 1st Jan 2000.

4.3 Installation of the Chiller Panel Controller

x Disconnect the unit and ensure no others unit energy source that supplies the panel.

x Open the rear panel of the Chiller Panel (insert a ‘flat-head’ screwdriver in the top joint of main casing with

rear panel to open the rear panel)

x Pass the necessary wires of the panel across the large opening in the rear panel. Place the rear panel flat

support against the wall and make marks on the wall through the four installation holes (inner or outer).

x Drill four appropriate holes in the marked places.

x Attach the rear panel to the wall and put on the screws on it. Ensure that all cables are passed through the

hole of the rear panel.

x Connect the wires to the corresponding terminal according to the wiring bus network. The power supply and

communication wires must be correctly connected to ensure that the panel works.

x Close the Chiller panel (ensure the bottom joint is aligned for the casing, then complete others joint part.

Ensure that the contacts at the back of the panel are aligned with each others)

BUS WIRING NETWORK

7

Page 9

5. SOFTWARE DESCRIPTION

5.1 Introduction

The Chiller Panel Controller can be used to control/display the status of Chiller.

Status viewing:

x ON/OFF status

x Mode (Cooling/Heating/Boiling)

x Mode set temperature

x Compressor status (ON/OFF/DEFROST)

x Water in, Water out, Outdoor air and Panel temperature

x Chiller Model (Chiller, Heat Pump, Chiller/Boiler, Chiller+Boiler, Heat Pump/Boiler, Heat Pump+Boiler)

x Advance Parameter settings

x Defrost sensor temperatures

x Compressor Discharge sensor temperatures

x Compressor run times

x Incoming alarm/fault/error

Status settings:

x ON/OFF switching

x Mode setting (Cooling/Heating/Boiling)

x Mode set temperature

x Manual entering defrost

x Advance Parameter settings

x Password changing

x Panel Option setting (Backlight, Alarm Buzzer, Screen saver, Contrast, Brightness, temperature unit)

x Time and Date settings

x 7 day programmable settings

x Clearing compressor run time

8

Page 10

5.2 Menu Structure

Menu Structure Diagram for Chiller

9

Page 11

5.3 Chiller Menu Structures

[00]

[00]

[00]

[00]

5.3.1 Summary Pages

There are 4 pages in [Summary Pages]. Press UP or DOWN for page scrolling. Press ENTER to go into [Main

Menu].

Time and date are shown on top of each page. Beside that, the bottom of each page shows current control unit of the

Chiller.

For example: [00] – Chiller Panel controls Chiller ID 0 currently

[03] – Chiller Panel controls Chiller ID 3 currently

[All] – Chiller Panel controls all Chiller currently

1st page: Display ON/OFF status, Mode Settings and Temperature settings.

01/01/2000 12:00am

Status : ON

Mode : Cooling

Cool Temp : 12.0ºC

2nd page: Display Compressor status.

01/01/2000 12:00am

Compressor 1 : ON

3rd page : Display Water In, Water Out, Outdoor Air and Panel temperatures.

01/01/2000 12:00am

Water In : 19.8ºC

Water Out : 25.6ºC

Outdoor Air : 32.2ºC

Panel : 20.5ºC

4th page : Display Chiller model, Compressor No. and Chiller ID.

01/01/2000 12:00am

Model : Chiller

No. Comp : 1 Comp

Unit No. : 0

10

Page 12

5.3.2 Main Menu

y

Press ENTER in [Summary Pages] to go into this menu.

Operating Menu

Setting Menu

Timer Menu

Alarm Menu

Displa

MAIN MENU

Menu

Operation Menu

MAIN MENU

There are 5 sub menus in [Main Menu]. Press UP or DOWN to select sub menus, ENTER to enter into the sub menu

or press ESC to exit to [Summary Pages].

5.3.2.1 Operation Menu

Select [Operation Menu] in [Main Menu] and press ENTER to go into this menu.

OPERATION MENU

Status :ON

Mode : Cooling

Cool Temp : 12.0ºC

Heat Temp : 40.0ºC

OPERATION MENU

Some normal settings can be found here. Press UP or DOWN to select each settings, ENTER to start the setting or

press ESC here to exit to [Main Menu].

Settings: - ON/OFF unit

- Mode changing (Cooling/Heating/Boiling)

- Cooling temperature setting

- Heating temperature setting

- Manual Defrost Selection

Comp 1

5.3.2.1.1 Manual Defrost

Select [Manual Defrost] in [Operation Menu] and press ENTER to go into this menu.

Defrost Compressor

Comp 1

This menu lets user select one compressor to enter into defrost cycle manually, as long as the environment

fulfill the defrost requirement.

11

Page 13

5.3.2.2 Settings Menu

Select [Settings Menu] in [Main Menu] and press ENTER to go into this menu.

SETTINGS MENU

Set Parameter

Change Password

Panel Option

Set Panel ID

Operation Menu

MAIN MENU

Some advance settings can be found here. Press UP or DOWN to select each settings, ENTER to start the setting or

press ESC here to exit to [Main Menu].

Settings: - Set Parameter

- Password Changing

- Panel Option

- Set Panel ID

5.3.2.2.1 Set Parameter

Select [Set Parameter] in [Settings Menu] and press ENTER to go into this menu.

1.General

2. Sensor

3. Regulator

4. Compressor

5. Defrost

6. Antifreeze

7. Alarm and Contact

Comp 1

There are 7 groups of advance parameters for user to set in this menu. Press UP or DOWN to select the

group, ENTER to go into the group or ESC to exit to [Setting Menu].

Settings: - General

- Sensor

- Regulator

- Compressor

- Defrost

- Antifreeze

- Alarm and Contact

5.3.2.2.2 Password Changing

Select [Password Changing] in [Settings Menu] and press ENTER to go into this menu.

Please enter the

old password………

0

- - - -

User can change the old password in this menu.

Press ESC to exit to [Settings Menu].

12

Page 14

5.3.2.2.3 Panel Option

Select [Panel Option] in [Settings Menu] and press ENTER to go into this menu.

Operation Menu

MAIN MENU

User can do some miscellaneous settings for the panel. These settings would not affect whole system

performance.

Settings - toggle Backlight

Press ESC to exit to [Settings Menu].

5.3.2.2.4 Set Panel ID

Select [Set Panel ID] in [Settings Menu] and press ENTER to go into this menu.

Backlight : Normal

Buzzer : On

Screen Saver : Disable

Timeout : 5m

Contrast : 50%

Brightness : Medium

Temp Unit : ºC

- Alarm Buzzer

- Enable/Disable Screen Saver

- Screen Saver timeout

- Contrast display

- Backlight brightness

- Temperature unit

Please enter the0

Panel ID...

=> Unit 0

User can assign the ID no. to the panel.

Example: If ID no. 0 has been assigned, the panel acts like Master Panel Unit. It can choose to control each

Chiller in the network.

If other ID no. (1-50) has been assigned, the panel acts like Slave Panel Unit. It is dedicated to one

particular Chiller. It can only control the Chiller with same ID in the network.

Press [ESC] to exit to [Settings Menu].

13

Page 15

5.3.2.3 Timer Menu

Select [Timer Menu] in [Main Menu] and press ENTER to go into this menu.

TIMER MENU

Clock Setting

Date Setting

Timer Schedule

Timer : Disable

Operation Menu

MAIN MENU

All the timer/schedule settings are included in this menu. Press UP or DOWN to select each settings, ENTER to start

the setting or press ESC here to exit to [Main Menu].

Settings: - Set Clock

- Set Date

- Set Schedule (7 days Programmable Timer)

- Enable/Disable Timer Schedule

5.3.2.3.1 Set Clock

Select [Clock Setting] in [Timer Menu] and press ENTER to go into this menu.

Set Time :

hh mm

00 : 00

User can set the time in this menu. The time setting is in 24-hour format.

Press [ESC] to exit to [Timer Menu].

14

Page 16

5.3.2.3.2 Set Date

Select [Date Setting] in [Timer Menu] and press ENTER to go into this menu.

Operation Menu

MAIN MENU

User can set the date in this menu. The date is set according to sequence below:

Press [ESC] to exit to [Timer Menu].

5.3.2.3.3 Set Schedule

Select [Schedule Timer] in [Timer Menu] and press ENTER to go into this menu.

Set Date :

yyyy mm dd

2000 / 01 / 01

(year) / (month) / (day)

Timer 1 Timer 2

ON OFF ON OFF

Sun 0800 1600 - - - - - - - - -

Mon 0800 1600 - - - - - - - - Tue 0800 1600 - - - - - - - - Wed 0800 1600 - - - - - - - - -

This is the 7 days programmable timer schedule menu. There are 2 ON/OFF events in one day. User can

choose to set each day of week (Sunday – Saturday) ON/OFF timer. Before this schedule carry their effect to

the Chiller, user need to set the [Timer] in [Timer Menu] to enable.

Press [ESC] to exit to [Timer Menu].

5.3.2.4 Alarm Menu

Select [Alarm Menu] in [Main Menu] and press ENTER to go into this menu.

ALARM MENU

Show Alarms

Erase All Alarms

This place keeps records for all previous occurred fault/alarms. User can view the alarm history and clear that

record (alarm history) as well. The panel can keep up to 20 fault/alarm records.

Press ESC to exit to [Main Menu].

15

Page 17

5.3.2.4.1 Show Alarms

Select [Show Alarms] in [Alarm Menu] and press ENTER to go into this menu.

Operation Menu

MAIN MENU

Alarm 1

[Ch 0]

Comp 1 overload

01/ 01 / 00 12:00am

User can view all the fault/alarm records in this menu.

The record shows - Alarm type

- Alarm occurred date

- Alarm occurred time

- Alarm occurred unit (Chiller ID)

Beside that, user can erase the alarm record in this menu.

Press [ESC] to exit to [Alarm Menu].

5.3.2.4.2 Erase All Alarms

Select [Erase All Alarms] in [Alarm Menu] and press ENTER to go into this menu.

Are you sure ?

Press Enter to erase,

or ESC to exit

User can erase all the alarm/fault records at once in this menu.

Press [ESC] to exit to [Alarm Menu].

5.3.2.5 Display Menu

Select [Display Menu] in [Main Menu] and press ENTER to go into this menu.

DISPLAY MENU

Detrost Sensor

Discharge Sensor

Comp Run Time

This menu displays Defrost Sensor temperature, Compressor Discharge sensor temperature and Compressor Run

Time. Beside that, user can clear each Compressor Run Time for Chiller.

Press ESC to exit to [Main Menu].

16

Page 18

Operation Menu

MAIN MENU

5.3.2.5.1 Defrost Sensor

Select [Defrost Sensor] in [Display Menu] and press ENTER to go into this menu.

Defrost Sensor

Cimo 1 : 12.8ºC

User can view the defrost sensor temperature for each compressor in the Chiller.

Press [ESC] to exit to [Display Menu].

5.3.2.5.2 Discharge Sensor

Select [Discharge Sensor] in [Display Menu] and press ENTER to go into this menu.

Discharges Sensor

Comp 1 : 36.5ºC

User can view the discharge sensor temperature for each compressor in the Chiller.

Press [ESC] to exit to [Display Menu].

5.3.2.5.3 Comp Run Time

Select [Comp Run Time] in [Display Menu] and press ENTER to go into this menu.

.

Comp Run Time

Comp 1 : 13579h

User can view the compressor run time for each compressor in the Chiller. Beside that, user can

clear each compressor run time in this menu. User needs to key in the correct password before

clearing the compressor run time.

Press [ESC] to exit to [Display Menu].

17

Page 19

6. OPERATION USER MANUAL

6.1 Starting

Chiller panel can be set as Master or Slave panel unit. When the Panel ID is set to ‘0’, it acts like a Master panel,

whereas it is Slave panel if Panel ID is set to others number (1-50).

Chiller panel can control the Chiller if both ID no. (Panel ID and Chiller ID) are same.

For example: Panel ID 1 can only control Chiller ID 1

Master Panel can choose to control each Chiller or control all Chiller at once in the network.

For example: Panel ID 0 (master) can control Chiller ID 0 / ID 1 / ID 32…. or all Chillers at once.

Panel ID can be set in Set Panel ID in Settings Menu:

Please enter the

Panel ID….

=> Unit 0

18

Page 20

6.2 Chiller Operation Control

[00]

[00]

[00]

6.2.1 Starting

During power on for the Chiller Panel, it needs to take several times to collect information from the Chiller. At this time,

all the status will show ‘--’. Please ensure the particular Chiller exists in the network. When the process is completed,

user can start to control the Chiller using the panel.

01 / 01 /2000 12:00am

Status : --

Mode : --

Cool Temp : --

01 / 01 /2000 12:00am

Status : ON

Mode : Cooling

Cool Temp : 12.0ºC

In gathering information process Gathering information completed

6.2.2 Changing Display Unit

Chiller Panel (Master) can choose to control/display each Chiller status. This can be done in [Summary Pages] only.

01 / 01 /2000 12:00am

Status : ON

Mode : Cooling

Cool Temp : 12.0ºC

In [Summary Pages], press and hold ENTER button (1

second) to go into [Unit Selection] menu.

Unit Selection :

Select All

Select One : 0

Unit Selection :

Select All

Select One : 0

Select “Select All” and press ENTER if user want

to control all Chiller in the network, or select

“Select One” to control a particular Chiller. Press

ESC to exit to [Summary Pages].

Select a Chiller ID via UP or DOWN and press

ENTER to confirm or ESC to cancel.

19

Page 21

6.2.3 Switching ON/OFF

There are several ways to switch ON/OFF for the Chiller.

i) [Summary Pages]

Press and hold ON/OFF button (hold 1 second). Please note that the ON/OFF button will only function in

[Summary Pages].

ii) [Operation Menu]

<ENTER> <ENTER>

Summary Pages Main Menu Operation Menu

<ESC> <ESC>

OPERATION MENU

Status :ON

Mode : Cooling

Cool Temp : 12.0ºC

Heat Temp : 40.0ºC

OPERATION MENU

Status : ON

Mode : Cooling

Cool Temp : 12.0ºC

Heat Temp : 40.0ºC

iii) [Timer Menu]

In [Operation Menu], select “Status” and press

ENTER.

Toggle ON/OFF via UP or DOWN button, and then

press ENTER to confirm the change or ESC to

cancel.

<ENTER> <ENTER>

Main Menu Timer MenuSummary Pages

<ESC> <ESC>

7 days programmable timer can turn chiller ON/OFF. User can set the schedule in this [Timer Menu].

Please refer 6.2.11 (page 27) for schedule settings.

20

Page 22

6.2.4 Switching Mode

There are several ways to switch the mode for the Chiller. Please take note that some mode cannot be set due to

current Chiller model settings.

Chiller Model

Chiller ¥ xx

Heat Pump

Chiller / Boiler

Heat Pump / Boiler

Chiller + Boiler

Heat Pump+ Boiler

Cooling Heating Boiling

¥

¥

¥

¥

¥

Mode

¥ x

X ¥

¥¥

x Auto

¥ Auto

¥ - Allow to set

x - Not allow to set

Auto - Turn ON automatically

i) [Summary Pages]

Cooling - Press and hold COOL button.

Heating - Press and hold HEAT button (if it allows to set).

Boiling - Press and hold HEAT button again (if it allows to set).

ii) [Operation Menu]

<ENTER> <ENTER>

<ESC> <ESC>

OPERATION MENU

Main Menu Summary Pages

Operation Menu

Status : ON

Mode : Cooling

Cool Temp : 12.0ºC

Heat Temp : 40.0ºC

OPERATION MENU

Status : ON

Mode : Cooling

Cool Temp : 12.0ºC

Heat Temp : 40.0ºC

In [Operation Menu], select “Mode” and press

ENTER to start setting or ESC to exit to [Main Menu].

Toggle ON/OFF via UP or DOWN button, and then

press ENTER to confirm the change or ESC to

cancel.

21

Page 23

6.2.5 Changing Mode Set Temperature

There are 2 ways to change the mode set temperature for the Chiller.

i) [Operation Menu]

OPERATION MENU

Status : ON

Mode : Cooling

Cool Temp : 12.0ºC

Heat Temp : 40.0ºC

OPERATION MENU

Status : ON

Mode : Cooling

Cool Temp : 12.0ºC

Heat Temp : 40.0ºC

ii) [Set Parameter]

<ENTER> <ENTER>

Main Menu Summary Pages

<ESC> <ESC>

In [Operation Menu], select “Cool Temp” / “Heat

Temp” and press ENTER to start setting or ESC to exit

to [Main Menu].

Change value via UP or DOWN button, and then

press ENTER to confirm the change or ESC to

cancel.

Operation Menu

Summary Pages Main Menu

<ENTER> <ENTER>

Settings Menu

<ESC> <ESC>

<ENTER> <ESC>

KeyinPassword

Set Parameter

1. General

2. Sensor

3. Regulator

4. Compressor

5. Defrost

6. Antifreeze

7. Alarm and Contact

R1 Cool SP : 12.0ºC

R2 Cool Diff : 3.0ºC

R3 Heat SP : 40.0ºC

R4 Heat Diff : 3.0ºC

R5 Min Cool SP : -20ºC

R6 Max Cool SP : 40ºC

R7 Min Heat SP : -20ºC

R1 Cool SP : 12.0ºC

R2 Cool Diff : 3.0ºC

R3 Heat SP : 40.0ºC

R4 Heat Diff : 3.0ºC

R5 Min Cool SP : -20ºC

R6 Max Cool SP : 40ºC

R7 Min Heat SP : -20ºC

3. Regulator

In [Set Parameter], select “Regulator” and press

ENTER. Press ESC to exit to [Main Menu].

3. Regulator

Select “R3” / “R5” and press ENTER to start

setting or ESC to exit to [Set Parameter] menu.

Change value via UP or DOWN button. The

borderlines limited by R5&R6 (cool), R7&R8 (heat).

Press ENTER to confirm or ESC to cancel.

22

Page 24

6.2.6 Manual Defrost

User can choose which compressor will go into manual defrost cycle by using the Chiller Panel, as long as the

condition is fulfilled with defrost condition. This can be done in [Operation Menu].

<ENTER> <ENTER>

<ESC> <ESC>

Main Menu Summary Pages

Operation Menu

Please take note that “Manual Defrost” option will only available in HEATING mode. It will disappear in

COOLING/BOILING mode.

OPERATION MENU

Status : ON

Mode : Cooling

Cool Temp : 12.0ºC

Heat Temp : 40.0ºC

OPERATION MENU

Status : ON

Mode : Heating

Cool Temp : 12.0ºC

Heat Temp : 40.0ºC

Manual Defrost

“Manual Defrost” disappear when Chiller not in HEATING mode

OPERATION MENU

Status : ON

Mode : Cooling

Cool Temp : 12.0ºC

Heat Temp : 40.0ºC

Manual Defrost

In [Operation Menu], select [Manual Defrost],

press ENTER to go into it, or ESC to exit to [Main

Menu].

Defrost Compressor

Comp 1

Comp 1

Select which compressor to go into defrost cycle

via UP or DOWN button. Press ENTER to confirm

or ESC to exit to [Operation Menu].

23

Page 25

6.2.7 Advance Parameter Settings

The Chiller Panel provide user a lot of advance parameter settings for the Chiller. The parameters are divided into 7

groups. There all are stored in [Set Parameter] menu and it is password-protected layer in the panel.

*CAUTION: INPROPER SETTINGS WILL CAUSE PERMANENT DAMAGE TO THE CHILLER!!!

Summary Pages Main Menu

7 groups of Advance Parameter:

1) General

G1 Model : Chiller

G2 No.Comp : 1 Comp

G3 On/Off In : Disabale

G4 Co/ Heat In : Disable

G5 Ext Alarm in : Disable

G6 Water Sys : Isolated

G7 Unit No : 0

2) Sensor

S1 Water Enter : 0.0ºC

S2 Water Leave : 0.0ºC

S3 Air Sensor : 0.0ºC

S4 Defrost 1 : 0.0ºC

S5 Defrost 2 : 0.0ºC

S6 Defrost 3 : 0.0ºC

S7 Defrost 4 : 0.0ºC

<ENTER> <ENTER>

Settings Menu

<ESC> <ESC>

<ENTER> <ESC>

Key in password

Set Parameter

S8 Cp Dish 1 : 0.0ºC

S9 Cp Dish 2 : 0.0ºC

S10 Cp Dish 3 : 0.0ºC

S11 Cp Dish 4 : 0.0ºC

3) Regulator

R1 Cool SP : 12.0ºC

R2 Cool Diff : 3.0ºC

R3 Heat SP : 40.0ºC

R4 Heat Diff : 3.0ºC

R5 Mix Cool SP : -20ºC

R6 Max Cool SP : 40ºC

R7 Min Heat SP : -20ºC

R8 Max Heat SP : 90ºC

R9 Ax Heat SP : 5.0ºC

R10 Ax Heat Diff : 2.0ºC

R11 Au Bo SP : 5.0ºC

R12 Au Bo Diff : 2.0ºC

R13 Au Bo Start : 30m

24

Page 26

4) Compressor

p

C1 Min Run : 120s

C2 Min Stop : 240s

C3 2On Interval : 360s

C4 2Cp ON Dly : 15s

C5 P-Cp ON Dly : 60s

C6 Cp-P OFF Dly : 60s

Cut Off : 120ºC

C7 C

5) Condenser Defrost

D1 Start Temp : -3ºC

D2 End Temp : 14ºC

D3 Max Dura : 10m

D4 Interval : 45m

D5 Dly Bfr Def : 0s

D6 Dly Aft Def : 0s

6) Cool Mode Antifreeze

A1 Heater SP :5ºC

A2 Heater Diff : 2.0ºC

A3 Sensor : Leave

A4 Alarm SP : 3ºC

A5 Alarm Diff : 2.0ºC

7) Alarm and Contact

P1 FS Confirm :5s

P2 FS Delay : 180s

P3 LP Delay : 30s

P4 CO Reset : Manual

P5 HP Rest : Auto

P6 LP Reset : Auto

P7 FO Reset : Manual :

P8 RO Reset : Manual

P9 FS Reset : Manual

P10 Aux Reset : Manual

P11 A/F Reset : Manual

P12 CO Contact : Normal

P13 HP Contact : Normal

P14 LP Contact : Normal

Please refer to 8. APPENDIX for detail description.

P15 FO Contact : Normal

P16 PO Contact : Normal

P17 FS Contact : Normal

P18 EA Contact : Normal

P19 DE Contact : Normal

25

Page 27

6.2.8 Changing Password

For security purpose, some places in the panel are password-protected. User can change the password at anytime.

Summary Pages

<ENTER> <ENTER>

<ESC> <ESC>

<ENTER> <ESC>

Please enter the

Old password…….

Main Menu

Settings Menu

Change Password

User needs to enter the old password in order to

change the password.

0

- - - -

Change the 1st digit value via UP or DOWN. Press

ENTER to start enter 2nd digit and the rest, or ESC to

exit at anytime.

Password accepted ….

Access granted !

Password error ….

Access denied !

If password correct, this message will be If password not correct, this message will be

shown and proceed to new password shown and exit to [Settings Menu]

settings.

Please enter the

New password…….

0

- - - -

New password

has been set……

Same as previous, UP DOWN to change value, ENTER

to go to next digit, ESC to exit.

User is not allowed to set the password to 0000.

New password

‘0 0 0 0’

Is not accepted ……

If new password is accepted, this message If new password is ‘0000’, this message will be

will be shown and then exit to [Settings shown and then exit to [Settings Menu]. The

Menu]. password remains as previous.

26

Page 28

6.2.9 Clock Setting

User can set the clock for the panel.

Summary Pages Main Menu

<ENTER> <ESC>

Set Time :

hh mm

00 : 00

<ENTER> <ENTER>

Timer Menu

<ESC> <ESC>

Set Time

UP or DOWN to change ‘hour’. ENTER to set ‘minute’

or ESC to exit to [Timer Menu].

UP or DOWN to change ‘minute’. ENTER to confirm or

ESC to set ‘hour’ again.

6.4.10 Date Setting

User can set the date for the panel.

Summary Pages Main Menu

<ENTER> <ENTER>

Timer Menu

<ESC> <ESC>

<ENTER> <ESC>

Set Date

Set Date :

yyyy mm dd

2000 / 01 / 01

000

UP or DOWN to change ‘year’. ENTER to set ‘month’ or

ESC to exit to [Timer Menu].

UP or DOWN to change ‘month’. ENTER to set ‘day’ or

ESC to set ‘year’ again.

UP or DOWN to change ‘day’. ENTER to confirm or

ESC to set ‘month’ again.

27

Page 29

6.2.11 7 Days Programmable Setting

There are 2 ON/OFF events in one day for the schedule. This schedule is applicable to all the chillers in the network.

Summary Pages

<ENTER> <ESC>

Timer 1 Timer 2

ON OFF ON OFF

Sun 0800 1800 - - - - - - - -

Mon 0800 1800 - - - - - - - Tue 0800 1800 - - - - - - - Wed 0800 1800 - - - - - - - -

Timer 1 Timer 2

ON OFF ON OFF

<ENTER> <ENTER>

Main Menu

<ESC> <ESC>

Sun

UP or DOWN select day of week. ENTER to select

event or ESC to exit to [Timer Menu].

OFF ON OFF

UP or DOWN select event. ENTER to start setting or

Timer Menu

Set Schedule

ESC to back to select day of week.

Sun 0800 1800 - - - - - - - Mon 0800 1800 - - - - - - - Tue 0800 1800 - - - - - - - Wed 0800 1800 - - - - - - - -

Event setting is same like time setting. User can disable

the event by set it to‘- - - -’

Before the schedule will carry the effect, user need to set ENABLE for “TIMER” in [Timer Menu].

OFF ON OFF

TIMER MENU

Set Time

Set Date

Set Schedule

Timer : Disable

Select “Timer” and press ENTER to start the settings.

UP or DOWN to toggle Enable/Disable, ENTER to

confirm or ESC to cancel.

28

Page 30

6.2.12 Viewing Alarm / Erase Alarm Record

Whenever a new fault/alarm is occurred, there will be a message pop up to show the fault/alarm. Backlight

will blinking with beeping sound (if “Alarm Buzzer” is set ON). If the fault/alarm has not been dissolved

from the Chiller, a sign [A] will be shown in the [Summary Pages]. Whereas, it will return to [Summary

Pages] (from pop up menu) automatically if the fault/alarms have been dissolved.

While the fault/alarms have not been dissolved (sign [A]), user can check that fault/alarm by go into [Alarm

Menu]. If all the fault/alarm have been dissolved, user can view the fault/alarm history records in [Alarm

Menu] as well. Screen saver will be deactivated while all the alarms have not been dissolved.

If panel ID is set 0 (Master panel), it can receive and view all the fault/alarms from all chillers in the network.

New Alarm 1

Comp 1 overload

12:00am 01/01/2000

<ENTER> <ESC>

Alarm 1

Comp 1 overload

01/01/00 12:00am

[Ch 0]

[Ch 0] show alarm occurred unit.

Press any button to stop backlight blinking and beeping.

Press ESC again to exit to normal page.

<ENTER> <ENTER>

Summary Pages Main Menu

<ESC> <ESC>

[Ch 0]

Press UP or DOWN to scroll the record.

Press ENTER if user want to erase the record, or ESC

to exit to [Alarm Menu].

Alarm Menu

Show Alarms

Erase Alarn ?

Press Enter to erase,

Or ESC to exit

000

Press ENTER to erase the alarm, or ESC to cancel.

User can erase all the fault / alarm record at once time through [Erase All Alarms] in [Alarm Menu].

29

Page 31

6.2.13 Viewing Defrost Sensor Temperature

The Chiller Panel displays defrost sensor temperature for each compressor in [Defrost Sensor] in [Display Menu].

Summary Pages Main Menu

<ENTER> <ESC>

Defrost Sensor

<ENTER> <ENTER>

Display Menu

<ESC> <ESC>

Defrost Sensor

Press ESC to exit to [Display Menu]

Comp 1 : 12.8ºC

6.2.14 Viewing Compressor Discharge Temperature

The Chiller Panel displays compressor discharge temperature for each compressor in [Discharge Sensor] in

[Display Menu].

<ENTER> <ENTER>

Main Menu Summary Pages

<ESC> <ESC>

<ENTER> <ESC>

Display Menu

Discharge Sensor

Comp1 36.5ºC

Discharge Sensor

000

Press ESC to exit to [Display Menu]

30

Page 32

6.2.15 Viewing/Clear Compressor Run Time

f

l

User can view / clear the compressor run time for the Chiller in [Comp Run Time] in [Display Menu].

Summary Pages Main Menu

<ENTER> <ENTER>

<ESC> <ESC>

Comp Run Time

Comp 1 : 13579h

Clear Run Time ?

Press Enter to clear,

Or ESC to exit

Display Menu

<ENTER> <ESC>

Comp Run Time

Press UP or DOWN to select the compressor. ENTER

to start clear the run time, or ESC to exit to [Display

Menu].

Press ENTER and key in the password to confirm or

ESC to cancel.

6.2.16 Miscellaneous Settings

User can do some miscellaneous settings to the panel.

<ENTER> <ENTER>

Summary Pages Main Menu

<ESC> <ESC>

Backlight : Normal

Buzzer : ON

Screen Saver : Disable

Timeout : 5m

Contrast : 50%

Brightness : Medium

Temp Unit : ºC

000

Press UP or DOWN to select the item. ENTER to set,

or ESC to exit to [Settings Menu].

Press UP or DOWN to toggle the value. ENTER to

irm, or ESC to cance

con

Settings Menu

<ENTER> <ESC>

Panel Option

31

Page 33

Parameter Value Description

Backlight

Buzzer

* Screen Saver

* Timeout 1 – 30m Timeout for showing screen saver

Contract 0 – 100% Adjust the contrast setting for the LCD panel

Brightness

Temp Unit

Normal Turn ON backlight for 30s via key press

Always Always ON backlight

ON Enable beeping sound when fault/ alarm occurred

OFF Disable beeping sound when fault / alarm occurred

Enable Show screen saver when timeout

Disable No screen save

OFF No backlight

Low, Medium, High Adjust the backlight intensity

ºC Display temperature in degree Celsius

ºF Display temperature in Fahrenheit

* This product must be branded. Screen saver will be deactivated for brand less panel

6.3 CMOS Reset

x CMOS reset allows user to reset some settings to default value such as:

Password -> 0001

Backlight -> Normal

Buzzer -> ON

Screen Saver -> Disable

Timeout -> 5m

Contrast -> 50%

Brightness -> Medium

Temp Unit -> ºC

x Procedures

1. Power OFF the panel

2. Close the jumper JH2 with the provided jumper header

3. Power ON the panel and the LCD panel should display as follow:

CMOS is resetting ……….

CMOS reset completed!

Please remove JUMPER

and restart the panel

4. Remove the jumper header (put the jumper header on 1 pin only), power OFF and then power ON the panel.

32

Page 34

7. PROBLEMS AND TROUBLESHOOTING

Symptoms Possible Cause Troubleshooting

Panel gets hot

1

abnormally

The LCD no display

2

(blank screen)

'- -' for all status (quite

3

a long time)

• Wiring fault in 12VDC supply

• Wiring fault in the 12VDC

supply

• No power supply • Check the wiring and supply 12VDC to panel

• Voltage supply too low • Check the power source

• Module defective • Change a new panel module

• Panel cannot/not yet

received the information

from Chiller or FCU

completely

• That particular unit address

is not recognized by the

panel

• Module defective • Change a new module

• Change a new panel module and turn ON the unit again

after the verification

• Correct the wiring problem

• Ensure the selected unit exists in the network.

• Ensure the wiring is correct.

• Ensure the wiring is not defective.

• Ensure the wiring has been isolated from high power cable

• Select a coherent unit address on the panel (refer to

6.2.2)

ON/OFF, COOL or

4

HEAT button not

function

Cannot switch to

5

HEATING mode

Cannot switch to

6

BOILING mode

No "Manual Defrost"

7

item

Cannot step inside [Set

8

Parameter]

7 Days Programmable

9

Timer not function

No beeping sound

10

when new alarm

occurred

No screen saver after

11

timeout

• Software limitation

• Module defective • Change a new module

• Software limitation

• Software limitation

• Software limitation • Ensure current running mode is HEATING

• Software limitation. Panel

has not received all the

information from Chiller

completely

• Software limitation. User

did not activate the

schedule

• Software limitation. User

did not set ON to the alarm

buzzer

• Software limitation. User

did not set ENABLE to the

screen saver

• Ensure it is pressed (hold 1s) in [Summary Pages],

not in others menu.

• Ensure this mode is available in current "Model" of

Chiller. Please refer to 6.2.4

• Ensure this mode is available in current "Model" of

Chiller. Please refer to 6.2.4

• Refer to symptoms 3

Control of Chiller:

• Ensure the "Timer" in [Timer Menu] is set ENABLE

Control of Chiller:

• Ensure the "Timer" in [Operation Menu] is set

ENABLE

• Ensure "Buzzer" in [Panel Option] is set ON

• Ensure "Screen Saver" in [Panel Option] is set

ENABLE

12

Time always reset to

12:00am,1

Panel stop operation.

13

Whole operation

freezing (hang)

St

Jan 2000

• No backup battery

• Energy of the backup

battery is low

• Unstable power supply

• Energy of the backup

battery is low

• Replace a coin cell battery

• Power off the panel. Take out the backup battery as

well. Replace with a new 3V coil cell battery if

necessary. Put back the backup battery into the

panel and power on again.

33

Page 35

8. APPENDIX

)0(0)

)0(0)

)0(0)

)0(0)

)0(0)

)0(0)

)0(0)

)0(0)

)0(0)

)

g

)

)

)10(18)

p

)

)

)10(18)

y

y

GENERAL Type Unit Default

G1 Model

O=Chiller,

1=Heat Pump,

2=Chiller/ Boiler,

3=Heat pump/Boiler, 4=Chiller+Boiler,

5=Heat pump+Boiler

Number of compressor

G2

1=1 compressor,

2=2 compressor

3=3 compressor,

4=4 compressor

On/off input

G3

0=disable, 1=enable

Cool/Heat input

G4

0=disable, 1=enable

External alarm input

G5

0=disable, 1=enable

Water system for chiller network

G6

0=independent, 1=modular

G7 Unit number F Flag 0 0 50 1

Min Max Resolution

FFlag4

(Chiller+Boiler)

FFlag1 14 1

FFlag0(disable)01 1

F Flag 0 (disable) 0 1 1

FFlag0(disable)01 1

FFlag0(disable)01 1

0 2 1

SENSOR

S1 Entering water sensor calibration

S2 Leavingwater sensor calibration U °C(°F

S3 Air sensor calibration U °C(°F

S4 Defrost(condenser) sensor 1 calibration U °C(°F

S5 Defrost(condenser) sensor 2 calibration U °C(°F

S6 Defrost(condenser) sensor 3 calibration U °C(°F

S7 Defrost(condenser) sensor 4 calibration U °C(°F

S8 Compressor discharge sensor 1 calibration U °C(°F

S9 Compressor discharge sensor 2 calibration U °C(°F

S 10 Compressor discharge sensor 3 calibration U °C(°F

S11 Compressor discharge sensor 4 calibration U °C (°F) 0 (0) -12 (-21.6) 12 (21.6) 0. 1

REGULATOR Type Unit Default Min Max Resolution

R1 Cooling set-point D °C (°F) 12 (53.6) R5 R6 0.1

R2 Cooling differential U °C (°F) 1.5* (2.7) 0.4 (0.7) 10(1 8 ) 0.1

R3 Heating set-point D °C (°F) 40 (104) R7 R8 0.1

R4 Heating differential U °C (°F) 1.5* (2.7) 0.4 (0.7) 10 (18) 0.1

R5 Minimum Cooling set-point U °C (°F) 7 (44.6) -20 (-4) R6 1

R6 Maximum Cooling set-point U °C(°F)20(68

R7 Minimum Heating set-point U °C (°F) 3 0 (8 6 ) -20 (-4) R8 1

R8 Maximum Heating set-point U °C (°F) 50 (122) R7 90 (194) 1

Auxiliary heater set-point (threshold below

R9

R10 Auxiliary heater differential U °C(°F)2(3.6

R11

R12 Auto boiler differential U °C(°F)2(3.6

R13 Auto boiler start time threshold U min 30 0 199 1

set-point

heatin

Auto boiler set-point (threshold below heating

oint

set-

Type Unit Default Min Max Resolution

U

U °C (°F) 5 (9) 0 (0) 40 (72) 0.1

U °C (°F) 5 (9) 0 (0) 40 (72) 0.1

ºC( F) 0 (0) -12 ( 216) 12 (21.6) 0.1

-12(-21.6)12(21.6)0.1

-12(-21.6)12(21.6)0.1

-12(-21.6)12(21.6)0.1

-12(-21.6)12(21.6)0.1

-12(-21.6)12(21.6)0.1

-12(-21.6)12(21.6)0.1

-12(-21.6)12(21.6)0.1

-12(-21.6)12(21.6)0.1

-12(-21.6)12(21.6)0.1

R5 40(104)1

0.4(0.7

0.4(0.7

0.1

0.1

COMPRESSOR Type Unit Default Max Min Resolution

C1 Compressor minimum run time

C2 Compressor minimum stop time U sec 180 0 1990 10

C3 Time interval between two starts U sec 450 0 1990 10

C4 Start delay between two compressors U sec 15 0 199 1

C5 Pump on ĺ compressor on dela

C6 Comp off ĺ pump off dela

C7 Discharge cut-off set-point U °C 120 (248) 0 (32) 150 (302) 1

CO ND EN SE R DE FR OST Typ e Unit Default Max Min Resolution

D1 S ta rt d ef rost t em pera tu re U °C (ºF ) 0 (32) -20 (-4) D2 1

D2 End defrost temperature U °C (ºF) 14 (57) D1 40 (104) 1

Usec120

U sec 180 0 1990 10

U sec 60 0 199 10

0

1990 10

34

Page 36

D3 Maximum duration of defrost cycle U min 10 1 40 1

g

r

(

g)

(

)

5

(

)

g

(

)

g

(

)

8

g

(

)

g

(

)

g

(

)

g

(

)

y open(NO)

g

y open(NO)

g

y open(NO)

g

y op

)

g

y open(NO)

g

y open(NO)

g

y open(NO)

g

D4 Defrost interval time U min 4 5 0 199 1

D5 Delay before defrosting U sec 0 0 1990 10

D6 Delay after defrosting U sec 120 0 1990 10

COOL MODE ANTIFREEZE Type Unit Default Min Max Resolution

A1 Antifreeze heater set-point U °C ( F) 5 (41) -40 (-40) 40 (104) 1

A2 Antifreeze heater differential U °C (°F) 2 (3.6) 0.4 (0.7) 10 (18) 0.1

Antifreeze sensor select

A3

0=Leavin

A4 Antifreeze alarm set-point U °C (°F) 3 (37) -40 (-40) 40 (104) 1

A5 Antifreeze alarm differential U °C (°F) 2 (3.6) 0.4 (0.7) 10 (18) 0 .1

water, 1=Entering wate

U Flag

0

leavin

01

1

ALARM AND CONTACT

P1 Flow switch confirmation time U sec 5 0

P2 Flow switch alarm delay at pump start U sec 120 0 199 1

P3 Low pressure alarm delay at compressor start-up U sec 30 0 199 1

P4 Comp overload alarm reset type U Flag 0 0 1 1

0=Manual reset, 1=Auto reset

P

High pressure alarm reset type U Flag 1 0 1 1

0=Manual reset, 1=Auto reset

P6 Low pressure alarm reset type U Fla

0=Manual reset, 1=Auto reset

P7 Fan overload alarm reset typeUFla

0=Manual reset, 1=Auto reset

P

Pump overload alarm reset typeUFla

0=Manual reset, 1=Auto reset

P9 Flow switch alarm reset type U Fla

0=Manual reset, 1=Auto reset

P10 Auxiliary alarm reset type U Fla

0=Manual reset, 1=Auto reset

P11 Antifreeze alarm reset type U Fla

0=Manual reset, 1=Auto reset

P12 Comp overload contact type U Flag 0 0 1 1

0=Normally close (NC)

1=Normall

P13 High pressure contact type U Fla

0=Normally close (NC)

1=Normall

P14 Lowpressure contact typeUFla

0=Normally close (NC)

1=Normall

P15 Fan overload contact typeUFla

0=Normally close (NC)

1=Normall

P16 Pump overload contact typeUFla

0=Normally close (NC)

1=Normall

P17 Flow switch contact type U Fla

0=Normally close (NC)

1=Normall

P18 External alarm contact typeUFla

0=Normally close (NC)

1=Normall

P19 Defrost end contact typeUFla

0=Normally close (NC)

1=Normally open (NO)

en(NO

Type Unit Default Min Max Resolution

199 1

manual

auto

10 11

auto

10 11

auto

00 11

manual

00 11

manual

10 11

auto

10 11

auto

(NC)

00 11

(NC)

00 11

(NC)

00 11

(NC)

00 11

(NC)

00 11

(NC)

00 11

(NC)

00 11

(NC)

35

Page 37

Specifications

Air Cooled Chiller – R22 Cooling Only

MODEL MAC080C MAC100C MAC120C MAC150C

NOMINAL CAPACITY kcal/hr 19657 23437 29233 34777

MATERIAL

CASING FINISH

THICKNESS mm

HEIGHT (H) mm

DIMENSION W IDTH (W) mm

DEPTH (D) mm

WEIGHT kg 340 350 460 540

NOISE LEVEL dBA 65 66 67 69

PACKING HEIGHT (H) mm

DIMENSION W IDTH (W) mm

DEPTH (D) mm

CONDENSER COIL

TYPE

MATERIAL

TUBE W ALL THICKNESS mm

OUTER DIAMETER mm

MATERIAL

FIN THICKNESS mm

ROWS 2222

FIN PER INCH 14 14 14 14

TOTAL FACE AREA

EVAPORATOR

TYPE

PLATE MATERIAL

NOMINAL WATER FLOW L/s 1.08 1.31 1.67 2.00

CONDENSER FAN

TYPE/DRIVE

QUANTITY

BLADE MATERIAL

BLADE DIAMETER INCH

POWER SUPPLY V/Ph/Hz

RATED RUNNING CURRENT Amp 1.2 x 2 1.2 x 2 1.8 x 2 3.4 x 2

RATED INPUT Watt 386 x 2 766 x 2

RATED OUTPUT Watt 200 x 2 450 x 2

MOTOR POLES 8886

WATER LINE (HYDRAULIC KIT)

TYPE

PUMP MAX. WATER OPER. PRESSURE kPa

RUNNING CURRENT Amp 1.5 1.5 2.0 2.0

WATER FLOW RATE GPM 17.2 20.7 26.4 31.7

PIPING INSTALLATION PIPE CONNECTION

HEAD m 26 23.5 25 23

COMPRESSOR

TYPE

POWER SUPPLY V/Ph/Hz

RATED CURRENT Amp x 2 7.0 7.4 9.9 11.2

RATED INPUT Watt x 2 3526 4280 4717 5724

MAXIMUM STARTING CURRENT Amp 65 x 2 74 x 2 76 x 2 95 x 2

PROTECTION DEVICES

STAGE OF CAPACITY CONTROL

REFRIGERANT

TYPE

CONTROL

CHARGING MASS kg 4.5 x 2 3.9 x 2 6.0 x 2 7.1 x 2

Btu/hr 78000 93000 116000 138000

Watt 22860 27257 33998 40445

1245

1500

900

1452 1452

1732 2032

1032 1282

2

m

mm(in)

1.37 1.37 1.79 1.79

283 x 2

120 x 2

Overload Protection, Differential and H/L Pressure Switch

Electro-galvanized Mild Steel

Polyester Powder

1.5

Cross Finned Tubes

Seamless Copper

0.35

Aluminium (Hydrophilic)

Brazed Plate Heat Exchanger

24 26

Horizontal Multistage End-Suction

9.52

0.11

Stainless Steel

Propeller/Direct

Aluminium

220-240/1/50

1000

42mmBSP(1

SCROLL

380-415/3/50

0~50~100

R22

TXV

1

/4")

1245

1800

1150

22

Note : Nominal values are based on 12°C / 7°C entering / leaving evaporator water temperature , 35°C air ambient temperature.

36

Page 38

Air Cooled Chiller – R22 Heat Pump

MODEL MAC080CR MAC100CR MAC120CR MAC150CR

NOMINAL CAPACITY (COOLING / HEATING) k cal/ hr 19405 / 22680 23689 / 27721 28477 / 30241 34778 / 33266

MATERIAL

CASING FINISH

THICK NE SS mm

HEIGHT (H) m m

DIMENSION WIDTH (W) mm

DEPTH (D) mm

WEIGHT kg 350 360 480 560

NOISE LEVEL dBA 61 62 63 64

PACKING HEIGHT (H) mm

DIMENSION WIDTH (W) mm

DEPTH (D) mm

CONDENSER COIL

TYPE

MATERIAL

TUBE WALL THICKNESS mm

OUTER DIAM ETER m m

MATERIAL

FIN THICKNES S mm

ROWS 2222

FIN PERINCH 14141414

TOTAL FACE AREA m

EVAPORATOR

TYPE

PLATE MATERIAL

NOMINAL W ATER FLOW L/s 1.08 / 1.14 1.31 / 1. 37 1.67 / 1.79 2. 00 / 2. 10

CONDENSER FAN

TYPE/DRIVE

QU ANTITY

BLADE MATERIAL

BLADE DIAMETER INCH

POWER SUPPLY V/Ph/Hz

RATED RUNNING CURRE NT Amp 1.2 x 2 1. 2 x 2 1.8 x 2 3.4 x 2

RATED INPUT(COOLIING / HEATING) W att 386 x 2 766 x 2

RATED OUTPUT(COOLING / HEATING) W att 200 x 2 450 x 2

MOTOR POLES 8 8 8 6

WAT ER LINE (HYDRAULIC KI T)

TYPE

PUMP MAX. WATER OPER. PRESSURE kPa

RUNNING CURRENT Amp 1.5 1.5 2.0 2.0

WATER FLOW RATE GPM 17.2 / 18.1 20.7 / 21.7 26.4 / 28.4 31.7 / 33.3

PIPING INSTALLATION PIPE CONNECTION

HEAD m 26 / 25 23.5 / 22.5 25 / 24.5 23 / 22.5

COMPRESSOR

TYPE

POWER SUPPLY V/Ph/Hz

RATED CURRE NT (COOLING / HEA TING) A mp x 2 7.0 / 6.7 8.0 / 7. 6 10.2 / 10. 3 11.0 / 11.5

RATED INPUT (COOLING / HEATING) Watt x 2 3981 / 3857 4595 / 4347 5071 / 5188 5775 / 6120

MAXIMUM S TARTING CURRENT A mp 65 x 2 74 x 2 76 x 2 95 x 2

PROTECTION DEVICES

STAGE OF CAPACITY CONTROL

REFRIGERANT

TYPE

CONTROL

CHARGING MASS kg 4.3 x 2 4.5 x 2 7.6 x 2 6.5 x 2

Note : Nominal values are based on 12°C / 7°C entering / leaving evaporator water temperature , 35°C air ambient temperature.

Note : Nominal values are based on 40°C / 45°C entering / leaving evaporator water temperature , 7°C air ambient temperature.

Note : Unit dimension withouit hydraulic kit.

Btu/ hr 77000 / 90000 94000 / 110000 113000 / 120000 138000 / 132000

Wat t 22567 / 26376 27549 / 32239 33118 / 35169 40445 / 38686

1245

1500

1452 1452

1732 2032

1032 1282

2

mm(in)

1.37 1. 37 1.79 1. 79

283 x 2

120 x 2

Oveload Protection, Differential and H/L Pressure Switch

Elec tro-galvanized Mild S teel

Polyester Powder

1.5

900

Cross Finned Tubes

Seaml ess Copper

0.35

Aluminium (Hydrophilic)

Brazed Plate Heat Ex changer

24 26

Horizontal Multist age End-Suc tion

9.52

0.11

Stainless Steel

Propell er/Direct

Aluminium

220-240/1/ 50

1000

42mmBSP(1

SCROLL

380-415/3/ 50

ON/OFF

R22

Capillary Tube

1

/4")

1245

1800

1150

22

37

Page 39

Air Cooled Chiller – R407 Cooling Only

MODEL M4AC080C M4AC100C M4AC120C M4AC150C

NOMINAL CAPACITY kcal/hr 18649 22177 28982 34525

MATERIAL

CASING FINISH

THICKNESS mm

HEIGHT (H) mm

DIMENSION WIDTH (W) mm

DEPTH (D) mm

WEIGHT kg 340 350 460 540

NOISE LEVEL dBA 65 66 67 69

PACKING HEIGHT (H) mm

DIMENSION WIDTH (W) mm

DEPTH (D) mm

CONDENSER COIL

TYPE

MATERIAL

TUBE WALL THICKNESS m m

OUTER DIAMETER mm

MATERIAL

FIN THICKNESS mm

ROWS 2222

FIN PER INCH 14 14 14 14

TOTAL FACE AREA

EVAPORATOR

TYPE

PLATE MATERIAL

NOMINAL WATER FLOW L/s 1.08 1.31 1.67 2.00

CONDENSER FAN

TYPE/DRIVE

QUANTITY

BLADE MATERIAL

BLADE DIAMETER INCH

POWER SUPPLY V/Ph/Hz

RATED RUNNING CURRENT Amp 1.2 x 2 1.2 x 2 1.8 x 2 3.4 x 2

RATED INPUT Watt 386 x 2 766 x 2

RATED OUTPUT Watt 200 x 2 450 x 2

MOTOR POLES 8886

WATER LINE (HYDRAULIC KIT)

TYPE

PUMP MAX. WATER OPER. PRESSURE kPa

RUNNING CURRENT Amp 1.5 1.5 2.0 2.0

WATER FLOW RATE GPM 17.2 20.7 26.4 31.7

PIPING INSTALLATION PIPE CONNECTION

HEAD m 26 23.5 25 23

COMPRESSOR

TYPE

POWER SUPPLY V/Ph/Hz

RATED CURRENT Amp x 2 7.5 7.9 10.2 11.8

RATED INPUT Watt x 2 3924 4578 5117 6100

MAXIMUM STARTING CURRENT Amp 65 x 2 74 x 2 76 x 2 95 x 2

PROTECTION DEVICES

STAGE OF CAPACITY CONTROL

REFRIGERANT

TYPE

CONTROL

CHARGING MASS kg 4.0 x 2 3.9 x 2 5.6 x 2 6.0 x 2

Btu/hr 74000 88000 115000 137000

Watt 21688 25791 33705 40152

Electro-galvanized Mild Steel

Polyester Powder

1.5

1245

1500

900

1245

1800

1150

1452 1452

1732 2032

1032 1282

Cross Finned Tubes

Seamless Copper

0.35

9.52

Aluminium (Hydrophilic)

0.11

2

m

1.37 1.37 1.79 1.79

Brazed Plate Heat Exchanger

Stainless Steel

Propeller/Direct

22

Aluminium

24 26

220-240/1/50

283 x 2

120 x 2

Horizontal Multistage End-Suction

1000

mm(in)

42mmBSP(1

1

/4")

SCROLL

380-415/3/50

Overload Protection, Differential and H/L Pressure Switch

0~50~100

R407C

TXV

Note : Nominal values are based on 12°C / 7°C entering / leaving evaporator water temperature , 35°C air ambient temperature.

38

Page 40

Air Cooled Chiller – R407 Heat Pump

MODEL M4AC080CR M4AC100CR M4AC120CR M4AC150CR

NOMINAL CAPACITY (COOLING / HEATING) kcal/hr 18649 / 22681 22177 / 24697 27721 / 29737 33266 / 30997

MATERIAL

CASING FINISH

THICKNESS mm

HEIGHT (H) mm

DIMENSION WIDTH (W) mm

DEPTH (D) mm

WEIGHT kg 350 360 480 560

NOISE LEVEL dBA 61 62 63 64

PACKING HEIGHT (H) mm

DIMENSION WIDTH (W) mm

DEPTH (D) mm

CONDENSER COIL

TYPE

MATERIAL

TUBE WALL THICKNESS m m

OUTER DIAMETER mm

MATERIAL

FIN THICKNESS mm

ROWS 2222

FIN PER INCH 14 14 14 14

TOTAL FACE AREA

EVAPORATOR

TYPE

PLATE MATERIAL

NOMINAL WATER FLOW L/s 1.08 / 1.14 1.31 / 1.37 1.67 / 1.79 2.00 / 2.10

CONDENSER FAN

TYPE/DRIVE

QUANTITY

BLADE MATERIAL

BLADE DIAMETER INCH

POWER SUPPLY V/Ph/Hz

RATED RUNNING CURRENT Amp 1.2 x 2 1.2 x 2 1.8 x 2 3.4 x 2

RATED INPUT(COOLIING / HEATING) Watt 386 x 2 766 x 2

RATED OUTPUT(COOLING / HEATING) Watt 200 x 2 450 x 2

MOTOR POLES 8886

WATER LINE (HYDRAULIC KIT)

TYPE

PUMP MAX. WATER OPER. PRESSURE kPa

RUNNING CURRENT Amp 1.5 1.5 2.0 2.0

WATER FLOW RATE GPM 17.2 / 18.1 20.7 / 21.7 26.4 / 28.4 31.7 / 33.3

PIPING INSTALLATION PIPE CONNECTION

HEAD m 26/25 23.5/22.5 25/24.5 23/22.5

COMPRESSOR

TYPE

POWER SUPPLY V/Ph/Hz

RATED CURRENT (COOLING / HEATING) Amp x 2 7.1 / 7.3 8.1 / 8.1 10.5 / 10.3 11.7 / 12.4

RATED INPUT (COOLING / HEATING) W att x 2 4166 / 4180 4707 / 4760 5351 / 5407 6410 / 6746

MAXIMUM STARTING CURRENT Amp 65 x 2 74 x 2 76 x 2 95 x 2

PROTECTION DEVICES

STAGE OF CAPACITY CONTROL

REFRIGERANT

TYPE

CONTROL

CHARGING MASS kg 4.0 x 2 3.3 x 2 5.8 x 2 6.1 x 2

Btu/hr 74000 / 90000 88000 / 98000 110000 / 118000 132000 / 123000

Watt 21688 / 26377 25791 / 28722 32239 / 34583 38686 / 36049

Electro-galvanized Mild Steel

Polyester Powder

1.5

1245

1500

900

1245

1800

1150

1452 1452

1732 2032

1032 1282

Cross Finned Tubes

Seamless Copper

0.35

9.52

Aluminium (Hydrophilic)

0.11

2

m

1.37 1.37 1.79 1.79

Brazed Plate Heat Exchanger

Stainless Steel

Propeller/Direct

22

Aluminium

24 26

220-240/1/50

283 x 2

120 x 2

Horizontal Multistage End-Suction

1000

mm(in)

42mmBSP(1

1

/4")

SCROLL

380-415/3/50

Oveload Protection, Differential and H/L Pressure Switch

ON/OFF

R407C

Capillary Tube

Note : Nominal values are based on 12°C / 7°C entering / leaving evaporator water temperature , 35°C air ambient temperature.

Note : Nominal values are based on 40°C / 45°C entering / leaving evaporator water temperature , 7°C air ambient temperature.

Note : Unit dimension withouit hydraulic kit.

39

Page 41

4219 4640

AMBIENT TEMPERATURE (°C)

28 32 35

kW kW kW kW kW kW kW kW kW kW kW kW kW kW

CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT

COOL C OMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP.

LEAVING WATER TEMP (°C)

5 25.4 4.2 23.3 5.3 22.4 5 .8 21.7 6.2 19.7 6.9 18.8 7.2 17.2 7.8

6 26.2 4.5 24.0 5.7 23.1 6 .2 22.4 6.6 20.3 7.4 19.4 7.7 17.8 8.3

7 26.4 4.7 24.4 6.0 23.5 6 .6 22.9 7.0 20.9 7.8 20.1 8.1 18.5 8.7

8 26.7 5.0 24.7 6.3 23.9 6 .9 23.2 7.3 21.1 8.1 20.2 8.4 18.6 9.1

9 27.5 5.4 25.5 6.8 24.5 7 .4 23.8 7.9 21.6 8.7 20.7 9.0 18.9 9.6

5 28.9 5.0 27.2 6.5 26.5 7 .1 25.9 7.6 23.4 8.5 22.4 8.9 20.3 9.6

6 29.8 5.4 28.1 6.9 27.3 7 .6 26.7 8.1 24.1 9.1 23.1 9.4 21.0 10.2

7 30.5 5.5 28.7 7.2 27.9 8 .0 27.3 8.6 24.8 9.5 23.8 9.9 21.8 10.7

8 30.7 6.0 29.0 7.7 28.2 8 .4 27.7 9.0 25.1 10.0 24.0 10.4 22.0 11.2

9 31.2 6.5 29.7 8.3 29.0 9 .0 28.4 9.6 25.7 10.7 24.7 11.1 22.5 11.9

5 35.9 6.2 33.9 7.4 33.0 8 .0 32.3 8.4 30.1 9.4 29.2 9.8 27.3 10.6

6 37.1 6.5 35.0 7.9 34.0 8 .5 33.3 9.0 31.1 10.0 30.1 10.4 28.3 11.2

7 37.3 7.0 35.5 8.3 34.6 9 .0 34.0 9.4 31.8 10.6 30.9 11.0 29.1 11.9

8 38.1 7.4 36.1 8.8 35.2 9 .4 34.5 9.9 32.2 11.0 31.3 11.4 29.5 12.3

9 38.7 7.8 36.9 9.4 36.1 10.1 35.5 10.6 33.0 11.7 32.0 12.2 30.1 13.1

5 43.2 7.0 40.5 8.8 39.3 9 .6 38.4 10.2 35.7 11.3 34.6 11.8 32.4 12.7

6 44.5 7.6 41.6 9.4 40.3 10.3 39.4 10.9 36.7 12.0 35.7 12.5 33.6 13.4

7 45.4 8.0 42.6 9.9 41.4 10.8 40.4 11.4 37.8 12.7 36.8 13.2 34.7 14.2

8 45.8 8.4 43.1 10.5 41.9 11.4 41.0 12.0 38.2 13.2 37.1 13.7 34.9 14.7

10 28.2 5.8 26.0 7.5 25.0 8.2 24.2 8.7 22.2 9.4 21.4 9.7 19.7 10.2

MODEL

Performance Table

Cooling Only

Refrigerant: R22

MAC080C

MAC100C

10 32.1 7.0 30.3 9.1 29.5 10.0 28.9 10.7 26.3 11.6 25.2 11.9 23.1 12.6

MAC120C

10 39.8 8.5 37.7 10.3 36.7 11.2 36.0 11.8 33.3 13.2 32.1 13.8 29.9 15.0

9 46.7 9.1 44.1 11.2 43.0 12.2 42.2 12.9 39.4 14.2 38.3 14.7 36.0 15.8

10 47.9 9.8 44.9 12.4 43.6 13.5 42.6 14.3 40.0 15.3 39.0 15.7 36.9 16.5

MAC150C

CH4-40 PUMP (080 & 100)

CH8-30 PUMP (120 & 150)

40

Page 42

AMBIENT TEMPERATURE (°C)

4219 4640

28 32 35

kW kW kW kW kW kW kW kW kW kW kW kW kW kW

CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT

COOL COMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP.

LEAVING WATER TEMP (°C)

5 22.1 4.5 21.6 6.0 21.5 6.6 21.3 7.1 19.7 7.7 19.1 7.9 17.8 8.4

6 22.8 4.9 22.4 6.4 22.2 7.1 22.1 7.6 20.4 8.1 19.7 8.4 18.4 8.8

MODEL

Heat Pump – Cooling Mode

Refrigerant: R22

7 23.2 5.1 22.8 6.7 22.7 7.4 22.6 8.0 21.0 8.6 20.3 8.9 19.0 9.4

MAC080CR

8 23.6 5.4 23.3 7.1 23.1 7.8 23.0 8.4 21.3 9.0 20.7 9.2 19.4 9.7

9 24.2 5.9 23.8 7.6 23.6 8.4 23.5 9.0 21.7 9.6 21.0 9.9 19.6 10.4

5 27.5 5.3 26.7 6.9 26.3 7.7 26.0 8.2 23.8 9.1 22.9 9.4 21.1 10.1

6 27.7 5.7 27.3 7.4 27.1 8.2 26.9 8.8 24.7 9.7 23.8 10.0 22.0 10.7

7 29.0 5.9 28.2 7.8 27.8 8.6 27.5 9.2 25.2 10.2 24.2 10.5 22.4 11.3

8 29.6 6.3 28.7 8.2 28.3 9.1 28.1 9.7 25.6 10.6 24.7 11.0 22.7 11.7

9 30.2 6.8 29.3 8.8 29.0 9.7 28.7 10.4 26.3 11.3 25.3 11.7 23.4 12.5

5 33.7 6.2 32.4 7.8 31.8 8.5 31.3 9.1 28.6 9.8 27.5 10.1 25.4 10.7

6 34.4 6.6 33.3 8.3 32.8 9.1 32.4 9.7 29.7 10.4 28.6 10.7 26.4 11.3

7 35.2 7.0 34.0 8.8 33.5 9.6 33.2 10.2 30.3 11.0 29.1 11.3 26.8 11.9

8 35.6 7.4 34.6 9.3 34.1 10.1 33.8 10.7 30.7 11.4 29.5 11.7 27.0 12.3

9 36.4 8.0 35.4 9.9 34.9 10.8 34.5 11.5 31.5 12.2 30.3 12.5 27.9 13.2

5 39.6 6.9 38.8 8.8 38.5 9.6 38.2 10.3 35.5 11.1 34.4 11.5 32.2 12.1

6 41.0 7.4 40.2 9.4 39.8 10.3 39.5 11.0 36.7 11.8 35.5 12.2 33.3 12.9

7 41.6 7.9 40.9 9.9 40.7 10.8 40.4 11.5 37.6 12.5 36.5 12.9 34.3 13.6

8 42.7 8.3 41.9 10.4 41.5 11.4 41.2 12.1 38.1 13.0 36.9 13.4 34.4 14.1

10 24.8 6.3 24.5 8.4 24.4 9.3 24.3 10.0 22.4 10.4 21.7 10.6 20.2 11.0

MAC100CR

10 31.0 7.4 30.3 9.7 29.9 10.8 29.7 11.5 27.2 12.3 26.2 12.6 24.2 13.3

MAC120CR

10 37.7 8.6 36.6 10.9 36.1 12.0 35.7 12.7 32.6 13.3 31.3 13.5 28.8 14.0

9 43.6 9.0 42.8 11.2 42.4 12.2 42.1 13.0 39.1 13.9 37.9 14.2 35.5 15.0

10 45.2 9.7 44.3 12.3 43.9 13.5 43.6 14.4 40.5 15.1 39.2 15.4 36.7 15.9

MAC150CR

CH8-30 PUMP (120 & 150)

CH4-40 PUMP (080 & 100)

41

Page 43

AMBIENT TEMPERATURE (°C)

-5 0 4 21-7 15710

kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW

CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT

HEATING COMP. HEATING COMP. HEATING COMP. HEATING COMP. HEATING COMP. HEATING COMP. HEATING COMP. HEATING COMP.

LEAVING WATER TEMP (°C)

35 16.5 4.2 18.1 4.6 22.2 5.4 25.4 6.1 27.8 6.6 33.7 8.2 43.6 10.7 55.5 13.8

40 16.1 4.8 17.7 5.1 21.6 6.0 24.7 6.7 27.0 7.3 32.8 8.8 42.6 11.2 54.2 14.2

45 15.8 5.1 17.3 5.5 21.1 6.4 24.1 7.1 26.4 7.7 32.3 9.3 42.1 11.9 53.8 15.0

50 15.2 5.1 16.7 5.5 20.5 6.5 23.5 7.4 25.8 8.0 31.6 9.7 41.2 12.4 52.7 15.7

55 14.5 5.2 16.0 5.6 19.7 6.7 22.7 7.7 24.9 8.4 30.5 10.0 39.9 12.8 51.2 16.2

35 20.7 6.5 22.6 6.6 27.3 7.0 31.0 7.2 33.8 7.5 35.7 7.9 38.7 8.6 42.3 9.4

40 20.3 7.3 22.1 7.4 26.6 7.7 30.2 8.0 32.9 8.2 34.8 8.5 37.9 9.1 41.7 9.7

45 19.5 8.1 21.4 8.2 25.9 8.4 29.5 8.6 32.2 8.7 34.1 8.9 37.2 9.3 41.0 9.8

50 19.0 8.2 20.8 8.3 25.3 8.6 28.9 8.8 31.6 9.0 33.4 9.4 36.4 9.9 40.0 10.6

55 18.1 8.3 19.9 8.5 24.3 8.9 27.8 9.2 30.4 9.4 32.2 9.8 35.3 10.3 39.0 11.0

35 21.1 7.3 23.0 7.5 28.8 8.1 33.5 8.6 36.9 8.9 39.1 9.1 42.6 9.5 46.9 9.9

40 19.9 8.2 22.2 8.5 27.9 9.0 32.4 9.4 35.9 9.8 38.0 9.9 41.6 10.0 45.9 10.2

45 19.7 8.8 22.0 9.1 27.5 9.6 31.9 10.0 35.2 10.4 37.3 10.4 40.8 10.4 45.1 10.5

50 19.3 9.1 21.2 9.3 26.7 9.9 31.1 10.4 34.5 10.8 36.6 10.9 40.2 11.1 44.4 11.3

55 18.2 9.3 20.2 9.6 25.6 10.3 30.0 10.8 33.2 11.3 35.3 11.3 38.9 11.5 43.2 11.6

35 21.5 8.8 23.8 9.0 30.8 9.7 36.4 10.2 40.6 10.6 42.1 10.7 44.7 11.1 47.8 11.4

40 20.5 9.9 23.2 10.2 30.0 10.8 35.4 11.2 39.5 11.6 41.1 11.6 43.8 11.7 47.0 11.8

45 20.1 10.4 22.8 10.7 29.4 11.4 34.7 11.9 38.7 12.3 40.3 12.2 43.0 12.2 46.2 12.1

50 19.6 10.6 22.2 10.9 28.7 11.7 34.0 12.3 37.9 12.8 39.4 12.8 41.9 12.9 44.9 13.0

55 18.5 10.7 20.9 11.1 27.4 12.0 32.6 12.8 36.5 13.3 38.0 13.4 40.6 13.4 43.6 13.4

MODEL

Heat Pump – Heating Mode

Refrigerant: R22

MAC080CR

MAC100CR

MAC120CR

MAC150CR

CH8-30 PUMP ( 120 & 150 )

CH4-40 PUMP ( 080 & 100 )

42

Page 44

AMBIENT TEMPERATURE (°C)

4219 4640

28 32 35

MODEL

Cooling Only

Refrigerant: R 407C

COOL COMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP.

kW kW kW kW kW kW kW kW kW kW kW kW kW kW

CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT

LEAVING WATER TEMP (°C)

5 24.0 4.6 21.9 6.1 21.1 6.6 20.6 6.9 19.3 7.3 17.4 7.8 15.0 8.5

6 24.7 4.9 22.6 6.6 22.2 7.1 21.3 7.4 20.0 7.8 18.0 8.3 15.5 9.1

7 24.9 5.1 23.0 6.9 22.3 7.5 21.7 7.8 20.4 8.2 18.6 8.7 16.1 9.5

8 25.2 5.5 23.2 7.3 22.6 7.9 22.0 8.2 20.8 8.6 18.7 9.1 16.2 9.9

9 26.0 5.9 23.6 7.9 23.1 8.5 22.6 8.8 21.4 9.2 19.1 9.7 16.5 10.5

5 26.5 5.2 25.5 7.2 24.9 7.8 24.5 8.2 23.2 8.7 21.6 9.2 18.9 10.0

6 27.3 5.6 26.3 7.7 26.1 8.4 25.3 8.7 24.0 9.2 22.3 9.8 19.5 10.6

7 27.9 5.7 26.7 8.1 26.2 8.8 25.8 9.2 24.5 9.7 23.0 10.3 20.3 11.1

8 28.1 6.2 27.1 8.6 26.6 9.3 26.2 9.7 25.0 10.1 23.2 10.7 20.4 11.6

9 28.6 6.7 27.5 9.3 27.2 10.0 26.9 10.4 25.7 10.8 23.7 11.4 20.9 12.3

5 34.1 6.3 33.4 8.0 32.6 8.7 32.0 9.1 30.4 9.6 28.2 10.2 26.3 11.5

6 35.2 6.7 34.5 8.6 34.2 9.3 33.0 9.7 31.4 10.2 29.3 10.9 27.2 12.2

7 35.5 7.1 35.0 9.0 34.3 9.8 33.7 10.2 32.0 10.7 30.2 11.4 28.0 12.9

8 36.2 7.5 35.5 9.5 34.8 10.3 34.2 10.7 32.7 11.2 30.4 11.9 28.3 13.3

9 36.8 8.0 36.1 10.3 35.6 11.1 35.2 11.5 33.7 12.0 31.1 12.7 28.9 14.2

5 42.5 7.6 41.3 9.5 39.6 10.4 38.2 10.9 37.0 11.5 34.9 12.3 31.8 14.0

6 43.8 8.2 42.6 10.3 41.5 11.1 39.4 11.6 38.2 12.2 36.1 13.0 32.9 14.8

7 44.7 8.6 43.3 10.8 42.0 11.7 40.2 12.2 39.0 12.8 37.3 13.7 34.0 15.6

8 45.1 9.1 43.8 11.4 42.4 12.3 40.8 12.8 39.8 13.4 37.6 14.2 34.2 16.2

M4AC080C

10 26.6 6.4 24.3 8.5 23.4 9.1 23.0 9.8 22.1 9.8 19.8 10.3 17.2 11.2

M4AC100C

10 29.4 7.2 28.3 10.0 27.6 10.8 27.3 11.5 26.5 11.6 24.6 12.2 21.5 13.1

M4AC120C

10 37.8 8.7 37.1 11.1 36.1 11.9 35.7 12.8 34.7 12.8 32.2 13.5 29.9 15.0

M4AC150C

9 45.9 9.9 44.6 12.3 43.1 13.3 41.9 13.7 41.0 14.3 38.4 15.2 35.3 17.4

10 47.2 10.6 45.8 13.3 44.0 14.3 42.6 15.3 42.2 15.3 39.8 16.1 36.2 18.2

CH8-30 PUMP (120 & 150)

CH4-40 PUMP (080 & 100)

43

Page 45

4219 4640

AMBIENT TEMPERATURE (°C)

28 32 35

COOL COMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP. COOL COMP.

MODEL

Heat Pump - Cooling Only

Refrigerant: R 407C

kW kW kW kW kW kW kW kW kW kW kW kW kW kW

CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT

LEAVING WATER TEMP (°C)

5 21.2 4.7 20.8 6.5 20.6 7.1 20.5 7.4 19.4 7.8 18.1 8.3 16.8 8.9

6 21.9 5.1 21.5 7.0 21.3 7.6 21.2 7.9 20.1 8.3 18.9 8.8 17.4 9.4

7 22.3 5.3 22.0 7.4 21.8 8.0 21.7 8.3 20.6 8.7 19.2 9.3 18.0 10.0

8 22.7 5.7 22.4 7.8 22.2 8.4 22.1 8.7 20.9 9.1 19.5 9.7 18.3 10.3

9 23.2 6.2 22.9 8.4 22.7 9.1 22.6 9.3 21.5 9.8 20.1 10.3 18.5 11.0

5 25.9 5.4 25.0 7.7 24.7 8.4 24.4 8.8 23.1 9.3 21.5 9.9 20.0 10.5

6 26.1 5.8 25.6 8.3 25.4 9.0 25.2 9.4 23.9 9.8 22.4 10.5 20.9 11.1

7 27.3 6.0 26.5 8.7 26.1 9.5 25.8 9.8 24.5 10.3 22.8 11.0 21.3 11.7

8 27.8 6.4 26.9 9.2 26.6 9.9 26.3 10.3 24.9 10.8 23.2 11.5 21.6 12.1

9 28.4 7.0 27.5 9.9 27.2 10.7 26.9 11.1 25.5 11.6 23.9 12.2 22.3 13.0

5 33.2 6.3 31.7 8.6 31.0 9.4 30.5 9.8 28.9 10.4 26.9 11.1 24.5 12.0

6 33.9 6.8 32.6 9.3 32.0 10.1 31.5 10.5 29.9 11.0 28.1 11.8 25.5 12.7

7 34.7 7.2 33.3 9.8 32.7 10.6 32.2 11.0 30.6 11.6 28.5 12.4 25.9 13.4

8 35.1 7.6 33.8 10.3 33.3 11.2 32.9 11.6 31.1 12.1 29.0 12.9 26.1 13.8

9 35.9 8.1 34.6 11.2 34.0 12.0 33.6 12.4 31.9 13.0 29.9 13.7 26.9 14.8

5 39.0 7.6 37.6 9.7 37.0 10.6 36.6 11.1 34.6 11.7 32.3 12.5 31.3 13.7

6 40.4 8.2 39.0 10.5 38.3 11.4 37.8 11.9 35.9 12.5 33.7 13.3 32.3 14.5

7 41.0 8.6 39.7 11.0 39.1 12.0 38.7 12.5 36.7 13.1 34.2 14.0 33.3 15.3

8 42.1 9.1 40.6 11.7 39.9 12.6 39.4 13.1 37.3 13.7 34.8 14.5 33.4 15.9

10 23.8 6.6 23.6 9.1 23.5 9.7 23.4 10.4 22.1 10.4 20.8 11.0 19.1 11.6

M4AC080CR

M4AC100CR

10 29.2 7.5 28.4 10.7 28.1 11.5 27.8 12.3 26.3 12.4 24.8 13.0 23.0 13.8

M4AC120CR

10 37.2 8.8 35.8 12.0 35.2 12.9 34.8 13.8 32.9 13.9 31.0 14.6 27.9 15.7

9 43.0 9.8 41.5 12.6 40.8 13.6 40.3 14.0 38.3 14.7 35.9 15.5 34.5 16.8

10 44.5 10.6 42.9 13.6 42.2 14.6 41.7 15.6 39.5 15.7 37.1 16.5 35.7 17.9

M4AC150CR

CH8-30 PUMP (120 & 150)

CH4-40 PUMP (080 & 100)

44

Page 46

AMBIENT TEMPERATURE (°C)

-5 0 4 21-7 15710

kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW kW

CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT CAP. INPUT

HEATING COMP. HEATING COMP. HEATING COMP. HEATING COMP. HEATING COMP. HEATING COMP. HEATING COMP. HEATING COMP.

LEAVING WATER TEMP (°C)

35 16.0 6.4 18.6 6.5 25.1 6.7 26.9 6.9 27.7 7.2 28.3 7.7 29.5 8.2 33.6 8.5

40 15.6 7.2 18.2 7.3 24.5 7.5 26.1 7.8 26.9 7.9 27.9 8.1 29.1 8.4 32.9 8.7

45 15.2 7.7 17.7 7.8 24.0 7.9 25.6 8.2 26.4 8.4 27.4 8.5 28.5 8.9 32.6 9.2

50 14.6 7.8 17.2 7.9 23.5 8.0 25.1 8.5 25.9 8.7 26.9 9.0 28.0 9.3 31.9 9.6

55 14.0 7.9 16.4 8.0 22.4 8.2 24.4 8.8 24.9 9.1 26.1 9.2 27.2 9.6 31.0 9.9

35 16.9 7.3 19.2 7.4 27.3 7.6 29.3 7.8 30.2 8.2 30.8 8.7 32.2 9.3 36.4 9.5

40 16.5 8.1 18.7 8.3 26.7 8.6 28.4 8.8 29.3 9.0 30.4 9.2 31.7 9.6 35.8 9.8