Page 1

Installation and Maintenance IM 254-5

Hi-Line™ Fan Coil Unit

Model KZZ S03 through S08

Group: Fan Coil

Part Number: 667754200

Date: December 2005

© 2005 McQuay International

Page 2

Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Receiving and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Risers (Field supplied & installed) . . . . . . . . . . . . . . . . . . . . . .2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Furring In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Finishing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Twin Units Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Drain Pans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fan and Motor Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Electric Heater Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 13

Electric Heater Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

McQuay and MicroTech II are registered trademarks of McQuay International.

Copyright © 2005 McQuay International. All rights reserved throughout the world.

Page 3

General Information

McQuay HiLine fan coil air conditioning units are designed

for use in multiple floor apartments, office buildings, hotels,

and other similar applications. They require a minimum

amount of floor space and one unit may do the job that

formerly required more than one conventional unit.

The 300 through 800 cfm, blow-through configuration units

described in this manual are designed to meet individual room

control requirements. Two-pipe and four-pipe systems are

available, with single, double, triple, and top discharge

arrangements. Optional equipment is available to provide

complete application flexibility.

Installation and maintenance must follow accepted industry

practices as described in the ASHRAE Handbook, the National

Electric Code, and other applicable s t a n da r d s . Install this

equipment in accordance with regulations of authorities having

jurisdiction and with all applicable codes.

Installation and maintenance must be performed by qualified

personnel familiar with applicable codes and regulations and

experienced with this type of equipment.

CAUTION

SHARP EDGES ON SHEET METAL AND COIL SURFACES

if not avoided could result in cuts.

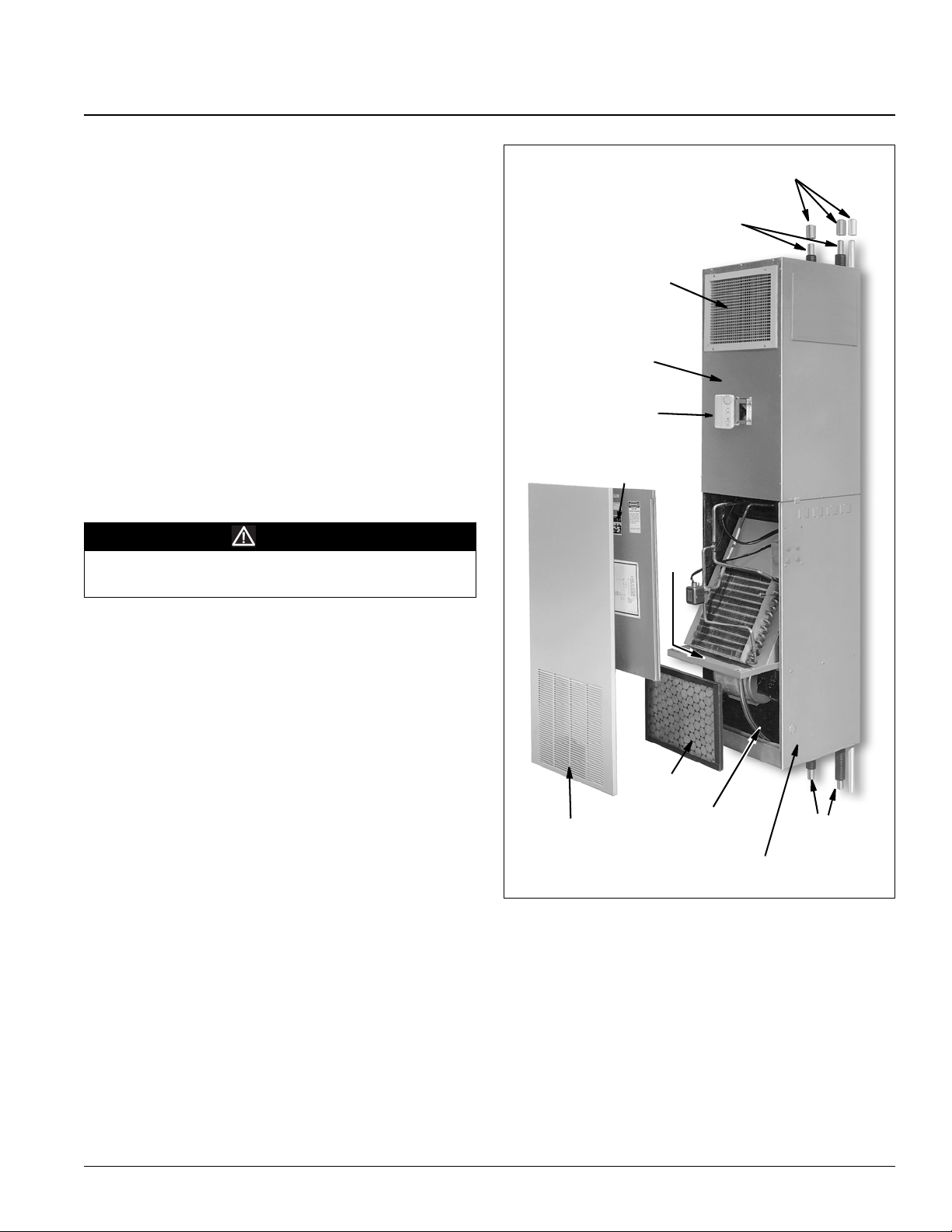

Figure 1: HiLine fan coil unit

Couplings

Risers

Discharge Air

Top Plenum

Cabinet

Controls

Access panel and

sound baffle

Coil

Receiving and Handling

Carefully check items against the bills of lading to verify all

crates and cartons have been received. The units normally ship

four to a pallet.

Carefully inspect all units for shipping damage. Report

damage immediately to the carrier and file a claim.

Check the electrical nameplate to be sure it agrees with the

power supply available.

DO NOT handle units by the riser piping. Riser clamps hold

the riser in position; they are not designed to support the

cabinet weight. They are removed after the unit is installed.

Filter

Return air grille panel

Motor and fan

assembly

Bottom Cabinet

Risers

Units are shipped with the top plenum cabinet and top plenum

front panel not assembled to the lower cabinet. KZZ units are

factory wired and have individual thermostat controls. They

are installed by stacking one unit on top of the other. While

installing, prevent dirt and other foreign matter from entering

the risers and plugging lines or valves.

McQuay IM 254-5 1

Page 4

Installation

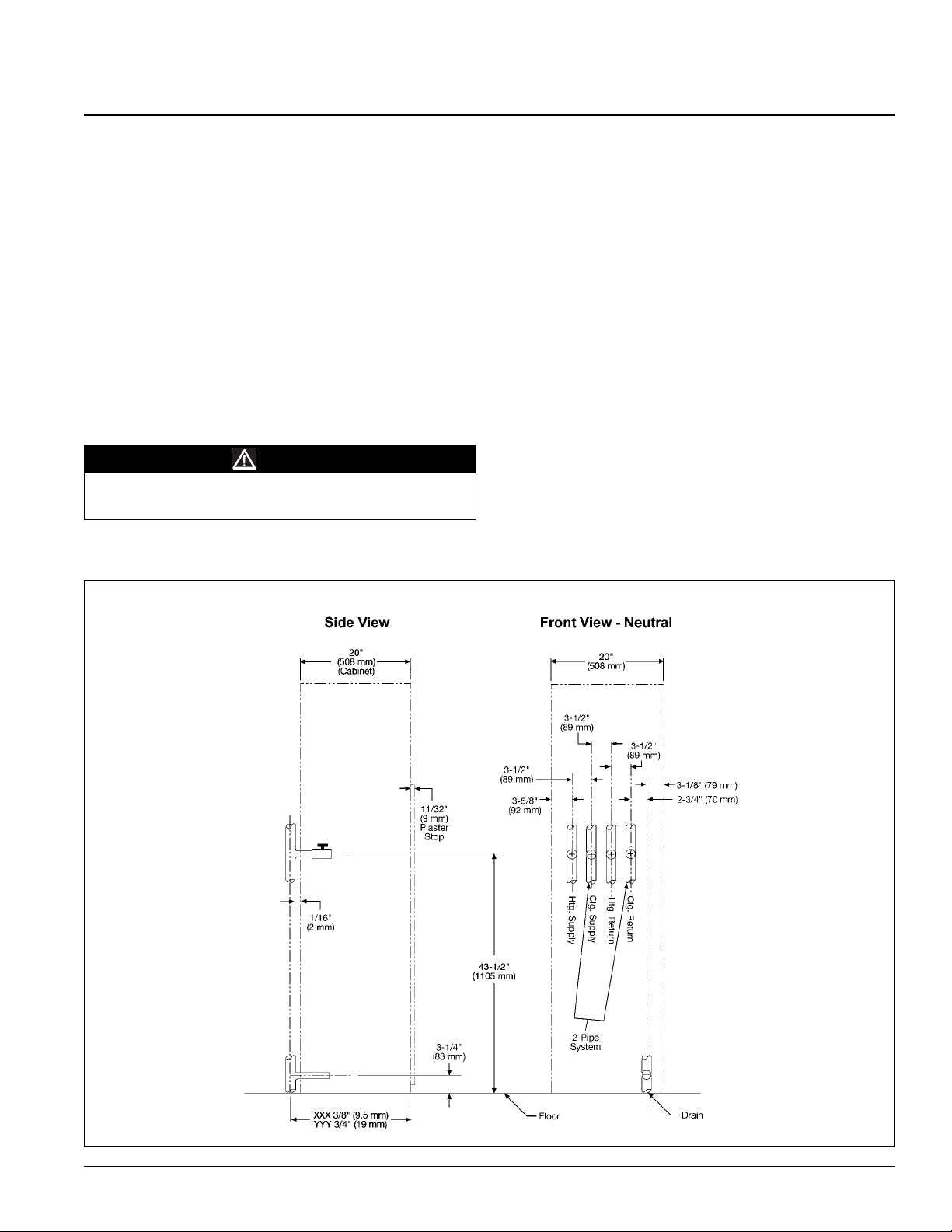

Risers (Field supplied & installed)

The coupling stub-outs must be properly positioned so that the

coil connections will line up when the units are placed in

position. Construct a fixture to maintain dimensions shown in

figure 2, during the soldering process.

• If field-supplied isolator pads are used, install them now.

This additional thickness must be considered before

installation of risers.

• The unit has provisions for plus or minus one inch of vertical

movement of risers. If the riser system movement exceeds

this value, compensating provisions must be provided by the

installing contractor.

• Anchor risers to the building structure to prevent vertical

riser movement greater than ±1" (25mm) due to riser

expansion or contraction. (Anchors by others).

CAUTION

The unit is not designed to support the weight of the risers.

Anchor them securely to the building structure.

Figure 2: Risers and stub-outs locations

• Care must be taken to prevent dirt and other foreign matter

from entering the risers as clogged lines or valves could

result.

• Close all ball valves on the coupling stub-outs and cement

joints to avoid condensation problems.

• Apply insulation to stub-outs and cement joints to avoid

condensation problems.

To c omply with existi ng building codes, the installing contractor must

restore the original fire resistance rating of the structure by sealing the

access space around the risers with material having the same fire

rating as the structure. This procedure is very important so that a seal

is provided between floors to prevent the passage of warm, humid air

which can cause condensation on riser insulation. This is most critical

in unpressurized buildings with high infiltration rates.

2 McQuay IM 254-5

Page 5

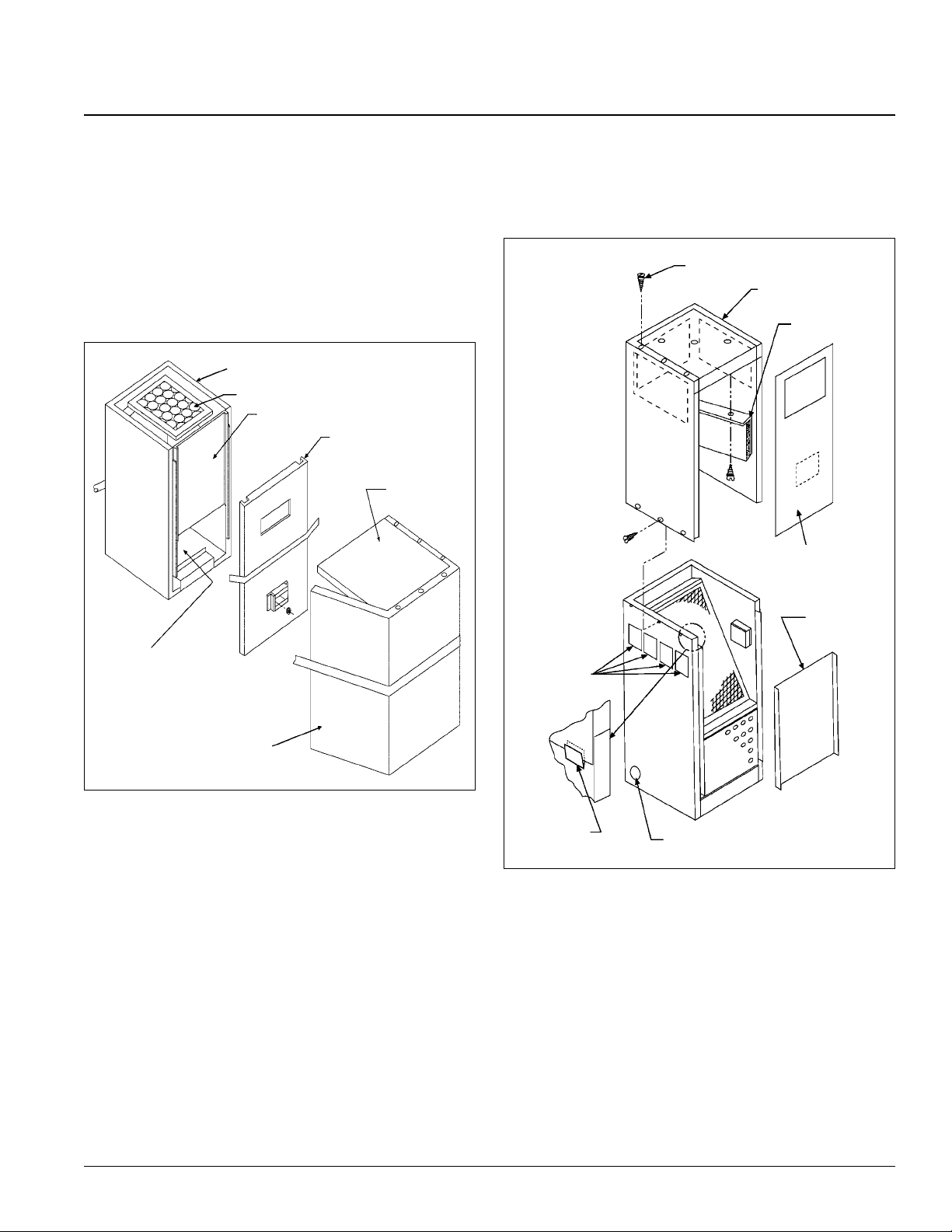

Installation

Cabinet

1 Carefully separate the top plenum cabinet from the lower

cabinet so as not to tear the fiberglass insulation.

See Figure 3.

2 Separate the top plenum front panel from the lower cabinet.

3 The fasteners and parts needed for assembly are located in

the base of the lower cabinet. Remove the riser blockoffs,

sight baffle (if required), and the valve package supports.

The filter is located above the coil. See Figure 3.

Figure 3: Unit preparation for field assembly

Lower Cabinet

Filter

Serial Plate & Coil Location

Top Plenum Cabinet-

Front Panel

Top Panel

11 With the unit in the final location, check level to insure

proper condensate drainage and operation.

12 Fasten the top panel of the plenum by installing the three

sheet metal screws “A”. See Figure 4.

Figure 4: Installation of top plenum cabinet

“A”

Top Plenum Cabinet

Optional

Sight Baffle

Top Plenum Cabinet-

Front Panel

Fasteners & Parts

Location

Top Plenum Cabinet

4

Bend out the tabs used to support the top plenum cabinet to

the lower cabinet as shown in Figure 4.

5 Remove the appropriate riser and drain knockouts in the

lower cabinet. See Figure 4.

6 Slit the fiberglass insulation within the riser knockout

openings to allow the riser valves to protrude into the lower

cabinet.

7 Position the riser blockoffs over the riser stub-outs. See

Figure 5 on page 4.

8 Position the lower cabinet so it aligns properly with the

risers. See Figure 6b. Align the horizontal stub-outs so they

are centered within the knockout openings in the cabinet.

This is important to allow riser expansion and contraction

of plus or minus one inch.

9 Solder connections if sweat valves have been supplied.

10 Attach plastic drain hose to drain line. Be sure hose clamp

is properly installed.

Front Access

Panel

Riser Knockouts

(All Sides)

Support Tabs

13 Install the sight baffle (if required) to the top as shown in

Drain Knockout (All Sides)

Figure 4.

14 Place the top plenum cabinet on the lower cabinet. See

Figure 4 & 6c.

15 Fasten the top plenum cabinet to the lower cabinet with

sheet metal screws. See Figure 4.

16 Attach the top plenum cabinet - front panel to the top

plenum cabinet with sheet metal screws enclosed.

McQuay IM 254-5 3

Page 6

Figure 5: Riser blockoff placement Figure 6: Installation overview

6a. Leak test and insulate

risers and stub-outs

prior to unit placement.

6b.Position the lower

cabinet so it aligns

properly with the risers

and stub-outs. Solder

the supply and return

connections. Attach

plastic drain hose to

drain line.

6c. Place the top plenum

cabinet on the lower

cabinet and fasten with

sheet metal screws.

Installation

6d.Unit “furred in” with

grille attached and

thermostat wired.

6e. Completely installed

unit.

McQuay IM 254-5 4

Page 7

Figure 7: Dimensional details

Installation

Neutral Hand Unit Shown

Hand of unit determined by facing return air opening.

Risers on right = Right hand unit.

Risers on left = Left hand unit.

Risers on back = Neutral unit.

Note – (1) With return air grille mounted on unit, dimension becomes 2-3/8”.

(2) Can be field adjusted to 3-7/8” for furred-in application.

McQuay IM 254-5 5

Page 8

Installation

Furring In

1 When furring in units, make sure no screws or nails

penetrate the unit cabinet, other than grille or plaster frame

attaching screws. Grille or plaster frame attaching screws

should not penetrate the cabinet more than 2" (51 mm).

2 The thermostat box can be positioned up to 3 7/8" (98 mm)

from the unit for furring in. The mud ring can be positioned

vertically or horizontally and has 2" x 4" opening. (see

Figure 7).

3 If the wall board or other wall material does not fit flat

against the face of the unit, install field-supplied extension

sleeves for both the return and supply air openings.

Wiring

The complete unit system wiring diagram is located on the

front of the access panel. Wire in accordance with local codes

or the National Electrical Code, whichever is applicable.

1 Provide branch circuit overcurrent protection and

disconnect means.

2 Bring electrical wiring through the side of the cabinet into

the wiring box located on the right side of the cabinet (see

Figure 7 Side View) using the two 7/8" (22 mm) diameter

knockouts.

3 When routing wiring through the cabinet, make sure the fan

remains accessible for possible removal.

4 Connect control wiring to the unit-mounted thermostat and

fan switch or a remote mounted control.

5 A 10 K thermistor is mounted on all units for sensing return

air temperatures. The sensor on the remote-mounted

thermostat may also be used for this purpose.

6 Rotate the fan wheel by hand to make sure it rotates freely.

• Design the ducts for velocities in accordance with the

methods outlined in the ASHRAE guidebooks.

• Control airborne noise by installing sound attenuating

materials and by installing flexible connections between the

unit and ductwork.

Finishing

1 Attach the return air grille plaster frame on the opening

over the top of the wall board. Use the wall board frame as

a template to drill pilot holes into the wall or unit for the

attaching screws (see Figure 8).

Note – Mount the plaster frame with the corners square so that

the grille panel will fit over it properly.

2 Attach the supplied retaining clips to the plaster frame

adjacent to the lower attaching screws (see Figure 9 on

page 7).

Figure 8: Grille panel with plaster frame

Ducts

If ducts are added:

• Install in accordance with NFPA 90A and 90B.

• Check that the resistance is within the limits of the external

static pressures shown in the catalog for the particular unit

being installed.

6 McQuay IM 254-5

Page 9

Figure 9: Plaster frame retaining clip installation

Installation

Twin Units Installation

Twin opposite hand units share a common riser system; i.e.,

supply, return, and drain riser. This is commonly called a

“master/slave” arrangement. The master unit is shipped with

the risers attached. These special risers have stub-outs which

must be field connected to the slave units. In addition to the

instructions in bulletins IM 254 (KZZ units) or IM 255 (HSS

units), the following procedures must be followed for all twin

unit installations.

1 The slave unit has no risers and no stub-outs. Knockout

holes are provided for internal piping connections.

2 HSS-S10 and -S12 units will not match up with the smaller

units sizes S03, S04, S06 and S08 due to differences in riser

stub-out locations.

3 Master units are offered in two-pipe or four-pipe systems

with either right-hand or left-hand connections. Slave units

are offered to accommodate internal connections to any of

these riser systems or locations.

4 The riser location (right or left) is determined by facing the

return air grille panel. The risers are located on either the

right or left of the unit. This defines the riser location. See

Figure 10.

Figure 10: HiLine Twin Unit Arrangements

Right-Hand

Master

Wall

Left-Hand

Slave

Note–Arrows refer to return air panel position.

5

The riser block-off plates are located in the base of the

Left-Hand

Master

Right-Hand

Slave

slave unit. Block-offs must be installed on the slave unit

before putting it into position. (see Figure 5 on page 4).

6 Install the master unit per IM 254 or IM 255.

7 Recommended wall opening locations for the slave unit

risers and stub-outs are shown in Figure 2 on page 2.

8 The openings must provide enough space to allow easy

installation of the unit. During installation, the unit is tilted

at an angle to set into place. Unless the opening in the wall

is large enough, there will be interference and the unit

cannot be set into position.

9 Openings must be large enough to accommodate riser stubs

with foam insulation. An allowance must be made for

insulation thickness, fitting connections, and hand valves

on the stub-outs.

McQuay IM 254-5 7

Page 10

Installation

10

The opening in the wall must provide space for vertical

movement of riser stubs as a result of riser expansion and

contraction.

11 The slave unit piping terminates with 5/8" sweat

connections. The piping is also supported inside the cabinet

to prevent any damage to them during shipment. This

support bracket must be removed to allow expansion or

contraction in the piping after unit is installed.

12 The ball valves are not factory mounted to the slave unit

piping because there would be insufficient room between

ball valve and cabinet to make field connections to the unit.

The ball valves (quantity 2 on two-pipe, 4 on four-pipe), if

ordered from McQuay, will be shipped in a separate box.

The correct installation procedure, as outlined in

subsequent paragraphs, is to first mount the ball valves to

the riser stub-outs and then set the slave unit in place with

the ball valves protruding through the slave unit riser

knockouts. The connections can then be made between ball

valves and unit piping within the HiLine slave unit.

13 The length of tubing between the 5/8" O.D. slave unit stub-

out and the hand valve for the slave unit is to be provided

by the contractor. The length will be determined by the

dimension between the walls.

After the master unit is set in place, the field supplied

tubing should be sweated to the riser stub-outs and ball

valves sweated to the field supplied tubing. Hand valves

should be closed and risers pressurized to locate any leaks.

Leaks should be repaired before slave units are installed

and access is restricted.

14 Stub-outs from the supply and return risers are on center

from the bottom of the unit. They are to be made of copper

tubing. The standard stub-out length is 2 3/4" (70 mm)

beyond the outside diameter of the riser.

15 The drain stub-out is either 1/2" PVC or 5/8" O.D. copper,

depending on which was ordered for the job.

16 Slave unit stub-outs should be well insulated by the

contractor to prevent condensation problems.

17 Remove the appropriate riser and drain knockouts in the

lower cabinet of the slave unit.

18 Slit the fiberglass insulation so that the riser ball valves can

be pushed through and into the slave unit.

19 Install the slave unit riser block-off plates as shown in

Figure 5 on page 4.

20 Position the slave unit to the hand valves. The horizontal

stub-outs should be centered in the opening in the cabinet.

21 Solder connections if sweat valves have been supplied.

22 Attach plastic drain hose to the drain line. Be sure hose

clamp is properly installed and that there are no kinks in the

hose.

23 With unit in final location, check level to provide proper

condensate drainage and operation.

24 Use IM 254 or IM 255 to complete the installation of the

slave unit.Figure 10 shows a typical example of a master/

slave arrangement for a two-pipe system. For four-pipe

master/slave riser location, refer to Certified Drawing CDFC-KZZ 03-08 Specs.

8 McQuay IM 254-5

Page 11

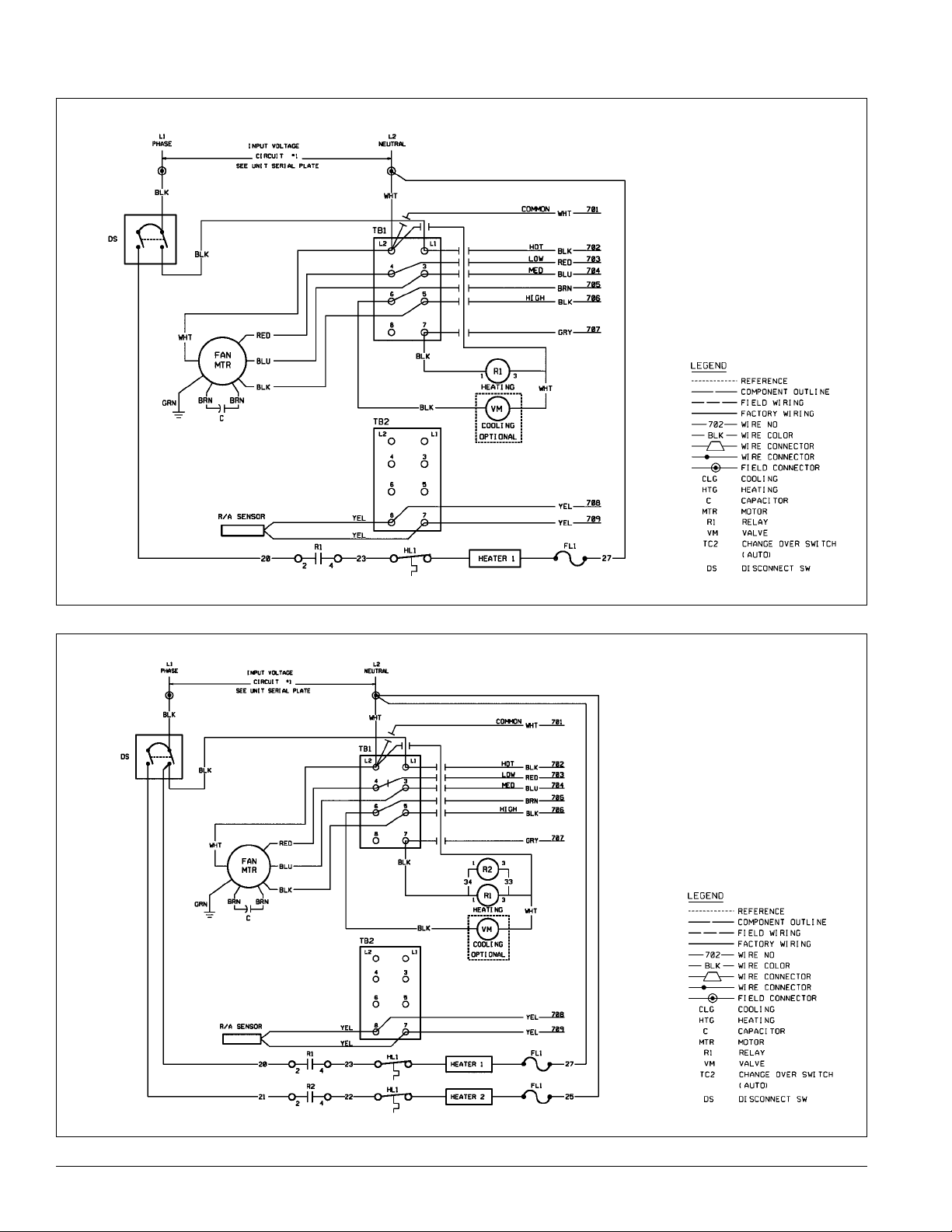

Wiring Diagrams

Figure 11: 2-Pipe (041538651)

Figure 12: 4-Pipe (041538652)

McQuay IM 254-5 9

Page 12

Wiring Diagrams

Figure 13: 2-Pipe with 1 circuit electric heat (041538653)

Figure 14: 4-Pipe with 2 circuit electric heat (041538654)

10 McQuay IM 254-5

Page 13

Start-Up

CAUTION

Prior to unit start-up, make sure no foreign material remains in

the unit, paying particular attention to the drain pan and drain

line. Blocked drains can result in drain pan water overflow.

1 Remove all foreign material from unit.

2 Open supply and return water service valves.

3 If the unit does not have the automatic flow control option,

balance the water flow rate with the hand valve on the

return line.

4 Install the front access panel.

5 Put the filter into position.

6 Install the return air grille.

7 Close all windows and doors.

8 Switch the unit to ON and check for proper operation of

fans, fan speed switch, and thermostat.

Note – When there is a high amount of moisture in the air, this

initial pull down should be gradual to reduce the

possibility of unit sweating (i.e., high fan speed for

maximum air flow with reduced GPM and elevated chilled

water temperature for reduced capacity). Do not operate

outside air supplies or toilet exhaust systems until the

gradual pull down is complete.

McQuay IM 254-5 11

Page 14

Maintenance

Filters

• Clean filters to obtain maximum unit performance.

• Inspect filters every three or four months under normal

operating conditions and replace when necessary.

• Do NOT operate units without a filter.

Drain Pans

• In areas where airborne bacteria or other microorganisms are

known to produce growth in the drain pan, treat the water

chemically to minimize the problem. Contact your local

McQuay representative or one of the many companies

dealing with water conditioning.

• The condensate drain pan can pick up lint and dirt,

especially with dirty filters. Inspect the drain pan twice a

year to avoid the possibility of overflow.

Fan Motor

Note – The fan motor is oiled at the factory. Under continuous

• Oil the fan motor every six months with one teaspoon or 5 cc

operation; it is not necessary to oil it in the first six

months.

per bearing of SAE No. 20 nondetergent oil. Do NOT

overlubricate.

Coil

• The coil must be clean to obtain maximum performance.

• Check the coil once a year, under normal operating

conditions. If it is dirty, brush or vacuum clean. Take care

not to damage the aluminum fins while cleaning.

CAUTION

SHARP EDGES ON SHEET METAL AND COIL SURFACES

if not avoided could result in cuts.

McQuay IM 254-5 12

Page 15

Service

WARNING

Before removing or replacing any component, lock out and tag

out all power to the unit. Live electrical components, fans and

belts can cause severe personal injury or death.

Fan and Motor Removal

If fan or motor service is required, remove th e fan motor through

the return air opening as follows:

1

Shut off electrical power to the unit.

2

Remove the return air grille panel.

3

Remove the front access panel.

4

Disconnect the fan motor leads at the wiring box.

5

To reassemble, reverse the above steps.

To reassemble, reverse the above steps.

Electric Heater Troubleshooting

McQuay electric heater elements, if furnished, are designed with a

high limit control set to trip when cabinet temperatures reach

175°F and automatically reset when cabinet temperatures drop to

140°F.

If the high limit temperature is tripping, the unit is not performing

properly. Some probable causes are

•

Not enough air over the heater due to dirty filter

•

Fan motor not operating

•

Dirty coil

•

Fan wheel loose on the motor shaft

•

Loose electrical connections

Electric Heater Removal

If the electric heater requires service, remove it as follows:

1

Shut off electrical power to the unit.

When requesting service or replacement parts, direct your

inquiries to McQuayService. Refer to the model number and

the serial number of the heater stamped on the serial plate

attached to the heater kit. If replacement parts are required,

provide the date of the heater kit installation and the date of the

failure. Also, describe the part being replaced and explain its

malfunction.

Figure 15: Replacing high limit control or heater detail

McQuay IM 254-5 13

Page 16

McQuay Training and Development

Now that you have made an investment in modern, efficient McQuay equipment, it s care should be a high priority.

For training information on all McQuay HVAC products, please visit us at www.mcquay .com and click on train ing, or

call 540-248-9646 and ask for the Training Department.

Warranty

All McQuay equipment is lold pursuant to its standard terms and conditions of sale, including Limited Product

Warranty. Consult your local McQuay Representative for warranty details. Refer to Form 933-43285Y. To find your

local McQuay Representative, go to www.mcquay.com.

This document contains the most current product information as of this printing. For the most up-to-date product

information, please go to www.mcquay.com.

Products Manufactured in an ISO Certified Facility.

© 2005 McQuay International • www.mcquay.com • 800-432-1342 12/05

Loading...

Loading...