Page 1

Installation Manual

IM 783-2

MicroTech II®

Remote I/O Panel Installation Manual

Group: Controls

Part Number: IM 783

Date: November 2006

Supersedes: IM 783-1

Page 2

Table of Contents

Notice....................................................................................................................................................3

Reference Documents ...........................................................................................................................3

Revision History....................................................................................................................................3

Introduction ...........................................................................................................................4

Panel Location and Mounting..............................................................................................5

Unpack the Remote I/O Panel...............................................................................................................5

Physical Installation ..............................................................................................................................5

Tools Required..................................................................................................................................5

Before Installation.............................................................................................................................5

Mounting...........................................................................................................................................5

Opening and Closing the Cover............................................................................................................8

Opening the Cover of a Remote I/O Panel........................................................................................ 8

Closing the Cover of a Remote I/O Panel.........................................................................................8

Field Wiring............................................................................................................................9

Power Wiring........................................................................................................................................9

About the Transformer..........................................................................................................................9

Connecting Power to the Transformer..................................................................................................9

Remote I/O Modules............................................................................................................12

Mounting Remote I/O Modules .......................................................................................................... 12

General Control Wiring of Remote I/O Modules................................................................................12

Designation of Remote I/O Modules...................................................................................................13

Maintenance.........................................................................................................................14

Cleaning .............................................................................................................................................. 14

Parts List..............................................................................................................................................14

Warranty...............................................................................................................................15

Warranty Return Material Procedure.................................................................................................. 15

Replacement Parts...............................................................................................................................15

Page 2 IM 783-2

Page 3

Notice

McQuay International reserves the right to change any information contained herein without prior notice. The user is

responsible for determining whether this product is appropriate for his or her application.

The following are trademarks or registered trademarks of their respective companies. L

ONWORKS from Echelon

Corporation; McQuay and MicroTech II from McQuay International.

Reference Documents

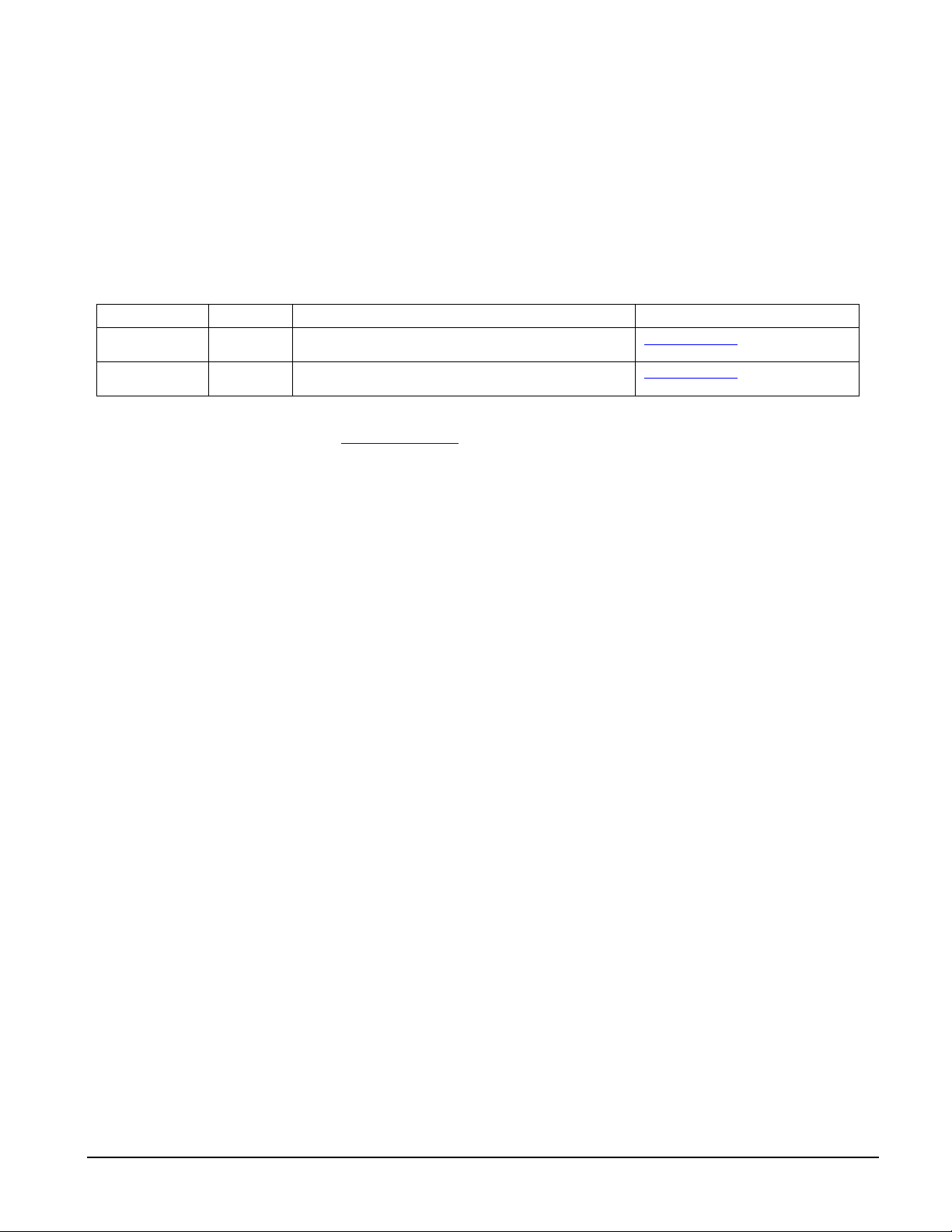

Company Number Title Available At:

McQuay

International

McQuay

International

OM 780 MicroTech II Chiller System Manager Operation Manual

IM 781 MicroTech II Chiller System Manager Installation Manual

www.mcquay.com

www.mcquay.com

All McQuay documents are available at www.mcquay.com

.

Revision History

IM 783-0 February 28, 2004 First release.

IM 783-1 July 7, 2004 Revised Standard Replacement Parts List.

IM 783-1 August 26, 2004 Added hardwired to Designation of Remote I/O

IM 783-2 November 28, 2006 Changed entire panel enclosure and wiring

modules section.

schematic per new supplier.

IM 783-2 Page 3

Page 4

Introduction

The MicroTech II® Remote I/O panel consists of a sheet metal enclosure housing a transformer, and remote I/O modules.

These modules provide additional input/output for use with a Chiller System Manager (CSM) supervisory controller. These

modules communicate with the supervisory controller via a two wire L

be mounted at strategic locations around the building, near the controlled devices to avoid long runs of control wires back to

the supervisory controller.

A CSM can control pumps, fans, valves, boilers, etc. The supervisory controllers use remote I/O modules as an expandable

platform of inputs and outputs to control different size pump stations, cooling towers, etc. For example, a large chiller plant

may have more secondary pumps to control than a smaller plant and fewer remote I/O modules are required to control the

smaller plant.

Remote I/O modules are not application specific. All the application software resides in the CSM supervisory controller.

This means that the same remote I/O modules are used on a CSM. Remote I/O modules may be purchased and mounted in

the field. They can also be purchased pre-mounted in a remote I/O panel ready for wall mounting.

A remote I/O panel may have from one to four remote I/O modules. The number of modules per panel is determined by job

requirements. See the installation manual of the supervisory controller to determine specific uses for the modules. Each

module provides the following input/outputs:

• 4 Universal Inputs

• 4 Digital Inputs

• 4 Relay Outputs (normally-open contacts rated for 6 Amps @ 230 Volts)

• 2 Analog Outputs (0-10 Volts DC)

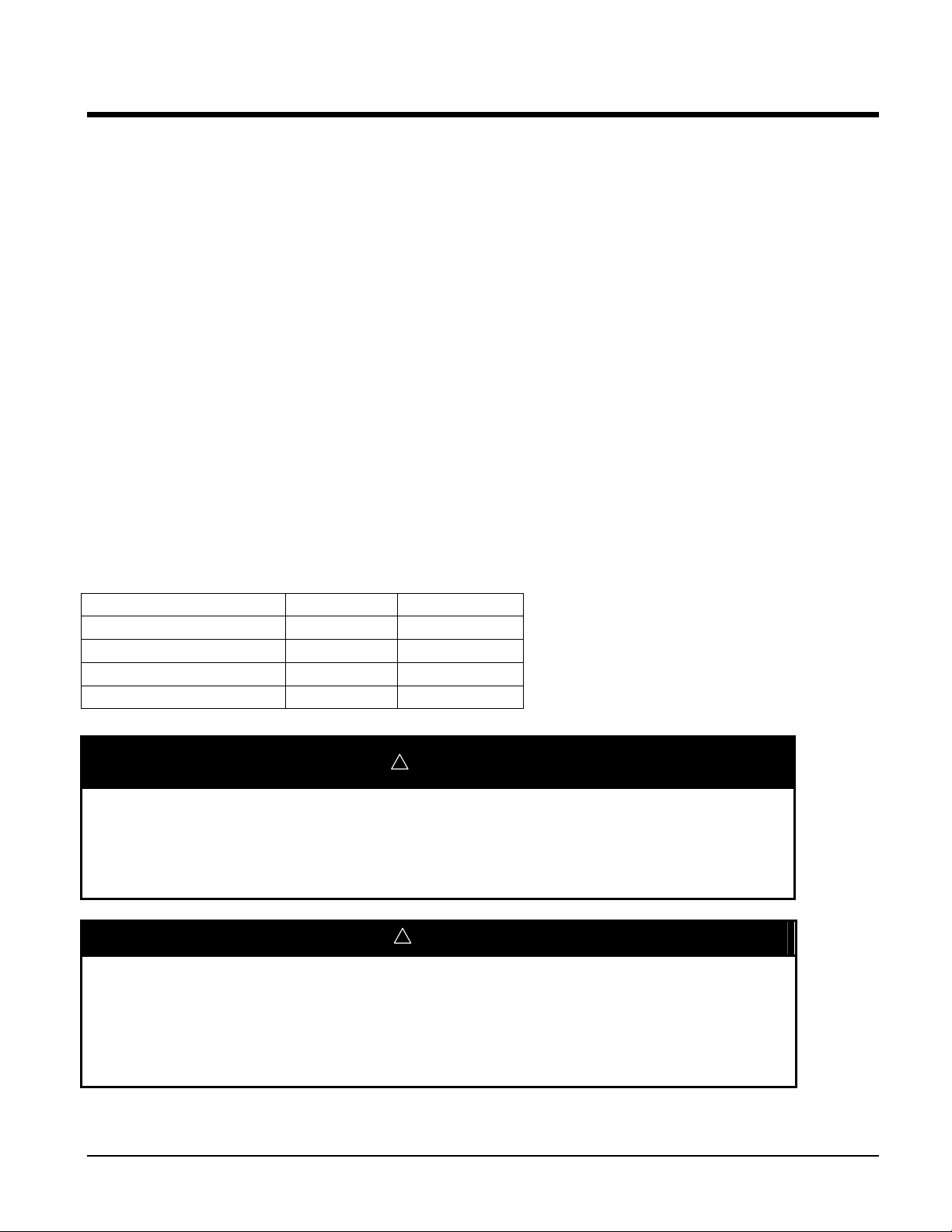

Remote I/O panels come with either 120 volt or a 240 volt power supplies. See the part number designation table below:

ONWORKS® communications network. The panel can

Table 1. Remote I/O Panel Part Numbers

Number of Modules per Panel 120 Volt 240 Volt

1 112028701 112029401

2 112029101 112029501

3 112029201 112029601

4 112029301 112029701

WARNING

!

Electric shock hazard.

Can cause personal injury or equipment damage.

This equipment must be properly grounded to the MicroTech II control panel. Connections and service must

be performed by trained personnel with experience with the equipment being controlled.

!

CAUTION

Static sensitive components.

Can cause equipment damage.

Discharge any static electrical charge by touching the bare metal inside the control panel before performing

any service work. Never unplug cables, circuit board terminal blocks, or power plugs while power is applied to

the panel.

Page 4 IM 783-2

Page 5

Panel Location and Mounting

Unpack the Remote I/O Panel

Unpack the remote I/O panel and inspect the contents of the package for damaged or missing components. If damaged, notify

the appropriate carrier at once and contact your local McQuay representative for immediate repair or replacement.

Physical Installation

Tools Required

The following tools and supplies may be required for installation:

• Small flat-blade screwdriver: used for terminal connections

• Phillips screwdriver: used to secure the door

Before Installation

To reduce the risk of condensation resulting from shipping at low temperatures, keep the remote I/O panel at room

temperature for at least 24 hours before applying power.

Avoid mounting this panel in areas where high electromagnetic interference (EMI) can affect its operation.

Mounting

• Mount the remote I/O panel in a location that allows clearance for wiring, servicing, and module removal. For mounting

details and drill hole locations, refer to the Mounting Guide and Mounting Details, Figure 1 and Figure 2.

• Mount the remote I/O panel within the maximum node-to-node distance to another node of your L

See IM 781 for detail on L

this means the panel must be mounted within 820 ft (250 m) of the nearest L

CSM, a chiller, another remote I/O module, etc). This typical node-to-node distance can be increased to a maximum of

8855-ft (2700 m) by using thicker cable (up to 16 AWG) and doubly terminated networks.

• This product is intended for indoor use only. Do not expose this unit to ambient conditions outside of the range of 0° to

50° C (32° to 122° F) and relative humidity outside the range 5% to 90%, non-condensing (pollution degree 1).

• If the controller is mounted inside an enclosure, that enclosure must be designed to keep the unit within its required

operating range, considering 40-watts heat dissipation. This is especially important if the panel is mounted inside an

enclosure with other heat dissipating equipment.

• For proper mounting clearances see Figure 2. Minimum clearance from the wall on which the unit is mounted is 0.2

inches (provided by the dimpled mounting feet). Provide ample space so that airflow is not blocked behind the unit.

• DO NOT mount the unit:

• In an area where excessive moisture, corrosive fumes, or explosive vapors may be present.

• Where vibration or shock is likely to occur.

• In a location subject to electrical noise. This includes large electrical contactors, electrical machinery, variable

frequency drives, welding equipment, spark igniters, and other equipment of this nature.

• The unit is designed to be wall mounted with the transformer situated towards the top of the unit. For the maximum

airflow, do not mount the unit oriented in any other way.

ONWORKS

®

network wiring and maximum node-to-node distance charts. On a typical network

ONWORKS device (other devices can be the

ONWORKS network.

IM 783-2 Page 5

Page 6

Figure 1. Remote I/O Panel Mounting Guide

.406"

(1.03cm)

DETAIL KEYHOLE

Upper Mounting

Remote I/O Panel

Mounting Guide

Ø

.312"

(0.79cm)

.5"

Ø

(1.27cm)

17.875"

(45.4cm)

Mount with this end up.

Note

: Drawing not

to scale.

Verify all measurements

before drilling.

Lower mounting holes are 0.3 12" (0.7 9 cm ) dia.

Clearance for a ¼” screw.

11"

(27.94cm)

Page 6 IM 783-2

Page 7

Figure 2. Remote I/O Mounting Detail

IM 783-2 Page 7

Page 8

Opening and Closing the Cover

Opening the Cover of a Remote I/O Panel

Note: The cover is held closed with a latch. The latch requires a tool, such as a straight-blade screw driver, to open.

To open, insert a straight-blade screw driver in the screw slot (latch), located on the front cover of the remote I/O panel.

Rotate the latch 90 degrees counter-clockwise. The cover will now swing open.

Closing the Cover of a Remote I/O Panel

Close the cover and insert a straight-blade screw driver in the screw slot, located on the front cover of the remote I/O panel.

Rotate the latch 90 degrees clockwise. The cover is now locked shut.

Page 8 IM 783-2

Page 9

Field Wiring

Following are descriptions of the various field-wiring requirements. Wiring must comply with the Natio nal Electrical Code

and all local codes and ordinances. Failures caused, or contributed to, by wiring not in accordance with these instructions will

not be covered under McQuay International’s standard warranty policy.

Power Wiring

Building power is wired to the transformer supplied with the remote I/O panel. Wire the transfor mer to an external switch or

breaker, as there is no disconnect switch in the unit. Some local codes require the switch to be in sight of the unit. The switch

must be capable of 120VAC or 240VAC service (depending on model) to switch the transformer primary.

About the Transformer

The remote I/O panel ships with a 120VAC or 208/240VAC (depending on model), 40 VA, 50/60 Hz transformer. The

transformer provides 24-volt power to the remote I/O modules. The panel ships with from one to four remote I/O modules.

Each module requires 10 VA of power. Do not power other devices from this transformer.

The following things should be noted about the remote I/O panel transformer:

WARNING

!

Improper wiring can cause severe personal injury or death. All connections must be made in accordance with

national and local electrical codes. Use copper conductors only.

The transformer must be dedicated to running the devices in the remote I/O panel. Do not power other devices

from the transformer.

Do not use any other power source or otherwise defeat the isolation provided by the integral transformer. A twowire power source, including a 24V transformer, can cause permanent damage or greatly shorten the life of the

unit.

!

CAUTION

Verify that neither wire of the transformer's secondary winding is connected to earth ground or building neutral.

Ground loops on the analog inputs and outputs can result and damage the modules or connected equipment.

Connecting Power to the Transformer

The following procedure is provided for supplying high voltage power to the remote I/O panel:

1. Remove the ½” knockout provided above the transformer.

2. Run the electrical supply wires through the knockout hole.

3. Using the provided two-position terminal block, connect high voltage power to the transformer primary lead wires.

4. Connect a ground wire to the grounding lug provided.

IM 783-2 Page 9

Page 10

!

CAUTION

Do not run LONWORKS communication wiring alongside higher-voltage supply or higher-voltage control wiring.

Communication problems over the L

ONWORKS network can occur.

On 120 VAC models, connect 120 VAC, 50/60 Hz power to the two position terminal block provided using the information

in Table 2.

Table 2. 120 VAC models building power termination

Building Power Source Termination point

Type of Wire Typical Color of Wire

Ungrounded—Hot Black Either empty terminus of the terminal block

Grounded—Neutral White Other empty terminus of the terminal block

Grounding—Ground Green or bare copper Grounding stud

On 240 VAC models, connect 208/240 VAC, 50/60 Hz power to the two-position terminal block provided using the

information in Table 3. The transformer’s primary wiring is factory wired to the terminal block for 240 VAC power. If your

power supply is closer to 208 VAC, switch the primary wiring from 240 VAC to 208 VAC by replacing the orange wire in

the terminal block with the red wire from the transformer. The remote I/O modules require 24 VAC ± 20%.

Table 3. International Models - 240 VAC models building power termination

Building Power Source Termination point

Type of Wire Typical Color of Wire

Ungrounded—Hot Brown Either empty terminus of the terminal block

Ungrounded--Hot Blue Other empty terminus of the terminal block

Grounding—Ground Green or bare copper Grounding stud

When power is supplied to the remote I/O module, a green LED appears. The LED is located on the lower left-hand side on

the top of the module.

Page 10 IM 783-2

Page 11

Figure 3. Remote I/O Panel General Wiring Diagram

y

y

d

d

h

Power Suppl

120 VAC or 208/240 VAC

(depending on model)

Transformer

Primar

24 VAC

If the module’s relay outputs will be

controlling high voltage (230 Volt

maximum) devices, bring high

voltage control wires to modules 3

and 4 through the top of the panel.

Ground

Bring low

voltage

control

wires and

LonWorks

network

cable in

through the

sides of the

panel.

High Voltage Terminals-Orange

t

4

Remote I/O Module

Low Voltage Terminals-Brown

Yellow

Blue

Low Voltage Terminals-Brown

n

2

Remote I/O Module

High Voltage Terminals-Orange

If the module’s relay outputs will be

controlling high voltage (230 Volt

maximum) devices, bring high voltage

control wires to modules 1 and 2

through the bottom of the panel.

High Voltage Terminals-Orange

r

3

Remote I/O Module

Low Voltage Terminals-Brown

1 2 23 221 2 23 22

Blue

Yellow

Yellow

Blue

Low Voltage Terminals-Brown

1st Remote I/O Module

High Voltage Terminals-Orange

Legend

Notes

1. Depending on the model ordered,

the panel will contain from 1 to 4

modules. Additional modules may be

purchased separately and added to a

panel in the field.

2. See the supervisory controller

installation manual (e.g. IM-781 for

the Chiller System Manager) for

wiring diagrams of the control wiring.

Blue

Yellow

22 23 2 122 23 2 1

Factory wiring

Field wiring

Field wiring terminal

Bring low

voltage

control

wires and

LonWorks

network

cable in

through the

sides of the

panel.

IM 783-2 Page 11

Page 12

Remote I/O Modules

Mounting Remote I/O Modules

Each remote I/O module mounts on a DIN rail. The modules are snapped in place on the rail. To remove a module from a

rail, slip a flat-head screwdriver into the stirrup located on the base of the module (center tab under the brown terminals).

Gently pull the stirrup away from the housing while lifting up on the module.

General Control Wiring of Remote I/O Modules

The remote I/O panel comes with the 24 VAC power wires supplied from the transformer to the modules. All control wiring

is field supplied in accordance with the CSM supervisory controller Installation Manual with which the panel will be used.

All wiring must comply with applicable electrical codes and ordinances.

2

Note: Terminals on the remote I/O module accept wire from 20 AWG (0.5 mm

Each remote I/O module is equipped with four 230 VAC, digital outputs (i.e. relays). Two are normally open (N.O.) and two

are changeover (C.O.) relays. All four normally open contacts are rated for 6 amps continuous current while the normally

closed contacts of the two C.O. relays are rated for 1 amp continuous current. These high-voltage relay terminals are the

orange touchless terminals on the module (separated from the brown low-voltage terminals). The modules are mounted so

that the orange high-voltage terminals are directed toward the top and bottom of the remote I/O panel to keep high-voltage

wiring separated from low-voltage wiring (see Figure 3).

If you are wiring to remote I/O modules mounted in the remote I/O panel and high-voltage devices are being switched, run

the wiring from these devices into the top or bottom of the panel. Connect these wires directly into the touchless orange relay

terminals on the high voltage side of the module. Wire the low-voltage and communication wiring into the sides of the panel

and connect these wires directly into the brown terminals on the low-voltage side of the modules.

If these relays are used for control of high-voltage devices, the wiring must be run separately from any

Do not mix relay control of high voltage and low voltage devices on the same module.

) to 14 AWG (2.5 mm2).

low-voltage wiring.

WARNING

!

Electric shock hazard.

Can cause personal injury or equipment damage.

If the remote I/O module relay outputs will be switching higher voltage devices, higher voltage wiring must be run

separately from low voltage wiring.

Do not mix low-voltage and higher-voltage wires on the relay side (orange terminals) of a remote I/O module.

Note: Local wiring guidelines may take precedence over recommendations provided in these instructions.

Page 12 IM 783-2

Page 13

Designation of Remote I/O Modules

When you receive a remote I/O module(s) in a remote I/O panel, it has not yet been assigned a designation (meaning it has

not yet been assigned to be Hardwired, Remote A, Remote B, etc.). The module only becomes a Remote I/O module A (or B,

or C, etc.) or a Remote I/O module for Hardwired Chillers after it has been commissioned into the CSM’s L

communications network. This assignment is accomplished at the Device Addressing screen of the CSM user interface.

To designate a remote I/O module(s), go to the Device Addressing tab in the CSM user interface. The Device Addressing

screen contains both a Chiller table and a Remote I/O table. To designate a remote I/O module, click on the Service Pin

button associated with the appropriate Remote I/O device (e.g. Remote I/O - A) in the Remote I/O table. While the Service

Pin timer is counting down, (the timer appears as a pop-up box on the screen) press down on the Service Pin button located

on the remote I/O module. After you have assigned a module, label it for future reference. Labels are included with the

remote I/O panel for this purpose.

To designate a module as Hardwired, follow these steps using the CSM user interface:

1. Navigate to the Chiller table

2. Click on the dropdown menu and change the default in the Hardwire Selection field from MicroTech II to Hardwired

3. Click on the Service Pin button associated with that chiller.

4. While the Service Pin timer is counting down, (the timer appears as a pop-up box on the screen) press down on the

Service Pin button located on the remote I/O module.

5. After you have assigned a module, label it for future reference. Labels are included with the remote I/O panel for this

purpose.

ONWORKS

IM 783-2 Page 13

Page 14

Maintenance

This section provides information on the following topics:

• Cleaning

• Replacement Parts

Cleaning

If dust or metal filings are present inside the unit, clean with vacuum or compressed air. Otherwise, no cleaning inside the

unit is required. Optionally, if the outside of the metal enclosure becomes dirty, you can wipe it with a damp cloth and mild

detergent.

Parts List

Standard replacement parts are listed in Table 4 and can be ordered from stock without restriction. Standard replacement parts

cannot be returned for credit and should be disposed of in an appropriate manner.

Table 4. Standard Replacement Parts

Part Number Description

060630801 Remote I/O panel Transformer, 120V

063042401 Remote I/O panel Transformer, 208/240V

112024401 Remote I/O module

Page 14 IM 783-2

Page 15

W arranty

Consult your local McQuay Representative for warranty details. Refer to Form 933-43285Y. To find your local McQuay

Representative, go to www.mcquay.com

Warranty Return Material Procedure

Defective material may not be returned without prior authorization of authorized factory service personnel of McQuay

International in Minneapolis, Minnesota, phone number (763) 553-5330. A "Return Goods" tag must be included with the

returned material. Enter the required information to expedite handling and prompt issuance of credits. All parts must be

returned to the appropriate McQuay facility, designated on the "Return Goods" tag. Transportation charges must be prepaid.

The return of the part does not constitute an order for replacement. Therefore, a purchase order must be entered through the

nearest McQuay representative. The order should include part number, model number, and serial number of the unit involved.

Credit will be issued on customer's purchase order following an inspection of the returned part and upon determination that

the failure is due to defective material or workmanship during the warranty period.

Replacement Parts

When writing to McQuay for service or replacement parts, refer to the model number and serial number of the unit as

stamped on the serial plate attached to the unit. If replacement parts are required, include the date of installation of the unit

and date of the failure, along with an explanation of the malfunctions and a description of the replacement parts required.

.

IM 783-2 Page 15

Page 16

This document contains the most current product information as of this printing. For the most up–to-date product

information, please go to www.mcquay.com

.

www. mcquay.com • (800) 432-1342

Loading...

Loading...