Page 1

ICM 450

Programmable Three Phase Voltage

Monitor with 25-Fault Memory

Protects motors from premature failure

and burnouts

Installation, Operation & Application Guide

For more information on our complete range of American-made

products – plus wiring diagrams, troubleshooting tips and more,

visit us at www.icmcontrols.com

Page 2

Specication

Input

• Line Voltage: Universal, 190-630 VAC

• Frequency: 50-60 Hz

• Load Side Monitoring: Optional

• Control Voltage: 18-240 VAC

• Frequency: 50-60 Hz

Output

• Type: Relay, SPDT

• Voltage Range: 240VAC @ 10A maximum

• Frequency: 50-60 Hz

Control Operating Temperature

• Operating Temperature: -40ºF to +167ºF (-40ºC to +75ºC)

• Storage Temperature: -40ºF to +185ºF (-40ºC to +80ºC)

LCD Operating Temperature

• Operating Temperature: -4ºF to +167ºF (-20ºC to +75ºC)

Mechanical

• Mounting: Surface mount using (2) #8 screws

• Terminations: Screw terminals

• Weight: 12 ounces (341 grams)

Dimensions

• 6 1/2” L, 4 1/4” W, 1 3/8” H (16.5 cm. L, 10.8 cm. W, 3.5 cm. H)

Parameters

Phase Unbalance Protection

• Voltage Unbalance: 2-20% adjustable

Over/Under Voltage Protection

• Under Voltage: 2-25% adjustable

• Over Voltage: 2-25% adjustable

Phase Loss Protection

• Phase Loss Condition: Equals 25% of nominal for any given phase; system

will shut down and a fault will be recorded should this occur

Delay on Break Timer

• Control Voltage: 18-240 VAC

• Time Delay: 0 to 10 minutes adjustable

Fault Interrogation Delay

• Time Delay: 0 to 15 seconds adjustable

• Provides a delay between fault detection and system shutdown - helps to

eliminate nuisance trips or unnecessary shutdowns

Caution

Installation of the ICM450 shall be performed by trained technicians only.

Adhere to all local and national electric codes.

Disconnect all power to the system before making any connections.

Page 3

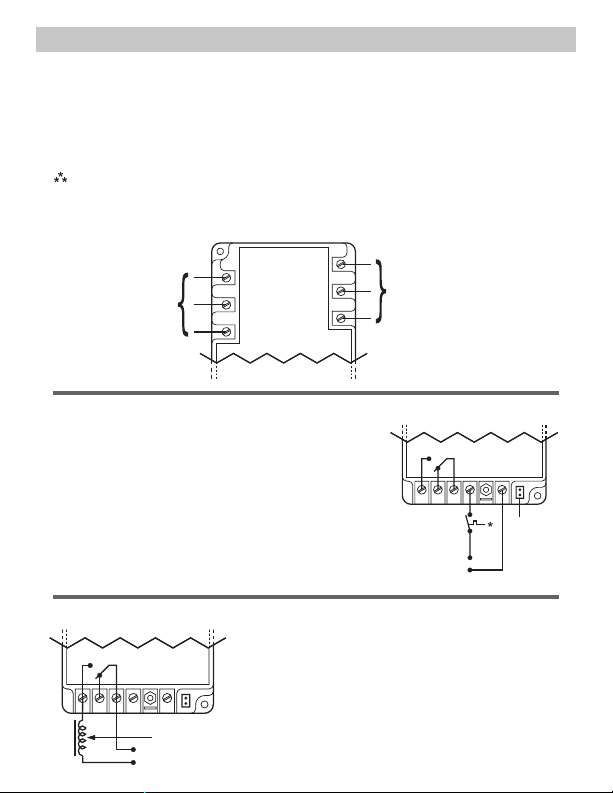

Installation

1. Using (2) #8 screws, mount the ICM450 in a cool, dry, easily accessible

location in the control panel.

2. Connect voltage as shown in Figure 1 (below). Leave existing line and load

side connections intact on the contactor.

3. Load side monitoring is optional (unit may be used to monitor line side

only). Wire the contactor and optional control voltage monitoring as in

Figures 2 and 3 (below).

Note: Load/line wire must be rated for 3-phase voltage rating, 20ga

4. Upon application of power, the ICM450 will be on line and will begin to

monitor the system.

“back” side of contactor

minimum.

Figure 1

Incoming 3-phase

voltage from load or

(optional)

LOAD

3

LOAD

2

LOAD

1

LINE

3

LINE

2

LINE

1

Incoming 3-phase voltage from

line or “front” side of contactor

The incoming 3-phase voltage is

used to power up the ICM450 as

well (190-600)

• Terminals 1 and 3 are the control signal input terminals

• “Control Mode” is turned ON or OFF in setup

• With “Control Mode” set to “ON,” there must be a

voltage present on terminals 1 and 3 for the relay

output terminals 4 and 6 to close; this voltage can be

supplied from a thermostat, pressure switch, etc.

• When the voltage on these terminals is re-applied,

the unit will not re-energize until the delay on break

(0-10 minutes) time has elapsed

• Use of terminals 1 and 3 is optional; they will be

ignored if the “Control Mode” is set to “OFF”

Figure 3

• Terminals 4 and 6 are “dry,” normally open

6 5 4

13

Contactor Coil

Contactor Voltage (18-240 VAC)

contacts

• Terminals 4 and 6 are closed when power is

within specifications

• Terminals 4 and 6 open when there is a fault

condition or loss of control signal

Figure 2

6 5 4

* Switch can be

a thermostat,

pressure

switch, etc.

Control Voltage

(18-240 VAC)

13

Short pins

when using

24 VAC

control

voltage

1

Page 4

ICM450 Wiring Diagrams

2-Pole Contactor 3-Pole Contactor

3

2

1

LOAD

LOAD

LOAD

L03

LINE

3

LINE

2

LINE

1

LI3

LI2

LI1

3

2

1

LOAD

LOAD

LOAD

LINE

3

LINE

2

LINE

1

LI3

LI2

LI1

Control

Voltage

L01

L02

* Thermostat, pressure switch, etc. * Thermostat, pressure switch, etc.

L0AD

Control

Voltage

L01

L02

L03

L0AD

Setting the Parameters

1. Press the green SETUP button to enter Setup mode. Setup LED will light.

2. Use the and arrows to change user parameters.

3. Scroll through setup by pressing and releasing the SETUP button.

4. When the last parameter has been set, the phase average will be

displayed and the Setup LED will automatically turn OFF.

Button Functions

Press arrows to scroll through

and select user parameter

settings in Setup mode.

HOLD down for fast edit.

Press to enter

Setup mode

and select user

parameters.

Hold for

voltage display

a b, b c, a c

(simultaneously).

Press to read faults.

Hold for 5 seconds

to clear faults and

reset memory.

2

Page 5

Parameters

Parameter Description Range Default Recommended

Line

Voltage

Delay On

Break

Fault Inter-

rogation

Over/Under

Voltage

% Phase

Unbalance

Reset

Mode

Control

Mode

Average phase to phase

line voltage

Amount of time between

the load de-energizing and

re-energizing

Amount of time before

the load de-energizes due

to a non-critical fault*

%

Maximum/minimum phase

to phase average voltage,

respectively

Amount of allowable

voltage unbalance

AUTO or number of

times the load can be

re-energized after a load

side fault before a manual

reset is necessary

Note: When monitoring

With control mode set

to OFF, the load will

energize if no 3- phase

fault conditions exist;

with control mode ON,

the load will energize if no

fault conditions exist and

control voltage is present

at terminals 1 and 3 of

the ICM450

line side only, the

reset mode will

always be AUTO

190-600 208 Nameplate

0-10

minutes

0-15

seconds

2-25% 20% 12-15%**

2-20% 20% 4-5%**

AUTO,

0-10

ON

or

OFF

.1

minute

15

seconds

AUTO

ON Based on wiring

Voltage

4 minutes**

7-8 seconds**

AUTO

* Non-critical faults are faults such as High/Low Voltage and Phase Unbalance.

Critical faults, such as Phase Loss and Phase Reversal, have a fault

interrogation of under 2 seconds and it is not user adjustable.

** For best recommendations, consult manufacturer of equipment.

3

Page 6

Fault Conditions

Press and release fault button to scroll through all saved faults.

Note: For initial setup, press and hold FAULT for 5 seconds to

remove any previously stored faults.

Fault Problem Corrective Action

Back

Not all three of the

Phase

phases on the load side

Loss

are present

Back

Loads 1, 2, or 3 are not

Phase

in sequence (not 120º

Rev

phase shifted)

Back

A voltage unbalance

Phase

between the three load

Unbal

phases exceeds the

unbalance setpoint

Front

Average phase-phase

Over

voltage exceeds the

Volt

maximum percentage

Front

Not all three of the

Phase

phases on the line side

Loss

are present

Front

Lines 1, 2, or 3 are not

Phase

in sequence (not 120º

Rev

phase shifted)

Front

A voltage unbalance

Phase

between the three line

Unbal

phases exceeds the

unbalance setpoint

Front

Average phase-phase

Under

voltage is below the

Volt

minimum percentage

* Only swap phases during initial setup, not after the ICM450 has been in operation without

errors.

1. Re-energize the contactor.

2. If the fault reappears after the load energizes:

a. Turn all power OFF

b. Check all load side connections

c. Check the contacts of the contactor for debris

or excess carbon.

1. Turn OFF all power.

2. Swap any 2 phases on the load side of the

ICM450 only (example: swap load 1 and load 2) *

3. Re-apply power.

1. Press the READ button to observe the present

load voltages. Check system for unbalance cause.

2. Increase the fault interrogation time if necessary.

3. Increase the percent unbalance setting if

necessary.

1. Check system for over-voltage cause.

2. Increase the percent over-voltage setting if

necessary.

3. Increase the fault interrogation time if necessary.

1. Press and hold the READ button on the phase

monitor or use an AC voltmeter to carefully

measure all three phase-phase line voltages

(example: Line 1 Line 2, Line 2 Line 3, Line

3 Line 1).

2. Repair the missing phase.

1. Turn OFF all power.

2. Swap any 2 phases on the line side of the ICM450

(example: swap load 1 and load 2)*

3. Re-apply power.

1. Press the READ button to observe the present

load voltages. Check system for unbalance cause.

2. Increase the fault interrogation time if necessary.

3. Increase the percent unbalance setting if

necessary.

1. Check system for under-voltage cause.

2. Increase the percent under-voltage setting if

necessary.

3. Increase the fault interrogation time if necessary.

4

Page 7

Problem

Load will not

energize

Load will not

energize

Fault LED

blinks

repeatedly

while load is

energized

Load will not

de-energize

when control

voltage is OFF

Setup LED

is on while

load is being

energized

Load will not

energize

Load turns ON

and OFF

repeatedly

Troubleshooting

LCD

Readout

Phase

Avg.

Phase

Avg.

Phase

Avg.

Phase

Avg.

Anything

Other Than

Phase Avg.

Reset Fault LED

Readout is

Irrelevant

LED Status Corrective Action

All LEDs Off Confir m that the control input

Load LED Off,

Fault LED

blinking

Fault LED

Blinking,

Load LED On

Load LED On,

Control LED Off

Setup LED On,

Load LED On

Blinking

Fault LED

Blinking

(terminals 1 & 3) is properly

connected and configured (see

Pages 1 and 3)

Press FAULT to observe the

current fault; correct the

condition of the first fault that

appears (see Fault Conditions,

Page 4 for a list of corrective

actions)

Indicates there are faults

saved in the memory, press

FAULT rapidly to scroll through

saved faults; to clear the

faults, press and hold FAULT

for more than 5 seconds

The control mode setting is

OFF; press SETUP to get to

the control mode. Press to

set the control mode ON

To exit the setup mode, press

either READ or FAULT

Unit in lockout; maximum

number of retries in manual

reset mode has been reached;

to reset unit, press FAULT and

hold for more than 5 seconds

Fix load side fault; press FAULT

to observe condition; the delay

on break period may be too

short; press SETUP to enter

the delay on break mode;

press to lengthen the delay

5

Page 8

ONE-YEAR LIMITED WARRANTY

The Seller warrants its products against defects in material or

workmanship for a period of one (1) year from the date of manufacture.

The liability of the Seller is limited, at its option, to repair, replace or

issue a non-case credit for the purchase prices of the goods which are

provided to be defective. The warranty and remedies set forth herein

do not apply to any goods or parts thereof which have been subjected

to misuse including any use or application in violation of the Seller’s

instructions, neglect, tampering, improper storage, incorrect installation

or servicing not performed by the Seller. In order to permit the Seller

to properly administer the warranty, the Buyer shall: 1) Notify the

Seller promptly of any claim, submitting date code information or any

other pertinent data as requested by the Seller. 2) Permit the Seller to

inspect and test the product claimed to be defective. Items claimed

to be defective and are determined by Seller to be non-defective are

subject to a $30.00 per hour inspection fee. This warranty constitutes

the Seller’s sole liability hereunder and is in lieu of any other warranty

expressed, implied or statutory. Unless otherwise stated in writing,

Seller makes no warranty that the goods depicted or described herein

are fit for any particular purpose.

7313 William Barry Blvd., North Syracuse, NY 13212

(Toll Free) 800-365-5525 (Phone) 315-233-5266 (Fax) 315-233-5276

www.icmcontrols.com

LIA164-4

Loading...

Loading...