Page 1

HiLine™ Vertical Stacking

Fan-coil Units

Type HSS & KZZ

Catalog 770-14

ARI 440 CUL Listed

Page 2

Contents

Application flexibility ...............................................................................................................................................................2

McQuay HiLine™ fan-coil units ..............................................................................................................................................2

Installing The HSS (Basic) Unit: .............................................................................................................................................9

Installing the KZZ (Knock-down) Unit:....................................................................................................................................9

HiLine™ selection data ........................................................................................................................................................13

Model KZZ (Knock-down Unit) Unit Sizes S03 Thru S08 (300 thru 800 cfm) .....................................................................17

Model HSS (Basic Unit) Unit Sizes S03 Thru S08 (300 thru 800 cfm) ................................................................................18

Riser Location — HSS and KZZ Unit Sizes S03 Thru S08 (300 thru 800 cfm)...................................................................19

Model HSS (Basic Unit) Unit Sizes S10 Thru S12 (1000 thru 1200 cfm) ............................................................................20

Riser Location — HSS Unit Sizes S10 and S12 (1000 thru 1200 cfm) ...............................................................................21

Engineering guide specifications .......................................................................................................................................... 25

ARI certification, U.L. and CUL listing

McQuay HiLine fan-coil units are tested and rated in accordance

with Air Conditioning and Refrigeration Institute (ARI) Standard

440 and certified in accordance with the ARI certification program.

ARI certification assures you full rated performance and offers

confidence in unit selection.

HiLine fan-coil units are listed by Underwriters Laboratories as

complying with nationally recognized safety standards for fan-coil

air conditioning units.

“HI-F” and “HiLine” are registered trademarks of McQuay International.

“McQuay” is a registered trademark of McQuay International.

“Bulletin illustrations cover the appearance of McQuay International products at the time of publication and

Page 2 / Catalog 770-14

we reserve the right to make changes in design and construction at anytime without notice.”

©2011 McQuay International. All rights reserved throughout the world.

Ratings Certified By

The Air Conditioning

& Refrigeration

Institute

CUL Listed

Page 3

McQuay HiLine™ fan-coil units

The McQuay HiLine fan-coil air conditioning units are

designed for use in multiple floor apartments, office

buildings, hotels and other similar applications and require

a minimum amount of floor space. Just one HiLine unit

may do the job that formerly required more than one

conventional unit.

The results of many years of experience in the development,

design and manufacture of fan-coil air conditioners have

been incorporated in the McQuay HiLine units to provide

highly efficient, quiet performance; individual thermostatic

control; simple, low cost installation; application flexibility;

and low maintenance and operating costs with no sacrifice

in room comfort, design, or appearance.

For the ultimate in design, performance, efficiency, flexibility

of application, and ease of installation and maintenance,

look to McQuay HiLine fan-coils.

Application flexibility

Two distinct designs are available with the complete

flexibility necessary for any application requirement.

• Low cfm design - The 300 through 800 cfm blowthrough configuration units are designed to meet

individual room control requirements.

• High cfm design - The 1000 and 1200 cfm drawthrough configuration units are designed for multiple

discharge arrangements so that one unit can serve

more than one room.

Both designs are available for two-pipe and four-pipe

systems with single, double, triple and top discharge

arrangements. Optional equipment is available to provide

complete application flexibility.

Contact your McQuay representative for a copy of the

McQuayTools™ selection program to choose a unit meeting

your needs.

Nomenclature

F HSS 1 S03 A C

Product Category

F=Fan Coil

Product Identifier

HSS Hi-line Series Vertical Unit

KZZ Knock Down Hi-line w/o Valves

Design Series

1=A Design

2=B Design

3=C Design

4=D Design

5=E Design

Nominal CFM

S02=200

S03=300

S04=400

S06=600

S08=800

etc......

Coil Options (Not available on all prod.)

C=Lo-Flow

N=Lo-Flow Coil w/2-Way Valve

P=Lo-Flow Coil w/3-Way Valve

Q=Lo-Flow Coil w/2-Way Valve Deluxe

R=Lo-Flow Coil w/3-Way Valve Deluxe

Voltage

A=115-60-1

B=200-60-3

G=230-60-1

I=230/460-60-3

J=265-60-1

L=575-60-3

Q=115/230-60-1

Z=Not applicable

Catalog 770-14/ Page 3

Page 4

Low cfm design (300 thru 800 cfm)

Blow-Through Units to Meet Individual Room Requirements

LOW SOUND LEVEL OPERATION - The low cfm design features a

NEUTRAL UNIT SHOWN

(Risers in back)

quiet, energy efficient motor and fan assembly, carefully located within

a fully insulated cabinet to provide low sound level operation.

DISCHARGE ARRANGEMENTS

- Single, double, triple and top

discharge arrangements are

available.

CONTROLS - Face mounted, plug-in type,

combination 3-speed switch and thermostat.

Thermostat electrical box is adjustable for wall

thickness. No wiring required.

ACCESS & SOUND BAFFLE

PANEL - Insulated galvanized steel.

Easily removed for complete access

for service.

RISERS - Factory cut 104” long.

No on-the-job cutting required.

Supply and return risers have

factory installed sweat ball valves

and are factory insulated

FAST, SIMPLE INSTALLATION -

Simply stack one unit above the other,

sweat the couplings to the risers and

connect the power. The unique nonstop slip couplings require only one

person for setting and connecting.

CABINET - Heavy

gauge galvanized

steel. Fully insulated

for quiet operation.

Optional valve packages can

be provided for 24V, 115V,

and 277V.

RETURN AIR GRILLE PANEL -

Heavygauge steel with stamped grille

and attractive Antique Ivory finish.

Available as an accessory.

Page 4 / Catalog 770-14

FILTER - Easily accessible by

simple removal of return air

grille panel.

OPPOSITE HAND UNITS - Two adjacent

room units can be connected to a single

set of risers and still retain individual room

temperature control. Twin units must be joined

in the field. Reverse piping for same hand

units not available.

COILS - High efficiency type

for full rated capacity. AHRI

certified.

REMOVABLE CHASSIS

- All components are

mounted on a single

removable chassis so that

a different capacity chassis

can be installed in the

same cabinet should future

needs require it.

MOTOR & FAN ASSEMBLY -

Quiet, energy efficient, permanent

split capacitor motors and

centrifugal fans for low sound

level. Fan housings are of a split

type design or have separate inlet

rings to allow easy removal of the

fan motor.

Page 5

High cfm design (1000 thru 1200 cfm)

For Multiple Discharge Arrangements

SPECIALLY DESIGNED FOR HIGH CFM PERFORMANCE - These draw-through type units are ideal for luxury hotel

and condominium type buildings where multiple discharge arrangements with a common return air location, high cfm

peformance and quiet operation are required.

NEUTRAL UNIT SHOWN

(Risers in back)

FAST, SIMPLE INSTALLATION - Simply stack one unit

above the other, sweat the couplings to the risers and

connect the power. The unique non-stop slip couplings

require only one person for setting and connecting.

RISERS (Not shown) - Factory cut 104” long. Supply and return

risers are factory insulated. The unique non-stop slip couplings

require only one person for unit setting and connecting.

DISCHARGE ARRANGEMENTS - Single,

double, triple and top discharge arrangements

are available.

OPPOSITE HAND UNITS - Two

adjacent room units can be

connected to a single set of risers

and still retain individual control of

each unit. Twin units must be joined

in the field. Reverse hand piping for

same hand units not available.

CABINET - Heavy gauge galvanized steel.

Fully insulated for quiet operation.

CONTROLS - Unit-mounted combination

3-speed switch and thermostat. Thermostat

electrical box is adjustable for wall thickness.

Thermostat wiring required in the field

(optional molex connections can be provided).

MOTOR & FAN ASSEMBLY (Not

shown) - Quiet, energy efficient,

permanent split capacitor motors

and centrifugal fans, mounted in

the draw-through position with a

common return air location, provide

high cfm performance with low

sound level.

SWEAT BALL VALVES - are

factory mounted on coil.

Optional valve packages can

be provided for 24V, 115V,

and 277V.

COILS - High efficiency type for

full rated capacity. ARI certified.

RETURN AIR GRILLE PANEL - Heavy

gauge steel with stamped grille and

attractive Antique Ivory finish.

ACCESS & SOUND BAFFLE PANEL -

Easily removed for complete access to

internal controls, motor and fan assembly

for service.

FILTER - Easily accessible by simple

removal of return air grille panel.

Catalog 770-14/ Page 5

Page 6

Design features for high performance

and low operating cost

Unit configuration

Telescoping

Thermostat Box

Plug-in Field Mounted Thermostat

Unit sizes S03 through S08 feature a blow-through

design with completely removable chassis. The motor,

fan assembly, coil(s), drain pan and valve packages are

mounted on a compact chassis which slides out through the

return air grille and access panel.

Unit sizes S10 and S12 feature a draw-through design.

Filter, drain pan and drain line are accessible by removing

the return air grille. Controls, valves, motor and fan

assembly are accessible by removing the access panel.

Knock-down unit

The KZZ knock-down unit configuration, available for unit

sizes S03 through S08, allows installation, leak testing

and insulation of the risers and stub-outs prior to the

unit placement. Risers can be field provided or factory

supplied and shipped to the jobsite before the units. After

riser installation, the bottom half of the unit is set in place.

Connections are then made to the supply, return and drain

risers as well as the power supply. Then the top half of the

unit is installed.

Sizes

S06 -S12

Fan and Motor Assembly

Sizes

S03 & S04

Control systems

A variety of thermostats, unit or wall mounted, are offered

to control all different options for fan and valve cycling. For

unit mounted thermostats all wiring is provided to the control

box for easy field installation (optional Molex connections

are available upon request). A 10K thermistor is mounted

in all units. It can be used for factory provided thermostats

or for field provided controls. The thermostat electrical

box is adjustable for any wall thickness up to 3-7/8" and is

provided with a 1/2" mud ring (an optional 5/8" mud ring can

be provided upon request).

Thermostats

• Unit mounted 2 or 4-pipe systems (24v–277v)

• Wall mounted 2 or 4-pipe systems (24v–277v)

• Automatic or manual changeover

• Digital display

• Optional quick connect for unit mounted thermostats

(Please reference ED 18513 for thermostat availability and

options)

Efficient, quiet fans and motors

Three-speed, permanent split capacitor motors coupled

with DWDI forward curved direct drive fans provide

efficient operation. Motors have sleeve bearings, oilers and

inherent automatic reset thermal overload protection. Unit

sizes S03 through S04 have a two-piece fan housing with

integral scroll and inlet. Unit sizes S06 through S12 have

a heavy-gauge steel fan housing with integral scroll and

separate inlets. All fan wheels are statically and dynamically

balanced. Efficient fans, PSC motors, resilient motor mounts

and a fully insulated cabinet provide quiet operation.

Page 6 / Catalog 770-14

Page 7

Factory- and field-installed risers

Insulated risers are available factory-installed or can be

shipped with or prior to the units for field installation (factoryinstalled risers are not available for KZZ knock-down units).

See details below. On S03 through S08 units, sweat ball

valves are included with factory risers.

All copper risers are factory cut to 104” in length. Nonstop slip couplings for supply and return risers and stop

type couplings for drain risers may be ordered separately.

Insulation meets or exceeds current flammability

classification UL94. Insulation to cover slip couplings must

be field provided.

• Supply and return risers are of type “L” copper in

nominal 3/4", 1", 1-1/4", 1-1/2", 2", 2-1/2" diameters with

3/4" factory installed, closed cell flexible foam insulation.

• Drain risers are available in PVC or type “L” copper

(insulation included), in nominal 3/4" or 1-1/4" diameter.

• Optional 1/2" closed cell insulation is available for

supply, return, and drain risers.

• Optional M or K type copper is available with closed cell

insulation.

Note:

When risers are factory-mounted on master-slave units, the

master unit is shipped with the riser attached. This riser will

have 3" stubs that match up to the slave unit. The slave

unit will not have ball valves attached to the valve package.

See Page 22 for master-slave riser locations. Ball valves, if

required, must be purchased separately and will ship loose

for field mounting. See IM 283 for additional information.

Fast, low-cost installation

Installation time is minimized by the unit’s design, riser slip

couplings, and unit mounted controls. Units are completely

factory assembled and wired and have individual thermostat

controls. Risers are factory cut to 104” in length and

insulated. Optional riser couplings are available. Installation

is accomplished by simply stacking the units one above

the other floor-by-floor, brazing the couplings and risers

together, and connecting the power. Only one person is

required for installation because the slip couplings eliminate

the requirement for perfect unit alignment with the swedged

riser joints of other manufacturers.

Twin units

To reduce installed cost, two units of opposite hand on

each floor can share a set of supply, return and drain risers.

Individual thermostat control is retained by each unit. Units

can be placed side-to-side, or side-to-back

Coils

High-capacity, low-flow heating/cooling coils are standard.

Separate row heating coils are available for 4-pipe systems.

All coils are furnished with manual air vents..

Riser, Slip Coupling and Insulation

High performance coils

Two-pipe system units have a standard low-flow, high

capacity cooling/heating coil. Four-pipe system units have

a standard low-flow, high capacity cooling coil and a onerow heating coil. All coils are seamless copper tubes in a

staggered pattern and feature the patented HI-F rippled and

corrugated aluminum fins for high heat transfer efficiency.

Full depth collars are drawn in the fin stock for accurate

control of fin spacing and completely cover the copper

tubes to lengthen coil life. Copper tubes are mechanically

expanded into the fin collars to provide a positive primary

to secondary surface bond. Manual air vents on coils are

provided. Ball valves on supply and return lines are provided

at the coil on S10 and S12 models. Coils are positioned for

rapid condensate drainage, balanced airflow and full rated

capacity. Unit capacities are ARI certified.

Factory-installed valve packages and options

Multiple configurations of two- and three-way motorized

valves are available as described below, without or without

unions. Ball hand valves and flow metering devices are also

available.

• Standard high voltage valve package 115–277v

(includes 2 or 3-way motorized On/Off valve and shutoff valves for supply and return)

• Deluxe high voltage valve package 115–277v (includes

2 or 3-way motorized On/Off valve, strainer, circuit

setter, P/T ports, and shut-off valves)

• Optional 24v On/Off or modulating valves

• Custom valve packages available

• Fixed flow control

• Optional stainless steel braided hoses

Insulation to cover slip

coupling (by others)

Optional Valve Package Components

Motorized Valve

Automatic

change-over

control

Ball Valve

P/T Plug

“Y” Strainer

Flow Control

Device

Catalog 770-14/ Page 7

Page 8

Optional features and accessories

Motors

115/60/1 and 277/60/1 motors are available. All motors

Electric Heat

Fresh Air Dampers

are 3-speed permanent split capacitor type with sleeve

bearings, oilers, resilient mounts and automatic reset

internal overload protection.

Electric heat

A specially designed, optional electric heat unit is available

for supplementary heat between seasons or to provide full

electric heating. All heaters are protected by automaticreset, high-limit thermal cutouts. Service access to electric

heaters is through the return air grille and access panel for

unit sizes S03 through S08. It is through the discharge grille

for unit sizes S10 and S12.

Cabinet closed cell insulation

Cabinets can be supplied fully insulated with 1/2" closed

cell insulation (1/2" multi-density glass fiber is standard).

Fresh air dampers

A motorized, two-position fresh air damper kit is available

for field mounting in one of three locations. A manual fresh

air damper kit is also available. Outside fresh air must be

tempered before entering the unit if freezing conditions are

expected.

Discharge Grilles

Double Deflection

Discharge

Arrangements

Single Deflection

Return air grilles

Return air grille options include the standard stamped

return air grille or an optional bar type grille. Both grilles

are manufactured of heavy-gauge steel and coated with an

electrostatically applied baked-on Antique Ivory finish. A

plaster frame is standard to provide easy access for filter

replacement.

Filters

One inch throwaway filters are standard.

Discharge arrangements and grilles

Two sizes of aluminum single deflection or double

deflection grilles are available. Grilles may be field mounted

on the panel opposite the riser and on one or both panels

adjacent to the risers. A top discharge opening is also

available.

Line-of-sight baffle

A line-of-sight baffle is available for applications involving

two opposing discharge openings.

Page 8 / Catalog 770-14

Page 9

Installing The HSS (Basic) Unit:

Installing the KZZ* (Knock-down) Unit:

1. The McQuay HiLine basic

unit is simply lifted into place

directly above the unit on the

floor below.

2. This unit has been set in

place, ready to accept the

unit above.

3. Next, using factory available

slip couplings, connect the

prefabricated supply, return

and drain risers together,

connect the

basic installation is completed.

Wall board can be applied

directly to the unit.

power, and your

1. Unlike the basic unit, the

KZZ unit allows installation,

leak testing and insulation of

the risers and stubouts prior

to unit placement.

2. The bottom half of the unit is

set in place, and the supply,

return and drain risers are

connected to the unit along

with the power supply.

3. The top half of the unit is

then easily installed and the

factory suppled thermostat

harness is connected

.

4. After the unit has been

“furred-in” and the room

painted, it takes only a few

minutes to attach the grilles

and plug in the thermostat.

5. When the installation is

completed, the unit blends

in beautifully with the

surrounding decor and takes

up a minimum of floor space.

*The “KZZ sectioned cabinet for room air conditioning unit” is covered under U.S. Patent No. 4,426,120.

4. Finishing the installation

is the same with either the

standard HSS model or the

knock-down KZZ model.

5. Both HiLine units can be

located away from an outside

wall to form a curtain cove,

or built into a room divider.

It’s easy to conceal the units

in a corner or build them into

a wall to serve two or more

rooms. And, of course, the

creative architect will think of

many more applications for

this versatile unit.

Catalog 770-14/ Page 9

Page 10

Application considerations

Piping systems

Reverse Return Piping Systems - If possible, the same size

HiLine units should be installed one above the other all the

way up each stack in the building. This way, each unit in the

stack requires the same amount of water. No balancing is

required, because the loop of water from each unit travels

the same distance and has the same pressure drop.

Our experience indicates that the reverse return piping

system, Figure 1, is the most popular one because the

system tends to be self-balancing. Only one express riser is

required to gather the return water, at the top or bottom of

the building, and return it to the boiler or chiller.

Direct Return Piping System - In the direct return piping

system, Figure 2, each unit must be individually balanced to

obtain proper water flow through each unit.

Expansion and contraction

Proper allowance must be made for pipe expansion.

Provisions have been designed into the HiLine unit to allow

for plus or minus 1" of riser movement. For riser systems

where the movement exceeds ±1", provisions must be

provided in the riser system to restrict the movement. As a

rule of thumb, 100 feet of copper pipe will expand 1" when

exposed to a 100°F temperature difference. See Figure 4

for thermal expansion of copper risers. The temperature

difference is the difference between the temperature at

which the piping is installed and the water temperature

during operation. On a two-pipe system, this temperature

difference becomes even greater due to the change in water

temperature from cooling to heating.

One method of limiting riser expansion is by anchoring

the riser pipes at the center of the riser stack and allowing

the pipes to expand away from the anchor point. Thus, a

200 ft. length would expand approximately 1" each way.

Another method is anchoring the riser pipes at the end and

absorbing the expansion with an expansion compensator.

If an expansion compensator is used, the pipe should be

guided. In some situations, a combination of both methods

may be required. The risers must be secured at some point

as the units have not been designed to support the riser

weight.

Number of floors per riser

The standard HiLine unit with service valves, expansion

loops, etc., will operate at 250 PSI working pressure which

is equivalent to a 35 to 40 story building.

Selection of riser piping

Riser piping should be selected based on economic

considerations. Detailed information may be found in the

ASRHAE Handbook series. The guidelines offered in Figure

4 are based on water velocity only. A water velocity of

2 FPS is considered to be the minimum requirement for

entraining and carrying air with water flow. Water velocities

of over 8 FPS may cause undue erosion of water pipe.

Risers may be sized on the highest water velocity that will

not cause noise or erosion. We recommend that the water

velocity in risers and units fall within the range of 4 FPS to 6

FPS. Since HiLine units have risers outside the unit cabinet

and usually within a partition wall, noise should not be a

problem. Riser sizes need not be changed at every floor to

accommodate flow changes but may be carried at one size

until water velocities fall outside the recommended ranges.

Contractor piping responsibility

Factory available copper riser couplings are non-stop type

for ease of installation. PVC couplings have stops. Field

installation involves clamping the slip coupling in place

and brazing or sweat soldering it to the risers above and

below. PVC couplings are field cemented to the drain risers.

Reducing couplings, anchors and expansion compensators,

if required, must be provided by the contractor.

Insulation to cover slip couplings must be field provided.

Providing a good cement bond at the joints between the

field installed insulation and the factory installed riser

insulation is the contractor’s responsibility.

Fire stop

For building code compliance, a fire stop must be provided

by the contractor in the riser opening between floors and

between twin units serving adjacent rooms.

Page 10 / Catalog 770-14

Page 11

Insulation limitations

Under high humidity start-up conditions, care should be

taken by utilizing a gradual pull-down to minimize sweating

of cabinet and/or risers.

Temperature control

A wide variety of fan and valve cycle control systems

are offered for McQuay HiLine units. Valve cycle control

systems have a higher first cost but offer significantly lower

operating costs than fan cycle systems. Valve cycle control

systems provide superior temperature control resulting in

improved occupant comfort.

Both unit mounted and remote wall mounted thermostats

are available. The 10K thermistor is positioned in front

of the filter and is provided with all units. The thermostat

electrical box is field adjustable for any wall thickness up to

3-7/8". Direct sunlight falling on thermostats for either unit or

remote mounted control applications should be avoided.

Twin units

Equipment and installation costs can be significantly

reduced by designing a floor layout involving twin units.

Twin units, of opposite hand, are placed side-to-side, or

side-to-back and share a common set of risers. Individual

thermostat control is retained by each unit. Twin unit risers

have two sets of stubouts to accept piping from both units.

A short link of field supplied copper tubing may be required

depending upon wall thickness between units.

Catalog 770-14/ Page 11

Page 12

Figure 4. Type “L” Copper Riser Pressure Drop

AREA OUTSIDE OF RECOMMENDED DESIGN RANGE.

Figure 5. Thermal Expansion of Copper Risers

Page 12 / Catalog 770-14

Page 13

HiLine™ selection data

System design

The achievement of an efficient fan coil system is dependent

upon accurate system design and proper equipment

selection. Variations, limitations and control of fan coil

systems, design conditions and design load calculations

are not described in detail in this catalog. More detailed

information may be found in the ASHRAE Handbook series.

Prior to selecting the individual unit sizes, the design

engineer must fix or determine the following factors:

1. Inside and outside wet and dry bulb temperatures.

2. Method of introducing the ventilation.

3. Wet and dry bulb temperatures of the air mixture

entering the unit coil.

4. Total and sensible heat gains and losses of the area to

be served.

5. Properties of the heating and cooling mediums.

6. Available electric power service.

7. Any special design requirements of the building or

system.

Computer fan coil selection

The capacity ratings presented in this catalog are provided

for initial unit selection only. Unit size selection should be

determined by using the SelectTools™ fan coil selection

computer program. Water cooling and heating capacities,

unit airflow, static pressure, electric heat, glycol solutions

and jobsite elevation are all incorporated into the program

to provide the best possible selection. Consult your

representative for a selection tailored to your application.

Unit sizes for the ideal system should be selected by

calculating the peak load requirements due to unusually

high occupancy or severe climatic conditions and with fan

operating at high speed. Ordinary day to day cooling and

heating requirements are then achieved at low and medium

speeds. Ventilation requirements should be considered

along with the following to determine the proper unit size.

Cooling Coil Requirements - Having checked the minimum

unit size to meet the ventilation requirement, the unit size

is generally selected on the basis of matching the sensible

cooling capacity of the unit with the calculated requirements

when operating at high speed.

The initial unit selection should be checked for air volume

in the design system and the cooling capacities checked at

the actual operating conditions. While units selected on the

basis of sensible load will generally meet the total cooling

load, total load should be checked in all cases.

Coil Type - Standard low flow coils are available for all units

sizes to permit unit selections for optimum performance.

Low flow coils are designed to meet both the normal cooling

and heating requirements while operating with reduced

GPM and correspondingly higher water temperature rises.

Their use is enhanced by the lower first cost of both riser

piping and pump plus lower overall fan coil unit and water

pump operating cost.

Heating Requirements - Heating requirements for two-pipe

systems are generally met by employing the same water

flow rate as cooling and adjusting the entering hot water

temperature to obtain a matching unit heat output at low

fan speed. Four-pipe systems are generally designed by

specifying a design hot water temperature and adjusting

the flow rate through the separate heating coil to meet the

required heat load with the fan operating at low speed.

Maximum water temperature in coils should be limited to

200°F (160°F for HSS sizes S10 and S12), and should be

adjusted to reflect outside temperatures.

Electric heaters are available for primary year-round heating

or intermediate between-seasons heat loads for twopipe

systems when chilled water is in the system. Units having

top duct discharge and electric heat must have a

discharge duct face area equal to or greater than the

top duct opening.

Catalog 770-14/ Page 13

Page 14

ARI approved standard ratings

Table 2. Low Flow Coil Water Cooling Capacity Ratings

UNIT SIZE

S03 10500 7200 2.0 14.6

S04 17000 11400 3.5 44.7

S06 22200 14200 4.6 28.8

S08 28800 20100 5.7 44.1

S10 39600 26600 7.9 29.7

S12 44900 30400 8.9 39.6

(TOTAL BTUH) (SENSIBLE BTUH)

COOLING CAPACITY2

1

WATER FLOW (GPM) WATER FLOW P.D. (FT-WC

NOTES:

1 Rated in accordance with AHRI Standard 440. Cooling capacities based on 80ºF DB/67ºF WB entering air, 45ºF entering water, 10ºF water temperature

rise and high fan speed. See Table 7 for air volume capacities.

2 For cooling coil capacity ratings at conditions other than that listed, refer to the McQuayTools™ computer selection program or consult your McQuay

representative.

Table 3. Low Flow Coil Water Heating Capacity Ratings

UNIT SIZE

S03 20940 2.2 9.8

S04 25970 2.8 22.1

S06 38320 3.9 15.5

S08 48560 4.9 22.6

S10 64720 6.6 14.5

S12 77600 7.9 20.8

HEATING CAPACITY2

(SENSIBLE BTUH)

1

WATER FLOW (GPM) WATER FLOW P.D. (FT-WC

NOTES:

1 Water heating coils rated at 70ºF DB entering air, 140ºF entering water, 20ºF water temperature drop and high fan speed.

2 For heating coil capacity ratings at conditions other that listed refer to the McQuayTools™ computer selection program or

consult your McQuay representative.

Table 4. Separate Hot Water Coil Water Heating Capacity Ratings

UNIT SIZE

S03 12240 1.2 1.6

S04 16380 1.7 3.5

S06 22200 2.2 7.2

S08 25600 2.6 9.4

S10 40200 4.1 27.5

S12 46530 4.7 39.0

HEATING CAPACITY

(SENSIBLE BTUH)

2

WATER FLOW (GPM) WATER FLOW P.D. (FT-WC

1

NOTES:

1 Water heating coils rated at 70º F DB entering air, 140ºF entering water, 20ºF water temperature drop and high fan speed.

2 For heating coil capacity ratings at conditions other that listed refer to the McQuayTools™ computer selection program or

consult your McQuay representative.

Page 14 / Catalog 770-14

Page 15

Technical data

Table 5. Air Volume versus External Static Pressure.

UNIT

SIZE

S03 339 258 183 311 243 173 281 222 159 249 197 140 — — — — — — — — —

S04 408 310 221 397 298 207 384 284 193 368 268 178 350 252 160 — — — — — —

S06 609 519 422 588 499 404 565 479 383 539 456 360 512 429 315 — — — — — —

S08 798 621 452 781 606 440 759 590 428 736 574 416 712 556 402 686 535 386 — — —

S10 1020 800 646 1000 780 630 976 761 614 950 741 598 923 720 581 895 698 564 868 677 547

S12 1220 972 778 1192 954 765 1164 932 755 1137 910 748 1109 887 745 1080 865 747 1050 840 753

0.00 0.05 0.10 0.15 0.20 0.25 0.30

HI MED LO HI MED LO HI MED LO HI MED LO HI MED LO HI MED LO HI MED LO

NOTES:

Air volumes based on 115/60/1 electrical services, normal unit features and dry coils.

Medium and low speed air volume based on unit peformance in a system with tabulated external static pressure produced at high speed.

Table 6. Motor and Physical Data.

NOMINAL MOTOR DATA AT HIGH SPEED

MODEL NUMBER

S03 0.65 70 0.40 70 13-3/4" × 18-7/8" x 1" 16" × 12"

S04 1.30 146 0.45 120 13-3/4" × 18-7/8" x 1" 16" × 12"

S06 1.60 218 0.70 200 13-3/4" × 18-7/8" x 1" 16" × 12"

S08 2.40 314 1.10 290 13-3/4" × 18-7/8" x 1" 16" × 12"

S10 3.60 350 1.30 350 (1) 24" × 24" x 1" 24" × 14"

S12 4.80 498 2.10 500 (1 ) 24" × 24" x 1" 24" × 14"

115/60/1 265/60/1

AMPS WATTS AMPS WATTS

EXTERNAL STATIC PRESSURE (INCHES H20)

RETURN AIR FILTER SIZE

MAXIMUM DISCHARGE GRILLE

SIZE

Table 7. Approximate HSS Shipping Weights (Lbs.)

HKD UNIT SIZE SINGLE UNIT, NO PALLET SINGLE UNIT with PALLET TWO UNITS with PALLET FOUR UNITS with PALLET1

S03 155 205 380 720

S04 160 210 390 740

S06 175 225 420 800

S08 180 230 430 820

S10 256 306 585 1130

S12 267 317 605 1180

NOTES:

1

Standard shipping arrangement.

Table 8. Approximate KZZ (Knock-down Unit) Shipping Weights (Lbs.)

HKD UNIT SIZE SINGLE UNIT, NO PALLET TWO UNITS, with PALLET OUR UNITS, WITH PALLET1

S03 155 380 720

S04 160 390 740

S06 175 420 800

S08 180 430 820

NOTES:

1 Standard shipping arrangement.

Catalog 770-14/ Page 15

Page 16

Table 7. Electric Heat Data.

UNIT SIZE

S03

S04

S06

S08

S10

S12

*Electric heat voltage must match motor voltage.

WATTS BTUH AMPS WATTS BTUH AMPS

1000 3413 8.3 — — —

— — — — — —

2000 6826 16.7 2000 6826 7.2

— — — — — —

— — — 3000 10239 10.8

1000 3413 8.3 — — —

— — — — — —

2000 6826 16.7 2000 6826 7.2

— — — — — —

— — — 3000 10239 10.8

— — — — — —

1000 3413 8.3 — — —

— — — — — —

2000 6826 16.7 2000 6828 7.2

— — — — — —

— — — 3000 10239 10.8

— — — — — —

— — — — — —

— — — — — —

1000 3413 8.3 2000 6828 7.2

— — — — — —

2000 6826 16.7 3000 10239 10.8

— — — — — —

— — — — — —

— — — 6000 20748 21.6

— — — — — —

— — — — — —

2000 6826 16.7 3000 10239 10.8

— — — 6000 20748 21.6

— — — 8000 27304 28.8

— — — — — —

2000 6826 16.7 3000 10239 10.8

— — — 6000 20748 21.6

— — — 8000 27304 28.8

— — — — — —

120V/60/1 265/60/1

Page 16 / Catalog 770-14

Page 17

Dimensional data (inches)

Model KZZ (Knock-down Unit) Unit Sizes S03 Thru S08 (300 thru 800 cfm)

Recommended Riser Hole Size in Floor (inches)

RISER 3/4 1 1-1/4 1-1/2 2 2-1/2 3

A 3-1/2 4 4 4-1/2 5 5-1/2 6

(TWO PIPE) B 13-1/2 14 14 14-1/2 15 15-1/2 16

(FOUR PIPE) B 17 17-1/2 17-1/2 18 18-1/2 19 19-1/2

Thermostat Box Detail

Mud ring can be mounted

vertically or horizontally.

Opening is 2" × 4×

ALL DIMENSIONS APPROXIMATE.

CERTIFIED DRAWINGS

AVAILABLE UPON REQUEST.

NEUTRAL HAND UNIT SHOWN.

Hand of unit determined by facing return air opening.

Risers on right = Right hand of unit.

Risers on left = Left hand of unit.

Risers on back = Neutral unit.

NOTES:

(1) With return air grille mounted on unit, dimension becomes 23/8”.

(2) Fire Stop: If required, must be provided by contractor.

FIELD RISER LOCATION AND DISCHARGE OPENINGS: SEE PAGE 19 FOR DETAIL.

Catalog 770-14/ Page 17

Page 18

Dimensional data (inches)

Model HSS (Basic Unit) Unit Sizes S03 Thru S08 (300 thru 800 cfm)

Recommended Riser Hole Size in Floor (inches)

RISER 3/4 1 1-1/4 1-1/2 2 2-1/2 3

A 3-1/2 4 4 4-1/2 5 5-1/2 6

(TWO PIPE) B 13-1/2 14 14 14-1/2 15 15-1/2 16

(FOUR PIPE) B 17 17-1/2 17-1/2 18 18-1/2 19 19-1/2

Thermostat Box Detail

Mud ring can be mounted

vertically or horizontally.

Opening is 2" × 4×

ALL DIMENSIONS APPROXIMATE.

CERTIFIED DRAWINGS

AVAILABLE UPON REQUEST.

NEUTRAL HAND UNIT SHOWN.

Hand of unit determined by facing return air opening.

Risers on right = Right hand of unit.

Risers on left = Left hand of unit.

Risers on back = Neutral unit.

NOTES:

(1) With return air grille mounted on unit, dimension becomes 23/8”.

(2) Fire Stop: If required, must be provided by contractor.

FIELD RISER LOCATION AND DISCHARGE OPENINGS: SEE PAGE 19 FOR DETAIL.

Page 18 / Catalog 770

Page 18 / Catalog 770-14

Page 19

Riser Location — HSS and KZZ Unit Sizes S03 Thru S08 (300 thru 800 cfm)

1 2 3 4 REPRESENT AIR DISCHARGE POSITIONS DETERMINED BY FACING RETURN AIR OPENING.

DISCHARGE OPENINGS

WITH ONE OPENING ONLY, LOCATIONS 1 2 3 4 SHOULD BE 16” × 12”.

WITH TWO OR MORE OPENINGS, LCOATIONS 1 2 3 4 SHOULD BE 16” x 6”.

Catalog 770 / Page 19

Catalog 770-14/ Page 19

Page 20

Dimensional data (inches)

Model HSS (Basic Unit) Unit Sizes S10 Thru S12 (1000 thru 1200 cfm)

Recommended Riser Hole Size in Floor (inches)

RISER 3/4 1 1-1/4 1-1/2 2 2-1/2 3

A 3-1/2 4 4 4-1/2 5 5-1/2 6

(TWO PIPE) B 13-1/2 14 14 14-1/2 15 15-1/2 16

(FOUR PIPE) B 17 17-1/2 17-1/2 18 18-1/2 19 19-1/2

Thermostat Box Detail

Mud ring can be mounted

vertically or horizontally.

Opening is 2" × 4×

ALL DIMENSIONS APPROXIMATE.

CERTIFIED DRAWINGS

AVAILABLE UPON REQUEST.

NEUTRAL HAND UNIT SHOWN.

Hand of unit determined by facing return air opening.

Risers on right = Right hand of unit.

Risers on left = Left hand of unit.

Risers on back = Neutral unit.

NOTES:

(1) With return air grille mounted on unit, dimension becomes 23/8”.

(2) Fire Stop: If required, must be provided by contractor.

FIELD RISER LOCATION AND DISCHARGE OPENINGS: SEE PAGE 21 FOR DETAIL.

Page 20 / Catalog 770

Page 20 / Catalog 770-14

Page 21

Riser Location — HSS Unit Sizes S10 and S12 (1000 thru 1200 cfm)

1 2 3 4 REPRESENT AIR DISCHARGE POSITIONS DETERMINED BY FACING RETURN AIR OPENING.

DISCHARGE OPENINGS

WITH ONE OPENING ONLY, LOCATIONS 1 3 SHOULD BE 24” x 14”; LOCATIONS 2 4 SHOULD BE 16” × 14”.

WITH TWO OR MORE OPENINGS, LCOATIONS 1 2 SHOULD BE 24” x 8”; ; LOCATIONS 3 4 SHOULD BE 16” × 12”.

Catalog 770-14/ Page 21

Catalog 770 / Page 21

Page 22

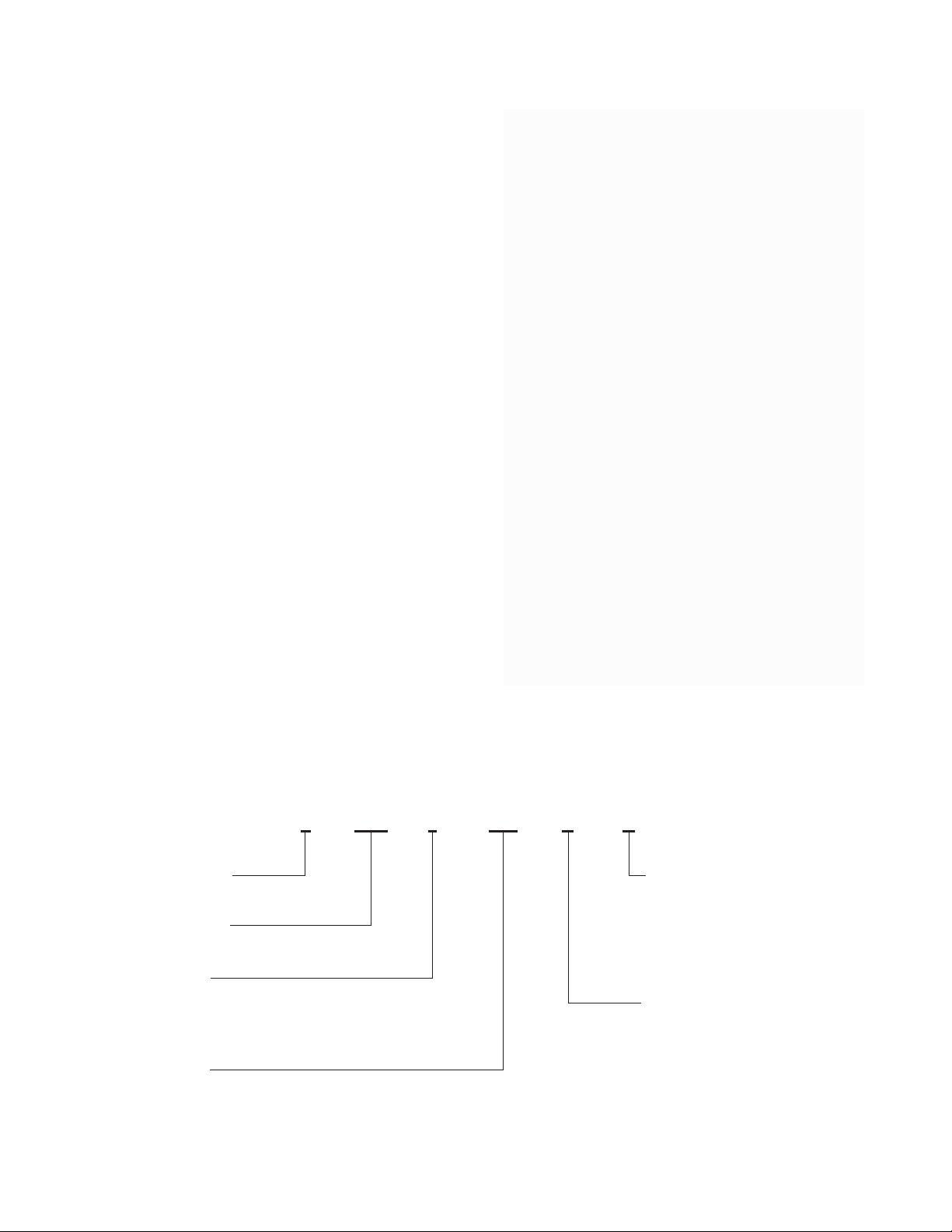

Riser Location for Master-Slave Units

= Return Air = Discharge Air

Right Hand

Master

Right Hand

Slave

Left Hand

Slave

Left Hand

Master

Master units ship with risers attached to the

unit. These risers have 3" stub-out’s to match

with our slave unit piping.

Slave units do not have ball valves attached

to the valve package. Ball valves must be

purchased separately for field installation

(see IM 283-8).

Neutral

Master

Neutral

Slave

Page 22 / Catalog 770-14

Page 23

Typical Fan Cycle Control System Wiring Diagrams

Figure 5.

2-Pipe

Figure 6.

4-Pipe

Catalog 770-14/ Page 23

Page 24

Figure 7.

2-Pipe with 1Circuit Electric Heat

Figure 8.

4-Pipe with 2Circuit Electric Heat

Page 24 / Catalog 770-14

Page 25

Engineering guide specifications

Model HSS (Basic Unit) Unit Sizes S03 thru

S08 (300 thru 800 cfm)

Furnish and install where shown on plans McQuay low cfm design HiLine

– units. Unit sizes, performance and equipment shall be as tabulated in the

schedule. Unit performance shall be substantiated by computer generated

output data.

UNIT CONFIGURATION – Unit shall be (two-pipe)(four-pipe) system

blow-through configuration with completely removable chassis. Filter, fan

assembly, drain line and motor shall be accessible by removing the return

air grille panel. Internal controls, service valves, drain pan and coil shall be

accessible by removing the access and sound baffle panel. Hand of unit shall

be tabulated in the schedule.

CABINET – Cabinet shall be fabricated of heavy-gauge galvanized steel and

fully insulated with 1/2" multi-density glass fiber. An insulated galvanized steel

access and sound baffle panel shall completely enclose the coil section. The

return air grille panel shall be heavy-gauge steel with a stamped (bar type)

grille and electrostatically applied baked semi-gloss finish and extend 5/8" in

front of unit face.

PLASTER FRAME – A plaster frame shall be provided to hold the return air

grille panel away from the wall when the unit is furred in. A snap-on return air

grille panel shall be provided with the plaster frame.

COILS – Units shall be ARI certified with standard low flow heating/cooling

coils in two-pipe systems, or, standard low flow cooling coil plus one-row

heating coil in four-pipe systems. All coils shall be seamless copper tubes in

a staggered pattern with rippled and corrugated aluminum fins. Tubes shall

be mechanically expanded into the fin collars for positive fin-to-tube bond.

Coils shall have manual air vents. Internal piping shall allow for vertical riser

expansion of ±1". Coil performance shall be as tabulated in the schedule. Coil

shall be positioned to provide positive condensate drainage.

FAN ASSEMBLY – Unit sizes S03 and S04: Fan housings shall be two-piece

with integral scroll and inlets. Fan wheels shall be DWDI forward curved

centrifugal direct drive type.

Unit sizes S06 and S08: Fan housings shall be painted steel with integral

scroll and separate inlets. Fan wheels shall be painted steel DWDI forward

curved centrifugal direct type.

All fan wheels shall be statically and dynamically balanced.

MOTORS – Motors shall be permanent split capacitor type (115/60/1)

(277/60/1) with sleeve bearings, oilers, inherent thermal overload protection

with automatic reset and resilient mounts.

DRAIN PAN – Drain pan shall be galvanized steel with drain line and closed

cell insulation on the external surface to prevent condensation.

SUPPLY & RETURN RISERS – Supply and return risers shall be type “L”

copper (optional copper types and diameters shall be as tabulated in the

schedule), with 3/4” closed cell flexible foam insulation, factory installed ball

valves on risers. Slip couplings shall be factory available for field connection.

Insulation shall meet or exceed current flammability classification UL94.

DRAIN RISER – Drain riser shall be PVC. (Optional copper types and

diameters shall be as tabulated in the schedule). Stop type couplings shall be

factory available for field connection.

CONTROL SYSTEMS – A variety of thermostats, unit or wall mounted,

shall be offered to control all different options for fan and valve cycling. For

unit mounted thermostats all wiring shall be provided to the control box for

easy field installation (optional Molex connections shall be available upon

request). A 10K thermistor shall be mounted in all units. The 10K thermistor

shall be used for factory provided thermostats or for field provided controls.

The thermostat electrical box shall be adjustable for any wall thickness up to

3-7/8" and a 1/2" mud ring shall be provided (an optional 5/8" mud ring shall

be provided upon request).

FILTERS – Filters shall be nominal 1” thick throwaway.

DISCHARGE GRILLES (OPTIONAL) – Optional aluminum (single deflection)

(double deflection) discharge grilles shall be provided in sizes and positions

as tabulated in the schedule.

LINE-OF-SIGHT BAFFLE (OPTIONAL) – An optional line-of-sight baffle shall

be supplied as tabulated in the schedule.

FRESH AIR DAMPERS (OPTIONAL) – Two-position (motorized)(manual)

fresh air damper shall be factory available as tabulated in the schedule.

ELECTRIC HEAT (OPTIONAL) – Electric heating elements and controls shall

be completely installed, wired and enclosed at the factory. Heating element

shall be fully protected by a high limit cut-out with automatic reset.

OPTIONAL CONTROLS & VALVES – Valve cycle control systems for two-

pipe and four-pipe systems, two-way or three-way motorized valves and other

combinations of ball valves and automatic flow metering devices shall be

installed as tabulated in the schedule.

TWIN UNITS (OPTIONAL) – Twin unit configuration, as tabulated, shall be

such that two adjacent room units will be piped to a single set of risers and

will operate with separate controls on each unit.

Catalog 770-14/ Page 25

Page 26

Unit Sizes S10 & S12 (1000 thru 1200 cfm)

Furnish and install where shown on plans McQuay high cfm design HiLine

Fan Coil units. Unit sizes, performance and equipment shall be as tabulated

in the schedule. Unit performance shall be substantiated by computer

generated output data.

UNIT CONFIGURATION – Unit shall be (two-pipe)(four-pipe) system draw-

through configuration. Filter, drain line and drain pan shall be accessible by

removing the return air grille panel. Controls, service valves, coil, motor and

fan assembly shall be accessible by removing the inner sound baffle panel.

Hand of unit shall be as tabulated in the schedule.

CABINET – Cabinet shall be fabricated of heavy-gauge galvanized steel and

fully insulated with 1/2" multi-density glass fiber. An insulated galvanized steel

access and sound baffle panel shall completely enclose the internal controls

and fan assembly section. The return air grille panel shall be heavy-gauge

steel with a stamped (bar type) grille and electrostatically applied baked semi-

gloss finish and extend 5/8" in front of unit face.

PLASTER FRAME – A plaster frame shall be provided to hold the return air

grille panel away from the wall when the unit is furred in. A snap-on return air

grille panel shall be provided with the plaster frame.

COILS – Units shall be ARI certified with standard low flow heating/cooling

coils in two-pipe systems, or, standard low flow cooling coil plus one-row

heating coil in four-pipe systems. All coils shall be seamless copper tubes

in a staggered pattern with rippled and corrugated aluminum fins. Tubes

shall be mechanically expanded into the fin collars for positive fin-to-tube

bond. Coils shall have manual air vents and ball valves on the supply and

return lines. Internal piping shall allow for vertical riser expansion of ±1". Coil

performance shall be as tabulated in the schedule. Coil shall be positioned to

provide positive condensate drainage.

FAN ASSEMBLY – Fans shall be DWDI forward curved centrifugal, direct

drive type and statically and dynamically balanced. Fan housings shall be

painted steel with integral scroll and inlets.

MOTORS – Motors shall be permanent split capacitor type (115/60/1)

(265/277/60/1) with sleeve bearings, oilers, inherent thermal overload

protection with automatic reset and resilient mounts.

DRAIN PAN – Drain pan shall be galvanized steel and easily accessible.

SUPPLY & RETURN RISERS – Supply and return risers shall be type “L”

copper (optional copper types and diameters shall be as tabulated in the

schedule), with 3/4” closed cell flexible foam insulation factory installed. Non-

stop slip couplings shall be factory available for field connection. Insulation

shall meet or exceed current flammability classification UL94.

DRAIN RISERS – Drain risers shall be PVC (optional copper types and

diameters shall be as tabulated in the schedule). Couplings shall be factory

available for field connection.

CONTROL SYSTEMS – A variety of thermostats, unit or wall mounted,

shall be offered to control all different options for fan and valve cycling. For

unit mounted thermostats all wiring shall be provided to the control box for

easy field installation (optional Molex connections shall be available upon

request). A 10K thermistor shall be mounted in all units. The 10K thermistor

shall be used for factory provided thermostats or for field provided controls.

The thermostat electrical box shall be adjustable for any wall thickness up to

3-7/8" and a 1/2" mud ring shall be provided (an optional 5/8" mud ring shall

be provided upon request).

FILTERS – Filters shall be nominal one-inch thick throwaway.

DISCHARGE GRILLES (OPTIONAL) – Optional aluminum (single deflection)

(double deflection) discharge grilles shall be provided in sizes and positions

as tabulated in the schedule.

LINE-OF-SIGHT BAFFLE (OPTIONAL) – An optional line-of-sight baffle shall

be supplied as tabulated in the schedule.

ELECTRIC HEAT (OPTIONAL) – Electric heating elements and controls shall

be completely installed, wired and enclosed at the factory. Heating element

shall be fully protected by a high limit cut-out with automatic reset.

OPTIONAL CONTROLS & VALVES – Valve cycle control systems for two-

pipe and four-pipe systems, two-way or three-way motorized valves and other

combinations of ball valves and automatic flow metering devices shall be

installed as tabulated in the schedule.

TWIN UNITS (OPTIONAL) – Twin unit configuration, opposite hand only, as

tabulated, shall be such that two adjacent room units will be piped to a single

set of risers and will operate with separate controls on each unit.

Page 26 / Catalog 770-14

Page 27

Model KZZ (Knock-down Unit) Unit Sizes S03

Thru S08 (300 Thru 800 cfm)

Furnish and install where shown on plans McQuay knock-down HiLine Fan

Coil units. Unit sizes, performance and equipment shall be as tabulated in the

schedule. Unit performance shall be substantiated by computer generated

output data.

UNIT CONFIGURATION – Unit shall be (two-pipe)(four-pipe) system

blow-through configuration with completely removable chassis. Filter, fan

assembly, drain line and motor shall be accessible by removing the return

air grille panel. Internal controls, service valves, drain pan and coil shall be

accessible by removing the access and sound baffle panel. Hand of unit shall

be as tabulated in the schedule.

CABINET – Cabinet shall be fabricated of heavy-gauge galvanized steel and

fully insulated with 1/2" multi-density glass fiber. An insulated galvanized steel

access and sound baffle panel shall completely enclose the coil section. The

return air grille panel shall be heavy-gauge steel with a stamped (bar type)

grille and electrostatically applied baked semi-gloss finish and extend 5/8" in

front of unit face.

PLASTER FRAME – A plaster frame shall be provided to hold the return air

grille panel away from the wall when the unit is furred in. A snap-on return air

grille panel shall be provided with the plaster frame.

COILS – Units shall be ARI certified with standard low flow heating/cooling

coils in two-pipe systems, or, standard low flow cooling coil plus one-row

heating coil in four-pipe systems. All coils shall be seamless copper tubes in

a staggered pattern with rippled and corrugated aluminum fins. Tubes shall

be mechanically expanded into the fin collars for positive fin-to-tube bond.

Coils shall have manual air vents. Internal piping shall allow for vertical riser

expansion of ±1". Coil performance shall be as tabulated in the schedule. Coil

shall be positioned to provide positive condensate drainage.

FAN ASSEMBLY – Unit sizes S03 and S08: Fan housings shall be two-piece

with integral scroll and inlets. Fan wheels shall be DWDI forward curved

centrifugal direct drive type.

Unit sizes S06 and S08: Fan housings shall be painted steel with integral

scroll and separate inlets. Fan wheels shall be painted steel DWDI forward

curved centrifugal direct type.

All fan wheels shall be statically and dynamically balanced.

MOTORS – Motors shall be permanent split capacitor type (115/60/1)

(277/60/1) with sleeve bearings, oilers, inherent thermal overload protection

with automatic reset and resilient mounts.

DRAIN PAN – Drain pan shall be galvanized steel with drain line and closed

cell insulation on the external surface to prevent condensation.

SUPPLY & RETURN RISERS – Supply and return risers are to be (field

supplied)(factory supplied) and field installed. Risers can be installed prior to

unit placement.

DRAIN RISER – Drain risers are to be (field supplied)(factory supplied) and

field installed. Risers can be installed prior to unit placement.

CONTROL SYSTEMS – A variety of thermostats, unit or wall mounted,

shall be offered to control all different options for fan and valve cycling. For

unit mounted thermostats all wiring shall be provided to the control box for

easy field installation (optional Molex connections shall be available upon

request). A 10K thermistor shall be mounted in all units. The 10K thermistor

shall be used for factory provided thermostats or for field provided controls.

The thermostat electrical box shall be adjustable for any wall thickness up to

3-7/8" and a 1/2" mud ring shall be provided (an optional 5/8" mud ring shall

be provided upon request).

FILTERS – Filters shall be nominal one-inch thick throwaway.

DISCHARGE GRILLES (OPTIONAL) – Optional aluminum (single deflection)

(double deflection) discharge grilles shall be provided in sizes and positions

as tabulated in the schedule.

LINE-OF-SIGHT BAFFLE (OPTIONAL) – An optional line-of-sight baffle shall

be supplied as tabulated in the schedule.

FRESH AIR DAMPERS (OPTIONAL) – Two position (motorized)(manual)

fresh air damper shall be factory available as tabulated in the schedule.

ELECTRIC HEAT (OPTIONAL) – Electric heating elements and controls shall

be completely installed, wired and enclosed at the factory. Heating element

shall be fully protected by a high limit cut-out with automatic reset.

OPTIONAL CONTROLS & VALVES – Valve cycle control systems for two-

pipe and four-pipe systems, two-way or three-way motorized valves and other

combinations of ball valves and automatic flow metering devices shall be

installed as tabulated in the schedule.

TWIN UNITS (OPTIONAL) – Twin unit configuration, opposite hand only, as

tabulated, shall be such that two adjacent room units will be piped to a single

set of risers and will operate with separate controls on each unit.

Catalog 770-14/ Page 27

Page 28

Total system capability.

Cabinet

Horizontal

ThinLine™ Fan-coils

Vertical (Slope Top)

Large Capacity Fan-coils

Hideaway

Unit Heaters

HiLine™

Fan-coil

Vertical Unit Heater

Horizontal Unit Heater

McQuay Training and Development

Now that you have made an investment in modern, efficient McQuay equipment, its care should be a

high priority. For training information on all McQuay HVAC products, please visit us at www.mcquay.

com and click on training, or call 540-248-9646 and ask for the Training Department.

Warranty

All McQuay equipment is sold pursuant to its standard terms and conditions of sale, including Limited

Product Warranty. Consult your local McQuay Representative for warranty details. Refer to Form 93343285Y. To find your local McQuay Representative, go to www.mcquay.com.

This document contains the most current product information as of this printing. For the most up-todate product information, please go to www.mcquay.com.

Products manufactured in an ISO certified facility.

©2011 McQuay International • www.mcquay.com • 800-432-1342 (07/11)

Loading...

Loading...