Page 1

9

OPERATION AND MAINTENANCE DATA

PROJECT: Banner Desert Medical Center

Hybrid / Endovascular OR

LOCATION: Mesa, AZ

CONTRACTOR: Comfort Systems USA SW

SUBMITTED BY: Climatec, Inc.

2851 W. Kathleen Rd.

Phoenix, AZ. 85053

602-944-3330

MANUFACTURER: McQuay

PRODUCT: Single Tube – Steam Coil

5SA0601C

SERIAL #: FBOU120100779

TAG: RH - 33

DATE: 1/25/12

Page 2

Installation and Maintenance Manual IM 901

McQuay Steam Coils

Types HI-F5, HI-F8, & E-F5

Group: Applied Air

Part Number: IM 901

Date: February 2008

© 2008 McQuay International

Page 3

Contents

Introduction .............................................................. 3

General Information................................................ 3

Hazard Identification Information............................ 3

Receiving Instructions ............................................ 3

Coil Types............................................................... 3

Distributing.......................................................... 3

Single Tube ........................................................ 3

Nomenclature ......................................................... 4

Installation ................................................................ 5

Mounting ................................................................ 5

Installation.............................................................. 5

Operation and Maintenance.................................... 8

Operation ............................................................... 8

General .............................................................. 8

Maintenance .......................................................... 8

General .............................................................. 8

Page 4

Introduction

Introduction

General Information

These are general guidelines for the installation, operation and

maintenance of McQuay steam heating. They may have to be

tailored to meet the specific requirements of any one job. An

experienced installation company or fully trained personnel

should perform the installation and maintenance of any coil.

Hazard Identification Information

DANGER

Dangers indicate a hazardous situation which will result in

death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which can

result in property damage, severe personal injury, or death if

not avoided.

CAUTION

Cautions indicate potentially hazardous situations, which can

result in personal injury or equipment damage if not avoided.

3 Coils are factory tested at 315 psig (minimum air pressure)

while submersed in water.

4 For additional assistance, contact your local McQuay sales

representative.

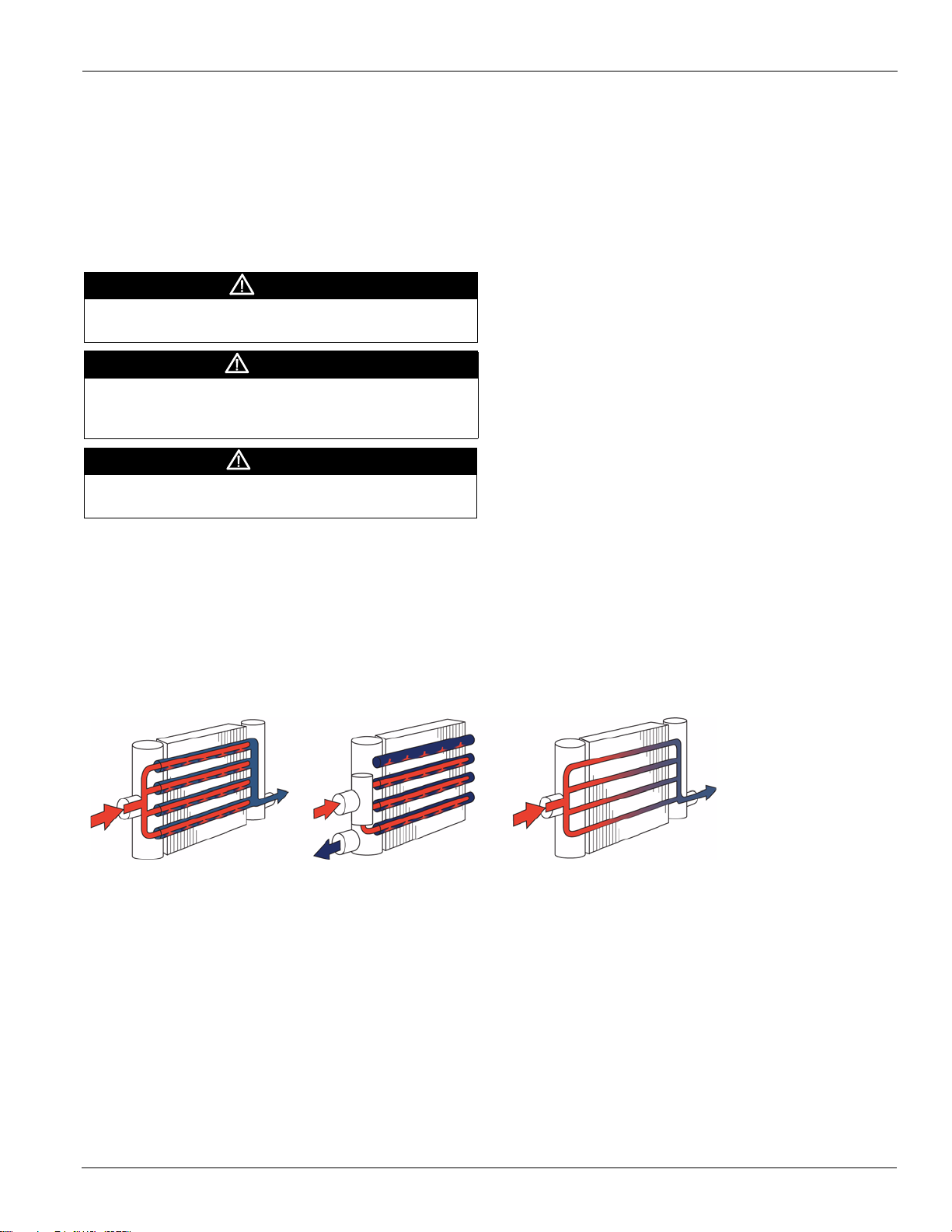

Coil Types

Distributing

McQuay models JA, RA and DA jet-tube steam distributing

coils (Figure 1) are excellent for any general purpose heating

application. With the superior freeze resistance provided by

the tube-with-in-a-tube construction, it is ideal for low

temperature preheating and special process applications. The

construction features inner tubes with directional orifices to

aid in steam distribution and condensate removal. Model JA

offers same-end supply and return connections. Model RA

offers opposite-end supply and return connections. Model DA

offers dual-supply opposite-end connections for long coils that

see sub-freezing air temperatures. Models GA, TA and LA

utilize cupro-nickel, carbon steel and stainless steel tubing for

high-pressure construction.

Single Tube

Receiving Instructions

1 Coils should be inspected for shipping damage upon

receipt. The freight bill should also be checked against

items received for complete delivery.

2 Damaged and/or missing items should be noted on the

carrier's freight bill and signed by the driver.

Figure 1: Coil Types

5R 5T

5J 5G

McQuay model SA steam coils (Figure 1) are designed for

general purpose heating. The construction features a single

tube design with opposite-end supply and return connections.

A perforated baffle located directly behind the supply

connection insures proper steam distribution. Model HA

utilizes cupro-nickel, carbon steel and stainless steel tubing for

high-pressure construction.

5S 5H

McQuay IM 901 3

Page 5

Introduction

Nomenclature

5 SA 12 01 C 24.00 x 110.00

Tube O.D.

8=1"

5=5/8"

Coil Type

5SA: single tube, opposite end connection

5JA, 8JA: distributing tube, same end connection

5DA, 8DA: distributing tube, dual supply,

opposite end connection

8RA:

5HA: high-pressure construction single tube,

opposite end connection

5GA, 8GA: high-pressure construction distributing

tube, same end connection

5LA, 8LA: high-pressure construction

opposite end connection

8TA: high-pressure construction distributing tube,

opposite end connection

5SB: single tube, 3" center to center

opposite end connection

distributing tube, opposite end connection

dual supply,

Finned Length (inches)

Finned Heigth (inches)

Fin Design

A - flat (AI, Cu)

B - corrugated (AI, Cu)

C - sine wave (AI, Cu)

F - flat (SS, CS)

G - corrugated (SS, CU)

H - sine wave (SS, CU)

Rows Deep

Fins Per Inch

4 McQuay IM 901

Page 6

Installation

Mounting

Installation

Installation

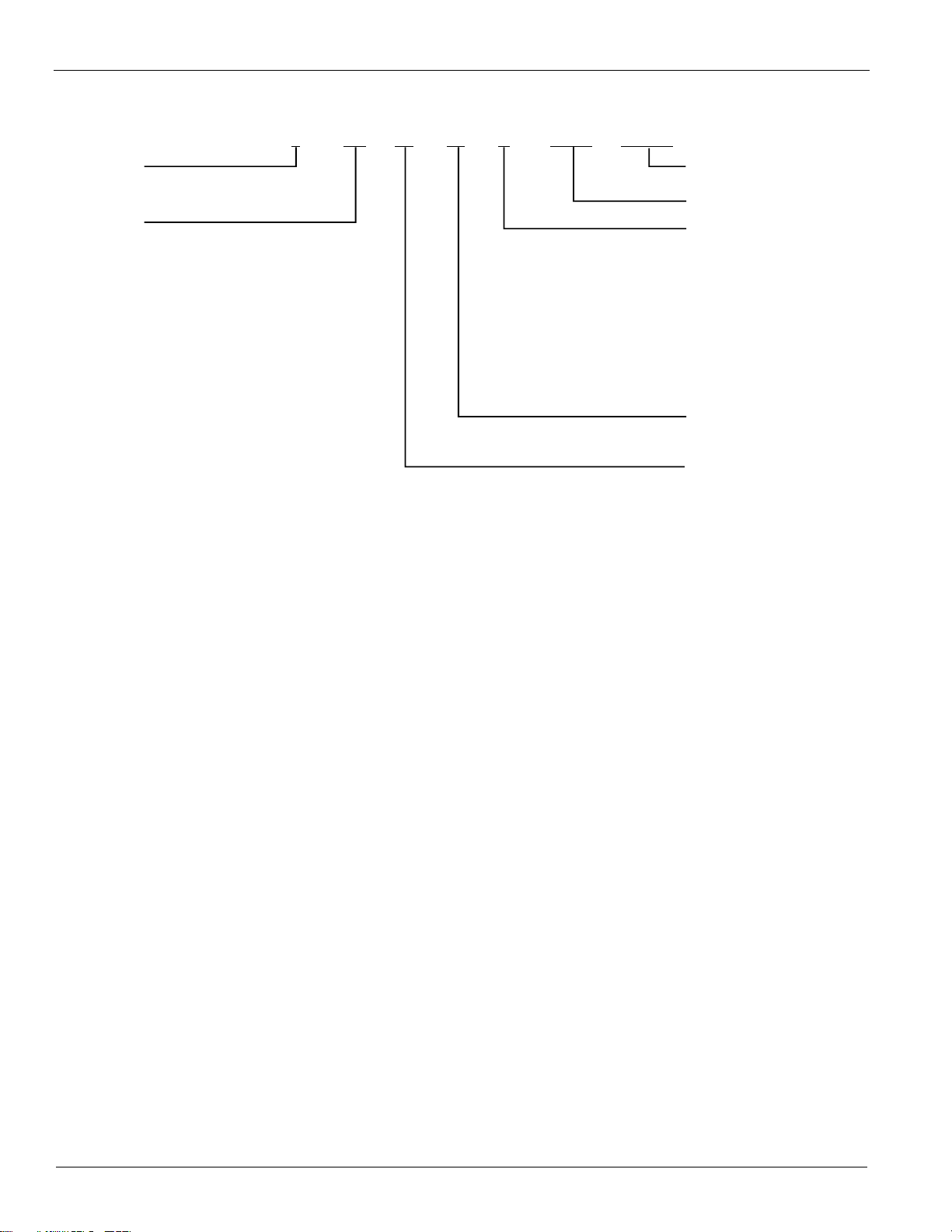

Steam coils must be properly mounted for condensate removal.

This will aid in preventing destructive water hammer, keeping

coils from freezing and preventing corrosive elements from

collecting in the tubes. Case-pitched coils (Figure 2) should be

installed level. McQuay models SA, SB, HA, JA, GA, DA,

LA, RA and TA come standard pitched in the casing.

Coils that are un-pitched (Figure 3) must be installed with the

tubes pitched towards the return connection. A minimum pitch

of 1/8” per foot of coil length is required (pitch has been

exaggerated in Figure 3). Coils with opposite end connections

(RA, TA, SA, & HA) should be furnished with an expansion

joint or provisions made for expansion on opposite connection

end.

Figure 2: Case Pitched

Figure 3: Case Unpitched

WARNI NG

Steam, even at low pressure, can cause serious bodily injury

that may result in death. Be sure the system is off or the

components are isolated before beginning work..

CAUTION

Sharp edges on sheet metal and fasteners can cause

personal injury. This equipment must be installed, operated,

and serviced only by an experienced installation company and

fully trained personnel.

Protective equipment such as safety glasses, steel toe boots

and gloves are recommended during the installation and

routine maintenance of the coil.

CAUTION

Failure to properly install the coil can result in irreparable

damage to the coil as well as other components in the system.

If you are unsure about any portion of the installation, contact

your local steam specialist for assistance.

1 Carefully remove the coil from the shipping package to

avoid damage to the finned surface area. Damaged fins can

be straightened using an appropriate fin comb.

2 McQuay recommends cleaning the coil with a

commercially available coil cleaner prior to installation.

Refer to “Operation and Maintenance” on page 8 for

cleaning recommendations.

Note: Vacuum breakers and air vents should be piped to a

drain or other suitable location where discharged

steam cannot lead to personal injury.

3 Mount coil properly to provide positive condensate

drainage. Refer to “Mounting” on this page.

4 Proper clearance should be maintained between the coil

and other structures such as the fan, filter racks, transition

areas, etc.

5 Utilize vacuum breakers on each coil. Steam traps require a

positive pressure differential to force the condensate

through the valve seat. If the coil's pressure drops below

atmospheric, the pressure differential across the valve will

be negative and the condensate will not drain. This

condition can lead to serious damage or failure of the coil

due to freezing, water hammer and corrosion. Refer to

Figure 4 and Figure 5 for recommended placement.

McQuay IM 901 5

Page 7

Installation

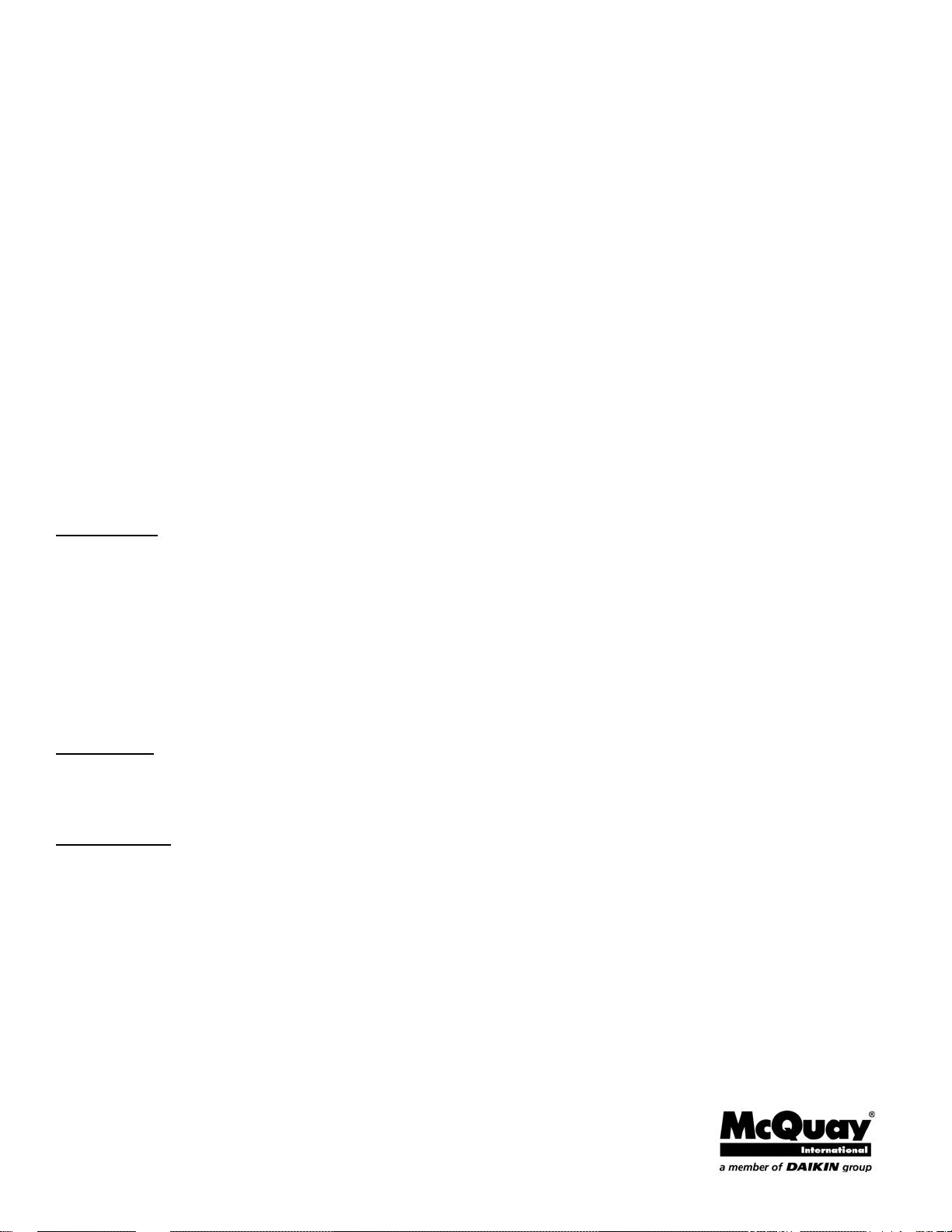

Figure 4: Low Pressure Steam Coil Piping Diagram

SYMBOLS FOR PIPING ARRANGEMENTS

LOW PRESSURE (TO 25 PSI)

*5SA coil installed for vertical airflow. Installer

must pitch coil toward the return connection on

vertical airflow installations. For horizontal airflow installation, the required pitch is built into

the casing.

* NOTE: Rating data is ARI certified only for the

standard ARI coil orientation; i.e., horizontal

tubes, vertical coil face and horizontal airflow.

*5JA or 8JA coil installed with tubes vertical.

The coil supply piping must be dripped ahead of

the coil on an installation of this type.

5JA or 8JA coil installed in

series. Note that each coil

must have a separate control

valve and trap.

8RA and 5SA coils banked three high by

three deep. Individual trapping of each coil

as shown is preferred. Note that it is necessary to provide a separate control valve

for each bank in the direction of airflow.

*5SA coils installed with tubes vertical. Diagram

shows single trap; however, it is always preferable

to trap each coil individually.

* NOTE: Rating data is ARI certified only for standard ARI coil orientation; i.e., horizontal tubes,

vertical coil face and horizontal airflow.

6 McQuay IM 901

Page 8

Figure 5: High Pressure Steam Coil Piping Diagram

SYMBOLS FOR PIPING ARRANGEMENTS

HIGH PRESSURE (OVER 25 PSI)

Installation

5GA or 8GA coils. Note the addition of a vacuum

breaker to permit the coil to drain during shutdown.

Trap each coil separately. Differences in pressure from coil

6

to coil can result in the backing-up of condensate that will

result in poor coil performance and possible damage.

7 Provide an air vent for each coil at its highest location.

Non-condensable gasses present in the steam will collect in

a coil and reduce its capacity. Therefore, it is necessary to

provide a means for the removal of these gasses. Also,

these gasses can diffuse into the condensate forming biproducts, which can lead to severe corrosion.

8 Steam supply lines need to be drained of condensate. This

can be accomplished by the use of drip legs. This ensures

that high quality steam enters the coil.

9 Condensate return piping should be the same size as the

coil's return connection from the coil outlet to the steam

trap.

10 Once installed, the coil should be pressurized to 100 psig

with dry nitrogen or other suitable gas. The coil should be

left pressurized for a minimum of 10 minutes. If the coil

holds the pressure, the hook-up can be considered leak free.

If the pressure drops by 5 psig or less, re-pressurize the coil

and wait another 10 minutes. If the pressure drops again,

8TA or 5HA coils. Condensate is lifted to overhead return main.

there are more than likely one or more small leaks, which

should be located and repaired. Pressure losses greater than

5 psig would indicate a larger leak, which should be

isolated and repaired. Be sure to check valves and fittings

as potential sites for leakage or bleed. If the coil itself is

found to be leaking, contact your local McQuay

representative.

Note: Unauthorized repair to the coil may void the coil's

warranty (see McQuay’s warranty policy on back

cover).

11 All field brazing and welding should be performed using

high quality materials and an inert gas purge (such as

nitrogen) to reduce oxidation of the internal surface of the

coil.

12 All field piping must be self-supporting. System piping

should be flexible enough to allow for thermal expansion

and contraction of the coil. The use of flexible connections

and/or swing joints is recommended.

13 The coil along with the control valve and trap should be

isolated by manual valves to allow for servicing.

McQuay IM 901 7

Page 9

Operation and Maintenance

Operation and Maintenance

Operation

General

1 Proper air distribution is vital to coil performance. Airflow

anywhere on the coil face should not vary by more than

20%.

2 Air velocities should be maintained within McQuay’s

recommended values of between 200 and 1500 fpm.

3 Operating pressures must be at or below the maximum

operating pressure for that coil at the steam temperature.

Operating pressure maximum is 150 psig @ 300 F for low

pressure steam coils and 350 psig @ 450 F for high

pressure steam coils.

Maintenance

DANGER

Follow the manufacturer’s guidelines for lockout/tagout and

disconnect all power to the unit before performing maintenance.

Contact with high voltage power will cause electrical shock,

resulting in severe personal injury or death.

WARNING

Moving parts, high pressure, and/or high temperature fluids can

cause serious personal injury.

General

1 Filters should be inspected on a regular basis and changed

as needed. Clean filters help maintain maximum coil

performance and service life.

2 Periodic inspection of the coil for signs of corrosion and/or

leaks is recommended. Repair and replacement of the coil

and the connecting piping, valves, etc., should be

performed as needed by a qualified individual.

3 Should the coil surface need cleaning, caution should be

exercised in selecting the cleaning solution as well as the

cleaning equipment. Improper selection can result in

damage to the coil and/or health hazards.

4 Suggested cleaning instructions:

a When handling strong chemicals, be sure to wear

chemical impervious gloves, apron and splash goggles.

b Acti-Brite (AB-1) is the recommended cleaning

solution. Contact your local McQuay Parts Distributor.

CAUTION

Carefully read and follow the manufacturer's recommendations

before using any cleaning fluid.

c Determine required dilution for the specific application.

It is recommended to start with a dilution ratio of 10:1

and increase concentration until the desired results are

achieved.

d As with mixing all acids, place the desired amount of

water into the tank and then add the chemicals.

e Turn off fans and allow hot coils to cool before

applying.

f Using plain water, wet both the coil as well as the area

surrounding the equipment. Wetting the coil with water

aids in product penetration and performance.

g Apply properly diluted product to coil surface.

whenever possible, apply solution from the outlet side

of the coil. Allow solution to remain on surface,

normally 5-10 minutes. Do not allow solution to dry on

the coil.

Note: Note; In extreme cases, application may have to be

repeated to achieve desired results.

h If foaming does not occur, check for extreme grease

buildup which will slow cleaning process. Foaming may

not occur if coil is coated or painted.

i Rinse coils, tools and surrounding area thoroughly after

the coil cleaning.

j Clean the coil from the leaving airside so that foreign

material will be washed out of the coil rather than

pushed further in.

5 Internal coil maintenance consists of preventing scale and

corrosion. This is accomplished through aggressive boiler

water treatment, removal of dissolved oxygen and the

removal of non-condensable gasses such as carbon dioxide.

Note: Boiler water treatment is beyond the scope of this

manual. Contact your local water treatment

specialist for assistance in establishing a proper

boiler-water treatment program.

8 McQuay IM 901

Page 10

McQuay Training and Development

Now that you have made an investment in modern, efficient McQuay equipment, its care should be a high priority.

For training information on all McQuay HVAC products, please visit us at www.mcquay.com and click on training, or

call 540-248-9646 and ask for the Training Department.

Warranty

All McQuay equipment is sold pursuant to its standard terms and conditions of sale, including Limited Product

Warranty. Consult your local McQuay Representative for warranty details. Refer to Form 933-43285Y. To find your

local McQuay Representative, go to www.mcquay.com.

This document contains the most current product information as of this printing. For the most up-to-date product

information, please go to www.mcquay.com.

© 2008 McQuay International • www.mcquay.com • 800-432-1342

Page 11

LIMITED PRODUCT WARRANTY

(North America)

McQuay International (“Company”) warrants to contractor, purchaser and any owner of the product (collectively “Owner”) that

Company, at its option, will repair or replace defective parts in the event any product manufactured by Company, including products

sold under the brand names McQuay Air Conditioning, AAF Air Conditioning, AAF HermanNelson and McQuay Factory Service,

and used in the United States o r Canada, proves d efective in material or workmanship within twelve (12) months from initial startup

or eighteen (18) months from the date shipped by Company, whichever occurs first. Authorized replaced parts are warranted for the

duration of the original warranty. All shipments of such parts will b e made FOB factory, freight prepaid and allowed. Company

reserves the right to select carrier and method of shipment.

In addition, labor to repair or replace warranty parts is provided during Company normal working hours on products with rotary

screw compressors, centrifugal compressors and on absorption chillers. Warranty labor is not provided for any other products.

Company’s liability to Owner under this warranty shall not exceed the lesser of the cost of correcting defects in the products sold or

the original purchase price of the products.

PRODUCT STARTUP ON ABSORPTION, CENTRIFUGAL AND SCREW COMPRESSOR PRODUCTS IS MANDATORY and

must be performed by McQuay Factory Service or a Company authorized service representative.

It is Owner’s responsibility to complete and return the Registration and Startup Forms accompanying the product to Company within

ten (10) days of original startup. If this is not done, the ship date and the startup date will be deemed the same for warranty period

determination, and this warranty shall expire twelve (12) months from that date.

EXCEPTIONS

1. If free warranty labor is available as set forth above, such free labor does not include diagnostic visits, inspections, travel time

and related expenses, or unusual access time or costs required by product location.

2. Refrigerants, fluids, oils and expendable items such as filters are not covered by this warranty.

3. This warranty shall not apply to products or parts which (a) have been opened, disassembled, repaired, or altered by anyone other

than Company or its authorized service representative; or (b) have been subjected to misuse, negligence, accidents, damage, or

abnormal use or service; or (c) have been operated, installed, or startup has been provided in a manner contrary to Company’s

printed instructions; or (d) were manufactured or furnished by others and which are not an integral part of a product

manufactured by Company; (e) have been exposed to contaminates, or corrosive agents, chemicals, or minerals, from the water

supply source; or (f) have not been fully paid for by Owner.

ASSISTANCE

To obtain assistance or information regarding this warranty, please contact your local sales representative or McQuay Factory Service

office.

SOLE REMEDY

THIS WARRANTY CONSTITUTES THE OWNER’S SOLE REMEDY. IT IS GIVEN IN LIEU OF ALL OTHER

WARRANTIES. THERE IS NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT AND UNDER NO CIRCUMSTANCE SHALL COMPANY BE LIABLE FOR INCIDENTAL,

INDIRECT, SPECIAL, CONTINGENT OR CONSEQUENTIAL DAMAGES, WHETHER THE THEORY BE BREACH OF

THIS OR ANY OTHER WARRANTY, NEGLIGENCE OR STRICT LIABILITY IN TORT.

No person (including any agent, sales representative, dealer or distributor) has the authority to expand the Company’s obligation

beyond the terms of this express warranty or to state that the performance of the product is other than that published by Company.

For additional consideration, Company will provide an extended warranty(ies) on certain products or components thereof. The terms

of the extended warranty(ies) are shown on a separate extended warranty statement.

Form No. 933-430285Y-00-D (2/03, 10/05, 11/08)

Loading...

Loading...