Page 1

Installation and Maintenance Manual IM-803

Group: Unitary

Part Number: IM-803

Date: August 2005

Supersedes: March 2005

HCC Cased Horizontal “A” Indoor Coil

2 to 5 Ton

© 2005 McQuay International

IM-803 Page 1

Page 2

Table of Contents

M

H

g

A

MODEL NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . 2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Codes and Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Important Message to the Installer . . . . . . . . . . . . . . . . . . . 3

Important Message to the Owner . . . . . . . . . . . . . . . . . . . . . 3

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

GENERAL WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

APPLICATION INFORMATION . . . . . . . . . . . . . . . . . . . . . . 3

Special Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Thermal Expansion Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PLASTIC DRAIN PAN APPLICATION . . . . . . . . . . . . . . . . . 4

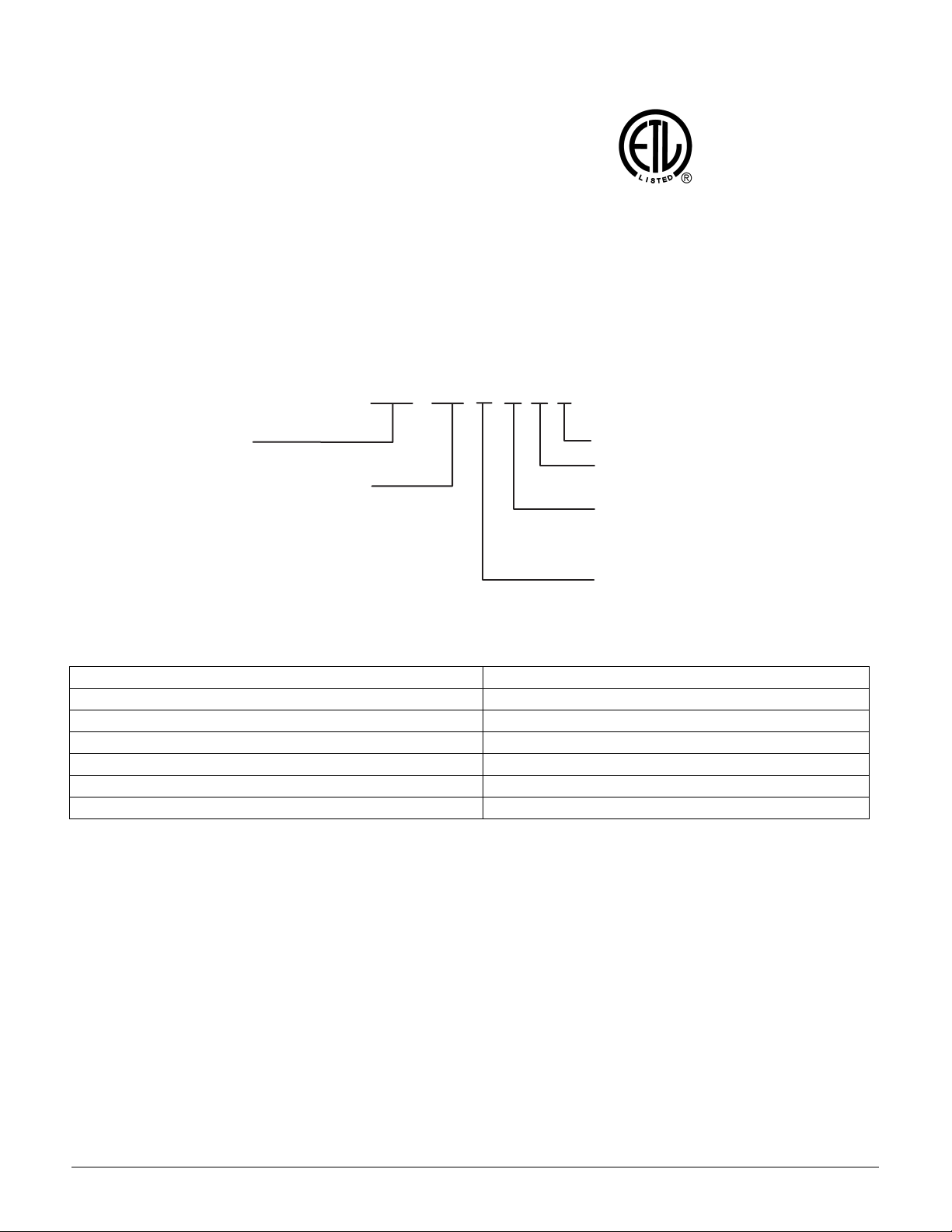

MODEL NOMENCLATURE

"McQuay" is a registered trademark of McQuay International.

"Illustrations and information cover the McQuay International products

at the time of publication and we reserve the right to make changes in

design and construction at any time without notice."

© 2005 McQuay International

odel

CC = Horizontal Cased Coil

Nominal Capacity (tons)

24 = 2

30 = 2-1/2

36 = 3

42 = 3-1/2

48 = 4

60 = 5

*Field mounted Thermal Expansion Valve is available as an accessory.

Table 1: Unit Nameplate Model Number Identifier

Unit Nameplate McQuay Model Number

CHPF024A2A HCC024AAFY

CHPF030A2A HCC030AAFY

CHPF036B2A HCC036ABFY

CHPF042B2A HCC042ABFY

CHPF048D2A HCC048ACFY

CHPF060D2A HCC060ACFY

HCC 024

AFY

Future Use

Refrigerant Meterin

F = Flowrater*

Cabinet Heigth

A = 14"

B = 17-1/2"

C = 24-1/2"

Vintage

INTRODUCTION

General Description

These installation instructions cover the indoor installation of

cased horizontal “A” indoor coils, sizes 2 to 5 tons. See the

product catalog applicable to your model for information

regarding specifications applicable to your model and accessories.

Receiving Inspection

McQuay products are carefully inspected prior to shipment

and the carrier has assumed responsibility for loss or damage

upon acceptance of the shipment.

Upon receiving your shipment, check all items carefully

against the Bill of Lading. Inspect the unit and/or accessories

for shipping damage as soon as they are received. Immediately file claims for loss or damage, either shipping or concealed, with the shipping company.

Page 2 IM-803

Check the unit nameplate to verify the model number and electrical characteristics are correct. In the event an incorrect unit

is shipped, it must be returned to the supplier and must NOT

be installed. The manufacturer disclaims all responsibility for

the installation of incorrectly shipped units.

Codes and Regulations

This product is designed and manufactured to permit installation in accordance with National Codes. System design

should, where applicable, follow information presented in

accepted industry guides such as the ASHRAE Handbooks. It

is the installer' s responsibility to install the product in accordance with National Codes and/or prevailing local codes and

regulations. The manufacturer disclaims all responsibility for

equipment installed in violation of any code or regulations

Page 3

.

IMPORTANT

The United States Environmental Protection Agency

(EPA) regulations cover introduction and disposal of

refrigerants in this unit. Failure to follow those

regulations can harm the environment and lead to

substantial fines. Because regulations can change over

time, a certified technician should perform any work

done on this unit. If you have any questions, please

contact the local office of the EPA.

Important Message to the Installer

This equipment is to be installed by an experienced installation

company and fully trained personnel. Carefully read all

instructions and take into account any special considerations

prior to installing the unit. Give this manual to the owner and

explain its provisions.

Important Message to the Owner

Read these instructions carefully and keep them near the product for future reference. Although these instructions are

addressed primarily to the installer, useful maintenance information is included. Have the installer acquaint you with the

operation of the product and periodic maintenance requirements.Recognize Safety Symbols, Words, and Labels

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner's and installer's responsibility to read and comply with

all safety information and instructions accompanying these

symbols. Failure to heed safety information increases the risk

of property damage and/or product damage, serious personal

injury or death. Improper installation, operation and maintenance can void the warranty.

GENERAL WARNINGS

CCAUTION

Read these instructions before performing this

installation or servicing this unit. All installations must

be in accordance with all national, state, or local

building codes.

APPLICATION INFORMATION

1. Coil must be installed upstream (on the discharge air side)

of the furnace.

2. Condensate Drain Piping - In all cooling applications, the

installer should provide a secondary drain pan. Place the

pan under the entire unit with a separate drain line properly sloped and terminated in an area visible to the owner.

This secondary drain pan can provide an added drain trap

in the area under the unit in the event the primary drain

plugs up and overflows. McQuay will not be liable for

any damages, structural or otherwise due to the failure to

follow this installation requirement.

Condensate drain connections are located in the drain pan at

the bottom of the coil/enclosure assembly. The threaded fitting

protrudes outside of the enclosure for connecting externally.

1. The drain hole in the drain pan must be clear.

2. Insulate the drain line to prevent sweating and dripping.

Use armaflex or similar material.

A Secondary Condensate Drain Connection, now called for by

many building codes, has been provided. Pitch the drain line

1/4" per foot to provide free drainage. Install a condensate trap

to provide proper drainage.

DANGER

Immediate hazards which WILL result in property

damage, product damage, severe personal injury and/

or death.

WARNING

Hazards or unsafe practice CAN result in property

damage, product damage, sever personal injury and/or

death.

CAUTION

Hazards or unsafe practices which CAN result in

property damage, product damage, and/or personal

injury.

Replacement Parts

Replacement parts can be obtained by contacting McQuay at

1

-800-37-PARTS. When contacting McQuay for service or

replacement parts, refer to the model number and serial number of the unit as stamped on the nameplate attached to the

unit.

Note: If a secondary drain is not installed, the second-

ary access must be plugged.

Special Instructions

This indoor coil contains the flowrater distributor assembly,

which consists of a flare nut, distributor body, copper tubes

feeding the coil, and the internal flow check piston. It is essential that the indoor and outdoor sections be properly matched.

When matching the indoor coil with other than the matching

outdoor section, the flow check piston in the indoor section

should be changed to match the outdoor section to obtain rated

performance as specified in our product catalog. (See Piston

Kit Chart ).

A piston size that is too small will cause starving and one that

is too large will cause flooding. Change the piston in the distributor on the indoor coil before installing the coil and charging the system following the procedure shown below.

1. Using a back-up wrench on the flare fitting, remove the 3/

8" flare nut.

2. Using a back-up wrench on the distributor body, remove the

3/8" flare fitting and Teflon seal.

3. Using the wire provided with replacement pistons, run wire

(hooked end) through hole in piston.

4. Hook nose end of piston and lift gently from distributor

body.

IM-803 Page 3

Page 4

5. Referring to the Piston Kit Chart, replace piston with one of

proper size.

6. Install piston with Teflon seal end of piston in distributor

first. Do not force piston into distributor.

Note: With piston in distributor, seal end should be

down and should not be seen looking in end of

distributor. Piston must be free to rotate and

move up and down. Make sure piston is free to

move in distributor body.

7. Replace 3/8" flare fitting with Teflon seal using back-up

wrench on distributor body. Torque fitting with 8 to 10 ft.

lb. Do not over tighten.

8. Replace 3/8" flare nut using back-up wrench on flare fitting.

Torque 3/8" flare nut with 40 to 45 ft. lb.

9. Remove old piston size label from outside of distributor

body.

10. Remove new piston size label from the poly bag the new

piston came in and install new size label on outside of distributor.

11. Check fittings for leaks after installation, and make sure

evacuation and charging of low side are complete.

Thermal Expansion Valve

The TXV bulb is supplied as an optional accessory. To prevent

damage, remove the bulb when welding and attach/insulate to

the suction line after welding. For the majority of installations,

no adjustment to the TXV setting is required. However, if the

measured superheat is less than 8° or greater than 20° an

adjustment is required. The adjustment stem is at the base of

the valve (opposite the diaphragm) under a flair nut. To

increase the superheat when measured at the condenser base

valve, turn the stem clockwise (3). Similarly to decrease the

superheat, turn the stem counterclockwise (4). Use a ¼”

refrigeration wrench for this function.

NOTE FOR QUICK CONNECT COILS INSTALLATION

OF PRECHARGED SYSTEM

A brief description follows, for specific instructions refer to

the Condensing Unit’s Installation and Operating Instructions.

C. Check to be sure mating surfaces are clean.

D. Lubricate rubber seal with clean refrigerant oil and

thread couplings together by hand to be sure they are

not cross threaded.

E. Tighten connections using backup wrench on evapora-

tor quick connect fitting until coupling bottoms; then

tighten 1/6 turn to complete knife edge seal.

2. Connect lines to condensing unit in the same manner as

to evaporator coil. Observe same precautions.

3. After making all connections and opening valves, check

all piping for leaks.

PLASTIC DRAIN PAN APPLICATION

CCAUTION

DO NOT USE THIS COIL ON ANY APPLICATIONS

WHERE THE TEMPERATURE OF THE DRAIN PAN

MAY EXCEED 300°F. USE A FIELD-FABRICATED

METAL DRAIN PAN FOR THESE TYPES OF

APPLICATIONS.

Do not use a low temperature material in a high temperature

application. Strictly adhere to these instructions.

The drain pan has a primary and an optional secondary drain

with 3/4" NPT female connections. The connectors required

can be 3/4" NPT male PVC pipe or metal. Do not over torque,

or drain pan connection will be damaged. If secondary drain

line is required it must be run separately from the primary

drain and should end where it is easily seen. Water coming

from this line means the coil primary drain is plugged and

needs clearing.

A trap must be installed in the drain line below the bottom of

the drain pan. If a copper drain line is used, solder a short piece

of pipe to connector before installing a drain fitting. Again do

not over torque the 3/4" copper connector to the plastic drain

connection. Use a wet rag or heat sink material on the short

piece to protect plastic drain pan, when completing drain line.

Refer to Figure 1.

Figure 1. Condensate Drain Installation

1. Connect lines to evaporator coil before connecting to the

condensing units.

A. Form tubing so it properly aligns with coil connec-

tions.

B. Remove plugs and caps from connections.

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

www.mcquay.com • 800-432-1342

Page 4 IM-803

Loading...

Loading...