Page 1

Engineered for flexibility and performance™

ThinLine™ 3G Vertical Fan Coils Catalog 722

Type FCVC, FCVH, FCVS Vertical Design

Model FCVC

Model FCVS

Page 2

Contents

Nomenclature and Certification 3

ThinLine 3G Vertical Fan Coils . . . . . . . . . . . . . . 3

ARI Certification . . . . . . . . . . . . . . . . . . . . . . . 3

Agency Listed . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features and Benefits 4

The ThinLine™ 3G Advantage. . . . . . . . . . . . . . . 4

For building owners. . . . . . . . . . . . . . . . . . . . . 4

For specifying engineers. . . . . . . . . . . . . . . . . 4

For contractors . . . . . . . . . . . . . . . . . . . . . . . . 5

Options and Accessories 6

Control Options . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Manual 4-Position Fan Switch. . . . . . . . . . . . . 6

Unit-Mounted, Mechanical Thermostat With 4-Po-

sition Fan Switch. . . . . . . . . . . . . . . . . . . . . . . 6

Digital Thermostats. . . . . . . . . . . . . . . . . . . . . 6

DDC Interface Board. . . . . . . . . . . . . . . . . . . . 7

Customer-Supplied Controls. . . . . . . . . . . . . . 7

Decorative Wall Plate Option 8

Fresh Air Damper Options (Manual and Motorized).

8

Fresh Air Intake Box Option. . . . . . . . . . . . . . . . . 8

Condensate Overflow Switch Option . . . . . . . . . . 8

Tamperproof Cabinet Option . . . . . . . . . . . . . . . . 8

Rear Cabinet Extension Option . . . . . . . . . . . . . . 8

Leveling Legs Option . . . . . . . . . . . . . . . . . . . . . . 9

Raised Sub-Bases and Extended-Width End Pock-

ets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Return Air Grille . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Factory Valve & Piping Packages . . . . . . . . . . . . 9

Available Packages. . . . . . . . . . . . . . . . . . . . 10

Control Valve Options. . . . . . . . . . . . . . . . . . 10

Unit Selection 12

Unit Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Basic design data . . . . . . . . . . . . . . . . . . . . . . . 12

Unit size . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Coil types . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Performance Data 13

Two-Pipe Systems, Hot Water Heat 13

Four-Pipe Systems - Hot Water Preheat (1 or 2 row)

or Reheat (1 row) 14

Four-Pipe Systems - Steam Preheat or Reheat 15

Electric Heat Data 16

Air Volume Capacity Data 17

Motor Electrical Data 18

Physical Data 19

Unit Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Unit Dimensions 20

Decorative Wall Plate Dimensions. . . . . . . . . . . 24

Fresh Air Intake Box Dimensions . . . . . . . . . . . 24

Engineering Guide Specification 25

McQuay ThinLine 3G Fan Coil . . . . . . . . . . . . . 25

Performance. . . . . . . . . . . . . . . . . . . . . . . . . 25

General Construction - All Units . . . . . . . . . . 25

Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Supply Fan . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Filter Section. . . . . . . . . . . . . . . . . . . . . . . . . 26

Fresh Air Damper. . . . . . . . . . . . . . . . . . . . . 26

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Valve/Piping Packages. . . . . . . . . . . . . . . . . 27

Other Available Options . . . . . . . . . . . . . . . . 28

Page 3

Nomenclature and Certification

FC V S - 1 02 A

Unit Type

FC = Fan Coil

FH = Cabinet Unit Heater

Unit Configuration

V= Vertical

W = Wall Hung

Cabinet Type

C = Cabinet (Flat Top)

S = Slope Top

H = Hideaway

Voltage

A = 115/60/1

E = 208-230/60/1

J = 265-277/60/1

Unit Size

02 = 200 CFM

03 = 300 CFM

04 = 400 CFM

06 = 600 CFM

08 = 800 CFM

10 = 1000 CFM

12 = 1200 CFM

Design Series

ThinLine 3G Vertical Fan Coils

Figure 1: Nomenclature

Nomenclature and Certification

ARI Certification Agency Listed

Standard size units certified in accordance

with the Room Fan-Coil Unit certification

program, which is based on ARI Standard

All standard units

All Canadian units

440.

McQuay Catalog 722 3

Page 4

Features and Benefits

Multiple Control Options

• From 3-speed switch to DDC interface board

• Remote or unit-mounted

• 3-speed or staged fan

Multiple

Configurations

• Flat top

• Slope top

• Hideaway

• Wall mounted

Multiple Coil Options

• 2, 3 or 4-row main coil

• 1 or 2-row preheat or 1-row

reheat coil

• Hot water or steam

• Same or opposite end

connections

Multiple Grille Options

• Stamped and multi-

directional outlet grilles

• Return grille option

Diverse, Flexible Valve

& Piping Packages

• Factory-mounted, wired and

tested

• Or, factory-assembled and

shipped loose

• Normally closed or open, on/

off or modulating valves

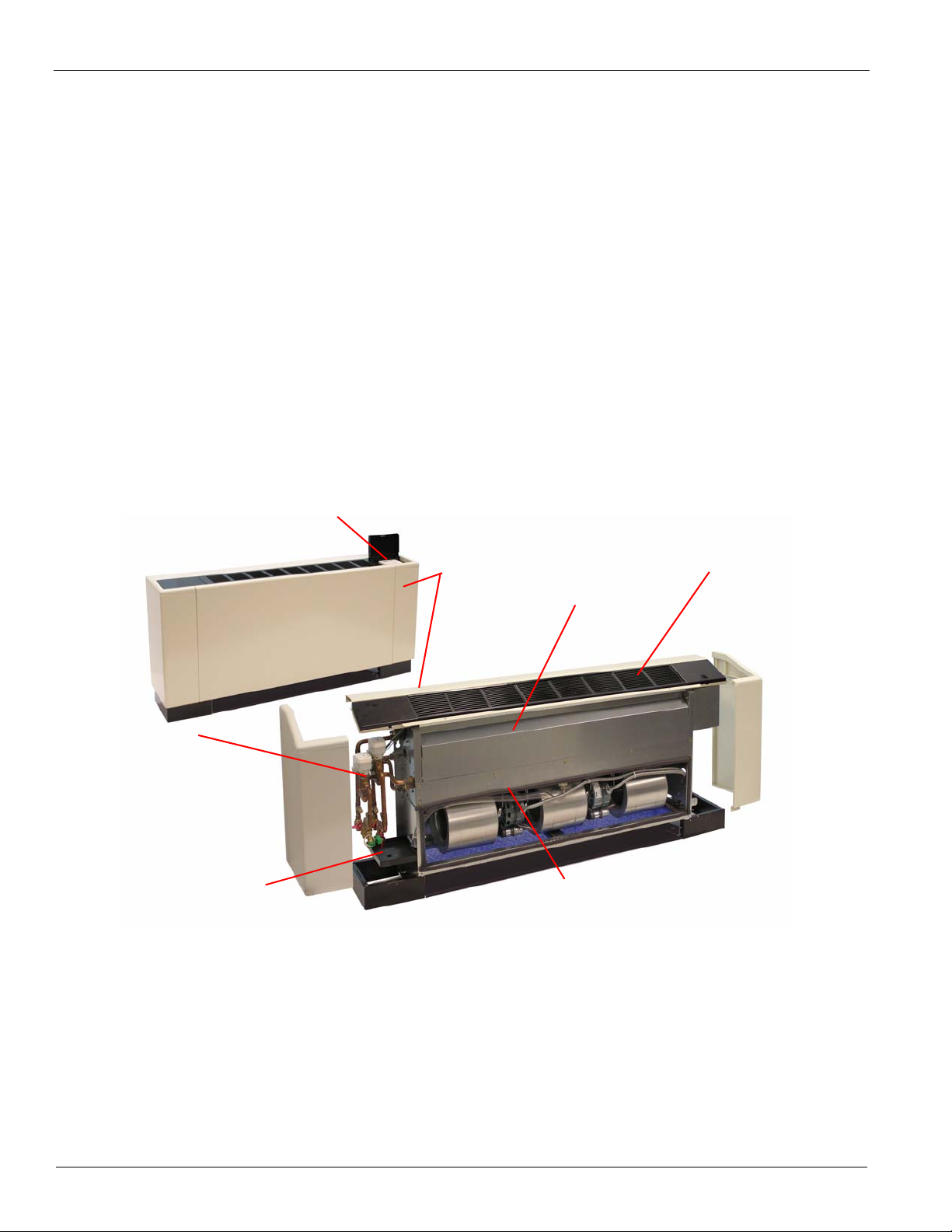

Easily Removed Drain Pan & Motor Assembly

• For easy maintenance and service

• Sloped, polymer drain pan for good IAQ

Optional Secondary

Drain Pan

• Noncorrosive

• Easily removed

Features and Benefits

The ThinLine™ 3G Advantage

New ThinLine 3G vertical fan coils combine the features most

desired in a fan coil by building owners, specifying engineers

and contractors alike. The result is a new, third generation fan

coil design that meets the needs of all three.

For building owners

ThinLine 3G fan coils offer quiet operation. They fully comply

with ASHRAE 62.1-2004 standards for high indoor air quality.

And they offer a range of control options that can enhance

occupant comfort and reduce operating costs. These units are

also easy to maintain, with easy access to filters, fan motors

and control systems.

Figure 2: Unit Features

For specifying engineers

ThinLine 3G fan coils provide great versatility. A variety of

vertical models are available with multiple arrangements and

configurations.

• Coil options include two, three, and four-row main coils to

provide precise heating and cooling performance for any

requirement. Separate, single-row reheat coils (hot water or

steam) are available. Separate, one-row or two-row preheat

coils are also available with same or opposite-end coil

connections.

• Multiple control options range from a simple fan speed

switch to a DDC interface board that can tie into most

building automation systems. Non-communicating or

communicating control options for LonTalk and BacNet will

be available soon. Contact your McQuay representative for

details.

4 McQuay Catalog 722

Page 5

Features and Benefits

• Grille options include stamped inlet and outlet grilles and

multidirectional grilles. Aluminum fresh air boxes are also

available.

• Appearance options include cabinet units with a durable,

powder paint finish and decorative wall plate panels for

hideaway units in cupola white or antique ivory. Custom

colors are available as a special. Leveling feet are available,

as are rear cabinet extensions in 4 and 8-inch depths.

Tamper- proof units are another option, with 16-gauge steel

panels, a return grille and key-operated, locking access

doors.

For contractors

For contractors, ThinLine 3G fan coils feature Quick Ship

options for fast delivery and a number of features that make

installation fast and simple.

• Factory-mounted, wired and tested valve and piping

packages for quick hookup to the building piping to reduce

installation time. Packages can also be shipped loose with

the unit. Valve and piping packages are designed for

entering-water-temperature sampling. This eliminates the

need for inefficient bleed lines to sense automatic

changeover on two-pipe units.

• Factory-mounted and tested controls minimize field setup.

Depending on the option requested, controls can be wired

with a 24 VAC transformer to provide a single-source power

connection to the unit. Several options are available for unit

or wall mounted thermostats and sensors. All wall-mounted

thermostat and zone sensors require only low-voltage

control wiring from the device to the unit control box.

• Easy, end-panel removal for hookup of electrical and piping

connections minimizes field-labor time and cost.

• End compartment panels can be removed for installation and

service without removing the front panel covering the fan

blower section. This means that airflow through the filter

and coil is not jeopardized for taking temperature and

performance readings.

• Both the main drain pan and optional secondary drain pan

are easily accessed for cleaning.

• The fan deck and motor assembly is easily removed when

required for service.

McQuay Catalog 722 5

Page 6

Options and Accessories

Options and Accessories

Control Options

Manual 4-Position Fan Switch

This four-position fan switch (Off, High,

Med, Low) option is available remotemounted It operates on low-voltage or linevoltage power and can be provided with a

factory-mounted, low-voltage DDC

interface board, which contains 3-24 volt

relays with line voltage contactors and

terminal connections. The transformer is

factory-installed and wired.

Sequence of operation

• Off: Fan is turned off. The two-position, motorized fresh-air

damper, when supplied, is closed.

• High, Medium, Low: Fan runs continuously at the selected

speed. The two-position, motorized fresh-air damper, when

supplied, is opened.

Unit-Mounted, Mechanical Thermostat With 4-Position Fan Switch

This unit-mounted

option combines the

four-position fan switch

described above with a

mechanical thermostat.

For two-pipe systems

with a factory installed

valve package, it can be

provided with a manual

switch (shown in

picture to the right) to

change from heating to

cooling. Or changeover

can be automatic.

Sequence of operation

• Fan Switch

• Off: Fan is turned off. The two-position, motorized

fresh-air damper, when supplied, is closed.

• High, Medium, Low: Fan runs continuously at the

selected speed. The two-position, motorized fresh-air

damper, when supplied, is opened.

• Thermostat

• Cycles the valve(s) open or closed on demand based on

occupant-desired level.

• Changeover Switch: With a manual switch, the user selects

whether heating or cooling is desired. With automatic

changeover, a pipe sensor works with the thermostat to

operate the heating or cooling valve.

• Heating: Opens the valve when the temperature is below

the setpoint.

• Cool: Opens the valve when the temperature is above the

setpoint.

Digital Thermostats

McQuay offers a broad

range of unit-mounted and

remote, wall-mounted

digital thermostats with

the capability to control

on-off, 3-wire and

proportional modulating

valves, and normally

closed or normally open

actuator valves. See

Table 1. For more

information, refer to the McQuay publication ED 18513.

MT155 Thermostat

The MT155 series thermostat provides on-off control for lowvoltage or line-voltage valves and fan motors. It is remote-wall

mounted. Options include manual or automatic changeover

and three-speed fan control for continuous or cycling fan

operation.

Figure 3: MT155 Thermostats

Three standard control options are available:

• On-off fan cycle operation only: The thermostat cycles the

fan from the manually selected fan speed (high, medium or

low) to off.

• Continuous fan and on-off valve cycle operation: The

thermostat cycles the valves on and off. The fan runs

continuously at the manually selected fan speed.

• On-off fan and on-off valve cycle operation: The thermostat

cycles the fan from the manually selected fan speed to off

and it cycles the valves on and off.

When the system switch is in the off position, the fan coil

system including the fan is shut off.

MT158 and MT168 Thermostat-Controllers wi th

Digital Display

Series MT158 and MT168 microprocessor-based thermostatcontrollers combine a proportional integral control algorithm

with adaptive logic. They can be unit-mounted or remote-wall

mounted.

6 McQuay Catalog 722

Page 7

Options and Accessories

Figure 4: MT158 and MT168 Thermostats

Heating and cooling outputs for the MT158 are individually

configurable for three-wire floating control valves or on/off

valves in the normally open or normally closed modes.

Heating and cooling outputs for the MT168 provide 0-10 Vdc

or 4-20 mA The integrated, three-speed fan control switch is

line voltage to allow direct connection to the fan motors.

Manual or automatic changeover is provided with remote

setback capability from a time clock or facility management

system. Features include a Fahrenheit or Celsius digital display

and a built-in purge cycle which assists the controller to

determine if the system is supplying hot water or cooling.

Two standard control options are available:

• Continuous fan and modulating (or on-off) valve operation.

The fan runs continuously at the manually selected fan speed

(high, medium or low). The controller modulates the valves

or, on the MT158, dip-switches can be set to cycle the valves

on and off.

• On-off fan cycle operation and modulating (or on-off) valve

operation. The controller cycles the fan from the manually

selected fan speed to off. The controller modulates the

valves or, on the MT158, dip-switches can be set to cycle the

valves on and off.

Table 1: Thermostats

Thermostat Type Mounting

Manual three speed fan switch Remote

Single-pull, double-throw heating/cooling thermostat

with manual heat-off-cool system switch and manual

three-speed fan switch

Single-pull, double-throw thermostat only Unit

Two-pole dead-band auto-changeover thermostat with

manual on-off system switch and manual three-speed

fan switch

Two-pole, dead-band, auto-changeover, heating/

cooling thermostat

Digital thermostat 24 vac/120-277 vac with 3-speed fan

control (continuous or fan cycle)

Digital thermostat 24 vac/120-277 vac with staged fan

(continuous or fan cycle)

Digital thermostat with dead-band auto-changeover for

heating/cooling. On/off or three-wire floating valve

control.

Digital thermostat with dead-band auto-changeover for

heating/cooling, On/off or three-wire floating valve

control, and manual three speed fan switch

Digital thermostat with auto-changeover, dead-band,

and modulating valve

Digital thermostat with auto change over, dead band,

modulating valve, and three speed fan switch

Unit

Unit

Unit

Remote

Remote

Unit or

Remote

Unit or

Remote

Unit or

Remote

Unit or

Remote

DDC Interface Board

The low-voltage,

DDC interface

board is used with

any remote (wall

mounted) McQuay

thermostat or

control. It can also

be used with a BAS

(Building

Automation

System) control

where low voltage

is needed to operate

the fan coil.

The DDC interface board includes:

• Three 24-volt relays with line-voltage contactors to operate

the fan motor speeds.

• Terminal connections for interfacing to:

• An optional wall-mounted thermostat.

• Low-voltage actuators for heating and cooling valves.

• A return air sensor.

• A pipe temperature sensor for changeover from heating

to cooling on two-pipe systems.

• An optional condensate overflow switch, when selected.

• A factory-wired and installed transformer.

Customer-Supplied Controls

Your McQuay representative can work with engineers and/or

contractors to factory install and wire other manufacturers’

DDC controllers in one of the end pockets of the fan coil.

Contact your local McQuay representative for assistance with

your specific project.

McQuay Catalog 722 7

Page 8

Options and Accessories

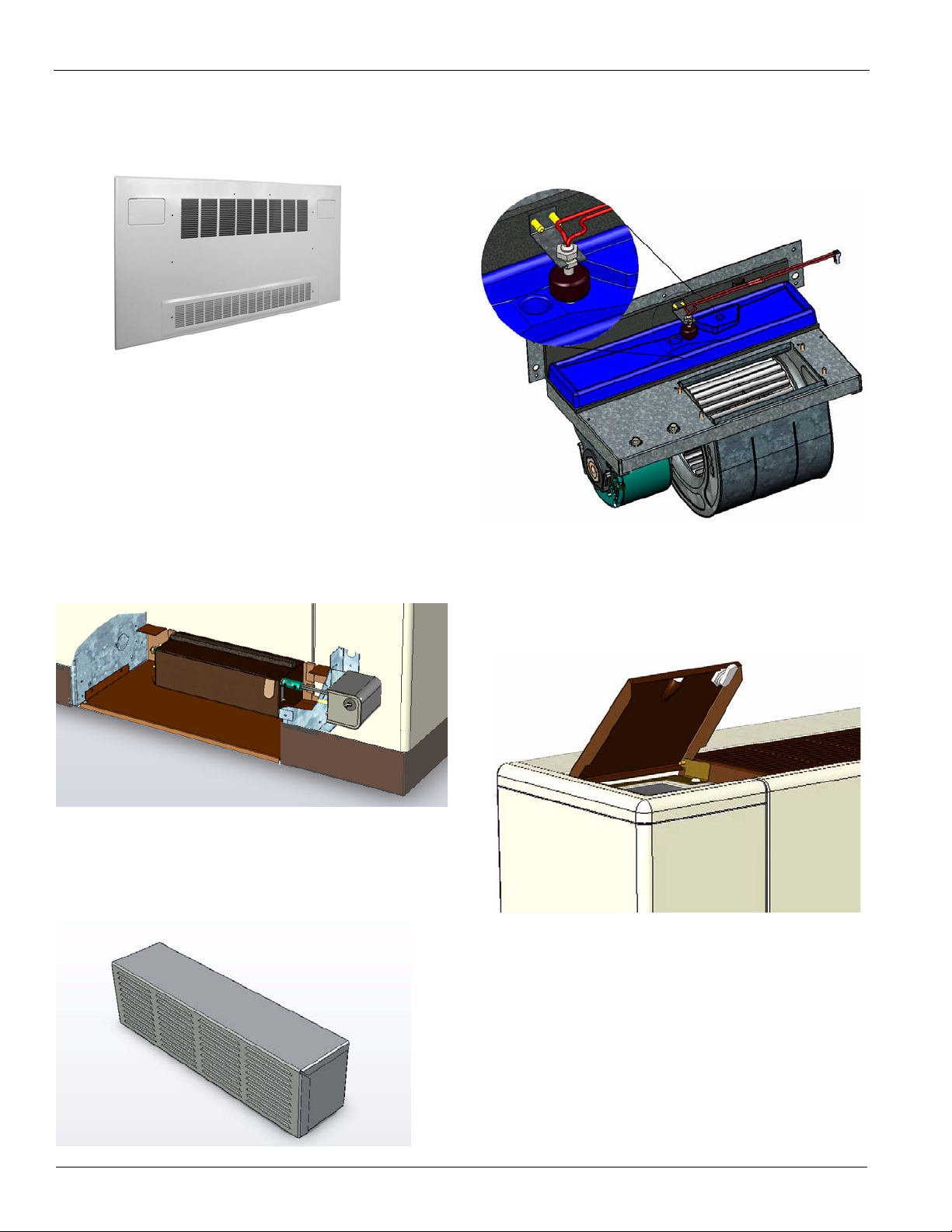

Decorative Wall Plate Option

Decorative wall plates have rounded corners and an antique ivory.

finish for an attractive appearance. Other colors are available upon

request.

Fresh Air Damper Options (Manual and Motorized)

A fresh air intake that will provide up to 25% fresh air with insect air

screen and damper blade, can be ordered either factory installed or as

a field installed kit. The kit consists of an intake with damper blade

and insect screen. The damper may be manually controlled through

the return air opening or with an optional field-installed damper

motor. If freezing air temperatures are expected, the damper must be

closed or outside air must be tempered before entering the unit. A

provision to install a low-temperature sensor is recommended.

Condensate Overflow Switch Option

With proper mounting, the condensate overflow switch will detect

water collecting in the primary drain pan before overflow can occur.

This is an on-off switch that goes back to the normal position when

water is no longer present.

Tamperproof Cabinet Option

This option can be factory- or field-installed on cabinet units to

prevent access to unit controls and easy removal of cabinet panels. It

includes a key lock access door to unit controls and torx head screws

for cabinet panels.

Fresh Air Intake Box Option

Fabricated of aluminum with weep holes and a double set of louvers

in series to prevent moisture draw-through. This is used with a fresh

air damper and is mounted in an exterior wall.

Rear Cabinet Extension Option

This kit is available for applications where additional depth is

necessary. Four-inch extension kits are available. Other

extension depths are available as a special. Contact your

McQuay Representative for details. This kit is not designed to

be an air duct or outside air plenum.

Some common applications for the rear cabinet extension

include:

• Allow additional depth for appearance of unit.

8 McQuay Catalog 722

Page 9

Options and Accessories

• Allow additional clearance for cross-over piping and

connections.

• Extend the discharge grille past drapery or wall hangings.

• Cover floor covering terminations in remodeling projects.

• Allow for piping entry through the side panels of the unit.

Return Air Grille

A stamped-steel, return air grille is available as an option,

factory or field-installed.

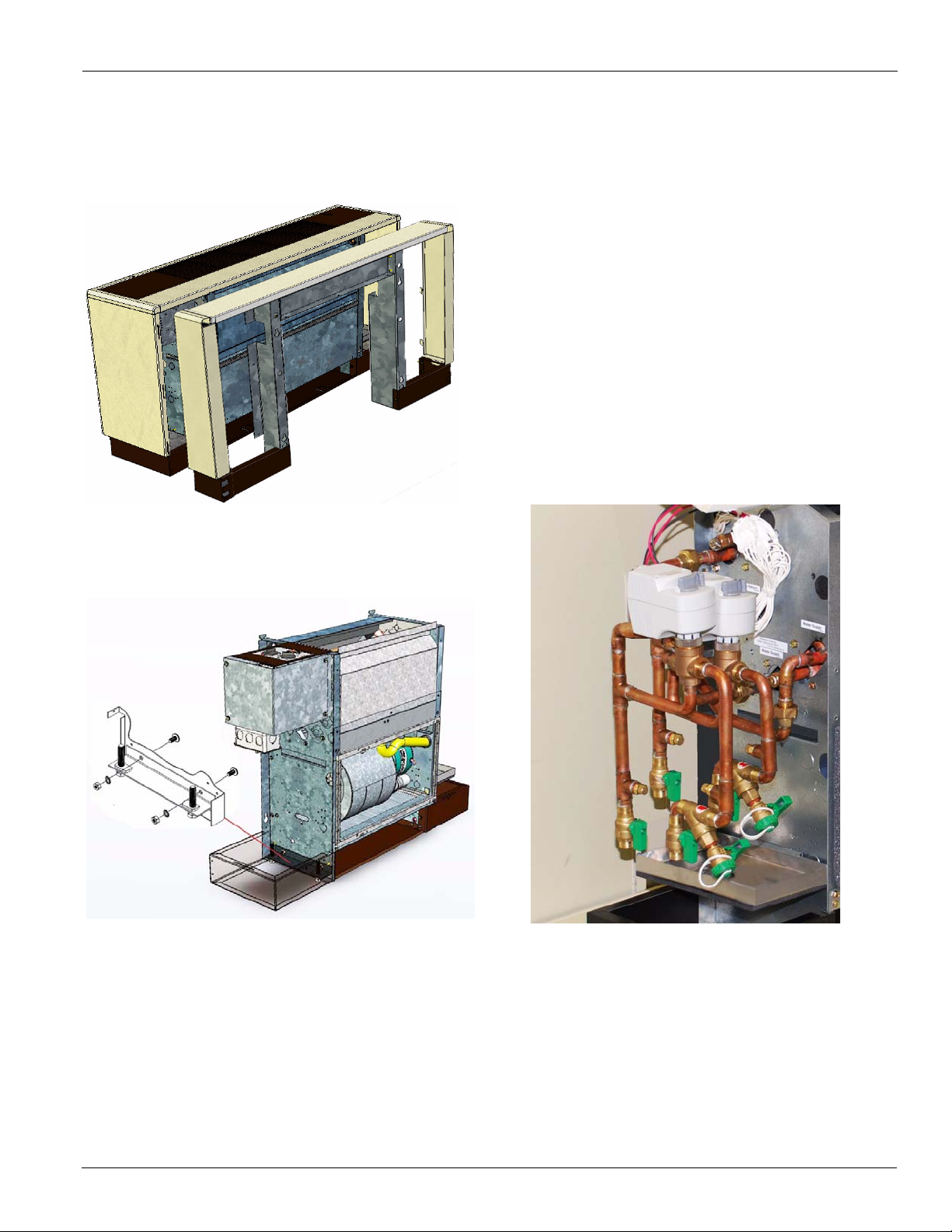

Factory Valve & Piping Packages

Factory valve and piping packages are available for both twopipe and four-pipe systems with either right or left hand

connections. Four-pipe systems can be configured with the

heating and cooling connections on the same or opposite sides

of the unit. Packages can be either factory-installed or factoryassembled and shipped loose with the unit. Units are also

available without a valve and piping package in either a righthand or left-hand configuration. All packages are fully leak

tested.

Factory-installed packages are sweated to the coil and wired to

the unit control box or DDC. Chilled and hot water pipes are

the only field connections required. Piping is 1/2” nominal

copper (5/8” OD).

Figure 5: Four-pipe deluxe valve and piping package

Leveling Legs Option

Field or factory-installed kits are available with 0” to 1" adjustment

for positive leveling of floor-mounted units.

Raised Sub-Bases and ExtendedWidth End Pockets

Extended-height subbases and extended end pockets are

available as a special. Contact your McQuay Representative

for more information.

Note: S tandard end pockets on McQuay units can accomodate

most requirements. Therefore, extended pockets are

seldom needed.

Pre-determined field connection points are located for easy

access. See Figure 6, page 11 for connection locations. The

installing contractor can pre-pipe the building water

connections before the units arrive on the jobsite. A label

clearly identifies chilled and hot water connection points on

every unit.

All chilled water piping and components are located to allow

condensate to drain into the secondary drain pan. Insulation of

the factory piping package is not required.

McQuay Catalog 722 9

Page 10

Options and Accessories

Available Packages

Numerous piping packages are available to match your

configuration. Additional components can be added to meet

your exact requirements, including P/T ports, unions, and

flexible, stainless steel hoses.

Shut-off Only Packages

Shut-off only piping packages provide interconnecting copper

piping and shut-off ball valves for easily connecting supply

and return lines to the unit. Four-pipe packages include a

venting valve for the preheat or reheat coil. Primary coils on

all units have an integral venting valve.

Basic Packages

Basic valve and piping packages add control valves to the

Shut-off Only package. All McQuay control valves are

factory-mounted in the supply water pipe. See Control Valve

Options‚ page 10 for more information on the variety of

control valves available.

Enhanced Packages

Enhanced valve and piping packages replace the ball valve on

the Basic package’s supply water pipe with a manual circuit

setter, also known as a manual flow control valve. The circuit

setter acts as both a flow-setting device and a shut-off valve. It

allows water flow through the fan coil to be set quickly and

accurately.

P/T ports are included, which are used to measure the

temperature or pressure drop across the valve. This pressure

drop can be compared to factory-supplied tables that relate the

pressure drop to a specific flow rate. The valve also has a

memory stop so that the correct setting can be found quickly.

Premium Packages

Premium valve and piping packages replace the Enhanced

package’s manual circuit setter with an automatic circuit setter.

The circuit setter includes a cartridge within the valve body

that is sized to allow a specific flow rate through the coil. This

valve sets flow through the coil without any action required by

a system piping balancer.

Deluxe Packages

Deluxe valve and piping packages add a strainer to the

Premium package. The strainer is attached to the supply water

pipe at the coil connections. The strainer body is cast brass

construction with a stainless steel mesh that is easily removed

for cleaning. The strainer is available with or without an

optional draining (blow-off) valve.

Control V a lve Opt ions

Except for Shut-off Only packages, all valve and piping

packages include control valves for controlling water flow. All

McQuay control valves are factory-assembled and mounted in

the supply water pipe downstream of the coil. Several options

are available as follows.

Two-Way/Two-Position Valves

These valves will be either fully open or fully closed in

response to a line voltage (115 or 265-277 VAC) or a 24 VAC

signal from the McQuay thermostat or controller. Some means

of relieving pump head pressure should be accounted for when

two-way valves are selected. Normally open or normally

closed valves are available. Both are spring-return.

Three-Way, Two-Position Valves

These valves either allow full water flow through the coil or

divert the flow through a bypass line. The valves respond to a

line voltage (115 or 265-277 VAC) or to a 24 VAC signal from

the McQuay thermostat or controller. All standard three-way

valves come with a fixed-balance orifice in the bypass line to

compensate for flow balancing in the bypass position,

eliminating the need for an additional balancing valve.

Normally open or normally closed valves are available.

Two-Way Modulating Valves

These valves modulate the water flow through the coil in

response to a signal from the McQuay thermostat or controller.

All standard McQuay modulating valves are three-wire

floating point equal percentage valves. Zero to 10 VDC

proportional valves are also available as a special option upon

request. The modulating valves are factory mounted in the

supply water pipe upstream of the coil.

Three-Way Modulating Valves

These valves modulate the water flow through the coil in

response to a signal from the McQuay thermostat or controller.

Three-way valves allow water that is directed through the coil

to mix with water that is directed through the bypass line. This

mixture exits through the leaving water pipe. All modulating

valves are three-wire, floating-point equal percentage valves.

The modulating valves are factory mounted in the supply

water pipe upstream of the coil.

Selecting the Correct Size Modulating Valve

McQuay SelectTools™ software automatically selects the best

modulating valve size for the unit and coil being considered.

By combining the ARI performance data, the coil flow rate

and the DP across the water coil, the water coil Cv is

calculated and the best matching modulating port size is

selected.

10 McQuay Catalog 722

Page 11

Figure 6: Hook Up Locations: Factory-installed Valve & Piping Packages

Front View

4-Pipe, Right Hand with

Same-Side Secondary Coil

4.2”

[107 mm]

6.9” [175 mm]

End View

Primary Coil Piping

(preheat piping hidden)

4.9” [125 mm]

6.4”

[163 mm]

1.3” [33 mm]

2” [51 mm]

Supply

Return

End View

Preheat Coil Piping

(primary piping hidden)

4.8” [122 mm]

1.3” [33 mm]

3.5”

[90 mm]

Supply

Return

End View:

Reheat Coil Piping

(primary piping hidden)

3.7” [94 mm]

1.3” [33 mm]

4.7” [120 mm]

3.4” [86 mm]

Supply

Return

4.2” [107 mm]

1.7”

[43 mm]

2.8”

[71 mm]

3.4” [86 mm]

1.4” [36 mm]

4.9” [124 mm]

5.5”

[140 mm]

End View:

Preheat Coil Piping

Return

Supply

End View:

Primary Coil Piping

Front View: 4-Pipe, Right Hand with Opposite-End Preheat

y pg

4.9” [125 mm]

2”

[51 mm]

6.7”

[170 mm]

1.2” [32 mm]

Return

Supply

Front View

2-Pipe, Right Hand

4.2”

[107 mm]

End View

2-Pipe, Right Hand

4.9” [125 mm]

6.4”

[163 mm]

1.3” [33 mm]

2” [51 mm]

Supply

Return

4-Pipe Arrangement with Same-End Connections

4-Pipe Arrangement with Opposite-End Connections

2-Pipe Arrangement

Note: All valve packages, regardless of

components included, have the same

hookup locations. RIght-hand connections

are shown here. Left-hand connection

distances are the same. Distances to

connections from chassis are from unit

mounting holes. Dimensions may vary

slightly from given values.

Options and Accessories

McQuay Catalog 722 11

Page 12

Unit Selection

Unit Selection

Unit Selection

The achievement of an efficient fan coil system is dependent

upon accurate system design and proper equipment selection.

Variations, limitations and control of fan coil systems, design

conditions and design load calculations are not described in

detail in this catalog. More detailed information may be found

in the ASHRAE Guide. This catalog contains ARI certified

ratings and application ratings for ThinLine 3G fan coil units

from which the design engineer can make initial unit selections

to meet the requirements of the system.

The mechanical system designer must select the unit types best

suited to the overall system before the actual unit sizes can be

determined. The factors that generally influence this decision

are intended building usage, building layout, architectural and

aesthetic values, economics, geographical location, and type of

maintenance service available. The general results may be a

mixture of various unit types within a given system. McQuay

International manufactures a fan coil unit to meet your every

need including ThinLine, HiLine and Large Capacity models.

For McQuay product information, please go to

www.mcquay.com.

Unit size

The capacity ratings presented in this catalog are provided for

initial unit selection only. Water cooling and heating

capacities, unit air flow, static pressure and glycol solutions ar

all incorporated into the program to provide the best possible

selection. Consult your McQuay representative for a selection

tailored to your application.

Unit sizes for the ideal system should be selected by

calculating the peak load requirements due to unusually high

occupancy or severe climatic conditions and with fan

operating at high speed. Ordinary day to day cooling and

heating requirements are then achieved at low and medium

speeds.

The initial unit selection should be checked for air volume in

the design system and the cooling capacities checked at the

actual operating conditions. While units selected on the basis

of sensible load will generally meet the total cooling load, total

load should be checked in all cases.

The unit size is generally selected on the basis of matching the

sensible cooling capacity of the unit with the calculated

requirements when operating at high speed.

Basic design data

Prior to selecting the individual unit sizes, the design engineer

must fix or determine the following factors:

• Inside and outside wet and dry bulb design temperatures.

• Total and sensible heat gains and losses of the area to be

served.

• Ventilation air.

• Properties of the heating and cooling medium.

• Available electric power service.

• Any special design requirements of the building or system.

Coil types

Standard coils are designed to meet both the cooling and

heating requirements in a typical system. Two additional levels

of enhanced primary coils are available to meet the total and

sensible requirements of any application.

Heating requirements for two-pipe systems are generally met

by employing the same water flow rate as cooling and

adjusting the entering hot water temperature to obtain a

matching unit heat output at low fan speed.

Four-pipe systems are generally designed by specifying the

flow rate through the separate heating coil to meet the required

heat load with the fan operating at the desired fan speed.

McQuay offers two coil options for preheat and one option for

reheat.

12 McQuay Catalog 722

Page 13

Performance Data

Two-Pipe Systems, Hot Water Heat

Performance Data

All performance measured on high speed tap, 115 V, zero ESP,

with a throwaway filter. Cooling performance is based on 80/

67°F (27/19 C) entering air temperature, 45°F (7°C) entering

chilled water temperature with a 10°F (5.5°C) ΔT.

Table 2: Cooling and hea tin g pe rformance - two-pipe systems

Unit

Size

02

03

04

06

08

10

12

Main

Coil

Rows

2 Row 218 4.2 (1.2) 3.8 (1.1) 0.9 (0.06) 0.3 (0.9) 14.1 (4.1) 0.128 (0.067) 0.9 (0.06) 0.3 (0.9)

3 Row 209 5.7 (1.7) 4.6 (1.3) 1.2 (0.08) 0.5 (1.5) 17.2 (5.0) 0.156 (0.082) 1.2 (0.08) 0.5 (1.5)

4 Row 200 5.9 (1.7) 4.7 (1.4) 1.2 (0.08) 0.6 (1.8) 19.2 (5.6) 0.175 (0.092) 1.2 (0.08) 0.6 (1.8)

2 Row 299 5.0 (1.5) 4.8 (1.4) 1.1 (0.07) 0.4 (1.2) 19.8 (5.8) 0.180 (0.095) 1.1 (0.07) 0.4 (1.2)

3 Row 291 6.9 (2.0) 6.0 (1.8) 1.5 (0.09) 0.5 (1.5) 24.4 (7.2) 0.222 (0.118) 1.5 (0.09) 0.5 (1.5)

4 Row 265 9.4 (2.8) 6.9 (2.0) 1.9 (0.12) 1.5 (4.5) 27.2 (8.0) 0.247 (0.131) 1.9 (0.12) 1.5 (4.5)

2 Row 398 8.0 (2.3) 7.2 (2.1) 1.7 (0.11) 1.0 (3.0) 28.3 (8.3) 0.257 (0.136) 1.7 (0.11) 1.0 (3.0)

3 Row 385 10.7 (3.1) 8.7 (2.5) 2.2 (0.14) 1.3 (3.9) 34.0 (10.0) 0.309 (0.164) 2.2 (0.14) 1.3 (3.9)

4 Row 374 14.3 (4.2) 10.2 (3.0) 2.9 (0.18) 3.4 (10.2) 38.9 (11.4) 0.354 (0.187) 2.9 (0.18) 3.4 (10.2)

2 Row 602 14.0 (4.1) 11.5 (3.4) 2.9 (0.18) 4.4 (13.1) 41.0 (12.0) 0.373 (0.196) 2.9 (0.18) 4.4 (13.1)

3 Row 565 17.7 (5.2) 13.3 (3.9) 3.7 (0.23) 5.2 (15.5) 47.1 (13.8) 0.428 (0.226) 3.7 (0.23) 5.2 (15.5)

4 Row 554 22.4 (6.6) 15.2 (4.5) 4.6 (0.29) 9.0 (26.9) 52.6 (15.4) 0.478 (0.252) 4.6 (0.29) 9.0 (26.9)

2 Row 675 17.0 (5.0) 13.4 (3.9) 3.6 (0.23) 7.7 (23.0) 50.3 (14.7) 0.457 (0.241) 3.6 (0.23) 7.7 (23.0)

3 Row 656 21.7 (6.4) 15.9 (4.7) 4.5 (0.28) 8.0 (23.9) 58.7 (17.2) 0.534 (0.281) 4.5 (0.28) 8.0 (23.9)

4 Row 634 26.4 (7.7) 17.8 (5.2) 5.5 (0.35) 14.8 (44.2) 64.3 (18.8) 0.585 (0.308) 5.5 (0.35) 14.8 (44.2)

2 Row 831 20.9 (6.1) 16.7 (4.9) 4.4 (0.28) 6.8 (20.3) 62.4 (18.3) 0.567 (0.299) 4.4 (0.28) 6.8 (20.3)

3 Row 808 27.4 (8.0) 19.9 (5.8) 5.7 (0.36) 8.7 (26.0) 73.2 (21.5) 0.665 (0.352) 5.7 (0.36) 8.7 (26.0)

4 Row 795 32.4 (9.5) 21.9 (6.4) 6.7 (0.42) 11.1 (33.2) 80.8 (23.7) 0.735 (0.388) 6.7 (0.42) 11.1 (33.2)

2 Row 1118 27.1 (7.9) 21.2 (6.2) 5.6 (0.35) 12.5 (37.4) 78.3 (22.9) 0.712 (0.375) 5.6 (0.35) 12.5 (37.4)

3 Row 1059 34.5 (10.1) 24.9 (7.3) 7.1 (0.45) 15.5 (46.3) 95.4 (28.0) 0.867 (0.458) 7.1 (0.45) 15.5 (46.3)

4 Row 1022 40.2 (11.8) 27.0 (7.9) 8.3 (0.52) 18.3 (54.7) 103.8 (30.4) 0.944 (0.497) 8.3 (0.52) 18.3 (54.7)

SCFM

Total

TMBh

(kW)

Cooling Performance Heating Performance

Sensible

TMBh

(kW)

Gpm (L/s)

Heating performance is based on 70°F (21°C) entering air

temperature, 180°F (82°C) entering hot water temperature with

a 30°F (17°C) T.

WPD

FtofH

(kPa)

O

TMBh (TkW) Q/ITD

2

Gpm (L/

s)

WPD

FtofH2O

(kPa)

McQuay Catalog 722 13

Page 14

Performance Data

Four-Pipe Systems - Hot Water Preheat (1 or 2 row) or Reheat (1 row)

All performance measured on high speed tap, 115 V, zero ESP,

with a throwaway filter. Cooling performance is based on 80/

67°F (27/19 C) entering air temperature, 45°F (7°C) entering

Heating performance is based on 70°F (21°C) entering air

temperature, 180°F (82°C) entering hot water temperature with

a 30°F (17°C) T.

chilled water temperature with a 10°F (5.5°C) ΔT.

Table 3: Cooling and heating performance - four-pipe systems, hot water heat

Main

Unit

Size

Rows

2 Row

3 Row

02

4 Row

2Row

3 Row

03

4 Row

2 Row

3 Row

04

4 Row

2 Row

3 Row

06

4 Row

2 Row

3 Row

08

4 Row

2Row

3 Row

10

4 Row

2 Row

3 Row

12

4 Row

Note: *2-Row hot water coils are only available in the preheat position

Coil

Heating

Coil

Rows

1 Row 201 4.0 (1.2) 3.6 (1.1) 0.8 (0.05) 0.3 (0.9) 8.4 (2.5) 0.076 (0.041) 0.9 (0.1) 1.4 (4)

2 Row* 192 3.9 (1.1) 3.5 (1.0) 0.8 (0.05) 0.3 (0.9) 11.6 (3.4) 0.105 (0.056) 0.8 (0.1) 0.6 (1.8)

1 Row 192 5.3 (1.6) 4.3 (1.3) 1.1 (0.07) 0.4 (1.2) 8.2 (2.4) 0.075 (0.039) 0.9 (0.1) 1.3 (4)

2 Row* 184 5.1 (1.5) 4.2 (1.2) 1.1 (0.07) 0.4 (1.2) 11.3 (3.3) 0.102 (0.054) 0.8 (0.1) 0.6 (1.8)

1 Row 184 5.7 (1.7) 4.5 (1.3) 1.2 (0.08) 0.6 (1.8) 8.1 (2.4) 0.073 (0.039) 0.9 (0.1) 1.3 (4)

2 Row* 176 6.4 (1.9) 4.7 (1.4) 1.3 (0.08) 0.7 (2.1) 11.0 (3.2) 0.100 (0.052) 0.8 (0.1) 0.5 (1.5)

1 Row 275 4.7 (1.4) 4.5 (1.3) 1.0 (0.06) 0.4 (1.2) 12.4 (3.6) 0.113 (0.059) 1.3 (0.1) 3.5 (10)

2 Row* 263 4.6 (1.3) 4.4 (1.3) 1.0 (0.06) 0.4 (1.2) 17.3 (5.1) 0.157 (0.083) 1.2 (0.1) 1.5 (4.5)

1 Row 268 6.5 (1.9) 5.6 (1.6) 1.4 (0.09) 0.4 (1.2) 12.3 (3.6) 0.112 (0.059) 1.3 (0.1) 3.4 (10)

2 Row* 256 6.3 (1.8) 5.4 (1.6) 1.3 (0.08) 0.4 (1.2) 17.0 (5.0) 0.154 (0.082) 1.2 (0.1) 1.4 (4.2)

1 Row 244 8.8 (2.6) 6.4 (1.9) 1.8 (0.11) 1.3 (3.9) 11.7 (3.4) 0.107 (0.056) 1.2 (0.1) 3.2 (10)

2 Row* 233 8.4 (2.5) 6.1 (1.8) 1.8 (0.11) 1.2 (3.6) 16.0 (4.7) 0.145 (0.077) 1.1 (0.1) 1.3 (3.9)

1 Row 366 7.5 (2.2) 6.8 (2.0) 1.6 (0.10) 0.9 (2.7) 16.9 (5.0) 0.153 (0.082) 1.8 (0.1) 7.1 (21)

2 Row* 350 7.3 (2.1) 6.5 (1.9) 1.5 (0.09) 0.8 (2.4) 23.7 (6.9) 0.215 (0.113) 1.7 (0.1) 2.9 (8.7)

1 Row 354 10.1 (3.0) 8.1 (2.4) 2.1 (0.13) 1.2 (3.6) 16.6 (4.9) 0.151 (0.080) 1.8 (0.1) 6.9 (21)

2 Row* 339 9.7 (2.8) 7.8 (2.3) 2.0 (0.13) 1.1 (3.3) 23.2 (6.8) 0.211 (0.111) 1.7 (0.1) 2.8 (8.4)

1 Row 344 13.4 (3.9) 9.4 (2.8) 2.8 (0.18) 3.0 (9.0) 16.4 (4.8) 0.149 (0.079) 1.7 (0.1) 6.7 (20)

2 Row* 329 12.9 (3.8) 9.1 (2.7) 2.7 (0.17) 2.8 (8.4) 22.7 (6.7) 0.207 (0.110) 1.6 (0.1) 2.7 (8.1)

1 Row 554 13.3 (3.9) 10.8 (3.2) 2.8 (0.18) 4.0 (12.0) 23.2 (6.8) 0.211 (0.111) 2.8 (0.2) 19.6 (59)

2 Row* 530 12.9 (3.8) 10.4 (3.0) 2.7 (0.17) 3.8 (11.4) 32.9 (9.6) 0.299 (0.157) 2.6 (0.2) 7.7 (23.0)

1 Row 520 16.7 (4.9) 12.4 (3.6) 3.4 (0.21) 4.6 (13.7) 22.5 (6.6) 0.205 (0.108) 2.7 (0.2) 18.5 (55)

2 Row* 497 16.1 (4.7) 12.0 (3.5) 3.3 (0.21) 4.3 (12.9) 31.6 (9.3) 0.287 (0.152) 2.5 (0.2) 7.2 (21.5)

1 Row 510 21.0 (6.2) 14.2 (4.2) 4.3 (0.27) 8.0 (23.9) 22.3 (6.5) 0.203 (0.106) 2.6 (0.2) 18.2 (54)

2 Row* 488 20.2 (5.9) 13.6 (4.0) 4.2 (0.26) 7.5 (22.4) 31.2 (9.1) 0.284 (0.149) 2.5 (0.2) 7.0 (20.9)

1 Row 621 16.1 (4.7) 12.6 (3.7) 3.4 (0.21) 7.0 (20.9) 28.3 (8.3) 0.257 (0.136) 3.2 (0.2) 28.0 (84)

2 Row* 594 15.6 (4.6) 12.2 (3.6) 3.3 (0.21) 6.6 (19.7) 40.0 (11.7) 0.364 (0.191) 3.0 (0.2) 10.7 (32.0)

1 Row 604 20.4 (6.0) 14.9 (4.4) 4.2 (0.26) 7.2 (21.5) 27.9 (8.2) 0.254 (0.134) 3.1 (0.2) 27.3 (82)

2 Row* 577 19.7 (5.8) 14.3 (4.2) 4.1 (0.26) 6.8 (20.3) 39.2 (11.5) 0.357 (0.188) 2.9 (0.2) 10.4 (31.1)

1 Row 583 24.8 (7.3) 16.6 (4.9) 5.1 (0.32) 13.2 (39.4) 27.4 (8.0) 0.249 (0.131) 3.1 (0.2) 26.4 (79)

2 Row* 558 23.9 (7.0) 16.0 (4.7) 5.0 (0.32) 12.4 (37.1) 38.4 (11.3) 0.349 (0.185) 2.9 (0.2) 9.9 (29.6)

1 Row 765 19.8 (5.8) 15.7 (4.6) 4.1 (0.26) 6.2 (18.5) 35.9 (10.5) 0.326 (0.172) 4.0 (0.3) 51.1 (153)

2 Row* 731 19.2 (5.6) 15.2 (4.5) 4.0 (0.25) 5.8 (17.3) 50.6 (14.8) 0.460 (0.242) 3.8 (0.2) 18.8 (56.2)

1 Row 743 25.7 (7.5) 18.6 (5.5) 5.3 (0.33) 7.8 (23.3) 35.3 (10.3) 0.321 (0.169) 4.0 (0.3) 49.7 (149)

2 Row* 711 24.9 (7.3) 18.0 (5.3) 5.1 (0.32) 7.3 (21.8) 49.6 (14.5) 0.451 (0.237) 3.7 (0.2) 18.2 (54.4)

1 Row 731 30.2 (8.9) 20.4 (6.0) 6.2 (0.39) 9.8 (29.3) 35.1 (10.3) 0.319 (0.169) 3.9 (0.2) 49.0 (146)

2 Row* 700 29.1 (8.5) 19.6 (5.7) 6.0 (0.38) 9.2 (27.5) 49.1 (14.4) 0.447 (0.236) 3.7 (0.2) 17.8 (53.2)

1 Row 1029 25.9 (7.6) 20.1 (5.9) 5.4 (0.34) 11.5 (34.4) 43.8 (12.8) 0.398 (0.209) 5.2 (0.3) 93.6 (280)

2 Row* 984 25.2 (7.4) 19.4 (5.7) 5.2 (0.33) 11.0 (32.9) 62.7 (18.4) 0.570 (0.301) 5.0 (0.3) 34.6 (103.4)

1 Row 974 32.7 (9.6) 23.3 (6.8) 6.7 (0.42) 14.0 (41.8) 45.1 (13.2) 0.410 (0.216) 5.1 (0.3) 89.0 (266)

2 Row* 932 31.7 (9.3) 22.6 (6.6) 6.6 (0.42) 13.3 (39.7) 64.1 (18.8) 0.583 (0.308) 4.8 (0.3) 32.4 (96.8)

1 Row 940 37.8 (11.1) 25.2 (7.4) 7.8 (0.49) 16.2 (48.4) 44.3 (13.0) 0.403 (0.213) 5.0 (0.3) 86.2 (258)

2 Row* 899 36.5 (10.7) 24.3 (7.1) 7.6 (0.48) 15.2 (45.4) 62.6 (18.3) 0.569 (0.299) 4.7 (0.3) 31.0 (92.6)

SCFM

Total

TMBh

(kW)

Cooling Performance Heating Performance

Sensible

TMBh

(kW)

Gpm

(L/s)

WPD

Ft H

(kPa)

O

2

TMBh

(TkW)

Q/ITD

Gpm

(L/s)

WPD

Ft H2O

(kPa)

14 McQuay Catalog 722

Page 15

Four-Pipe Systems - Steam Preheat or Reheat

Performance Data

All performance measured on high speed tap, 115 V, zero ESP,

with a throwaway filter. Medium and low-speed capacities are

approximately 88% and 68% respectively of the high-speed

capacity.

Q/ITD =

Saturated steam temp – Entering air temp

MBh (kW)

pressure or entering air temperature, compute the new ITD and

multiply it by the Q/ITD shown. See Table 5 to determine the

saturated steam temperatures at various entering steam

pressures. For more accurate values, use McQuayTools™

selection program available from your McQuay representative.

To determine heating capacities at different entering steam

Table 4: Steam Coil Performance with Free-Discharge Motor

Unit

Size

02 Pre/ReHeat 1 Row 10.2 (3.0) 11.3 (3.3) 0.069 (0.036)

03 Pre/ReHeat 1 Row 14.4 (4.2) 16.0 (4.7) 0.098 (0.052)

04 Pre/ReHeat 1 Row 19.1 (5.6) 21.1 (6.2) 0.130 (0.069)

06 Pre/ReHeat 1 Row 28.7 (8.4) 31.7 (9.3) 0.195 (0.103)

08 Pre/ReHeat 1 Row 32.7 (9.6) 36.2 (10.6) 0.222 (0.117)

10 Pre/ReHeat 1 Row 40.9 (12.0) 45.4 (13.3) 0.279 (0.147)

12 Pre/ReHeat 1 Row 52.7 (15.4) 58.1 (17.0) 0.358 (0.189)

Note: *2-Row coils only available in preheat position.

Steam Coil Rows

Table 5: Steam Properties

Steam Pressure PSIG (kPa) 2 (14) 5 (34)

Sat. Steam Temp. F (C) 219 (104) 227 (108)

Latent Heat Btu/Lb (kJ/kg) 965 (2240) 960 (2230)

2 psig (14 kPa)

Total MBH (KW)

5 psig (103 kPa)

Total MBH (KW)

Q/ITD MBH/dF

(KW/dC)

McQuay Catalog 722 15

Page 16

Performance Data

Electric Heat Data

Table 6: Electric Heat kW*

Unit

Size

02

03

04

06

08

10

12

Note: *Electric heat MBh = (Heater kW) (3.413)

Unit

Voltage

115 0.5 1.0 1.5

230 0.5 1.0

277 0.5 1.0 1.5

208 0.5 0.9

115

230 1.0

277 1.0 1.5

208 0.9

115

230 1.0 1.5 2.0

277 1.0 1.5 2.0

208 0.9 1.4 1.8

115

230 1.5 2.0 2.5 3.0

277 1.5 2.0 2.5 3.0 4.0

208 1.4 1.8 2.3 2.7

115

230 2.0 2.5 3.0 4.0

277 2.0 2.5 3.0 4.0

208 1.8 2.3 2.7 3.6

115

230 2.5 3.0 4.0

277 2.5 3.0 4.0

208 2.3 2.7 3.6

115

230 3.0 4.0 5.0 6.0

277

208

1.0 1.5 2.0

1.0 1.5 2.0

1.5 2.0

2.0

kW

3.0 4.0 5.0 6.0

2.7 3.6 4.5 5.4

MCA (Minimum Circuit Ampacity) Calculations

and MFS (Maximum Fuze Size) Calculations

HACR (Heating, Air-Conditioning and Refrigeration) type

circuit breakers are required in the branch circuit wiring for all

fan coils with electric heat.

Note: MCA ratings are based on the unit and electric heat

power supply having the same voltage. If the electric heat

power supply is different, a separate circuit breaker may be

required. Follow local codes.

Select a standard fuse size or HACR type circuit breaker equal

to the MCA. Standard Fuse Sizes are: 15, 20, 25, 30, 35, 40,

45, 50, 60 amps. Use the next larger standard size if the MCA

does not equal a standard size.

Heater Amps = (Heater kW x 1000)/Heater Voltage

Note: Use 120V heater voltage for 115V units. Use 240V

heater voltage for 230V units.

MCA = 1.25 x (heater amps + all motor FLAs)

MFS or HACR Type Circuit Breaker = (2.25 x Largest Motor

FLA) + Second Motor FLA + Heater Amps (If Applicable)

See Tab le 8 through Tab le 1 0 for motor FLAs.

16 McQuay Catalog 722

Page 17

Air Volume Capacity Data

Performance Data

Air volumes shown in the table are measured at the motor

speeds indicated with 115v/60/1 electrical power, with a 1”

on a vertical cabinet unit or a discharge duct collar on a

hideaway unit at approximately 0.10 inch of pressure drop.

throwaway filter installed, and with a stamped discharge grille

Table 7: SCFM, 115/60/1 Motor, Four-Row Primary Coil + Two-Row Preheat or Reheat (Factor 88%)

SCFM SCFM

Unit

Size

02

03

04

06

Main

Rows

2 Row

3 Row

4 Row

2 Row

3 Row

4 Row

2 Row

3 Row

4 Row

2 Row

3 Row

4 Row

Heating

Coil

Coil

Rows

None 214 197 167

1 Row 197 181 154 1 Row 614 538 428

2 Row* 188 173 147 2 Row* 588 515 409

None 204 190 161

1 Row 188 175 148 1 Row 601 530 419

2 Row* 180 168 142 2 Row* 575 507 401

None 197 183 159

1 Row 181 169 146 1 Row 581 517 414

2 Row* 173 161 140 2 Row* 556 495 396

None 296 264 211

1 Row 272 243 194 1 Row 764 655 504

2 Row* 260 232 186 2 Row* 731 626 482

None 292 256 205

1 Row 268 236 188 1 Row 742 640 493

2 Row* 257 225 180 2 Row* 710 612 472

None 283 253 206

1 Row 260 233 189 1 Row 726 625 481

2 Row* 249 223 181 2 Row* 695 598 460

None 380 330 261

1 Row 349 304 241 1 Row 1021 916 773

2 Row* 334 291 230 2 Row* 977 876 740

None 365 325 250

1 Row 336 299 230 1 Row 974 883 756

2 Row* 321 286 220 2 Row* 932 845 723

None 368 319 249

1 Row 338 294 229 1 Row 943 856 739

2 Row* 323 281 219 2 Row* 902 818 707

None 600 524 421

1 Row 552 482 387

2 Row* 528 461 371

None 559 483 373

1 Row 514 445 343

2 Row* 492 425 329

None 554 486 409

1 Row 510 447 376

2 Row* 488 427 360

Motor on

High

Speed

Motor on

Medium

Speed

Motor

on Low

Speed

Unit

Size

08

10

12

Main

Coil

Rows

2 Row

3 Row

4 Row

2 Row

3 Row

4 Row

2 Row

3 Row

4 Row

Heating

Coil

Rows

None 668 585 465

None 654 576 456

None 632 562 450

None 831 712 548

None 807 696 536

None 789 680 523

None 1110 995 840

None 1059 960 822

None 1025 930 803

Motor on

High

Speed

Motor on

Medium

Speed

Motor

on Low

Speed

McQuay Catalog 722 17

Page 18

Performance Data

Motor Electrical Data

Table 8: Electrical Data - Standard (Free Discharge) Motor - 2 Row Coil

Motor

Speed

High 0.49 53 1059 0.56 63 993 0.68 72 991 1.32 123 1122 1.20 129 1015 1.37 148 987 2.52 237 1123

Med 0.42 44 984 0.48 53 886 0.57 59 876 0.99 95 987 1.01 108 910 1.16 124 866 1.81 175 1013

115 V

Low 0.35 36 856 0.39 42 726 0.45 45 705 0.90 81 815 0.83 84 741 0.92 95 681 1.64 153 864

High 0.27 53 955 0.30 62 837 0.38 75 928 0.61 122 1102 0.77 154 1070 0.72 147 860 1.15 236 1113

Med 0.23 48 766 0.24 52 639 0.30 59 764 0.44 87 910 0.58 48 709 0.58 120 681 0.83 166 960

208 V

Low 0.19 39 561 0.19 42 485 0.25 49 611 0.36 65 691 0.50 39 504 0.45 93 533 0.70 127 708

High 0.27 57 1026 0.30 67 949 0.37 75 998 0.63 133 1124 0.80 180 1093 0.73 163 954 1.19 261 1131

Med 0.23 52 914 0.25 60 791 0.31 64 880 0.41 89 1011 0.57 131 1006 0.61 139 797 0.81 178 1021

230

Low 0.20 45 742 0.21 50 607 0.26 6 737 0.36 78 844 0.50 111 870 0.50 113 616 0.71 149 831

High 0.28 55 1026 0.29 61 931 0.34 77 917 0.47 117 1118 0.79 172 1097 0.65 149 906 0.95 246 1104

Med 0.20 49 915 0.21 44 778 0.27 64 771 0.34 85 986 0.56 133 1007 0.50 126 737 0.74 188 933

265 V

Low 0.16 41 758 0.16 43 597 0.20 46 609 0.30 69 836 0.47 114 882 0.38 99 594 0.63 152 737

High 0.29 57 1049 0.29 66 948 0.35 75 955 0.49 132 1125 0.81 183 1110 0.71 159 948 0.97 265 1115

Med 0.22 51 953 0.22 58 788 0.27 65 820 0.34 86 1018 0.57 139 1030 0.51 135 791 0.72 196 968

277 V

Low 0.16 44 827 0.17 47 625 0.21 56 682 0.30 72 890 0.47 120 924 0.39 108 638 0.64 159 793

Table 9: Electrical Data - Standard (Free Discharge) Motor - 3 Row Coil

Motor Size 2 Size 3 Size 4 Size 6 Size 8 Size 10 Size 12

Speed Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM

High 0.48 52 1067 0.55 62 1005 0.68 72 994 1.29 121 1120 1.20 129 1018 1.37 149 992 2.48 231 1127

Med 0.41 43 1007 0.48 53 899 0.57 59 876 1.01 96 976 1.01 108 915 1.15 124 871 1.76 169 1029

115 V

Low 0.34 35 889 0.39 42 722 0.45 45 700 0.89 80 783 0.83 84 749 0.91 95 689 1.60 149 895

High 0.26 52 962 0.29 62 847 0.38 75 931 0.60 120 1100 0.77 154 1073 0.72 148 865 1.13 230 1117

Med 0.22 46 784 0.24 52 648 0.30 59 764 0.45 88 900 0.58 48 713 0.57 119 685 0.81 160 975

208 V

Low 0.18 38 583 0.19 42 482 0.25 49 607 0.36 64 664 0.50 39 509 0.45 93 539 0.68 124 733

High 0.26 55 1034 0.29 66 960 0.37 75 1001 0.62 131 1122 0.80 179 1096 0.72 163 959 1.17 254 1135

Med 0.22 50 935 0.25 59 803 0.31 64 880 0.42 90 1000 0.57 130 1011 0.60 138 802 0.79 172 1037

230

Low 0.19 44 771 0.21 50 604 0.26 6 732 0.36 77 811 0.50 111 879 0.49 113 624 0.69 145 861

High 0.27 54 1034 0.28 61 942 0.34 77 920 0.46 115 1116 0.79 172 1100 0.65 150 911 0.93 240 1108

Med 0.20 47 936 0.21 44 789 0.27 64 771 0.35 86 975 0.56 133 1012 0.49 126 742 0.72 182 948

265 V

Low 0.16 41 787 0.17 44 594 0.20 46 605 0.30 68 803 0.47 114 891 0.38 99 601 0.61 148 763

High 0.28 56 1057 0.29 65 959 0.35 75 958 0.48 130 1123 0.81 183 1113 0.70 159 953 0.95 258 1119

Med 0.21 49 975 0.22 58 800 0.27 65 820 0.35 87 1007 0.57 139 1035 0.51 134 796 0.70 189 983

277 V

Low 0.16 43 859 0.17 48 622 0.21 56 677 0.30 71 855 0.47 120 933 0.39 108 646 0.62 155 821

Size 2 Size 3 Size 4 Size 6 Size 8 Size 10 Size 12

Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM

Table 10: Electrical Data - Standard (Free Discharge) Motor - 4 Row Coil

Motor Size 2 Size 3 Size 4 Size 6 Size 8 Size 10 Size 12

Speed Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM Amps Watts RPM

High 0.48 52 1069 0.54 61 1019 0.68 71 1002 1.28 118 1127 1.17 126 1027 1.36 152 993 2.46 228 1131

Med 0.41 43 1007 0.47 52 923 0.57 59 890 0.93 88 1017 0.98 105 935 1.15 123 863 1.73 166 1036

115 V

Low 0.34 35 888 0.38 41 779 0.45 45 712 0.86 77 873 0.81 83 769 0.91 94 684 1.57 147 909

High 0.26 52 964 0.29 60 859 0.38 74 938 0.60 117 1107 0.75 150 1083 0.71 151 865 1.12 227 1121

Med 0.22 46 784 0.23 50 665 0.30 59 776 0.41 81 938 0.56 47 729 0.57 118 678 0.80 157 982

208 V

Low 0.18 38 582 0.19 41 520 0.25 49 617 0.35 62 740 0.48 39 523 0.45 92 535 0.67 122 744

High 0.26 55 1036 0.29 64 973 0.37 74 1009 0.62 128 1129 0.78 175 1106 0.72 166 959 1.16 251 1139

Med 0.22 50 935 0.24 58 824 0.31 64 894 0.39 83 1042 0.55 127 1034 0.60 137 795 0.78 169 1044

230

Low 0.19 44 770 0.20 49 652 0.26 6 745 0.35 74 904 0.49 110 903 0.49 112 619 0.68 143 874

High 0.27 54 1036 0.28 59 955 0.34 76 927 0.46 112 1123 0.77 167 1110 0.65 153 911 0.92 237 1112

Med 0.20 47 936 0.21 42 810 0.27 64 783 0.32 79 1016 0.55 130 1034 0.49 125 735 0.71 179 954

265 V

Low 0.16 40 786 0.16 43 641 0.20 46 615 0.29 65 895 0.45 113 915 0.37 98 597 0.60 146 775

High 0.28 56 1059 0.28 63 972 0.35 74 966 0.48 127 1130 0.79 178 1123 0.70 162 953 0.94 255 1123

Med 0.21 49 975 0.21 56 821 0.27 65 833 0.32 80 1049 0.55 136 1058 0.51 133 789 0.69 186 990

277 V

Low 0.16 42 858 0.17 46 671 0.21 56 689 0.29 68 953 0.46 119 959 0.39 106 641 0.61 153 834

18 McQuay Catalog 722

Page 19

Physical Data

Physical Data

Unit Data

Table 11: Unit Data

02 03 04 06 08 10 12

Primary Coil Data

Face Area, ft2 (cm2)

Fins/inch (cm) 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7]

Coil Dimensions

2-Row

L x D x H, in (cm)

3-Row

L x D x H, in (cm)

4-Row

L x D x H, in (cm)

Coil Volume, Gal (Liters)

2-Row 0.15 (0.6) 0.19 (0.7) 0.24 (0.9) 0.32 (1.2) 0.37 (1.4) 0.46 (1.7) 0.55 (2.1)

3-Row 0.20 (0.7) 0.26 (1.0) 0.32 (1.2) 0.45 (1.7) 0.52 (2.0) 0.64 (2.4) 0.77 (2.9)

4-Row 0.26 (1.0) 0.34 (1.3) 0.43 (1.6) 0.61 (2.3) 0.70 (2.6) 0.87 (3.3) 1.05 (4.0)

Reheat Coil Data: 1-Row, Hot Water or Steam

Face Area, ft2 (cm2)

Fins/inch (cm) 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7]

L x D x H, in (cm) 11.8 x 0.9 x 6

Volume, Gal (Liters) 0.04 (0.1) 0.05 (0.2) 0.07 (0.3) 0.10 (0.4) 0.11 (0.4) 0.14 (0.5) 0.17 (0.7)

Preheat Coil Data, 2-Row, Hot Water or Steam

Hot Water or Steam

Face Area, ft2 (cm2)

Fins/inch (cm) 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7] 12 [4.7]

L x D x H, in. (cm) 11.8 x 1.7 x 6

Volume, Gal (Liters) 0.08 (0.3) 0.10 (0.4) 0.13 (0.5) 0.19 (0.7) 0.22 (0.8) 0.29 (1.1) 0.35 (1.3)

Fan/Motor Data

Fan Quantity 1 1 2 2 3 4 4

Size, Dia” x W” (cm) 6.26 x 6.3

Motor Quantity 1 1 1 1 2 2 2

Filter Data

Part Number 668332901 668332902 668332903 668332907 668332905 668332906 668332904

1” (25.4 cm) Media TA only TA only TA only TA only TA only TA only TA only

Quantity 1 1 1 1 2 2 2

L x D x H, in. (cm) 16 x 8.75 x 1

0.74 (685) 1.08 (1004) 1.43 (1323) 2.11 (1962) 2.46 (2281) 3.14 (2917) 3.83 (3559)

11.8 x 1.7 x 9

(30.0x4.4x22.9)

11.8 x 2.6 x 9

(30x6.6x22.9)

11.8 x 3.5 x 9

(30.0x8.8x22.9)

0.49 (456) 0.72 (669) 0.95 (882) 1.41 (1308) 1.64 (1521) 2.09 (1944) 2.55 (2372)

(30.0x2.2x15.2)

0.49 (456) 0.72 (669) 0.95 (882) 1.41 (1308) 1.64 (1521) 2.09 (1944) 2.55 (2372)

(30.0x4.4x15.2)

(15.9 x 16)

(40.6 x 22 x 2.5)

17.3 x 1.7 x 9

(43.9x4.4x22.9)

17.3 x 2.6 x 9

(43.9x6.6x22.9)

17.3 x 3.5 x 9

(43.9x8.8x22.9)

17.3 x 0.9 x 6

(43.9x2.2x15.2)

17.3 x1.7 x 6

(43.9x4.4x15.2)

7.95 x 6.3

(20 x 16)

21.5 x 8.75 x 1

(54.6 x 22 x 2.5)

22.8 x 1.7 x 9

(57.9x4.4x22.9)

22.8 x 2.6 x 9

(57.9x6.6x22.9)

22.8 x 3.5 x 9

(57.9x8.8x22.9)

22.8 x 0.9 x 6

(57.9x2.2x15.2)

22.8 x 1.7 x 6

(57.9x4.4x15.2)

6.26 x 6.3

(15.9 x 16)

27 x 8.75 x 1

68.5 x 22 x 2.5

33.8 x 1.7 x 9

(85.9x4.4x22.9)

33.8 x 2.6 x 9

(85.9x6.6x22.9)

33.8 x 3.5 x 9

(85.9x8.8x22.9)

33.8 x 0.9 x 6

(85.9x2.2x15.2)

33.8 x 1.7 x 6

(85.9x4.4x15.2)

7.95 x 6.3

(20 x 16)

38 x 8.75 x 1

(96.5 x 22 x 2.5)

39.3x 1.7 x 9

(99.8x4.4x22.9)

39.3 x 2.6 x 9

(99.8x6.6x22.9)

39.3 x 3.5 x 9

(99.8x8.8x22.9)

39.3 x 0.9 x 6

(99.8x2.2x15.2)

39.3 x 1.7 x 6

(99.8x4.4x15.2)

6.26 x 6.3

(15.9 x 16)

21.7 x 8.75 x 1

(56.1 x 22 x 2.5)

50.2 x 1.7 x 9

(127.6x4.4x22.9)

50.2 x 2.6 x 9

(127.6x6.6x22.9)

50.2 x 3.5 x 9

(127.6x8.8x22.9)

50.2 x 0.9 x 6

(127.6x2.2x15.2)

50.2 x 1.7 x 6

(127.6x4.4x15.2)

6.26 x 6.3

(15.9 x 16)

27.2 x 8.75 x 1

(69.0 x 22 x 2.5)

61.3 x 1.7 x 9

(155.7x4.4x22.9)

61.3 x 2.6 x 9

(155.7x6.6x22.9)

61.3 x 3.5 x 9

(155.7x8.8x22.9)

61.3 x 0.9 x 6

(155.7x2.2x15.2)

61.3 x 1.7 x 6

(155.7x4.4x15.2)

7.95 x 6.3

(20 x 16)

32.7 x 8.75 x 1

(83.1 x 22 x 2.5)

Table 12: Approximate Ship ping Weights - lbs (kg)*

Unit Type

FCVC,FCVS 84 (38) 95 (43) 108 (49) 131 (60) 152 (69) 177 (80) 202 (92)

FCVH 55 (25) 63 (29) 74 (34) 91 (41) 110 (50) 129 (59) 149 (68)

Note: *Approximate shipping weights do not include valve packages, hot water coils, electric heaters or other options.

S02S03S04S06S08S10S12

Unit Size

McQuay Catalog 722 19

Page 20

Physical Data

PREHEAT OPTION NOITPO TAEHERNOITPO TAEH CIRTCELE

PRIMARY

PREHEAT

EE

DD

GG

AA

CC

BB

HH

FF

A

B

F

FRONT VIEW

5 [127]

8.9

227

6.1

154

8.8

[224]

8.8

[224]

BACK VIEW

ELECTRICAL

CONTROL BOX

OPTIONAL

DISCONNECT

SWITCH

DRAIN PAN 7/8" OD

CONNECTION

ELECTRIC HEAT

PANEL BOX

1.3

33.8

C

3.6

90.3

E

TOP VIEW

DISCHARGE

GRILL

ELECTRICAL CONTROL

ACCESS DOOR

ELECTRIC

HEAT

PRIMARY

EE

AA

BB

DD

CC

GG

1.0

24.7

PRIMARY

REHEAT

DD

GG

BB

EE

HH

FF

CC

AA

4.6

[117]

9.3

[236]

3.4 [86]

15.7

[399]

17.6

[447]

Unit Dimensions

Figure 7: Dimensions: Flat Top Fan Coils

Dimension

S02 S03 S04 S06 S08 S10 S12

inch mm inch mm inch mm inch mm inch mm inch mm inch mm

Unit Width A 35.0 889 40.5 1029 46.0 1168 57.0 1448 62.5 1588 73.5 1867 84.5 2146

Unit Height B 25.0 635 25.0 635 25.0 635 25.0 635 25.0 635 25.0 635 25.0 635

Unit Depth C 10.0 254 10.0 254 10.0 254 10.0 254 10.0 254 10.0 254 10.0 254

Discharge Grille - Width E 16.3 414 21.8 554 27.3 693 38.3 973 43.8 1113 54.8 1392 65.8 1671

Return Air Opening - Width F 16.2 411 21.7 551 27.2 691 38.2 970 43.7 1110 54.7 1389 65.7 1669

Primary Coil - Water Supply BB 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424

GG 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198

Primary Coil - Water Return DD 21 533 21 533 21 533 21 533 21 533 21 533 21 533

Preheat Coil - Water Return CC 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475

EE 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28

HH 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30

Preheat Coil - Water Supply AA 15 381 15 381 15 381 15 381 15 381 15 381 15 381

Reheat Coil - Water Return CC 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589

FF 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119

HH 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107

Reheat Coil - Water Supply AA 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516

FF 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211

Electric Heat Connection AA 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384

CC 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76

20 McQuay Catalog 722

Page 21

Figure 8: Dimensions: Slope Top Fan Coils

A

B

F

FRONT VIEW

6.1

154

8.9

227

5

[127]

15.7

[399]

17.6

[447]

BACK VIEW

ELECTRICAL

CONTROL BOX

OPTIONAL

DISCONNECT

SWITCH

DRAIN PAN 7/8" OD

3.7

95.1

C

1.9

47.4

E

TOP VIEW

ELECTRIC HEAT OPTION

PREHEAT OPTION

REHEAT OPTION

DISCHARGE

GRILL

ELECTRIC CONTROL

ACCESS DOOR

AA

DD

CC

HH

FF

EE

GG

BB

4.6

[117]

9.3

[236]

3.4 [86]

.9

23.1

REHEAT

PRIMARY

DD

EE

GG

CC

AA

HH

FF

BB

PREHEAT

PRIMARY

DD

EE

GG

AA

CC

BB

PRIMARY

ELECTRIC

HEAT

8.8

[224]

8.8

[224]

Physical Data

McQuay Catalog 722 21

Dimension

Unit Width A 35.0 889 40.5 1029 46.0 1168 57.0 1448 62.5 1588 73.5 1867 84.5 2146

Unit Height B 27.6 701 27.6 701 27.6 701 27.6 701 27.6 701 27.6 701 27.6 701

S02 S03 S04 S06 S08 S10 S12

inch mm inch mm inch mm inch mm inch mm inch mm inch mm

Unit Depth C 10.0 254 10.0 254 10.0 254 10.0 254 10.0 254 10.0 254 10.0 254

Discharge Grille - Width E 16.3 414 21.8 554 27.3 693 38.3 973 43.8 1113 54.8 1392 65.8 1671

Return Air Opening - Width F 16.2 411 21.7 551 27.2 691 38.2 970 43.7 1110 54.7 1389 65.7 1669

Primary Coil - Water Supply BB 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424

Primary Coil - Water Return DD 21 533 21 533 21 533 21 533 21 533 21 533 21 533

Preheat Coil - Water Return CC 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475

GG 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198

EE 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28

HH 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30

Preheat Coil - Water Supply AA 15 381 15 381 15 381 15 381 15 381 15 381 15 381

Reheat Coil - Water Return CC 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589

Reheat Coil - Water Supply AA 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516

Electric Heat Connection AA 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384

FF 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119

HH 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107

FF 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211

CC 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76

Page 22

Physical Data

ELECTRIC

HEAT

DRAIN PAN 7/8 OD

CONNECTION

BB

D

D

E

E

GG

B

A

A

C

C

HH

F

F

PRIMARY

REHEAT

5

127

4.6

1

17

9.3

2

36

ELECTRIC HEAT OPTION

PREHEAT OPTION REHEAT OPTION

E

5.4

138.2

F

1.0

7.3

[185]

26.6

H

G

F

RON

T VIEW

FRONT DISCHARGE

E

LECTRIC

CONTROL BOX

OPTIONAL

DISCONNECT

SWITCH

8.9

227

6.1

154

BACK VIEW

E

LECTRIC HEAT

PANEL BO

X

A

C

TOP VIEW

PRIMARY

B

B

D

D

EE

G

G

AA

CC

B

FF

HH

AA

BB

CC

DD

EE

GG

PRIMARY

PREHEAT

0.6 [15.9]

0.6 [15.9]

H

G

Figure 9: Dimensions: Hideaway, Front-Discharge Fan Coils

Dimension

Unit Width A 18.8 475 24.3 617 29.8 757 40.8 1036 46.3 1176 57.3 1455 68.3 1735

Unit Height B 24.0 610 24.0 610 24.0 610 24.0 610 24.0 610 24.0 610 24.0 610

Unit Depth C 9.6 243 9.6 243 9.6 243 9.6 243 9.6 243 9.6 243 9.6 243

Discharge Grille - Width E 16.3 414 21.8 554 27.3 693 38.3 973 43.8 1113 54.8 1392 65.8 1671

Return Air Opening - Width F 16.2 411 21.7 551 27.2 691 38.2 970 43.7 1110 54.7 1389 65.7 1669

Control Box to Floor G 17.6 447 17.6 447 17.6 447 17.6 447 17.6 447 17.6 447 17.6 447

Disconnect Switch to Floor H 15.7 399 15.7 399 15.7 399 15.7 399 15.7 399 15.7 399 15.7 399

Primary Coil - Water Supply BB 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424

Primary Coil - Water Return DD 21 533 21 533 21 533 21 533 21 533 21 533 21 533

Preheat Coil - Water Return CC 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475

Preheat Coil - Water Supply AA 15 381 15 381 15 381 15 381 15 381 15 381 15 381

Reheat Coil - Water Return CC 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589

Reheat Coil - Water Supply AA 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516

Electric Heat Connection AA 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384

S02 S03 S04 S06 S08 S10 S12

inch mm inch mm inch mm inch mm inch mm inch mm inch mm

GG 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198

EE 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28

HH 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30

FF 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119

HH 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107

FF 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211

CC 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76

22 McQuay Catalog 722

Page 23

Figure 10: Dimensions: Hideaway, Top-Discharge Fan Coils

1.3

32.9

1.3

32.9

ELECTRIC

HEAT

5

127

4.6

117

9.3

236

F

H

G

FRONT VIEW

ELECTRIC

CONTROL BOX

OPTIONAL

DISCONNECT

SWITCH

0.6 [15.9]

8.9

227

6.1

154

BACK VIEW

A

E

3.5

89.6

4.8

120.7

TOP V

IEW

TOP DISCHARGE

PRIMARY

DRAIN PAN 7/8 OD

CONNECTION

REHEAT

BB

DD

EE

GG

AA

CC

HH

FF

B

1.3

32.9

PRIMARY

PREHEAT

FF

HH

AA

BB

CC

DD

EE

GG

B

PRIMARY

BB

DD

EE

GG

B

AA

CC

ELECTRIC HEAT OPTION

PREHEAT OPTION REHEAT OPTION

0.6 [15.9]

ELECTRI

C

CONTROL BO

X

OPTIONAL

DISCONNECT

SWITCH

7.3

[185]

Physical Data

Dimension

Unit Width A 18.8 475 24.3 617 29.8 757 40.8 1036 46.3 1176 57.3 1455 68.3 1735

Unit Height B 24.0 610 24.0 610 24.0 610 24.0 610 24.0 610 24.0 610 24.0 610

Unit Depth C 9.6 243 9.6 243 9.6 243 9.6 243 9.6 243 9.6 243 9.6 243

Discharge Grille - Width E 16.3 414 21.8 554 27.3 693 38.3 973 43.8 1113 54.8 1392 65.8 1671

Return Air Opening - Width F 16.2 411 21.7 551 27.2 691 38.2 970 43.7 1110 54.7 1389 65.7 1669

Control Box to Floor G 17.6 447 17.6 447 17.6 447 17.6 447 17.6 447 17.6 447 17.6 447

Disconnect Switch to Floor H 15.7 399 15.7 399 15.7 399 15.7 399 15.7 399 15.7 399 15.7 399

Primary Coil - Water Supply BB 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424 16.7 424

Primary Coil - Water Return DD 21 533 21 533 21 533 21 533 21 533 21 533 21 533

Preheat Coil - Water Return CC 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475 18.7 475

Preheat Coil - Water Supply AA 15 381 15 381 15 381 15 381 15 381 15 381 15 381

Reheat Coil - Water Return CC 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589 23.2 589

Reheat Coil - Water Supply AA 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516 20.3 516

Electric Heat Connection AA 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384 15.1 384

S02 S03 S04 S06 S08 S10 S12

inch mm inch mm inch mm inch mm inch mm inch mm inch mm

GG 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198 7.8 198

EE 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28 1.1 28

HH 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30 1.2 30

FF 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119 4.7 119

HH 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107 4.2 107

FF 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211 8.3 211

CC 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76 3.0 76

McQuay Catalog 722 23

Page 24

Physical Data

Figure 11: Wall plate dimensions and kit part numbers

Unit

Size

Inches (mm) Kit Part Number

Wall Plate

Recommended

Wall Opening

Front

Discharge

Top

Discharge

02

37.25 x 26.5

(946 x 673)

34 x 23

(864 x 584)

668114901 668114908

03

42.75 x 26.5

(1086 x 673)

40 x23

(1016 x 584)

668114902 668114909

04

48.25 x 26.5

(1226 x 673)

45 x 23

(1143 x 584)

668114903 668114910

06

59.25 x 26.5

(1505 x 673)

56 x 23

(1422 x 584)

668114904 668114911

08

64.75 x 26.5

(1645 x 673)

62 x 23

(1575 x 584)

668114905 668114912

10

75.75 x 26.5

(1924 x 673)

72 x 23

(1828 x 584)

668114906 668114913

12

86.75 x 26.5

(2203 x 673)

84 x 23

(2134 x 584)

668114907 668114914

Access doors on

both sides of

wall plate

Discharge grille

(front discharge

units)

Intake grille

Note: Wall plate is designed for use with ThinLine vertical

hideaway units mounted a minimum of 1.5 inches

(38 mm) above the floor. Wall plates for Size 08, 10

and 12 units are in two sections. For installation

instructions, see McQuay IM 1022.

STYLE

DIMENSIONS (INCHES)

ABC

2 BRICK X 2 BRICK 163⁄

4

43⁄

4

33⁄

4

4 BRICK X 2 BRICK 331⁄

2

43⁄

4

33⁄

4

ALL DIMENSIONS APPROXIMATE.

CERTIFIED DRAWINGS AVAILABLE ON REQUEST.

Decorative Wall Plate Dimensions

Fresh Air Intake Box Dimensions

Figure 12: Fresh Air Intake Box Dimensions

24 McQuay Catalog 722

Page 25

Engineering Guide Specification

McQuay ThinLine 3G Fan Coil

Engineering Guide Specification

McQuay ThinLine 3G Vertical -floor type and wall/hideaway

type fan coil are furnished as a vertical blow-through with

either a primary coil for cooling only or for heating and

cooling, or with a combination of a primary coil for cooling

and a secondary coil for heating, which can either be in the

preheat or reheat position.

Performance

Unit capacities are certified under Industry Room Fan-Coil Air

Conditioner Certification Program in accordance with ARI

Standard 440-97. All standard units are ETL listed in the

United States and Canada and comply with NFPA 90A

requirements.

General Construction - All Units

The unit includes a chassis, coil(s), fan wheel(s), fan casing(s),

fan board and motor(s). Units also include a noncorrosive,

ABS main drain pan, positively sloped in every plane and

insulated with closed-cell insulation. All units with factory

provided standard piping packages also include a noncorrosive secondary drain pan. Steel parts exposed to moisture

are galvanized and if necessary are insulated to prevent

condensation. The complete fan assembly, which includes the

drain pan and motor is easily removed for service and

maintenance. A quick-disconnect motor electrical plug is also

provided. The standard chassis construction is 18-gage

galvanized steel. The unit is acoustically and thermally

insulated with closed-cell insulation.

Cabinet

The exposed panels and cabinetry are aesthetically designed

and fabricated of heavy gauge steel, available in either 18 or

16 gauge. They have an electrostatically applied, baked-on

powder paint finish available in Antique Ivory as standard.

Cupola White, Soft Gray, Off White and Putty Beige are

available as option. Other colors can be made available upon

request. Standard finish meets ASTM B117 specifications (salt

spray test).

Vertical Cabinet (Flat Top) and Slope Top Units

Discharge air grilles are recessed to resist condensate

formation and provided with either a multi-directional

discharge air grille or a stamped metal grille. Multi-directional

discharge air grilles allow the end-user to change the

discharged air to four different directions by rotating in 90°

increments. Painted and aesthetically designed metal hinged

control access doors are made rigid by channel forming and

constructed to be flush with the top panel. Units equipped with

the tamperproof option have a key-operated locking access

door and tamper-proof access door screws, as well as 16-gauge

front and side panels to help prevent nuisance tampering with

unit and/or controls.

Individual and removable side panels are furnished on both

ends of the unit to allow full access to valves, piping, electrical

connections and optional secondary drain pan without the need

to remove the front. The separate removable front panel allows

full access to fans, motors and the main drain pan. When

requesting a vertical cabinet it is strongly suggested to provide

sub-bases. For McQuay the 3.5" sub-base is a standard part of

the unit. Other heights are available as special option to help

elevate the cabinet units to a specified height; for example, to

reach the bottom of a window sill. The sub-base is also the

area where the motorized fresh air damper is situated. Subbases are 16-gage steel construction and have an oxford

brown/black paint finish. The sub-base depth and width is

identical to the unit's dimensions.

Hideaway (Fully Recessed) Units

Hideaway units are available for top discharge with a duct

collar or for front discharge.

An exposed, finished, decorative Wall plate panel is available

on hideaway units. It is available standard with18-gage steel

construction or tamperproof with 16-gage steel construction.

Wall plates are shipped separately from the unit.

Coils

All water coils are first leak tested at 400 psig (2760 kPa) then

re-tested at 300 psig (690 kPa) after all final piping

connections are made, including valve/piping packages.

Maximum main coil working pressure is 300 psig (2,069 kPa).

Maximum entering water temperature is 200°F (93°C). Tubes

and u-bends are 3/8" (10 mm) OD copper. Fins are aluminum

and are mechanically bonded to the copper tubes. Coil stubouts are 5/8" (16 mm) OD copper tubing. Piping connections

are expanded to accept standard copper tubing 5/8" (16 mm)

OD. Water coil fins have full drawn collars to provide a

continuous surface cover over the entire tube for maximum

heat transfer. Seamless copper tubes are mechanically

expanded into the fins to provide a continuous primary-tosecondary compression bond over the entire finned length for

maximum heat transfer rates.

Water coils are provided with headers of seamless copper

tubing with intruded tube holes to permit expansion and

contraction without creating undue stress or strain. Coil casing

are constructed of galvanized steel. Coil connections are

copper sweat connections with connection size to be

determined by manufacturer based upon the most efficient coil

circuiting. Vent and drain connections are furnish soldered and

installed on the primary coil by the coil connection. An air

vent is provided for the secondary heating coil-factory

installed when provided with a valve package, shipped loose

when valve/piping packages are provided by others. Vent

connections are provided at the highest point to ensure proper

venting. Drain connections are at the lowest point.

McQuay Catalog 722 25

Page 26

Engineering Guide Specification

Primary and Secondary Coils

Primary coils for cooling only or for cooling and heating are

available as 2, 3, 4 row coils and can be used in combination

with a secondary heating coil. Secondary, 1-row heating coils

are available in the preheat or reheat position. 2-row coils are

available in the preheat position. The secondary heating 1 row

coils are available for use with both hot water and steam. Hot

water maximum working pressure is 300 psig (2,069 kPa), and

the maximum entering water temperature is 200°F (93°C). The

steam coil maximum working pressure is 15 psig (103 kPa).

Electric Heating Coils

The auxiliary electric heating coil can be provided as either the

total source of heat or auxiliary intermediate season heating.

The electric heat coils are located in the preheat position, and

are the open-wire type. The electric heat option is available to

operate at the same voltage as the unit or with a separate power

supply voltage to reduce amperage consumption. Single power

connection is provided when unit and electric heat is of same

voltage. A second power connection must be used when the

fan coil and electric heat have different voltages. All standard

electric heat coils are ETL listed and interlocked with the fan

motor switch. Therefore, electric heat operation is possible