Page 1

Installation and Maintenance Manual IM 343-5

3 – 1 Standard Modulating

Group: Applied Systems

Part Number: IM 343-5

Forced Draft Gas Fired Furnace on

McQuay Applied Rooftop Systems

FC****A* with RM7897A Flame Safeguard

LP Gas (Propane) Supplement to IM 684-4

McQuay Applied Rooftop natural gas furnaces can also be used with LP gas with minor factory modifications. These

modifications must be made at the factory by McQuay personnel. IM 684-4 “Forced Draft Gas Fired Furnace” is also

applicable for LP gas and should be referred to with the following exceptions noted:

1. The CO

2. The main pressure regulator has adjustable output of 5.5 to 12" w.c. and it is factory set for 9" w.c. (for proper gas orifice

pressure, see the back page of this supplement). The maximum LP gas inlet pressure is 0.5 psi.

reading (check CO2, CO, and stack temperature on page 14 of IM 684-4) when properly adjusted:

2

a. High fire = 10.5 through 12%

b. Low fire = 10 through 11.5%

Date: October 2007

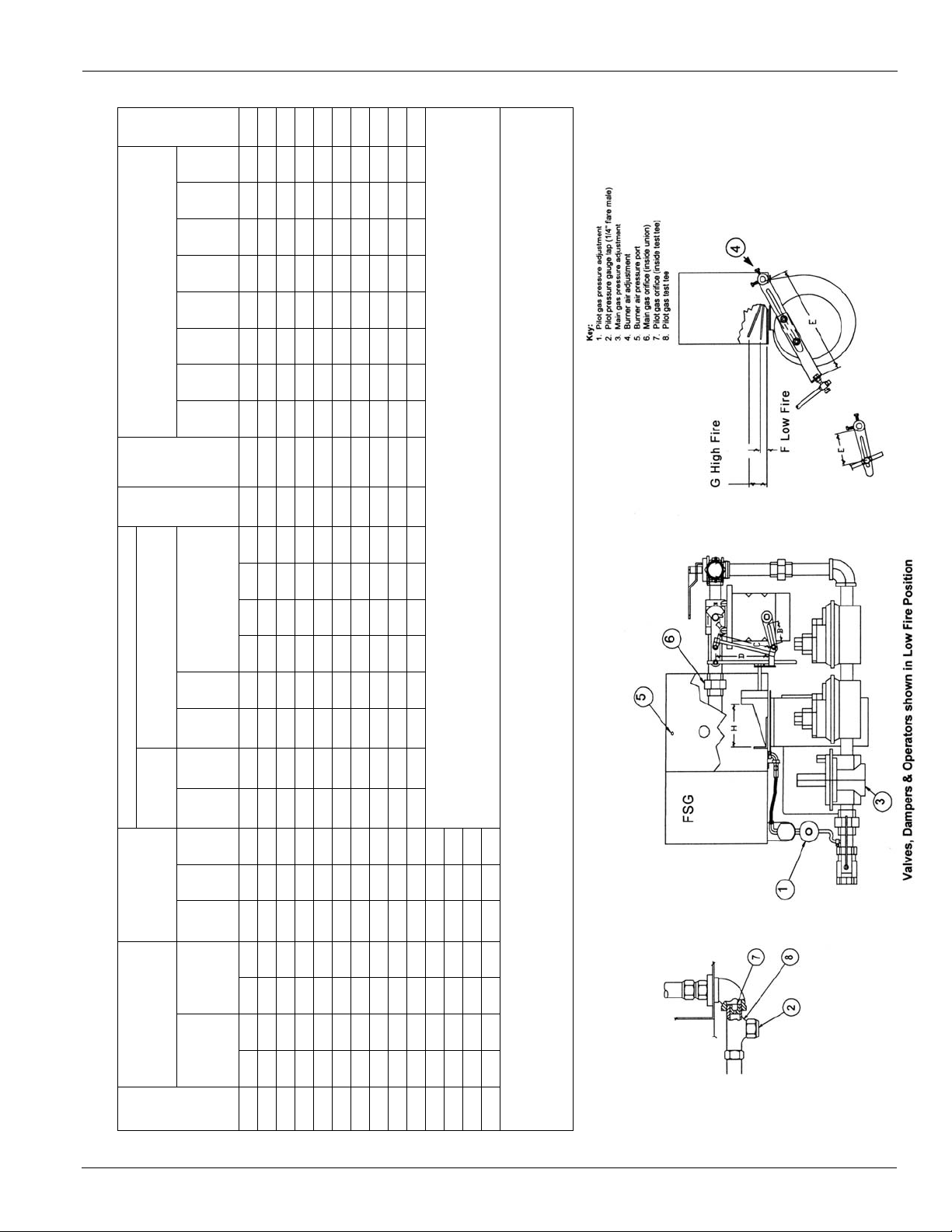

3. The “Capacities and Adjustments” table from page 26 of IM 684-4 has been converted for LP gas and is reproduced on

the back page of this supplement. The new orifice sizes indicated are factory provided for LP gas applications.

4. The differences between a natural gas and LP furnace:

a. The burner air slide plate located at the discharge of the fan box is changed.

b. The modulating gas valve linkage adjustments and some components are changed.

c. The main gas orifice and the pilot gas orifice is changed.

d. Models 020 – 032 use a different combination gas control.

e. The main gas pressure regulators use different springs.

f. Models 032 – 050 require detuning baffles for LP application.

g. Models 032 – 064 must be modulating for LP application.

© 2007 McQuay International

Page 2

IPS

Gas

Size

Conn.

Dimensions

ABCDEFGH

Amps

Current

Running

(1)

LP Gas @ 2500 Btu/Cubic Feet

(4) Pilot

in.

w.c .

Gas

Min.

Inlet

Press.

Models FC 110 – 200 not available for LP gas

.

% of Max. Input in. w.c

Gas Manifold Orifice Press. for

Std.

(5) Air

Gas

(3) Air

Drill

Orif.

Box

Press.

Adj.

Press.

Typ .

Press.

FLC

Limit

TR

Max

Min

CFM

100% 90% 50% 33%

in.

in.

w.c.

in.

w.c.

in.

w.c.

°F

°F

Main Burner

Drill

Orifice = #62

(2)

(5)

MBH CFH

@ Min. Rate

Capacities and Adjustments – 60 Hz

Input Furnace

Model

No.

(2)

@ Max Rate

MBH CFH

FC 020 250 100 83 33 2300 80 215 2.00 3.60 2.13 .177 7.98 6.46 2.00 .86 11.0 3.3 .44 .18 2.93 5.50 6.75 .38 1.62 .31 .75

FC 025 312 125 104 42 3800 61 160 2.05 3.70 2.76 .199 6.45 6.84 2.11 .98 11.0 3.4 .38 .25 3.04 5.50 6.75 .40 1.70 .62 .75

FC 032 400 160 133 53 2950 100 196 1.80 2.80 2.76 .234 7.88 6.38 1.97 .90 11.0 3.5 .38 .36 3.36 6.00 7.06 .46 2.03 .75 .75

FC 040 500 200 167 67 6000 61 154 1.90 2.70 2.77 .261 8.58 7.03 2.17 .95 11.0 3.6 .25 .32 3.70 6.00 6.00 .66 2.30 .00 1.00

FC 050 625 250 208 83 4600 100 229 1.80 3.00 2.14 .290 8.20 6.64 2.05 .87 11.0 3.6 .25 .35 3.84 6.00 5.00 .70 2.42 .00 1.00

FC 064 800 320 267 107 9600 61 185 1.70 3.10 2.80 .316 8.92 7.23 2.23 1.01 11.0 3.9 .25 .30 3.72 6.00 3.35 .48 2.75 1.62 1.25

FC 065 812 325 271 108 5970 100 232 1.55 3.80 2.55 .316 9.06 7.34 2.27 1.00 11.0 3.9 .25 .16 3.57 6.75 3.06 .90 2.84 .88 1.25

FC 079 1000 400 333 133 12000 61 181 1.40 3.89 2.63 .348 8.75 7.09 2.19 1.00 11.0 3.9 .35 .30 3.80 7.25 3.92 .87 2.90 1.25 1.25

FC 080 1000 400 333 133 7340 100 229 1.60 3.00 2.50 .348 8.75 7.09 2.19 .93 11.0 3.9 .35 .30 3.84 7.00 4.00 .85 2.65 1.25 1.25

FC 100 1250 500 417 167 15000 61 170 1.45 2.60 2.67 .413 7.98 6.46 2.00 .81 11.0 4.2 .12 .52 4.09 6.00 7.81 .93 2.78 1.62 1.25

FC 110 1375 550 495 196 10100 100 222

Warranty: All McQuay equipment is sold pursuant to its standard terms and

conditions of sale, including Limited Product Warranty. Consult your local

(2) CFH of LP gas @ 2500 Btu/cu. ft.

(3) Reading is with air damper at low fire position on modulating burners, cold heat exchanger.

(4) Pilot gas orifice No. 62 drill (0.038 in. dia.)

(5) Minimum fire on modulating burner

(6) Reading at high fire

FC 140 1750 700 583 233 21000 61 168

FC 150 1875 750 788 315 13700 100 194

FC 200 2500 1000 833 333 30000 61 151

Notes: (1) Pressure is for modulating burner with standard gas train. for On/Off burners, deduct 0.50". Gas inlet pressures over 0.50 psis (13.9 in. w.c., 8 oz/sq. in) require an additional high pressure regulator.

McQuay Representative for warranty details. Refer to Form 933-43285Y. To

find your local McQuay Representative, go to www.mcquay.com.

Loading...

Loading...