Page 1

INVERTER CEILING CASSETTE

SPLIT TYPE AIR CONDITIONER

(E Series)

© 2009 McQuay International

INSTALLATION MANUAL

IM-5CKYER-1009(1)-McQuay

Part Number: R08019034195A

Page 2

Page 3

1-1

English

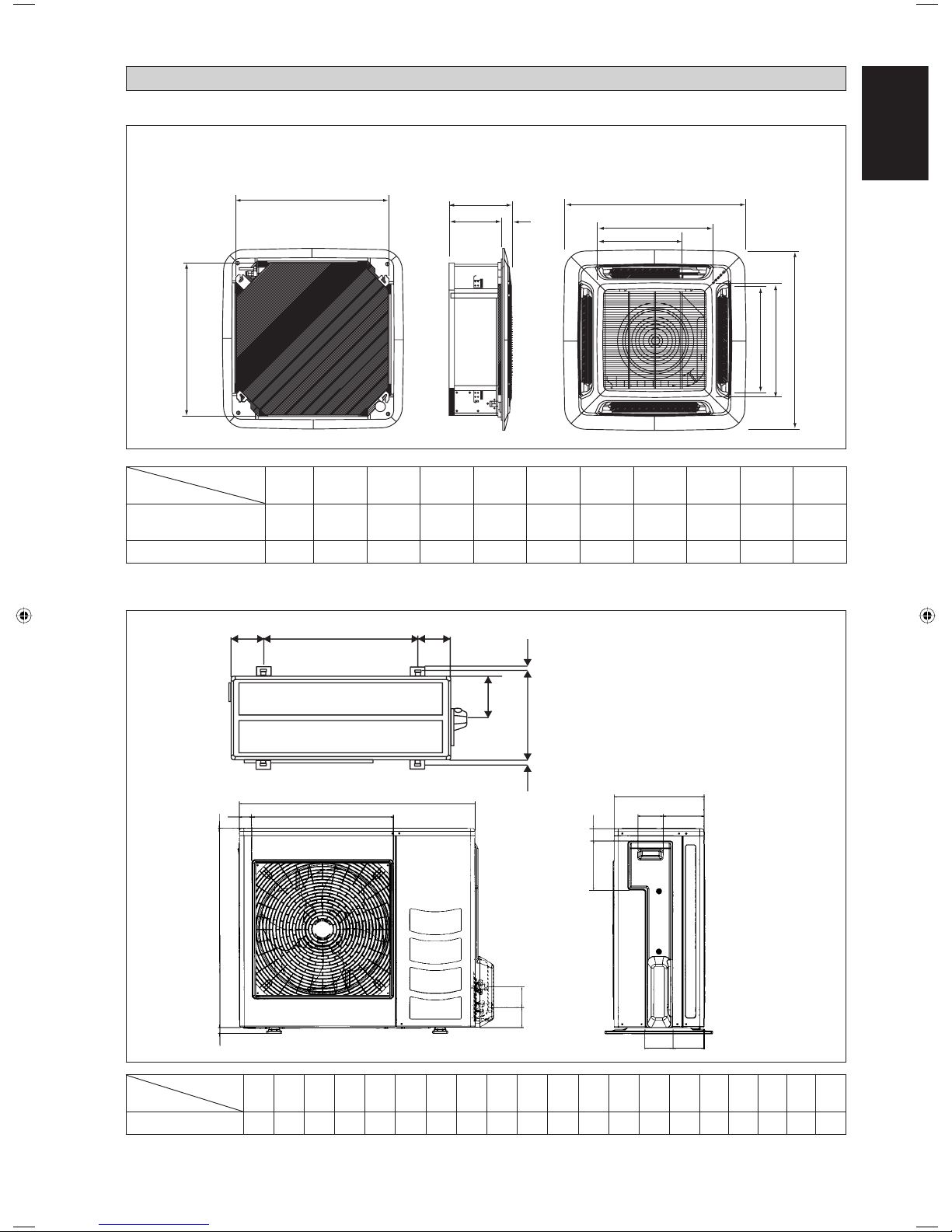

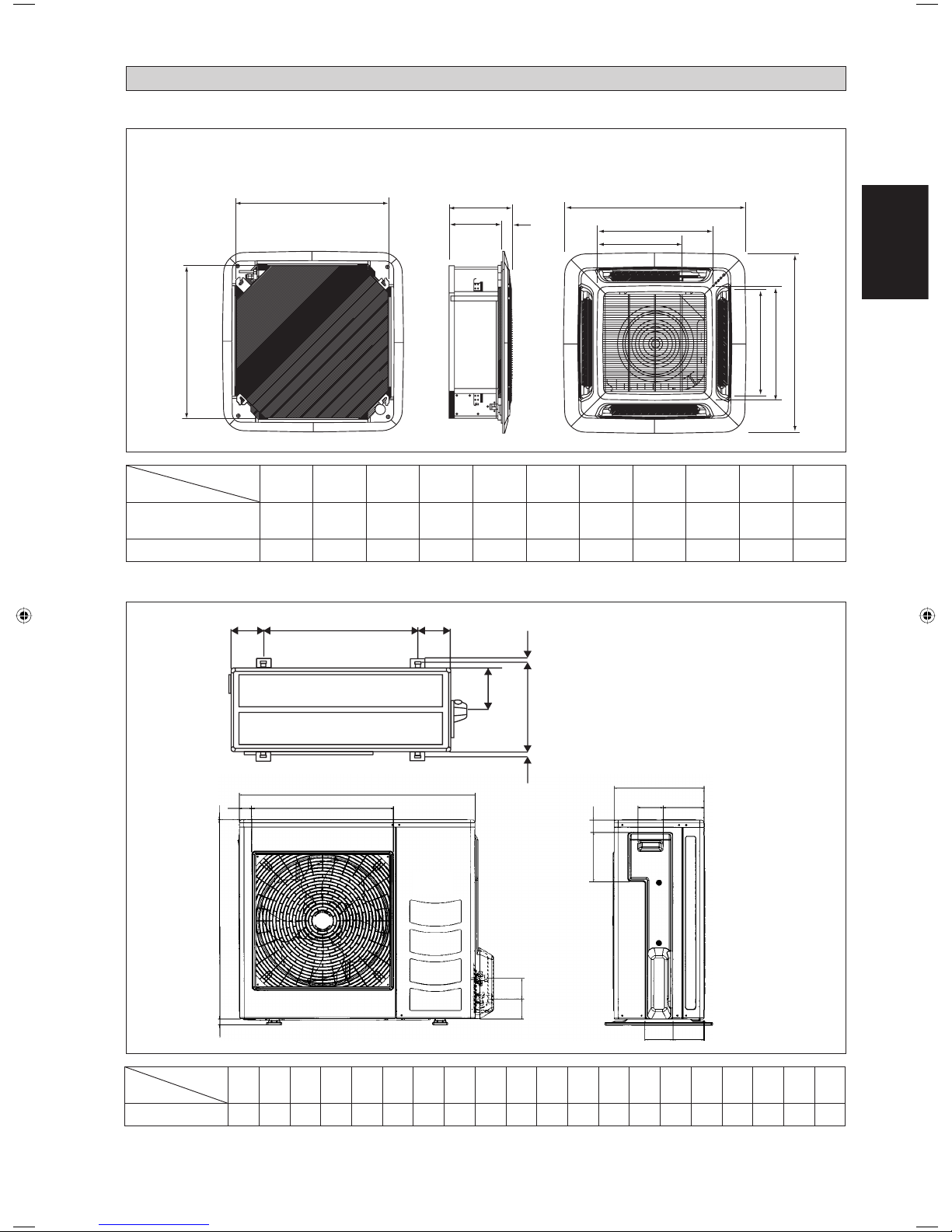

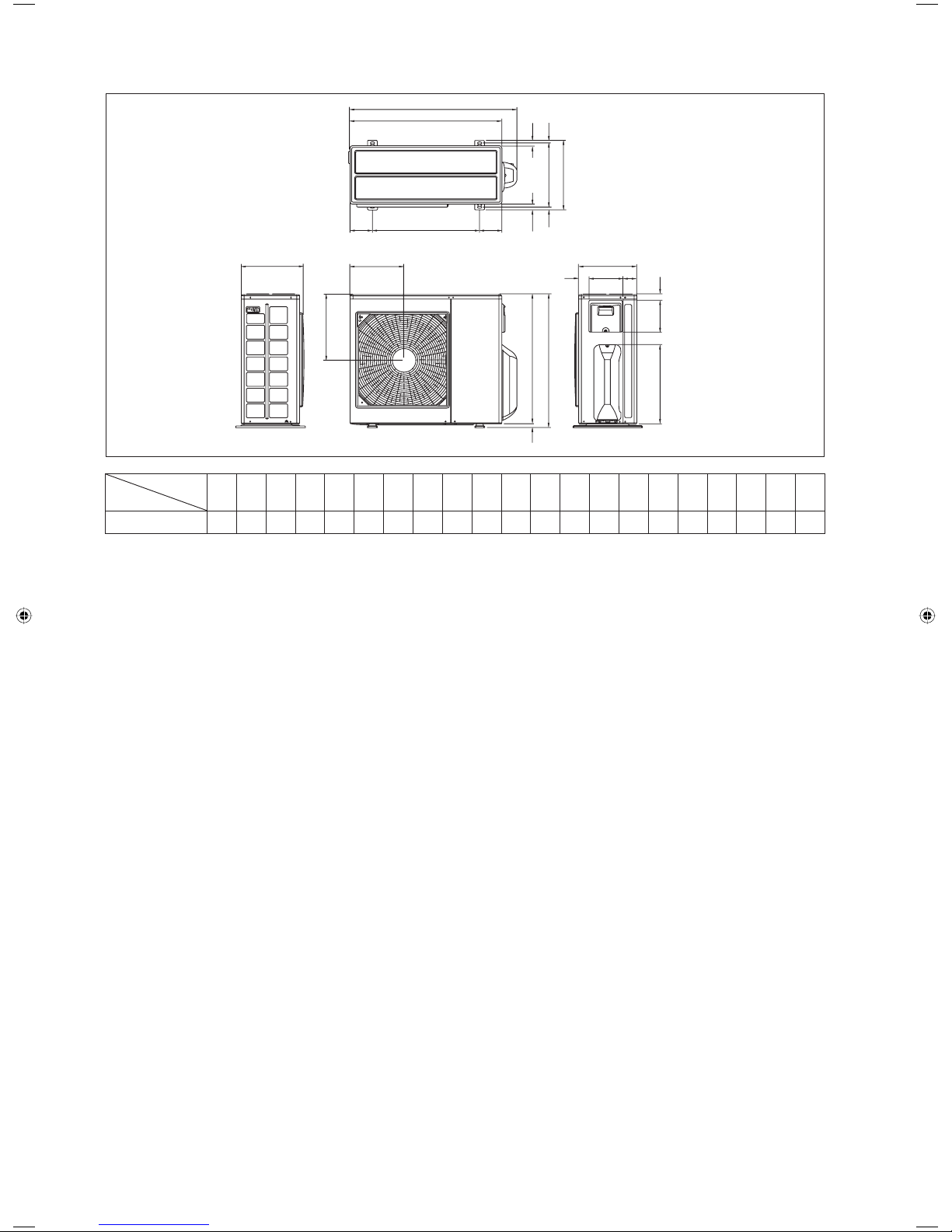

Indoor Unit 5CKY20/25E/ER & 5CKY28/40/50ER

A

B

C

D

E

F

H

K

J

I

G

Original Instruction

All dimensions are in mm

OUTLINE AND DIMENSIONS

Dimension

Model

AB C D E F GH I J K

5CKY20/25E/ER

5CKY28ER

820 820 340 300 40 990 990 627 627 607 430

5CKY40/50ER 820 820 375 335 40 990 990 627 627 607 430

Outdoor Unit 5SLY20/25C/CR

All dimensions are in mm

N

L

KL

TN

M

A

D

O

PBQ

RS

C

HG

FE

IJ

Dimension

Model

ABCDE FGH I JKLMNOPQRST

5SLY20/25C/CR 855 730 328 513 182 44 93 149 101 113 603 126 164 15 47 3 23 73 75 362

Page 4

1-2

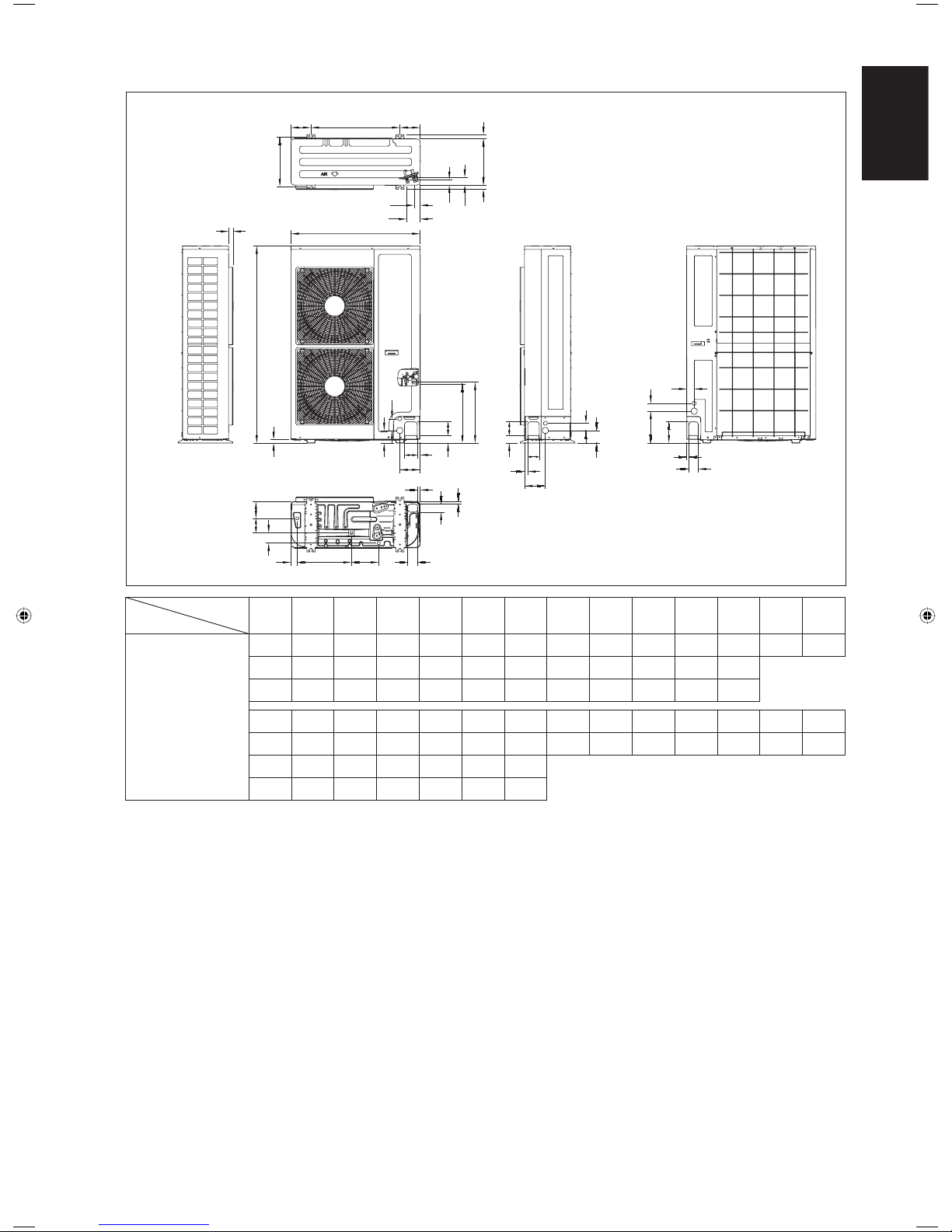

Outdoor Unit 5SLY28CR

A

D

K

E

S

T

S

T

GRR

OMN

H

P

Q

L

C

FU

J

B

I

Dimension

Model

ABCDE FGH I JKLMNOPQRSTU

5SLY28CR 940 348 753 855 392 733 603 328 303 370 362 448 190 80 58 180 32 126 32 15 23

Page 5

1-3

English

Outdoor Unit 5SLY40/50FR

AB AC AD

AE

AFAG

AH

AI

AA

AJ

AK

A

C

B

D

F

E

L

M

KJ

NO

Q

P

R

S

T

U

V

W

Z

X

Y

AT

AS

H

G

AU

AP

AQ

AO

AL

AM

AN

Dimension

Model

ABCDE FGH I JKLMN

5SLY40/50FR

900 1374 30 24 60 89 142 89 19 54 95 423 430 95

OPQRSTUVWXYZ

54 19 89 145 84 55 55 223 148 13 52 67

AA AB AC AD AE AF AG AH AI AJ AK AL AM AN

350 140 620 140 30 320 30 59 43 40 94 117 102 70

AO AP AQ AR AS AT AU

45 376 191 70 58 16 16

All dimensions are in mm

AR

I

Page 6

1-4

SAFETY PRECAUTIONS

! WARNING ! CAUTION

•

Installation and maintenance should be performed by qualifi ed

persons who are familiar with local code and regulation, and

experienced with this type of appliance.

•

All fi eld wiring must be installed in accordance with the national

wiring regulation.

•

Ensure that the rated voltage of the unit corresponds to that of

the name plate before commencing wiring work according to

the wiring diagram.

•

The unit must be GROUNDED to prevent possible hazard due

to insulation failure.

•

All electrical wiring must not touch the refrigerant piping, or

any moving parts of the fan motors.

•

Confi rm that the unit has been switched OFF before installing

or servicing the unit.

•

Disconnect from the main power supply before servicing the

air conditioner unit.

•

DO NOT pull out the power cord when the power is ON. This

may cause serious electrical shocks which may result in fi re

hazards.

•

Keep the indoor and outdoor units, power cable and transmission

wiring, at least 1m from TVs and radios, to prevent distorted

pictures and static. {Depending on the type and source of the

electrical waves, static may be heard even when more than 1m

away}.

Please take note of the following important points when

installing.

•

Do not install the unit where leakage of fl ammable gas may

occur.

If gas leaks and accumulates around the unit, it may cause

fi re ignition.

•

Ensure that drainage piping is connected properly.

If the drainage piping is not connected properly, it may

cause water leakage which will dampen the furniture.

•

Do not overcharge the unit.

This unit is factory pre-charged.

Overcharge will cause over-current or damage to the

compressor.

•

Ensure that the unitʼs panel is closed after service or

installation.

Unsecured panels will cause the unit to operate noisily.

•

Sharp edges and coil surfaces are potential locations which

may cause injury hazards.

Avoid from being in contact with these places.

•

Before turning off the power supply, set the remote

controllerʼs ON/OFF switch to the “OFF” position to

prevent the nuisance tripping of the unit. If this is not done,

the unitʼs fans will start turning automatically when power

resumes, posing a hazard to service personnel or the user.

•

Do not operate any heating apparatus too close to the air

conditioner unit. This may cause the plastic panel to melt or

deform as a result of the excessive heat.

•

Do not install the units at or near doorway.

•

Do not operate any heating apparatus too close to the air

conditioner unit or use in room where mineral oil, oil vapour

or oil steam exist, this may cause plastic part to melt or

deform as a result of excessive heat or chemical reaction.

•

When the unit is used in kitchen, keep fl our away from going

into suction of the unit.

•

This unit is not suitable for factory used where cutting oil

mist or iron powder exist or voltage fl uctuates greatly.

•

Do not install the units at area like hot spring or oil refi nery

plant where sulphide gas exists.

•

Ensure the color of wires of the outdoor unit and the

terminal markings are same to the indoors

respectively.

•

IMPORTANT: DO NOT INSTALL OR USE THE AIR

CONDITIONER UNIT IN A LAUNDRY ROOM.

•

Donʼt use joined and twisted wires for incoming power

supply.

•

Avoid direct contact of any coil treatment cleaners on plastic

part. This may cause plastic part to deform as a result of

chemical reaction.

•

For any enquiries on spare parts please contact your

authorized dealer.

•

The equipment is not intended for use in a potentially

explosive atmosphere.

This manual provides the procedures of installation to ensure a safe and good standard of operation for the air conditioner unit.

Special adjustment may be necessary to suit local requirements.

Before using your air conditioner, please read this instruction manual carefully and keep it for future reference.

This appliance is intended to be used by expert or trained users in shops, in light industry and on farms, or for commercial use by lay persons.

INSTALLATION MANUAL

NOTICE

Disposal requirements

Your air conditioning product is marked with this symbol. This means that electrical and electronic products shall not be mixed with unsorted

household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of the refrigerant, of oil and of other parts

must be done by a qualifi ed installer in accordance with relevant local and national legislation.

Air conditioners must be treated at a specialized treatment facility for re-use, recycling and recovery. By ensuring this product is disposed of

correctly, you will help to prevent potential negative consequences for the environment and human health. Please contact the installer or local

authority for more information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant local and national legislation.

Page 7

1-5

English

IMPORTANT

Important information regarding the refrigerant used

This product contains fl uorinated greenhouse gases covered by the Kyoto Protocol.

Do not vent gases into the atmosphere.

Refrigerant type: R410A

GWP

(1)

value: 1975

(1)

GWP = global warming potential

Please fi ll in with indelible ink,

n 1 the factory refrigerant charge of the product,

n 2 the additional refrigerant amount charged in the fi eld and

n 1 + 2 the total refrigerant charge

on the refrigerant charge label supplied with the product.

The fi lled out label must be adhered in the proximity of the product charging port (e.g. onto the inside of the service cover).

1 factory refrigerant charge of the product:

see unit name plate

(2)

2 additional refrigerant amount charged in the fi eld

3 total refrigerant charge

4 contains fl uorinated greenhouse gases covered by the Kyoto Protocol

5 outdoor unit

6 refrigerant cylinder and manifold for charging

(2)

In case of multiple indoor systems, only 1 label must be adhered*, mentioning the total factory refrigerant charge of all

indoor units connected in the refrigerant system.

Periodical inspections for refrigerant leaks may be required depending on European or local legislation. Please contact your

local dealer for more information.

* on the outdoor unit

Page 8

1-6

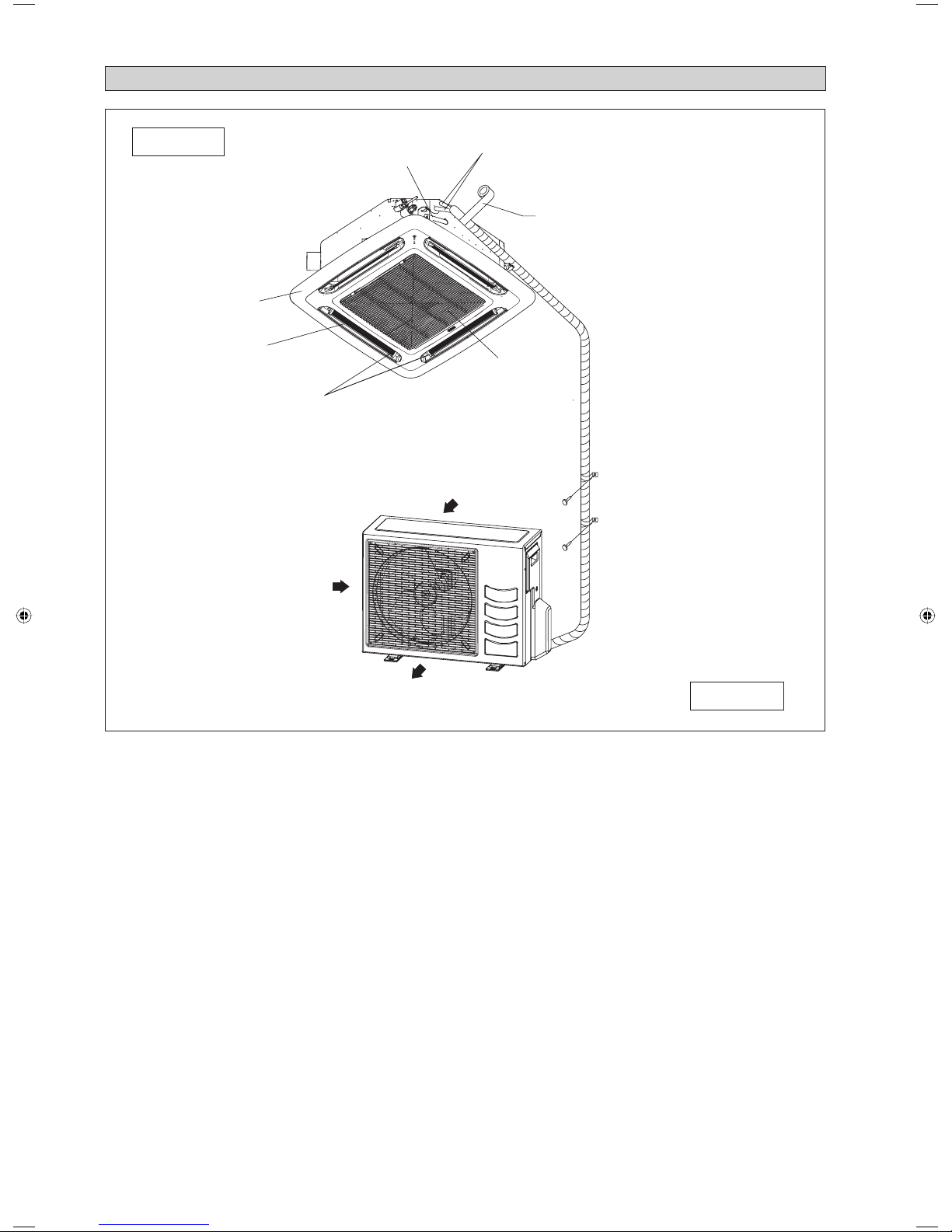

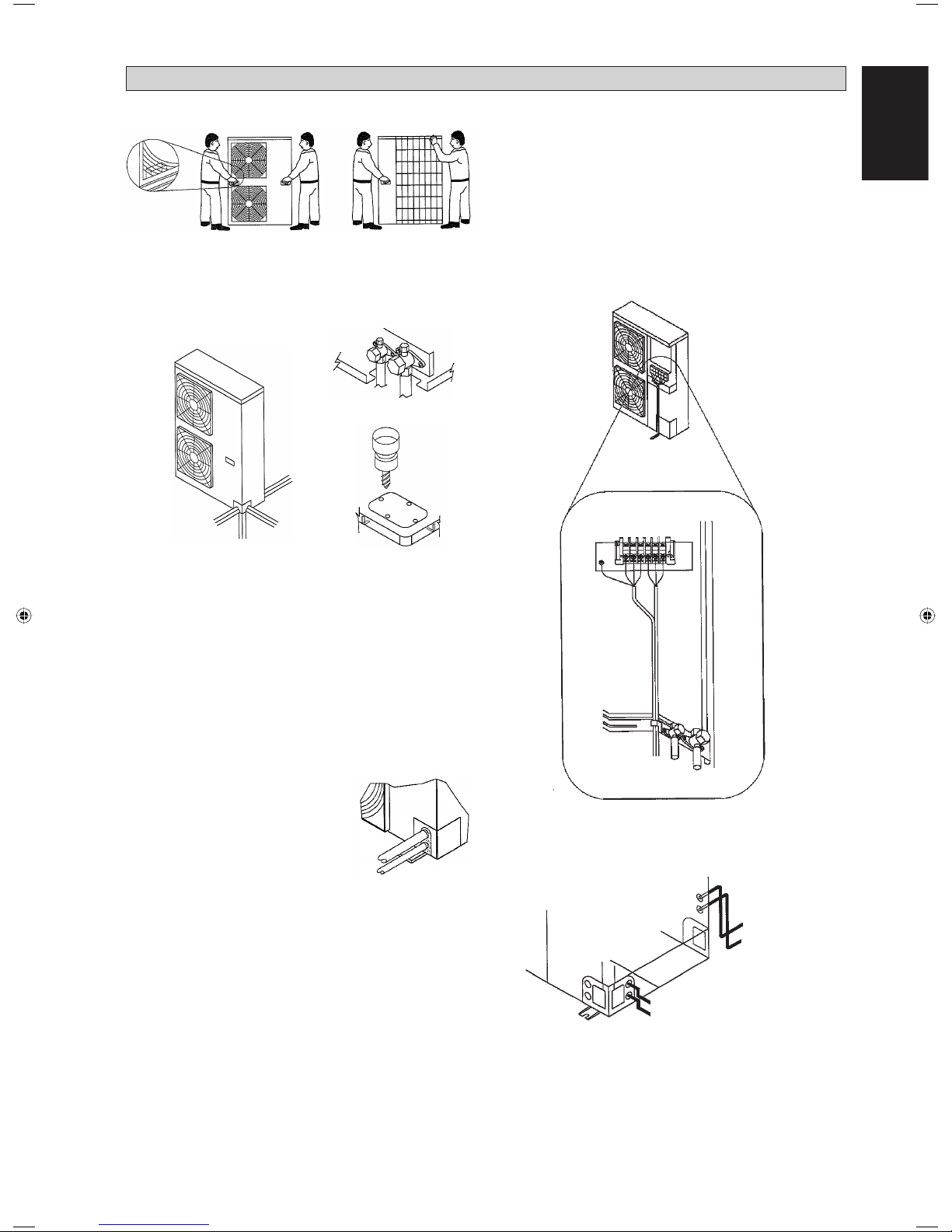

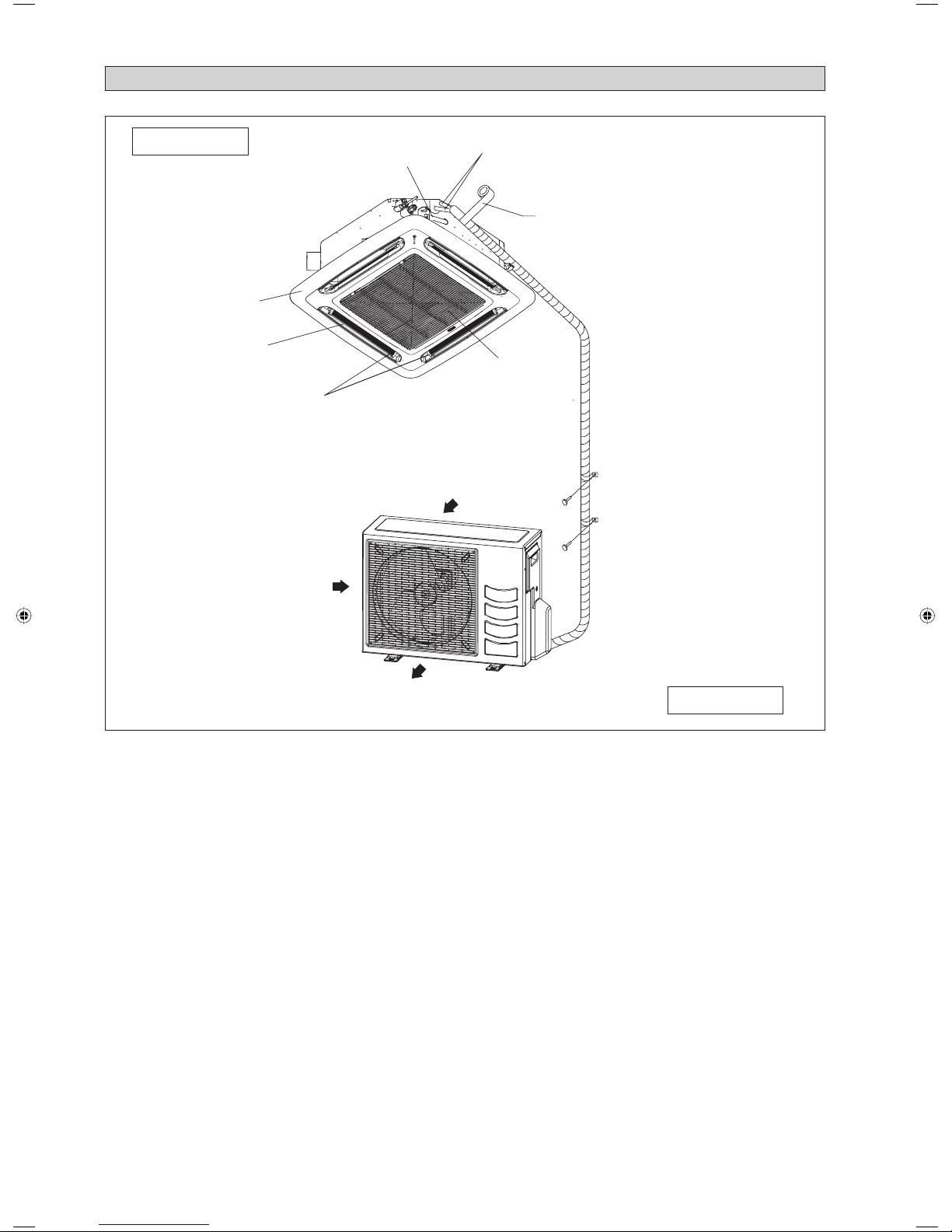

INSTALLATION DIAGRAM

Drain Piping

Front Panel

Air Filter

(behind the grille)

Air Intake Grille

Air Discharge

Air Discharge Louver

Air Intake

Air Intake

Thermal Insulation

Wrap the insulated pipe with the

fi nishing tape from bottom to top

Indoor Unit

Outdoor Unit

Page 9

1-7

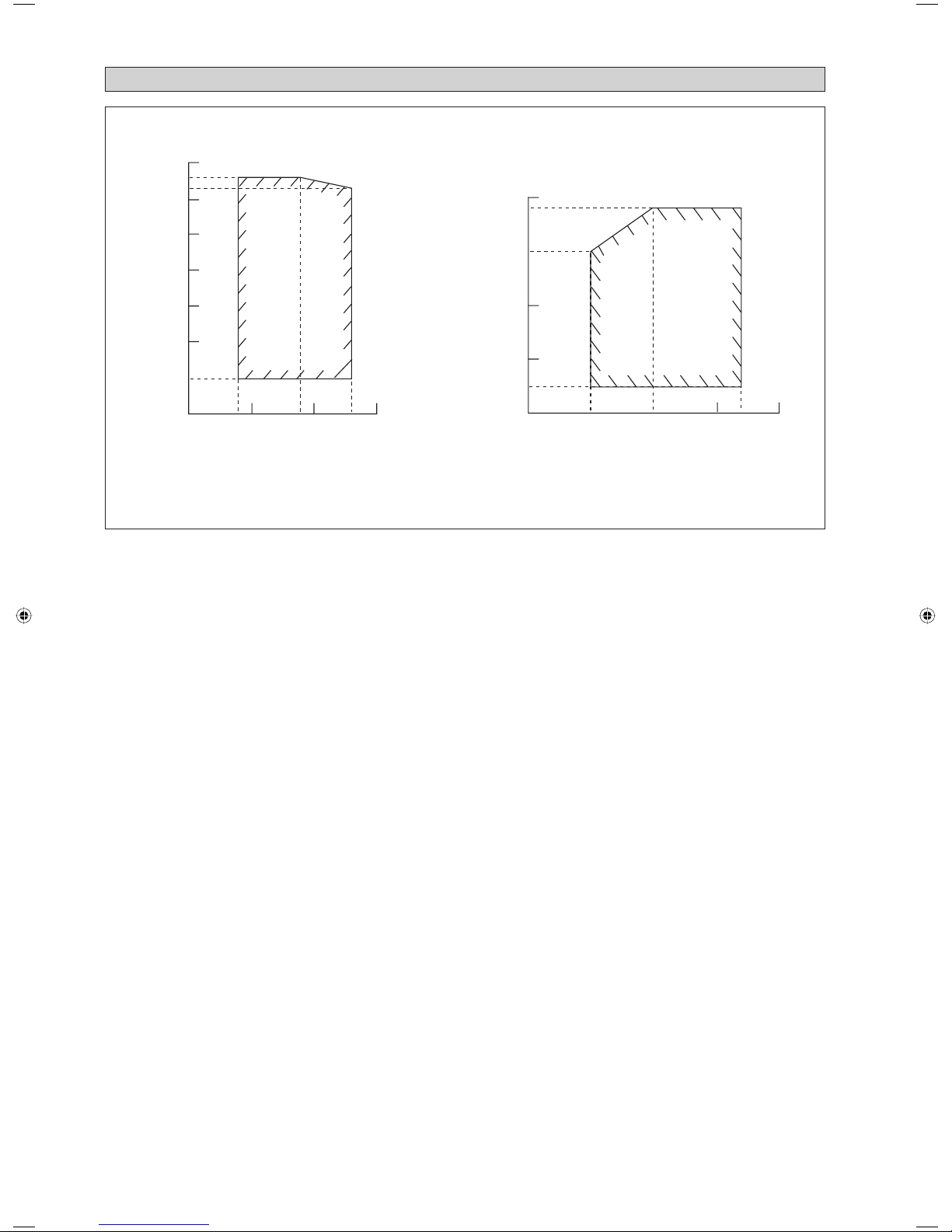

English

Obstacle

1m or more

3m or more

Floor

0.5m or more 0.5m or more 0.5m or more

0.3m or less

Beam

990.0mm

30 mm

Indoor Unit

Ceiling

Board

NOTE

Be sure to discuss the ceiling drilling work with the installers

concerned.

• Measure and mark the position for the hanging rod. Drill

the hole for the angle nut on the ceiling and fi x the hanging

rod.

• The installation template is extended according to

temperature and humidity. Check on dimensions in use.

• The dimensions of the installation template are the same as

those of the ceiling opening dimensions.

• Before ceiling laminating work is completed, be sure to fi t

the installation template to the indoor unit.

• Confi rm the pitch of the hanging rod is 770mm 622mm

sharp.

• Hold the unit and hang it on the hanging rod with the nut

and washer.

• Adjust the unit height to 30 mm between the indoor unit

bottom surface and the ceiling surface.

• Confirm with a level gauge that the unit is installed

horizontally and tighten the nut and bolt to prevent unit

falling and vibration.

• Open the ceiling board along the outer edge of the paper

installation template.

Unit Hanging

Unit Installation

INSTALLATION OF THE INDOOR UNIT

Preliminary Site Survey

Be sure to read this manual before installing the air-conditioner indoor unit.

• Voltage supply fl uctuation must not exceed ±10% of rated voltage. Electricity supply lines must be independent of welding

transformers which can cause high supply fl uctuation.

• Ensure that the location is convenient for wiring, piping and drainage.

• Do not exert pressure on the resin parts when opening the unit or when moving it after opening.

• Do not move the unit from packaging while moving, until it reaches the installation site. Use safe material or protection

plates when unpacking it or lifting it to avoid damage or scratches to the unit.

880.0~990.0mm (Ceiling Opening Site = 890mm)

770.0mm (Hanging Rod)

880.0~990.0mm (Ceiling Opening Site)

Piping Direction

622.0mm (Hanging Rod)

• Ensure a location where:

a) Drainage can be done easily.

b) Convenient for wiring and piping.

c) Which have enough space for installation and service work.

d) Where no risk of fl ammable gas leakage.

e) When free from any obstacles in path of cool air discharge and warm air return and must allow spreading of air throughout

the room (near the center of the room).

f) Must be provided clearance for indoor unit from the wall and obstacles as shown in fi gure below.

g) The installation place must be strong enough to support a load 4 times the indoor unit weight to avoid amplifying noise

and vibration.

h) The installation place (hanging ceiling surface) must be assuring levelness and the height in the ceiling is 350mm or

more.

i) The indoor unit must be away from heat and steam sources (avoid installing it near an entrance).

990.0mm

Page 10

1-8

Open

Screw

From

Unit

Control

Box

From

Front

Panel

LED Wire

Air Swing Wire

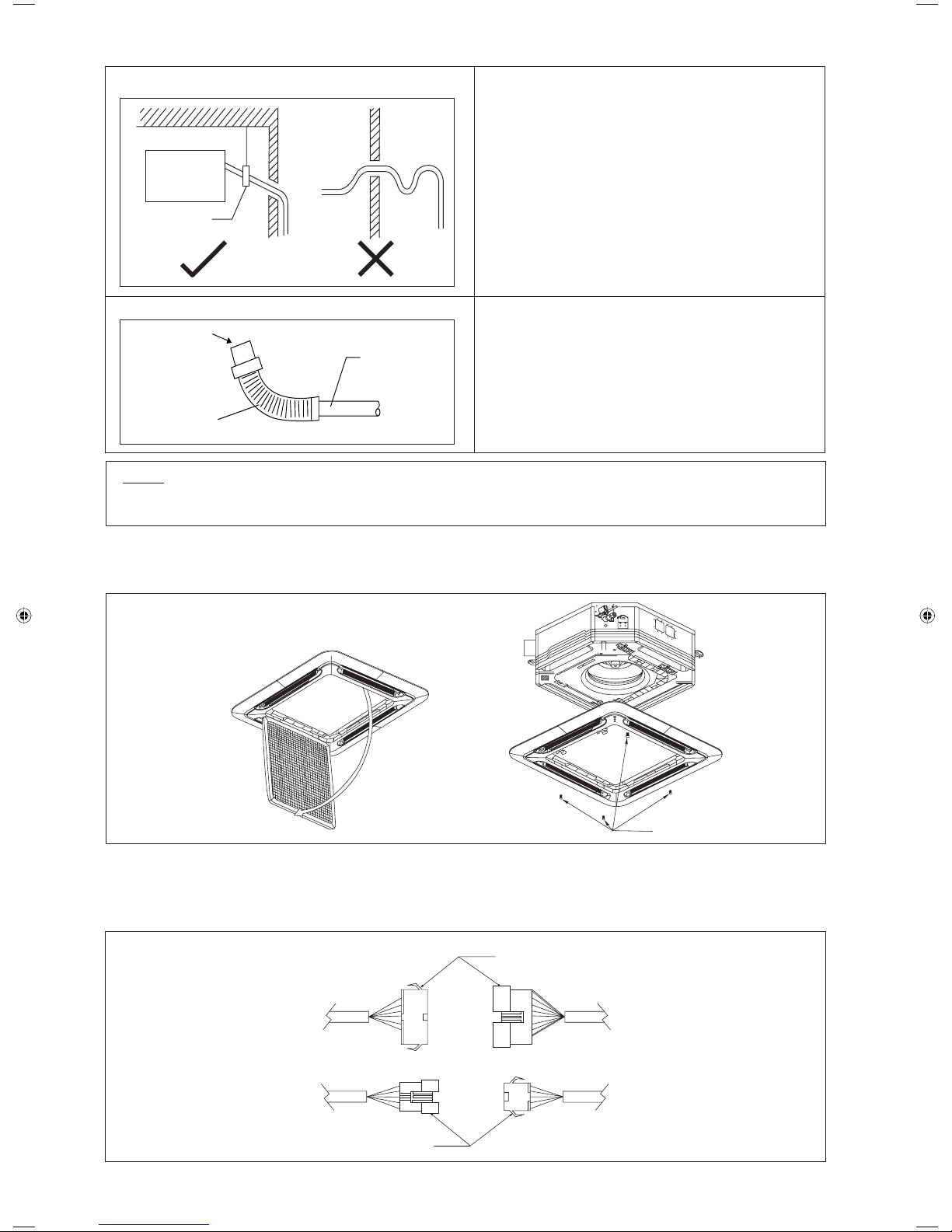

•

The front panel can only be fi tted in one direction, follow the piping direction. (Follow piping arrow sticker on front panel)

• Be sure to remove the installation template before installing the front panel.

Panel Installation

• Open the air intake grille by pulling back the catchers and removing it together with fi lter from panel.

• Install the front frame panel onto the indoor unit by 4 screws and tighten it completely to prevent cool air leakage.

• Connect the LED wire and air swing wire to the indoor unit.

• The air swing connector must put inside the control box after connected.

NOTE

This Indoor Unit uses a drain pump for condensed water drainage. Install the unit horizontally to prevent water leakage

or condensation around the air outlet.

Indoor Unit

Pipe Clamp

Feed Water

Flexible Drain Hose

Main Drain Pipe

•

Drain pipe must be in downward gradient for smooth

drainage.

•

Avoid installing the drain pipe in up and down slope to

prevent reversed water fl ow.

•

During the drain pipe connection, be careful not to exert

extra force on the drain connector at indoor unit.

•

The outside diameter of the drain connection at the

fl exible drain hose is 20 mm.

•

Be sure to execute heat insulation (polyethylene foam

with thickness more than 8.0 mm) on the drain piping to

avoid the condensed water dripping inside the room.

• Connect the main drain pipe to the fl exible drain.

• Feed water from fl exible drain hose to check the piping

for leakage.

• When the test is completed, connect the fl exible drain

hose to the drain connector on the indoor unit.

Drain Pump Work

Drain Test

Page 11

1-9

English

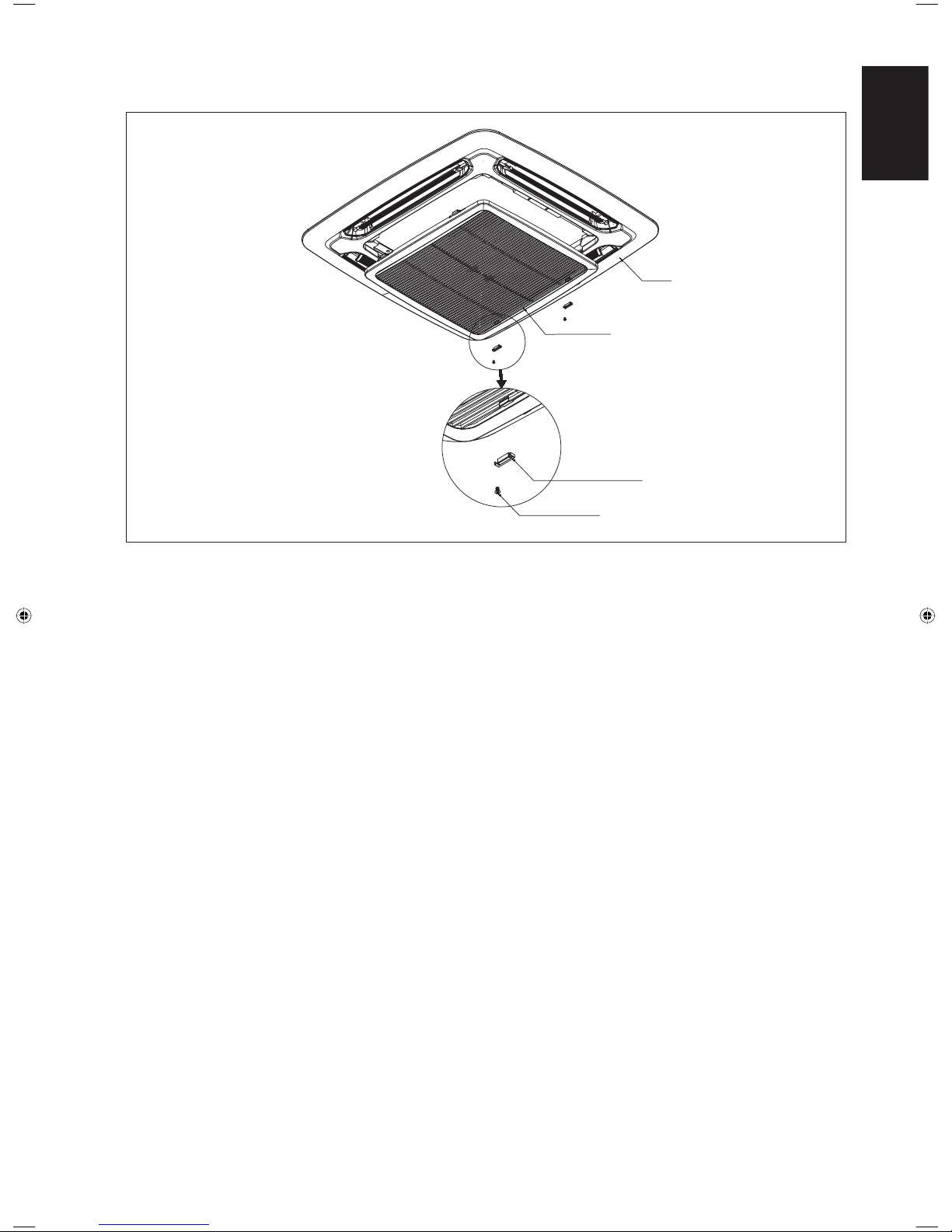

Frame

Intake Grille

Cover Lock Grille

(2pcs)

Screw M4 x 6

(2pcs)

Cover Lock Grille (The moving part protection for user direct touching)

Cover lock grill must be installed as the fi gure below.

If the unit need to be service, steps below shall be followed:

1. Confi rm that the unit had been switched off before servicing the unit.

2. Use screwdriver to unlock the screw on the cover lock grille.

3. Remove the cover lock grille and open the intake grille for the service purpose.

4. Install the intake grille and screw the cover lock grille after service and make sure the unit is proper install.

Page 12

1-10

Figure 2 Figure 3

Figure 4 Figure 5

Wires Installation

Figure 1 and Figure 2 shows the location of cover wire in CKE unit.

Steps to install power supply wires and wires from outdoor unit.

1. Remove wire cover by removing 2 screws as shown in Figure 3.

2. Wires will go through the hole as shown in Figure 4 and 5 respectively without crossing the height of the hole.

3. After that, wire cover will be assembled back to close the wire.

Figure 1

! CAUTION

Do not install the unit at altitude over 2000m for both indoor and outdoor.

Page 13

1-11

English

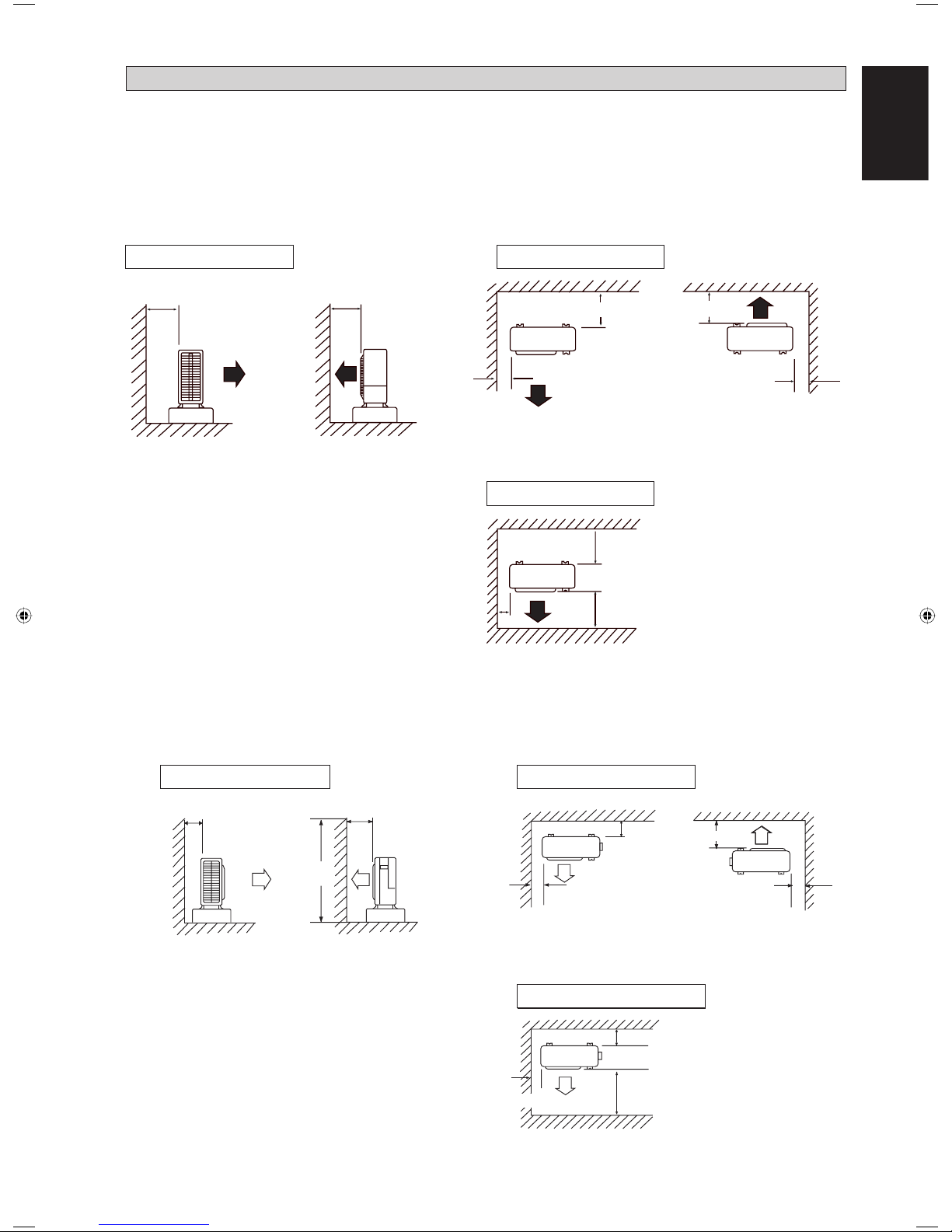

• The outdoor unit must be installed in such a way, so as to prevent short circuit of the hot discharged air or obstruction to

the smooth air fl ow. Please follow the installation clearance shown in the fi gures below. Select the coolest possible place

where intake air temperature is not greater than the outside air temperature.

• Where a wall or other obstacles is in the path of outdoor unitʼs intake or exhaust airfl ow, follow the installation guidelines

below.

• For any of the below installation patterns, the wall height on the exhaust side should be 1200mm or less.

5SLY20/25C/CR

More than 50 More than 100

Side View

Top View

Top View

More than 50

More than 50

More than 50

More than 150

More than 100

More than 150

More than 300

Unit: mm

INSTALLATION OF THE OUTDOOR UNIT

Wall facing one side

More than 100 More than 350

More than 50

More than 50

Top View

Top View

Side View

More

than 100

More than 350

More than 100

More than 350

Unit: mm

5SLY28CR

1200

or less

More than 50

Wall facing two sides

Wall facing two sides

Wall facing one side Wall facing two sides

Wall facing three sides

Page 14

1-12

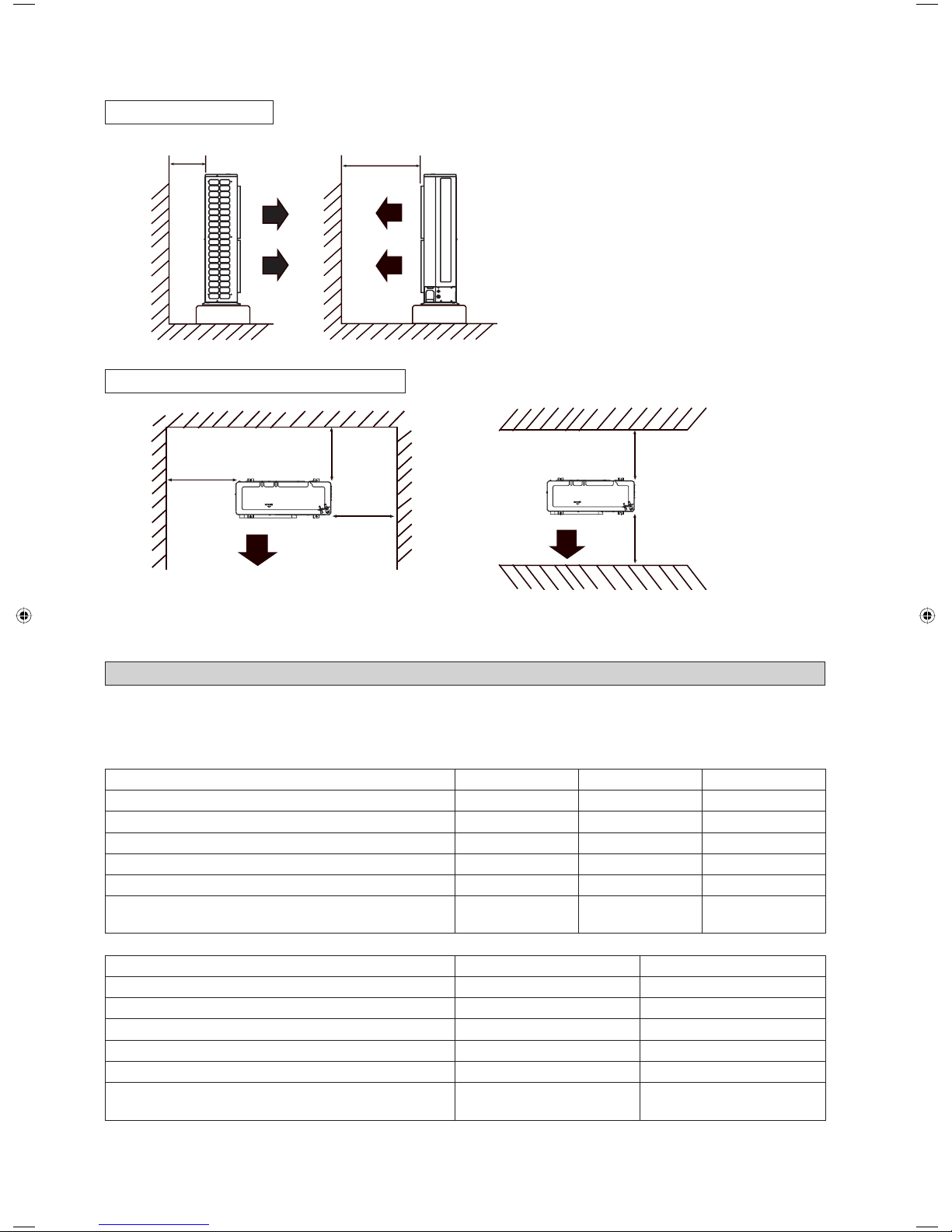

5SLY40/50FR

More than 100 More than 500

More

than 100

More

than

100

More than 100

More than 100

More than 500

• Allow more space for installation above with additional obstacle at top side and installation in series.

Top View

Side View

Unit: mm

REFRIGERANT PIPING

Indoor 5CKY20E/ER 5CKY25E/ER 5CKY28ER

Outdoor 5SLY20C/CR 5SLY25C/CR 5SLY28CR

Max. allowable length, m 30 30 50

Max. allowable elevation, m 10 10 30

Liquid pipe size, mm/(in) 6.35 (1/4") 6.35 (1/4") 9.52 (3/8")

Gas pipe size, mm/(in) 12.70 (1/2") 15.88 (5/8") 15.88 (5/8")

Additional charge of refrigerant, g/m

(for piping length above 7.5m)

20 20 50

Indoor 5CKY40ER 5CKY50ER

Outdoor 5SLY40FR 5SLY50FR

Max. allowable length, m 75 75

Max. allowable elevation, m 30 30

Liquid pipe size, mm/(in) 9.52 (3/8") 9.52 (3/8")

Gas pipe size, mm/(in) 15.88 (5/8") 15.88 (5/8")

Additional charge of refrigerant, g/m

(for piping length above 30m)

50 50

Allowable Piping Length

When the pipe length becomes too long, both the capacity and reliability drop. As a result, compressor reliability will be

affected. Always choose the shortest path and follow the recommendation as tabulated below:

Wall facing one side

Wall facing more than 1 side of obstacle

Page 15

1-13

English

D

A

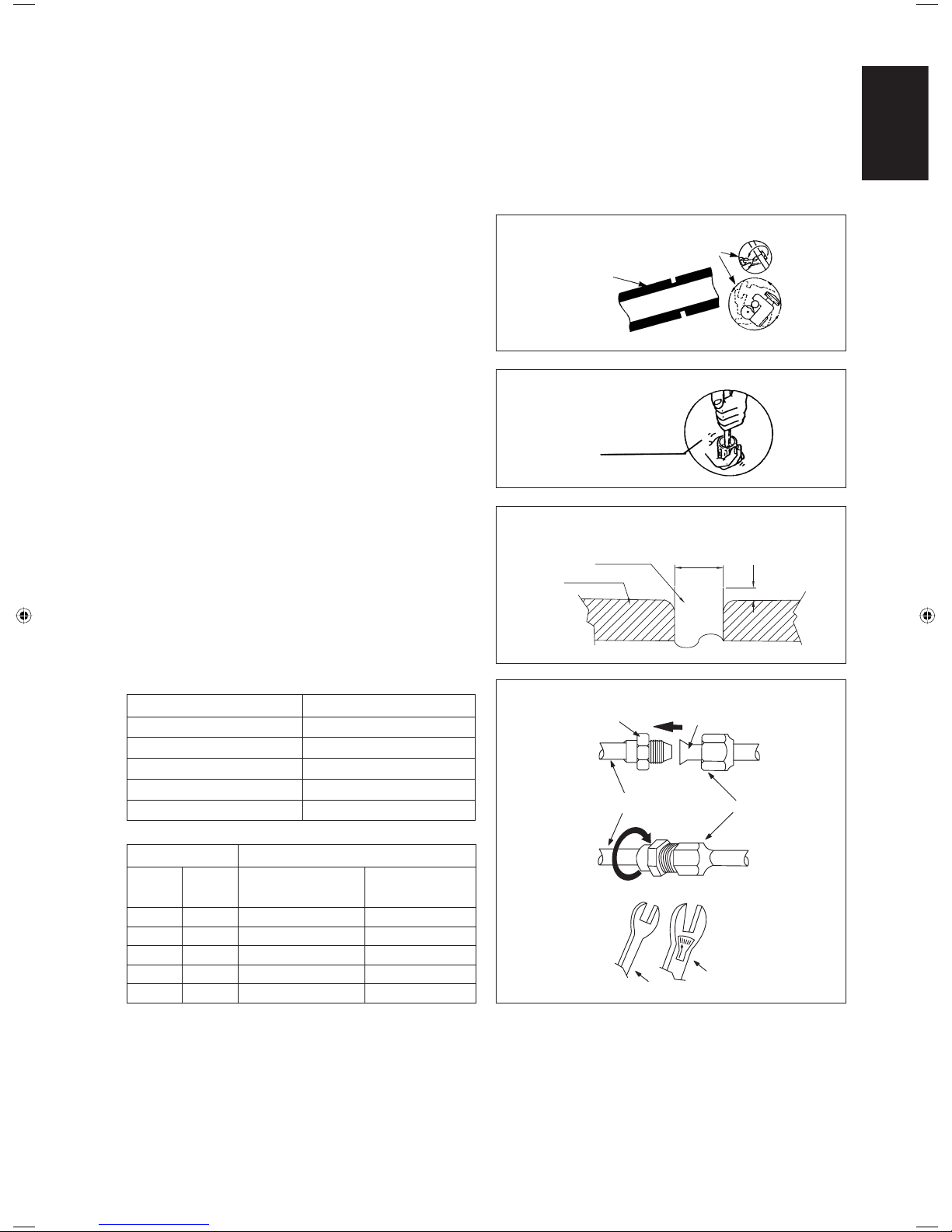

Piping Works And Flaring Technique

• Do not use contaminated or damaged copper tubing. If any pipings, evaporator or condenser had been exposed or had been

opened for 15 seconds or more, the system must be vacuumed. Generally, do not remove plastic, rubber plugs and brass

nuts from the valves, fi ttings, tubings and coils until it is ready to connect suction or liquid line into valves or fi ttings.

• If any brazing work is required, ensure that the nitrogen gas is passed through coil and joints while the brazing work is

being done. This will eliminate soot formation on the inside walls of the copper tubings.

• Cut the pipe stage by stage, advancing the blade of the pipe cutter slowly. Extra force and deep cut will cause more distortion

on the pipe and thus extra burr. See Figure A.

Cutting Copper Tube

Fig. B

Fig. A

Remove Burr

Fig. C

Copper Tube

Swaging Block

• Remove burrs from cut edges of the pipes with remover

as shown in Figure B. This will avoid unevenness on the

fl are faces which will cause gas leak. Hold the pipe on

top position and burr remover at lower position to prevent

metal chips from entering the pipe.

• Insert the fl are nuts, mounted on the connection parts of

both the indoor unit and outdoor unit, into the copper

pipes.

• The exact length of pipe protruding from the top surface of

the swaging block is determined by the fl aring tool. Refer

Figure C.

• Fix the pipe fi rmly on the swaging block. Match the centers

of both the fl are die and the fl aring punch, and then tighten

the fl aring punch fully.

Piping Connection To The Units

• Align the center of the piping and tighten the fl are nut

suffi ciently with fi ngers. Refer Figure D.

• Finally, tighten the fl are nut with the torque wrench until

the wrench clicks.

• When tightening the fl are nut with the torque wrench,

ensure that the tightening direction follows the arrow

indicated on the wrench.

• The refrigerant pipe connection are insulated by closed

cell polyurethane.

Spanar

Torque Wrench

Indoor Piping

Flare Nut

Flared Tube

Flare Joint

Fig. D

Ø Tube, D A (mm)

Inch mm Imperial

(Wing-nut Type)

Rigid

(Clutch Type)

1/4" 6.35 1.3 0.7

3/8" 9.52 1.6 1.0

1/2" 12.70 1.9 1.3

5/8" 15.88 2.2 1.7

3/4" 19.05 2.5 2.0

Pipe Size (mm/in) Torque (Nm/ft-lb)

6.35 (1/4) 18 (13.3)

9.52 (3/8) 42 (31.0)

12.70 (1/2) 55 (40.6)

15.88 (5/8) 65 (48.0)

19.05 (3/4) 78 (57.6)

1/4t

Page 16

1-14

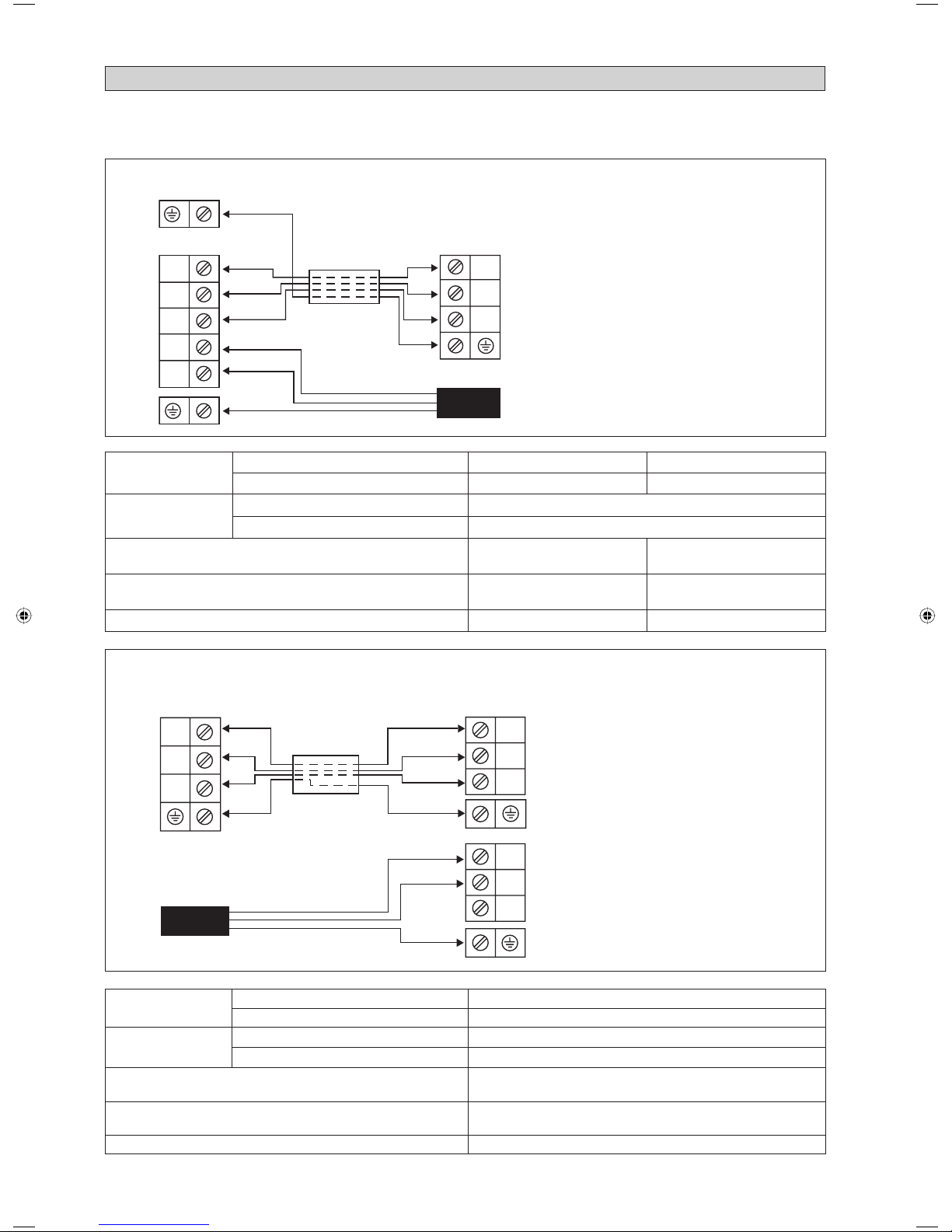

Power Supply Cable

Outdoor Unit

Terminal Block

Indoor Unit

Terminal Block

L

N

SIG

2

1

SIG

2

1

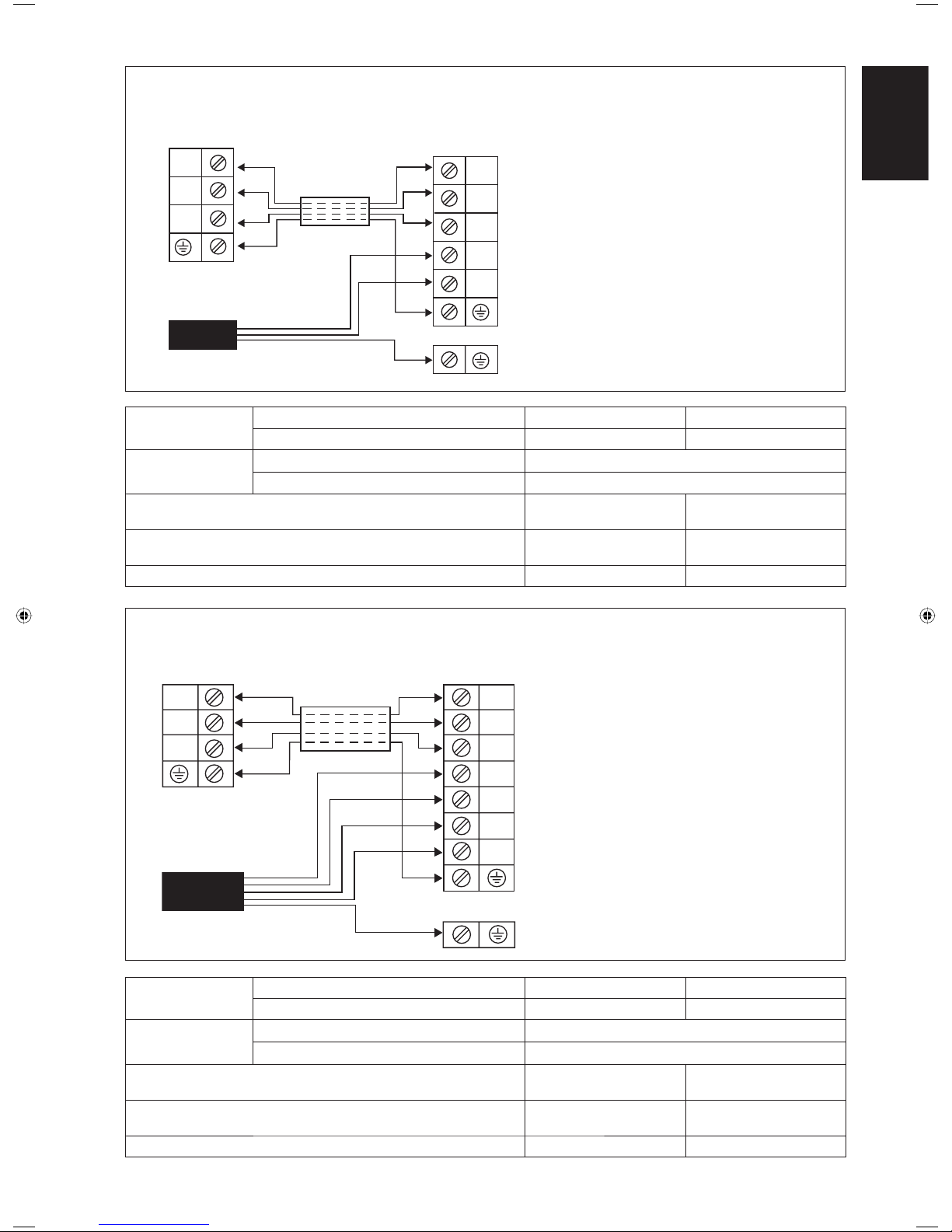

5CKY20/25E/ER - 5SLY20/25C/CR

IMPORTANT: *

These values are for information only, they should be checked and selected to comply with the local and/or national

codes and regulations. They are also subjected to the type of installation and size of conductors used.

**

The appropriate voltage range should be checked with the label data on the unit.

Interconnection

Cable

ELECTRICAL CONNECTION

Model Indoor 5CKY20E/ER 5CKY25E/ER

Outdoor 5SLY20C/CR 5SLY25C/CR

Voltage range** Indoor

220V - 240V /1Ph /50Hz + !

Outdoor

220V - 240V /1Ph /50Hz + !

Power supply cable size* mm

2

Number of conductors

2.5

3

2.5

3

Interconnection cable size* mm

2

Number of conductors

2.5

4

2.5

4

Recommended time delay fuse* A 20 20

5CKY28ER - 5SLY28CR

Indoor Unit

Terminal Block

L

Interconnection

Cable

Model Indoor 5CKY28ER

Outdoor 5SLY28CR

Voltage range** Indoor

220V - 240V/1Ph/50Hz + !

Outdoor

220V - 240V/1Ph/50Hz + !

Power supply cable size* mm

2

Number of conductors

2.5

3

Interconnection cable size* mm

2

Number of conductors

1.5

4

Recommended time delay fuse* A 25

Power Supply Cable

There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

!

There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

!

Outdoor Unit

Terminal Block

N

SIG

SIG

N

L

N

L

Page 17

1-15

English

3

2

1

3

2

1

L1

L2

L3

N

Power Supply Cable

Outdoor Unit

Terminal Block

Indoor Unit

Terminal Block

5CKY40ER - 5SLY40FR (1 Phase)

5CKY50ER - 5SLY50FR (1 Phase)

3

2

1

2

1

3

L

N

Interconnection

Cable

Model Indoor 5CKY40ER 5CKY50ER

Outdoor 5SLY40FR 5SLY50FR

Voltage range** Indoor

220V - 240V/1Ph/50Hz + !

Outdoor

220V - 240V/1Ph/50Hz + !

Power supply cable size* mm

2

Number of conductors

6

3

6

3

Interconnection cable size* mm

2

Number of conductors

1.5

4

1.5

4

Recommended time delay fuse* A 32 32

5CKY40ER - 5SLY40FR (3 Phase)

5CKY50ER - 5SLY50FR (3 Phase)

There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

!

Model Indoor 5CKY40ER 5CKY50ER

Outdoor 5SLY40FR 5SLY50FR

Voltage range** Indoor

220V - 240V/1Ph/50Hz + !

Outdoor

380V - 415V/3N~/50Hz + !

Power supply cable size* mm

2

Number of conductors

4

5

4

5

Interconnection cable size* mm

2

Number of conductors

1.5

4

1.5

4

Recommended time delay fuse* A 20 20

Power Supply Cable

Indoor Unit

Terminal Block

Interconnection

Cable

Outdoor Unit

Terminal Block

There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

!

Page 18

1-16

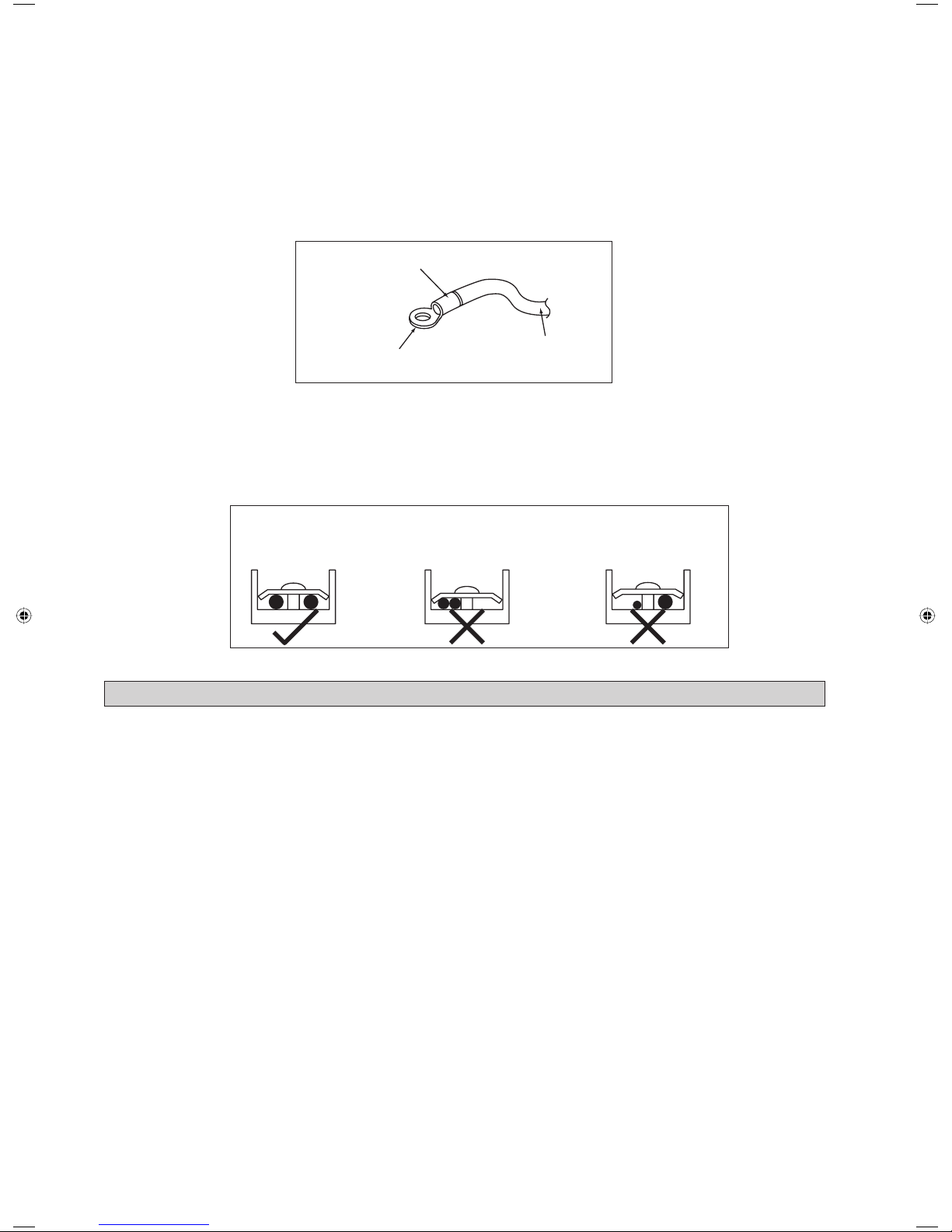

Attach insulation sleeve

Round crimp-style terminal

Electric wire

Connect wires of the

same gauge to both side.

Do not connect wires of the

same gauge to one side.

Do not connect wires

of different gauges.

• All wires must be fi rmly connected.

• Make sure all the wire do not touch the refrigerant pipings, compressor or any moving parts.

• The connecting wire between the indoor unit and the outdoor unit must be clamped by using provided cord anchorage.

• The power supply cord must be equivalent to H07RN-F which is the minimum requirement.

• Make sure no external pressure is applied to the terminal connectors and wires.

• Make sure all the covers are properly fi xed to avoid any gap.

• Use round crimp-style terminal for connecting wires to the power supply terminal block. Connect the wires by matching

to the indication on terminal block. (Refer to the wiring diagram attached on the unit).

• Use the correct screwdriver for terminal screws tightening. Unsuitable screwdrivers can damage the screw head.

• Over tightening can damage the terminal screw.

• Do not connect wire of different gauge to same terminal.

• Keep wiring in an orderly manner. Prevent the wiring from obstructing other parts and the terminal box cover.

R410A is a new HFC refrigerant which does not damage the

ozone layer. The working pressure of this new refrigerant is 1.6

times higher than conventional refrigerant (R22), thus proper

installation / servicing is essential.

• Never use refrigerant other than R410A in an air conditioner

which designed to operate with R410A.

• POE or PVE oil is used as lubricant for R410A

compressor, which is different from the mineral oil used

for R22 compressor. During installation or servicing, extra

precaution must be taken not to expose the R410A system

too long to moist air. Residual POE or PVE oil in the piping

and components can absorb moisture from the air.

• To prevent mischarging, the diameter of the service port

on the fl are valve is different from that of R22.

• Use tools and materials exclusively for refrigerant R410A.

Tools exclusively for R410A are manifold valve, charging

hose, pressure gauge, gas leak detector, fl are tools, torque

wrench, vacuum pump and refrigerant cylinder.

• As an R410A air conditioner incurs higher pressure

than R22 units, it is essential to choose the copper pipes

correctly. Never use copper pipes thinner than 0.8mm even

though they are available in the market.

• If the refrigerant gas leakage occurs during installation /

servicing, be sure to ventilate fully. If the refrigerant gas

comes into contact with fi re, a poisonous gas may occur.

• When installing or removing an air conditioner, do not

allow air or moisture to remain in the refrigerant cycle.

SPECIAL PRECAUTIONS WHEN DEALING WITH R410A UNIT

Page 19

1-17

English

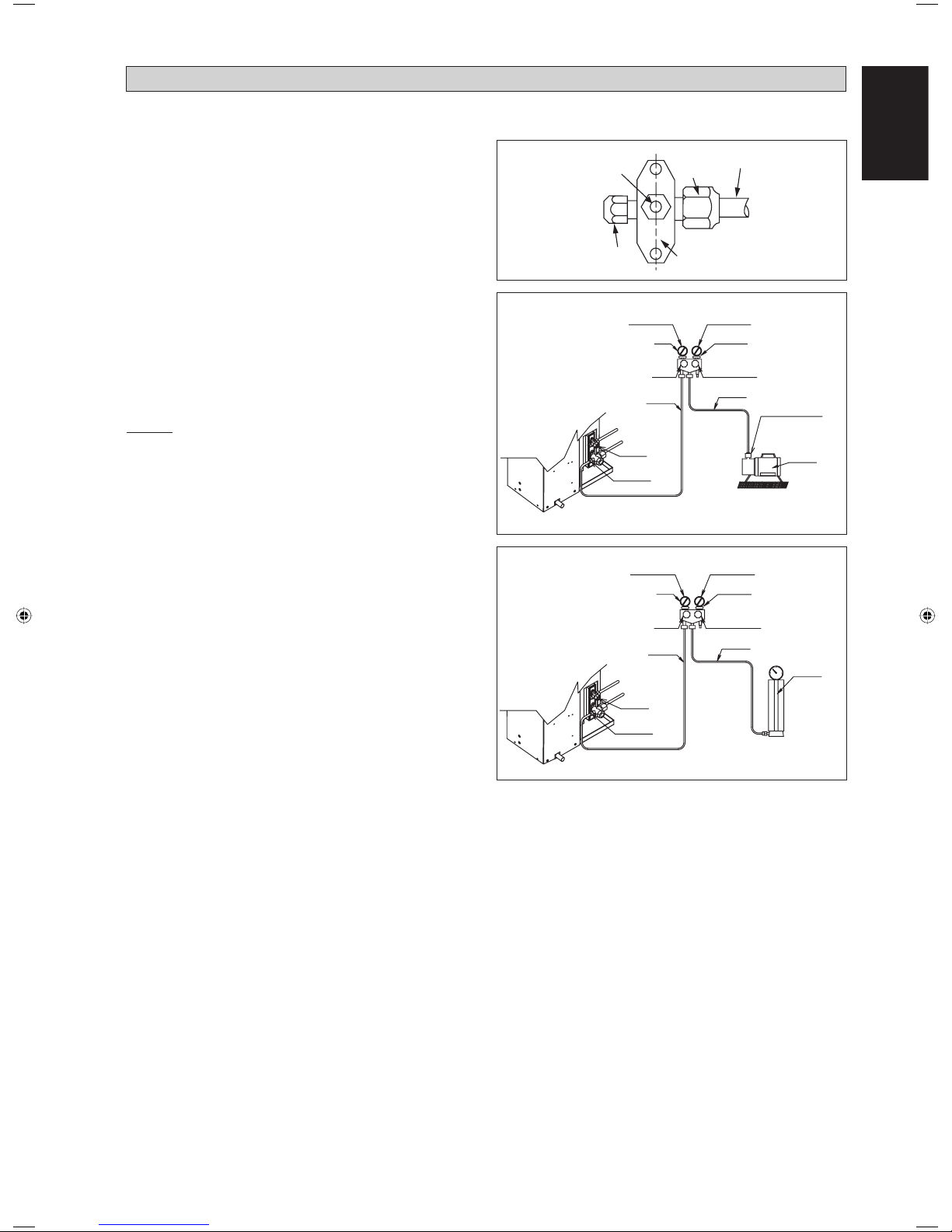

Vacuuming is necessary to eliminate all moisture and air from the system. The series II Outdoor Unit is provided with fl are

valve fi ttings.

Vacuuming The Piping And The Indoor Unit

Except for the outdoor unit which is pre-charged with

refrigerant, the indoor unit and the refrigerant connection

pipes must be air-purged because the air containing moisture

that remains in the refrigerant cycle may cause malfunction

of the compressor.

• Remove the caps from the valve and the service port.

• Connect the center of the charging gauge to the vacuum

pump.

• Connect the charging gauge to the service port of the 3-way

valve.

• Start the vacuum pump. Evacuate for approximately 30

minutes. The evacuation time varies with different vacuum

pump capacity. Confi rm that the charging gauge needle has

moved towards -760mmHg.

Caution

• If the gauge needle does not move to -760mmHg, be sure to

check for gas leaks (using the refrigerant detector) at fl are

type connection of the indoor and outdoor unit and repair

the leak before proceeding to the next step.

• Close the valve of the changing gauge and stop the vacuum

pump.

• On the outdoor unit, open the suction valve (3 way) and

liquid valve (2 way) (in anti-clockwise direction) with 4mm

key for hexagon sacked screw.

Charge Operation

This operation must be done by using a gas cylinder and a

precise weighing machine. The additional charge is topped-up

into the outdoor unit using the suction valve via the service

port.

• Remove the service port cap.

• Connect the low pressure side of the charging gauge to the

suction service port center of the cylinder tank and close

the high pressure side of the gauge. Purge the air from the

service hose.

• Start the air conditioner unit.

• Open the gas cylinder and low pressure charging valve.

• When the required refrigerant quantity is pumped into

the unit, close the low pressure side and the gas cylinder

valve.

• Disconnect the service hose from service port. Put back the

service port cap.

VACUUMING AND CHARGING

Refrigerant Piping

Outdoor Unit 3 ways valve

Allen key

Service Port

Flare nut

HIGH PRESSURE GAUGE

GAUGE MANIFOLD

LOW PRESSURE GAUGE

HANDLE HI (ALWAYS CLOSED)

CHARGE HOSE

-760mmHg

HANDLE LO

CHARGE HOSE

VACUUM PUMP

ADAPTER FOR

COUNTER FLOW

PREVENTION

CHECK VALVE

LIQUID VALVE

HIGH PRESSURE GAUGE

LOW PRESSURE GAUGE

GAUGE MANIFOLD

-760mmHg

HANDLE LO

HANDLE HI (ALWAYS CLOSED)

CHARGE HOSE

CHARGE HOSE

CHECK VALVE

LIQUID VALVE

GAS VALVE

(3-WAY)

CONFIGURATION OF AIR

PURGE BY CHARGING

CONFIGURATION OF AIR

PURGE BY CHARGING

GAS VALVE

(3-WAY)

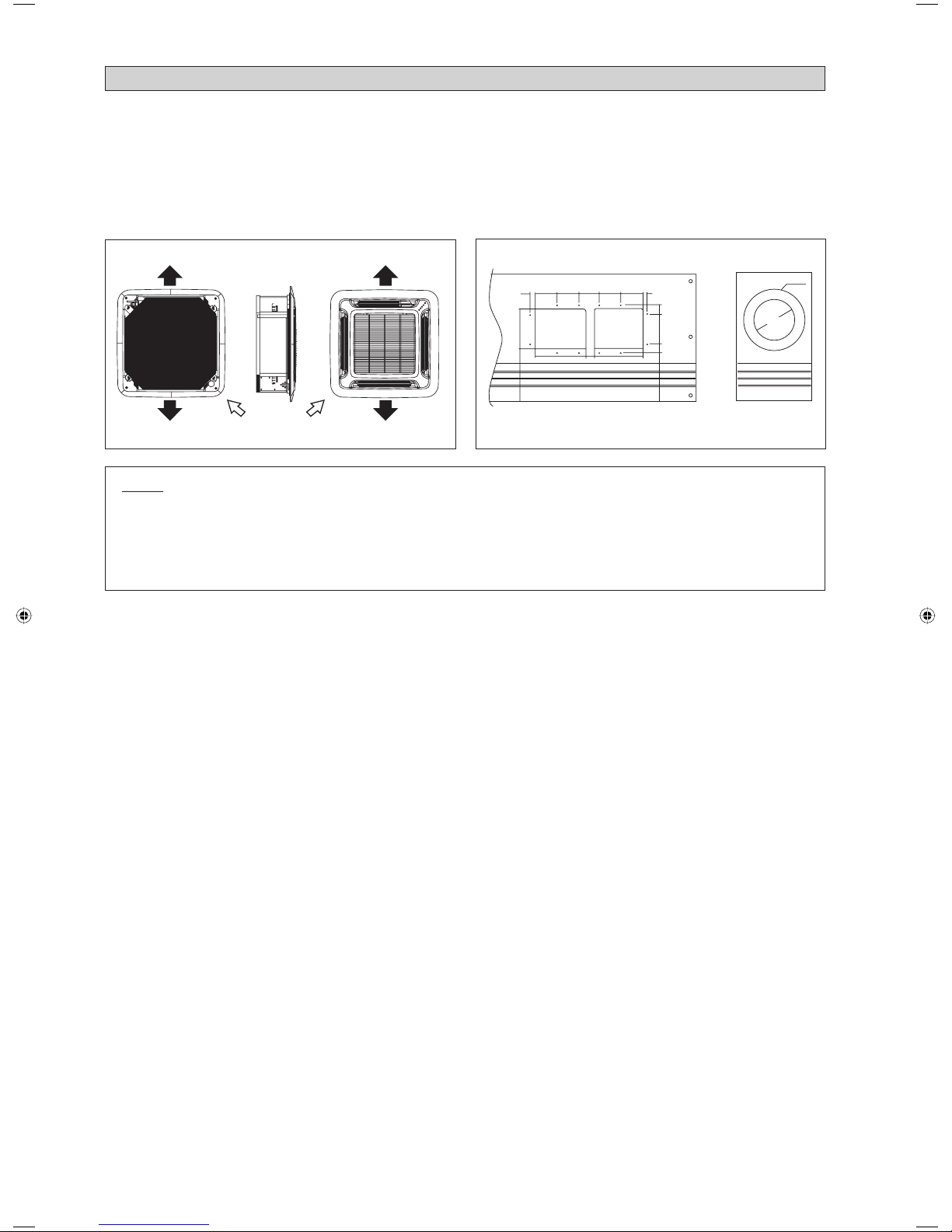

Page 20

1-18

Sealing Material

• It is possible to seal one of the four air discharge outlet. (sealing two or more air discharge outlet could cause a

malfunction)

• Remove the front panel and insert the sealing material into the air discharge outlet on the indoor unit to seal the air

outlet.

• The sealing material is the same length as the longer air discharge outlet. If it is desired to seal the shorter air discharge

outlet, cut the sealing material to shorten it.

• Push the sealing material in about 10 mm beyond the bottom surface of the indoor unit so that it does not touch the air

louver. Be sure not to push the sealing material in any farther than about 10mm.

Short Duct Specifi cation

• The indoor unit is provided with air discharge and air intake “knock-out” hole for duct connection. However the connection

of the short duct for air discharge is possible on only one side.

• The use of short duct for air discharge will improve airfl ow distribution if there is an obstruction (such as a lighting fi xture)

or in a long, narrow room or an L-shaped room. It also use for air conditioning of two rooms simultaneously.

Possible Opening Dimension For Duct Connection

Air Discharge Knock Out Hole

Air Intake Knock

Out Hole

Possible Direction For Air Discharge And Air Intake

Air Intake

Air DischargeAir Discharge

Air Discharge Air Discharge

10

50 50 50 50 50 10

207020

90

Ø100

PCD Ø140

115 20 115

ACCESSORY PARTS

NOTE

• Avoid using the short duct on which the air discharge grille can be completely closed, to prevent evaporator

freezing.

• In order to prevent condensation forming, be sure that there is suffi cient thermal insulation and no leakage of cool

air when installing the short duct.

• Keep the introduction of fresh air intake within 20% of total air fl ow. Also provide chamber and use booster fan.

Page 21

1-19

English

As shown in Figure above, it is recommended to move the

unit by grabbing the left and right grip. Place your hands on

the corner to avoid deforming of the casing.

Figure 1

A total of 4 direction options (refer fi gure 2a) for connecting

pipe (w, x, y, z) are available for your convenience.

Cutting out the 2 slits with a metal saw make it possible to

install as shown in Figures 2a.

In order to make the connecting pipe in a downward direction

(refer Figure 2b), make a knockout hole by drilling through

the center area around the knockout hole.

It is recommended to use a Ø6mm drill for this process

(refer Figure 2c).

After completing the knockout process, it is recommended

to apply repair paint to the edge and surrounding surfaces to

prevent rusting.

Z

Y

X

W

Figure 2a

Figure 2b

Figure 2c

1. Handling

2. Refrigerant piping

Cover the pipe through-holes with

insulation material to conceal all gaps

to prevent small animals or insects from

entering the outdoor unit which may

result short circuit in the control box.

Figure 3

3. Caution for handling service port

To be able to recover all remaining refrigerant at charge

hose, always use a fl exible charge hose with a push-rod and

valve. After the work, tighten the valve cover in place with

tightening torque: 11.5~13.9N.m

4. Charging refrigerant

For cases where complete recharge of refrigerant is required,

vacuuming via service part is mandatory, do not use stop valve

port in this case because vacuuming through this stop valve

port can not be executed completely.

Outdoor units have 1 port on the piping. It is between the heat

exchanger and the 4-way valve.

5. Pump-down operation

Never by-pass the low pressure switch or low pressure sensor

during pump down operation.

Power supply must be cut off before pump-down operation.

After opening the front panel, cover the PCB and terminal

board with insulation sheet to avoid electric shock by

accidental touching of LIVE parts.

Do not leave the unit unattended if the front panel is open.

Close the front panel before leaving the outdoor unit.

Turn on the power supply and carry out pumping-down

operation according to the steps written at front panel.

6. Electrical wiring work

BELOW INFORMATION IS APPLICABLE FOR 5SLY40/50FR ONLY

Figure 4

Secure the ground wire to the stop valve attachment plate

(refer Figure 4) so that it does not slide.

Ensure the front cover does not rise up after the wiring work

is down. Close the front cover securely.

1

2

1

2

Figure 5

When cables are routed from the unit, a protection sleeve for

the conduits can be inserted at the knock-out hole.

It there is no wire conduit, do protect the wires with

vinyl tubes to prevent cutting the wires by sharp edges of

knock-out hole.

1 Power supply wiring and earth wire

2 Interconnection wire

Page 22

1-20

20

18

10

0

-10

-15

-20-20

10 15 20 25 27 30

50

46

43

40

20

30

10

0

-10

10 1415 19 20 23 25

COOLING HEATING

INDOOR TEMP. WB (˚C) INDOOR TEMP. DB (˚C)

DB: Dry bulb WB: Wet bulb

OUTDOOR TEMP. DB (˚C)

OUTDOOR TEMP. WB (˚C)

OPERATING RANGE

Page 23

1-21

English

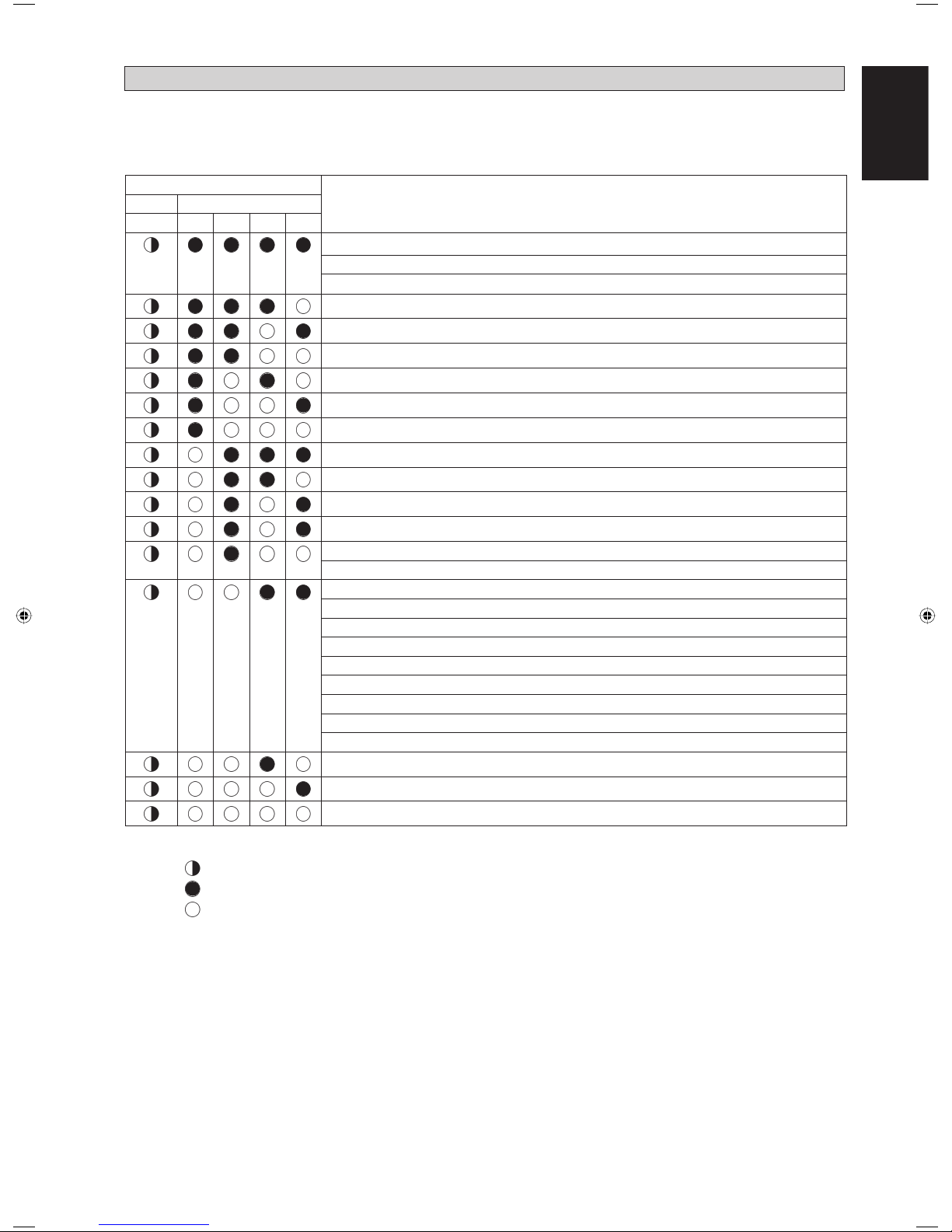

INDICATOR LIGHTS

Fault Diagnosis

LED INDICATION

DescriptionGreen Red

A1234

NORMAL

INSTALLATION ERROR

ANTIFREEZE (OTHER ROOMS)

HEAT SINK OVERHEAT

IPM ERROR/IGBT ERROR

INSUFFICIENT GAS

AC INPUT OVER CURRENT

COMPRESSOR START-UP ERROR

COMMUNICATION ERROR (OUTDOOR CONTROL PCB AND IPM PCB)

4 WAY VALVE ERROR

DC VOLTAGE OUT OF RANGE

COMPRESSOR MOTOR LOCK/COMPRESSOR OVERLOADED

DISCHARGE PIPE OVERHEAT

ANTIFREEZE (COOLING)/HEAT EXCHANGER OVERHEAT (HEATING)

HEAT EXCHANGER OVERHEAT

COMPRESSOR SENSOR SYSTEM ERROR

COMPRESSOR FEEDBACK DETECTION ERROR

AC CURRENT SENSOR ERROR

OUTDOOR AIR THERMISTOR SHORT/OPEN

COMPRESSOR DISCHARGE PIPE THERMISTOR SHORT/OPEN/MISPLACED

OUTDOOR HEAT EXCHANGER THERMISTOR SHORT/OPEN

LIQUID PIPE THERMISTOR SHORT/OPEN

GAS PIPE THERMISTOR SHORT/OPEN

HEAT SINK THERMISTOR SHORT/OPEN

OUTDOOR CONTROL BOX OVERHEAT

OUTDOOR PCB ERROR

OUTDOOR DC FAN MOTOR LOCK

The outdoor unit LED indicates the running condition of the system:

If faulty condition occurs, please contact the nearest local dealer or qualifi ed service personnel. Do not attempt to

troubleshoot the unit yourself. For any enquiries on spare parts please contact your authorized dealer.

Legend

Blinks

Off

On

5SLY28CR

Page 24

MEMO

Page 25

2-1

Français

Unité Intérieure 5CKY20/25E/ER & 5CKY28/40/50ER

A

B

C

D

E

F

H

K

J

I

G

Traduction des instructions dʼorigine

Toutes les dimensions sont données en mm

CONTOUR ET DIMENSIONS

Dimension

Modèle

ABCDE FGH I JK

5CKY20/25E/ER

5CKY28ER

820 820 340 300 40 990 990 627 627 607 430

5CKY40/50ER 820 820 375 335 40 990 990 627 627 607 430

Unité Extérieure 5SLY20/25C/CR

N

L

KL

TN

M

A

D

O

PBQ

RS

C

HG

FE

IJ

Dimension

Modèle

ABCDE FGH I JKLMNOPQRST

5SLY20/25C/CR

855 730 328 513 182 44 93 149 101 113 603 126 164 15 47 3 23 73 75 362

Toutes les dimensions sont données en mm

Page 26

2-2

Unité Extérieure 5SLY28CR

A

D

K

E

S

T

S

T

GRR

OMN

H

P

Q

L

C

FU

J

B

I

Dimension

Modèle

ABCDE FGH I JKLMNOPQRSTU

5SLY28CR

940 348 753 855 392 733 603 328 303 370 362 448 190 80 58 180 32 126 32 15 23

Page 27

2-3

Français

Unité Extérieure 5SLY40/50FR

AB AC AD

AE

AFAG

AH

AI

AA

AJ

AK

A

C

B

D

F

E

L

M

KJ

NO

Q

P

R

S

T

U

V

W

Z

X

Y

AT

AS

H

G

AU

AP

AQ

AO

AL

AM

AN

Dimension

Modèle

ABCDE FGH I JKLMN

5SLY40/50FR

900 1374 30 24 60 89 142 89 19 54 95 423 430 95

OPQRSTUVWXYZ

54 19 89 145 84 55 55 223 148 13 52 67

AA AB AC AD AE AF AG AH AI AJ AK AL AM AN

350 140 620 140 30 320 30 59 43 40 94 117 102 70

AO AP AQ AR AS AT AU

45 376 191 70 58 16 16

Toutes les dimensions sont données en mm

AR

I

Page 28

2-4

PRÉCAUTIONS DE SÉCURITÉ

! ATTENTION ! AVERTISSEMENT

•

Lʼinstallation et la maintenance doivent être exécutées par une personne

qualifi ée qui est familiarisée avec les lois et réglementations en vigueur,

et aussi expérimentée dans ce type dʼéquipements.

•

Tous les câblages doivent répondre aux réglementations électriques

nationales.

•

Avant de commencer le raccordement suivant le schéma électrique,

sʼassurer que la tension nominale de lʼappareil corresponde bien à celle

indiquée sur la plaque signalétique.

•

Lʼunité doit être raccordée à la TERRE pour prévenir tous les risques

possibles dûes à un défaut dʼisolation.

•

Aucun câble électrique ne doit toucher la tuyauterie du réfrigérant, le

compresseur ou les pièces mobiles des moteurs de ventilation.

•

Avant lʼinstallation ou lʼentretien du climatiseur, sʼassurer que lʼappareil

est éteint (OFF).

•

Débrancher lʼappareil du circuit dʼalimentation secteur avant de procéder

à lʼentretien du climatiseur.

•

NE PAS retirer le câble dʼalimentation électrique de la prise quand

lʼappareil est sous branché. Il peut en résulter des décharges électriques

importantes susceptibles de provoquer un incendie.

•

Les unités intérieures et extérieures, le cordon dʼalimentation et le

câblage de transmission doivent rester à une distance dʼau moins 1m

des téléviseurs et des radios, ce afi n dʼéviter les images déformées et

les parasites. {En fonction du type et de la source des ondes électriques,

des parasites peuvent être entendus même avec une distance supérieure

à 1m}.

Vérifi er les points suivants au cours de lʼinstallation.

•

Ne pas installer lʼappareil où il peut se produire des fuites de gaz

infl ammable.

En cas de fuite et accumulation de gaz autour de lʼappareil, il y a

risque dʼincendie.

•

Sʼassurer que le tuyau dʼévacuation du condensat est correctement

branché.

Si le tuyau dʼévacuation nʼest pas correctement branché, les

éventuelles fuites dʼeau risquent de mouiller le mobilier.

•

Ne pas surcharger lʼunité (en fl uide frigorigène).

Cet appareil est préchargé en usine.

Une charge trop importante risque de provoquer une surcharge

électrique ou dʼendommager le compresseur.

•

Sʼassurer que le panneau supérieur de lʼappareil est remis en place

après lʼinstallation ou lʼentretien.

Avec un panneau mal fixé lʼ appareil va fonctionner

bruyamment.

•

Les bords coupants et les surfaces du refroidisseur tuulaire présentent

un risque de blessure.

Mieux vaut éviter le contact avec ces endroits.

•

Avant de couper lʼalimentation électrique, veiller à ce que

lʼinterrupteur ON/OFF de la télécommande soit en position

« OFF » afi n dʼéviter une mise en marche intempestive de lʼappareil.

Si lʼinterrupteur de la télécommande nʼest pas en position « OFF », les

ventilateurs de lʼappareil se mettront en marche dès que lʼalimentation

électrique est rétablie. Il peut en résulter un danger pour le personnel

dʼentretien ou lʼutilisateur.

•

Ne pas utiliser dʼappareil de chauffage trop près du climatiseur. Une

chaleur excessive peut déformer ou faire fondre le boîtier de plastic.

• Ne pas installer les appareils à proximité ou près dʼun passage de porte.

•

Ne pas utiliser un appareil de chauffage trop près dʼune unité de

climatisation ou lʼutiliser dans une pièce où, de lʼhuile minérale ou

de la vapeur dʼhuile existent, cela peut faire fondre ou se déformer

les pièces en plastique en raison de la chaleur excessive ou de réaction

chimique.

•

Lorsque lʼappareil est utilisé dans la cuisine, le garder loin de la

farine qui peut aller dans dʼaspiration de lʼappareil.

•

Cet appareil nʼest pas approprié pour une utilisation en usine

lorsquʼun brouillard dʼhuile de coupe ou de la poudre de fer existe

ou bien quand la tension fl uctue grandement.

•

Ne pas installer les unités à des endroits comme une source dʼeau

chaude ou une raffi nerie de pétrole où des gaz sulfureux existent.

•

Sʼassurer que la couleur des câbles de lʼunité extérieure et les

marquages de bornes sont identiques à ceux de lʼunité intérieure.

•

IMPORTANT: NE PAS INSTALLER OU UTILISER LE

CLIMATISEUR DANS UNE BUANDERIE.

•

Nʼutilisez pas de câbles joints et torsadés pour lʼalimentation

électrique entrante.

•

Évitez dʼappliquer directement des produits de nettoyage et de

traitement pour bobines sur les pièces en plastique. Une réaction

chimique pourrait se produire et déformer les pièces en plastique.

•

Pour tout renseignement concernant les pièces détachées, contacter

votre revendeur agree.

•

Lʼéquipement nʼest pas conçu pour une utilisation dans une

atmosphère potentiellement explosive.

Ce manuel fournit les procédures dʼinstallation pour assurer le bon fonctionnement et la sécurité de cet appareil.

Des ajustements peuvent être nécéssaires pour suivre les réglementations locales.

Avant dʼinstaller et de faire fonctionner le climatiseur, lisez attentivement ce manuel et conservez le.

Cet appareil est destiné à être utilisé par des utilisateurs experts ou formés dans les magasins, dans lʼindustrie légère ou dans les fermes,

oupour un usage commercial par des personnes non spécialisées.

MANUEL DʼINSTALLATION

AVIS

Instructions dʼélimination

Cet appareil de conditionnement dʼair porte le symbole ci-joint. Ce symbole signifi e que les appareils électriques et électroniques doivent être éliminés

séparément des ordures ménagères non triées.

Nʼessayez pas de démonter vous-même lʼappareil : le démontage de lʼappareil de conditionnement dʼair ainsi que le traitement du réfrigérant, de lʼhuile

et dʼautres composants doivent être effectués par un installateur qualifi é, en accord avec les réglementations locales et nationales en vigueur.

Les appareils de conditionnement dʼair doivent être traités dans des installations spécialisées de dépannage, réutilisation ou recyclage. En vous assurant

que cet appareil est éliminé correctement, vous contribuez à éviter les conséquences potentiellement néfastes sur lʼenvironnement et la santé. Veuillez

contacter votre installateur ou les autorités locales pour plus dʼinformation.

Les piles de la télécommande doivent être enlevées et éliminées séparément, conformément aux réglementations locales et nationales en vigueur.

Page 29

2-5

Français

IMPORTANT

Information importante relative au réfrigérant utilisé

Ce produit contient des gaz fl uorés à effet de serre encadrés par le Protocole de Kyoto.

Ne pas laisser les gaz sʼéchapper dans lʼatmosphère.

Type de réfrigérant : R410A

Valeur GWP

(1)

: 1975

(1)

GWP = potentiel de réchauffement global

Prière de compléter à lʼencre indélébile,

n 1 la charge de réfrigerant dʼusine du produit,

n 2 la quantité de réfrigérant supplémentaire chargée sur place et

n 1 + 2 la charge de réfrigérant totale

sur lʼétiquette de charge de réfrigérant fournie avec le produit.

Lʼétiquette complétée doit être apposée à proximité de lʼorifi ce de recharge du produit (par ex. à lʼintérieur du couvercle

dʼentretien).

1 charge de réfrigérant dʼusine du produit :

voir plaquette signalétique de lʼunité

(2)

2 quantité de réfrigérant supplémentaire chargée sur place

3 charge de réfrigérant totale

4 contient des gaz à effet de serre fl uorés relevant du Protocole de Kyoto

5 unité extérieure

6 cylindre de réfrigérant et collecteur de recharge

(2)

Dans le cas de multiples systèmes intérieurs, seule 1 étiquette doit être apposée*, mentionnant la charge de réfrigérant dʼusine

totale de toutes les unités intérieures raccordées au système de réfrigérant.

Des inspections périodiques de fuites de réfrigérant peuvent être exigées en fonction de la législation européenne ou locale.

Veuillez contacter votre distributeur local pour plus dʼinformations.

* sur lʼunité extérieure

Page 30

2-6

DIAGRAMME DʼINSTALLATION

Tuyauterie dʼévacuation

Grille avant

Filtre à air

(derrière la grille)

Conduait de ventilation

Enveloppez le tuyau isolé de bande

defi nition de bas en haut

Grilles de reprise dʼair

Isolation thermique

Reprise air

Reprise air

Refoulement dʼair

Unité intérieure

Unité extérieure

Page 31

2-7

Français

• Assurez-vous que lʼinclinaison de la tige suspendue est de

770mm 622mm.

• Mainrenez lʼunité et accrochez-la à la tringle dʼaccrochage

à lʼaide des écrous et des joints.

• Laissez un espace de 30 mm entre la surface inférieure de

lʼunité intérieure et la surface du plafond.

• A lʼaide dʼun indicateur de niveau, assurez-vous que lʼunité

est installée horizontalement et serrez lʼécrou et le boulon

pour empêcher que lʼunité ne tombe et ne vibre.

• Ouvrez le coffrage du plafond le long du bord extérieur du

gabarit dʼinstallation en papier.

Obstacle

1m ou plus

3m ou plus

Sol

0,5m ou plus 0,5m ou plus 0,5m ou plus

0,3m ou moins

Poutre

30 mm

Unité Intérieure

Plaque

de faux-

plafond

REMARQUE

Assurez-vous de discuter le perçage du plafond avec les

installateurs.

• Mesurez et marquez lʼemplacement de la tige suspendue.

Percez un trou pour lʼécrou dʼangle dans le plafond et fi xez

la tige suspendue.

• Le gabarit dʼinstallation est allongé selon la température et

lʼhumidité. Vérifi ez les dimensions utilisées.

• Les dimensions du gabarit dʼinstallation sont les mêmes

que celles des dimensions de lʼouverture du plafond.

• Lorsque le travail de stratifi cation du plafond nʼest pas

terminé, veillez à fi xer le gabarit dʼinstallation sur lʼunité

intérieure.

Accrochage de lʼunité

Installation de lʼunité

INSTALLATION DE LʼUNITÉ INTÉRIEURE

Etude Preliminaire Du Site

Veillez à lire ce manuel avant dʼinstaller lʼunité de climatisation intérieure.

• La fl uctuation de lʼalimentation secteur ne doit pas dépasser +10 % de la tension nominale. Les lignes dʼalimentation électrique

doivent être indépendantes des transformateurs de soudage qui pourraient provoquer de fortes fl uctuations dʼalimentation.

• Assurez-vous que lʼemplacement est pratique pour les câblages, la tuyauterie et lʼévacuation.

• Nʼexercez pas de pression sur les pièces en résine pour ouvrir lʼunité ou lors de son déplacement après lʼouverture.

• Ne sortez pas lʼunité de son emballage avant quʼelle ne soit sur son site dʼinstallation. Utilisez des matériaux ou des plaques

de protection lors du déballage ou du soulèvement de lʼunité afi n dʼéviter de lʼendommager ou de la rayer.

• Choisissez un emplacement:

a) Qui permet une évacuation facile.

b) Pratique pour le câblage et les tuyauteries.

c) Assez dégagé pour lʼinstallation et lʼentretien.

d) Exempt de risque de fuite de gaz infl ammable.

e) Où aucun obstacle ne bloque le jet dʼair froid et la reprise de lʼair chaud, et où lʼair peut se répandre dans la pièce (près

du centre de la pièce).

f) Un espace de dégagement doit être respecté entre lʼunité intérieure et les murs et obstacles comme le montre

lʼillustration.

g) Lʼendroit dʼinstallation doit être assez fort pour supporter une charge quatre fois supérieure au poids de lʼunité intérieure

pour éviter lʼamplifi cation du bruit et des vibrations.

h) Lʼendroit dʼinstallation (surface du plafond) doit être plane et la hauteur du plafond dʼau moins 350mm.

i) Lʼunité intérieure doit être à lʼécart de sources de chaleur ou de vapeur (évitez de lʼinstaller près dʼune entrée).

990,0mm

880,0~990,0mm (Site dʼouverture au plafond = 890mm)

770,0mm (Tige suspendue)

880,0~990,0mm (Site dʼouverture au plafond)

Direction Tuyauterie

622,0mm (Tige suspendue)

990,0mm

Page 32

2-8

Ouvert

Vis

Depuis le

boîtier de

commandes

de lʼunité

Du

panneau

avant

Fil de la DEL

Fil de direction dʼair

•

Le panneau avant ne tient que dans un sens, suivez la direction de la tuyauterie. (Suivez le sens de la fl èche de lʼautocollant sur le panneau

avant)

•

Assurez-vous dʼôter le gabarit dʼinstallation avant dʼinstaller le panneau avant.

Installation du panneau

•

Ouvrez la grille dʼaspiration dʼair en tirant le dispositif de prise de griffes et ôtez-la avec le fi ltre.

•

Installez le panneau du cadre avant sur lʼunité intérieure à lʼaide de 4 vis et serrez-les complètement pour éviter que lʼair froid ne

sʼéchappe.

•

Connectez le fi l du voyant DEL et le fi l de direction dʼair à lʼunité intérieure.

•

Le connecteur de direction dʼair doit être placé à lʼintérieur de lʼarmoire de commande après la connexion.

REMARQUE

Cette Unite Interieure utilise une pompe dʼevacuation pour lʼevacuation de lʼeau condensee. Installez lʼunite horizontalement pour eviter que

lʼeau ne fuie ou ne se condense autour du defl ecteur exterieur.

Unité Intérieure

Collier pour

tuyaux

Envoyez

lʼeau

Tuyau dʼévacuation fl exible

Tuyau

dʼévacuation

principal

•

Le tuyau dʼévacuation doit être incliné vers le bas pour une

évacuation facile.

•

Evitez de positionner le tuyau vers le haut puis vers le bas afi n

dʼéviter que le fl ux dʼeau ne soit inversé.

•

Lorsque vous connectez les tuyaux dʼévacuation, assurezvous de ne

pas exercer de pression supplémentaire sur le connecteur de lʼunité

intérieure.

•

Le diamètre extérieur du connecteur de drainage au tuyau fl exible

est de 20 mm.

•

Assurez-vous dʼisoler le tuyau dʼévacuation contre la chaleur

(mousse en polyéthylène de plus de 8,0 mm dʼépaisseur) afi n dʼéviter

que lʼeau condensée ne goutte à lʼintérieur de la piéce.

•

Connectez le tuyau dʼévacuation principal au tuyau dʼévacuation

fl exible.

•

Envoyez de lʼeau dans le tuyau dʼévacuation fl exible et vérifi ez

quʼil nʼy a pas de fuite dans la tuyauterie.

•

Lorsque le test est terminé, connectez le tuyau fl exible au connecteur

dʼévacuation sur lʼunité intérieure.

Tuyauterie dʼévacuation

Test dʼévacuation

Page 33

2-9

Français

Cadre

Grille dʼadmission

Grille de protection verrouillée

(2 pièces)

6 vis M4

(2 pièces)

Grille de protection verrouillée (Protection des pièces mobiles pour éviter le contact direct de lʼutilisateur)

La grille de protection verrouillée doit être installée comme sur le schéma ci-dessous.

Si lʼunité nécessite un entretien, les étapes ci-dessous doivent être suivies :

1. Assurez-vous que lʼunité est hors tension avant dʼentretenir lʼunité.

2. Utilisez un tournevis pour retirer les vis de la grille de protection verrouillée.

3. Retirez la grille de protection verrouillée et ouvrez la grille dʼadmission pour lʼentretien.

4. Installez la grille dʼadmission et vissez la grille de protection verrouillée après lʼentretien, et vérifi ez la bonne installation

de lʼunité.

Page 34

2-10

Schéma 2 Schéma 3

Schéma 4 Schéma 5

Installation des fi ls

Le schéma 1 et le schéma 2 montrent lʼemplacement du couvercle des fi ls dans lʼunité CKE.

Étapes dʼinstallation des fi ls dʼalimentation et des fi ls partant de lʼunité extérieure.

1. Retirez le boîtier des fi ls en ôtant les 2 vis, comme sur le schéma 3.

2. Les fi ls passeront à travers le trou, comme montré dans les Schémas 4 et 5, sans occuper toute la hauteur du trou.

3. Ensuite, le boîtier des fi ls sera remis en place pour fermeture.

Schéma 1

! AVERTISSEMENT

Nʼinstallez pas lʼunité, intérieure comme extérieure, à une altitude supérieure à 2 000 m.

Page 35

2-11

Français

•

Lʼunité extérieure doit être installée de manière à ce quʼil nʼy ait pas de court-circuit de lʼair de rejet chaud ni dʼobstruction au passage régulier

de lʼair. Respecter les dégagements dʼinstallation illustrés ci-dessous. Choisir lʼemplacement le plus frais possible où la température de lʼair

dʼadmission nʼest pas plus élevée que la température extérieure.

•

Si un mur ou tout autre obstacle se trouve sur le chemin du jet dʼair dʼadmission ou de rejet de lʼunité extérieure, suivre les directives dʼinstallations

ci-dessous.

•

Pour nʼimporte lequel des schémas dʼinstallation ci-dessous, la hauteur du toit côté rejet doit être de 1 200 mm maximum.

5SLY20/25C/CR

Plus de 50 Plus de 100

Vue latérale

Vue de dessus

Vue de dessus

Plus de 50

Plus de 50

Plus de 50

Plus de 150

Plus de 100

Plus de 150

Plus de 300

Unité : mm

INSTALLATION DE LʼUNITÉ EXTÉRIEURE

Plus de 100 Plus de 350

Plus de 50

Plus de 50

Vue de dessus

Vue de dessus

Vue latérale

Plus de 100

Plus de 350

Plus de 100

Plus de 350

Unité : mm

5SLY28CR

1200 ou

moins

Plus de 50

Mur face à un côté Mur face à deux côtés

Mur face à trois côtés

Mur face à un côté Mur face à deux côtés

Mur face à trois côtés

Page 36

2-12

5SLY40/50FR

Plus de 100 Plus de 500

Plus de

100

Plus

de

100

Plus de 100

Plus de 100

Plus de 500

• Pour lʼinstallation ci-dessus, laissez plus dʼespace avec un obstacle supplémentaire sur le dessus et pour lʼinstallation en

séries.

Mur face à un côté

Mur face à plus dʼun côté de lʼobstacle

Vue de dessus

Vue latérale

Unité : mm

RACCORDEMENTS DES TUYAUTERIES

Intérieure 5CKY20E/ER 5CKY25E/ER 5CKY28ER

Extérieure 5SLY20C/CR 5SLY25C/CR 5SLY28CR

Longueur admissible maxi, m 30 30 50

Élévation admise max, m 10 10 30

Racc. tube liquide, mm / (pouces) 6,35 (1/4") 6,35 (1/4") 9,52 (3/8")

Racc. tube aspiration, mm / (pouces) 12,70 (1/2") 15,88 (5/8") 15,88 (5/8")

Complément de charge de réfrigérant, g/m

(pour longueur de tuyau supérieure à 7,5 m)

20 20 50

Intérieure 5CKY40ER 5CKY50ER

Extérieure 5SLY40FR 5SLY50FR

Longueur admissible maxi, m 75 75

Élévation admise max, m 30 30

Racc. tube liquide, mm / (pouces) 9,52 (3/8") 9,52 (3/8")

Racc. tube aspiration, mm / (pouces) 15,88 (5/8") 15,88 (5/8")

Complément de charge de réfrigérant, g/m

(pour longueur de tuyau supérieure à 30 m)

50 50

Longueur admissible de tuyauterie

Lorsque le conduit est trop long, la capacité et la fi abilité diminuent. En conséquence, la fi abilité du compresseur sʼen trouve

affectée. Choisissez toujours le chemin le plus court et suivez les recommandations données dans le tableau ci-dessous :

Page 37

2-13

Français

D

A

Travail Des Tuyaueries Et Technique Flare

• Ne pas utiliser de tuyauteries en cuivre encrassé ou endommagé. Si de la tuyauterie, un évaporateur ou un condensateur

a été exposé ou a été ouvert pendant 15 secondes ou plus, le système doit être mis sous vide. Dʼune manière générale, ne

pas retirer les bouchons en plastique ou caoutchouc et les écrous en laiton des vannes, raccords, tubes et serpentins jusquʼà

ce que les tuyauteries dʼaspiration ou de liquide soient prêtes à être raccordées aux vannes ou raccords.

• Si lʼon doit effectuer un travail de soudage, sʼassurer que lʼazote passe par les serpentins et les joints durant le travail du

soudage. Cela éliminera la formation de suie sur les parois internes des tuyauteries de cuivre.

• Couper les tuyaux progressivement, en faisant avancer la lame du coupe-tube lentement. Une force supplémentaire ou une

coupe profonde vont déformer le tube davantage et ainsi causer plus de bavures. Voir Schéma A.

Coupe des Tubes Cuivre

Schéma B

Schéma A

Ebavurage

Schéma C

Tube Cuivre

Dudgeonniere

• Ebarber les bords coupés des tubes à lʼaide dʼun alésoir,

comme le montre la Schéma B, pour éviter toutes

irrégularités sur les faces évasées, qui risqueraient de

causer des fuites de gaz. Tenir le tuyau en haut et lʼébarbeur

à une position plus basse pour éviter que des morceaux de

métal nʼentrent dans le tuyau.

• Relier les écrous ʻfl areʼ montés sur les connexions des

unités intérieure et extérieure aux tubes de cuivre.

•

La longueur exacte de tube dépassant de la dudgonnière

dépend du type de dudgonnière utilisé. Voir la Schéma C.

• Placer le tube fermement dans la dudgeonnière. Aligner

les centres du moule arrondi et du poinçon dʼévasement,

puis serrer totalement le poinçon dʼévasement.

Raccordement de la tuyauterie aux unités

• Aligner le centre de la tuyauterie et serrer assez fort le

raccord conique à la main. Voir la Schéma D.

• Enfi n, serrer lʼécrou à lʼaide dʼune clef dynamométrique

jusquʼau clic.

• En serrant lʼécrou avec la clef dynamométrique, veiller à

respecter le sens de la fl èche indiqué sur la clef.

• Le raccordement du tuyau de réfrigérant doit être isolé par

du polyuréthane à cellules fermées.

Clef dʼImmobilisation

Clef Dynamométrique

Tube de lʼUnité Intérieure

Écrou

Tube Avec Dudgeon

Raccord à Visser

Schéma D

Ø Tube, D A (mm)

Pouce mm Impérial

(Type dʼécrou à

oreilles)

Normal

(Type

dʼembrayage)

1/4" 6,35 1,3 0,7

3/8" 9,52 1,6 1,0

1/2" 12,70 1,9 1,3

5/8" 15,88 2,2 1,7

3/4" 19,05 2,5 2,0

Tuyau (mm/pouce) Couple (Nm/ft-lb)

6,35 (1/4) 18 (13,3)

9,52 (3/8) 42 (31,0)

12,70 (1/2) 55 (40,6)

15,88 (5/8) 65 (48,0)

19,05 (3/4) 78 (57,6)

1/4t

Page 38

2-14

L

N

SIG

2

1

SIG

2

1

SIG

N

L

SIG

N

L

N

L

Cordon Electrique

Unité Extérieure

Bornier

Bornier de

lʼunité intérieure

5CKY20/25E/ER - 5SLY20/25C/CR

IMPORTANT : *

Ces valeurs sont données à titre indicatif seulement; elles doivent être vérifi ées et ajustées en fonction des normes

et de la réglementations en vigueur. Elles dépendent aussi du type dʼinstallation et de la taille des conducteurs

utilisés.

**

Le voltage adéquat doit être vérifi é avec les données de lʼétiquette sur lʼappareil.

Il doit y avoir une déconnexion

de tour les pôles de lʼalimentation

secteur avec une séparation des

contacts dʼau moins 3 mm.

!

Câble

dʼinterconnexion

RACCORDEMENT ELECTRIQUE

Modèle Intérieure 5CKY20E/ER 5CKY25E/ER

Extérieure 5SLY20C/CR 5SLY25C/CR

Tension dʼalimentation** Intérieure

220V - 240V /1Ph /50Hz + !

Extérieure

220V - 240V /1Ph /50Hz + !

Section du câble dʼalimentation* mm

2

Nombre de conducteurs

2,5

3

2,5

3

Section du câble de liaison* mm

2

Nombre de conducteurs

2,5

4

2,5

4

Fusible temporisé recommandé* A 20 20

5CKY28ER - 5SLY28CR

Unité Extérieure

Bornier

Bornier de

lʼunité intérieure

Câble

dʼinterconnexion

Modèle

Intérieure

5CKY28ER

Extérieure

5SLY28CR

Tension dʼalimentation**

Intérieure

220V - 240V/1Ph/50Hz + !

Extérieure

220V - 240V/1Ph/50Hz + !

Section du câble dʼalimentation* mm

2

Nombre de conducteurs

2,5

3

Section du câble de liaison* mm

2

Nombre de conducteurs

1,5

4

Fusible temporisé recommandé* A 25

Cordon Electrique

Il doit y avoir une déconnexion

de tour les pôles de lʼalimentation

secteur avec une séparation des

contacts dʼau moins 3 mm.

!

Page 39

2-15

Français

3

2

1

3

2

1

L1

L2

L3

N

3

2

1

2

1

3

L

N

Cordon Electrique

Unité Extérieure

Bornier

Bornier de

lʼunité intérieure

5CKY40ER - 5SLY40FR (1 Phase)

5CKY50ER - 5SLY50FR (1 Phase)

Câble

dʼinterconnexion

Modèle Intérieure 5CKY40ER 5CKY50ER

Extérieure 5SLY40FR 5SLY50FR

Tension dʼalimentation** Intérieure

220V - 240V/1Ph/50Hz + !

Extérieure

220V - 240V/1Ph/50Hz + !

Section du câble dʼalimentation* mm

2

Nombre de conducteurs

6

3

6

3

Section du câble de liaison* mm

2

Nombre de conducteurs

1,5

4

1,5

4

Fusible temporisé recommandé* A 32 32

Modèle Intérieure 5CKY40ER 5CKY50ER

Extérieure 5SLY40FR 5SLY50FR

Tension dʼalimentation** Intérieure

220V - 240V/1Ph/50Hz + !

Extérieure

380V - 415V/3N~/50Hz + !

Section du câble dʼalimentation* mm

2

Nombre de conducteurs

4

5

4

5

Section du câble de liaison* mm

2

Nombre de conducteurs

1,5

4

1,5

4

Fusible temporisé recommandé* A 20 20

5CKY40ER - 5SLY40FR (3 Phase)

5CKY50ER - 5SLY50FR (3 Phase)

Cordon Electrique

Bornier de

lʼunité intérieure

Câble

dʼinterconnexion

Unité Extérieure

Bornier

Il doit y avoir une déconnexion

de tour les pôles de lʼalimentation

secteur avec une séparation des

contacts dʼau moins 3 mm.

!

Il doit y avoir une déconnexion

de tour les pôles de lʼalimentation

secteur avec une séparation des

contacts dʼau moins 3 mm.

!

Page 40

2-16

Fixez le manchon dʼisolation

Borne à sertir ronde

Fil électrique

Connectez des fi ls de même

section des deux côtés.

Ne connectez pas de fi ls de

même section sur un côté.

Ne connectez pas de fi ls

de sections différentes.

• Tous les fi ls doivent être fermement connectés.

• Aucun fi l électrique ne doit toucher ni la tuyauterie du réfrigérant, ni le compresseur, ni les pièces mobiles du moteur de

ventilation.

• Le câble de raccordement entre lʼunité intérieure et lʼunité extérieure doit être fi xé à l'aide du collier fourni.

• Le cordon électrique doit être êquivalent à H07RN-F au minimum.

• Les connecteurs et les câbles du répartiteur ne doivent subir aucune pression externe.

• Tous les couvercles doivent être correctement fi xés pour éviter tout vide.

• Utilisez des bornes à sertir rondes pour la connexion des fi ls au bloc dʼalimentation. Connectez les fi ls en les faisant

correspondre aux indications du bornier. (Référez-vous au schéma de câblage apposé sur lʼunité).

• Utilisez le bon tournevis pour serrer les vis du répartiteur. Utiliser un tournevis non adapté peut endommager la tête de la vis.

• Ne pas trop serrer sous peine dʼendommager la vis de la borne.

• Ne connectez pas de fi ls de sections différentes au même répartiteur.

• Réalisez le câblage de façon ordonnée. Le câblage ne doit pas obstruer les autres pièces ni le couvercle du boîtier du

répartiteur.

R410A est un nouveau réfrigérant de HFC qui nʼendommage

pas la couche dʼozone. La pression de travail de ce nouveau

réfrigérant est 1,6 fois supérieure à celle dʼun réfrigérant

conventionnel (R22), une installation appropriée et un bon

entretien sont donc essentiels.

• Jamais réfrigérant de lʼutilisation autre que R410A dans un

climatiseur qui est conçu pour fonctionner avec R410A.

• De lʼhuile POE ou PVE est employée comme lubrifi ant

pour le compresseur de R410A, qui est différente de

lʼhuile minérale utilisée pour le compresseur R22.

Pendant lʼinstallation ou lʼentretien, des précautions

supplémentaires doivent être prises pour ne pas exposer

le système de R410A trop long à lʼair moite. Lʼhuile

résiduelle de POE ou de PVE dans la tuyauterie et les

composants peuvent absorber lʼhumidité de lʼair.

• Pour empêcher mischarging, le diamètre du port de service

sur la valve de fusée est différent de celui de R22.

• Employez les outils et les matériaux exclusivement

pour le réfrigérant R410A. Les outils exclusivement

pour R410A sont valve diverse, tuyau de remplissage,

indicateur de pression, détecteur de fuite de gaz, outils de

fusée, clé dynamométrique, pompe de vide et cylindre de

réfrigérant.

• Car un climatiseur de R410A encourt une pression plus

élevée que les unités R22, il est essentiel de choisir les

pipes de cuivre correctement. Jamais diluant de cuivre

de pipes dʼutilisateur que 0,8 mm quoiquʼils soient

disponibles sur le marché.

• Si le gaz de réfrigérant fuit pendant lʼinstallation/servicing,

soyez sûr dʼaérer entièrement. Si le gaz réfrigérant entre

en contact avec le feu, un gaz toxique peut se produire.

• En installant ou en enlevant un climatiseur, ne laissez pas

lʼair ou lʼhumidité rester dans le cycle réfrigérant.

PRÉCAUTIONS SPÉCIALES EN TRAITANT LʼUNITÉ DE R410A

Page 41

2-17

Français

Aspirer est nécessaire pour éliminer toute humidité et air du système. La série II Unité Extérieure est fournie avec des raccords

de valve fl are.

Aspiration sous vide des tuyauteries et de lʼunité

intérieure

Hormis pour lʼappareil extérieur pré-chargé de réfrigérant,

lʼappareil intérieur et les tuyaux de connexion doivent

être purgés car lʼair restant dans le cycle frigorifique

contient de lʼhumidité et est susceptible de provoquer un

dysfonctionnement du compresseur.

• Enlever le bouchon central, ainsi que le bouchon de la prise

de pression sur chaque vanne.

• Raccorder le centre de la jauge de chargement à la pompe

à vide.

• Raccorder la jauge de chargement à lʼorifi ce de service de

la valve à trois voies.

• Démarrer la pompe à vide. Évacuer pendant environ 30

minutes. La période dʼévacuation varie selon la capacité

de la pompe à vide. Sʼassurer que lʼaiguille de la jauge de

chargement se soit déplacée vers –760mmHg.

Avertissement

• Si lʼaguille de la jaudge ne se déplace pas vers –760mmHg,

vérifi er quʼil nʼy ait pas de fuite de gaz (à lʼaide dʼun

détecteur de gaz) au niveau des raccordements évasés des

unités intérieures et extérieures, puis réparer la fuite avant

de passer à lʼétape suivante.

• Fermer la valve de la jauge de chargement et éteindre la

pompe à vide.

• Sur lʼunité extérieure, ouvrir la valve de succion (3 voies)

et la valve de liquide (2 voies) (dans le sens inverse

des aiguilles dʼune montre) à lʼaide dʼune clé pour vis

hexagonales de 4 mm.

Opération de chargement

Cette opération nécessite impérativement lʼutilisation dʼun

cylindre de charge ou une balance de précision. Le complement

de charge se fait sur lʼunité extérieure par la vanne dʼaspiration

via la prise de pression de la vanne de service.

• Enlever le bouchon de la vanne de service.

• Raccorder le côté de basse pression de la jauge de

chargement à lʼorifi ce de succion du réservoir cylindrique

et fermer le côté de haute pression de la jauge. Éliminer

lʼair du tuyau de service.

• Mettre le climatisateur en marche.

• Ouvrir le cylindre de gaz et la valve de chargement de basse

pression.

• Lorsquʼune quantité suffi sante de réfrigérant est injectée

dans lʼunité, fermer le côté basse pression et la valve du

cylindre de gaz.

• Débrancher le tuyau de service de lʼorifi ce de service.

Remettre le bouchon de lʼorifi ce de service.

TIRAGE AU VIDE ET CHARGE

Tuyauteries Frigorifi ques

Unité Extérieure Vannne 3 Voies

Cléf Allen

Prise de Pression

Écrou

MANOMÈTRE HAUTE PRESSION

MANOMÈTRE DE PRESSION

MANOMÈTRE BASSE PRESSION

POIGNÉE HI (HAUTE) (TOUJOURS FERMÉE)

TUYAU DE REMPLISSAGE

-760mmHg

POIGNÉE LO

TUYAU DE REMPLISSAGE

ADAPTATEUR DE

POMPE A VIDE POUR

LA PRÉVENTION DE

RETOUR DE FLOT

CLAPET DE

NON-RETOUR

ROBINET DU

LIQUIDE

MANOMÈTRE HAUTE PRESSION

MANOMÈTRE BASSE PRESSION

MANOMÈTRE DE PRESSION

-760mmHg

POIGNÉE LO

POIGNÉE HI (HAUTE) (TOUJOURS FERMÉE)

TUYAU DE REMPLISSAGE

TUYAU DE REMPLISSAGE

CLAPET DE

NON-RETOUR

ROBINET DU

LIQUIDE

ROBINET DE

GAZ ( 3 VOIES)

CONFIGURATION DE PURGE

DʼAIR PAR CHARGE

CONFIGURATION DE PURGE

DʼAIR PAR CHARGE

ROBINET DE

GAZ ( 3 VOIES)

Page 42

2-18

Matériau de bouchage

• Il est possible de boucher lʼun des quatre défl ecteurs de refoulement. (en boucher deux ou plus peut causer un mauvais

fonctionnement).

• Otez le panneau avant et insérez le matériau de bouchage dans le défl ecteur de refoulement dʼair de lʼunité intérieure pour

boucher lʼévent.

• Le matériau de bouchage est dʼune longueur égale à celle du défl ecteur de refoulement dʼair le plus long. Si vous souhaitez

boucher le défl ecteur le plus court, coupez le matériau de bouchage pour le raccourcir.

• Poussez le matériau de bouchage à lʼintérieur, environ 10 mm plus loin que la surface inférieure de lʼunité intérieure afi n

quʼil ne touche pas le volet dʼaération. Veillez à ne pas pousser le matériau de bouchage de plus de 10 mm.

Spécifi cation de canalisation courte

• Lʼunité intérieure est fournie avec un trou dʼéjection de refoulement dʼair et dʼaspiration dʼair pour la connexion de la

canalisation. Cependant, la connexion de la canalisation courte pour le refoulement dʼair nʼest possible que dʼun côté.

• Lʼutilisation dʼune canalisation courte pour le refoulement dʼair améliorera la distribution du fl ux dʼair sʼil y a obstruction

(comme un lustre) ou dans une longue pièce étroite ou une pièce en L. Elle est également utilisée pour la climatisation

simultanée de deux pièces.

Direction possible pour le refoulement dʼair et

lʼaspiration dʼair

Trou dʼéjection du refoulement dʼair

Trou dʼéjection

de lʼaspiration

dʼair

Direction possible pour le refoulement dʼair et

lʼaspiration dʼair

Reprise Air

Refoulement dʼairRefoulement dʼair

Refoulement dʼair Refoulement dʼair

10

50 50 50 50 50 10

207020

90

Ø100

PCD Ø140

115 20 115

PIÈCE ACCESSOIRE

REMARQUE

• Evitez dʼutiliser la canalisation courte sur laquelle la grille de refoulement dʼair peut être complètement fermée pour

empêcher que lʼévaporateur ne gèle.

• Afi n dʼéviter la formation de condensation, assurez-vous que lʼisolation thermique est suffi sante et quʼil nʼy a pas

de fuite dʼair froid lorsque vous installez la canalisation courte.

• Maintenez lʼintroduction dʼaspiration dʼair frais à 20% du fl ux dʼair total. Fournissez également une chambre et

utilisez un ventilateur dʼappoint.

Page 43

2-19

Français

Comme illustré ci-dessus, il est conseillé de déplacer lʼunité

en saisissant les poignées de gauche et de droite. Placer les

mains sur le coin afi n dʼéviter de déformer lʼenveloppe.

Schéma 1

Au total, 4 possibilités de sens (voir schéma 2a) sont

disponibles pour le raccordement du tuyau (w, x, y, z).

En découpant les 2 fentes à lʼaide dʼune scie à métal, il est

possible de réaliser lʼinstallation illustrée dans la Schéma 2a.

Pour que le tuyau de raccordement soit dirigé vers le bas

(voir Schéma 2b), faire un trou défonçable en perçant la zone

centrale autour du trou défonçable.

Pour ce faire, il est conseillé dʼutiliser un foret de perceuse

de Ø 6 mm (voir la Schéma 2c).

Une fois les trous réalisés, il est conseillé dʼappliquer une

peinture de réparation sur les bords et autour des surfaces

afi n dʼéviter la rouille.

Z

Y

X

W

Schéma 2a

Schéma 2b

Schéma 2c

1. Manipulation

2. Tuyauterie de réfrigérant

Couvrir les trous de tuyau à lʼaide

de matériau isolant afi n de boucher