Page 1

MGQumi”

Absorption Chiller/Heater

Operation and

Maintenance Data

Bulletin No. OM 114

March, 1993

Form No. 573442Y

DC-U Model

I

/

Page 2

NOTESTO USERS

1 . Before operating this chiller/heater, You should first thoroughly

read this manual.

You may not

you firstly read this booklet, however, please strictly follow the

directions as drown hereinafter.

3. Be sure not to leak the airinto the chiller/heater atany

(Take care when You handle the manual purge valves and service

valves. )

4 . Perform sufficiet ventilation in the machine room.

Required fresh airratefor combustion;

Approximately 1.2 m3/h (43 ft3/h) per fuel

1,000 kcal/h (4,000 But/h) .

5 . If You smell gas in the machine room, stop the chiller/heater

immediately and close the main gas cock, then advise thesituation

toour agency assoon aspossible.

When you could find out theleak point you maytemporarily rectify

it.

understand all of the explanations foroperations when

consumption of

I

cases.

7 . Keep the operation of chilled water pump(s) and air handling unit(s)

even when chiller/heater runs into dilution cycle operation, to

avoid damage of the chiller/heater caused by over cooling or any

other unusual situation.

(Diluted cycle operation)

normal operation or at emergency,

working until the density of the absorbent comes to a specified

value. )

8 . Before operating the chiller/hinter on the beginning of cooling OF

heating season, it shall be assured that the Cooling/heating change

over procedure inaccordance

9 . Specifications and equipment may be changed as required by the

manufacture without any notice and obligation tothe users.

: When the chiller/heater is stopped under

the chiller/heater continues its

with Section 3.3 has been made.

814-6-0502-449-01

Page 3

(HMTKYIMWUtK

CONTENTS

Page No.

SEmON 1

;:;

1.3

1.4

SUXON 3

3.1

3.2

3.3

3.4

3.5

3.6

NYIES ‘R) m--------------------------------------------------------------

GmwRALDE92UPTION------------------------------------------------------1

m FRIWPLE OF MHIRI1-roN -----------------------------------------2

(XIOHNG/HE4TIlKCYUE DIHRIFI’ION ------------------------------20

U-IIIllR/HE41TR IIJMJRATKM.I-----------------------------------------25

SAFEIYDEvm --------------------------------------------------------------37

WERATION ----------------------------------------------------------------------39

OPIRATIONDIRD -----------------------------------------------------------40

lRdFfRAluRE SEXTING“----”-------”--”------------------------------------ 43

fEJ?-DIAGNOH’ICSRINCMRJ -------------------------------------------51

FIWARATIONFOR HART UP-----------------------------------------------54

OPJMTION ---------------------------------------------------------------------58

MmnmANm

DAILYh9AMlmIMXz '---"---"----------------------------"---------"----"----73

SASCNALMAINIHWMX-----------------------------------------------------75

UXHJNG/HEATING(l-l/ME OVIR -----------------------------------------80

WATFR‘IREAM ------------------------------------------------------------82

M41NllMME m

PARTSlNSfK1’ION------------------------------------------------------------89

~`"-------------" -"-"--"-""----------------------86

72

i

ii

mm 4 ‘IROuBU9-IOOTING------------------------------------------------------------91

4.1 ALARMINDICATIONIMP ---------------------------------------------------92

4.2 K3WlR FAILURE---------------------------------------------------------------94

4.3 ALARMIN ‘II-WCOOLINGOFIRAT~ -------------------------------------95

4.4 ALARMIN ‘IHE HEATINGOPERATION-------------------------------------98

4.5 ALARMTIME ~------------------------------------------------------------lOl

Page 4

SECTION1 GENERAI-DESCRIPTION

CONTENTS

Page No.

SECTION1

1.1

1.2 (lXILIIW/HEATINGCYCLEDEWWTION

1.3 CWJJIR/HEAIERIiLUSIRATION

GENERALDE!XRIPTION

THEPRINCIPLEOF AES3RPTION

(1) ~ ~A

(2) ~pRI~I~ @ ~r~ ....................................... q

(3) SINGLEEmmT TYPE (BASICCYUE)

(~] m m ~ .................................................... ;

(~) ~~~ ~A~ .............................................................. 9

(~) “Am .....................................................................lo

(7) LIIHUMBROMIDE(LiBr

(8) ~~~ ~~ ............................................................l6

(9) HEATINGCYCLE--------------------------------------------------------------19

( 1) mIM mm -------------------------------------------------------------2O

(2) WTIM am -------------------------------------------------------------24

~TI~ ~1~ ? . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . ~

............................................

............

: ABWWENT)--”---”------”--------””-----11

................................

------------------------------------------25

...........

... ..........

.............

1

2

20

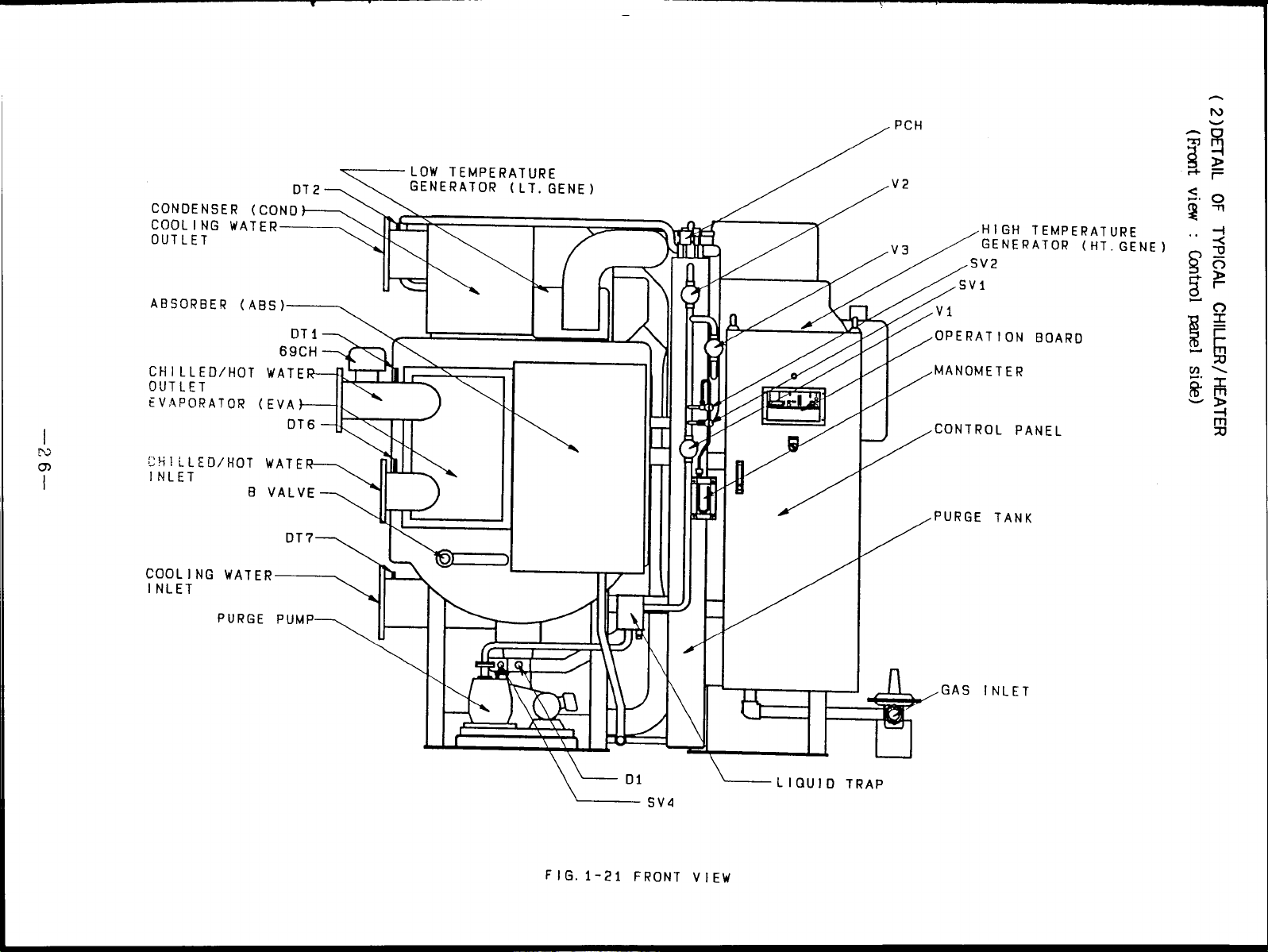

(1) ILLUSTRATION

(2) DETAIT@ TYPICAL~IWWm(mm VIEW) ------- 26

(3) DETAITOF TYPICAL(llIUJZR/HEAllR(REARVIEW)---------- 27

(4) ~AIT w ~Im ~Iw~~(RI~ Vim) ------- 28

(5) ~AIT OF TYPICALGIILJ.JWHE4TER(IJFTVIEW)-----------29

(6) TYPICAL~= pm -----------------------:----------------------30

(7) TYPICALBURNER,GAS‘IRAINANDB. CONTPANEL-----------32

(8) m .......................................................................34

1.4 S4FETYDEVICES---------------------------------------------------------------37

(XII.UD/HOTWATERANo~1~ WA~ ..........................37

(1)

~~~ ~~ -TfJR ......................................37

(2)

BURNER---------------------------------------------------------------------38

(3)

MOTUR--------------------------------------------------------------------------38

(4)

U1’HRS ------------------------------------------------------------------------38

(5)

--------------------------------------------------------------25

—l–

Page 5

1.1 THEPRINCIPLEOFABSORPTION

(1) WHY DOES A HEATINGCHILL ?

I

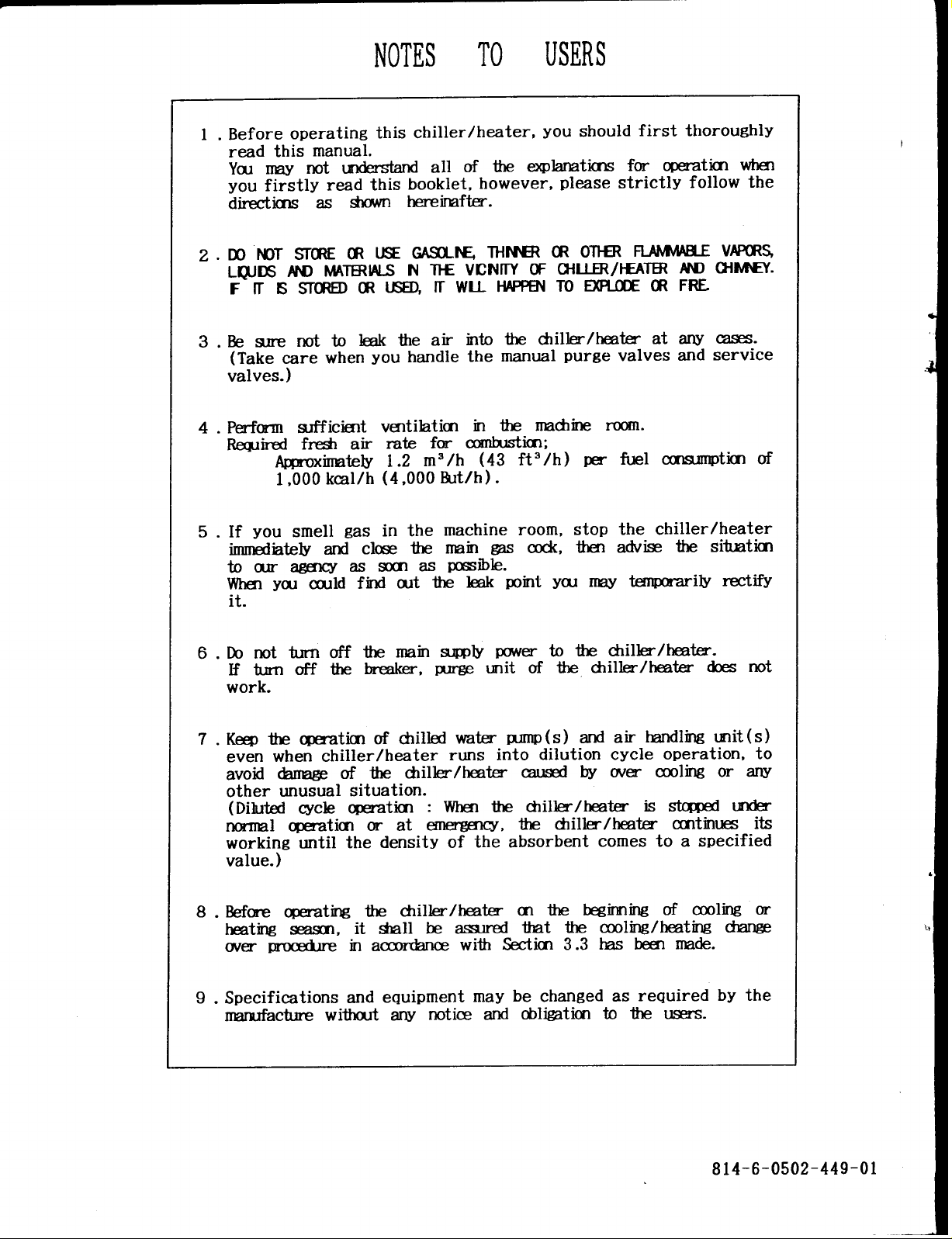

The cooling means keeping the room temperature lower than outside temperature. AS

shown Fig.1-1, operate to carry the heat from the room with a lower temperature (28”C,

82”F) to the open air with a higher temperature is required.

heat cannot move from alowtemperature side toahigh temperature side. So, to

transmit the heat as oppposed to this law (principle), some way (apparatus) is

necessary.

That is, a heat pump (chiller) is used topump out thehear from low

temperature one asifawater pump isused todraw upthewater from adeep well.

But, in the nature, the

IU l~C AI I-IUGU-I-U

COOLING LOAD

(82 “F) (90 ‘F)

AIR CONDITIONER

FIG . 1-1 HEAT FLOW

+

HEAT FLOW

–2–

Page 6

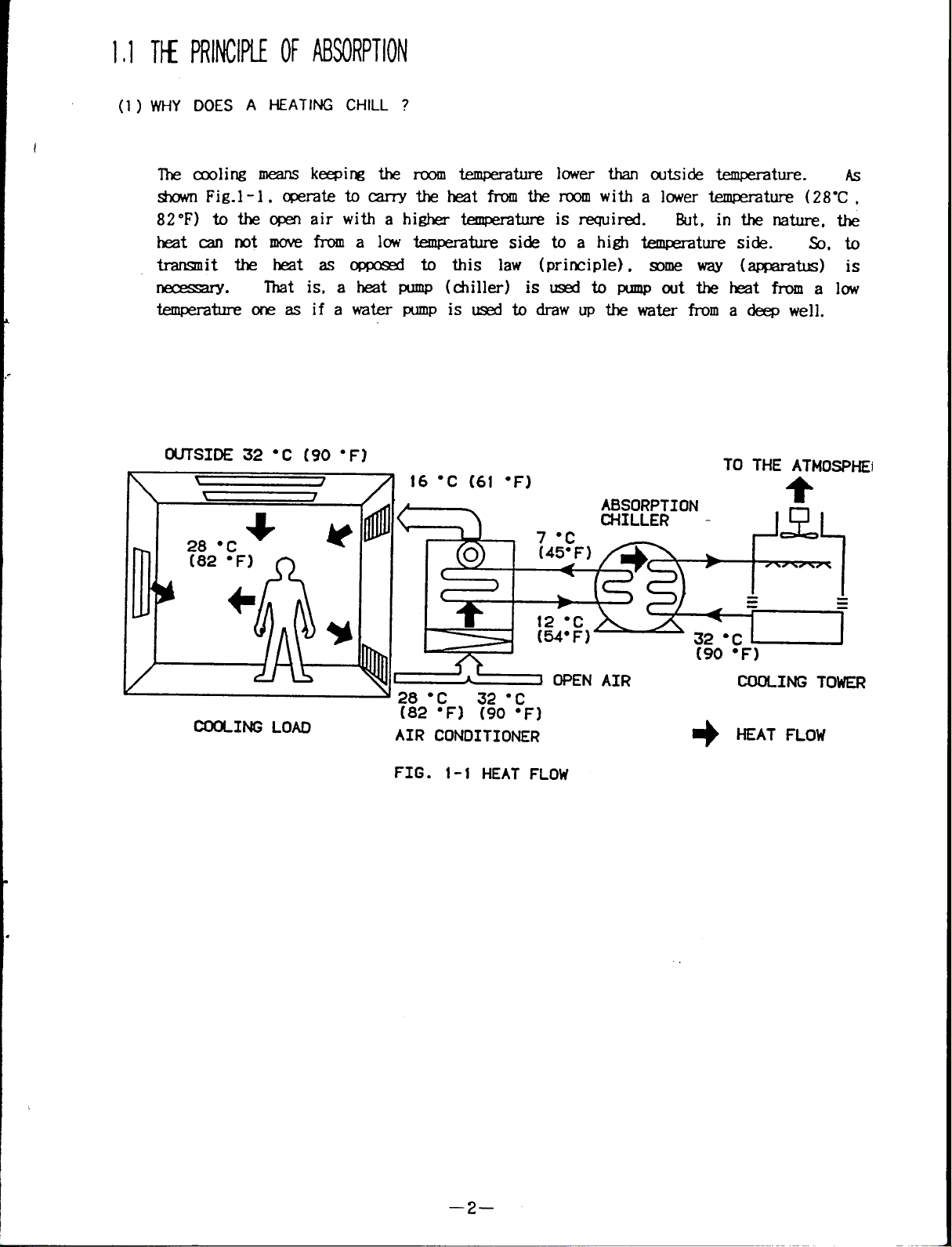

The typical c+iller using an electric as a operation

curry the heat in Fig.1-2 is an electric turbo chiller

heat energy is an absorption chiller.

power source as a conveyer to

and the typical chiller using a

Chilled water is made by using the latent hear released byaliquid asitevaporates.

We can find this principle through our experience in a daily life.

having an injection, after applying as alcohol for disinfection on the arm, we feel

thepartofarm cool..

heat from thearmwhen itevaporates.

we sweat in a hot day or bytaking exercise.

automatically controlled by the evaporation of sweat which takes theheat fromthe

body.

necessary to return to liquid for using vaporized liquid.

compressor is used in anelectric turbo chiller and anabsorbent isusedin an

absorption

The

absorbing the vaporized solution. To recover

concentrating Process of the absorbentis required.

natural gas, steam or hot water.

A chiller also uses an latent heat of evaporation

chiller.

absorbent decrease

Because. the alcohol is heated by body's temperature. took the

And another sample is that we feel cool when

Because, the body temperature

But in a chiller, it is

the absorption power when it becomes diluted solution by

the absorption power, the heating and

Asheat source itis used by

For example, when

For this purpose, the

n

:&KOWEIJ:PERATIRE SIDE

I

A GRAIN OF HEAT

FIG .1-2 HEAT FLOW AT CJ30UNG

iv

HIGHER TEt4PERATuRE

ENERGY

SIDE

–3–

Page 7

(2) TI-E PRlNCIPLE OF ABSORPTION

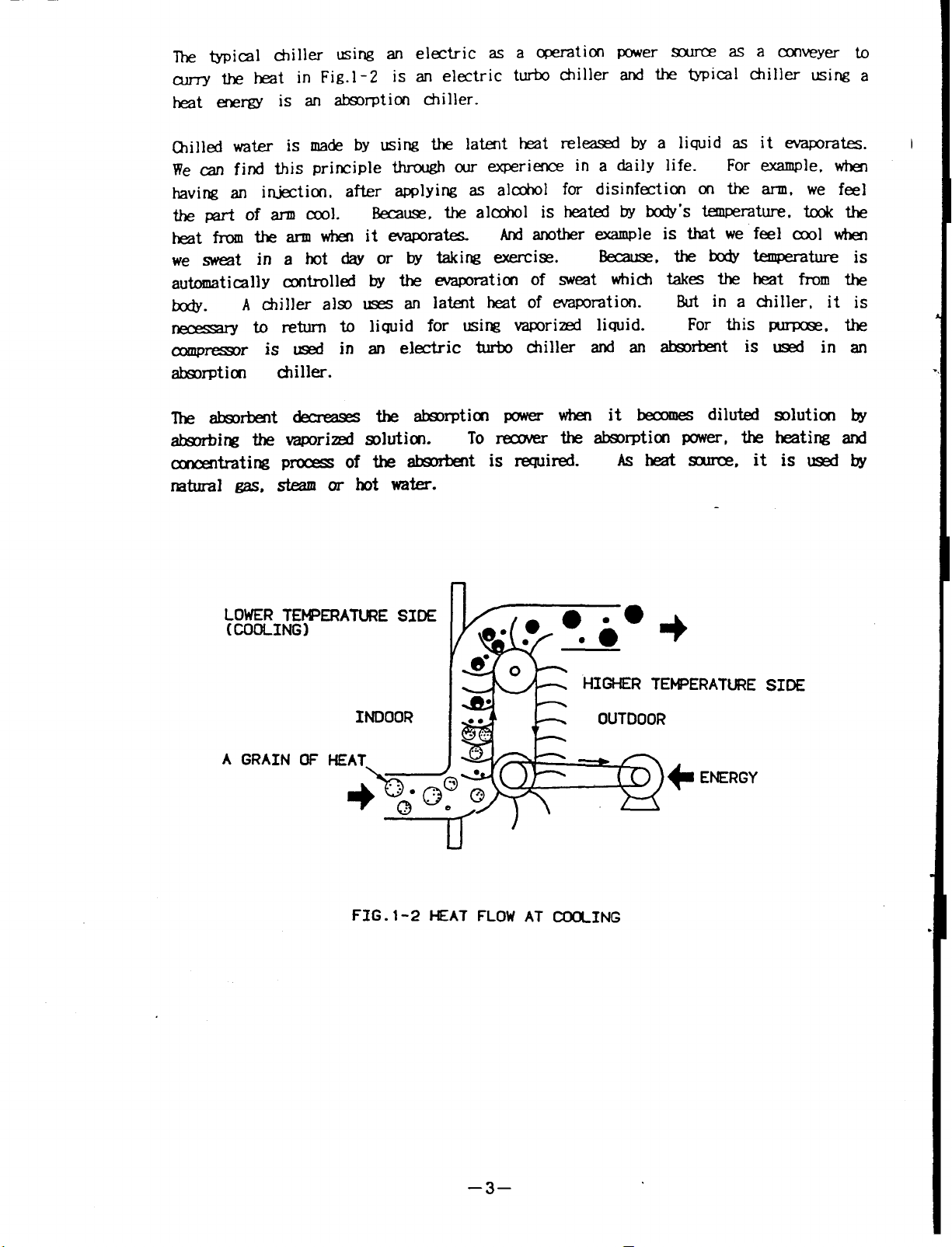

Install heat transfer tubes in a closed vessel and put a dry silicagel (Silicagel is

high quality absorbent material) in it as shown Fig.l -3.

vessel tomake avacuum

with the pressure

of approx. 6.5mmHg (1/4 inchHg). Drops of

water are allowed to fall on the heat transfer tubes (Evaporator).

vacuum vessel evaporates at5-C (41 ‘F) .

The water takes an evaporation heat from the

water intheheat transfer tubes, when it become vapor.

Take out an air in the

The water in the

(Such liquid is called a

refrigerant and shown as a refrigerant liquid or a refrigerant vapor for the

following. )

silicagel, a vacuum

As this evaporated refrigerant vapor is absorbed immediately by a

is kept inside the vessel.

Onthe other hand. the water in the

heat transfer tubes becomes chilled because the heat equivalent to the exaporation

heat is taken.

impossible to keep a vacuum

But, when the silicagel reaches the limit of absorptiono it

in the vessel and chilled water can not be obtained.

WATER

(REFRIGERANT)

is

CHILLED

WATER

WATER

tiEAT

I k P’=

~lcAGEL

TRANSFER

TUBE

FIG. 1-3

–4–

Page 8

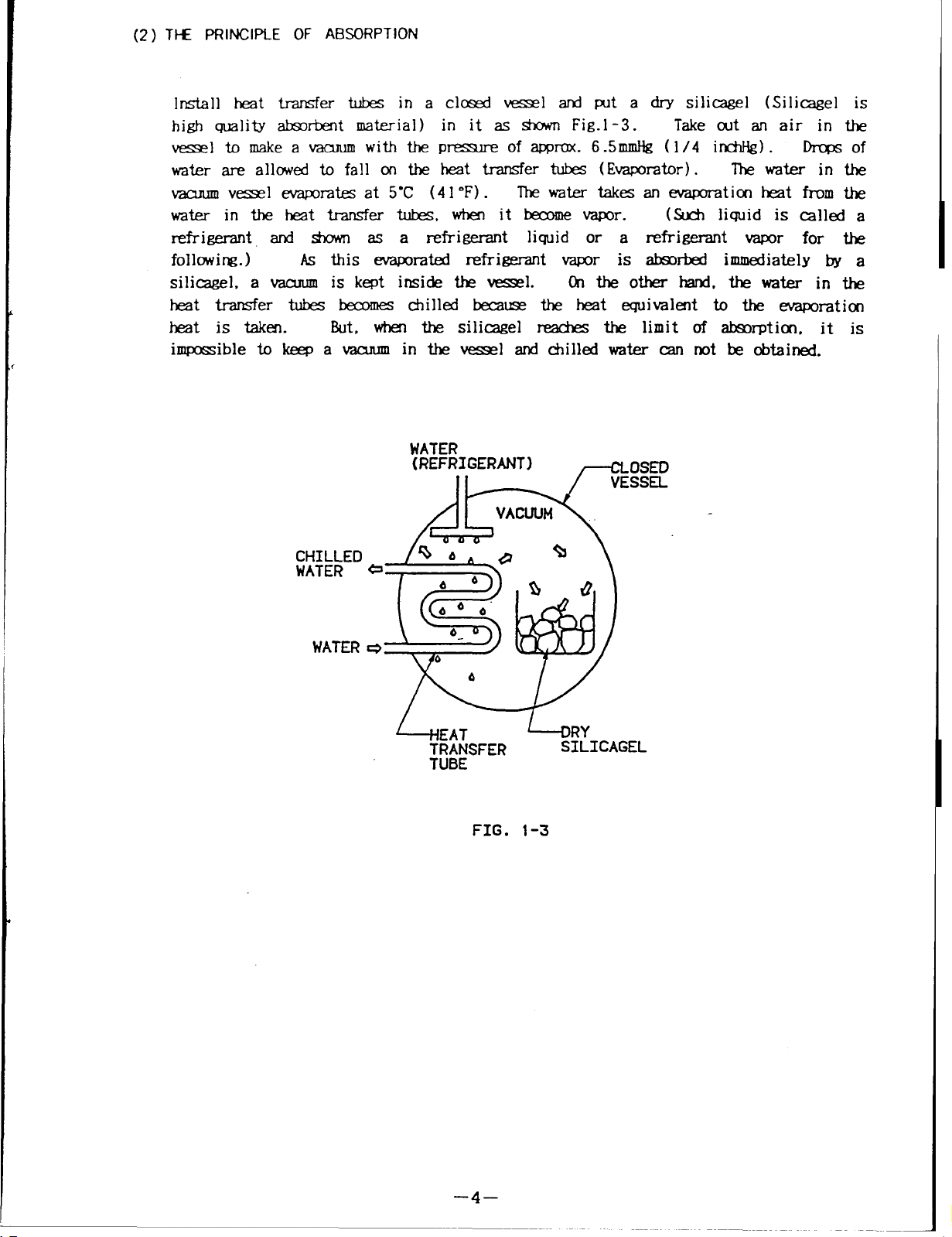

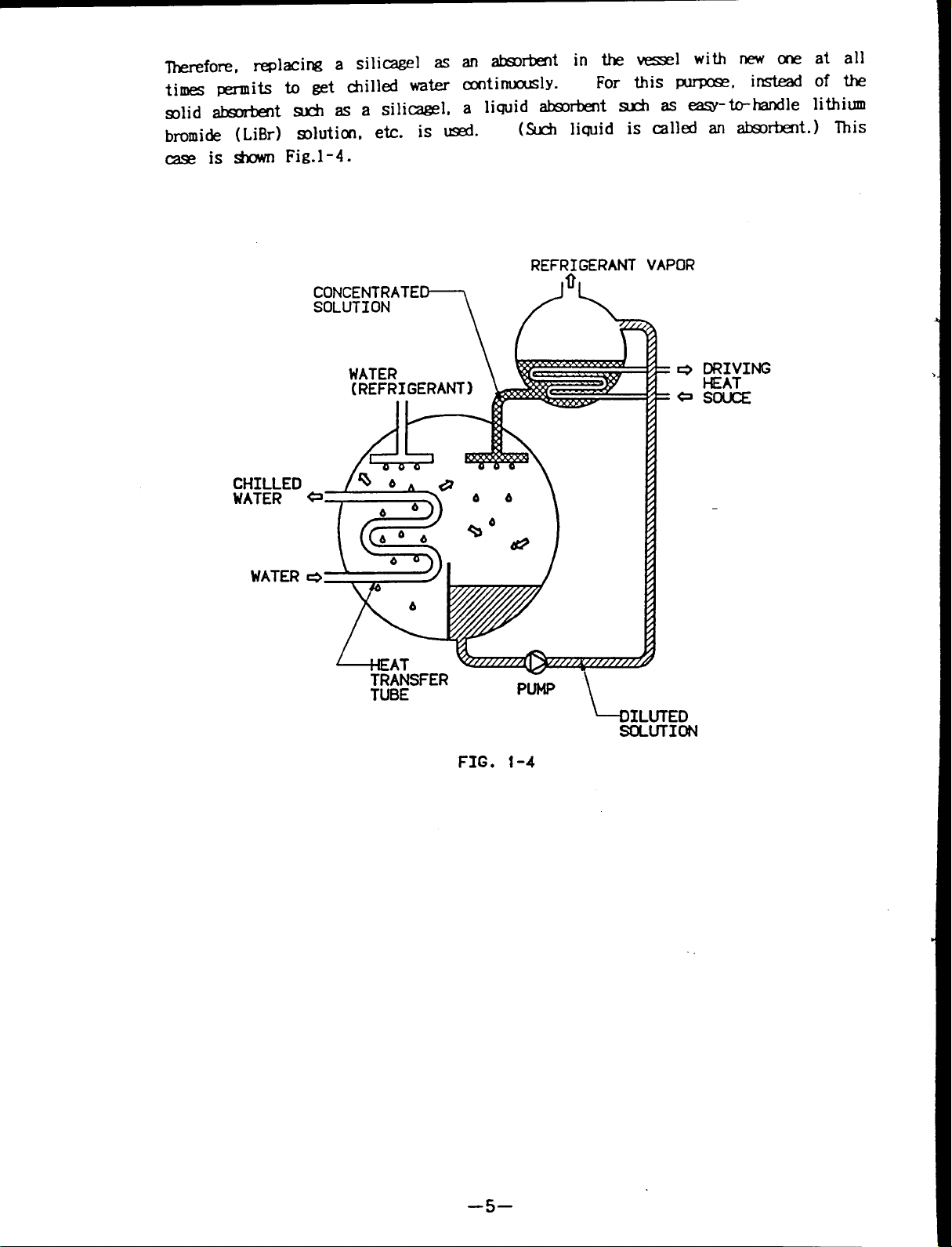

lherefore, replacing a silicagel as absorbent

lithiu

times permits to get chilled water continuously.

solid absorbent such asasilicagel,

bromide (LiBr) solution, etc. is used.

a liquid absorbent such as easy-to-handle

(Such liquid is called an absorbent.) This

case is shown Fig.l -4.

REFR~GERANT VAPOR

CHILLED

WATER

in the vessel with new one at all

For this purpose, instead ofthe

DRIVING

HEAT

SOUCE

WATER

‘+31LUTED

SOLUTION

FIG. 1-4

–5–

Page 9

Drops ofLiBr solution are allowed

solution absorbs refrigerant vapor.

refrigerant vapor, it is diluted and decreases

chilled water can not be obtained.

in continuously.

At this stage, the diluted solution isheated bydriving heat

to fall (Absorber) inside the vessel. The LiBr

But, when the absorbent once absorbs the

ability to absorb. Resulting in the

This means that concentrated solution must be fed

source (natural gas, steam orhot water:Generator). The heat causes thesolution to

release the absorbed refrigerant and also

reconcentrates the solution.

The refrigerant vapor which is relased from the solution when heated is cooled in a

seperate vessel (Condenser) tobecome

liquid refrigemnt.

Drops of this water are

again introduced into the vacuum vessel and recyled. This is shown Fig.l -5.

COOLIN

WATER

e ~R;ING

FIG. 1-5

Put@

C=

SOUCE

Page 10

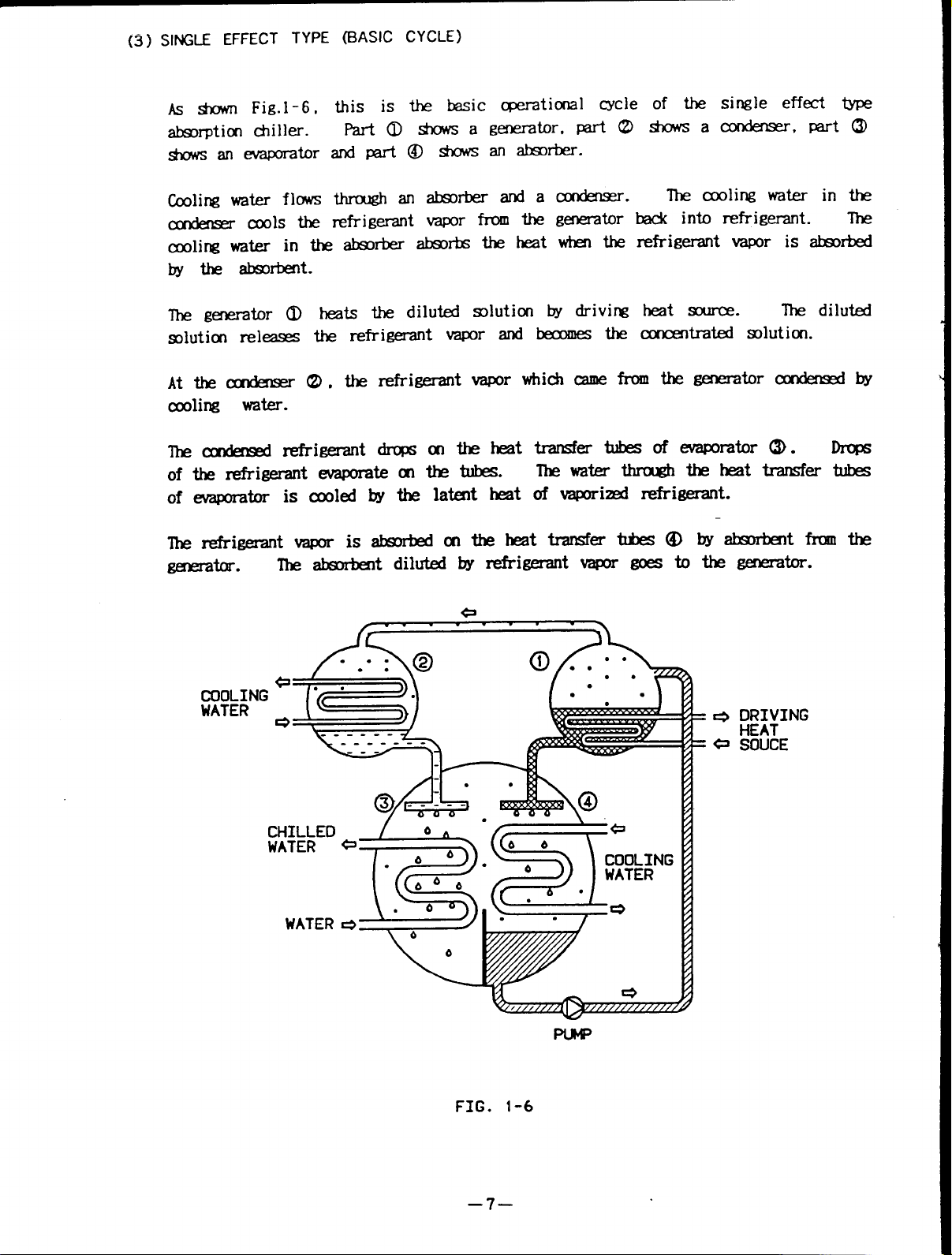

(3] SINGLE EFFECT TYPE (BASIC CYCLE)

AS * Fig.l -6.

absorption chiller.

shows an evaporator

Cooling water flows

condenser—cools the

cooling water in the absorber absorbs the heat when the refrigerant vapor is absorbed

by the absorbent.

The generator 0 heats the diluted solution by driving heat source.

solution releases the refrigerant vapor and becomes the concentrated solution.

Atthe condenser (2),the refrierant vapor which came from thegenerator condensed by

cooling water.

The condensed refrigerant drops onthe heat transfer tubes ofevaporator(3).Drops

of the refrigerant evaporate on the tubes.

of evaporator is cooled by the latent heat of vaporized refrigerant.

f--=--n

,— . .

The water Through the heat transfer tubes

The diluted

/?h@

COWING 1-, -

c=-&-=s /.” ”-w

WATE

~.\

I*-=

d

‘----’’--”=44 ~

CHILLED

WATER

WATER

(“~>” ‘ “ ‘WATER

COOLING

FIG. 1-6

—7–

Page 11

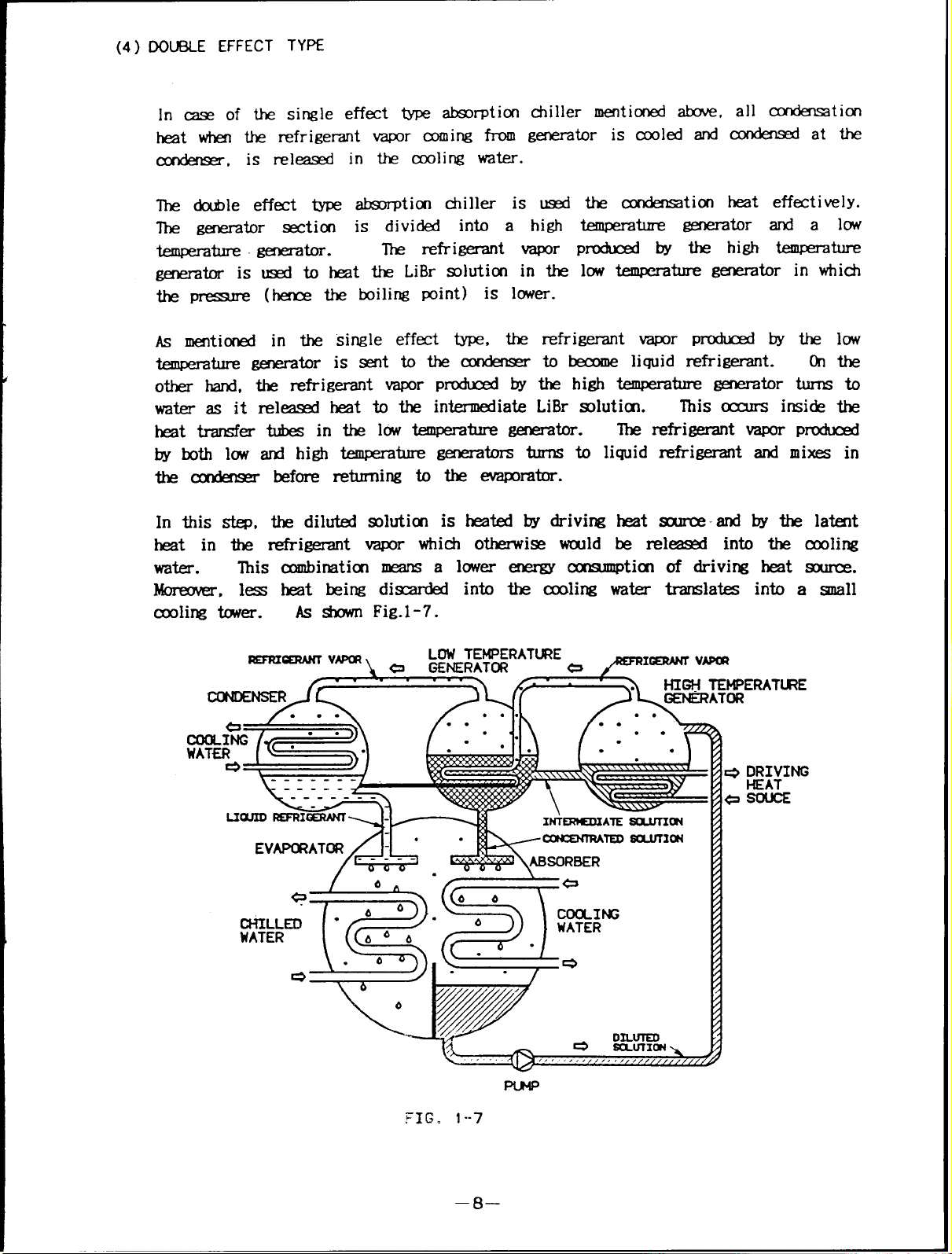

(4) DOU8LE EFFECT TYPE

In case of the single effect type absorption chiller mentioned above

heat when the refrigerant vapor coming from generator is cooled and

all condensation

condensed at the

condenser, is released in the cooling water.

The double effect type absorption chiller is used

The generator section is divided into a high

temperature generator.

The refrigerant vapor

generator is used to heat the LiBr solution in the

temperature generator and a low

produced by the high temperature

low temperature generator in which

heat effectively.

the pressure (hence the boiling point) is lower.

As mentioned in the single effect type, the refrigerant vapor produced by the low

temperature generator issent tothe condenser

to become liquid refrigerant. On the

other hand, the refrigerant vapor produced by the high temperature generator turns to

water as it released heat to the intermediate LiBr solutitn.

heat transfer tubes in the low temperature generator.

The refrigerant vapor produced

This occurs inside the

by both low and high temperature generators turns to liquid refrigerant and mixes in

the condenser before returning to the evaporator.

In this step, the diluted solution is heated by driving heat source by the latent

heat in the refrigerant vapor which otherwise would be released into the cooling

water.

This combinatiom means a lower energy consumption of driving heat source.

Moreover, less heat being discarded into the ceding water translates into a small

cooling tower. As shown Fig.1-7.

‘~ ‘-\ a GENERATCR

LDW TEMPERATL8?E

@ -x~ ‘-

DRIVING

HEAT

–8–

Page 12

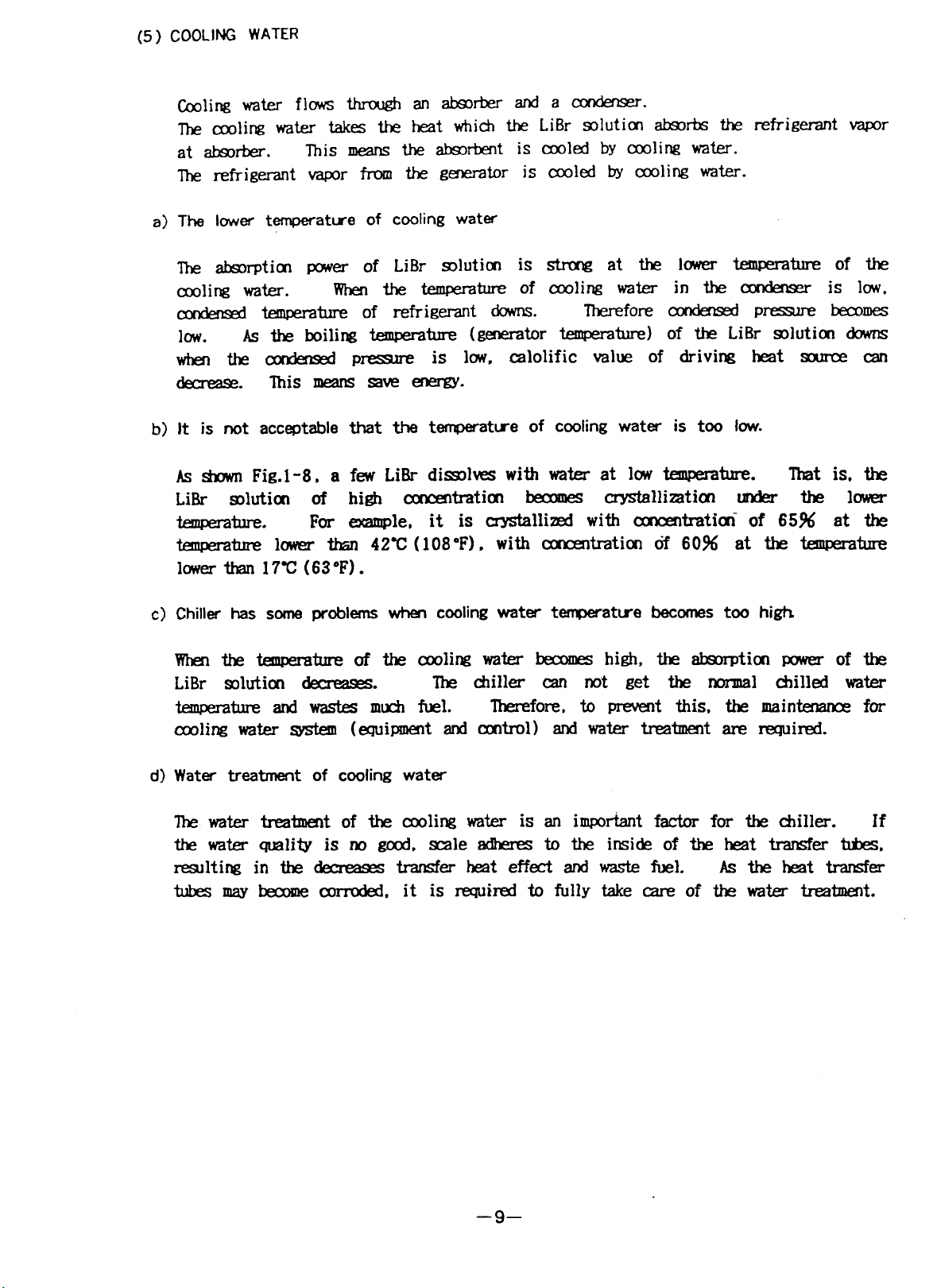

(5) COOLIK WATER

Cooling water flows through an absorber and a condenser.

The cooling water takes the heat which the LiBr solution absobs the refrigerant vapor

at absorber.

This means the aborbent is cooled by cooling water.

The refrigerant vapor from the generator is cooled by cooling water.

The lower temperate of cooling water

a)

The absorption power of LiBr solution is strong at the lower temperature

cooling water.

condensed temperature of refrigerant downs.

low.

AS the boiling temperature (generator temperature) of the LiBr solution downs

when the condensed

decrease.

It is not acceptable

b)

This means save energy.

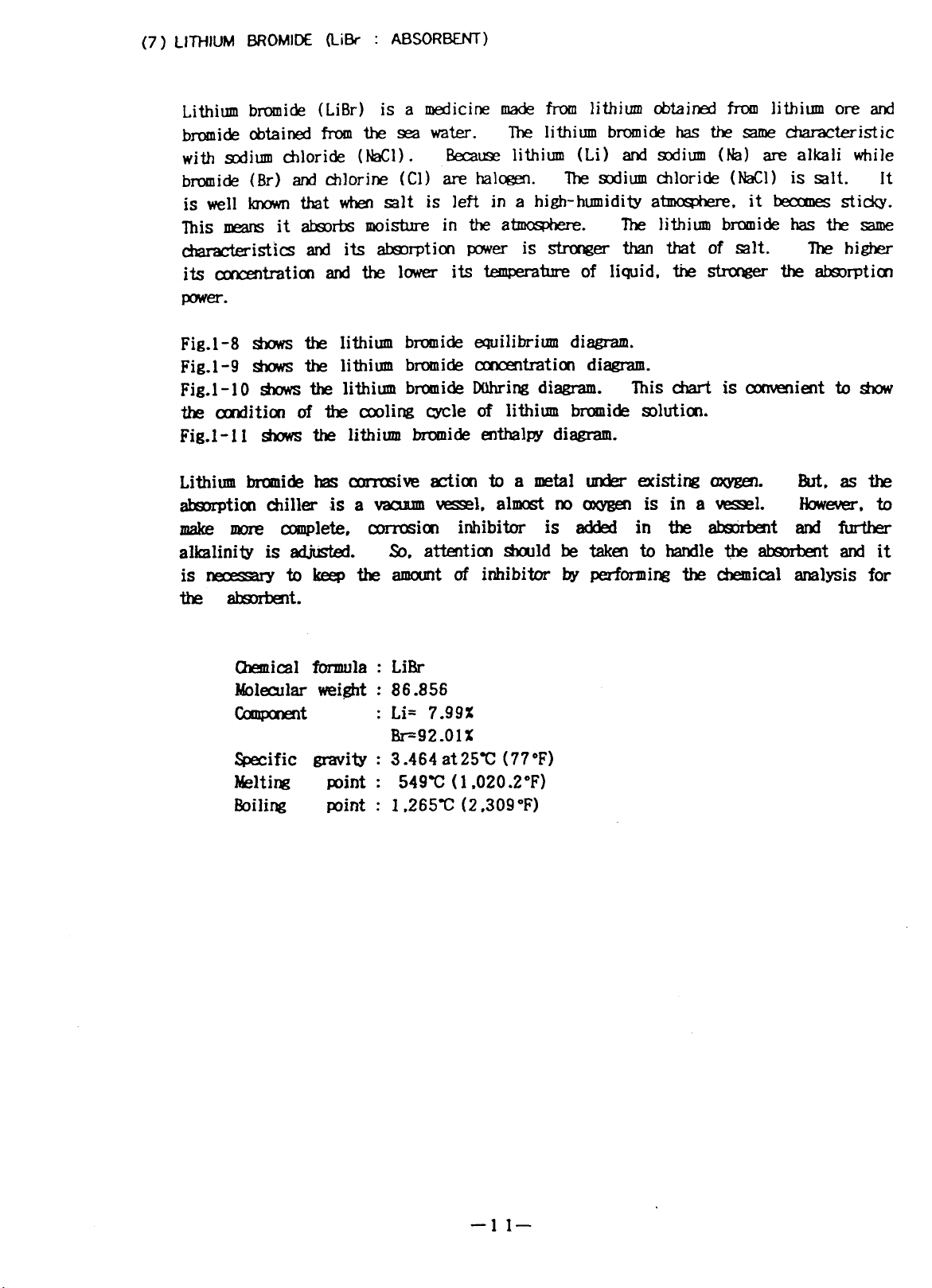

As shown Fig.1-8, a

LiBr solution of

temperature. For

When the temperature ofcooling water inthe condenser

Therefore condensed pressure

pressure is low, calolific value of driving heat source can

that the temperature of cooling water is too low.

few LiBr dissolves with water at low temperature.

high concentration becomes crystallization under the lower

example, it is crystallized with concentration” of 65% at the

temperature lower then 42C (108F) with concentration of 60%

lower than 17C (63°F).

Chiller has some problems when cooling water temperature becomes too high

c)

When the temperature of the cooling water becomes high, the absorption power of the

LiBr solution decreases.

temperature and wastes much fuel.

The chiller can not get the normal chilled water

Therefore. to prevent this, the maintenance for

cooling water system (equipment and control) and water treatment are required.

of the

is low.

becomes

lhat is, the

at the temperature

d)

Water treatment of

cooling water

The water treatment of the cooling water is an important factor for the chiller. If

the water quality is no good, scale adheres to the inside of the heat transfer tubes,

resulting in the decreases transfer heat effect and waste fuel.

Asthe heat transfer

tubes may become corroded, itisrequired to fully take care of the water treatment.

–9–

Page 13

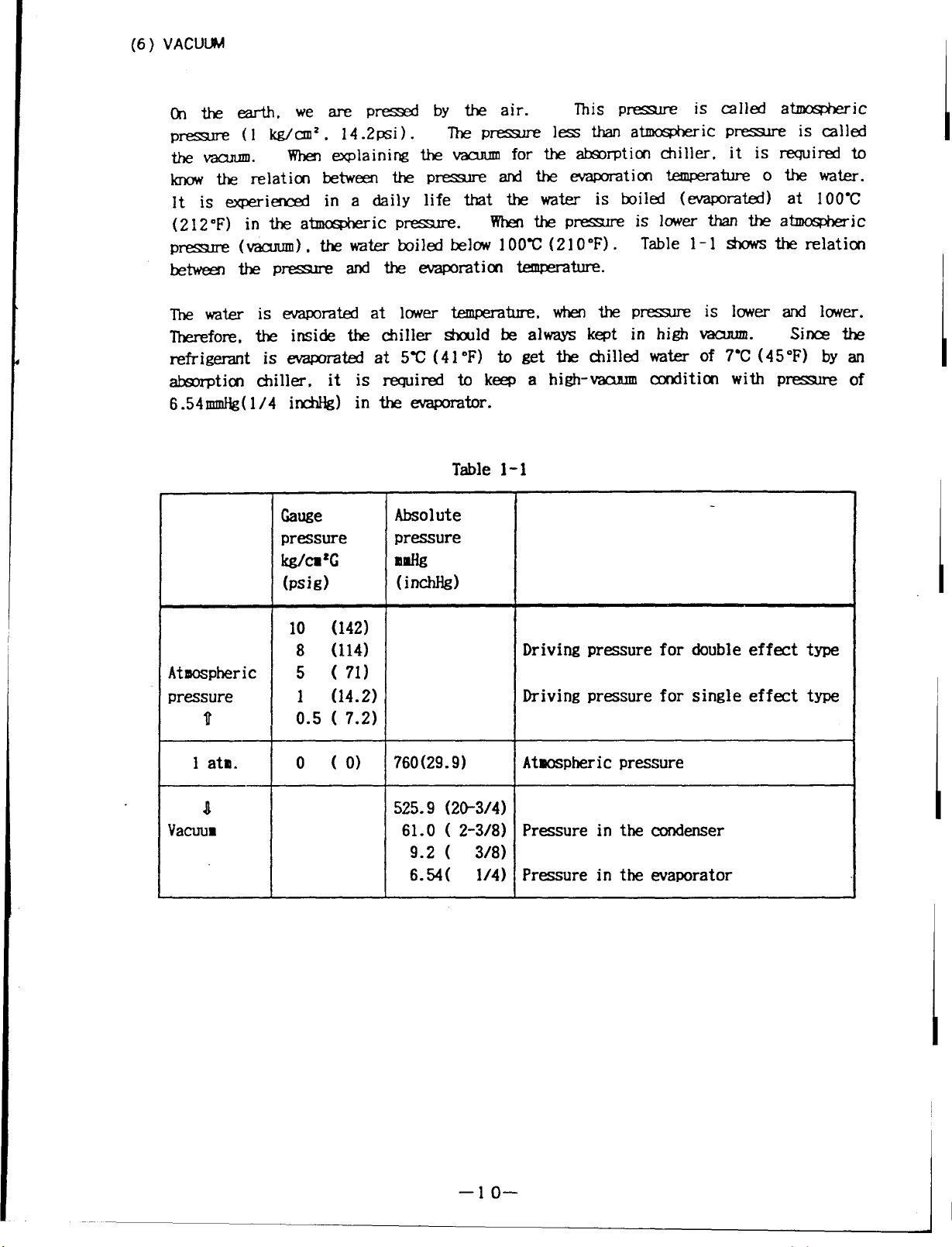

(6) VACUUM

Onthe earth, wearepressed by the air.

pressure (1 kg/cm2, 14.2psi). The pressure

the vacuum.

know the relation between the pressure

lt is experienced in a daiily life that the water is boiled (evaporated) at 100C

(212”F) in theatmospheric pressure.

pressure

between the pressure

Ihe

Therefore, the inside the chiller should be always kept in high vacuum.

refrigerant is evaporated at 5C (41 oF) to get the chilled water of 7C (45F) by an

absorption chiller,

6.54mmHg(1/4 inchHg) in the evaporator.

(

water is evaporated at lower temperature, when the pressure

When explaining the vacuum

vacuum), the water boiled below 100C (210”F). Table 1-1 shows the relation

and the evaporation temperature.

it is required to keep a high-vacuum condition with

Table 1-1

Gauge

pressure pressure

kgh’e

(psig)

Absolute

mldk

(inchM)

for the absorption chiller. it is required to

and the

When the pressure

This pressure

less than atmospheric pressure

evaporation t.emperature o the water.

is lower than the atmospheric

is called atmospheric

is called

is lower and lower.

Sines the

Pressure

of

10 (142)

8 (114)

Atmospheric

pressure 1 (14.2)

u

1 ata.

n

Yacmm

5 ( 71)

0.5 ( 7.2)

o (o) 760(29. 9)

Driving pressure for double effect type

Driving pressure for single effect type

Atwpheri c pressure

525.9 (2&3/4)

61.0 ( 2-3/8) Pressure in the condenser

9.2 ( 3/8)

6.54( 1/4) Pressure in the waporator

I

I

–lo–

Page 14

(7) LITYIUM BROMIDE (LiBr : ABSORBENT)

Lithium bromide (LiBr) is a medicine made from lithium obtained from lithium ore and

bromide obtained from the sea water.

with sodium chloride (NaCl) .

Because lithium (Li) and sodium (Na) are alkali while

brumide (Br) and chlorine (Cl) are halcgen.

The lithium bromide has the same characteristic

the sodium chloride (Ml) is salt. It

is well known that when salt is left in a high-humidity atmosphere. it becomes sticky.

This means it absorbs moisture in the atmosphere.

The lithium bromide has the same

characteristics and its absorption power is Stronger than that of salt.

its concentration and the lower itstemperature of liquid. thestronger the absorption

power.

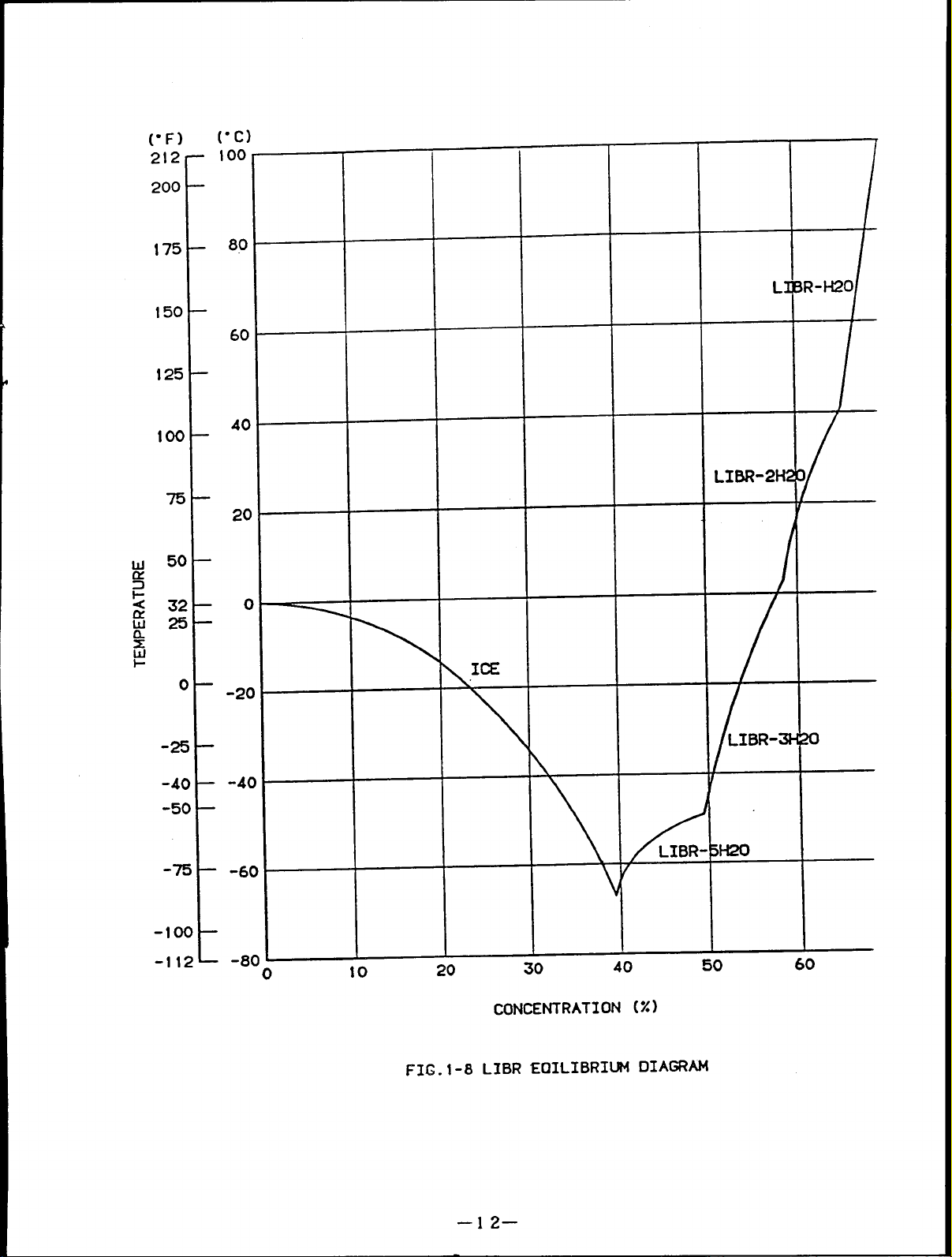

Fig.1-8 shows the lithium bromide equilibrium diagram.

Fig.1-9 shows the lithium bromide concentration diagram.

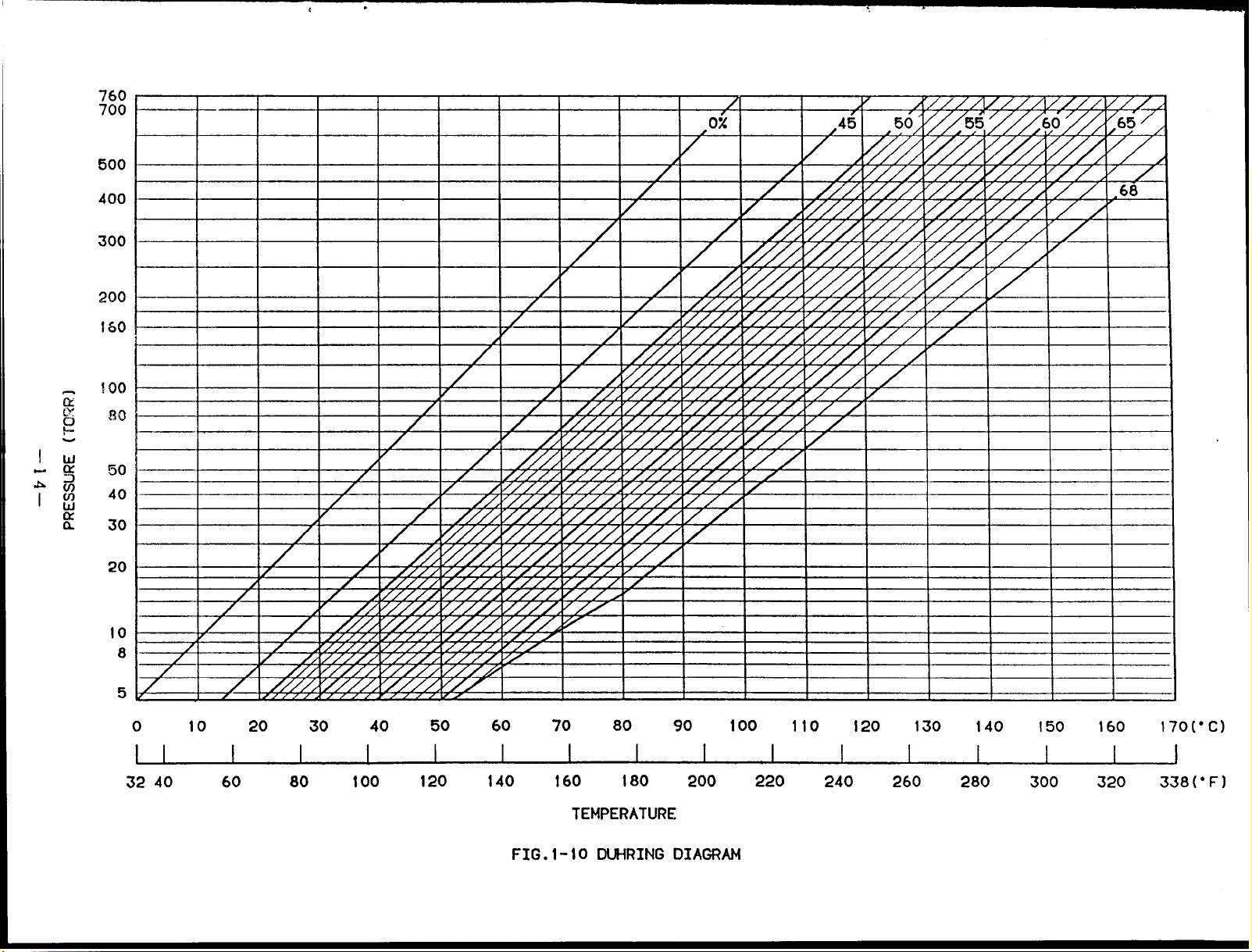

Fig.1-l0 shows the lithium bromide DUhring diagram.

This chart is convenient to show

thecondition of the cooling cycle of lithium bromide solution.

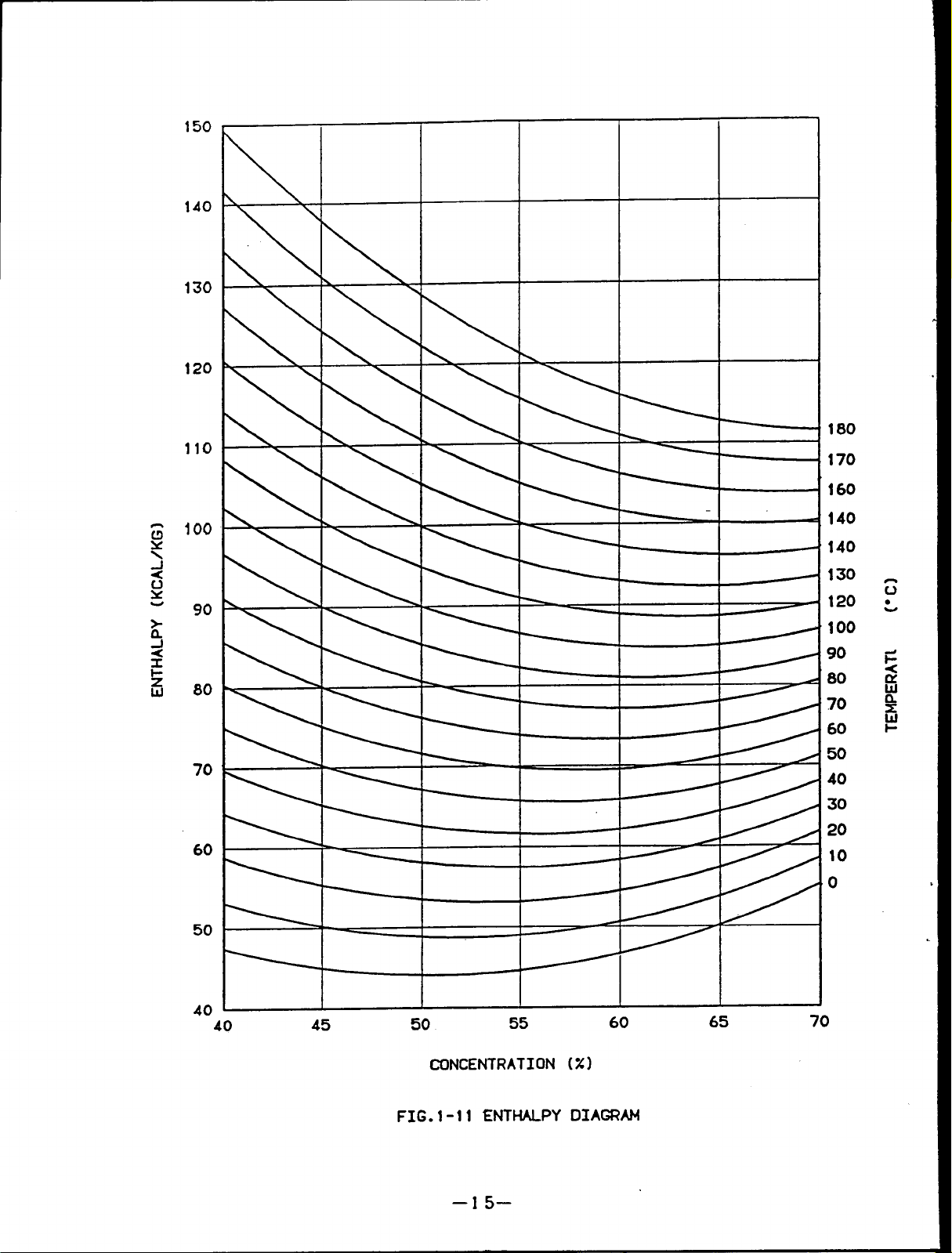

Fig.1-l1 shows the lithium bromide enthalpy diagram.

Ihe higher

Lithium bromide has corrosive action to a metal under existing oxygen.

absorption chiller is a vacuum vessel, almost no oxygen is in a vessel.

But, as the

However, to

make more complete, corrosion inhibitor is added in the absorbent and further

alkalinity is adjusted.

So, attention should be taken to handle the absorbent and it

isnecessary to keep the amount of inhibitor by performing the chemical analysis for

the absorbent.

Chemical formula : Li13r

Molecular weight : 86.856

Component

: Li= 7.99%

Br=92.01%

Specific gravity : 3.464 at25C (77”F)

Melting

Boiling point : 1,265C

point :

549C ( 1,020.2”F)

(2,309Φ)

–11–

Page 15

(“F)

2!2

200

(“c)

I 00

17!5

150

125

10C

5(

x

80

60

40 ‘

20

0

-20

-lo

-2!

-4(

-5’

-7

-40

-60

-80

10

20

CONCENTRATION (X)

FIG.1-8 LIBR

30

EOILIBRI~ DIAGRAM

40

50

60

–12–

Page 16

TEMPERATURE

1.90°

1.85

1.80

1.75

1.70

32 50

10

-

75

I

I

100

I

125

I

150

I

20 30 40 50 60 70 80 90

I I

175

I

1

200 212(”FI

I

1OO(”C)

I

67

66

65

64

63

62

61

60

I

1.65

1.60

1.55

1.50

1.45

1.401

59

58

m

57

56

l=+

1

I

55

54

53

52

-1

51

50

49

48

47

46

45

0

10 20 30 40 50 60 70 80 90

100[”CI

32 50 75

FIG.

100 125 150

TEt@ERATURE

1-9 CDNCENTRATICN DIAGRAM

–13–

175

200 212(”F)

Page 17

;::

500

400

300

200

160

!cm

f30

50

40

30

‘z

J21

20

10

8

5

0

32 40

10 20 30 40 50 60 70 80 90

60

80

100

120 140 160

TEMPERATURE

FIG.1-10

180 200

DUHRINGDIAGRAM

100 110 120

220

240

260

130

280

140

150

160

300 320

170(”C)

338(°F)

Page 18

150

140

130

120

110

— 160

100

90

k -.

80

70

60

170

50

40

40

45 50

FIG.1-11 ENTHALPY DIAGRAM

55

CONCENTRATION (%)

–15–

60

65

70

Page 19

r

(8) COOLING CYCLE

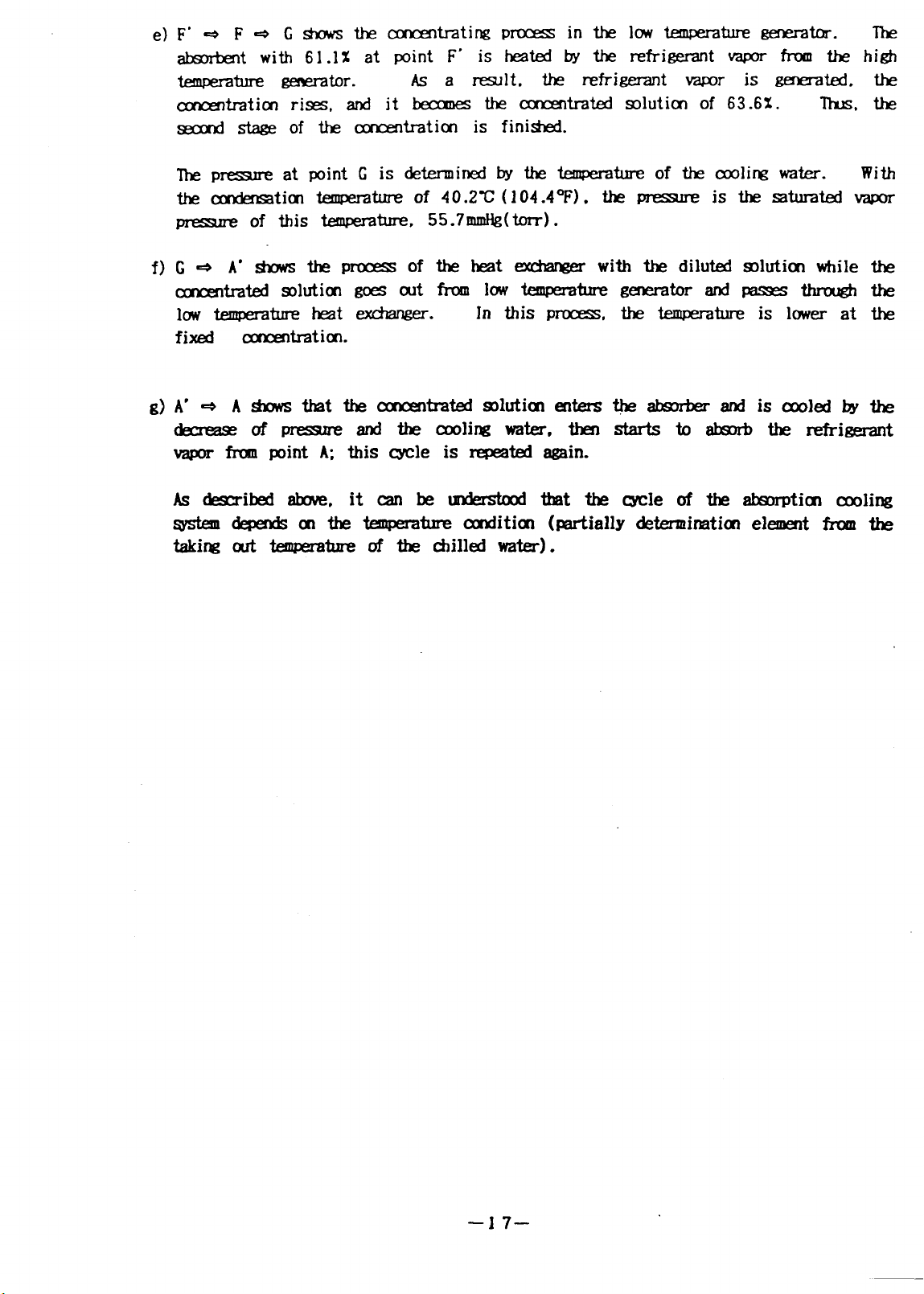

An example for the actual driving cycle of double effect type is explained using the

Duhring diagram.

A Bshows the absorption process in theabsorber.

a)

The absorbent with concen-

tration of 63.6% at point A absorbs the refrigerant vapor from the evaporator as it is

cooled until 36.3-C (97.3”F) by cooling water, then becomes diluted solution with

concentration of 58.1% at point B.

The pressure of this point is 6.31mmHg(torr) which is equal to the saturation vapor

pressure of water at 4.3C (39.7°F) (cross point on

the chilled water at 7C (44.6°F) can be produced in

Therefore, the higher the temperature of the cooling

internal pressure (equal to the evaporator internal

evaporation temperature of refrigerant becomes high

the saturation liquid line) , so,

the evaporator.

water, the higher the absorber

pressure) .

As a result, the

and chilled water can not be

obtained.

B+ C+ D”shows the temperature rise

b)

process under the fixed concentration when

the diluted solution pass through the low

D’+D+E shows the heating and concentrating process inthe high temperature

c)

generator..

The diluted solution at point D’ is heated until point D.

the refrigerant vapor and

is concentrated. Then it becomes the intermediate

It releases

solution of 61.1% at point E and finishes the first stage of concentrating.

The pressure at point E becomes approx. 707.lmmHg(torr).

the pressure of 55.7mmHg(torr) in the condenser

temperature of cooling water.

That is, the pressure inside the low temperature

determining it according to the

(This pressure

depends on

generator has to be performed at the temperature higher than 91.1C(196”F) of the

concentrated solution obtained from the cross point with the concentrated solution

of 63.6%. Whensetting to 97.9C (208.2 “F) by making this as AT 6.8C (12.2”F) , the

pressure of the high temperature generator becomes 707.lmmHg(torr).

d)

--16–

Page 20

e

absorbent with 61.1% at point F’ is heated by the refrigerant vapor from the

temperature generator.

concentration rises, and it becomes the concentrated solution of 63.6%. thus

second stage of the concentration is finished.

As a result.

the refrigerant vapor is generated.

F+F+Gshows the

The

high

the

the

conce

The pressure at point G is determined by the temperature of the cooling water.

the condensation temperature of 40.2C (104.4”F). the

pressure of this temperature. 55.7mmHg(torr).

f)

A’+Ashows that the concentrated solution enters the absorber and iscooled bythe

g)

decrease ofpressure and

vapor from point A; this cycle is repeated again.

Asdescribed above, itcanbeunderstood that the cycle of the absorption cooling

system depends onthe temperature condition (partially dertermination element from the

taking out temperature of the chilled water).

With

pressureis thesaturated vapor

thecooling water, then starts toabsorb the refrigerant

–17–

Page 21

w

-1

cl

z

-1

t-

ti

-. —

v,

m“

.,

CfJ

u

e

C6

u

—18—

.-,

m

It+

Page 22

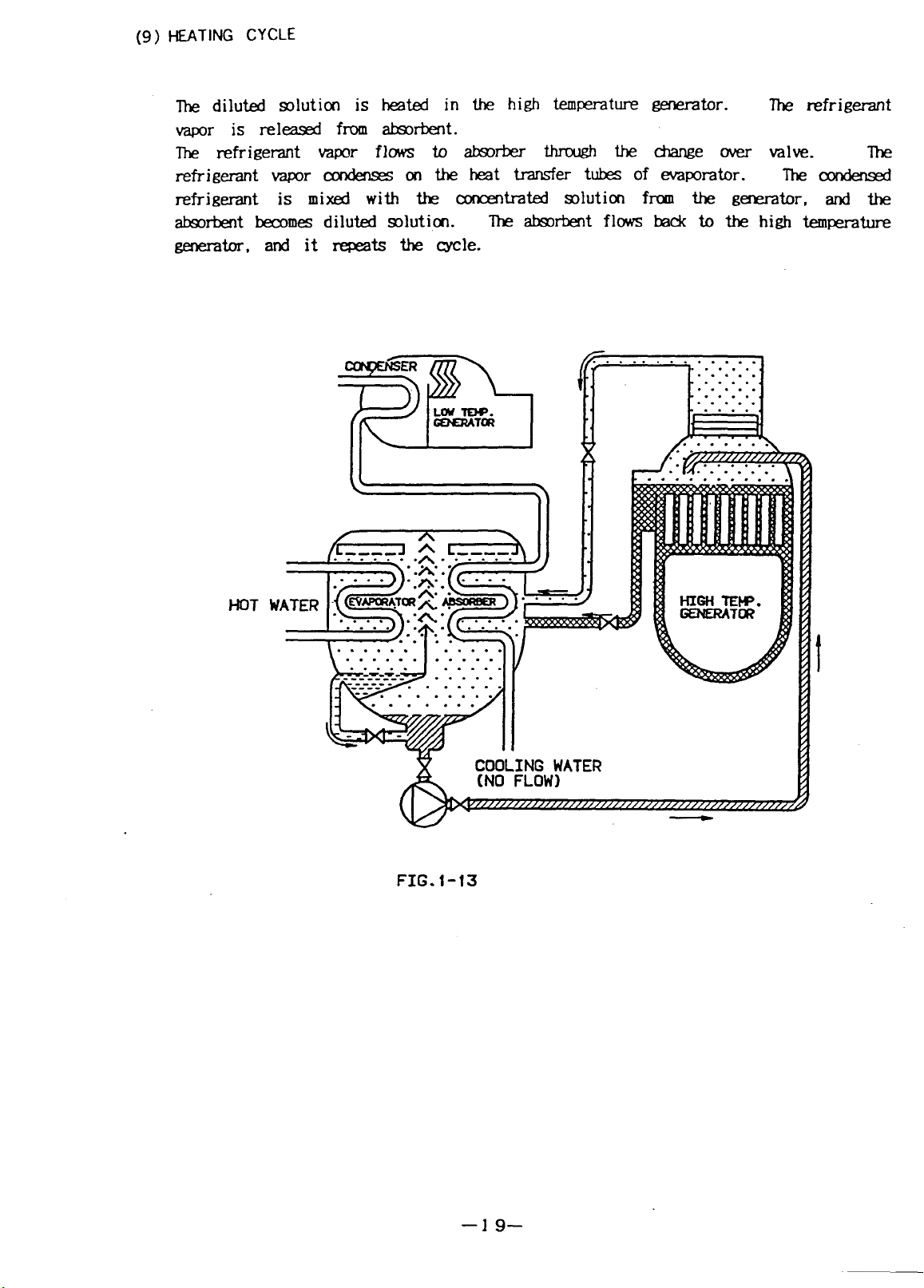

HEATING CYCLE

(9)

The diluted solution is heated in the high temperature generator.

The refrigerant

vapor is released from absorbent.

The refrigerant vapor flows to absorber through the change over valve.

refrigerant vapor

condenses on the heat transfer tubes of evaporator. The condensed

The

refrigerant is mixed with the concentrated solution from the generator, and the

absorbent becomes diluted solution.

The absorbent flows back to the high temperature

generator, and it repeats the role.

ER

LtM W.

~TU?

m

HOT

w

t

FIG. f-13

–19–

Page 23

I

N

7’

6

G

I

CHILLED

INLET

PURGE I

UNIT

I

I

t

COOLING WATER I )

OUIL T—

t

II

Ii n JJ15Ld

—

I

I

I

I

I

I

I

I

I

I

L!Kx__d3cH

mcoNcENTRATEO SOLUTION

=INTERMEo IATE SOLUTION

~~OILUTEO SOLUTION

REFRIGERANT PUMP

012

n I

Cotjofi

. . . . . .

L

/wl

/

/

B VALVE

1

[-J REFRIGERANT

[-] REFRIGERANT VAPOR

I I

——

——_

“T

LOW TEMP. GENERATOR

I

.< ‘ “

w

DT 7

‘P

_+

——

——

—

——— __

—

— — _ _ _ _—_—_—_

t

COOLING WATER’

LuL___

L 81 ABSORBENT PUMP

~OPEN

MCLOSE

..

1-

63GH ~

(II

km

I

I

I

I

I

I

I

I

I

I

I

REa_Ns

—

—

—

—

—

——

—_ ___ ___ _

—-l

—

— —

I

I

I

I

I

I

-H ‘

G ‘xcHANG”-

(THIS PUMP IS PRC)VIOEO ON

MOOEL OC-23 TO OC-83 ONLY)

LOW TEMP.

HEAT EXCHANGER

FIG. 1-14 COOLING FLOW CHART

Page 24

Evapaator

a)

The refrigerant isdispersed on the heat transfer

through the heat transfer tubes ofevaporator

vaporized

Absorber

b)

refrigerant.

tubes of evaporator.

Chilled water

is cooled by the latent beat of

FIG. I-15

–21–

Page 25

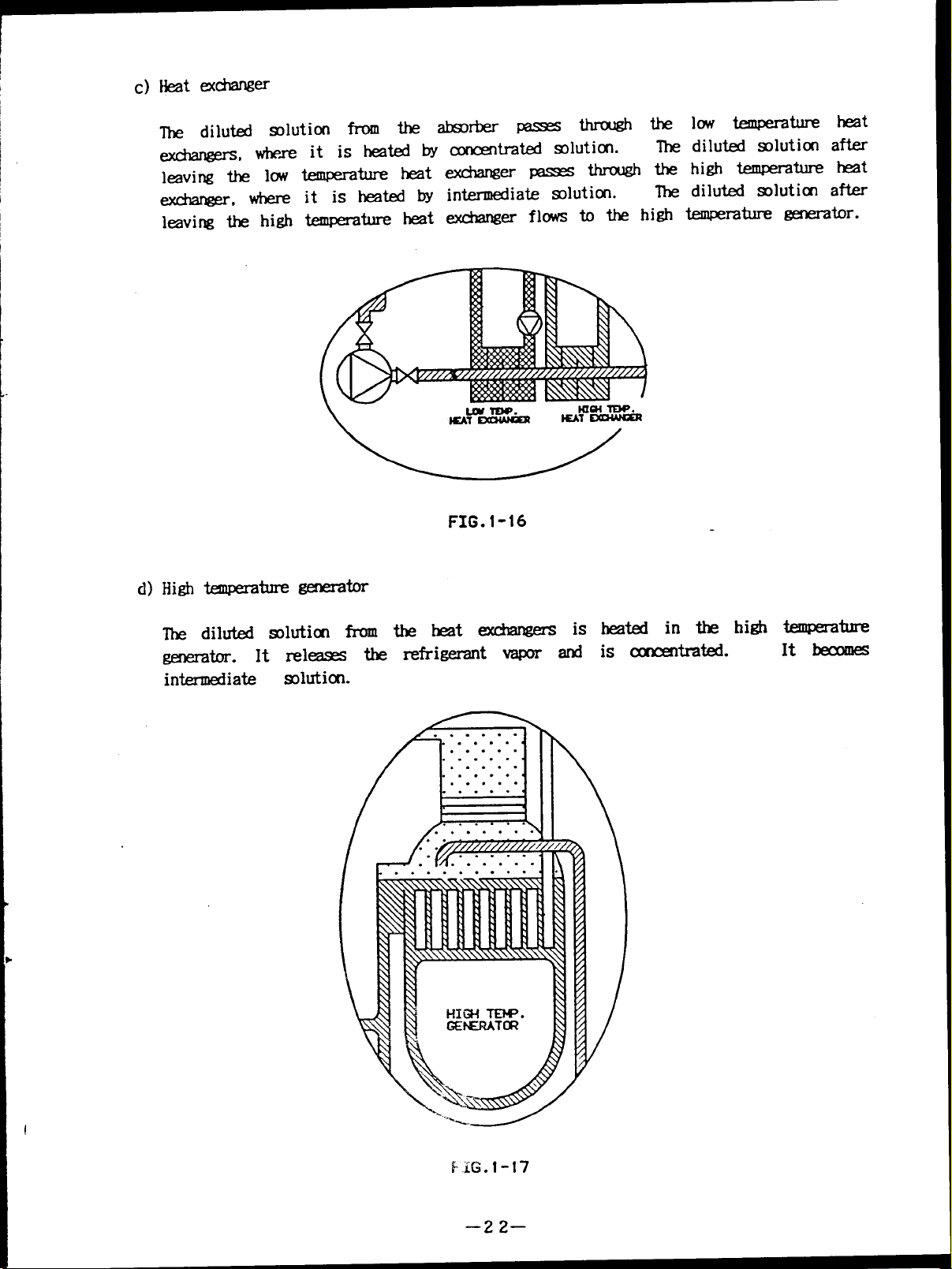

low temperature

the

diluted solution

The

high temperature

the

diluted solution

The

heat

after

heat

after

leaving the high temperature heat exchanger flows to the high temperature generator.

FIG. I-16

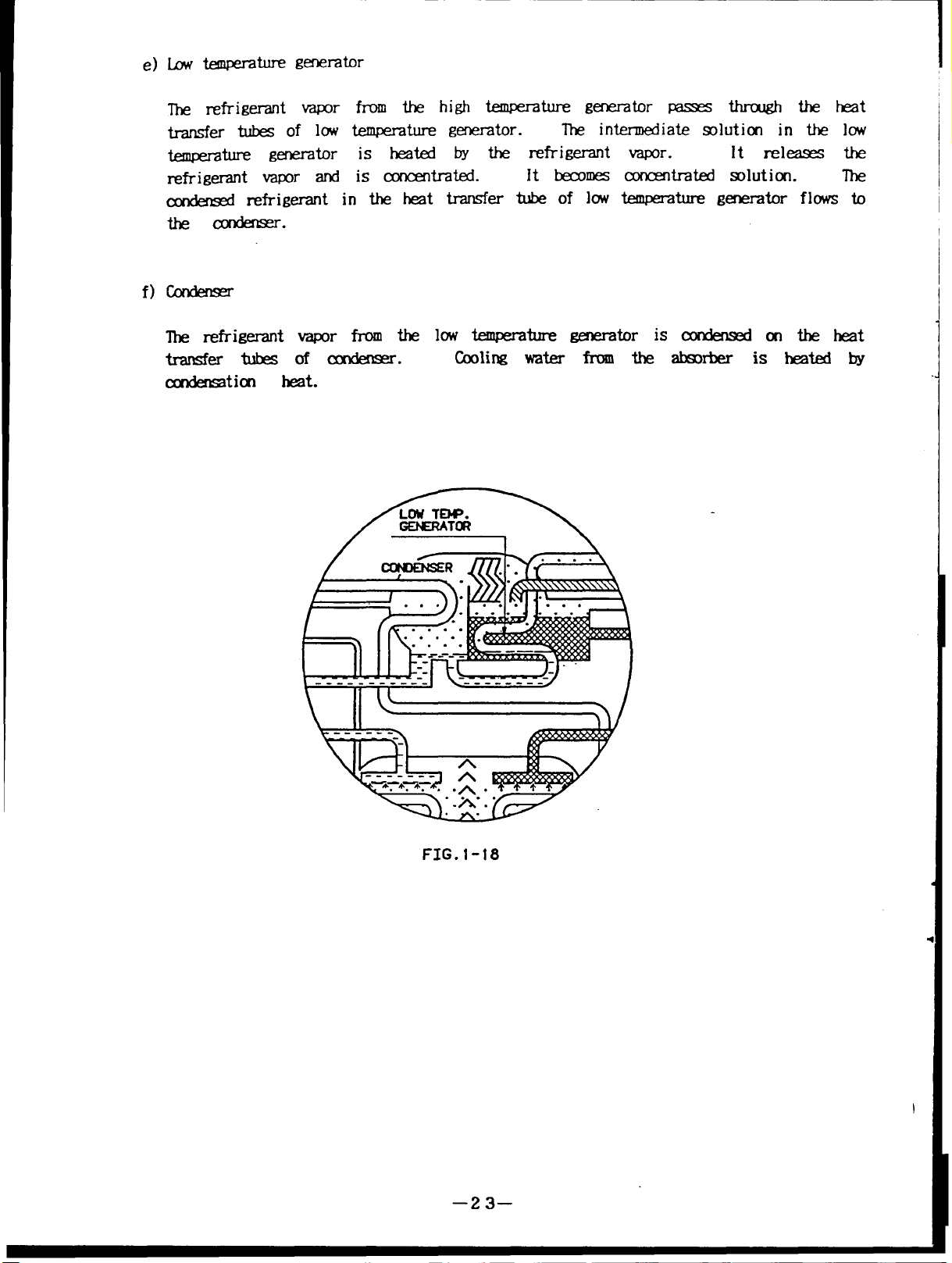

The diluted slution from the heat exchangers

is heated in the high temperature

generator. It releases therefrigerantvapor and is concentrated.

intermediate

solution.

It becomes

EiG.l -17

–22–

Page 26

The refrigerant vapor from the high temperature passes through the heat

transfer

temperature generator is

tubes of low temperature generator.

heated by the refrigerant vapor.

refrigerant vapor and is concentrated.

The intermediate solution in the low

It releases the

lt becomes concentrated solution. The

condensed refrigerant in the heat transfer tube of low temperature generator flows to

the condenser.

f)Condenser

The refrigerant vapor from the low temperature

transfer tubes ofcondenser.

Cooling water

condensation heat.

generator is condensed

from the absorber isheated by

onthe heat

FIG.1-18

–23–

Page 27

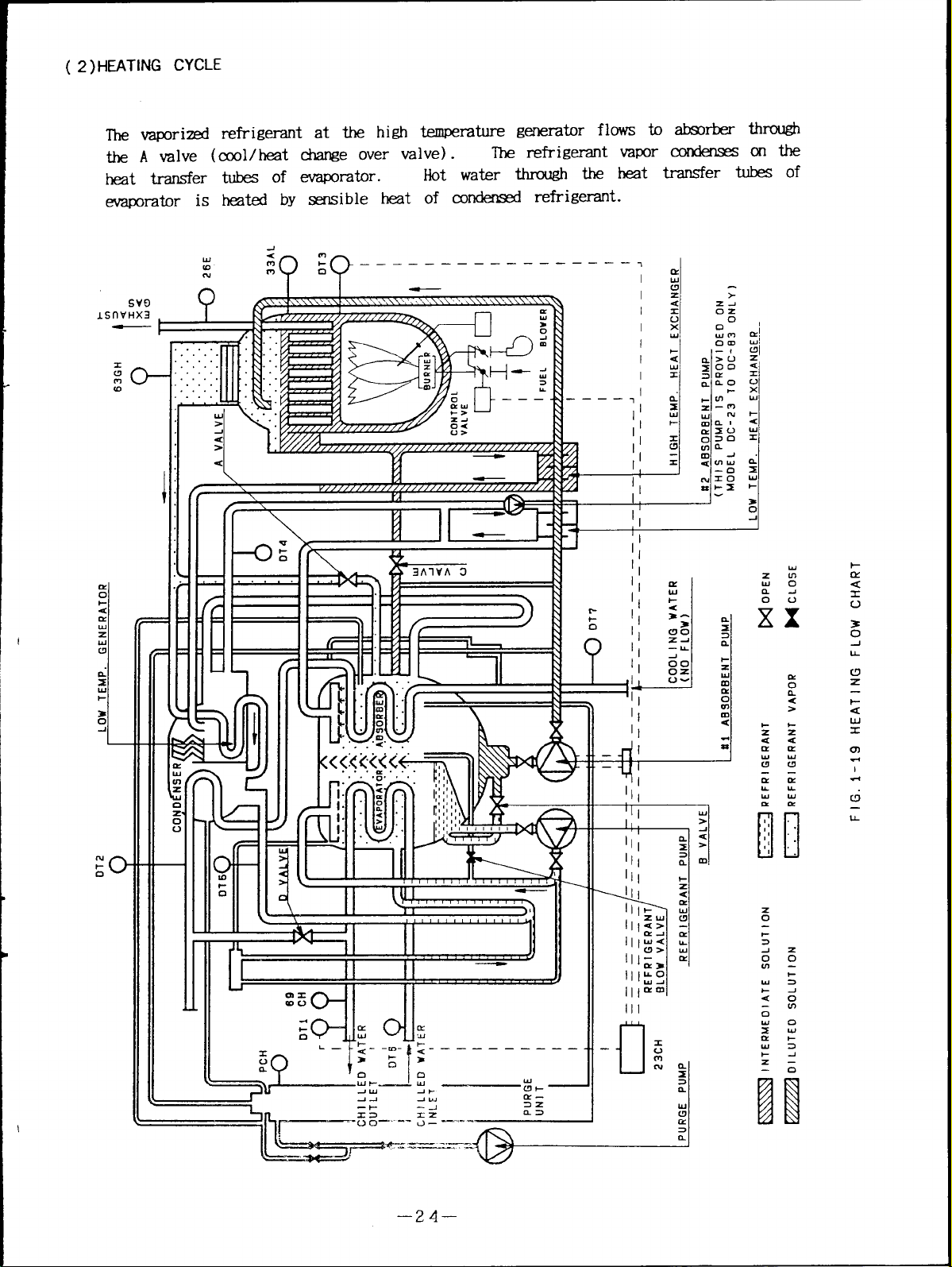

( 2) HEATING CYCLE

The vaporized refrigemnt at the high temperature generator flows to absorber through

the A valve (cool/heat change over valve).

—.-

transfer tubes of evaporator.

heat

Hot water through the heat

The refrigerant condenseson the

transfer tubes of

evaporator is heated by sensible heat of condensed refrigerant.

Svfl

‘HX3

m

:

k——————— —

‘? ?

———————

.

v>y\\.,..\\\\\\.>\\\.\

il

\

.

.

B

0

——T

I

0-

. . .

,

UJ

z

4

>

.-

. . .

. .

yr---

0<

u>

<

w’,nff!j‘!

~

I

r. m, —

‘“’”mr~

Zll 111~

1111-11

III

r

I

1

L

II 7 II ~~ II II

\

\

Y

1X1

II 1111

II 111[

,

1

1

II

—

t$---l’

,1

1;

II

.

—

!1

I

I

I

3-

--J

>1

UJ

>

A

-1

>

m

1

z

i!

t-

4

u

x

n

0)

.

I

.+

cl

u

.,______ .=

–24–

u

1-

2

Page 28

m

I L

)LplIr“

.,

n

u

F

r

c

C/?

+

m

>

~

o

z

t

!!!

‘CONTROL PANEL

PURGE UNIT

FIQ. 1-20 ILLUSTRATION

I

‘HIGH TEMPERATURE GENERATOR

I

~GAS TRAIN

$

L BURNER

Page 29

—

PCH

I

w

T

LOW TEMPERATURE

CONOENSER (CON,

,12-T

COOLING WATER

OUTLET

“sORBER(ABs)AlxlM

CHILLEOiHOT

OUTLET

EVAPORATOR

CH1iLEEJ/HOT

INLET

69CH

WATER--- r

(

EVA+

oT6—

WATE

B

VALVE

GENERATOR (LT. GENE)

\

‘/

OT7=

11/

,’

/“’-”

/

,V2

/-”

/“”

/

/vf

,OPERATION BOARD

,MANOMETER

,CONTROL PANEL

,PURGE TANK

SV2

Svl

HIGH TEMPERATURE

GENERATOR (HT. GENE)

M

xl

‘URGE‘uMp----k

FIG. 1-21 FRONT VIEW

‘L-- LIQU,D

TRAP

GAS INLET

+’

Page 30

( 3 )DETAIL OF TYPICAL CHILLER/ HEATER

(Rear

view : Burner side)

WE

no

zl-

wa

I-CY

n

3Y

OUJ

-lC!J

t<

m

0

n

4

>

1-

1-

\\k\

/

>

m

ml

W

I

.

u

rY

n

1-

a

&w

U.l (cl

Z3

–27–

Ck

5

a

CE

1-

m

a

C!Y

Page 31

( 4 )DETAIL OF TYPICAL CHILLER/ HEATER

(Right side view

: High temperature genmtor side)

m

J

z

a

w

1-

‘“d

an

>

Ida

~ >>

\

‘%

<

.w\

L1.1./F

o

d

>

u)

\

w

1-

zm JO

0< an

l-+ (J-)

J

)

)

>

-1

Otx

(no

-u-

Lua

>Z

-1=1

an

>

zm

0<

—

I-tu

a=

-1

Om

o-1o

-L

m

rY

m

Cd

+

Ci

IL

1

0’!

n

I

-J

w

z

a

o.

-1

0

w

t-z

G

L1

‘1

LLJn

>ZILJ

-13 >

-xn_l

>a

m>

zm -

0< v

l-ml

an

$CK

U-JO

—LA-

–28–

Page 32

CHECK VALVE

COOLING WATER

OUTLET

r

D VALVE

REFRIGERANT TANK

rOT’

*

SV9

I

N

T

1

1# .

I

1

1

CHILLED/HOT WATER

OUTLET

CHILLEO/HOT WATER

INLET

#2 ABS PUMP

P

-IsOLATION VALVE

FOR REF PUMP

L

ISOLATION VALVE

FOR REF PUMP

FOR Ill ABS PUMP

L

\

ISOLATION VALVE

81 ABS PUMP

FOR

NO. 1 ABSORBENT PUMP

ISOLATION VALVE

NO, 2 ABSORBENT PUMP

(82 ABS PUMP)

(81 ABS PUMP)

FIG. 1-24 LEFT VIEW

Page 33

(6) TYPCALCCNTROLP-

f

‘<

INDICATION LAMP

m

OPERATION BOARD

EMERGENCY

STOP SWITCH

II

‘“ CONTROL PANEL

/ HIGH VOLTAGE

FIELD W

/

CONTROL

FIELD W

I

b

II

RING OPEN

CIRCUIT

RING OPEN

NG

NG

FIT. 1-25 CONTROL PANEL

—3 o—

Page 34

/,/”

/’

/

/’-’-’

,’

.

,cONTROL BOARD

CONTROL RELAY

FAN MOTOR

,MODE SELECT SWITCH UNIT

\

,/

.

.

/’-” ‘“’ES

,

~ TERMINAL BLOCK

~ CONTROL TRANSFORMER

PoTENTIOMETER

FUSE HOLDERS

I

POWER TRANSFORMER

INVERTER

000

REACTOR

L

000

CIRCUIT BREAKER

/“”

,

WIRE CHANNELS

I //

I-’-J

w.,

[

FIG. 1-26 INSIDE OF CONTROL PANEL

I

‘-=--

.

--....

1.

.

‘“‘-\

.

~MAGNETIC CONTACTOR

~MAGNETIC coNTAcTOR

— REFRIGERANT PUMP

~ CONTRO CIRCUIT

~ MOTOR TERMINAL BLOCK

-~

=-..

NO. 1 ABSORBENT PUMP

NO. 2 ABSORBENT PUMP

MAGNETIC CONTACTOR

PURGE PUMP

MAGNETIC CONTACTOR

TERMINAL BLOCKS

HIGH VOLTAGE

FIELD WIRING TERMINAL BLOCK

= INTERNAL WIRING

\,

‘\

CONTROL CIRCUIT

FIELD WIRING TERMINAL BLOCK

–31—

Page 35

( 7) TYPICAL BURNER, GAS TRAIN AND BURNER CONTROL PANEL

MA NI HOLD PRESSURE GAUGE

/

I-7’ / “

14

,MODULATUIN MOTOR

/BUTTERFLY VALVE

URNER BLOWER

/’

P

FIG. 1-27 TYPICAL

BURNER

CONTROL

PANEL

BURNER

MANUAL GAS SHUTOFF VALVE

I

REGULATOR

n

~1 g

/

2N0 SOLENOID VALVE

FIG. 1-28 TYPICAL GAS TRAIN

MAIN SOLENOID VALVE

/

BUTTERFLY VALVE

—32–

Page 36

ON-OFF SWITCH

\.

CALL FOR

HEAT LIGHT

“’/,, \

“/ / \

‘\

‘w,

OJOIO

IGNITION LAMP

FUEL ON LAMP

ALARM LAMP

i\

\

~llllt !

!

,/’

‘//

/

6’ @&j

/FUEL TRANFER SWITCH

/

,,

/MANUAL/AUTO

SELECT SWITCH

FIRING RATE

CONTROLLER

\\

\\

‘\,

\

AIR FLOW

SAFETY SWITCH

///

\

MAGNETIC CONTACTOR

\

\ OVERCURRENT RELAY

FIG. I-29 BURNER CONTROL PANEL

\ TRANSFORMER

/

\ BURNER

(FLAME

CONTROLLER

SAFEGUARO)

“–33–

Page 37

(8)SYMBOL

a) Chiller/heater

EVA

AM

CCND

HT.GENE

LT.GENE

HT.EX

LT.EX

#l ABs PuMP No.1 Abmrbent w

#2 A5s PuMP NO.2 Absxbent Pump

REF

constrwtion

symbol

Evawrator

Nxwber

High temperature fmemtir

Imw temper-alum mhemtor

High temperature heat exchanger

I.m temperature heat @&langer

FuMP Refrigerant m

Name

b) Temperatum smsor

s@Xd

DT1

DT2

Chilled/hot water ~tlet (%illed/hot water outlet pipe

Cooling water outlet

bcation

before

flange.

Cooling water outlet pipe

before

flange.

—

DT3 High temperature generator Back side of high tenuxrature

~t.or.

DT4 b t.enwemture generator

Intermediate mlution pipe of

LT.GENE outlet.

-—

DT5 Refrigerant pipe of mndensx

outlet.

—

DT6

.

DT7 Cooling water outlet

Chilled/hot water inlet

Chilled/hot water inlet pipe

before flarge

Cooling wak inlet pipe

before

flange.

–34–

Page 38

I

c) Sensor

d) Valve

Name

23CH

26E

Electronic controller

Exhaust gasikrmmXat

El J12J13J?4 Gmednr dutim level

electrod

33AL

beratur soluticn level

cmtrol board switch

63GH GmeAor presmre switch

69CH I ~illedhot water flow Witch

PCH

symbol

A valve

Palladium cell heater

Name

holing/hmting &al-l@ W=

A valve

Location

Incllxkxl opemticn board

Flue Pipecnthe HrLENE

Solution level box beside the

high t.empemturw ~tor

In the control panel

Near the

duticn level box

Chilled/hot Wati mtlet P@

ropal them tank

Location

Refrigerant vapor pipe bAind

the control panel

B valve

cooling/hinting change W=

B valve

C valve

cooling/hinting change wetC valve

D valve Cooling/hinting dangle w=

D valve

V1

V2

V3

V4 IRefrigerant blow valve

No.1 ~ valve

Ib2 ~ valve

No.3 mrge

valve

Under theevaporator heack?r

(Front side)

E!ehind the

invef-ter ml

NmrtheevapomtQ- hea&T

llesidethe~tank

E!esi&ttK? *tank

Bd&?thepLm3tank

EvaPcmtorside

—3 5—

Page 39

e) Service valve

SW-M

Name

Svl Service Mve for maintenance

Location

Besi&!the PlJr13e tank

-—

SV2 Service wdve far

SV3 Sewice valve for refrmt

SV4

Service valve for diluted

solution

SV5 Service valve for intermediate

solution

SV6

Service valve for ancmtratd Beside thelowtempemtln-e

solution

-.

SV7 Service valve for gmerator

Inamxm?ter BeSick them tank

h the refrigerant pipe

IbX-the No.labmrflmt pump

(outlet Pipe of #l m HJMP)

Besi& Ihe high tenwerati

heat ex&angel-

hmt eXc&nger-

On the solution level box

~-

SV8 =i~ valve for gmetator

maintmance

SV9

Service valve for heat

exchanEEr

mainterlanm hmt exdanger’s hemkr

Bottcmofthehightempemture

~b

E?esi& of high temperature

Svl 1

Setvice valve for Blladium

TcQthe~ tank

cell

f) IkmlP=

ml

D1

I

Name

IhnmY for diluted soluticn

Location

outlet pipe of#ll AIISFuIvlP

after check nlve

D2

Damper for intermediate

solution

D3

kmPer for Cmcmtrated

solution

.

g) Sight glass

symbol

Name

Mermdiate dutim Pipe

betwem ~EX and

Cmcmtratd Smtial pipe

LTIXNE

betwxm LTGJ3JEand LT.EX

Location

—

SGl

sight gk for refrigerant

Evaporator

level

—

SG2

sight glass for @lemtcr

Hfgmed.orbox

SG3

sight glass far kurw!r flare

.— .-—

—36–

Behind the gmezatcu-

Page 40

1,4SAFETYDEVICES

( l) CHILLED/HOT WATER AND COOLING WATER

No

Item

1 Interlock of chilldhot water pump

—

2 interlock of cooling water pump

3 Few flow ME of chiWcJ/hot water

4 Chilled water freeze protection

(Unv-d of chilled water outlet *.)

5 High-cut of hot water outlet temperatu.m

6 M-cut of cooling water inlet teuwerati

( 2)

HIGH TEMPERATURE GENERATOR

Setting point

Alarm indication

Mication lamp

klication lamp

50 % Indication lamP

2 .5°C (36 .50F) Itiication lamP

70T (158”F)

19°C (66.2°F)

Indication lamP

Indication lamp

after 30 min.

—

No

7 High-cut of generatnr temperature (Cooling)

8 High-cut of generator temperature(lleating)

Item Setting point Alarm indication

165°C (329°F)

130”C (266”F)

9 High-cut of generator pressure

10 High-cut of gened.or mlution level

+

—

11 *cut of gerxmtor ~lution level

—

12 High-cut of exhaust gas t.ewerature(bs) 300”C (5720F)

13 High-cut of exhaust gas temperature(Oil) 350”C (662°F)

14 Crystallization

(High-at of =lution concdration)

protection

65%

after 10 min.

—

Indication lamp

Indication lamP

Indication lamP

Indication lamP

Itiication lamP

Indication lamP

–3 7–

Page 41

(3)BURNER

No

15 Flame failure

16 Abrmnal combustion

(4)

MOTOR

No

Ovemlrrent relay of No.1 akrbent pump Rated ampemge

17

Ov

18

19

ermrrent relay of NO.2 akxberlt pump Rated amperage

0/

erarrent relay of refrigerant pump Rated amperage

Item

Item

Setting point

——

Setting point

Alarm

indication

Indication lamp

Indication lamp of

flame failure

AlamI indication

Indication lamP

Indication lamP

Indication lamP

( 5)

(Iv

20

[

OTHERS

No

21

22

23

24

[

ercmrent relay of burner blower

Item

Inverter

protection

Power interruption protect icm

Chattering protection of flow switch

Rupture di&

MM ~e

Indication lamp

Setting point Alarm indication

Indication lamp

100 m =.

I

I

3 sec.

I

Indication lamp

I

–38–

Page 42

SKKItf2 OMATMI

Si33VON2 OFIRATION--------------------------------------------------------------------39

2.1 OFiTtATIONBOARD------------------------------------------------------------40

CONTENTS

Page No.

.

(1) ~A~ ~

(2) INSITUTm OF ~S---------------------------------------------------42

2.2 lXMFIRAluRESEITING ""----------"-----"--"----"----------"--"------"--"---43

(I) ~AJL ~ M~~ ........................................................43

(2) ~ ~ ~ D~~~ D~y ................-................44

(3) %1-1’IM ~ --------

2.3 SIZJ?-DIAGKSI’ICSF’UNCI’ION---------------------------------------------51

(1)

SLF-DIIMNXTIGS FUhKXION -------------------------------------------51

o~T~ ~~.- .. . . . .. . . . . . . . . .. . . . . . . . ..__.. _. . . . . . . ...40

------------------------------------------------46

(2)ERtURMESSAGEBY SllF-DIAGNO~D--------------------------52

2.4 PRD31RATIONFOR STARTW------------------------------------------------54

( 1) ~IRMATION W

(2) CONFIRMATION~ ~~ po~s .................................55

(3) ~IRMATION OF U4AlWEOVIR VAL~--------------------------55

(4) ~wT~ ~ ~~m-- .........................................56

OHRATIONSWI’IUES--------------------------54

2.5 OPEiATION -----------------------------------------------------------------------58

CXXIJNGOFIRAT~ -------------------------------------------------------58

(1)

HEATIMOFIRATION-------------------------------------------------------6O

(2)

OPIRATIONBOARDCURINGOPIRATION-----------------------------62

(3)

COMBUSTIONTIME ~-------------------------------------------------65

(4)

CONTROLTIME CHART---------------------------------------------------67

(5)

MAXIMJM~ ~-----------------------------------------------69

(6)

mm CONIROLOF #l A6s

(7)

FR12X1’ OF U-IW

(8)

—3 9–

WATIRTEMFEWTURE-----------------------71

FUMP-’--------”-------------------70

Page 43

21 OPERATIONBOARD

(

l) DETAIL OF OPERATION BOARD

m--,

......... .. ................----

; TMZRATORE

I 0 GENERATOR

[ 0 EXHAUSTGAS

; 0 CH/HT W CWLET

:o CO WINLET

!mz&ilzi&’5 ‘::’ ~

!WATER ALARM

!ocHv TRm’.

:0 CH/NT W FLIX RATEO

~Ot?JWTEMp.

;O CO W FLIX RATE O BURNDi BLOWER O

\oHTw TEMP.

OPERATIONREtORD

0 C/H OPERATION

0 C/H ON-OFF

0 REF. PUMP OPERATION ,....................

0 COHINJSTION

MOTOR ALARM

0 REF. PUMP

Ail AK. PUMP O

0 112A6$. POMP O

OCHWTENP. ::

OHTWTEUP. [j

.........................

v .... .. . .. . . . . . ... .

GENERATORALARM

PRESSORE

o

SOLUTIONLEVEL

TFNPXDNCENTNATION O CM PRFMJN.E !

EXHAUSTGAS TEMP.

Cz..: @.;

SET POINT ~

,,

:;

::

.. .... ....

;TOP RUN

0 0 CHILLER/HE4TER

O 0 REF. POMP

O 0

#l ABS. PUMP

o 0 #z Ms.

0 0

0 0 BURNER BLOWER

SYSTEM AL4RN (1NTERLOCK)

0 CH W FUMP

o co w FunP

0 AIR FAN

PUMP

PURGE PIMP

CD -:

,.CZ3 ;-m a.:

:,

...........

~o COOLINC

;0 HEATIM

......... . .

-----.---------l––--i

OPERATION REMOTE

r––n c––~ ..

STOP

r-––l ~–’1 j

COMBUSTIONALAN ;

O AIR FLOW ~

O FLAKE FAILURE ;

0 BURNER

0 ALARM

IEZER STCP

————.

——

.........

... ....

!-CD

FIG. 2-1 Typical C&ration Board

A

Page 44

(i) Monitor

This area has some indication lamps (Red) which indicate temperature of several

points, operating hours,

temperature, and digital display (Red) which indicates data of lighted item.

(2) Select key

There is “SELECT”key for selection

insequence bypush thekey.

automatically after approx. 1 minute.

chilled and hot water parameter.

@ Equipment RUN-STOPindicator

This area has some “RUN” indication

(Red) which indicate conditions of

@ Operation mode indicator

The indication lamp

indicates operaton mode.

@ Combustion indicator

The indication lamp

lights during combustion.

number of burner ON-OFF times and setting point of

of display data item.

The item is displayed

The item returns to generator temperature

There are” A”and” V”keys forgetting of

lamps (Green) and some “STOP" indication 1amps

the equipment.

@ Alarm indicator

The indication lamp

flickers when the chiller/heater has abnormal condition.

@ Alarm item indicator

The indication lamp

@ Operation mode mode key

indicates alarm item.

There are keys for chiller/heater cperation.

@ Alarm buzzer stop key

There isbuzzer stop key when the abnormal condition ofthe

chiller/heater.

—41–

Page 45

( 2) INSTRUCTION OF KEYS

“ SELECT”

I

For the use of item selection for display.

The item is displayed in sequence

Change the item automatically when

by push the key.

You push the key continuously more

than 1second.

“A” For the use of change of setting Point.

Setting number is increased by push the key.

Increase

the number automatically when You push the key continuously

more than 1 second.

“v”

For the use of change of setting point.

Setting number is decreased

bythekey.

Decrease the number automatically when YOUpush the key continuously

more than lsecond.

“ OPERATION”

Operate the

chiller/beater by local mode.

The chiller/heater does not operate when the mode is set “Remote”.

The indication lamp on “OPERATION”key flickers when the male is set

“Local” .

For the chiller/heater operation, You must push the key more than

1 second ccntinuously.

This is protection of the chiller/heater.

Please Push the key continuously until flicker the indication lamp on

the key.

“ STOP” Stop the chiller/heater by local mode.

“STOP” key is accepted on either mode of “Local” and “Remote”.

The indication lamp on “STOP” key flickers when the stop signal is

accepted by push thekey.

For the chiller/heater stop, You must push the key over 1 second

continuously.

This is protection of the chiller/beater.

Please push the key continuously until flicker the indication lamp on

the key.

“

LOCAL” For the use of operation

on of the chiller/heater by “OPERATION”key on

the operation board.

not operate.

does

remote panel.

“ REMOTE”

When the mode isset

“Remote”,

the chiller/heater

For the use of operation of the chiller/beater by

“OPERATION”key is not accepted on “Remote” mode.

“ BUZZER STOP” For the use of stop of alarm buzzer when the

buzzer sounds by

abnormal condition of the chiller/heater.

I

-–4 2–

Page 46

2,2TEMPERATURESETTING

(1)

DETAIL OF MONITOR

I

TEMPERATURE

● GENERATOR

C) EXHAUSTGAS

0 CH/HT W OUTLET

C) CO W

INLET

OPERATIONRECORD

() C/H OPERATION

() C/H ON-OFF

0 REF. PUMPOPERATION

0

COMBUSTION

0 BURNER

ON-OFF

SET POINT

0 CHWTEMP.

0 HTW

TEMP.

● ‘F

I

: z

The data is displayed on the digital display by “SELECT”key.

indicated by indication lamp of item.

The data on the digital display is returned to generator temperature after approx.

1 minute automatically.

Fig. 2-2 is shown generator temperature.

The indication lamp after digital display lights according to unit of item.

Unit of temperature is “F ( Fahrenheit ).

3.

FIG. 2-2 Monitor

- 0 HOURS

OSTARTS

The item is selected by push on “SELECT”key.

C571

The selected item is

I

–43–

)

Page 47

(2) SEWN= (N TtE DGITAL DISPIAY

item is dimlwed in SEXWME

Sequene

K%%‘tiimtim1-

1 Gek&;emPerature

Exhaust gas

2

(EXI-lAw GAS)

3 Cb

4 Cooling witer

5 (%i 1lerkater

i 1led/hot water

out let temeratum

(CHm w m)

inlet temperature

WINIXI’)

(CO

operating hours :

(C/H CIPI33ATION)

temperature

Mmhka’.

Semmce ikms are as follows;

~le on the digital display

3

G G- =

(

300.0)

3 9

v w G

B

D G G

a

5. n

n

(

390.0)

(

44.0)

(

85.0)

( 1000)

6 Nmber of Chiller/heater

ON-OFFtimes :

(cm O?wFlv

Refrigerant pmm

7

operating hours

(R13?.FIRI!P0P13MTICN)

8

Combustion hours

(COMBUSTION)

9 BAmberof burner

ON-OFFt ims

(Buwm a+Om

z D

(

3 c E

( 900)

9

s G

(

z D G

( 200)

120)

950)

—44—

Page 48

Sequence

——.

10

——

11

Lighted indication lamP

——

Chilled water

temperature setting

for temperature

(CHW TEMP.)

Chilled water

temperature setting P z- G

for proportional

(CHW TEMP.)

12

13 Chilled water

Chilled water

temperature setting

for integral

(CHU

TEMP.)

_——

temperature setting

for differential

(CHWTEMP.)

Sample on the digital display

——. —

: B

[

d

4

4. D

Z2 a

:

(t44.0)

2.0)

(P

—

I

(1800)

E

(d 10)

14

Hot water

temperature setting

for temperature

k :

3

:- =

(HTW TIM’.) (t131.o)

15 Hot water

temperature setting

for proportional

(HTW TEMP.)

—

‘-1-6-”-

17 Hot water

Display sequence repeats No.1 thru No. 17.

Note) l.It will happen to display below number between No.1O and No.11.

This temperature which is controlled the chilled water outlet temperature by

external condition.

Hot water

temperature setting

for integral

(HTWTEMP.)

temperature setting

for differential

(HTU TEMP.)

“- ‘“””

..—.. ..— -.

——

F 5- Z

(P 6.0)

:

d

s G

(I 50) ~

3 ~

(d 30)

~

I

J

~(c

2.It will happen to display below number

This temperature which is controlled

external condition.

~(h,z,l)

–4 5–

46.4)

between No.14 and No.15.

the hot water outlet temperature by

.

—

Page 49

(3) SETTING METHOD

Chilled/hot water outlet temperature is mtrolled by digital PID (proportional.

Integral and differential).

temperature.

a) Chilled water setting point range

Setting item

Chilled water outlet

temperature

Proportional

Integral

Differential

Note) Temperati data sampling is 10 second interval.

b) Hot water setting point range

Setting item

Hot water outlet

temperature

::L 2.;:+

(1)

(D)

(t) \

41.0- 53.6 ‘F .-.

0

.—

o - 100s

I

I 104.0 -140.0 ‘F1 0.1-0.2 I

It is able to get chilled/hot water of stable

.—

:: -

- 2500 sec 10 sec P or PD action at O sec

1

- P or PI acticn at O sec

I

Range

step

I

1=

I

Remark

.—

—

Proportional

Integral

Differential

Note) Temperatum data sampling is 10 second interval.

Notice 1.

2.

3.

4.

5.

6.

-nij---p: ,00 sJ---T-

Please confirm the indication lamp of setting item before setting.

“A”and” V

If you change the setting during chiller/heater operation, chiller/heater is

controlled by new setting point soon.

Original setting point is set at factory.

Setting point of chilled water outlet temperature is for cooling mode.

And setting point of hot water outlet temperature is for heating mode.

Setting point is stored by non-volatile memory of semiconductor.

Therefore, setting point is kept continuously when power cut off.

(P) (

(1) I

2.0- 10.0 I 0.1-0.2 /

o - 2500 sec I 10 sec Por PDactionat Osec

1 secl Por PIactionat Osec

“ keys do not accept to cross the range number.

—.

Page 50

c) To take

an example((hilled water setting)

Setting item

. ..—

Chilled water outlet

temperature

Proportional

Integral

Differential

(t)

(P)

(1)

(D)

$

Setting procedure is as follows;

“ A “

2

‘ImlIII1

Original

+-

2.0 –

800 sec

—.. .— —

Iosefl

Target

———

46.0 “F

2.5

—.——

+----

——

t

900 S

40 Sec

‘p’ma=--l

se] ect the chi 11ed water temperatur~

setting(CH WTEMP.) by push the key.

The indication lamp of “CHWTEMP.”

1ights.

——

Push the “ A “ key.

Display data increases 0.1.

._L__-L-..-(t 44”2)

“SELECT” 1

4

~

(P

2.0)

“A”

5

‘EIIElll

(1’ 2.1)

“A”

6

EmIzIEl

(P 2.5)

Push the “ A “ key until 7.5.

If display data increases over 7.5,

push the “ v “ key.

data decreases 0.1.

..-

The display

Push the ‘“SELECT”key.

Display data indicates proportional

of chilled water outlet temperature.

.—

Push the “ A “ key.

Displw” data increases 0.1.

?ush the “ A

“ key until 2.5.

If display data increases over 2.5,

msh the “ V “ key.

The display

~ata decreases 0.1.

–47–

Page 51

No. Key

“SELECT’”

7

Digital display Explanation

Display data indicate; integral of

— ————

“A”

8

, &?”’’sELEon “Y -

J_

..—

(I 800)

I ~hi ]led water outlet

+

t,e~p~rat”r~o

———

‘ DmiiIEl ‘~’~;t:i;$;;es ‘0-

(1 810)

,

,.

~-- +

10

+

“SELECT”

, IItEiEl ~~ ~~ ; :;

If display data increases ove~ 900

~“nt~e’~sp~ay

.

.

“A”

9

Display data lndlcate~ differential

*7

(d 10)J

——

of chilled water outlet temperature.

11 “A”

~ 1‘:&;4i&&es 1-

I

(d 11)

L

12

“A”

I

~

(d 40)

If dlspla~ data increases ov~r 40

~~”~ “ :: ~ ‘nt~fli~p~~

data decreases 1. “

–48–

Page 52

an example{Hot water setting)

setting item

‘-.ter .+:-

temperature

Proportional

Integral

%

Differmtial

Procdure is as follows;

No.

—— .—

1

2

3

4

Key

“SELECT”

“ A “

“A”

“SELECT”

I

(t)

(P)

(I) – -

—.

(D) ~

6.0

50 s=

30 = 20 =

Digital display

&

(t131. o)

EImEIIl

(t131 .1)

EIImEl

(t134.6)

~

(P 6.0)

=1=

1:?’”

5.0

900 SEX

—. —

Explanation

Select the hot water temperature

setting(HT WTEMP.)by push the key.

The indication lamp of “HTW TEMP.”

lights.

——

‘:1%;:t$i:5J’es010 -

L-

—.

If display dat: increases ov&”57 O,

~~ ~ :: “ ~

‘nt~e’li~p]~

data decreases 0.1. ”

Push the “SELECT”key.

Display data indicates proportional

of hot water outlet temperature.

—

“v”

5

~

+

“v”

6

9

(P 5.9)

~J=2;;es 0’

If display data decreases ~l~w 5 0,

ti-

(P 5.0)

~~ ~~ ““:: ~

data increases 0.1. ”

“nt~~d~sp]a~

–4 9–

Page 53

No.

“nt~

7

__#_T..

Key

“SELECT;

A

“A”

Digital display

““m-;sE”a” “Y

(I 50) ~

~ ~~~~~~~$~~es ‘0-

.—.

(1 60)

I Display data indicate; integral of

hot water outlet temperature.

If display data increases ove~ 900

EuIIIiI,~~~~:::~

,.

:~1

“SELECT”

~

——

11 “v”

d ‘;~e;:;zies ‘-

‘k

12 “v”

(1 900)

(d 30) ,

(d 29)

——

data decreases 10. “

Push the “SELECT”key.

Display data indicates differential

of hot water outlet temperature.

Explanation

~ ~~i~i~~ ~z;~e~~~~

(d 20)

data decreases 1. “

–50–

Page 54

283 SELF-DIAGNOSTICS FUNCTIONS

(

1) SELF-DIAGNOSTIC FUNCTIONS

Self -diagxxtics

a) Some

indidim

FUWTCN

fmcticn darts, * the breaker of the chiller/hinter tum cn.

lamps light as - Fig.2-3.

Symbol O: Indication lamp does not light

Symbol ●

Symbol B

TEwmTtRE

0 CfNERAT~

ormALLsTc4s

Ooullrwm

Oalwlhlm

mm5zl:k55 “

VATTRALARM

● CHWTEW. ● Rm. F’lMP

● cW?fTw FUWmntilw. w

● CD WIWP.

● covmwm ● BLFuJm-

● Hrw TTMP.

: Indication lamp lights.

: lndication lamp of the key lights.

OPERATIONRKYRD

0 C/H cP!WT1f14

() c/H WCFF

0 RET. W cffJblTION

o mlKlmmN

Omm

KmRw GEMmm

● mEssmJ!

● scUJrlcN IJzWL ● mvl l!=’

● #2 Jws. fwK’

● -/CIXENRATICN

● EMML!STC4STEW.

m mlNr

OCHWTFMF’.

OtlrwTmP.

v

AIAFN

SRx’lw

● ● aiIulwHEAm

● ● Rm. FIM’

● ● al Ars. Fwr’

● ● #2 APs. PIJMP

● ● FIRCEFWF’

● ● EumTRRuMm

SYSml AIAml (Ir’mNmo

● ouHrwFIJw

● AIR FAN

ccuBusTIcNAuRm

● AIR FUM

● W FAIURE

● C4SPIURWU?

FIG. 2-3

Buzzer sounds 4times after1second ofturn onthebreaker.

b

Some indication lamp turn off after buzzer.

Self-diagnostics is worked.

c

Verson number isdisplayed onthe digital

self -diagnostics.

d)

error by self-diagnostics.

(Blew number

is for reference. )

Gnerator temperature is as shown;

UIEIzEl (,.,)

dis

Verson number isasshown:

(v 7.00)

chiller/heater’s specificatim.

digital display, if control circuit has no

.

—51–

Page 55

(2) ERROR MESSAGE BYSELF-DIAGNOSTICS

Error massage is displayed

on the digital display, when the error is found in the

circuit.

lncase of theerror, itis

necessary, please call to

If

necessay to call Sanyo’s service

Sanyo’s service represenative after memorized the error

representative.

message.

Power supply error

a)

This error massge is indicated the error of power supply to electronic controller.

The key access is not accept on this message.

It is necessary to call to Sanyo’s service

represenative.

(P-u))

Electronic controller error and setting point error

b)

message (on the digital display flickers)

(The

This error message is indicated the error of electronic controller or setting point.

Please call to Sanyo’s service

represenative with below error number.

It is not accepted the chiller/heater operation during indication of this message.

~(.rr.)

Kind oferrur mesage

~-----------------@ EYror rnmter

-“-1

}.............. @

— ------------

: ;“-{ 1------------- @ Error nuuber EU-2

::

-

;!

::

: ..............

●--------- @ Error nunber EU+-8

.......

----------- (3) I&ror nunber ERR-3

------- 6 FYror nmber EIR-5

---------- CDError nunber D?R-4

cDEI-rornumbermR-~

CDErmrnumkrmR-2

@Errwnumber ERR-3

(D Eh’-urnumber ERR-4

@ Ermrnumber E?R-5

@ Err0r~f33~-6

CDE-rOrnumkl- ERR-7

@Errurnumker EiRR-8

(Electrcmic cmtroller

(~~m mint err-or)

(Electrmic cmtroller

(Number of tiws data

(eating hours data

(Electrmic

(Etiic cGYtroIlet(Electrcmic ccdimller

:,

.......

‘------ hxlicate thekindofemr~

ERR-6

~or -r ~_~

(D Error nmber ITU+l

error) :

envr) :

error) :

err(r) :

cdroller

error) :

en-m) :

error) :

Call to service.

- the setting point and call

to service.

Call to service.

Call to service.

Call to service.

Call to service.

Call to service.

Cdl to service.

–52—

Page 56

Power failure error

c)

(lhe message on the digital display flickers)

This error message is indicated to return the power after power failure during

operation( include dilution cycle operation).

The power failure means not only power failure( include over 100 millisecond power

interruption) but also artifical power turn off the breaker.

If will happen to indicate this message when the breaker is turned on at first after

field wiring.

This error massage

d

Sensor error

(The message on the digital displav flickers)

This error massage is indicated the temperature sensor trouble.

Chiller/heater stops safety when high temperature generator temperature sensor( DT3)

and chilled/hot water outlet temperature sensor( DT1) are broken during operation.

the chiller/heater operates continuously, when other sensors(DT2, DT4, DT5, DT6 and

DT7) are broken.

Please call to Sanyo’s service representative.

~(~~r~)

Kind of error message

,----------------------------------------@ Error number SER-2 (DT2: Cooling water outlet)

_;:

I

10

~..;; , ,

— ,.....~ ;..,

is cleared when “OPERATION”key is Pushed.

But it is Possible to control bad condition.

.............-.

‘------------Indicate the kind of error message

:----------------------------------@ Error number SER-5 (DT5: Condenser)

~------------------------------@ Error number SER-3 (DT3: High temp. generator)

— -------------@ Error number SER-4 (DT4: Low temp. generator)

1---------- @ Error

—

‘---------------------------@ Error number SER-6 (DT6: Chilled/hot w.inlet)

...

number SER-1 (DT1: Chilled/hot w.outlet)

● ---------@ Error number SER-7 (DT7: Cooling water inlet)

Note) It is possible to change the displav data and *tting point on the digital displav

using & “SUET”,“-A “ and ‘“ V

Electronic controller error, setting point error,

error.

–53–

“ keys duriu- error massage ;ndicati& of

power failure error and smsor

Page 57

2.4 PREPARATIONfOR START UP

Please confirm

(1)CONFIRMATION OF

below items again before operation.

OPERATIONSWITCHES

a) Operation switches inthecontrol panell

~;C)U:OL REFRIGERANT BURNER COOL/HEAT

AuTO

MANUAL

~ CLOSE

\ \ \ \ \ \ 1

> pu~p

AUTO RUN COOL STOP

STOP

MANUAL TEST HEAT START

FIG.

CHANGE OVER PUMP

2-4 TYPICAL OPERATION SWITCHES

PURGE

@Gas

control valve mode select switch ------------------”AUTO" position

@ Gascontrol valve open-close switch -------------------”SKIP” position

@Refrigerant pump mode select switch

@Burner mode select switch

@Cooling/Heating change over

.....................

switch ----------------------“COOL”position for “COOLINGmode“

------------------- "AUTO" position

......... ..

“RUN- posistion

“HEAT” position for “HEATING mode”

@Pump purge operation switch

0 Auxiliary switch -----------------

b) Burner control panel

Burner ON-OFF switch -----------

-------------------------------”STOP"- position

---------------------------------oneither side

..................................

“ON” position

—54–

Page 58

( 2) CONFIRMATION OF SETTING POINTS

a) Chilled water temperature setting point

(Setting sample)

0 Chilled water outlet temperature ..... .................... 44F

@ Proportional

... .................. ................ . ---------------

@ Integral --------------------------------------------------------------800

@ Differential

b) Hot water temperature setting point

.... ....................... .... ..... .------ ----

(Setting sample)

@ Hot water- outlet temperature ................................ 131F

(2) Proportional

@ Integral --------------------------------------------------------------50

@) Differential

( 3) CONFIRMATION OF CHANGE OVER VALVES

No

Valve name Cooling mcde

-------------------------------------------------------"-"30

Heating mode

2

10

6

1 A valve close

2

B valve

3

c valve

4 D valve close

Note)

a) When the cooling water is kept in the chiller/heater,, D valve opens.

.

b) When the cooling water is drained from the chiller/heater, D valve

closes.

2. In heating mode, Please close isolating valves of cooling water inlet and

outlet.

close

close

——

see note 1.

–55–

—

Page 59

(4 )CONFIRMATION OF EQUIPMENT

a) Combustion equipment

@ Open the main and pilot gas cocks in the gas train and the gas valve of supply gas

@ Never smell gas around burner and gas train.

@ Linkage between burner and gas train.

b) Water system

@ Some valves for chilled/hot water line.

@ Some valves for cooling water line.

@ Other system line.

c) Cooling water inlet temperature

0 holing water inlet temperature

@ Take care that the cooling water inlet temperature is kept above 66 ‘F

d) Electric wiring connection

@ Interlock of chilled/hot water pump

@ Interlock of cooling water pump

Note) Interlock signal is detected by energized DC 24V from the chiller/heater.

Please select the contact resistance within 100Q .

(Please Separate other power line. )

–56–

Page 60

e) Remote signal connection

No Signal name

1

Answer hxk simal

for operation

—

2

S@ indicitial kunp

3

Operation indication

lamp

4

Alarm indicatrn lamp

5

Cooling mo& ixliatim

lamp

6

Hmtti lmde i’ldimti(n output

lamp

7

Cuntu3titn

ilxlialtiul output

lamp

8

Ramlte ON-m Sifg’lal

Signal

Introduction Notice

output Opmiticn : ON Please select the

——

: OFF

resistance within

AC250V O.IA.

output

stop

ON signal when

chilk/hmk St@

output

ON s@al whm C/H

operates.

outPut Aixxmnal : ON

C@xatim : OFF

outPut

Cmlingxno&:CN

——.

Hmtinglno&:oN

king cmtxlstial

-

ON

Input

ON-OEFsignal of C/H

No-voltage

–57–

Page 61

2,5OPERATION

(

l) COOLING OPERATION

Local mode operation

a)

(Operation)

Confirm the operation

“COOLING”indication

Confirm the operation

“LoCAL” indication lamp of the key is lighting.

Confirm the mode of change over valves again.

A, B, C and D valves are closed.

If you operate the system by manual, Please operate Chilled/hot water pump and

cooling water pump sequentially.

Please continue to Push the “OPERATION”key on the operation board at least 1 SEC”

Confirm to light “OPERATION”indication lamp of the key.

Chilled/hot water pump and cooling water pump are operated by automatically, if the

system is connected to the chiller/heater.

Chiller/heater is operated automatically by sequentially.

(STOP)

Please continue to Push the “STOP”’key on the operation board at least 1 second.

a)

Confirm to light “STOP” indication lamp of the key.

mode indicator on the operation board.

lamp is lighting.

mode select key on the operation board.

When the system is connected to the chiller/heater, pumps are stop as follows;

@

Cooling water pump stops approx. 1 thru 5 minutes later.

Chilled/hot water pump stops approx. 2 thru 6 minutes later.

Chiller/heater stops after dilution cycle operation for approx.6 thru 15 minutes.

Please stop the secondary air conditioning units after stopped chilled/hot water

@

pump.

I

–58–

Page 62

b) Remote mode operation

(Operation)

Confirm the operation

al

“COOLING”indication

Confirm the operation

2

“REMOTE”indication lamp of the key is lighting.

Confirm the mode of change over valves, again.

3

A, B, C and D valves are closed.

If you operate the

4

cooling water pump

Please make contact

5

panel.

Chilled/hot water pump and cooling water pump are operated by automatically, if the

6

system is connected to the chiller/heater.

Chiller/heater is operated automatically by sequentially.

7

mode indicator on the operation board.

lamp is lighting.

mode select key on the operation board.

the by manual, Please cperate chilled/hot water pump and

sequentially.

with chiller/beater operation switch on the remote control

(STOP)

Please cut off the chiller/heater operation switch(or stop switch) on the remote

1

control panel.

When the system is connected to the chiller/heater, pumps are stop as follows;

2

(Cooling water PUmPstops aPPrOX. 1 thru 5 minutes later.

Chilled/hot water pump stops approx. 2 thru 6 minutes later.

(biller/beater stops after dilution cycle operation for approx.6 thru 15 minutes.

Please stop the secondary air conditioning units after stopped chilled/hot water

3

pump.

–59–

Page 63

( 2 )HEATING OPERATION

a) local mode operation

( Qperation)

Confirm the operation

“HEATING”indication

Confirm the operation

“LOCAL”indication lamp of the key is lighting.

Confirm the mode of change over Values, again.

A, B, C and D valves are opened.

If You operate the system by manual, Please operate chilled/hot water pump.

Please continue to Push the “OPERATION”key on the operation board at least 1 sec.

Confirm to light “OPERATION”indication lamp of the key.

Chilled/hot water pump is operated by automatically, if the system is connected to

the chiller/heater.

Chiller/heater is operated automatically by sequentially.

(STOP)

Please continue to push the “STOP” key on the operation board at least 1 second.

1

Confirm to light “STOP” indication lamp of the key.

mode indicator on the operation board.

lamp is lighting.

mode select key on the operation board.

When the system is connected to the chiller/heater, chilled/hot water pump stops

2

approx. 5 minutes later.

Chiller/heater stops after dilution cycle operation for appprox. 5 minutes.

Please step the secondary air conditioning units after stopped chilled/hot water

3

pump.

–6 O–

Page 64

b) Remote mode Operation

(Operation)

(1) Confirm the operation mode indicator on the operation board.

“HEATING”indication lamp is lighting.

2 Confirm the operation mode select key on the operation board.

“REMOTE’indication lamp of the key is lighting.

3 Confirm the mode of change over valves, again.

A, B, C and D valves are opened.

4 If YOUoperate the system by manual, please operate chilled/hot water pump.

5 Please make contact with chiller/heater operation switch on the remote control

6 Chilled/hot water pump is operated by automatically, if the system is connected to

the chiller/heater.

7 Chiller/heater is operated automatically by sequentially.

(STOP)

1 Please cut off the chiller/heater operation switch(or stop switch) on the remote

control panel.

2When the System isconnected

approx. 5 minutes later.

(killer/beater stops after dilution cycle operation for approx. 5 minutes.

(3) P1ease stop the secondary air conditioning units after stopped chilled/bet water

pump.

to the chiller/heater, chilled/hot water pump stops

–61–

Page 65

( 3) OPERATION BOARD DURING OPERATION

a) The

operation board during normal operation

Generator temperature is indicated on the digital display during operation.

Indication lamps light

Symbol O : Indication

Symbol

● : Indication

Symbol 1 : Indicaition

TEMFt?RATURE

. GENERATOR

0 EXliAUSTGAS

O CMIT W OUTLET

0 CO W INLET

WATER L:NE ALARM

OCHWTMP.

0 CMfT W FLCX RATEO #11ALIS.PUMP

OCDWTENP.

0 CO W FLIX RATE O BURNER BLOW.R

0 NT W TEMP.

OPERATIM R!XORD

o C/H O!%RATION

() C/H ON-OFF

0 REF. F(JMPOPERATION

0 COMBUSTION

O BURNERON+WF

N9TOR ALARM CENRRATOKALARN

0 REF. PUMP

0$12 A13S.FUNP 0 TEMP/OINCENTRATION

during operation as follows;

lamp does not light.