Page 1

BULLETIN NO. IM 116

JANUARY 1968

FORM 2164341

INSTALLATION AND

MAINTENANCE DATA

MODEL CUB

AIR COOLED CONDENSING UNIT

7

1/2

THRU 60 TONS

INC.. 13600 INDUSTRIAL PARK BLVD.. P.O. BOX 1551, MINNEAPOLIS, MINNESOTA 55440

PHONE: 545-2892. AREA CODE: 612

Page 2

Page 3

Page 4

INTRODUCTION

McQUAY SEASONCON air cooled condensing units are

for outdoor installation, basically designed for use

with direct expansion coils, air handling units, or

water chillers. The SEASONCON air cooled

ing units are factory assembled on a single base,

wired, evacuated, performance tested, given a holding

refrigerant charge, and shipped ready for installation.

Each unit consists of accessible hermetic

condens-

compress-

NOMENCLATURE

117

CUB-027s 1

D

1

INSTALLATION

GENERAL Commerical equipment of this type is in-

tended for installation by qualified refrigeration mechanics only. As a condition of the warranty the check,

test, and startup procedure must be performed by such

personnel and properly reported on the form provided.

Failure to do so voids the warranty. Arrangement for

service should be made prior to installation, as it is

not included in the warranty or the catalog price. See

warranty terms on Page 3.

INSPECTION When the equipment is received, all

items should be carefully checked against the bill of

lading to be sure all crates and cartons have been

received. All units should be carefully inspected for

damage when received. Visible or concealed damage

should be reported immediately to the carrier and a

claim

filed fordamage. The electrical nameplate should

be checked to be sure it agrees with the power supply

available.

LOCATION The

ing units are designed for outdoor application. The

evaporator and accessories connected to the unit are

ordinarily installed indoors.

The cabinet is made of heavy reinforced aluminum

panels to give a fairly light but durable unit.

The condensing unit should be located so that all

four sides of the unit have free area for inlet air flow.

The unit should not be located closer than one fan

diameter from a wall or other obstructions. The units

have an

in from the underside of the unit.

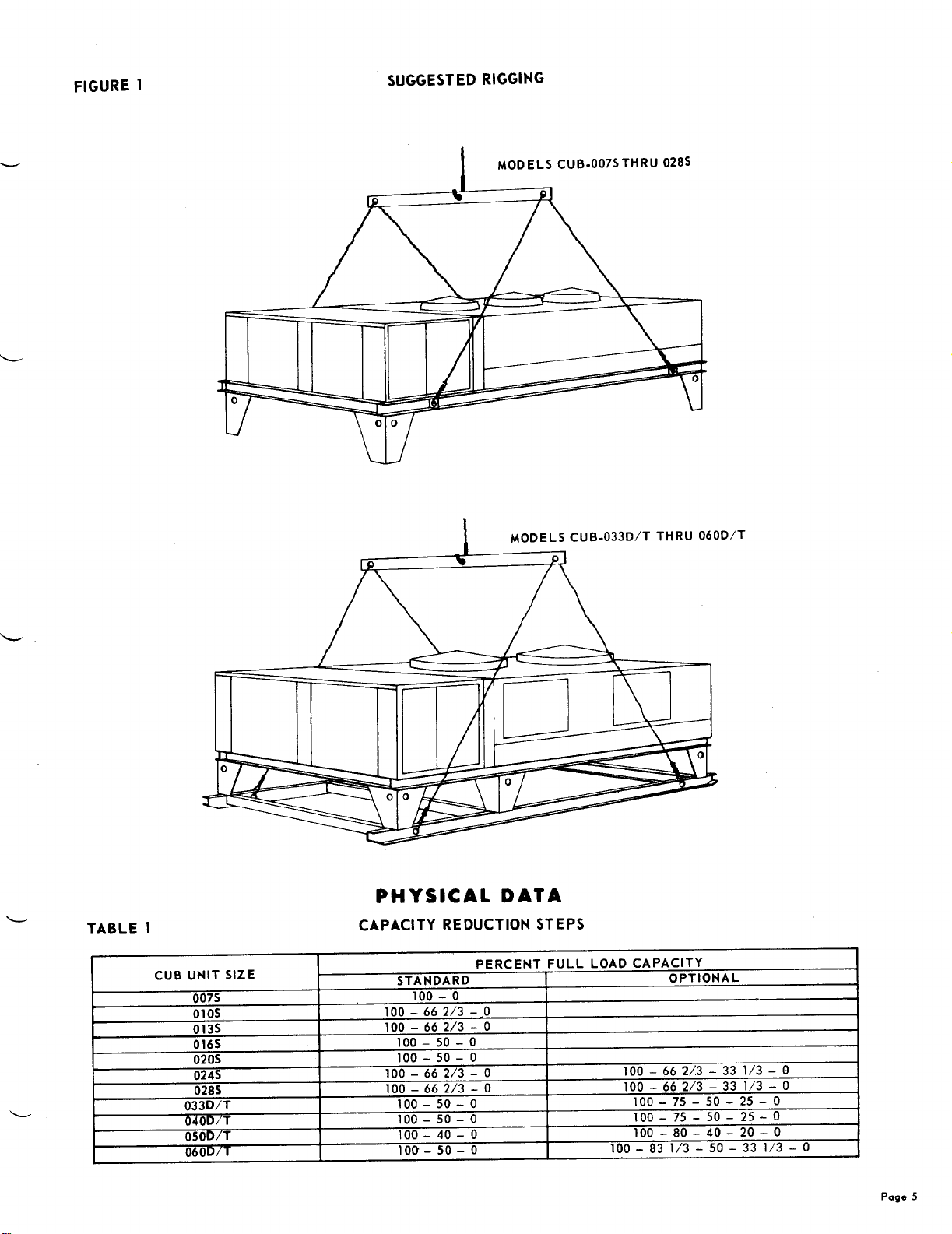

ished with suitable holes in the legs and channels for

use by the riggers. See Figure 1, Page 5.

man has free access to the compressor compartment

and to the access panel and the condenser fans and

motors. If the location of the

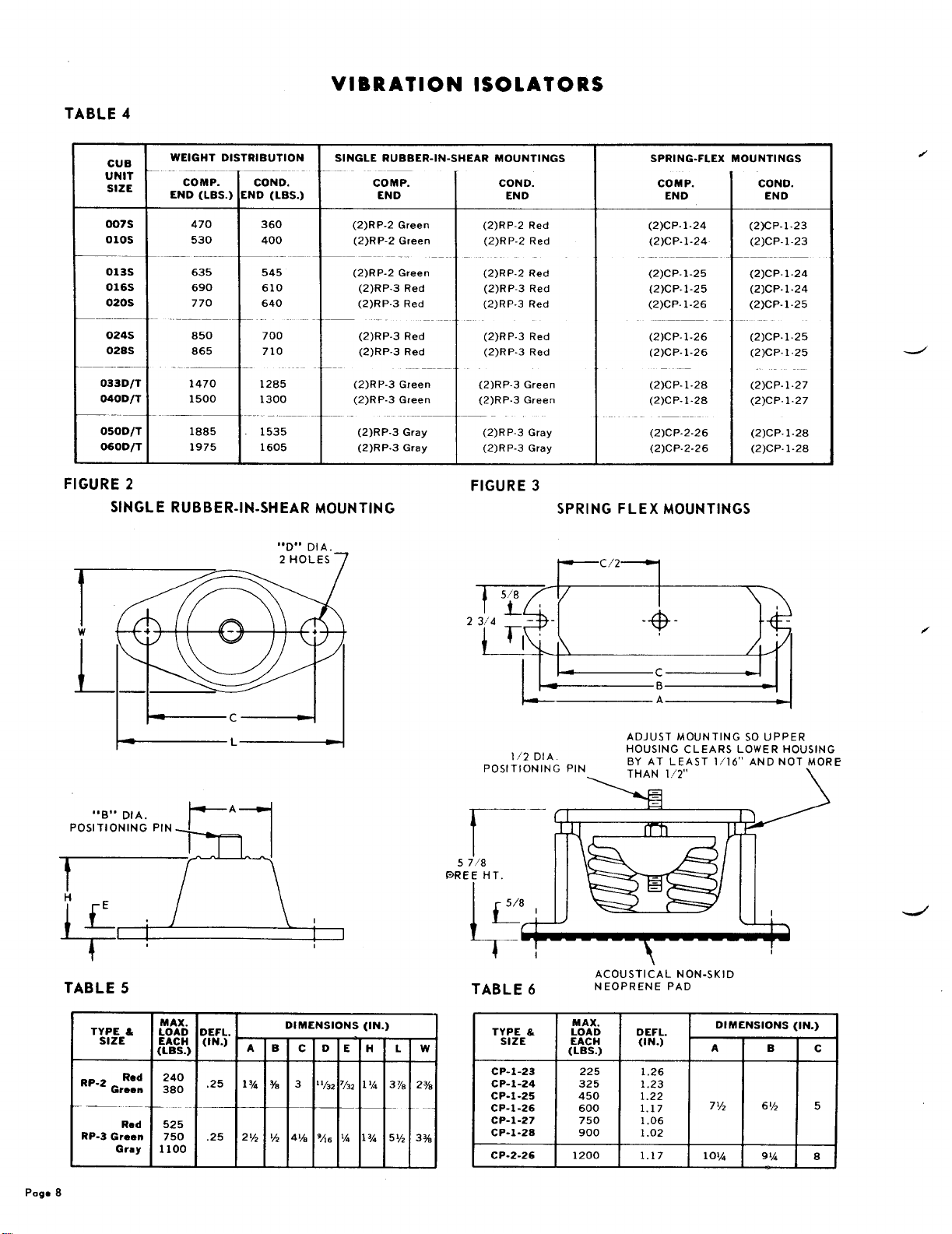

tion may be transmitted objectionably to the building+

vibration isolators should be used.

upflow

The unit must be mounted level. The unit is furn-

The unit location should be such that the service

McQUAY

condenser air discharge, with air taken

line of air cooled condens-

unit

is such that

vibra-

or(s) (single, dual, or tandem), air cooled condenser

with propeller fans & motors and a completely wired

control panel in a heavy aluminum cabinet. The control panel includes a power terminal block, circuit

breaker protection for all motor phases, starting

tactors,

ready for operations.

SERVICEABILITY The compressor compartment is

accessible from the top and two sides by simply removing panels. Under no condition should any access

panel be blocked or locked in place by mounting parts

on them or running piping through them.

area has generously sized access doors for checking

the fan motors, belts, and drive. On direct drive units

access is through the fan orifice.

enclosure having a

the first section of the line proper.

that vibration from the unit is not transmitted from the

equipment to the bui

joints

or flexible connectors in the lines will be required.

All refrigeration lines must be checked and secured to

prevent wear or vibration at all operating conditions.

and safety and overload controls, wired and

Air Cooled Condensing Unit

Series Designation

Nominal Capacity (Tons)

Single Compressor

Dual Compressors

Tandem Compressor

On the belt driven fan units, the condenser fan motor

The control panel is protected by a weather proof

REFRIGERANT PIPING The refrigerant piping should

be installed according to standard practice and should

follow latest

the motor-compressors are resilient mounted, it is

necessary that a vibration eliminator be installed between the suction connection on the compressor and

There must be sufficient flexibility in the piping so

at the unit are not stressed. Loops, hairpins,

A filter-drier must be installed in the liquid line to

pick up acids, dirt and moisture that may be left in

the system. A moisture indicating sight glass, located

in the liquid line, must also be installed. A suction

line filter is also recommended to prevent grit or dirt

from getting to the compressor.

The unit is furnished with a liquid line shut off

valve located ot the subcooler outlet.

It is urged that dry nitrogen be run through the connecting refrigerant lines during the brazing operation

to prevent oxidation of

joints are not acceptab e.

CONTROL PANEL All operational and refrigerant

safety controls are located in the control panel. Also

note following section on fuses and circuit breakers.

ASHRAE

gasketed

and hinged door.

guide recommendations. In that

Iding,

and so that the brazed

iping

P

interior. Soft soldered

con-

Page

4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

ELECTRICAL

ELECTRICAL

CONTROL

CENTER

The McQuay SEASONCON air cooled condensing

unit has a superior electrical control center desi

with safety and reliability as the foremost

tion. It is enclosed in a weathertight cabinet with

hinged access doors and key lock for added protection.

All necessary safety and operating controls are included

and are factory wired in accordance with the

National Electric Code. The control cabinet,

ible from outside the unit, protects all controls from

accidental damage and prevents unauthorized

nel from tampering with them.

A partition separates the

from the storting controls. A dead-front panel covers

the starting controls to protect the operator from any

FIGURE 6

adjustable

cons1

safety controls

ned

.8

era-

access-

person-

exposed terminals or contacts. All refrigeration controls are covered and can be

contacting line voltage.

panels removed to show internal controls and wiring.

It is important to have a qualified electrician service

this panel.

can cause serious damage to equipment and void the

warronty.

WARRANTY: Warranty is voided if wiring is not in

accordonce with specifications. A blown fuse or

ped protector indicates a short, ground or

before replacing fuse or restarting compressor, the

trouble must be found ond corrected.

Unqualified

adjusted

Figure 6 shows dead-front

tampering with the controls

without fear of

trip-

overload -

.13

12

9

SWITCHES-ON/OFF

RELAYS

SWITCHES-RESET

FUSE-CONTROL CIRCUIT

PART WINDING START

(Optional)

CONTACTOR-

FAN MOTORS

1.

THERMOSTAT-

FAN CYCLING

2. OIL PRESSURE CONTROL

(Manual Reset)

3. HIGH PRESSURE

CONTROLS

4. LOW PRESSURE CONTROLS

5. TIME DELAY RELAYCOMPRESSOR SEQUENCING

8

6.

7.

8.

9.

10. TIME DELAY RELAY-

11.

FIELD WIRING

Wiring

with al

Threemain power leads must be connected to the

condensing unit. Table 8, Page 16, gives the recommended lead wire sizes for three conductors in a

raceway.

Maximum supply voltage variation is

plate value. Phase voltage unbalance must not exceed

2%.

The condensing unit is wired to operate on a nonrec

sta

The liquid line solenoid is to be controlled by a return

air or space thermostat for air conditioning duty, or

of the systems should be done in accordance

applicable codes and ordinances.

9

?

10% of name-

clingpumpdown cycle and it is necessary to

ll

I

24 volt liquid line solenoid valves in the system.

in-

10

suitable thermostat for water chilling. For dual compressor units,

valves should be used as shown in Diagram 1, Page 11.

Although there is no specific requirement, interlocking of the evaporator fan motor is recommended so the

condensing unit will not run unless the evaporator fan

motor is running.

locking on auxiliary contact of the evaporator fan

motor starter across terminals 25

Diaaram 3. A sail switch could be wired across the

same

Refer to wiring diagrams provided

specific wiring diagram for each model.

11

12. CONTACTORSCOMPRESSORS

13. CIRCUIT

FAN MOTORS

14. CIRCUIT BREAKERSCOMPRESSORS

15. POWER TERMINAL BLOCK

& POWER CONNECTION

a two-stage thermostat and two solenoid

This can be accomplished by inter-

terminals to accomplish the

BREAKER-

& 26 as shown in

same results.

with units for

Page 10

Page 11

UNLOADERS Cylinder unloading capacity control is

available on all except the

CUB-007S.

Unloading con-

sists of opening a gas by-pass circuit from the cylin-

der head to the low pressure side of the compressor

by means of a solenoid valve. Unloading results when

the solenoid valve coil is energized. The unloading is

controlled by an open-on-rise pressure control switch

in series with the unloader solenoid coil. The pressure

control is

adjustable

in both range and differential.

The pressure control is set at the factory on a nominal basis. Final adjustment must be made in the field

based on the individual system compressor

-

evapora-

tor balance. For nominal settings, refer to Table 15,

Page 21.

FUSES AND CIRCUIT BREAKERS The circuit breakers for the compressor and condenser fan motor

tactors

are located in the control box. In addition,

con-

there are small fuses for the compressor control circuits located in the end of the compressor terminal

box.A fuse in the control box also protects the control

circuit.

Most local electrical codes also require a fused

disconnect switch in the unit supply circuit, located

within easy reach or within sight of the unit.

CONTROL WIRING INFORMATION Temperature controls ore usually separate from the main condensing

unit controls. These controls usually consist of a

liquid line solenoidvalve opened and closed by a room

thermostat. The thermostat can be either low voltage

or line voltage.On a year around system consisting

of cooling and heating, a combination heating and

cooling thermostat is commonly used.

CRANKCASE HEATERS The compressors are equipped

with crankcase heaters. The 15HP and smaller model

compressors have heaters installed externally below

the crankcase. The 20HP and larger model compressors have heaters inserted into the crankcase.

The function of the heater is to keep the temperature

in the crankcase high enough to retard refrigerant from

migrating to the crankcase and condensing in the oil.

When a system is to be started up initially in cold

ombient, the power to the heaters should be turned on

for some time (at least 8 hrs.) before the compressor

system is started.

The crankcase should be up to

about 8OF before the system is started up, to minimize

lubrication problems or liquid slugging of compressor

on startup.

IMPEDANCE RELAY OVERLOAD PROTECTION

order to provide reset of unit in conditioned space or

at the unit, an impedance relay is incorporated into the

control circuit. Basically, this type of control is centered around a relay with a high impedance holding

coil connected in series with the basic relays and

contactors,

but in parallel with the safety automatic

reset control or controls. The impedance relay normally

closed contacts are located in the safety control circuit. A normally open momentary contact reset button

installed at the panel or remotely is connected in para-

llel with the relay normally closed contacts, or relay

coil.

For typical operation, refer to Diagram 2, Pages 12

and 13. Note that coil of impedance relay R4 is in

series with the group of controls Ml, M2, and R2. The

coil is also in parallel with the high pressure control

HP1,

and the normally closed relay contacts R4. In

normal operation, HP1 and R4 are closed and, therefore, there is no voltage across relay coil R4. However, when the system goes out on high head pressure,

control HP1 opens; R4 coil is now in series with the

group of controls Ml, M2 and R2. Although the relay

coil R4 is in series with the group of controls, there

is sufficient voltage across it to open the normally

closed contact R4. When the high pressure control HP1

closes again on reduction in head pressure,

the

normally closed contact R4 is still held open by voltage across coil R4.

It is, therefore, necessary to push reset switch S3

to jumper contact R4 and drop out the impedance relay

so that the system can start. A remote momentary con-

tact reset switch in parallel with

S3

may be installed

for remotely restarting the unit.

Where compressors have external overload protection, both the HPC and the external overload control

circuit is reset by the impedance circuit. Where compressors have internal overload protection, automatic

reset, only the HPC outage is reset by the impedance

circuit.

In

DIAGRAM 1

I0 DIIco**rcI

m.1-)10 >Y) “OLT

‘my: ~~c;~~‘,~‘“‘“”

!

TYPICAL FIELD WIRING

CUB AND AIR HANDLER

NOTES:

(1)

R3 Relay Coil voltage

to be same as motor

voltage

starter

(2) Rl and R2 Relays are

in condensing unit

control center.

(3) All items except

and R2

others.

(4)

_29

terminal strip numbers in condensing

unit control center.

Designates

Relays by

R1

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

EVACUATING AND CHARGING The condensing unit,

as shipped from the factory, has been checked under

normal operating conditions. The unit is shipped with

a holding charge of R-22 refrigerant.

Care should be used to keep the system closed as

long as possible when making the piping connections.

Every precaution must be followed to prevent dirt and

moisture from entering the system. Under no condition

is the unit piping or components of the system to be

exposed to atmospheric moisture. Always cap or seal

all exposed pipe ends or refrigerant tubing during in-

stallotion.

Standard

be followed after piping and pressure testing is completed.

evacuation

and charging procedures should

NORMAL REFRIGERANT CHARGE The condenser

coil has a built-in subcooler. For optimum operation,

the liquid sight glass in the liquid line between the

receiver and subcooler should be substantially free of

bubbles. A completely clear sight glass indicates an

overcharged system.

pected unless the overcharge is sufficient to create

No adverse affect need be ex-

an excessive head pressure caused by appreciable

liquid flooding of a portion of the condenser coil. The

minimum charge at which the unit will operate properly

is with clear sight glass between the filter-drier and

thermostatic expansion valve. Sight glass, filter-drier,

liquid line solenoid, and expansion valve are neces-

sary and must be furnished by others.

-

CHARGING SYSTEMS

erant systems using the SEASONTROL head pressure

control require a substantially larger refrigerant charge

than a standard system designed for summer use only.

The following procedures

TROL head pressure control system are recommended:

A. If the ambient is such that the system is condens-

ing at a temperature of 95F or above, charge the

unit like a standard unit. That is, charge until you

have a clear sight glass with a nominal reserve.

Then add a charge equal to the difference between

summer and winter charge, as given in Tables 2 &

3, Pages 6 and 7.

WITH SEASONTROL Refrig-

for charging the

SEASON-

\L;hT;

B.

nor;ally’

the specific system.Th

the condenser with cardboard or other material

until the head pressurerises to a pressureof about

225 psig to make sure the SEASONTROL head

pressure control is open and that no refrigerant is

blocked up in the condenser. Then add

until the sight glass clears up with a nominal

reserve. Then add the winter operation charge

which should be equal to the difference between

the required summer charge and winter charge for

the specific unit or section. See Tables 2 & 3,

Pages 6 and 7.

stem is char ed when the ambient is quite

or lower, a d a nominal charge that might

F

be considered a reasonable amount for

B

en cover the inlet side of

refrigerant

OIL CHARGE Because of the rather large refrigerant

charge required in an air cooled condensing unit system, it is usually necessary to put additional oil into

the system. The oil level should be watched carefully

upon initial startup and for some time thereafter.

At the present time, Suniso #3G oil is the only oil

approved by

sors. The oil level should be maintained at a level

about midpoint of the glass bullseye on the compressor body.

Copeland

for the use in these compres-

SETTING LOW PRESSURE CONTROL FOR LOW

AMBIENT START

and cut-in point of the low pressure control depends

upon the lowest ambient in which the air conditioning

system is expected to be used. Inasmuch as both the

condenser and the receiver are

ambient, it is necessary to set the low pressure control at a pressure considerably lower than the pressure

corresponding to the temperature of the lowest ambient

point. Otherwise,the low pressure control will not

cut-in to get the system started; or, in marginal tem-

perature, may cut-in but short-cycle.

Table 10, Page 18, shows the nominal low pressure

control settings for systems using R-22 refrigerant to

insure starting at the given ambient temperatures.

These are nominal settings. Final settings must be

based

on actual checkout of the individual system.

The proper setting of the cut-out

located

in the outside

TABLE 9

REFRIGERANT LINE CAPACITIES FOR REFRIGERANT R-22

(TONS OF REFRIGERATION RESULTING IN A LINE FRICTION DROP PER 100 FT. EQUIV.

PIPE LENGTH CORRESPONDING TO 2F

(AT)

CHANGE IN SATURATION TEMP.)

Page

17

Page 18

TABLE

10

CONTROL SETTING FOR LOW

AMBIENT OPERATION

LOW PRESSURE CONTROL

MINIMUM

OPERATING

AMBIENT

*The

settings are all for singles, duals and #1 tandem

compressor low pressure controls. #2 tandem control must

remain ret at

normal settings.

(F)

+30

+20

+10

0

-10

-20

normal

setting. See Table 15, Page 21, for

CONTROL SETTING

CUT-IN

(PSIG)

50

38 20

28

20

12 2

7 0

*

CUT-OUT

(PSIG)

32

10

5

OPERATION

PERIODIC SERVICE (At end of first week of opera-

tion and once a month thereafter).

A.

Check compressor oil level.’ Oil should

proximately

Compressors are furnished with oil fill plug on the

side of crankcase.

B.

Check liquid sight glass for proper refrigerant

charge.

C.

Check belt tension, and observe condition of belts.

D.

Check condenser coil face for obstruction. If necessary, flush with cold water, brush off, or use

vacuum cleaner.

E.

Make general inspection of entire system for any

unusual sound or condition.

1/2

of the oil level glass. Copelond

WEEK END OR SHORT PERIOD SHUTDOWN

A. Turn off switch

noid valve(s).

B. Wait for system to pump down.

C. Turn off shut-off switch

fan motor.

closing evoporator liquid line sole-

S1.

Turn off evoporator

START UP FOLLOWING WEEK END SHUTDOWN

A. Turn on evaporator fan motor.

B. Turn system switch

C. Turn to “on”

valve(s). Observe operation for several minutes,

noting any unusual sounds, or unusual cycling of

compressors.

EXTENDED SHUTDOWN

Close the liquid line shut-off valve.

A.

Wait for the compressor to pump down until it

B.

shuts off on low pressure control.

C.

Turn off the power to the compressors, condenser

fan motors, cronkcose heaters, and evaporator fan

motor.

D.

Close the suction and discharge shut-off

E.

all

Tag

ogainst starting up the compressor before properly

re-opening the shut-off volves.

opened disconnect switches warning

S1

to “on” position.

switch opening liquid line solenoid

START UP AFTER EXTENDED SHUTDOWN

A.

Inspect all equipment.

B.

Check face of condenser coil for paper or other

obstruction that might be lodged on the

Open the suction and discharge service valves.

C.

D.

Turn on the electric power to the system.

Open the liquid line shut-off valve or valves.

Start the air handler or chilled water pump.

FE:

Check crankcase heater & crankcase warmth.

G.

cover

valves.

surface.

ap-

TABLE 11

WEIGHT OF REFRIGERANT (R-22) IN

COPPER LINES*

LBS. PER 100 LINEAL FEET

*Type L copper tubing.

H. Start the unit by turning on system switches.

J. After the unit has run for severol minutes, check

the oil level in the crankcase, and observe flow

through the refrigerant sight glass for sufficient

refrigeront charge.

SEASONTROL

stalled system,

back into the condenser coil, thereby reducing the effective condenser surface available for condensing.

The SEASONTROL head pressure control system is

an improved method of head pressure control incorporating two modulating valves. Its operotion is independent of difference of elevation between the condenser

and receiver.

The main, or liquid line, valve is normally closed,

and opens on

valve IS locate in the liquid line between the conden-

ser and receiver. The gas, or bypass, volve is normally

open ond closes on pressure rise. This valve is located in the line between the hot gos header and the

liquid line section between the liquid SEASONTROL

head pressure control valve and the receiver. See

Figure 9, Page 20.

The system operates

up, the bypass valve is normally open and the moin or

liquid valve is closed. Hot gas moves from the compressor, part going into the condenser, and port going

through the byposs circuit through the open volve ond

into the receiver. The bypass gas goes directly into

the receiver to maintain or build up pressure in the

receiver as liquid leaves. As the compressor contin-

ues to run, hot gos condenses in the condenser and

roises the liquid level since the main valve on the

leaving side of the condenser is still closed. As the

liquid level in the condenser rises, the condensing

capacity of the condenser

the head pressure rises. The bypass gas maintains or

raises the pressure in the receiver. As the pressure

in the condenser rises to the control point of the

valve, the liquid valve starts moduloting towards the

open position, permitting liquid to leove the conden-

ser and flow into the receiver. At the same time, the

bypass valve starts modulatin

position, limiting the hot gas low into the receiver.

The modulation of the two valves maintain the proper

iiquid level in the condenser to mointoin proper head

Yessure.

rquid fromthe condenser to near saturation tempera-

ture.

head pressure control Is o factory in-

based on liquid refrigerant flooding

Bressure,

The bypass gos also warms up the cold

rise in the condenser. This

OS follows: On system start

decreases

and, OS a result,

towards the closed

9

Page

18

Page 19

CHECKING

CONTROLS

FANTROL head pressure control is an automatic

winter control method and will maintain a condensing

pressure within reasonable limits by cycling one fan

on a two fan unit, or two fans in sequence on a three

fan unit in response to outsideair temperature entering

the condensing coil.

One of the more obvious advantages of multiple fon

condensers over sin

expensive woy in w

may be achieved. On

le

fan units is the simple and in-

it*

rch

controlled

a

two fan unit, stopping one fan

capacity

reduction

reduces the condenser capacity to approximately 55%

of full rating. On a three fan unit, stopping two fans

reduces the condenser capacity to approximately 40%

of full roting.

DIAGRAM 4

FANTROL head pressure control

SYSTEM WI RING

NOTE: On CUB

TABLE 13

0075-0285

employed and only two wires

single

phase

condenser fan motors are

are

broken by the thermostat.

FANTROL THERMOSTAT SETTING (F)

Fan motors are internal inherent overload protected,

and are started by a single contactor, with the individual fan motors cycled by use of two

thermostats. See Diagram 4,

Page

19.

pole,

heovy duty

Thermostats are nominally set to maintain condensing temperatures between a high of 120F and a

low

of about 80F. The final setting of the thermostats

varies with system design conditions. The settings

shown on Table 13, Page 19, will ordinarily give satisfactory operation.

Where operation at ambients below the range shown

on Table 12, Page 19, are required, Seasontrol or

Dampertrol may be added.

TABLE 12

FANTROL head pressure control (Std)

(Ambient Low Limit)

“NlT

CUB

!K

zx

0135

0166

ii%

0285

OJ9T

go; :: 28

033D

2;

PData

based on:

Capmtv

_

50

66%

step %

MinimumCondensing

UNIT WITH STANDARD

CAPACIYY

REDUCTION

MINIMUM

CAPACITY

STEP

g

6%

loo

:x

5

Tamp.

“zN;?E\?

TEMP.

m*

:t

21

;;

10

fZ :8

3”:

zt

100

1

9OF

WITH ADDITIONAL

CAPACITY REDUCTION

MINIMUM

c:Tp:pe’;ry

3%

33%

s:

3:Os

25

fl

33%

1

67.60

1

BOF

z%F

TEMP.

42

35

56

48 :d

T

39

1

50.20

1

70

(Fy

F

TWO FAN UNITS

THERMOSTAT

CUT-IN

65

CUT-OUT

I

55

THERMOSTAT

CUT-IN

65

DAMPERTROL head pressure control The discharge

side face and bypass dampers ore controlled

by

a pressure actuated operator connected to the high pressure

side of the refrigeration system. As pressure increas-

es in the system, the operator opens the face damper

blades and closes the two bypass blades to prevent

recirculation of air around the fan. The damper operator starts moving at 175 psig (from closed position)

and is fully extended at 250

PSIG

(fully opened posi-

tion).

TABLE 14

DAMPERTROL head pressure control (Opt)

(Ambient Low Limit)

Data

CUB

XK

based

on:

Capacity

UNIT

WITH

CAPACITY REDUCTION

MINIMUM

Step %

STANDARD

UNIT WITH

CAPACITY REDUCTION

ADDITIDNAL

THREE FAN UNITS

#1

CUT-OUT

I

55

THERMOSTAT

CUT-IN

I

50

CUT-OUT

FIGURE 7

DAMPERTROL C head pressure control

DAMPERTROL C IN OPEN POSITION

DAMPERTROL C IN BYPASS POSITION

DAMPERTROL C head pressure control sections.

Show air flow in

(winter start) position. For operation to

open

(normal) position and closed

-2OF

#2

40

ambient.

Page

19

Page 20

SEASONTROL head pressure control VALVE CHECK-

ING AND SETTING

control valves are factory set and checked to maintain

a minimum head pressure equivalent to 90F condensing.

The valves have a nominal 15

range between fully open and fully closed positions.

Typical settings for Refrigerant-22 use is to have the

valves modulate between 160 and 175 PSIG. This will

maintain a nominal 90F condensing.

Referring to Figure 8, Page 20, it is to be noted that

on pressure Increase on the system, the pressure

tend to compress the bellows and the valve stroke

will be u

This

or toward the adjustment end of the valve.

r

app

res to both the liquid and gas valves. The

239 series, or liquid valves, open on pressure rise.

The 237 series, or gas bypass valves, close on pressure rise. The valve travel is a nominal one tenth inch

for all models.

A

S indicated in the diagrams, the adjustment of the

nut in a clockwise direction will increase the modula-

ting pressure point.

similar instrument inserted into the nut slot may be

used for making the

The modulating pressure point and range may be

checked as follows:

A. Make up a “depth gauge” for inserting through the

FIGURE 8

The SEASONTROL head pressure

PSIG

modulating

will

A wide bladed screwdriver or

adjustment.

SEASONTROL head pressure control

TYPE 239 LIQUID VALVE

8A. SECTIONAL VIEW

adjusting

nut opening and long enough to hit the

bottom of the bellows section as indicated in

Figure

8B,

Page 20. A piece of insulated wire, 8

to 12 auge, is a simple and convenient material

from w

rch

to make a gauge. Insert a piece of the

1.

wire into the valve as shown in the diagram. Trim

off insulation, for about one inch of the end to be

inserted, and at a point just above the top of the

valve at the other end. When in use hold the gauge

down lightly against the bellows and sight along

the top of valve.

A high side gauge should be connected to a line

B.

so it can be brought to the valve area unless a

second person is available to call out head pres-

sure readings while valve observations are made.

Start up the unit and note pressures at which valve

C.

bellows rise.

We assume

that the pressure was low

enough at start up so that the bellows is in the

down position. The test may also be done in re-

verse by running the system u to a high head

B

making observa-

pressure,

stopping the unit,

an

tions at what pressure the valve changes position.

The valves should be set so that the movement of

D.

both valves is through the same pressure range.

Be sure system has sufficient refrigerant before

E.

making any change in valve adiustment.

8B.

CONTROL SETTING

FIGURE 9

t

LIQUID

OUTLET

HOT GAS HEADER

LIQUID HEADER

LIQUID LINE

BY PASS LINE

ADJUSTING NUT

CONTROL SPRING

VALVE SEAT

SEASONTROL III head pressure

For operation to -20F ombient.

w

. .

..I-~“-

-------

ED

l/10”

TRAVEL

FEELER GAUGE INSE

RTED

LIQUID VALVE

RECEIVER

RELIEF VA

PURGE VALVE

\GAS

SUBCOOLER SECTION

VALVE

Page 21

Page 22

Page 23

Page 24

MAINTENANCE

GENERAL

MOTOR

A. The air cooled condenser section requires a mini- A.

mum of maintenance. All that is required is to

lubricate the fan shaft bearings, motor bearings,

and occasionally clean the surface of the coil.

During the initial break-in period, it is advisable

to check the belt tension after the first 48 hours of

operation. Usually, by this time, the belts have

acquired their permanent stretch, and further ad-

‘ustments should not be necessary. It is advisable,

/l

owever,

intervals and, if necessary, make any

B. The fan shaft bearings do not require lubrication

at the time the unit is out into service. The fan

shaft bearings should be greased once a year using

STANDARD OIL COMPANY

Lithium Grease. DO NOT OVERLUBRICATE. The

C. The coil will require a periodic cleaning and this

can be accomplished by a brush, vacuum cleaner

or a pressurized air stream.

to recheck the belt tension at 3 month

adjustments.

Multi-Purpose

All motors are ball bearing, pre-lubricated and do

not require the addition of grease at the time of in-

stallation. Periodically, the ball bearings should

be cleaned and the grease renewed, to gain the

ultimate in service from the motor bearings.

Extreme care must be exercised to prevent foreign

B.

matter from entering the ball bearings. It is also

Important to avoid

clean mineral grease having the following characteristics should be used. Consistency: a little

stiffer than that of Vaseline, maintained over the

operating temperature range; melting point preferably over 150C (302 F); freedom from separation

of oil and soap under operating and storage condi-

tions, and freedom from abrasive matter, acid alkali

and moisture.

Specific greasing instructions are to be found on

C.

the tag attached to the motor and should be genera I ly fol lowed.

overgreasing

Only a

high

grade

REPLACEMENT PARTS

Replacement service parts can be ordered throu hJinvolved. Replacement parts for the motor-compressor

your nearest

complete description of service port, part number if

known, plus complete serial and model number of unit

McQUAY

representative. Always

prove

e

assembly can be procured direct from your nearest

franchised

saler.

Copeland

Refrigeration Corporation Whole-

INC.*

13600 INDUSTRIAL PARK BLVD., P.O. BOX 1551. MINNEAPOLIS, MINNESOTA 55440

PHONE:

545-2892

l AREA CODE: 612

@

Loading...

Loading...