Page 1

Installation and Maintenance Manual IM-799

Air-Cooled Split Systems

Models ACU 075 to 300

75 to 300 MBH

60 Hz, R-22 Refrigerant

ACU 075 to 150

Group: Unitary

Part Number: IM-799

Date: August 2005

Supersedes: July 2004

ACU 200 to 300

© 2004 McQuay International

IM-799 Page 1

Page 2

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Vibration Isolators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 7

Location For Installation of Condensing Units . . . . . . . . 7

Field Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sound Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Vacuuming and Charging . . . . . . . . . . . . . . . . . . . . . . . . 8

Vacuuming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Charging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Field Charging Precautions . . . . . . . . . . . . . . . . . . . . . . . 8

Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Charging Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Typical Service Valves on ACU Units . . . . . . . . . . . . . 9

How Much Refrigerant? . . . . . . . . . . . . . . . . . . . . . . . . . 9

Charging Procedures - Single Phase Compressor . . . . 10

Piping Works and Flaring Technique . . . . . . . . . . . . . 11

Special Precautions When Mounting TXV Bulb . . . . . 11

Refrigerant Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Suction Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Underground Refrigerant Lines . . . . . . . . . . . . . . . . . . 12

Long Vertical Riser Installation . . . . . . . . . . . . . . . . . . 12

Liquid Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Start-up and Shutdown . . . . . . . . . . . . . . . . . . . . . . . . 18

Pre Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electrical Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Condensers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Refrigerant Sight Glass . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

..................................................................................................................................................................................................................

Manufactured in an ISO certified facility.

"McQuay" is a registered trademark of McQuay International.

© 2004 McQuay International

"Illustrations and information cover the McQuay International products at the time of publication and we reserve the right to make changes in

Page 2 IM-799

design and construction at any time without notice."

Page 3

INTRODUCTION

General Description

McQuay air-cooled condensing units are complete, self-contained automatic refrigerating units. Every unit is completely

assembled, factory wired, and tested. Each unit consists of air-

cooled condensers, Copeland Compliant Scroll

compressor, and internal refrigerant piping, ready to be piped

to a field-supplied evaporator and liquid line accessories.

The electrical control center includes all equipment protection

and operating controls necessary for automatic operation

except for the staging control for the steps of capacity in the

unit. Condenser fan motors are three-phase and started by their

own contactors with inherent overload protection. The compressor has internal line breakage motor protection for inherent

thermal overload protection, except Model ACU 300 which

has solid-state motor protection.

®

hermetic

Receiving Inspection

McQuay products are carefully inspected prior to shipment

and the carrier has assumed responsibility for loss or damage

upon acceptance of the shipment.

Upon receiving your shipment, check all items carefully

against the Bill of Lading. Inspect the unit and/or accessories

for shipping damage as soon as they are received. Immediately file claims for loss or damage, either shipping or concealed, with the shipping company.

Check the unit nameplate to verify the model number and electrical characteristics are correct. In the event an incorrect unit

is shipped, it must be returned to the supplier and must NOT

be installed. The manufacturer disclaims all responsibility for

the installation of incorrectly shipped units.

Important Message to the Installer

This equipment is to be installed by an experienced installation

company and fully trained personnel. Carefully read all

instructions and take into account any special considerations

prior to installing the unit. Give this manual to the owner and

explain its provisions.

Important Message to the Owner

Read these instructions carefully and keep them near the product for future reference. Although these instructions are

addressed primarily to the installer, useful maintenance information is included. Have the installer acquaint you with the

operation of the product and periodic maintenance requirements.

Recognize Safety Symbols, Words, and

Labels

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner's and installer's responsibility to read and comply with

all safety information and instructions accompanying these

symbols. Failure to heed safety information increases the risk

of property damage and/or product damage, serious personal

injury or death. Improper installation, operation or maintenance can void the warranty.

DANGER

Immediate hazards which WILL result in property

damage, product damage, severe personal injury and/

or death.

Codes and Regulations

This product is designed and manufactured to permit installation in accordance with National Codes. System design

should, where applicable, follow information presented in

accepted industry guides such as the ASHRAE Handbooks. It

is the installer' s responsibility to install the product in accordance with National Codes and/or prevailing local codes and

regulations. The manufacturer disclaims all responsibility for

equipment installed in violation of any code or regulations.

IMPORTANT

The United States Environmental Protection Agency

(EPA) regulations cover introduction and disposal of

refrigerants in this unit. Failure to follow those

regulations can harm the environment and lead to

substantial fines. Because regulations can change, a

certified technician should perform any work done on

this unit. If you have any questions, please contact the

local office of the EPA.

WARNING

Hazards or unsafe practice CAN result in property

damage, product damage, sever personal injury and/or

death.

CAUTION

Hazards or unsafe practices which CAN result in

property damage, product damage, and/or personal

injury.

Replacement Parts

Replacement parts can be obtained by contacting McQuay at

1

-800-37-PARTS. When contacting McQuay for service or

replacement parts, refer to the model number and serial number of the unit as stamped on the nameplate attached to the

unit.

General Warning

WARNING

Sharp edges and coil surfaces can cause personal

injury. Wear protective gear and avoid contact with

them.

IM-799 Page 3

Page 4

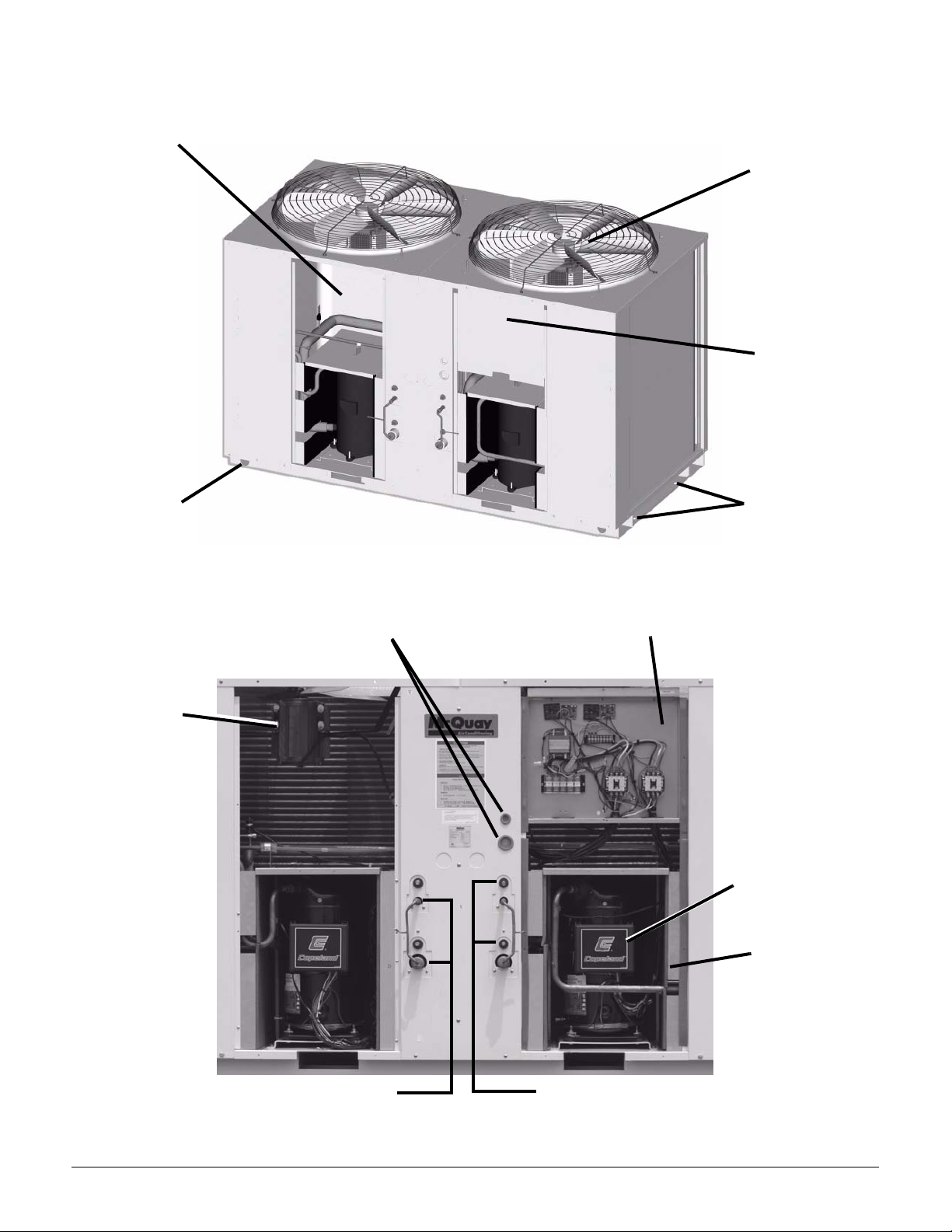

Component Location

Condenser Fan and Motor

Access (Access Panel

Removed)

Lifting Holes

(units are skid

mounted)

Direct Drive

Condenser

Fans

Control Box

Access Panel

Factory Provided

Holes For

Optional Spring

Vibration Isolation

Condenser Fan

Motor

Power and Control Connection

Knock Outs

Control Box

Compressor Motor

Protector

Compressor

Access

Extended Liquid and Suction Lines

For Easy Connection

Page 4 IM-799

Extended High and Low Pressure

Schrader Connections

Page 5

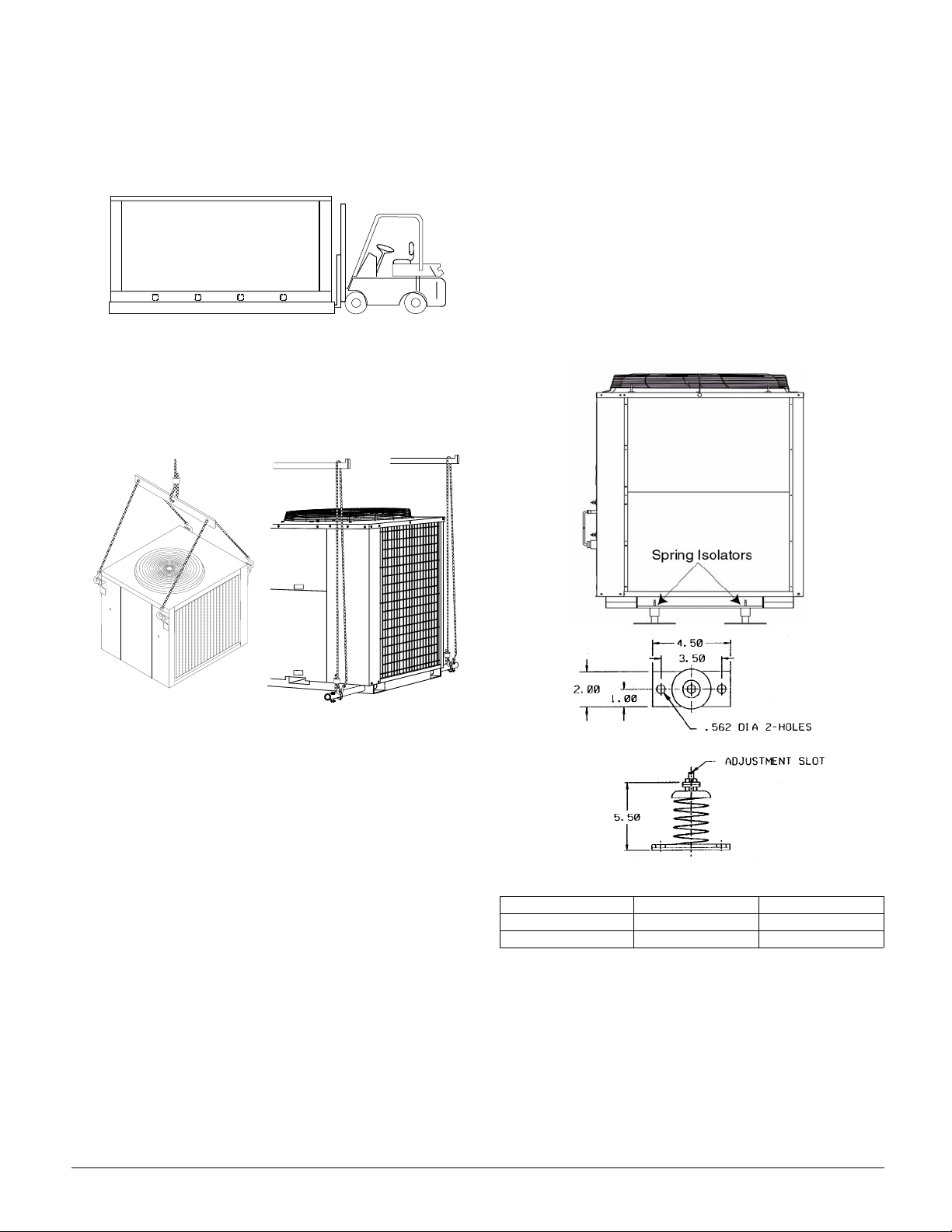

Handling

Be careful to avoid rough handling of the unit. Do not push or

pull the unit from anything other than the shipping skid supplied with the unit to avoid damage to the sheet-metal cabinet

and end frame (see Figure 1).

Figure 1. Suggested Pushing Arrangement

Lifting instructions vary for single circuit (Models 075 to 150)

and dual circuit (Models 200 to 300) units. Models 200 to 300

require spreader bars to help prevent cabinet damage (Figure

2).

Figure 2. Suggested Lifting Arrangement

Models 075 to 150 Models 200 to 300

The fan deck with the condenser fans and motors can be

removed from the top of the unit.

Vibration Isolators

Vibration isolators are recommended for all roof-mounted

installations, or when vibration transmission is a consideration.

Initially, the unit should be on shims or blocks at the listed free

height. When all piping, wiring, flushing, charging, etc. is

completed, adjust the springs upward to loosen the blocks or

shims so they can be removed.

A rubber anti-skid pad is part of the isolator. Installation of

spring isolators requires flexible piping connections and at

least three feet of flexible conduit to avoid straining the piping

and transmitting vibration and noise.

Figure 3. McQuay Spring Isolator Option

Location

Unit Placement

ACU units are for outdoor applications and can be mounted on

a roof or at ground level. Set units on a solid and level foundation. For roof-mounted applications, install the unit on a steel

channel or I-beam frame to support the unit above the roof. For

ground level applications, install the unit on a substantial base

that will not settle. A one-piece concrete slab with footings

extended below the frost line is recommended. Be sure the

foundation is level (within 1/2" [13 mm] over its length and

width). The foundation must support the operating weights

listed in the Physical Data Table on page 14.

Since its operation is affected by wind, the unit should be

located so that the Control Box is perpendicular to the prevailing wind. If this is not practical, field fabricated wind deflectors may be required.

Service Access

Each end of the unit must be accessible after installation for

periodic service. Motor protector controls are on the compressor. Most operating, equipment protection, and starting controls are located in the unit control box. (See page 7 for

details.)

ACU Model Spring Weight Color

075D to 150D (4) 175 lb. Red

200D to 300D (4) 600 lb. Orange

Notes:

1.5.50" free height

2.300 lb./in. mounting construction

3.Base: 2.0" x 4.50" with two (2).562 mtg holes at 3.5 c/c

4.Includes adjustable leveling bolt with slot and.50 locking nut, acoustical

non-skid neoprene pad.

IM-799 Page 5

Page 6

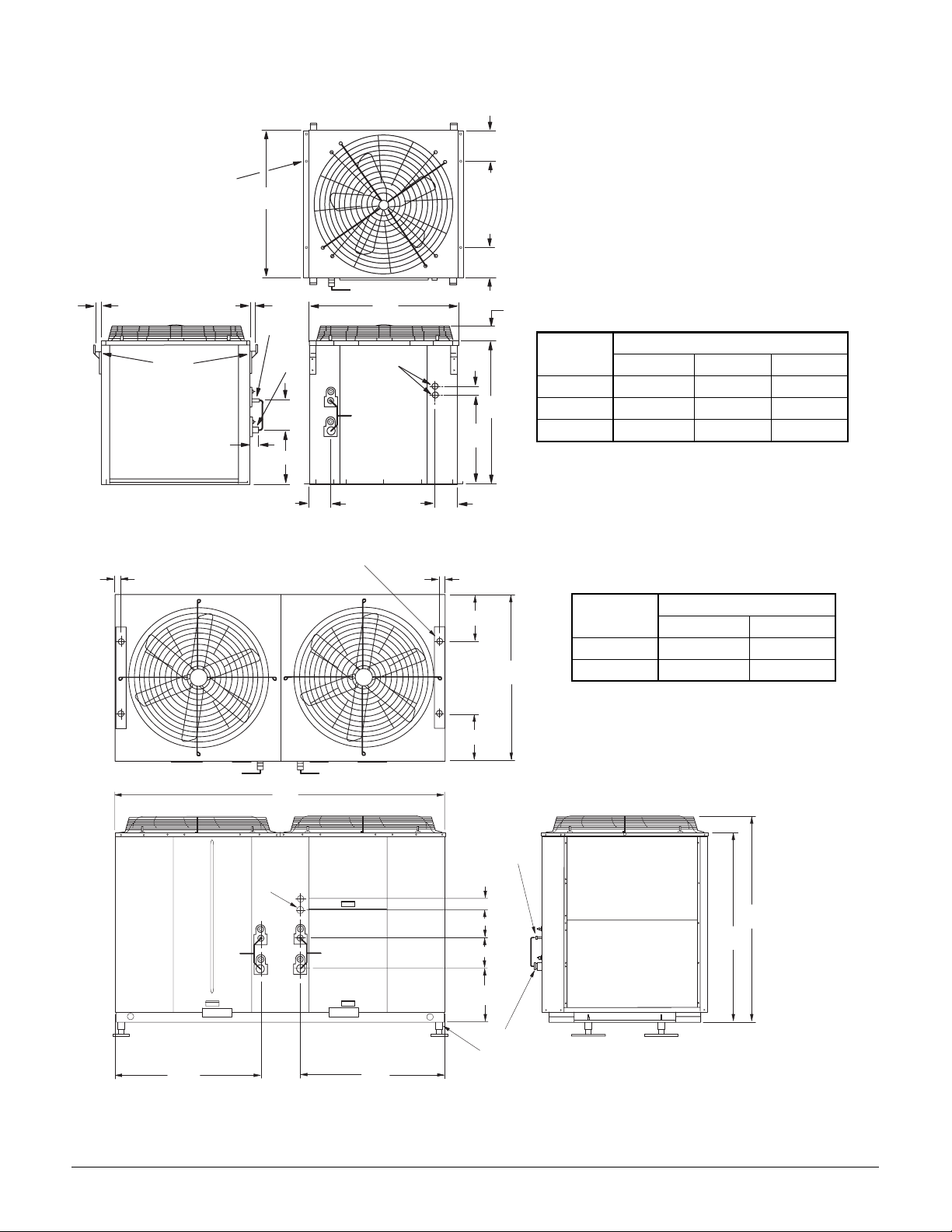

Dimensions

.7

H

Figure 4. ACU 075D to 150D Dimensions (all dimensions in inches)

0.6" Diameter

Mounting Holes

W

7.9

7.9

1.4

1.4

W

Liquid

Lifting

Brackets

Suction

Power

Entry

2.4

7.9

2.0

22.9

A

5.7

5.9

Figure 5. ACU 200D to 300D Dimensions (all dimensions in inches)

0.8" Diameter Mounting Holes

1.6

1.6

12.8

12.8

3

Dimension

(inches)

H

H

W

A

Liquid, suction and hot gas connection sizes are found in Table 3 ACU 075 to ACU 300 Physical Data.

Hot gas bypass connections are inside the cabinet. A 2" knock out is

provided.

075D-100D 125D 150D

37.2 37.2 41.2

38.6 42.6 42.6

13.8 13.9 13.9

Dimension

(inches)

H

45.6

A

Liquid, suction and hot gas connection sizes are found in

Table 3 - ACU 075 to ACU 300 Physical Data.

Hot gas bypass connections are inside the cabinet. A pair

of 2" knock outs are provided.

Model Size

Model Size

200D-250D 300D

48.3 56.4

44.0 52.1

90.2

Liquid

Power

Entry

3.1

7.5

A

7.9

15.4

39.539.5

Suction

Spring Isolator

Page 6 IM-799

Page 7

Installation Instructions

S

P

G

Location For Installation of Condensing

Units

As condensing temperature rises, evaporating temperature

rises and cooling capacity drops. In order to achieve maximum

cooling capacity, the selected location should fulfill the following requirements

A. Sufficient clearance must be provided for proper operation,

service and maintenance. To avoid short circuiting condenser air, the minimum distance between adjacent AHU

units is 40 inches. Do not install a unit above another.:

AIR DISCHARGE

C

SPACE

A

ERVICE

A

ANEL

Dimension Minimum Clearance

A 24”

B 42”

C 59”

B

B

C. Must be well ventilated so that the unit can draw and dis-

tribute plenty of air, which helps lower the condensing temperature.

D. Must be capable of bearing the weight of the unit and iso-

lating noise and vibration.

E. Should be protected from direct sunlight. If necessary, use

an awning for shade.

F. Avoid annoying neighbors with the hot air discharge and

operating sound level.

G. Must not be susceptible to dust or oil mist.

CAUTION

If the condensing unit is operated in an atmosphere

containing oils (including machine oils), salt (coastal

area), sulphide gas (near hot spring, oil refinery plant),

such substances can cause failure of the unit.

Sound Isolation

The ultra-low sound levels for the ACU condensing units is

sufficient for most applications. However, there will be applications where sound generation can be an issue. The most

effective isolation method is to locate the unit away from

sound sensitive areas. Avoid locations beneath windows or

between structures where normal operating sounds can be

objectionable. Reduce structurally transmitted sound by isolating refrigerant lines, electrical conduit and the unit itself. Use

wall sleeves and rubber isolated piping hangers to reduce

transmission of refrigerant flow noise into occupied spaces.

Use flexible electrical conduit to isolate sound through electrical conduit. Spring isolators are effective in reducing the low

amplitude sound generated by scroll compressors and for unit

isolation in sound sensitive areas.

B. Avoid obstructing airflow into or out of the unit. Remove

obstacles that block air intake or discharge.

OBSTACLE BLOCKING

AIR OUTLET

Field Piping

For satisfactory operation and performance, note the following for the field piping arrangements of the complete refrigerant cycle:

A. Liquid loops or oil traps must be provided according to the

position of the outdoor and the indoor units (depending on

whether the indoor unit is above or below the outdoor unit).

OBSTACLE BLOCKIN

AIR INLET

B. Provide the field supplied expansion valve as close to the

indoor unit (evaporator) as possible.

C. Field supplied sight glass and filter drier must be assembled

and mounted next to the expansion valve.

IM-799 Page 7

Page 8

Maximum Pipe Length and Maximum Number of

Bends

When piping is too long, the required refrigerant quantity

increases and both the capacity and reliability decrease. As the

number of bends increase, system piping resistance to the

refrigerant flow increases, which lowers the cooling capacity

and the may cause compressor failure. If the height difference

between the evaporator and the condenser is excessive, the

cooling capacity drops, the lubricating oil return is diminished

and compressor efficiency is adversely affected.

Always choose the shortest piping path and follow the recommendations shown Figures 6 and 7:

Maximum Elevation Maximum Length

Maximum Number

of Bends

Figure 7. Maximum Total Piping

OUTDOOR UNIT

T

H

G

I

E

H

N

O

I

T

A

V

E

L

E

M

U

M

I

X

A

M

G

N

I

P

I

P

L

A

'

T

5

1

O

1

T

M

U

M

I

X

A

M

INDOOR

UNIT

65’ 115’ 8

CAUTION

1. Warranty will be revoked if the height, length

and/or the number of bends of the refrigerant

piping system installed is beyond the limits set

out above.

2. Bends must be carefully made to avoid crush-

ing the pipe. Use a pipe bender.

Figure 6. Maximum Piping Elevation)

T

H

G

I

E

H

N

O

I

T

A

V

E

L

OUTDOOR UNIT

E

M

U

M

I

X

A

M

Condensing Unit Below Coil

N

O

I

T

A

V

E

L

E

G

'

N

5

I

6

P

I

P

M

U

M

I

X

A

M

INDOOR

UNIT

INDOOR

UNIT

Condensing Unit Above Coil

Vacuuming and Charging

Vacuuming is necessary to eliminate all moisture and air from

the system. Model ACU condensing units are provided with

Schrader valve fittings and charging nipples for this purpose.

Vacuuming

After the system piping is properly connected, connect the

flexible hoses to the correct charging nipples as shown in the

diagrams. Use standard servicing valves and pressure gauges

(gauge manifold) to connect the flexible hose to the vacuum

pump. Vacuum the air conditioner system to at least 500

microns Hg.

Figure 8.

Liquid Line

Vaccum Pump

Suction Line

Page 8 IM-799

Page 9

Charging

Before charging, the vacuum must be held at 500 microns Hg

for at least 15 minutes. After this period, the vacuum can be

broken by charging the unit with R-22 refrigerant. Operate the

unit for 15 minutes and monitor the running current and suction and liquid line pressures to verify that the refrigerant

charge is the correct quantity. Suction and discharge pipe pressures should be in the region of 75 psig and 275 psig, respectively. After verifying that the system is correctly charged,

remove flexible hose from the charging nipples and replace the

caps.

Figure 9.

R22

Liquid Line

Charging Hoses

Most field-charging is accomplished using standard service

hoses. Hoses are made in different colors with different working pressures and different leak rates; but the most important

feature required for the charging hose is the presence or

absence of Schrader valve depressors. Schrader valve depressors severely restrict the flow through the service hoses. This

slows evacuation and vapor charging dramatically. In most

cases, the Schrader valve depressor can be removed; but it is

recommended that you have two sets of hoses - one with and

one without Schrader valve depressors.

Suction Line

Field Charging Precautions

Scroll compressors have a very high volumetric efficiency and

they can quickly pump a deep vacuum if there is insufficient

refrigerant in the system, or if refrigerant is added too slowly.

Operation with low suction pressure will quickly lead to very

high discharge temperatures. While this process occurs, the

scrolls are not being well lubricated because they depend on

the oil mist in the refrigerant for lubrication. A lack of lubrication leads to high friction between the scroll flanks and tips

and generates additional heat. The combination of the heat of

compression and heat from increased friction is concentrated

in a small, localized discharge area where temperatures can

quickly rise to more than 300°C. These extreme temperatures

can damage the Scroll spirals and the orbiting Scroll bearing in

less than one minute, especially on larger compressors. Damage that occurs during field charging may occur in the first few

hours of operation, or it may become evident some time later.

Other typical field charging problems include undercharging,

overcharging, moisture or air in the system, etc. Each of these

problems can also cause compressor failure.

Equipment

Minimal equipment is required for field charging. The minimum equipment required for satisfactory field charging

includes:

• Set of service gauges

•Hoses

• Vacuum pump

• Vacuum gauge

• Scales

• Thermometer

Hose with Schrader

valve depressor

Hose without Schrader

valve depressor

Hose selection is important depending on whether the system

is being evacuated or charged. Charging liquid from the cylinder into the liquid line should be carried out using an open

hose connected to an unrestricted fitting. This will reduce

charging time.

Typical Service Valves on ACU Units

Schrader

Core

Model ACU Has

Suitable Connection

Schrader Valve With

Core In Place

Schrader Valve With

Core Removed

Schrader valves provide easy system access for pressure reading and the addition of refrigerant. They provide a restriction

that slows the speed of liquid charging into the suction side.

They also provide a reasonable connection for evacuation on

the 6 to 13 ton circuits used on the model ACU.

IM-799 Page 9

Page 10

How Much Refrigerant?

Proper refrigerant charge is determined by several factors:

1. The best criteria is condenser subcooling. It should be 12°F

to 18°F. Add charge if subcooling is insufficient.

2. Suction super heat should be 12°F to 18°F. High super heat

is a potential indicator of low charge.

3. Bubbles in the liquid line sight glass are a potential indicator of low charge.

4. The charge can be calculated by adding the operating

charge for the condensing unit, piping and evaporator:

Condensing Unit Operating Charge

ACU Model Size 075 100 125 150 200 250 300

Operating Charge (lbs.) 9 1215182 x 112 x 142 x 17

Field Piping Operating Charge

Liquid Line Suction Line

Piping Diameter 5/8" 7/8" 1-1/8" 1-3/8" 1-5/8"

Lbs. of R-22 / 100 ft. Pipe Length 7.1 24.0 0.8 1.3 1.8

Evaporator Operating Charge

The evaporator operating charge is determined by the evaporator manufacturer.

CHARGING PROCEDURES

Evacuate the system to 500 microns Hg. (67Pa). The quality of

the vacuum cannot be determined by time. A reliable vacuum

gauge must be used. A battery-powered model similar to the

gauge shown below is practical since it avoids the necessity of

finding a correct power outlet.

Charging

Cylinder on

Scale

Close-up of Scale

Turn the refrigerant cylinder upside down, purge the charging

hose and charge liquid through the liquid line charging port

until refrigerant no longer flows, or until the correct charge has

been weighed in. If additional charge is required, start the system and slowly bleed liquid into the suction side until the system is full.

Charge liquid in a "controlled" manner into the suction

side until the system is full. This recommendation does not

hold true for reciprocating compressors where liquid charging

into the suction side can cause severe damage.

Carefully monitor the suction and discharge pressures. Do not

allow the suction pressure to fall below 25 psig (1.7 bar) at any

time during the charging process.

CAUTION

Manifold Gauge will show cylinder pressure

rather than suction pressure if the cylinder valve

and Manifold valve "A" are both open. This can

result in inaccurate suction pressure readings.

There are many ways of charging liquid in a "controlled manner" into the suction side:

1. Use valve A on the manifold gauge set

2. Use the valve on the refrigerant cylinder

3. Charge through a Shrader valve

4. Use a hose with a Shrader valve depressor

5. Charge into the suction side at some distance from the compressor.

6. All of the above

Page 10 IM-799

Page 11

Check to make sure compressor is running the right direction.

The compressor can run in the wrong direction on starting. If

this happens, reverse any two phases and start again. Shortterm reverse rotation will not damage the compressor, but prolonged reverse rotation can severely damage the equipment.

All compressors have internal discharge temperature protectors that are very effective in preventing exceptionally high

discharge temperatures during charging. The Size ACU 300

protection module will trip and lock the compressor out for 30

minutes. It is not normally necessary to wait 30 minutes for the

module to reset. When the compressor has cooled down, the

module can be reset by breaking the power supply to the control circuit. The ACU 075 - 250 motor protection devices have

no anti-cycle timers and compressors will restart after they

cool. Do not use a jumper wire to bypass the protection module and continue charging the system. This will cause damage

to the equipment and premature failure even if the compressor

runs after the jumper is removed and the protector is back in

the circuit.

All compressors displace some oil during operation. Oil is carried into the compressor with suction gas; and that same gas

entrains oil present on the compressor walls as it is being compressed. The sum of the two is then pumped into the discharge

piping.

More oil is displaced at compressor start-up than during the

normal running periods. If a compressor experiences excessive

starts because of recycling pumpdown control, the oil can be

pumped out and trapped in the condenser with the refrigerant

charge. This oil cannot return regardless of the adequacy of the

piping system. To a lesser extent, a similar problem occurs

when the equipment is oversized for the available cooling load.

In short, exercise extreme care to verify that both piping and

controls are suitable for the application such that displaced oil

is returned to the compressor moderately. Note that oil loss to

the system can be due to a hang up in the evaporator, as well as

in the piping.

Piping Works and Flaring Technique

• Do not use contaminated or damaged copper tubing. Generally, do not remove plastic, rubber plugs or brass nuts

from the valves, fittings, tubings or coils until it is time to

connect suction or liquid line into valves or fittings.

• If any brazing work is required, pass nitrogen gas through

the coil and joints while the brazing is being done. This

will eliminate soot formation on the inside walls of the

copper tubing.

• Cut the pipe in stages, advancing the blade of the pipe cutter slowly. Extra force and a deep cut will result in more

distortion of the pipe and more burrs (Figure 10)

Figure 10. Proper Cutting Technique

Cutting

Cutrting Copper Tube

CAUTION

Never jumper motor protectors. Damage and

premature equipment failure will result.

Refrigerant Piping

Introduction

Proper refrigerant piping can represent the difference between

a reliable, trouble free system and months or years of inefficient, problematic performance. System concerns related to

piping are:

1. Refrigerant pressure drop

2. Solid liquid feed to the expansion valve(s)

3. Continuous oil return

The most important and least understood is number 3, "Continuous oil return". The failure of oil to return at or close to the

rate of displacement from the compressor can result in oil trapping and ultimate compressor failure.

On the other hand, the instantaneous return of a large volume

of compressor oil (slug) can be equally damaging to a compressor.

1/4 Tube

Remove Burr

• Remove burrs from the cut edges of the pipe as shown in

Figure 10. This will help avoid leaks that result from

unevenness on the flare. Hold the end of the pipe downward to prevent metal chips from entering the pipe.

• Flare nuts are mounted on the connection parts of the condensing unit. Insert them onto the copper pipe.

• Fix the pipe firmly on the flare die. Match the centers of

both the flare die and the flaring punch, and fully tighten

the flaring punch.

IM-799 Page 11

Page 12

Suction Lines

Use ASHRAE for guidelines in sizing and routing piping with

one exception. See the 2002 ASHRAE Handbook Refrigeration Edition, Chapter 2 for tables and guidelines. The single

exception is piping direct expansion cooling coils located

above the compressors. In all cases, regardless of whether the

equipment has pumpdown control or not, place a trap in the

suction line equal to the height of the coil section. In its

absence, upon a power failure, all of the liquid in the coil will

fall by gravity to the compressor below.

Suction line gas velocities can range between 900 and 4000

feet per minute. Where objectionable noise in or adjacent to

occupied space is a concern, gas velocities on the low side are

recommended.

Routing must also take into account the requirement established in the latest ANSI/ASHRAE 15.

To size the suction line, determine:

A. The maximum tons for the circuit

B. The actual length in feet

C. The equivalent length contributed by elbows, fittings,

valves or other refrigerant specialties (ASHRAE

Tables 2-10, 11 & 12).

D. If a vertical riser exists including the trap at the coil, deter-

mine the minimum tons for the circuit.

Add "B" and "C" above to obtain the total equivalent feet. Use

the ASHRAE table for R-22. Suction line selections are based

upon the pressure equivalent of a 2ºF loss per 100 equivalent

feet.

Select a line size that displays an equal or slightly larger tons

than that determined in "A" above.

.

CAUTION

Avoid excessive pressure drop:

• It reduces compressor capacity.

• It increases power consumption.

• It can affect the performance of both the evaporator and the expansion valve previously selected

for the application.

The line loss calculated, expressed in temperature or PSID

pressure drop, will be used to establish the temperature

required at the evaporator to produce the required cooling and

the suction pressure that the compressor must operate at to

deliver the required capacity.

Having selected the suction line size, based upon total equivalent length and maximum tons, verify the line size selected

will maintain entrainment of the lubricating oil up any vertical

risers at the minimum tons for the circuit. See "D" above and

ASHRAE Tables.

If the line size selected will not maintain satisfactory oil return

in a suction riser, the following options are available:

• The vertical length can be sized smaller to accommodate

the lower circuit tons at reduced load.

• An oil separator can be installed in the discharge line.

Note: In horizontal refrigerant gas lines, oil return to com-

pressors is provided by sizing lines at a velocity

above the minimum recommended and pitching the

lines in the direction of refrigerant flow.

To determine the actual line loss:

1. Modify the table tons by the value for the design condensing temperature.

2. Use the formula in the notes to calculate the line loss in

terms of the saturation temperature.

3. Convert the saturation temperature loss calculated to a

pressure drop equivalent using the (Delta) listed in the table

for the comparable delta temperature

Page 12 IM-799

Page 13

Underground Refrigerant Lines

e

McQuay does not recommend installing suction lines underground. If job conditions require that they be located below

ground, a suitably sized suction accumulator must be installed

ahead of the compressor to interrupt liquid refrigerant slugs at

start-up.

Figure 12. DX Coil Piping (Condensing Unit Below Coil)

n

o

i

t

c

r

u

o

s

S

s

h

e

r

c

t

i

p

P

m

o

C

o

T

Long Vertical Riser Installation

Where job conditions require refrigerant gas lifts of more than

25 feet, McQuay recommends installing a short trap half-way

up the riser or at not more than 20 foot intervals. These traps

are required to capture and hold small quantities of oil during

off cycles.

Figure 11. DX Coil Piping (Condensing Unit Above Coil)

n

o

i

t

c

r

u

o

S

s

s

Liquid

to Coil

t

c

r

p

i

e

c

t

i

P

o

T

Su cti on Trap

Short as

Fittings Permit

n

o

r

o

s

s

h

e

r

p

m

o

C

A

i

r

F

l

o

w

Expansion Valv

Control Bulb

Str ap To Lin e

and Insulate

A

i

r

F

l

o

w

Expansion Valve

Control Bulb

Strap To Line

and Insulate

Hot gas bypass valve

an d so len oid

valve located as

close to condensing

unit as possible.

h

c

t

i

P

C

o

T

i

o

C

o

t

P

B

G

H

Liquid

to Coil

Suction Trap

Short as

Fittings Permit

u

S

m

o

l

Hot gas bypass valve

and solenoid

valve located as

close to condensing

unit as possible.

G

H

Liquid

to Coil

Liquid

to Coil

c

t

i

P

C

o

T

o

C

o

t

P

B

Suction Trap

Short as

Fittings Permit

u

S

h

p

m

o

l

i

Suction Trap

Short as

Fittings Permit

n

o

i

t

c

r

o

s

s

e

r

A

i

r

F

l

o

w

Expansion Valve

Control Bulb

Strap To Line

and Insulate

A

i

r

F

l

o

w

Expansion Valve

Control Bulb

Strap To Line

and Insulate

Special Precautions When Mounting TXV Bulb

• The TXV bulb should be clamped to the suction line near

the evaporator outlet. If possible, it should be mounted on a

horizontal run.

• Clean the suction line completely before clamping the bulb

in place.

• Clamp the bulb to a free draining suction line.

• Insulate the bulb from ambient.

Note: The TXV bulb must be fixed at the suction line at

8 o'clock or 4 o'clock.

Figure 13. TVX Bulb Placement

IM-799 Page 13

Page 14

Liquid Lines

Liquid lines are generally sized for 1 to 2 degree F line losses

or their equivalent in pressure drop. Actual selection can vary

based upon the pressure drop expected from refrigerant specialties such as solenoids, refrigerant driers, valves, etc., piping

lifts or risers and the amount of condenser sub-cooling

expected.

The principal concern in sizing and routing liquid lines is

assurance that liquid is present in the line at start-up of the

compressor, and that liquid and not vapor is available at the

inlet to the expansion valve during system operation.

Liquid cannot be available in a liquid line at start-up if:

A. An excessive length of liquid line is located in a heated

ambient and the application permits migration of the refrigerant to a cold air-cooled condenser.

B. Liquid refrigerant is permitted to gravitate from the liquid

line to the condenser because of the relative location of

components.

In the event A or B above are possible, the application should

include a check valve at the condenser end of the liquid line.

The check valve should be a low-pressure drop valve. As the

line becomes heated, refrigerant trapped in the confined space

will increase in pressure. The check valve should include a

pressure relief device, relieving from the line side to the condenser side of the circuit. The relief can be sized for a pressure

differential from 80 to 180 psi, but not more than 180 psi, and

should be auto-resetting as the pressure is relieved.

If liquid lines are short, they may be of smaller diameter than

the size indicated in the current ASHRAE Refrigerant Handbook. As indicated above, the designer must size the liquid line

to verify that pure liquid will reach the inlet of the expansion

valve. If the condenser is sized to produce 10ºF of subcooling,

and each degree represents 3.05 psi with R-22, the liquid line

and its refrigerant specialties can have pressure losses totaling

10 x 3.05 psi (or 10 x 2.2) and still satisfy the objective of

delivering pure liquid to the expansion valve.

In calculating the pressure losses, or gains, note that each foot

of rise in a liquid line results in an approximate 0.5 psi loss.

Thus, a 10 foot rise represent 5 pounds per square inch loss in

refrigerant pressure, or the equivalent of 1.6ºF subcooling with

R-22. Total line losses will include values for line friction,

equivalents for valves and elbows and pressure losses from

manufacturers' catalogs for driers, sight glasses, etc.

When calculating condenser subcooling, note that saturated

condensing pressure should be read at the same point in the

system where the liquid refrigerant temperature is obtained.

Page 14 IM-799

Page 15

Physical Data

Table 1: ACU 075 to 300

Model

Nominal MBH

EER At ARI

Casing

Weight (lb.)

Sound Power (dBA)

Tubes

Fins

Rows 1222223

FPI 20161616141614

Condenser

Compressor

Electrical

Refrigeration

Face Area (Sq. Ft.) 24.7 24.4 27.4 30.4 42.0 50.4 50.4

Fan

RPM 540 540 480 480 480 480 480

Motor HP [1] 0.5 [1] 0.5 [1] 0.6 [1] 0.6 [2] 0.6 [2] 0.6 [2] 0.6

Fan Dia (in.) 32323636363636

Copeland Model [1] ZR 72 [1] ZR 94 [1] ZR 125 [1] ZR144 [2] ZR 108 [2] ZR 125 [2] ZR 16

Over Load Protection In line In line In line In line In line In line Module

Voltage

Compressor RLA each 10 16.4 19.2 19.6 17.3 19.2 25

Compressor LRA each 74 95 125 125 114 125 167

Fan Motor FLA each 1.6 1.6 1.9 1.9 1.84 1.84 1.84

Unit Ampacity 14.1 22.1 25.9 26.4 42.6 46.9 59.9

Unit Maximum Fuse Size 20.0 35.0 45.0 45.0 55.0 65.0 80.0

Unit Recommended Fuse Size 20.0 30.0 35.0 40.0 50.0 60.0 70.0

Voltage

Compressor RLA each 20.7 32.1 42 47 33.6 42 47.1

Compressor LRA each 172 203 247 245 225 247 350

Fan Motor FLA each 3.1 3.1 3.9 3.9 3.79 3.79 3.79

Unit Ampacity 29.0 43.2 56.4 62.7 83.2 102.1 113.6

Unit Maximum Fuse Size 45.0 70.0 90.0 100.0 110.0 140.0 160.0

Unit Recommended Fuse Size 40.0 60.0 80.0 90.0 100.0 120.0 140.0

Cond. Unit Charge (lb. R-22) 9 12 15 18 2 x 11 2 x 14 2 x 17

Suction Connection (in.) 1 1-1/8 1-3/8 1-3/8 2 x 1-1/8 2 x 1-3/8 2 x 1-3/8

Liquid Connection (in.) 1/2 5/8 5/8 5/8 2 x 5/8 2 x 5/8 2 x 5/8

Hot gas Connection (in.) 1-1/4 1-1/4 1-1/4 1-1/4 2 x 1-1/4 2 x 1-1/4 2 x 1-1/4

075D 100D 125D 150D 200D 250D 300D

75 100 125 150 200 250 300

12.1 10.4 11.7 11.6 11.6 11.7 11.2

Galvanized steel with powder coat finish

374 405 434 590 1036 1116 1340

64 64 66 67 70 70 70

3/8" grooved copper tube with 0.013" wall

0.005" aluminum fin with electro-plated coating

Direct drive with propeller blades

460-60-3 amps

220-60-3 amps

Notes for "Electrical Data Single-and Multi-Point" Power:

1. Unit wire size ampacity (MCA) is equal to 125% of the largest compressor-motor RLA plus 100% of RLA of all other loads in

the circuit.

2. The control transformer is furnished and no separate 115V or 24V power is required.

3. "Recommended Fuse Sizes" are selected at approximately 150% to 175% of the largest compressor RLA, plus 100% of all other

loads in the circuit.

4. Must be electrically grounded according to national and local electrical codes.

Voltage Limitations:

Within ±10 percent of nameplate rating.

Notes for "Compressor and Condenser Fan Amp Draw":

1. Compressor RLA values are for wiring sizing purposes only but do not reflect normal operating current draw at rated capacity.

Notes for "Field Wiring Data"

1. Requires a single disconnect to supply electrical power to the unit. This power supply requires short circuit protection in accordance with local codes.

2. All field wiring to unit power block must be THW type copper wire.

IM-799 Page 15

Page 16

Wiring Diagram

Figure 14. ACU 075D to 150D Typical Wiring Diagram

F I E L D

P O W E R

U P P L Y

B R O W N

B L A C K

F I E L D S U P P L Y

C B

{

G R N - Y E L E Q U P G R N

B R O W N

B Y P A S S T I M E R

2 3

B L A C K

L O G I C

N / O P E N

L P S

B L A C K

1

B L U E

B L A C K

Y E L L O W

C

B L A C K

B L A C K

Y E L L O W

B L U E

Y E L L O W

B L A C K

C

T R A N S F O R M E R

3 . 1 5 A M P

B R O W N

F U S E

T 2

T 3

R E D

Y E L L O W

Y E L L O W

C

Y E L L O W

B R O W N

2 4

B R O W N

T 1

R E D

D E L A Y T I M E R

L O G I C

N / C L O S E D

C

H P S

B L U E

B L A C K

B L A C K

B L A C K

Y E L L O W

B L U E

R E D

W H I T E

B L U E

C H

T 1

C M

T 2

T 3

L 1

O F M

L 2

L 3

F I E L D S U P P L Y

T H E R M O S T A T

R

Y

W

G

C

S W I T C H

I F C

T H

I F C

LEGEND

1) CM - COMPRESSOR MOTOR

2) C - CONTACTOR COMPRESSOR

3) OMF - OUTDOOR FAN MOTOR

4) LPS - LOW PRESSURE SWITCH

5) HPS - HIGH PRESSURE SWITCH

6) CH - CRANKCASE HEATER

7) TB - TERMINAL BLOCK

• - CONNECTOR BUD

8)

9) GND GROUND

10) IFC - INOOR FAN CONNECTOR

11) TH - THERMOSTAT

12) CB - CIRCUIT BREAKER

13) ----- FIELD CONTROL WIRE

NOTE

FOR 24V CONTROL

Page 16 IM-799

Page 17

Figure 15. ACU 200D to 250D Typical Wiring Diagram

F I E L D S U P P L Y

T H 2

S W I T C H

T H E R M O S T A T

I F C

T H 1

T 1

C H

B L A C KB L A C K

B L A C K

Y E L L O W

C H

B L A C K

B L A C K

C M 2

T 3

T 2

B L A C K

Y E L L O W

C 1C 2

T 1

C M 1

T 2

B L A C K

Y E L L O W

L 1

O F M 2

L 3

L 2

B L U E

T 3

B L U E

B L U E

R E D

W H I T E

L 1

O F M 2

L 3

L 2

R E D

B L U E

W H I T E

R

Y 1

Y 2

Y E L L O W

Y E L L O W

G

W 1

D E L A Y T I M E R 2

B Y P A S S T I M E R 2

B R O W N

C

W 2

Y E L L O W

T 3

T 2

B R O W N

L O G I C

N / C L O S E D

T 1

O R A N G E

L O G I C

N / O P E N

2 3

B L U E

H P S 2

B L U E

1

O R A N G E

B R O W N

B L A C K

L P S 2

B L A C K

B R O W N

I F C

C

R E D

B L U E

B L A C K

Y E L L O W

Y E L L O W

B L A C K

Y E L L O W

F U S E

3 . 1 5 A M P

R E D

Y E L L O W

T 3

T 2

L O G I C

N / C L O S E D

C

B R O W N

LEGEND

1) CM - COMPRESSOR MOTOR

2) C - CONTACTOR COMPRESSOR

3) OMF - OUTDOOR FAN MOTOR

T 1

T R A N S F O R M E R

2 4

B L A C K

T B 1

B L U E

Y E L L O W

L 1

L 2

Y E L L O W

B L A C K

L 3

C

B R O W N

C

D E L A Y T I M E R 1

Y E L L O W

O R A N G E

B L U E

H P S 1

B L U E

1

O R A N G E

4) LPS - LOW PRESSURE SWITCH

5) HPS - HIGH PRESSURE SWITCH

6) CH - CRANKCASE HEATER

7) TB - TERMINAL BLOCK

• - CONNECTOR BUD

8)

9) GND GROUND

10) IFC - INOOR FAN CONNECTOR

11) TH - THERMOSTAT

12) CB - CIRCUIT BREAKER

13) ----- FIELD CONTROL WIRE

C B

F I E L D S U P P L Y

G R N - Y E L E Q U P G R N

{

F I E L D

P O W E R

S U P P L Y

L O G I C

2 3

B Y P A S S T I M E R 1

B R O W N

B R O W N

N / O P E N

B L A C K

L P S 1

B L A C K

B L A C K

NOTE

FOR 24V CONTROL

IM-799 Page 17

Page 18

Figure 16. ACU 300D Typical Wiring Diagram

T H 2

S W I T C H

T H E R M O S T A T

F I E L D S U P P L Y

I F C

T H 1

T 1

C H

B L A C KB L A C K

B L A C K

Y E L L O W

C H

B L A C K

B L A C K

C M 2

T 2

B L A C K

Y E L L O W

C 1C 2

T 1

C M 1

T 2

B L A C K

Y E L L O W

L 1

T 3

B L U E

T 3

B L U E

O F M 2

L 3

L 2

B L U E

R E D

W H I T E

L 1

O F M 2

L 3

L 2

R E D

B L U E

W H I T E

R

Y 1

Y 2

Y E L L O W

Y E L L O W

G

W 1

D E L A Y T I M E R 2

B Y P A S S T I M E R 2

B R O W N

C

W 2

Y E L L O W

T 3

T 2

L O G I C

N / C L O S E D

B L A C K

T 1

O R A N G E

L O G I C

N / O P E N

2 3

C O T P 2

B L U E

H P S 2

B L U E

1

O R A N G E

B R O W N

B L A C K

L P S 2

B L A C K

B R O W N

I F C

C

Y E L L O W

R E D

B L U E

B L A C K

Y E L L O W

Y E L L O W

B L A C K

T R A N S F O R M E R

B L U E

Y E L L O W

B L A C K

T B 1

L 1

L 2

C B

F I E L D S U P P L Y

Y E L L O W

B L A C K

L 3

G R N - Y E L E Q U P G R N

C

Y E L L O W

F U S E

3 . 1 5 A M P

R E D

2 4

Y E L L O W

B R O W N

C

{

F I E L D

P O W E R

S U P P L Y

Y E L L O W

T 3

T 2

L O G I C

N / C L O S E D

T 1

D E L A Y T I M E R 1

C

Y E L L O W

LEGEND

B L A C K

C O T P 1

1) CM - COMPRESSOR MOTOR

2) C - CONTACTOR COMPRESSOR

3) OMF - OUTDOOR FAN MOTOR

4) LPS - LOW PRESSURE SWITCH

5) HPS - HIGH PRESSURE SWITCH

O R A N G E

B L U E

H P S 1

B L U E

1

O R A N G E

6) COTP - COMPRESSOR OVER

TEMPERATURE PROTECTION

7) CH - CRANKCASE HEATER

8) TB - TERMINAL BLOCK

• - CONNECTOR BUD

9)

10) GND GROUND

11) IFC - INOOR FAN CONNECTOR

L O G I C

N / O P E N

B R O W N

B L A C K

12) TH - THERMOSTAT

13) CB - CIRCUIT BREAKER

14) ----- FIELD CONTROL WIRE

2 3

B Y P A S S T I M E R 1

B R O W N

L P S 1

NOTE

B L A C K

B L A C K

FOR 24V CONTROL

Page 18 IM-799

Page 19

Start-up and Shutdown

Pre Start-up

1. Verify there is no shipping damage and no detectable

refrigerant leaks.

2. The evaporator air filters must be checked for cleanliness

and replaced as necessary.

3. Open all electric disconnects and check all electric connections for tightness.

4. Verify field-installed refrigerant piping is installed per the

Refrigerant Piping instructions and includes a liquid line

sight glass, filter drier and expansion valve. Verify the

expansion valve bulb and equalizer lines are installed in

accordance with page 13 and the manufacturer's instructions.

5. Verify that thermostat connections for one stage (sizes 075

to 150) and two stages (size 200 to 300) of control have

been connected to unit terminals R, G, C and Y (or Y1 and

Y2)

6. Check compressor oil level. The oil level should be visible

in the oil sightglass.

7. Check voltage of the unit power supply and make certain

voltage is within ±10% of nameplate rating. Check unit

power supply wiring for proper ampacity and a minimum

insulation temperature of 75

using a phase sequence meter.

8. Verify all mechanical and electrical inspections have been

completed according to local codes.

9. Disconnect the thermostat connection to terminal Y (or Y1

and Y2) to prevent compressor operation. Turn on the

main power disconnect switches. This will energize crankcase heaters. Wait at least 24 hours before starting up unit.

o

C. Check for proper phasing

Start-up

1) Start the air handling equipment by turning on the system

through time clocks, service switches, et.

2) Verify the evaporator is loaded:

a) The DX coil must have full airflow and entering air tem-

perature must be similar to design conditions.

b) The chiller must have full water flow and entering water

temperature must meet design conditions.

c) Ambient temperature must exceed 70°F.

3) Set the thermostat to call for no cooling and reconnect the

Y (size 075 to 150) or Y1 and Y2 (size 200 to 300) thermostat connections.

4) Charge the system as instructed in Vacuuming and Charg-

ing.

5) Set the thermostat to call for full cooling and watch the

condensing unit cycle on. Immediately verify proper phase

and rotation.

a)The condenser fans must rotate in the proper direction.

b)The compressor discharge pressure must exceed the suc-

tion.

6) After a few minutes, verify the suction pressure is approxi-

mately 75 psig and discharge pressure is approximately

275 psig Record these pressures, ambient temperature

and evaporator load temperatures for future reference.

7) Verify suction superheat is 12°F to 18°F or adjust the

expansion valve as necessary.

8) Verify subcooling is 12°F to 15°F.

9) Verify low pressure equipment protective devices trip at 18

psig by turning off the supply fan.

10)Verify high pressure equipment protective devices trip at

426 psig by turning off the condenser fans.

IM-799 Page 19

Page 20

System Maintenance

General

On initial start-up and periodically during operation, it will be

necessary to perform certain routine service checks. Among

these are taking electric leg readings.

Lubrication

No routine lubrication is required on the ACU units. The fan

motor bearings are of the permanently lubricated type and

require no lubrication.

Electrical Terminals

Normal heating and cooling of the wire will cause terminals to

loosen. Retighten all power electrical terminals every six

months.

WARNING

Electric shock hazard. Disconnect and tag-out all

sources of power to the unit before continuing

with following service to avoid risk of severe personal injury.

Condensers

Condensers are air-cooled and constructed with 3/8" (9.5mm)

O.D. internally finned copper tubes bonded in a staggered pattern into slit aluminum fins. No maintenance is ordinarily

required except occasionally removing dirt and debris from the

outside surface of the fins. Use locally purchased foaming condenser coil cleaners for periodically cleaning the coil. Condenser cleaners may contain harmful chemicals. Wear

protective gear and read and follow manufacturer's safety

instructions. Take care not to damage the fins during cleaning.

Thoroughly rinse all chemical cleaners from the coils.

Refrigerant Sight Glass

Observe the refrigerant sight glass monthly. A clear glass of

liquid indicates adequate sub-cooled refrigerant charge in the

system to provide proper feed through the expansion valve.

Bubbling refrigerant in the sight glass indicates the system is

short of refrigerant charge. Sub-cooling should be verified to

prevent overcharging. Refrigerant gas flashing in the sight

glass could also indicate an excessive pressure drop in the line,

possibly due to a clogged filter-drier or a restriction elsewhere

in the system. The sight glass indicates what moisture condition corresponds to a given element color. If the sight glass

does not indicate a dry condition after about 12 hours of operation, the refrigerant and oil should be tested for moisture.

Troubleshooting

If any malfunction of the condensing unit is noted, immediately switch off the power supply to the unit. Check the following fault conditions and causes for simple troubleshooting

tips.

Motor Protection Devices - The compressor motor protection device varies based on unit size. All motor protection

devices trip all 3 power phases on any trip and have an automatic reset once acceptable temperatures and currents are

experienced.

1.Model 075- An internal line break, current sensing protection device is provided that trips on high current or

compressor temperatures. An internal thermal disk is provided that picks up the discharge refrigerant temperature

and increases the sensitivity to the compressor temperature. No anti-cycle timers are provided.

2.Models 100-250- Same as Model 075 but no thermal disk

is provided.

3.Model 300- An internal pilot duty temperature sensing

protection device is provided that also responds indirectly to excessive current. These overloads have a control module with 30-minute anti-cycle timers. The

compressor can be restarted prior to the 30-minute time

delay by breaking control power to the module and re-setting it, provided the compressor has cooled sufficiently.

Low Pressure Equipment Protection Device

The low pressure equipment protection device trips at 18 psig

+/- 7 psig. Likely causes are insufficient charge, insufficient

evaporator air (or water) flow or dirty filters, low ambient

operation (50° F is the minimum allowed), an undersized or

malfunctioning expansion valve, or a liquid line blockage at

start-up.

High Pressure Equipment Protection Device

The high pressure equipment protection device trips at 426

psig +/- 22 psig. Likely causes are excessive charge, blocked

or recycling condenser air flow, a condenser fan failure, or

high ambient operation (115° F is the maximum allowed).

If the fault persists, contact your local service provider.

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

www.mcquay.com • 800-432-1342

Loading...

Loading...