McQuay ACU018ARAY, ACU036APAY, ACU030ARAY, ACU036ARAY, ACU042ARAY Installation And Maintenance Manual

...

Installation and Maintenance Manual IM-800

Group: Unitary

Part Number: IM-800

Date: August 2005

Supersedes: January 2005

ACU Split System Air Conditioners

1-1/2 to 5 ton

© 2004 McQuay International

IM-800 Page 1

Table of Contents

NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . . 4

Codes and Regulations . . . . . . . . . . . . . . . . . . . . . . . . 4

Important Message to the Installer . . . . . . . . . . . . . . . 4

Important Message to the Owner . . . . . . . . . . . . . . . . 4

Recognize Safety Symbols, Words, and Labels . . . . 4

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL WARNINGS . . . . . . . . . . . . . . . . . . . . . . . 5

CLEARANCES AND ACCESSIBILITY . . . . . . . . . . . 5

LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

REFRIGERANT TUBING . . . . . . . . . . . . . . . . . . . . . 6

EVAPORATOR COIL . . . . . . . . . . . . . . . . . . . . . . . . . 6

Field Connection to the Valve and Valve Opening . . . 6

QUICK CONNECT COILS . . . . . . . . . . . . . . . . . . . . . 7

Precharged System Installation . . . . . . . . . . . . . . . . . 7

SYSTEM START UP . . . . . . . . . . . . . . . . . . . . . . . . . 7

Processing Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CHARGE CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Capillary Tube/Fixed Orifice System. . . . . . . . . . . . . . 8

Superheat Determination . . . . . . . . . . . . . . . . . . . . . . 8

Expansion Valve System . . . . . . . . . . . . . . . . . . . . . . 8

WIRING DIAGRAM - SINGLE PHASE . . . . . . . . . . . 9

WIRING DIAGRAM - THREE PHASE . . . . . . . . . . . 10

"McQuay" is a registered trademark of McQuay International.

"Illustrations and information cover the McQuay International products at the time of publication and we reserve the right to make changes in

Page 2 IM-800

© 2004 McQuay International

design and construction at any time without notice."

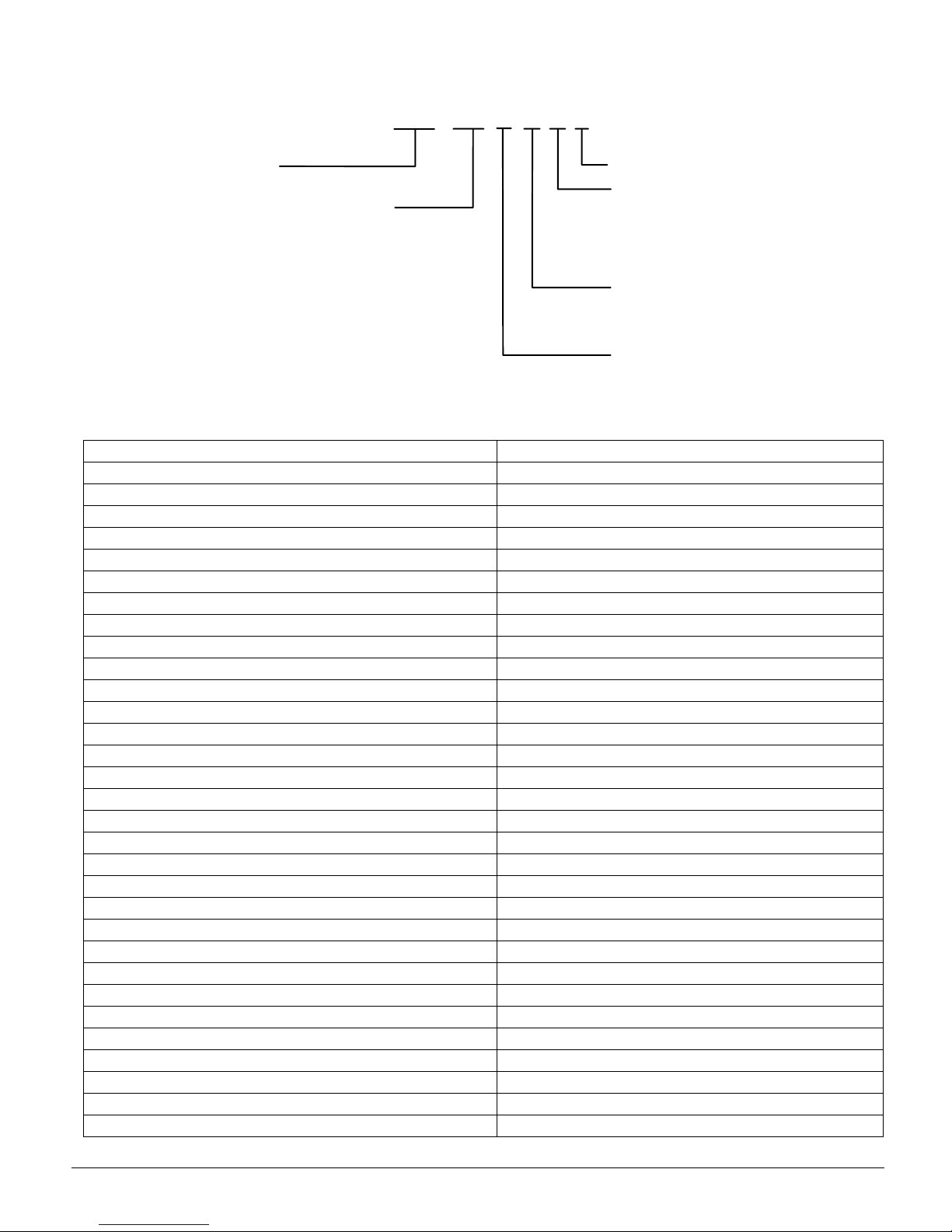

MODEL NOMENCLATURE

Model

ACU = Air Cooled Cooling Unit

Nominal Capacity (tons)

18 = 1-1/2

24 = 2

36 = 3

42 = 3-1/2

48 = 4

49 = 4

60 = 5

61 = 5

62 = 5

* 10 SEER Size 036, 049 and 060 only.

**10 SEER Size 060 only.

Table 1: Unit Nameplate Model Number Identifier

Unit Nameplate McQuay Model Number

CKL18-1L ACU018ARAY

CKL24-1L ACU024ARAY

CKL30-1L ACU030ARAY

CKL36-1L ACU036ARAY

CKL36-3L ACU036APAY

CKL42-1L ACU042ARAY

CKL49-1L ACU049ARAY

CKL49-3L ACU049APAY

CKL60-1L ACU060ARAY

CKL60-3L ACU060APAY

CKL60-4L ACU060AQAY

CKL62-1L ACU062ARAY

CLJ18-1C ACU018ARBY

CLJ24-1C ACU024ARBY

CLJ30-1C ACU030ARBY

CLJ36-1C ACU036ARBY

CLJ42-1C ACU042ARBY

CLJ48-1C ACU048ARBY

CLJ60-1C ACU060ARBY

CLT24-1B ACU024ARCY

CLT30-1B ACU030ARCY

CLT36-1B ACU036ARCY

CLT42-1B ACU042ARCY

CLT48-1B ACU048ARCY

CLT60-1B ACU060ARCY

CLQ24-1B ACU024ARDY

CLQ30-1B ACU030ARDY

CLQ36-1B ACU036ARDY

CLQ42-1B ACU042ARDY

CLQ48-1B ACU048ARDY

CLQ60-1B ACU060ARDY

ACU 018

A

RAY

Future Use

SEER

A = 10

B = 12

C = 13

D = 14

Voltage/Phase

P = 208-230/3/60*

Q = 460/3/60**

R = 208-230/1/60

Vintage

IM-800 Page 3

INTRODUCTION

General Description

These installation instructions cover the outdoor installation of

cooling only split systems from ½ to 5 tons. See the product

catalog applicable to your model for information regarding

specifications applicable to your model and accessories.

Receiving Inspection

McQuay products are carefully inspected prior to shipment

and the carrier has assumed responsibility for loss or damage

upon acceptance of the shipment.

Upon receiving your shipment, check all items carefully

against the Bill of Lading. Inspect the unit and/or accessories

for shipping damage as soon as they are received. Immediately file claims for loss or damage, either shipping or concealed, with the shipping company.

Check the unit nameplate to verify the model number and electrical characteristics are correct. In the event an incorrect unit

is shipped, it must be returned to the supplier and must NOT

be installed. The manufacturer disclaims all responsibility for

the installation of incorrectly shipped units.

Codes and Regulations

This product is designed and manufactured to permit installation in accordance with National Codes. System design

should, where applicable, follow information presented in

accepted industry guides such as the ASHRAE Handbooks. It

is the installer' s responsibility to install the product in accordance with National Codes and/or prevailing local codes and

regulations. The manufacturer disclaims all responsibility for

equipment installed in violation of any code or regulations.

Important Message to the Owner

Read these instructions carefully and keep them near the product for future reference. Although these instructions are

addressed primarily to the installer, useful maintenance information is included. Have the installer acquaint you with the

operation of the product and periodic maintenance requirements.

Recognize Safety Symbols, Words, and Labels

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner's and installer's responsibility to read and comply with

all safety information and instructions accompanying these

symbols. Failure to heed safety information increases the risk

of property damage and/or product damage, serious personal

injury or death. Improper installation, operation and maintenance can void the warranty.

DANGER

Immediate hazards which WILL result in property

damage, product damage, severe personal injury and/

or death.

WARNING

Hazards or unsafe practice CAN result in property

damage, product damage, sever personal injury and/or

death.

IMPORTANT

The United States Environmental Protection Agency

(EPA) regulations cover introduction and disposal of

refrigerants in this unit. Failure to follow those

regulations can harm the environment and lead to

substantial fines. Because regulations can change over

time, a certified technician should perform any work

done on this unit. If you have any questions, please

contact the local office of the EPA.

Important Message to the Installer

This equipment is to be installed by an experienced installation

company and fully trained personnel. Carefully read all

instructions and take into account any special considerations

prior to installing the unit. Give this manual to the owner and

explain its provisions.

CAUTION

Hazards or unsafe practices which CAN result in

property damage, product damage, and/or personal

injury.

Replacement Parts

Replacement parts can be obtained by contacting McQuay at

1

-800-37-PARTS. When contacting McQuay for service or

replacement parts, refer to the model number and serial number of the unit as stamped on the nameplate attached to the

unit.

Page 4 IM-800

GENERAL WARNINGS

WARNING

Before servicing or installing, the electrical power must

be in OFF. More than one disconnect may exist.

Failure to disconnect all power can cause electrical

shock, serious personal injury or death.

WARNING

The unit must have an uninterrupted, unbroken

electrical ground. Failure to properly ground can cause

severe personal injury or death.

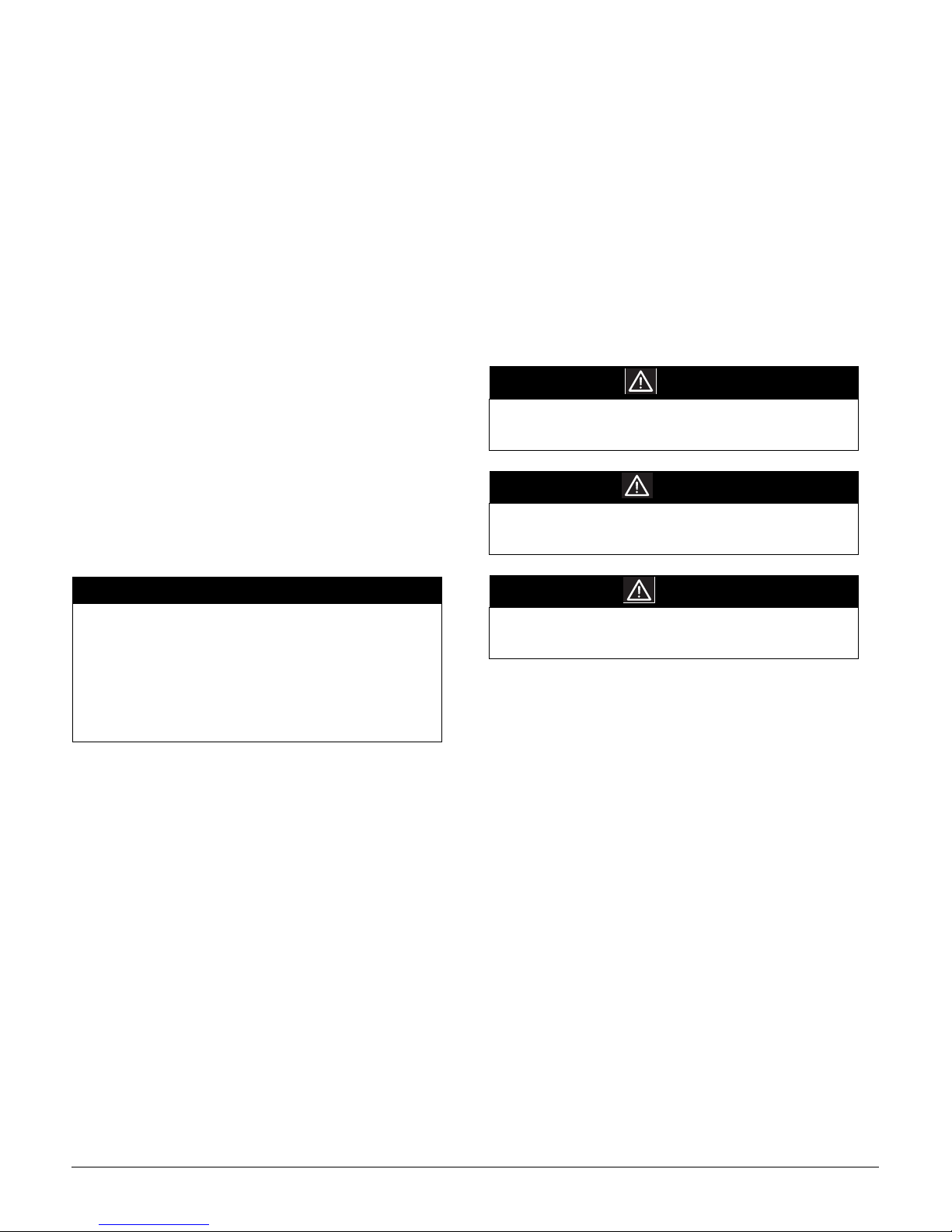

Figure 1. Clearances and Accessibility

Service Access

18" Min.

10" Min.

WARNING

Installation and service by trained, qualified technicians

only. High pressure and electricity can cause severe

personal injury or death. Observe ALL warnings

contained in this manual and the labels/tags attached to

the equipment.

WARNING

When installing or servicing, wear protective gloves,

gear and eyeware. Also observe special safety

requirements (hard hats etc.).

CCAUTION

To protect the unit when welding close to the painted

surfaces, use a quenching cloth to prevent scorching or

marring the equipment finish.

CCAUTION

Read these instructions before performing this

installation or servicing this unit. All installations must

be in accordance with all national, state, or local

building codes.

Service Access

18" Min.

Figure 2. Clearances and Accessibility

10" Min.

10"

10"

CLEARANCES AND ACCESSIBILITY

The condensing unit is designed to be located outside the

building with unobstructed condenser air inlet and discharge.

Additionally, the unit must be situated to permit access for service and installation. Condenser air enters from three sides.

Air discharges upward from the top of the unit. Refrigerant

tube electrical connections are made on the right side of the

unit as you face the compressor compartment. The best and

most common application is for the unit to be located 10” from

the back wall with the connection side facing the wall. Refer to

Figures 1 and 2. This “close to the wall” application minimizes exposed tubing and wiring and reduces the space for

children to run around the unit. This will help to avoid possible damage to the tubes or wiring and/or personal injury.

IM-800 Page 5

Close to the wall application provides free, unobstructed air to

the other two sides. In more confined application spaces, such

as corners, provide a minimum 10” clearance on all air inlet

sides. Allow 18” minimum for service access to the compressor compartment and controls.

The top of the unit should be completely unobstructed. If units

are to be located under an overhang, there should be a minimum of 36” clearance and provisions made to deflect the

warm discharge air out from the overhang.

LOCATION

If unit is to be located under an overhang, there should be a

minimum of 36” clearance and provisions made to deflect the

water discharge air out from the overhang. If the outdoor unit

is mounted above the air handler, the maximum lift should not

exceed 70’ (suction line). If the air handler is mounted above

condensing unit, the lift should not exceed 50’ (liquid line.).

Refer to Figure 3 and Table 2 for maximum refrigerant line

lenghts.

Figure 3. Maximum Refrigerant Line Lengths

70' MAX

CONDENSING UNIT

LIQUID LINE

CONDENSING UNIT

CONDENSING UNIT

LIQUID LINE

SUCTION LINE OIL TRAPS WHEN INDOOR UNIT

IS 4 FEET OR MORE BELOW OUTDOOR UNIT

INVERTED LOOP

PITCH SUCTION LINE TOWARD OUTDOOR

UNIT 1/2" FOR EVERY 10' OF LINE

LIQUID LINE

EVAPORATOR BLOWER

SUCTION LINE

EVAPORATOR BLOWER

ADDITIONAL SUCTION LINE OIL

TRAP FOR EACH 20' RISE OF PIPE

EVAPORATOR BLOWER

8'

50' MAX

ELECTRICAL

Electrical installation will consist of power supply wiring to

the condensing unit, as well as control wiring between thermostat, indoor unit and the condensing unit as shown on wiring

diagram. All wiring must be in accordance with National

Electrical Code and/or local codes that may apply.

The condensing unit rating plate lists pertinent electrical data

necessary for the selection of proper size electrical service and

over-current protection. The installer should make the owner

familiar with the location of the over-current protection, the

proper size for this application, and the proper procedure for

disconnecting power service to the unit.

The condensing unit control wiring requires a 24 Volt minimum 25 VA service from the indoor transformer as shown on

the wiring diagram.

REFRIGERANT TUBING

Use only refrigerant grade (dehydrated and sealed) copper tubing of the size indicated in Table 1 to interconnect the condensing unit with the indoor evaporator. Take extreme care to keep

the refrigerant tubing clean and dry prior to and during installation.

Do not remove plugs from ends of tubing until connection is

ready to be made. Suction line insulation is necessary to prevent condensation from forming on and dropping from suction line. Generally 3/8" wall thickness of Armflex or

equivalent is satisfactory. In severe applications (hot, high

humidity areas) greater thickness may be required. Apply suction line insulation by sliding it on the sealed tubing before

cutting and making connections.

Table 2: Maximum Refrigerant Line Lengths

REFRIGERANT LINE LENGTH (Ft)

Cond

Unit

Ton s

1 1/2 5/8 1/4 3/4 3/8 3/4 3/8

2 5/8 1/4 3/4* 3/8 3/4 3/8

2 1/2 3/4 3/8 3/4** 3/8 7/8 3/8

3 3/4 3/8 3/4** 3/8 7/8 3/8

3 1/2 3/4 3/8 7/8** 3/8 1 1/8 3/8

4 7/8 3/8 1 1/8 3/8 1 1/8 3/8

5 7/8 3/8 1 1/8 3/8 1 1/8 3/8

0-24 25-49 50-74***

Line Diameter (In. OD)

Suct Liq Suct Liq Suct Liq

* 7/8" required for full ratings

** 1 1/8" required for full ratings

The condensing unit must be mounted on a solid, level foundation (i.e. pre-formed concrete slab or other suitable base). For

rooftop application, verify that the building construction can

support the weight and that proper consideration is given to the

weather-tight integrity of the roof. The condensing unit contains moving components and can vibrate. Therefore, sound is

also a consideration in rooftop application. Since this unit discharges warm condenser air from the top with cooler air being

drawn in three sides, plantings can be made in relatively close

proximity to the unit. However, debris on the fan coil surface

reduces product efficiency. Avoid lawn mower discharge

toward the unit.

EVAPORATOR COIL

Suction and liquid lines are under pressure. Point lines away

from persons and obects that can be damaged. Use extreme

care when removing caps. Use fittings on the liquid line to

remove pressure.

Do not remove caps until installation is complete and final

connections are to be made.

Field Connection to the Valve and Valve Opening

1. Cut tubing square. Make sure it is round and free of burrs

at the connecting ends. Clean the tubing to prevent contaminants from entering the system.

2. Wrap a wet rag around the copper valve stub before braz-

ing.

3. Braze or silver solder the joint.

4. After brazing, quench with a wet rag to cool the joint.

Evacuate and charge the connecting lines as outlined in this

manual.

5. Remove the valve top cap. It is important to keep the cap

in a clean area to provide proper sealing once replaced.

6. Using a standard L shaped Allen wrench, break open the

valve body. To expedite opening the valve body after it is

broken, use a ratchet wrench with a short Allen stub.

Please note that it is normal to see oil on the valve stem

body once the cap is removed.

7. Replace the valve cap and tighten with a wrench, making

sure that the the cap is sealed.

Page 6 IM-800

QUICK CONNECT COILS

Precharged System Installation

Installation procedure will differ when condensing units are

provided for use with precharged refrigerant coils and lines.

Condensing units are provided with #6 and #11 male quick

connects instead of liquid and suction valves attached to cabinet to contain the R-22 charge that is sufficient for matching

evaporator coils and 15’ of interconnecting lines.

Coils are provided with #6 and #11 male quick connects. Line

sets are required with #6 and #11 female quick connects on

both ends. Access ports are required in the fittings of both liquid and suction lines at condenser end. Both coil and line sets

include R-22 holding charge only.

1. Connect lines to evaporator coil before connecting to the

condensing unit, locating access ports adjacent to condensing unit.

a. Form tubing so it properly aligns with the coil connec-

tions.

b. Remove plugs and caps from connections.

c. Check to verify mating surfaces are clean.

d. Lubricate rubber seal with clean refrigerant oil and

thread couplings together by hand to verify they are not

cross threaded.

e. Tighten connections using backup wrench on stationary

fitting until coupling bottoms; then tighten 1/6 turn to

complete knife edge seal.

SYSTEM START UP

Processing Checks

Condensing units are supplied with R-22 charge sufficient for

typical matching evaporator and approximately 15’ of interconnecting tubing. Condensing unit liquid and suction valves

are closed to contain the charge within the unit.

The recommended procedure for processing and charge adjustment is as follows:

1. Connect vacuum pump to both base valve service ports.

2. Evacuate tubing and evaporator through liquid and suction

base valve ports, to 500 microns or less for a minimum of

30 minutes. Close valve to pump and wait 15 minutes.

Vacuum should not rise above 800 microns. If unable to

obtain 500 micorns, or vacuum rises above 800 microns

over a 15 minute period, discontinue evacuation, pressurize

and check for leaks. Repair any leaks found and repeat

step 2.

3. Close valve to vacuum pump and stop pump. Break vacuum by opening liquid and suction base valves. Fully open

base valves and remove pump lines. Connect service

gauges to verify lines are purged.

4. Set thermostat system switch to “COOL” and temperature

to highest setting. Close all disconnects.

5. Set thermostat to call for cooling. Check for operation of

indoor and outdoor fans. Allow for at least 10 minutes.

6. Check charge and adjust if necessary. Refer to appropriate

“Check Charge” section.

2. Connect lines to condensing unit in the same manner as to

evaporator coil. Observe same precautions.

3. After making all connections and opening valves, check all

piping for leaks.

IM-800 Page 7

CHARGE CHECKS

Capillary Tube/Fixed Orifice System

1. Fully open both base valves.

2. Connect service gauge manifold to base-valve service ports

to purge lines. Run system at least 10 minutes to allow

pressure to stabilize.

3. Temporarily install thermometer on suction (large) line

near condensing unit. Provide good contact between the

thermometer and line. Wrap thermometer with insulating

material to provide an accurate reading.

4. Refer to Table 3 for proper system superheat. Add charge

to lower superheat. Remove charge to raise superheat.

5. Remove gauge lines carefully.

CWARNING

Escaping liquid refrigerant can cause burns. Wear

protective gloves, gear and eyewear.

Table 3: System Superheat

AMBIENT CONDENSER INLET

TEMPERATURE (

o

F DB)

100

95

90

85

80

75 5 10172529

70 5 14202832

65 13 19 26 32 35

60 17 25 30 33 37

RETURN AIR TEMPERATURE (

65 70 75 80 85

579

71218

5101720

5122126

Superheat Determination

1. Read suction pressure. Using Table 4, determine saturated

suction temperature.

2. Read suction line temperature.

3. Use the following formula to determine superheat:

Superheat = Suction Line Temp. - Saturated Suction Temp.

Table 4: Saturated Suction Pressure (R-22)

SUCTION PRESSURE PSIG

50 26

53 28

55 30

58 32

61 34

63 36

66 38

69 40

72 42

75 44

78 46

81 48

SATURATED SUCTION

TEMPERATURE

o

F DB)

55

o

F

Expansion Valve System

1. Fully open both base valves.

2. Connect service gauge manifold to base-valve service parts

making sure lines are purged. Run system at least 10 minutes to allow pressure to stabalize.

3. Temporarily install the thermometer to liquid (small) line

near condensing unit. Provide good contact between thermometer and line. Wrap thermometer with insulating

material to provide an accurate reading.

4. Referring to Table 5, adjust charge to obtain a temperature

12-15°F below the saturated liquid temperature.

Example:

If the Liquid Pressure is 260 psig then the Saturated Temperature will be 120°F. Adjust the Saturated Temperature by subtracting 12-15°F. This will give you a Liquid Line

Temperature of 105° - 108°F.

Table 5: Saturated LIquid Temperature

LIQUID PRESSURE PSIG

200 102

210 105

220 108

230 111

240 114

250 117

260 120

270 123

280 126

290 128

300 131

SATURATED TEMPERATURE

o

F

SPECIAL NOTE: For systems with more than 15’ of interconnecting tubing, please refer to Table 6 for line charge

allowance per foot of tubing.

Table 6: Line Charge Allowance (R-22 - oz./ft.)

LINE O.D. (IN) LIQUID LINE SUCTION LINE

1/4 0.22

3/8 0.58

1/2 1.14

5/8 1.86 0.04

3/4 0.06

7/8 0.08

1 1/8 0.15

1 3/8 0.22

NOTE: Systems with over 50’ separation between condensing unit and evaporator may require oil charge adjustment

(Table 7).

Table 7: Oil Charge Adjustment

UNIT MODEL

(TONS)

1 - 1 1/2 0.25

2 - 5 0.5

*Use either Texaco WF-32 (formerly cappella B) or Suniso 3G-S oil.

ADDITIONAL OIL CHARGE PER EACH ADDI-

TIONAL 10’ OF LINE (OZ)*

Page 8 IM-800

WIRING DIAGRAM - SINGLE PHASE

FAN MOTOR

COMPRESSOR

SC

Y

R

R

BK

BK

CRANKCASE HEATER IF USED

WIRING C ODE

HIGH VOLTAGE

LOW VOLTAGE

WIRE NUT

OPTIONAL START ASSIST

PU

BK

BK

OUTDOOR CONTROL BOX

BR

FACTORY

WIRING

C

R

F

HERM

Y

COMPRESSOR/FAN

CAPACITOR

START ASSIST

Y

(START ASSIST

IF USED)

PU

FIELD

WIRING

PU

R

Y

R

Y

WIRING FOR

FACTORY

OPTIONS

BR

NOTES:

REPLACEMENT WIRE MUST BE SAME

GAGE AND INSULATION THICKNESS,

105° C APPLIANCE W IRING MATERIAL.

BK

PU

BK

BK

ALT. DOUBLE

POLE CONTACTOR

T1

T2

C

L2

O

N

T

L2

BK

PU

R

R

T2

T1

L2

L1

CONNECT TO APPROP.

CONTROL CIRCUIT HAVING

MIN. 40 VA 24 VOLT

N.E.C. CLASS 2

TRANSFORMER OR FOR

CERTIFIED C.S.A.

INSTALLATION. USE C.S.A.

CERTIFIED ENERGY LIMITED

CLASS 2 TRANSFORMER.

COLOR CODE

BK

R

Y

BL

PU

LTBL

BR

G

L1

OUTDOOR POWER

SUPPLY - (SEE

UNIT RATING

PLATE)

USE COPPER

CONDUCTORS ONLY

USE L1 FOR

NEUTRAL OR

GROUNDED SUPPLY

IF USED

EQUIPMENT GROUND

BLACK

RED

YELLOW

BLUE

PURPLE

LIGHT BLUE

BROWN

GREEN

A

C

T

O

T2

R

THERMOSTAT

R

R

OUTDOOR POWER SUPPLY

COMPRESSOR

MOTOR

START ASSIST

(IF USED)

THERMOSTAT

FAN SWITCH

THERMOSTAT

COOL

ANTICIPATOR

BULB

THERMOSTAT

ADJ. HEAT

ANTICIPATOR

R

S

ON

AUTO

COOL

HEAT

CRANKCASE HEATER

(IF USED)

C

COMPRESSOR

INTERNAL

OVERLOAD

G

FAN RELAY

Y

THERMOSTAT

SYSTEM

SWITCH

W

LOW VOLTAGE

TRANSFORMER

FAN MOTOR

CAPACITOR

OFF

24V

CONTACTOR

COIL

COIL

COIL

L1

C

O

N

T

A

C

T

O

T1

R

C

INDOOR POWER SUPPLY

IM-800 Page 9

WIRING DIAGRAM - THREE PHASE

HP

Y

BR

V

BK

BK

R

Y

T3

L3

Y

BK

R

S

C

COMP

V

FC

POWER SUPPLY

MAIN

AUX

CM

IO

BR

V

BR

BK

R

(SEE RATING PLATE)

USE COPPER CONDUCTORS ONLY

R

BL

V

T1BLT2

L1CL2

BK

BK

BK

BK

CH

V

Y

CONNECT TO APPROP. CONTROL

CIRCUIT HAVING

N.E.C. CLASS 2

CERTIFIED C.S.A

CERTIFIED ENERGY

TRANSFORMER.

COPPER CONDUCTORS ONLY

R

MIN. 40 VA. 24 VOLT

TRAMSFORMER OR FOR

INSTALLATION. USE C.S.A.

LIMITED CLASS 2

EQUIPMENT GROUND USE

COLOR CODE

BK

BLACK

R

RED

Y

YELLOW

BL

BLUE

V

VIOLET

LTBL

LIGHT BLUE

BR

BROWN

G

GREEN

O

ORANGE

W

WHITE

USE N.E.C. CLASS 2 WIRE

C

L3

T3

R

THERMOSTAT

BULB

R

OUTDOOR POWER SUPPLY

L2

C

T2

2

3

COMP

THERMOSTAT

FAN SWITCH

THERMOSTAT

COOL

ANTIC IPATOR

THERMOSTAT

ADJ. H EAT

ANTIC IPATOR

CH

1 CAP

ON

G

AUTO

Y

COOL

OFF

HEAT

24V

THERMOSTAT

SYSTEM

SWITCH

COIL

W

LOW VOLTAGE

TRANSFORMER

MOTOR

CONTACTOR

COIL

FAN RELAY

COIL

L1

L1

C

C

T1

T1

P

H

C

HIGH VOLTAGE

LOW VOLTAGE

WIRE NUT

LINE SPLICE

WIRING CODE

FACTORY WIRING

FIELD WIRING

COMPONENT CODE

OUTDOOR FAN MOTOR

CM

COMPRESSOR

COMP

CONTACTOR

C

DEFROST CONTROL

DC

LOW VOLTAGE DEFROST RELAY

LDVR

CRANKCASE HEATER

CH

INTERNAL OVERLOAD

IO

LOW PRESSURE CONTROL

LP

HIGH PRESSURE CONTROL

HP

OUTDOOR THERMOSTAT (OPTIONAL)

OT

FAN CAPACITOR

FC

DEFROST THERMOSTAT

DFT

REVERSING VALVE COIL

RVC

HIGH VOLTAGE DEFROST RELAY

HVDR

CONTROLS SHOWN WITH UTILITIES

IN 'ON'POSITION

IN 'OFF' POSITION.

AND THERMOSTAT

INDOOR POWER SUPPLY

NOTES:

1) TO INDOOR UNIT LOW

VOLTAGE TERMINAL BLOCK &

INDOOR THERMOSTAT.

2) SEE INDOOR UNIT &

OUTDOOR UNIT INSTALLATION

INSTRUCTIONS FOR CONNECTION

OF OPTIONAL OUTDOOR THERMOSTAT.

Page 10 IM-800

IM-800 Page 11

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

www.mcquay.com • 800-432-1342

Loading...

Loading...