Page 1

Installation, Operation and Maintenance Manual

IOMM A-C Cond

Air-Cooled Condensers

Model ACH 014 - 225

Model ACX 014 - 225

Model ACL 014 - 225

Capacities from 130 MBH to 2225 MBH

R-22, R-134a

Group: Chiller

Part Number: 331376901

Effective: AUGUST 2007

Supersedes:

JULY 2007

Page 2

Table of Contents

Introduction................................................................................... 3

Installation..................................................................................... 3

Handling .........................................................................................................3

Holding Charge...............................................................................................3

Unit Location..................................................................................................4

Sound/Vibration..............................................................................................4

Rigging ...........................................................................................................5

Walls or Obstructions......................................................................................5

Multiple Units.................................................................................................6

Units in Pits.....................................................................................................6

Decorative Fences...........................................................................................6

Dimensions..................................................................................... 7

Refrigerant Piping......................................................................... 8

Refrigerant Piping...........................................................................................8

Valves..............................................................................................................8

Discharge Lines ..............................................................................................9

R-410A ...........................................................................................................9

Physical Data...............................................................................10

Electrical Data..............................................................................11

Operation..................................................................................... 18

Start-Up.........................................................................................................18

Discharge Gas Pulsation...............................................................................18

Discharge Pressure Control ..........................................................................18

Fan/Circuit Configuration .............................................................................18

Control options:............................................................................................19

Maintenance ................................................................................ 26

Cleaning Instructions....................................................................................26

Manufactured in an ISO certified facility

©2007 McQuay International

Illustrations cover the general appearance of McQuay International products at the time of publication and we reserve the right

to make changes in design and construction at anytime without notice.

2 IOMM A-C Cond

Page 3

MODEL CODE

AC H 100 A S

Air-cooled Condenser

Series: H, L, X

Nominal Evaporator Tons

Fan Rows/Circuits

S=Single, D=Dual

Vintage

Introduction

Carefully check each shipment against the bill of lading and account for all items. Report any shortage or

damage to the delivering carrier.

On receipt of equipment, check the unit nameplate for correct electrical characteristics and working pressure.

Refrigerants R-22, R-134a, R-407c have 450 psi; R-410a has 650 psi.

Be careful to prevent damage when uncrating. Heavy equipment should be left on unit’s shipping base until it

has been moved to the final location.

This equipment must be installed in accordance with accepted industry standards. Failure to meet the following

conditions may void the warranty:

1. System piping must be installed following industry standards for good piping practices.

2. Inert gas must be charged into piping during brazing/welding.

3. System must be thoroughly leak-checked and evacuated before initial charging. High vacuum gauge capable

of reading microns is mandatory. Dial indicating pressure gauges are not acceptable.

4. Power supply to system must meet the following conditions:

Voltage for 208/230 motors not less than 195 volts or more than 253 volts.

All other voltages must be within 10% of nameplate ratings.

Phase imbalance not to exceed 2%.

5. All controls and safety switch circuits properly connected per wiring diagram.

6. Factory installed wiring must not be changed without written factory approval.

7. Relief valves must meet all code requirements.

Installation

Handling

Note: Installation and maintenance are to be performed only by qualified personnel who are familiar with local

codes and regulations, and experienced with this type of equipment.

Avoid rough handling shock due to impact or dropping the unit. Do not push or pull the unit.

Never allow any part of the unit to fall during unloading or moving, as this can result in serious damage.

! DANGER

Improper lifting or moving of unit can result in property damage, severe personal injury

or death. Follow rigging and moving instructions carefully.

Holding Charge

The unit is shipped with a holding charge of dry nitrogen under nominal pressure.

IOMM A-C Cond 3

Page 4

Unit Location

Units are designed for outdoor application and may be mounted on a roof or concrete slab (ground level

installation). Install roof-mounted units on steel channels or an I-beam frame to support the unit above the roof.

Use of vibration pads or isolators is recommended. The roof must be strong enough to support the operating

weight of the unit.

For ground level installation, mount units on a one-piece concrete slab with footings extending below the frost

line. Be certain concrete slabs are installed level and are properly supported to prevent settling.

Locate the condenser far enough away from any wall or other obstruction to provide sufficient clearance for air

entrance. Do not attach ductwork to the coil inlet or fan outlet. Avoid air recirculation conditions that may be

caused by sight screening, walls, etc. and keep unit fan discharge away from any building air intakes. Do not

install unit where exhaust or ventilation equipment will affect entering air temperature or foul coils.

! WARNING

Warnings indicate potentially hazardous situations, which can result

in property damage, severe personal injury, or death if not avoided.

This equipment may contain a substance which harms the public

health and environment by destroying ozone in the upper

atmosphere. Venting of certain refrigerants to the atmosphere is

illegal. Refrigerant recovery devices must be used when installing or

servicing this product.

Sound/Vibration

Install units away from occupied spaces, utility areas, corridors and auxiliary spaces to reduce the transmission of

sound and vibration to occupied spaces. The refrigerant piping should be flexible enough to prevent the

transmission of noise and vibration from the unit into the building. If the refrigerant lines are to be suspended

from the structure of the building, use isolation hangers to prevent the transmission of vibration. Where piping

passes through a wall, pack fiberglass and sealing compound around the lines to minimize vibration and retain

flexibility. The unit must be secured in its final location. Holes are provided in the base runner for this purpose.

4 IOMM A-C Cond

Page 5

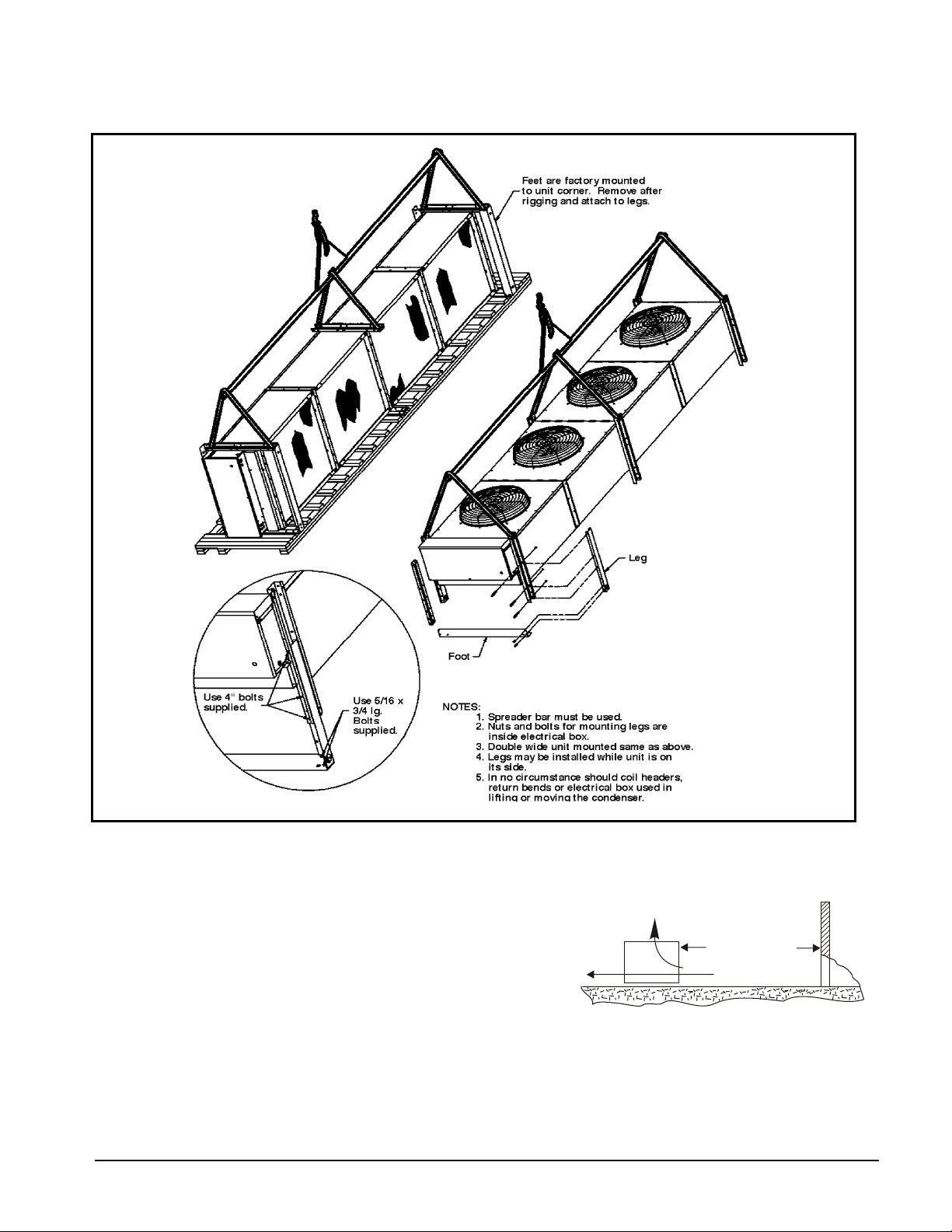

Rigging

A

A

A

Figure 1, Unit Rigging

Walls or Obstructions

Locate the unit to ensure air can circulate freely and not be

recirculated. For proper air flow and access, maintain the

minimum distance from the unit to the wall as shown to the right.

Increase this distance whenever possible. Leave maintenance

room through access doors and panels. Overhead obstructions are

not permitted. When enclosed by three walls, install unit as

indicated for units in a pit.

IOMM A-C Cond 5

IR FLOW

CH = 4 ft.

CL/ACX = 6 ft.

Page 6

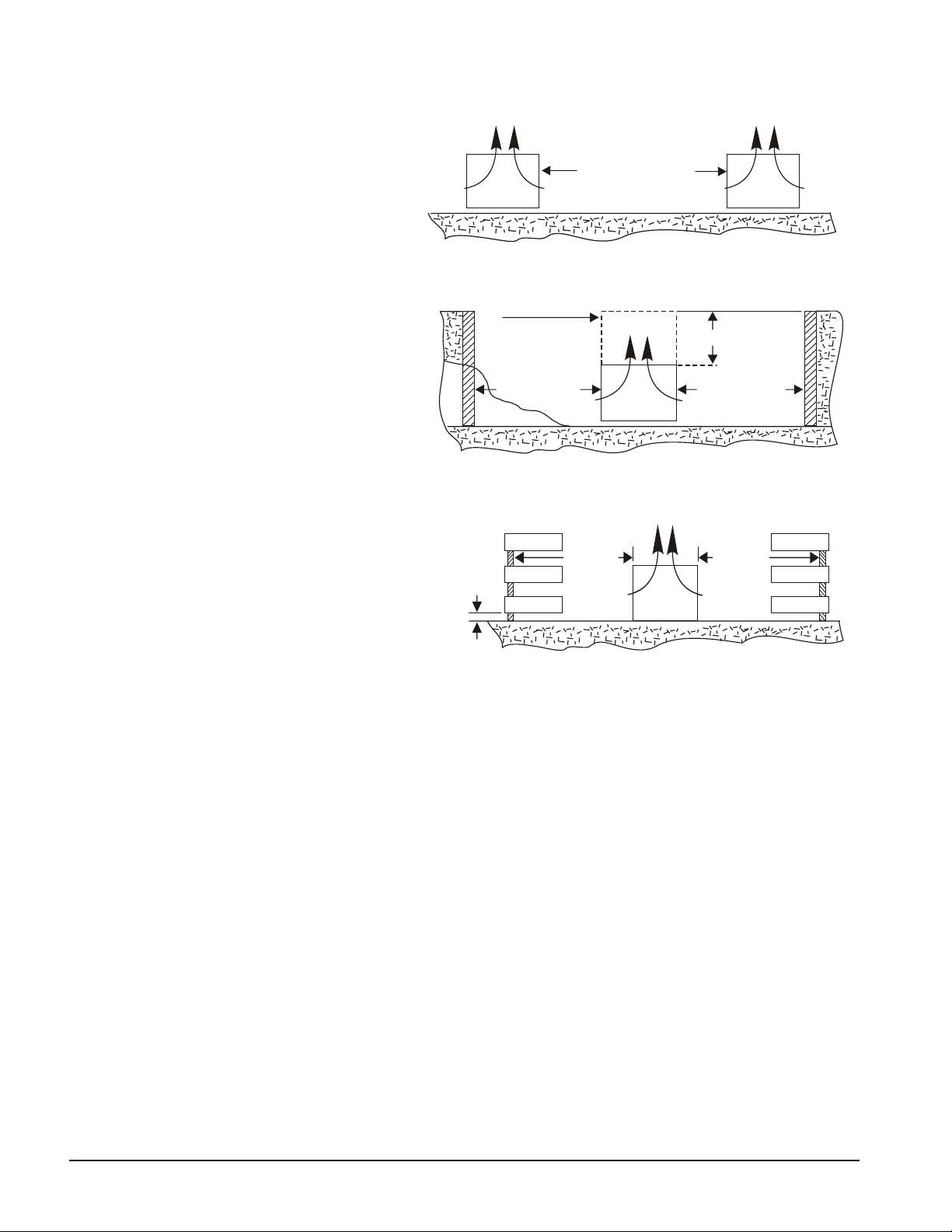

Multiple Units

A

A

A

A

A

A

A

A

A

A

A

A

A

A

For units placed side by side, the minimum

distance between units must be as shown to

the right. If units are placed end to end, the

minimum distance between units is 4 feet.

Units in Pits

The top of the unit should not be more than two

feet below top of the pit, and side distance

should be as shown. If the top of the unit is not

level with the top of pit, discharge cones or

stacks must be used to raise discharge air to the

top of the pit. This is a minimum requirement.

Decorative Fences

Fences must have 50% free area, with 1 foot

undercut, at least the width of condenser minimum

clearance, and must not exceed the top of unit. If

these requirements are not met, unit must be

installed as indicated for "Units in pits".

IR FLOW

1 IN.

MIN.

STACK

(BY OTHERS

IF SUPPLIED)

CH = 4 ft.

CL/ACX = 6 ft.

CH = 6 ft.

CL/ACX = 8 ft.

IR

FLOW

CH = 3 ft

.

CL/ACX

= 4 ft.

2 FT. MAX.

IR FLOW

IR FLOW

CH = 4 ft.

CL/ACX = 6 ft.

CH = 3 ft

CL/ACX

= 4 ft.

6 IOMM A-C Cond

Page 7

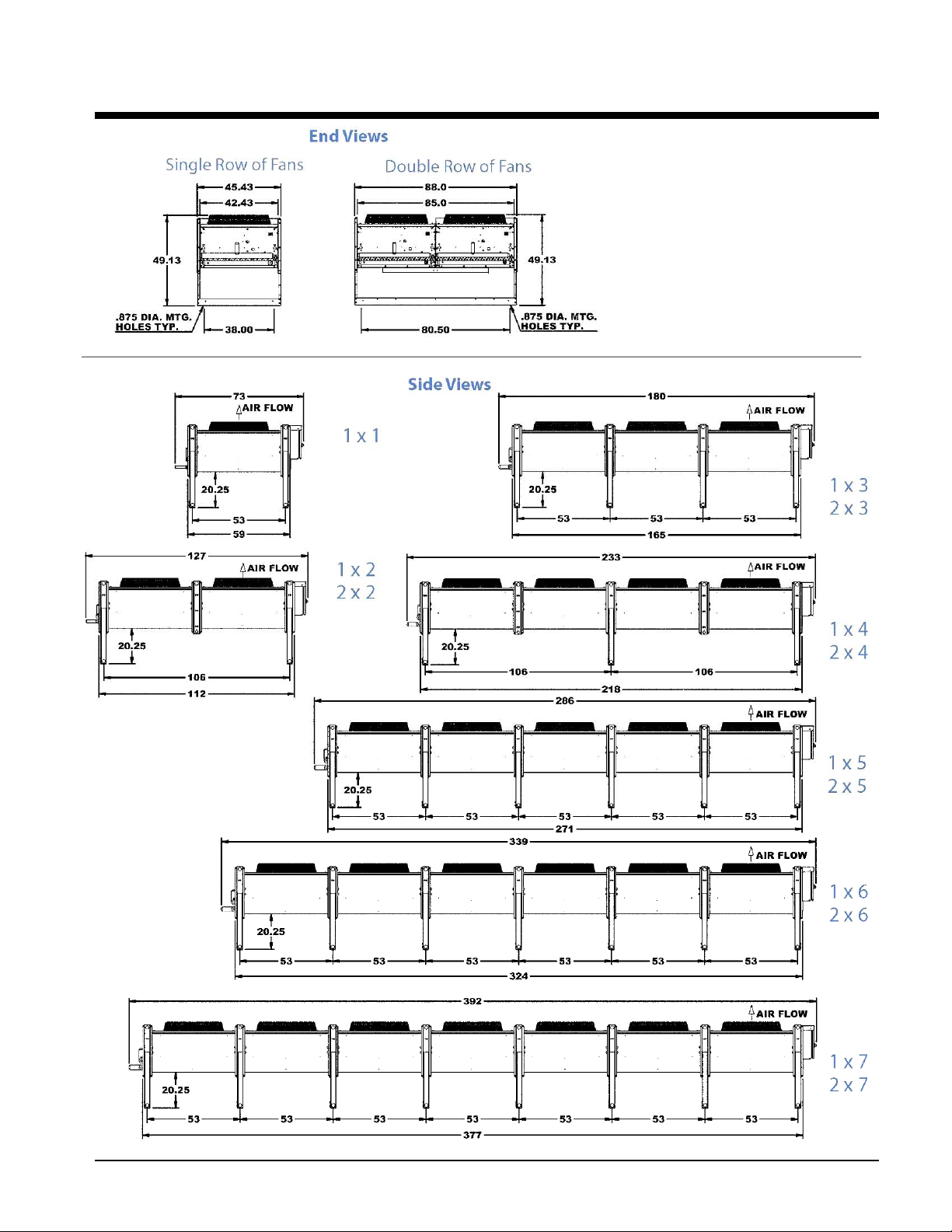

Dimensions

Note: All dimensions in inches

unless otherwise indicated

IOMM A-C Cond 7

Page 8

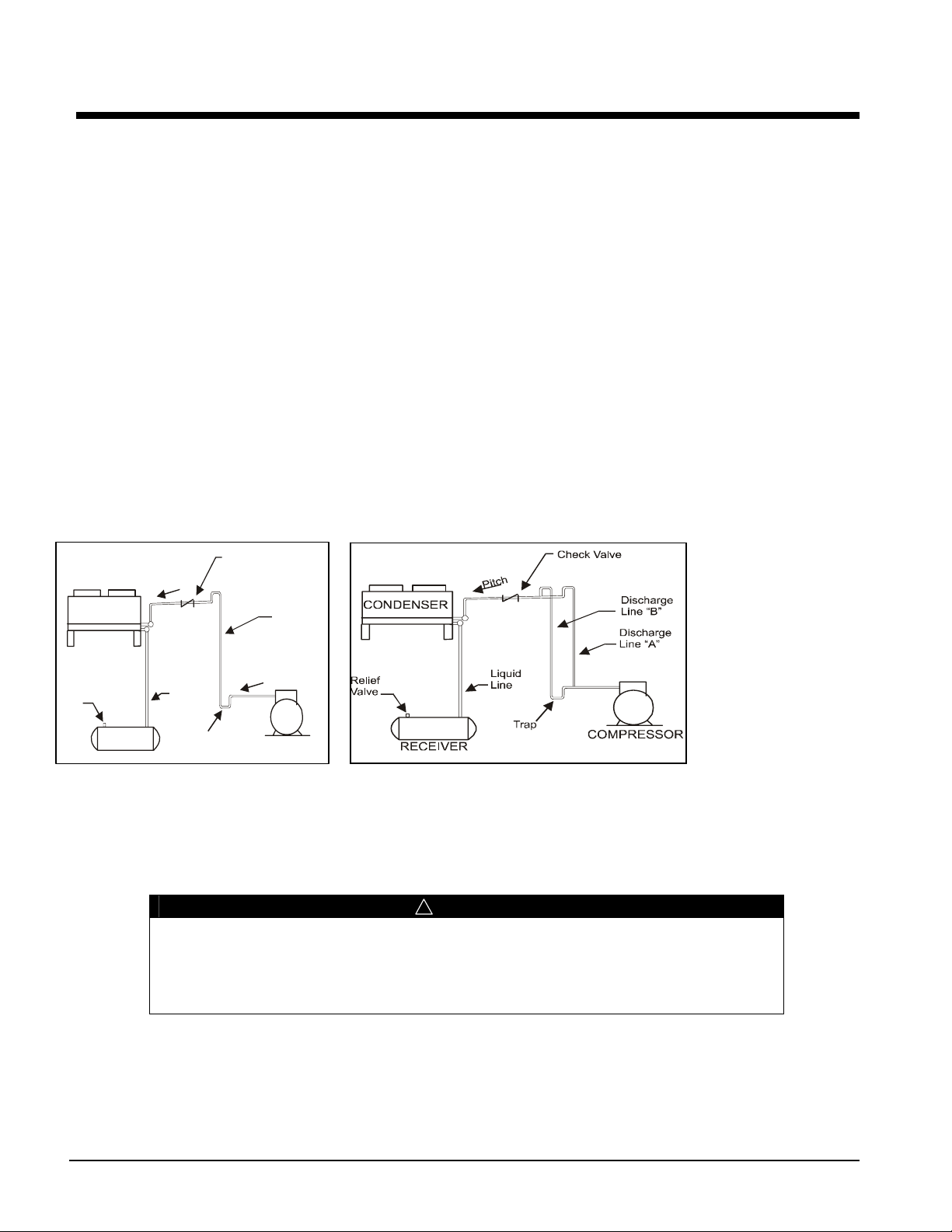

Refrigerant Piping

R

Figure 2 illustrates a typical piping arrangement involving a remote condenser located at a higher elevation, as

commonly encountered when the condenser is on a roof and the compressor and receiver are on grade level or in

a basement equipment room. In this case, the design of the discharge line is very critical. If properly sized for

full load condition, the gas velocity might be too low at reduced loads to carry oil up through the discharge line

and condenser coil. Reducing the discharge line size would increase the gas velocity sufficiently at reduced load

conditions; however, when operating at full load, the line would be greatly undersized, and thereby create an

excessive refrigerant pressure drop. This condition can be overcome in one of the two following ways:

1. Size discharge line for the desired pressure drop at full load conditions and install an oil separator at the

bottom of the trap in the discharge line from the compressor.

2. Use a double riser discharge line as shown in

Figure 2

conditions and size line "B" at full load conditions; both lines should have sufficient flow velocity to carry

the oil to the condenser.

For more complete information, see the ASHRAE Handbook on Systems.

Be aware of the following when fabricating piping:

All oil traps are to be as short in radius as possible. The trap may be fabricated using three 90- degree ells. •

Use pressure relief valves at the condenser to protect the coil.

•

Use a drain line check valve when the condenser is at a lower temperature than the receiver.

•

Figure 2, Typical and Double Riser Discharge Piping Arrangement

. Size line "A" to carry the oil at minimum load

CONDENSER

Check Valve

h

c

t

i

P

Discharge

Line

Relief

Valve

RECEIVE

Typical Piping Arrangement

Liquid

Line

Trap

h

c

t

i

P

COMPRESSOR

Double Riser Discharge Piping Arrangement

Refrigerant Piping

Install piping according to standard accepted refrigeration practice. See Ta b le 1 and Ta bl e 2 for discharge and

liquid drain line sizes for remote condenser connections. Use only refrigeration grade copper tubing and put dry

nitrogen through lines while brazing.

! CAUTION

Cautions indicate potentially hazardous situations which can result in

personal injury or equipment damage if not avoided.

Do not use soft solder joints. Do not leave dehydrated piping or

components open to the atmosphere any longer than is absolutely

necessary.

Valves

Equip major components with isolation valves and install a relief valve in the discharge line between the check

valve and the condenser inlet isolation valve.

8 IOMM A-C Cond

Page 9

Discharge Lines

Design discharge lines so that refrigerant pressure drop is minimized (high pressure losses cause increased

compressor horsepower) and a sufficiently high gas velocity to carry oil through to the condenser coil and

receiver at all loading conditions is maintained.

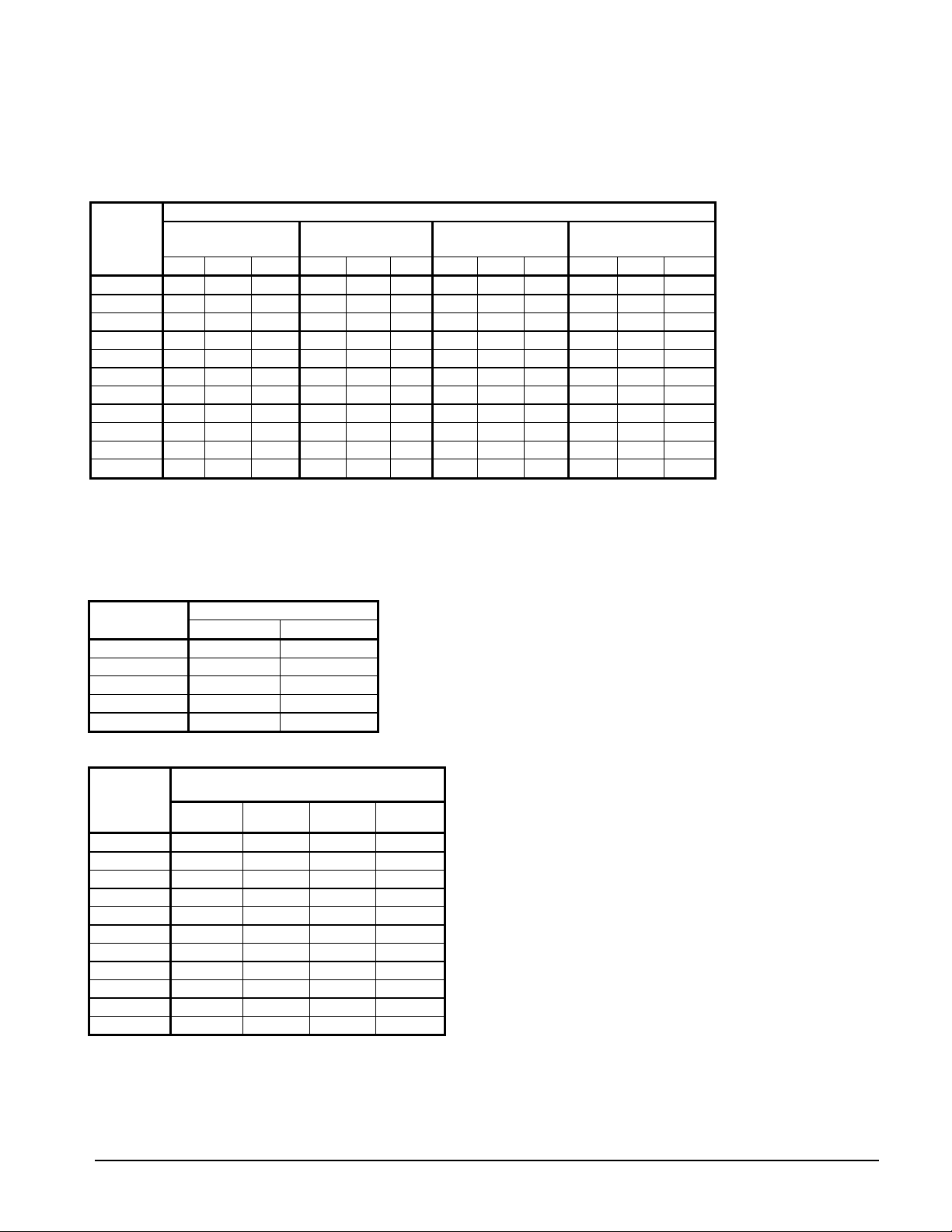

Table 1, Discharge Line Sizing

Line Size

Type L

Copper

OD (in.)

1/2

5/8

7/8

1 1/8

1 3/8

1 5/8

2 1/8

2 5/8

3 1/8

3 5/8

4 1/8

Notes:

1. Source: ASHRAE Refrigeration Handbook:

2. Line sizes based on pressure drop equivalent to one degree F. per 100 equivalent feet

3. Values in Table are based on 105°F condensing temperature. Multiply Table capacities by the factors in

4. If the line is short, a smaller line size may be used and very long lines may require larger sizes.

128.2 132.2 136.2 86.7 91.2 95.5 130.5 136.0 141.2 198.4 204.3 209.0

190.3 196.2 202.1 129.0 135.0 142.0 193.3 201.4 209.2 293.9 302.7 309.6

267.8 276.1 284.4 181.0 191.0 200.0 272.6 284.0 295.0 413.8 426.1 435.9

temperatures.

R-22 R-134a R-407C R-410A

Sat. Suction Temp. Sat. Suction Temp. Sat. Suction Temp Sat. Suction Temp

0°F 20°F 40°F 0°F 20°F 40°F0°F 20°F 40°F0°F 20°F 40°F

0.8 0.8 0.8 0.5 0.6 0.6 0.8 0.9 0.9 1.3 1.3 1.3

1.5 1.6 1.6 1.0 1.1 1.1 1.5 1.6 1.7 2.4 2.4 2.5

4.0 4.1 4.2 2.7 2.8 2.9 4.1 4.2 4.4 6.2 6.4 6.5

8.0 8.3 8.5 5.4 5.7 6.0 8.2 8.5 8.9 12.5 12.9 13.2

14.0 14.4 14.8 9.4 9.9 10.4 14.2 114.8 15.4 21.7 22.4 22.9

22.1 22.7 23.4 14.9 16.7 16.4 22.5 23.4 24.3 34.3 35.3 36.1

45.7 47.1 48.5 30.8 32.4 34.0 46.5 48.4 50.3 70.8 72.8 74.6

80.4 82.9 85.4 54.4 57.2 59.9 82.0 85.4 88.7 124.5 128.3 131.2

Discharge Line Capacity in Evaporator Tons

Table 2 for other condensing

Table 2, Condensing Temperature Correction Factor

Condensing

Temperature

90°F

100°F

110°F

120°F

130°F

Discharge Line

R-22 R-404, R-507

0.88 0.91

0.95 -0.97

1.04 1.02

1.10 1.08

1.18 1.16

Table 3, Liquid Line Sizing

Line Size

Type L

Copper

OD (in.)

1/2

5/8

7/8

1 1/8

1 3/8

1 5/8

2 1/8

2 5/8

3 1/8

3 5/8

4 1/8

In Evaporator Tons at 100 FPM Velocity

R-22 R-134a R-407C R-410A

13.2 12.1 37.9 45.8

20.2 18.4 66.2 79.7

28.5 26.1 104.7 125.9

49.6 45.3 317.1 260.7

76.5 69.9 383.7 459.7

109.2 100.0 611.3 733.0

147.8 135.0 907.9 1087.5

192.1 175.0 1281.5 1530.2

Liquid Line Capacity

2.3 2.1 3.8 4.6

3.7 3.4 7.1 8.6

7.8 7.1 18.7 22.6

R-410A

R-410A can have discharge pressures well in excess of 450 psi and special care must be exercised in designing

and installing refrigerant components and piping.

IOMM A-C Cond 9

Page 10

Physical Data

Table 4, Physical Properties of Models ACH, ACL, ACX

Model

Size

014 S 1 1 9,900 1 3/8 330 1 8,400 1 3/8 330 1 7,600 1 3/8 330

016 S 1 1 9,500 1 3/8 360 1 8,000 1 3/8 360 1 7,300 1 3/8 360

020 S 1 2 20,500 1 3/8 580 2 17,500 1 3/8 580 2 15,900 1 3/8 580

025 S 1 2 19,800 1 5/8 630 2 16,700 1 5/8 630 2 15,200 1 5/8 630

030 S 1 2 19,000 2 1/8 680 2 16,100 2 1/8 680 2 14,700 2 1/8 680

040 S 1 3 29,700 2 1/8 930 3 25,100 2 1/8 930 3 22,900 2 1/8 930

050 S 1 3 28,500 2 1/8 1000 3 24,100 2 1/8 1000 3 22,000 2 1/8 1000

055 S 1 4 38,600 2 1/8 1210 4 32,800 2 1/8 1210 4 29,800 2 1/8 1210

060 S 1 4 37,000 2 5/8 1310 4 31,200 2 5/8 1310 4 28,400 2 5/8 1310

070 S 1 5 48,300 2 5/8 1510 5 41,000 2 5/8 1510 5 37,300 2 5/8 1510

080 S 1 5 46,200 2 5/8 1640 5 39,100 2 5/8 1640 5 35,500 2 5/8 1640

100 S 1 6 55,400 2 5/8 1950 6 46,900 2 5/8 1950 6 42,600 2 5/8 1950

110 S 1 7 64,700

040 D 2 2 41,000

050 D 2 2 39,600

060 D 2 2 38,100

080 D 2 3 59,400

100 D 2 3 57,100

110 D 2 4 77,200

130 D 2 4 73,900

140 D 2 5 96,500

160 D 2 5 92,400

200 D 2 6

225 D 2 7

No.

of

Row

Fans

/Row

ACH ACL ACX

CFM

110,90 (2)2

129,40 (4)2

Conn

(in.)

(2)2

(2)1

(2)1

(2)2

(2)2

(2)2

(2)2

(2)2

(2)2

(2)2

Weight

(lbs)

2240 7 54,700

1240 2 35,000

1340 2 33,500

1440 2 32,100

1990 3 50,200

2140 3 48,200

2630 4 65,600

2830 4 62,500

3290 5 82,000

3540 5 78,100

4230 6 93,700

4910 7

Fans

/Row

CFM

109,30 (4)2

Conn

(in.)

(2)2

(2)1

(2)1

(2)2

(2)2

(2)2

(2)2

(2)2

(2)2

(2)2

(2)2

Weight

(lbs)

2240 7 49,700

1240 2 31,700

1340 2 30,500

1440 2 29,300

1990 3 45,700

2140 3 44,000

2630 4 59,700

2830 4 56,800

3290 5 74,600

3540 5 71,000

4230 6 85,200

4910 7 99,400

Fans

/Row

CFM

Conn

(in.)

(2)2

(2)1

(2)1

(2)2

(2)2

(2)2

(2)2

(2)2

(2)2

(2)2

(2)2

(4)2

Weight

(lbs)

2240

1240

1340

1440

1990

2140

2630

2830

3290

3540

4230

4910

10 IOMM A-C Cond

Page 11

Electrical Data

Install all electrical wiring according to the National Electrical Code, local codes and regulations. Use copper

conductors only. All standard motors have internal inherent overload protectors, allowing contactors to be used

instead of starters requiring thermal protectors.

! WARNING

Warnings indicate potentially hazardous situations, which can result

in property damage, severe personal injury, or death if not avoided.

There may be more than one source of electrical current in this unit.

Do not service before disconnecting all power supplies.

All condensers are furnished with either single-phase or three-phase fan motors, which are identified by the unit

dataplate. Electrical leads from each motor terminate at the unit junction box. Field connections must be made from

these leads in accordance with local, state and national codes. The motors are wired into a common junction box.

Where fan cycling is furnished and factory installed, the motors are completely wired through the control and to the

contactors. Check motors for proper rotation and be sure motor voltage and control voltage agree with electric

services furnished.

Table 5, ACH Electrical Data, S=Single Fan Row, D=Dual Fan Row

208-230/3/60 460/3/60 575/3/60

FLA MCA MOPD FLA MCA MOPD FLA MCA MOPD

Model

No. of

Rows

No. of

Fans

per

Row

UNIT

kW

ACH 014A S 1 1 7.0 15.0 25 3.5 15.0 15 2.8 15.0 15 1.9

ACH 016A S 1 1 7.0 15.0 25 3.5 15.0 15 2.8 15.0 15 1.9

ACH 020A S 1 2 14.0 20.0 35 7.0 15.0 15 5.6 15.0 15 3.8

ACH 025A S 1 2 14.0 20.0 35 7.0 15.0 15 5.6 15.0 15 3.8

ACH 030A S 1 2 14.0 20.0 35 7.0 15.0 15 5.6 15.0 15 3.8

ACH 040A S 1 3 21.0 22.8 40 10.5 15.0 20 8.4 15.0 15 5.8

ACH 050A S 1 3 21.0 22.8 40 10.5 15.0 20 8.4 15.0 15 5.8

ACH 055A S 1 4 28.0 29.8 45 14.0 15.0 20 11.2 15.0 15 7.7

ACH 060A S 1 4 28.0 29.8 45 14.0 15.0 20 11.2 15.0 15 7.7

ACH 070A S 1 5 35.0 36.8 50 17.5 20.0 25 14.0 15.0 20 9.6

ACH 080A S 1 5 35.0 36.8 50 17.5 20.0 25 14.0 15.0 20 9.6

ACH 100A S 1 6 42.0 43.8 60 21.0 21.9 30 16.8 20.0 25 11.5

ACH 110A S 1 7 49.0 50.8 70 24.5 25.4 35 19.6 20.3 25 13.5

ACH 040A D 2 2 28.0 29.8 45 14.0 15.0 20 11.2 15.0 15 7.7

ACH 050A D 2 2 28.0 29.8 45 14.0 15.0 20 11.2 15.0 15 7.7

ACH 060A D 2 2 28.0 29.8 45 14.0 15.0 20 11.2 15.0 15 7.7

ACH 080A D 2 3 42.0 43.8 60 21.0 21.9 30 16.8 20.0 25 11.5

ACH 100A D 2 3 42.0 43.8 60 21.0 21.9 30 16.8 20.0 25 11.5

ACH 110A D 2 4 56.0 57.8 70 28.0 28.9 35 22.4 23.1 30 15.4

ACH 130A D 2 4 56.0 57.8 70 28.0 28.9 35 22.4 23.1 30 15.4

ACH 140A D 2 5 70.0 71.8 90 35.0 35.9 45 28.0 28.7 35 19.2

ACH 160A D 2 5 70.0 71.8 90 35.0 35.9 45 28.0 28.7 35 19.2

ACH 200A D 2 6 84.0 85.8 100 42.0 42.9 50 33.6 34.3 40 23.1

ACH 225A D 2 7 98.0 99.8 110 49.0 49.9 50 39.2 39.9 45 26.9

NOTE: MOPD = Motor Overload Protection Device.

IOMM A-C Cond 11

Page 12

Table 6, ACL Electrical Data, S = Single Fan Row, D = Dual Fan Row

Model

ACL 014A S 1 1 6.6 15.0 25 3.3 15.0 15 2.6 15.0 15 1.4

ACL 016A S 1 1 6.6 15.0 25 3.3 15.0 15 2.6 15.0 15 1.4

ACL 020A S 1 2 13.2 15.0 30 6.6 15.0 15 5.2 15.0 15 2.7

ACL 025A S 1 2 13.2 15.0 30 6.6 15.0 15 5.2 15.0 15 2.7

ACL 030A S 1 2 13.2 15.0 30 6.6 15.0 15 5.2 15.0 15 2.7

ACL 040A S 1 3 19.8 21.5 35 9.9 15.0 15 7.8 15.0 15 4.1

ACL 050A S 1 3 19.8 21.5 35 9.9 15.0 15 7.8 15.0 15 4.1

ACL 055A S 1 4 26.4 28.1 45 13.2 15.0 20 10.4 15.0 15 5.4

ACL 060A S 1 4 26.4 28.1 45 13.2 15.0 20 10.4 15.0 15 5.4

ACL 070A S 1 5 33.0 34.7 50 16.5 20.0 25 13.0 15.0 20 6.8

ACL 080A S 1 5 33.0 34.7 50 16.5 20.0 25 13.0 15.0 20 6.8

ACL 100A S 1 6 39.6 41.3 50 19.8 20.6 25 15.6 20.0 20 8.1

ACL 110A S 1 7 46.2 47.9 60 23.1 23.9 30 18.2 20.0 25 9.5

ACL 040A D 2 2 26.4 28.1 45 13.2 15.0 20 10.4 15.0 15 5.4

ACL 050A D 2 2 26.4 28.1 45 13.2 15.0 20 10.4 15.0 15 5.4

ACL 060A D 2 2 26.4 28.1 45 13.2 15.0 20 10.4 15.0 15 5.4

ACL 080A D 2 3 39.6 41.3 50 19.8 20.6 25 15.6 20.0 20 8.1

ACL 100A D 2 3 39.6 41.3 50 19.8 20.6 25 15.6 20.0 20 8.1

ACL 110A D 2 4 52.8 54.5 70 26.4 27.2 35 20.8 21.5 25 10.8

ACL 130A D 2 4 52.8 54.5 70 26.4 27.2 35 20.8 21.5 25 10.8

ACL 140A D 2 5 66.0 67.7 80 33.0 33.8 40 26.0 26.7 30 13.5

ACL 160A D 2 5 66.0 67.7 80 33.0 33.8 40 26.0 26.7 30 13.5

ACL 200A D 2 6 79.2 80.9 90 39.6 40.4 45 31.2 31.9 35 16.2

ACL 225A D 2 7 92.4 94.1 110 46.2 47.0 50 36.4 37.1 40 18.9

No. of

Rows

No. of

Fans per

Row

NOTE: MOPD = Motor Overload Protection Device.

208-230/3/60 460/3/60 575/3/60

FLA MCA MOPD FLA MCA MOPD FLA MCA MOPD

UNIT

kW

12 IOMM A-C Cond

Page 13

Table 7, ACX Electrical Data, S = Single Fan Row, D = Dual Fan Row

p

Model

ACX 014A S 1 1 4.8 15.0 15 2.4 15.0 15 1.1

ACX 016A S 1 1 4.8 15.0 15 2.4 15.0 15 1.1

ACX 020A S 1 2 9.6 15.0 20 4.8 15.0 15 2.2

ACX 025A S 1 2 9.6 15.0 20 4.8 15.0 15 2.2

ACX 030A S 1 2 9.6 15.0 20 4.8 15.0 15 2.2

ACX 040A S 1 3 14.4 20.0 25 7.2 15.0 15 3.4

ACX 050A S 1 3 14.4 20.0 25 7.2 15.0 15 3.4

ACX 055A S 1 4 19.2 20.4 30 9.6 15.0 15 4.5

ACX 060A S 1 4 19.2 20.4 30 9.6 15.0 15 4.5

ACX 070A S 1 5 24.0 25.2 35 12.0 15.0 15 5.6

ACX 080A S 1 5 24.0 25.2 35 12.0 15.0 15 5.6

ACX 100A S 1 6 28.8 30.0 40 14.4 20.0 20 6.7

ACX 110A S 1 7 33.6 34.8 45 16.8 20.0 20 7.8

ACX 040A D 2 2 19.2 20.4 30 9.6 15.0 15 4.5

ACX 050A D 2 2 19.2 20.4 30 9.6 15.0 15 4.5

ACX 060A D 2 2 19.2 20.4 30 9.6 15.0 15 4.5

ACX 080A D 2 3 28.8 30.0 40 14.4 20.0 20 6.7

ACX 100A D 2 3 28.8 30.0 40 14.4 20.0 20 6.7

ACX 110A D 2 4 38.4 39.6 50 19.2 20.0 25 8.9

ACX 130A D 2 4 38.4 39.6 50 19.2 20.0 25 8.9

ACX 140A D 2 5 48.0 49.2 60 24.0 24.6 30 11.2

ACX 160A D 2 5 48.0 49.2 60 24.0 24.6 30 11.2

ACX 200A D 2 6 57.6 58.8 70 28.8 29.4 35 13.4

ACX 225A D 2 7 67.2 68.4 80 33.6 34.2 40 15.6

No. of

Fans

No. of

Fans

er Row

208-230/3/60

FLA MCA MOPD FLA MCA MOPD

NOTES:

1. MOPD = Motor Overload Protection Device.

2. Model ACX units are not available in 575 volts.

460/3/60

UNIT

kW

IOMM A-C Cond 13

Page 14

Figure 3, Eight Fan, Two Row Wiring with Optional Pressure Switch and FanTrol™

N

OPTIO

P66

L1

M1

GND

L2 L3

L1

3PH/50/60HZ

T2 T3

T1

MAIN POWER CIRCUIT

TERMINAL

BOARD

DOOR

DISCONNECT

SWITCH

F1

TRANSFORMER

460VOR230V

INPUT

F2

C1

T2L2

T1

L1

L2

L1

24V

C2

L2

T2

T1

L1

GND

GND

GND

ELECTRONIC

FAN

SPEED

CONTROL

L2R

L1C

M1

S

VARIABLE SPEED

L1

M1

GND

P66

ELECTRONIC

FAN

SPEED

CONTROL

L2R

L1C

M2

S

VARIABLE SPEED

CONTROL MOTOR

CONTROL MOTOR

T3L3

T2

L2

T1

L1

OPTION

F7

3A-500V

SEE NOTE 5

LEGEND:

C1-C8 FAN CONTACTOR

M1-M8 FAN MOTOR

FCP FAN CYCLE PRESSURE CONTROL

F1-F8 FUSES (REFER TO LABLE ADJACENT

TO FUSE HOLDER FOR REPLACEMENT)

NOTE:

1. UNIT MUST BE GROUNDED

2. TO BE FIELD FUSED, REFER TO

UNIT DATE PLATE FOR VOLTAGE

3. ALL MOTORS ARE INHERENTLY

PROTECTED

4. USE 60° C WIRE

END

HEADER

2

1

4

3

5

6

7

8

9

10

11

12

FAN MOTOR IDENTIFICATION

TRANSFORMER

5. WIRED ONLY WITH CONTROL

CIRCUIT TRANSFORMER OPTION

6. USE COPPER CONDUCTOR S ONLY

F3

L3

T3

L2

T2

T1

L1

F4

F5

F6

F7

F8

T3

L3

L2

T2

T1

L1

C5 C4 C3

T3

L3

T2

L2

T1

L1

T3

L3

T2

L2

T1

L1

C7 C6

T3

L3

L2

T2

T1

L1

C8

L3

L2

M3M4

L1

L3

L2

L1

L3

L2

M5

L1

L3

L2

M6

L1

L3

L2

M7

L1

L3

L2

M8

L1

FCP #7, #8

FCP #3, #4 FCP #5, #6

FCP #1, #2

MCQUAY PRESSURE FAN CYCLING

FANS/CIRCUIT

230/170

190/140

2

230/170

230/170

220/160

210/150

220/160

190/140

190/140

3

4

ADJUSTABLE RANGE (MINIMUM RANGE 125 -250#)

(DIFFERENTIAL RANGE 20 - 100#)

ELECTRIC BOX

TERMINAL

115V

CONTROL CIRCUIT

BOARD

T1 T2

1PH/50/60HZ

15 AMPS MAX

OVERCURRENT PROTECTION

C1

FCP 1

FCP 2

GND

C3

C2

FCP 3

FCP 4

C5

C4

FCP 5

FCP 6

C7

C6

FCP 7

C8

FCP 8

14 IOMM A-C Cond

Page 15

Figure 4, Ten Fan, Two Row, Wiring with Optional Pressure Switch and Fantrol Control

OPTION

P66

L1

M1

GND

T3

L1 L2 L3

3PH/50/60HZ

MAIN POWER CIRCUIT

DOOR

DISCONNECT

SWITCH

T2

T1

TERMINAL

BOARD

TRANFORMER

460VOR230V

INPUT

F1

24V

F2

C1

L2

T2

L1

T1

L2

L1

C2

L2

T2

L1

T1

GND

GND

GND

ELECTRONIC

FAN

SPEED

CONTROL

L2R

C

L

1

M1

S

VARIABLE SPEED

CONTROL MOTOR

L1

M1

GND

ELECTRONIC

FAN

SPEED

P66

CONTROL

L2R

C

L

1

M2

S

VARIABLE SPEED

CONTROL MOTOR

L3

T3

L2

T2

L1

OPTION

F7

3A-500V

LEGEND:

C1-C10 FAN CONTACTOR

M1-M10 FAN MOTOR

FCP FAN CYCLE PRESSURE CONTROL

F1-F10 FUSES (REFER TO LABEL

ADJACENT TO FUSE HOLDER

FOR REPLACEMENT)

SEE NOTE 5

TRANSFORMER

NOTE:

1. UNIT MUST BE GROUNDED

2. TO BE FIELD FUSED, REFER TO UNIT

DATA PLATE FOR VOLTAGE

3. ALL MOTORS ARE INHERENTLY

PROTECTED

4. USE 60° C WIRE

5. WIRED ONLY WITH CONTROL CIRCUIT

TRANSFORMER OPTION

6. USE COPPER CONDUCTORS ONLY

END

HEADER

F3

F4F5F6

F7

F8

F9

F10

T1

C3

L3

T3

L2

T2

L1

T1

L3

T3

L2

T2

L1

T1

C5 C4

T3

L3

L2

T2

L1

T1

C6

L3

T3

L2

T2

L1

T1

C7

L3

T3

L2

T2

L1

T1

C8

L3

T3

L2

T2

L1

T1

C9

L3

T3

L2

T2

L1

T1

C10

L3

L2

M3

L1

L3

L2

L1

L3

L2

L1

L3

L2

M6 M5 M4

L1

L3

L2

M7

L1

L3

L2

L1

L3

L2

M9 M8

L1

L3

L2

M10

L1

MCQUAY PRESSURE FAN CYCLING

230/170

FCP#7, #8

220/160

FCP#5, #6

210/150

FCP#3, #4

190/140

FCP#1, #2

(DIFFERENTIAL RANGE 20 - 100#)

ADJUSTABLE RANGE (MINIMUM RANGE 125 - 250#)

5.6

FANS/CIRCUIT

FAN MOTOR IDENTIFICATION

ELECTRIC BOX

C9

TERMINAL

BOARD

T1 T2

115V

FAN CONTROL CIRCUIT

1PH/50/60HZ

15 AMPS MAX

OVERCURRENT PROTECTION

GND

C1

C2

FCP 2

FCP 1

FCP 3

C4

C3

FCP 4

C5

FCP 5

C7

C6

FCP 6

C8

C10

FCP 7

FCP 8

IOMM A-C Cond 15

Page 16

Figure 5, Twelve Fan, Two Row, Wiring with Optional Pressure Switch and FanTrol

OPTION

P66

L1

M1

GND

C1

L2

T2

T1

L1

L2

L1

C2

L2

T2

T1

L1

TRANSFORMER

460VOR230V

INPUT

F1

24V

F2

L2 L3

L1

3PH/50/60HZ

T2 T3

T1

MAIN POWER CIRCUIT

TERMINAL

DOOR

DISCONNECT

SWITCH

BOARD

GND

GND

GND

ELECTRONIC

FAN

SPEED

CONTROL

L2 R

L1 C

M1

S

VARIABLE SPEED

L1

M1

GND

ELECTRONIC

FAN

SPEED

L1 C

L2 R

CONTROL

M2

S

VARIABLE SPEED

CONTROL MOTOR

P66

CONTROL MOTOR

L3

T3

L2T1T2

OPTION

F7

LEGEND:

C1-C12 FAN CONTACTOR

M1-M12 FAN MOTOR

FCP FAN CYCLE (REFER TO LABEL

ADJACENT TO FUSE HOLDER

FOR REPLACEMENT)

NOTE:

1. UNIT MUST BE GROUNDED

2. TO BE FIELD FUSED, REFER TO

UNIT DATA PLATE FOR VOLTAGE

3. ALL MOTORS ARE INHERENTLY

PROTECTED

4. USE 60° C WIRE

5. WIRED ONLY WITH CONTROL

CIRCUIT TRANSFORMER OPTION

6. USE COPPER CONDUCTORS ONLY

END

HEADER

FAN MOTOR IDENTIFICATION

ELECTRIC BOX

3A-500V

SEE NOTE 5

TRANSFORMER

L1

F3

C3

L3

T3

L2

T2

T1

L1

F4

C4

L3

T3

T2

L1L2T1

F5

C5

L3

T3

T2

L1L2T1

C6

F6

L3

T3

L2T1T2

L1

F7

C7

L3

T3

T2

L1L2T1

F8

C8

L3

T3

T2

L1L2T1

F9

C9

L3

T3

L2

T2

T1

L1

F10

C10

L3

T3

L2

T2

T1

L1

F11

C11

L3

T3

L2T1T2

L1

F12

C12

L3

L2

M3

L1

L3

L2

M4

L1

L3

L2

M5M6

L1

L3

L2

L1

L3

L2

M7

L1

L3

L2

M8

L1

L3

L2

M9

L1

L3

L2

M10

L1

L3

L2

M11

L1

L3

L2

M12

L1

230/170

FCP#7, #8

220/160

FCP#5, #6

210/150

FCP#3, #4

190/140

MCQUAY PRESSURE FAN CYCLING

FCP#1, #2

(DIFFERENTIAL RANGE 20 - 100#)

ADJUSTABLE RANGE (MINIMUM RANGE 125 - 250#)

5.6

FANS/CIRCUIT

TERMINAL

BOARD

T2

T1

115V

FAN CONTROL CIRCUIT

1PH/50/60HZ

15 AMPS MAX

OVERCURRENT PROTECTION

FCP 1

C2

C1

FCP 3

FCP 2

C4

C3

FCP 4

GND

C7

C5

FCP 5

C9

C6

C8

C11

C10

C12

FCP 8

FCP 7

FCP 6

16 IOMM A-C Cond

Page 17

Figure 6, Twelve Fan, ACH/ACL/ACX, Wiring with Contactors for Field Installed Control

OPTION

P66

L1

GND

L3

L2

L1

3PH/50/60HZ

T2 T3

T1

MAIN POWER CIRCUIT

TERMINAL

BOARD

DOOR

DISCONNECTSWITCH

L

O

R

T

N

L

R

E

O

E

B

C

D

A

L

E

L

R

O

O

U

H

)

R

T

S

T

E

O

S

R

N

S

T

E

E

E

U

C

R

F

R

F

M

A

E

O

T

P

E

T

O

R

N

E

(

C

O

T

L

A

O

T

S

M

C

L

C

N

E

Y

P

N

N

E

E

C

A

A

C

US

:

D

N

E

G

E

L

:

E

T

O

N

D

N

E

R

E

D

A

E

H

N

O

I

T

A

C

I

F

I

T

N

E

D

IN

R

O

T

O

M

N

A

F

R

F

N

F

F

A

2

A

R

J

2

2

1

F

1

D

O

1

M

F

C

F

A

-

P

-

-

1

1

1

C

F

F

C

M

Y

L

E

N

G

O

Y

O

A

L

T

R

D

E

E

F

E

D

R

N

,

U

D

O

E

R

S

G

U

F

E

B

D

T

L

S

E

I

U

F

M

E

T

B

I

N

O

U

T

.

.

1

2

T

T

S

T

L

I

N

R

O

U

E

O

V

C

R

T

R

R

E

I

C

H

O

C

U

F

N

D

L

I

N

E

O

E

T

O

R

R

A

E

T

C

L

R

A

N

I

D

P

R

S

O

E

E

W

A

R

T

C

P

T

O

C

C

A

P

T

T

°

E

L

D

O

0

O

T

O

6

C

T

I

M

O

V

E

E

N

R

L

5

S

S

L

U

P

1

U

U

1

A

.

.

.

.

4

3

6

5

X

O

B

C

I

R

T

C

E

L

E

F7

3A-500V

TRANSFORMER

N

O

I

T

P

O

L

7

A

D

N

I

R

M

A

R

1

2

O

E

T

T

B

T

C2

F1

T

R

A

N

S

F

R

O

M

E

R

24V

460VOR250V

INPUT

F3

F5

L3

L2

L1

F6

F7

F9

L3

L2

L1

F10

F11

L

A

N

I

M

R

E

T

L

8

D

R

A

O

B

9

A

D

N

I

R

M

A

2

1

R

O

T

T

E

B

T

C4

C1

L2

T2

T1

L1

L1 L2

C3

L3

T3

T2

L2

T1

L1

F4

C5

T3

T2

T1

C6

L3

L2

L1

F8

C9

T3

T2

T1

C10

L3

L2

L1

F12

2

1

T

T

6

C

C4

L3

T3

L2

T2

L1

T1

L3

L2

M5

L1

T3

T2

T1

L3

L2

L1

T3

T2

T1

L3

L2

L

1

L

A

N

I

M

R

E

T

L3

L2

1

L

C7

T3

T2

T1

C8

L3

T3

L2

T2

L1

T1

L3

L2

M9

L1

L3

L2

L1

C11

T3

T2

T1

C12

L3

T3

L2

T2

L1

T1

0

1

D

R

A

2

1

T

O

T

B

C9

GND

ND

G

L1

GND

GND

P66

L3

L2

M3

L1

L3

L2

M4

L1

M6

L3

L2

M7

L1

L3

L2

M8

L1

M10

L3

L2

M11

L1

L3

L2

M12

L1

L

1

L

1

A

N

D

I

R

M

A

R

O

E

B

T

2

1

A

N

D

I

R

M

A

2

1

2

R

T

T

T

O

E

B

T

C10

L

C

I

O

R

R

D

T

M1

T

E

C

N

E

E

N

O

L

P

A

E

S

F

C

L2 R

L1 C

M1

S

VARIABLE SPEED

M1

LECTRIC

E

FAN

L2 R

L1 C

1

T

C12

CONTROL MOTOR

TROL

SPEED

CON

TOR

M2

S

VARIABLE SPEED

CONTROL MO

N

7

C

L

4

A

2

1

D

N

I

T

T

R

M

A

R

O

E

B

T

C8

L

5

A

1

2

D

N

T

T

I

R

M

A

R

O

E

B

T

C11

2

1

T

T

T1

BOARD 6

TERMINAL

NAL BOARDS

TERMI

FOR FIELD CONTROL

OF FAN CONTACTORS

FAN CONTROL CIRCUIT

1PH/50/60HZ

C1

L

1

A

2

D

IN

T

R

M

A

R

O

E

B

5 AMPS MAX

1

T

OVERCURRENT PROTECTIO

C3

L

2

A

2

1

D

N

I

T

T

R

M

A

R

O

E

B

T

C5

L

3

A

2

1

D

N

I

T

T

R

M

A

R

O

E

B

T

IOMM A-C Cond 17

Page 18

Operation

Start-Up

Check for proper fan rotation. Air is drawn through the coil on all units. Be sure the fans turn freely. Rotation of

the motors and blades should be in a "clock-wise" direction looking at the unit from the blade side. On threephase units, it may be necessary to reverse two of the three power leads to the unit.

Discharge Gas Pulsation

Gas pulsations in a refrigeration system are most commonly associated with the compressor and connecting

discharge piping. Variations in the system piping configuration, line sizing, operating pressures and compressor

and component mounting all contribute to the presence and magnitude of these pulsations. The vibration and

movement of components caused by the pulsations may result in line breakage or damage to the condenser.

Install a discharge muffler in the refrigeration piping to eliminate discharge pulsations and the potential for

related condenser damage. Follow the recommendations of the compressor or muffler manufacturer when

selecting these components.

Discharge Pressure Control

Proper application of controls is important to a successful installation. McQuay air-cooled condensers have

several options to meet the needs.

The capacity of an air-cooled condenser varies with the difference between the entering air dry bulb temperature

and the condensing temperature of the refrigerant. Since air temperature varies from summer to winter, the

condensing temperature must be kept high enough to ensure proper operation of the refrigerant expansion valve

during low ambient air temperature operation, and also allow enough capacity so excessively high condensing

temperatures do not occur during high ambient conditions.

The low limit of the head pressure is dependent upon the required pressure drop across the thermostatic

expansion valve. For normal air conditioning applications, maintain head pressure above a condensing

temperature corresponding to 90°F. This corresponds to a normal lower limit of about 60°F ambient air. When

operation is required below 60°F ambient air temperature, additional head pressure control will be required.

A decrease in ambient air temperature results in a capacity increase in the air-cooled condenser. This capacity

increase is directly proportional to the temperature difference between the condensing temperature and the

temperature of the ambient air entering the condenser. Air-cooled condensers are often required to operate over a

wide range of ambient air temperatures and variable loading conditions so provisions must be made to maintain

the overall system balance. Low head pressures cause poor expansion valve operation and poor system

operation.

The cycling of condenser fans provides an automatic means of maintaining head pressure control, within

reasonable limits, at lower ambient air temperatures. A fan cycling control system allows fans to cycle in

sequence by sensing condensing pressures. Short cycling is normally caused by too close a differential in the

control settings or setpoints. If field supplied flooding valves are used with fan cycling, set valves to follow the

fan cycling. Set pressure switches to at least 35 PSIG differential setting.

Any fan cycle that is less than three minutes is considered short cycling, and could be detrimental to the system.

Adjust controls accordingly.

Use optional SpeedTrol™ variable speed fan control for operation below 35°F ambient air temperature

Fan/Circuit Configuration

Fan Rows: All models have either one or dual rows of fans with up to seven fans per row, a maximum total of 14

fans for a dual row unit. The number of fan rows and fans is shown in various tables where appropriate.

Refrigerant Circuits: Dual row condensers have two refrigerant circuits, one for each row of fans and match up

with McQuay WGZ and WGS chillers, which have two circuits. The two refrigerant circuits can be optionally

equipped with a factory manifold to make one refrigerant circuit.

18 IOMM A-C Cond

Page 19

Single row condensers have a single refrigerant circuit and must be used in pairs on McQuay chillers, each

condenser matched to one of the chiller circuits. A pair of single row units is usually only used in the rare case

when space requirements dictate two long narrow condensers end to end or when they are in separate locations.

The single row configuration allows more ambient air to flow through the coils than does a unit with a dual row,

side-by-side fans and so they often have a little more capacity than a two row unit with the same number of fans.

For a given capacity, two single row condensers will cost more than a single dual row unit.

Dual fan, two circuit condensers can be manifolded together to form a single refrigeration circuit.

Control options:

One of four control options will have been supplied on any unit. Other special options can be offered to meet

individual requirements.

1. Standard Control (Code NN)

The standard unit is provided with a contactor for each fan motor. A customer-supplied, and field-installed,

control signal from another source is required to energize each contactor based on the condenser pressure. Field

wiring between the compressorized product and remote condenser is required. Refer to local codes for this

wiring. The contactor control voltage is 115 volts and a transformer is not provided but is an available option.

Typical control logic is to start additional fans as condensing pressure increases. Although the parameters of the

companion refrigeration system dictates, it is good practice to only use this option only for operation above

ambient air temperatures of 35°F.

Standard Control Using Chiller MicroTech II® Control Staging

The Standard Control (Code NN) or Standard Control with SpeedTrol (Code ST) added can utilize the standard

pressure sensing capability of a McQuay chiller’s MicroTech II controller(s) to stage the fans. The WGZ chiller

has a single microprocessor with eight fan control digital outputs, four for each refrigerant circuit. The WGS

chiller has a separate controller for each of the two circuits with six fan stages, for a total of twelve for the unit.

Field wiring is required between the chiller MicroTech II controller and the fan contactors located in the

condenser. The number of connections will depend on the condenser size and arrangement as show in

Table 13.

or

Table 12

This option uses the standard condenser control included with the condenser and the standard MicroTech II

control included with the chiller. Field-supplied interconnecting wiring is the only cost. It does not provide

variable speed for operation below 35°F. Use control option #2 to add variable speed for operation from 0°F to

35°F.

2. Standard Control with SpeedT rol (Code ST)

This option is identical to the Standard Control (Code = NN) except the “first on, last off” fan will have a

variable speed drive. As the ambient air temperature drops below 35°F, the fan speed will slow down, reducing

condenser air flow, to maintain the minimum allowable condensing pressure for the companion unit. A control

transformer is provided to power the variable speed drive.

Important: This option by itself does not include a method of starting or cycling the balance of fans on the

condenser. Some means to do so must be supplied, mounted and wired in the field. The MicroTech II controller

on McQuay WGZ or WGS chillers can provide this staging function or some other multi-step controller.

Setting: SpeedTrol is performed by a Johnson Controls P66 Electronic Fan Speed Control driving a single-phase

fan motor. The control senses discharge pressure and varies the voltage to the motor and hence its speed.

Operation is in accordance with the following table.

Table 8, P66 Speed Control Operation

Pressure Input Motor Voltage (VAC, True RMS)

Pressure is between 0 psig and the low end of the

operating range.

Pressure is at the low end of the operating range.

0 to 5 volts, motor off

Start voltage (10% to 40% of line volts, model

IOMM A-C Cond 19

Page 20

specific)

Pressure is in the operating range.

Pressure is above the operating range.

Motor voltage (and fan speed) varies directly with

pressure from the start voltage to 90% of line volts.

A further pressure increase of 20 to 30 psi will

increase motor voltage to 97% of the applied volts.

The setting of the P66 control must be coordinated with the settings of the fan staging controls, so that the fan is

the first fan to start and the last to shut off. To adjust the operating range, locate the adjustment screw on the

control’s transducer. The screw can be accessed through the opening in the upper left-hand corner of the

control’s base. Turn the screw clockwise to increase, or counterclockwise to decrease, the operating range. One

turn equals approximately 35 psig of change.

A P66AAB-9 control is used for R-22. It has an operating (throttling) range of 170 to 230 psig. This 60 psi

throttling range is not adjustable. The adjustment moves the entire range up or down. For example, one screw

turn clockwise will change the setting from 170/230 psig to 205/265 psig.

97%

90%

e

g

a

t

l

o

V

r

o

t

o

M

No fan operation

in this

pressure range.

0

psig

Throttling

Range

Operating Range

(i.e., 190/250 psig)

Operating Range

Plus 20 or 30 psi*

*20 psi for 30 psi Effective Throttling Range (ETR)

30 psi for 60 psi Effective Throttling Range (ETR)

350 psig

Pressure Input

Figure 7, SpeedTrol Operating Range

The setting of the speed control must be coordinated with pressures switch settings (or MicroTech II staging) so

that the fan starts (at minimum speed) when the pressure switch closes, starting the fan. As the discharge

pressure increases, the fan speed will increase. Additional fans may stage on and the control should float the # 1

fan speed up and down as the fans stage on, avoiding sudden changes in discharge pressure that can upset unit

operation, especially expansion valve control. With the first fan on, set the fan control to start the motor at the

same pressure.

20 IOMM A-C Cond

Page 21

Table 9, Troubleshooting Chart

Problem Possible Causes Possible Solution

Input pressure is below operating range. No problem, normal operation.

No 24 volt control voltage. Check for 24 VAC at control.

Alignment. Schrader valve not

depressed sufficiently.

Disconnect power. Place a jumper

from L to M, and reconnect power.

If fan does not run, motor is bad

and should be replaced.

See Pressure Transducer

Troubleshooting following.

See Pressure Transducer

Troubleshooting following

No fan operation

Fan stops when pressure

reaches the high end of

the operating range.

Fan starts at full speed

Erratic fan operation

Fan motor is cycling on

thermal overload

No input pressure to control.

Bad fan motor

Pressure transducer problem

Control is not wired correctly See wiring diagram

Control is not wired correctly See wiring diagram No fan modulation

Pressure transducer problem

Dirty or blocked condenser coil Clean condenser coil

Pressure Transducer Troubleshooting

1. Disconnect 6-pin connector from the right side of control.

2. Place a jumper wire between third pin from the top and the bottom pin on the control, not the cable.

a. If the fan goes to full speed, check for input pressure

b. If there is adequate pressure, the transducer is bad and the control must be replaced.

3. Optional Pressure Switch Control with Control Transformer (Ordering Code = MH)

This option provides direct control of discharge pressure through a series of factory-mounted and wired pressure

switches (designated as FCP-Fan Cycle Pressure Control-on the wiring diagrams). As the condenser pressure

increases, more pressure switches close and start additional condenser fans. Field wiring between the

compressorized product and the remote condenser is not required. A control power transformer is included for

115 volt power for the control voltage. The parameters of the refrigerant system dictates, but, it is good practice

to only use this option only for operation above ambient air temperatures of 35°F.

Setting: The fan pressure switches (FCP) are set per the following table. For example, a setting of 190-140

means that the switch closes at 190 psig starting the fan and opens at 140 psig, shutting it off

IOMM A-C Cond 21

Page 22

Table 10, Electronic Fan Cycling Thermostat Settings

Number of Fans

Single Row

2 4

3 6

4 8

5 10

6 / 7 12 / 14 20

Double

Ro ws

Design

T.D.

30

25

20

15

10

30

25

20

15

10

30

25

20

15

10

30

25

20

15 10

30

25

15

10

A350 Setpoint

60

65

70

75

80

60

65

70

75

80

60

65

70

75

80

60

65

70

75

80

55

65

70

75

80

NOTES

1. Johnson Controls Style S350 operation.

2. 5° differential set on all modules. All modules set in the “heating” mode.

S350 Temperature Stage

Modules Offset Settings

2

20

10

10

10

15

10

10

5

5

5

5

5

5

5

5

5

5

5

5

5

3 4 5

30

25

20

15

10

15

15

10

10

10

15

10

10

10

10

30

30

30

20

15

25

20

20

15

15

30

30

30

25

20

Table 11, Fan Pressure Switch Settings

Number of Fans

Single

Row

2 4 20

3 6 20

4 8 20

5 10 20

6 / 7 12 / 14 20

Double

Rows

Design

T.D

Refrigerant

R134a 147

R22 215

R134a 147 155

R22 215

R134a 147 155

R22 215

R134a 147 153

R22 215

R134a 147 150

R22 215

NOTES

1. Based on 20º T.D.

2. For R134A set cutout 25 PSIG below cut-in.

Control Settings Pressure Switch

Cut-In Settings

PC1 PC2 PC3 PC4 PC5

245

231

225

223

160

247

156

236

153

230

160

247

157

239

160

247

3. Fan on header end to remain on whenever compressor is operating.

4. Optional Pressure Switch Control with Control Transformer & SpeedTrol (Code=VM)

This option is identical to the pressure switch control system described above except with the addition of variable

speed control to the “first on, last off” fan for each circuit. The fan pressure switches should be set per

Ta bl e 11.

The P66 fan speed controller is set as explained in Section 2, above.

Standard Control (Code NN) or SpeedTrol (Code ST) Using Unit MicroTech II Control Staging

The Standard Control (Code NN) or Standard Control with SpeedTrol (Code ST) can utilize the pressure sensing

capability of a McQuay chiller’s MicroTech II controller(s) to stage the fans. The WGZ chiller has a single

microprocessor with eight fan control digital outputs, four for each refrigerant circuit. The WGS chiller has a

separate controller for each of the two circuits with six fan stages, for a total of twelve for the unit.

22 IOMM A-C Cond

Page 23

Field wiring is required between the chiller controller(s) and the fan contactors located in the condenser. The

number of connections will depend on the condenser size and arrangement as show in the table below.

Table 12, WGZ Fan Staging and Field Wiring Circuits

Fan Stage

Fans

4

6

8

10

12

1 2 3 4 5 6 7 8

Circuit #1 Circuit#2

1 3 2 4 - 1 3 5 2 4 6

1 3 5 7 2 4 6 8

1 3 5 7, 9 2 4 6 8, 10

1 3 5, 7 9, 11 2 4 6, 8 10, 12

Table 13, WGS Fan Staging and Field Wiring Circuits

Fans

4

6

8

10

12

Circuit #1 Circuit#2

1 2 - - - - 1 2 - - - 1 2 3 - - - 1 2 3 - - 1 2 3 4 - - 1 2 3 4 - 1 2 3 4 5 - 1 2 3 4 5 1 2 3 4 5 6 1 2 3 4 5 6

Fan Stage

Fan Locations

Electric Panel

12 10 8 6 4 2

11 9 7 5 3 1

Circuit #2

Circuit #1

Electric Panel

Flooding Head Pressure Controls

6 5 4 3 2 1

Circuit #1

Another means of head pressure control is to change the condenser capacity by filling the inside of the condenser

with liquid refrigerant. Flooding controls are ideal for condensers operating in low ambient conditions (beyond

the limits of fan cycling controls) or under partial load conditions. These controls require additional refrigerant

charge (and a receiver) to flood the condenser. This additional refrigerant charge can often be reduced by

incorporating the flooded control with one of the fan cycle controls previously described.

Several styles of flooding valves or combinations of valves are available. Contact the valve manufacturer for

specific recommendations.

Refrigerant Charge

The refrigerant charge for summer operation can be found in

charge required by flooding style controls when fan control is not also used.

Table 14. This table also contains the additional

Table 16 contains the recommended

flooding charge required when combining fan cycling with flooding valves. The addition of fan cycling to

flooded control greatly reduces the required refrigerant charge.

IOMM A-C Cond 23

Page 24

Table 14, Refrigerant Charge. (lbs). R-22 for Flooded Condenser Without Fan Cycling (Times

0.99 for R-134a)

Model

ACH

ACL

ACX

014A-S

016A-S

020A-S

025A-S

030A-S

040A-S

050A-S

060A-S

070A-S

080A-S

100A-S

110A-S

040A-D

050A-D

060A-D

080A-D

100A-D

110A-D

130A-D

140A-D

160A-D

200A-D

225A-D

NOTE: See for factors for Temperature Differences other than 20 degrees.

Refrigerant

R-22 Charge

for Summer

Operation,

Lbs.

8 7 10 11 11 11

10 10 13 15 15 16

10 10 13 14 15 15

15 15 19 21 22 23

29 30 39 43 45 47

22 22 29 32 34 35

30 29 38 42 44 46

70 66 87 96 100 105

64 62 83 92 95 99

86 83 110 122 127 132

102 100 132 147 153 159

118 117 155 172 179 186

19 20 27 29 31 32

29 30 39 44 46 47

40 39 51 57 59 62

44 44 58 64 67 70

58 59 78 86 90 94

104 99 131 146 152 158

140 131 174 193 201 209

125 126 168 186 194 201

172 165 219 243 253 263

201 201 267 296 308 320

236 233 310 343 357 372

Additional Refrigerant R-22 Charge Required for Flooded

Condenser Operation Lbs. For 20°F TD Minimum Ambient at

Condenser

+60 +40 +20 +0 -20

24 IOMM A-C Cond

Page 25

Table 15, Flooded Charge Temperature Difference Factor

Ambient, °F

60

40

20

0

-20

30 25 20 15 10

-- 0.38 1.0 1.74 2.46

0.59 0.80 1.0 1.19 1.40

0.76 0.88 1.0 1.13 1.25

0.84 0.91 1.0 1.07 1.16

0.88 0.93 1.O 1.06 1.13

Design T.D.

Table 16, Refrigerant Charge for Flooded Condenser With Fan Cycling (lbs.) R-22

(Times 0.99 for R-134a)

Model

ACH

ACL

ACX

014A-S

016A-S

020A-S

025A-S

030A-S

040A-S

050A-S

055A-S

060A-S

070A-S

080A-S

100A-S

110A-S

040A-D

050A-D

060A-D

080A-D

100A-D

110A-D

130A-D

140A-D

160A-D

200A-D

225A-D

40 20 0 -20 40 20 0 -20 40 20 0 -20 40 20 0 -20

25° TD 20° TD 15° TD 10° TD

Ambient temperature (°F)

7 8 9 9 8 9 10 10 9 10 11 11 13 12 12 12

9 12 13 14 11 13 14 15 13 14 15 16 17 18 17 18

1 6 8 10 4 8 10 11 7 10 12 13 10 13 14 14

2 9 12 15 7 12 15 17 12 16 18 19 17 19 21 22

4 17 24 29 14 24 30 34 24 31 36 39 33 38 41 43

0 3 10 15 0 10 16 20 0 17 22 25 0 24 27 29

0 4 13 20 0 12 20 26 0 21 27 32 0 29 34 38

0 0 8 22 0 6 23 35 0 22 38 48 0 37 52 61

0 0 11 29 0 8 31 46 0 29 51 63 0 49 71 80

0 0 0 15 0 0 17 33 0 0 39 52 0 0 60 70

0 0 0 19 0 0 22 44 0 0 50 69 0 0 78 93

0 0 0 6 0 0 8 37 0 0 37 69 0 0 66 100

0 0 0 0 0 0 0 29 0 0 0 69 0 0 0 108

3 12 17 20 9 17 21 23 15 22 25 26 21 27 29 29

4 17 24 29 13 24 30 34 22 31 36 39 31 38 41 43

5 22 32 38 17 31 39 44 29 40 46 50 41 49 53 56

0 5 20 31 0 18 31 40 0 31 42 49 0 44 53 59

0 7 27 42 0 25 42 54 0 43 57 66 0 61 71 79

0 0 17 44 0 12 47 69 0 43 77 95 0 74 107 119

0 0 22 57 0 16 62 91 0 57 102 125 0 99 141 157

0 0 0 30 0 0 34 67 0 0 77 105 0 0 120 141

0 0 0 39 0 0 44 88 0 0 100 137 0 0 156 186

0 0 0 11 0 0 16 74 0 0 74 137 0 0 132 200

0 0 0 0 0 0 0 57 0 0 0 135 0 0 0 213

NOTE: See Table 14 for summer charge.

IOMM A-C Cond 25

Page 26

Maintenance

Air-cooled condensing units require a minimum of maintenance. The unit coil will require a periodic cleaning.

Clean the unit using a brush, vacuum cleaner, pressurized air stream or a commercially available coil cleaning

foam. All of the condenser fan motors have sealed ball bearings and do not need maintenance. If bearings fail,

then replace bearings.

Cleaning Instructions

! CAUTION

Cautions indicate potentially hazardous situations, which can result

in personal injury or equipment damage if not avoided.

Never clean this unit with an acid-based cleaner. Off-spray can be

dangerous to health and the acids are corrosive to aluminum

components.

Clean the finned surface at least every six months; more frequent cleaning may be required if extreme conditions

cause clogging or fouling of air passages through the finned surface.

Use Calgon Corporation's CalClean 41352 (or equal). Apply CalClean liberally to entering air and leaving air

surfaces of the finned area according to label directions and rinse thoroughly to remove all cleaners.

26 IOMM A-C Cond

Page 27

Page 28

This document contains the most current product information as of this printing. For the most up-todate product information, please go to

www.mcquay.com.

All McQuay equipment is sold pursuant to McQuay’s Standard Terms and Conditions of Sale and

Limited Product Warranty.

(800) 432-1342 • www.mcquay.com IOMM A-C Cond (08/07)

Loading...

Loading...