Page 1

AIR COOLED CHILLER

(C Series)

INSTALLATION MANUAL

Group: MINI CHILLER

Part Number: A08019025453

Date: JULY 2003

IM-ACC1&2-0703-McQuay

© 2003 McQuay International

Page 2

Page 3

English

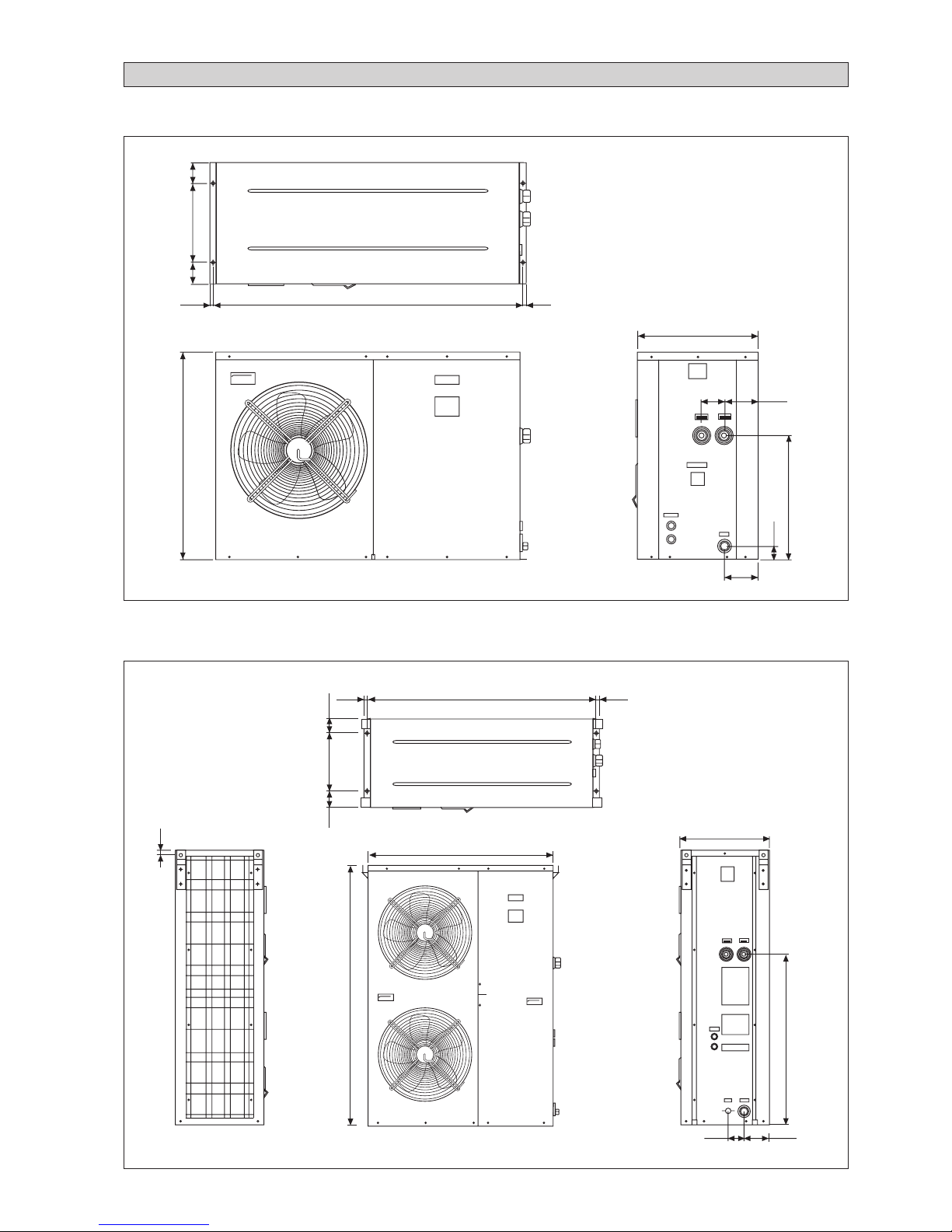

4AC/AC 20/25/30 C/CR

4AC/AC 40/50/60 C/CR

1181,610,0 10,0

460,0

85,0 128,5

WATER

INLET

DRAINAGE

WATER

OUTLET

128,5

789,5

475,0

55,2

80,0 300,0

80,0

1181,6

460,0

85,0

128,5

15,0 15,0

300,079,7

20,0

80,3

116 0,0

1409,4

878,8

WATER

INLET

DRAINAGE

WATER

OUTLET

OUTLINE AND DIMENSIONS

i

Page 4

! Caution

Sharp edges and coil surfaces are potential locations which may cause

injury hazards. Avoid from being in contact with these places.

! Avertissement

Les bords coupants et les surfaces du refroidisseur tuulaire présentent

un risque de blessure. Mieux vaut éviter le contact avec ces endroits.

! Vorsicht

Scharfe Kanten und Wärmetauscherflächen stellen eine Gefahrenquelle dar.

Jeglicher Kontakt mit diesen Stellen ist zu vermeiden.

! Cautela

Per preservarsi da eventuali ferite, evitare di toccare gli spigoli affilali e la

superficie della serpentina.

! Осторожно

Острые края и поверхности змеевиков являются

потенциальными местами нанесения травм. Остерегайтесь

контакта с этими местами.

! Cuidado

Los Bordes afilados y la superficie del serpentín pueden producir lesiones.

Evite tocarlos.

ii

This product is subjected to Waste of Electrical and Electronic Equipment Regulations (WEE

E

Regulations). The waste product shall be separately collected by specific collection and treatment centre

.

P

lease refer to local authorithy for these centres. This is only applicable to European Union countries

.

Ce produit est soumis

à

la r

ééé

é

lectriques e

t

ййкйй

ééé

é

tre ces centres. Ceci

est uniquement applicable aux pays de l'Union Euro

p

é

enne

.

Questo prodottoè soggetto alle disposizioni RAEE (Rifiuti di apparecchiature elettriche ed elettroniche)

.

à

à

locali. Questa disposizione

è

valida solamente i paes

i

dell

U.E.

é

ctrico y Electrnico en materia d

e

fico

de colecc

i

solamente aplicable a los pases de la Un

i

n

Europea

.

Dieses Produkt unterliegt den Bestimmungen zur Entsorgung von elektrischen und elektronische

n

er

tes

ü

ll bei Ihrer

ü

ndiges Abfall-Amt. Dieser

Hinweis gilt nur f

ischen Union

.

Процес

с

у

тилизациианногопродуктарегулируетсяправиламип

о

у

тилизаци

и

отходо

в

(WEEE Regulations).

т

и

правил

а

Европейског

о

NOTICE

Page 5

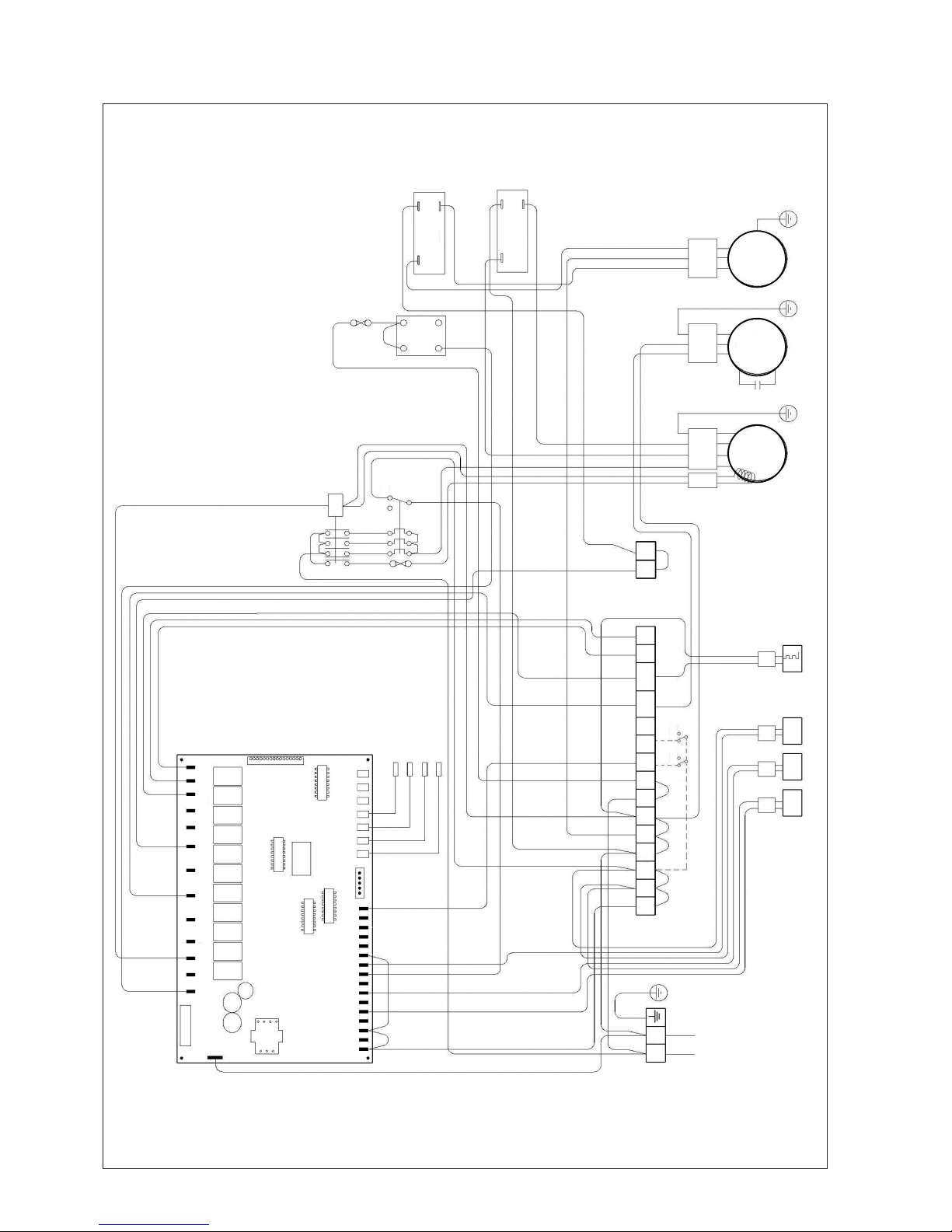

English

HEAT

OFF

COOL

ON

LIVE

COM2

COM1

BOILER

W_PUMP

OUT_FAN2

4WV2

A_FREEZE

ALM_OUT

ALM_IN

4WV1

OUT_FAN1

AUX-H

12V

F02

F01

LP2

LP1

HP2

HP1

C02

C01

FLOW

PO

ALM

DE2

DE1

C/H

ON/OFF

WI

CN6

WO OA

CD1 CD2DF1 DF2

N

COMP DISCHARGE SENSOR (1)

OUTDOOR AIR TEMP SENSOR

LEAVING WATER SENSOR

ENTERING WATER SENSOR

N/L2

220-240/1pH/50Hz

L/L1TB1

12V 12V 12V N1 N1 N1 1 2 O/F PUMPC/H

4WV

HTR

AL

IN

AL

OUT

LP HP FL

H

T

R

OF

OUT

OF

IN

TB3

L

N

C

OF

C

S

R

E

COMP.

L

N

E

PUMP

FUSE

10A

5B

4B 1A

2A

SWITCH

A

B

COMP

COMP

CAP

98

95

96

C O/L

TB2

OF

CAP

R

R

C

S

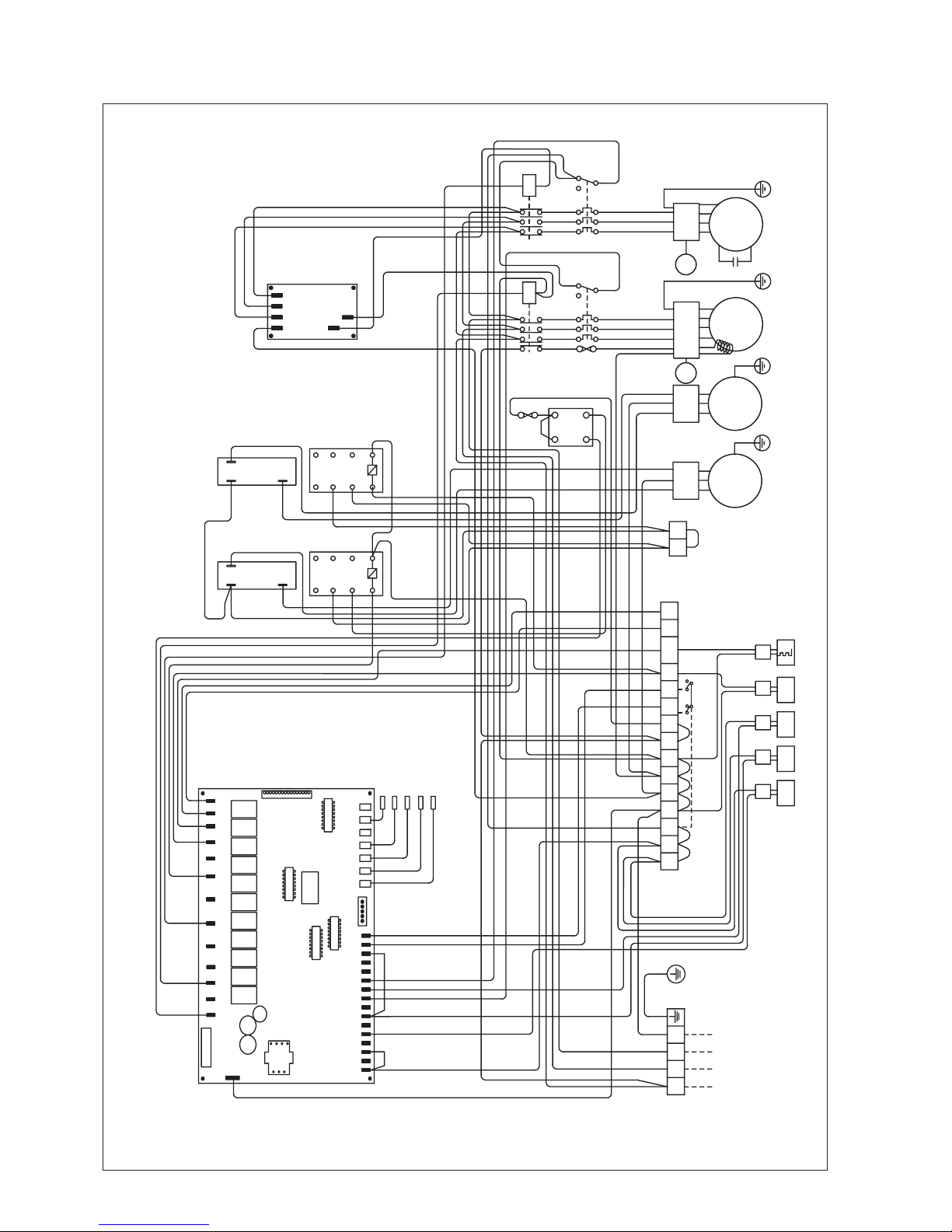

MODEL : 4AC / AC 20 C

PART NO : 50 13 4 066991

ELECTRICAL WIRING DIAGRAM

iii

Page 6

CN6

N

WI WO OA

CD1 CD2DF1 DF2

HEATOFF

COOLON

LIVE

COM2

COM1

BOILER

W_PUMP

OUT_FAN2

4WV2

A_FREEZE

ALM_OUT

ALM_IN

4WV1

OUT_FAN1

AUX-H

12V

F02

F01

LP2

LP1

HP2

HP1

C02

C01

FLOW

PO

ALM

DE2

DE1

C/H

ON/OFF

COMP DISCHARGE SENSOR (1)

OUTDOOR AIR TEMP SENSOR

LEAVING WATER SENSOR

ENTERING WATER SENSOR

N/L2

220-240/1pH/50Hz

L/L1TB1

12V 12V 12V N1 N1 N1 1 2 O/F PUMPC/H

4WV

HTR

AL

IN

AL

OUT

LP HP FL

H

T

R

OF

OUT

OF

IN

TB3

L

N

C

OF

C

S

R

E

COMP.

L

N

E

PUMP

FUSE

10A

5B

4B 1A

2A

SWITCH

A

B

COMP

COMP

CAP

98

95

96

C O/L

TB2

OF

CAP

R

R

C

S

MODEL : 4AC / AC 25 / 30 C

PART NO : 50 13 4 066992

iv

Page 7

English

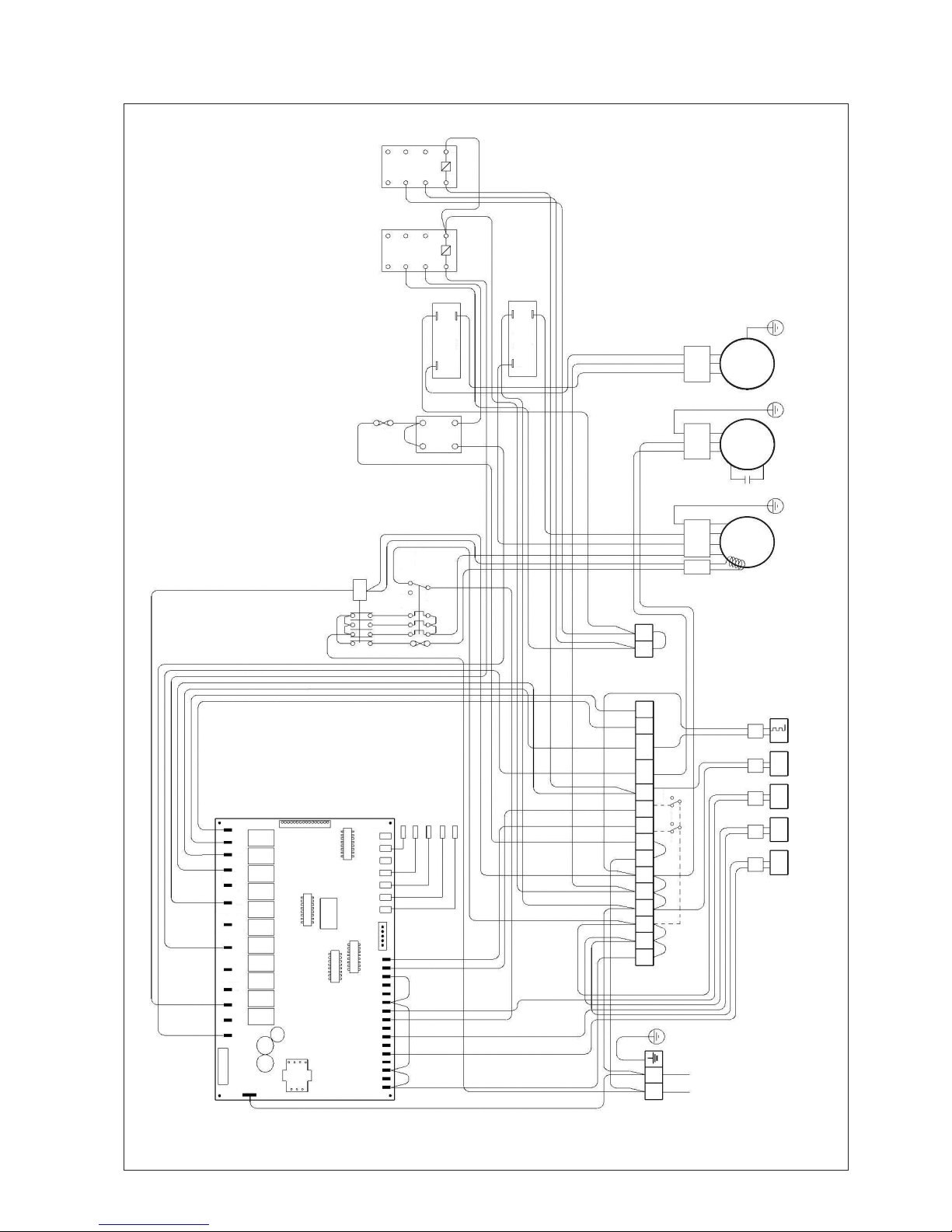

MODEL : 4AC / AC 40 / 50/ 60 C

PART NO : 50 13 4 076741

v

LIVE

COM2

COM1

BOILER

W_PUMP

OUT_FAN2

4WV2

A_FREEZE

ALM_OUT

ALM_IN

4WV1

OUT_FAN1

AUX-H

12V

F02

F01

LP2

LP1

HP2

HP1

CO2

CO1

FLOW

PO

ALM

DE2

DE1

C/H

ON/OFF

WI

CN6

WO OA

CD1CD2 DF1DF2

N

CA

B

OF 1

CAP

CA

B

OF 2

CAP

COMP DISCHARGE SENSOR (1)

OUTDOOR AIR TEMP SENSOR

LEAVING WATER SENSOR

ENTERING WATER SENSOR

S

380-415/3pH/50Hz

RTB1 T N

12V 12V 12V N1 N1 N1 N1 1

ON

OFF

COOL

HEAT

2 O/F C/H

4WV

HTR

AL

IN

AL

OUT

LP HP

FL

H

T

R

OF OUT

OF IN

TB3

TB2

L

N

C

OF 1

L

N

42 41

C

OF 2

U

V

W

E

COMP.

U

V

W

E

PUMP

FUSE

10A

5B

4B 1A

2A

SWITCH

31

81

71

NRST

PHASE

PROTECTOR

32

COMP PUMP

98

95

96

C O/L

98

95

96

P O/L

Page 8

MODEL : 4AC / AC 20 CR

LIVE

COM2

COM1

BOILER

W_PUMP

OUT_FAN2

4WV2

A_FREEZE

ALM_OUT

ALM_IN

4WV1

OUT_FAN1

AUX-H

12V

F02

F01

LP2

LP1

HP2

HP1

C02

C01

FLOW

PO

ALM

DE2

DE1

C/H

ON/OFF

N

CN6

WI WO OA

CD1 CD2DF1 DF2

COMP DISCHARGE SENSOR (1)

OUTDOOR AIR TEMP SENSOR

LEAVING WATER SENSOR

ENTERING WATER SENSOR

N/L2

220-240/1pH/50Hz

L/L1TB1

12V 12V 12V N1 N1 N1 1 2 O/F PUMPC/H

HEATOFF

COOLON

4WV

HTR

AL

IN

AL

OUT

LP HP FL

H

T

R

OF

OUT

OF

IN

TB3

L

N

C

OF

C

S

R

E

COMP.

L

N

E

PUMP

FUSE

10A

5B

4B 1A

2A

SWITCH

A

B

COMP

COMP

CAP

98

95

96

C O/L

1

3

2

4

DEFROST SENSOR (1)

TB2

4WV

OF

CAP

R

R

5

7

6

8

R

E

L

A

Y

1

3

2

4

5

7

6

8

R

E

L

A

Y

R1

R2

C

S

PART NO : 50 13 4 066985

vi

Page 9

English

MODEL : 4AC / AC 25 / 30 CR

PART NO : 50 13 4 066986

HEATOFF

COOLON

LIVE

COM2

COM1

BOILER

W_PUMP

OUT_FAN2

4WV2

A_FREEZE

ALM_OUT

ALM_IN

4WV1

OUT_FAN1

AUX-H

12V

F02

F01

LP2

LP1

HP2

HP1

C02

C01

FLOW

PO

ALM

DE2

DE1

C/H

ON/OFF

WI

CN6

WOOA

CD1CD2DF1DF2

N

COMP DISCHARGE SENSOR (1)

OUTDOOR AIR TEMP SENSOR

LEAVING WATER SENSOR

ENTERING WATER SENSOR

N/L2

220-240/1pH/50Hz

L/L1TB1

12V 12V 12V N1 N1 N1 1 2 O/F PUMPC/H

4WV

HTR

AL

IN

AL

OUT

LP HP FL

H

T

R

OF

OUT

OF

IN

TB3

L

N

C

OF

C

S

R

E

COMP.

L

N

E

PUMP

FUSE

10A

5B

4B 1A

2A

SWITCH

A

B

COMP

COMP

CAP

98

95

96

C O/L

1

3

2

4

DEFROST SENSOR (1)

TB2

4WV

OF

CAP

R

R

5

7

6

8

R

E

L

A

Y

1

3

2

4

5

7

6

8

R

E

L

A

Y

R1

R2

C

S

vii

Page 10

MODEL : 4AC / AC 40/ 50/ 60 CR

PART NO : 50 13 4 076742

HEATOFF

COOLON

LIVE

COM2

COM1

BOILER

W_PUMP

OUT_FAN2

4WV2

A_FREEZE

ALM_OUT

ALM_IN

4WV1

OUT_FAN1

AUX-H

12V

F02

F01

LP2

LP1

HP2

HP1

C02

C01

FLOW

PO

ALM

DE2

DE1

C/H

ON/OFF

N

C

A

B

OF 1

CAP

C

A

B

OF 2

CAP

COMP DISCHARGE SENSOR (1)

OUTDOOR AIR TEMP SENSOR

LEAVING WATER SENSOR

ENTERING WATER SENSOR

S

380-415/3pH/50Hz

RTB1 T N

12VTB2 12V 12V N1 N1 N1 N1 1 2 O/F C/H

4WV

HTR

AL

IN

AL

OUT

LP HP FL 4WV

OF OUT

OF IN

TB3

L

45 44

N

C

OF 1

L

N

C

OF 2

U

V

W

E

COMP.

U

V

W

E

PUMP

FUSE

10A

5B

4B 1A

2A

SWITCH

31

32

COMP PUMP

98

95

96

C O/L

98

95

96

P O/L

DEFROST SENSOR (1)

1R

E

L

A

Y

3

2

4

5

R1

R

E

L

A

Y

R2

7

6

8

1

3

2

4

5

7

6

8

H

T

R

CN6

WI WO OA

CD1 CD2DF1

DF2

81

71

NRST

PHASE

PROTECTOR

viii

Page 11

English

ix

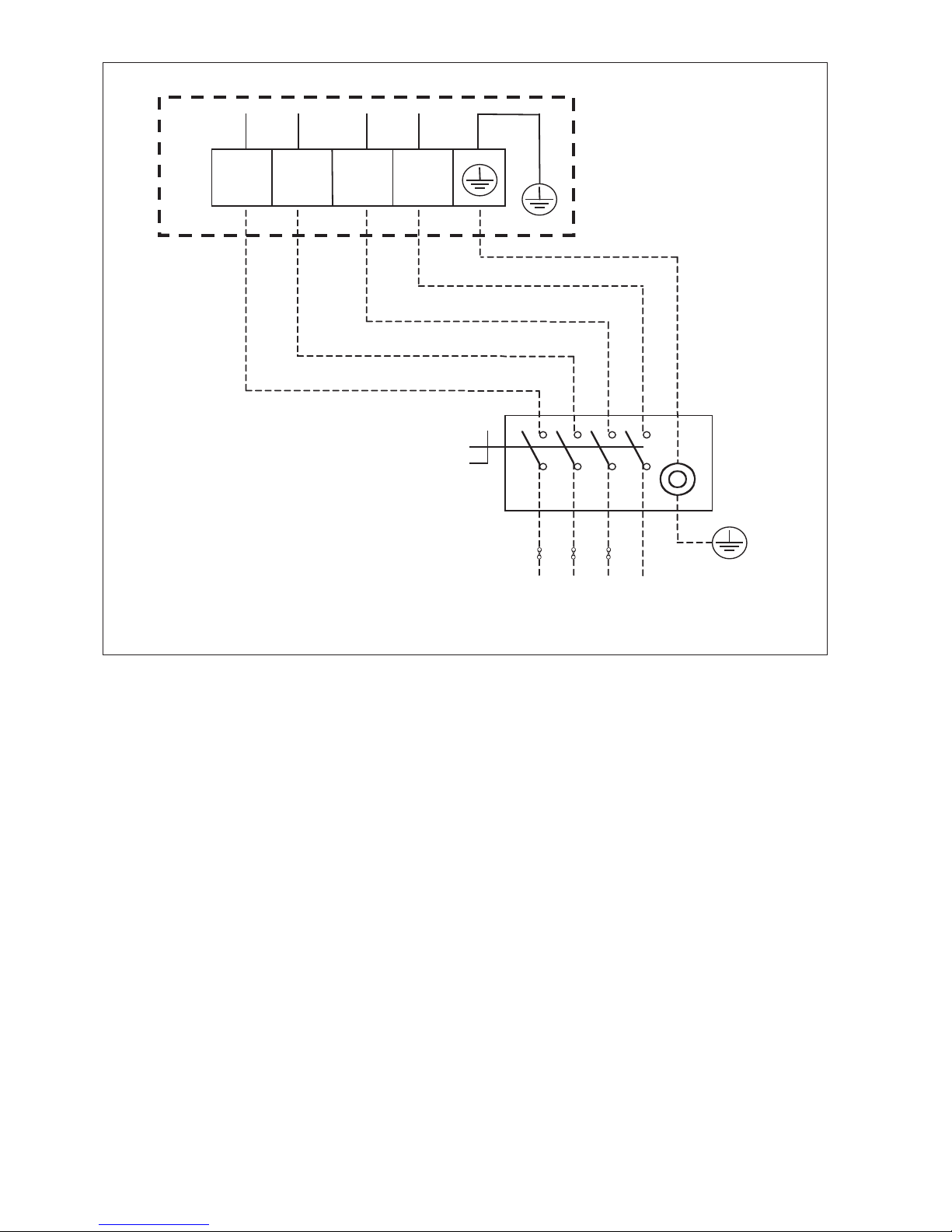

ISOLATOR DIAGRAMS

TB1 L/L1 N/L2

N

L1

Power supply 230V / 1Ph-N / 50Hz

4AC/AC20/25/30 C/CR

AC TERMINAL BOX

ISOLATOR

E

FUSE

Page 12

TB1 R S T N

NL1 L2

L3

Power supply 400V / 3Ph-N / 50Hz

4AC/AC40/50/60 C/CR

AC TERMINAL BOX

ISOLATOR

E

FUSE

x

Page 13

English

This manual provides the procedures of installation to ensure a safe and good standard of operation for the

chiller.

Special adjustments may be necessary to suit local requirements.

Before using the chiller, please read this instruction manual carefully and keep it for future reference.

INSTALLATION MANUAL

AIR COOLED CHILLER

MODEL

Part No.: A08019025453

COOLING ONLY

R22

AC20C / MAC020C

AC25C / MAC025C

AC30C / MAC030C

AC40C / MAC040C

AC50C / MAC050C

AC60C / MAC060C

R407C

4AC20C / M4AC020C

4AC25C / M4AC025C

4AC30C / M4AC030C

4AC40C / M4AC040C

4AC50C / M4AC050C

4AC60C / M4AC060C

HEAT PUMP

R22

AC20CR / MAC020CR

AC25CR / MAC025CR

AC30CR / MAC030CR

AC40CR / MAC040CR

AC50CR / MAC050CR

AC60CR / MAC060CR

R407C

4AC20CR / M4AC020CR

4AC25CR / M4AC025CR

4AC30CR / M4AC030CR

4AC40CR / M4AC040CR

4AC50CR / M4AC050CR

4AC60CR / M4AC060CR

IM-ACC1&2-0703 (1)-McQuay

!!

!!

! WARNING

• Installation and maintenance should be performed by qualified person who are familiar with local code and

regulation, and experienced with this type of appliance.

Page 14

1-1

- Recommended Fuse And Cable Sizes page 8

- Water Piping System Setup page 11

- Refrigerant Circuit page 11

-

Special Precautions When Dealing With R407C Unit

page 11

- Control Operation Guide page 12

- Servicing And Maintenance page 13

- Troubleshooting page 14

- Fan Speed Controller (Optional) page 15

- Isolator Switch Field Installation page 15

!!

!!

! CAUTION

Please take note of the following important points when installing.

• Do not install the unit where leakage of flammable gas may occur.

If gas leaks and accumulates around the unit, it may cause fire ignition.

• Do not overcharge the unit.

This unit is factory pre-charged. Overcharge will cause over-current or damage to the compressor.

• Sharp edges and aluminium fin coil surface are potential which may cause injury hazards.

Avoid from being in contact with these locations.

INDEX

- Outline And Dimensions page i-ii

- Electrical Wiring Diagram page iii-viii

- Isolator Diagram page ix-x

- Transportation page 1

- Installation Location page 2

- Unit Installation page 4

- Physical Data page 5

- Water Piping and Fitting page 7

- Electrical And Wiring page 7

- Electrical Data page 8

TRANSPORTATION

• Use spreader bars or forklift to lift the unit to avoid damage to the panels. Figure 1 provides the dimensions of the crate for

lifting. Avoid violent movements. Do not remove crate until it is at its final location.

If necessary, use crane for unit above 11kW. Check that the hanger belts are able to support the unit. Refer to the weight

of the unit given in the specification manual for assistance.

Ensure that the hanger belts are not touching the coil, top panel and front panel. Use hosting bracket (provided along with

this manual) as shown in Figure 2. Lift the unit slightly to make sure it is balance before placing it in location. Never swing

or roll the unit.

Figure 1

577

577

Page 15

1-2

English

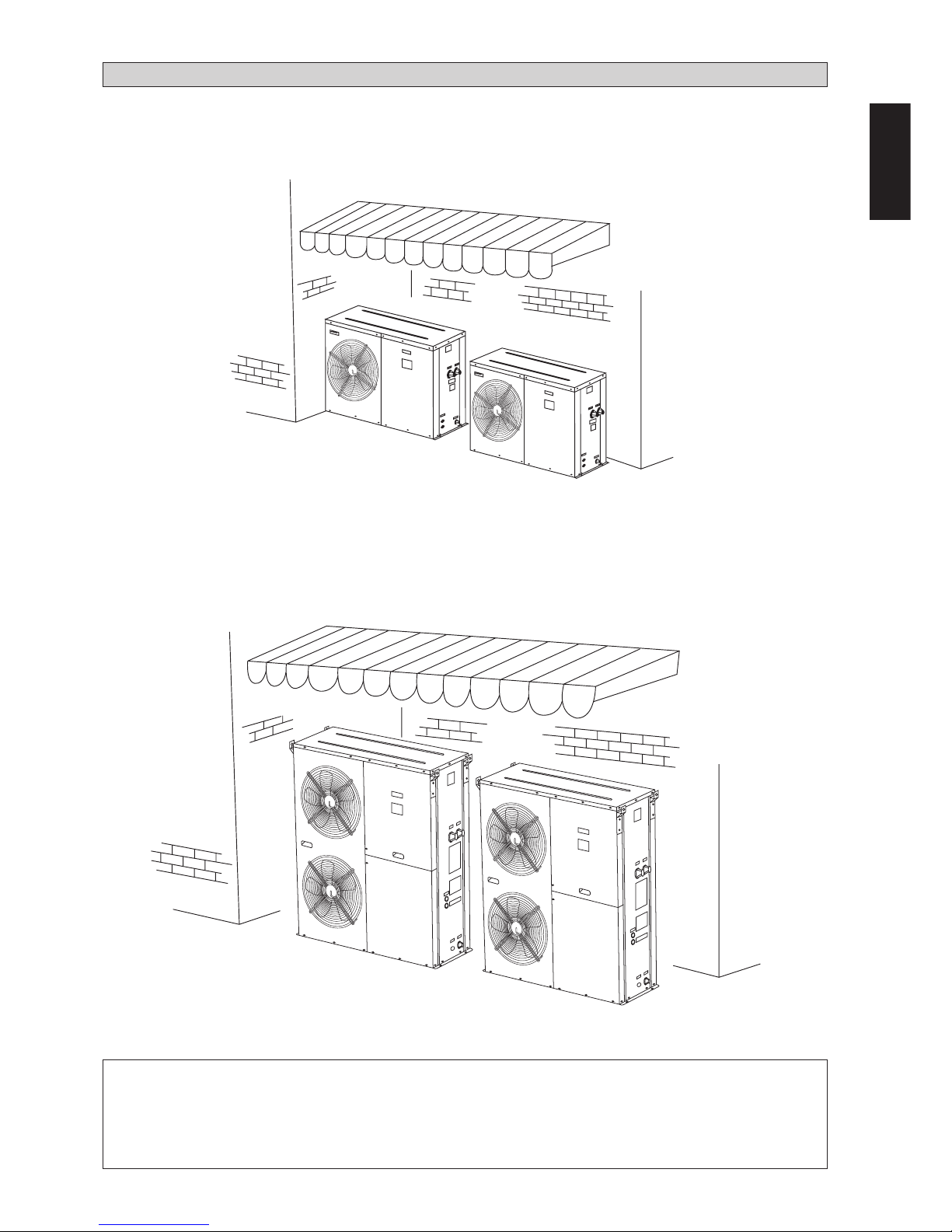

INSTALLATION LOCATION

• Installation work should be done by the authorized dealer or qualified contractor. Never install the unit yourself.

• Make sure there is sufficient space for airflow around the unit. The discharged air should be directed outside using a duct

should the unit be installed in a plant room.

• Vibration isolator should be provided to prevent vibration and noise from the unit.

• When installing the unit on the ground, make sure the selected site is not subject to flooding.

• There should be sufficient space allocated for ventilation, servicing and maintenance when installing the unit. Refer to the

following figures for proper location.

500 500

500

1500

Figure 3: For single unit installation

AIR FLOW

AIR FLOW

AIR FLOW

MIN 500

Figure 2

HANGER

HANGING BELT

Page 16

1-3

• Unit subjects to floor installation must be placed on a concrete slab. The slab must have thickness of 100mm and 50mm

wider and longer than the footprint of the unit (Figure 5). Place the concrete slab a distant from building to prevent

vibration and noise.

• In the case of heatpump operation with an outdoor temperature below 0°C, the unit must be installed at least 300mm above

ground level. This is necessary to prevent ice from accumulating on the frame and to permit proper operation in the event

of heavy snowfalls.

• The unit must be leveled on both axes. (Tolerance is less than 2mm per meter.)

Figure 5: For floor installation

Note: All units are in mm unless specified.

500

1000

1000 500

1500

Figure 4: For multiple unit installation

AIR FLOW

AIR FLOW

AIR FLOW

AIR FLOW

AIR FLOW

AIR FLOW

AIR FLOW

MIN 500

50 50

100

Page 17

1-4

English

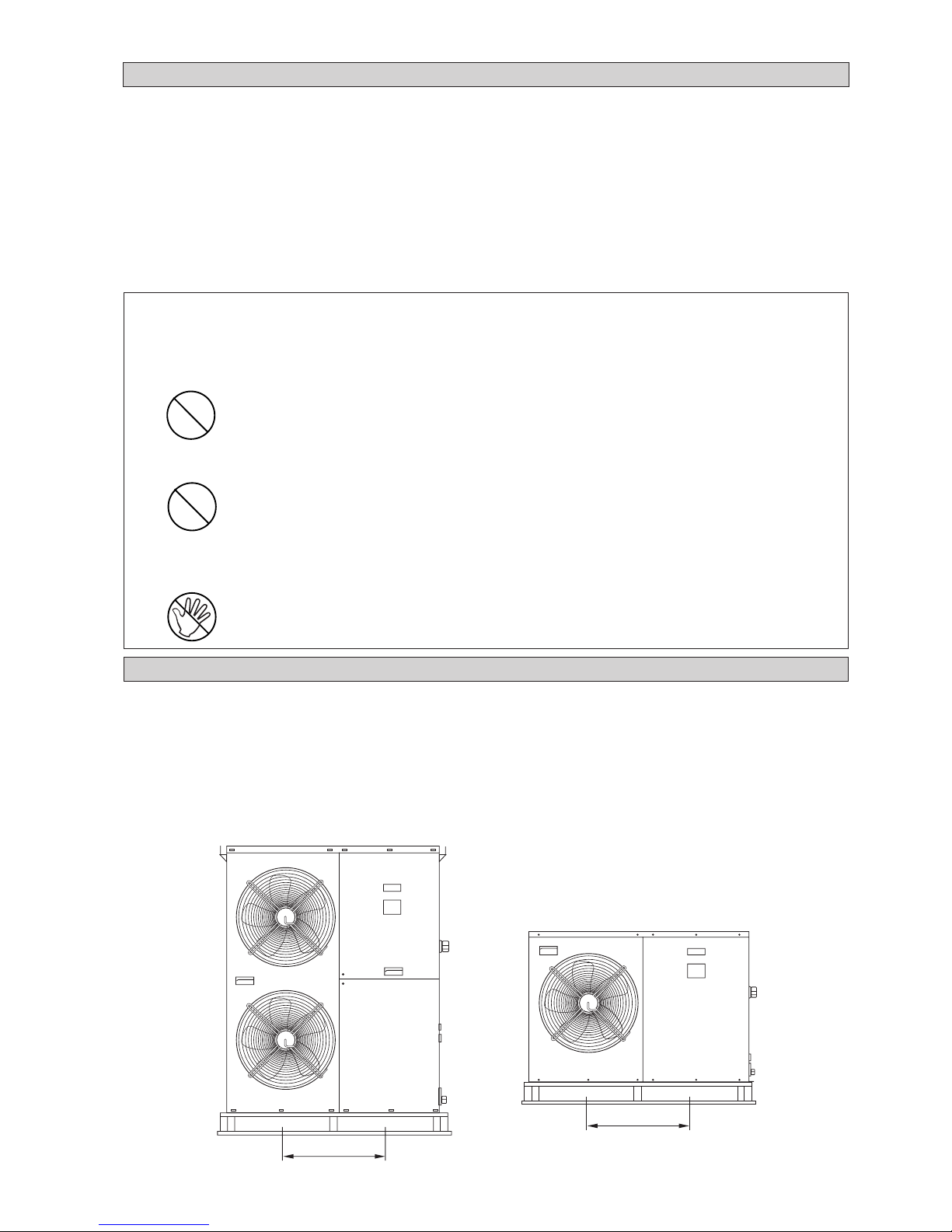

4AC/AC 020/025/030 C/CR

UNIT INSTALLATION

!!

!!

! CAUTION

• Improper handling of unit during installation could result in leaks, electrical shock or unit malfunction.

• Contact your dealer for reinstallation or dismantling of unit.

• Do not introduce foreign objects such as fingers, sticks etc. into the air inlet and air outlet.

• Do not climb or place objects on top of mini chiller.

4AC/AC 040/050/060 C/CR

Page 18

1-5

PHYSICAL DATA

Note: For cooling nominal values are based on 12°C / 7°C entering / leaving evaporator water temperature, 35°C air ambient temperature.

Table A-1 : R407C - Cooling Only

Model 4AC20C 4AC25C 4AC30C 4AC40C 4AC50C 4AC60C

Nominal cooling capacity kW 6.15 6.74 7.91 11.72 14.65 15.24

Operating Weight kg 115.5 122.5 128 195 196.4 203.2

Refrigerant charge R407C kg 1.13 1.85 1.65 3.40 3.35 3.45

Compressor 1 Rotary comp 1 Scroll compressor

Control system LCD Electronic Control

Refrigerant - water heat exchanger Brazed Plate Heat Exchanger

Water connections (BSP) inches 111111

Maximum water pressure kPa 1000 1000 1000 1000 1000 1000

Hydronic circuit

Pump High Head Circulator Horizontal Multistage End-Suction

Available pressure kPa 72.94 98.58 89.27 91.70 67.51 70.32

Water inlet connection (BSPT) inches 111111

Water outlet connection (BSPT) inches 111111

Drain tap coupling (BSPT) inches 1/2 1/2 1/2 1/2 1/2 1/2

Closed expansion tank water volume litre 222555

Refrigerant - air heat exchanger

Tube diameter mm 9.52 9.52 9.52 9.52 9.52 9.52

No. of rows 122222

Tubes/row 30 30 30 54 54 54

Fin spacing mm

1.27 1.59 1.59 1.59 1.59 1.59

O/D Fan

Diameter inches 18 18 18 18/2 18/2 18/2

No. of blades 555555

Air flow (high speed) m3/min 62.3 62.3 62.3 62.3 62.3 62.3

Fan speed (high speed) r/min 910 920 920 920 920 920

Table A-2 : R22 - Cooling Only

Model AC20C AC25C AC30C AC40C AC50C AC60C

Nominal cooling capacity kW 5.28 6.89 8.06 11.72 14.65 15.53

Operating Weight kg 115.5 122.5 128 195 196.4 203.2

Refrigerant charge R22 kg 1.13 1.80 1.56 2.68 3.10 3.10

Compressor 1 Rotary comp 1 Scroll compressor

Control system LCD Electronic Control

Refrigerant - water heat exchanger Brazed Plate Heat Exchanger

Water connections (BSP) inches 111111

Maximum water pressure kPa 1000 1000 1000 1000 1000 1000

Hydronic circuit

Pump High Head Circulator Horizontal Multistage End-Suction

Available pressure kPa 83.55 97.39 88.08 91.70 67.51 65.98

Water inlet connection (BSPT) inches 111111

Water outlet connection (BSPT) inches 111111

Drain tap coupling (BSPT) inches 1/2 1/2 1/2 1/2 1/2 1/2

Closed expansion tank water volume litre 222555

Refrigerant - air heat exchanger

Tube diameter mm 9.52 9.52 9.52 9.52 9.52 9.52

No. of rows 122222

Tubes/row 30 30 30 54 54 54

Fin spacing mm

1.27 1.59 1.59 1.59 1.59 1.59

O/D Fan

Diameter inches 18 18 18 18/2 18/2 18/2

No. of blades 555555

Air flow (high speed) m

3

/min 62.3 62.3 62.3 62.3 62.3 62.3

Fan speed (high speed) r/min 910 920 920 920 920 920

Page 19

1-6

English

Note: For cooling nominal values are based on 12°C / 7°C entering / leaving evaporator water temperature, 35°C air ambient temperature.

For heating nominal values are based on 40°C / 45°C entering / leaving evaporator water temperature, 7°C/6°C (DB/WB) air ambient temperature.

Table A-3 : R407C - Heatpump

Model 4AC20CR 4AC25CR 4AC30CR 4AC40CR 4AC50CR 4AC60CR

Nominal cooling capacity kW 4.98 6.45 7.33 11.72 13.48 14.95

Nominal heating capacity kW 5.86 7.47 9.53 13.19 14.95 17.58

Operating Weight kg 115.5 122.5 128.0 195.0 196.4 203.2

Refrigerant charge R407C kg 1.50 1.75 1.60 3.00 3.45 4.00

Compressor 1 Rotary comp 1 Scroll compressor

Control system LCD Electronic Control

Refrigerant - water heat exchanger Brazed Plate Heat Exchanger

Water connections (BSP) inches 111111

Maximum water pressure kPa 1000 1000 1000 1000 1000 1000

Hydronic circuit

Pump High Head Circulator Horizontal Multistage End-Suction

Available pressure (Cooling / Heating) kPa 87.21/76.47 100.89/92.77 93.89/76.38 91.70/74.54 82.15/63.75 74.67/35.27

Water inlet connection (BSPT) inches 111111

Water outlet connection (BSPT) inches 111111

Drain tap coupling (BSPT) inches 1/2 1/2 1/2 1/2 1/2 1/2

Closed expansion tank water volume litre 222555

Refrigerant - air heat exchanger

Tube diameter mm 9.52 9.52 9.52 9.52 9.52 9.52

No. of rows 122222

Tubes/row 30 30 30 54 54 54

Fin spacing mm

1.27 1.59 1.59 1.59 1.59 1.59

O/D Fan

Diameter inches 18 18 18 18/2 18/2 18/2

No. of blades 555555

Air flow (high speed) m

3

/min 62.3 62.3 62.3 62.3 62.3 62.3

Fan speed (high speed) r/min 910 920 920 920 920 920

Table A-4 : R22 - Heatpump

Model AC20CR AC25CR AC30CR AC40CR AC50CR AC60CR

Nominal cooling capacity kW 5.28 6.74 8.06 11.72 13.48 15.53

Nominal heating capacity kW 6.45 7.33 9.23 12.60 15.24 17.29

Operating Weight kg 115.5 122.5 128.0 195.0 196.4 203.2

Refrigerant charge R22 kg 1.55 1.93 1.75 3.00 3.65 4.00

Compressor 1 Rotary comp 1 Scroll compressor

Control system LCD Electronic Control

Refrigerant - water heat exchanger Brazed Plate Heat Exchanger

Water connections (BSP) inches 111111

Maximum water pressure kPa 1000 1000 1000 1000 1000 1000

Hydronic circuit

Pump High Head Circulator Horizontal Multistage End-Suction

Available pressure (Cooling / Heating) kPa 83.55/69.27 98.58/93.89 88.08/78.76 91.70/81.42 82.15/60.12 65.98/39.62

Water inlet connection (BSPT) inches 111111

Water outlet connection (BSPT) inches 111111

Drain tap coupling (BSPT) inches 1/2 1/2 1/2 1/2 1/2 1/2

Closed expansion tank water volume litre 222555

Refrigerant - air heat exchanger

Tube diameter mm 9.52 9.52 9.52 9.52 9.52 9.52

No. of rows 122222

Tubes/row 30 30 30 54 54 54

Fin spacing mm

1.27 1.59 1.59 1.59 1.59 1.59

O/D Fan

Diameter inches 18 18 18 18/2 18/2 18/2

No. of blades 555555

Air flow (high speed) m3/min 62.3 62.3 62.3 62.3 62.3 62.3

Fan speed (high speed) r/min 910 920 920 920 920 920

Page 20

1-7

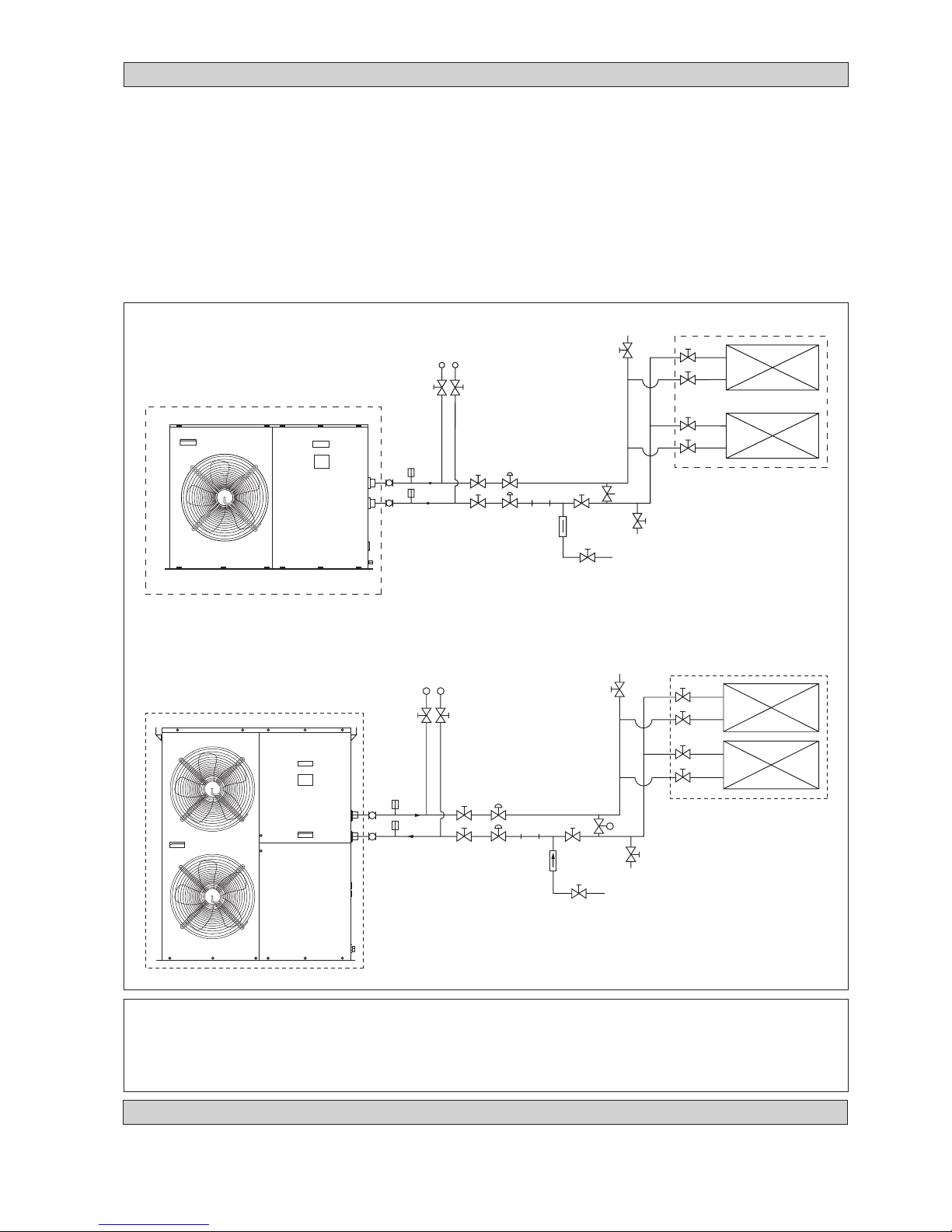

WATER PIPING AND FITTING

• All water pipe must be adequately insulated to prevent capacity losses and condensation.

• Install a 40 to 60-mesh strainer to ensure good water quality.

• Water pipes recommended are black steel pipe and copper pipe.

• During installation, the piping of the unit should be clamped before rotating the installation pipe to reduce the moment

induce on the piping.

• Users are recommended to install the pipes and accessories as shown in Figure 6.

• An air vent must be installed at the highest position, while a drainage plug at the lowest position of the water circuit. After

the leak test (0.6MPa), open the air vent to release any air trapped in the water circuit.

• Run the clean water through the water inlet and operate the pump to drain out the dirty water. Clean the strainer after

running the pump for 30 minutes.

• Fill up the water circuit after connecting the pipes and equipment. Check water leakage at all connections and joints. Do

not start the unit when the system is leaking.

• To optimize the capacity of the system, ensure that the system is free of air bubbles. The air trapped in the system would

make the system unbalanced.

!!

!!

! CAUTION

• Do not allow water to remain in the water pipes if the unit is not operating for a long period.

Water must be drained out if the unit is not running during winter. Failing to do so would cause the pipe to crack.

• Do not drink the chilled water in the unit.

P

P

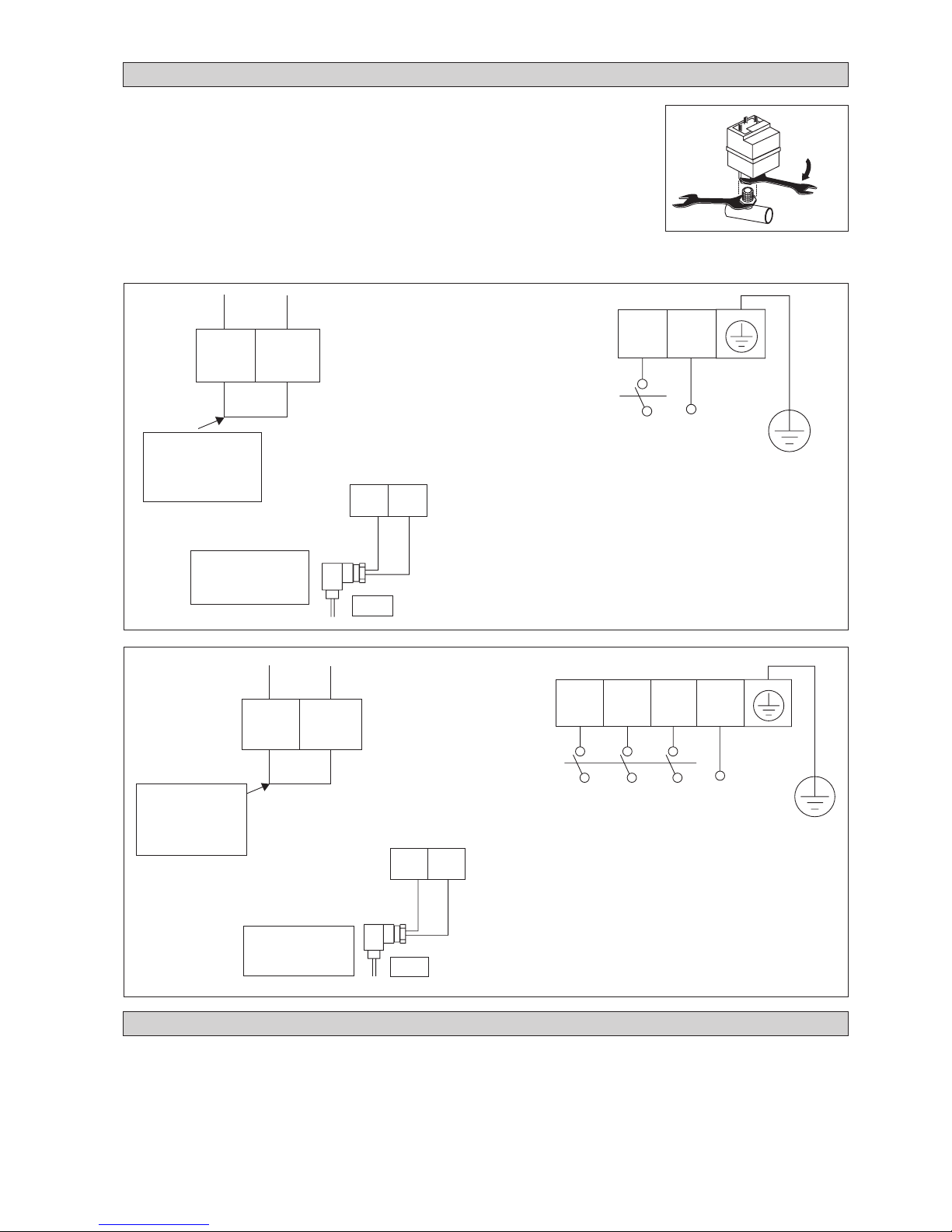

4AC/AC 20/25/30 C/CR

4AC/AC 40/50/60 C/CR

PRESSURE GAUGE

GATE

VALVE

GATE

VALVE

BALANCING

VALV E

THERMOMETER

FLEXIBLE

GATE VALVE (LOWER

POSITION FOR DRAINAGE)

AIRVENT (INSTALL

HIGHEST POSITION)

FAN COIL UNIT/AIR HANDLING UNIT

GATE

VALV E

Figure 6

THERMOMETER

GATE VALVE

GATE VALVE

BALANCING

VALV E

STRAINER

CHECK

VALVE

MAKE UP

VALV E

BYPASS VALVE

(DIFFER ENT PRESSURE TYPE)

PRESSURE GAUGE

GATE

VALVE

GATE

VALVE

BALANCING

VALV E

THERMOMETER

FLEXIBLE

GATE VALVE (LOWER

POSITION FOR DRAINAGE)

AIRVENT (INSTALL

HIGHEST POSITION)

FAN COIL UNIT/AIR HANDLING UNIT

GATE

VALVE

THERMOMETER

GATE VALVE

GATE VALVE

BALANCING

VALV E

STRAINER

CHECK

VALV E

MAKE UP

VALV E

BYPASS VALVE

(DIFFER ENT PRESSURE TYPE)

ELECTRICAL AND WIRING

• Refer to the wiring diagram provided on the unit when making electrical wiring.

• Do not ground any electrical equipment to the water piping.

• Install an external isolator switch (if it is not provided) to prevent electrical shock.

Page 21

1-8

English

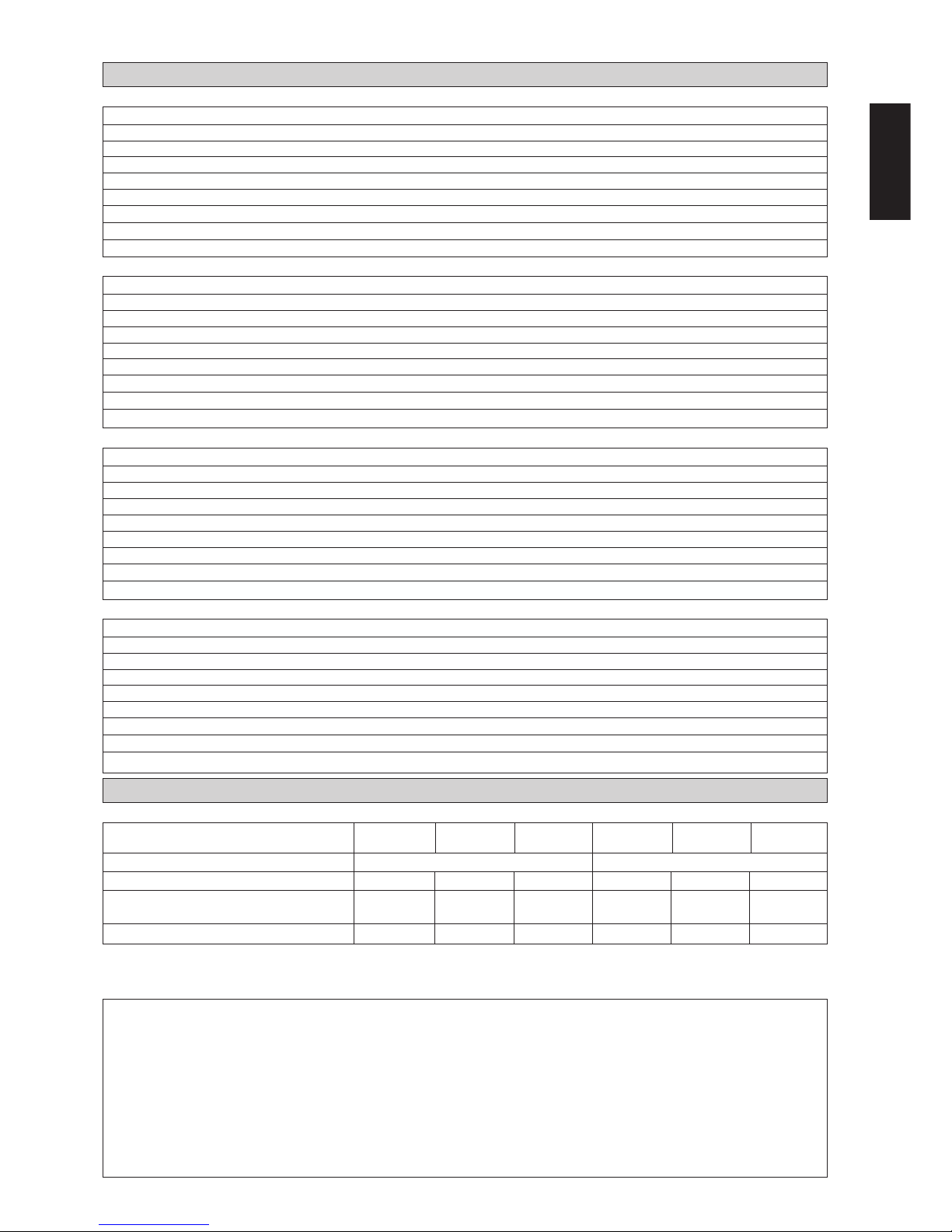

4AC20C/CR 4AC25C/CR 4AC30C/CR 4AC40C/CR 4AC50C/CR 4AC60C/CR

Model

AC20C/CR AC25C/CR AC30C/CR AC40C/CR AC50C/CR AC60C/CR

Voltage Range ** 220 ~ 240V /1Ph /50Hz + N + ! 380 ~ 415V /3Ph /50Hz + N + !

Recommended Fuse * A 27 38 45 22 24 29

Power Supply Cable Size * mm

2

10 10 10 5 5 5

Number of Conductor 3 3 3 5 5 5

Interconnection Cable Size * mm

2

1.5 1.5 1.5 1.5 1.5 1.5

ELECTRICAL DATA

Table B-1 : ( R407C - Cooling Only )

Model 4AC20C 4AC25C 4AC30C 4AC40C 4AC50C 4AC60C

Power supply V-ph-Hz 230 / 1 / 50 400 / 3 / 50

Voltage range V 220 - 240 380 - 415

Nominal Power Input kW 2.62 2.96 3.69 4.94 5.97 6.88

Nominal Current Input A 12.70 13.59 17.48 9.29 10.22 12.93

Maximum Continuous Current A 18.3 23 27 14 14 17

Full Load Current (FLA) A 14 17.5 22.5 12.4 11.8 14.3

Locked Rotor Current (LRA) A 57 82 114 65.5 74 101

Pump Power Input W 183 189 199 320 345 349

Cooling / Heat Pump

RECOMMENDED FUSE AND CABLE SIZES

IMPORTANT : *

The figures shown in the table are for information purpose only. They should be checked and selected to comply with

the local/national codes of regulations. This is also subjected to the type of installation and conductors used.

**

The appropriate voltage range should be checked with label data on the unit.

!!

!!

! CAUTION

• All field wiring must be installed in accordance with the national wiring regulation.

• All the terminals and connections must be tightened. Improper connection and fastenings could cause electric shock, short

circuit and fire.

• Ensure that the rated voltage of the unit corresponds to that of the name plate before commencing wiring work according to

the wiring diagram.

• The unit must be GROUNDED to prevent possible hazards due to insulation failure.

• All electrical wiring must not touch the refrigerant piping, compressor, pump, fan motor or any moving parts of the fan

motors.

• Do not operate the chiller with wet hands. It would result in electric shock.

• Do not use fuse of different amperage than stated. Using wire etc. to replace a fuse could cause equipment damage or fire.

Table B-2 : ( R22 - Cooling Only )

Model AC20C AC25C AC30C AC40C AC50C AC60C

Power supply V-ph-Hz 230 / 1 / 50 400 / 3 / 50

Voltage range V 220 - 240 380 - 415

Nominal Power Input kW 2.68 2.74 3.50 4.50 5.26 6.38

Nominal Current Input A 12.64 12.11 16.70 8.80 9.30 12.32

Maximum Continuous Current A 18.3 23 27 14 14 17

Full Load Current (FLA) A 14 16.5 21.4 10.5 11.3 12.3

Locked Rotor Current (LRA) A 57 82 114 65.5 74 101

Pump Power Input W 175 190 201 320 345 351

Table B-3 : ( R407C - Heatpump )

Model 4AC20CR 4AC25CR 4AC30CR 4AC40CR 4AC50CR 4AC60CR

Power supply V-ph-Hz 230 / 1 / 50 400 / 3 / 50

Voltage range V 220 - 240 380 - 415

Nominal Power Input (Cooling/Heating) kW 2.61/2.69 3.09/2.75 3.82/4.00 4.85/5.01 5.47/5.66 6.53/6.28

Nominal Current Input (Cooling/Heating)

A 12.69/12.99 14.3/14.1 19.29/20.19 9.13/9.23 9.59/9.96 12.77/12.67

Maximum Continuous Current A 18.3 23 27 14 14 17

Full Load Current (FLA) A 14 17.5 22.5 12.4 11.8 14.3

Locked Rotor Current (LRA) A 57 82 114 65.5 74 101

Pump Power Input (Cooling/Heating) W 173/181 186/195 194/214 320/334 336/347 347/358

Table B-4 : ( R22 - Heatpump )

Model AC20CR AC25CR AC30CR AC40CR AC50CR AC60CR

Power supply V-ph-Hz 230 / 1 / 50 400 / 3 / 50

Voltage range V 220 - 240 380 - 415

Nominal Power Input (Cooling/Heating) kW 2.61/2.70 2.95/2.83 3.55/3.56 4.59/4.65 5.07/5.01 6.57/6.26

Nominal Current Input (Cooling/Heating)

A 12.38/12.73 13.4/12.8 18.24/18.37 8.67/8.78 8.99/8.95 13.49/13.03

Maximum Continuous Current A 18.3 23 27 14 14 17

Full Load Current (FLA) A 14 16.5 21.4 10.5 11.3 12.3

Locked Rotor Current (LRA) A 57 82 114 65.5 74 101

Pump Power Input (Cooling / Heating) W 175/186 189/194 201/211 320/329 336/349 351/357

Page 22

1-9

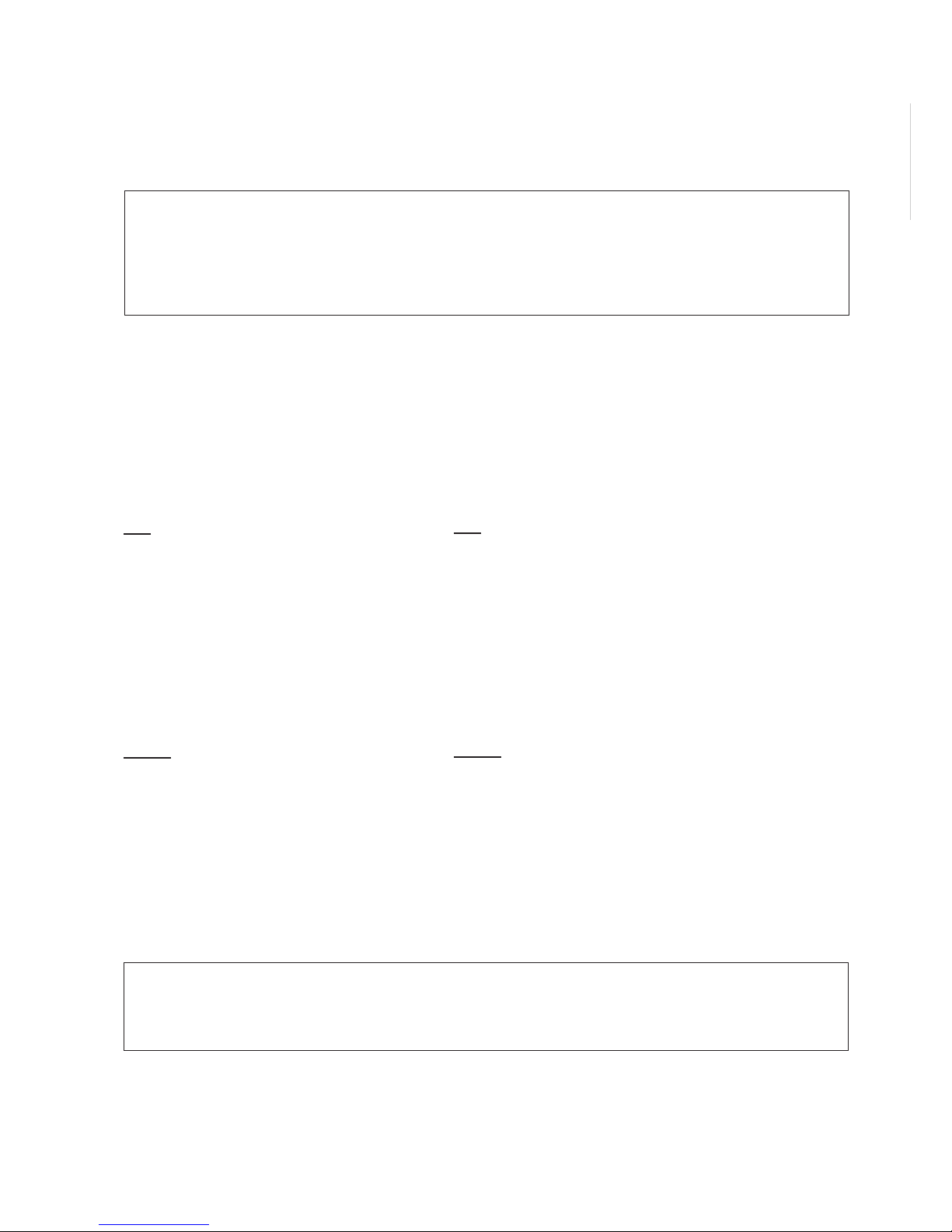

P

P

4AC / AC 20C/ 25C/ 30C

Water / Refrigerant Circuit Diagram

FILTER

DRIER

CAP TUBE

BPHE

COMPRESSOR

WATER PUMP

AUTO PRESS RELIEF VALVE

WATER

OUT

WATER

IN

EXPANSION

TANK

WATER STORAGE

TANK

4AC / AC 40C/ 50C/ 60C

Water / Refrigerant Circuit Diagram

FILTER

DRIER

CAP TUBE

BPHE

COMPRESSOR

WATER PUMP

AUTO PRESS RELIEF VALVE

WATER

OUT

WATER

IN

EXPANSION

TANK

WATER STORAGE

TANK

PART NO : 70-03-4-067460

PART NO : 70-03-4-087461

Page 23

1-10

English

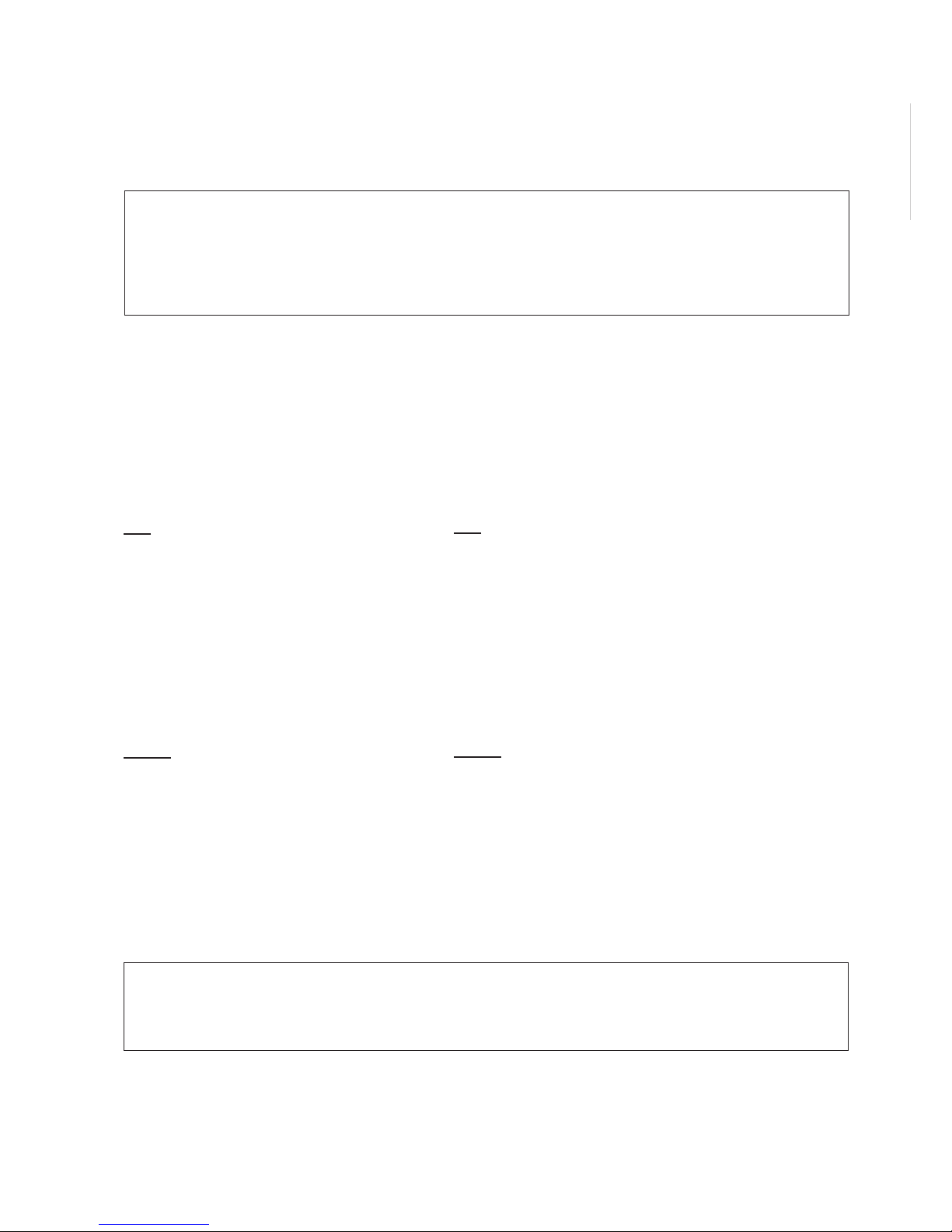

P

P

4AC / AC 20CR/ 25CR/ 30CR

Water / Refrigerant Circuit Diagram

CHECK

VALV E

BPHE

COMPRESSOR

CHARGE

COMPENSATOR

AUTO PRESS RELIEF VALVE

WATER

OUT

WATER

IN

EXPANSION

TANK

WATER STORAGE

TANK

PART NO : 70-03-4-067458

4AC / AC 40CR/ 50CR/ 60CR

Water / Refrigerant Circuit Diagram

BPHE

COMPRESSOR

WATER PUMP

AUTO PRESS RELIEF VALVE

WATER

OUT

WATER

IN

EXPANSION

TANK

WATER STORAGE

TANK

PART NO : 70-03-4-067459

CHECK

VALV E

FILTER

DRIER

HEATING

CAP

TUBE

COOLING

CAP

TUBE

SUCTION

ACCUMULATOR

CHECK

VALV E

LIQUID

RECEIVER

CHECK

VALV E

FILTER

DRIER

HEATING

CAP

TUBE

COOLING

CAP

TUBE

SUCTION

ACCUMULATOR

Page 24

1-11

REFRIGERANT CIRCUIT

• All mini chiller units are pre-charged with R22 or R407C refrigerant.

SPECIAL PRECAUTIONS WHEN DEALING WITH R407C UNIT

• R407C is a zeotropic refrigerant mixture which has zero ozone depletion potential and thus conformed to the Montreal

Protocol regulation. It requires Polyester oil (POE) oil for its compressor lubricant. Its refrigerant capacity and performance are about the same as the refrigerant R22.

• POE oil is used as lubricant for R407C compressor, which is different from the mineral oil used for R22 compressor.

During installation or servicing, extra precaution must be taken not to expose the R407C system too long to moist air.

Residual POE oil in the piping and components can absorb moisture from the air.

• Refrigerant R407C is more easily affected by dust of moisture compared with R22, make sure to temporarily cover the

ends of the tubing prior to installation.

• No additonal charge of compressor oil is permitted.

• No other refrigerant other than R407C.

• Tools specifically for R407C only (must not be used for R22 or other refrigerant)

i) Manifold gauge and charging hose

ii) Gas leak detector

iii) Refrigerant cylinder/charging cylinder

iv) Vacuum pump c/w adaptor

v) Flare tools

vi) Refrigerant recovery machine

!!

!!

! CAUTION

• R407C must be charged as liquid. Usually R407C cylinder is equipped with a dip-pipe for liquid withdrawal.

If there is no dip-pipe, the cylinder should be inverted so as to withdraw liquid R407C from the valve.

• Do not top-up when servicing leak, as this will reduce the unit performance. Vacuum the unit thoroughly and then

charge the unit with fresh R407C according to the amount recommended in the specification.

• Do not touch the compressor or refrigerant piping when the chiller is running. If necessary wear protective gloves.

WATER PIPING SYSTEM SETUP

• Fill up the water circuit after connecting all the pipes and equipment. Perform leak checks for all connections and joints.

Do not start the unit when the system is leaking.

• To optimize the capacity of the system, ensure that the system is free of air bubbles. The air trapped in the system would

make the system unbalanced.

• Ensure that the water tank is not full. This is to ensure optimal performance of the mini chiller. If the pressure is too high,

release the pressure from the auto pressure relief valve on the tank.

Page 25

1-12

English

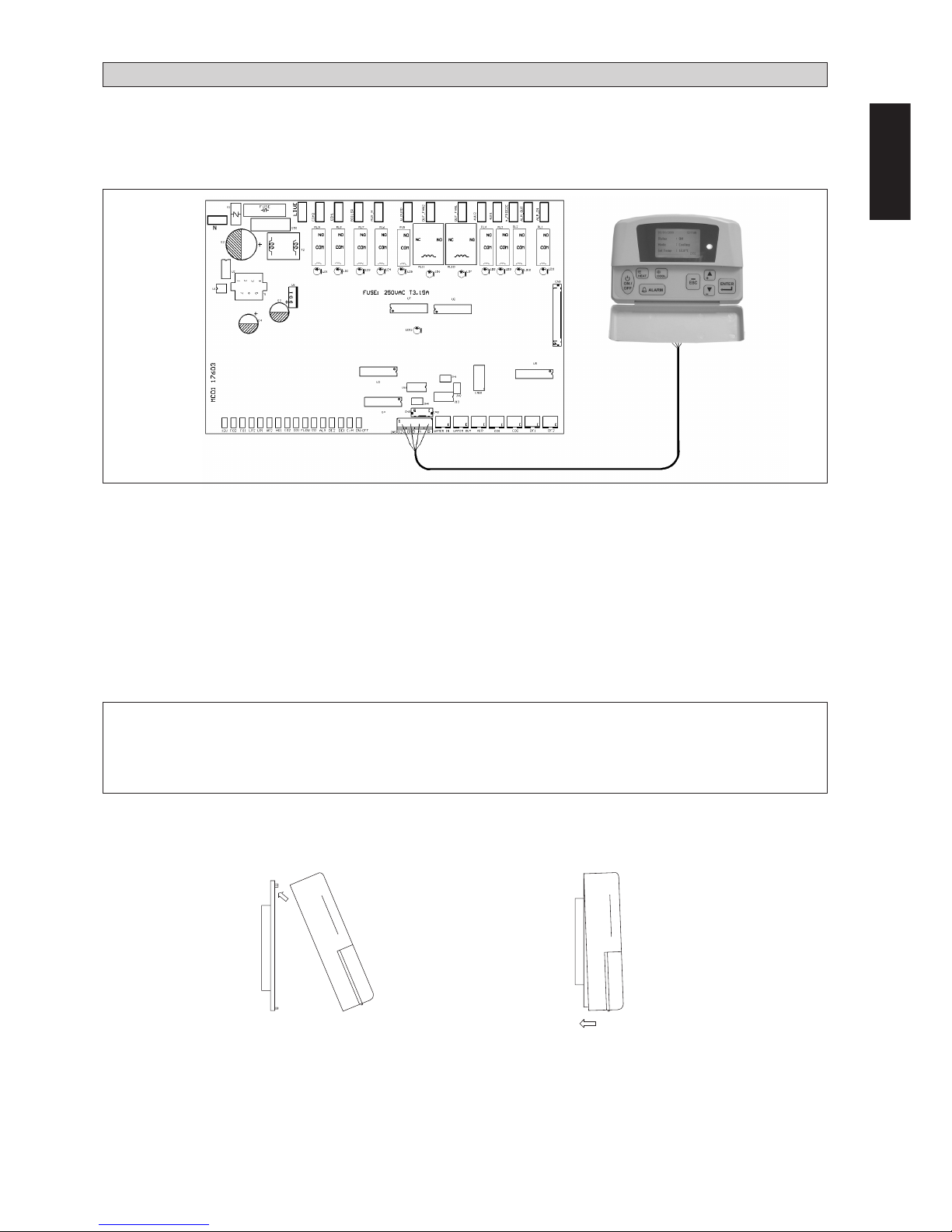

1. Handset location

The handset is located in the terminal box behind the service panel.

2. LED Display (microprocessor board)

The keypad LED will light up when the unit is powered up.

The LCD will light up when the unit is turned on.

3. LCD display (controller handset)

During normal operations, the LCD can display the entering water temperature, the leaving water temperature, the entering water setpoint temperature, compressor on or off status and outdoor air temperature. When malfunctioning occurred,

the LCD would blink. The display would show the faulty parameter and the date and time of the occurrence.

4. Controller functioning specification

There is a 3 minute delay for the compressor and fan motor to restart (default setting).

CONTROL OPERATION GUIDE

The unit is equipped with a microprocessor controller board. The microprocessor controller is provided to give temperature

control for the system by accurately measuring and controlling the water entering and water leaving temperature. The temperature setting in the unit is preset in the factory. It is not recommended to change the setting unless necessary. A wired

controller handset is connected to the microprocessor board. Every parameter setting and reading can be observed from the

LCD of the handset.

!!

!!

! CAUTION

• Use the controller handset to switch on / off the unit. Do not plug off the main power supply directly, it would cause

the unit to breakdown.

• Do not change the settings of the safety devices.

• Installation

When fastening the LCD panel to the bracket,

Step 1 Step 2

Hook the LCD panel

from the top first

Push to fasten the LCD

panel to the bracket

Page 26

1-13

• Servicing

Servicing or maintenance of these units must be carried out by experienced personnel with specific training in refrigeration.

Repeatedly check the safety devices and continuous cycling of control components. These items must be analyzed and

corrected before being reset.

The simple design of the refrigeration circuit totally eliminates potential problems during normal unit operation. No maintenance work is needed on the refrigeration circuit as long as the unit is operating normally.

Ease of maintenance has been taken into consideration during the design stage such that the unit is easily accessible from the

service panels. The electrical components are especially easy to access since it is located in the terminal box in the front

service panel (Figure 7).

SERVICING AND MAINTENANCE

Figure 7

1. A 3V DC battery is supplied with the LCD. It is used to ensure that the LCD displays real time once the timer is set.

2. The LCD is wired to the main board via CN8 connection. (This is factory installed)

If the wiring between the LCD and PCB must be longer, an alternative is used. Use a 4-core wire of the desired length and

connect this wire between the terminal block CN2 on the LCD to the terminal block CN5 on the PCB. Ensure that the

correct wire terminals are connected.

3. Networking between chillers can be carried out. Connect the wire as shown

When removing the LCD panel from the bracket,

Step 1 Step 2

Remove the LCD panel

from the bottom part first

with help of a screw driver

Remove the

LCD panel

Factory installed

Alternative wiring between LCD panel and PCB

For networking only

A

A

A

B

B

B

12V

12V

12V

GND

GND

GND

JP13

CN8

CN2

CN5

Main Board Unit 00

LCD Panel

PCB Unit 01

Page 27

1-14

English

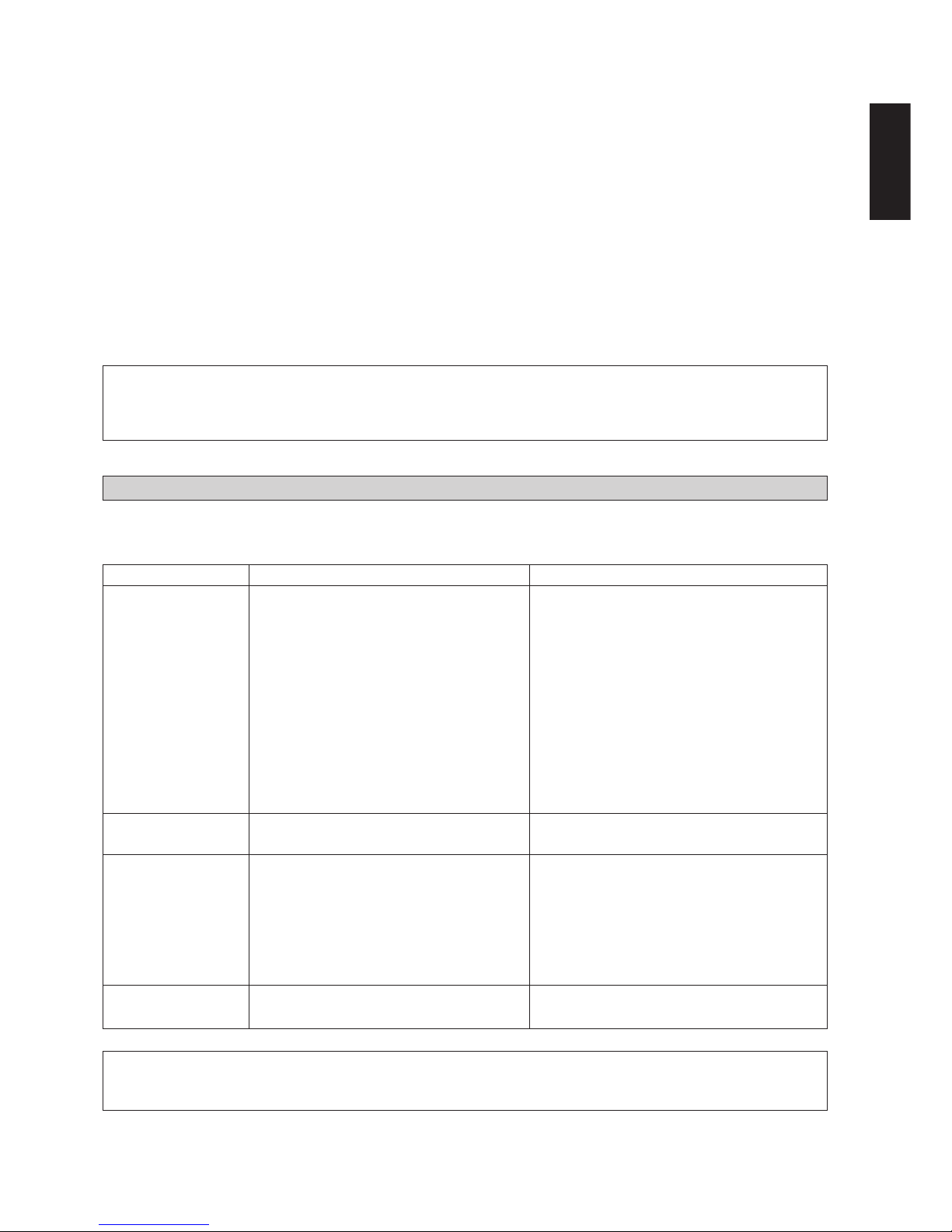

1. Compressor does

not start.

2. Fan does not work.

3. Unit does work,

but insufficient

cooling.

4. Flow Switch Error

TROUBLESHOOTING

When any malfunction is occurred, immediately switch off the power supply to the unit, and contact the local dealer, if

necessary. Some simple troubleshooting tips are given below :

SYMPTOMS POSSIBLE CAUSES REMEDIAL ACTION

• No power supply.

• Fuses blown or automatic circuit breakdown open.

• Defective contactor or coil.

• Unit is stopped because safety device has

tripped.

• Loose wires.

• Compressor faulty.

• No power supply.

• Fan motor faulty.

• Thermostat setting too high.

• Condenser coil dirty.

• Obstacle blocking air inlet or outlet of the

unit.

• Insufficient refrigerant in the system.

• Improper water flow rate.

• Water in the system is contaminated.

• No water in the system.

• Low water level in the system.

• Check power supply.

• Look for short circuit or grounded wires in

motor windings. Replace fuses and reset

circuit breakers when the fault has been

corrected. Check tightness and soundness of

all electrical connections.

• Repair or replace.

• Determine the type of safety shut down and

correct the default before the unit is restarted.

• Check wire connections and tighten terminal

screws.

• Contact local dealer.

• Check power supply.

• Contact local dealer.

• Reset thermostat.

• Contact local dealer.

• Remove the obstacle.

• Contact local dealer.

• Contact local dealer.

• Contact local dealer.

• Check water supply.

• Check water supply.

!!

!!

! CAUTION

• Troubleshooting must be performed by qualified personnel.

!!

!!

! CAUTION

• Do not attempt to do any service or maintenance when the unit is operating.

• Do not spray any chemical agents or flammable agents to the unit. It could cause fire or explosion.

Under normal circumstances, these chillers required only a check and cleaning of air intake through the coil surface. These

can be done monthly or quarterly depending on the surrounding where the units are installed.

When the surrounding is very oily or dusty, then the coils must be regularly cleaned by a qualified air condition service

technician to ensure sufficient cooling capacity and efficient unit operation. The normal life span might be shortened if no

proper service is provided.

• Maintenance

For consistent performance and durability, always conduct proper and regular maintenance to the unit.

For prolong period of operation time, the heat exchanger will become dirty impairing its effectiveness and reducing the

performance of the units. Consult your local dealer about the cleaning of the heat exchanger.

No major maintenance or servicing is needed for the internal water circuit in the unit except the water pump failure. It is

advisable to conduct regular check on the filter and change the water filter if it is dirty or choked.

Always check the water level in the system in order to protect the moving components in the hydraulic kit from over heating

and excessive wear.

Page 28

1-15

Figure 9

4AC/AC40/50/60 C/CR

Remove this wire

when doing

wiring for fan

speed controller

Wiring for fan

speed controller

(FSC)

FSC

OF IN

OF OUT

TB3

TB3

OF IN OF OUT

TO (PCB)

OUT_FAN1

TO (A) OF_1

CAPACITOR

Power supply 400V / 3Ph-N / 50Hz

L1 N

TB1

R

S

TN

L2

L3

ISOLATOR SWITCH FIELD INSTALLATION

The isolator switch does not come as standard item with the units. It is advisable to have it field installed. The isolator switch must

be capable of making, carrying and breaking currents under normal circuit condition. It must be of AC23A duty and fully compliant

to IEC: 947-3.

For isolator switch selection, check the starting and running consumption specified in Table B. Be sure to connect a ground wire

from incoming power supply, either direct to the terminal box panel or use an auxiliary ground terminal in the isolator switch. To

install an isolator switch, wire it to the terminal block as shown in the two figures in page ix.

Operation of the mini chillers without any fan speed control is limited to an ambient temperature

of 17°C. With the fan speed control, the units are able to operate down to -5°C.

The fan speed controller does not come as a standard item in the mini chiller units. It is fieldinstalled.

All mini chillers will have a 1/4" access valve provided for along the liquid line of the refrigerant

circuit. This valve is for direct pressure connection to the fan speed controller.

To install the fan speed controller, screw in the female adaptor to the 1/4" access valve. Use a

pair of spanners to tighten properly (max. torque 15 Nm). See Fig. 8. Ensure there is no leakage

at the joint.

Wire the fan speed controller to the terminal blocks. See Fig. 9.

FAN SPEED CONTROLLER (OPTIONAL)

TB3

Power supply 230V / 1Ph-N / 50Hz

Remove this wire

when doing wiring

for fan speed

controller

Figure 8

OF IN OF OUT

OF IN

OF OUT

Wiring for fan

speed controller

(FSC)

FSC

TB3

TO (PCB)

OUT_FAN1

TO (A) OF

CAPACITOR

L1 N

TB1

L/L1 N/L2

4AC/AC20/25/30 C/CR

15 Nm

Page 29

English

Le présent manuel fournit les procédures d’installation pour assurer le bon fonctionnement et la sécurité du

refroidisseur.

Des ajustements spésifiques peuvent être nécessaires pour se conformer aux réglementations locales.

Avant d’employer le refroidisseur, lisez attentivement ce manuel, et conservez-le pour consultation future.

MANUEL D’INSTALLATION

REFROIDISSEUR À AIR

MODÈLE

FROID SEUL

R22

AC20C / MAC020C

AC25C / MAC025C

AC30C / MAC030C

AC40C / MAC040C

AC50C / MAC050C

AC60C / MAC060C

R407C

4AC20C / M4AC020C

4AC25C / M4AC025C

4AC30C / M4AC030C

4AC40C / M4AC040C

4AC50C / M4AC050C

4AC60C / M4AC060C

POMPE À CHALEUR

R22

AC20CR / MAC020CR

AC25CR / MAC025CR

AC30CR / MAC030CR

AC40CR / MAC040CR

AC50CR / MAC050CR

AC60CR / MAC060CR

R407C

4AC20CR / M4AC020CR

4AC25CR / M4AC025CR

4AC30CR / M4AC030CR

4AC40CR / M4AC040CR

4AC50CR / M4AC050CR

4AC60CR / M4AC060CR

!!

!!

! ATTENTION

• L’installation et la maintenance doivent être exécutées par une personne qualifiée qui est familiarisée avec les lois

et réglementations en vigueur, et aussi expérimentée dans ce type d’équipements.

Part No.: A08019025453

IM-ACC1&2-0703 (1)-McQuay

Page 30

2-1

- Sections Des Cables Et Fusibles De Protection page 8

- Montage des Conduites d’Eau page 11

- Circuit Frigori Fique page 11

- Précautions Spéciales Pour les Appareils Au R407C page 11

- Unité de Contrôle des Opérations page 12

- Entretien et Maintenance page 13

- Recherche Et Anlyse Des Pannes page 14

- Contrôle de la Vitesse du Ventilateur (en Option) page 15

-

Installation sur Place d’un Interrupteur d’Isolement

page 15

!!

!!

! AVERTISSEMENT

Lors de l’installation, vérifier soigneusement les points suivants.

• Ne pas installer dans des endroits où il y a risque de fuites de gaz.

Danger d’incendie en cas de fuite ou de concentration de gaz à proximité du conditionneur.

• Ne pas surcharger le conditionneur.

L’appareil est pré-chargé en usine. Toute surcharge provoquerait une surintensité et des dommages au

compresseur.

• Les angles pointus et la surface des ailettes en aluminium du condenseur peuvent être

dangeureux et provoquer des accidents. Evitez tout contact avec ce type d’endroits.

SOMMAIRE

- Disposition et Dimensions page i-ii

- Schéma de Câblage Électrique page iii-viii

- Schéma de Sectionnement page ix-x

- Transport page 1

- Sélection de l’Emplacement page 2

- Installation de l’unité page 4

- Données Physiques page 5

- Circuit Hydraulique page 7

- Equipement Electrique et Câblage page 7

- Données Électriques page 8

TRANSPORT

• Soulever l’unité avec un palonnier ou un chariot à fourche pour éviter d’endommager les panneaux. La figure 1 indique les

dimensions de la pallette pour le levage. Éviter les mouvements brusques. Ne pas retirer la pallette avant d’atteindre

l’emplacement final.

Au besoin, utiliser une grue pour soulever une unité de plus de 11kW. Vérifier que les élingues sont assez fortes pour

soutenir l’unité. Consulter le manuel technique pour en connaître le poids.

S’assurer que les élingues ne touchent ni la batterie du condenseur, ni le panneau supérieur, ni le panneau avant. Utiliser

une ferrure de levage (fournie avec le présent manuel) comme indiqué dans la figure 2. Soulever légèrement l’unité pour

vérifier qu’elle est en équilibre avant de la mettre en place. Ne jamais balancer ou rouler l’unité.

Figure 1

577

550

Page 31

2-2

Français

SÉLECTION DE L’EMPLACEMENT

• L’installation doit être effectvée par un distributeur autorisé ou par du personnel qualifié. Ne jamais installer l’unité soimême.

• S’assurer de la présence d’un flux d;air suffisant autour de l’appareil. L’air refoulé doit être acheminé dehors à l’aide d’un

conduit si l’unité est installée dans un local d’usine.

• Un dispositif d’isolation doit être fourni pour réduire les vibrations et le bruit de l’appareil.

• Lors d’une installation au sol de l’unité, s’assurer que l’emplacement choisi n’est pas à risque d’inondation.

• Lors de l’installation, prévoir un espace libre pour la ventilation, l’entretien et la maintenance de l’unité. Voir les figures

suivantes pour une mise en place correcte.

500 500

500

1500

Figure 3: Pour l’installation d’une seule unité

FLUX D’AIR

FLUX D’AIR

FLUX D’AIR

MIN 500

Figure 2

CROCHET

ELINGUE

Page 32

2-3

• L’unité installée au sol doit être déposée sur une dalle de béton. La dalle doit avoir une épaisseur de 100mm et dépasser de

50mm le pourtour de l’unité (Figure 5). Placer la dalle de béton à distance de l’édifice pour prévenir les vibrations et le

bruit.

• En cas d’emploi d’une thermopompe à une température extérieure sous 0°C, l’unité doit être installée au moins 300mm audessus du sol. C’est nécessaire pour empêcher la glace de s’accumuler sur le cadre et pour permettre un fonctionnement

adéquat lors de chutes de neige abondantes.

• L’unité doit être à niveau sur ses deux axes. (Tolérance inférieure à 2mm par mètre.)

50 50

100

Figure 5: Pour l’installation sur plancher

Remarque: Toutes les mesures sont en mm à moins d’indication contraire.

500

1000

1000 500

1500

Figure 4: Pour l’installation de multiples unités

FLUX D’AIR

FLUX D’AIR

FLUX D’AIR

FLUX D’AIR

FLUX D’AIR

FLUX D’AIR

FLUX D’AIR

MIN 500

Page 33

2-4

Français

4AC/AC 020/025/030 C/CR

INSTALLATION DE L’UNITÉ

!!

!!

! AVERTISSEMENT

• De mauvaises manoeuvres lors de l’installation peuvent entraîner des fuites, des chocs électriques ou des

disfonctionnements de l’appareil.

• Contacter le distributeur pour la réinstallation ou le démontage de l’appareil.

• Ne pas introduire d’objets étrangers comme les doigts, des petits bâtons, etc., dans l’ouverture d’entrée et de sortie

d’air.

• Ne pas grimper ou déposer des objets sur le dessus du mini-refroidisseur.

4AC/AC 040/050/060 C/CR

Page 34

2-5

DONNÉES PHYSIQUES

Remarque: Les valeurs nominales pour la réfrigération sont calculées en fonction de la température de l’eau, entre 12°C/7°C à l’entrée / sortie de

l’évaporateur, et de la température de l’air ambiant 35°C.

Tableau A-1 : R407C - Froid Seul

Modèles 4AC020C 4AC025C 4AC030C 4AC040C 4AC050C 4AC060C

Puissance frigorifique kW 6,15 6,74 7,91 11,72 14,65 15,24

Poids kg 115,5 122,5 128 195 196,4 203,2

Charge de Réfrigérant R-407C kg 1,13 1,85 1,65 3,40 3,35 3,45

Compresseur 1 Compresseur rotatif 1 Compresseur scroll

Système de Contrôle Contrôle électronique LCD

Échangeur de chaleur à eau Échangeur de chaleur á plaque

Raccordement (BSP) pouces 111111

Pression maximale de l’eau kPa 1000 1000 1000 1000 1000 1000

Circuit hydraulique

Pompe

Circulateur à hauteur manométrique élevée

Pompe Centrifugale

Moyenne de la pression kPa 72,94 98,58 89,27 91,70 67,51 70,32

Raccordement à l’entrée de l’eau (BSPT) pouces 111111

Raccordement à la sortie de l’eau (BSPT) pouces 111111

Raccordement de la vanne d’écoulemen (BSPT)

pouces 1/2 1/2 1/2 1/2 1/2 1/2

Volume d’eau du réservoir d’expansion fermé

litres 222555

Échangeur de chaleur à air

Diamètre du tube mm 9,52 9,52 9,52 9,52 9,52 9,52

Nombre de rangs 122222

Tube/rangs 30 30 30 54 54 54

Espace entre les ailettes mm

1,27 1,59 1,59 1,59 1,59 1,59

Ventilateur O/D

Diamètre pouces 18 18 18 18/2 18/2 18/2

Nombre de pales d’hélice 555555

Débit d’air (grande vitesse) m3/min 62,3 62,3 62,3 62,3 62,3 62,3

Vitesse du ventilateur (grande vitesse) r/min 910 920 920 920 920 920

Tableau A-2 : R22 - Froid Seul

Modèles AC020C AC025C AC030C AC040C AC050C AC060C

Puissance frigorifique kW 5,28 6,89 8,06 11,72 14,65 15,53

Poids kg 115,5 122,5 128 195 196,4 203,2

Charge de Réfrigérant R-22 kg 1,13 1,80 1,56 2,68 3,10 3,10

Compresseur 1 Compresseur rotatif 1 Compresseur scroll

Système de Contrôle Contrôle électronique LCD

Échangeur de chaleur à eau Échangeur de chaleur á plaque

Raccordement (BSP) pouces 111111

Pression maximale de l’eau kPa 1000 1000 1000 1000 1000 1000

Circuit hydraulique

Pompe

Circulateur à hauteur manométrique élevée

Pompe Centrifugale

Moyenne de la pression kPa 83,55 97,39 88,08 91,70 67,51 65,98

Raccordement à l’entrée de l’eau (BSPT) pouces 111111

Raccordement à la sortie de l’eau (BSPT) pouces 111111

Raccordement de la vanne d’écoulemen (BSPT)

pouces 1/2 1/2 1/2 1/2 1/2 1/2

Volume d’eau du réservoir d’expansion fermé

litres 222555

Échangeur de chaleur à air

Diamètre du tube mm 9,52 9,52 9,52 9,52 9,52 9,52

Nombre de rangs 122222

Tube/rangs 30 30 30 54 54 54

Espace entre les ailettes mm

1,27 1,59 1,59 1,59 1,59 1,59

Ventilateur O/D

Diamètre pouces 18 18 18 18/2 18/2 18/2

Nombre de pales d’hélice 555555

Débit d’air (grande vitesse) m

3

/min 62,3 62,3 62,3 62,3 62,3 62,3

Vitesse du ventilateur (grande vitesse) r/min 910 920 920 920 920 920

Page 35

2-6

Français

Remarque: Les valeurs nominales pour la réfrigération sont calculées en fonction de la température de l’eau, entre 12°C/7°C à l’entrée / sortie de

l’évaporateur, et de la température de l’air ambiant 35°C.

Les valeurs nominales pour le chauffage sont calculées en fonction de la température de l’eau, entre 40°C/45°C à l’entrée / sortie de

l’évaporateur, et de la température de l’air ambiant a 7°C/6°C (DB/WB).

Tableau A-3 : R407C - Pompe à Chaleur

Modèles 4AC020CR 4AC025CR 4AC030CR 4AC040CR 4AC050CR 4AC060CR

Capacité frigorifique nominale kW 4,98 6,45 7,33 11,72 13,48 14,95

Capacité calorifique nominale kW 5,86 7,47 9,53 13,19 14,95 17,58

Poids kg 115,5 122,5 128,0 195,0 196,4 203,2

Charge de Réfrigérant R407C kg 1,50 1,75 1,60 3,00 3,45 4,00

Compresseur 1 Compresseur rotatif 1 Compresseur scroll

Système de Contrôle Contrôle électronique LCD

Échangeur de chaleur à eau Échangeur de chaleur á plaque

Raccordement (BSP) pouces 111111

Pression maximale de l’eau kPa 1000 1000 1000 1000 1000 1000

Circuit hydraulique

Pompe

Circulateur à hauteur manométrique élevée

Pompe Centrifugale

Moyenne de la pression kPa 87,21/76,47 100,89/92,77 93,89/76,38 91,70/74,54 82,15/63,75 74,67/35,27

Raccordement à l’entrée de l’eau (BSPT) pouces 111111

Raccordement à la sortie de l’eau (BSPT) pouces 111111

Raccordement de la vanne d’écoulemen (BSPT)

pouces 1/2 1/2 1/2 1/2 1/2 1/2

Volume d’eau du réservoir d’expansion fermé

litres 222555

Échangeur de chaleur à air

Diamètre du tube mm 9,52 9,52 9,52 9,52 9,52 9,52

Nombre de rangs 122222

Tube/rangs 30 30 30 54 54 54

Espace entre les ailettes mm

1,27 1,59 1,59 1,59 1,59 1,59

Ventilateur O/D

Diamètre pouces 18 18 18 18/2 18/2 18/2

Nombre de pales d’hélice 555555

Débit d’air (grande vitesse) m3/min 62,3 62,3 62,3 62,3 62,3 62,3

Vitesse du ventilateur (grande vitesse) r/min 910 920 920 920 920 920

Tableau A-4 : R22 - Pompe à Chaleur

Modèles AC020CR AC025CR AC030CR AC040CR AC050CR AC060CR

Capacité frigorifique nominale kW 5,28 6,74 8,06 11,72 13,48 15,53

Capacité calorifique nominale kW 6,45 7,33 9,23 12,60 15,24 17,29

Poids kg 115,5 122,5 128,0 195,0 196,4 203,2

Charge de Réfrigérant R22 kg 1,55 1,93 1,75 3,00 3,65 4,00

Compresseur 1 Compresseur rotatif 1 Compresseur scroll

Système de Contrôle Contrôle électronique LCD

Échangeur de chaleur à eau Échangeur de chaleur á plaque

Raccordement (BSP) pouces 111111

Pression maximale de l’eau kPa 1000 1000 1000 1000 1000 1000

Circuit hydraulique

Pompe

Circulateur à hauteur manométrique élevée

Pompe Centrifugale

Moyenne de la pression kPa 83,55/69,27 98,58/93,89 88,08/78,76 91,70/81,42 82,15/60,12 65,98/39,62

Raccordement à l’entrée de l’eau (BSPT) pouces 111111

Raccordement à la sortie de l’eau (BSPT) pouces 111111

Raccordement de la vanne d’écoulemen (BSPT)

pouces 1/2 1/2 1/2 1/2 1/2 1/2

Volume d’eau du réservoir d’expansion fermé

litres 222555

Échangeur de chaleur à air

Diamètre du tube mm 9,52 9,52 9,52 9,52 9,52 9,52

Nombre de rangs 122222

Tube/rangs 30 30 30 54 54 54

Espace entre les ailettes mm

1,27 1,59 1,59 1,59 1,59 1,59

Ventilateur O/D

Diamètre pouces 18 18 18 18/2 18/2 18/2

Nombre de pales d’hélice 555555

Débit d’air (grande vitesse) m3/min 62,3 62,3 62,3 62,3 62,3 62,3

Vitesse du ventilateur (grande vitesse) r/min 910 920 920 920 920 920

Page 36

2-7

P

CIRCUIT HYDRAULIQUE

• Toutes les conduites d’eau doivent être isoleés afin d’éviter la formation de condensation et de réduire les deperditions

calorifiques.

• Installer un filtre à maille de 1,5mm de type GI, en acier noir, en acier normal ou en plastique (PVC, PPR).

• Les conduites d’eau recommandées sont en acier noir et en cuivre.

• Les tuyaux doivent être fixés avant de raccorder le tuyaux de l’installation pour evitér de tordre les tuyauteries de

l’appareillors du serrage des raccords.

• Il est recommandé aux utilisateurs de mettre en place les tuyaux et les accessoires comme indiqué dans la Figure 6.

• Une vanne de purge doit être installé sur lapartie la plus haute, ains, qu’une vanne de drainage sur la partie la plus basse du

circuit de l’eau.

• Faire passer de l’eau propre côté “IN” entrée d’eau et actionner la pompe pour evacuer l’eau chargée de particules côté

“OUT”. Nettoyer le filtre après 30 minutes de fonctionnement de la pompe.

• Remplir le circuit d’eau après avoir raccordé tous les tuyaux et l’appareil. Vérifier qu’il n’y a pas de fuites sur tous les

raccordements et les assemblages. Ne pas démarrer l’appareil en cas de fuite.

• Dans le but d’optimiser la capacité du système, s’assurer qu’il n’y ait pas de bulles d’air. Et aussi afin déviter le phénomène

de cavitation.

!!

!!

! AVERTISSEMENT

• Ne pas laisser d’eau dans les tuyauteries si l’appareil ne doit pas être utilisé pendant une longue période.

L’eau doit être vidangée si l’appareil ne sert pas en hiver. Le non-respect de cette précaution peut provoquer la

rupture des tuyaux.

• Ne pas consommer l’eau refroidie par l’appareil.

P

4AC/AC 020/025/030 C/CR

4AC/AC 040/050/060 C/CR

MANOMÈTRE

VANNE

VANNE

SOUPAPE

EQUILIBRANT

THERMOMÈTRE

FLEXIBLE

VANNE (POSITION LA PLUS

BASSE POUR LE DRAINAGE)

PURGE (INSTALLE LA

PLUS HAUTE POSITION)

UNITE AIR DE VENTILATEUR

VANNE

Figure 6

THERMOMÈTRE

VANNE

VANNE

SOUPAPE

EQUILIBRANT

STRAINER

SOUPAPE

DE

CHÈQUE

FORME LA

SOUPAPE

ROBINET DE DÉRIVATION

(TYPE DE PRESSION DIFFÉRENT)

MANOMÈTRE

VANNE

VANNE

SOUPAPE

EQUILIBRANT

THERMOMÈTRE

FLEXIBLE

VANNE (POSITION LA PLUS

BASSE POUR LE DRAINAGE)

PURGE (INSTALLE LA

PLUS HAUTE POSITION)

UNITE AIR DE VENTILATEUR

VANNE

THERMOMÈTRE

VANNE

VANNE

SOUPAPE EQUILIBRANT

STRAINER

SOUPAPE

DE

CHÈQUE

FORME LA

SOUPAPE

ROBINET DE DÉRIVATION

(TYPE DE PRESSION DIFFÉRENT)

EQUIPEMENT ELECTRIQUE ET CÂBLAGE

• Pour le câblage électrique se reporter au schéma de câblage fourni avec l’appareil.

• Pour la mise à terre, ne raccorder pas les équipments électriques aux tuyaux d’eau.

• Installer un interrupteur isolant externe (s’il n’est pas fourni) pour prévenir une électrocution.

Page 37

2-8

Français

4AC020C/CR 4AC025C/CR 4AC030C/CR 4AC040C/CR 4AC050C/CR 4AC060C/CR

Modèles

AC020C/CR AC025C/CR AC030C/CR AC040C/CR AC050C/CR AC060C/CR

Plage de tension

** 220 ~ 240V /1Ph /50Hz + N + ! 380 ~ 415V /3Ph /50Hz + N + !

Fusibles préconisés

* A273845222429

Section du câble d’alimentation électrique

* mm

2

10 10 10 5 5 5

Nombre des conducteurs

333 555

Section du câble d’interconnexion

* mm2 1,5 1,5 1,5 1,5 1,5 1,5

DONNÉES ÉLECTRIQUES

Table B-1 : (R407C - Froid Seul)

Modèles 4AC020C 4AC025C 4AC030C 4AC040C 4AC050C 4AC060C

Alimentation électrique V-ph-Hz 230 / 1/ 50 400 / 3 / 50

Plage de tension V 220 - 240 380 - 415

Puissance nominale d’alimentation kW 2,62 2,96 3,69 4,94 5,97 6,88

Courant nominal d’alimentation A 12,7 13,59 17,48 9,29 10,22 12,93

Courant continu maximal A 18,3 23 27 14 14 17

Intensité de pleine charge (IPC)

A 14 17,5 22,5 12,4 11,8 14,3

Intensité à rotor bloqué (IRB) A 57 82 114 65,5 74 101

Puissance d’alimentation de la pompe W 183 189 199 320 345 349

Froid Seul / Pompe à Chaleur

SECTIONS DES CABLES ET FUSIBLES DE PROTECTION

IMPORTANT : * Les valeurs ci-dessus ne sont données qu’à titre indicatif. Elles doivent, par conséquent, être vérifiées et choisies de

façon à répondre aux lois et aux réglementations en vigueur dans le pays concerné. Elles sont en plus fonction du type

d’installation et des conducteurs utilisés.

**La plage de tension adaptée doit être comparée avec des données inscrites sur la plaque de l’appareil.

!!

!!

! AVERTISSEMENT

• Tous les câblages de l’installation doivent répondre aux réglementations électriques nationales.

• Toutes les bornes et les connexions doivent être serrées. Des mauvais raccordements électriques peuvent provoquer des chocs

électriques, des court-circuits et être la cause d’incendie.

• Avant de commencer le raccordement suivant le schéma électrique, s’assurer que la tension nominale de l’appareil correspondra

bien à celle indiquée sur la plaque signalétique.

• L’unité doit être raccordée à la TERRE pour prévenir tous les risques des pertes électriques suite à une rupture de l’isolant.

• Aucun câble électrique ne doit toucher la tuyauterie du réfrigérant, le compresseur, la pompe, le moteur du ventilateur ou

toutes autres pièces mobiles des moteurs de ventilation.

• Ne pas faire fonctionner le mini-refroidisseur avec des mains humides. Cela peut causer des chocs électriques.

• Ne pas utiliser des fusibles avec un ampérage différent de celui préconisé. L’utilisation d’un fil électrique ou similaire, au lieu

et place d’un fusible peut causer des dégâts ou un incendie.

Table B-2 : (R22 - Froid Seul)

Modèles AC020C AC025C AC030C AC040C AC050C AC060C

Alimentation électrique V-ph-Hz 230 / 1/ 50 400 / 3 / 50

Plage de tension V 220 - 240 380 - 415

Puissance nominale d’alimentation kW 2,68 2,74 3,50 4,50 5,26 6,38

Courant nominal d’alimentation A 12,64 12,11 16,70 8,80 9,30 12,32

Courant continu maximal A 18,3 23 27 14 14 17

Intensité de pleine charge (IPC)

A 14 16,5 21,4 10,5 11,3 12,3

Intensité à rotor bloqué (IRB) A 57 82 114 65,5 74 101

Puissance d’alimentation de la pompe W 175 190 201 320 345 351

Table B-3 : (R407C - Pompe à Chaleur)

Modèles 4AC020CR 4AC025CR 4AC030CR 4AC040CR 4AC050CR 4AC060CR

Alimentation électrique V-ph-Hz 230 / 1/ 50 400 / 3 / 50

Plage de tension V 220 - 240 380 - 415

Puissance nominale d’alimentation kW 2,61/2,69 3,09/2,75 3,82/4,00 4,85/5,01 5,47/5,66 6,53/6,28

Courant nominal d’alimentation A 12,69/12,99 14,3/14,1 19,29/20,19 9,13/9,23 9,59/9,96 12,77/12,67

Courant continu maximal A 18,3 23 27 14 14 17

Intensité de pleine charge (IPC)

A 14 17,5 22,5 12,4 11,8 14,3

Intensité à rotor bloqué (IRB) A 57 82 114 65,5 74 101

Puissance d’alimentation de la pompe W 173/181 186/195 194/214 320/334 336/347 347/358

Table B-4 : (R22 - Pompe à Chaleur)

Modèles AC020CR AC025CR AC030CR AC040CR AC050CR AC060CR

Alimentation électrique V-ph-Hz 230 / 1/ 50 400 / 3 / 50

Plage de tension V 220 - 240 380 - 415

Puissance nominale d’alimentation kW 2,61/2,70 2,95/2,83 3,55/3,56 4,59/4,65 5,07/5,01 6,57/6,26

Courant nominal d’alimentation A 12,38/12,73 13,4/12,8 18,24/18,37 8,67/8,78 8,99/8,95 13,49/13,03

Courant continu maximal

A 18,3 23 27 14 14 17

Intensité de pleine charge (IPC)

A 14 16,5 21,4 10,5 11,3 12,3

Intensité à rotor bloqué (IRB)

A 57 82 114 65,5 74 101

Puissance d’alimentation de la pompe W 175/186 189/194 201/211 320/329 336/349 351/357

Page 38

2-9

P

P

4AC / AC 020C/ 025C/ 030C

Schéma Du Circuit D’Eau / De Réfrigération

FILTRE

DÉSHYDRATEUR

TUYAU CAP.

BPHE

COMPRESSEUR

POMPE À EAU

SOUPAPE DE DÉCHARGE

AUTOMATIQUE

SORTIE

D’EAU

ENTRÉE

D’EAU

RÉSERVOIR

D’EXPANSION

RÉSERVOIR DE

STOCKAGE DE L’EAU

4AC / AC 040C/ 050C/ 060C

Schéma Du Circuit D’Eau / De Réfrigération

FILTRE

DÉSHYDRATEUR

TUYAU CAP.

BPHE

COMPRESSEUR

POMPE À EAU

SOUPAPE DE DÉCHARGE

AUTOMATIQUE

SORTIE

D’EAU

ENTRÉE

D’EAU

RÉSERVOIR

D’EXPANSION

RÉSERVOIR DE

STOCKAGE DE L’EAU

NO D’ARTICLE : 70-03-4-067460

NO D’ARTICLE : 70-03-4-087461

Page 39

2-10

Français

P

P

4AC / AC 020CR/ 025CR/ 030CR

Schéma Du Circuit D’Eau / De Réfrigération

CLAPET

ANTI

RETOUR

BPHE

COMPRESSEUR

COMPENSATEUR

DE CHARGE

SOUPAPE DE DÉCHARGE

AUTOMATIQUE

SORTIE

D’EAU

ENTRÉE

D’EAU

RÉSERVOIR

D’EXPANSION

RÉSERVOIR DE

STOCKAGE DE L’EAU

NO D’ARTICLE : 70-03-4-067458

4AC / AC 040CR/ 050CR/ 060CR

Schéma Du Circuit D’Eau / De Réfrigération

BPHE

COMPRESSEUR

POMPE À EAU

SOUPAPE DE DÉCHARGE

AUTOMATIQUE

SORTIE

D’EAU

ENTRÉE

D’EAU

RÉSERVOIR

D’EXPANSION

RÉSERVOIR DE

STOCKAGE DE L’EAU

NO D’ARTICLE : 70-03-4-067459

CLAPET ANTI

RETOUR

FILTRE

DÉSHYDRATEUR

CAP.

CHAUFFAGE

TUYAU

CAP.

REFRIGERATION

BOUTEILLE

ANTICOUP DE LIQUIDE

CLAPET ANTI

RETOUR

BOUTEILLE

ACCUMULATRICE

DE LIQUIDE

CLAPET ANTI

RETOUR

FILTRE

DÉSHYDRATEUR

CAP.

CHAUFFAGE

TUYAU

CAP.

REFRIGERATION

BOUTEILLE

ANTICOUP DE

LIQUIDE

Page 40

2-11

CIRCUIT FRIGORI FIQUE

• Les unités mini chiller sont pré-chargées avec réfrigérant R22 ou R407C.

PRÉCAUTIONS SPÉCIALES POUR LES APPAREILS AU R407C

• Le fluide R407C est un mélange réfrigérant zeótropique avec un potentiel de destruction de l’ozone de zéro et donc

conforme au ‘Protocole de Montréal’. Pour la lubrification du compresseur est nécessaire l’huile polyester (POE). Les

performances réfrigérantes du R407 sont équivalent à celles du R22.

• L'huile POE est utilisé comme lubrifiant pour les compresseurs R407C, et il est différent par rapport à l’huile minérale

utilisée pour les compresseurs R22. Lors de l’installation ou de la maintenance des précautions supplémentaires doivent

être adoptées pour ne pas exposer le système R407C trop de temps à l’air humide. L’huile POE résiduelle restée dans les

tuyauteries et les équipments peut absorber l’humidité de l’aria.

• Le réfrigérant R407C est plus facilement affecté par l’humidité par rapport à R22, s’assurer de protéger temporairement

les extrémités des tuyauteries avant de l’installation.

• Il n’est pas permis de rajouter de l’huile dans le compresseur.

• Aucun autre réfrigérant que le R407C n'est permis.

• Garder des instruments seulement pour le R407C (ils ne doivent pas être utiliser pour le réfrigérant R22 ou autres)

i) Manifold et flexible de charge

ii) Détecteur de fuite de gaz

iii) Cylindre de charge/bouteille de réfrigérant

iv) Adaptateur c/w pompe à vide

v) Citalumeau et outillage à flare

vi) Machine de récupération du réfrigérant

!!

!!

! AVERTISSEMENT

• La charge du R407C doit être réalisée en phase liquide. Normalement la bouteille de R407C est équipé d’un tube

plongeur pour le prélèvement du liquide. Si la bouteille n’est pas pourvu de ce tube il doit être inversé de façon à

prélever le liquide au moyen de la vanne.

• Ne pas rajouter en cas de réparation de fuites afin de ne pas réduire les performances de l’appareil. Vidanger

complètement l’unité pour la recharger avec de R407C frais suivant le poids préconisé dans les spécifications techniques.

• Ne pas toucher le compresseur ou la tuyauterie du réfrigérant lorsque le mini-refroidisseur est en marche. Porter des

gants si besoin est.

MONTAGE DES CONDUITES D’EAU

• Remplir le circuit d’eau après avoir connecté tous les tuyaux et l’équipement. Effectuer des contrôles d’étanchéité à tous

les raccordements et les assemblages. Ne pas démarrer l’unité s’il y a une fuite.

• Pour optimiser la capacité de l’appareil, vérifier qu’il ne contient aucune bulle d’air. L’air emprisonné à l’intérieur causerait

un déséquilibre de l’appareil.

• Vérifier que la cuve à eau n’est pas pleine. C’est pour assurer une performance optimale du mini-refroidisseur. Si la

pression est trop élevée, dégager la pression du réservoir en activant sa soupape de décharge automatique.

Page 41

2-12

Français

1. Emplacement de la commande

Le combiné se situe dans la boîte de jonction derrière le panneau de service.

2. Afficheur LED (carte microprocesseur)

Les voyant seront allumés, dés la mise sous tension l’appareil.

L’écran LCD sera allumé dès que l’appareil est allumé.

3. Afficheur LCD (clavier de commande)

Lors des normales opérations, l’afficheur LCD visualise la température d’entrée d’eau. Lorsqu’un disfonctionnement

arrive, l’afficheur LCD clignote et l’alarme disparaît. Sur l’afficheur les paramètres défectueux sont visualisés.

4. Caractéristique de fonctionnement du contrôleur

Un délai de 3 minutes est prévu pour le redémarrage du compresseur et du moteur du ventilateur (réglage par défaut).

UNITÉ DE CONTRÔLE DES OPÉRATIONS

L’unité est équipée d’un module de contrôle à microprocesseur. Le module de contrôle à microprocesseur contrôle la température

pour le système en mesurant exactement et en contrôlant la température d’entrée d’eau et de sortie. Le réglage de la température

de l’appareil est préréglé en usine. Il n’est pas conseillé de changer ce réglage sauf dans les cas vraiment nécessaires. Un

boitier de commande ccp est relié électriquement à la carte microprocesseur. Tous les réglages et les lectures des paramètres

peuvent être visualisés au moyen de l’afficheur à cristaux liquides du clavier.

!!

!!

! AVERTISSEMENT

• Utiliser le clavier de la commande pour allumer/éteindre l’appareil. Ne pas débrancher directement l’alimentation

électrique principale, cela engendrerait des dommages à l’appareil.

• Ne pas modifier le réglage des dipositifs de sécurité.

• Installation

Pour bloquer le panneau LCD sur le support,

Point 1 Point 2

Accrochez

l’afficheur à

cristaux liquides en

commençant par le

haut

Commencer à enlever le

panneau LCD par le

haut

Page 42

2-13

• Entretien

L’entretien ou la maintenance de ces unités doit être effectuée par du personnel qualifié avec une formation particulière à la

réfrigération. Vérifier maintes fois les sécurités et le cycle continu des contrôles. Ces éléments doivent être analysés et corrigés

avant d’être réinitialisés.

Le simple modèle du circuit de réfrigération élimine totalement les problèmes potentiels au cours de l’exploitation normale de

l’unité. Aucune maintenance du circuit de réfrigération n’est requise tant que l’unité fonctionne normalement.

La facilité de maintenance a été prise en compte à l’étape de la conception, où on a rendu l’unité accessible grâce à des

panneaux de service. Les equipments électriques sont d’un accès particulièrement facile parcequ’ils sont situés dans la boîte

de jonction du panneau de service avant (Figure 7).

ENTRETIEN ET MAINTENANCE

Figure 7

1. Une batterie ‘A’ de 3 V. D.C. è fournie avec l’afficheur à cristaux liquides sert à garantir que ce dernier indique l’heure

exacte si le minuteur est activé.

2. L’afficheur à cristaux liquides est branché à la carte principale à l’aide de la connexion CN8. (Ce branchement est effectué

en usine).

Prévoir une connexion supplémentaire s’il est nécessaire d’avoir une connexion plus longue entre l’afficheur et PCB.

Utiliser un câble de 4 fils ayant la longueur voulue et le brancher entre le plot terminal CN2 sur l’afficheur et le plot

terminal CN5 sur PCB. Contrôler si les cosses des câbles sont fixées correctement.

3. Il est également possible de créer un réseau de plusieurs chillers. Brancher les câbles de la façon suivante.

Pour enlever le panneau LCD du support,

Point 1 Point 2

Retirez l’afficheur à cristaux

liquides en commençant par

le bas à l’aide d’un tournevis

Enlever le

panneau

LCD

Installé en usine

Connexion supplémentaire entre le panneau et PCB

Uniquement pour créer un réseau

A

A

A

B

B

B

12V

12V

12V

GND

GND

GND

JP13

CN8

CN2

CN5

Carte Principale 00

Panneau

LCD

Unit PCB 01

Page 43

2-14

Français

RECHERCHE ET ANLYSE DES PANNES

En cas de disfonctionnement, mettre immédiatement hors tension l’appareil et, si besoin est, contacter le distributeur local.

Certains suggestions pour le dépannage de l’appareil sont indiquées ci-après :

1. Le compresseur ne

démarre pas.

2. Le ventilateur ne

fonctionne pas.

3. Le nanque de puissance d’u.

4. Mauvaise

circulation d’eau

SYMPTÔMES CAUSES POSSIBLES REMÈDES

• Pas de tension.

• Disjocteurs défectueux.

• Contacteur ou bobine défectueux

• Le système s’est arrêté à cause d’une

sécurité déclenchée.

• Fils lâches.

• Compresseur en panne.

• Pas de tension.

• Moteur du ventilateur défectueux.

• Réglage du thermostat trop élevé.

• Batterie condenseur sale.

• Obstructions en entrée et sortie d’air de

l’appareil.

• Réfrigérant de l’appareil insuffisant.

• Débit d’air irrégulier.

• Eau dans l’appareil contaminé.

• Pas d’eau dans l’appareil.

• Niveau d’eau insuffisant dans l’appareil.

• Vérifier l’alimentation.

• Vérifier s’il y a eu un court-circuit ou des fils

à terre dans la bobine du moteur. Apres avoir

éliminé le défaut, remplacer les fusibles et

enclencher les disjoncteurs. Contrôler les

résistances et la tenue des raccordements

électriques.

• Réparer ou remplacer.

• Identifier le type d’arrêt de sécurité et éliminer

le défaut avant de redémarrer l’appareil.

• Contrôler les raccordements des fils et serrer

les vis des bornes.

• Contacter le distributeur local.

• Vérifier l’alimentation.

• Contacter le distributeur local.

• Remettre en état d’origine le thermostat.

• Contacter le distributeur local.

• Eliminer l’obstacle.

• Contacter le distributeur local.

• Contacter le distributeur local.

• Contacter le distributeur local.

• Vérifier l’arrive d’eau.

• Vérifier l’arrive d’eau.

!!

!!

! AVERTISSEMENT

•

Les opérations de dépannage doivent être réalisées par du personnel qualifié.

Dans des circonstances normales, ces refroidisseurs ne nécessitent qu’une vérification et un nettoyage de l’aspiration d’air par

la surface du condenseur. C’est à faire chaque mois ou chaque trimestre selon le milieu où les unités sont installées.