Page 1

AM - MAC

Page 2

Contents

Introduction .............................................................................................................. 1 - 3

1. Chiller Mounting ................................................................................................... 4 - 8

2. Water Pipe Circuit............................................................................................... 9 - 27

3. Water Pipe and Fittings ................................................................................... 28 - 66

4. Pipe and Fitting Size ....................................................................................... 67 - 72

5. Water Pump ..................................................................................................... 73 - 86

6. Water Storage Tank and Expansion Tank ..................................................... 87 - 93

7. Insulation Material ......................................................................................... 94 - 106

8. Pipe Support ......................................................................................................... 107

9. Water Side Treatment .................................................................................. 108 - 114

10. Heating Operation ...................................................................................... 115 - 120

11. Electrical Wiring Control ............................................................................ 121 - 140

12. Flow Switch................................................................................................. 141 - 145

13. System Balancing....................................................................................... 146 - 148

14. Chiller Shut Down....................................................................................... 149 - 150

Appendix (Appendix 1-19) ...............................................................................37 Pages

Copyright©2003 by McQuay International. All rights reserved. This publication is strictly confidential and

is meant for DISTRIBUTORS of McQuay International only. No part of this publication may be reproduced

or distributed in any form or by any means, or stored in a data base or retrieval system, without the prior

written permission of McQuay International.

Page 3

Introduction

The air-cooled mini chillers form part of a complete integrated water hydronic system with the

chiller water fan coil units. The range of capacity from 30,000 Btu/hr to 150,000 Btu/hr (8.79 –

43.96 KW) makes them suitable for various applications:

- Office Rooms

- Private Houses

- Business Rooms

- Club, Pubs, Coffee Houses

- Hotels

- Restaurants

- Process Cooling

The advantages of using these chillers are:

1. Due to its compact design, the mini-chillers require a smaller space for installation.

The design also allows for flexibility in design to meet various types of application

requirements.

2. The amount of refrigerant used is small compared with other split and multi-split direct

expansion systems, i.e. they are more environmental friendly.

3. There is no necessity to use cooling towers.

4. No refrigerant is used in the occupied space.

5. The usage of water as the cooling medium allows for excellent load variability with minimal

system complexity as against equivalent VRV systems.

6. Ability to have long piping distances.

A water hydronic system can be classified as a close

or open system.

Definition

: A close water system is one with no more than one point of interface with a

compressible gas or surface. [ASHRAE handbook: 1996 System & Equip.]

The basic design of the mini-chiller is for a close system. However, a modification for an open

system is possible.

The close hydronic system will consist of the following fundamental components:

a. Source

b. Load

c. Expansion Tank

d. Pump

e. Distribution System

Introduction Page 1

Page 4

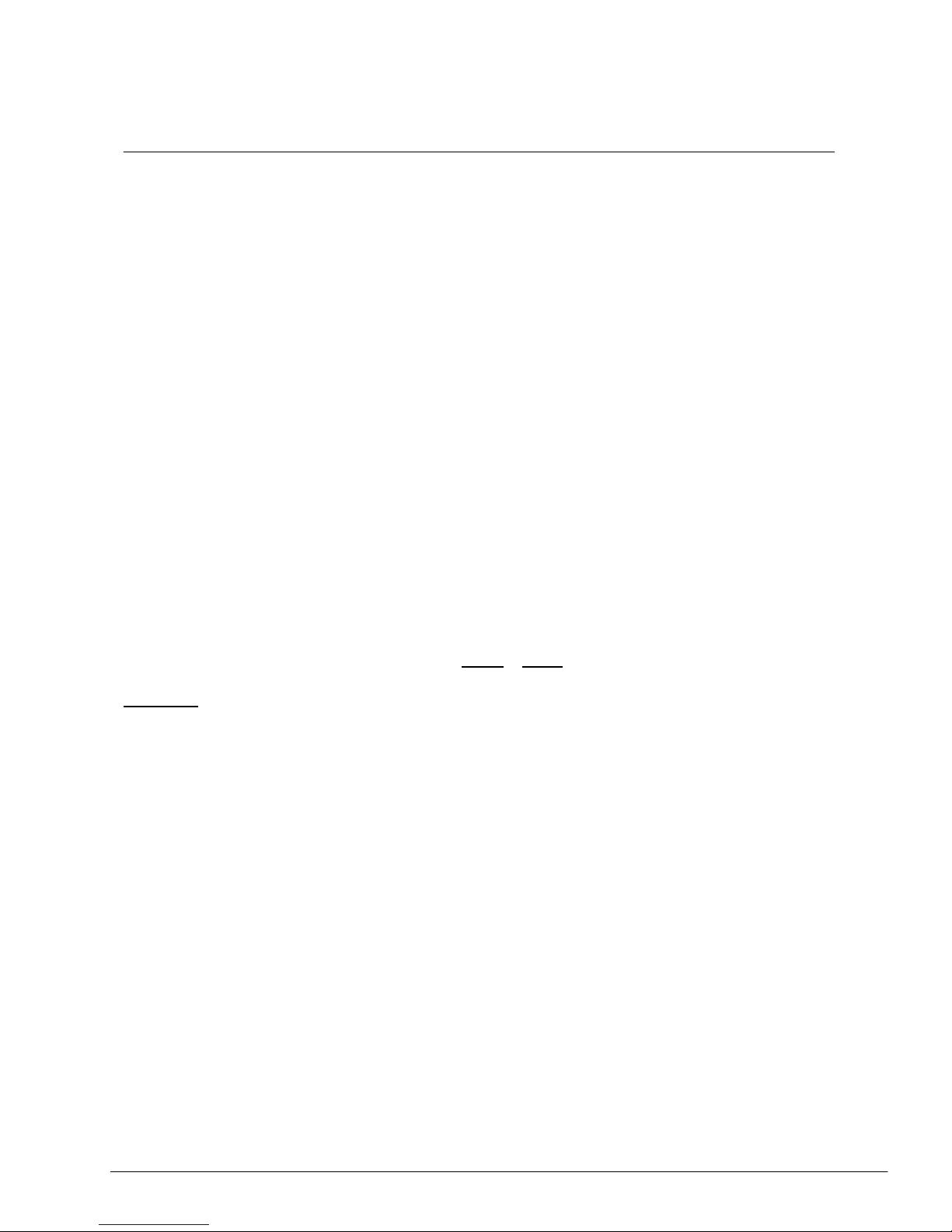

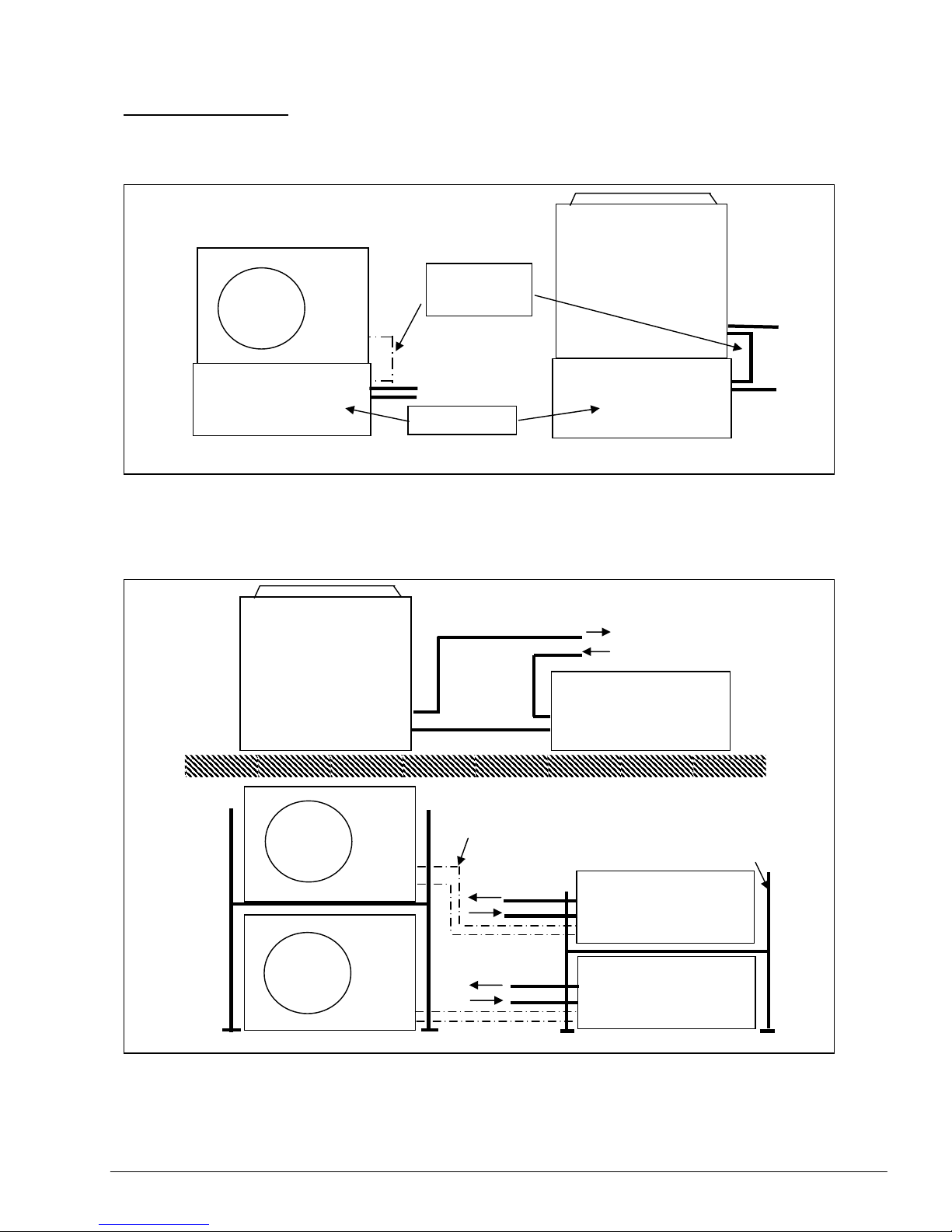

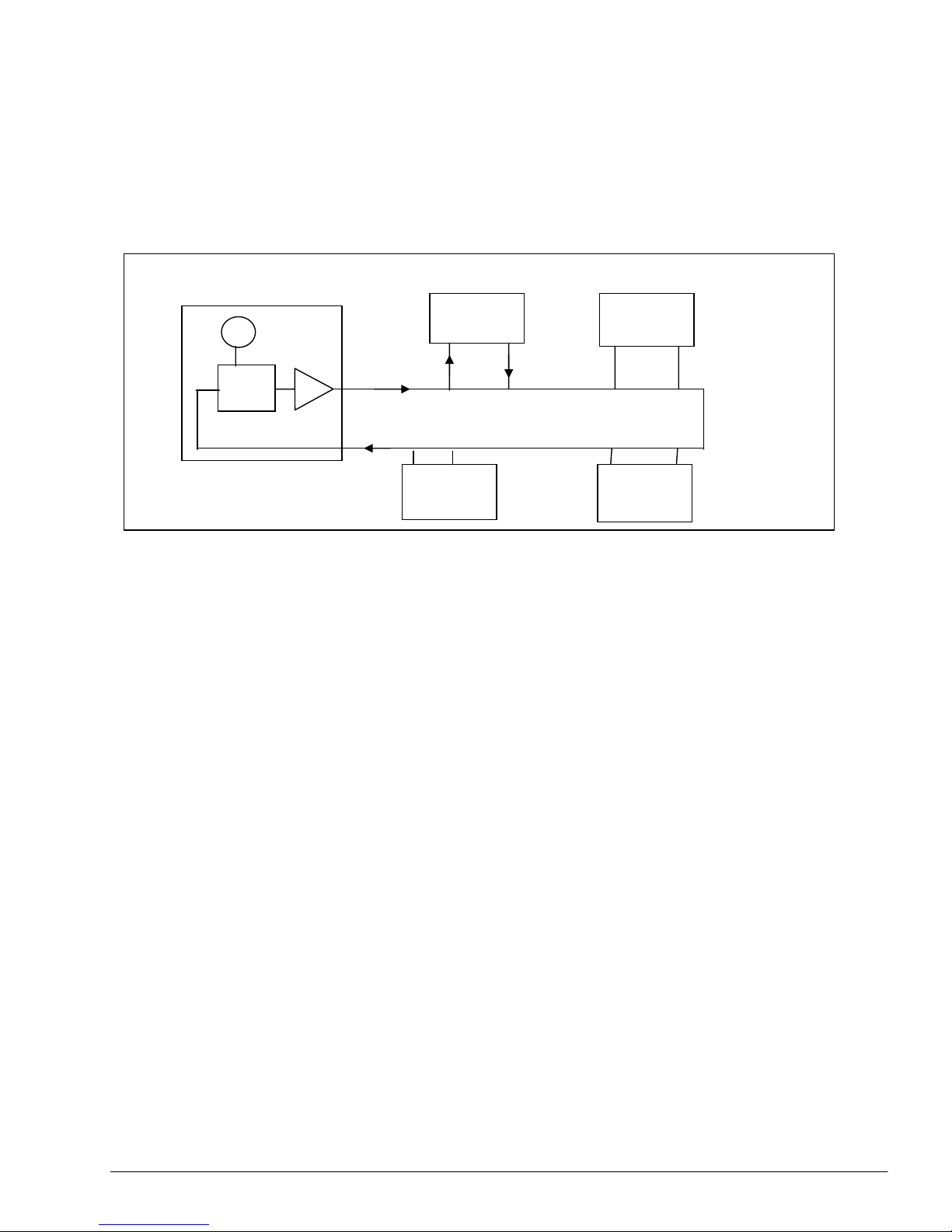

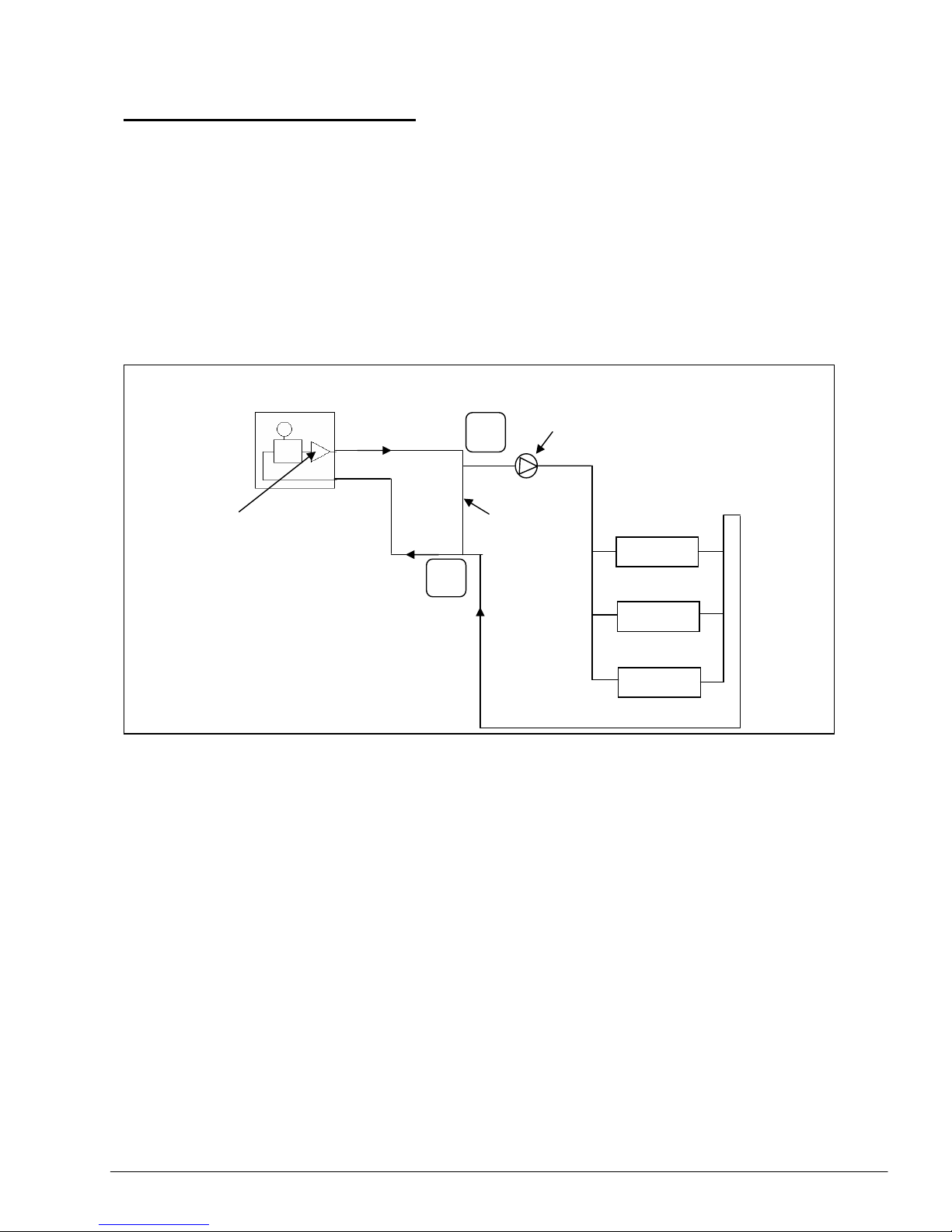

Schematic diagram of the basic close hydronic system:

Expansion

tank

Heat Pump Heat

Distribution system

SOURCE LOAD

In the mini chiller, the source will comprise of the refrigeration circuit, i.e. compressor, expansion

device, condenser and evaporator. A brazed plate heat exchanger (BPHE) is used as the

evaporator to produce the chilled water.

A built-in water tank is also provided in the mini chiller to act as a buffer storage. See next page.

For integration, both the expansion tank and pump are incorporated together into the mini chiller.

Hence, the schematic diagram of the system becomes as follows:

Introduction Page 2

Page 5

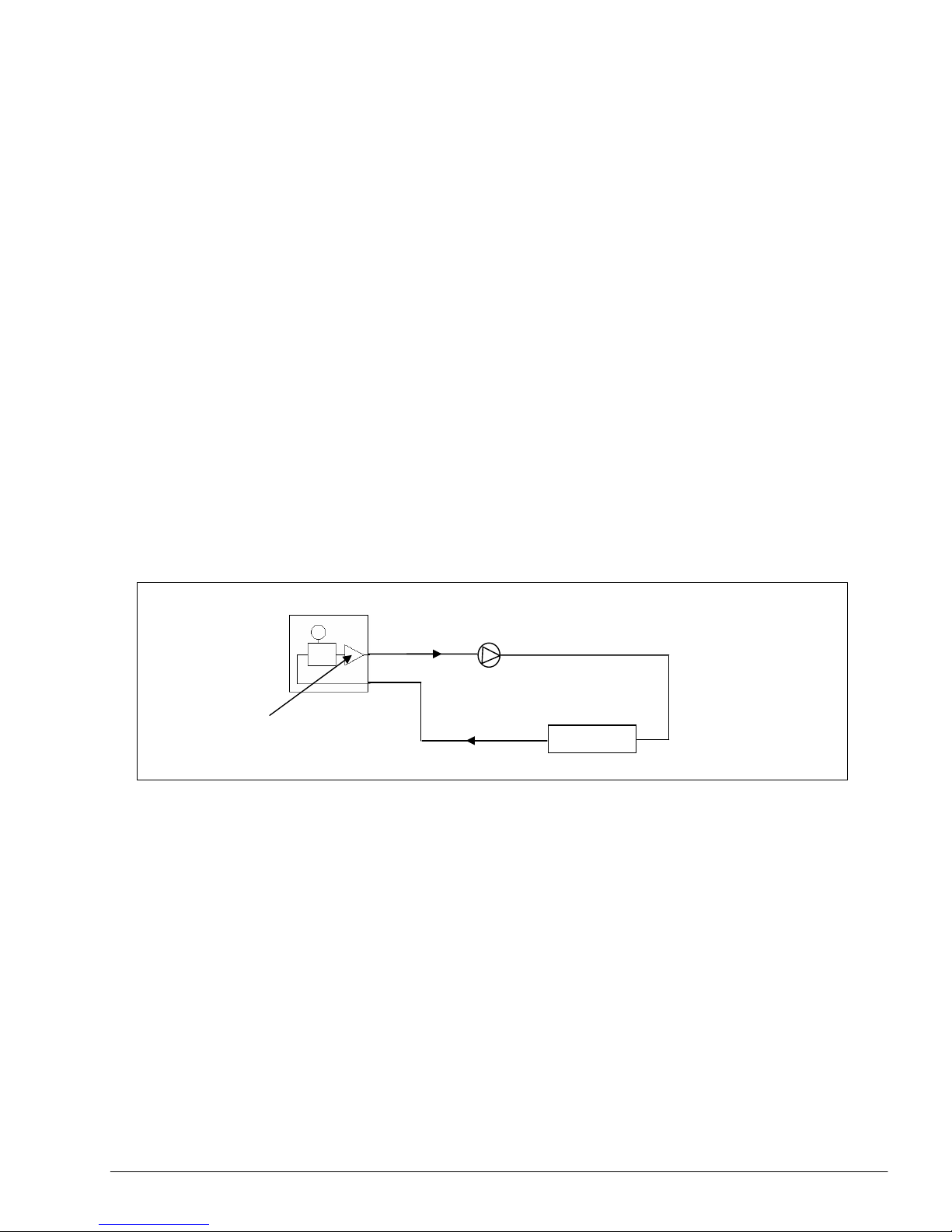

If both chilled water and hot water are required in the system, a mini chiller with a reverse

cycle operation will be used. The unit will have an additional 4-way valve and accumulator for

this purpose.

It is by such integration of components of the hydronic system that the mini chiller becomes

compact. Installation of the chiller will thus only involve:

1. The chiller mounting

2. Indoor fan coil unit installation

3. Water piping installation between the chiller and fan coil unit

4. Electrical wiring connection

This manual is written with the purpose of providing guidelines as to the installation and operation

of the hydronic system; i.e. both the chiller and fan coil unit. Application design guidelines will also

be discussed. Selection criteria of piping, valve, pump and other equipment are also given.

Examples of such complete installations are as shown in the following pages. This manual will

give some technical information and details on how such installations are designed and done

at site.

In general, there are three series of mini chillers available:

a) A series (from 30,000 Btu/hr [8.79 kW] to 50,000 Btu/hr [14.65 kW])

- double stack design, with built-in buffer tank

b) B series (from 75,000 Btu/hr [21.98 kW] to 125,000 Btu/hr [36.64 kW])

- double stack design, with built-in buffer tank

c) C series (from 80,000 Btu/hr [23.45 kW] to 150,000 Btu/hr [43.96 kW])

- monoblock design, without buffer tank

This manual must be used in conjunction with the Technical Manual and Installation and

Operation Manual (IOM) of the mini chillers and chilled water fan coil units.

Introduction Page 3

Page 6

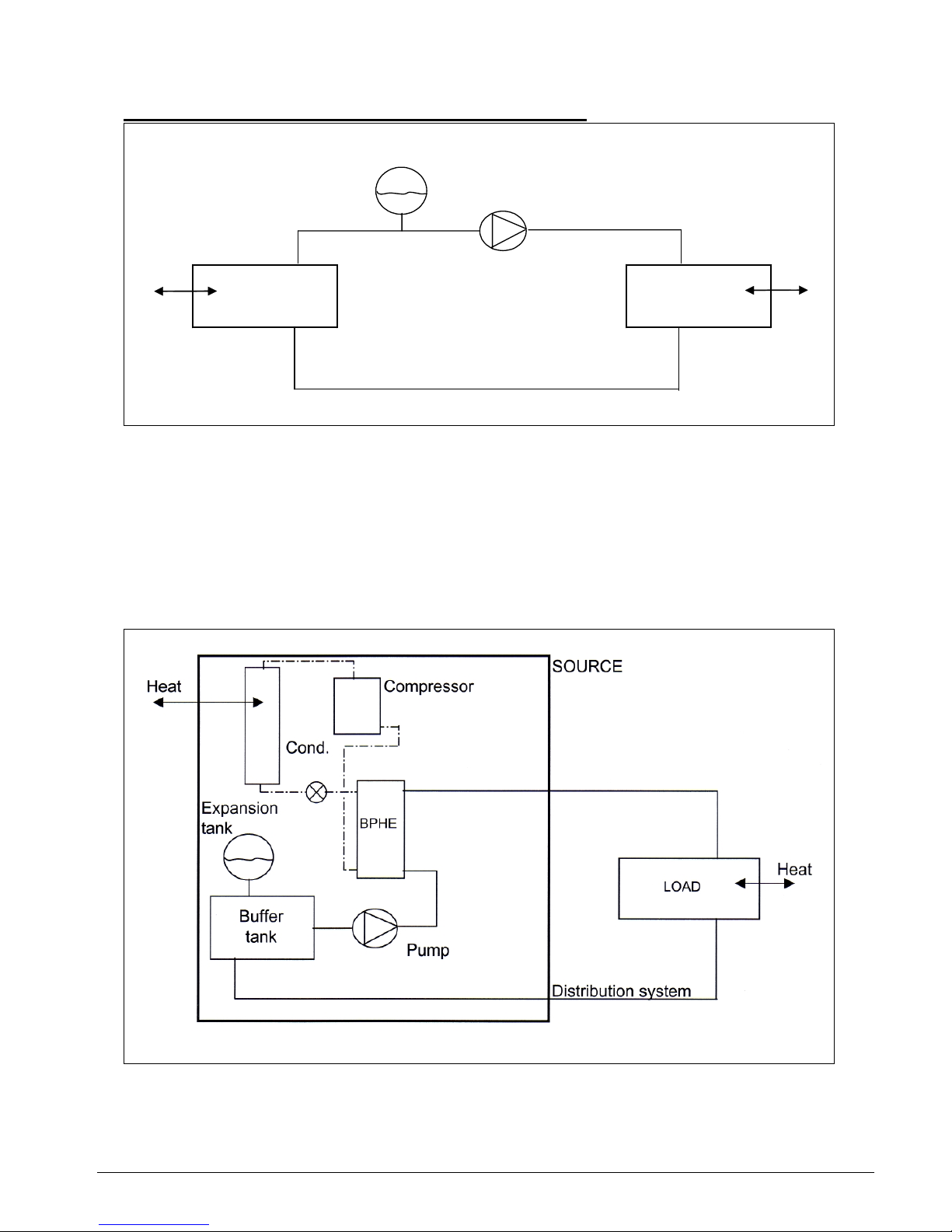

Section 1: Chiller Mounting

Care must be taken to locate the air-cooled chiller at the proper place. Ensure sufficient

clearance around the unit to allow proper air flow and to facilitate access for maintenance.

Location of the units must also prevent short-circuiting of the discharge air. Do not block any air

passage in and out of the units.

Please refer to the corresponding Technical Manual for further information.

The chiller unit must be placed on a firm surface, e.g. concrete flooring, slab or plinth. Due

to space consideration, the chiller may be mounted onto a steel bracket which is secured to

a firm surface, e.g. brick wall, concrete wall or a steel structure.

concrete flooring

Series B Chiller

Plinth

Wall

Steel bracket

Plinth

Section 1 Page 4

Page 7

Such brackets must have sufficient strength to carry the weight of the chiller unit. It is

recommended that angle bars (e.g. 38mm*38mm*3mm

t

) or hollow section bars (e.g. 25mm*

50m*2mm

t

) to be used for fabricating these brackets.

These brackets must also allow clearance for removal of service panels for maintenance

purposes.

In any case, it is vital that the chiller unit is secured firmly onto the concrete floor/slab or steel

bracket by using studs, wall plugs or bolts/nuts at the four (4) mounting holes located at the base

plate of the chiller. The weight of the chiller unit and the water pipe connections are not sufficient

to prevent unit movement should any sudden impact or strong vibrations occur in the unit. Failure

to do so may cause the water pipes to deform and break.

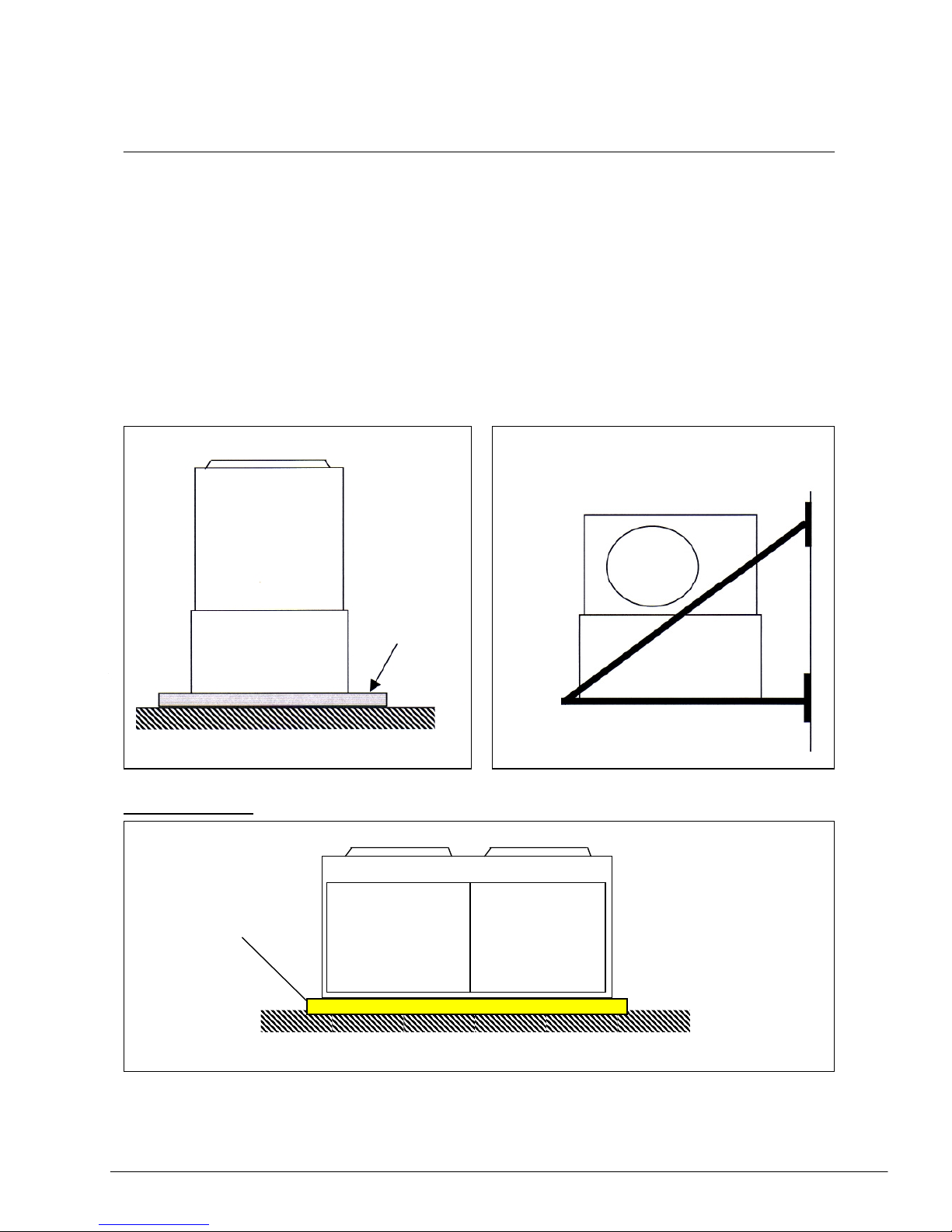

It is further recommended that rubber isolation pads (1/2" thick) to be placed beneath each

mounting hole to prevent excessive vibration and noise. If necessary, isolating springs can

also be mounted.

The following pages are examples of these isolation pads and springs.

Section 1 Page 5

Page 8

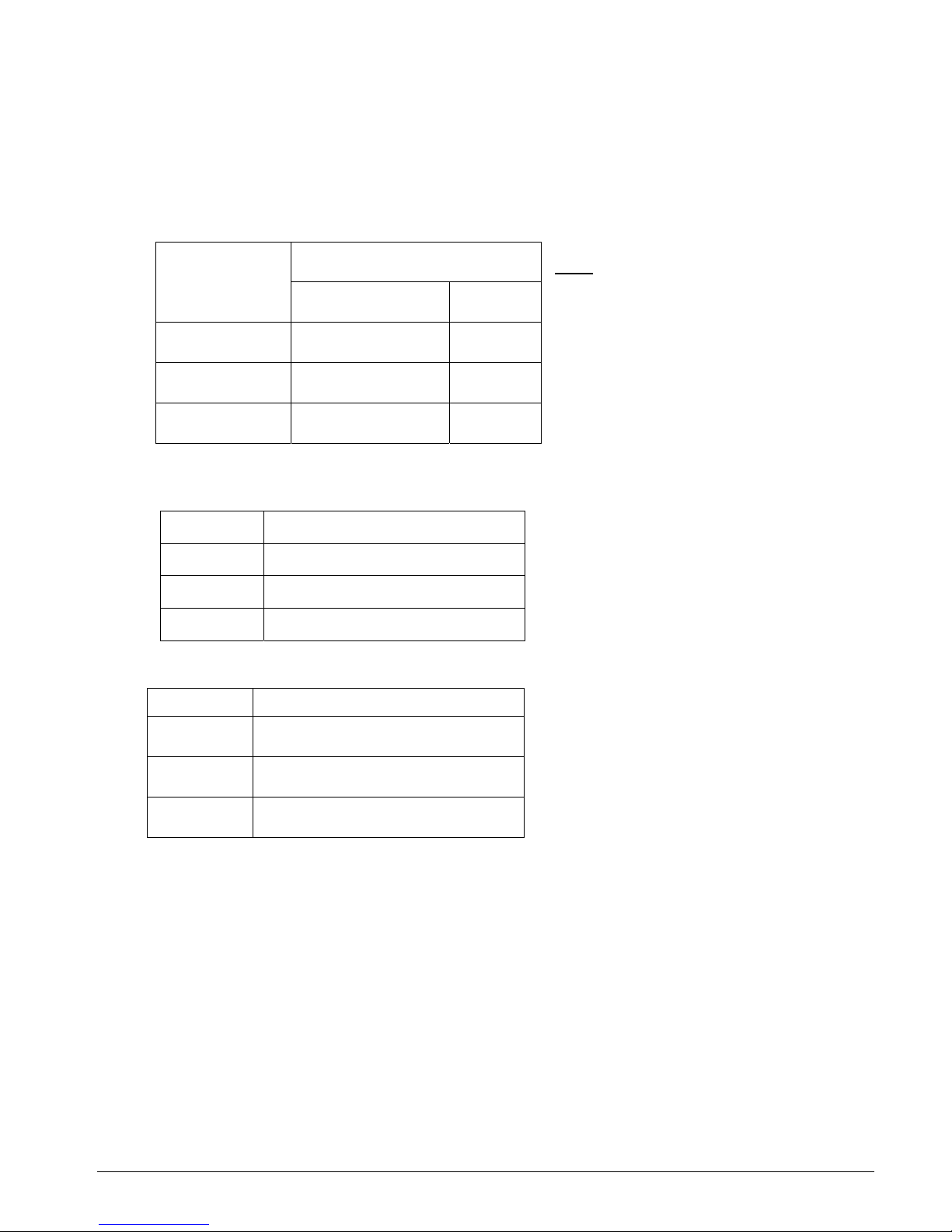

Special installation:

The A and B series mini chiller units have been designed with the refrigerant circuit located in the

top compartment and the hydraulic kit in the bottom compartment:

A-series B-series

Hydraulic kit

Piping

connection

Refrigerant

Water

B-series

A

-series

In some special installations whereby the available space (especially the height) is not

sufficient to install the chiller, it is possible to to detach these two compartments and install

them side by side. This is especially useful when there are multiple units which are stacked

together with a steel bracket.

Bracket

Hydraulic kit

Water

pip

es

Refrigerant pipe

connection

Hydraulic kit

Water pipes

Section 1 Page 6

Page 9

For the A-series type of mini chiller, the inter-connecting pipes between the two

compartments are the refrigerant pipes. For the B-series type, there is a water pipe in

between the two compartments.

Therefore, the detached installation of the A-series mini chillers is very similar to the

installation of a split type air-conditioning unit.

Note:

Gas line to be insulated with

tube insulation. Use the

correct size for each pipe, thickness

¼

”

Refrig. Pipe size

Liquid Gas

AC 040A

3/8” ¾”

AC 050A

3/8” ¾”

AC 058A

½” ¾”

Take care of the following items [for detached A-series installations]:

Maximum pipe length,m

AC 040C

20

AC 050C

20

AC 058C

20

a) Do not allow excessive refrigerant pipe

length between the two compartments.

Always choose the shortest path.

Long piping will cause high pressure

drops and reduces the capacity of the

system. Use the following

recommendations:

Maximum elevation, m

AC 040A

10

AC 050A

10

AC 058A

10

b) It is possible to have the hydraulic kit

higher or lower than the refrigerant

compartment. Do not allow excessive

elevation between these two

compartments. Use the following

recommendations:

If the elevation exceeds the above recommendations, care must be taken to ensure sufficient oil

return to the compressor. Use oil traps (one every 30ft height interval) or oil separators, if

necessary.

c) The longer pipe lengths will require more refrigerant charge for optimum

performance.

Recommendation: Additional 50g (R-22) for every 1 meter of connecting pipe length.

Similarly, additional refrigerant oil charge may be required.

Section 1 Page 7

Page 10

d) Use as few bends as possible in the pipe run. Each bend will cause extra pressure drop and

reduces the capacity of the system. Do not use more than 10 bends. For both A and B series chillers, locating the hydraulic kit at a far distance will also mean having a longer

water pipe length. This will incur a higher pressure head to the water pump in the chiller

unit. If not careful, this will reduce the water flow rate through the system and may cause

system failure, e.g. water freezing, compressor tripping.

Furthermore, the longer pipe will increase the cost of installation.

Always look for the closest possible locations for these two compartments.

External drain pan

In some instances, it is necessary to install an external drain pan beneath the unit to collect

any condensate water from the chiller unit. This is especially so for the heat pump versions

,where water will condense on the heat exchanger coil during the heating mode. Further more,

a lot of water will flow out during the defrost cycle.

Such external drain pans are needed when the chiller units are installed inside a plant

room where it is not appropriate for the floor to be wet. (Note A)

It is recommended that the drain pan to be fabricated out of galvanised iron (GI) sheet

metal, at least 0.8 mm in thickness. Allow the drain pan depth of about 20mm.

This external drain pan should be laid out on the floor first before placing the entire chiller

unit on top of it. It is recommended that the chiller unit to be raised up by 20 - 30mm from

the drain pan so as to prevent rusting of the chiller base pan.

Note A: Caution! Please ensure adequate ventilation in the plant room else the

chiller unit may trip.

Section 1 Page 8

Page 11

Section 2: Water Pipe Circuit

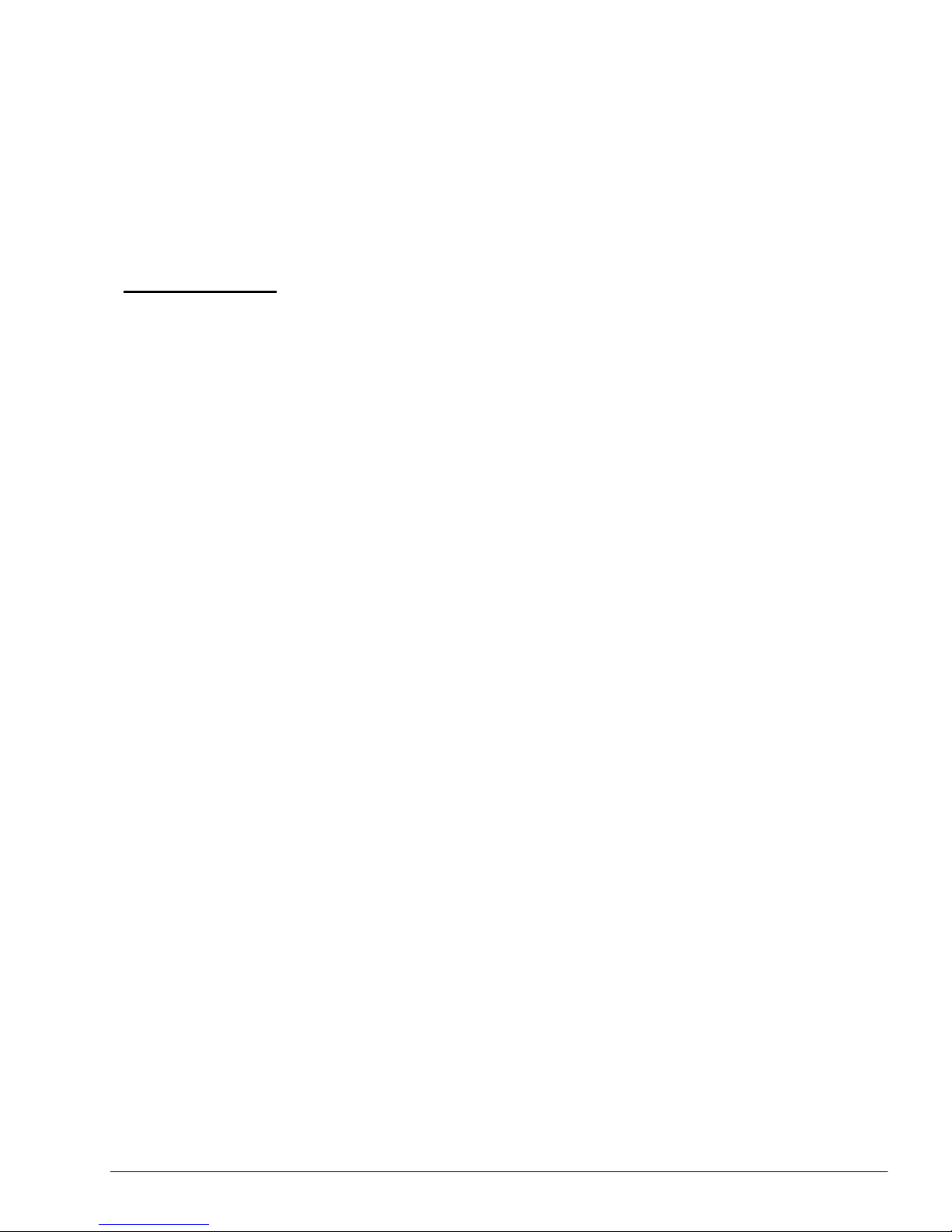

We have seen that the mini chiller has an integrated buffer storage tank, expansion tank and

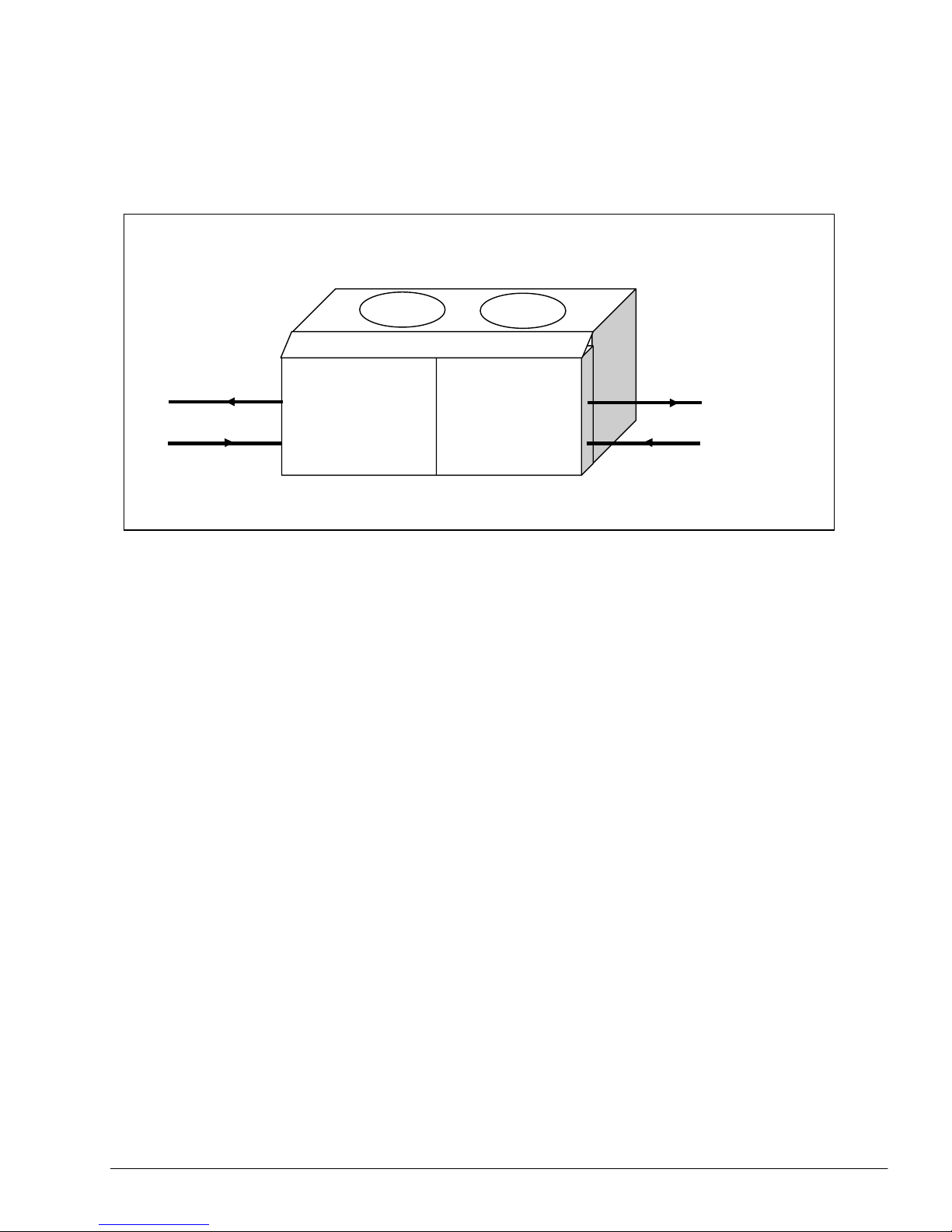

water pump together as one unit. Henceforth, we will represent the unit as such:

MINI CHILLER UNIT

In this section, we will look at the various piping circuits which we can use to connect the chiller

unit with the load fan coil units.

There are many different piping circuit configurations which can be used, depending on:

a) the geometry of the building

b) the available space for installation (e.g. the dimensions of the plant room)

c) the economics of installation

d) loading capability requirements

The general rule of thumb in designing and determining the piping circuit network is:

KEEP IT SIMPLE!

The more extensive a pipe network is, the more complex it is and it becomes more difficult to

analyse and control.

In general, there are 4 types of this pipe configuration:

1. Series

2. Diverting

3. Parallel direct return

4. Parallel reverse return

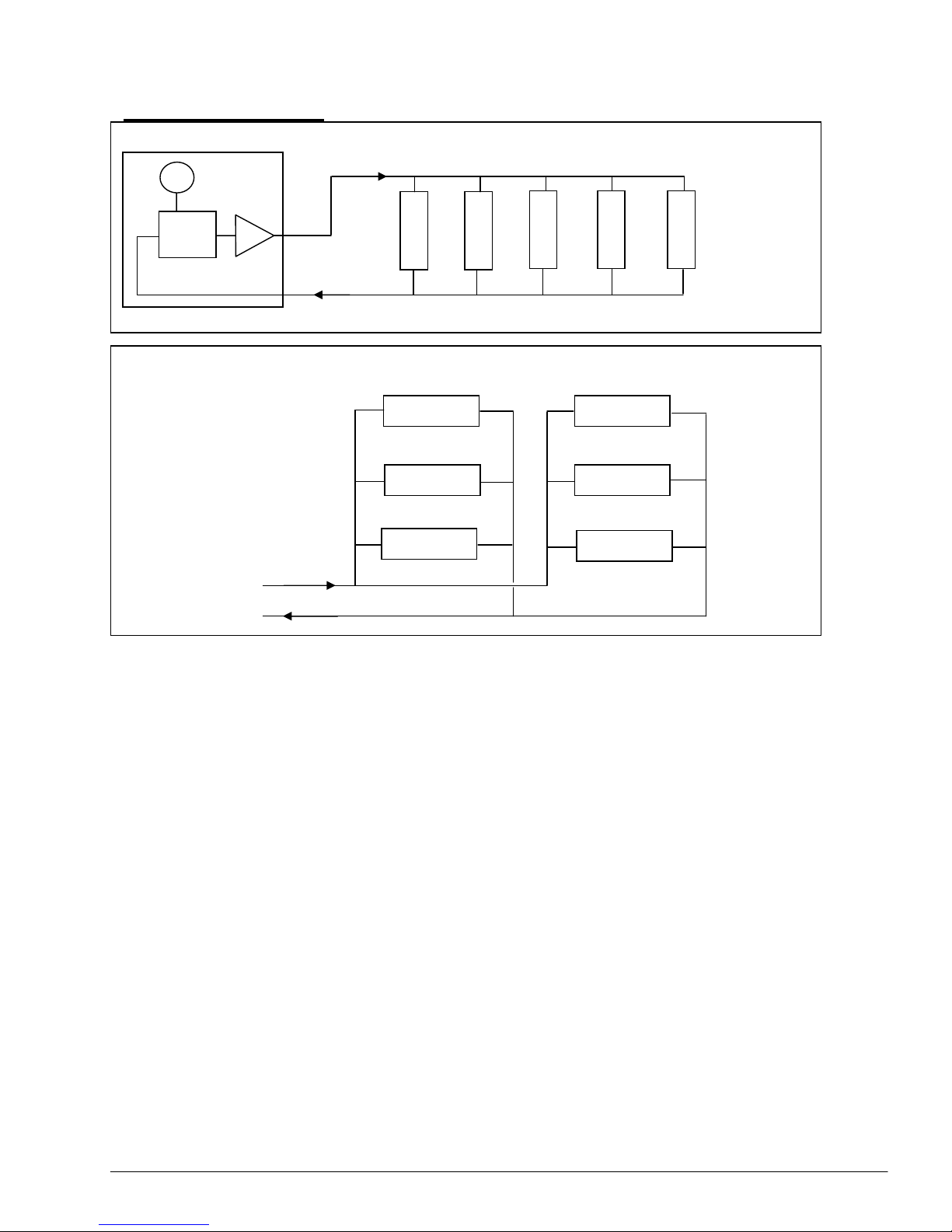

Series Circuit:

Note: For C-series, the buffer tank is not

applicable but the fundamentals of water piping

circuitry is still the same

Water out

Water in

LOAD

FCU 1

LOAD

FCU 4

LOAD

FCU 3

LOAD

FCU 2

Section 2 Page 9

Page 12

Advantages:

i. Lower piping cost

ii. High water temperature drops

Disadvantages:

i. Each fan coil loading cannot be controlled separately

Diverting Circuit:

LOAD

FCU 3

LOAD

FCU 1

LOAD

FCU 2

LOAD

FCU 4

Advantages:

i. Allows individual control to each fan coil unit

Disadvantages:

i. Only fan coil units with low pressure drops can be used

ii. Due to low water velocity in each fan coil, an air vent is required for

each fan coil

iii. Higher installation cost

iv. Water entering temperature for each fan coil is different, i.e. it gets

higher further away from the source

However, both the series and diverting circuits are seldom used in hydronic systems. The

more commonly used are the parallel circuits because they allow the same water

temperature to be available to all fan coil units.

It is recommended that the parallel circuits to be used in the installation of the mini chillers

with the fan coil units.

Section 2 Page 10

Page 13

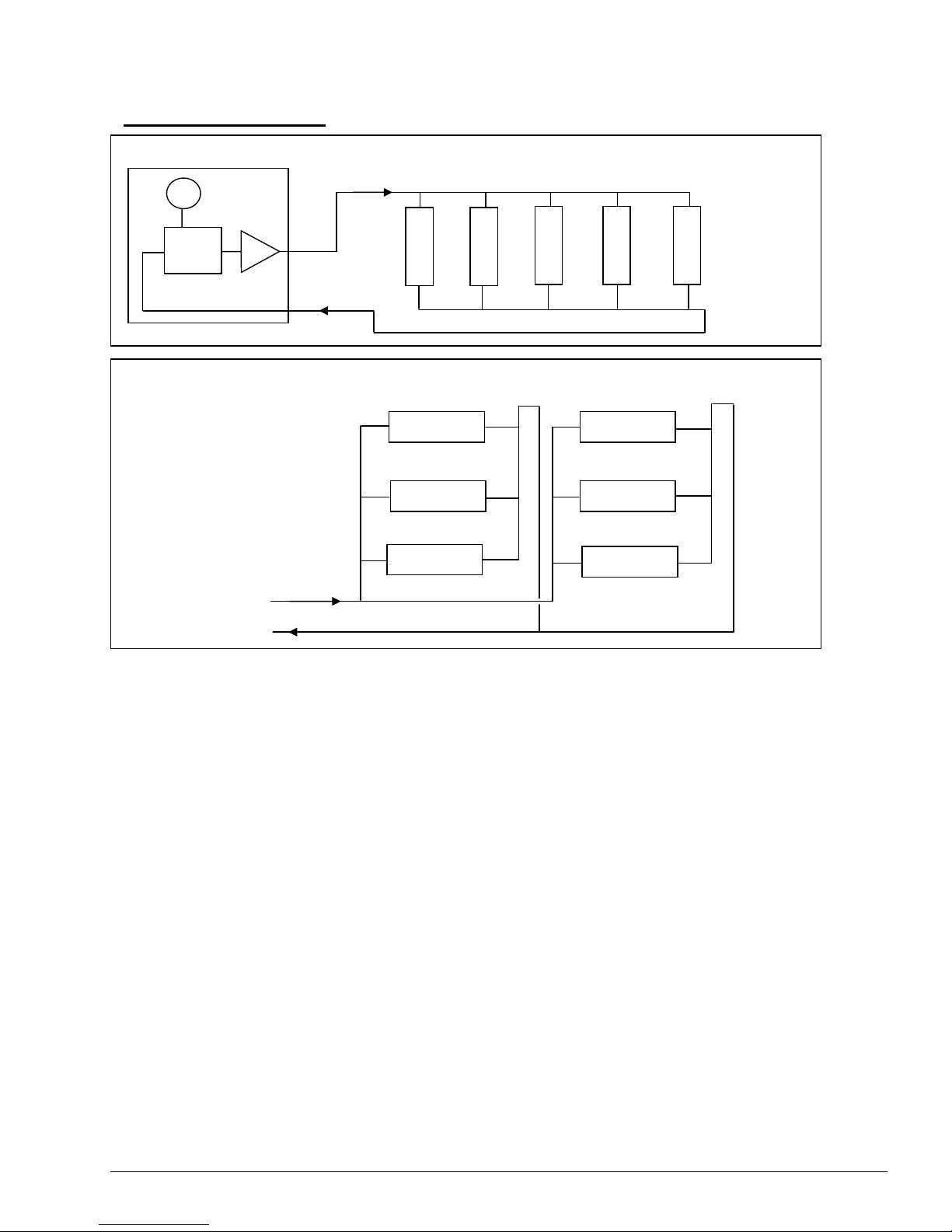

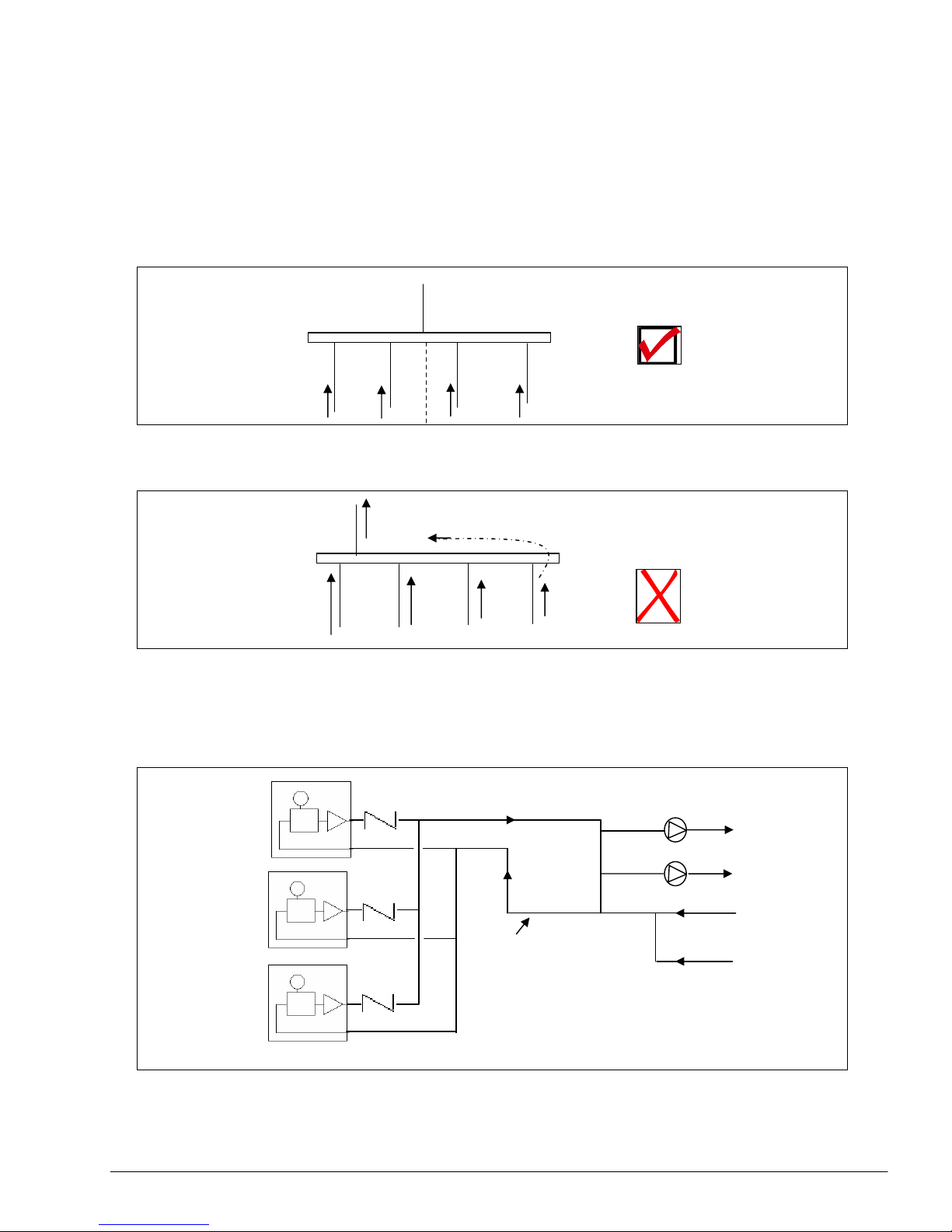

Parallel Direct Return

Vertical installation

Fan coil

unit

Horizontal installation

The basis for the design is "First In - First Out".

In this system, the length of supply and return piping for each fan coil is unequal. This will

affect the water flow rate through each individual load. Proper balancing is required to

provide adequate water flow rate for each fan coil.

Nevertheless, the cost of installation is lower compared with the reverse return configuration

due to the shorter pipe length needed. Therefore, this method is more economical for

installation of fan coils with different pressure drops and balancing valves are used.

This method is also suitable for open system applications whereby the return from the

fan coil loads are discharged into a external tank.

Section 2 Page 11

Page 14

Parallel Reverse Return

Horizontal Installation

Fan coil

unit

V

ertical Installation

The basis for the design is "First In - Last Out".

In this installation, the supply and return water pipes or of nearly equal lengths. Thus, it seldom

requires balancing of water flow rate for individual fan coil unit. If required, this balancing will be

easier.

This method is recommended if all the fan coil units have the same or nearly the same

pressure drops.

Another advantage of this reverse return system is a reduction of the working pressure drop

across any balancing valves used for the fan coil units.

However, such a system is not recommended for high-rise buildings because of the vertical

weight of the extra piping required. In such instances, it may be more practical to use direct

return systems.

The extra piping also does not give any advantage in open system applications because the

same atmospheric conditions exist at all open points of the system.

Section 2 Page 12

Page 15

Parallel Reverse Return Header, Direct Supply Rise

This is a variation of both the direct and reverse return systems, whereby it is not feasible to

have a full reverse return piping.

Instead, only the return header is in reverse, whereas the supply to the individual fan coils are in

direct configuration.

direct supply

reverse

return

This method will have the advantage of lower installation cost with some benefits of a better

water balanced system.

Balancing valves are required for each fan coil unit for proper flow balancing.

Section 2 Page 13

Page 16

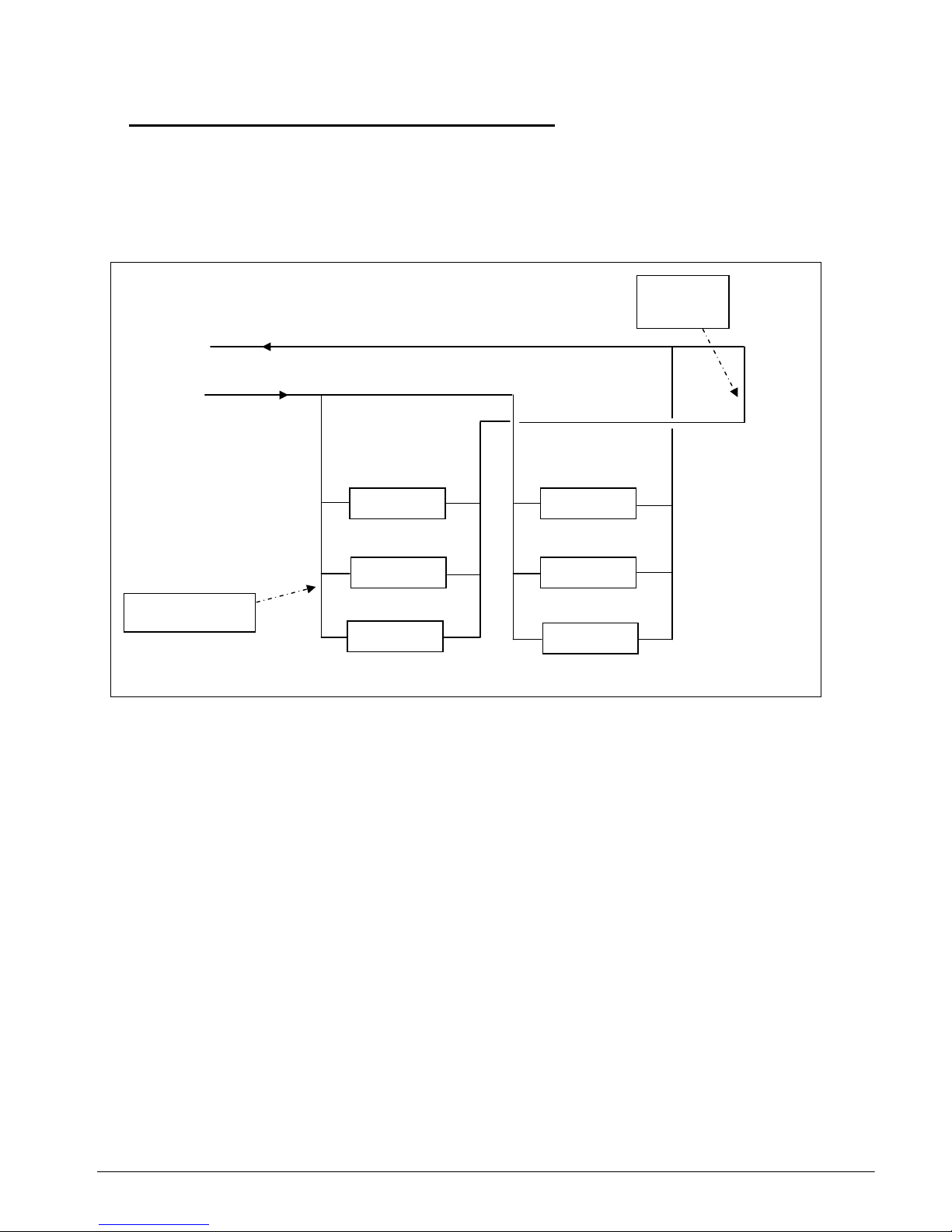

Close System vs. Open System

The mini chiller has been designed with an application for a close water piping system.

However, it is still possible to use the unit with an open system by means of an additional

buffer tank.

In such a system, the chiller will discharge the chilled water into the tank while a secondary

external pump will then pump the water to the fan coil units.

It is recommended that the tank to have a baffle plate in between to isolate the two return

water from the chiller and fan coil load. This will prevent the hotter return water temperature

from the load mixing with the cold chilled water from the chiller.

Such a method is suitable for:

- multiple chillers operation

- multiple secondary pumps supplying chilled water to several zones

The water volume in the tank can also be sized to act as a storage to provide cold water to the fan

coil units. By doing so, the chiller may be cycled-off for longer periods of time, hence saving energy

costs.

However, since this is an open system, there is a higher chance of air entering the water.

Care must also be taken to ensure there are no leakages along the pump suction line else

air will enter the system. The air will be drawn into the buffer tank and accumulate there. This

may affect the water flow rate and trip the chiller unit. Always ensure the automatic air vent

on the buffer tank is operating properly to release any trapped air.

Supply to load

Return from load

Tank

Chiller Secondary pump

Check if this air

vent is OK or not!!

Buffer tank

*** See Page 25 for more information

Section 2 Page 14

Page 17

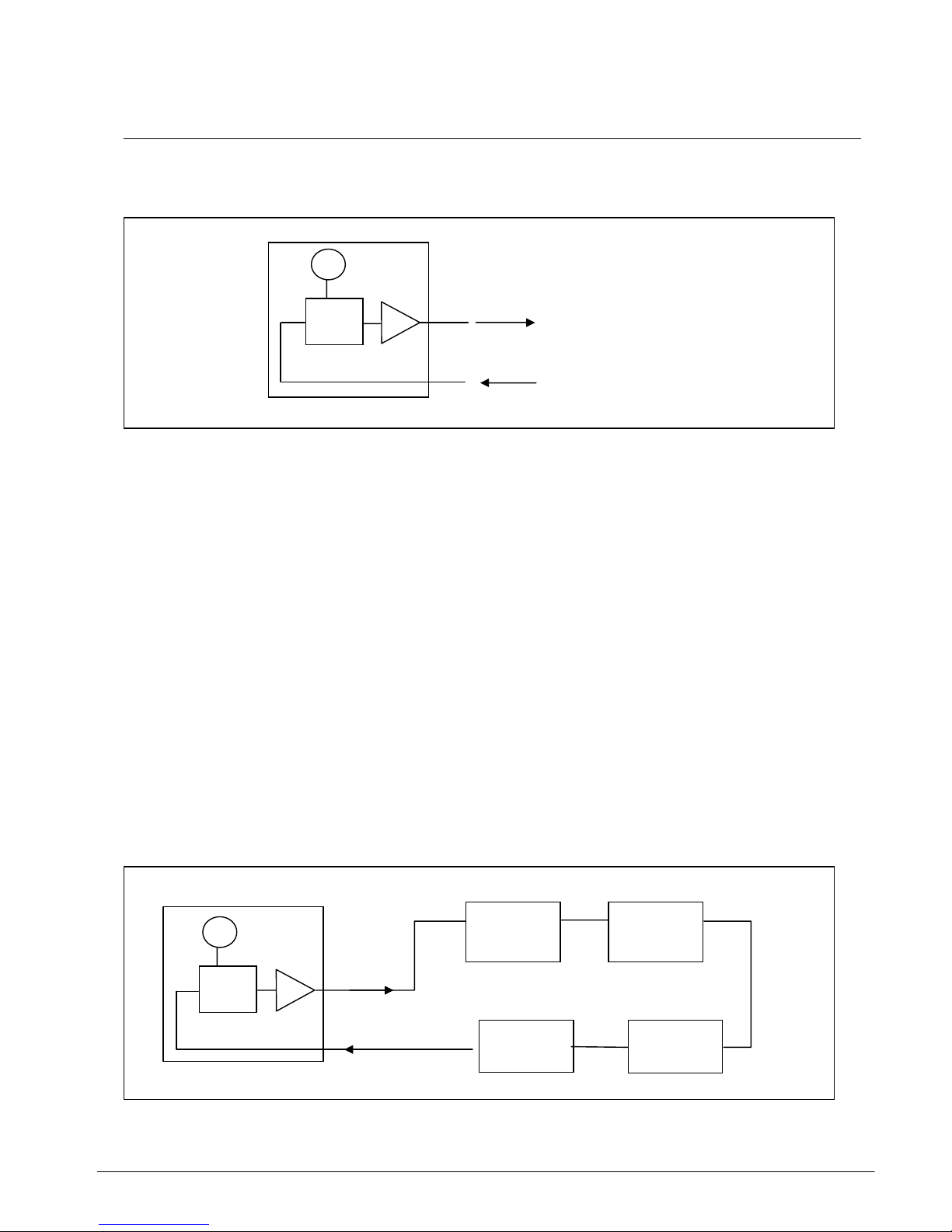

Primary - Secondary Pump System

There may be instances when the integrated pump in the mini chiller is not able to deliver the

required head pressure to the load in a close piping system.

To overcome this problem:

1. Change the water pump with a higher head pressure capability.

Please consult with the factory as to the requirements. Calculate the required

head pressure and select suitable replacement pump.

2. Install a booster pump.

It is recommended that this booster pump to be installed as a primary - secondary

system; as follows:

A

B

Primary pump in

chiller unit

Secondary booster pump

Bypass loop

Load

More than one secondary pumps can be installed together, e.g to serve several zones.

There are two drawbacks to this system:

a) Cost - additional two or more pumps are required

b) The bypass chilled water is sent back to the chiller unused

Keep the bypass loop as short and large as practical possible. Do not put any valve in

this loop. This is to minimise the pressure loss between the entry and exit points of the

loop.

However, this length must be sufficient to prevent recirculation turbulence.

Section 2 Page 15

Page 18

The temperature of water entering the load will depend very much on the sizing of the

secondary pump.

1. If the capacity of primary pump = secondary pump, there will be no flow in the bypass

loop. Hence, the water temperature entering the load will be equal to the water

temperature leaving the chiller.

2. If the capacity of primary pump > secondary pump, there will be a nett flow down the

loop and returned to the chiller unused. Therefore, tee A becomes a diverging tee and

tee B becomes a mixing tee. The water temperature entering the load will also be equal

to the water temperature leaving the chiller. However, the water temperature entering

the chiller will be colder due to mixing of the unused chilled water at tee B.

3. If the capacity of primary pump < secondary pump, there will be a nett flow up the loop

from B to A. Thus, tee A becomes a mixing tee and tee B becomes a diverging tee.

Then, the water temperature entering the load will be in between the water temperature

leaving the chiller and the water temperature entering the chiller.

There may be installations using pumps in series to boost the head pressure.

But this is not recommended due to a high chance of wrong pump sizing which can

cause damage to the pumps themselves.

Primary pump

Secondary pump in series

Load

For this to work properly, both the primary and secondary pumps must be of the

same capacity. Else, the greater capacity pump will overflow the lesser pump and

cause:

a. Cavitation problems to the lesser pump.

b. Excessive pressure drops across the pump itself.

c. The extra head pressure build-up may cause damage to some of the

components in the chiller itself.

Section 2 Page 16

Page 19

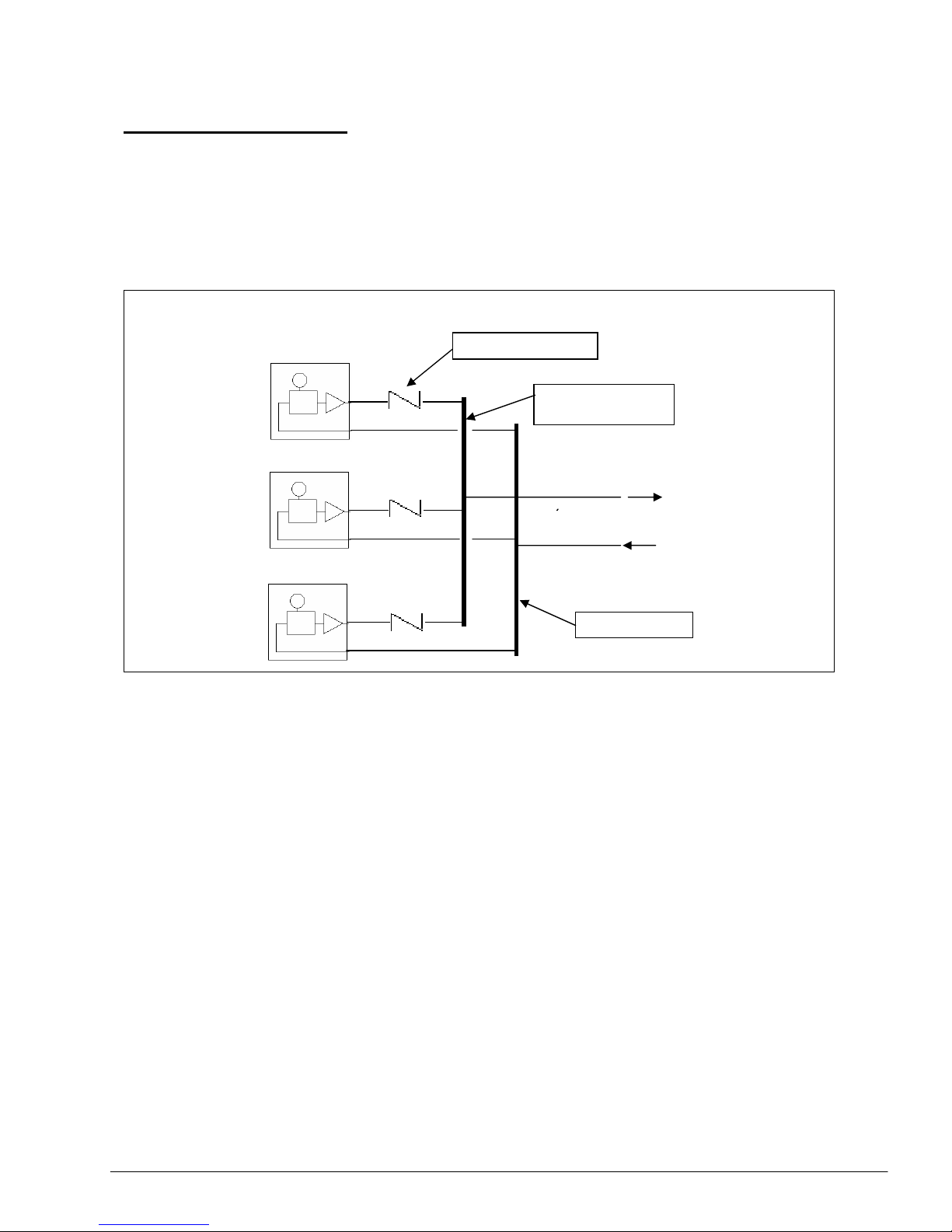

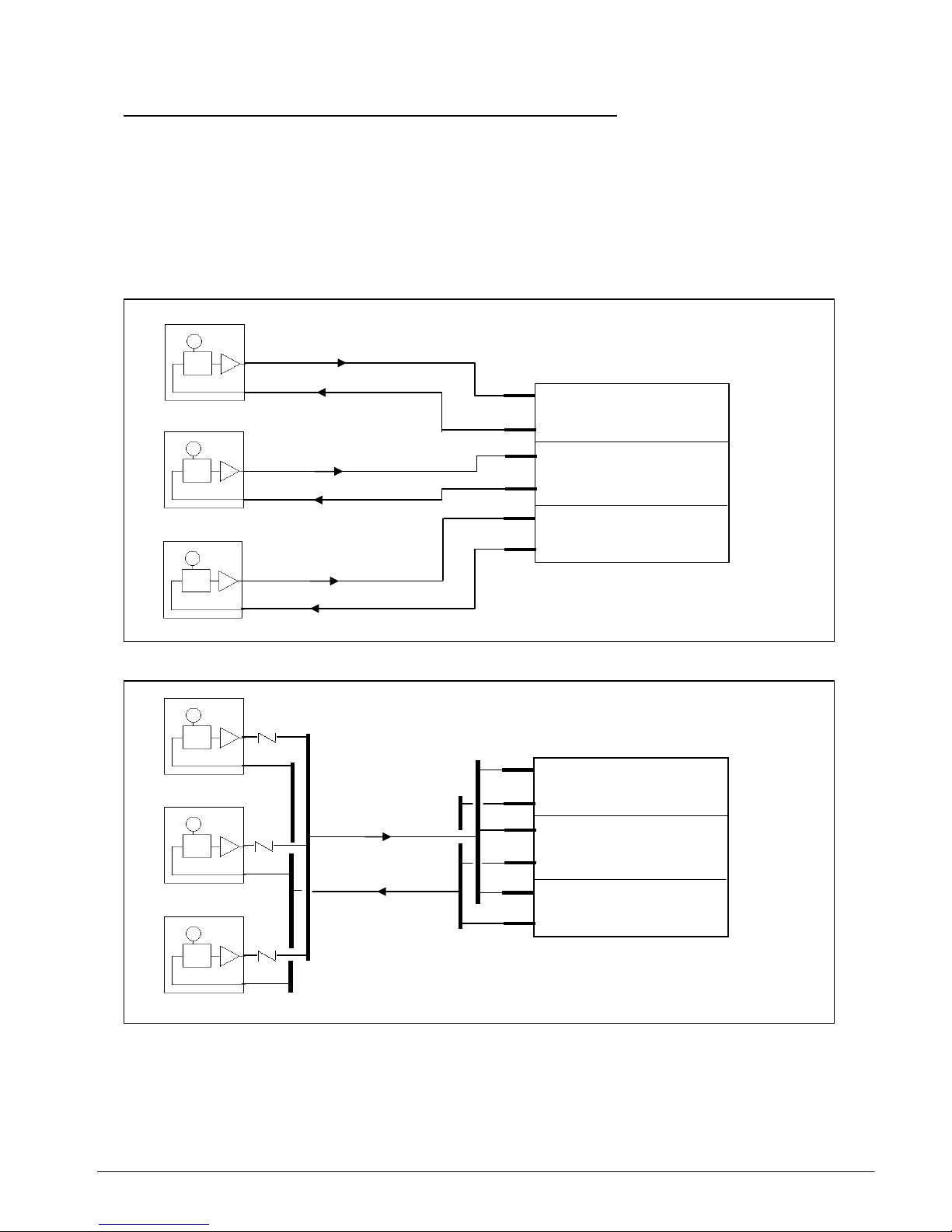

Multiple Chiller Installation

In most cases, one single chiller will not be sufficient to provide the cooling load of a system.

Several chillers must be combined together to give the required loading.

Generally, these chillers will be installed together in parallel. There are several ways to do

this:

1) Common Supply and Return Headers

Check valve

CHILLER 3

CHILLER 2

CHILLER 1

Chiller water return

Chilled water supply

Supply header

R

etu

rn h

eade

r

This method is most preferred and commonly used because of the lower cost and ease

of installation.

Each chiller is normally set at different return water temperature to facilitate load staging.

As the temperature becomes colder, the chillers will switch off one by one.

Generally, the header pipe size is larger than the supply and return pipes, e.g. one or two

size larger. This is to have a low pressure drop along the header. Check valves are usually

located along each chiller supply pipe to prevent back flush of water once the chiller is

switched off. Such back flow may damage the water pump.

However, this method has several drawbacks:

a) Proper balancing of the water flow rate through each chiller is crucial.

b) If any one chiller is off, the water flow to the load will be affected. So much so

that during low load conditions, when the return water temperature is cold, and

all the chillers have cycled off, no water will be pumped to the load. To

overcome this problem, it is necessary to wire the chiller controls for continuous

pump running as long as one fan coil unit is in operation. See Section 11.

Section 2 Page 17

Page 20

c) Since all the water is pumped into one supply line, there is less flexibility in zoning

the water distribution. The pump head may not be sufficient to deliver water to

zones of high pressure losses, e.g. at the furthest end of the pipe system.

Because of the importance of water flow balancing among all the parallel chillers,

the design of the header is very important.

Place the common pipe near the center of the header pipe. This will help to balance

the water distribution between the left and right sides of the header.

If the common pipe is at one end of the header, water from the branches at the

other end of the header will find more difficulty to flow into the common pipe.

Balancing valves must be installed at each supply branch to ensure adequate

water flow rate through each chiller unit.

2) Primary-Secondary System

header

Water will experience a higher

Resistance to flow to common pipe

From the furthest branches.

Secondary pumps

To load

Return from load

Bypass loop

CHILLER 1

CHILLER 2

CHILLER 3

Section 2 Page 18

Page 21

In this method, the load side of the system is isolated from the chiller side. Chillers of different

capacities can be installed together without much balancing problems and effect on the supply

flow rate to the loading. It just requires individual balancing of the flow rate through each chiller by

using the balancing valves. Check valves and balancing valves are recommended to be installed

for each chiller supply pipe.

The secondary pump alone will handle the flow and pressure requirements of the loads.

Because of this secondary pump, the sequencing of the chillers will not affect the

water supply to the load when any of the primary pumps switches off. Several secondary

pumps can also be installed to the bypass loop to serve several zones. This creates

flexibility of installation.

The only drawback to this method is cost. The piping network is more extensive and

additional water pumps are required.

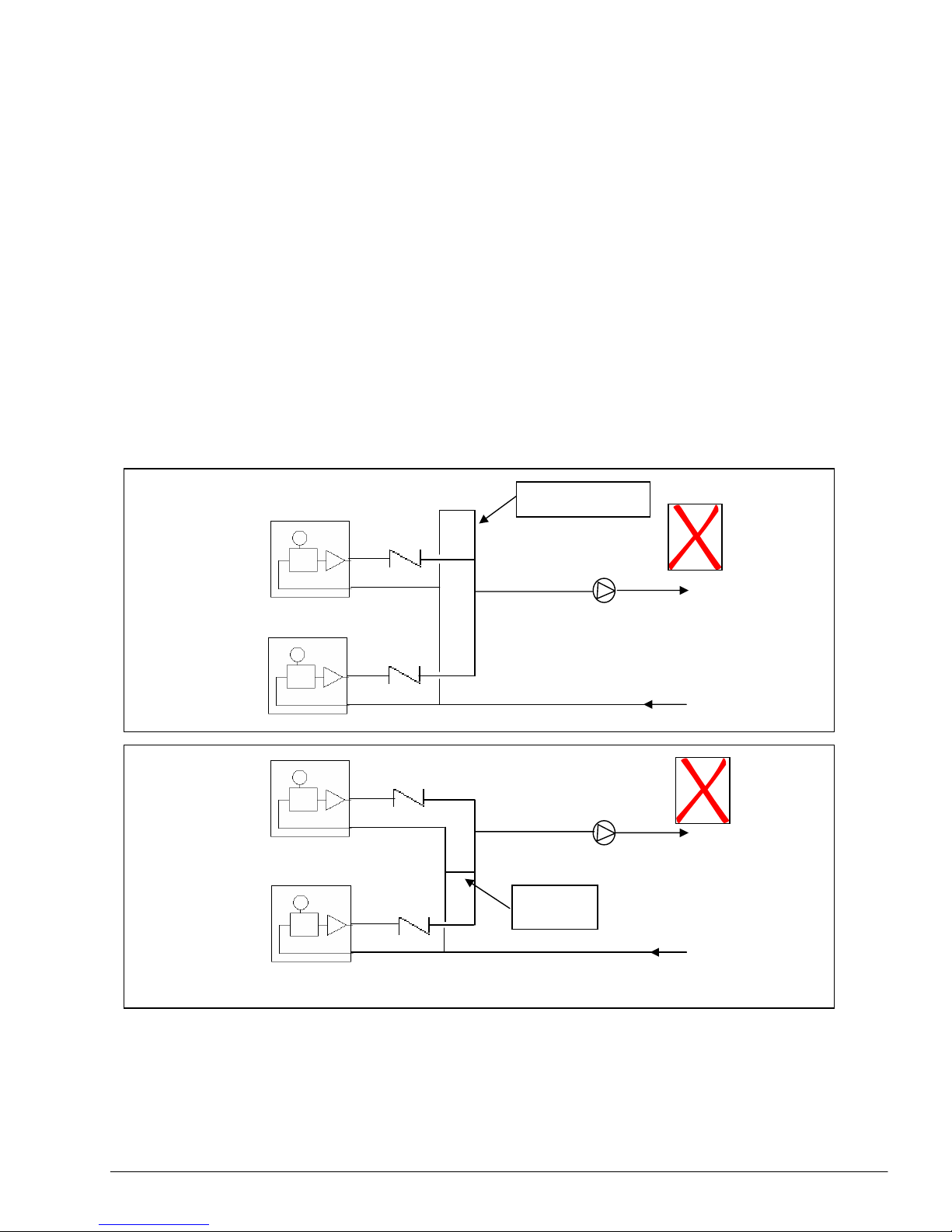

It is important that the bypass loop is located correctly. The following two are questionable

variations to the above method:

By pass loop

By pass

[A]

[B]

Secondary pump

Secondary pump

To load

To load

Return from load

Return from load

Section 2 Page 19

Page 22

For both method [A] and [B], the return water temperature for the multiple chillers will not be the

same due to mixing. This will cause inefficiencies and energy wastages to the chiller operation.

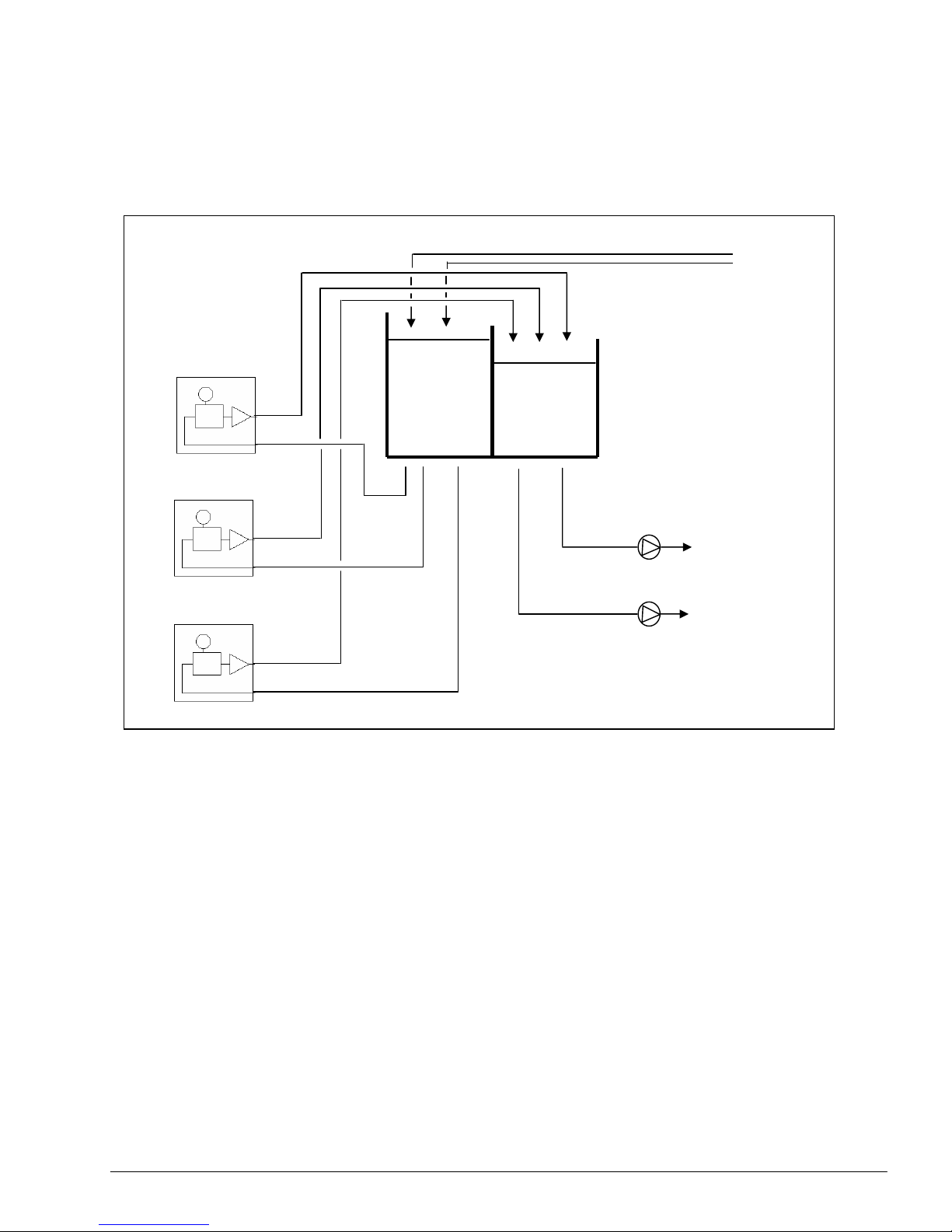

3) Common Tank System

This method is for an open system.

CHILLERS

to load

Tank

return from load

As seen from the diagram, each chiller and secondary pump forms its own individual pipe

circuit. There is no cross flow among each of them. This has been achieved with the

common tank which acts as a buffer storage tank.

Therefore, there is no need of check valves. Normal globe valves will suffice to ensure

proper water flow through each chiller.

Usually, the tank is at a higher elevated position, to allow gravity feed of water to the chillers

and pumps.

This method is most expansive to install due to the additional piping and tank required for

the system.

Please refer to Page 14 for cautions during installation and operation.

Section 2 Page 20

Page 23

4) In some instances, variation to method (1) have been used whereby common

headers are NOT installed to the multiple chillers. Instead, the chillers are connected

together with one supply and return pipe only.

This method is still possible but there will be higher pressure drops along the common

pipe lines. It is recommended that a larger pipe size to be used along this common line

to reduce the friction losses.

Water flow rate tends to be faster at the tee nearest to the main supply lines due to

lower friction. Therefore, proper balancing to ensure sufficient distribution to each

chiller is vital.

A First In - Last Out arrangement between the supply and return lines may be

useful to reduce the problem of distribution.

5) Another variation to the primary-secondary system mentioned in (2) above, is to use

an auxillary tank to replace the by-pass loop. By using this tank, we can ensure a

minimal pressure drop between the entry tee and exit tee of the secondary circuit.

This is not a common

header pipe

To load

Return from load

To load

Return from load

A

uxiliary tank

Section 2 Page 21

Page 24

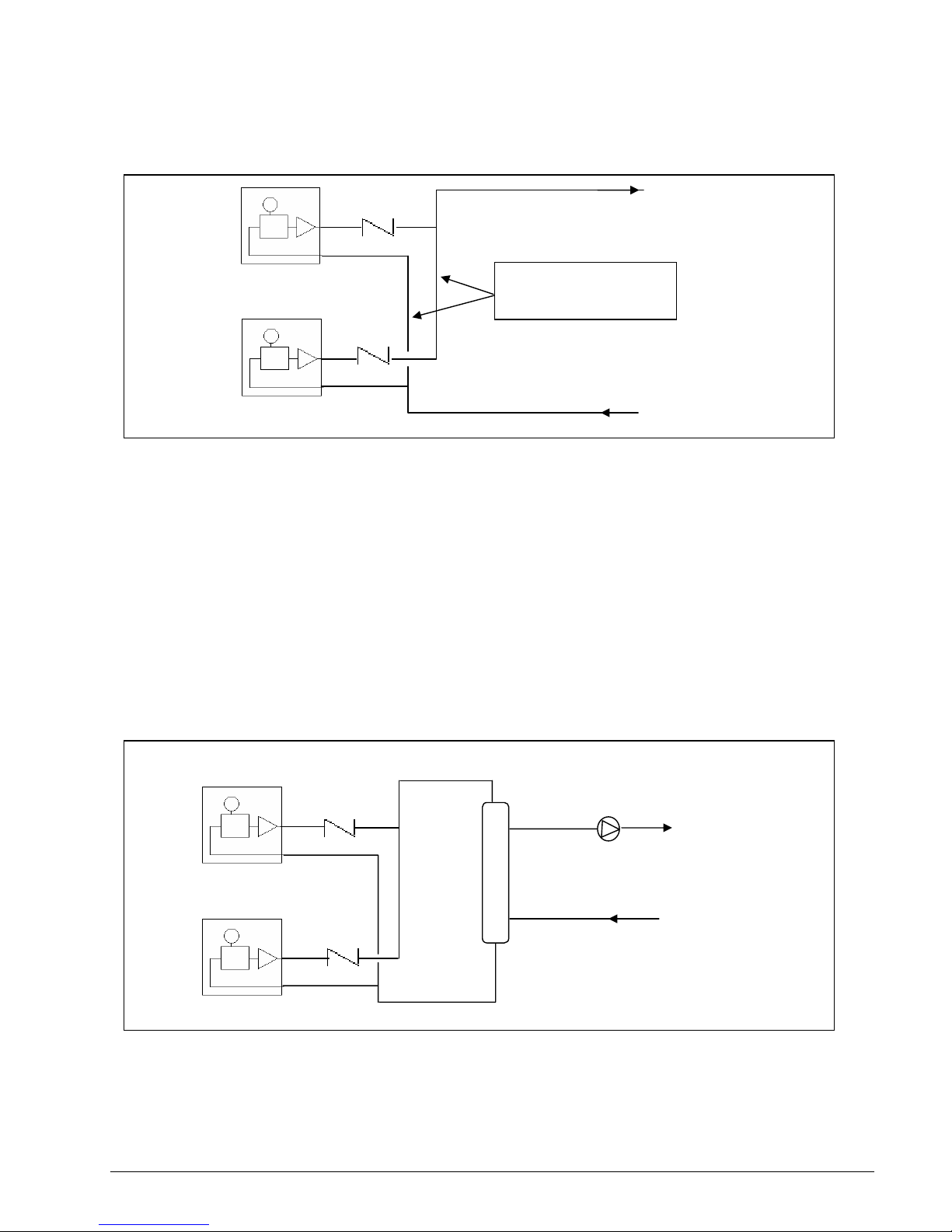

Multiple Chiller, Single Fan Coil Load With Multiple Circuits

There are instances where several chillers are used to supply the chilled water to a large

single fan coil unit. Each chiller will serve one of the multiple circuits of the heat exchanger coil

in the fan coil unit.

There are two ways to install the pipe circuits for this system:

a) Individual Circuiting

b) Common Header

CIRCUIT 1

CIRCUIT 2

CIRCUIT 3

CHILLER 1

CHILLER 2

CHILLER 3

CIRCUIT 1

CIRCUIT 2

Section 2 Page 22

Page 25

The first method has more extensive pipe works. But the water side flow control is

easier and there is less pressure drop. Globe valves may be needed to ensure

sufficient flow rate. Check valves are not required.

Due to the header pipes in the second method, check valves are needed for each

chiller. Globe valves or balancing valves are also needed for each chiller for water

balancing. All the pumps will operate in parallel and a higher water pressure drop is

expected. Furthermore, balancing valves are also required in each circuit of the fan

coil unit for proper balancing of the entire coil.

Nevertheless, if any one of the chiller is OFF, the second method will always allow an

even water distribution to the whole heat exchanger in the fan coil unit. In the first

method, hot air will by-pass through the portion of the coil which the chiller is OFF.

Section 2 Page 23

Page 26

Make Up Water Supply

The make up water supply is used to refill water back into the hydronic system in the event of:

a) Leakage in the system

b) Maintenance service

The supply is usually from the main domestic pipe and it is usually connected to the water return

pipe of the pump; due to the lower pressure which will assist in "sucking" in the water. However,

should the pressure in the main supply pipe is lower than the pressure in the return pipe, water will

not enter the system. Rather, switch off the pump and allow the mains pressure to fill the system.

In view of this, it is necessary to install a check valve along the make up supply pipe to

prevent back flow out of the system.

Other equipment which can be installed (optional) along the make up supply pipe:

a) Pressure gauge

b) Safety relief valve - to prevent over filling [see Section 10]

c) Pressure regulating valve

d) Filter element [see Section 9]

e) Water meter

Domestic water supply

Pressure gauge

Check valve

CHILLER

Return

Section 2 Page 24

Page 27

Loop Piping Installation

One of the main advantages of using mini chillers is the ability to have long water piping

installations. However, it is important to check that the water pump head pressure capability is

adequate to pump the water through the pipe network. The longer the pipe length is, the higher

is the pressure drop. If the pump head is insufficient, it may be necessary to change the water

pump itself. See Section 5.

With such installations, it is also important to check the condition of the automatic air vent valve.

A high pressure drop along such pipe network may result in the return water to have a negative

pressure (i.e. suction vacuum pressure in the buffer tank). Due to the mechanism of the air vent,

air will be drawn into the buffer tank itself! This in turn will cause the pump to be air-locked. A

symptom of such condition is that air will always be purged out of the tank when we manually

open the air vent.

The solution to this problem is to remove the automatic air vent and plug up the hole. Make

sure that all the air trapped are purged out of the system before plugging it. This can be done

by continuously filling up the system with water until no air bubbles comes out of the hole.

Section2 Page 25

Page 28

Water Pipe Connections

All mini chiller units comes with ∅1-1/4” pipe connections.

1] A-Series

The pipe connections are on the right-hand side of the unit (when facing the fan blade).

2] B-Series

The pipe connections are on the same side as the control box compartment

Water inlet

Water outlet

Water inlet

Water outlet

Section 2 Page 26

Page 29

3] C-Series

The pipes can be connected either from the left or right side of the unit (with

respect to the compartment doors).

Water inlet

Water outlet

Section 2 Page 27

Page 30

Section 3: Water Pipe and Fittings

There are several types of pipe we can use for the water piping:

1. Black carbon steel pipe

2. Copper pipe

3. PVC pipe

Do not use galvanised iron (GI) steel pipe! This is because the zinc coating on the GI pipe will

have an electrolytic reaction with the copper components of the system, e.g. the brazed plate heat

exchanger and fan coil unit heat exchanger.

The zinc will be the sacrificial metal and deposit itself on the copper surfaces.

a) The pipe wall thickness will slowly eat away and cause leakages

b) The zinc deposit on the copper surfaces will retard heat transfer process. It may also

reduce the gap between plates in the BPHE and slows the water flow rate.

The mini chiller water piping connections is for a pipe size of 1-1/4". For a single run installation,

the recommended maximum pipe length is 150 meters, but this will depend very much on the

method of installation and the fittings used. The more complex the piping network is and the more

fittings there are, the higher will be the friction losses. This will limit the piping length available.

Always calculate the friction losses in the system and compare this with the capability of the water

pump in the chiller unit. See Section 4

1. Black Steel Pipes

The black steel pipes are the most commonly used in chiller installations. It is relatively cheap and

by far the strongest among the 3 types mentioned above.

However, these pipes are heavier and requires more extensive work to join and install.

The common pipe sizes are determined from the ASME (American Society of Mechanical

Engineers) standard B36.1 OM which specifies the pipe dimensions. See Appendix 1.

Generally, steel pipes are sold in lengths of 6 meters each. The dimensions of importance which

we need to know is the nominal pipe size (NIPS) and schedule number (wall thickness).

For pipes 14" (350mm) and larger, the nominal diameter is the same as the actual outside

diameter.

For pipes between 3" (80mm) to 12" (300mm), the nominal diameter is close to the actual inside

diameter.

However, for pipes smaller than that, the nominal value does not correspond to any actual

dimension.

Steel pipes are manufactured with different wall thickness. The ASME standard has defined

schedule numbers to identify these specifications. A pipe with a nominal pipe size may have

several schedule numbers. See also Appendix 1

Section 3 Page 28

Page 31

Therefore, pipes may have the same nominal diameters (outside diameters) but with different

inside diameters because of the different schedule numbers.

The usual schedule numbers are 10, 20, 30, 40, 60, 80, 100, 120, 140 and 160 with the thickness

increasing with the numbers.

These numbers are further classified as Standard (ST), Extra Strong (XS) and Double Extra

Strong (XXS) whereby applications requiring higher pressures will need pipes with thicker walls.

However, in the HVAC industry and for our mini chiller installation, a standard schedule 40 pipe

will suffice.

The steel pipes may be joined by several methods:

1. Arc welding

2. Thread (usually up to 50mm) with PTFE Teflon white tape

3. Flange with gaskets

2. Copper Pipes

Copper pipes are chosen for water piping because of their resistance to corrosion and ease of

installation. The pipes are light and ductile.

However, the cost of these pipes are higher compared with steel pipes (generally by 3 5 times).

The sizes of these copper pipes are defined by the ASTM (American Society for Testing and

Materials) standard B88 for water and drain services. See Appendix 2.

There is also another ASTM standard B280 which specifies the sizes of pipes used for

refrigeration services with different wall thickness. This standard uses the outside diameter as

the nominal size.

These pipes are also generally sold in lengths of 6 meters.

Generally, the B88 standard defines 4 types of copper tubes: Type K, L, M and DMV with

descending wall thickness. The most commonly used types are type L and M which have higher

internal working pressures. These may be of hard drawn or soft annealed temper.

The copper pipes may be joined by:

1. Brazing

2. Soldering

3. Flare joint / compression joint fittings

Section: 3 Page 29

Page 32

3. PVC Pipes

The plastic PVC (polyvinyl chloride) pipes are light, generally inexpensive and corrosion resistant.

The pipes also have a very low friction factor (i.e. with smooth surface) which results in lower

pumping power and smaller pipe sizes. However, these pipes are not suitable for high

temperature applications as they losses strength rapidly at temperatures above ambient. The

pipes also have high coefficient of expansion, i.e. at high temperatures any pipe joint made may

become loose and leaks. Because of the weaker strength of the material, such pipes must be

installed with shorter support spans.

As a result of the above mentioned disadvantages, it is not recommended for PVC pipes to be

used for external applications, especially under direct exposure to sunshine. They may be

suitable for piping water indoors, e.g. under ceiling spaces, attics, plant rooms, etc.

The PVC material is classified as a thermoplastic. Generally, there are two types:

1. U-PVC (unplasticized PVC): for general usage up to 60°C

2. C-PVC (chlorinated PVC): for higher temperature applications.

The PVC pipes and fittings used inside the mini chiller unit (factory assembled) are of DIN

8061/8062 standard. Therefore, use back pipes and fittings with the same standard when running

pipes from the chiller to the fan coil units. It is recommended that pipes with pressure rating of

PN16 (16 bar working pressure) to be used. See Appendix 3.

Do not use PVC pipes manufactured to other standard specifications, e.g. BS 3505/3506

as the fittings will not match with those used in the chiller. The pipe wall thicknesses are also

different.

The usual method of joining the pipes and fittings is with solvent cementing/welding. Some fittings

also have threads for joining purposes (with PTFE white tape).

It is recommended that 'IPS Weld-on PVC 717' solvent cement to be used. It is gray in

colour and used for heavy-body applications.

The following are some guidelines to ensure that the solvent cement joint is done properly:

a. Cut the pipe square and deburr. Clean and dry surfaces before coating the cement.

b. Apply a full, even layer of cement equal to the depth of the socket. Avoid excess and

puddling.

c. Assemble while the cement is wet. If not wet, recoat parts.

d. Ensure pipe fits snugly into socket. Give a twist of 1/8 to 1/4 turn.

e. Hold for 30 seconds to prevent push out and allow for initial set. Wipe off excess.

f. Allow curing time at least 5 minutes, up to 30 minutes. Longer curing time is better for

higher pressure/temperature applications.

Section: 3 Page 30

Page 33

Typical Pipe Fittings

The following are typical pipe fittings used for installing the mini chillers. Note that the pipe

fitting size of the chiller itself is 1-1/4".

a) Steel Pipe

Because of the pipe fitting size, it is recommended that the connecting pipes and fittings

to be joined with thread. However, where necessary, fittings for weld joining may also be

used.

The following standards are applicable for these fittings:

ASME B16.9, ASME B16.11, ASME B16.28 and ASME B1.20.1

Internal

thread

Tee joint

Internal

thread

90º elbow

Internal

Page 31 Section 3

thread

Reducer

45º elbow are also available

but not commonly used, unless

necessary

A tee joint can either be a flow

mixing or flow diverging point,

depending on the design of the

pipe work.

Some reduces/ fittings do not

have these ribs: used for better

gripping when tightening with

pipe wrench.

Page 34

Section: 3 Page 32

with reducing ends

Nipples are usually used

for joining different types

of fittings, e.g. an elbow

with a reducer.

ni

pp

le

External

thread

connector

Used for joining two

lengths of pipes

together

Internal

thread

Union/ coupling

Used for joining two

lengths of pipes

together

Made up of two halves,

each screwed into a

pipe end.

Both are then joined

with a locking nut in

between

Page 35

flange

connector flange

holes for bolt and

nut

nipple

gasket to be placed on the mating

surfaces of both flanges

This method is not recommended for the small pipe size used for the mini chiller.

** The fittings for weld joining are very similar to those mentioned above, i.e. they do

not come with the thread portion. They may be butt-welded or socket-welded.

BUTT

SOCKET

Section: 3 Page 33

Page 36

b) Copper Pipe

The most commonly used method of joining copper pipes is brazing with an oxy-acetylene

flame and copper filler rods. For this purpose, one end of the pipe is expanded by using

an expander tooling, and the end of the other pipe is inserted into the expanded end. The

joint is then brazed together. [see Appendix 4 for expansion dimensions]

Similarly, fittings are available for such brazing joints:

90º elbow

expanded end

reduce

r

Usually, the pipe outer

diameter will insert into

the reducer inside

diameter

tee

j

oint

expanded end

some may come with

reducer end

Section: 3 Page 34

Page 37

connectors

expanded end

Sometimes, copper connectors are used instead of expanding the copper ends.

This is especially with larger pipes where expanding becomes more difficult

because of the thicker wall thickness.

Also, an alternative to using elbows is to just bend the pipes with a pipe bender to suit the

installation requirement. Various bending angles can be achieved with this method. However, the

larger the pipe size, the more difficult this will become.

expanded end

Pipe bend

CAUTION! Do not bend the pipes with hands. This will cause the pipe to collapse at the bending

portion. Use the suitable pipe bending tool.

Manual hand benders allows a maximum size of 3/4". Pipes up to 1-3/8" can still be bended by

using bending machine.

NOTE:

During brazing of copper-to-copper pipes, copper filler rods of 0% silver may be used. It is a good

practice to pass nitrogen gas inside the copper pipes while

brazing to prevent oxidation.

Section: 3 Page 35

Page 38

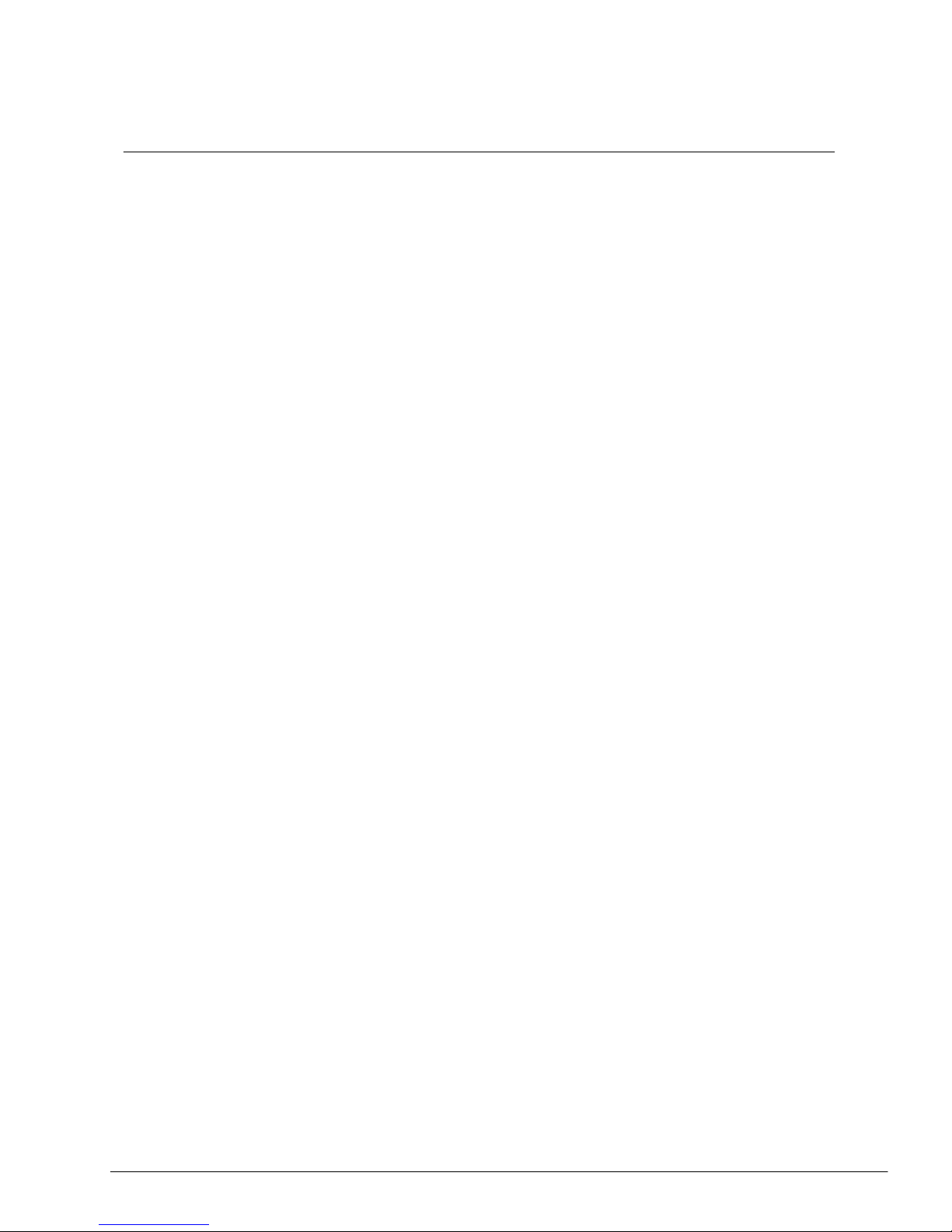

Copper Pipe: Compression Fittings

For some installations, the piping are connected using compression fittings. These fittings

enable easy installation and dismantling. However, the cost for these fittings are higher.

They are also not as strong as brazing joints. Chances of leakage are higher.

Generally, the fittings have mounting rings which are slipped onto the copper pipes. The

ring is then pushed against the fitting internal surface and a locking nut is used to hold the

assembly together.

90° elbow

L

ocking nut

mounting ring

90

° elbow with threaded ends

normal elbow

female thread

with steel pipe fittings,

male thread

Such elbows are for special

applications. For example,

connection with steel pipe

fittings, connection with a

water tank.

tee joint

ribs for gripping with

a wrench

Section: 3 Page 36

Page 39

connector

female thread

Used for connecting two pipes together.

Some have threaded ends for connection with other fittings.

union

locking nut The two halves opened up

threaded end

Similar to the steel type. Used for connecting two pipe together with flexibility of easy connection

and dismantling.

Some have threaded ends, others with compression fitting ends.

In some installations, the copper pipes are brazed (with silver flux) onto each half of the union and

then connected together with the locking nut.

NOTE: Brazing of copper to brass requires filler rods with 34% silver.

Section: 3 Page 37

Page 40

c) PVC Pipe

It is recommended that the PVC pipe fittings used to be in accordance to the DIN 8062

standards. These fittings have thicker walls and able to withstand higher pressures and

temperatures.

Generally, these fittings are the cheapest and easiest to install.

90° elbow

With the threaded end,

some elbows it is also possible to

have threaded connect with a steel pipe

ends or steel fitting.

tee joints

connector

Used to connect two PVC

Pipes together with solvent

cement

Section: 3 Page 38

Page 41

adaptor/sockets

The sockets may have

male or female threaded

ends.

Such sockets are useful

to adapt connection with

a steel pipe or tank.

union

locking nut the two halves of the

union

Similar to the steel and copper versions, these unions enable easy connection and dismantling of

two PVC pipe ends.

The PVC pipes are joined to the two halves by using solvent cement and then they are

assembled together with the locking nut.

reducer

Section: 3 Page 39

Page 42

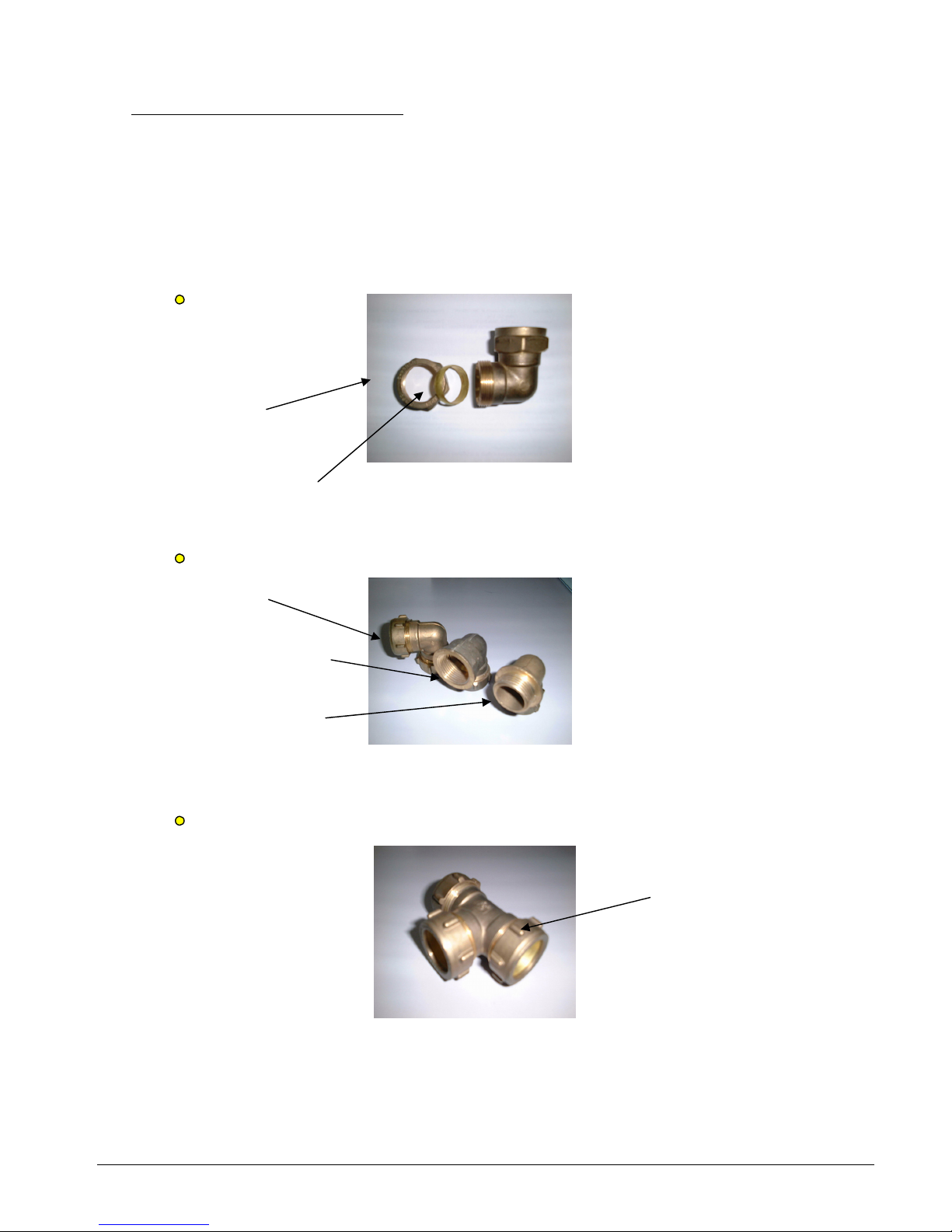

Tee Joint Installation

Care must be taken during installation of tee joints. Two cases are mentioned here

to demonstrate the importance of understanding the design of the water flow system.

a. Avoid "bullheading"

Do not connect piping to the tee connection with opposing flow directions.

turbulence occurs here and

causes high friction losses

b

. Encourage eduction out of a bypass tee branch.

return

wate

r

the higher velocity of flow in

the run of the ‘pulls’ water

our of the tee branch

bypass

branch

bypass

branch

Do not allow the higher return

water velocity to ‘ram’ into the tee

joint. This may cause a backflow

into the bypass branch.

backflow of

water

return water

Section: 3 Page 40

Page 43

Valves

In Section 2, we have look at several piping network configurations. The diagrams shown in that

section have been simplified. In actual situation, the piping will have most of the pipe fittings

described earlier in this Section 3. In addition, valves are also installed along the piping lines.

Valves are used for the following purposes:

a. To isolate a component of the hydronic system from the rest of the system; thereby enabling

easy maintenance and repair of that component.

b. To regulate the water flow rate through the system.

c. To divert or mix flow directions, optimizing the water temperature in the system.

d. To relieve or regulate pressure.

e. To prevent backflow.

Valves are constructed to withstand a specific range of temperature, pressure, corrosion and

mechanical stress. Careful selection of the correct valve for a particular application is

important to give the best service with consideration of economic requirements.

The following diagram gives the general anatomy of a valve:

Section 3 Page 41

Page 44

Generally, valves can be categorised as manual or automatic valves.

Manual Valves

The following are the types of manual valves commonly used in hydronic systems:

1. Globe Valve

Flow is controlled by a circular disc forced against or withdrawn from an annular

ring, or seat, that surrounds an opening through which flow occurs.

The movement of the disc is parallel to the flow direction.

- used for pipe diameters up to 300mm

- used for throttling duty where positive shutoff is required

2. Gate Valve

Flow is controlled by means of a wedge disc fitting against seating faces.

Gate movement is pependicular to the flow direction.

- has straight-through openings as large as the full bore of the pipe.

- this type of valves are intended to be fully open or fully closed

- should not be used to regulate or control flow

- useful for isolation/shut-off purposes.

Section 3 Page 42

Page 45

3. Ball Valve

This valve has a precision ball seated between two circular seals or seats.

A 90° turn of the handle will change the operation from fully open to fully closed.

- may be used for throttling duty

- generally used with smaller pipe diameters (up to 75mm)

4. Butterfly Valve

This valve has a cylindrical body with an internal rotatable disc serving as the fluid flow

regulating device. This disc's axis of rotation is the valve stem and it is pependicular to

the flow direction. A 90° turn will change the operation from fully open to fully closed.

- has low pressure drops

- fast operation of valve

- may be used for throttling duty

Section 3 Page 43

Page 46

5. Balancing Valve

This type of valve provide throttling duty to regulate water flow rate for balancing purposes.

Two ports are provided in the inlet and outlet ports of the valve to permit measurement of

pressure drop across the valve. By using performance charts provided, the value of flow

rate through the valve can be determined. The valve handwheel will have a setting scale to

determine the amount of valve opening. This is useful during field commissioning and

balancing.

Generally, the internal construction is similar to a globe valve. It is more costly

than the conventional throttling valves and it is only used in systems where

proper and accurate balancing is required.

Normally, connected via

tubing to a hand-held

meter readout

pressure tapping

Setting handwhell

Section 3 Page 44

Page 47

Automatic Valves

This type of valves operate in conjunction with an automatic controller or device to control

the fluid flow. These controllers are also called as actuators. There are several types of

actuators commonly used:

a. Solenoid

b. Electric motor

c. Pneumatic

Such actuators will have gears, rack-and-pinion, cams and linkages to convert movement

and allow opening and closing of the valve stem.

a. Solenoid Valve

This type of valve only allows either a totally open or close position. It has a

magnetic coil which will lifts or drops a plunger in the valve to open and close the

flow of water. This occurs when the coil is either energized or de-energized.

Such valves are generally used for pipe sizes up to 50mm only. They are suitable

for small fan coil units which require water shut-off when the fan coil is switched

off.

solenoid coil

b. Electric Motorised Valve

The actuator has a built-in motor to produce a rotary motion. By using gears,

cams or linkages, the valve stem will be opened or closed. Usually, the motor runs

on DC power supply (24V).

Generally, the actuator has positioning controls whereby the valve can stroke to

any position between fully close to fully open. This is accomplished with a control

signal from an external feedback controller.

With this feature, it is possible to vary the water flow rate to suit any demand load

of an application.

Nevertheless, the cost of such valves is high.

Section 3 Page 45

Page 48

motor drive

valve (encased in

insulation)

position indicator

c. Pneumatic Valve

This type of valve has a flexible diaphragm clamped between an upper and lower

housing. The valve stem is attached to the diaphragm. By injecting air pressure

into the upper housing, the diaphragm will push the valve stem. An opposing

spring force on the valve stem will also resist this movement. Therefore, by varying

this air pressure, valve positioning can be achieved.

For this to work, an external pneumatic converter/positioner must be used to

regulate the air pressure. A thermostat may be used together for such a purpose.

This cost for this type of valves is also high.

upper housing

diaphragm

lower housing

spring

valve body

air pressure inlet

Section 3 Page 46

Page 49

Two Way and Three Way Valves

Automatic control valves used in hydronic systems may be classified as either two-way

or three-way. All three types of actuators mentioned above may be used for these two

types of valves.

In the two-way valve, water flows into the inlet port and exits from the outlet port. By means

of the actuator, the flow rate may vary from full flow to zero.

There are two types available: single-seated

and double-seated. For most applications,

the single-seated type will suffice. In this type, there is only one valve seat and one plug-disc

to clsoe against the flow. However, for applications with higher operating pressures, the

double-seated types may be used.

attachment to actuator

Water In

Water Out

In the three-way valve, three ports are available. Depending on the application, these

can be configured as a mixing

or diverting valve.

1. Mixing Valve attachment to

- two streams of water blends into a single stream

actuator

A A+B

B

1

2. Diverting Valve

-splits one stream into two different streams

2

A+B B

3

A

Section 3 Page 47

Page 50

Capacity Control With 2-Way and 3-Way Valves

supply return supply ret

urn

The load of the fan coil unit can be calculated from the equation:

Q = 4180 * (water flow rate, L/s) * (water temperature differential.°C) Watt

th the 2- ay and 3- ay

alve will vary t

∆t".

LOAD LOAD

LOAD

diverting

mixing

Therefore, the load is propotional to the water flow rate and ∆t. Bo w w

v he flow rate to accomodate changes in the load demand.

With the 2-way valve, the system is considered as "variable flow, constant ∆t".

With the 3-way valve, the system is considered as "constant flow, variable

It is recommended that the 3-way valve to be configured as a diverting valve

instead of a mixing

valve. This is because when the fan coil unit is OFF, cold water will not enter into the heat

exchanger with the valve diverting the water away to the return line. Unlike the mixing valve, even

though the valve may be closed, cold water can still enter into the heat exchanger and ccumulate

there. As a result, sweating

on the heat exchanger and the connecting joints will occur even

the fan coil unit is not running.

However, on the o

when

ch valves, choosing instead the mixing configuration.

ther hand, 3-way diverting valves cost more than mixing valves. This is why

some designs do not call for su

Section 3 Page 48

Page 51

Application:

Both the two-way and three-way valves are suitable for shut-off and flow regulation purposes.

The cost of the two-way valves are cheaper compared with the three-way valves. Thus,

there is a tendency to use the two-way valves during installations.

A typical two-way valve installation:

The problem with the above installation occurs when both the fan coil units are switched off.

he controls of the fan coil unit will also at the same time switch off the solenoid valves, i.e.

FAN COIL UNIT 1

FAN COIL UNIT 2

Mini Chiller

2-way solenoid

2-way solenoid

T

there will not be any water flow through the system when the fan coils are not in use.

However, the chiller pump is still running. Therefore, the water pressure built-up in the piping

may cause damage to the water pump or to the valves themselves (valve stem lifting).

Usage of 2-way valves will require additional design considerations:

a. Add a Bypass Line to Relief Pressure

LOAD

∆

P

LOAD

LOAD

Different pressure transmitter to monitor the amount of water used. If

pressure goes higher than preset value, it will open the relief

bypass the water

valve and

Section 3 Page 49

Page 52

b. Use a Variable Speed Drive for the Secondary Water Pump.

LOAD

LOAD

LOAD

∆

P

INV

primary loop

When the differential pressure becomes higher, the inverter will slows

down the water pump to maintain the head pressure. If no demand,

the water pump will stop running.

c. Modify the Control Wiring for Chiller and Fan Coil Unit.

The above two methods will incur high cost due to the extra piping, pressure transmitter and

other necessary fittings/equipment.

An easier method is to change the control wiring of the system. Conventionally, when the

fan coil unit thermostat cuts-off, the power supply to the control 2-way valve will be off.

It is possible to run a line from the thermostat to the chiller remote switch whereby

when the thermostat cuts-off, the chiller unit (and the pump) will also switch off.

See Section 11 on 'Electrical Wiring Control' for more details.

However, the disadvantage with this method is that the chiller cycle on-off more frequently

and the water supply temperature will fluctuate up and down.

d. In view of the difficulties mentioned above, it is recommended that 3-way

diverting valves to be used in the mini chiller hydronic system.

Since the 3-way valve gives a constant flow system, there will not be any problem when

there is no load demand since the water will bypass through the valve when it is in the

fully closed position (with respect to the load).

Section 3 Page 50

Page 53

LOAD

LOAD

LOAD

However, this system has one main disadvantage. Since the supply water is by-passed around

the load coil, energy is wasted

. This will cause the chiller to cycle on-off more frequent as the

return water temperature becomes lower.

Therefore, in terms of energy efficiency, applications with 2-way valves are better.

Section 3 Page 51

Page 54

Other Type of Valves and Fittings

a. Check Valve

This valve will only allow flow in one direction, i.e. to prevent back flow of water.

We have seen an example of usage in Section 2 with multiple chillers installation.

There are two basic design of these check valves:

1. swing check valve - can be installed in horizontal or vertical piping

2. lift check valve - only for horizontal piping installation

Swing check valve

Lift check valve

b. Plug Cock/Plug Valve

This type of valve is also used for throttling duty. It is less expansive compared with the

globe valve or balancing valve. The setting also cannot be tampered with as easily as the

globe valve.

Valve stem without handwheel. Use

a spanner or wrench to open and close

valve.

Plug with orifice port. With a 90° turn, the

port will operate from fully open to fully

close.

Section 3 Page 52

Page 55

c. Pressure Gauge Cock

Generally, this valve is a ball valve. It is used to isolate pressure gauges installed along

the water pipe lines.

Main pipe line

Pressure gauge

Impulse tubing loop

Gauge cock (Ball valve)

The gauge cock is only opened during pressure measurement. When not in use, the valve

is closed to prevent prolonged pressurising to the gauge, therefore preventing damage

to the gauge itself. It is also closed when changing a new gauge.

d. Safety Relief Valve [Optional]

The valve will open when the pressure exceeds a set value to prevent over pressuring the

system which may cause damage. Normally, this is used when the system is running

hot water (mini chiller in heating mode/reverse cycle) in a closed piping. The hotter the water

temperature, the higher is the pressure due to expansion.

Such valves are also useful for protection against sudden pressure shocks, e.g. water

hammering, and overpressuring from water fill system.

If the system is with an open piping and external tank, this valve may be exempted.

The setting of the valve should be at least 10% higher than the expected maximum operating

pressure. It should be installed at the location where this pressure may be expected to

occur, e.g. near any expansion tanks or pump discharge lines.

Pipe the exhaust from the relief valve to an external drain.

Section 3 Page 53

Page 56

e. Air Vent Valve

The mini chiller unit has an automatic air vent located on top of the buffer tank. This is to

release any trapped air inside the tank which may cause problem to the pumping operation.

This is especially so during heating operation where oxygen and hydrogen gases are formed

from the water and gets accumulated inside the tank. Air entrainment and microleaks along

the joints and valves of the pump suction line will also cause air to enter the water system.

Therefore, it is a good practice to install another air vent at the highest position

of the piping

network to ensure that the pump performance do not deteriorates.

Such air vents are also useful during commissioning and system start-ups to release any

air trapped in the piping system.

Always install the valve in a vertical position on top of a tank or pipe.

pipe

air vent

air vent

CORRECT INCORRECT

Under normal condition, water will enter inside the valve and lifts a floating body

which will raise a mechanism to close a pin-shutter. Reduction of the water level

as a result of accumulated air will cause the float to drop and opens the pin-shutter

thus releasing the air automatically.

float body

pin-shutter opens

Air venting Normal

Section 3 Page 54

Page 57

f. Strainer

The strainer is an important element in the piping system to remove particles (e.g. sand)

and dirt from the water. If not, these impurities will damage the pumping mechanism and

clogged-up valves and fittings.

IMPORTANT!!!

The mini chiller unit do not have a strainer built-in. Always install a strainer on

the water inlet pipe into the chiller to protect the internal water pump.

straine

r

CHILLER

water outlet

water inlet

Do not install strainer on the water outlet pipe as the water velocity is higher.

Install the strainer with the filter element in a downward position. This is to facilitate easy

flushing during periodic cleaning.

allow sufficient s

p

ace to remove filte

r

strainer with filter in downward

p

osition

pump

floor

## This method is not recommended

pump

straine

r

Section 3 Page 55

Page 58

water inlet

filter mesh 16 – 20

recommended

There is also a practice to install a strainer on the inlet pipe to a fan coil unit. This is

done to protect the control valve, located at the outlet pipe, from clogging.

strainer

FAN COIL UNIT

2-way valve

to measure th water te peratur

stallation can be done with a socket welded onto the pipe or a tee joint connection.

g. Thermometer

Glass thermometers are installed on the inlet and outlet pipes of either the chiller unit

or fan coil units. This is e m e differential to determine the

capacity performance.

Usually, these thermometers are installed together with the pressure gauges.

In

r

threadedjoint

welded

j

oint

threaded

thermomete

socket

Flow

j

oint

tee

j

oint

Thermometers can be installed vertically, horizontally or even at an angle.

Section 3 Page 56

Page 59

During installation, it is important to ensure that the sensing bulb is in touch with the flowing

stream of water. If the thermometer is installed too "high" up the connecting socket, the

bulb will measure the temperature of stagnant water in the socket.

thermometer too

high up

stagnant water

Thermometer bulb

measuring correct

water flow

temperature

CORRECT INCORRECT

Section 3 Page 57

Page 60

Valve Sizing

In selecting the suitable valve to use for an application, the following items must be

considered:

1. What is the fluid medium of usage.

In chillers, the fluid is water. There are valves specially designed other fluids e.g. steam and

air, which are not suitable for water.

2. What is maximum operating pressure and temperature.

3. What is the valve duty required - is it for throttling, shut-off, balancing, mixing, etc.

4. What is the pipe size to be connected

Do not oversize or undersize a valve to suit the pipe size. Size the valve according to the

flow requirements. Use reducers where applicable.

5. What is the flow rate required through the valve

6. What is the flow characteristics required - linear, equal percentage (See following pages)

7. What is the piping connection method to the valve - threaded, flanged

Most of the above mentioned information may be obtained from the valve catalogs provided

by the valve manufacturers.

In sizing the valve, the general accepted method is by means of the C

v

(flow coefficient).

Different valves will have different C

v

values.

Formula:

Q = Cv * (∆p)

Definition: The C

v

rating of any valve is the amount of water,Q (GPM) at standard conditions

(60°F, specific graviti = 1) which will pass through the valve with a pressure drop, ∆p of 1 psi

with the valve in a full open position.

By using conversion factors, we can have the flow coefficient K

v

in metric units:

1 C

v

= 0.857 Kv

Definition: The K

v

rating of any valve is the amount of water (m3/hr) at standard conditions

(20°C, specific graviti = 1) which will pass through the valve with a pressure drop of 1 kg/cm

2

with the valve in a full open position.

If the reference pressure is 1 bar, then:

1 C

v

= 0.867 Kv

Section 3 Page 58

Page 61

For a given flow rate, we can select a valve with suitable Cv to give an appropriate pressure

drop. These data are available in graphs provided by the manufacturer. See Appendix 5.

Selection of the valve must be done so as not to have too high a pressure drop, else the

water pump head will be insufficient for the system. The values of these valve pressure

drop can also be used during pump sizing. See Section 5.

For control valves (modulating, throttling duty, 2-way and 3-way), the pressure drop should

be no less than half the total pressure drop in the branch. This will allow a stable control.

Example :

Pressure drop = 6 feet

FAN COIL UNIT

A

B

3-wa

y

supply

return

Pressure losses along piping works from A to B = 4.6 feet

Pressure drop across 2 gate valves + coil heat exchanger = 6 feet

Therefore, the control 3-way valve should have a pressure drop of at least

= 2 * (4.6 + 6)

= 21.2 feet

= 9.2 psi ** Conversion: 1 psi = 2.309 feet water

If the flow rate through the branch is 6 GPM, what valve C

v

should be used?

Refering to the graph in Appendix 5, the C

v

should be 2.

Therefore, a 3-way diverting valve with C

v

of 2 (at full opening) should be selected

for the above application.

As can be seen from the example above, the valve sizing was done with the design flow

at full opening. Thus, at reduced flows, the valve will close and this will increase the

pressure drop.

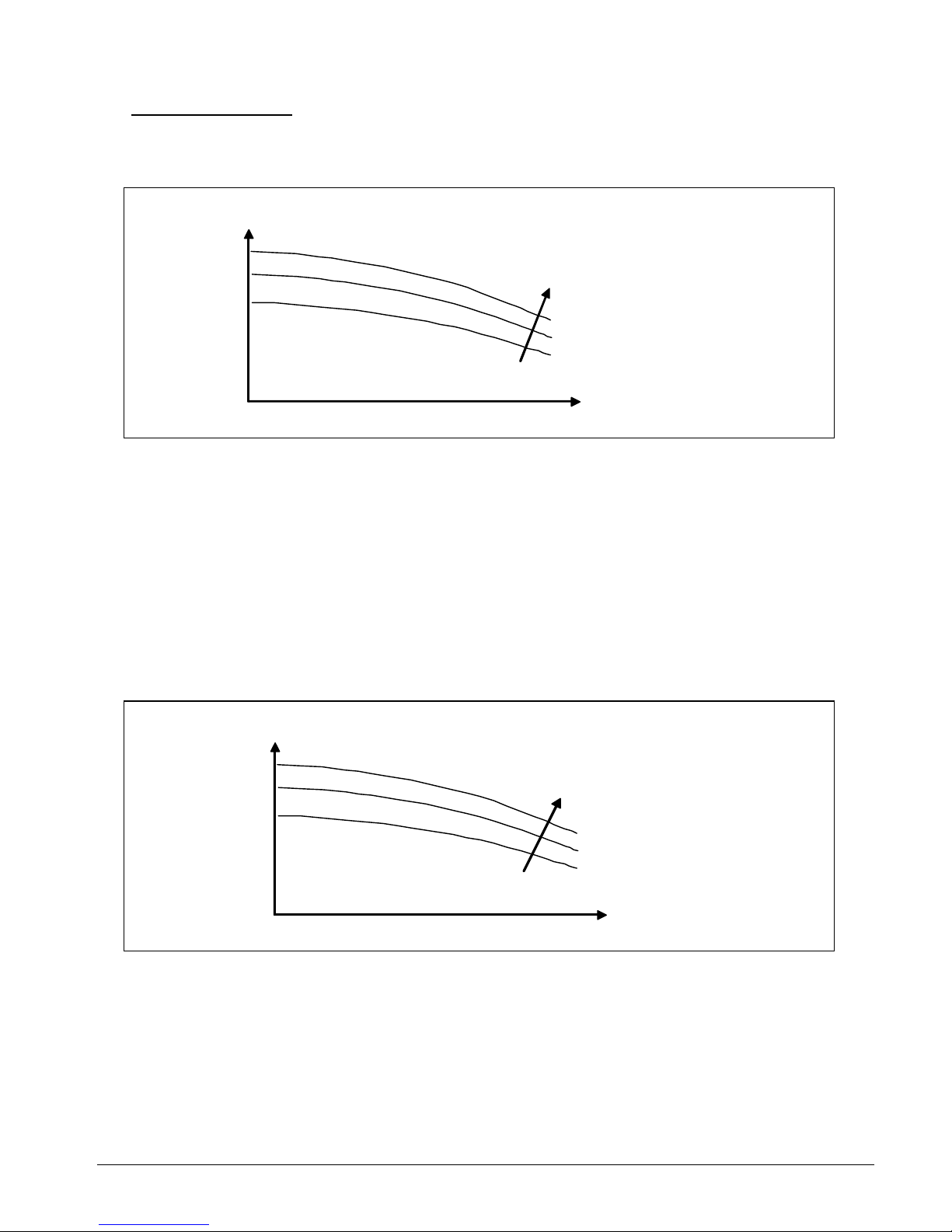

This can be seen from the following graph which depicts the system curve and pump

curve for a single fan coil load. See Section 5 for more details on pump curves.

Section 3 Page 59

Page 62

Head Pressure

pressure drop

of control valve

at full opening

increased

pressure

drop with

reduced

flow

pressure

drop of

val ve wi th

zero flow

pump curve

system curve w/o control valve

Flow rate

Reduced flow Design flow

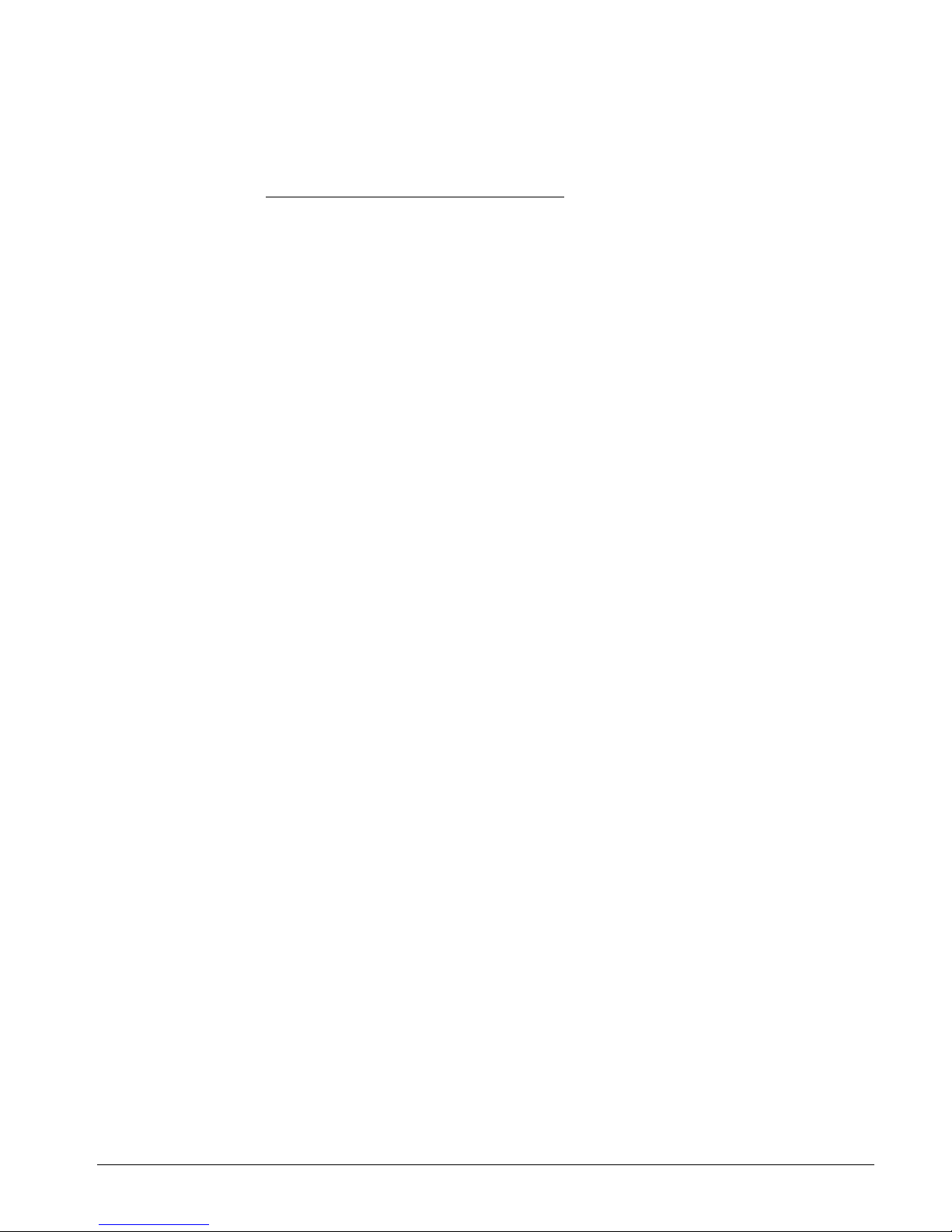

Another consideration in selecting the suitable valve is to determine the flow characteristic

through the valve. Generally, there are three types:

1. Quick Opening

The valve shows a quick increase of flow for a small increase of opening. But as it reaches

the open position, the rate at which the flow increases per movement of the opening reduces.

2. Linear

This valve produces equal rate of flow increase per equal rate of opening.

3. Equal Percentage

This type of valve produces an exponential flow increase as the valve opens up. The term

equal percentage means that for equal amouts of valve opening, the flow increases by the

same percentage.

SELECT THIS TYPE OF

CHARACTERISTICS

Section 3 Page 60

Page 63

Selection of valve with equal percentage flow characteristics will give the best performance

as this will give a linear heat transfer rate with flow rate:

Heat transfer

rate, %

Valve opening Flow rate, %

For automatic on-off valves (e.g. solenoid 2-way, 3-way), the selection is easier. Generally,

use the same size as the pipe size, with a low pressure drop (e.g; 2 -5 psig: fully open).

Using a smaller size (with pipe reducers and adaptors), for economic reasons, is possible,

but check for excessive pressure losses which will reduce the pump performance.

Section 3 Page 61

Page 64

Guidelines for Valve and Fitting Installation:

a. Gate valves (shut-off) are installed in the entering and leaving piping to the chiller and

fan coil unit. This is to permit servicing and replacement of the equipment without draining

the system. A globe valve may be used to serve as one of the shut-off valve and in

addition to balance the flow rate.

b. Valves and fittings using threaded or welded joints will require unions to permit easy

removal for servicing or replacement. Unions are usually located between each gate valve

and the equipment. Unions are also place before and after the control valve, and in the

branch of the 3-way valve.

If flange joints are used, the need for unions is eliminated.

c. Locate the control valve in between the gate valve and the equipment to permit removal

of the control valve without draining the system.

d. Strainers, thermometers and pressure gauges are located between the gate valve and

the equipment.

Section 3 Page 62

Page 65

The following diagrams illustrate examples of piping layout:

P

T

P

T

Typical Mini Chiller Piping Installation:

Water su

pply

Water return

1-1/4” connecto

r

Make-up water (from

main supply or water

tank)

RETURN

SUPPLY

gauge cock

FAN COIL UNIT

Typical Fan Coil Unit Installation:

a. Horizontal installation

Section 3 Page 63

Page 66

Section 3 Page 64

Supply riser T

Return riser

T

FAN COIL UNIT

3-way mixing valve

tee joint

air vent

globe valve

FAN COIL 1 FAN COIL 2 FAN COIL 3

T

T

3-way

diverting

valve

b. Vertical Installation

T

T

o Multiple Fan Coil Unit Installation

T

** All three fan coil units to serve one area with a

common thermostat. When temperature has

reached set point, thermostat will send signal to 3 way valve to divert water away.

Page 67

Section 3 Page 65

CHILLER 3

CHILLER 2

CHILLER 1

T

P

T

P

check valve glove valve

Make-up

water

Return

Supply

Multiple Chiller Installation

Common Header

** Globe valve will be used to balance the flow rate through each chiller unit.

** Additional gate valves may be installed along the main supply and return lines

to isolate the entire chiller assembly.

Page 68

Primary-Secondary System

glove valve

secondary pump

RETURN

CHILLER

tee joint

(Remember ! Do not encourage

bullheading here)

Water Tank Installation (Open System)

RETURN

RETURN

TANK

adaptor(c/w nubber gasket)

To external pump

CHILLER

SUPPLY

Section 3 Page 66

Page 69

Section 4: Pipe and Fitting Sizing

In the previous section, we have looked at the different types of pipes which can be used in a

hydronic system. We have also looked at the various types of fittings used in conjunction with

the piping.

In this section, we will examine the friction losses

which occur when water flows through the pipes

and fittings.

Friction losses are dependent on the following factors:

a. Water velocity

b. Pipe internal diameter

c. Pipe length

d. Pipe internal wall roughness

Generally, friction increases when:

- Water velocity increases

- Internal diameter decreases

- Pipe length increases

- Wall roughness increases

The basic formula to calculate pipe friction losses (Hf) is the Darcy-Weisbach formula:

Hf = f * (L/D) * v

2

/2g where f = friction factor

L = pipe length

D = pipe internal diameter

v = mean velocity

g = acceleration due to gravity

The friction factor is a function of the roughness parameter, e, which in turn

depends on the pipe material (e.g. steel, copper, PVC), and the Reynolds number,

Re.

Re = D * v ρ / * µ where ρ = density

µ = dynamic viscosity

Generally, the friction losses are presented in graphical form, for various pipe material.

See attached charts for steel pipe Schedule 40,copper pipe and PVC.

Note that Carrier

has developed two different type of graphs for steel pipes, i.e. for close and

open system. The friction losses for the open system is higher than the close system, for the

same parameters. This is to take into account the vulnerability of open systems to cause pipe

fouling and scaling on the internal surfaces. A factor of approximately 1.75 is used for this

purpose.

It is to be noted that the pipe friction loss charts presented are all for flows in the turbulent regime

(Re > 10 000).

Section 4 Page 67

Page 70

Water Flow Limitations