Page 1

Catalog

413-4

McQuay®Steam Coils

Types HI-F5, HI-F8 & E-F5

Page 2

HI-F5, HI-F8 & E-F5 steam coils HI-F5, HI-F8 & E-F5 steam coils

SelectTOOLSTM for

Contractor Coils

McQuay offers an unmatched variety of standard fin spacings,

row and circuiting combinations. For optimum coil selection,

McQuay's SelectTOOLSTM for Contractor Coils selection program makes it easy to select the most economical standard or

special application coil to meet your job requirements.

Contact your local McQuay representative for a coil selection

that meets the most exacting specification.

ARI certification

McQuay steam coils are certified in accordance with the forced

circulation air cooling and air heating

coil certification program, which is

based on ARI Standard 410.

To obtain ARI certification ratings, it is

first necessary to have the testing facilities reviewed for proper instrumentation, control and accuracy of test data.

A coil is then submitted to an ARI

approved independent testing facility

for comparative tests. ARI then

approves the coil manufacturer’s testing facilities. After the testing facilities are approved, the coil is tested over a wide range

of operating conditions. All rating data is the reviewed by ARI

engineers for accuracy and confirmation that procedures established by ARI have been followed. Periodic check lists of production coils by ARI, on a random basis, assures compliance

with ARI standards.

SelectTOOLSTM.........................................................1

ARI certification..........................................................1

Nomenclature .............................................................2

Standard availability chart......................................3, 4

Design features ......................................................3, 4

Steam circuiting arrangements ..................................5

General specifications ...............................................6

Coil selection considerations......................................7

Sample coil selection and general formulas...............8

Conversion of air volume to standard air ...................9

Capacity data ...........................................................10

Hl-F5 capacity curves...............................................10

E-F5 capacity curves................................................11

HI-F8 capacity curves............................................. 12

Condensate loading factors .....................................13

Air pressure drop..................................................... 14

Coil selection data ................................................... 16

Dimensional data .................................................... 17

Piping data.............................................................. 19

Engineering guide specifications............................. 21

Note: special application coils may be outside the scope of ARI

Standard 410.

“McQuay" and "HI-F" are registered trademarks of McQuay International, Minneapolis, MN.

The McQuay HI-F fin surface is covered by U.S. Patent No. 3,645,330.

Copyright © 2001 McQuay International. All rights reserved throughout the world.

Bulletin illustrations cover the general appearance of McQuay International products at time of publication

and we reserve the right to make changes in design and construction at any time without notice.

Catalog 413 / Page 1

Page 3

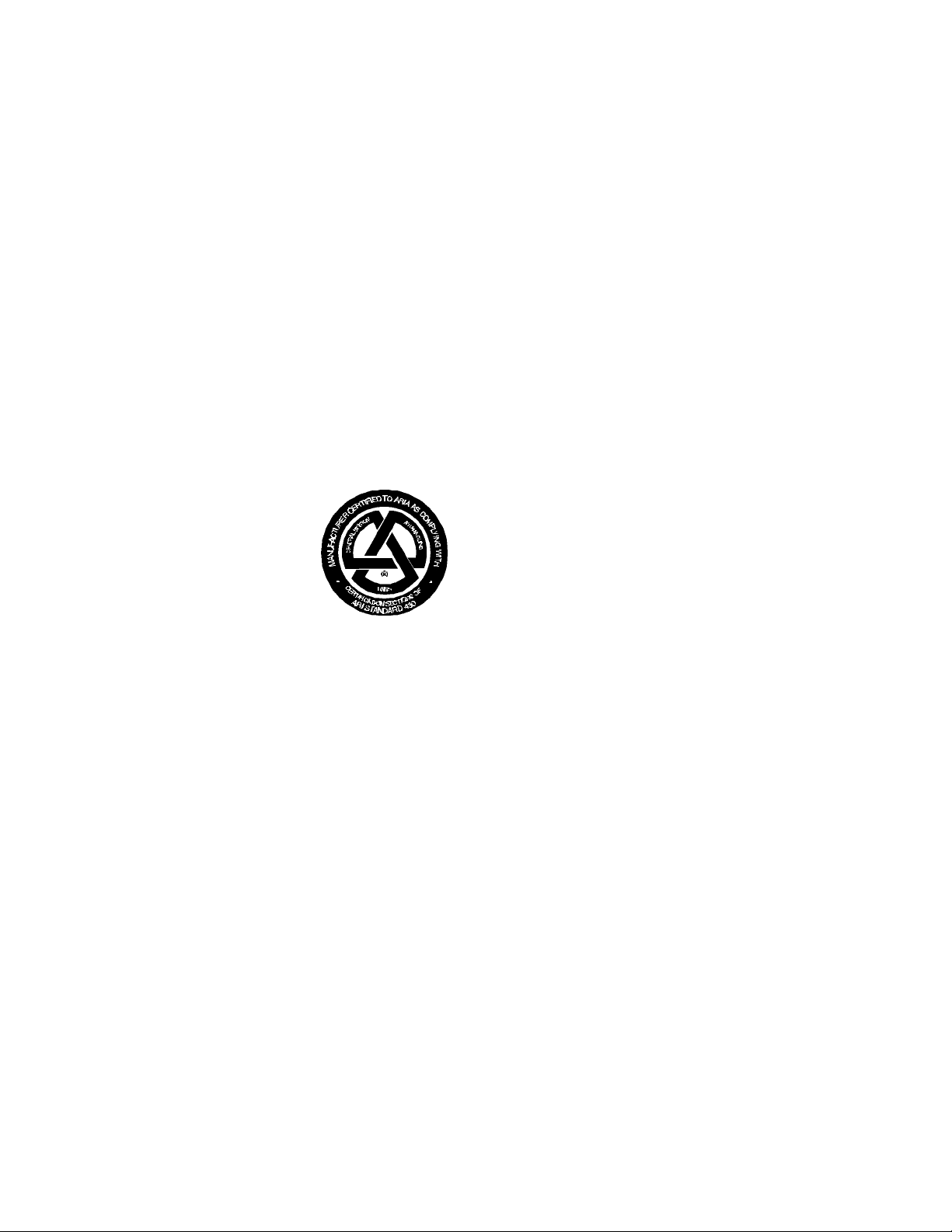

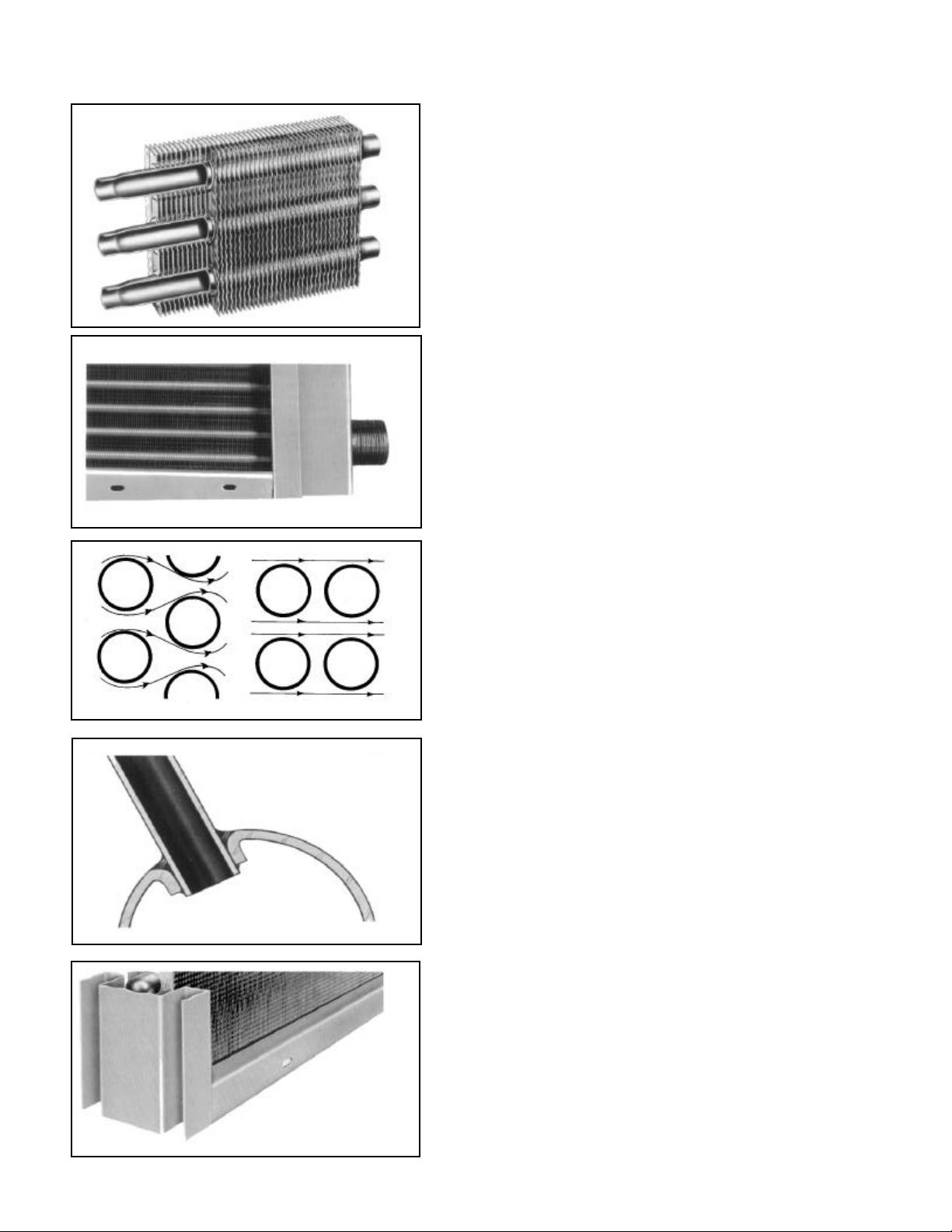

A pioneer in corrugated fin development A pioneer in corrugated fin development

HI-F Means High Efficiency

A principal factor governing fin heat transfer efficiency is the

boundary layer film of air adhering to any fin surface. This

boundary layer insulates the fin, severely reducing the rate

of heat exchange.

The advanced rippled-corrugated HI-F design creates a

state of continuous turbulence which effectively reduces the

boundary layer formation. The exclusive rippled edge

instantly deflects the incoming air to create initial turbulence.

A succession of corrugations across the fin depth, in conjunction with the staggered tubes, increases the turbulating

effect and eliminates the "dead spots" behind the tubes. In

this manner, the HI-F design establishes a high standard in

heat transfer efficiency yielding sharply increased performance. The rippled fin edge also strengthens the fin edge

and provides a pleasing overall appearance.

E-F Means Energy Efficient

The term "energy efficient," which is used to describe how

well a system utilizes energy, has become a common

expression in the HVAC industry.

With costs of energy rising, the need for cutting operating

expenses is apparent. Lowering the air pressure drop

across the face of the coil will reduce the fan brake horsepower requirement and fan motor electrical demand. The

need to cut operating energy expenses is met by the E-F fin

surface. The smoother fin design of the E-F surface results

in lower operating costs over the life of the equipment.

NomenclatureNomenclature

TUBE O.D.:

5 = 5/8 inch

8 = 1 inch

COIL TYPE:

5SA = Single tube, opposite end

5JA,8JA = Distributing tube, same end

8RA = Distributing tube, opposite end

5HA = High pressure construction,

5GA,8GA = High pressure construction,

8TA = High pressure construction,

Page 2 / Catalog 413

connection

connection

connection

single tube, opposite end connection

distributing tube, same end connection

distributing tube, opposite end connection

5 SA - 12 02 C - 033.00 - 090.00

FINS PER INCH:

HI-F5, E F5 (06, 07, 08, 09, 10, 11, 12, 13, 14)

HI-F8 (03, 04, 05, 06, 07, 08, 09, 10, 11, 12, 13, 14)

FINNED LENGTH (INCHES)

FIN HEIGHT (INCHES)

FIN DESIGN:

B = 01 & 02 ROW E-F5

C = 01 & 02 ROW HI-F5

B = 01 ROW HI-F8 (1”)

ROWS DEEP:

HI-F5, E-F5 (01, 02)

HI-F8 (01)

Page 4

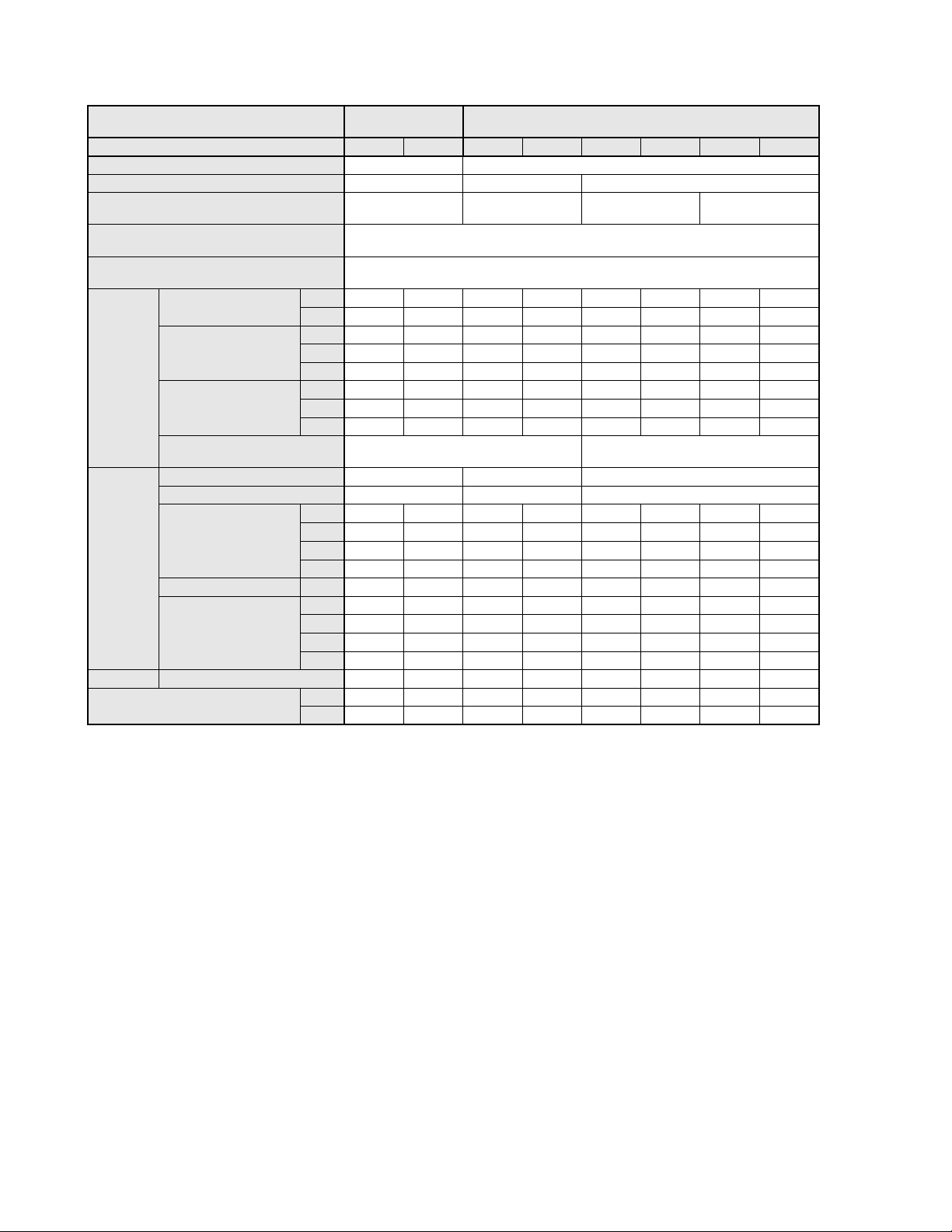

Standard availability chart Standard availability chart

COIL TYPE

COIL MODEL 5SA 5HA 5JA 5GA 8JA 8GA 8RA 8TA

SERPENTINE CIRCUIT Does not apply Does not apply

ROWS 1,2 1,2 1

CONNECTION

LOCATION

FIN HEIGHT

3" INCREMENT

FINNED LENGTH

1-1/2" INCREMENT

FIN TYPE

ALUMINUM

FINS

COPPER

SPACING

(FPI)

DIAMETER 5/8 5/8 1

FACE C/C 1.5 1.5 3.0

COPPER

TUBING

ADMIRALTY BRASS .049 ll ll

CUPRO-NICKEL

HEADERS STANDARD MAT'L Copper Cu Ni Copper Cu Ni Copper Cu Ni Copper Cu Ni

MAXIMUM STD.

OPERATING LIMITS

HI-F

E-F

.0075

.0095

.0120

.006 ll

.0075 ll

.0095 ll

.020

.025

.035

.049 ll ll ll ll

.020 ll ll

.032 ll ll

.035 ll ll

.049 ll ll ll ll

P 150 Psig 350 Psig 150 Psig 350 Psig 150 Psig 350 Psig 150 Psig 350 Psig

T 366 F 450 F 366 F 450 F 366 F 450 F 366 F 450 F

STEAM

(SINGLE TUBE)

Opposite End Same End Same End Opposite End

12-42

12-129

ll ll ll ll

ll ll ll ll

ll ll ll ll

ll ll ll

ll ll ll ll* ll* ll* ll*

ll ll ll ll* ll* ll* ll*

6,7,8,9,10,11,12,13,14 3,4,5,6,7,8,9,10,11,12,13,14

ll

ll

ll

ll

ll ll ll

ll

STEAM

(DISTRIBUTING TUBE)

ll ll ll ll

ll* ll* ll* ll*

ll ll ll

ll

ll Feature Available

* Requires 6 fins per inch or more.

Flexibility

Along with the standard offerings, optional materials and special configurations are provided to meet many different specifications. Extra long finned lengths, intermediate tube supports, along with a wide variety of tube wall and fin thicknesses are available. Casings can be constructed of galvanized steel, aluminum, stainless steel or copper. Optional connection materials such

as steel, red brass or copper (sweat) are offered along with butt-weld, victaulic or flange type connections. Coil coatings can be

phenolic or Electro Fin. These are just a few of the options and specials that can be provided. Consult your local representative

for your special coil requirements.

*Note: Special application coils may be outside the scope of ARI standard 410.

Catalog 413 / Page 3

Page 5

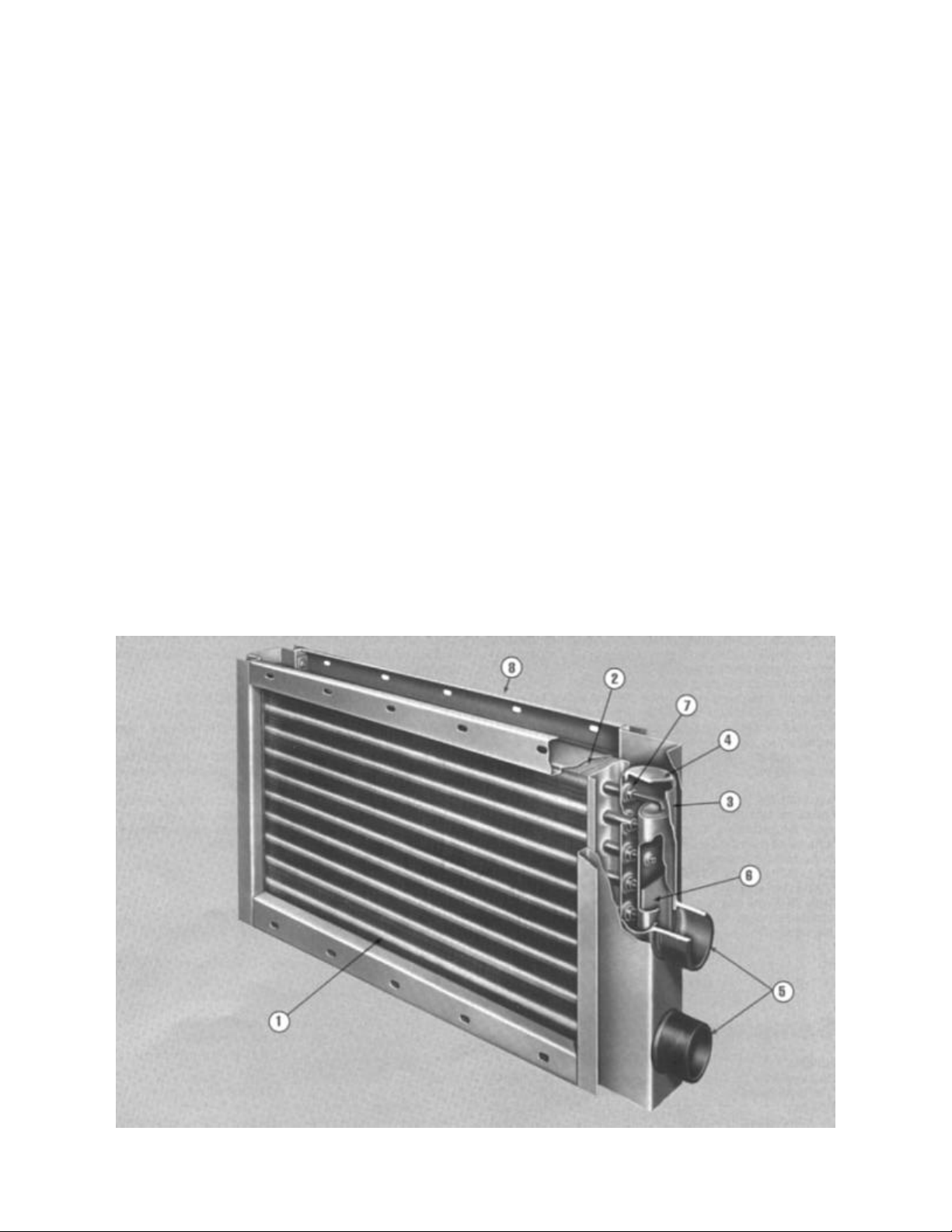

Design features

PATENTED FIN DESIGNS

The HI-F and E-F fin surfaces give the flexibility needed to perform at optimum efficiency. Seamless drawn copper tubes are

mechanically expanded into full drawn, die-formed fin collars to

provide positive metal-to-metal contact for high heat transfer

efficiency and long coil life.

PITCHED IN THE CASING

The specially designed casing automatically provides the

proper pitch for positive condensate removal resulting in

reduced installation and expense. Supply and return connections are properly sized for each coil to assure optimal distribution and proper condensate removal.

STAGGERED TUBE DESIGN FOR HIGH PERFORMANCE

The more moving air in contact with tubes in the coil, the more

performance obtained from the total available surface. The

staggered tube design exposes the tubes to more moving air

than the in-line design. The geometry of the staggered design

also allows the rows to be spaced closer together. This results

in a more compact coil providing higher capacities.

BRAZED COPPER TUBES-TO-COPPER HEADER JOINT

Seamless copper tubes brazed into heavy-gauge seamless

drawn copper headers. This combination of similar metals eliminates unequal thermal expansion and greatly reduces stress in

the tube-header joint. Intruded tube holes in the header allow

an extra large mating area for increased strength and flexibility

designed to provide many years of trouble-free service.

FREE FLOATING CORE

One of the most important requirements of a steam coil design

is to allow for thermal expansion without creating stress and

wear on the tubes.

To provide for this requirement, the coil core must be free to

expand and contract within the casing without inducing wear

on the tubes. A special coil casing has been designed in which

the coil core is free to float in a recessed fin channel. Since the

core is not supported by the tubes there is no resultant tube

wear. The recessed fin channel prevents air bypass while adding structural support to the casing.

Page 4 / Catalog 413

Page 6

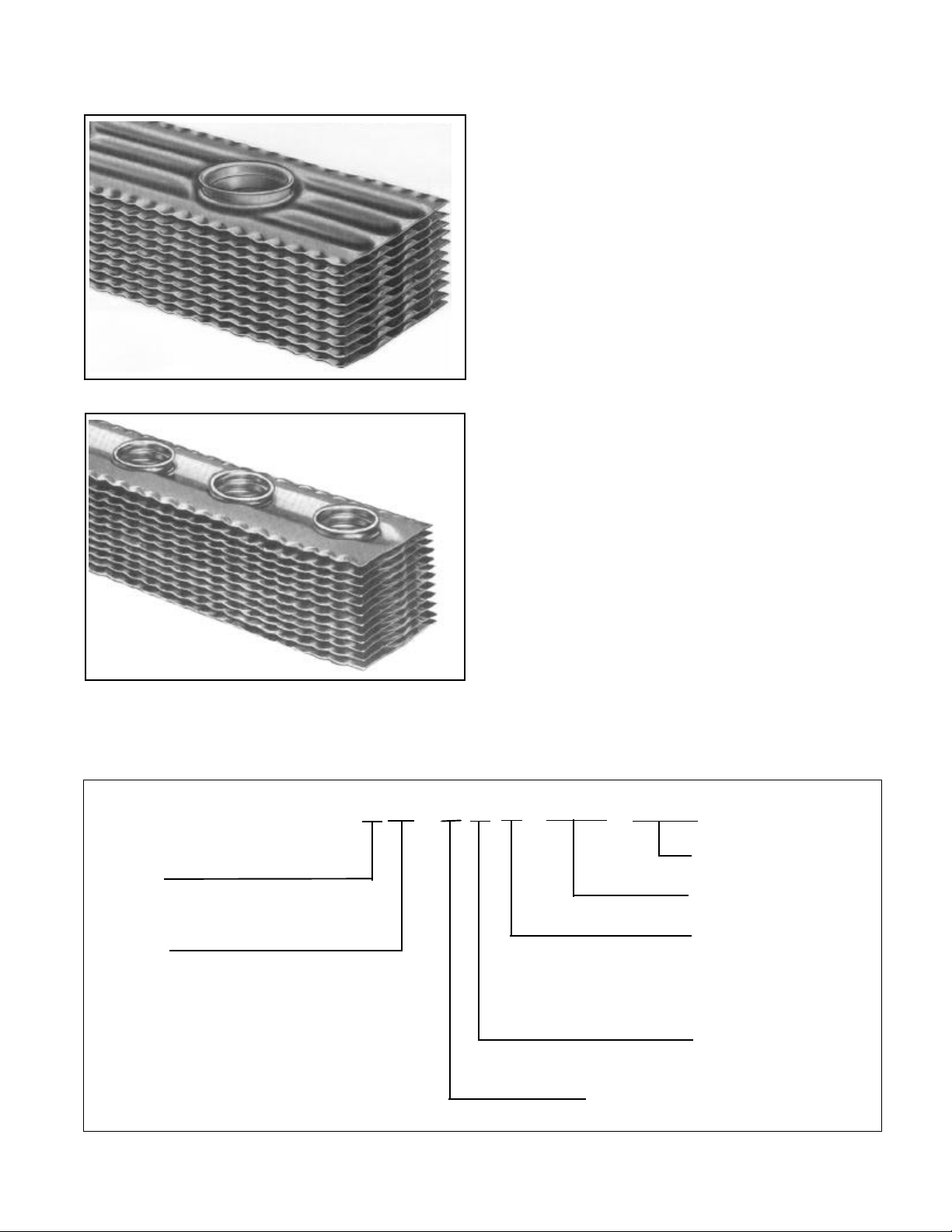

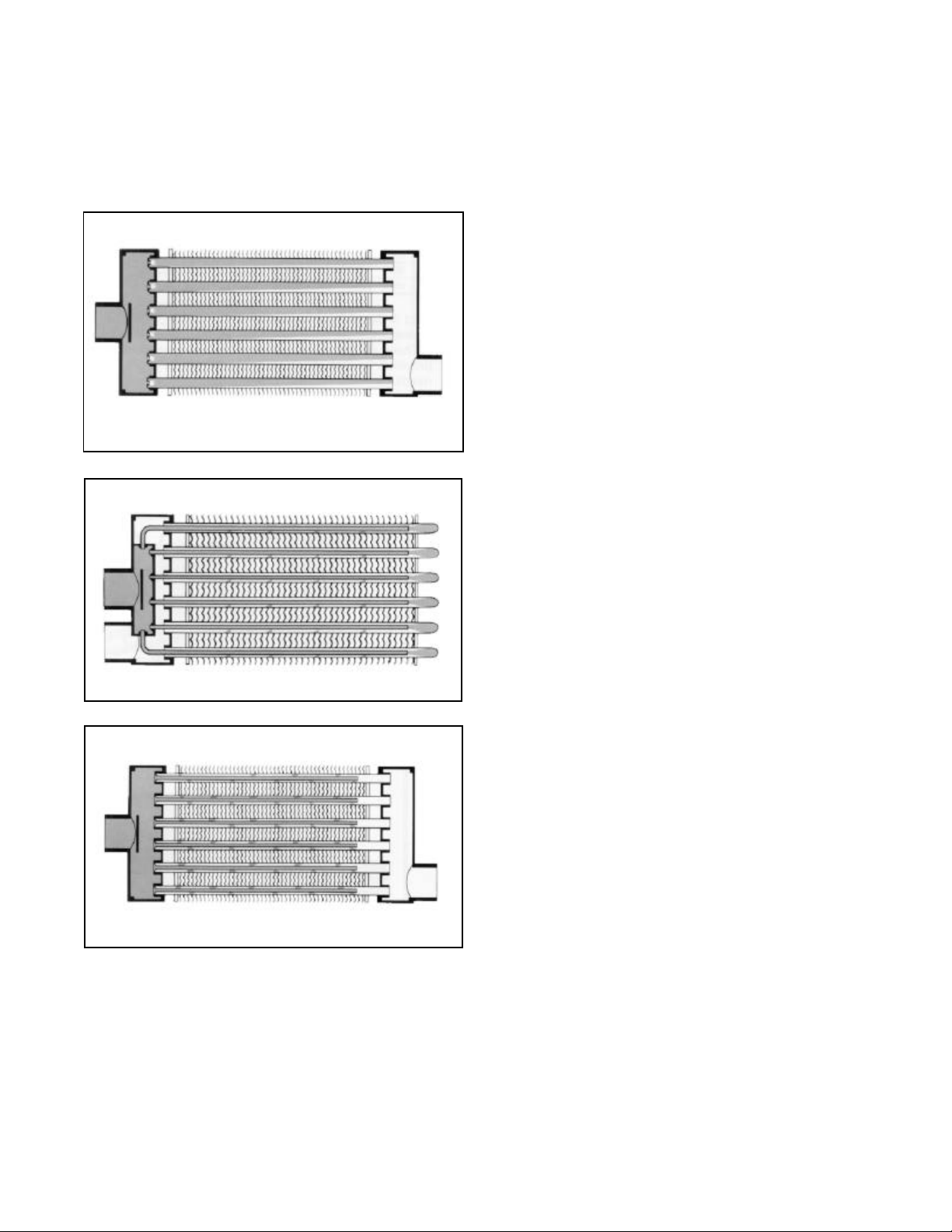

Steam circuiting arrangements Steam circuiting arrangements

Select Hl-F5, E-F5 and HI-F8 steam coils from three different circuiting arrangements: the general purpose 5SA coil, and two jet

tube steam distributing styles-5JA, 8JA and 8RA coils-intended for both general and special purpose heating. While each of

these arrangements has been carefully designed to serve a particular area in steam coil application, sufficient similarities are

present in design and performance to render them interchangeable in many cases. Optimal fin design provides a high performing heat transfer surface while a host of exclusive features provide extended coil life.

5SA & 5HA GENERAL PURPOSE STEAM COILS

5SA and high pressure 5HA steam coils are specifically

designed for economical general purpose heating. Featuring high quality and high capacity, they are an ideal choice

for all regular steam applications - heating, reheating,

booster and process use.

The sectional diagram illustrates the steam circuiting of

this single tube design. A perforated plate type steam baffle directly behind the supply connection ensures even

steam pressure across the entire header length. Inlet tube

orifices meter a uniform flow of steam into each tube.

5JA, 8JA, 5GA & 8GA

JET TUBE DISTRIBUTING COILS

5JA, 8JA and high pressure 5GA and 8GA jet tube steam

distributing coils are excellent for any general purpose

heating application. With the superior freeze resistance

provided by the tube-within-a-tube construction, they are

ideal for low temperature preheating and special process

applications.

The construction, as illustrated, features directional orificed inner tubes, a unique elliptical supply header located

inside the heavy-duty return header and a circuiting

arrangement which provides both supply and return connections at the same end of the coil.

8RA & 8TA OPPOSITE END CONNECTION

JET TUBE DISTRIBUTING COILS

8RA and high pressure 8TA jet tube steam distributing

coils are very similar in design and operation to the "JA"

coils except that supply and return connections are

located on opposite ends.

The directional orifices properly meter steam along the

entire tube length to assure a consistent temperature rise

across the full coil face and accelerate condensate

removal. This important feature is standard on all of our jet

tube steam distributing coils.

Catalog 413 / Page 5

Page 7

General specifications General specifications

1. PRIMARY SURFACE

5/8” O.D. and 1” O.D. round seamless copper tubes.

Cupro-nickel tubes are used for high pressure construction. Tubes are mechanically expanded to provide a continuous compression bond to the fins.

2. SECONDARY SURFACE

HI-F5, E-F5 and HI-F8 rippled-corrugated aluminum dieformed plate type fins. Fin collars are full drawn to provide

accurate control of fin spacing and maximum contact with

tubes.

3. HEADERS

Extra-heavy seamless copper tubing with intruded tube

holes. Provides flexibility for uneven stress during coil

expansion and contraction. Cupro-nickel used for high

pressure construction.

4. HEADER END CAPS

Heavy-gauge, die-formed copper. Monel used for high

pressure construction.

5. CONNECTIONS

Steel male pipe supply and return connections properly

sized for coil capacity. Other materials available on

request. (Red brass connections recommended for coils

used with non-ferrous piping.)

6. STEAM BAFFLES

Supply header baffle disperses entering steam. Prevents

blow-through or short circuiting and ensures equal steam

distribution to all coil tubes.

7. BRAZING

All core joints are brazed with copper brazing alloys.

Headers have intruded tube holes which provide maximum brazing surface and ensure lasting strength.

8. CASINGS

Die-formed heavy-gauge continuous galvanized steel

with reinforced flanges and 3/8” x 3/4” slots on 6” centers for easy mounting. Fin channels brace the core

assembly in the casing, preventing air bypass and

damage in handling.

9. PITCHED IN CASING

Coil cores are pitched in the casing toward the return

connection for horizontal airflow. Provides proper condensate drainage and ease of installation.

10. FREE FLOATING CORE

Design permits coil core to “float” free in the coil casing

during expansion and contraction.

11. TESTS

Complete coil tested leak free at 315 psig air pressure

under warm water containing special wetting agent.

12. OPERATING CONDITIONS

Standard coils rated up to 150 psig and up to 366°F

temperatures. High pressure coils up to 350 psig and

450°F. When steam pressure is above 25 psig, high

pressure coils are recommended for longer coil life.

Page 6 / Catalog 413

Page 8

Coil selection considerations Coil selection considerations

Because we offer a wide variety of steam coil types, materials and fin spacings, you can obtain a very accurate selection. To obtain proper selection of each coil, the following

variables should be considered.

ENTERING AIR TEMPERATURE

Two basic types of steam coils are offered - the single tube

steam coil and the jet distributing tube steam coil.

The single tube steam coil, type 5SA, is generally more

economical when applied in an above freezing environment.

When the entering air is near or below freezing, the jet distributing tube steam coils, types 5JA or 8JA, should be

selected to provide maximum resistance to coil freeze-up.

LEAVING AIR TEMPERATURE

The selection of a coil to deliver a desired leaving air temperature is relatively simple, as it involves only dry bulb temperatures and sensible heating. Steam coils may be accurately

selected to deliver the desired leaving air temperature by

varying the fin series and number of rows deep. In the interest of coil economy, the higher fin series should be used in

place of additional rows deep. However, in some instances,

the system air pressure drop and/or condensate loading may

dictate the use of a lower fin series and more rows deep.

Note: Oversized steam coils can present a control problem. Coils should be sized as accurately as possible.

OPERATING STEAM PRESSURES

Standard steam coil construction is designed to withstand

operating pressures up to 150 psig and give very satisfactory

service. However, the primary factors in coil life are erosive

and corrosive actions, both of which are greatly accelerated

with increased steam pressures. Corrosive action may be

partially controlled by using compounds that will maintain the

proper pH in the system. However, the best protection to prolong coil life is to use heavy-duty high pressure steam coil

construction. Although high pressure construction is not necessary up to 150 psig, it is highly recommended for longer

coil life and coil economy when operating steam pressures

exceed 25 psig.

LOWERING AIRSIDE PRESSURE DROP

The E-F5 fin is designed to lower the air pressure drop

from 20% to 30% for a given application. Although more

surface may be necessary to maintain capacity, the cost

can be amortized by the lower fan brake horsepower

requirements. The payback may be realized in just a few

months.

FREEZING CONDITIONS

When the entering air to the coil is below freezing, the use

of coils in series airflow and the correct control system is

the best protection against coil freeze-up. In such a system, the first coil in the direction of airflow would use a

two-position control valve that would open to full steam

pressure (5 psig minimum) whenever the outside air temperature drops below freezing and would be capable of

raising the entering air from the minimum expected outside temperature to at least 35° F. The second coil would

use a modulating control valve and would raise the entering air up to the final required leaving air temperature. By

using this type of system, the first coil could not freeze,

because it would always be in full operation when the

entering air temperature is below 35°F. The second coil

could not freeze because the entering air temperature

would always be above 35°F.

For ease of control and maximum freeze protection, the

use of an additional preheat coil is recommended when

the entering air temperature is expected to drop well below

freezing. In such a system, the first coil would be the

smallest and would open at 35°F. The second coil would

open at about 10°F to 15°F outside air temperature,

depending on the capacity of the first coil. A third coil

would be modulated to obtain the final leaving air temperature.

In calculating the air temperature rise through the second and third coil, the leaving air temperature off the first

coil is used as the entering air temperature to the second

coil, etc.

For additional recommendations regarding freezing conditions, refer to page 19.

AIR VOLUME (CFM)

The CFM to be handled will be determined by the consideration of the installation. The coil size selected must be capable of handling the total CFM at face velocities (FPM)

acceptable to the heating application. Face velocities may

range from 200 to 1500 FPM with 600 to 700 FPM a common design range.

When the specified air volume is not at standard air conditions, 70°F and sea level, the CFM must be corrected, as

Illustrated on page 9, before using the curves and tables in

this catalog.

Sample coil selection

BTUH required...................................................... 1,830,000

CFM (standard air)..................................................... 24,000

Coil face................................................................36” x 120”

Saturated steam pressure..........................................10 psig

Entering air temperature.............................................-10° F

Coil type..............................................HI-F Single Tube Coil

INDIVIDUAL INSTALLATION REQUIREMENTS

Each installation will have its own particular requirements.

Normally one of the wide variety of our steam coils will

conveniently fill these requirements without modification.

If the application is to be zoned, the uniform air temperature distribution of types 5JA, 8JA and 8RA makes these

coils well suited.

Where problems such as special controls, atmosphere

contamination, special process applications, etc., indicate

the need for a special coil, contact your local representative. This individual welcomes the opportunity to assist you.

Coil face area: FA = 36 x 120 = 30.0 sq. ft.

144

Coil face velocity: FV = CFM = 24,000 = 800 FPM

FA 30.0

Catalog 413 / Page 7

Page 9

TR/ITD METHOD:

1. Determine TR/ITD:

TR = Lvg. Air - Ent.Air = BTUH

1.09 x CFM

1,830,000 = 70°F

1.09 x 24,000

ITD = Sat. Steam Temp. - Ent. Air Temp.

Sat. Steam Temp. = 239.4 (Table 2, page 16)

TR/ITD = 70 = 0.281

239.4 - (-10)

2. Initial Selection

Enter Figure 3 at 800 FPM to determine which coil meets

or exceeds a TR/ITD of 0.281. A 5SA1001C coil has a

TR/lTD of 0.292.

3. Determine Condensate Loading Factor (FL)

BASE TEMPERATURE RISE METHOD:

1. Determine Air Temperature Rise

TR = BTUH = 1,830,000 = 70°F

1.09 x CFM 1.09 x 24,000

2. Determine Steam Conversion Factor (FS)

FS = 1.098 (Table 1, page 16)

3. Determine Condensate Loading Factor (FL)

Condensate Loading = BTUH

Assume 1-row coil. If 1-row coil does not meet required

capacity, the following steps should be repeated for a 2row coil:

Latent Heat x Tubes Fed

Latent Heat = 952.6

(Table 2, page 16)

Condensate Loading = BTUH

Latent Heat = 952.6 (Table 2, page 16)

Tubes Fed = 24 (Table 3, page 16)

1,830,000 = 80.0 Lb./Hr./tube

952.6 x 24

Enter Figure 6 at 80.0 lbs./hr./tube and 10 psig to find

FL = 0.995.

4. Final Selection

Actual TR/ITD = 0.292 x 0.995 = 0.290 (greater than 0.281)

Final Selection: 5SA1001C - 36 x 120

5. Air Pressure Drop

Refer to Figure 12 and find air pressure drop of 0.37” H20.

6. Determine Actual Condensate Loading

Actual TR = 0.290 x [239.4 - ( - 10)] = 72.3

Actual BTUH = (1.09)(24,000)(72.3) = 1,892,000

Actual Condensate Load = BTUH

1,892,000 = 1986 Lb./Hr.

7. Determine Actual Leaving Air Temperature

Actual Lvg. Air Temp. = Ent. Air Temp. + TR

= (-10) + 72.3 = 62.3°F

Latent Heat x Tubes Fed

Latent Heat

952.6

Tubes Fed = 24 (Table 3, page 16)

1,830,000 = 80.0 Lb./Hr./tube

952.6 x 24

FL = 0.995 (Figure 6)

4. Determine Base Temperature Rise Required

Base Temp. Rise Required = Air Temp. Rise

FT x F

70 = 64.1°F

1.098 x 0.995

5. Coil Selection

Enter Figure 3 at 800 FPM to determine which coil

meets or exceeds a base temperature of 64.1°F A

5SA1001C coil has a base temperature of 66.2° F.

Final Selection: 5SA1001C - 36 x 120.

6. Air Pressure Drop

Refer to Figure 12 and find air pressure drop of

0.37” H20.

7. Actual Condensate Loading

Actual TR = Base x FT x F

66.2 x 1.098 x 0.995 = 72.3

Actual BTUH (1.09)(24,000)(72.3) = 1,892,000

Actual Condensate Load = BTUH

Latent Heat

1,892,000 = 1986 lb/hr.

952.6

L

L

General formulas

1. BTUH: BTUH = 1.09 x CFM x Temperature Rise

Where: 1.09 = 0.242 x 60 x 0.075

0.242 = Sp. Ht. of Air at 70°F

60 = Min./Hr.

0.075 = Density Std. Air in Lbs./Cu.Ft.

Temp. Rise = Lvg. Air Temp. - Ent. Air Temp.

2. Temperature Rise (TR): TR = BTUH

1.09 x CFM

3. Leaving Air Temperature

Lvg. Air Temp. = Ent. Air Temp. + Temp. Rise

4. Initial Temperature Difference (ITD):

Page 8 / Catalog 413

5. Face Velocity (FPM):

FPM = CFM

Face Area (Sq. Ft.)

6. Pounds Condensate:

Lbs. Cond./Hr. = BTUH

Latent Heat of Steam

7. Condensate Loading:

Lbs. Cond./Hr./Tube = BTUH

Latent Heat of Steam x No. Tubes Fed

Page 10

Conversion of air volume to standard air Conversion of air volume to standard air

Figure 1. Temperature Conversion Factor

When the specified air volume

(CFM) is given at any temperature

other than 70°F or any altitude

other than sea level, these charts

should be used for correction

before using the capacity and pressure drop tables which are based

on CFM at standard air conditions.

EXAMPLE:

To convert 15,900 CFM of air at

95°F and at 3,000 feet altitude to

standard conditions:

CFM of Standard Air

= (CFM of Specified Air x F

= 15,900 x 0.955 x 0.896

= 13.600

x FA )

T

Where:

FT = Temperature Conversion Factor

FA = Altitude Conversion Factor

The CFM of standard air should be

used to determine face velocity

through the coil, which in turn is

used to determine heat transfer values, and the air pressure drop

through the coil.

The air pressure drop value taken

from Figures 12, 13, and 14 must

be converted to altitude to be used

for static pressure calculations. To

convert the air pressure drop from

standard air at sea level to the air

pressure drop at altitude use the

following equation:

Pressure Drop = Pressure Drop at Sea Level

at Altitude FT x F

A

1.30

1.25

1.20

1.15

1.10

1.05

1.00

0.95

0.90

0.85

0.80

TEMPERATURE CONVERSION FACTOR

0.75

0.70

0.65

Figure 2. Altitude Conversion Factor

1.025

1.000

0.975

0.950

0.925

0.900

0.875

0.850

0.825

0.800

0.775

ALTITUDE CONVERSION FACTOR

0.750

0.725

0.700

-500 0 500 1500 2500 3500 4500 5500 6500 7500

TEMPERATURE CONVERSION FACTOR - F

-50 -25 0 25 50

ALTITUDE CONVERSION FACTOR - F

75

ALTITUDE (FEET ABOVE SEA LEVEL)

125 150 175 200 225 250 275 300 325 350

100

TEMPERATURE (°F)

T

1.30

1.25

1.20

1.15

1.10

1.05

1.00

0.95

0.90

0.85

0.80

TEMPERATURE CONVERSION FACTOR

0.75

0.70

0.65

A

8500

1.025

1.000

0.975

0.950

0.925

0.900

0.875

0.850

0.825

0.800

0.775

ALTITUDE CONVERSION FACTOR

0.750

0.725

0.700

Catalog 413 / Page 9

Page 11

Capacity data Capacity data

Figure 3. Steam Capacity Curves for HI-F5 Coils - 5SA & 5HA*

CAPACITY FOR ODD FIN SPACINGS MAY BE FOUND BY INTERPOLATION

.90

HI-F5HI-F5

.80

180

170

.60

.70

.50

.40

.30

FPI & ROWS 1402

FPI & ROWS 1202

FPI & ROWS

1002

FPI & ROWS

0802

FPI & ROWS

FPI & ROWS

FPI & ROWS

FPI & ROWS

FPI & ROWS

FPI & ROWS

0602

1201

1001

0801

160

150

140

130

120

110

100

1401

90

80

70

BASE TEMPERATURE RISE (°F) AT 5 PSIG & 0°F ENTERING AIR

60

0601

.20

TR/ITD AIR TEMPERATURE RISE/DEGREE TEMPERATURE DIFFERENCE BETWEEN STEAM AND ENTERING AIR

.10

300

* 5J/G coils may have slightly less capacity than shown. Use SelectTOOLSTM for Contractor Coils Program for optimum selection.

500

700

STANDARD AIR FACE VELOCITY, FT/MIN.

900

1100 1300 1500

Page 10 / Catalog 413

50

40

30

20

10

Page 12

Figure 4. Steam Capacity Curves E-F5 Coils - 5SA & 5HA*

CAPACITY FOR ODD FIN SPACINGS MAY BE FOUND BY INTERPOLATION

.90

.60

.80

.70

.50

.40

E-F5

FPI & ROWS 1402

FPI & ROWS

1202

FPI & ROWS

1002

FPI & ROWS

0802

180

170

160

150

140

130

120

110

100

90

80

.30

.20

TR/ITD AIR TEMPERATURE RISE/DEGREE TEMPERATURE DIFFERENCE BETWEEN STEAM AND ENTERING AIR

.10

300

* 5J/G coils may have slightly less capacity than shown. Use SelectTOOLSTM for Contractor Coils Program for optimum selection.

500

700

STANDARD AIR FACE VELOCITY, FT/MIN.

FPI & ROWS

FPI & ROWS

FPI & ROWS

FPI & ROWS

FPI & ROWS

900

1401 & 0602

1201

1001

0801

0601

1100 1300 1500

Catalog 413 / Page 11

70

60

50

40

30

20

10

BASE TEMPERATURE RISE (°F) AT 5 PSIG & 0°F ENTERING AIR

Page 13

Figure 5. Steam Capacity Curves for HI-F8 Coils - 8JA, 8RA, 8GA & 8TA

CAPACITY FOR ODD FIN SPACINGS MAY BE FOUND BY INTERPOLATION

.90

HI-F8HI-F8

.80

180

170

.70

.60

.50

.40

FPI & ROWS 1401

.30

.20

TR/ITD AIR TEMPERATURE RISE/DEGREE TEMPERATURE DIFFERENCE BETWEEN STEAM AND ENTERING AIR

.10

FPI & ROWS

FPI & ROWS

FPI & ROWS

FPI & ROWS

FPI & ROWS

FPI & ROWS

1201

1001

0801

0601

0401

0301

160

150

140

130

120

110

100

90

80

70

BASE TEMPERATURE RISE (°F) AT 5 PSIG & 0°F ENTERING AIR

60

50

40

30

20

300

* 5J/G coils may have slightly less capacity than shown. Use SelectTOOLSTM for Contractor Coils Program for optimum selection.

Page 12 / Catalog 413

500

700

STANDARD AIR FACE VELOCITY, FT/MIN.

900

10

1100 1300 1500

Page 14

Condensate loading factors Condensate loading factors

Figure 6. 5SA & 5HA Coils

1.00

L

100

.95

.90

CORRECTION FACTOR, F

.85

0

20 40

Figure 7. 5JA & 5GA Coils

1.00

L

.95

.90

CORRECTION FACTOR, F

.85

0

PSIG 2

20 40

PSIG 2

60 80 100

CONDENSATE LOADING, LB/HR/TUBE

5

60 80

CONDENSATE LOADING, LB/HR/TUBE

5

10

100 120

15

120

20

10

140

25

140

30

15

160

160

50

30

25

20

180 200 220 240

100

50

180 200 220 240

Figure 8. 8JA, 8RA, 8GA & 8TA Coils

1.00

L

.95

.90

CORRECTION FACTOR, F

.85

20

0

40

PSIG 2

60 80

CONDENSATE LOADING, LB/HR/TUBE

5

100 120

10

140

15

20

160

100

50

30

25

180 200 220 240

Catalog 413 / Page 13

Page 15

Air pressure drop Air pressure drop

Figure 12. 5SA, 5HA, 5JA & 5GA Coils Figure 13. 8JA, 8GA & 8RA Coils

HI-F5

HI-F8

NOTE: Air pressure drop for odd fin spacings may be found by interpolation.

Page 14 / Catalog 413

Page 16

Figure 14. 5SA, 5HA, 5JA & 5GA Coils

E-F5

NOTE: Air pressure drop for odd fin spacings may be found by interpolation.

Catalog 413 / Page 15

Page 17

Coil selection dataCoil selection data

Table 1. Steam Conversion Factors (FS)

ENT.

AIR

TEMP

-20 1.021 1.050 1.088 1.142 1.187 1.227 1.263 40 0.757 0.786 0.824 0.878 0.923 0.963 0.999

-15 0.999 1.028 1.066 1.120 1.165 1.205 1.241 45 0.753 0.764 0.802 0.856 0.901 0.941 0.977

-10 0.977 1.003 1.044 1.098 1.143 1.183 1.219 50 0.713 0.742 0.780 0.834 0.879 0.919 0.955

-5 0.955 0.984 1.022 1.076 1.121 1.161 1.197 55 0.691 0.720 0.758 0.812 0.857 0.897 0.933

0 0.933 0.962 1.000 1.054 1.099 1.139 1.175 60 0.669 0.698 0.736 0.790 0.835 0.875 0.911

5 0.911 0.940 0.978 1.032 1.077 1.117 1.153 65 0.647 0.676 0.714 0.768 0.813 0.853 0.889

10 0.889 0.918 0.856 1.010 1.055 1.095 1.131 70 0.625 0.654 0.692 0.746 0.791 0.831 0.867

15 0.867 0.896 0.934 0.988 1.033 1.073 1.109 75 0.603 0.632 0.670 0.724 0.769 0.809 0.845

20 0.845 0.874 0.912 0.966 1.011 1.051 1.087 80 0.581 0.610 0.648 0.702 0.747 0.787 0.823

25 0.823 0.852 0.890 0.944 0.989 1.029 1.065 85 0.559 0.588 0.626 0.680 0.725 0.765 0.801

30 0.801 0.830 0.868 0.922 0.967 1.007 1.043 90 0.537 0.566 0.604 0.658 0.703 0.743 0.779

35 0.779 0.808 0.846 0.900 0.945 0.985 1.021 100 0.493 0.522 0.560 0.614 0.659 0.699 0.735

NOTE: To calculate conversion factors not given in the above table, use this formula: Conversion Factor = Saturated Steam Temperature - Entering Air Temperature

227.1

STEAM – PRESSURE – TEMPERATURE – LATENT HEAT

0

212.0°

970.3

0

218.5°

966.1

5

227.1°

960.6

10

239.4°

952.6

15

249.7°

945.6

20

258.8°

939.6

25

266.8°

934.0

ENT.

AIR

TEMP

STEAM – PRESSURE – TEMPERATURE – LATENT HEAT

0

212.0°

970.3

0

218.5°

966.1

5

227.1°

960.6

10

239.4°

952.6

15

249.7°

945.6

20

258.8°

939.6

Table 2. Properties of Saturated Steam, BTU/Lb.

PSIG TEMP.

(°F)

2 218.5 966.1 60 307.3 904.7

5 227.1 960.6 70 316.0 898.0

10 239.4 952.6 80 323.9 891.9

15 249.7 945.7 90 331.2 886.2

20 258.8 939.6 100 337.9 880.8

25 266.8 934.0 125 352.9 868.3

30 274.0 929.0 150 365.9 857.2

40 286.7 919.9 175 377.4 846.9

50 297.7 911.8 200 387.8 837.5

LATENT

HEAT

PSIG TEMP.

(°F)

LATENT

HEAT

25

266.8°

934.0

Table 3. Number of Tubes Fed

COIL TYPE

8JA,8RA,8GA,8TA

5SA,5JA,5HA,5GA

ROWS

1 4 5 6 7 8 9 10 11 12 13 14

1 8 10 12 14 16 18 20 22 24 26 28

2 15 19 23 27 31 35 39 43 47 51 55

Page 16 / Catalog 413

FIN HEIGHT (FH) - INCHES

12 15 18 21 24 27 30 33 36 39 42

Page 18

Dimensional data Dimensional data

Figure 15. 5SA, 5HA, 8RA & 8TA Cased Coils

2.75

AIR

FLOW

LH

RH

AIR

FLOW

B + .500

2.50

5.00

MAX

RETURN

4.062

.375 X .750 SLOTS ON

6.00 C/C FROM CENTER

OF FINNED LENGTH

.750

W- .625

.750

FINNED LENGTH (FL)

FL + 3.00 (OVER FLANGES)

FL + 8.125 (APPROX)

2.75

MAX

SUPPLY

SEE NOTE 6

CD-0601340B-03

2.50

W + 3.00

ONE ROW COIL

TWO ROW COIL

MODEL ROW

SUPPLY

CONN

SIZE

RETURN

CONN

SIZE

B W

5SA, 5HA 01 1-1/2 1-1/2 2.25 12.00 - 18.00

5SA, 5HA 01 2 1-1/2 2.25 21.00 - 42.00

5SA, 5HA 02 2-1/2 2-1/2 2.75 12.00 - 42.00

8RA, 8TA 01 2-1/2 2-1/2 2.75 12.00 - 42.00

Figure 16. 5JA, 5GA, 8JA & 8GA Cased Coils

AIR

RH

FLOW

AIR

LH

FLOW

SEE NOTE 7

B + .500

ONE ROW COIL

5.00

TWO ROW COIL

MODEL ROW

CONN

SIZE

B W

5JA, 5GA 01 2 2.50 12.00 - 42.00

5JA, 5GA 02 2-1/2 2.75 12.00 - 42.00

8JA, 8GA 01 2-1/2 2.75 12.00 - 42.00

2.50

SUPPLY

RETURN

2.50

CD-0601320B-01

GENERAL NOTES:

1. HORIZONTAL AIR FLOW.

2. ALL COILS DRAINABLE.

3. CONNECTIONS ARE PIPE, NPT (EXT.)

4. ALL DIMENSIONS ARE IN INCHES.

5. CONNECTION LOCATION ± .125.

6. .125 TO .562 ABOVE COIL CENTER LINE.

7. TUBES ARE PITCHED TOWARD RETURN CONNECTION.

8. STEAM DISTRIBUTNG INNER TUBES (8RA & 8TA).

.375 X .750 SLOTS ON

2.75

MAX

4.062

6.00 C/C FROM CENTER

OF FINNED LENGTH

.750

W - .625

.750

FINNED LENGTH (FL)

FL + 3.00 (OVER FLANGES)

FL + 5.75 (APPROX)

GENERAL NOTES:

1. HORIZONTAL AIR FLOW.

2. ALL COILS DRAINABLE.

3. CONNECTIONS ARE PIPE, NPT (EXT.)

4. ALL DIMENSIONS ARE IN INCHES.

5. CONNECTION LOCATION ± .125

6. STEAM DISTRIBUTING INNER TUBES.

7. .125 TO .562 BELOW COIL CENTER LINE.

8. TUBES ARE PITCHED TOWARD RETURN CONNECTION.

W + 3.00

NOMENCLATURE: 5 S A

TUBE DIAMETER

5 = 5/8 inch O.D.

8 = 1 inch O.D.

TUBE CENTERS:

A = 1-1/2 inch (except all HIF8 coils are 3” CC)

COIL TYPE:

S = Standard construction, Fig. 15 & 16 with single tube

J = Standard construction, Fig. 15 & 16 with distributing tube

R = Standard construction, Fig. 15 & 16 with distributing tube

H = High pressure construction, Fig. 15 & 16 with single tube

G = High pressure construction, Fig. 15 & 16 with distributing tube

T = High pressure construction, Fig. 15 & 16 with distributing tube

Catalog 413 / Page 17

Page 19

Figure 17. 5SA, 5HA, 8RA & 8TA Uncased Coils

1.469

AIR

LH

FLOW

1/2 W

AIR

RH W

FLOW

MODEL ROW

SEE VIEW A

SUPPLY

DEPTH (2.938)

SUPPLY

CONN

SIZE

ONE ROW COIL

TWO ROW COIL

RETURN

CONN

SIZE

C = CONN. LENGTH

0.40 TYP.

FINNED LENGTH (FL)

A MAX

D MAX

A B D W

RETURN

1.469

5SA, 5HA 01 1-1/2 1-1/2 3.250 1.125 3.250 12.00 - 18.00

5SA, 5HA 01 1-1/2 1-1/2 3.750 1.125 3.250 21.00 - 42.00

5SA, 5HA 02 2-1/2 2-1/2 3.875 1.625 3.875 12.00 - 42.00

8RA, 8TA 01 2-1/2 2-1/2 3.875 1.625 3.875 12.00 - 42.00

=CONN. LENGTH

C

B

VIEW A

NOTCH TYP 4 CORNERS

EACH END FIN

.078

.375

GENERAL NOTES:

1. HORIZONTAL AIR FLOW.

2. ALL COILS DRAINABLE.

3. CONNECTIONS ARE PIPE, NPT (EXT.)

4. ALL DIMENSIONS ARE IN INCHES.

5. CONNECTION LOCATION ± .125.

6. STEAM DISTRIBUTNG INNER TUBES

(8RA & 8TA).

CONN LENGTH

OPTION C

CONTRACTOR 3.00

STD. UNIT 7.00

LINED UNIT 8.50

VISION UNIT 8.50

Figure 18. 5JA, 5GA, 8JA & 8GA Uncased Coils

1.469

1/2 W

AIR

LH

AIR

FLOW

FLOW

B

RH

MODEL ROW

5JA, 5GA 01 2 3.750 1.375 12.00 - 42.00

5JA, 5GA 02 2-1/2 3.875 1.625 12.00 - 42.00

8JA, 8GA 01 2-1/2 3.875 1.625 12.00 - 42.00

SEE VIEW A

SUPPLY

RETURN

1.469

DEPTH (2.938)

CONN

SIZE

C = CONN. LENGTH

W

FINNED LENGTH (FL)

A MAX

ONE ROW COIL

TWO ROW COIL

A B W

NOMENCLATURE: 5 S A

1.125

0.40 TYP.

VIEW A

NOTCH TYP 4 CORNERS

EACH END FIN

.078

.375

CONN LENGTH

OPTION C

CONTRACTOR 3.00

STD. UNIT 7.00

LINED UNIT 8.50

VISION UNIT 8.50

GENERAL NOTES:

1. HORIZONTAL AIR FLOW.

2. ALL COILS DRAINABLE.

3. CONNECTIONS ARE PIPE, NPT (EXT.)

4. ALL DIMENSIONS ARE IN INCHES.

5. CONNECTION LOCATION ± .125

6. STEAM DISTRIBUTING INNER TUBES.

TUBE DIAMETER

5 = 5/8 inch O.D.

8 = 1 inch O.D.

Page 18 / Catalog 413

TUBE CENTERS:

A = 1-1/2 inch (except all HIF8 coils are 3” CC)

COIL TYPE:

S = Standard construction, Fig. 17 & 18 with single tube

J = Standard construction, Fig. 17 & 18 with distributing tube

R = Standard construction, Fig. 17 & 18 with distributing tube

H = High pressure construction, Fig. 17 & 18 with single tube

G = High pressure construction, Fig. 17 & 18 with distributing tube

T = High pressure construction, Fig. 17 & 18 with distributing tube

Page 20

Piping data Piping data

APPLICATION RECOMMENDATIONS

Satisfactory operation and service are best provided when coils

are installed with proper piping, trap, and support arrangement.

The following notes and diagrams are recommended.

General

1. Provide separate supports and hangers for the coil and for

the piping.

2. Be certain that adequate piping flexibility is provided.

Stresses resulting from expansion of closely coupled piping

and coil arrangement can cause serious damage. Coils having opposite end connections must be piped with expansion

joints.

3. Standard coils are pitched in the casings when installed for

horizontal airflow. The installation should be checked to

ensure that the casing is level. On vertical airflow applications, the coils must be pitched when installed.

4. Do not reduce pipe size at the coil return connection. Carry

return connection size through the dirt pocket, making the

reduction at the branch leading to the trap.

5. Install vacuum breakers on all applications to prevent retaining condensate in the coil. Generally, the vacuum breaker is

to be connected between the coil inlet and the return main,

as shown. However, for a system with a flooded return main,

the vacuum breaker should be open to the atmosphere and

the trap design should allow venting of large quantities of air.

6. Do not drip supply mains through the coil.

7. Do not attempt to lift condensate when using modulating or

on-off control.

Traps

1. Size traps in accordance with trap manufacturer’s recommendations. Be certain that the required differential will

always be available. DO NOT UNDERSIZE.

2. Float and thermostatic or bucket traps are recommended for

low pressure steam. On high pressure systems, bucket traps

are normally recommended. The thermostatic traps should

be used only for air venting.

3. Bucket traps are recommended for use with on-off control

only.

4. Locate traps at least 12 inches below the coil return

connection.

5. Multiple coil installation:

a. Each coil or group of coils that is individually controlled

must be individually trapped.

b. Coils in series — separate traps are required for each

coil, or bank of coils, in series.

c. Coils in parallel — a single trap may generally be used

but an individual trap for each coil is preferred.

Controls

1. With coils arranged for series airflow, a separate control is

required on each bank, or coil, in the direction of airflow.

2. On high pressure installations, a two-position steam valve

with a face and bypass arrangement is preferred where

modulating control is required.

3. Modulating valves must be sized properly. DO NOT

UNDERSIZE.

Freezing Conditions

(Entering air temperatures below 35°F)

1. 5JA, 8JA and 8RA coils are definitely recommended.

2. 5 psi steam must be supplied to coils at all times.

3. Modulating valves are not recommended. Control should

be by means of face and bypass dampers.

4. Consideration should be given to the use of two or three

coils in series with two-position steam control valves on

that coil or coils which will be handling 35°F or colder air.

The desired degree of control can be attained with a modulating valve on the downstream coil.

5. Provision should always be made to thoroughly mix fresh

air and return air before it enters coil. Also, temperature

control elements must be properly located to obtain true air

mixture temperatures.

6. As additional protection against freeze-up, the trap should

be installed sufficiently far below coil to provide an adequate hydrostatic head to help remove of condensate during an interruption in the steam pressure. Estimate 3 feet

for each 1 psi of trap differential required.

7. On startup, admit steam to coil ten minutes before admitting outdoor air.

8. Provisions must be made to close fresh air dampers if

steam supply pressure falls below minimum specified.

SYMBOLS FOR PIPING ARRANGEMENTS

LOW PRESSURE (TO 25 PSI)

*5JA or 8JA coil installed with tubes vertical. The

coil supply piping must be dripped ahead of the

coil on an installation of this type.

*5SA coil installed for vertical airflow. Installer

must pitch coil toward the return connection on

vertical airflow installations. For horizontal airflow installation, the required pitch is built into

the casing.

* NOTE: Rating data is ARI certified only for the

standard ARI coil orientation; i.e., horizontal

tubes, vertical coil face and horizontal airflow.

Catalog 413 / Page 19

Page 21

LOW PRESSURE (TO 25 PSI)

5JA or 8JA coil installed in

series. Note that each coil

must have a separate control

valve and trap.

*5SA coils installed with tubes vertical. Diagram

shows single trap; however, it is always preferable

to trap each coil individually.

* NOTE: Rating data is ARI certified only for standard ARI coil orientation; i.e., horizontal tubes,

vertical coil face and horizontal airflow.

HI PRESSURE (OVER 25 PSI)

8RA and 5SA coils banked three high by three

deep. Individual trapping of each coil as shown

is preferred. Note that it is necessary to provide

a separate control valve for each bank in the

direction of airflow.

5GA or 8GA coils. Note the addition of a vacuum

breaker to permit the coil to drain during shutdown.

Page 20 / Catalog 413

8TA or 5HA coils. Condensate is lifted to overhead return main.

Page 22

Engineering guide specifications Engineering guide specifications

Furnish and install as shown on plans and as described in the tabulated specifications, McQuay ARI certified steam

heating coils of extended surface, staggered tube, HI-F or E-F rippled, corrugated plate fin type. Coil performance

should be substantiated by computer generated output data.

HEADERS shall be of non-ferrous materials using seamless copper tubing with intruded tube holes to permit expansion and contraction without creating undue stress. Rolled-in joints or dissimilar metals will not be acceptable. Both

the supply and return headers shall be completely encased by the coil casing. Heating surface tubes shall not pass

through a header end sheet and be subjected to wear of the tubes because of movement which occurs when the

coils expand and contract.

Orificed baffle plates shall be installed in the supply headers opposite the supply connection to provide proper dif-

fusion of the entering steam.

PRIMARY SURFACE shall be round, seamless (5/8” O.D.) (1” O.D.) copper tubing brazed into intruded header tube

holes using brazing alloys. Tubes on two-row coils shall be staggered in the direction of airflow. Tubes shall be on

1-1/2” or 3” centers. High pressure coils shall have cupro-nickel tubes and headers.

SECONDARY SURFACE shall consist of rippled aluminum plate fins (HI-F5, E-F5 or HI-F8) for higher capacity and

structural strength. Fins shall have full drawn collars to provide a continuous surface cover over the entire tube. Fins

shall not have sharp edges which accumulate dirt. Tubes shall be expanded into the fins to provide a continuous primary to secondary compression bond over the entire finned length for maximum heat transfer rates.

CASINGS shall be constructed of continuous galvanized steel. Coil side plates shall be reinforced type for greater

strength and ease of stacking and shall have 3/8” x 3/4” slots on 6” centers for mounting. Full length fin channels

shall be furnished to brace the coil core and prevent air bypass.

Coils shall be pitched in casing for horizontal airflow toward the return header end. A minimum of 1/8” pitch per foot

of coil finned length shall be used to allow proper condensate drainage.

5SA, 5HA, 8RA & 8TA COILS shall have the supply header on one end and return header on the other end. The

supply header end of each coil tube shall be properly orificed to meter the steam uniformly to each tube.

5JA, 5GA, 8JA & 8GA COILS shall have both the supply header and return header on the same end. The supply

header shall be enclosed by the return header and shall feed the inner steam distributing tubes. The coil end opposite the connection end shall be free to float within the casing as expansion and contraction occurs.

TESTS: The complete coil core shall be tested with 315 pounds air pressure under warm water and suitable for

working conditions up to 150 psig and 366° F. High pressure coils shall be suitable for working conditions up to 350

psig and 450 °F. Individual tube tests and core tests before installation of headers are not considered satisfactory.

Hydrostatic tests alone will not be acceptable. Capacities shall be as outlined in the tabulation and substantiated by

computer generated output data.

Suggested Steam Coil Tabulation

TAG NO. QTY. COIL TYPE FIN SERIES ROWS FIN HEIGHT FINNED LENGTH

FACE AREA

MAX. FACE

VELOCITY

CFM

ENT. AIR

TEMP. (°F)

LVG. AIR

TEMP (°F)

PSIG STEAM

MAX. AIR PRESSURE

DROP INCHES OF

WATER

Catalog 413 / Page 21

Page 23

13600 Industrial Park Boulevard, Minneapolis, MN 55441 USA • (800) 432-1342 • www.mcquay.com

Loading...

Loading...