Page 1

BACnet VAV Actuator Installation Manual

IM 1037

Group: Controls

Part Number: IM 1037

Date: 3/4/2010

Supersedes: New

BACnet® VAV Actuator Installation Procedures

Model #: 2508021

Page 2

Table of Contents

Table of Contents .................................................................................................................. 2

Revision History.................................................................................................................................... 3

Reference Documents............................................................................................................................ 3

Limited Warranty .................................................................................................................................. 3

General Information .............................................................................................................. 4

Hazard Identification Messages ............................................................................................................ 4

Description ............................................................................................................................................ 5

Application............................................................................................................................................ 5

Component Data.................................................................................................................................... 5

Installation ............................................................................................................................. 6

Required Tools and Materials ............................................................................................................... 6

Installing a new BACnet VAV Actuator ............................................................................................... 6

To Install the BACnet VAV Actuator ............................................................................................... 6

To Wire the BACnet VAV Actuator ............................................................................................... 10

2 IM 1037

Page 3

Revision History

IM xxx Date Initial release

Reference Documents

Number Company Title Source

OM 1063 McQuay International VAV Actuator Owners Manual www.mcquay.com

Limited Warranty

Consult your local McQuay Representative for warranty details. Refer to Form 933-43285Y. To find your local

McQuay Representative, go to www.mcquay.com.

Notice

Copyright © 2010 McQuay International, Minneapolis MN. All rights reserved throughout the world.

McQuay International reserves the right to change any information contained herein without prior

notice. The user is responsible for determining whether this software is appropriate for his or her

application.

® ™ The following are tradenames or registered trademarks of their respective companies: BACnet

from the American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc.; Windows

from Microsoft Corporation; D-Net, McQuay and MicroTech III from McQuay International.

IM 1037 3

Page 4

General Information

This manual contains the information you need to install the BACnet® VAV Actuator on a VAV box.

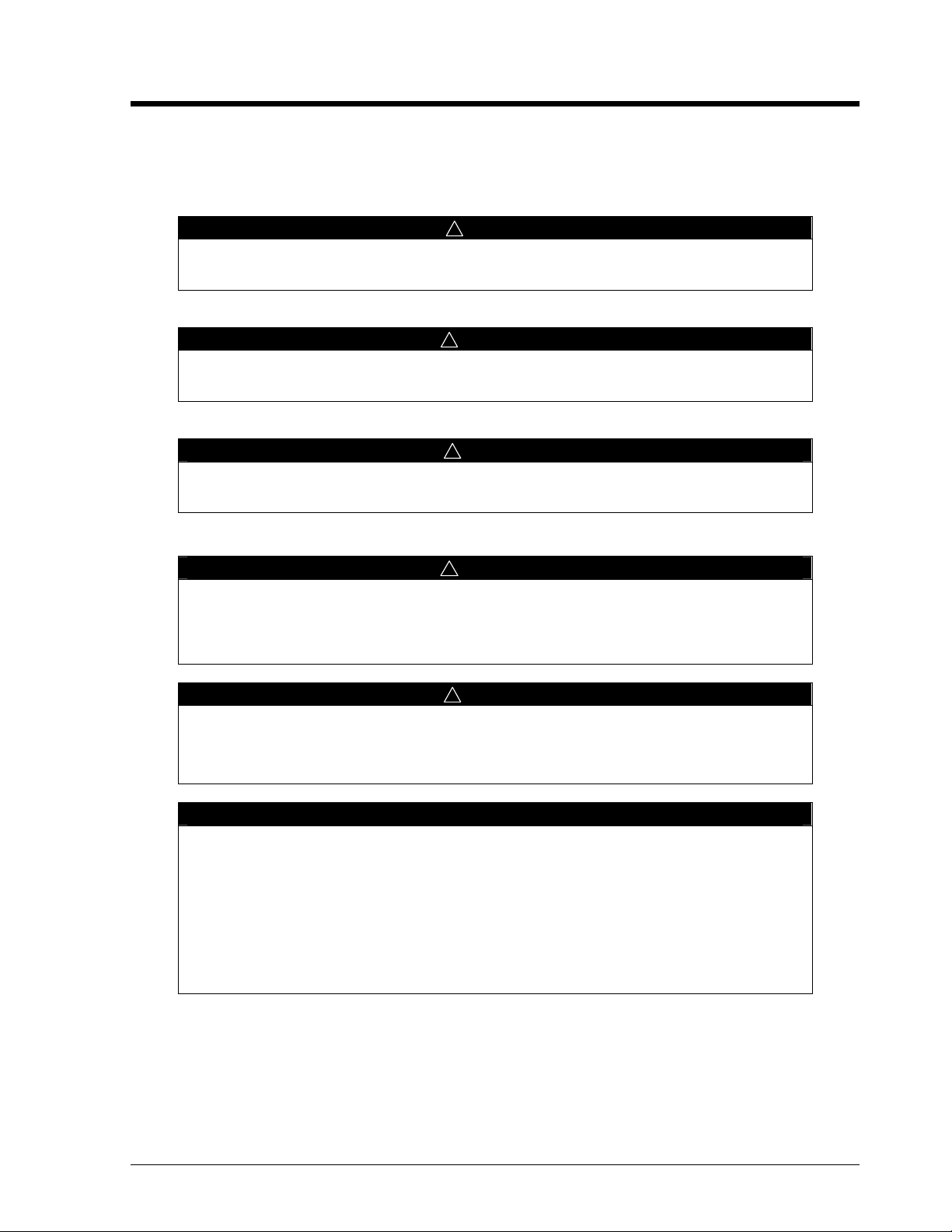

Hazard Identification Messages

!

DANGER

Dangers indicate a hazardous situation that will result in death or serious injury if not

avoided.

!

WARNING

Warnings indicate potentially hazardous situations, which can result in property damage,

severe personal injury, or death if not avoided.

!

CAUTION

Cautions indicate potentially hazardous situations, which can result in personal injury or

equipment damage if not avoided.

WARNING

!

Electric shock hazard. Can cause personal injury or equipment damage.

This equipment must be properly grounded. Connections and service to the MicroTech III

Chiller Unit Controller must be performed only by personnel knowledgeable in the

operation of the equipment being controlled.

!

CAUTION

Static sensitive components. Can cause equipment damage.

Discharge any static electrical charge by touching the bare metal inside the control panel

before performing any service work. Never unplug cables, circuit board terminal blocks, or

power plugs while power is applied to the panel.

NOTICE

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with this instruction manual, may cause interference to

radio communications. It has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. Operation of this equipment in a residential area

is likely to cause harmful interference in which case the user will be required to correct the

interference at his or her own expense. McQuay International disclaims any liability

resulting from any interference or for the correction thereof.

4 IM 1037

Page 5

Air Velocity

Sensor

Power

Connection

Status/DO LEDs

BACnet

Connection

Airflow

Pickup Tubes

Description

These Installation Instructions describe direct-coupled mounting of the BACnet VAV Actuator, McQuay’s Nonspring Return Rotary Electronic Damper Actuator.

Application

This VAV Actuator can be used in control applications 2560 through 2567. For a full description of application

specifics please refer to the VAV Actuator Owners Manual (OM 1063).

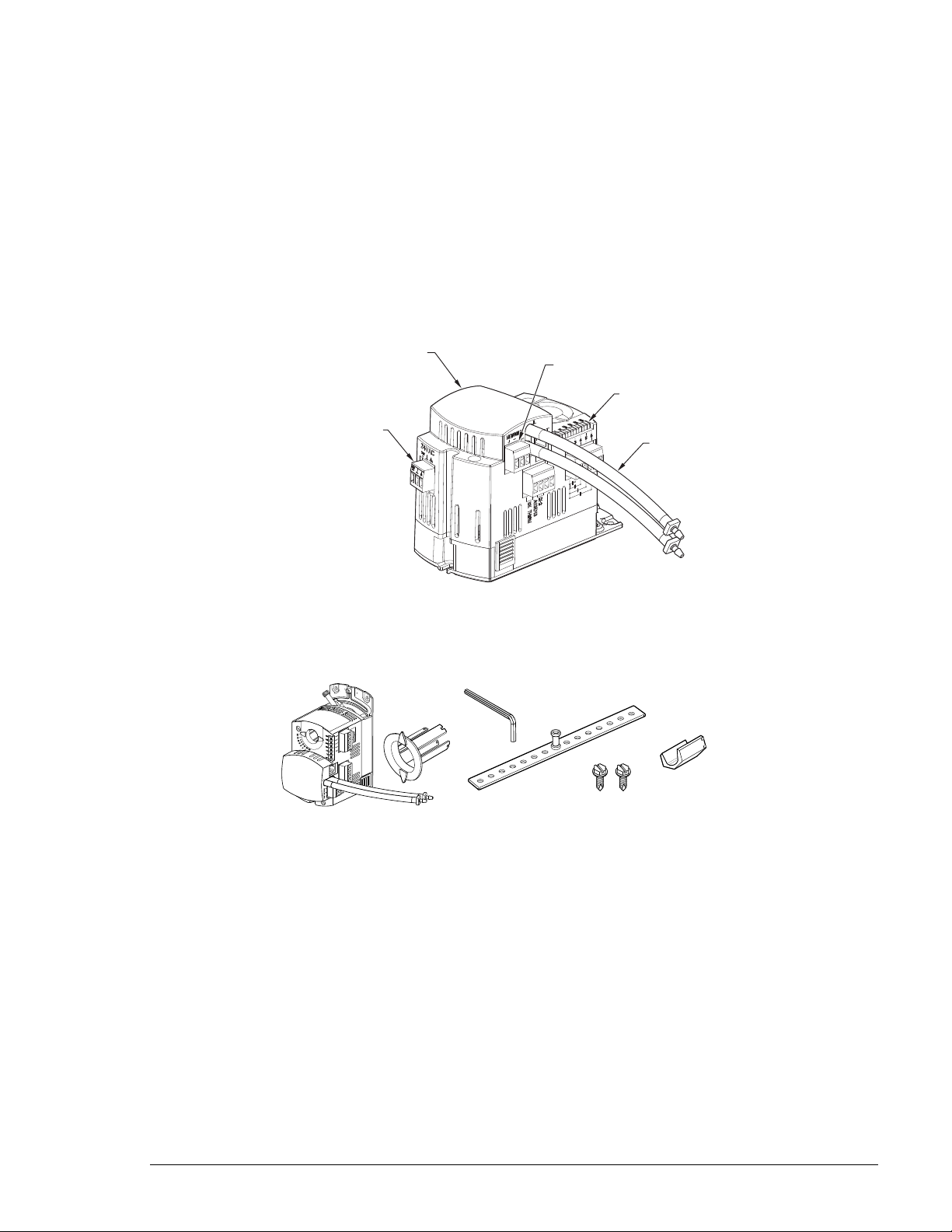

Component Data

Figure 1 shows the BACnet VAV Actuator. Figure 2 shows the parts associated with the installation of the VAV

Actuator.

Figure 1. BACnet VAV Actuator.

90

45

TEC0495R1

STAT

a

b

Figure 2. Actuator Parts.

Parts List

a. Actuator with pre-terminated tubing

b. Position indicator

c. Mounting bracket

d. Self-tapping mounting screws

e. 4 mm hex key

f. 3/8-inch shaft adapter (8 to 10 mm shafts)

e

c

f

d

IM 1037 5

Page 6

Installation

!

The following section describes how to field install a new BACnet VAV Actuator or replace an existing

BACnet VAV Actuator on a McQuay VAV unit.

Expected Install Time: 25 minutes

CAUTION

Electrostatic discharge hazard. Can cause equipment damage.

This equipment contains sensitive electronic components that may be damaged by

electrostatic discharge from your hands. Before you handle a communications module, you

need to touch a grounded object, such as the metal enclosure, in order to discharge the

electrostatic potential in your body.

Required Tools and Materials

• 4 mm hex wrench

• Small, flat-blade screwdriver

• 1/4-inch Hex drill/driver set

• Marker or pencil

• Torque Wrench

Installing a new BACnet VAV Actuator

Follow these steps to install a BACnet VAV Actuator on the VAV unit.

To Install the BACnet VAV Actuator

WARNING

!

Electric shock hazard. Can cause personal injury or equipment damage.

This equipment must be properly grounded. Only personnel knowledgeable in the operation of the

equipment being controlled must perform connections and service to the BACnet VAV Actuator.

1. Determine the size of the damper shaft.

• If the damper shaft is 1/2-inch, proceed to Step 2.

NOTE: The actuator comes with a factory-installed 1/2-inch damper shaft guide.

• If the damper shaft is 5/8-inch:

a. Remove the 1/2-inch shaft guide, Figure 3.

6 IM 1037

Page 7

TEC0498R1

Mounting

3/8-inch

8...10 mm shafts

~

~

STAT

45

90

TEC0497R1

Figure 3. Removing the 1/2-inch Shaft Guide.

b. Proceed to Step 2.

• If the damper shaft is 3/8-inch:

a.

Remove the 1/2-inch shaft guide, Figure 3.

b.

Use the 3/8-inch adapter, provided in the actuator packaging, Figure 4. Hold the shaft insert so

that the raised tabs are inserted last when placing the insert into the back of the actuator.

Figure 4. Installing the 3/8-inch Shaft Adapter.

c.

Proceed to Step 2.

2. Determine the damper blade rotation, clockwise or counterclockwise to open, Figure 5.

CLOCKWISE

TO OPEN

TEC0499R1

"0"

Figure 5. Damper Rotation.

COUNTER

CLOCKWISE

TO OPEN

• If the blades will rotate counterclockwise, slide the manual override switch to manual, and move the

adjustment lever to the right. Return the switch to automatic, Figure 6.

• If the blades will rotate clockwise, slide the manual override switch to manual, and move the

adjustment lever to the left. Return the switch to automatic, Figure 6.

IM 1037 7

Page 8

ADJUSTMENT

TEC0501R1

TEC0503R1

STAT

45

90

LEVER

90

45

STAT

TEC0500R1

MANUAL

Figure 6. Setting the Direction of Rotation.

3. Close the damper blades, Figure 8.

Figure 7. Setscrew in Shaft Hole.

4. Mark the end of the damper shaft with a pencil/marker, Figure 8.

5. Tighten the setscrew until the first thread can be seen in the shaft hole, Figure 7.

Figure 8. Mounting the Actuator.

6. Mount the actuator on the damper shaft, Figure 8.

7. Install the position indicator, Figure 9.

8. Tighten the adjustment lever to the proper torque listed:

8 IM 1037

Page 9

TEC0502R1

1/2

1/2

CENTER THE

MOUNTING BRACKET

IN THE SLOT

CAUTION:

These holes for use

with accessory kits only.

Do not use in the

installation of directcoupled applications.

1/4 in.

Hex Drive

• 70 +/- 5 inch-pounds for solid metal

• 37 +/- 2 inch-pounds for plastic graphite composite (hollow metal shafts require an insert to

prevent shaft damage).

4 mm

90

45

STAT

TEC0504R1

Figure 9. Position Indicator and Adjustment Lever.

9. Attach the mounting bracket, Figure 10.

NOTE: When installing the mounting bracket directly on the ductwork, be sure to position the bracket

so that the screws do not obstruct the damper blade movement inside the box.

Figure 10. Installing the Mounting Bracket.

10. Connect the airflow tubing for the Differential Pressure Sensor.

• RED connects to HIGH.

• BLUE connects to LOW.

IM 1037 9

Page 10

TEC0507R1

.156

(4)

3.437

(87)

5.368

(136.35)

min. 6 inch

152.4 mm

.937

(94)

min.

4 inch

101.6 mm

.4375

(11)

min. 4 inch

100 mm

.0312

(0.8)

5.574

(141.58)

2.677

(68)

min.

.25 inch

6 mm

min. 8 inch

203.2 mm

4.189

(106.39)

min. .375 inch

10 mm

.8126

(21)

2.948

(74.88)

To Wire the BACnet VAV Actuator

WARNING

!

Electric shock hazard. Can cause personal injury or equipment damage.

This equipment must be properly grounded. Only personnel knowledgeable in the operation of the

equipment being controlled must perform connections and service to the BACnet VAV Actuator.

WARNING: Installations requiring CE Conformance

• All wiring for CE rated actuators must be Separated Extra Low Voltage (SELV) or Protective Extra

Low Voltage (PELV) per HD384-4-41.

• Use safety-isolating transformers (Class III transformer) per EN 61558. They must be rated for 100%

duty cycle.

• Over current protection for supply lines is maximum 4A.

Figure 11. BACnet VAV Actuator Dimensions in Inches (Millimeters).

10 IM 1037

Page 11

Wiring Instructions

Wiring the 24VSC

Power

Wiring the power connector

as shown in the diagram

below. Note the orientation

of the power connector

and the location of the

Earth (E) , Common (C)

and Hot (H) connections

before wiring.

TEC0514R1

24V

Actuator

24V

24VAC Line

24VAC Neutral

Earth

Field Wiring Neutral Bond Wire

24VAC

24V

24V

Dependent On

Local Codes

Required If Primary

Is Over 150 VAC

Figure 12. Power Wiring.

Digital Outputs (DO):

The Digital Outputs on the VAV Actuator are dry output Triac type outputs. 24 VAC must be applied to the

“C” pin of the DO connector. The side view of the Actuator shows output pin details.

By providing dry output Triac DO’s, the application can switch either Phase or Neutral depending on

application needs. In a 24 VAC circuit, neutral is determined by which side of the transformer is earth

grounded. If neither side is earth grounded (at the transformer) then the 24 VAC is considered a floating

(isolated) source.

24Vac 5 00ma

per Triac Max.

TEC0511R1

Interna l

Thermal Overloa d

C

DO3

DO4

DO5

DO6

24 Va c (50/60 Hz)

Heat St age1

Heat St age2

Heat St age3

FAN

Figure 13. BACnet VAV Actuator with Electric Heat and Fan.

IM 1037 11

Page 12

TEC0512R1

24Vac 5 00ma

per Triac Max.

DO3

DO4

DO5

DO6

Interna l

Thermal Overloa d

FAN

Spare DO

M

Valve Act uator

Open

Close

C

24 Va c (50/60 Hz)

Figure 14. BACnet VAV Actuator with Hot Water Reheat, Fan and Spare DO.

DI

10K Therm

-8Vdc

+5Vdc

+9Vdc

1

2

3

4

TEC0513R1

Figure 15. Wiring for D12/A13.

Wiring DI Common (pin 4) to 10K Thermistor - 8Vdc (pin 2) incorrectly, will cause the actuator to shut

down. No damage will occur. When the wiring is corrected the actuator will resume operation.

DO/DI Wiring Diagrams

DO 6

DO 5

DO 4

DO 3

ROOM TEMPERATURE SENSOR

DI 2

AI3 / DI3

TEC2560WDR1

Figure 16. Application 2560 Wiring Diagram (Cooling Only).

AUTOZERO MODULE (OPTIONAL) OR SPARE DO

SPARE DOS

"COMMON" TERMINATION FOR ALL DOs

WALL SWITCH (OPTIONAL)

OR SPARE DI (DRY CONTACT)

SPARE AI (10K THERMISTOR)

OR SPARE DI (DRY CONTACT)

12 IM 1037

Page 13

TEC2561WDR1

AUTOZERO MODULE (OPTIONAL) OR SPARE DO

DI 2

DO 6

DO 5

DO 4

DO 3

AI3 / DI3

"COMMON" TERMINATION FOR ALL DOs

SPARE DOS

WALL SWITCH (OPTIONAL)

OR SPARE DI (DRY CONTACT)

DUCT TEMPERA

TURE SENSOR

OR (10K THERMISTOR)

ROOM TEMPERATURE SENSOR

ELECTRIC HEAT STAGE 3

ELECTRIC HEAT STAGE 2

ELECTRIC HEAT STAGE 1

AUTOZERO MODULE (OPTIONA

L) OR SPARE DO

DI 2

DO 6

DO 5

DO 4

DO 3

AI3 / DI3

"COMMON" TERMINATION FOR ALL DOs

WALL SWITCH (OPTIONAL)

OR SPARE DI (DRY CONTACT)

SPARE AI (10K THERMISTOR)

OR SP

ARE DI (D

RY CONTACT)

ROOM TEMPERATURE SENSOR

TEC2562BWDR1

2 - POSITION VALVE

AUTOZERO MODULE (OPTIONAL) OR SPARE DO

DI 2

DO 6

DO 5

DO 4

DO 3

AI3 / DI3

"COMMON" TERMINATION FOR ALL DOs

SPARE DOS

WALL SWITCH (OPTIONAL)

OR SPARE DI (DRY CONTACT)

SPARE AI (10K THERMIS

TOR)

OR SP

ARE DI (D

RY CONTACT)

ROOM TEMPERATURE SENSOR

TEC2563AWDR1

VALVE

ACTUATOR

AUTOZERO MODULE (OPTIONAL) OR SPARE DO

DI 2

DO 6

DO 5

DO 4

DO 3

AI3 / DI3

"COMMON" TERMINATION FOR ALL DOs

SPARE DO

WALL SWITCH (OPTIONAL)

OR SPARE DI (DRY CONTACT)

SPARE AI (10K THERMIST

OR)

OR SP

ARE DI (DRY CONTACT)

ROOM TEMPERATURE SENSOR

CLOSED

OPEN

Figure 17. Application 2561 Wiring Diagram (Heating or Cooling).

Figure 18. Application 2562 Wiring Diagram (Electric Heat Stages).

Figure 19. Application 2562 Wiring Diagram (Baseboard Radiation).

IM 1037 13

Figure 20. Application 2563 Wiring Diagram (Hot Water Heat and Spare DO).

Page 14

TEC2563BWDR1

VALVE

ACTUATOR

DI 2

DO 6

DO 5

DO 4

DO 3

AI3 / DI3

"COMMON" TERMINATION FOR ALL DOs

WALL SWITCH (OPTIONAL)

OR SPARE DI (DRY CONTACT)

SPARE AI (10K THERMISTOR)

OR SP

ARE DI (DRY CONTACT)

ROOM TEMPERATURE SENSOR

CLOSED

OPEN

VALVE

ACTUATOR

CLOSED

OPEN

TEC2564and2566WDR1

FAN

ELECTRIC HEAT STAGE 3

ELECTRIC HEAT STAGE 2

ELECTRIC HEAT STAGE 1

DI 2

DO 6

DO 5

DO 4

DO 3

AI3 / DI3

"COMMON" TERMINATION FOR ALL DOs

WALL SWITCH (OPTIONAL)

OR SPARE DI (DRY CONTACT)

SPARE AI (10K THERMISTOR)

OR SP

ARE DI (D

RY CONTACT)

ROOM TEMPERATURE SENSOR

TEC2565and2567WDR1

FAN

VALVE

ACTUATOR

DI 2

DO 6

DO 5

DO 4

DO 3

AI3 / DI3

"COMMON" TERMINATION FOR ALL DOs

SPARE DO

WALL SWITCH (OPTIONAL)

OR SPARE DI (DRY CONTACT)

SPARE AI (10K THERMISTOR)

OR SPARE DI (DRY CONTACT)

ROOM TEMPERATURE SENSOR

CLOSED

OPEN

Figure 21. Application 2563 Wiring Diagram (Hot Water Heat 2 Motors).

Figure 22. Application 2564/Application 2566 Wiring Diagram (Electric Heat Stage and Series or Parallel Fan).

Figure 23. Application 2565/Application 2567 Wiring Diagram (Hot Water Heat and Series or Parallel Fan).

The installation is now complete.

14 IM 1037

This document contains the most current product information as of this printing. For the most

current product information, please go to www.mcquay.com. All McQuay equipment is sold

pursuant to McQuay’s Standard Terms and Conditions of Sale and Limited Warranty.

©2010 McQuay International ● www.mcquay.com ● 800-432-1342

Loading...

Loading...