The MicroControllerShop

http://microcontrollershop.com

PIC-P40-28

Prototyping Board

User Manual

Rev. 1.0

February 2008

The MicroControllerShop

MicroController Pros Corporation

http://microcontrollershop.com

Table of Contents

1.0 Preface ................................................................................................................................................... 3

1.1. Cautions............................................................................................................................................. 3

1.2. Trademarks........................................................................................................................................ 3

1.3. Limited Guarantee and Support ........................................................................................................ 3

1.4. Copyright ........................................................................................................................................... 3

2.0 Introduction............................................................................................................................................. 4

3.0 Hardware ................................................................................................................................................ 5

3.1. PIC-P40-28 Board Components........................................................................................................ 5

3.2. Power Supply Requirements ............................................................................................................. 6

3.3. 14- and 18-pin MCU sockets ............................................................................................................. 6

3.4. MCU Oscillator Circuit ....................................................................................................................... 7

3.5. In-Circuit Serial Programming (ICSP) and In-Circuit Debug (ICD) Interface..................................... 7

3.6. RS232 Interface................................................................................................................................. 9

3.7. Reset Circuit .................................................................................................................................... 11

3.8. LED.................................................................................................................................................. 11

3.9. Push Button ..................................................................................................................................... 11

3.10. Board Dimensions & PCB Material................................................................................................ 11

Appendix A. Board Schematic.................................................................................................................... 12

PIC-P40-28 User Manual February 2008

The MicroControllerShop

MicroController Pros Corporation

http://microcontrollershop.com

1.0 Preface

1.1. Cautions

Caution: Check power supply requirements. Incorrect voltage will damage the board. See chapter 3.2

for details.

Caution: Only populate one socket at a time. Do not insert microcontrollers into more than one socket

at a time, or you may damage the microcontroller chips.

Caution: Check the pin orientation of the sockets before inserting a chip. The 28- pin socket is

rotated by 180 degrees in relation to the 40-pin socket (see ). This means that the pin 1

location for the 28-pin socket is in the lower right hand corner, whereas the pin 1 position for the 40-pin

socket is in the upper left hand corner of the socket. Make sure you align pin 1 of your microcontroller

with pin 1 of the socket. Inserting a microcontroller chip incorrectly can damage it.

1.2. Trademarks

Figure 3-1

All brand or product names used in this manual are trademarks or registered trademarks of their

respective companies or organizations.

1.3. Limited Guarantee and Support

MicroController Pros Corp. warrants the PIC-P40-28 board to be free from component or assembly

defects for a period of 180 days from the date of purchase. Settlement is limited to repair or replacement

of the product only. MicroController Pros Corp. does not assume any liability arising out of the application

or use of any product, circuit or procedure described herein. No other liability or warranty applies,

expressed or implied. While every attempt has been made to ensure accurate documentation,

MicroController Pros Corp. cannot be held responsible for errors or omissions, and reserves the right to

make changes without prior notice.

This prototype board is intended as a low-cost development tool with limited support. It is assumed that

you are familiar with basic electrical engineering concepts and microcontroller code development. Our

support does not include us teaching you those concepts. If you experience functional issues with this

board, you can contact support via email: support@microcontrollershop.com

General information on Microchip PIC microcontrollers can be found at the following URL:

http://www.microchip.com

1.4. Copyright

© 2008 MicroController Pros Corporation. All rights reserved.

Website: http://microcontrollershop.com

PIC-P40-28 User Manual 3/ 12 February 2008

The MicroControllerShop

MicroController Pros Corporation

http://microcontrollershop.com

2.0 Introduction

The PIC-P40-28 is a prototype board for Microchip PIC microcontrollers in a 28- or 40-pin DIP package.

Check the pinout of the PIC microcontroller, which you intent to use with this board, in the Microchip PIC

device datasheet. Verify that the PIC’s Vdd, Vss, OSC1, OSC2, ICSP programming, and UART Rx and

Tx signals match the location of those pins on the appropriate MCU socket of this board (see schematic).

The board comes completely assembled and tested and offers the following features:

• 28-pin, and 40-pin DIL microcontroller sockets

• Jumper selectable +3.3V or +5.0V board supply voltage

• Power plug-in jack: 5.5mm outer, 2.5mm inner diameter

o Accepts AC and DC input voltage

• RS232 DB9 female connector with MAX2232 interface circuit and Tx, Rx, CTS and DTR/RTS

signals. Rx and Tx signals are routed to 28-pin and 40-pin MCU sockets (see schematics).

• RJ12 and 6-pin, single row In-Circuit Serial Programming (ICSP) connectors for in-circuit

programming and debugging with a PIC In-Circuit Debugger & Programmer.

• 20 MHz quartz crystal oscillator in machined, spring-loaded socket for easy oscillator replacement

• Reset button

• Push button connected to PIC I/O pin via removable jumper

• Status LED connected to PIC I/O pin via removable jumper

• Extension solder pads for every µC pin

• Prototyping area with 100 mils grid

• Prototyping GND bus

• Prototyping Vcc bus

• FR-4, 1.5 mm (0.062″), single layer, electroless nickel/immersion gold (ENIG) plating, green

soldermask, white silkscreen component print

• Four mounting holes

PIC-P40-28 User Manual 4/ 12 February 2008

MicroController Pros Corporation

Socketed 20MHz Crystal

ge

L

D

ct

M

T

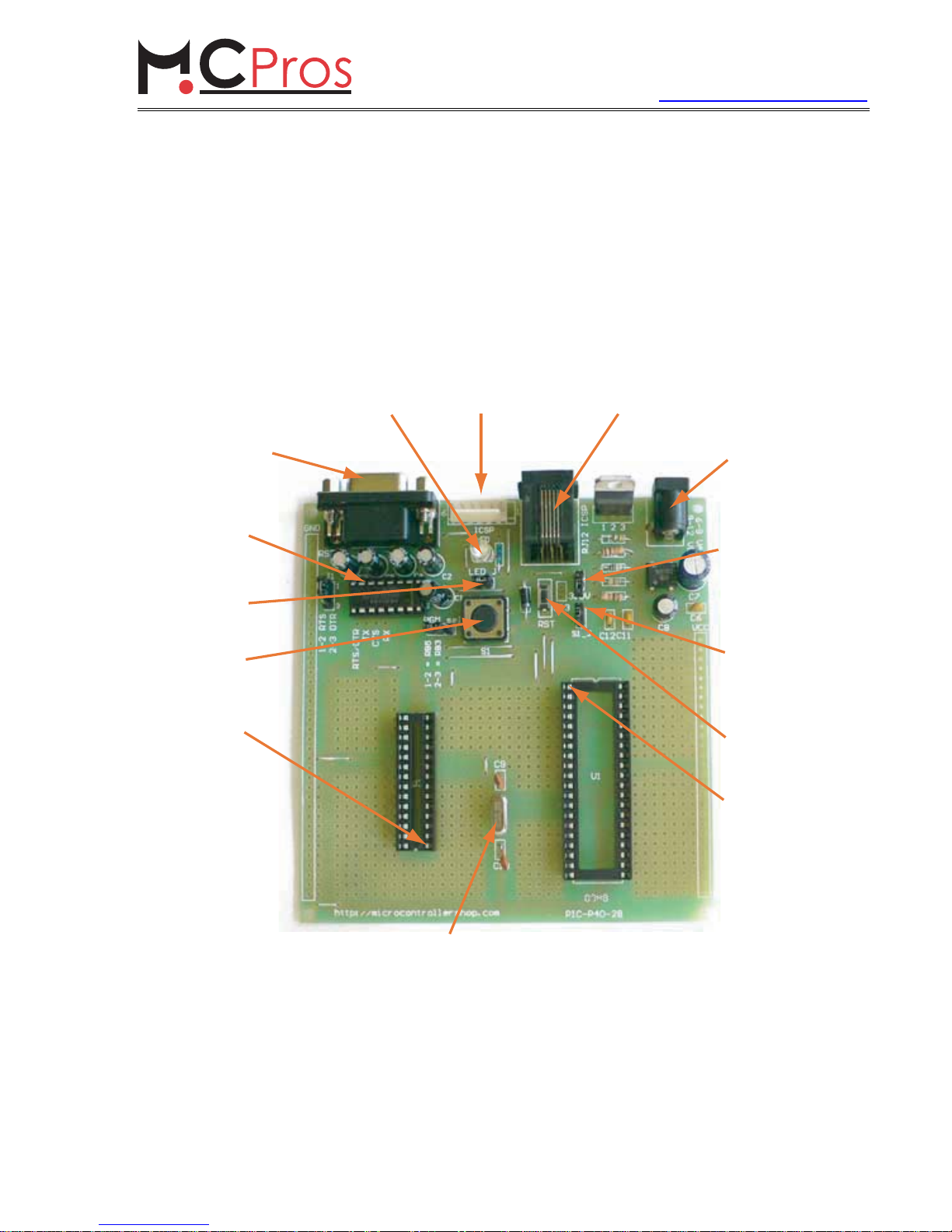

3.0 Hardware

3.1. PIC-P40-28 Board Components

Figure 3-1

shows the PIC-P40-28 Board with major components identified.

The MicroControllerShop

http://microcontrollershop.com

6-pin, single row

LED

RS232 Interface

(D-Sub 9 female)

AX2232 RS232

ransceiver

ED Connect/

isconnect Jumper

Push Button

S1

Pin 1 of

28-pin socket

ICSP/ICD Connector

RJ12 Jack

ICSP/ICD Connector

Power Connector

Board Supply Volta

Selection Jumper

Open: 5.0V

Closed: 3.3V

Push Button

Connect/Disconne

Jumper

Reset Button

Pin1 of

40-pin socket

S1

PIC-P40-28 User Manual 5/ 12 February 2008

Figure 3-1: PIC-P40-28 Board

The MicroControllerShop

MicroController Pros Corporation

3.2. Power Supply Requirements

Power input to the board is supplied via a barrel connector with 5.5mm outer and 2.5mm inner diameter.

An on-board bridge rectifier provides polarity reversal protection and allows you to use both AC or DC

input voltages.

An on-board LM317 adjustable output voltage regulator can be set via a jumper to provide the board with

either 5.0V or 3.3V DC operating voltage. In the open position of jumper 3.3V, the output voltage is 5.0V.

In the jumper-closed position, the output voltage is 3.3V

Jumper 3.3V Board Operating Voltage (BOV)

Open 5.0V DC

Closed 3.3V DC

The input voltage supplied to the board should be at least 3.5V above the desired board operating voltage

(BOV) if you use a DC power supply, and 2.5V above BOV if you use an AC power supply.

Minimum AC input voltage

Minimum DC input voltage

The following maximum input voltages should not be exceeded by your power supply, otherwise you risk

damaging the board:

Maximum AC input voltage

Maximum DC input voltage

The current rating of your power supply is uncritical, as this board requires less than 100mA to operate.

Therefore, any power supply with a current rating of 100mA or higher can be used. A higher current rating

is not a problem, as the board will only draw as much current from the supply as is needed for operation.

In general, you should use voltages close to the minimum required input voltage. It reduces stress on the

voltage regulator, as a smaller voltage differential has to be dissipated into heat.

A word of caution, however: Many cheap transformer-based wall-plug power supplies provide an

unregulated output voltage that under no load is usually much higher than the rated output voltage printed

on the supply. This high output voltage then “collapses” under load and can be lower than the rated

output voltage. To avoid damage to your board, verify with a multi-meter that the true voltage of your

power supply is within the above stated limits before connecting it to this board.

5.0V Board Operating Voltage 3.3V Board Operation Voltage

7.5V AC 5.8V AC

8.5V DC 6.8V DC

10.5V AC

15V DC

http://microcontrollershop.com

3.3. 28- and 40-pin MCU sockets

Caution: Only populate one socket at a time. Do not insert microcontrollers into more than one socket

at a time, or you may damage the microcontroller chips.

Caution: Check the pin orientation of the sockets before inserting a chip. The 28- pin socket is

rotated by 180 degrees in relation to the 40-pin socket (see ). This means that the pin 1

location for the 28-pin socket is in the lower right hand corner, whereas the pin 1 position for the 40-pin

socket is in the upper left hand corner of the socket. Make sure you align pin 1 of your microcontroller

with pin 1 of the socket. Inserting a microcontroller chip incorrectly can damage it.

PIC-P40-28 User Manual 6/ 12 February 2008

Figure 3-1

The MicroControllerShop

MicroController Pros Corporation

Check the pinout of the PIC microcontroller, which you intent to use with this board, in the Microchip PIC

device datasheet. Verify that the PIC’s Vdd, Vss, OSC1, OSC2, ICSP programming, and UART Rx and

TX signals match the location of those pins on the appropriate MCU socket of this board (see schematic).

The board has routed connections from both sockets to the RS232 Rx and Tx pins, ICSP signals, a push

button, a reset button, an LED and a crystal oscillator.

Each unused MCU pin has a direct connection to the solder pad next to it. You can solder square header

pins into those locations and then use prototyping jumper wires to connect to other circuitry. Alternatively,

you can directly solder wire connections or component pins to these pads. Using header pins and jumper

wires gives you the flexibility to connect the MCU pins to different components on the board quickly.

For header pins, see: http://microcontrollershop.com/product_info.php?products_id=2115

For prototyping jumper wires, see: http://microcontrollershop.com/product_info.php?products_id=791

3.4. MCU Oscillator Circuit

A 20MHz crystal oscillator is connected to the 28-pin and 40-pin socket oscillator pins. The crystal is

socketed, so you can easily replace it with a different frequency value.

http://microcontrollershop.com

Figure 3-2: Socketed Crystal

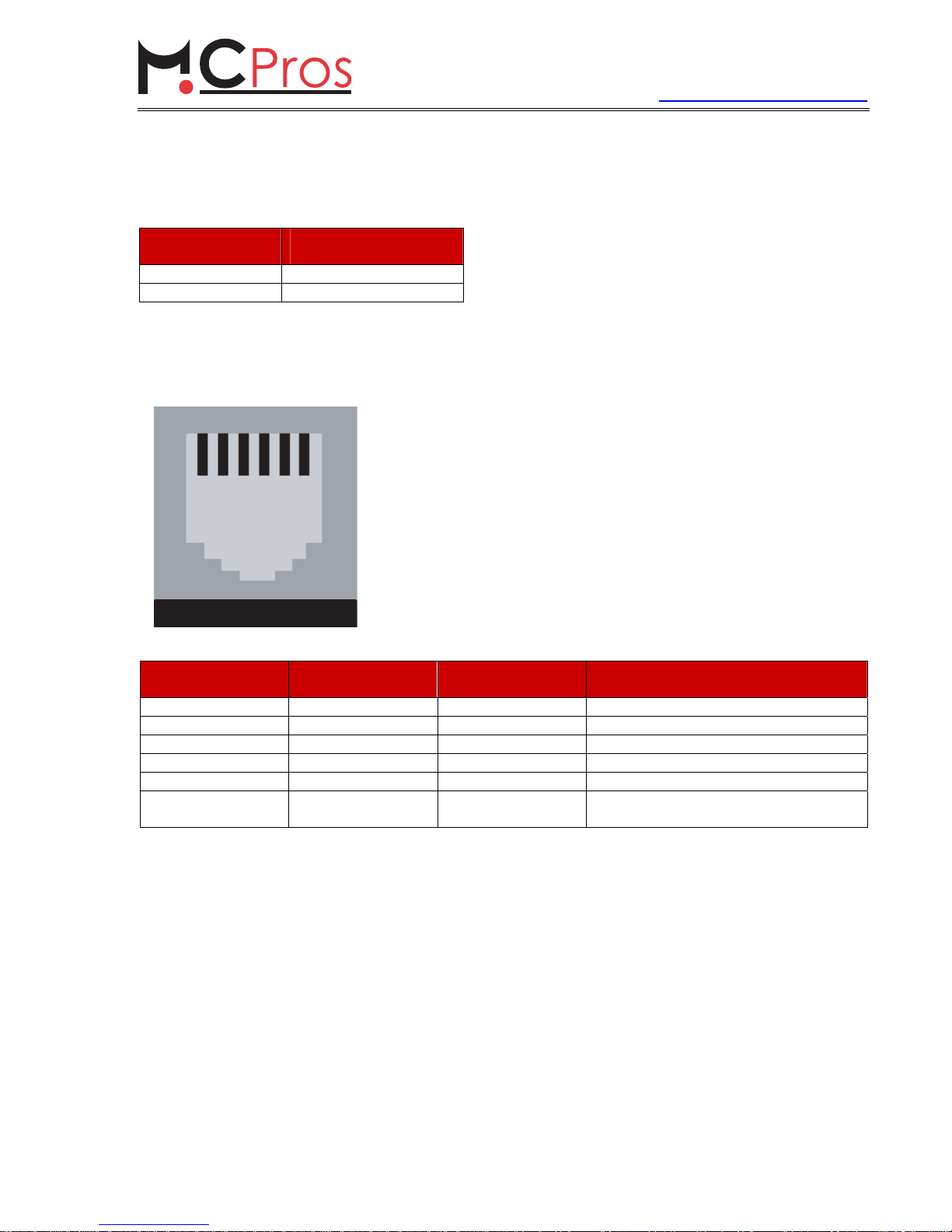

3.5. In-Circuit Serial Programming (ICSP) and In-Circuit Debug (ICD) Interface

PIC microcontrollers use the same connection for in-circuit serial programming (ICSP) and in-circuit

debugging (ICD). Figure 3-1 shows the location of the ICSP/ICD connectors. The board features two

ICSP/ICD connectors - an RJ12 jack and a 6-pin single row, latched header - to provide compatibility with

a broad selection of PIC programmers and in-circuit debuggers. The ICSP signals are routed to the

appropriate pins of both PIC MCU sockets.

PIC-P40-28 User Manual 7/ 12 February 2008

The MicroControllerShop

1

2

3

4 5

6

MicroController Pros Corporation

Some 40-pin PIC microcontrollers have the optional PGM programming signal on pin 38 (RB5), others on

pin 25 (RB3). If you use a programmer that requires the PGM signal, make sure you connect it to the

correct MCU pin, by setting jumper PGM_sel according to the table below.

PGM_sel

position

40-pin PIC Socket Pin

# (Name)

1-2 PGM_RB5 38 (RB5)

2-3 PGM_RB3 36 (RB3)

The board’s RJ12 ICSP/ICD jack is connected as shown in the figure and table below.

http://microcontrollershop.com

1

Figure 3-3: RJ12 PIC ICSP Connector

Signal Name Board ICSP/ICD

Connector Pin

28-pin PIC Socket

Pin

40-pin PIC Socket Pin

/MCLR 1 1 1

Vdd (Vcc) 2 20 11 & 32

Vss (GND) 3 8 & 19 12 & 31

PGD 4 28 40

PGC 5 27 39

PGM (optional) 6 24 36 or 38 (depending on PGM_sel

Jumper position)

PIC-P40-28 User Manual 8/ 12 February 2008

The MicroControllerShop

C

D

D

d

r

LR

MicroController Pros Corporation

The board’s 6-pin, single row ICSP/ICD header is connected as shown in the figure and table below.

http://microcontrollershop.com

6

5

4

3

2

1

Signal Name Board ICSP/ICD

/MCLR 1 1 1

Vdd (Vcc) 2 20 11 & 32

Vss (GND) 3 8 & 19 12 & 31

PGD 4 28 40

PGC 5 27 39

PGM (optional) 6 24 36 or 38 (depending on PGM_sel

For compatible PIC ICSP programmers, see:

http://microcontrollershop.com/default.php?cPath=112_97

For compatible PIC ICD in-circuit debuggers & programmers, see:

http://microcontrollershop.com/default.php?cPath=112_152

PGM

PG

PG

GN

Vd

/MC

Figure 3-4: 6-pin, Single Row, PIC ICSP

Connecto

Connector Pin

with Latch and 0.1” Spacing

28-pin PIC Socket

Pin

40-pin PIC Socket Pin

Jumper position)

3.6. RS232 Interface

RS232 devices are classified as Data Terminal Equipment (DTE) or Data Communications Equipment

(DCE). This defines for each device which wires will be sending and receiving each signal.

PCs or terminals have male connectors with DTE pin functions; the PIC-P40-28 board has a female

connector with DCE pin functions.

As a minimum requirement for communicating with a PC or Terminal, only the RxD and TxD signals are

required. All other signals are optional. If hardware flow control is desired, connect the CTS and RTS/DTR

signals to free PIC I/O pins (you must then implement the hardware handshake in your PIC firmware).

The RS232 standard defines RTS/CTS as the signaling protocol for hardware flow control for data

transmitted from DTE to DCE.

PIC-P40-28 User Manual 9/ 12 February 2008

The MicroControllerShop

MicroController Pros Corporation

Figure 3-5: D-Sub 9 RS232 Connector

http://microcontrollershop.com

RS232 Pin #

- DTE Name

Connected to

(28/40 pin package)

Function

1 - CD Not connected Carrier Detect. Asserted by DCE when a connection has

been established with remote equipment (dial-up modem).

2 - RXD PIC TxD pin (6/8) TX solder pad: PIC transmit, PC receive (Data sent from

DCE to DTE)

3 - TXD PIC RxD pin (5/7) RX solder pad: PIC receive, PC transmit (Data sent from

DTE to DCE)

4 - DTR Jumper J1 DTR position Data Terminal Ready handshake signal. If jumper J1 is in

DTR position, pin 4 of DB9 connector is connected to

RTS/DTS solder pad via RS232 Transceiver R2OUT.

Asserted by DTE to indicate that it is ready to be

connected. If the DCE is in power save mode, this may

“wake up” the DCE, bringing it out of a power-saving

mode. When this signal is de-asserted, the DCE may

return to its power-save mode.

5 - GND GND Ground

6 - DSR Not connected Data Set Ready. Asserted by DCE to indicate an active

connection .

7 - RTS Jumper J1 RTS position Request to Send handshake signal. If jumper J1 is in RTS

position, pin 7 of DB9 connector is connected to RTS/DTS

solder pad via RS232 Transceiver R2OUT. Asserted by

DTE to prepare DCE to receive data. This may require

action on the part of the DCE, e.g. asserting the CTS

signal.

8 - CTS CTS solder pad Clear to Send handshake signal. Asserted by DCE to

acknowledge RTS and allow DTE to transmit.

9 - RI Not connected Ring indicator. Asserted by DCE when it detects a ring

signal from the telephone line.

PIC-P40-28 User Manual 10/ 12 February 2008

The MicroControllerShop

MicroController Pros Corporation

3.7. Reset Circuit

An RC reset circuit (R2 and C13) is connected to the MCLR pin to assure that a proper power-on reset is

generated when a PIC microcontroller is used that has no integrated Brown-Out-Reset (BOR) or where

BOR is disabled. C13 is not mounted. If you use a PIC chip without BOR or with BOR disabled, then you

should mount C13. See the PIC datasheet for recommended values.

Using the RC reset does not assure a proper reset in brown-out conditions (sudden, short voltage drops).

Certain brown-out conditions may corrupt the PIC’s on-chip Flash or EEPROM content. Some PIC chips

feature on-chip brown-out reset (BOR) circuitry that can be enabled (check the datasheet of your

particular device). It is recommended that you enable the PIC’s on-chip brown-out to avoid memory

corruption.

The PIC chip can also be reset by pressing and releasing the RST switch on the board.

3.8. LED

An LED is connected via jumper LED_J to a PIC I/O pin (see schematic).You can disconnect the LED by

removing jumper LED_J. You can easily connect the LED to any unused PIC I/O pin of your choice by

running a wire from the LED connect side of the jumper header to the desired PIC pin.

The LED is turned on by programming the I/O pin as a high output.

The table below shows to which PIC pin, depending on the jumper LED_J setting, the LED is connected.

LED_J 28-pin PIC Socket Pin

# (Name)

closed 2 (RA0/AN0) 2 (RA0/AN0)

open N.C. N.C.

40-pin PIC Socket Pin

# (Name)

http://microcontrollershop.com

3.9. Push Button

A push button S1 is connected via jumper S1_J to a pin on the PIC MCU sockets.

The table below shows to which PIC pin, depending on the jumper S1_J setting, S1 is connected.

S1_PB4 28-pin PIC Socket Pin

# (Name)

closed 7 (RA5/AN7) 10 (RE2/AN7)

open N.C. N.C.

40-pin PIC Socket Pin

# (Name)

3.10. Board Dimensions & PCB Material

• 112 mm by 110 mm

• FR-4, 1.5 mm (0.062″), single layer, electroless nickel/immersion gold (ENIG) plating, green

soldermask, white silkscreen component print

• RoHS compliant

• Four mounting holes

PIC-P40-28 User Manual 11/ 12 February 2008

The MicroControllerShop

MicroController Pros Corporation

Appendix A. Board Schematic

http://microcontrollershop.com

B

RJ12

6

PGM

5

PGC

4

PGD

3

GND

2

+5V

1

ICSP1

22

23

24

SDI/RC4

SDO/RC5

RD2/PSP221RD3/PSP3

VSS

RC3/SCK18RD0/PSP0

RD1/PSP1

PIC_40

17

19

20

OSC2

OSC1

1 2

22pF

GND

GND

+5V

20

MCLR

31

GND

12

LED

PGD

PGC

PGM

RX

18

23

28

26

21

24

RB122RB2

RB425RB5

PGC/RB627PGD/RB7

VDD

PGM/RB3

INT/RB0

RX/RC7

PGC

U1

PGM

1

40

VDD

MCLR#/THV

C

1

PGM_sel

38

PGC/RB639PGD/RB7

RA1/AN13RA0/AN0

4

2

R1

330

12

LED

+5V

2

3

1-2 = RB5

2-3 = RB3

RX

TX

26

25

29

36

RB437RB5

30

33

35

RB134RB2

INT/RB0

PGM/RB3

RE2/CS#/AN710RE1/WR#/AN6

RE0/RD#/AN58RA5/AN4

RA4/TOCK1

RA3/AN35RA2/AN2

9

7

6

1

2

LED_J

GND

S1

R6

10K

TX/RC6

RX/RC7

PSP4/RD427PSP5/RD528PSP6/RD6

PSP7/RD7

OSC1/CLKIN13OSC2/CLKOUT

RC0/T1OSD15RC1/T1OSI16RC2/CCP1

14

Q1

4-20MHz

C9

22pF

C10

1

2

S1

S1

D

ICSP

1

2

3

4

5

6

MCLR

1N4004

D1

C11

100nF

C12

100nF

R2

10K

C13

NA

RST

C8

+5V

100uF/16vdc

GND

GNDGNDGND

GND

PGD

11

32

A

1.9

Number RevisionSize

PIC-P40-28

Copyright 2008 MicroController Pros Corp.

A4

Title

TX

16

15

17

TX/RC6

SDO/RC5

SDI/SDA/RC4

VSS

Date: 17-Jan-2008 Sheet of

File: PIC-P40-28 Drawn By:

8

GND

19

R4

240/1%

2

OUT

1

ADJ

IN

LM317

3

G1 VR1

B-DIL

D

PIC-P40-28 User Manual 12/ 12 February 2008

C4

C6

100nF

R3

390/1%

C7

470uF/16vdc

GND GND

1

2

3.3V

GND

R5

330/1%

+5V

GNDGND

C1

1uF/16VDCC51uF/16VDC

3

1

4

U2

C1-

C1+

VDD

VCC

GND

2

C2

1uF/16VDC

16

GND

1uF/16VDC

GND

4

5

9

C

RX

TX

CTS

RTS/DTR

OSC1/CLKIN9OSC2/CLKOUT10RC0/T1OBO11RC1/T1OSI12RC2/CCP1

RA5/AN47RA4/TOCK16RA3/AN35RA2/AN2

RA1/AN13RA0/AN02MCLR#/THV

U3

R1OUT

R1IN13T1OUT

GND

9

15

GND

R2OUT

VEE

6

8

C3

1uF/16VDC

1

2

3

1-2 = RTS

2-3 = DTR

RS232

B

5

12

11

C2-

C2+

T2IN10T1IN

T2OUT7R2IN

14

J1

1

2

3

6

7

8

GND

4

1

MCLR

LED

S1

OSC1

OSC2

RC3/SCL/SCK

PIC_28

13

14

A

Loading...

Loading...