D

Mclennan Servo Supplies Ltd.

User Manual

for

SimStep

Single Axis

Stepper Drive & Controller

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 1

User Manual for SimStep

Single Axis Stepper Motor Drive and Controller

Mclennan Drg. No. 3400 Issue D

Associated Documents:

MSE570 E2 Data Sheet

PM600 Manual

Software:

McTerminal Terminal and Monitor Program

The associated documents are available from the technical documents section of our web site

www.mclennan.co.uk

SAFETY NOTICE!

Position control systems are inherently hazardous. Even a small motor, if

coupled to a leadscrew, gearbox, or any other form of mechanism that

provides a mechanical advantage, can generate considerable force and

could cause serious injury. Incorrect operation can also lead to damage to

the motor or associated machinery. It is essential that the purpose of the

various fault detection features built into the SimStep’s PM600 controller be

fully understood and used correctly.

Mclennan Servo Supplies Ltd.

22 Doman Road,

Yorktown Industrial Estate,

Camberley,

Surrey,

GU15 3DF

UK

Telephone: +44 (0)8707 700 700

FAX: +44 (0)8707 700 699

Sales EMAIL: sales@mclennan.co.uk

Technical support EMAIL: tech@mclennan.co.uk

The manufacturer reserves the right to update the data used in this manual in line with

product development without prior notice.

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 2

CONTENTS

1D

ESCRIPTION

.......................................................................................................................................... 3

1.1 R

EAR VIEW

: ..................................................................................................................................4

1.2 L

INK SETTINGS

.............................................................................................................................. 6

2E

XTERNAL INTERFACE CONNECTIONS

....................................................................................................... 7

3C

ABLES

................................................................................................................................................. 10

3.1 M

OTOR AND LIMIT/DATUM CABLES

................................................................................................ 10

3.2 E

LECTRO-MAGNETIC COMPATIBILITY

(EMC) ................................................................................. 10

3.3 E

NCODER CABLES

....................................................................................................................... 11

3.3.1 Typical Motor Encoders..................................................................................................11

4M

OTOR CONNECTIONS

........................................................................................................................... 12

4.1 C

OLOUR CODE FOR 8 LEAD MOTORS

: ........................................................................................... 12

4.2 C

ONNECTING TO THE

MSA889 J

UNCTION BOX

............................................................................ 13

4.3 C

ONNECTION OF LIMITS AND DATUM

............................................................................................ 14

4.3.1 Datum Position................................................................................................................15

4.3.2 Using Over-travel limits as datum inputs........................................................................ 15

5P

OWER SUPPLY UNIT

............................................................................................................................. 16

6 MSE570 S

TEPPER DRIVE

...................................................................................................................... 17

6.1 G

ENERAL SET-UP

:.......................................................................................................................17

6.2 C

URRENT SETTING

...................................................................................................................... 17

6.3 O

THER

MSE570 C

URRENT SETTINGS

.......................................................................................... 18

7M

ANUAL OPERATION USING THE JOG BOX OR JOYSTICK

.......................................................................... 19

7.1 J

OG BOXES

- JC S

ERIES

............................................................................................................. 19

7.2 S

INGLE AND DUAL AXIS JOG BOX OPERATION

............................................................................... 20

7.3 M

ULTI-AXIS JOG BOX OPERATION

................................................................................................ 20

7.4 J

OYSTICK

- JC S

ERIES

................................................................................................................ 21

7.5 J

OYSTICK OPERATION

.................................................................................................................. 21

8 PM600 I

NTELLIGENT STEPPER MOTOR CONTROLLER

............................................................................. 22

8.1 G

ENERAL

.................................................................................................................................... 22

8.2 S

ETTING UP THE ENCODER (CLOSED-LOOP CONTROL MODES ONLY

)............................................ 22

8.2.1 Encoder Termination ...................................................................................................... 22

8.2.2 Encoder Scaling.............................................................................................................. 23

8.2.3 Encoder Direction ........................................................................................................... 23

8.3 P

ROGRAMMING VIA THE

RS232 I

NTERFACE

.................................................................................. 23

8.4 G

ENERAL COMMAND STRUCTURE

................................................................................................ 25

8.5 E

XAMPLES OF COMMAND STRUCTURE

.......................................................................................... 25

9 I/O C

ABLE AND BREAKOUT BOX

............................................................................................................. 26

9.1 I

SOLATION

................................................................................................................................... 27

9.2 T

YPICAL CONNECTIONS

............................................................................................................... 27

9.3 R

EAD PORTS

............................................................................................................................... 27

9.4 W

RITE PORTS

............................................................................................................................. 28

9.4.1 Inductive Loads............................................................................................................... 28

10 SIMS

TEP

E

XAMPLE SEQUENCE

............................................................................................................... 28

10.1 S

EQUENCE DEFINITIONS

.............................................................................................................. 28

10.2 C

ONFIGURATION

.......................................................................................................................... 29

10.3 R

UN SEQUENCE

.......................................................................................................................... 29

11 O

RDER CODES

...................................................................................................................................... 30

11.1 S

YSTEM

...................................................................................................................................... 30

11.2 M

OTOR ENCODERS

..................................................................................................................... 30

11.3 C

ABLES

...................................................................................................................................... 30

11.4 J

UNCTION BOXES

........................................................................................................................ 30

11.5 J

OG BOXES

& J

OYSTICK

.............................................................................................................. 30

11.6 EMC F

ERRITES

........................................................................................................................... 30

12 L

IMITATIONS OF USE

.............................................................................................................................. 31

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 3

1 Description

The system is a single axis stepper motor control and drive rack. Motor motion is

commanded either from a computer or from a terminal via the RS232 (or RS485) serial

data port or from a manual Jog Box or Joystick controller. The controller can drive stepper

motors in open-loop (step counting) mode or encoded motors/mechanisms in closed-loop

mode.

The controller consists of:

1 MSE570-Evo2 3.5A Stepper Drive

1 PM600 Motor Controller

1 MSB867 Backplane

1 MSE779 Power Supply Board

These are mounted in a 3U high 28HP rack unit. The SimStep is supplied with a mains

lead, an RS232 cable and an RS232 terminator. A range of standard motor, encoder,

limits/datum and I/O cables are available.

Fig.1.1

SimStep

Front View

The system has a PM600 controller and a MSE570 Stepper drive powered by a power

supply based on the MSE779 power supply board.

The PM600 controller and the MSE570 plug into the MSB867 backplane.

Step, clock

and

direction

signals from the PM600 are fed to the MSE570 Stepper drive. The bipolar

stepper motor is connected to the MSB867 backplane via a rear panel connector.

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 4

The PM600 position controller generates the

clock

and

direction

signals for the MSE570

drive in response to move commands.

The PM600

enable

output is connected to the

enable

input of the MSE570 drive. If the

PM600’s

enable

output is turned off (e.g. as a result of an error) the motor current will

turned off. The

enable

output may be turned off by an AB

abort

command, or

reset

(turned

on) by an RS command (see Section 6.4).

The

Idle

output from the PM600 is connected to the

current reduction

input on the

MSE570 to reduce the motor current to about 25% when the motor is not moving.

An incremental encoder can be fitted to the motor or mechanism to monitor the movement

of the mechanism. The quadrature signals from the encoder are connected to the PM600

to allow passive closed-loop operation. The system is initially supplied with the PM600

configured for open-loop operation. The PM600 must be reconfigured for closed-loop

operation (see Section 8.2).

The MSB867 has a multi-axis jog receiver; it allows the PM600’s Jog inputs to be

controlled by a JC809 Jog Box. The axis addresses shown on the JC809 may be

changed by altering the settings of the rotary switches accessible by removing the top

cover of the unit.

The power supply provides +24V (nominal) to energise the supply rail on the PM600

controller, and +40V (nominal) to energise the supply rail on the MSE570 drive.

The PM600 manual referred to in this document can be found on www.mclennan.co.uk.

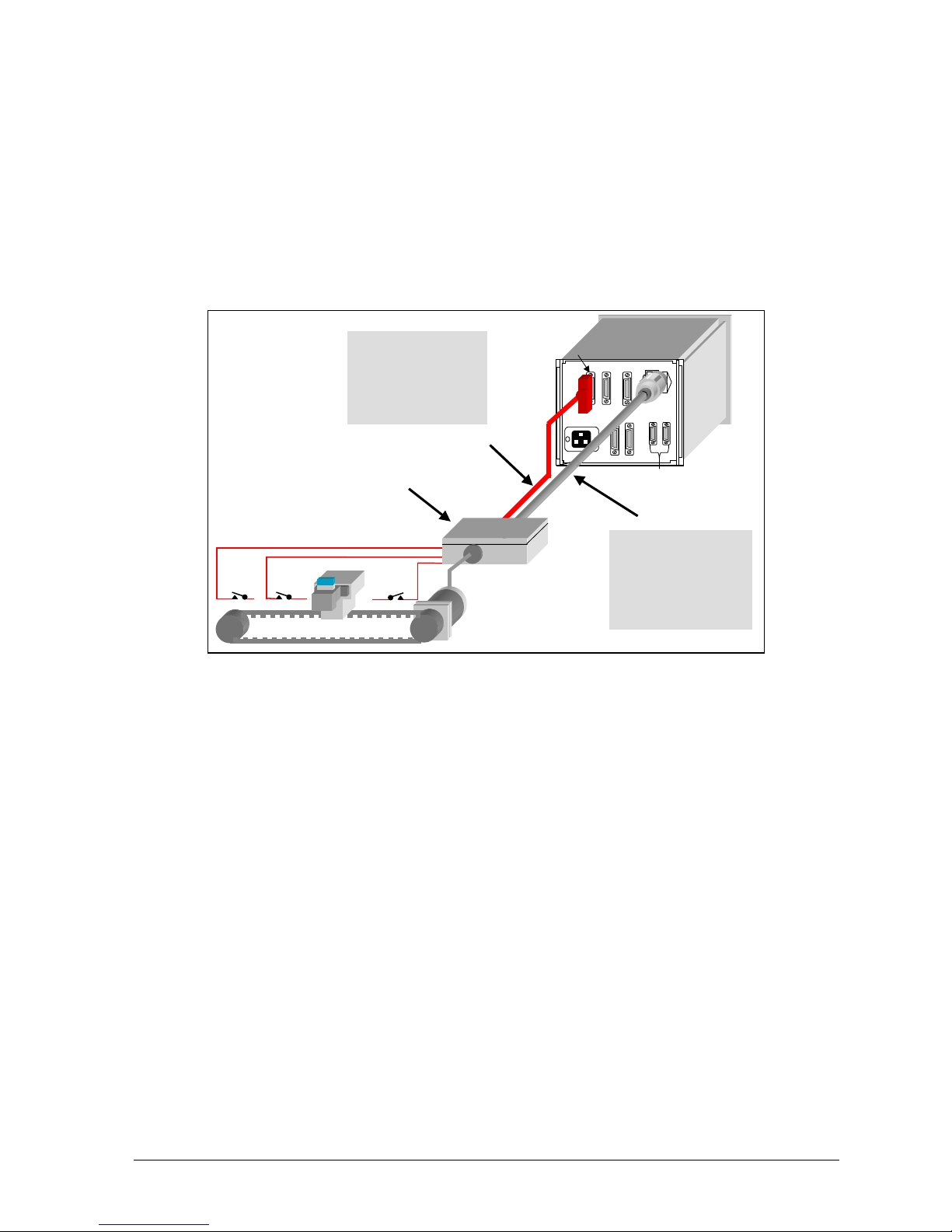

1.1 Rear View:

Fig.1.2 SimStep Rear Panel

Connections for motors, limits/datum, I/O, encoders, RS232 and mains are taken from the

MSB867 backplane to connectors on the rear panel.

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 5

The mains input is a filtered IEC inlet.

The MOTOR connector has outputs from the PM570-Evo2 stepper drive to connect to a

bipolar stepper motor.

WARNING! Serious damage will occur if the motor is connected or disconnected

whilst the power is switched on. Allow 30 seconds after switching off.

The LIMITS/DATUM connectors have inputs for the Upper and Lower Limit switches, a

Datum Approach switch and a Datum Stop switch. The connections to the Limit switch

inputs must be made for normal operation of the PM600 controllers.

Limit switches must not be used as a safety device or part of a safety system for

ensuring the safety of persons

The ENCODER connector is for the position encoder input. It has a +5V supply to

energise the encoder, complementary

quadrature

inputs and complementary

index

inputs.

The JOG A and JOG B connectors have inputs for Jog pushbuttons, a Joystick control

and data connections for a JC809 Jog Box.

They have connections for Jog, Jog- and Jog Fast pushbuttons compatible with a JC100

Jog Box and +5V, 0V Joystick input and Joystick centre tap compatible with a JC400

Joystick. The JC100 and JC400 may be plugged into either connector.

If using a JC809 Multi axis jog box, the axis address that is assigned to Jog is set on the

MSB867 interface board using a rotary switch (see section 5.2). The JC809 can be

connected to other axes by using a ‘Jog daisy-chain’ cable plugged into the vacant JOG A

or JOG B connector. The Jog Terminator supplied with the JC809 must be plugged into

the vacant connector in the last axis in the daisy-chain.

The I/O connector has inputs and outputs from PM600’s

Read

inputs and

Write

outputs.

There are also connectors for RS232 IN for connecting to the computer or terminal that

supplies the control data and RS232 OUT for connecting either to a subsequent control

rack (

daisy-chain

) or to an RS232 terminator. These connectors can also be configured for

RS485 communications (see section 1.2).

Note: The RS232 Terminator supplied with the control system must be fitted to the last

unit in the

daisy-chain

. This allows both replies from, and commands sent to, the controller

to be echoed back.

WARNING! To avoid overheating, the vents in the top and bottom of the unit must

be unobstructed at all times.

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 6

1.2 Link Settings

The control operation of the SimStep can be configured by means of links fitted to the

MSE867. The links can be accessed by removing the rear top cover of the unit.

Fig. 1 Link Location

Link Action Default

LK1 Select automatic current reduction from PM600 idle output On

LK2 Drive over-temperature activates PM600

abort stop

input On

LK3 Drive overload activates PM600

abort stop

input On

LK4 to LK7 1-2 selects RS485, 2-3 selects RS232 RS232

LK8 Select internal (on) or external (off)

abort stop

Internal

LK1 If LK1 is on, the current to the motor will be reduced to about 25% of the current

set on the drive when the motor has finished its move and the controller returns to

Idle

. The primary use of this function is to reduce the heating effect caused by the

motor. It is not intended to produce a precise holding-torque.

If LK1 is removed, the motor current will remain at the current set on the drive.

This setting is usually only needed when a high holding-torque is required. E.g.

when driving a mechanism with an offset load.

LK2 If LK2 is on, an over-temperature fault detected on the drive output stage will

cause the controller

abort stop

input to be activated.

LK3 Likewise if LK3 is on, an overload fault detected on the drive output stage will

cause the controller

abort stop

input to be activated.

LK4-7 These two position links select either the RS232 or RS485 communication

interfaces. When the links LK4 to LK7 are all in the 1-2 position, RS485 is selected

and when all in the 2-3 position, RS232 is selected.

If using RS485 communication, The last SimStep in the line should have SW3-8

on the PM600 switched to the ON position. This selects a 100Ω terminating

resistor. See figs 8.2 and 8.3 in section 8.3.

LK8 If LK8 is removed (off) the external ‘Abort Stop’ input selected. Pins 7 and 14 on

the Limits/Datum connector must be linked (via a normally-closed contact or

switch) to enable moves.

LK8 LK7 to LK1

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 7

2 External Interface Connections

MAINS supply

Connector type: IEC chassis plug

Terminal Connection

L Live input 115/230V AC

(Internally selectable)

N Neutral input

E

Earth. THIS UNIT MUST BE EARTHED

MOTOR

Connector type: HAN-4A socket

Mating Cable: 507MOCxx892 (xx = length)

Terminal Connection

1 Motor Phase A+

2 Motor Phase A3 Motor Phase B+

4 Motor Phase BE Screen

LIMITS/DATUM RED

Connector type: 15 way ‘D’ Plug

Mating Cable: 507LDCxx894 (xx = length)

Terminal Connection

1

2 0V

3 Upper Limit Input 4 Lower Limit Input 5 Datum Approach Input 6 Datum Stop Input 7 Abort Stop – (selected by internal link LK8)

8

9

10 Upper Limit Input + (24V)

11 Lower Limit Input + (24V)

12 Datum Approach Input + (24V)

13 Datum Stop Input + (24V)

14 Abort Stop + (24V)

15

Link pins 3 and 10 to enable positive moves

Link pins 4 and 11 to enable negative moves

Link pins 5 and 12 for fast datum search

If external ‘Abort Stop’ selected, link pins 7 and 14 to enable moves.

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 8

ENCODER BLUE

Connector type: 15 way ‘D’ socket

Mating Cable: 507ENCxx893 (xx = length)

Terminal Connection

1

2 0V

3 Channel A4 Channel B5 Channel I6

7

8

9 +5V

10

11 Channel A+

12 Channel B+

13 Channel I+

14

15

I/O YELLOW

Connector type: 25 way 'D' socket

Mating Cable: 507IOCxx895 (xx = length)

Terminal Connection

1 Write Port 1

2 Write Port 2

3 Write Port 3

4 Write Port 4

5 Write Port 5

6 Write Port 6

7 Write Port 7

8 Write Port 8

9 Write Port Common (Isolated Supply)

10 +VLL (Controller Supply)

11

12

13

14 Read Port 1

15 Read Port 2

16 Read Port 3

17 Read Port 4

18 Read Port 5

19 Read Port 6

20 Read Port 7

21 Read Port 8

22 Read Port Common (Isolated 0V)

23 0V (Controller 0V)

24

25

Refer to PM600 Manual sections 2.18 and 3.16 for typical connections.

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 9

JOG A and JOG B GREEN

Connector type: 15 way 'D’ socket

Compatible with JC100, JC400 and JC809 manual controls

Terminal Connection

1 Jog Common (~+24V)

2 0V

3 Jog + Input

4 Jog – Input

5 Jog Fast Input

6

7

8

9 Joystick Supply (+5V)

10 Joystick Input

11

12 Joystick Centre Tap Input

13

14 Data A

15 Data B

RS232 IN

Connector type: 9 way 'D' type socket

Terminal RS232 Connection RS485 Connection

1 RS485-A

2 Transmit Data

3 Receive Data

4

5 0V

6 RS485-B

7 CTS

8 RTS

9

RS232 OUT

Connector type: 9 way 'D' type plug

Terminal RS232 Connection RS485 Connection

1 RS485-A

2 Receive Data

3 Transmit Data

Link to echo replies

and commands

4

5 0V

6 RS485-B

7 RTS

8 CTS

Link to echo replies

and commands

9

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 10

3 Cables

3.1 Motor and Limit/Datum cables

Motor and limit/datum cables fitted with connectors to plug into the rear panel of the

SimStep may be specified. The available lengths are shown below. The motor cables

have a connector on both ends, which can be connected either to the connector fitted to

the stepper motor or to the stepper motor wires via an MSA889 Junction Box.

Likewise, the

Limit

and

Datum

connections can be made either by connecting to the

socket on the end of the cable or via an MSA889 junction box. The connections to the

MSA889 junction box are shown in figures 4.2 and 4.3.

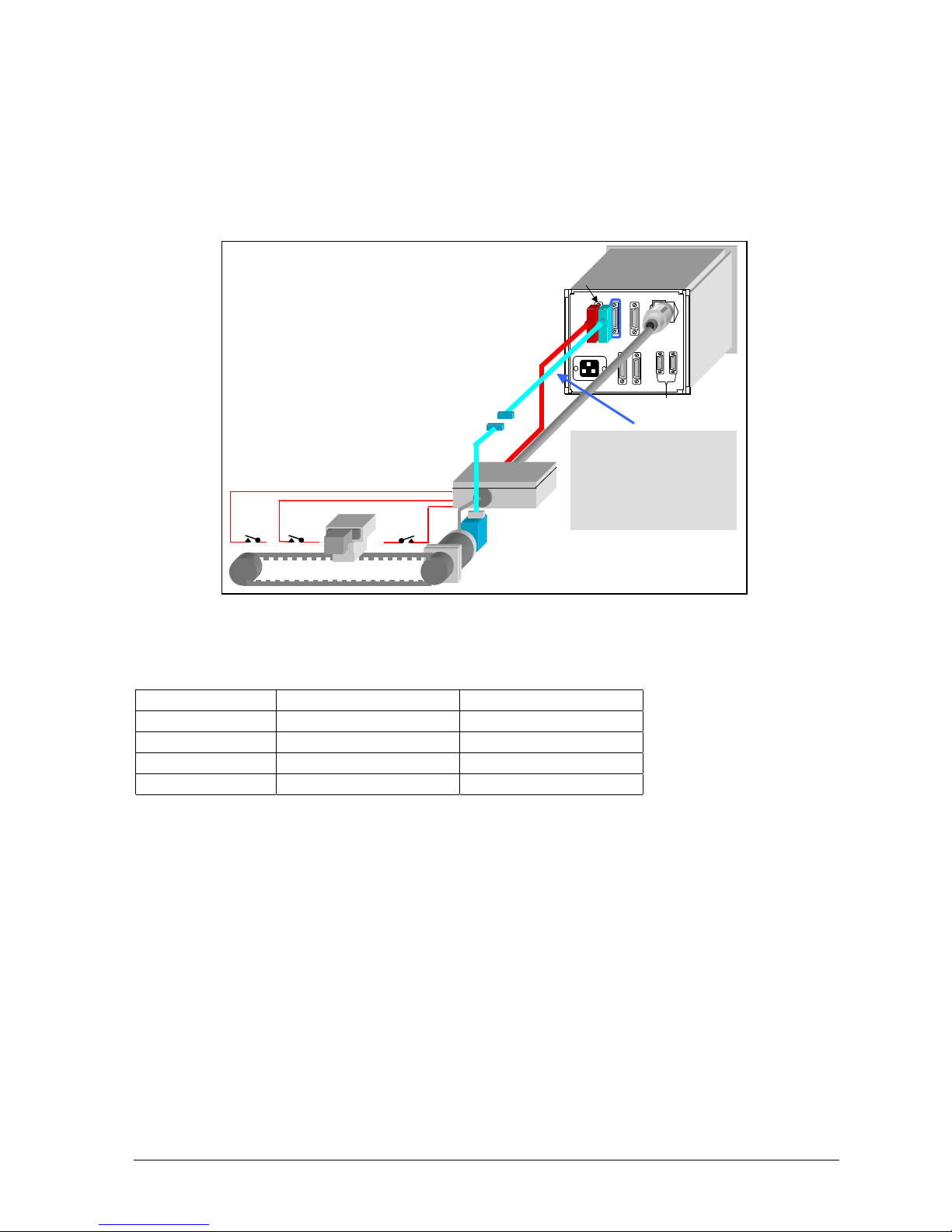

Fig. 3.1 Motor and Limit/Datum Cables

3.2 Electro-magnetic Compatibility (EMC)

The SimStep complies with EN-50081-1 and EN50082-1 when properly with cables that

use EMC connectors. The cable used to connect the motor to the drive should be a

screened, twisted pair type. The screen should be connected at both ends of the cable.

On the drive end, the screen should be connected to earthed metalwork of the case and

on the motor end, the screen should be connected to the motor body.

The EMC profile may be improved by fitting ferrite sleeves to the motor cables. For cable

diameters from 7mm to 8.5mm use RS part number 260-6492. For cable diameters from

8.5mm to 10mm use RS part number 309-7962.

Limit/Datum Cables

Length Type

1 m 507LDC01894

2 m 507LDC02894

3 m 507LDC03894

5 m 507LDC05894

10m 507LDC10894

Limit/Datum Cable

Junction Box

Type MSA889

Motor Cable

Motor Cables

Length Type

1 m 507MOC01892

- Limit Datum + Limit 2 m 507MOC02892

3 m 507MOC03892

Motor 5 m 507MOC05892

10m 507MOC10892

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 11

3.3 Encoder Cables

The SimStep can be connected to the encoder via an encoder cable that is equipped with

connectors at each end. One connector plugs into the controller, the other into the motorencoder extension cable as shown in fig 3.2.

Alternatively, if the motor has a connector box, the cable can be plugged in directly.

Fig. 3.2 Encoder Cable

3.3.1 Typical Motor Encoders

Frame size Motor Encoder Order Code

Size 23 23HSX-206 CI 500L 301HSE00053

23HSX-306 CI 500L 301HSE00054

Size 34 34HSX-108 RI 500L 301HSE00055

34HSX-208 RI 500L 301HSE00056

.

- Limit Datum + Limit

Motor-encoder

Encoder Cables

Type Cable length

507ENC01893 1 m

507ENC02893 2 m

507ENC03893 3 m

507ENC05893 5 m

507ENC10893 10 m

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 12

4 Motor Connections

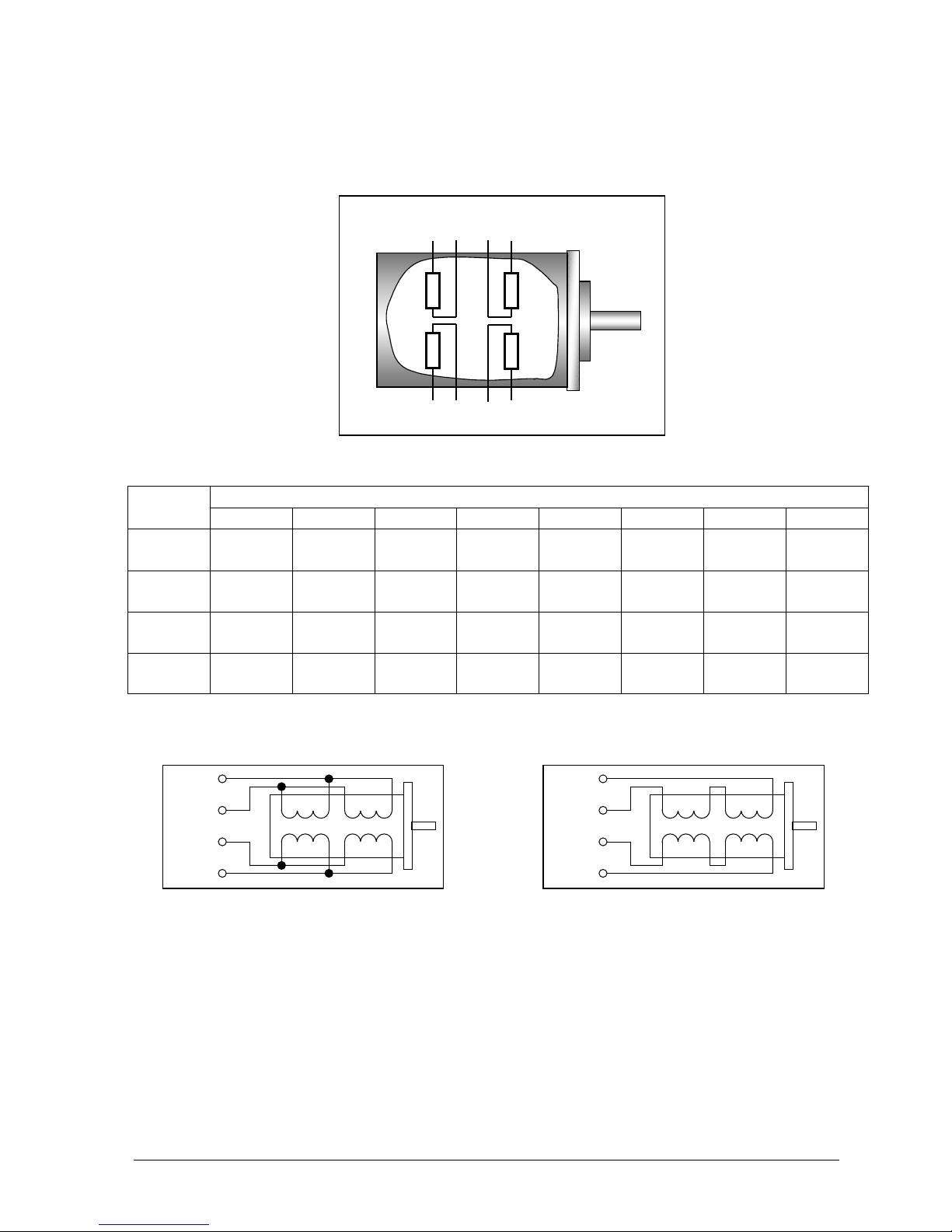

4.1 Colour Code for 8 lead motors:

The motor will have eight leads that can be identified as shown in figure 4.1.

Fig. 4.1 Eight lead 23 & 34 frame size motors

Lead identificationMotor

1 1’ 2’ 2 3 3’ 4’ 4

HS

Series

Red White/

Red

White/

Yellow

Yellow Black White/

Black

White/

Orange

Orange

or

Red Black White White/

Red

White/

Green

White/

Black

Orange Green

23HSX

Red White/

Red

White/

Yellow

Yellow Orange White/

Orange

White/

Brown

Brown

34HSX

Red White/

Red

White/

Yellow

Yellow Black White/

Black

White/

Orange

Orange

The motor can be connected into the MSA889 junction box as shown in fig. 4.4. Internal

links select parallel or series operation. This function is shown in figures 4.2 and 4.3.

The maximum drive current for coils wired in parallel is the unipolar motor phase current

rating x √2. The maximum drive current for coils wired in series is the unipolar motor

phase current rating / √2.

To reverse motor direction, swap the connections to one phase. E.g., swap B with B’.

1 1’ 3’ 3

2 2’ 4’ 4

Phase A’

Phase A

Phase B’

Phase B

11’2

2’

33’ 4

4’

Phase A’

Phase A

Phase B’

Phase B

11’2

2’

33’ 4

4’

Fig. 4.2 Coils in Parallel Fig. 4.3 Coils in Series

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 13

4.2 Connecting To The MSA889 Junction Box

Fig. 4.4 Parallel Motor Coil Connections

Fig. 4.5 Series Motor Coil Connections

57 mm

Motor Lead connections

4 Lead motors

1

1’ 1’

2’

2

3

Link for parallel 3’

Operation 4’

4

126 mm

8 Lead motors

Motor Lead 11

507MOCxx892 Motor leads 1’ 1’

2’ 2’

22

33

3’ 3’

4’ 4’

4 4

Junction Box MSA889

57 mm

Motor Lead connections

126 mm

Link for series

Operation

Motor Lead

507MOCxx892

8 Lead motors

Motor Leads

1

1’

2’

2

3

3’

4’

4

Junction Box MSA889

1

1’

2’

2

3

3’

4’

4

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 14

4.3 Connection of Limits And Datum

Fig. 4.5 Limit/Datum Connections

All limit and datum signal inputs should utilise normally closed contacts.

Note* The datum approach signal is not always required. This is the case when:

a) The motor is operated at slow (creep speed) since it is not necessary to

decelerate before stopping at the datum point. In this case the datum

approach terminals should not be connected.

b) When the controller is configured to utilise the high-speed datum registration

feature. In this case, the datum approach connections should be linked.

Note ** This connection enables an external open contact to abort a move. However

for this feature to be utilised it is necessary to remove an internal link LK8

within the controller.

It should be noted that the limit switches should be placed sufficiently within the total travel

distance to allow the motor to decelerate from high speed.

They should also be mounted for sliding operation, so that they do not become crushed on

first use. No mechanism can decelerate instantaneously.

Limit / datum connections

0VLL

+VLL +over-travel limit

Upper Limit

+VLL - over-travel limit

Lower Limit

Limits datum cable +VLL datum approach *

507LDCxx894 Datum App

+VLL datum stop

Datum stop

+VLL

Abort stop abort stop **

Allow sufficient deceleration over-travel

1’ deceleration deceleration

zone working zone zone

- Limit + Limit

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 15

4.3.1 Datum Position

The

datum

position is detected as the

datum stop

switch opens. It is also summed with

the encoder

index

signal (if fitted). For further information, refer to the Datum Search

Strategies section (2.13) of the PM600 manual.

4.3.2 Using Over-travel limits as datum inputs.

In applications where space is limited, the over-travel

limit switches may also be used as the datum stop

switch. In the example shown the lower limit switch is

also connected to the datum stop input and the

controller is configured to utilise the high-speed

datum approach facility.

Fig. 4.6 Limit/Datum Connections

0VLL

+VLL

Upper Limit

+VLL

Lower Limit

+VLL

Datum Approach

+VLL

Datum Stop

+VLL

Abort stop

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 16

5 Power Supply Unit

The power supply unit used in this system has been designed to energise an MSE570

stepper drive and a PM600 Position Controller.

It provides the unregulated logic supply of +24V (nominal) to the PM600, and an

unregulated supply of +40V (nominal) to the MSE570.

There is a mains fuse fitted in the mains inlet, its rating is 2A anti-surge. There are two

front panel fuseholders that protect the DC outputs of the power supply. The rating of the

fuses are 3.15A for the motor rail and 1A for the logic rail.

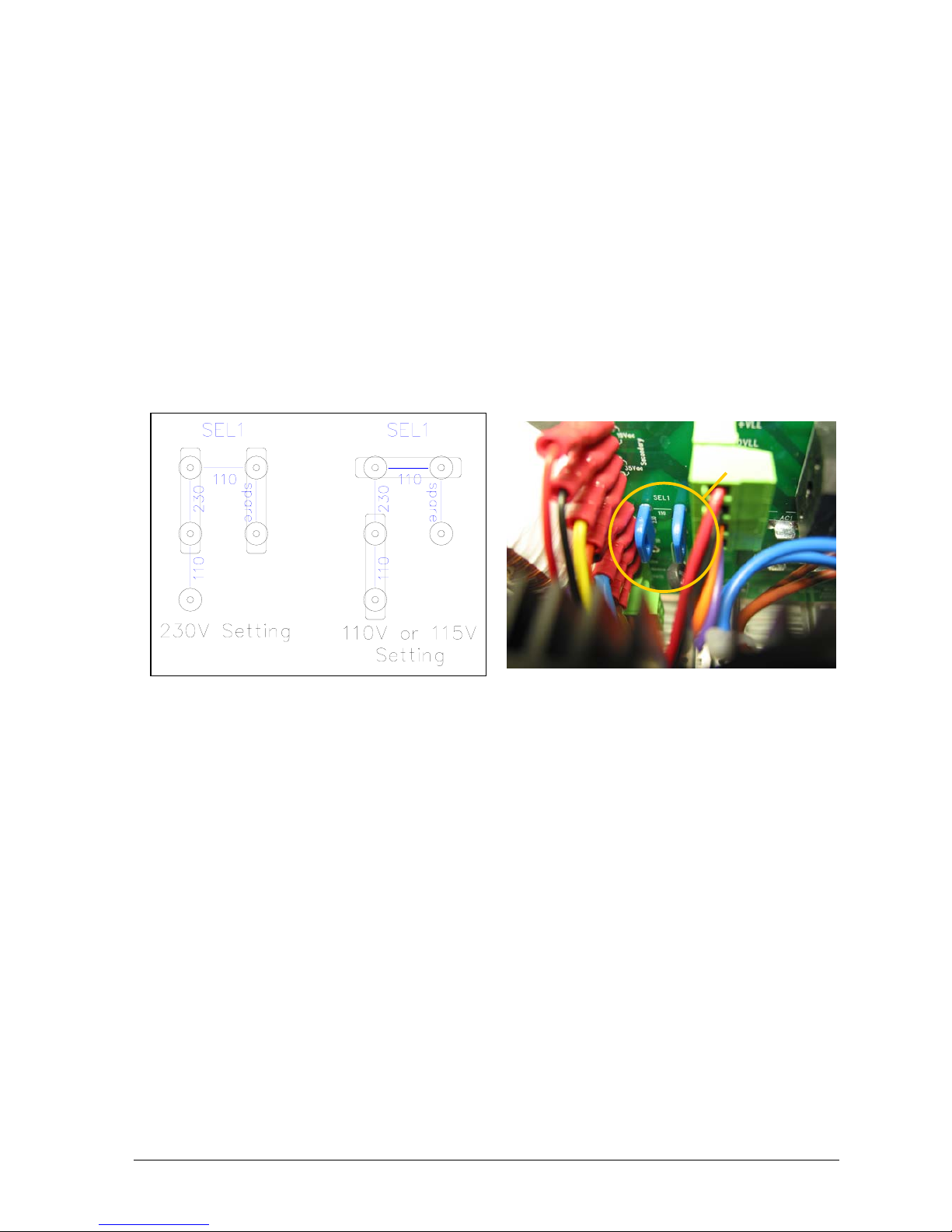

The mains voltage may be changed from 230V to 115V by changing the position of the

links on the MSE779 PCB.

Fig. 5.1 Mains Voltage Selector

SEL1

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 17

6 MSE570 Stepper Drive

The MSE570 stepper drive translator is a 3.5A per phase bi-polar stepper drive.

The clock and direction signals from the PM600 controller are converted into chopped,

constant current drive levels to energise a bipolar stepper motor.

The step sequence is set to

half step

. Using a hybrid type stepper motor, 400 steps per

revolution will be obtained.

A thermal sensor protects the output devices in case of overheating. If the drive

temperature exceeds 80° C, the thermal sensor will operate. With the switch settings

shown below, the drive is disabled (SW1-1=on) and the condition is latched (SW1-2=on).

The latched condition can only be reset by removing the power.

Fig. 6.1 MSE570 Set-up Switches

6.1 General Set-up:

1

4

3

2

DT

OnOff

SS

CC

LT

Disable on Overtemperature - on

Latch Overtemperature - on

Slave Sync – off

Current Control Type - slow

SW1

6.2 Current Setting

As delivered the motor phase current is set to 3.5A/phase.

1

4

3

2

OnOff

SW2

SW2

SW1

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 18

6.3 Other MSE570 Current Settings

The current setting for the motors detailed below when wired with coils in parallel is

3.5A (default).

Current settings for motors wired with coils in series.

Motor Current (A)

23HSX-206 2.1

23HSX-306 2.1

34HSX-108 2.7

34HSX-208 2.7

2

4

3

OnOff

0.0A 0.5A 0.9A 1.2A 1.3A 1.6A 1.85A 2.1A

1

SW2

2

4

3

OnOff

2.3A 2.5A 2.7A 2.9A 3.0A 3.1A 3.3A 3.5A

1

SW2

WARNING! Failure to make the correct current settings can damage the motor

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 19

7 Manual Operation Using the Jog Box or Joystick

The SimStep controller can be operated in manual mode by means of either a jog box or

joystick. These devices should be connected to the

Jog

connectors on the rear of the unit.

7.1 Jog Boxes - JC Series

JC Series Jog boxes provide a convenient way to manually control motor control systems.

Three models, the JC100 single-axis, the JC200 dual axis and the JC809 multi-axis are

available and provide the following manual control functions:

• Bi-directional single step (jog) function by momentary depression of ‘+’ or ‘-’ buttons.

• Slow speed continuous operation in desired direction by the depression and holding of

the ‘+’ or ‘-’ buttons. The speed of movement can be programmed using SJ command

into the SimStep during commissioning.

• Fast speed, continuous operation in desired direction by depressing & holding the ‘F’

button together with either the ‘+ or ‘- button. The fast positioning rates are can also be

programmed using SF command into the SimStep during commissioning.

Figures 7.1 to 7.3 show the connections of the JC series Jog Boxes to the SimStep.

For single axis drives specify JC100 Jog box and connect it to the green ‘D’ connector on

the SimStep as shown in fig 7.1.

Fig. 7.1 Single axis installations

For dual axis drives specify JC200 Jog box and connect it to the green ‘D’ connector on

the SimStep as shown in fig 7.2.

Fig. 7.2 Dual axis installations

Sim-Step

SINGLE

AXIS

JOG BOX

JC100

JC200

Use jog link cable 507JDC05916

AXIS

DUAL

AXIS

JOG

JC200

Note: Jog link cable is handed, identified by

the colour of the screw heads as shown

1

2

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 20

For 3-15 axes drives specify JC809 Jog Box and connect it to the green ‘D’ connector on

the SimStep as shown in fig. 7.3.

Fig. 7.3 3-15 axis installations

7.2 Single and Dual Axis Jog Box Operation

Jog box operation is very straightforward. Once connected, the jog box will control the

motor as follows. Pressing either the + or – button causes the motor to move in the

positive or negative rotation direction. The speed of rotation is determined by the

Slow Jog (SJ command) speed that has been set in the PM600. Momentarily

pressing the + or – buttons causes the motor to move in single steps.

Pressing the F button together with either the + or – buttons causes the motor to move

at the Fast Jog (SF command) speed that has been programmed into the PM600 (see

pages 7-48 and 7-49 of the PM600 manual)

7.3 Multi-axis Jog Box Operation

The MSB867 interfaces between the JC809 Multi-axis Jog Box and the PM600.

It communicates to the JC809 via signals transferred over a RS485 link. The outputs

from the MSB867 connect to the PM600’s Jog inputs. Connecting the ‘Jog DaisyChain’ lead between the JOG B connector on one system to the JOG A connector on

the next system allows further systems to be connected to the JC809.

A rotary switch on the MSB867 sets the axis address that is shown on the JC809. This

switch is accessible by removing the rear top cover of the unit. A setting of 0 will mean

that the axis cannot be controlled by the JC809. The default axis is 1 but any axis

between 1 and 15 can be selected. Note that axes 10, 11, 12, 13, 14 and 15 are

represented by the letters A, B, C, D, E and F respectively.

Fig. 7.4 Jog Axis Selector

JC809

Use jog link cables 507JDC05916

Fit terminator

Supplied with

JC809

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 21

7.4 Joystick - JC Series

The JC Series Joysticks provide an alternative way to manually control motor speed.

The JC400 is a dual axis Joystick that can be used to control either one or two axes.

The JC400 is connected in a similar way to the JC100 and JC200 Jog Boxes shown in

figures 7.1 and 7.2.

7.5 Joystick Operation

In order to set the joystick parameters, the RS232 connection must be connected to a

PC.

The joystick option gives variable control of the motor speed – the further the joystick

is moved from the centre position, the faster the motor moves. Before the joystick

option can be used, the joystick centre and minimum/maximum positions must be

calibrated. Note that the SimStep is set up for Jog Box operation as standard.

The controller must then be told to accept the joystick input using the command

1JM01000000 (see PM600 manual page 7-27).

Assume that the controller is set as Axis 1 and that the joystick is in the “free” (i.e. mid

range) position. The command 1AI3 will interrogate the joystick position; the controller

will then display a value in the format 01:2126, where 01: refers to Axis 1, and 2126 is

the joystick centre position.

Now hold the joystick at one extreme of its range and repeat the 1AI3 command; note

this number and then repeat at the other extreme of the joystick range. Let us assume

that the following data are given from the 1AI3 command:

Low 1688

Centre 2126

High 2568

This means that the

range

either side of centre is ~440 units (note that the “centre

position” may not be

exactly

in the middle of the upper and lower readings).

1JC2126 This sets the centre position. A value of JC=0 will use the value of a joystick

centre tap signal, connected to Analogue input 5, to set the centre position.

1JR340 This sets the +/- range of the joystick (JR =

range

– 2 x JT)

1JT50 This sets the joystick threshold – this is the “deadband” around the centre

position. If the joystick is moved by less than the deadband value, the

motor will not move.

Note: You must use the 1BD (backup digiloop) command in order to store these

parameters otherwise they will be lost when power to the controller is switched off.

For further information, refer to the Joystick Calibration section (2.19) of the PM600

manual.

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 22

8 PM600 Intelligent Stepper Motor Controller

The PM600 is a microprocessor-based unit for controlling servo or stepper motors. The

controller has a wide range of functions available; these are described in detail in the

PM600 manual included with this documentation. The SimStep will operate under manual

control with either a jog box or joystick, or can run under remote control through the

RS232 (or RS485) interface.

Basic information on the command structure and the RS232 interface is given below; the

user should refer to the PM600 manual for complete details.

8.1 General

The PM600’s switches have been set as follows:

RS232 Control

The controllers are set to axis address 1

The baud rate is set to 9600 baud

The word mode is set to 7 bits, even parity

Quiet mode is selected

Rotary switches SW1 and SW2 set the axis address. These are set to the actual

address required. SW3 sets the communication configuration. For further information

refer to the Switch Setting section (10) of the PM600 manual

The control mode has been set to open-loop stepper mode by the command 1CM11.

When using the SimStep with an encoder, the control mode can be changed to

closed-loop stepper by the command 1CM14.

8.2 Setting Up The Encoder (Closed-loop Control Modes Only)

Each edge of the quadrature signals is counted, so the number of encoder counts per

revolution will be four times the line count of the encoder.

The PM600 can be used with encoder producing either 5V TTL signals or

5V line

driver

signals. The correct termination should be set. This gives maximum noise

immunity. The use of encoders with

line driver

type signals is recommended where the

encoder lead length will exceed 1m.

8.2.1 Encoder Termination

Switch SW4 selects the termination for the encoder signals. If using differential signals

then the encoder termination should be switched on. With 5V TTL encoders, the

encoder termination switches should be switched off.

1B

1I

1A

3

O

N

1

2

1

2

Single

ended

(TTL)

3

1

2

Line Driver

(Default)

3

Fig.8.1 Encoder Termination Configuration Switch SW4

SW4

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 23

8.2.2 Encoder Scaling

The incoming encoder pulses are scaled by the encoder ratio (ER) formed by the

Encoder Numerator (EN) and the Encoder Denominator (ED) i.e. the number of

pulses received is multiplied by the numerator and divided by the denominator, to

become the Actual Position.

If the ratio between the number of steps and the encoder counts is 1:1 (e.g. 100 line

encoder = 400 counts per revolution mounted on a 400 step per rev motor) then the

encoder scaling factors; Encoder Numerator and Encoder Denominator can be left at

their default of 1, otherwise they will need to be changed.

If the Encoder Numerator (EN) is set to the number of motor steps per revolution and

the Encoder Denominator (ED) is set to the number of encoder counts per revolution,

then the ratio will be correct. For example, if a 400 step per revolution motor fitted with

a 500 line (2000 counts) encoder, then set the Numerator to 400 and the Denominator

to 2000 (ER400/2000 or EN400, ED2000).

8.2.3 Encoder Direction

On switch on, both the Command Position and the Actual Position will both be at zero.

Try a test move (e.g. MR1000) and query the positions with the OC and OA (or QP)

commands, to ensure the scaling is correct. If one is the negative of the other, then

the ‘sense of direction’ needs to be reversed, by either swapping the A and B signals

OR by setting the Encoder Numerator to a negative value.

8.3 Programming via the RS232 Interface

Any suitable communication programme can be used to communicate with the

SimStep controller. For example, the MyTerminal programme (available from

www.SimStep.co.uk) or the Windows Hyper Terminal programme can be used to

make the communications link.

Whichever software is used, the communications interface is set by default, as

follows:

Baud Rate 9600

Data Bits 7

Stop Bits 1

Parity Even

Flow Control None

Once the communications software has been set up, the remote computer should be

connected to the SimStep via the RS232 IN port. Multiple SimStep units can be

daisy-chained

together to build multi-axis systems. Rotary switches SW1 and SW2 on

the PM600 card are used to set the units axis address (0 to 99). This is the address of

the serial commands that it will respond to. Each controller in a system will be set to a

different address.

The switches on the PM600 are accessible by removing the slotted top cover of the

unit. The left-hand switch SW1 sets the decade value and SW2 sets the units. They

can be set using a small screwdriver. See figures 8.2 and 8.3.

Note that the RS232 loop-back connector must be fitted to the RS232 OUT connector

of the final SimStep in the RS232 chain.

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 24

Fig. 8.2 PM600 Switch Positions

Fig. 8.3 Positions of PM600 Switches SW1, SW2 and SW3

SW3

SW4

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

P2

LK2

SWAP8

LD1

ULOAD

SW1

SW2

10 1

1A

1B

1I

2I

2B

2A

3A

3B

LD2 LD3

ON

ON

LK1

1

32

SW2SW1 SW3

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 25

8.4 General Command Structure

The PM600 responds to a character string (sent over the RS232 interface) that

defines a command in the following way:

adXXnnn<cr> where

ad = address for the axis (see 8.1 above)

XX = command notation – all commands are two letters

nnn = numeric value for the command argument (if required)

<cr> = carriage return

Command strings must be terminated with a carriage return (ASCII 0D hex). Upper or

lower case characters maybe used for the command. Spaces in the command line are

ignored. Commands are acted upon sequentially, as they have been entered.

8.5 Examples of Command Structure

Set-up commands:

2SA5000 Set Axis 2 acceleration to 5000 steps/sec

2

1LL-20000 Set Axis 1 lower software limit to –20000 steps

1QA Query all settings for Axis 1

M

OVE COMMANDS

:

1MR5000 Move Axis 1 relative to current position by +5000 steps

1ST Soft stop on Axis 1

2MA-2000 Move Axis 2 to absolute position –2000 steps

2OA Output the encoder position of Axis 2

The SimStep controller responds to all commands once the command has been

accepted. However, not all commands can be accepted immediately. For example, a

move command sent whilst a previous command is still taking place, will be delayed

until the previous one is finished. Commands in general will have an OK response.

Some commands, however, will produce a numeric response (e.g.2OA) or produce a

string of data (e.g. 1QA).

All replies are preceded by the address of the axis that generated the response – e.g.

for axis one the replies will be preceded by 01:OK.

Important – if the set-up of the PM600 is changed then the BA (backup all command)

must be executed to save set-up values and sequences to Flash memory. If this not

done, the values will be lost on power-down.

The user may encounter error message from the controller under certain

circumstances, e.g. mistakes in commands or conflicting instructions. The messages

are usually self-explanatory; they are listed on page 8-1 of the PM600 manual.

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 26

9 I/O Cable and Breakout Box

Eight inputs (Read Ports) and eight outputs (Write Ports) can be used for external digital

interfacing.

An I/O cable with the ‘breakout’ DIN rail mounting terminal box can be used to interface to

the SimStep without needing to make a special cable.

The I/O breakout box features screw terminals to enable the 16 Digital I/O to be

connected. The unit is DIN rail mounted so that it can be sited next to a typical PLC

control unit

Fig. 9.1 I/O Breakout Box and I/O Cable

Fig. 9.2 I/O Breakout Box Connections

85 mm

70 mm

I O Breakout Box ordering details

- Limit Datum + Limit

I/O Breakout Box 506MSC00891

Motor 1m I/O Cable 507IOC01895

2m I/O Cable 507IOC02895

3m I/O Cable 507IOC03895

5m I/O Cable 507IOC05895

I / O Breakout box 506MSC00891 Connections

:

Output Lines Input Lines

WP1 RP1

WP2 RP2

WP3 RP3

WP4 RP4

WP5 RP5

WP6 RP6

WP7 RP7

WP8 RP8

WP com RP-com

Diode-com N/C

+VLL +VLL

0V 0V

Screw Terminal connections

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 27

9.1 Isolation

The

Read Port

inputs and

Write Port

outputs are opto-isolated. A +24V nominal supply

must be used as the common for these inputs. This supply can either be a separate

external supply or the SimStep’s internal +24V supply. If the internal supply is used, then

the WP-com terminal must be connected the +VLL terminal on the Breakout box and the

RP-com terminal must be connected the 0V terminal on the Breakout box. If a separate

supply is used then the WP-Com terminal must be connected to the +24V terminal of the

external power supply and the RP-Com terminal must be connected to the 0V terminal of

the external power supply. The +24V output from the external supply can be used for the

common of the switches.

9.2 Typical Connections

Fig. 9.3 Typical Connections to the I/O Breakout Box

Fig. 9.4 Typical I/O Connections using an External Supply

9.3 Read Ports

The

read ports

can be connected to a PNP signal output, a switch, or another SimStep’s

write port

.

The RP Read input Port command is used to check the operation of the

read ports

. This

instruction returns an eight digit binary number of either 0 or 1 characters to represent the

current state of the read port. These start with

read port

8, through to 1. Referring to

figures 9.3 and 9.4, a 1 represents a closed switch and a 0 represents an open switch.

The input voltage that is considered as a logic 1 signal is 10-35V and the input voltage that

is considered as a logic 0 is 0-5V.

Typical Output Line Connections Typical Input Line connections

WP RP

Low current Relay

WP – com RP-com

Diode com

+VLL +VLL

0V 0V

Typical Output Line Connections Typical Input Line connections

+24V 0V

External

PSU

WP

Diode com

WP – com

RP-com

RP

Low current Rela

y

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 28

9.4 Write Ports

The

write ports

can be connected to an indicator (LED), an opto-isolator, a low-current

relay or another SimStep’s

read port

. The WP(bit pattern) command is used to write to

the output port

.

The bit pattern is specified as an eight digit binary number. The digits will be either

characters 0, 1 or 2 starting with

write port

8 through to 1. A 0 defines that the output will

be off, a 1 defines that the output will be on and a 2 defines that the output will not

change from its current state. The power-on states of the

write ports

are 00000000 - i.e. all

off.

The outputs are rated at 50mA, 35V.

9.4.1 Inductive Loads

The

write ports

must not be reverse biased. If used to drive an inductive load such as a

relay, then protection diodes must be used. If using an MSE891, this can be done by

connecting Diode-Com to 0V (either 0V on the Breakout box or the external supply 0V).

10

SimStep

Example Sequence

An example sequence is shown below. Three switches are connected to the

Read Port

to

control the action of the sequence and three outputs are used to monitor the action of the

sequence. One switch executes a 'home to datum' move and two switches initiate moves.

The ‘home to datum’ move must be done before the other moves can be selected.

The moves are controlled by the following inputs.

Read Port 1 = home to datum (datum search)

Read Port 2 = move to position 1

Read Port 3 = move to position 2

When the moves are completed, the following outputs turn on.

Write Port 1 = datum search complete

Write Port 2 = at position 1

Write Port 3 = at position 2

10.1 Sequence Definitions

Sequence 0 waits for the ‘Home to Datum’ input to be ‘1’ and then executes a ‘home to

datum’ (HD) move.

1ds0 Sequence 0 – Search for Datum

1wp22222000 Turn off outputs

1wa22222221 Wait for Home input to go on

1hd Search for datum

1we Wait for end of move

1wp22222001 Turn on axis 1 homed

1wa22222220 Wait for Home input to go off

1xs2 Goto input scanning sequence

1es

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 29

Sequence 2 scans the read port inputs and depending on the state of the inputs executes

the moves in sequence 3 or 4. After the move is complete, the operation goes back to

scanning the

read port

inputs.

1ds2 Sequence 2 - Scan for Move inputs

1it22222212 Is Move 1 input on

1xs3 Yes - do move

1it22222122 Is Move 2 input on

1xs4 Yes - do move

1xs2 No rescan inputs

1es

1ds3 Sequence 3 - Move 1

1wp22222002 Turn off 'At Position' outputs

1ma1000 Move to position 1000

1we Wait for end of move

1wp22222012 Turn on 'At Position 1' output

1wa22222202 Wait for Move 1 input to go off

1xs2 Goto input scanning sequence

1es

1ds4 Sequence 4 - Move 2

1wp22222002 Turn off 'At Position' outputs

1ma5000 Move to position 5000

1we Wait for end of move

1wp22222102 Turn on 'At Position 2' output

1wa22222022 Wait for Move 2 input to go off

1xs2 Goto input scanning sequence

1es

1bs Save sequences

1ae0 Execute sequence 0 on power-up

10.2 Configuration

Configure the SimStep to set the position to zero when the datum position is found. This

will mean that moves are relative to the datum position.

1dm00100000 Set datum position to home position (0)

1bd Save settings

10.3 Run Sequence

Either the sequence can be run by sending a 1xs command or as sequence 0 has been

set as an automatically executing sequence, by cycling the power to the SimStep.

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 30

11 Order Codes

11.1 System

Type Order Code

SimStep

508SMS09749

11.2 Motor Encoders

Frame size Type Order Code

Size 23 23HSX-206 CI 500L 301HSE00053

23HSX-306 CI 500L 301HSE00054

Size 34 34HSX-108 RI 500L 301HSE00055

34HSX-208 RI 500L 301HSE00056

11.3 Cables

Type Order Code

Motor – 1m 507MOC01892

Motor – 2m 507MOC02892

Motor – 3m 507MOC03892

Motor – 5m 507MOC05892

Motor – 10m 507MOC10892

Encoder – 1m 507ENC01893

Encoder – 2m 507ENC02893

Encoder – 3m 507ENC03893

Encoder – 5m 507ENC05893

Encoder – 10m 507ENC10893

Limits/Datum – 1m 507LDC01894

Limits/Datum – 2m 507LDC02894

Limits/Datum – 3m 507LDC03894

Limits/Datum – 5m 507LDC05894

Limits/Datum – 10m 507LDC10894

Jog Link – 0.5m 507JDC05916

I/O – 0.5m 507IOC05895

I/O – 1m 507IOC01895

I/O – 2m 507IOC02895

I/O – 3m 507IOC03895

11.4 Junction Boxes

Type Order Code

MSA889 – Motor & Limits/Datum 506MSC00889

MSA891 – I/O Breakout 506MSC00891

11.5 Jog Boxes & Joystick

Type Order Code

JC100 – Single Axis 506JCT00100

JC200 – Dual Axis 506JCT00200

JC809 – Multi-Axis 506JCT00809

JC400 – Dual Axis Joystick 506JCT00400

11.6 EMC Ferrites

Type Order Code

Cable Dia. 7 – 8.5mm 114FER00003

Cable Dia. 8.5 – 10.5mm 114FER00004

SimStep Manual - 3400 Iss. D 7

th

June 2004 page 31

12 Limitations of Use

This system has been designed to drive a hybrid type stepper motor. Any other use has

not been considered, therefore could damage the drive and could be dangerous for the

users.

Good engineering practices should be employed when using this product.

The operating temperature should be between 0ºC and 30ºC.

Users should take suitable precautions in the application of this product, to ensure that the

overall system complies with EN50081-1 and EN50082-1 (EMC directive).

These products should not be put into service until the machinery in which they are

incorporated has been declared in conformity with the provisions of The Supply of

Machinery (Safety) Regulations 1992 and The Supply of Machinery (Safety) (Amendment)

Regulations 1994 (Machinery Directive).

Motor control systems are inherently hazardous. Even a small motor, if coupled to a

leadscrew, gearbox, or any other form of mechanism that provides a mechanical

advantage, can generate considerable force and could cause serious injury. Incorrect

operation can also lead to damage to the motor or associated machinery.

Loading...

Loading...