Protecting Electronics.

Exceeding Expectations.™

Pentair Technical Products

INSTRUCTION MANUAL

PROAIR

Air Conditioner

CR29

Rev. D

© 2011 Pentair Technical Products

P/N 10-1008-121

89055732

TABLE OF CONTENTS

RECEIVING THE AIR CONDITIONER .............................................................................................................................................................. 3

HANDLING AND TESTING THE AIR CONDITIONER ................................................................................................................................. 3

INSTALLATION INSTRUCTIONS ..................................................................................................................................................................... 4

SYSTEM CONTROLS .......................................................................................................................................................................................... 4

Level I Temperature Controller ............................................................................................................................................................. 4

Level II and III Temperature Controller ............................................................................................................................................... 4

TECHNICAL INFORMATION ............................................................................................................................................................................ 5

DESIGN DATA...............................................................................................................................................................................................5

DIMENSION DRAWING ............................................................................................................................................................................. 5

CR29 Models 2200-4000 BTU/Hr. (645-1172 Watt) ................................................................................................................ 5

Mounting Gasket Kit ................................................................................................................................................................................. 6

Design Notes ....................................................................................................................................................................................... 6

Mounting Cutout Dimensions .............................................................................................................................................................. 6

Components List ........................................................................................................................................................................................ 7

Parts List ........................................................................................................................................................................................................ 7

Wire Diagrams and schematics ............................................................................................................................................................ 8

Wire Diagram, Level 1, 2000 BTU .................................................................................................................................................8

Wire Diagram, Level 1, 4000 BTU .................................................................................................................................................9

Wire Diagram, Level II and III, 2000 BTU ..................................................................................................................................10

Wire Diagram, Level II and III, 4000 BTU ..................................................................................................................................12

TEMPERATURE CONTROL .............................................................................................................................................................................14

PRINCIPLES OF OPERATION .........................................................................................................................................................................14

MAINTENANCE .................................................................................................................................................................................................14

Compressor ...............................................................................................................................................................................................14

Inlet Air Filter .............................................................................................................................................................................................14

How To Remove, Clean or Install a New Inlet Air Filter ..............................................................................................................15

Condenser and Evaporator Air Movers ............................................................................................................................................15

Refrigerant Loss........................................................................................................................................................................................15

TROUBLE SHOOTING ......................................................................................................................................................................................16

Basic Air Conditioning Trouble Shooting Check List ..................................................................................................................16

Symptoms and Possible Causes: ........................................................................................................................................................17

WARRANTY ........................................................................................................................................................................................................18

RETURN AND REPAIR POLICY ......................................................................................................................................................................18

LIMITATION OF LIABILITY ..............................................................................................................................................................................19

- 2 -

© 2011 Pentair Technical Products

89055732

RECEIVING THE AIR CONDITIONER

Inspect the air conditioner. Check for concealed damage that may have occurred during shipment. Look for dents,

scratches, loose assemblies, evidence of oil, etc. Damage evident upon receipt should be noted on the freight bill.

Damage should be brought to the attention of the delivering carrier -- NOT to McLean Cooling Technology -- within 15

days of delivery. Save the carton and packing material and request an inspection. Then le a claim with the delivering

carrier.

Pentair Technical Products cannot accept responsibility for freight damages; however, we will assist you in any way

possible.

HANDLING AND TESTING THE AIR CONDITIONER

If the air conditioner has been in a horizontal position, be certain it is placed in an upright, vertical or mounting

position for a minimum of ve (5) minutes before operating.

CAUTION

Do not attempt to operate the air conditioner while it is horizontal

or on its side, back or front. The refrigeration compressor is lled

with lubricating oil. This will cause permanent damage to the air

conditioner and also voids the warranty.

TEST FOR FUNCTIONALITY BEFORE MOUNTING THE AIR CONDITIONER TO THE ENCLOSURE.

Refer to the nameplate for proper electrical current requirements, and then connect the power cord to a properly

grounded power supply. Minimum circuit ampacity should be at least 125% of the amperage shown in the design

data section for the appropriate model. No other equipment should be connected to this circuit to prevent

overloading.

Operate the air conditioner for ve (5) to ten (10) minutes. No excessive noise or vibration should be evident during

this run period. The condenser blower (ambient air), the evaporator blower (enclosure air), and the compressor should

be running.

Condenser air temperatures should be warmer than normal room temperatures within a few minutes.

The compressor is provided with automatic reset thermal overload protection. This thermo-switch is located and

mounted inside the plastic enclosure clipped to the compressor. The switch operates when the compressor overheats

due to clogged or dirty inlet air lter or if ambient air temperatures exceed nameplate rating or if enclosure dissipated

heat loads exceed the rated capacity of the air conditioner. The thermal overload switch will actuate and stop

compressor operation. The blowers will continue to operate and the compressor will restart after it has cooled to

within the thermal overload cut-in temperature setting.

© 2011 Pentair Technical Products89055732 - 3 -

INSTALLATION INSTRUCTIONS

1. Inspect air conditioner and verify functionality before mounting the air conditioner, see HANDLING

AND TESTING THE AIR CONDITIONER on page 3.

2. Using the cutout dimensions shown in this manual, prepare the air “IN” and air “OUT” openings, and

mounting bolt hole pattern for the enclosure.

3. Using the gasket kit provided, install gaskets to air conditioner. See Mounting Gasket Kit on page 6 for

proper location.

4. Mount air conditioner on enclosure using mounting bolts and washers provided to secure unit to

enclosure. Allow unit to remain upright for a minimum of ve (5) minutes before starting. Caution! Air

conditioner must be in upright position during operation.

5. Refer to the top of the nameplate for electrical requirements. Connect the power cord to a properly

grounded power supply. Use of an extension cord is not recommended. Electrical circuit should be

fused with slow blow or HACR circuit breaker.

6. When the unit is equipped with an automatic temperature controller, the controller is preset at the

factory for your convenience and should not require adjustment.

SYSTEM CONTROLS

Level I Temperature Controller

The Level I controller is located inside the air conditioner.

To adjust, disconnect power to the air conditioner and

open the front panel by loosening the front panel screw.

Refer to Figure 2 on page 7 to locate the controller. Turn

the controller adjustment screw slot counter-clockwise

to increase and clockwise to decrease the temperature

set point, see Figure 1. The thermostat cooling set point is

indicated by the alignment of the adjustment screw slot

with the dial decal. After completing adjustment, close

the front panel and tighten the front panel screw. Restore

power to the air conditioner for operation.

Level II and III Temperature Controller

The Level II and III controller mounted on the air

conditioner front panel is factory set for standard

operation. All operating parameters are programmable

for custom applications. Refer to the Level II and III

programming and Operating Instruction Manual,

10-1008-161.

CONTROLS COMPRESSOR

OFF

Figure 1

Level I control

- 4 -

© 2011 Pentair Technical Products

89055732

TECHNICAL INFORMATION

DESIGN DATA

Max

Model Voltage Hz Phase

BTU/Hr @

131 F/131 F

Amps @ 131

F/131 F

BTU/Hr @

95 F/95 F

Amps @

95 F/95 F

Amb

Temp

°F/°C

CR290216GXXX 115 50/60 1 2000/2200 7.4/7.4 1700/2000 7.0/6.0 131/55 98/44

CR290226GXXX 230 50/60 1 2500/2700 4.6/3.9 1900/2300 4.4/3.3 131/55 98/44

CR290416GXXX 115 50/60 1 3500/4000 13.5/13.5 2400/2800 10.7/9.6 131/55 118/54

CR290426GXXX 230 50/60 1 3500/4000 6.7/6.6 2400/2800 5.9/5.3 131/55 118/54

-XXX will be replaced with a three-digit number designating all desired options. Consult the factory for specic model numbers.

DIMENSION DRAWING

CR29 Models 2200-4000 BTU/Hr. (645-1172 Watt)

CLEANABLE, REUSABLE

ALUMINUM INLET FILTER

Shipping

Weight

lb./kg

TOP VIEW

FRONT VIEW

BOTTOM VIEW

AMBIENT

AIR OUT

STANDARD

CONDENSATE

DRAIN LOCATION

SIDE VIEW

ENCLOSURE

AIR IN

AMBIENT

AIR IN

COOL

AIR

OUT

BACK VIEW

© 2011 Pentair Technical Products89055732 - 5 -

Mounting Gasket Kit

Design Notes

1. Gasket kit included. Apply gasket to rear

of air conditioner before mounting on

enclosure.

2. Service cord terminated with appropriate

plug cap.

3. Millimeter dimensions [ ] are for reference

only; do not convert to inch dimensions.

4. Allow at least 4 inch inlet and 6 inch

outlet clearance for proper ambient

air ow. Allow 20 inch above lter for

removal.

Mounting gasket kit part no. 29-4100-02 as applied to

rear of CR29.

Mounting Cutout Dimensions

Cutout Instructions

NOTE:

1. DASHED LINES REPRESENT OUTSIDE OF AIR CONDITIONER

- 6 -

© 2011 Pentair Technical Products

89055732

Components List

Part Description

Blower, Condenser 29-4121-10 29-4121-10 29-4120-10 29-4120-10

Blower, Evaporator 29-4121-10 29-4121-10 29-4120-10 29-4120-10

Capacitor, Compressor N/A 10-1032-13 10-1032-09 10-1032-14

Compressor 10-1016-23 SP 10-1016-26 SP 10-1026-74 SP 10-1026-77 SP

Thermal Overload, Compressor 10-1007-19 10-1007-45 10-1007-57 10-1007-51

Filter, Air, Reusable 10-1000-32 10-1000-32 10-1000-32 10-1000-32

Thermostat, SPST, 55-100F 10-1061-16 10-1061-16 10-1061-16 10-1061-16

Mounting Gasket Kit 29-4100-02 29-4100-02 29-4100-02 29-4100-02

Relay, Compressor 10-1028-20 10-1028-14 10-1028-07 10-1028-15

Power Cord Consult factory Consult factory Consult factory Consult factory

115 Volt

2200

115 Volt

4000

230 Volt

2700

230 Volt

4000

Parts List

Part Description Part No.

1 Condenser Coil 29-4101-00

2 Filter, drier, refrigerant 52-6028-00

3 Compressor See Components List

Hot Gas bypass valve

4

(CR29-04xx units only)

5 Evaporator coil 29-4102-00

Inlet air lter,

6

reusable aluminum

Blower (115V)

7

Blower (230V)

Compressor thermal

8

overload switch

Capacitor, compressor

9

(CR29-04xx units only)

Capacitor, compressor

10

(CR29-0226 units only)

11 Terminal block 086912

12 Power cord Consult Factory

13 Temperature controller Consult Factory

Relay, compressor

14

(CR29-04xx units only)

Relay, compressor

15

(CR29-02xx units only)

16 Mounting gasket kit 29-4100-02

52-6027-11

10-1000-32

29-4121-10

29-4120-10

See Components List

See Components List

See Components List

See Components List

Figure 2

See Components List

© 2011 Pentair Technical Products89055732 - 7 -

Wire Diagrams and schematics

Wire Diagram, Level 1, 2000 BTU

MALFUNCTION

SWITCH

(OPTIONAL)

SERVICE CORD

THERMOSTAT

SUPPRESSOR

DOOR STUD

COMPRESSOR

HEATER

(OPTIONAL)

COMPRESSOR

LINE

SUPPRESSOR

BLOWER

COMPRESSOR HEATER (OPTIONAL)

THERMOSTAT

START RELAY,

COMPRESSOR AND

OVERLOAD

- 8 -

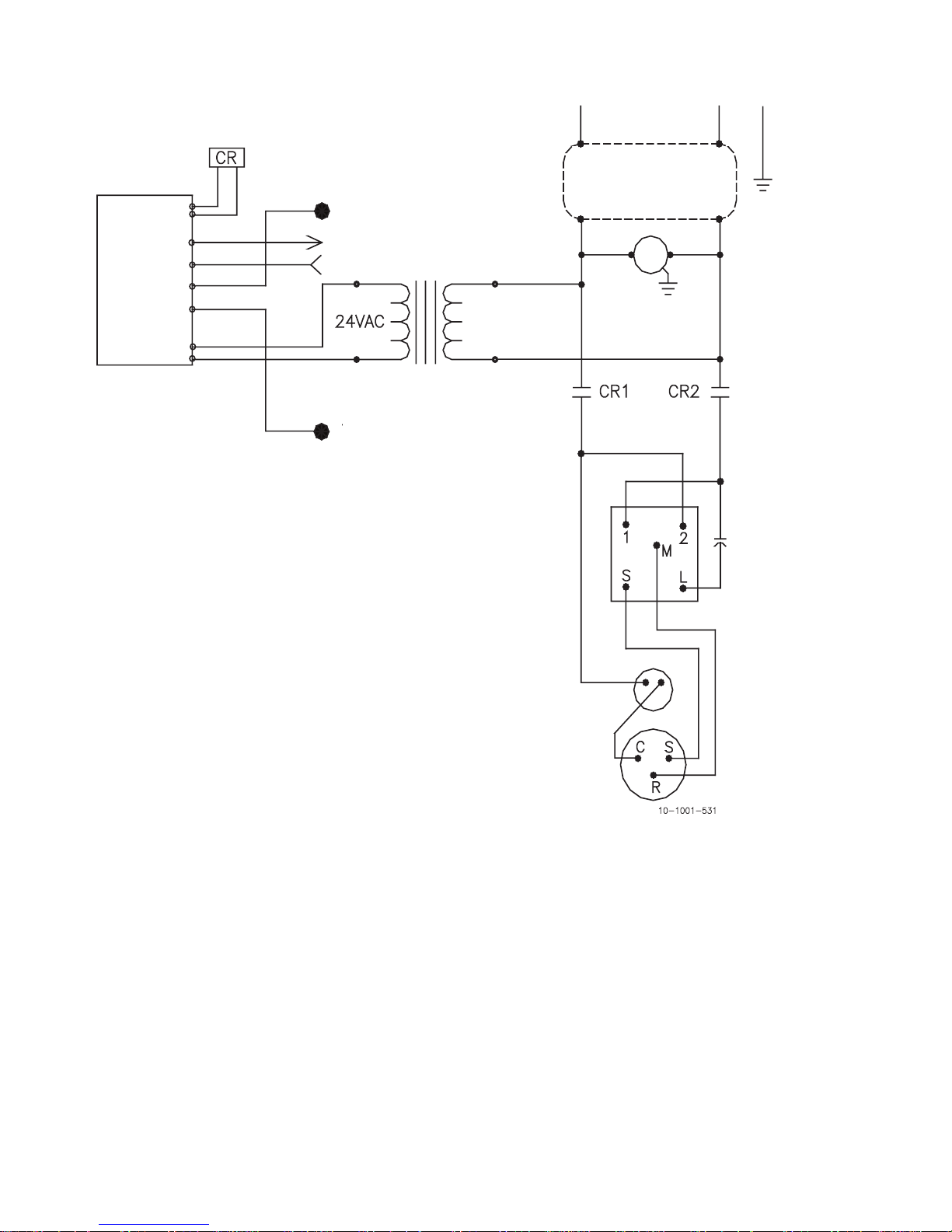

ELECTRICAL SCHEMATIC

© 2011 Pentair Technical Products

89055732

Wire Diagram, Level 1, 4000 BTU

START

CAPACITOR

RELAY

THERMOSTAT

SUPPRESSOR

SERVICE CORD

DOOR STUD

COMPRESSOR

HEATER

(OPTIONAL)

COMPRESSOR

LINE

SUPPRESSOR

BLOWER

COMPRESSOR HEATER (OPTIONAL)

THERMOSTAT

NOTE: For voltage, hertz, and options not shown in this manual, refer to the wiring diagram

attached to the unit.

START CAPACITOR

START RELAY

COMPRESSOR AND

OVERLOAD

ELECTRICAL SCHEMATIC

© 2011 Pentair Technical Products89055732 - 9 -

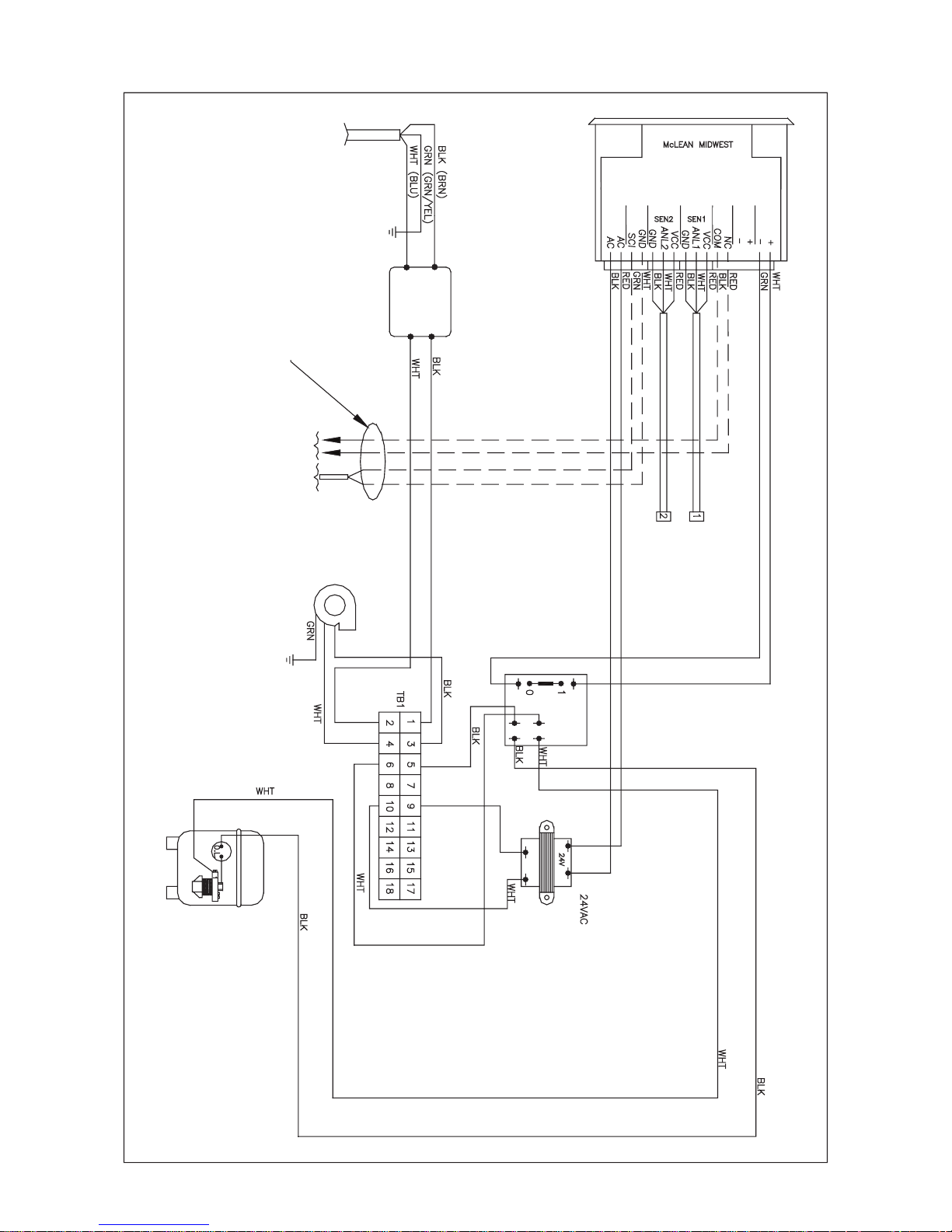

Wire Diagram, Level II and III, 2000 BTU

MODEL

DATE CODE

CONTROLLER

FIELD WIRED BY

CUSTOMER

ALARM OUTPUT NORMALLY

CLOSED

ALARM INPUT NORMALLY CLOSED

BLOWER

WIRING DIAGRAM

FILTER

EMI

POWER

ALARM

IN

TEMPERATURE SENSOR

AMBIENT AIR INLET

ALARM

OUT

TEMPERATURE SENSOR

ENCLOSURE

HEAT HEATCOOL

COMPRESSOR

RELAY

- 10 -

© 2011 Pentair Technical Products

TRANSFORMER

89055732

COOLING

RELAY

LINE

EMI FILTER

ENCLOSURE

TEMPERATURE SENSOR #1

CONTROLLER

ALARM OUTPUT NORMALLY CLOSED

ALARM INPUT NORMALLY CLOSED

ELECTRICAL SCHEMATIC

CONTROL

TRANSFORMER

TEMPERATURE SENSOR #2

AMBIENT AIR INLET

OVERLOAD

BLOWER

COMPRESSOR

RELAY

© 2011 Pentair Technical Products89055732 - 11 -

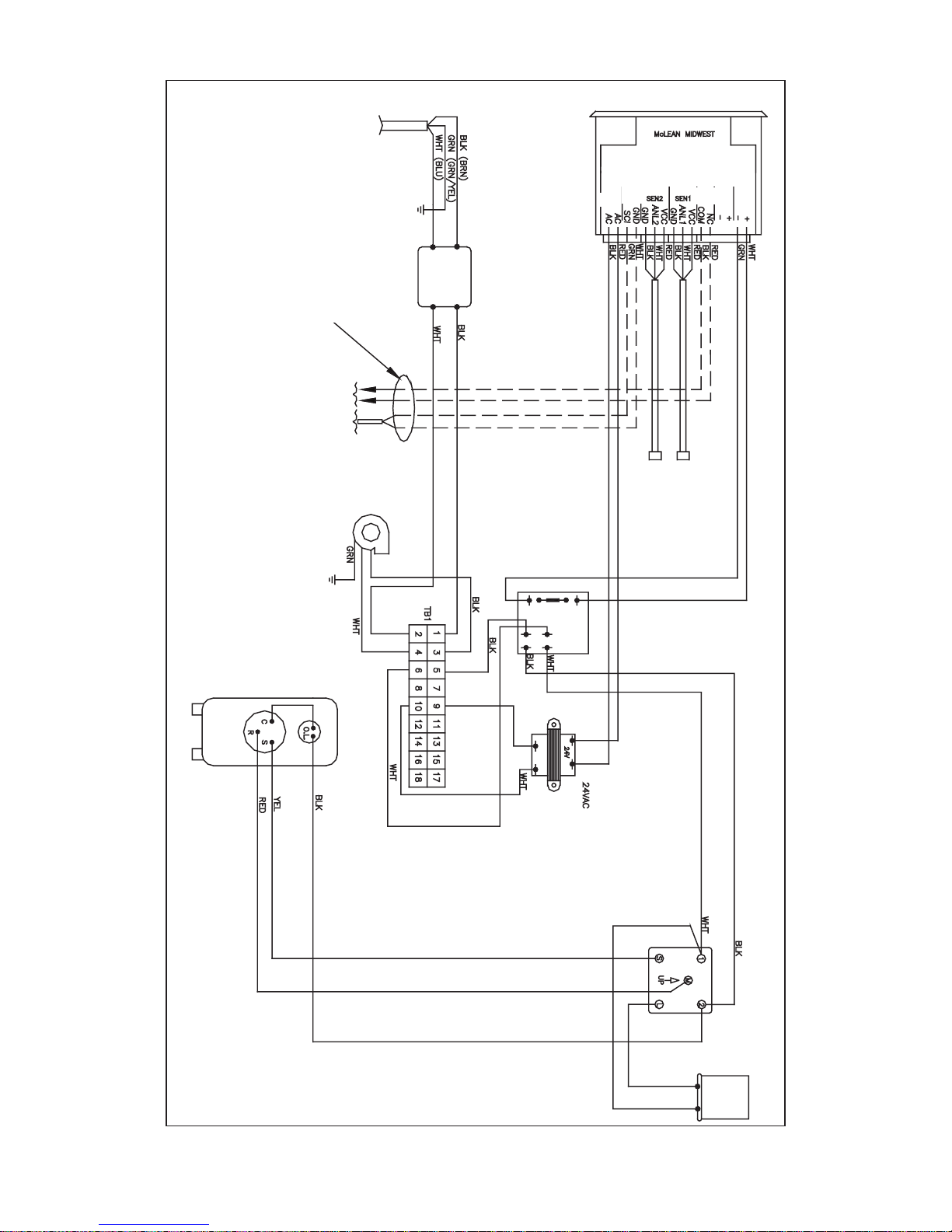

Wire Diagram, Level II and III, 4000 BTU

FIELD WIRED BY

CUSTOMER

ALARM OUTPUT NORMALLY

CLOSED

ALARM INPUT NORMALLY CLOSED

BLOWER

FILTER

EMI

DATE CODE

POWER

MODEL

ALARM

IN

CONTROLLER

TEMPERATURE SENSOR

AMBIENT AIR INLET

ENCLOSURE

ALARM

OUT

HEAT

TEMPERATURE SENSOR

COOL

COMPRESSOR

WIRING DIAGRAM

TRANSFORMER

NOTE: For voltage, hertz, and options not shown in this manual, refer to the wiring diagram

attached to the unit.

- 12 -

© 2011 Pentair Technical Products

RELAY

CAPACITOR

START

89055732

COOLING

RELAY

ENCLOSURE

TEMPERATURE SENSOR #1

LINE

EMI FILTER (OPTIONAL)

CONTROLLER

ALARM OUTPUT NORMALLY CLOSED

ALARM INPUT NORMALLY CLOSED

CONTROL

TRANSFORMER

TEMPERATURE SENSOR #2

AMBIENT AIR INLET

(LEVEL III ONLY)

BLOWER

START CAPACITOR AND

RELAY

OVERLOAD

ELECTRICAL SCHEMATIC

COMPRESSOR

© 2011 Pentair Technical Products89055732 - 13 -

TEMPERATURE CONTROL

The electromechanical thermostat is factory preset to 75 F/23 C. To change the temperature setting, refer to SYSTEM

CONTROLS on page 4.

PRINCIPLES OF OPERATION

If electrical power to the air conditioner is interrupted and reapplied immediately (within 3 to 5 seconds), the

compressor may not restart due to the high back pressure of the compressor. It takes a minimum of one (1) minute

after shut-down for the compressor suction and discharge pressures to equalize in order for the air conditioner to

restart.

Operating the air conditioner below the minimum ambient temperature or above the maximum ambient

temperatures indicated on the nameplate voids all warranties.

It is recommended that the warranty section of this manual be read in order to familiarize yourself with parameters of

restricted operation.

The moisture that the enclosure air can contain is limited. If moisture ows from the drain tube continuously this can

only mean that ambient air is entering the enclosure. Be aware that frequent opening of the enclosure’s door admits

humid air which the air conditioner must then dehumidify.

MAINTENANCE

Compressor

The compressor requires no maintenance. It is hermetically sealed, properly lubricated at the factory and should

provide years of satisfactory operating service.

Should the refrigerant charge be lost, recharging ports (access ttings) on the suction and discharge sides of the

compressor are provided for recharging and/or checking suction and discharge pressures.

Under no circumstances should the access tting covers be loosened, removed or tampered with.

Breaking of seals on compressor access ttings during warranty period will void warranty on hermetic system.

Recharging ports are provided for the ease and convenience of reputable refrigeration repair service personnel for

recharging the air conditioner.

Inlet Air Filter

Proper maintenance of the inlet air lter, located behind the front cover, will assure normal operation of the air

conditioner. If lter maintenance is delayed or ignored, the maximum ambient temperatures under which the unit is

designed to operate will be decreased.

If the compressor’s operating temperature increases above designed conditions due to a dirty or clogged lter (or

plugged condenser coil), the air conditioner’s compressor will stop operating due to actuation of the thermal overload

cut-out switch located on the compressor housing. As soon as the compressor temperature has dropped to within

the switch’s cut-in setting, the compressor will restart automatically. However the above condition will continue to

take place until the lter or coil has been cleaned. It is recommended that power to the air conditioner be interrupted

intentionally when abnormally high compressor operating temperature causes automatic shut-down of the unit.

The above described shut-down is symptomatic of a clogged or dirty lter, thus causing a reduction in cooling air ow

across the surface of the compressor and condenser coil.

Do not run the air conditioner for extended periods of time with the lter removed. Particles of dust, lint, etc., can plug

the ns of the condenser coil which will give the same reaction as a plugged lter. The condenser coil is not visible

through the lter opening, so protect it with a lter.

Continued operation under the above conditions can and will damage and shorten compressor life. The air

conditioner is available with an easily removable inlet lter to facilitate necessary cleaning. There should be no reason

to neglect this necessary maintenance.

- 14 -

© 2011 Pentair Technical Products

89055732

How To Remove, Clean or Install a New Inlet Air Filter

RP aluminum washable air lters are designed to provide excellent ltering eciency with a high dust holding

capacity and a minimum amount of resistance to air ow. Since they are constructed entirely of aluminum, they are

lightweight and easy to service. Optimum lter performance is maintained by recoating the lters after washing with

RP Super Filter Coat adhesive. To achieve maximum performance from your air handling equipment, air lters should

be cleaned on a regular basis.

The inlet air lter is located behind the right side panel. To access the lter, pull from slot on top cover. The lter may

now be cleaned or a new lter installed.

Cleaning Instructions:

1. Flush the lter with warm water from the exhaust side to the intake side. DO NOT USE CAUSTICS.

2. After ushing, allow lter to drain. Placing it with a corner down will assure complete drainage.

3. Recoat the lters with RP Super Filter Coat adhesive. When spraying lter do so from both sides for

maximum concentration of adhesive.

Condenser and Evaporator Air Movers

Blower motor requires no maintenance. All bearings, shafts, etc. are lubricated for the life of the motor during

manufacturing.

If one of the condenser impeller motors (ambient impellers) should fail, it is not necessary to remove the air

conditioner from the cabinet or enclosure to replace the blower. The condenser blower is mounted on its own

bulkhead and is easily accessible by removing the front cover.

CAUTION

Operation of the air conditioner in areas containing airborne

caustics or chemicals can rapidly deteriorate lters, condenser

coils, blowers and motors, etc. Contact Pentair Technical Products

for special recommendations.

Refrigerant Loss

Each air conditioner is thoroughly tested prior to leaving the factory to insure against refrigeration leaks. Shipping

damage or microscopic leaks not found with sensitive electronic refrigerant leak detection equipment during

manufacture may require repair or recharging of the system. This work should only be performed by qualied

professionals, generally available through a local, reputable air conditioning repair or service company.

Refer to the data on the nameplate which species the type of refrigerant and the charge size in ounces.

Before recharging, make sure there are no leaks and that the system has been properly evacuated into a deep vacuum.

© 2011 Pentair Technical Products89055732 - 15 -

TROUBLE SHOOTING

Basic Air Conditioning Trouble Shooting Check List

1. Check manufacturer’s nameplate located on the unit for correct power supply.

2. Turn on power to the unit. The evaporator (Enclosure or “COLD” air) blower should come on. Is there

airow?

YES, proceed to step 3.

NO, possible problem:

• Open motor winding

• Stuck blower motor

• Obstructed wheels/blades

Repair or Replace

defective part

3. Check thermostat setting and adjust thermostat to the lowest setting. This should turn on the

condenser blower and compressor. Did condenser blower and compressor come on when the

thermostat was turned on?

YES, proceed to step 4.

NO, possible problem:

• Defective thermostat Replace part

4. Are both blowers and the compressor running? If not, the unit will not cool properly.

5. Check condenser (Ambient or “HOT” air) blower for airow. Is there airow?

YES, proceed to step 6.

NO, possible problem:

• Defective thermostat

• Open motor winding

• Stuck blower motor

• Obstructed wheels/blades

Repair or Replace

defective part

6. Carefully check the compressor for operation - motor should cause slight vibration, and the outer case

of the compressor should be warm. Is the compressor showing signs of this?

YES, wait 5 minutes, then proceed to step 7.

NO, possible problem:

• Defective thermostat

• Defective capacitor

• Defective overload

• Defective relay

7. Make sure the coils are clean. Then check evaporator “air in” and “air out” temperatures. If the

temperatures are the same:

• Possible loss of refrigerant

• Possible bad valves in the compressor

8. To check for a bad thermostat, turn power o to the unit. Remove control box cover and place both

thermostat wires onto one terminal (replace control box cover for safety). This will bypass the switch

in the thermostat. Turn on the power. If both blowers and the compressor come on, the thermostat

needs to be replaced.

- 16 -

© 2011 Pentair Technical Products

Repair or Replace

defective part

Repair or Replace

defective part

89055732

Symptoms and Possible Causes:

SYMPTOM POSSIBLE CAUSE

Unit won’t cool

Compressor tries to start but won’t run

Blower not running

Compressor not running

Compressor runs, but has bad valves

Loss of refrigerant

Low line voltage at start. Should be +/-10% rated voltage.

Compressor motor stuck

Bad relay

Bad overload switch

Bad run/start capacitor

Unit blows breakers

Getting water in enclosure

Undersized breaker/fuse or not time delayed

Short in system

Drain plugged

Drain tube kinked

Enclosure not sealed (allowing humidity in)

© 2011 Pentair Technical Products89055732 - 17 -

WARRANTY

Pentair Technical Products warrants that the Goods manufactured by Pentair Technical Products will be free

from defects in material and workmanship for a period of one (1) year from the date of shipment by Pentair

Technical Products, subject to the following conditions and exclusions:

A. Conditions. All Goods must be installed and operated according to the following specications:

1. Maximum voltage variation no greater than plus or minus 10% of nameplate nominal rating;

2. Maximum frequency variation no greater than plus or minus 3 Hz. of nameplate nominal rating;

3. Must not exceed minimum and maximum stated temperatures on the nameplate;

4. Must not exceed (BTU/Hr) rating, including any heat sink as indicated on the nameplate;

5. Refrigerant bearing Goods must not be restarted for a period of one (1) minute after intentional or

accidental shut-o;

6. The lters (if applicable) must be cleaned regularly;

7. The Goods and any parts thereof must not be modied, unless prior written authorization is received

from Pentair Technical Products; and

8. All Goods must be installed and grounded in accordance with all relevant electrical and safety codes,

as well as the National Electric Code and OSHA rules and regulations.

9. All Goods must be installed in a stationery application, free of vibration.

A violation of any one of these conditions shall render the warranty hereunder void and of no eect.

B. Exclusions. This warranty shall be void if product is misapplied in any way or:

1. Buyer specied product is inappropriate for system or environment in which it is operating.

2. Pentair Technical Products product modied in any way without prior written authorization from

Pentair Technical Products.

3. Removal or modication of Pentair Technical Products label axed to product without written Pentair

Technical Products approval.

Pentair Technical Products must be notied of a claim in writing not later than fourteen (14) days from the

date when Buyer has become aware of such occurrence, or where the defect is such that it may cause damage,

immediately, such notice containing a description of how the defect manifests itself. Failure to provide such

prompt notice to Pentair Technical Products shall result in forfeiture of Buyer’s rights under this warranty.

In the event of a warranty claim, Buyer is to return defective goods to Pentair Technical Products in accordance

with Pentair Technical Products Return Policy. Warranty period for repaired goods remains at 1 year from

shipment of original goods. Pentair Technical Products sole obligation to Buyer under this warranty will be, at

Pentair Technical Products option:

A. Repair or replace Pentair Technical Products products or parts found to be defective in material or

workmanship.

B. Issue credit for the purchase price paid by Buyer relating to such defective Goods or part.

THIS WARRANTY CONSTITUTES THE ENTIRE WARRANTY WITH RESPECT TO THE GOODS AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY

AND IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

RETURN AND REPAIR POLICY

Pentair Technical Products products that: (i) are made to order, (ii) have been modied by Buyer, (ii) have

special nishes, or (iv) are determined by Pentair Technical Products to constitute “custom” products that

cannot be returned to stock or resold to other Buyers, will not be accepted for return by Pentair Technical

Products.

All returns require a Return Material Authorization number (RMA #), regardless of reason for return, whether

it be for warranty or out of warranty repair. Returns without an RMA # will be refused by our Receiving

Department. An RMA # is valid for 60 days.

A. An RMA # will be issued by our Repair Department in Anoka, MN at 866-545-5252. Buyer should have

following information available at time of RMA request:

- 18 -

© 2011 Pentair Technical Products

89055732

1. Complete Model Number, Serial Number and description of damaged unit being returned.

2. Original Buyer Purchase Order number and date product was received by Buyer.

3. Quantity to be returned and a brief description of failure for each unit, if dierent.

4. Contact information of Buyer that must include: name of company, billing and shipping address,

phone, number, fax number, freight carrier and the name and phone number of a Buyer contact who

can elaborate on the claimed defect in detail.

5. Buyer must provide a Repair Purchase Order number for both warranty and out of warranty repairs.

The PO will not exceed 50% of a new unit. Buyer will be notied of repair charges that exceed

approved PO amount.

B. All returns to Pentair Technical Products must be securely packed, using original cartons if possible. All

returns must have the RMA number visible on the outside of the carton. Pentair Technical Products is not

responsible for material damaged in transit. Any refrigerant-bearing Goods must be shipped upright for

return.

C. Shipping cost for all non-warranty repairs is the responsibility of the sender and must be shipped prepaid.

Shipping costs for all warranty related repairs will be covered by Pentair Technical Products provided the

goods are returned using a Pentair Technical Products approved carrier. If after diagnoses the product is

determined by Pentair Technical Products not be covered under warranty, Buyer will be responsible for all

shipping charges and will be billed accordingly.

D. Non-warranty repairs are subject to a $75 minimum analysis fee. Analysis fee will be waived if Buyer

approves repair work. If approval is not received within 30 days, material will be scrapped and all shipping

expenses and corresponding analysis fees will be billed to Buyer.

E. At Buyer’s request, Failure Analysis can be provided by Pentair Technical Products for warrantable goods at

no charge. Failure analysis for non-warranty repairs are subject to a $100 per hour Engineering charge plus

any other incurred testing costs.

F. All returned merchandise must be sent to the following address: Pentair Technical Products, 2100 Homan

Way, Anoka, MN 55303-1745.

G. Credit for accepted returns shall be at the original selling price or the current selling price, whichever is

lower, less the restocking charge indicated as follows:

1. Within 60 days of invoice date - 20% of applicable selling price.

2. Within 61-120 days of invoice date - 30% of applicable selling price.

3. Within 121-180 days of invoice date - 40% of applicable selling price.

4. Beyond 180 days - subject to individual review by Pentair Technical Products.

If product being returned for credit requires repair or modication, the cost of any labor or material necessary

to bring product into saleable condition will be deducted from credit. Buyer may not take credit against

returns without prior written Pentair Technical Products approval.

LIMITATION OF LIABILITY

PENTAIR TECHNICAL PRODUCTS WILL NOT BE LIABLE UNDER ANY CIRCUMSTANCES FOR ANY INCIDENTAL,

CONSEQUENTIAL OR SPECIAL DAMAGES, INCLUDING WITHOUT LIMITATION ANY LOST PROFITS OR

LABOR COSTS, ARISING FROM THE SALE, USE OR INSTALLATION OF THE GOODS, FROM THE GOODS BEING

INCORPORATED INTO OR BECOMING A COMPONENT OF ANOTHER PRODUCT, FROM ANY BREACH OF THIS

AGREEMENT OR FROM ANY OTHER CAUSE WHATSOEVER, WHETHER BASED ON WARRANTY (EXPRESSED

OR IMPLIED) OR OTHERWISE BASED ON CONTRACT, OR ON TORT OR OTHER THEORY OF LIABILITY, AND

REGARDLESS OF ANY ADVICE OR REPRESENTATIONS THAT MAY HAVE BEEN RENDERED BY PENTAIR TECHNICAL

PRODUCTS CONCERNING THE SALE, USE OR INSTALLATION OF THE GOODS

© 2011 Pentair Technical Products89055732 - 19 -

Protecting Electronics.

Exceeding Expectations.™

Rev. D

© 2011 Pentair Technical Products

P/N 10-1008-121

89055732

Loading...

Loading...