MCi J4500 Operator's Manual

TABLE OF CONTENTS

1-- Introduction 1..............................................

2--Daily Inspections 5.........................................

3--Switches, Warning Lights and Gauges 9.....................

4-- Steering Column and Floor -Mounted Controls 25..............

5-- Operating Features 29.......................................

6--Wheelchair Lift 31...........................................

7-- Engine Operation, Fuel and Exhaust 39.......................

8--Transmission Operation 43...................................

9-- Emergency Conditions 47....................................

10--Heating and Air Conditioning (HVAC) 55.....................

11--Audio and Video Systems 57................................

12--Service and Maintenance 63.................................

13--Specifications 73...........................................

14--Diagnostic Codes 77........................................

15--Index 85...................................................

16--Figure Index 90.............................................

1 - INTRODUCTION

Typical illustrations may be used, therefore

minor illustration differences may exist when

compared to actual parts or other

publications

COACH APPLICABILITY

This manual supports the MCI J4500 Coach.

TO THE DRIVER

This manual has been prepared to provide you with the

information you need to operate the MCI J4500 Series

Coach.

The specifications and information throughout this

manual are subject to change without notice.

CERTIFICATION PLATE

The certification plate ( Figure 1 ) is affixed beside the

driver's seat base, and certifies compliance with all

applicable Federal Motor Vehicle Safety Standards in

effect on the date of manufacture. It also lists the date

the coach was built, the GVWR, GAWR's, rim size, tire

pressures, coach model and coach serial number.

EMISSION CONTROL INFORMATION

DECAL

The emission control decal is affixed directly below the

certification plate shown in Figure 1.

Report immediately any problem or

malfunction that interferes with the operation

of the coach, particularly if safety may be

affected.

The term “Optional” in this manual pertains to all

equipment and features other than basic.

MCI SERVICE NUMBER: 1-800-241-2947

This manual is a permanent part of this vehicle.

It must stay with the coach if the coach is sold.

PUBLICATION DATE: June 2016

EFFECTIVE WITH UNIT NUMBER 67758

MCI PUBLICATION PART #.: 03-26-1426

Figure 1.

COACH NAMEPLATE

The nameplate ( Figure 2 ) is mounted in the engine

compartment at the rear of the coach. The vehicle

identification number (VIN), model year and date of

manufacture are shown on this plate.

Figure 2.

1June 2016

VEHICLE IDENTIFICATION NUMBER (VIN)

The nameplate and the certification plate both contain

the seventeen-character vehicle identification number

(VIN).The numbers correspond to the items in the

following list.

1. The first three characters identify the

manufacturing company:

1M8 = MCI Inc. (U.S.)

2MG = MCI Ltd. (Canada)

2. The fourth character identifies the coach model:

3 = J4500 Intercity

3. The fifth character identifies the series:

J = J-Series

4. The sixth character identifies the type of coach:

M = Intercity (MCI)

P = Incomplete Vehicle

5. The seventh character identifies the type of

engine:

B = Cummins ISX

8 = Detroit Diesel DD1

6. The eighth character identifies the type of

brakes:

A = Air Brake Intercity

7. The ninth character is the check number.

8. The tenth character identifies the year:

H = 2017

9. The eleventh character identifies the

manufacturing location:

W = Winnipeg, Manitoba

10. The twelfth through seventeenth characters is

the coach's unit number.

6

June 20162

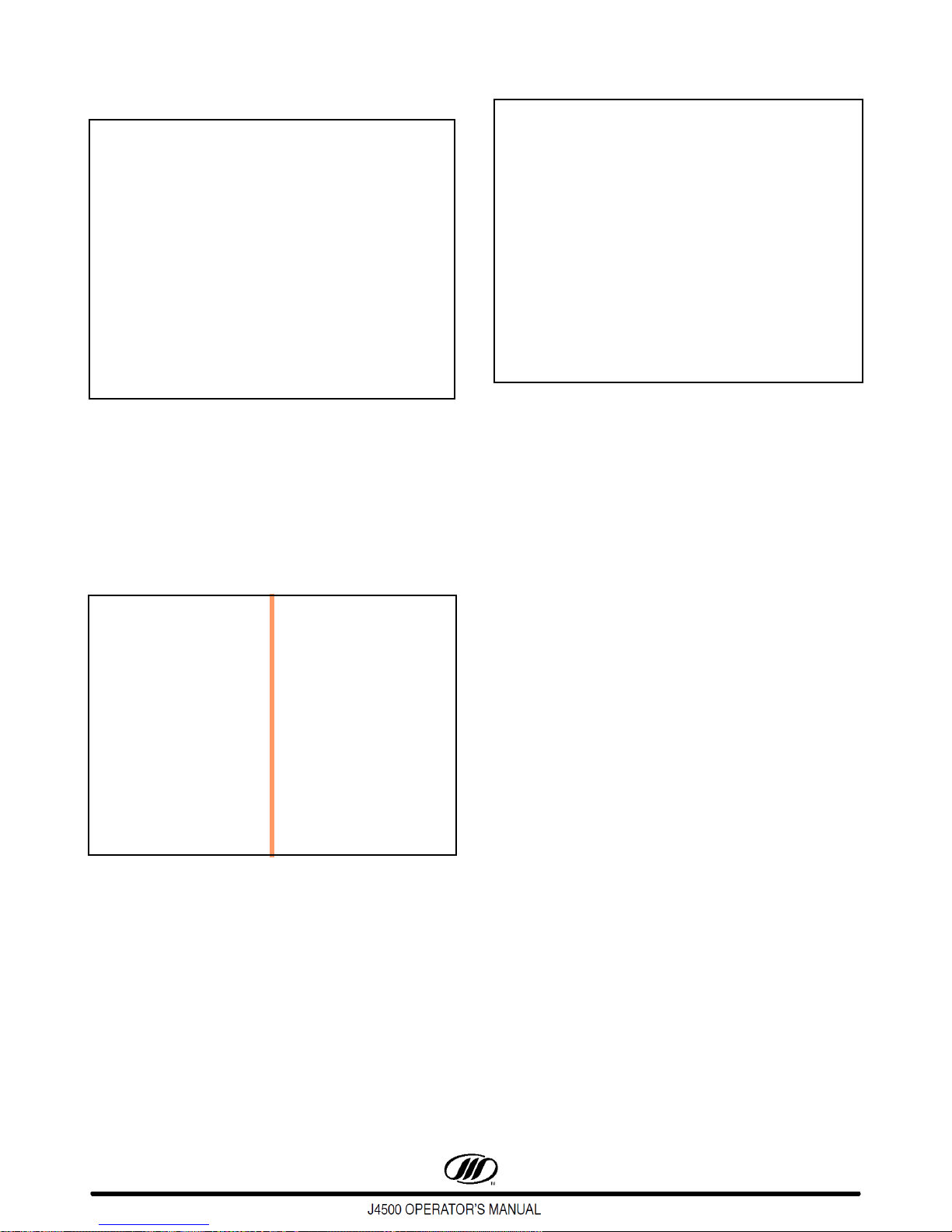

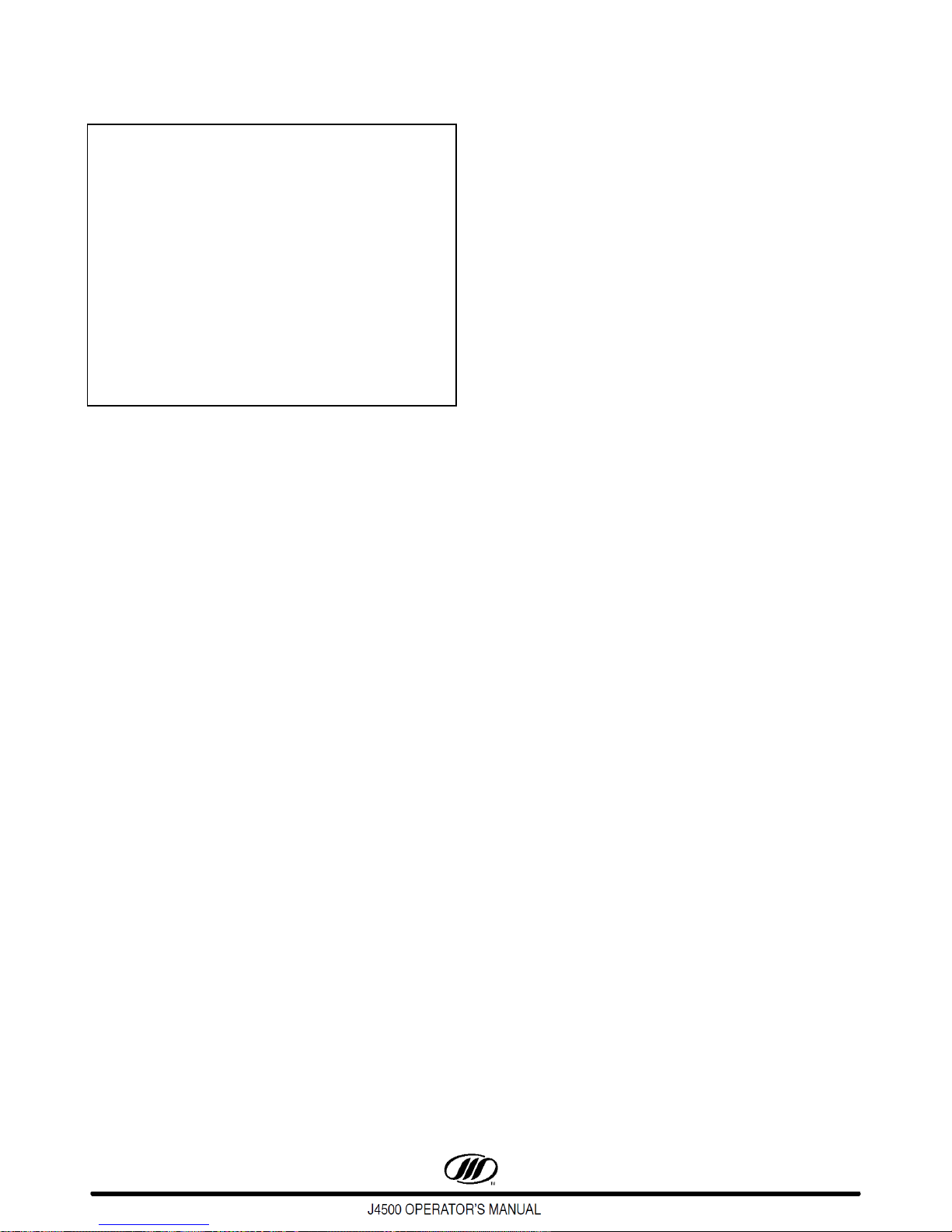

Figure 3. Driver’s Area

1

2

3

4

5

6

7

8

9

1. Instrument Panel

• System Gauges

• LH Tell-tale Cluster

• RH Tell-tale Cluster

• Driver’s Vents

2. Lower, LH Console

• Cup Holder

• Headlight Switch

• Mirror Controls

• Pushbutton Shift Selector

• Switches

• Wheelchair Master Switch ( Optional )

• 12 Volt Power Source

• Anti-Slip Pad

• Emergency Park Brake Release

• Front Service Compartment Door

Release

3. LH Switch Panel

• Driver’s Fan Control

• Driver’s Heat Control

• Micromate Control Panel

• Switches

4. RH Switch Panel

5. Steering Column

6. Entrance Door Override Valve

7. Amerex Fire Suppresion System Manual Fire

8. Microphone Receptacle

9. Certification and Emission Control Plate

• Switches

• Audio and Video System Controls

• Steering Wheel with Switch Pods

• Electric Horn

• Smart Stick Control, featuring Turn

Signals, Air Horn, Headlamp Dimmer,

Windshield Wipers and Washer

• Tilt and Telescoping Control Lever

Button

3June 2016

THIS PAGE INTENTIONALLY LEFT BLANK

June 20164

2 - DAILY INSPECTIONS

The following checks are in addition to the Federal Motor Carrier Safety Administration requirements,

not instead of them.

EXTERIOR INSPECTION

1. Ensure that all windows, mirrors and lights are

clean and unobstructed.

2. Ensure that all side windows are closed.

A protrusion of 1/4” ( 6mm ) or more indicates

that a window in not properly latched.

3. Check that the coach exterior is clear of debris,

and that all service doors are secure.

4. Check the tire pressure and inspect the tires for

damage. Check that the wheel nuts are tight

and inspect the wheels for damage.

INTERIOR COMPONENTS CHECKLIST

1. Ensure that the door(s), hatches and

emergency exit windows open, close, seal and

latch properly.

2. Check the brake pedal and linkage for any

obstruction that may prevent the brake from

being applied or completely releasing.

3. Ensure that the parcel rack doors are latched.

4. Inspect the seats and floor for debris. Clean if

necessary.

5. Look under the coach for fluid leaks, animals or

obstructions. Check behind the coach.

6. Check the engine oil level, coolant level,

condition of belts and power steering fluid level.

7. Check the engine compartment to ensure that

there are no loose or unsecured objects.

8. Check the windshield washer reservoir and fill if

required.

9. Ensure that the engine compartment remote

control box ENGINE ENABLE switch is ON and

the STARTER CONTROL switch is set to

FRONT.

10. Turn ON the main electrical switch.

11. Press the Step-well light switch to the ON

position.

5. Ensure that the interior and step-well lights

work.

6. Ensure that the lavatory door, windows and

wheelchair access door ( if equipped ) are

closed and latched.

7. Ensure that emergency equipment and

contents are in place and properly stowed.

8. Activate the entertainment control module and

verify the operation of the driver's and cordless

microphones ( if equipped ). Adjust output

volume if necessary.

Before starting ensure that the fast idle is OFF

and the parking brake is applied. Ensure that

there is ample distance ahead of and behind

the coach in case it moves unexpectedly

during starting.

DO NOT rev the engine while starting.

5June 2016

The following checks are in addition to the Federal Motor Carrier Safety Administration requirements,

not instead of them.

OPERATIONAL CHECKLIST

1. While the engine is running, look for oil or

coolant leaks and listen for air leaks.

2. While the engine is running, check the

alternator lights on the remote control box in the

engine compartment. The lights should be OFF.

Be very careful when the engine is running

and the engine door is open.

If it is necessary to have the engine running

for certain inspections or checks, keep a safe

distance from moving belts, pulleys, shafts or

fans.

Keep hands and limbs away from moving

belts and pulleys and also hot areas such as

exhaust and turbocharger components and

coolant lines.

Do not wear loose, baggy or frayed clothing

when working near any moving parts such as

pulleys, belts, shafts or fans.

3. Close and secure all baggage and service

doors.

4. Ensure that all exterior lights are working.

5. If the coach is equipped with a wheelchair lift,

check the lift operation. For more information

refer to the vendor manual.

7. Position the inside and outside mirrors, adjust

the driver's seat and fasten the seat belt.

8. Ensure that the tilt steering column is locked.

9. Ensure that the defroster, heater, horn,

windshield wipers and washers all function.

Do not move the coach until the front and rear

air gauges both read at least 100 psi.

10. Apply the service brakes, release the park

brake, then release the service brakes.

11. Apply and hold the brakes and observe the

pressure drop. It should not drop by more than

3 psi in 1 minute.

12. Move the coach slowly and bring it to a stop to

ensure that the brakes stop and hold the coach.

13. Ensure that brake pedal operation feels normal.

14. Ensure that all gauges stay in normal range.

15. Move the coach a short distance at low speed

and check the steering. Ensure that the coach

is under full control and handling properly. The

steering wheel must turn smoothly without any

unusual noises.

6. After the HVAC system has stabilized ( 10 to 15

minutes ), listen for abnormal noises in the

compressor and fan motors; check the

compressor oil level and check the refrigerant

level. Ensure that the self-test has been

performed successfully and that there are no

errors or alarms indicated.

June 20166

DRIVER'S SEAT BELT

MIRRORS

Driver's Seat Belt Adjustment

Using the restraint system can lessen the

severity of injury in an accident or sudden

maneuver.

While seated straight and well back into the seat,

adjust the belt as necessary.

To unfasten the belt, push the release button.

If a belt jams, you may be able to release it by

working the belt in and out until the belt rewinds far

enough to unlock. If the belt remains jammed or

other restraint system parts do not work properly,

report the condition to service personnel promptly.

Seat Belt Inspection

Every 30 days, check the belt, buckle, latch plate,

retractor and guide loops for proper operation.

Check for loose or damaged parts. Keep sharp

edges and sharp objects away from belts and other

parts of the restraint system.

Inside Rear-view Mirrors ( Optional )

The inside rear-view mirrors can be manually

adjusted up, down or sideways.

Exterior Rear-view Mirrors

Exterior mirrors have separate upper and lower

segments. The convex upper portion is for wideangle view.

Adjust the exterior mirrors so that you can see the

side of the coach in part of the mirror. This helps

determine the relationship of the coach to objects

seen in the mirror.

The roadside and curbside mirror controls are on

the lower LH console switch panel. Use the switch

in the center of each mirror control to select the

upper or lower mirror. Move the switch to the left to

adjust the lower mirror and to the right to adjust the

upper mirror.

Defrost the mirrors using the mirror heat switch

located below the mirror controls.

Keep the belts clean and dry. Replace belts if the

webbing appears frayed, cut or damaged. Replace

belts that have been involved in an accident. Have

parts replaced if there are any questions as to their

condition. Clean seat belts with mild soap and

lukewarm water only; do not bleach or dye.

7June 2016

PRE-TRIP INSPECTION,

INTERIOR / EXTERIOR LIGHTING

ANTI-THEFT PRECAUTIONS

Before the Pre-Trip Inspection function is

enabled, these functions must be met:

• Position the Master Power switch to the

“ON” position,

• Select “NEUTRAL” on the transmission

Shift Pad selector,

• Set the Park Brake,

• Position the Reading Light test switch to

the “ON” position.

• Apply and hold a service brake

application of 60 psi,

Only after these conditions are met, the Pre-Trip

Inspection function is enabled, automatically activating

all interior / exterior coach lighting and dash tell-tale

lights and buzzer will activate for two (2) minutes.

1. Do not leave the coach unattended with the

engine running.

2. Park in a lighted spot when possible.

3. Fully close all windows and doors.

4. Keep valuable items out of sight.

5. Press the Step-well light switch to the OFF

position ( anti-theft feature ).

6. Lock out the battery disconnect switch

The back-up lights do not illuminate during

the Pre-Trip Inspection.

The Pre-Trip Inspection function can be

canceled by positioning the Reading Light

test switch to “OFF”, or positioning the

Hazard switch to “ON”.

June 20168

3 - SWITCHES, WARNING LIGHTS AND GAUGES

2

4

6

Instrument Panel Components

1. Gauges

2. LH Tell-tale Cluster

3. RH Tell-tale Cluster

4. LH Switch Panel

5. RH Switch Panel

6. Vent

3

5

1

6

Figure 4. Instrument Panel

9June 2016

Figure 5. Instrument Panel Gauges

INSTRUMENT PANEL/GAUGES

Speedometer

The speedometer, which features an alphanumeric

message display, reads the forward speed of the coach

in miles per hour or kilometers per hour. The

speedometer features a MODE and TRIP button allow

the driver to select, set/reset displays and scroll

through active system warning messages, when the

coach is at a complete stop.

The MODE button is utilized to select the mode of

operation for the message display and to clear priority

messages.

The TRIP button is utilized to change what is

displayed on the lower line of the alphanumeric

message display.

The following settings can be selected on the

screen by utilizing the MODE and/or TRIP buttons

shown in Figure 7:

- Imperial / Metric Units,

- Contrast Adjust,

- Display Language (English, Spanish or French)

- Diagnostics Menu.

Figure 6. Speedometer

Figure 7. Alphanumeric Display

June 201610

4-in-1 Gauge

4

Front ( PSI ) Air Pressure - The secondary air

pressure gauge reads front brake air reservoir

pressure in pounds per square inch or kilo-pascals. If

the pressure is low during start-up, the LED lights

3

2

and a buzzer sounds. The alarms stop when the

pressure builds up to operating level. Do not operate

the coach under 100 psi (690 kPa).

Rear ( PSI ) Air Pressure - The primary air

pressure gauge reads rear brake air reservoir pressure

in pounds per square inch or kilo-pascals. If the

pressure is low during start-up, the LED lights and a

buzzer sounds. The alarms stop wh en the pressure

builds up to operating level. Do not operate the coach

under 100 psi ( 690 kPa ).

1

Figure 8. 4 in 1 Gauge tell-tales

1. Front Air PSI tell-tale

The low air warning tell-tale illuminates when the air

pressure drops below the pre-determined level.

In the event of a low air warning, stop the coach and

determine the cause of air loss before proceeding.

2. Rear Air PSI tell-tale

The low air warning tell-tale illuminates when the air

pressure drops below the pre-determined level.

In the event of a low air warning, stop the coach and

determine the cause of air loss before proceeding.

3. Water Temperature tell-tale

Tell-tale illuminates when the coolant temperature is

above normal. Obtain service as soon as possible.

4. Oil Pressure tell-tale

Tell-tale illuminates when the oil pressure is too low.

If a low air warning activates during driving,

stop the coach immediately and find the

cause of the air loss. If brake reservoir

pressure drops significantly, the parking

brakes apply automatically.

Oil Pressure - The oil pressure gauge reads

engine oil pressure in pounds per square inch or kilo

Pascals. Oil pressure should be between 50 - 70 psi

( 345 - 483 kPa ). The LED lights when the oil

pressure is too low.

Coolant ( Water ) Temperature - The coolant

temperature gauge reads engine coolant temperature

in degrees Fahrenheit or Celsius. The normal

operating range is 160-226F ( 71-108C ). The LED

lights when the temperature is above normal. Obtain

service as soon as possible.

Low air pressure will illuminate the LOW AIR

lamp and a buzzer will sound, indicating that

the air pressure is too low. Stop coach and

determine reason for pressure loss.

DO NOT operate the coach under 100 psi air

pressure.

11June 2016

3-in-1 Gauge:

Figure 9. 3 in 1 Gauge

Fuel - This gauge reads the fuel level in the tank.

Diesel Exhaust Fluid ( DEF ) - The DEF gauge

reads the fluid level in the tank.

Figure 11. SmarTire SmartWave FFD

SmarTire SmartWave Full Function Display -

The SmartWave tire monitor system provides tire

pressure deviation alert, low pressure warning and

high temperature alert for all tire positions.

Engine Tachometer - The engine tachometer

reads engine revolutions per minute.

Figure 10. Volt and Trans Temp Gauges

Voltmeter - The voltmeter reads the condition of

the 24-volt electrical system. The gauge is calibrated

in volts. The needle should be from 27 to 29 volts. If

below 27 volts, the batteries are undercharging. If

above 29 volts, the batteries are overcharging. Have

the system checked if over- or undercharging. The

LED lights when voltage is too low.

SmartWave display functions:

1. ALARM tell-tale light to alert driver.

2. Display screen shows alert icons, tire location

and numerical unit of pressure or temperature.

3. Control buttons to scroll through display.

Transmission Temperature - This gauge reads

transmission oil temperature in farenheit.

June 201612

TELL-TALE LAMPS

Left Turn Indicator (Green)

Wait to Start (Yellow) - This tell-tale will

illuminate when the grid heater is ON

(pre-heat function).

Check Engine (Yellow) - Engine fault.

Refer to vendor manual.

Stop Engine (Red) - Engine is powering

down or stopped.

Low Coolant (Yellow) - Tell-tale indicates

a low engine coolant level. Do not run

engine until condition is corrected.

Not Generating (Red) - Tell-tale

indicates that one or both alternators are

not functioning.

Regeneration (DPF) (Yellow) - Tell-tale

illuminates when a regeneration is

required. Tell-tale is OFF during Regen.

High Exhaust Temperatures (HET)

(Yellow) - Tell-tale will illuminate when the

coach is moving less than 5 mph (approx.)

and the exhaust outlet temperature

exceeds the predetermined level.

Diesel Exhaust Fluid (DEF) (Yellow) - Telltale illuminates indicating the DEF level is

low. Correct by refilling the DEF tank.

DEF tell-tale flashes indicating the DEF level

has fallen below a critical level. Correct by

refilling the DEF tank.

DEF tell-tale flashes and Check Engine

illuminates indicating the DEF level is critically

low and power loss will occur. Normal engine

power will be restored by refilling the DEF

tank.

DEF tell-tale flashes and Check Engine and

Stop Engine illuminates indicating the DEF

tank has been run dry. Engine will De-rate and

limit speed to 5 MPH. Normal engine power

and coach speed will restored by refilling the

DEF tank.

Tell-tales indicate various conditions by lighting. In general, yellow indicates system status and red indicates a fault

or warning. Tell-tales are located in RH and LH clusters, in the instrument cluster. Some tell-tales are accompanied

by a buzzer or bell. At system start-up, tell-tales light briefly to show that the LEDs work.

LH TELL-TALE CLUSTER

Figure 12. LH Tell-tale Cluster

13June 2016

MIL (Yellow) - Malfunction Indicator Tell

tale Lamp. Tell-tale indicates a failure of an

emission system component.

Blank

Water in Fuel (Yellow) - Tell-tale indicates

water in the fuel filter.

Park Brake Applied (Red)

Trailer Park (Red) - Tell-tale is disabled.

ABS (Yellow) - Tell-tale indicates anti-lock

braking system malfunction.

Electronic Stability Control / Automatic

Traction Control (Yellow) - Tell-tale

indicates an Electronic Stability Control

(ESC) or an Automatic Traction Control

(ATC) event.

Brake Lights (Green) - Tell-tale illuminates

throughout the service brake application.

Engine Brake (Yellow) - Tell-tale indicates

the engine brake is activated.

Check Transmission (Yellow) - Move the

coach to a safe location and turn OFF

ignition. DO NOT change gear.

Stop Transmission (Red) - Tell-tale is

disabled.

Retarder Temperature (Red) - Tell-tale

illuminates when retarder oil temperature is

above 168 degrees Celsius for more than

ten (10) seconds.

Brake Wear (Yellow) - Tell-tale is disabled.

Fuel Filter Restriction (Yellow) -

Indicates the fuel filter has been clogged.

Tag Lock Fault (Red) - Tell-tale illuminates

when coach speed reaches 15 mph and

the tag cylinder does not lock.

Tell tale is OFF when coach speed returns

to 10 mph.

No Hill Start (Yellow) - Tell-tale is

disabled.

June 201614

RH TELL-TALE CLUSTER

Driver Seat Belt (Red) - Tell-tale lights

when park brake is released and the

driver's seat belt is not buckled.

Check Info (Yellow) - Tell-tale indicates

message on alphanumeric display of

speedometer. Refer to next page for further

information.

Low Fuel (Yellow) - Tell-tale will illuminate

when fuel level is below 12 percent

(approx.) left in the tank.

Cruise Enabled (Green) - Tell-tale

indicates that the cruise control is

activated.

High Beams (Blue) - Hi-beam tell-tale will

illuminate when the main headlamps are on

HIGH intensity.

Right Turn Indicator (Green)

Rear Rise (Red) - Tell-tale illuminates and

a buzzer sounds when the Rear Rise

switched is pressed.

High Ride (Red) - Tell-tale will illuminate

and a buzzer sounds when the coach is in

transition and is maintained in HIGH RIDE.

Low Ride (Red) - Tell-tale flashes when

the coach is in transition to and is

maintained in LOW RIDE.

Ride Fault (Red) - Tell-tale illuminates

when a fault has occurred in the MDSS.

Report problem to maintenance personnel.

Kneel (Red) - Tell-tale flashes and a

buzzer sounds when the coach is kneeling

or recovering. When kneel is reached, the

lamp stays on and the buzzer stops.

Tag Unload (Red) - Tell-tale Illuminates

when the tag axle is unloaded.

WCL Door Open (Red) - Tell-tale will

illuminate indicating door ajar or

unlocked condition.

Figure 13. RH Tell-tale Cluster

15June 2016

WCL Interlock (Red) - Tell-tale illuminates

when the wheelchair lift interlock is

activated. The wheelchair interlock system,

when activated, disables the transmission

shift and throttle, sets the park brake

solenoid, and begins engine fast idle.

Front Door Open (Red) - Tell-tale light

illuminates when the entrance door is open.

WCL Stop Request (Blue) - Illuminates

Check Lube (Yellow) - Tell-tale is

disabled.

Back-up Alarm Off (Yellow)- Tell-tale is

disabled.

when a passenger in the wheelchair area

presses the stop button.

Lavatory Emergency (Yellow)- Tell-tale

illuminates when a passenger presses the

emergency button in the lavatory.

CHECK INFO TELL-TALE

Stop Request (Yellow) - Tell-tale lights

when a passenger presses the stop

request button.

Aux. Heat (Yellow) - Illuminates when the

auxiliary heater has been activated.

Fire Alarm (Red) - Illuminates when the

temperature sensors sense heat from a fire

in the engine compartment.

Emergency Lights (Yellow) - Tell-tale is

disabled.

Dock Lights (Blue) - Tell-tale is disabled.

Service Lights (Yellow) - Tell-tale

indicates engine compartment. light is ON.

The CHECK INFO tell-tale illumination indicates

that a message regarding additional tell-tale

information is displayed on the alphanumeric display of

speedometer. Dependant of the message displayed, a

buzzer may accompany the message.

Move the coach to a safe parking area to view the

message displayed on the alphanumeric display of

speedometer. After the message has been recorded,

the operator can press the TRIP button to dismiss the

message. The CHECK INFO tell-tale will remain

illuminated, but the message will not appear in the

alphanumeric display of speedometer until the system

re-broadcasts the signal.

The tell-tale information displayed on the

alphanumeric display of speedometer are

BACKUP ALARM, Digital Wheel End Sensor (WHL END),

TAG LOCK, SHOW MODE

and ALTERNATOR NOT GEN.

FAST IDLE,

The following Starter Diagnostic messages will

display when the

ENGINE START switch is pressed but

a condition is preventing the engine from cranking:

FRONT MODE SW, REAR RUN SW, TURN ON IGN,

SELECT NEUTRAL and STARTER LOCKOUT.

Bike Rack (Yellow) - Tell-tale is disabled.

Figure 14. Alphanumeric Display

June 201616

5. Override - Press to override an emergency

8

1

2

3

4

5

6

7

engine shutdown for 30 seconds. Press as

often as necessary to move coach to safe

parking.

This switch allows the operator to override an

emergency shutdown due to an engine

malfunction. Pressing the switch allows the

operator to run the engine for an additional 30

seconds so that the operator can move the

coach to a safe parking area.

In a driving situation, the override switch

should be utilized only to safely move the

coach to a safe parking area.

The engine overrule feature is not intended to

provide a ”limp home” capability. T his feature

should not be utilized to extend coach driving

to a garage or other destination, as engine

damage may result from over-extension of the

safety feature limitations.

Figure 15. - LH Switch Panel

LH SWITCH PANEL

1. Fog Lights Switch

2. Mirror Heat Switch - Press this switch to clear

the mirrors of fog and frost.

3. Parcel Rack Blower Switch - The PARCEL

RACK switch controls the parcel rack blowers,

LOW, OFF and HIGH.

4. Auxiliary Heater Switch - When the engine is

OFF, the engine can be preheated by pushing

the AUXILIARY HEATER switch forward, which

activates a 90 minute timer in the Proheat unit.

When the Proheat burner is ON, the HEATER

ON telltale lights.

To turn the Proheat OFF, push the switch back. It

will purge for 2 to 3 minutes. If the coach is

started during preheating, the temperatureDependant control overrides the timer.

6. Blank

7. Master Power Switch - Pressing this switch to

the ON (upper) position will enable all of the

multiplex modules and turn on the coach's

electrical system.

8. Engine Start Switch - Used to start the coach

using the rocker switch ignition.

To START the coach using the rocker switch

ignition, place the master power switch in the ON

(upper) position as well as the Step-well Light

switch. Press the upper portion of the engine

start momentary-on spring return switch to

engage the starter. Release the switch once the

coach has started.

Allow the coach to idle for 30 seconds.

To STOP the engine, place the master power

switch in the OFF (lower) position.

17June 2016

Figure 16. RH Switch Panel

1

2

3

4

5

6

7

8

9

11

10

13

14

15

12

RH SWITCH PANEL

1. Interior Light

2. Reading Lights - Turns reading lights ON and

OFF.

3. Blank Switch

4. Baggage Bay Lights - Turns the baggage bay

lights ON and OFF. The baggage bay lights

have a timer feature that automatically shuts

OFF the lights after 30 minutes, if the switch is

left in the ON position.

5. LH Baggage Lock - Locks and unlocks the LH

hand baggage doors.

6. RH Baggage Lock - Locks and unlocks the RH

hand baggage doors.

7. Kneeling - With the park brake applied, the

transmission in Neutral and the entrance door

closed, press and hold the KNEEL half of the

switch to lower the front of the coach 5" (127

mm).

8. Entrance Door Open/Close - Press and hold

the upper half of the switch to open the door.

Press and hold the switch to close the door.

Door movement stops if the switch is released.

9. Panel Lights - This switch controls the desired

panel brightness

10. Driver's Light - Turns lights on in the driver's

compartment.

11. Step-well Lights - When this switch is ON, the

step-well lights turn ON whenever the entrance

door opens. The switch must be ON for the

anti-theft feature to allow the coach to start.

12. Blue LED Light ( Optional )

13. Event Switch - Pressing this switch will

interrupt any audio or video, and play a prerecorded message.

14. Blank Switch

15. Hazard/Warning Lights - Flashes all front, rear

and side-mounted turn signal lights and both

telltales simultaneously.

June 201618

Figure 17. Lower, LH Console Switch Panel

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

LOWER LH CONSOLE SWITCH PANEL

1. Cup Holder

2. Headlight Switch

3. Mirror Controls - Adjust the RH and LH exterior

mirror heads (upper and lower).

4. 110 Volt - Press to turn ON the inverter and

supply power to passenger outlets.

5. Tag Lock / Auto Switch - Press the upper half,

LOCK, of the momentary switch to lock the tag

cylinder. The CHECK INFO tell tale flashes and

the alphanumeric display on th e speedometer

will display TAG LOCK.

When coach speed reaches 15 mph, the

alphanumeric display on the speedometer will stop

displaying the TAG LOCK message.

When coach speed reaches 10 mph and lower, the

tag cylinder will remain locked and the alphanumeric

display on the speedometer will display the TAG LOCK

message.

The tag cylinder can only be unlocked by pressing

the lower half, AUTO, of th e momentary switch or by

cycling the ignition.

6. Mud/Snow - On extra soft surfaces (snow, mud

or gravel), press the MUD/SNOW switch to

increase traction by slightly increasing permissible

wheel spin. The LOW TRACTION or ES C / A TC

telltale will blink continuously when MUD/SNOW is

active. Press the s witch again t o turn of f MUD/

SNOW. (Turning off the ignition also resets the

MUD/SNOW feature.)

7. Fast Idle - Place the transmission in Neutral,

apply the parking brakes and turn FAST IDLE on to

increase engine idle speed for engine warm-up, air

pressure build-up or A/C operation when the coach

is parked. Return the switch to n ormal when fast

idle is not required.

19June 2016

8. Tag Axle Unload - Press to unload the tag axle

to improve traction on the drive axle. Press again to

transfer the load back to the tag axle.

Only unload the tag axle in low traction

situations.

9. Rear Rise - When the coach is traveling under

20 mph (30 kph) and the RAISE half of the switch is

pressed, the rear of the coach rises, the HIGH

RIDE telltale lights and a buzzer sounds.

Pressing the lower section of the switch or traveling

above 20 mph (30 kph) returns the coach to normal

ride height.

10. Level Control Switch - Press the UPPER half

of the switch to raise the front and rear suspension

to the High Ride parameter height. Press the

LOWER half to lower the front and rear suspension

to Low Ride parameter height.

11. Normal Ride / Recover - Press switch to reset

front and rear suspension to Normal Ride height.

12. LH Blind Switch

13. RH Blind Switch

14. 12-Volt Power Source

15. Pushbutton Shift Selector ( PBSS )

16. Wheelchair Master Switch ( Optional )

17. Emergency Park Brake Release

18. Front Service Compartment Door Release

19. Emergency Seat Belt Cutter Tool

June 201620

Regeneration Switch

The regeneration toggle switch is located in the

rear, side service compartment.

To avoid serious personal injury or property

damage, ensure that no persons or objects

are at or within two feet of the exhaust outlet

at any time during a regeneration. Ensure that

exhaust and outlet are clear of any trash,

grasses, or other vegetation or debris.

Use extreme caution during a stationary

regeneration, as exhaust gas tail pipe outlet

temperatures can exceed 900 degrees F ( 482

degrees C ). Stationary regenerations are to

be performed outdoors only.

DO NOT leave the coach unattended during a

stationary regeneration.

DO NOT perform inside a garage or

maintenance facility.

DO NOT attach an exhaust extraction hose to

the exhaust outlet.

PARKING BRAKES

The coach has air-release spring activated parking

brakes. The Parking Brake control is a black, button

located under the LH switch panel.

Do not leave the coach without applying the

parking brake.

Figure 19. Parking Brake Knob

Normal Park Brake Operation

1. Stop the coach, put the transmission in neutral.

2. Pull the park brake knob out ( Figure 19 ) to set

the park brake. The valve will latch in this

position.

3. Ensure that the air pressure gauge shows 100

psi (689 Pa) or more.

4. Push the park brake knob fully in to release the

brakes. The valve will latch in this position.

Emergency Park Brake Release

In an emergency, where there is no pressure or

low pressure in the air system, the parking brake can

be released by pushing and holding down the

Emergency Park Brake Release.

Figure 18. Regen Switch

Park Brake Interlocks

The parking brake is interlocked with and affects

the operation of kneeling and wcl as follows:

• Kneeling - The park brake must be applied

to kneel. Releasing the park brake cancels

kneeling and returns the coach to normal ride

height.

• Wheelchair Lift - The park brake is

interlocked by the wheelchair lift key switch. The park

brake must be set before turning the wheelchair lift

master key switch on. Opening the wheelchair lift doors

also sets the parking brake.

The park brake emergency release air tank

has only enough air to release the parking

brake three times.

The Emergency Park Brake Release is a green,

circular button located on the lower LH console switch

panel ( Figure 20 ).

Figure 20. Emergency Park Brake Release

21June 2016

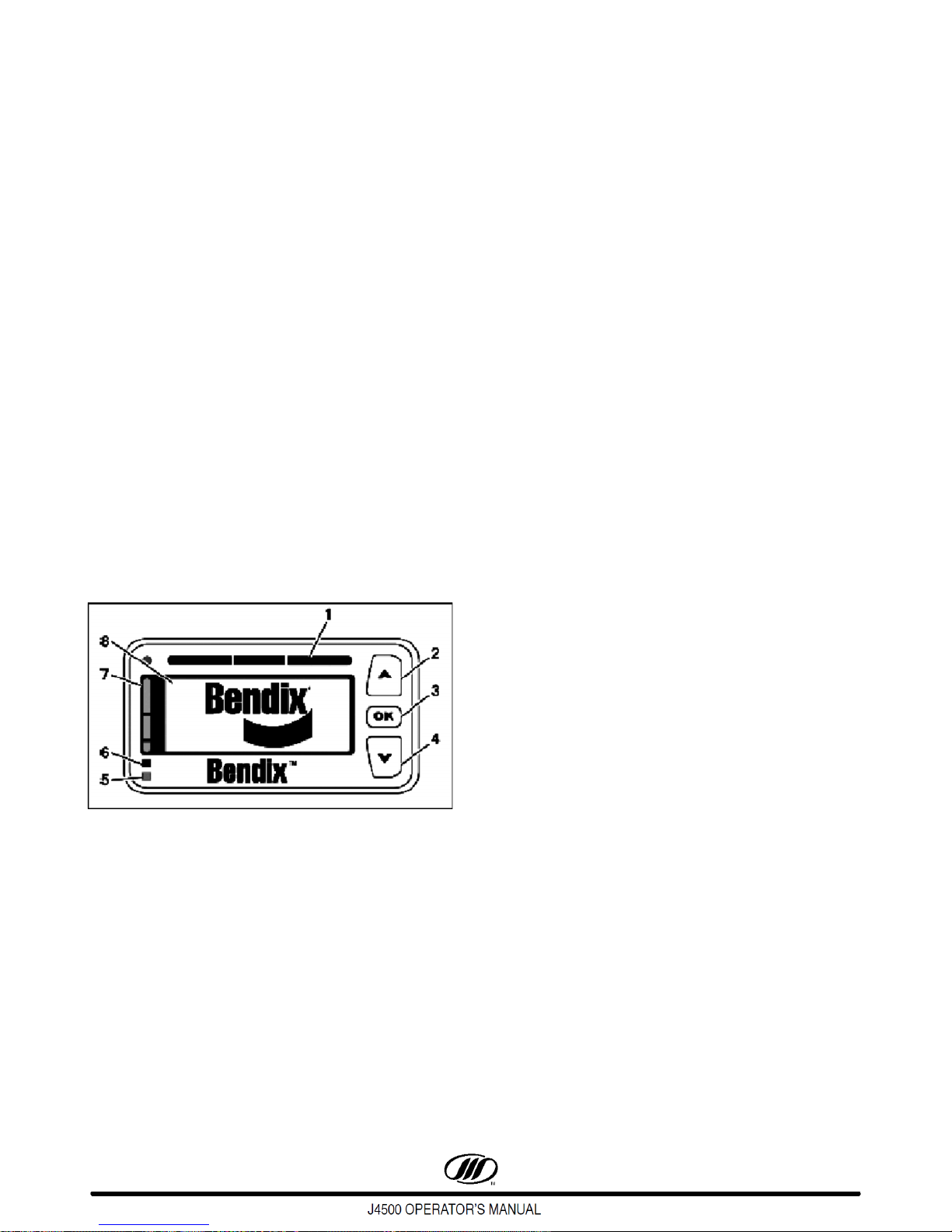

Bendix Wingman System (Optional)

Figure 21.

The Driver is always responsible for the

control and the safe operation of the vehicle

at all times. The Bendix Wingman Advanced

(or ACB) system does not replace the need

for a skilled, alert professional driver,

reacting appropriately and in a timely

manner, and using safe driving practices.

Any audible and/or visual alert by the system

means that your vehicle is too close to the

vehicle ahead, immediately act to potentially

avoid, or lessen the severity of, a collision.

Improper use of the Bendix Wingman

Advanced ( or ACB ) system can result in a

collision causing property damage, serious

injuries, or death.

Active Cruise with Braking (ACB)

The Wingman system is engaged by turning cruise

control ON and setting the vehicle speed. The system

helps maintain a set distance between the operated

vehicle and a detected vehicle ahead. To disengage

the system, turn the cruise control OFF or press the

brake pedal.

The Wingman Advanced ( or ACB ) system is

automatically ready when the cruise control

is set. However, cruise control must be used

only in the same conditions that are normally

recommended for ordinary cruise control. As

noted below, there are certain situations

when cruise control should NOT be used. Do

not use cruise control in the following

conditions or situations:

• Inclement weather (rain, snow, fog,

ice or other severe weather

conditions)

• Dense Traffic

• Sharp curves and winding roads

• Entrance or exit ramps

• Downhill grades

• Construction zones

• Smaller forward vehicles - Smaller

vehicles, such as motorcycles, may

be difficult for the radar to identify. It

is the driver’s responsibility to be

aware of these types of vehicles and

to slow down if necessary.

Any vehicle trouble code that disables

vehicle cruise control will also cause a

diagnostic trouble code in Wingman

Advanced ( or ACB ). The Wingman system

will not operate until the DTC is cleared.

Collision Mitigation (Advanced)

Audible and visual alerts are provided to the

operator through a Driver Interface Unit (DIU). All the

alerts are always active regardless whether cruise

control is engaged or not. Any alert means your vehicle

is too close to another vehicle or object. These alerts

will change as the distance between the two vehicles

decreases alerting the operator of the impending

hazard. As the distance closes, the system will

automatically intervene and slow the vehicle.

June 201622

The radar system only senses metallic

objects. Non-metallic or limited metallic

objects such as people, animals, RVs,

motorcycles, horse drawn buggies, logging

vehicles, or cross- traffic will not trigger the

system.

Due to inherent limitations of radar

technology, the collision mitigation

technology on rare occasions may not detect

moving vehicles or stationary objects in your

vehicle’s lane of travel.

Road curvature may impact the radar’s ability

to track vehicles ahead in the same lane.

Operator alerts, warnings, or brake

interventions may not occur. In addition, the

system may react to moving vehicles not in

your vehicle’s lane of travel. Operator alerts,

warnings, or brake interventions may occur.

Following Distance Alert (FDA)

A FDA is generated through the DIU using vehicle

speed, forward vehicle speed, distance and driving

scenarios.

These alerts indicate that the time between

your vehicle and the detected forward vehicle

ahead is less than one and a half ( 1.5 )

seconds and decreasing. Once the audible

alert is heard, the driver should increase the

distance between their vehicle and the vehicle

ahead until the audible alert stops.

Single, Yellow Illuminated LED

The forward vehicle is within a 1.5 seconds range

and traveling at the same speed or slower.

The screen will visually show the distance between

the vehicles, closing.

Two, Yellow Illuminated LEDs

The forward vehicle is much too close and traveling

at the same speed or slower. The screen will visually

show the vehicles slightly closer to each other.

Figure 22.

Bendix Wingman Driver Interface Unit (DIU)

1. Three Red LEDs

2. UP Button

3. OK Button

4. Down Button

5. Orange LED

6. Blue LED

7. Three Yellow LEDs

8. LCD Display

All Three, Yellow Illuminated LEDs

This is the closest and most urgent Following

Distance Alert. The forward vehicle is in this zone and

traveling at the same speed or slower. The screen will

visually show the distance between the vehicles as

very close.

All Three, Red Illuminated LEDs

This alert is the most severe warning. A loud solid

tone is generated, and the screen will flash. The

system will automatically slow down the vehicle. The

operator must apply additional braking to maintain a

safe distance from the vehicle ahead. If a collision is

likely to occur, and the collision mitigation feature

activates the brakes, the tone of the alert will change

and the screen will flash between two displays.

This alert indicates that a collision with the

detected forward vehicle is likely and the

driver must immediately act to potentially

avoid, or lessen the severity of a collision.

23June 2016

Two Yellow Illuminated LEDs

The radar detects a sizable, non-moving, metallic

object in the vehicle's path of travel.

Brake Overuse Alert

This alert is provided when the system is

intervening and using the brakes excessively .

Brake overuse can lead to overheating and a

potential loss of braking performance (brake

fade).

Using cruise control on downhill runs will

cause this alert. Do not use cruise control on

downhill grades.

Blinking Blue LEDs

When brake overuse is detected, a text message

and audible alert/alarm is generated and the DIU blue

LED will illuminate. The operator has 15 seconds to

take action (turn cruise control OFF or apply the

brakes).

All three types of alerts ( FDA, IA, and SOA )

will continue to be provided during the brake

overuse alert.

False Alerts

In certain unusual traffic or roadway conditions,

Wingman Advanced (or ACB) may issue a false alert.

While eliminating all false alerts is not possible, if false

alerts occur too frequently (more than twice a day), this

may indicate sensor misalignment. Service the system

at the earliest opportunity.

Front Bumper Radar Sensor

The sensor relaying information to the DIU is

located on the front bumper of the coach.

Solid Blue LEDs

If the operator doesn't take action within 15

seconds, the system will shut off and a DTC

(Diagnostic Trouble Code) will be generated. All

intervention features of the system will remain off until

the next ignition cycle. If the operator does intervene

within the 15 seconds, the system will remain

unavailable for 20 minutes. After 20 minutes the

displayed ACB Braking Overuse message will

disappear and the blue LED will turn off.

Figure 23. Radar Sensor

Radar sensor inspection for obstruction/

damage must be monitored routinely.

June 201624

4 - STEERING COLUMN & FLOOR-MOUNTED CONTROLS

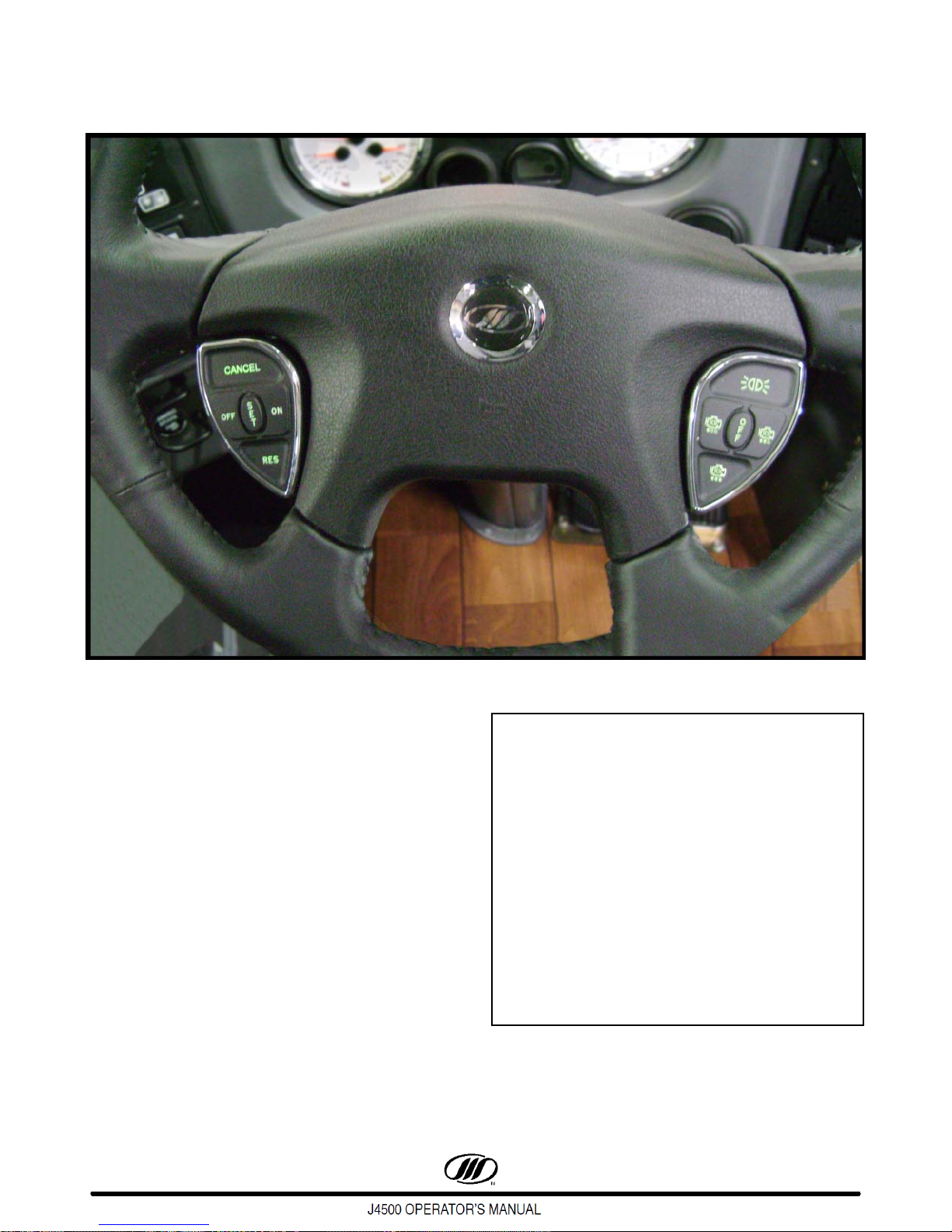

Figure 24. Steering Wheel

STEERING COLUMN

Ensure that the column is firmly locked

before driving. Do not adjust the steering

column while driving; steering control could

be lost.

The tilt and telescoping steering column has a

molded polyurethane steering wheel with fingertip

cruise and engine brake controls.

The tilt/telescoping control lever is on the LH side

of the steering column. Pull on the adjustment lever

and tilt the steering wheel to the desired position. Push

on the adjustment lever and raise or lower the

assembly as necessary. Release the lever to lock.

Ensure that the column is securely latched.

Figure 25. Tilt / Telescoping Control Lever

25June 2016

“SMART STICK” CONTROLS

1

2

3

4

The “Smart Stick”, on the LH side of the steering

column, controls the turn signals, air horn,

headlamp dimmer, windshield washer and

windshield wipers.

Turn Signals

Move the lever up for right turns, and down for left

turns. The corresponding telltale will flash.

Air Horn

Press the button on the end of the turn signal lever

to activate the air horn.

Headlamp Dimmer

Pull the turn signal lever forward and release it to

change from one setting to another. The HIGH

BEAM telltale lights when the headlights are on

high beam.

Windshield Washers

Push the sleeve towards the steering column.

Activating the washer turns the wipers ON for four

seconds on low speed.

Windshield Wipers

There are four rotary positions that operate the

wipers: OFF, intermittent, low speed and high

speed.

Figure 26. Smart Stick Features

1. Windshield Washer

2. Windshield Washer

3. Turn Signals

4. Air Horn

June 201626

CRUISE CONTROL

Do not use cruise control in heavy traffic, on

icy roads or in any other driving condition

that does not permit a constant speed.

Setting Vehicle Speed

Press the ON switch to turn on the cruise control.

Accelerate to the desired speed, press the Set

switch, then release the accelerator pedal. The

CRUISE ENABLED telltale on the RH cluster stays

on until the cruise control is turned off.

Cruise control will not operate under 20 mph

(32 km/h).

NOTE: When automatic operation is canceled,

RES may be used to return to cruise control.

Increasing Set Speed

1. Press and hold the RES switch until the desired

speed is reached, or,

2. Press the accelerator pedal until the desired

speed is reached, then press and release the

switch.

SET

When driving with cruise control, speed may

be increased (for passing, etc.) by pressing

the accelerator in the usual way. Releasing

the accelerator returns the coach to the set

speed

.

Decreasing Set Speed

1. Press and hold the SET switch until the desired

speed is reached, or,

2. Lightly press the brake to disengage the

system. Allow the vehicle to coast to the desired

speed, then press and release the

SET switch.

Figure 27. Switch Pod

ENGINE BRAKE

The engine brake controls are mounted on the RH

side of the steering wheel.

The four controls are: OFF, LOW, MEDIUM and

HIGH.

The transmission may be shifted in the

normal way without disengaging the cruise

control.

Canceling the Set Speed

1. Press the OFF switch or the CANCEL button, or,

2. Make a slight brake application.

Figure 28. Switch Pod

The button located at the top of the RH control

features a “courtesy light” that momentary flashes

the coach marker lights to acknowledge passing

vehicles.

27June 2016

Loading...

Loading...