MCi C, C1 Operation Manual

www.mcisolutions.ca

OPERATIONS MANUAL

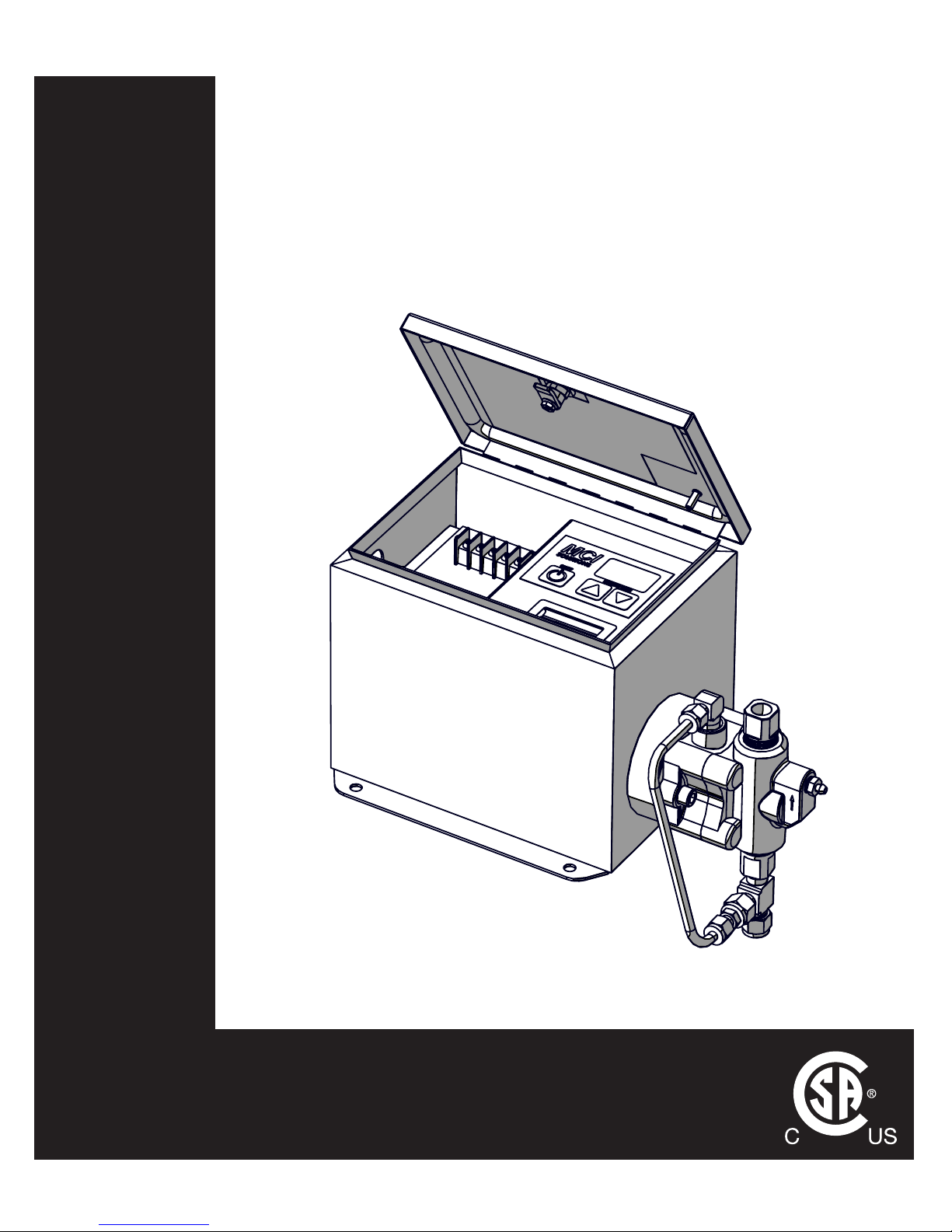

MODEL C1 ELECTRIC CHEMICAL

INJECTION SYSTEM

C SERIES

GENERAL SAFETY

ii

www.mcisolutions.ca

Table Of Contents

General Safety 1

Symbol Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Proper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Sources of Danger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Authorized Operators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Personal Protective Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

In Case of Emergency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

System Specications 5

Electric Drive Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Static Head Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Output Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation 8

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Standard Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Plumbing Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

System Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Operating Instructions 15

Controller Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setting Flow Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting 18

Bill of Materials 21

Material Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

General System Detail View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

FMT Fluid End . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Plunger Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

In-line Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Pressure Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Maintenance 27

Preventative Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Lubrication Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Plunger Seal Maintenance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Check Valve Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Limited Warranty 38

Maintenance Log 39

1

www.mcisolutions.ca

The C1 Electric Chemical Injection System has been subjected to a safety test and quality acceptance inspection. Please ensure all safety instructions in this manual are clearly understood. Misuse or incorrect

operation of the System may cause serious injury or death

Only properly and trained personnel should be involved in the setting up, putting into service, inspecting, servicing and repairing of this equipment.

Read and understand all instructions. Failure to follow the Dangers,

Cautions and Warnings contained in this owners manual may result in electric

shock, re, serious bodily injury or death

CAUTION!

General Safety

Symbol Usage

Designates an imminent danger. In case of non-observance of this information, death or severe injuries are an imminent risk

Designates possibility of a dangerous situation. In case of non-observance of this information, death or severe injuries can occur

Designates areas where the potential for severe crush injury exists.

These crush injuries can result in serious bodily injury

Electrical Shock Hazard Warning indicates a potential injury hazard that

can result in serious bodily injury or death

Designates important user tips and other useful information

Designates important installation information that if not followed could

cause System failure

DANGER!

CAUTION!

GENERAL SAFETY

2

www.mcisolutions.ca

NOTICE TO INSTALLER: This manual must be left with the owner/operator of the System and kept

for future reference

Proper Use

This System uses a reciprocating positive displacement pump. It serves the purpose of conveying and

circulating liquids. The System and these operating instructions are intended for commercial use exclusively

Severe skin injury can result from dangerous media used with this System.

(i.e. Aggressive, toxic and caustic media)

Unsuitable media can damage the pump and then escape into the surrounding area

If you intend to use dangerous media, the materials used for the pump parts

must be designed and compatible for this use

ANY form of liability on the part of the manufacturer shall be null and

void if the System has been modied by others without authorization

from MCI

When replacing parts in the System, use only spare parts approved by MCI. (Refer to the Bill of Materials

section in this manual for more information )

Always Disconnect power to the System before performing ANY maintenance

or repair activities

Sources of Danger

The System has been manufactured in compliance with CSA standards and complies with all applicable

safety requirements

Although most safety risks have been reduced through design and construction measures, residual risks

(i.e. explosive atmospheres, electrical, mechanical or thermal) cannot be excluded entirely during either

transport, maintenance and repair work, or regular operation

CAUTION!

CAUTION!

DANGER!

3

www.mcisolutions.ca

Authorized Operators

Only persons who have been properly authorized and trained by MCI or its authorized agent may work

on or with this equipment

The owner must:

■ Clearly dene and ensure the observance of the responsibilities for all tasks performed in con-

nection with the System

■ Make this manual accessible to all operations sta

■ Make sure operations have read and understood all operating instruction

For Extra copies of this manual or for more information please visit us online

at: www.mcisolutions.ca

Or, Scan the following QR code with your smart phone for a direct link to

digital copies of all MCI Operation Manauls:

Maintenance, upkeep and electrical tasks should only be performed by

technically competent, trained and/or qualied personnel

Technically competent people, trained and qualied personnel are dened as individuals who:

■ Possess sucient knowledge in a specic eld based on their specialized training and experi-

ence; and

■ Are familiar with all applicable work safety and accident prevention regulations (i.e. lock-out or

tag-out safety procedures)

CAUTION!

GENERAL SAFETY

4

www.mcisolutions.ca

Personal Protective Equipment

Wear appropriate protective equipment especially when performing any

maintenance, inspection or cleaning task on the System

Oils, Lubricants and cleaning agents can cause skin reactions and irritation.

Avoid skin contact with all chemical used in connection with the System

In Case of Emergency

In case of Emergency originating from the System or from conditions in the surrounding area, the System must be switched o immediately

The System cannot be put back into operation until the emergency has been identied and corrected.

Ensure corrective actions are taken to prevent future occurrence

In case of res, use only suitable re-extinguishing agents

If the instructions in this manual are not adhered to or are inadequately

adhered to , the warranty shall become null and void and the CSA declaration of conformity shall immediately cease to be valid

MCI makes no other warranty, including without limitation, any warranties or merchantability or of tness

for a particular purpose, whether express or implied. MCI will not be liable under any circumstances

whatsoever to the purchaser for any damages relating to loss of production, loss of product, environment

damage, or any incidental, consequential, special or punitive damages regardless of whether arising in

contract, strict liability, other tort or otherwise. The exclusive remedy of the purchaser for any and all

losses, injuries or damages resulting from the sale, use or handling of any product whether in contract,

warranty tort, negligence, strict liability or otherwise, will not exceed the purchase price paid, or at MCI’s

sole election, the repair or replacement of the product

CAUTION!

CAUTION!

5

www.mcisolutions.ca

System Specications

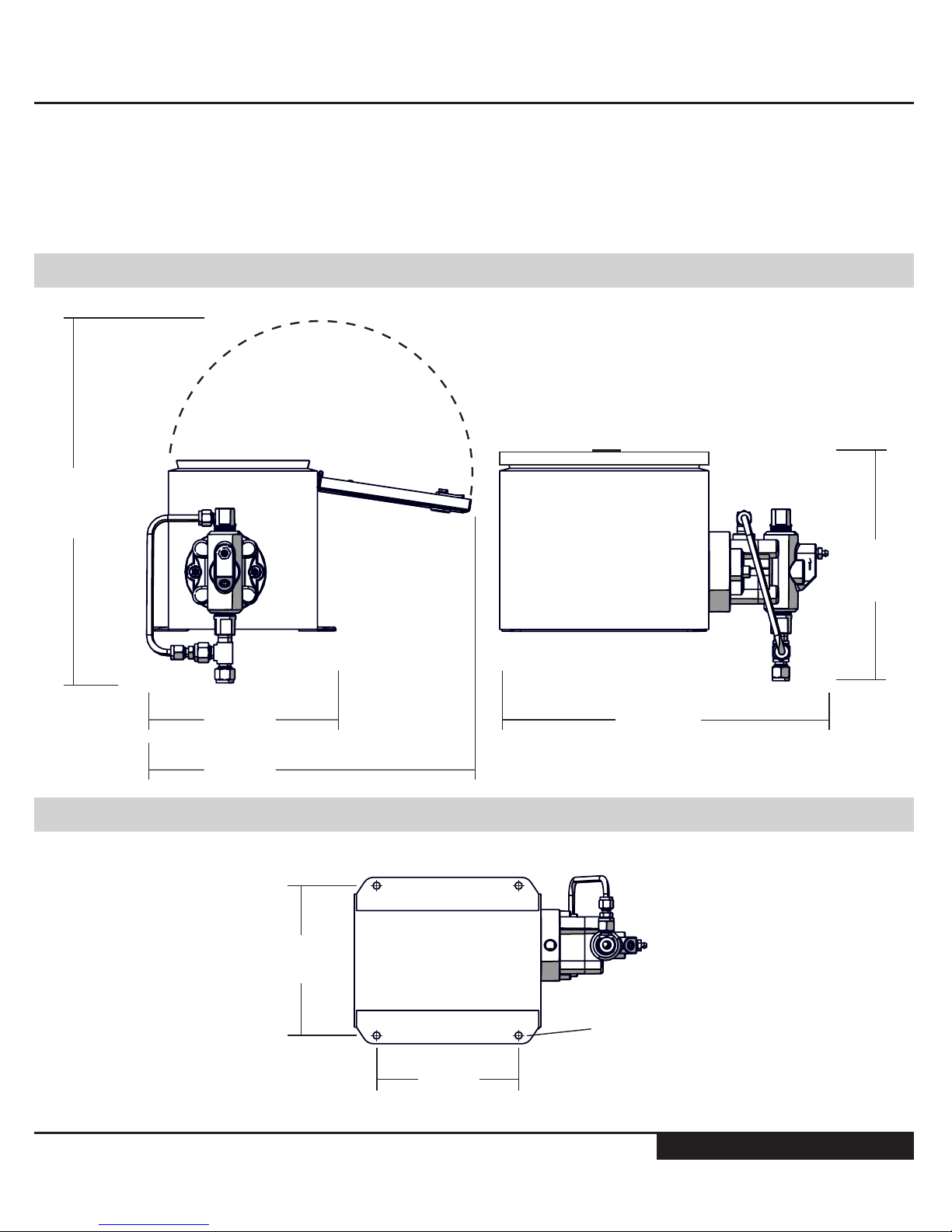

Electric Drive Dimensions

335 mm

(13.2 in)

370 mm

(14.5 in)

190 mm

(7.5 in)

330 mm

(13.0 in)

234 mm

(9.2 in)

LID CLOSED

Mounting Dimensions

173 mm

(6.8 in)

C/L TO C/L

163 mm

(6.4 in)

C/L TO C/L

7.9 mm

(0.313 in)

Diam. (x4)

GENERAL SAFETY

6

www.mcisolutions.ca

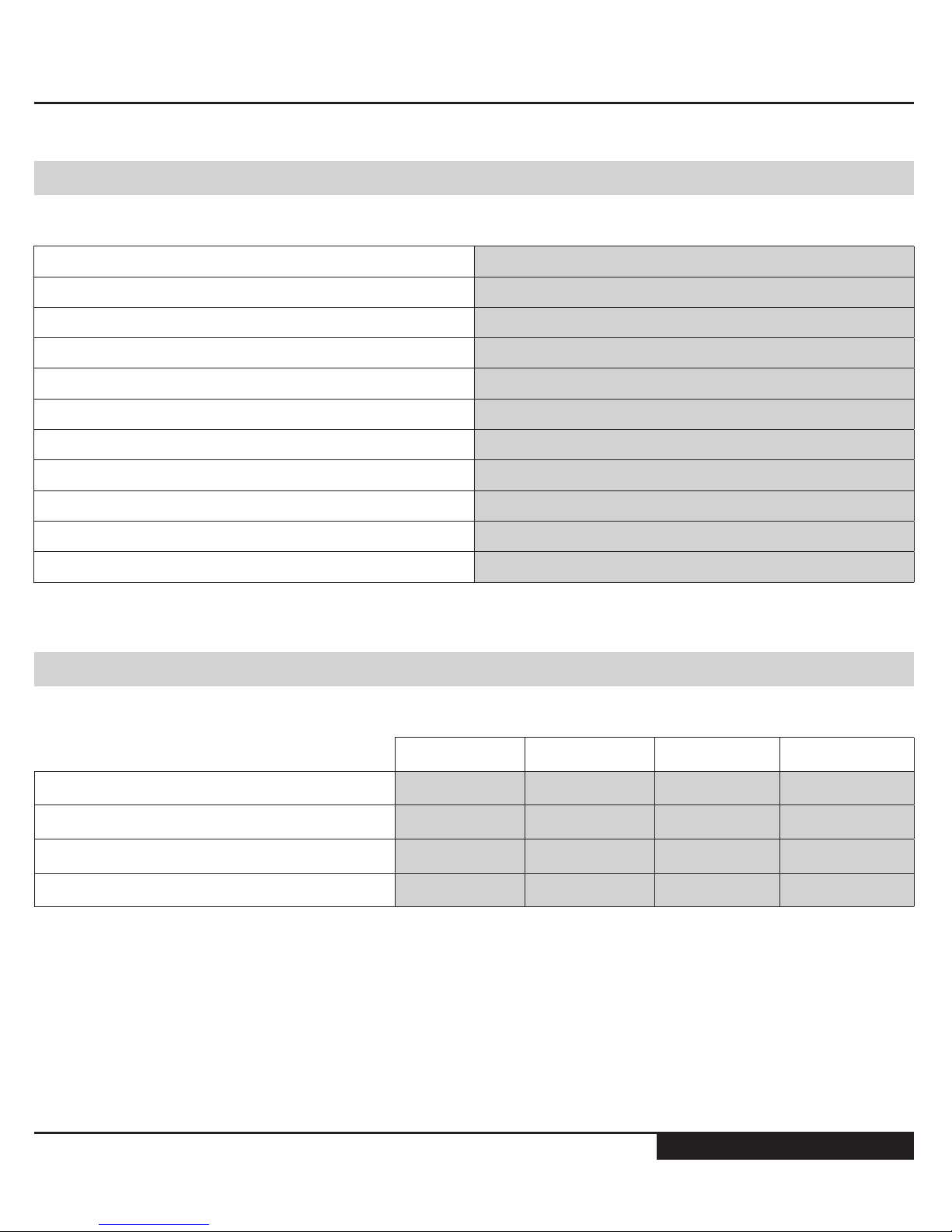

Static Head Requirements

MINIMUM (CL TO CL)

305 mm

(12.0 in)

Electrical Specications

Electrical Rating 24V DC

Classication CSA CLASS 1 DIVISION 2

Enclosure Rating Nema 3R

Temperature Code T4A

Motor Type 4 Pole Stepper Motor, 1.8 Degree Step

Inrush Current 950 (mA)

Avg. Power Consumption 450 (mA) MAX

Reverse Polarity Protection Standard

Analog Input [4-20 mA] Optional Upgrade [Innite Scale adjustments and

remote On/O capability]

Integrated Low Voltage Disconnect Standard [custoM set points AvAilAble]

7

www.mcisolutions.ca

General Specications

N-seal Leak Containment Adaptor Standard

Variable Speed Controller Electronic/ MOSFET

Electro-mechanical contactors / Relays N/A

Electro-mechanical Timers N/A

Dip Switch N/A

Fluid End Carbon Steel [316L S.S. Upgrade available]

Fluid End Suction and Discharge Seals OMX Fluoroelastomer®

Secondary Containment Static Seals Teon®

Seal Kit Dynamic Seals UHMW Polyethylene c/w Stainless Steel spring.

Plunger Material Tungsten Carbide

Operating Temperature -40 to +40 [oC]

Output Performance

1/4" Plunger 3/8" Plunger 1/2" Plunger 11/16" Plunger

Maximum Displacement Pressure [Psi] 3000 1500 750 400

Maximum Displacment Pressure [kPa] 20684 10342 5171 2758

Maximum Output Volume [Litres/day] 12 29 52 104

Minimum Output Volume [Litres/Day] 0.12 0.26 0.46 0.86

GENERAL SAFETY

8

www.mcisolutions.ca

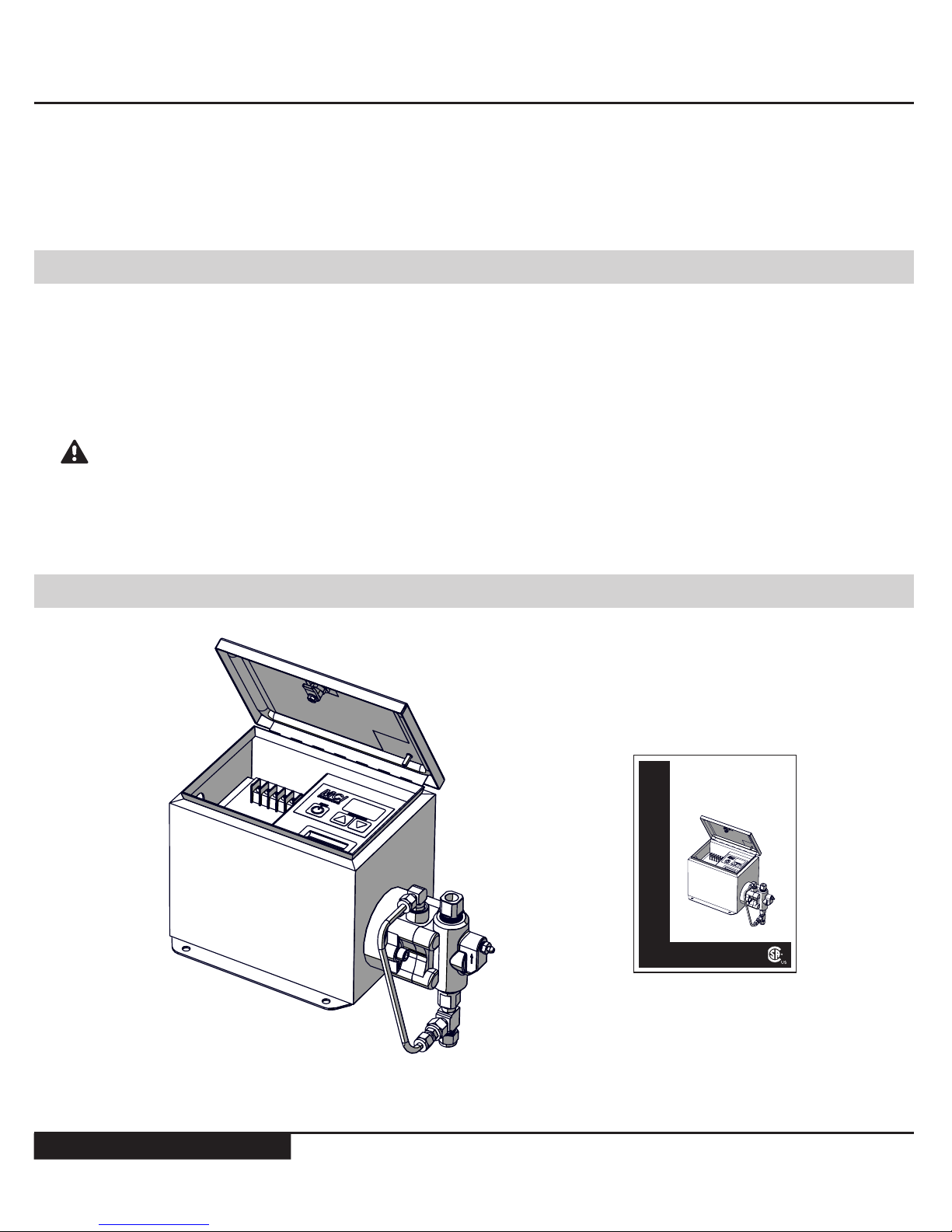

Installation

General

Congratulations. You have chosen the nest, most accurate electrically powered chemical injection System available. Before Installation, please inspect the pump carefully for any possible in-transit damage. If the pump appears damaged, call your local distributor or call MCI customer service direct at

+1.888.263.4565

Please ensure you have fully read and understood the general safety

section of this manual before proceeding with the System installation

The System is CSA approved for use in Class 1 Division 2 areas. It is the

responsibility of the owner to determine the classication of the area

where the System is to be installed

Standard Package Contents

C1 Electric Drive (x1)

Manual (x1)

OPERATIONS MANUAL

MODEL C1 ELECTRIC CHEMICAL

INJECTION SYSTEM

C SERIES

www.mcisolutions.ca

CAUTION!

9

www.mcisolutions.ca

The System is to be mounted securely in a safe location that satises the classication requirements.

The Systems Fluid End (Pump) must be oriented in a vertical position for proper check valve operation

Allow a minimum distance of 12 in. from the center line of the pump head to the lowest point on the

chemical storage container bulkhead to ensure adequate [positive] static head pressure is available. The

System relies on a positive suction pressure to run correctly [grAphic eXplAnAtion shown on pAge 6]

The membrane switch panel is covered with a clear plastic lm, remove prior to operating the System

Plumbing Overview

Only properly qualied and trained personnel should be involved in the

setting up , putting into service, inspecting, servicing and repairing of the

plumbing for the uid end

Ensure all National, Provincial/State and local codes are followed when plumbing equipment. Failure to follow these codes can result in serious bodily injury

or death

The following plumbing suggestions are examples of typical installations only and may not be the best

suited method for your custom installation

Ensure all process valves are closed prior to disconnecting or re-installing any chemical injection System

To avoid over-pressuring chemical discharge lines MCI requires placing a properly tested and calibrated

Pressure Relief valve (PRV) between the discharge port of the uid end and the process injection point.

The set point must not exceed the pumps maximum discharge pressure [MAXiMuM dischArge pressures cAn be

found in the 'systeM specificAtions' section under 'output perforMAnce']

Failure to add a CERTIFIED and CALIBRATED Pressure Relief Valve (PRV)

to the System is inherently unsafe. It can cause catastrophic System

damage and voids all System warranty. MCI is not responsible for any

damage caused by exceeding maximum System pressure. MCI oers

complete PRV solutions for all Systems. Please contact customer service

for latest pricing and availability: +1.888.263.4565

CAUTION!

GENERAL SAFETY

10

www.mcisolutions.ca

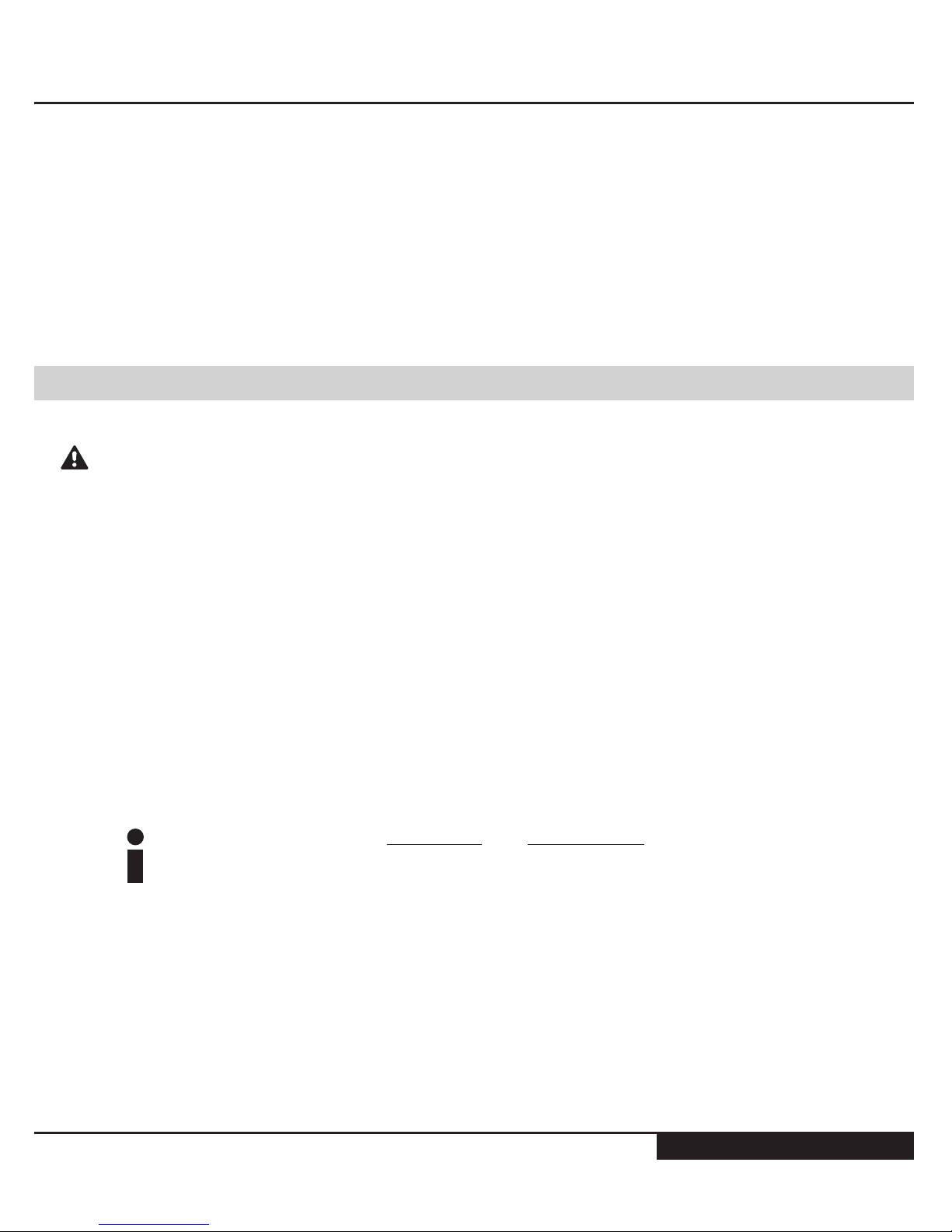

Standard Connection Points

Removing foreign debris from suction lines and chemical storage containers

will greatly extend the life of all dynamic seals used in the System. It is highly

recommended to use a pre-suction in-line lter on all Systems. MCI oers

in-line lter kits for all pump models. Please contact customer service for the

latest pricing and availability: +1.888.263.4565

Secondary Containment Line

1. Fluid End Discharge Point - 1/4” Fem. NPT

2. Pressure Transducer Port - 1/8" NPT

3. Fluid End Suction Point - 3/8” Tube

3

1

2

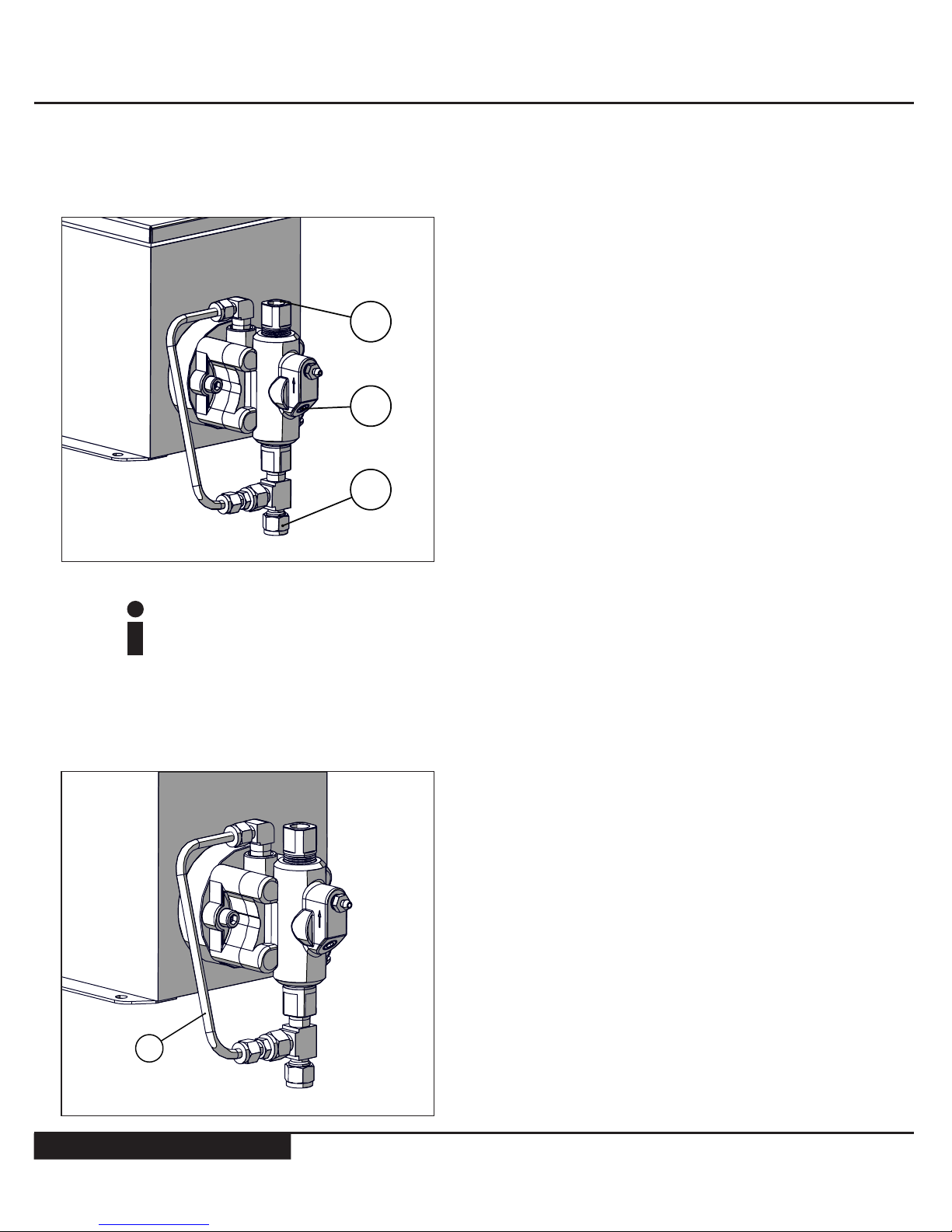

1. Secondary containment line - 1/4” Tube

1

11

www.mcisolutions.ca

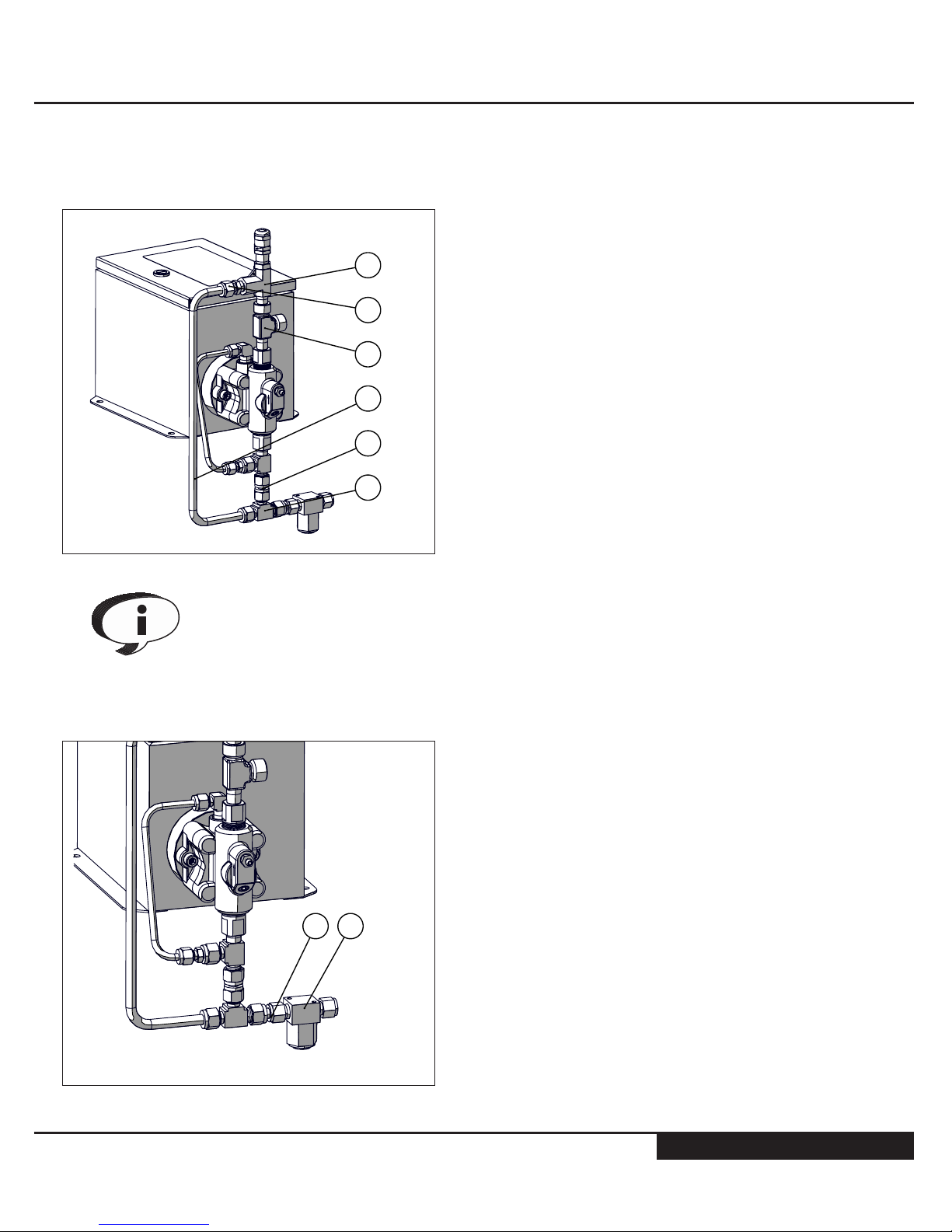

Pressure Relief Valve Tie-In [TYPICAL ARRANGEMENT SHOWN]

Pressure relief valve kits are available direct from MCI. Kits include all tubing

[where applicable] and ttings required to complete the installation. Contact

customer service for more information: +1.888.263.4565

Suggested in-Line Filter [TYPICAL ARRANGEMENT SHOWN]

1. Pressure Relief Valve

2. Male Connector - 1/4” NPT x 3/8” Tube

3. Run Tee - 1/4” NPT [Main Discharge Point]

4. Stainless Steel Tubing [.035] - 3/8”

5. Tube Connector - 3/8”

6. Union Tee - 3/8”

6

5

4

3

1

2

1. In-line lter - 440 Micron

2. Tube connector - 3/8”

12

GENERAL SAFETY

12

www.mcisolutions.ca

In-line lter assemblies are available direct from MCI. Kits include all tubing

[where applicable] and ttings required to complete the installation. Contact

customer service for more information: +1.888.263.4565

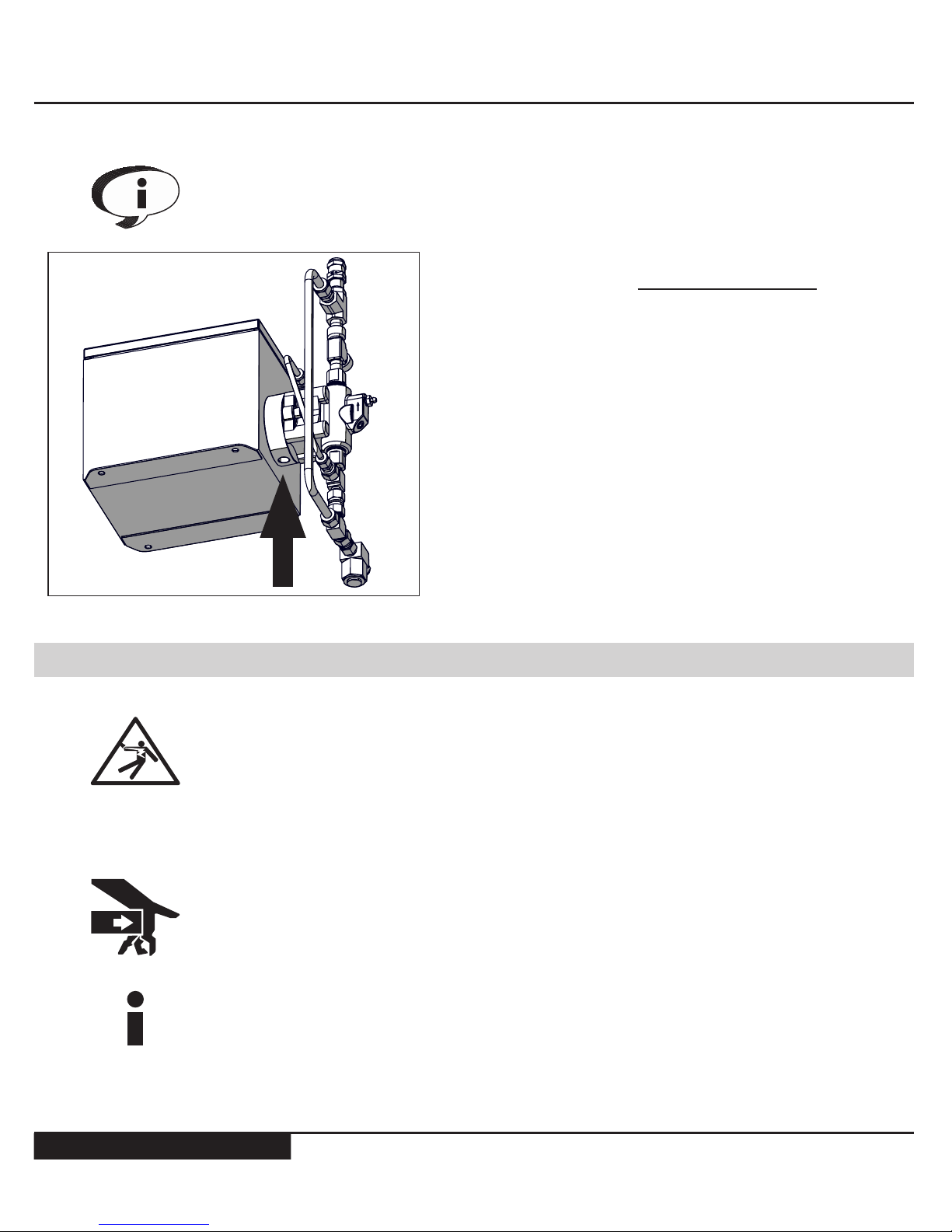

The 1/4” NPT drain port shown [Arrow] is a general

System drain port [DO NOT PLUG OFF] This port

must remain open or plumbed to a designated

containment area

Without routine maintenance it is possible for seal

bypass from the low pressure side to exit this port.

Ensure proper containment areas are in place and

suggested routine seal maintenance procedures

are followed to prevent spills

Power Supply

When wiring the System follow cable orientation labels found on the inside of

the enclosure lid. Failure to orientate wiring properly may result in damage to

the on-board electronics and could cause serious bodily injury or death

To protect the System and associated components the pump box must be

connected to ground. All electrical connections must satisfy National, Provincial/State and local electrical codes

SYSTEM CAN START AUTOMATICALLY - Before connecting power to the

control board ensure that you and all tools used in setup are clear of moving

parts, serious bodily injuries can occur

When connecting cables to the control module ensure keyed connections

are tight. Loose connections can cause arcing and erosion which destroy the

integrity of the connections

Loading...

Loading...