TPR UniLock

A Division of Systems, LLC

Patent Pending

Vehicle Restraint

Owner’s/User’s Manual

®

McGuire • Division of Systems, LLC • W194 N11481 McCormick Drive • Germantown, WI 53022

800.624.8473 • fax: 262.255.5917 • www.wbmcguire.com • techservices@loadingdocksystems.com

Printed in U.S.A.

© 2018 Systems, LLC - All Rights Reserved

Manual No. 4111-0073

Sept. 2018

Table of Contents

Page

Precautions

Recognize Precautionary Information ................................................ 1

General Operational Precautions ........................................................ 1

Operational Precautions ...................................................................... 2

Safety Decals ......................................................................................... 4

Placard ................................................................................................... 5

Owner’s/User’s Responsibilities ......................................................... 6

Introduction

General Information .............................................................................. 8

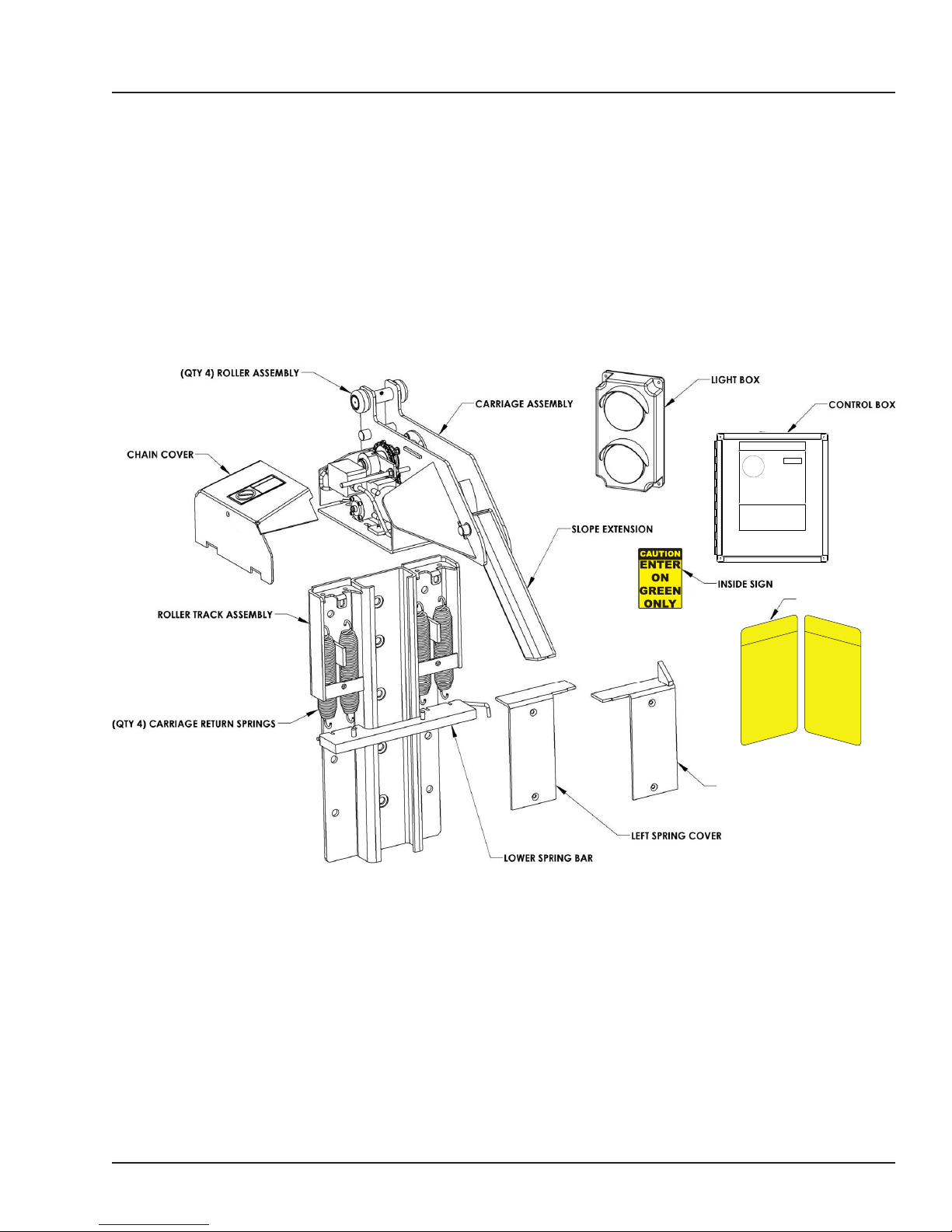

Component Identification ..................................................................... 9

Installation

Installation Precautions ...................................................................... 10

Installation Overview ........................................................................... 11

Roller Track Installation - Without Embed ........................................ 12

Roller Track Installation - With Embed .............................................. 14

Carriage Installation ............................................................................ 16

Install Control Panel and Wiring ........................................................ 17

Placard Installation Instructions ........................................................ 18

Operation

Operational Precautions ..................................................................... 20

Operating Instructions ........................................................................ 20

Maintenance

Maintenance Precautions .................................................................... 22

Periodic Maintenance .......................................................................... 23

Adjustments

Drive Chain & Brake Torque Adjustments ........................................ 24

Adjust Dock Leveler & Vehicle Restraint Interlock .......................... 26

Troubleshooting

Limit Switch Test Procedure .............................................................. 28

UniLock Sequence of Operation ........................................................ 29

UniLock Harness Wire Identification ................................................. 30

UniLock Field Wire Diagram ............................................................... 31

UniLock Troubleshooting ................................................................... 32

Parts

Control Box Parts ................................................................................ 34

UniLock Carriage Assembly ............................................................... 36

Roller Track & Springs ........................................................................ 38

Slope Extensions & Spring Plate ....................................................... 39

Cantilever Brackets ............................................................................. 40

OSLA (Outside Light Assembly) ........................................................ 41

Signs ..................................................................................................... 42

Miscellaneous

Customer Information ......................................................................... 45

Warranty ................................................................................ Back Cover

e

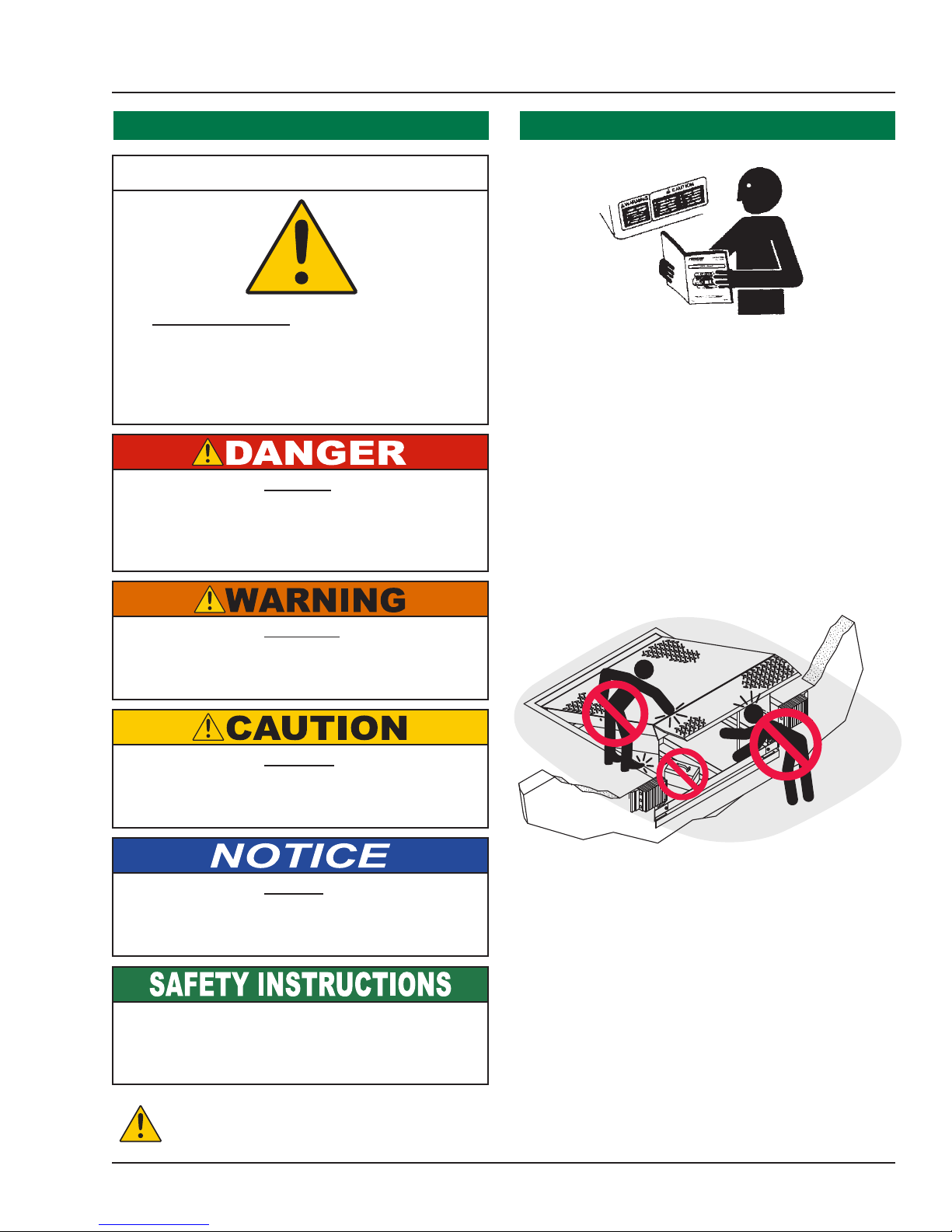

PRECAUTIONS

Recognize Precautionary Information

Safety-Alert Symbol

The Safety-Alert Symbol is a graphic representation

intended to convey a safety message without the

use of words. When you see this symbol, be alert

to the possibility of death or serious injury. Follow

the instructions in the safety message panel.

The use of the word DANGER signifies the

presence of an extreme hazard or unsafe practice

which will most likely result in death or severe

injury.

General Operational Precautions

Read and understand the Owner’s/User’s Manual and

become thoroughly familiar with the equipment and its

controls before operating the equipment.

Never operate equipment while a safety device or

guard is removed or disconnected.

Never remove DANGER, WARNING, or CAUTION

signs, Placards or Decals on the equipment unless

replacing them.

The use of the word WARNING signifies the

presence of a serious hazard or unsafe practice

which could result in death or serious injury.

The use of the word CAUTION signifies possible

hazard or unsafe practice which could result in

minor or moderate injury.

The use of the word NOTICE indicates information

considered important, but not hazard-related, to

prevent machine or property damage.

Indicates a type of safety sign, or separate panel on

a safety sign, where safety-related instructions or

procedures are described.

n

o

Z

g

n

i

t

a

r

e

p

O

n

o

Z

g

n

i

t

a

r

e

p

O

Figure 1

Do not start the equipment until all unauthorized

personnel in the area have been warned and have

moved outside the operating zone (Figure 1).

Remove any tools or foreign objects from the

operating zone before starting.

Keep the operating zone free of obstacles that could

cause a person to trip or fall.

e

WARNING: This product can expose you to chemicals including lead, which are known to the State of California to

cause cancer or birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov

4111-0073 — Sept. 2018

© 2018 Systems, LLC

1

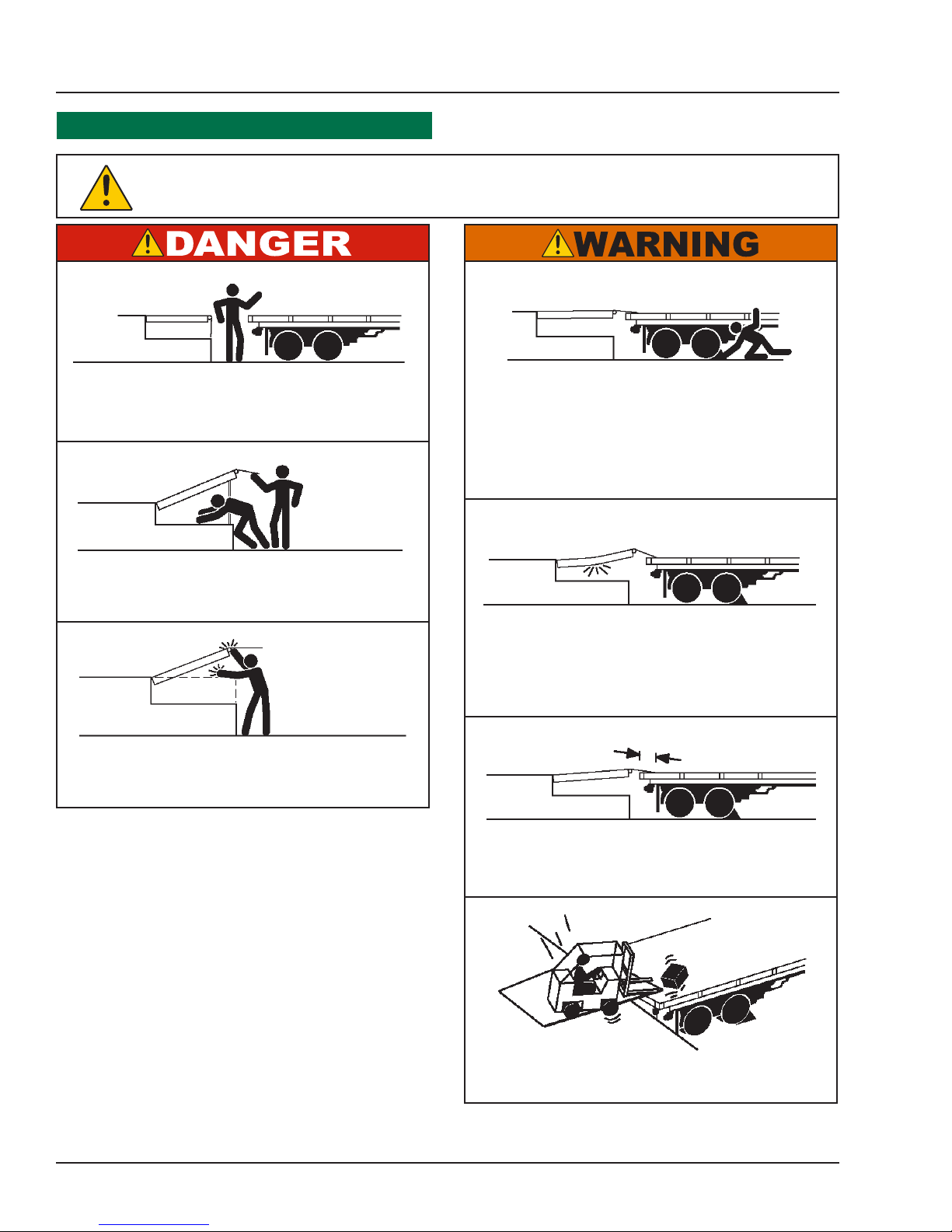

PRECAUTIONS

Operational Precautions

Learn the safe way to operate this equipment. Read and understand the

manufacturer’s instructions. If you have any questions, ask your supervisor.

Stay clear of dock leveling device when transport

vehicle is entering or leaving area.

Do not move or use the dock leveling device if

anyone is under or in front of it.

Keep hands and feet clear of pinch points. Avoid

putting any part of your body near moving parts.

Chock/restrain all transport vehicles. Never

remove the wheel chocks or release the

restraining device until loading or unloading is

finished, and transport driver has been given

permission to drive away.

Do not use a broken or damaged dock leveling

device or restraining device. Make sure proper

service and maintenance procedures have been

performed before using.

2

Make sure lip overlaps onto transport vehicle bed

at least 4 in. (102 mm).

Keep a safe distance from both side edges.

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Operational Precautions

Do not use dock leveling device if transport vehicle

is too high or too low.

PRECAUTIONS

Do not overload the dock leveling device.

Do not operate any equipment while under the

influence of alcohol or drugs.

Do not leave equipment or material unattended on

dock leveling device.

4111-0073 — Sept. 2018

© 2018 Systems, LLC

3

PRECAUTIONS

1751-1051 Rev A

1.50"

1751-0736 Rev A

1.50"

1751-0857 Rev A

Safety Decals

NO

1751-0149

STEP

1751-0149 Rev B

Dock Face

Hook

RIG

TPR Hook must securely

capture Rear Impact Guard

(RIG). Visually inspect before

loading/unloading transport

vehicle.

• Area around RIG should be

free of plates, lift gates or other

obstructions for hook to

securely capture the RIG.

If hook is NOT able to securely capture the RIG, transport vehicle

must be secured by other means.

TPR UniLock Hook must

securely capture Rear Impact

Guard (RIG). Visually inspect

before loading/unloading

transport vehicle.

Obstructions

Dock Face

RIG

Hook

Lift Gates

Arc Flash and

Shock Hazard

PPE [Personal Protection

Equipment] Required

De-energize equipment before

working on or inside. Do not

open cover without appropriate

PPE. Refer to NFPA 70E for

PPE requirements. This panel

may contain more than one

power source.

Hazardous Voltage

Will Result in Death

or Serious Injury

1751-0736

*Control box appearance may vary depending on options.

4

• Inspect all lights and alarm (if equipped) daily for proper

operation.

• Only authorized personnel who have read and understand

the owner’s/user’s manual should operate TPR vehicle

restraint.

• Maintain TPR vehicle restraint in accordance to

owner’s/user’s manual.

Call Systems Inc. for assistance at (800) 643-5424

1751-1051

Figure 2

Lockout/Tagout

power before

servicing.

Comply with

OSHA 1910.147

1751-0857

4111-0073 — Sept. 2018

© 2018 Systems, LLC

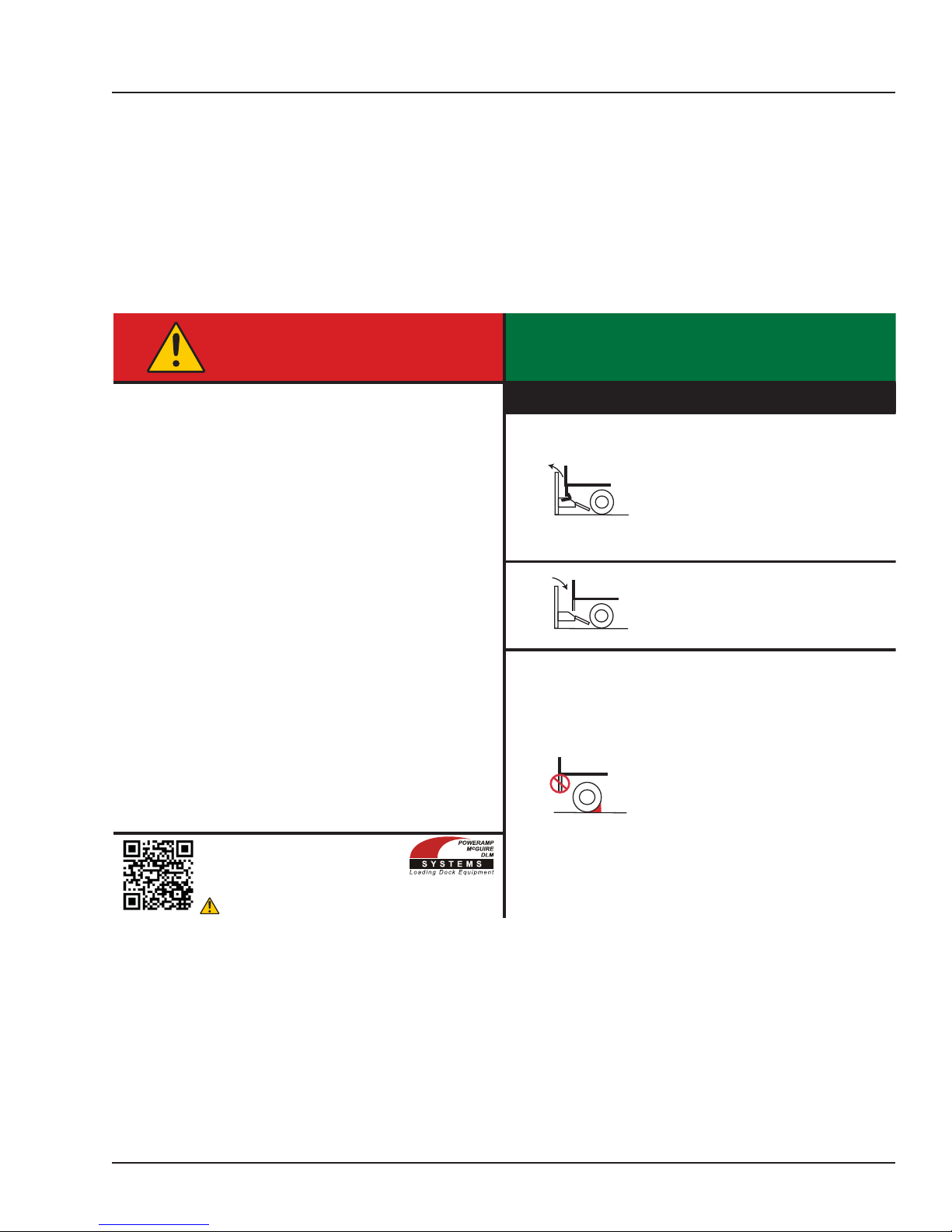

Placard

1. To release restraint press the RELEASE

1. If restraint is unable to secure transport

vehicle’s RIG, use wheel chocks to secure

wheel chocks are removed. Manual reset

of BY-PASS is accomplished by pressing

the RELEASE button or turning switch to

OPERATING

PRECAUTIONS

DANGER

DANGER

• Read and follow all instructions, warnings, and maintenance schedules in

the manual and on placards.

• Vehicle restraint operation and servicing is restricted to authorized

personnel.

1. Before using the vehicle restraint:

• Remove any debris, snow, or ice that may obstruct vehicle restraint

operation.

• Alert personnel in the area of potential vehicle restraint operation and

ensure area is clear.

• Operate the vehicle restraint through one complete cycle inspecting

it for proper operation and light sequence. Advise maintenance

personnel of any damage or improper operation immediately. Remove

all malfunctioning or damaged vehicle restraints from service using

approved lockout/tagout procedures.

2. Before attempting to restrain a transport vehicle:

• Verify that transport vehicle is positioned squarely against dock

bumpers.

• Inspect the transport vehicle’s rear impact guard (RIG). Damaged or

missing RIGs, lift gates, plates or other obstructions may not allow the

vehicle restraint to securely capture the RIG. Wheel chocks must be

used whenever the ability for the vehicle restraint to capture the RIG is

in question. (NOTE: The transport vehicle’s suspension and load

condition will affect trailer height.)

3. After activating vehicle restraint:

• Verify that the transport vehicle’s RIG has been restrained successfully.

In the event this cannot be determined, use wheel chocks in addition

to restraint.

• If equipped with a light communication system, load and unload on

GREEN light only.

4. Maintenance or service must be performed by authorized personnel only.

Follow approved lockout/tagout procedures.

FAILURE TO FOLLOW THESE INSTRUCTIONS WILL RESULT IN

DEATH OR OTHER SERIOUS INJURY.

INSTRUCTIONS

VEHICLE RESTRAINTS

ENGAGE RESTRAINT

1. Open overhead door and visually check that

transport vehicle is positioned squarely against

dock bumpers and has a RIG bar. Inside light

is RED and outside light is GREEN.

2. Press the ENGAGE button to activate restraint.

3. Once RIG has been secured, inside light is

GREEN and outside light is RED

RELEASE RESTRAINT

button. When safely stored, inside light is RED

and outside light is GREEN.

BY-PASS

transport vehicle at the dock.

2. Turn switch to BY-PASS. Inside light is GREEN

and outside light is RED.

3. Loading/unloading may proceed with caution.

BY-PASS RESET

1. When loading or unloading is completed and

(RETURN TO NORMAL OPERATION)

Scan to view our owner’s/user’s manuals online.

www.LoadingDockSystems.com

1.800.643.5424

Call for additional placards, or manuals, or with questions

regarding proper use, maintenance, and repair of dock leveler.

WARNING: CANCER AND REPRODUCTIVE HARM

www.P65Warnings.ca.gov

1751-0880

4111-0073 — Sept. 2018

© 2018 Systems, LLC

1751-0880 Rev F

NORMAL. Lights change to RED inside and

GREEN outside.

Use for PowerHook, PowerHold, HoldTite and TPR series

5

OWNER’S/USER’S RESPONSIBILITIES

1) The manufacturer shall provide to the initial

purchaser and make the following information

readily available to the owners/users and their

agents, all necessary information regarding

Safety Information, Operation, Installation and

Safety Precautions, Recommended Initial and

Periodic Inspections Procedures, Planned

Maintenance Schedule, Product Specifications,

Troubleshooting Guide, Parts Break Down,

Warranty Information, and Manufacturers Contact

Information.

2) The owner/user should recognize the inherent

dangers of the interface between the loading

dock and the transport vehicle. The owner/user

should, therefore, train and instruct all operators

in the safe operation and use of the restraining

device in accordance with manufacturer’s

recommendations and industry standards.

Effective operator training should also focus on

the owner’s/user’s company policies, operating

conditions and the manufacturer’s specific

instructions provided with the restraining device.

Maintaining, updating and retraining all operators

on safe working habits and operation of the

equipment, regardless of previous experience,

should be done on a regular basis and should

include an understanding and familiarity with all

functions of the equipment. Owners/users shall

actively maintain, update and retrain all operators

on safe working habits and operations of the

equipment.

3) When selecting a restraining device, it

is important to consider not only present

requirements but also future plans and any

possible adverse conditions, environmental

factors or usage. The owners/users shall provide

application information to the manufacturer

to receive recommendations on appropriate

equipment specifications.

4) The owner/user must see all nameplates,

placards, decals, instructions and posted

warnings are in place and legible and shall not

be obscured from the view of the operator or

maintenance personnel for whom such warnings

are intended for. Contact manufacturer for any

replacements.

5) Modifications or alterations of restraining devices

shall be made only with prior written approval

from the original manufacturer. These changes

shall be in conformance with all applicable

provisions of the MH30.3 standard and shall

also satisfy all safety recommendations of the

original equipment manufacturer of the particular

application.

6) An operator training program should consist of,

but not necessarily be limited to, the following:

a) Select the operator carefully. Consider the

physical qualifications, job attitude and

aptitude.

b) Assure that the operator reads and fully

understands the complete manufacturer’s

owners/users manual.

c) Emphasize the impact of proper operation

upon the operator, other personnel, material

being handled, and equipment. Cite all rules

and why they are formulated.

d) Describe the basic fundamentals of the

restraining device and components design as

related to safety, e.g., mechanical limitation,

stability, functionality, etc.

e) Introduce the equipment. Show the control

locations and demonstrate functions. Explain

how they work when used properly and

maintained as well problems when they are

used improperly.

f) Assure that the operator understands

nameplate data, placards and all

precautionary information appearing on the

restraining device.

g) Supervise operator practice of equipment.

h) Develop and administer written and practical

performance tests. Evaluate progress during

and at completion of the course.

i) Administer periodic refresher courses. These

may be condensed versions of the primary

course and include on-the-job operator

evaluation.

7) It is recommended that the transport vehicle

is positioned as close as practical to the dock

leveling device and in contact with both bumpers.

When an industrial vehicle is driven on or off a

transport vehicle during loading and unloading

operations, the transport vehicle parking brakes

shall be applied and wheel chocks or a restraining

device that provides equal or better protection of

wheel chocks shall be engaged. Also, whenever

possible, air-ride suspension systems should

have the air exhausted prior to performing said

loading and unloading operations.

6

4111-0073 — Sept. 2018

© 2018 Systems, LLC

OWNER’S/USER’S RESPONSIBILITIES

8) When goods are transferred between the loading

dock and a trailer resting on its support legs/

landing gear instead of a tractor fifth wheel

or converter dolly, it is recommended that an

adequate stabilizing device or devices shall be

utilized at the front of the trailer.

9) In order to be entitled to the benefits of the

standard product warranty, the dock safety

equipment must have been properly installed,

maintained and operated in accordance with

all manufacturer’s recommendations and/

or specified design parameters and not

otherwise have been subject to abuse, misuse,

misapplication, acts of nature, overloading,

unauthorized repair or modification, application in

a corrosive environment or lack of maintenance.

Periodic lubrication, adjustment and inspection

in accordance with all manufacturers’

recommendations are the sole responsibility of the

owner/user.

10) Manufacturer’s recommended maintenance

and inspection of all restraining devices shall

be performed in conformance with the following

practices: A planned maintenance schedule

program must be followed, only trained and

authorized personnel shall be permitted to

maintain, repair, adjust and inspect restraining

devices, and only the use of original equipment

manufacturer parts, manuals, maintenance

instructions, labels, decals and placards or

their equivalent. Written documentation of

maintenance, replacement parts or damage

should be kept. In the event of damage,

notification to the manufacturer is required.

11) Restraining devices that are structurally damaged

shall be removed from service, inspected by a

manufacturer’s authorized representative, and

repaired or replaced as needed or recommended

by the manufacturer before being placed back in

service.

4111-0073 — Sept. 2018

© 2018 Systems, LLC

7

INTRODUCTION

General Information

Figure 3

This manual provides current information on the TPR

UniLock® vehicle restraint. Due to ongoing product

improvement, some parts may have changed, along

with operation and troubleshooting methods. This

manual describes these changes where applicable.

The TPR UniLock is the only trailer-postioned vehicle

restraint that can automatically remove “RIG Wedge”

pressure. RIG Wedge is caused when the trailer

is pushed forward during loading/unloading and

the trailer’s Rear Impact Guard (RIG) applies so

much pressure to the restraint’s hook that the truck

driver must reverse the trailer in order to release

the restraint. The UniLock has an advanced cam

design that first rotates the hook away from the RIG

to remove the pressure, and then rotates down to a

stored position.

The UniLock vehicle restraint also has an internal

safety mechanism that locks the restraint’s hook in

place when pressure is applied, maintaining a secure

engagement. This makes it universally effective on

any obstructed Rear Impact Guard (RIG), including

intermodal trailers with cover plates that prevent the

restraint’s hook from latching on top of the RIG.

The UniLock is designed to withstand a pulling force

in excess of 32,000 lbs, and has a service range of 4”

to 10” horizontally from the face of the dock bumpers

and 9” to 30” vertically above drive approach. The

integral motor, gear and brake assembly is specifically

designed for the UniLock. The UniLock vehicle

restraint is highly adaptable to new or existing loading

docks.

To illustrate which connections are to be made in the

field at installation, electrical drawings are included

with each order or by contacting Systems, LLC

Technical Services.

Call Systems, LLC to discuss available options to

meet your specific needs.

Technical Service at 800-643-5424 or techservices@loadingdocksystems.com

8

4111-0073 — Sept. 2018

© 2018 Systems, LLC

INTRODUCTION

CAUTION

ONL

CAUTION

PULL

IN OR

OUT ON

GREEN

Component Identification

Inspect package and all components. Report any missing or damaged items immediately

and note on the shipping Bill Of Lading (BOL).

(QTY 15) CONCRETE ANCHORS INCLUDED (not shown)

Figure 4

OUTSIDE SIGNS

PULL

IN OR

OUT ON

GREEN

Y

RIGHT SPRING COVER

ONLY

*Control box appearance may vary depending on options.

4111-0073 — Sept. 2018

© 2018 Systems, LLC

9

INSTALLATION

Installation Precautions

Post safety warnings and barricade the work

area at dock level and ground level to prevent

unauthorized use of the dock leveler before

installation has been completed.

DO NOT grind or weld if hydraulic fluid or other

flammable liquid is present on the surface to be

ground or welded.

DO NOT grind or weld if uncontained hydraulic fluid

or other flammable liquid is present. Stray sparks

can ignite spills or leaks near the work area. Always

clean up the oil leaks and spills before proceeding

with grinding or welding.

Always keep a fire extinguisher of the proper type

nearby when grinding or welding.

Only trained installation professionals with the

proper equipment should install this product.

DO NOT connect the vehicle restraint electrical

wiring and ground connections until all welding has

been completed.

DO NOT ground welding equipment to any electrical

components of the vehicle restraint. Always ground

welding equipment to the vehicle restraint base,

NEVER to the moving components.

Failure to follow these instructions may damage the

motor, wiring, and/or control panel.

10

4111-0073 — Sept. 2018

© 2018 Systems, LLC

INSTALLATION

Disconnect

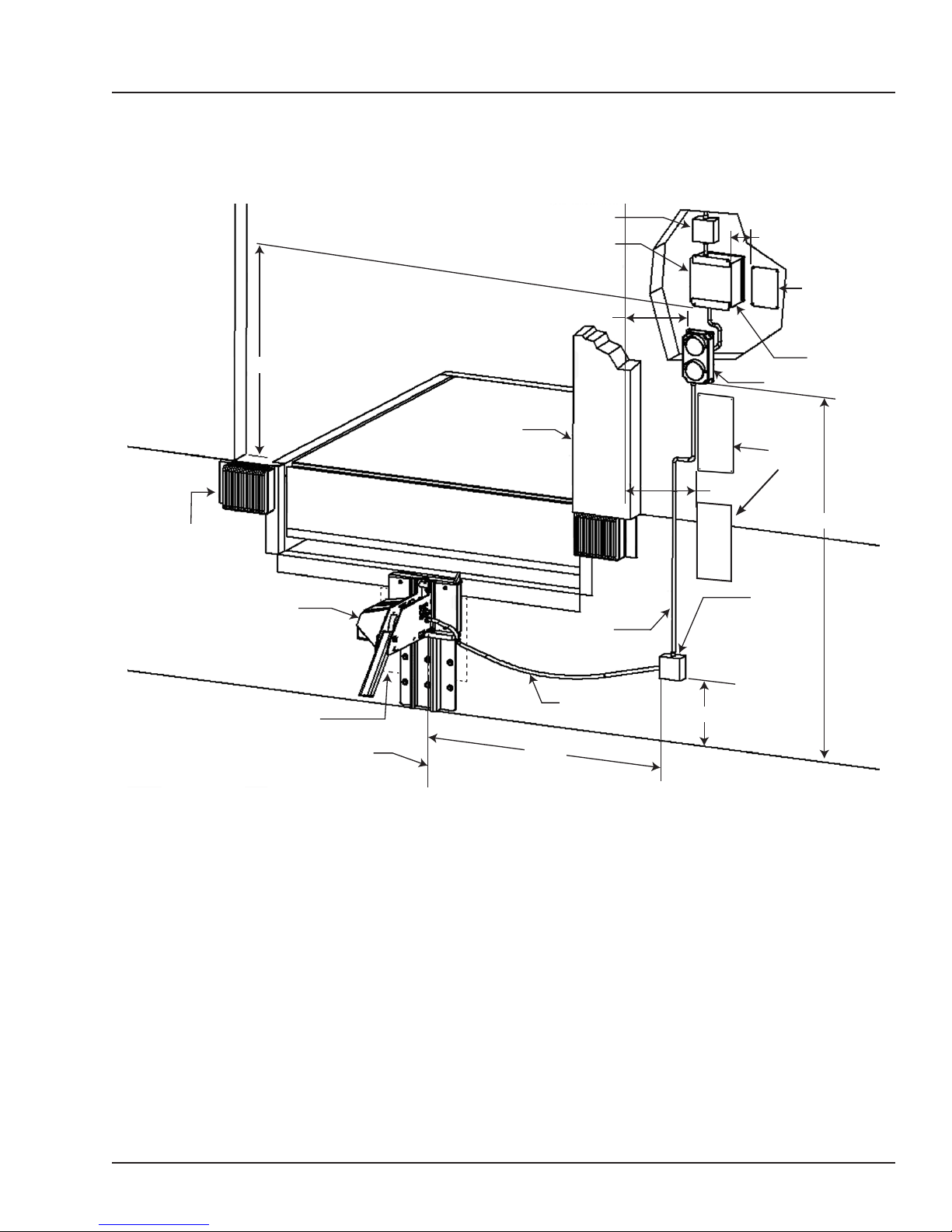

Installation Overview

Note: This is a generic overview of a typical UniLock installation. See full installation

instructions on pages 12-18 for different installation types and all steps.

4” Thick Bumpers

48”

“TPR”

“UniLock”

(supplied by others)

Place control box where best suited, within

arms reach, at eye level near door opening

Allow adequate space

for seals and shelters

Dock Seal

3/4” Conduit or

Diameter per Local Code

(Supplied by others)

5”

Inside

Caution sign

Inside light

and control

box

Outside lights

Outside

Caution

Sign

18”

96”

Junction box

mounted on

dock face, not

to extend out

more than 3”

(Supplied by

others)

Optional imbed

plated (20”x20”)

Center Line of

Dock and TPR

Figure 5

55”

58”

Wire Harness

15”

4111-0073 — Sept. 2018

© 2018 Systems, LLC

11

INSTALLATION

Roller Track Installation - Without Embed

Anchor Installation

Do not install the UniLock vehicle restraint directly

onto a concrete block or brick dock face; contact

Systems, LLC to purchase a suitable Z-bracket.

Minimum 4” thick bumpers are required at all

positions where a UniLock vehicle restraint is

installed. DO NOT install on docks without minimum

4” thick bumpers. For thicker bumpers, consult the

factory.

Install roller track plate onto dock face at specified

location by using the fifteen (15) concrete anchors

provided, in conjunction with welding to pit steel or a

leveler frame. If required, roller track can be trimmed

up to a maximum of 5” from the bottom.

The roller track plate must be plumb with the dock

face. If not, use and weld (6) shims 2” wide x 255/8” long. Shims must be the full length of the roller

track mounting plate. If shims are over 1/2” thick, use

longer anchors. If shims need to be 1” thick or more,

contact Systems, LLC Technical Services.’

Some levelers are slightly recessed within the pit and

thus require a shim to be inserted between the roller

track plate and the leveler front subframe and welded

in place.

Note: Some mechanical dock levelers have an

adjusting nut access hole in the leveler front

subframe. If the UniLock vehicle restraint roller track

interferes with the access hole, the track plate must

be cut to allow access.

Note: Fifteen (15) concrete anchors are provided

with each UniLock vehicle restraint. An anchor must

be installed in each roller track plate hole except for

those plug-welded to embedded steel.

1. Place roller track at desired location, spaced 5/8”

above the drive.

2. Using the roller track as a guide, drill holes of

5/8” diameter and minimum of 4-5/8” deep at all

locations where roller track is not overlapping

curb steel. Clean out holes.

3. Insert anchors and drive them flush with roller

track plate, making sure that the threaded wedge

is inserted first. Do not disassemble anchors prior

to installation.

4. Once all anchors are installed, torque to 60 ft-lbs.

Welding Instructions

Note: If the installation being worked on is a retrofit

or replacement, make sure that the power source

has been tagged and locked out according to OSHA

regulations and approved local electrical codes, then

remove the motor and limit switch connections from

the control harness located in the outside junction

box.

1. Disconnect power and ground leads to dock

leveler (if equipped).

2. Plug weld all holes that are in contact with

embedded steel. All fifteen (15) holes must

be either plug welded or anchored. Minimum

electrode must be 1/8” 7018 or better.

12

3. Weld across top of roller track plate to curb steel

or leveler frame with 3” long 1/4” fillet welds.

4. Once all welding has been completed, reconnect

power and ground leads to dock leveler (if

equipped).

5. Clean and touch up all welds once complete.

4111-0073 — Sept. 2018

© 2018 Systems, LLC

3”

INSTALLATION

Figure 6

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Figure 7

13

INSTALLATION

Roller Track Installation - With Embed

Welding Instructions

Do not install the UniLock vehicle restraint directly

onto a concrete block or brick dock face; contact

Systems, LLC to purchase a suitable Z-bracket.

Minimum 4” thick bumpers are required at all

positions where a UniLock vehicle restraint is

installed. DO NOT install on docks without minimum

4” thick bumpers. For thicker bumpers, consult the

factory.

Install roller track plate onto dock face at specified

location by welding to an embedded steel plate,

in conjunction with welding to pit steel or a leveler

frame, and using provided concrete anchors in the

remaining three (3) holes. If required, roller track can

be trimmed up to a maximum of 5” from the bottom.

The roller track plate must be plumb with the dock

face. If not, use and weld (6) shims 2” wide x 255/8” long. Shims must be the full length of the roller

track mounting plate. If shims are over 1/2” thick, use

longer anchors. If shims need to be 1” thick or more,

contact Systems, LLC Technical Services.’

Some levelers are slightly recessed within the pit and

thus require a shim to be inserted between the roller

track plate and the leveler front subframe and welded

in place.

Note: If the installation being worked on is a retrofit

or replacement, make sure that the power source

has been tagged and locked out according to OSHA

regulations and approved local electrical codes, then

remove the motor and limit switch connections from

the control harness located in the outside junction

box.

1. Disconnect power and ground leads to dock

leveler (if equipped).

2. Place roller track at desired location, spaced 5/8”

above the drive.

3. Plug weld all holes that are in contact with

embedded steel. All fifteen (15) holes must be

either plug welded or anchored.

4. Weld the sides of the roller track plate to the

embed mounting plate with 4” long, 1/4” llet

welds.

5. Weld across top of roller track plate to curb steel

or leveler frame with 3” long 1/4” fillet welds.

6. Once all welding has been completed, reconnect

power and ground leads to dock leveler (if

equipped).

7. Clean and touch up all welds once complete.

Anchor Installation

Note: Some mechanical dock levelers have an

adjusting nut access hole in the leveler front

subframe. If the UniLock vehicle restraint roller track

interferes with the access hole, the track plate must

be cut to allow access.

14

Note: Fifteen (15) concrete anchors are provided

with each UniLock vehicle restraint. An anchor must

be installed in each roller track plate hole except for

those plug-welded to embedded steel.

1. Using the roller track as a guide, drill holes of

5/8” diameter and minimum of 4-5/8” deep at all

locations where roller track is not overlapping

curb steel. Clean out holes.

2. Insert anchors and drive them flush with roller

track plate, making sure that the threaded wedge

is inserted first. Do not disassemble anchors prior

to installation.

3. Once all anchors are installed, torque to 60 ft-lbs.

4111-0073 — Sept. 2018

© 2018 Systems, LLC

INSTALLATION

3”

Figure 8

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Figure 9

15

INSTALLATION

Carriage Installation

D

E

C

F

H

A

B

Figure 10

Do not attempt to lift the carriage assembly by

hand! Use a lifting device (e.g. crane, jack) when

lifting the carriage (approx. 110 lbs.).

1. Attach the four (4) springs (A) to the lower spring

bar (B).

A

E

5. Install right and left spring covers (G) with clip nuts

and flat head screws provided.

6. Install the motor cover (D).

7. Install slope extension (H).

2. Pull springs (A) upward and slide over top spring

mounts (C) on the track roller plate.

3. Remove motor cover (D).

4. Slide the carriage assembly (E) into the roller track

(F), position and bolt the lower spring bar (B) to the

bottom of the UniLock carriage.

16

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Install Control Panel and Wiring

1.50"

1751-0736 Rev A

INSTALLATION

Make sure that the power source has been locked

out and tagged according to OSHA regulations and

approved local electrical codes.

DO NOT connect the vehicle restraint electrical

wiring and ground connections until all welding has

been completed.

DO NOT ground welding equipment to any electrical

components of the vehicle restraint. Always ground

welding equipment to the vehicle restraint base,

NEVER to the moving components.

Failure to follow these instructions may damage the

motor, hydraulics, wiring, and/or control panel.

All electrical work — including the installation of the

disconnect panel, control panel, and final connections

to the pit junction box — must be performed by a

certified electrician and conform to all local and

applicable national codes.

Where indicated, all components must be connected

to a SAFETY EARTH GROUND that conforms to

the 1999 National Electrical Code Section 250-50

section (a) or section (c) for a grounding electrode

system.

A

B

C

Figure 11

A— Disconnect Panel

B— Control Panel

(provided by others)

C— Distance, 48 in. (1219 mm)

1. Mount the push-button control panel (B) so

bottom of control panel-to-dock floor distance (C) is

48 in. (1219 mm). See Figure 11.

Arc Flash and

Shock Hazard

PPE [Personal Protection

Equipment] Required

De-energize equipment before

working on or inside. Do not

open cover without appropriate

PPE. Refer to NFPA 70E for

PPE requirements. This panel

may contain more than one

power source.

Hazardous Voltage

Will Result in Death

or Serious Injury

4111-0073 — Sept. 2018

© 2018 Systems, LLC

2. Install electrical disconnect panel (A) if not already

installed. Disconnect panel supplied by others.

3. Install and connect the control wiring.

4. Connect the control wiring to the field wires in the

restraint junction box. Refer to the electrical diagrams

supplied with the vehicle restraint. See pages 32-33

for wiring troubleshooting if needed.

5. Seal the conduit in any location where the conduit

crosses over temperature zones that could produce

condensation.

Optional: Install spacers between the wall and

enclosure to provide temperature insulation and air

flow. If the conduit could fill with water, a drip leg

may be needed.

6. Install placard (see page 18).

17

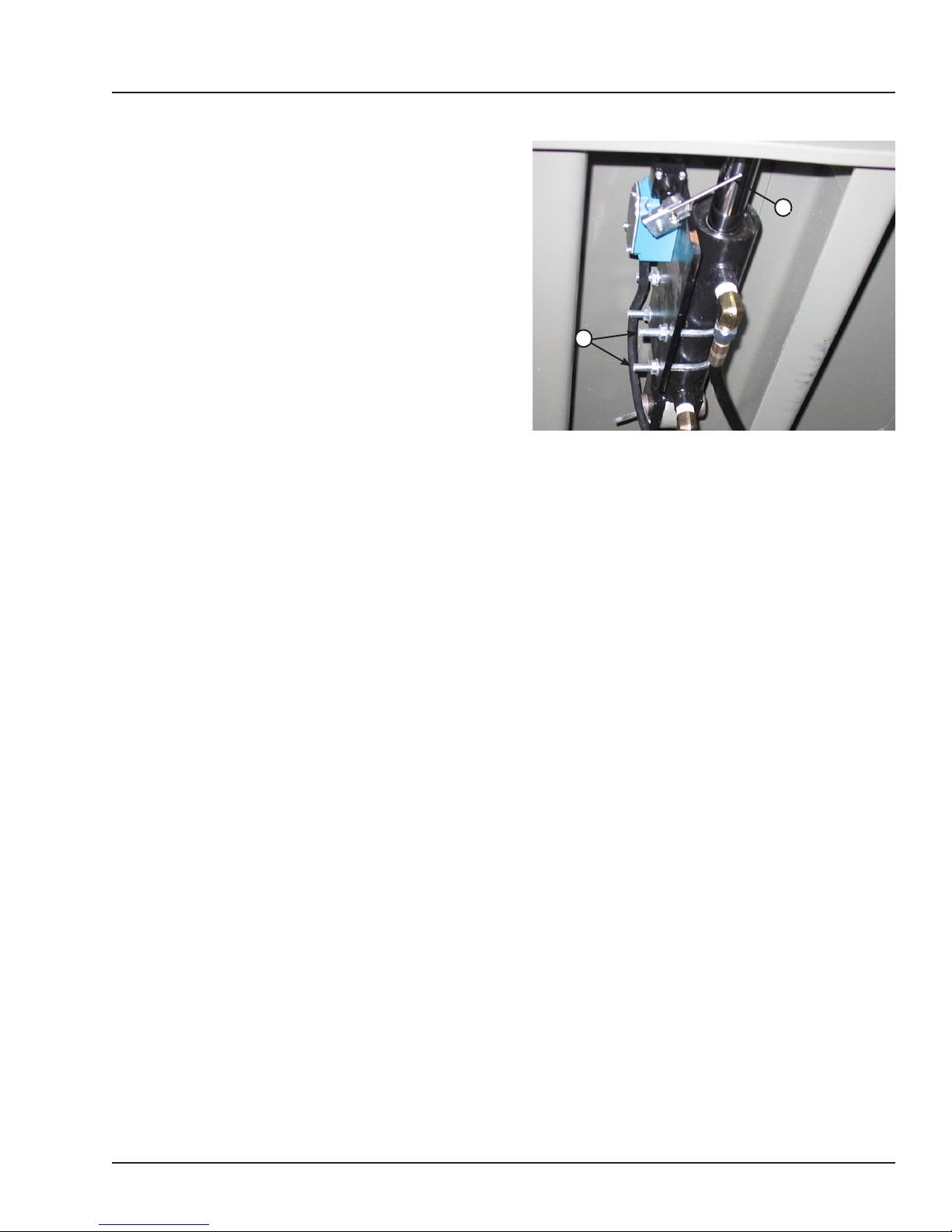

INSTALLATION

Placard Installation Instructions

Owner/Users are responsible for the installation and placement of product

Make sure placard is in plain view of dock leveler and/or vehicle restraint

Suggested placement of placard is near control box attached to electrical

conduit by using nylon tie. If there is no control box present, mount placard

Placard Installation Instructions

• Owner/Users are responsible for the installation and placement of product

placards.

placards.

• Make sure placard is in plain view of dock leveler and/or vehicle restraint

operations.

operations.

• Suggested placement of placard is near control box attached to electrical

conduit by using nylon cable tie. If there is no control box present, mount placard

on wall to the immediate left of leveler at eye level.

on wall to the immediate left of leveler at eye level.

Nylon Tie

C

Conduit

D

C

D

A

Control Box

A

(Placard placement shown

B

Placard

B

as example only.)

(Placard placement

shown as reference

only.)

A - Control Box B - Placard C - Nylon Cable Tie D - Conduit

18

Figure 12

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Operational Precautions

Stay clear of dock leveler and vehicle restraint

when transport vehicle is entering or leaving dock

area.

DO NOT move or use the dock leveler or restraint

if anyone is under or in front of leveler.

Keep hands and feet clear of pinch points. Avoid

putting any part of your body near moving parts.

Only trained personnel should operate the dock

leveler and vehicle restraint.

DO NOT use a broken or damaged dock leveler

or vehicle. Make sure proper service and

maintenance procedures have been performed on

the equipment before using.

OPERATION

Transport vehicle wheels must be chocked unless

the vehicle restraint is used. Never remove the

wheel chocks until loading/unloading is finished

and transport vehicle driver has been given

permission to leave.

Make sure platform lip rests on the transport

vehicle bed with at least 4 in. (102 mm) of overlap.

Maintain a safe distance from side edges of leveler

during the loading/unloading process.

Once the vehicle restraint has been activated, the

dock attendant must visually inspect to assure that

the restraint hook has properly engaged the Rear

Impact Guard (RIG) bar.

4111-0073 — Sept. 2018

© 2018 Systems, LLC

19

OPERATION

Operation - Normal

1. Check that the transport vehicle is positioned

squarely against both dock bumpers.

• Inside light - RED

• Outside light - GREEN

2. Push ENGAGE button to activate restraint.

• Inside lights - AMBER

• Outside light - RED

3. Restraint will ENGAGE on transport vehicle RIG.

• Inside light - GREEN

• Outside light - RED

4. Visually inspect restraint for proper engagement.

5. Position dock leveler onto transport vehicle.

6. When loading or unloading is complete, return

dock leveler to the stored position.

7. Push RELEASE button to store restraint.

• Inside lights - AMBER

• Outside light - RED

Operation - Auto Re-Engage

Note: Auto Re-Engage requires an iDock Control

System. Units without an iDock Control System do

not have this functionality.

After restraint has been engaged with successful

capture of RIG bar, these restraints will automatically

attempt to re-engage if they leave the working zone:

• When restraint hook is lowered to the stored

position without pressing the RELEASE button,

the controls will automatically attempt to reengage the hook one (1) time.

• If hook successfully captures the RIG bar

again, the light communication will remain the

same.

• If hook is unable to return to the working

zone after one (1) attempt, the hook will

automatically return to the stored position,

and the iDock Control System will alert

the operator that the restraint is no longer

engaged with a Bypass Mode prompt. See

“Operation - Unsuccessful Engage.

8. Transport vehicle can now depart.

• Inside light - RED

• Outside light - GREEN

RIG

Hook

Figure 13 Figure 14

20

Latch Mechanism

4111-0073 — Sept. 2018

© 2018 Systems, LLC

OPERATION

Operation - Bypass

If the trailer RIG (Rear Impact Guard) is damaged or

missing, dock leveler can be used in BYPASS.

1. Secure transport vehicle wheels by other means.

2. Activate BYPASS mode through menu screens

under OPERATION MODE.

• Inside light - GREEN & AMBER

• Outside light - RED

3. Position dock leveler onto transport vehicle trailer.

4. When loading or unloading is complete, return

dock leveler to the stored position.

5. Reset BYPASS mode to NORMAL mode by

pressing the RELEASE button once, or through

menu screens under OPERATION MODE.

• Inside light - RED

• Outside light - GREEN

6. Release the transport vehicle wheels when

transport vehicle is ready to depart.

Operation - Bypass From Unsuccessful Engage

If the restraint fails to successfully ENGAGE a trailer

RIG, the hook will automatically return to the stored

position.

• Inside light - AMBER & RED

• Outside light - RED

Bypass mode can then be activated by pressing

ENTER button (user code may be required).

• Inside light - GREEN & AMBER

• Outside light - RED

Or, to reset back to NORMAL mode, press RELEASE

button.

• Inside light - GREEN

• Outside light - RED

See the iDock Owner’s/User’s Manual for more

information on iDock menus and navigation.

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Lift GatesMissed RIG

Figure 15

21

OPERATION

Multi-Colored & Outside Light Sequence Charts

Normal Operation

Condition

Ready For Use Red Green

Leveler Operating or Restraint

Engaging/Releasing In Progress

Restraint Engaged Green Red

Restraint Engage Failure Red/Amber, Display Backlight* Red

Emergency Stop Active Red (solid)* Red (solid)

*If equipped, Audible Alarm will also be active.

Bypass Mode

Condition

Restraint Engage Failure

(Bypass Mode prompt)

Bypass Mode

Red/Amber, Display Backlight Red

(Green/Red on Dock Alert)

Inside Outside

Amber Red

Inside Outside

Green/Amber

Lights

Lights

Red

Reset Attempted (Leveler in Use) Red/Amber, Display Backlight Red

Reset Attempted (Door Open) Green/Amber, Display Backlight Red

Reset Lights to Normal Mode Red, Display Backlight (5 seconds) Green

Menu & Diagnostics

Condition

Main Menu Active Red (solid) Red (solid)

System Fault Present Red/Amber Red

Restraint Use Disabled Amber None

Inside Outside

Lights

22

4111-0073 — Sept. 2018

© 2018 Systems, LLC

OPERATION

4111-0073 — Sept. 2018

© 2018 Systems, LLC

This page intentionally left blank.

23

MAINTENANCE

Maintenance Precautions

D

C

Figure 18

A

B

Figure 16

Figure 17

B

A— Tag Out Device B —Lock Out Device C — Maintenance Prop D— Header

When working with electrical or electronic controls,

make sure that the power source has been tagged (A)

Unless the dock leveler is equipped with a tethered

remote, two people are required to engage the

maintenance prop: one person to operate the unit,

the other person to engage the maintenance prop.

In addition, it is recommended and good safety

practice to use an additional means to support

the dock platform and lip anytime when physically

working in front of or under the dock leveler. This

additional means may include, but is not limited to a

boom truck, fork truck, stabilizing bar or equivalent.

and locked out (B) according to OSHA regulations*

and approved local electrical codes (see Figure 16).

Whenever maintenance is to be performed under

the dock leveler platform, support the platform with

maintenance prop (C). Position the maintenance

prop behind front header plate (D) while staying clear

of the lip. The lip will fold down after the platform

has rested on the maintenance prop. Lock the

maintenance prop in the service (upright) position

using an OSHA approved lockout device* (B) and

tag out device* (A). See Figures 17 and 18.

A

Always post safety warnings and barricade the

work area at dock level and ground level to prevent

unauthorized use of the unit before maintenance is

complete.

24

Only the person servicing the equipment should have

the capability to remove the lockout devices. The tag

out devices* must inform that repairs are in process

and clearly state who is responsible for the lockout

condition.

A hard hat or other applicable head protection

should always be worn when working under or

around a dock leveler.

Always stand clear of platform lip when working in

front of the dock leveler.

* Refer to OSHA regulations 1910.146. Confined Space and 1910.147. Lockout/Tagout

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Periodic Maintenance

Daily Maintenance

MAINTENANCE

Quarterly Maintenance

• Verify that all inside and outside signal lights and

alarm (if equipped) work correctly.

Weekly Maintenance

• Operate the vehicle restraint through the complete

operating cycle to maintain lubrication.

• Remove debris around UniLock vehicle restraint

and in roller track.

• Verify carriage assembly is able to move up and

down freely with no binding or obstruction.

• Inspect motor and spring covers.

• Inspect latch barrier blocks for wear or damage;

replace as needed.

• Inspect latch plates and retaining ring on pivot pin

for damage or wear.

• Inspect latch plates and verify they rotate without

binding or obstructions. DO NOT lubricate the latch

plates.

• Complete Weekly Maintenance.

• Inspect the following for damage/abnormal wear:

• Check welds for cracks.

• Check motor mount bolts.

• Pivot pins and mounting holes.

• Check J-box for water damage.

• Control box and conduit for damage.

• Light bulbs and lenses.

• Bumpers for more than 1” of wear. Replace

worn, loose, damaged or missing bumpers.

• Lubricate the rollers at the fittings located on the

top and bottom axle with a synthetic oil-base moly

grease with a temperature range of –40° to 170° F.

• Lubricate the hook weldment at the tting with a

synthetic oil-base moly grease with a temperature

range of –40° to 170° F.

• Remove retaining ring, remove pivot pin and latch

plates, clean off dirt debris and other foreign matter

from the assembly and mating surfaces. Reinstall

parts; verify parts are moving freely without binding

or obstruction. DO NOT lubricate the latch plates.

• Inspect warning decals and placards. Replace if

damaged or missing

• Inspect chain tension, verify 1/8-1/4 inch of play.

• Lubricate drive chain and limit switch mounting

bracket between drive sprocket and cam with a

synthetic oil-base moly grease with a temperature

range of –40° to 170° F.

• Verify brake torque is greater than 42 ft-lbs and

less than 58 ft-lbs at the hook shaft, while rotating the

hook from ENGAGED (45 deg) to STORED.

• Check that all concrete anchor bolts are torqued

to 60 ft-lbs.

4111-0073 — Sept. 2018

© 2018 Systems, LLC

25

ADJUSTMENTS

Drive Chain & Brake Torque Adjustments

Brake Torque Adjustment

It is recommended and good safety practice to use

an additional means to support the dock platform

and lip anytime when physically working in front of

or under the dock leveler. This additional means

may include, but is not limited to a boom truck, fork

truck, stabilizing bar or equivalent.

Always post safety warnings and barricade the

work area at dock level and ground level to prevent

unauthorized use of the dock leveler before

maintenance is complete.

A hard hat or other applicable head protection

should always be worn when working under or

around a dock leveler.

Always stand clear of platform lip when working in

front of the dock leveler.

Drive Chain Adjustment

If the hook is dropping from the engaged to stored

position with very little effort, or seems like it is binding

and takes an unusually high amount of effort, a brake

torque adjustment may be required.

Verify brake torque is greater than 42 ft-lbs and less

than 58 ft-lbs at the hook shaft, while rotating the

hook from ENGAGED (45 deg) to STORED (see

Figures 19 and 20):

1. Loosen brake adjuster locknut while holding the

adjuster screw to prevent inadvertent adjustment.

2. Turn adjuster screw clockwise to increase brake

torque as needed.

3. Tighten adjuster locknut while holding the adjuster

screw to prevent inadvertent adjustment.

4. Verify brake torque is greater than 42 ft-lbs and

less than 58 ft-lbs at the hook shaft, while rotating

the hook from ENGAGED (45 deg) to STORED;

readjust as required.

Inspect the drive chain periodically for dirt and chain

slack. Open the motor enclosure and clean the chain

with solvent. After cleaning, spray with a high quality

chain spray type lubricant.

The drive chain should not have more than 1/4” slack

(see Figures 19 and 20). To tighten chain:

1. Open motor enclosure and loosen the four (4)

motor mounting bolts.

2. Pry the motor assembly forward, in the slotted

holes, until the chain is tight with proper alignment

between sprockets.

3. Hold in this position and tighten the four (4) motor

mounting bolts to 96 in-lbs in 10 in-lb increments.

26

4111-0073 — Sept. 2018

© 2018 Systems, LLC

45 DEGREES

ADJUSTMENTS

96 IN-LBS

LUBRICATE DRIVE CHAIN AND LIMIT

SWITCH MOUNTING BRACKET. USE

SPRAY GREASE (ZEP 2000 OR EQUAL)

LOCKNUT

BRAKE ADJUSTER SET SCREW

Figure 19

USE TORQUE WRENCH

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Figure 20

27

ADJUSTMENTS

Adjust Dock Leveler and Vehicle Restraint Interlock

Dock Leveler & Vehicle Restraint Interlock

Options

There are two options to interlock the dock leveler

and vehicle restraint*:

• Restraint Engage before Leveler Operate (RELO)

Interlock: Dock leveler can be interlocked with

a vehicle restraint to prevent the leveler from

operating until the restraint has engaged the

transport RIG (Rear Impact Guard) when the

OPERATION MODE is NORMAL and has NOT

been switched to BYPASS MODE.

• Leveler Stored before Restraint Release (LSRR)

Interlock: Vehicle restraint is interlocked with

the dock leveler so that the restraint cannot be

operated until the leveler is stored in the cross

traffic position (lip fully folded, inside the keepers,

and the platform level with the dock floor).

Interlocking is overridden when the OPERATION

MODE is in BYPASS. This allows the independent

operation of the leveler (the restraint cannot be

operated in BYPASS MODE).

Pressing the restraint RELEASE button when in

BYPASS mode will return the leveler to NORMAL

operating mode.

Special interlocking options are available upon

request. Call Systems, LLC to discuss interlock

options to meet your specific needs.

*Dock levelers equipped with Auto-Return-To-Dock

have limited interlocking options. Auto-ReturnTo-Dock feature is not available for dock levelers

equipped with combination dock leveler/vehicle

restraint control panels.

28

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Adjust Dock Leveler and Vehicle Restraint Interlock

1. The dock leveler should be in the cross traffic

position before beginning tests.

ADJUSTMENTS

2. Back a transport vehicle with RIG bar into dock. A

test fixture may be used to simulate the RIG bar.

Use care to avoid damage to the equipment or harm

to the operator.

3. Press the RAISE button. The dock leveler should

NOT raise. If the leveler did not raise, proceed with

step 4. If the leveler did raise, loosen U-bolts (A)

and adjust microswitch mounting plate forward so

that switch feeler arm (B) is engaged by leveler lip

when stored. See Figure 21.

4. Momentarily press the ENGAGE button. The vehicle

restraint automatic engage cycle will be activated

and the restraint will engage the transport vehicle

RIG bar.

5. Raise the dock by pressing the RAISE button until

the lip is fully extended. Release the RAISE button.

The leveler will drop to the floor of the transport

vehicle. If a RIG test fixture is used it should allow

the leveler to drop to the full below-dock position

without the contact between the lip and test fixture.

B

A

Figure 21

6. Press the RELEASE button. The vehicle restraint

should NOT disengage from the transport vehicle

RIG bar or test fixture. If the vehicle restraint did

NOT engage, proceed with step 7. If the vehicle

restraint DID disengage, loosen U-bolts (A) and

adjust microswitch mounting plate backward so that

switch feeler arm (B) is not engaged by leveler lip in

below-dock position. See Figure 21.

IMPORTANT: If adjustments are required in this

step, make sure that the interlocking described in

step 3 is still in effect after step 6 adjustments are

complete.

7. Press the RAISE button. The dock leveler will

raise. The leveler lip will fold as the platform raises.

When the lip is fully folded, release the RAISE push

button. The leveler will descend to the cross traffic

position.

8. Momentarily press the RELEASE button. The

vehicle restraint will return to the stored position.

4111-0073 — Sept. 2018

© 2018 Systems, LLC

29

TROUBLESHOOTING

Limit Switch Test Procedure

If the LS1 and/or LS2 limit switch is suspected to be

faulty, the switch can be tested with a multimeter.

1. Turn OFF all electrical power to the restraint.

2. Remove motor cover.

3. Remove LS1 and/or LS2 limit switch from

carriage (see Figure 23).

4. Set multimeter to Ohms (continuity test).

5. Attach multimeter leads to pins “B” and “C” of

limit switch connector (see Figure 22).

6. With the plunger released, there should be

no meter reading. With the plunger Pressed, there

should be a full-scale meter reading.

Note: The green (ground) wire of the limit switch does

not have to be tested. A continuity test lamp may be

used instead of a multimeter.

LS1

Figure 22

Figure 23

Hook Position LS1 Position LS2 Position Inside Outside

Stored

No Hook

(Under-Travel)

Hooked

(Approx. 90°)

No Hook

(Over-Travel)

* Audible Alarm (if equipped)

Closed

(Pressed)

Closed

(Pressed)

Open

(Released)

Closed

(Pressed)

Open

(Released)

Closed

(Pressed)

Closed

(Pressed)

Closed

(Pressed)

Red Green

Red & Amber* Red

Green Red

Red & Amber* Red

LS2

30

4111-0073 — Sept. 2018

© 2018 Systems, LLC

TPR Harness Wire Identification

TROUBLESHOOTING

Figure 24

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Figure 25

31

TROUBLESHOOTING

UniLock Troubleshooting

Unless the dock leveler is equipped with a tethered

remote, two people are required to engage the

maintenance prop: one person to operate the unit,

the other person to engage the maintenance prop.

In addition, it is recommended and good safety

practice to use an additional means to support

the dock platform and lip anytime when physically

working in front of or under the dock leveler. This

additional means may include, but is not limited to a

boom truck, fork truck, stabilizing bar or equivalent.

Before performing the detailed troubleshooting procedures, check the following items first:

• Check all fuses inside the control panel(s). Replace

any blown fuse(s) with a fuse of equal specification.

Symptom Possible Cause Solution

When service under the dock leveler is required,

always lock all electrical disconnects in the OFF

position after raising the platform and engaging the

maintenance prop.

Always post safety warnings and barricade the

work area at dock level and ground level to prevent

unauthorized use of the dock leveler before

maintenance is complete.

A hard hat or other applicable head protection

should always be worn when working under or

around a dock leveler.

Always stand clear of platform lip when working in

front of the dock leveler.

• Make sure the correct voltages are present at the

proper locations inside the control panel(s).

UniLock vehicle restraint

lights do not ash, and

the hook does not raise.

UniLock vehicle restraint

lights are ashing, but

the hook does not raise

or lower to full extent.

Power source malfunction. Check for blown fuse at branch circuit disconnect.

Incorrect wiring. Verify electrical schematics.

Chain is loose or broken. Adjust or replace as required.

Low incoming voltage. Verify incoming power at L1 and L2.

Drive motor faulty. Check motor, repair or replace.

Incorrect wiring. Verify wiring per electrical schematic.

Incorrect brake torque. Brake torque should greater than 42 ft-lbs.

32

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Symptom Possible Cause Solution

UniLock vehicle restraint

is operational, but the

hook drops while the

transport vehicle is being

serviced, causing the

lights to change.

UniLock vehicle restraint

is operational, but all

lights are out.

TROUBLESHOOTING

If brake torque is less than 42 ft-lbs, or chain is loose

Verify brake torque.

Drive motor faulty. Check motor. Repair or replace as needed.

Faulty LED lights. Check and replace LED lights as needed.

Faulty asher. Check asher; if bad replace.

Incorrect wiring. Verify all eld wiring connections are

or broken, adjust or replace as required.

correct.

UniLock vehicle restraint

lights not working in

correct order.

UniLock vehicle restraint

carriage does not return

to full up position.

UniLock vehicle restraint

does not release.

Inside red light does not

change.

Outside lights and inside

green light do not change.

Broken or weak springs. Replace all springs.

Damaged roller track plate. Verify that the roller track plate is straight and not

Carriage binding in track.

Motor or chain failure. Inspect motor and chain; repair or replace as

Defective LS1.

Defective LS2.

binding or catching.

Clean debris out of roller track and/or verify roller

bearings are greased and move freely.

required.

If additional troubleshooting assistance is required, contact Systems, LLC

Technical Services with equipment serial number or customer order number (CO#).

Technical Service at 800-643-5424 or techservices@loadingdocksystems.com

4111-0073 — Sept. 2018

© 2018 Systems, LLC

33

PARTS

P O W E R A M P

M C G U I R E

D L M

S Y S T E M S, I N C.

L o a d i n g D o c k E q u i p m e n t

www.wbmcguire.com 800.643.5424

www.wbmcguire.com

1.800.643.5424

™

www.wbmguire.com

1.800.643.5424

UniLock Carriage Assembly

30

23

27

9

1

34

48

20

22

47

43

26

49

26

14

39

14

4

33

12

42

19

32

15

18

46

45

3

21

5

49

10

24

41

17

21

35

31

8

13

6

39

16

29

38

50

41

44

28

40

11

7

37

36

™

2

NO

STEP

1751-0149 Rev B

34

4111-0073 — Sept. 2018

© 2018 Systems, LLC

UniLock Carriage Assembly (continued)

Item Quantity Part Number Description

1 1 9701-0237 Hook Cam Shaft

2 3 2101-0321 Screw,HHCS,5/16-18 X 5/8”

3 1 9701-0200 Ring, Snap

4 4 9701-0113 Roller Assembly

5 1 9701-0201 3/4” Conduit Nipple

6 1 0961-0570 Limit Switch, LS1

7 1 0961-0571 Limit Switch, LS2

8 1 9701-0247 Cam

9 2 9701-0111 Bearing Assembly

10 1 9701-0202 DECAL, CAM

11 1 9701-0109 Limit Switch Mounting Plate

12 1 9701-0244 Chain Cover

13 2 9701-0203 Lock Nut 7/16”-14 Serrated Flange

14 8 9701-0204 Nut, Lock 3/8”-16 Serrated Flange

15 2 9701-0205 Cap Screw 1/4”-20 x 1-1/2” Socket Head

16 1 2101-0039 Nut, Nylon Lock , 5/16-18 UNC

17 1 2101-0327 Screw, HHCS, 5/16-16 UNC x 3.75 GR5

18 2 2101-0005 Washer, Lock 1/4”

19 1 1751-0149 Decal, No Step

20 1 9701-0207 Key, Hook 1/4” x 1/4” x 1-1/4”

21 2 9701-0208 Key, Sprocket/Cam 1/4” x 1/4” x 1”

22 1 9701-0110 Hook Shaft

23 2 9701-0209 Nut, Lock 3/4” Conduit

24 1 9701-0114 Drive Sprocket,Hook w/Set Screw

26 8 9701-0211 Bolt, Carriage 3/8”-16 x 1”

27 1 9701-0212 Cord Grip

28 1 9703-0022 Hook Weldment, UniLock

29 1 9701-0106 Carriage Weldment

30 1 4301-0008 Wire Harness

31 1 9701-0115 Chain

32 1 3411-0050 Motor Assembly

33 1 1751-1104 Decal, Product

34 1 0521-0201 Fitting, Grease Zerk,1/8 NPT

35 1 1751-0010 Decal, Serial

36 1 1751-1105 Decal, UniLock Stripe RH

37 1 1751-1106 Decal, UniLock Stripe LH

38 4 2101-0339 Screw,HHCS-1/2-13UNC x 1.00 GR8

39 2 9701-0215 Grease Fitting

40 1 9201-0007 Pin, Dowel, Steel

41 2 9701-0253 Latch Barrier Block

42 2 2101-0010 Bolt, 5/16-18 x 7/8 LG

43 4 2101-0322 Screw,SHSS,1/4-28 UNF x 1/4 Socket Cup

44 2 9701-0248 Latch Plate

45 1 9701-0304 Pin, Pivot with Retaining Ring Groves

46 2 2101-0333 Ring, Retainer 3/4 DIA. External

47 6 2101-0034 Screw, FHCS, 1/4-20 UNC X 3/4

48 1 9701-0238 Hook Cam Cover UniLock

49 2 2101-0033 Screw,SHSS, 1/4-20 UNC X 3/8

50 4 2101-0079 Washer, Flat 1/2”

PARTS

4111-0073 — Sept. 2018

© 2018 Systems, LLC

35

PARTS

Roller Track & Springs

Item Quantity Part Number Description

1 1 9701-0101 SPRING COVER RIGHT HAND

2 1 9701-0100 ROLLER TRACK

3 4 9701-0216 NUT CAGE 5/16”-18

4 4 0941-0016 EXTENSION SPRING

5 15 2101-0319 5/8” X 4” CONCRETE ANCHOR (POWERS #6942 SD OR EQUIV)

6 1 9701-0102 SPRING COVER LEFT HAND

7 4 2101-0069 SCREW, SOCKET 5/16”-18 1-1/4” FLAT HEAD

36

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Slope Extensions & Spring Plate

PARTS

Item Quantity Part Number Description

1 2 9701-0217 WASHER, FLAT 1” X 18 GAUGE

2 1 9701-0218 PIN, COTTER

3 1 9701-0219 PIN, SLOPE EXTENSION PIVOT

4 1 9701-0105 SPRING MOUNTING PLATE ASSEMBLY

5 2 9701-0220 NUT,LOCK 7/16”-14 SERRATED FLANGE

6 1

7 1 9701-0103 CARRIAGE ASSEMBLY KIT (INCLUDES 1,2,3,5,6)

4111-0073 — Sept. 2018

© 2018 Systems, LLC

9701-0104 SLOPE EXTENSION

9701-0246 SLOPE EXTENSION WITH ROLLER (OPTIONAL)

37

TOLERANCES

(UNLESS OTHERWISE NOTE D)

FRACTIONAL: 1/32"

DECIMAL:

.00 =

.01"

MATERIAL

DRAWN BY

CHECKED BY

DRAWING NO.

DATE

ST 2/28/2012

FILLER WELDMENT 2" PROJECTION

P O W E R A M P

M C G U I R E

D L M

S Y S T E M S, I N C.

L o a d i n g D o c k E q u i p m e n t

STOCK NO.

PARTS

Cantilever Brackets

26”

15”

2”

2

26”

1

28”

28”

38

Note:

• 2” and 15” brackets shown for visual reference.

Item Part Number Projection

1 9703-0005 2”

9703-0009 3”

9703-0004 4”

9703-0011 5”

9703-0010 6”

9703-0012 7”

9703-0003 8”

9703-0013 9”

9703-0002 10”

9703-0014 11”

9703-0001 12”

2 9703-0016 15”

9703-0015 13”

9703-0017 14”

4111-0073 — Sept. 2018

© 2018 Systems, LLC

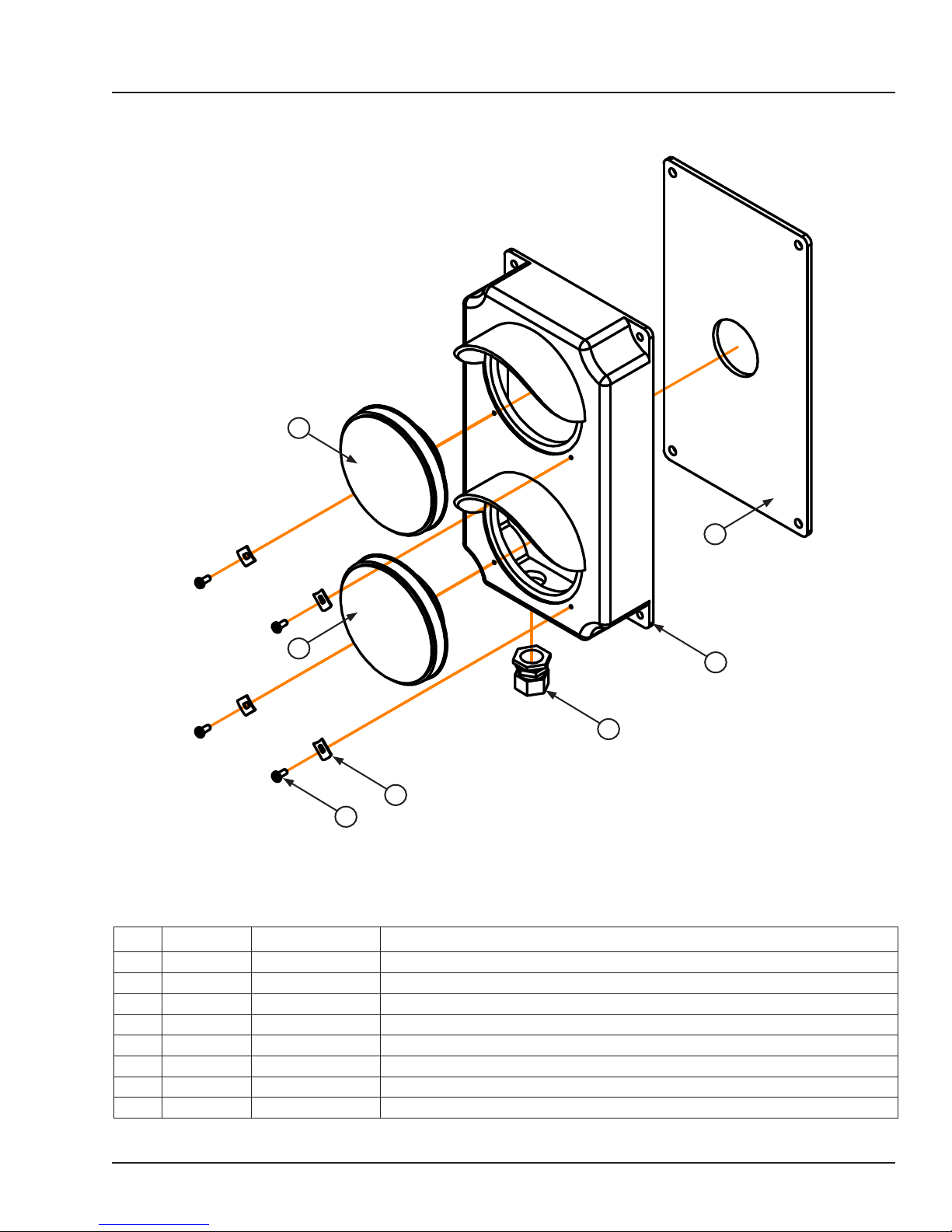

OSLA (Outside Light Assembly)

LOADING DOCK CONTROL LIGHTS

S Y S T E M S, I N C.

L o a d i n g D o c k E q u i p m e n t

2

PARTS

4

3

7

5

6

Item Quantity Part Number Description

1-7 1 3055-0011 Complete Light Housing, Yellow Plastic, With LED Lights

1 1 3051-0002 Light Housing Only, Yellow Plastic

2 1 3051-0147 Red LED Lens/Housing/Circuit Assembly, 12v

3 1 3051-0149 Green LED Lens/Housing/Circuit Assembly, 12v

4 1 3051-0068 Mounting Gasket

5 4 3051-0105 Clip, Lens Holding

6 4 3051-0104 Screw, Lens Holding

7 1 * Conduit Fastener, 3/4” x 3/8”

1

4111-0073 — Sept. 2018

© 2018 Systems, LLC

39

PARTS

Signs

1

3

Item Part Number Description

1 1751-0033 Outside Sign

2 1751-0034 Outside Sign (Mirror Image)

3 1751-0036 Inside Sign, Enter On Green

40

2

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Customer Information

MISCELLANEOUS

Figure 27

Figure 26

NOTE: Refer to Figure 26 for orientation of vehicle

restraint and Figure 27 for example of decals.

The model/serial number decal is located on the

right side panel of the restraint.

When you receive your new equipment, write down the

model and serial number in the form provided. This will

help ensure safe keeping of the numbers in the event

the model/serial number decal (A, B) becomes lost or

damaged.

Also, write down Systems, LLC’s order number, the

company that installed the equipment, and the original

owner’s name. This will all help to identify the specific

equipment if more information is required.

When ordering, use part numbers and description to help

identify the item ordered. Do not use “item” numbers.

These are only for locating the position of the parts. Always

give MODEL NUMBER and/or SERIAL NUMBER.

Serial Number

Carriage Number

Dock Leveler Information

Model ___________________________________

Serial No. ________________________________

Systems, LLC, Job No. ______________________

Vehicle Restraint Information

Model ___________________________________

Serial No. ________________________________

Systems, LLC Order No. ______________________

Original Owner Information

Name ___________________________________

For service, call or contact:

Systems, LLC

P.O. Box 309

Germantown, WI 53022

Phone: (800) 643-5424

Fax: (262) 255-5917

www.loadingdocksystems.com

4111-0073 — Sept. 2018

© 2018 Systems, LLC

Address _________________________________

________________________________

Installer Information

Name ___________________________________

Address _________________________________

_________________________________

Date of Installation ________________________

41

STANDARD PRODUCT WARRANTY

SYSTEMS, LLC warrants that its products will be free from defects in design, materials and workmanship

for a period of one (1) year from the date of shipment. All claims for breach of this warranty must be made

within 30 days after the defect is or can with reasonable care, be detected. In no event shall any claim

be made more than 30 days after this warranty has expired. In order to be entitled to the benefits of this

warranty, the product must have been properly installed, maintained and operated in accordance with all

manufacturer’s recommendations and/or specified design parameters and not otherwise have been subject

to abuse, misuse, misapplication, acts of nature, overloading, unauthorized repair or modification, application

in a corrosive environment or lack of maintenance. Periodic lubrication, adjustment and inspection in

accordance with all manufacturers’ recommendations are the sole responsibility of the Owner/User.

In the event of a defect, as determined by SYSTEMS LLC, covered by this warranty, SYSTEMS LLC shall

remedy such defect by repairing or replacing any defective equipment or parts, bearing the cost for the

parts, labor and transportation. This shall be exclusive remedy for all claims whether based on contract,

negligence or strict liability.

WARRANTY LIMITATIONS

THE ABOVE WARRANTIES ARE IN LIEU OF ANY OTHER WARRANTIES, WHETHER EXPRESSED OR

IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. SYSTEMS LLC AND ITS SUBSIDIARIES SHALL NOT IN ANY

EVENT BE LIABLE TO ANYONE, INCLUDING THIRD PARTIES, FOR INCIDENTAL, CONSEQUENTIAL

OR SPECIAL DAMAGES OF ANY KIND INCLUDING BUT NOT LIMITED TO, BREACH OF WARRANTY,

LOSS OF USE, LOSS OF PROFIT, INTERRUPTION OF BUSINESS OR LOSS OF GOODWILL.

Loading...

Loading...