McElroy TracStar 28, TracStar 412, TracStar 618 Operator's Manual

Operator’s

Manual

TracStar® No.28

TracStar® No.412

TracStar® No.618

Fusion Machines

Patent No’s. 5,814,182 6,212,748 6,212,747 6,021,832

(other patents pending)

Manual: T1210801 Revision: C 7/04

California

Proposition 65 Warning

Engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects, or other reproductive harm.

Introduction

Thank you for purchasing this

McElroy product

The McElroy TracStar

contained, self-propelled, all terrain fusion machine,

and is designed to produce consistently high quality

polyolefin pipe butt fusion joints with a minimum of

operator effort.

The TracStar® No.28 model fuses 2” IPS (63mm)

minimum to 8” DIPS (225mm) maximum pipe.

The TracStar® No.412 model fuses 4” IPS (110mm)

minimum to 12” DIPS (340mm) maximum pipe.

The TracStar® No.618 model fuses 6” IPS (180mm)

minimum to 18”IPS (450mm) maximum pipe.

With reasonable care and maintenance, this machine

will give years of exemplary service.

TX01853-9-27-00

®

No.28/No.412/No.618 self-

World Class Training

This manual is intended as a guide only and does not

take the place of proper training by qualified instructors.

The information in this manual is not all inclusive and

can not encompass all possible situations that can be

encountered during various operations.

Before operating this machine, please read this manual

thoroughly, and keep a copy with the machine for future

reference. This manual is to be considered part of your

machine.

Always return the manual to the literature compartment.

PH01894-9-27-00

Patent No’s. 5,814,182 6,212,748 6,212,747 6,021,832

(other patents pending)

McElroy Manufacturing, Inc., offers advanced training

classes to enhance efficiency, productivity, safety and

quality. Training is available at our facility or on-site at

your location. Call (918) 836-8611.

TX01315-4-7-97

8-15-97

PH00917-

Warranty

LIMITED WARRANTY

McElroy Manufacturing, Inc. guarantees this product to

the original purchaser against workmanship and material

defects for three (3) years from date of shipment, with the

exception of purchased items (such as electronic devices,

pumps, switches, etc.), in which case that manufacturer's

warranty applies. This warranty does not apply to any

product or component which has been repaired or

altered by anyone other than McElroy Manufacturing,

Inc., or has become damaged due to misuse, negligence

or casualty, or has not been operated or maintained

according to McElroy Manufacturing, Inc.'s printed

instructions and warnings.

Claims cannot be allowed until the questioned product

has been received, freight prepaid, at the manufacturer's

factory, with complete information and data regarding

the failure. Materials returned to McElroy Manufacturing,

Inc. for warranty work, repair, etc., must have a Return

Material Authorization (RMA) number, and be so noted

on the package at time of shipment. This number may be

obtained by calling (918) 836-8611. If seller's review

indicates that warranty applies, the defective product

will be repaired or replaced and returned to purchaser

F.O.B. Tulsa, Oklahoma.

McElroy Manufacturing, Inc. is not responsible or

liable for loss of any sort including incidental and

consequential damages.

McElroy Manufacturing, Inc. specifically disavows any

other representations as to warranty or liability, related to

the condition or use of the product.

For assistance, inquiries shall be directed to McElroy

Manufacturing, Inc., P.O. Box 580550, 833 North

Fulton, Tulsa, Oklahoma 74158-0550, (918) 836-8611,

Fax No. (918) 831-9285, www.mcelroy.com

Register Your Warranty Online:

www.mcelroy.com

DISCLAIMER OF LIABILITY

McElroy Manufacturing, Inc. accepts no responsibility of

liability for fusion joints. Operation and maintenance of

the product is the responsibility of others. We recommend

qualified joining procedures be followed when using

McElroy fusion equipment.

McELROY MAKES NO OTHER WARRANTY OF ANY

KIND WHATEVER, EXPRESS OR IMPLIED; AND ALL

IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE WHICH

EXCEED THE AFORESTATED OBLIGATION ARE HEREBY

DISCLAIMED BY McELROY.

PRODUCT IMPROVEMENT

McElroy Manufacturing, Inc. reserves the right to make

any changes in or improvements on its products without

incurring any liability or obligation to update or change

previously sold machines and/or the accessories thereto.

TERMS AND CONDITIONS

Net 30 Days - Subject to credit approval. A carrying

charge of 1-1/2% per month computed from invoice

date will apply to invoices not paid within 30 Day Terms.

McElroy Manufacturing, Inc. must be notified of any

discrepancy in shipment, order, and/or invoice within 10

days after receipt.

Freight is F.O.B. Tulsa, Oklahoma - usually motor freight

collect or UPS unless otherwise specified.

Prices are subject to change without notice.

Minimum order is $50.00.

(Copy information listed on the Warranty Card for your

records).

Model No. ________________________________________

Serial No. ________________________________________

Date Received _____________________________________

Distributor _________________________________________

TX01901-11-15-00

Equipment Safety

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Read and Understand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Wear Safety Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Fuel Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Units with Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Carbon Monoxide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Heater is Not Explosion Proof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Electric Motors and Alternators are Not Explosion Proof . . . . . . . . . . . . 1-3

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Crush Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Facer Blades are Sharp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Units with Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Keep Machine Away from Edge of Ditch . . . . . . . . . . . . . . . . . . . . . . 1-6

Operating Fusion Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Do Not Attempt to Tow Fusion Machine . . . . . . . . . . . . . . . . . . . . . . . 1-6

Heater is Hot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Fusion Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Periodically Check Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Hearing Protection Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Positioning Fusion Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Table of Contents

Overview

Theory of Heat Fusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Carriage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Gas Powered Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Tach and Hour Meter for Gas Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Diesel Powered Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Diesel & Gas Engine Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Power for Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Oil Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Hydraulic Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Hydraulic Manifold Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Hydraulic Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Facer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Insulated Heater Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

COPYRIGHT © 2004

McELROY MANUFACTURING, INC.

Tulsa, Oklahoma, USA

All rights reserved

All product names or trademarks are property of their respective owners. All information,

illustrations and specifications in this manual are based on the latest information available

at the time of publication. The right is reserved to make changes at any time without notice.

Operation

Table of Contents

Read Before Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Check Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Gas Powered Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Moving Machine into Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Prepare Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Set up Pipe Supports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Install Clamping Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Check Hydraulic Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Loading Pipe Into Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Positioning Pipe in Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Facing the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Remove Facer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Position Carriage for Heater Insertion . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Check Heater Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Select the Fusion Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Inserting Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Heating the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Fusing the Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Opening Movable Jaws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Opening Fixed Jaws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Raise Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Hydraulic Pipelifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Position Pipe for Next Joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Install Next Piece of Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Special Operations - In Ditch

Disconnect Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Remove Carriage Assembly from the Chassis . . . . . . . . . . . . . . . . . . . 4-1

Remove 3-Jaw Assembly from the Carriage . . . . . . . . . . . . . . . . . . . . 4-2

Remove Facer from TracStar No.412 & No.618 . . . . . . . . . . . . . . . . . 4-3

Remove Facer from TracStar No.28 . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Manual Facer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Removing Top Jaws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Lower 3-Jaw or 4-Jaw Carriage into Ditch . . . . . . . . . . . . . . . . . . . . . 4-6

Clamp Carriage Assembly to Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Attach Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Make Fusion Joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Remove Carriage Assembly from Ditch . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Reassemble Fusion Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Special Operations - Saddle Fusion Procedures

Saddle Fusion Procedure for TracStar No.28 . . . . . . . . . . . . . . . . . . . 5-1

Install Heater Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Assure Saddle will Fit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Install Clamping Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Remove Carriage Assembly from Vehicle . . . . . . . . . . . . . . . . . . . . . . 5-2

Attach Carriage Assembly to Main . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Set Hydraulic Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Clean Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Table of Contents

Special Operations - Saddle Fusion Procedures - Continued

Clamp Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Test for Slippage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Prepare Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Heat Pipe and Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Remove Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Fuse Fitting to Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Allow Joint to Cool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Special Operations - Lifting the Machine

Heavy Overhead Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Crush Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Required Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Attach Slings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Lifting Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Maintenance

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Washing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Check Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Change Hydraulic Fluid and Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Install/Remove Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Engine Belt Tension Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Tensioning the Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Adjusting System Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Engine Oil System - Diesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Engine Oil System - Gasoline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Check Gauge Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Clean Jaws and Inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Clean Thrust Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Clean Eyebolt Threads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Clean the Clamping Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Fasteners Must Be Tight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Facer Blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Check/Add Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Clean Heater Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Bleeding Air From Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Installing Butt Fusion Heater Adapter . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Adjusting Heater Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Indicator Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Checking Track Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Adjusting Track Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Setting Engine Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Machine Maintenance Checklist

Machine Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Determining Fusion Pressure

Determining Fusion Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Hydraulic Fluid

Hydraulic Fluid Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Specifications

TracStar® No.28 & No.412 Fusion Machine Specifications . . . . . . . . . 11-1

TX02032-7-8-02

TracStar® No.618Fusion Machine Specifications . . . . . . . . . . . . . . . . 11-2

Safety Alerts

Fusion Equipment Safety

This hazard alert sign appears in this manual.

When you see this sign, carefully read what it says.

YOUR SAFETY IS AT STAKE.

You will see the hazard alert sign with these words:

DANGER, WARNING, and CAUTION.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation which,

if not avoided, may result in minor or

moderate injury.

In this manual you should look for two other words:

NOTICE and IMPORTANT.

NOTICE: can keep you from doing something that might

damage the machine or someone's property. It may also

be used to alert against unsafe practices.

IMPORTANT: can help you do a better job or make

your job easier in some way.

-11-30-92

WR00051

TX00030-12-1-92

Read and Understand

Do not operate this equipment until you have carefully read, and

understand the "Safety" and "Operation" sections of this manual,

and all other equipment manuals that will be used with it.

Your safety and the safety of others depends upon care and

judgment in the operation of this equipment.

Follow all applicable federal, state, local, and industry specific

regulations.

McElroy Manufacturing, Inc. cannot anticipate every possible

circumstance that might involve a potential hazard. The warnings

in this manual and on the machine are therefore not all inclusive.

You must satisfy yourself that a procedure, tool, work method, or

operating technique is safe for you and others. You should also

ensure that the machine will not be damaged or made unsafe by

the method of operation or maintenance you choose.

TX00031-12-8-92

WR00052-12-1-92

1 - 1

Fusion Equipment Safety

General Safety

Safety is important. Report anything unusual that you notice

during set up or operation.

LISTEN for thumps, bumps, rattles, squeals, air leaks, or unusual

sounds.

SMELL odors like burning insulation, hot metal, burning rubber,

hot oil, or natural gas.

FEEL any changes in the way the equipment operates.

SEE problems with wiring and cables, hydraulic connections, or

other equipment.

REPORT anything you see, feel, smell, or hear that is different from

what you expect, or that you think may be unsafe.

TX00114-4-22-93

T-12-22-92

S

SAFE1

Wear Safety Equipment

Wear a hard hat, safety shoes, safety glasses, and other

applicable personal protective equipment.

Remove jewelry and rings, and do not wear loose-fitting clothing

or long hair that could catch on controls or moving machinery.

TX00032-4-7-93

Fuel Handling

Gasoline and diesel fuel are extremely flammable

and their vapors will explode if ignited.

Do not fill the fuel tank while the engine is hot or running, as

spilled fuel could ignite.

Refuel in a well ventilated area. Do not smoke or allow flames

or sparks in the area where the engine is refueled, or where

gasoline is stored.

Do not start the engine near spilled fuel. Wipe up spills

immediately.

Maker sure the fuel tank cap is closed and properly secured.

Avoid repeated or prolonged contact with skin or breathing of

vapor.

WR00053-12-2-92

-2-19-97

CD00365

FUEL

TX00953-2-19-97

1 - 2

Fusion Equipment Safety

Units With Engines

Combustion engines can cause explosions when

operated in a hazardous environment. Do not

operate gas or diesel powered machines in a

hazardous environment.

When operating in a hazardous environment, keep engine and

chassis in a safe area by using hydraulic extension hoses.

Help prevent fires by keeping machine clean of accumulated

trash, debris and facer shavings.

TX01266-2-21-97

Carbon Monoxide

Engine exhaust gases contain carbon monoxide

which can cause severe nausea, fainting and

death. Avoid inhaling exhaust fumes and never

run the engine in a closed or confined area.

WR00080-4-12-93

WR00093-5-14-96

TX00954-5-14-96

Heater Is Not Explosion Proof

The heater is not explosion proof. Operation

of heater is a hazardous environment without

necessary safety precautions will result in

explosion and death.

If operating in a hazardous environment, the heater should be

brought up to temperature in a safe environment, then unplugged

before entering the hazardous atmosphere for fusion.

TX00100-9-16-94

Electric Motors and Alternators are Not

Explosion Proof

Electric motors are not explosion proof. Operation

of these components in a hazardous environment

without necessary safety precautions will result in

explosion and death.

When operating in a hazardous environment, keep pump motor

and chassis in a safe area by using hydraulic extension hoses.

WR00034-11-30-92

WR00080-4-12-93

TX00424-8-12-94

1 - 3

Battery

Fusion Equipment Safety

Do not expose the battery to flames or electrical

sparks. Hydrogen gas generated by battery action

is explosive. Blindness or serious injury can result

from an exploding battery.

Do not allow battery fluid to contact your skin, eyes,

fabrics, or painted surfaces. Sulfuric acid can cause

burns. After touching a batter or battery cap, do not

touch or rub your eyes.

Thoroughly wash your hands. If the acid contacts

your eyes, skin or clothing, immediately flush with

water for at least 15 minutes and seek medical

attention.

CD00176-9-14-95

CD00177-9-14-95

TX00650-9-14-95

Electrical Safety

Always ensure power cords are properly

grounded. It is important to remember that you

are working in a wet environment with electrical

devices. Proper ground connections help to

minimize the chances of an electric shock.

Frequently inspect electrical cords and unit for damage. Have

damaged components replaced and service performed by a

qualified electrician.

Do not carry electrical devices by the cord.

NOTICE: Always connect units to the proper power source as

listed on the unit, or in the owner's manual. On units with two

power cords, plug each cord into separate power circuits. Do not

plug into both outlets of one duplex receptacle.

NOTICE: Disconnect the machine from the power source before

attempting any maintenance or adjustment.

WR00055-4-7-93

WR00025-11-30-92

TX00105-4-12-93

1 - 4

Fusion Equipment Safety

Crush Points

Hydraulically operated jaws are operated under

pressure. Anything caught in the jaws will be

crushed. Keep fingers, feet, arms, legs, and

head out of the jaw area. Always check pipe

alignment with a pencil or similar object.

TX00103-4-6-93

Facer Blades Are Sharp

Facer blades are sharp and can cut. Never

attempt to remove shavings while the facer is

running, or is in the facing position between the

jaws. Use care when operating the facer, and

when handling the unit.

NOTICE: Disconnect power from the facer, and remove the facer

blades before attempting any maintenance or adjustment.

WR00012-12-4-92

WR00073-4-6-93

TX00102-4-16-93

Units With Hydraulics

Although the hydraulic pressures in this machine are low

compared to some hydraulically operated equipment, it is

important to remember that a sudden hydraulic oil leak can cause

serious injury, or even be fatal if the pressure is high enough.

Escaping fluid under pressure can penetrate the

skin causing serious injury. Keep hands and

body away from pinholes which eject fluid under

pressure. Use a piece of cardboard or paper to

search for leaks. If any fluid is injected into the

skin, it must be immediately removed by a doctor

familiar with this type of injury.

NOTICE: Wear safety glasses, and keep face clear of area when

bleeding air from hydraulic system to avoid spraying oil into eyes.

WR00078-4-8-93

TX00110-8-23-95

1 - 5

Fusion Equipment Safety

0

100

200

300

400

500

600

700

800

900

1000

DIRECTIONAL

CONTROL

VALVE

FACING

PRESSURE

HEATING

PRESSURE

FUSING

PRESSURE

SELECTOR

VALVE

0

10

0

20

0

300

40

0

5

0

0

600

70

0

800

900

1

0

0

0

DIRECTIONAL

CONTROL

VALVE

FACING

PRESSURE

HEATING

PRESSURE

FUSING

PRESSURE

SELECTOR

VALVE

Keep Machine Away From Edge of Ditch

Heavy equipment too close to a ditch can

cause the walls of the ditch to cave-in. Keep

the machine far enough away from the edge

of the ditch to prevent injury to personnel and

equipment from a cave-in.

TX01447-12-30-97

Operating Fusion Machine

Place fusion machine on as level ground as possible.

If it is necessary to operate machine on unlevel grade, make

sure that the ground is stable. Some unstable conditions may be

ice, snow, mud and loose gravel.

For operation safety, never operate the machine

on a grade steeper than 30 %. (A 3 foot

elevation change in 10 feet)

CD00408b-9-27-00

CD00402c-9-27-00

3

TX011902-11-15-00

Do Not Attempt to Tow Fusion Machine

The machine is not designed for towing.

Attempting to tow the machine can result in

machine damage. Always transport the machine

by flat bed truck or similar means, and make sure

that unit is properly secured.

TX01888-11-15-00

Heater is Hot

The heater is hot and will burn clothing and skin.

Keep the heater in its insulated heater stand or

blanket when not in use, and use care when

heating the pipe.

NOTICE: Use only a clean non-synthetic cloth such as a cotton

cloth to clean the heater plates.

TX00104-8-12-94

10

CD00401b-9-27-00

WR00030-2-10-93

1 - 6

Fusion Equipment Safety

Fusion Procedures

Obtain a copy of the pipe manufacturer's procedures for the pipe

being fused. Follow the procedure carefully, and adhere to all

specified parameters.

Failure to follow pipe manufacturer's procedure

could result in a bad joint. Always follow pipe

manufacturer's procedures.

TX00113-4-12-93

Periodically Check Temperature

NOTICE: Incorrect heating temperature can result in bad fusion

joints. Check heater plate surface temperature periodically with a

properly calibrated pyrometer, and make necessary adjustments.

The thermometer on heaters indicates internal temperature, and

should be used as a reference only.

WR00079-1-24-96

WR00077-4-16-93

TX00107-11-13-95

Positioning Fusion Machine

Place fusion machine on as level ground as possible. If it is necessary to

operate machine on unlevel grade, chock the tracks and block the unit to

make it as stable as possible.

TX01889-11-15-00

Hearing Protection Required

When operating machine for more than 4 hours per day wear

hearing protection.

CD00633-9-27-00

WR00028-1-24-96

TX01890-11-15-00

1 - 7

Overview

Theory of Heat Fusion

The principle of heat fusion is to heat two surfaces to a

designated temperature, and then fuse them together by

application of force. This pressure causes flow of the melted

materials, which causes mixing and thus fusion. When the

polyethylene material is heated, the molecular structure is

transformed from a crystalline state into an amorphous condition.

When fusion pressure is applied, the molecules from each

Polyethylene part mix. As the joint cools, the molecules return to

their crystalline form, the original interfaces are gone, and the

fitting and pipe have become one homogeneous unit. The joint

area becomes as strong as the pipe itself in both tensile and

pressure conditions.

The principle operations include:

Clamping The pipe pieces held axially to allow all subsequent

operations to take place.

Facing The pipe ends must be faced to establish clean,

parallel mating surfaces perpendicular to the

centerline of the pipes.

Alignment The pipe ends must be aligned with each other to

minimize mismatch or high-low of the pipe walls.

Heating A melt pattern that penetrates into the pipe must be

formed around both pipe ends.

Joining The melt patterns must be joined with a specified

force. The force must be constant around the interface

area.

Holding The molten joint must be held immobile with a

specified force until adequately cooled.

PH00363B-1-4-96

Each pipe manufacturer has a slightly different approach for

fulfilling the heating, joining, and holding phases, but the end

result is the same -- a fusion joint that is as strong or stronger than

the pipe itself.

TX00441-9-22-94

2 - 1

Overview

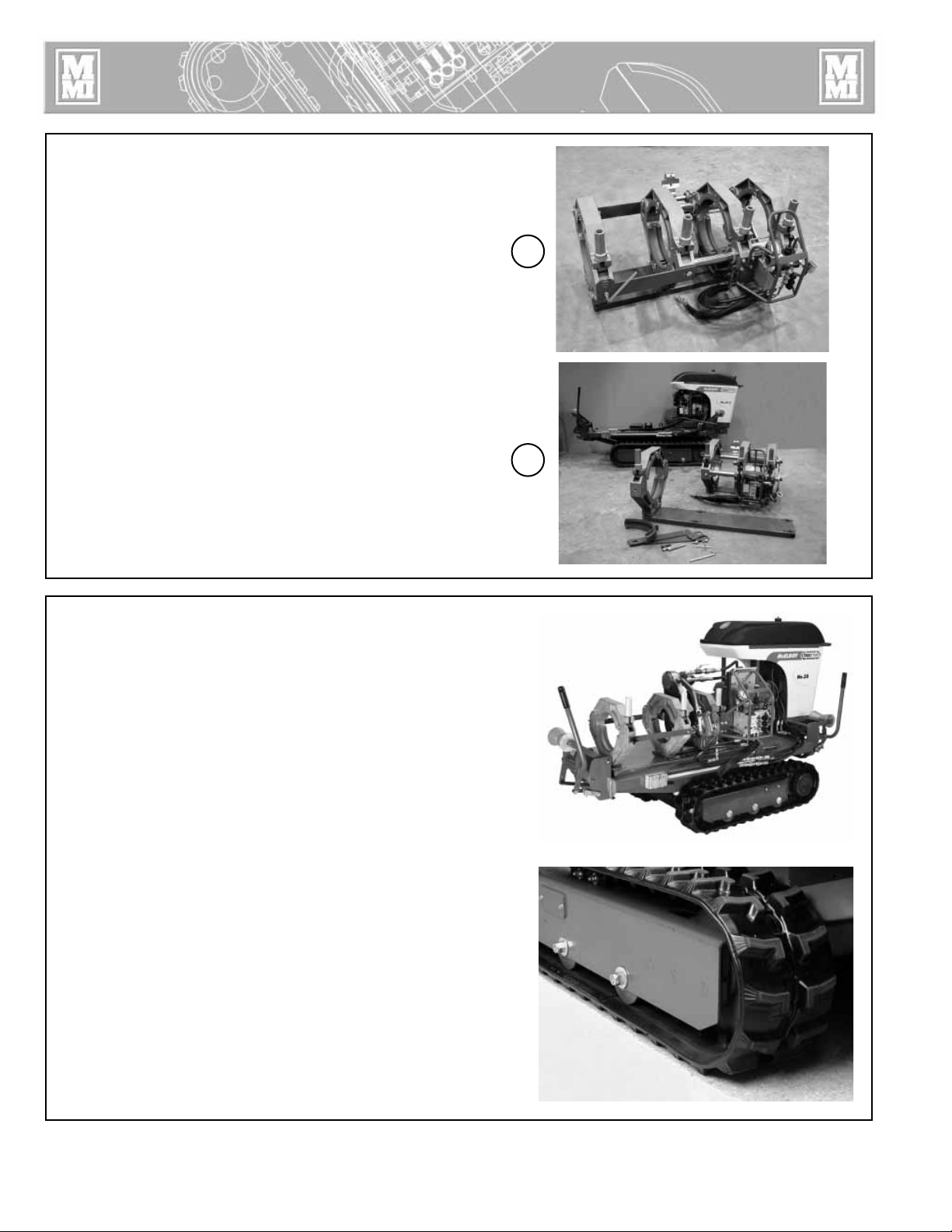

Carriage Assembly

The carriage assembly consists of two fixed jaws and two

hydraulically operated movable jaws bolted to the skid. For

remote operation the carriage can be set in ditch and connected

to the machine with optional hydraulic extension hoses.The

carriage assembly (A) can be disconnected from the chassis (B)

and removed for remote operation. The optional extension hose

kit is required for this operation.

For tight installations the outer fixed jaw and skid can be removed

from the carriage for an even more compact fusion unit.

A

PH01940-11-15-00

TX01891-11-15-00

Chassis

The carriage assembly is mounted on a track driven chassis for

easy loading and movement along the pipe line.

The engine powers an alternator, used to power the heater, and a

hydraulic pump, which powers the fusion machine and the track

drive. A belt drive is used to transfer the power. The hydraulic

reservoir is mounted above the engine. The fuel tank and battery

are installed between the tracks.

B

PH01953-11-15-00

PH01966-11-15-00

TX01854-11-15-00

PH01959-11-15-00

2 - 2

Overview

Gas Powered Units

Read the operating and maintenance instructions for the engine

before operating.

The engine is a single cylinder, overhead valve, air cooled

design. It uses a vacuum operated fuel pump.

The fuel shutoff valve is located by the carburetor.

PH01965-11-15-00

PH02243-1-10-02

TX01987-1-10-02

Tach and Hour Meter for Gas Unit

When the unit is running, the engine speed is displayed. When

the unit is not running, total hours of engine operation are

displayed.

On diesel powered units an hour meter is provided in the same

location.

TX01892-11-15-00

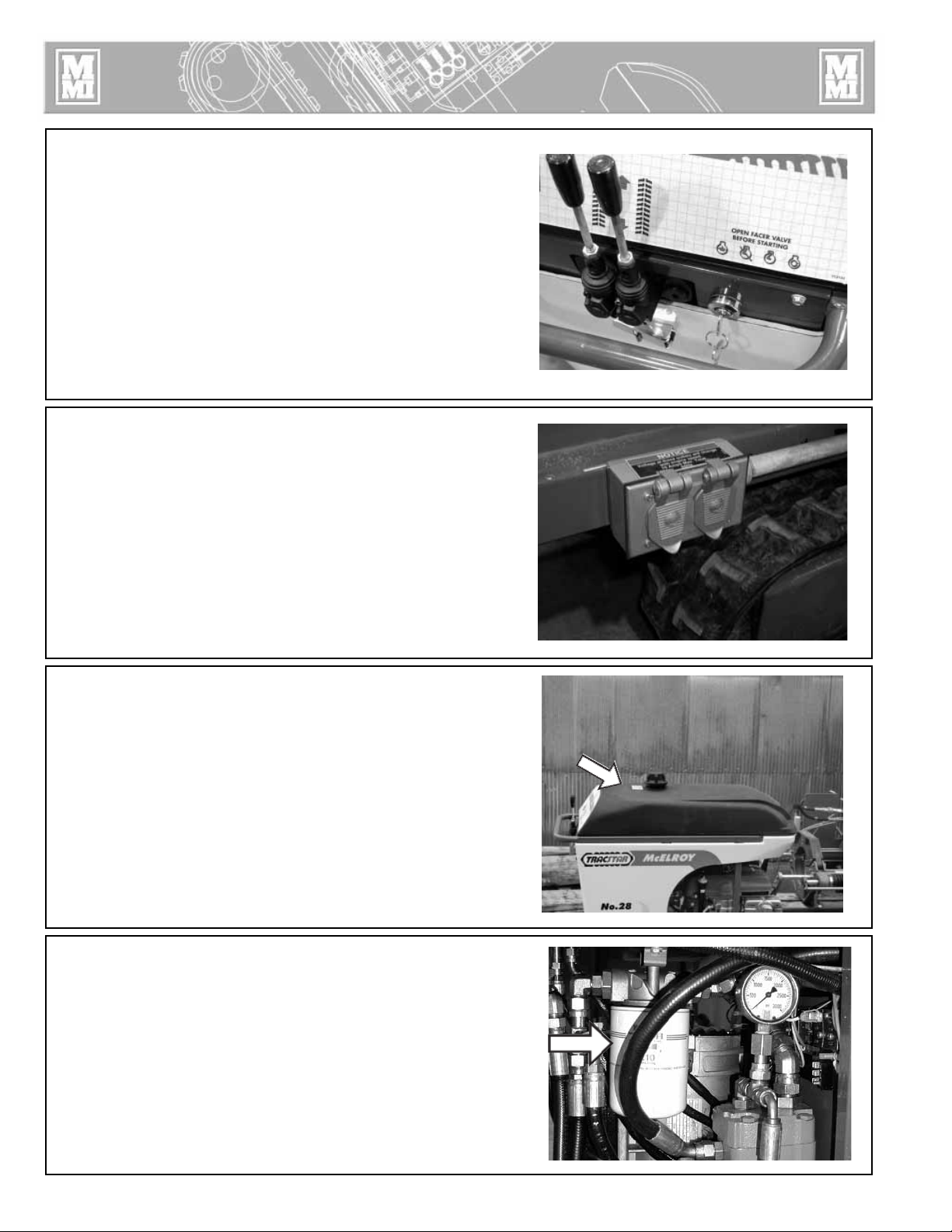

Diesel Powered Units

Read the operating and maintenance instructions for the engine

before operating.

The engine is a twin cylinder water cooled design. It uses an

electric fuel pump located near the fuel tank.

PH01988-11-15-00

PH01960-11-15-00

TX01855-11-15-00

2 - 3

Overview

Diesel Engine Controls

Read the operating and maintenance instructions for the engine

before operating.

There is a key ignition on the console that shows the preheat off,

run, and start positions.

Gas Engine Controls

Choke and throttle control is on the dash.

There is a key ignition on the console that shows the off, run, and

start positions.

TX01986-1-10-02

Power for Heater

The heater cord plugs into a receptacle on the frame.

The 110V receptacle is used for the No.28 Butt Fusion Heater.

The 220V receptacle is used for the No.412 Butt Fusion Heater

and the No.28 Sidewall Heaters.

PH01969-11-15-00

PH01922-11-15-00

TX01856-9-28-00

Oil Reservoir

The oil reservoir is located above the engine.

TX02306-7-28-04

Hydraulic Oil Filter

This machine is equipped with a 10 Micron filter on the return

side of the hydraulic system.

PH02709-07-29-04

PH01916-11-15-00

TX01893-11-15-00

2 - 4

Overview

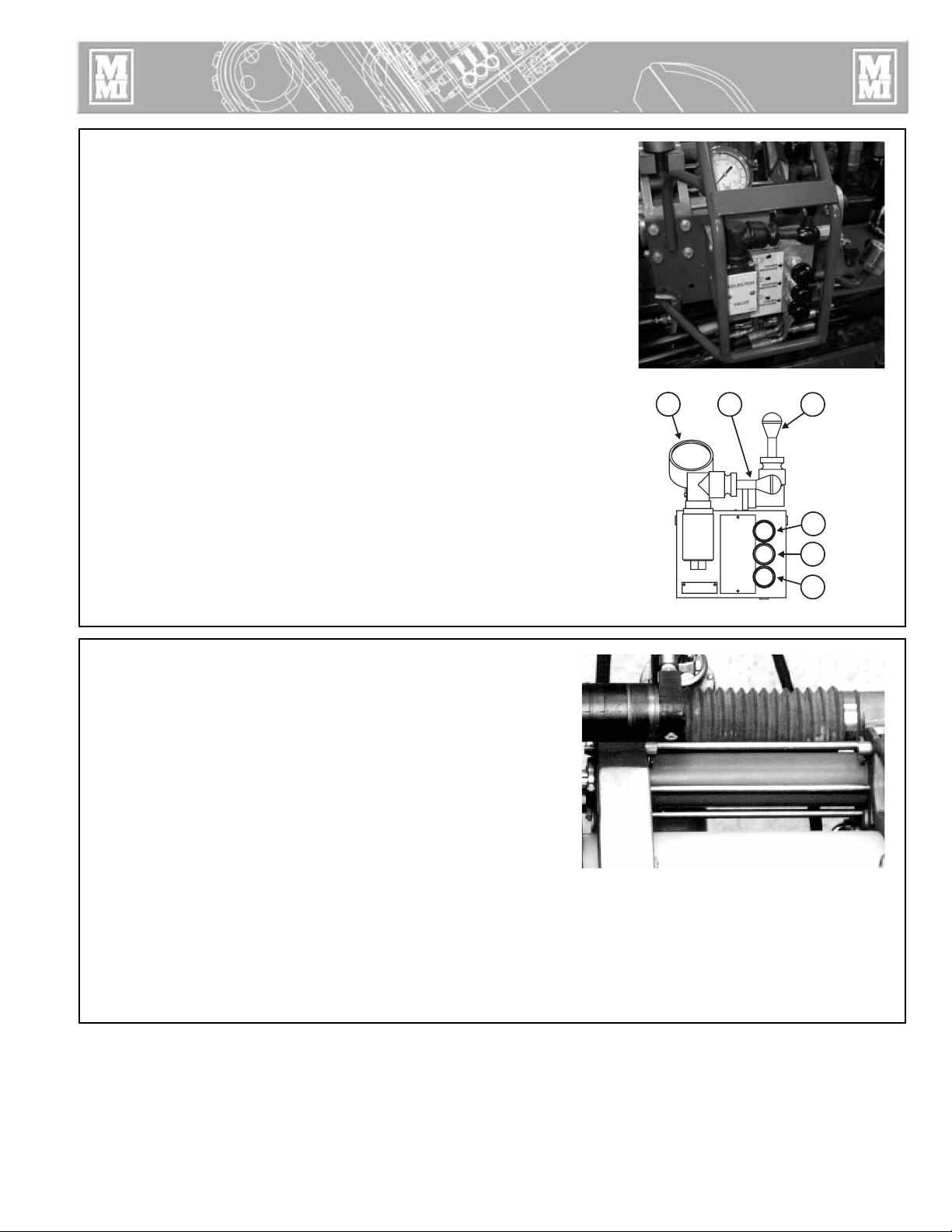

Hydraulic Manifold Block

Mounted on this block are a carriage directional control valve, a

pressure reducing selector valve, three pressure reducing valves,

and a 1500 psi gauge.

A) The carriage control valve, mounted on the top of the

manifold, determines whether the carriage is moving left,

right, or is in neutral.

B) A 1500 psi gauge is mounted on top of the manifold.

C) The selector valve, mounted on the front of the manifold,

selects a reduced pressure from one of the pressure reducing

valves.

Each pressure reducing valve is labeled with a different function:

D) The top valve adjusts facing pressure to a maximum of 400

psi.

E) The middle valve adjusts heating pressure to a maximum of

400 psi.

F) The bottom valve adjusts fusion pressure to a maximum of

1500 psi.

TX00357-11-3-94

B

C A

FACING

HEATING

FUSING

PH01924-11-15-00

CD00138A-9-12-94

D

E

F

Hydraulic Cylinders

HIGH FORCE hydraulic carriage cylinders are painted green.

High force cylinders are used when higher interfacil pressures are

required, when handling heavy wall pipe, or when large drag

factors need to be overcome.

MEDIUM FORCE cylinders are painted orange and have

approximately half the total effective piston area as High Force

cylinders. The cylinders move faster and are normally used for

medium density pipe and when lower interfacial pressures are

used.

LOW FORCE cylinders are painted yellow. These cylinders should

be selected when fusing pipe with a very low interfacial pressure

(22 psi).

TX01270-2-21-97

PH00410-9-22-94

2 - 5

Loading...

Loading...