Operator’s

Manual

MegaMc®

Hydraulic Pipe

Stand

Manual: 6513401 Revision: A 12/18

Original Language: English

Cancer and Reproductive Harm www.P65warnings.ca.gov

This product and other products

could be protected by patents or

have patents pending. All the latest

patent information is available at

patent.mcelroy.com

8163361

Introduction

Thank you for purchasing this McElroy product.

The McElroy® MegaMc® Pipe Stand allows efficient alignment

of pipe in the fusion machine jaws. Using the pipe stand's

34" vertical and 24" lateral adjustments, the pipe is efficiently

aligned with the fusion machine jaws. Aligning the pipe

quickly reduces the overall cycle time for the joint, increasing

productivity. Good alignment in the jaws means less stress

on the fusion machine, easier to close jaws and less hi-low

mismatch.

With reasonable care and maintenance, this machine will give

years of satisfactory service.

Before operating this machine, please read this manual

thoroughly, and keep a copy with the machine for future

reference. This manual is to be considered part of your machine.

TX03084-3-2-10

McElroy University

For more than 30 years, McElroy has been the only

pipe fusion machine manufacturer to continuously

offer advanced training. Course offerings are meant to

enhance your efficiency, productivity and safety in the

proper use of McElroy machines. McElroy University

classes are structured so that the skills learned and the

machines used in each class closely match the machines

found on pipelining jobsites. We offer training at

our facility or yours. Our uniquely qualified McElroy

University course instructors offer years of industry

experience.

Tuition for each course includes lunches, course materials

and a certificate of completion. Online registration,

as well as up-to-date course offerings and dates, is

available at www.mcelroy.com/university

This manual is intended as a guide only and does not

take the place of proper training by qualified instructors.

The information in this manual is not all inclusive and

can not encompass all possible situations that can be

encountered during various operations.

MU2-03-13-14

TX04659-03-24-14

Warranty

LIMITED WARRANTY

McElroy Manufacturing, Inc. (McElroy) warrants all

products manufactured, sold and repaired by it to be

free from defects in materials and workmanship, its

obligation under this warranty being limited to repairing

or replacing at its factory and new products, within 5

years after shipment, with the exception of purchased

items (such as electronic devices, pumps, switches, etc.),

in which case that manufacturer’s warranty applies.

Warranty applies when returned freight is prepaid and

which, upon examination, shall disclose to have been

defective. This warranty does not apply to any product

or component which has been repaired or altered by

anyone other than McElroy or has become damaged

due to misuse, negligence or casualty, or has not been

operated or maintained according to McElroy’s printed

instructions and warnings. This warranty is expressly in

lieu of all other warranties expressed or implied. The

remedies of the Buyer are the exclusive and sole remedies

available and Buyer shall not be entitled to receive any

incidental or consequential damages. Buyer waives

the benefit of any rule that disclaimer of warranty shall

be construed against McElroy and agrees that such

disclaimers herein shall be construed liberally in favor of

McElroy.

RETURN OF GOODS

Buyer agrees not to return goods for any reason except

upon the written consent of McElroy obtained in advance

of such return, which consent, if given, shall specify the

terms and conditions and charges upon which any such

return may be made. Materials returned to McElroy, for

warranty work, repair, etc., must have a Return Material

Authorization (RMA) number, and be so noted on the

package at time of shipment. For assistance, inquiry shall

be directed to:

McElroy Manufacturing, Inc.

P.O. Box 580550

833 North Fulton Street Tulsa, Oklahoma 74158-0550

PHONE: (918) 836–8611, FAX: (918) 831–9285.

EMAIL: fusion@McElroy.com

Note: Certain repairs, warranty work, and inquiries may

be directed, at McElroy’s discretion, to an authorized

service center or distributor.

DISCLAIMER OF LIABILITY

McElroy accepts no responsibility of liability for fusion

joints. Operation and maintenance of the product is the

responsibility of others. We recommend qualified joining

procedures be followed when using McElroy fusion

equipment.

McElroy makes no other warranty of any kind whatever,

express or implied; and all implied warranties of

merchantability and fitness for a particular purpose which

exceed the aforestated obligation are hereby disclaimed

by McElroy.

PRODUCT IMPROVEMENT

McElroy reserves the right to make any changes in or

improvements on its products without incurring any

liability or obligation to update or change previously sold

machines and/or the accessories thereto.

INFORMATION DISCLOSED

No information of knowledge heretofore or hereafter

disclosed to McElroy in the performance of or in

connection with the terms hereof, shall be deemed to be

confidential or proprietary, unless otherwise expressly

agreed to in writing by McElroy and any such information

or knowledge shall be free from restrictions, other than a

claim for patent infringement, is part of the consideration

hereof.

PROPRIETARY RIGHTS

All proprietary rights pertaining to the equipment or

the components of the equipment to be delivered by

McElroy hereunder, and all patent rights therein, arising

prior to, or in the course of, or as a result of the design

or fabrication of the said product, are exclusively the

property of McElroy.

LAW APPLICABLE

All sales shall be governed by the Uniform Commercial

Code of Oklahoma, U.S.A.

Register your product online to activate your warranty:

www.McElroy.com/fusion

(Copy information listed on the machine nameplate here

for your records).

TX02486-11-4-13

Model No.

Serial No.

Date Received

Distributor

Table of Contents

Equipment Safety

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Read and Understand . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Wear Safety Equipment . . . . . . . . . . . . . . . . . . . . . . . 1-2

Gas Powered Units . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Fuel Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Carbon Monoxide. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Crush Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Pipe Handling Safety . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Units with Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Operating on a Grade. . . . . . . . . . . . . . . . . . . . . . . . 1-5

Lifting Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Overview

MegaMc Pipe Stand . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Hydraulic Power Unit . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Fuel Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Engine Control Lever . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Hydraulic Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Operation

Read and Understand . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Check Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Check Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Starting the HPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Machine Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Stand Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Align Pipe with Fusion Machine. . . . . . . . . . . . . . . . . . 3-4

Lifting and Storage

Lifting Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Lifting the Pipe Stand . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Stacking Stands . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Lifting Sling Storage. . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Extended Period Storage . . . . . . . . . . . . . . . . . . . . . . 4-5

All product names or trademarks are property of their respective owners.All information, illustrations

and specifications in this manual are based on the latest information available at the time of

publication. The right is reserved to make changes at any time without notice.

COPYRIGHT © 2018, 2010

McELROY MANUFACTURING, INC.

Tulsa, Oklahoma, USA

All rights reserved

Table of Contents

Maintenance

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . 5-1

Washing the Machine . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Check Hydraulic Fluid . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Changing the Hydraulic Filter and Fluid . . . . . . . . . . . . 5-2

Pipe Stand Lubrication . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Lifting Slings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Fasteners Must Be Tight . . . . . . . . . . . . . . . . . . . . . . . 5-3

HPU Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Hydraulic Fluids

Hydraulic Fluids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Specifications

MegaMc® Hydraulic Pipe Stand. . . . . . . . . . . . . . . . . 7-1

Equipment Safety

Safety Alerts

This hazard alert sign appears in this manual.

When you see this sign, carefully read what it says.

YOUR SAFETY IS AT STAKE.

You will see the hazard alert sign with these words:

DANGER, WARNING, and CAUTION.

Indicates an imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation which,

if not avoided, may result in minor or

moderate injury.

In this manual you should look for two other words:

NOTICE and IMPORTANT.

NOTICE: can keep you from doing something that might

damage the machine or someone's property. It may also

be used to alert against unsafe practices.

IMPORTANT: can help you do a better job or make

your job easier in some way.

WR00051-11-30-92

TX00030-12-1-92

Read and Understand

Do not operate this equipment until you have carefully read,

and understand all the sections of this manual, and all other

equipment manuals that will be used with it.

Your safety and the safety of others depends upon care and

judgment in the operation of this equipment.

Follow all applicable federal, state, local, and industry specific

regulations.

McElroy Manufacturing, Inc. cannot anticipate every possible

circumstance that might involve a potential hazard. The warnings

in this manual and on the machine are therefore not all inclusive.

You must satisfy yourself that a procedure, tool, work method, or

operating technique is safe for you and others. You should also

ensure that the machine will not be damaged or made unsafe by

the method of operation or maintenance you choose.

WR00052-12-1-92

TX02946-4-15-09

1 - 1

Equipment Safety

General Safety

Safety is important. Report anything unusual that you notice during set

up or operation.

LISTEN for thumps, bumps, rattles, squeals, air leaks, or unusual sounds.

SMELL odors like burning insulation, hot metal, burning rubber, hot oil,

or natural gas.

FEEL any changes in the way the equipment operates.

SEE problems with wiring and cables, hydraulic connections, or other

equipment.

REPORT anything you see, feel, smell, or hear that is different from what

you expect, or that you think may be unsafe.

TX00114-4-22-93

SAFE1ST-12-22-92

Wear Safety Equipment

Wear a hard hat, safety shoes, safety glasses, and other applicable

personal protective equipment.

Remove jewelry and rings, do not wear loose-fitting clothing,

and tie back long hair that could catch on controls or moving

machinery.

TX00032-04-18-16

Gas Powered Units

Gasoline engines will cause explosions when

operated in a hazardous environment. Do not

operate gas powered machines in a hazardous

environment.

Do not place flammable substances near the engine while it is

operating.

A spark arrester is available as an optional part for this engine.

It is illegal in some areas to operate an engine without a spark

arrester. Check local laws and regulations before operating.

WR00053-12-2-92

WR00080-4-12-93

TX00955-5-14-96

1 - 2

Equipment Safety

FUEL

Fuel Handling

Gasoline and diesel fuel are extremely flammable

and their vapors will explode if ignited.

Do not fill the fuel tank while the engine is hot or running, as

spilled fuel could ignite.

Refuel in a well ventilated area. Do not smoke or allow flames or

sparks in the area where the engine is refueled, or where gasoline

is stored.

Do not start the engine near spilled fuel. Wipe up spills

immediately.

Make sure the fuel tank cap is closed and properly secured.

Avoid repeated or prolonged contact with skin or breathing of

vapor.

TX00953-2-19-97

CD00365c-3-31-97

Carbon Monoxide

Engine exhaust gases contain poisonous carbon

monoxide. Carbon monoxide can cause severe

nausea, fainting and death. Avoid inhaling

exhaust fumes, and never run the engine in a

closed or confined area.

TX00954-04-18-16

Crush Points

Hydraulically operated equipment operates

under high pressure and generates extremely

high forces. Anything inadvertently caught in

the machine will be crushed. Keep fingers, feet,

arms, legs, and head out of the machine while

operated. Always ensure machine power is off

before entering the machine for any reason.

WR00093-5-14-96

WR00012-12-4-92

TX03004-04-18-16

1 - 3

Equipment Safety

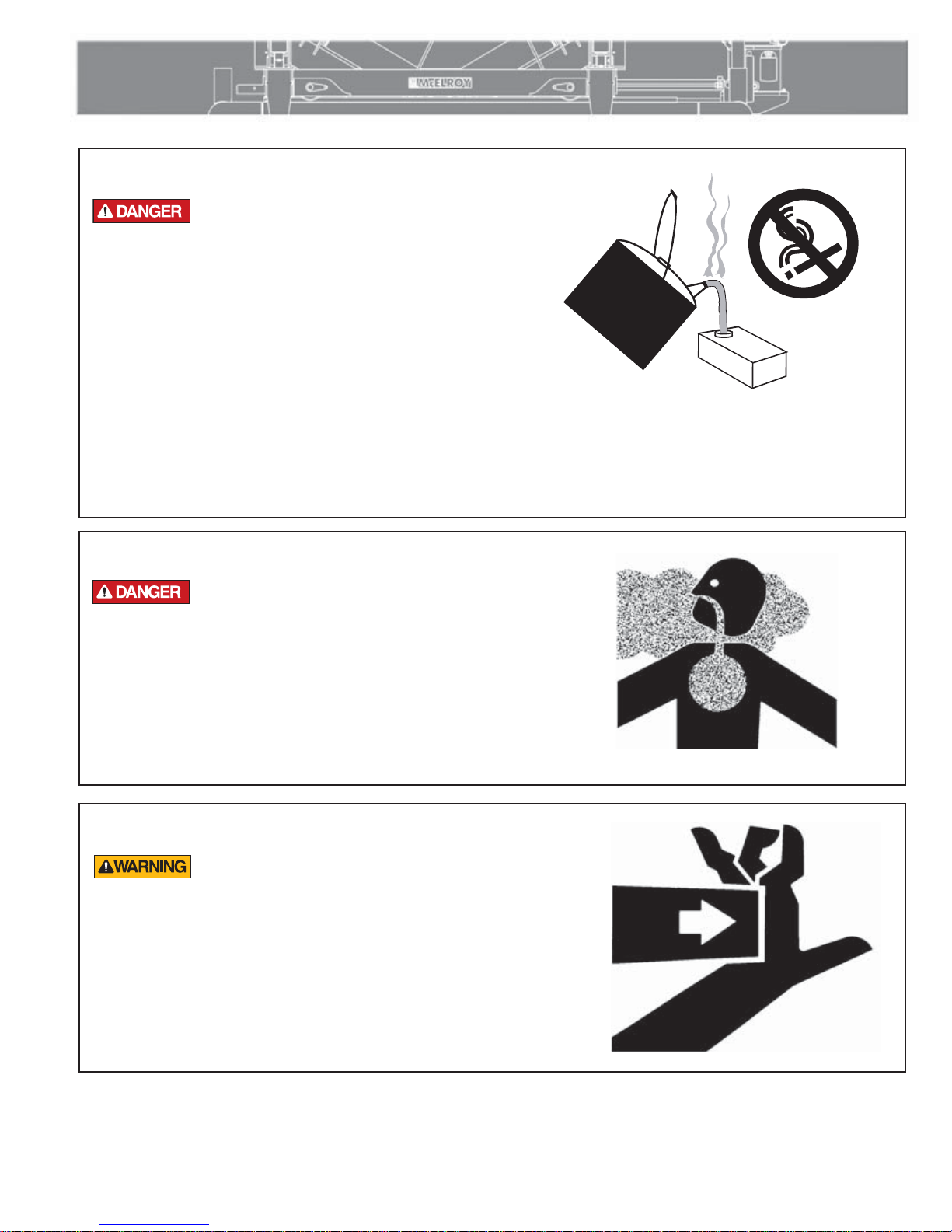

Pipe Handling Safety

Do not position yourself under supported

or raised pipe or near the end of the pipe.

Pipe could travel uncontrolled on the rollers

in either direction and cause serious injury

or death.

In order to minimize the potential for the pipe to travel

uncontrolled, keep the pipe level when it is placed on the

rollers of the fusion machine and on the rollers of the pipe

stand(s). Hold pipe securely by either clamping in the fusion

machine jaws or by other means.

NOTICE: Do not leave stand unattended while HPU is

running. When not operating the pipe stand, turn off the

HPU to prevent accidental or unintentional movement of the

stand.

IMPORTANT: Engine does not need to be running to hold

load. However, do not leave raised pipe unattended as the

hydraulic pressure may bleed off over time and lower the

load.

CD00785-1-13-10

CD00784-1-13-10

TX03057-3-2-10

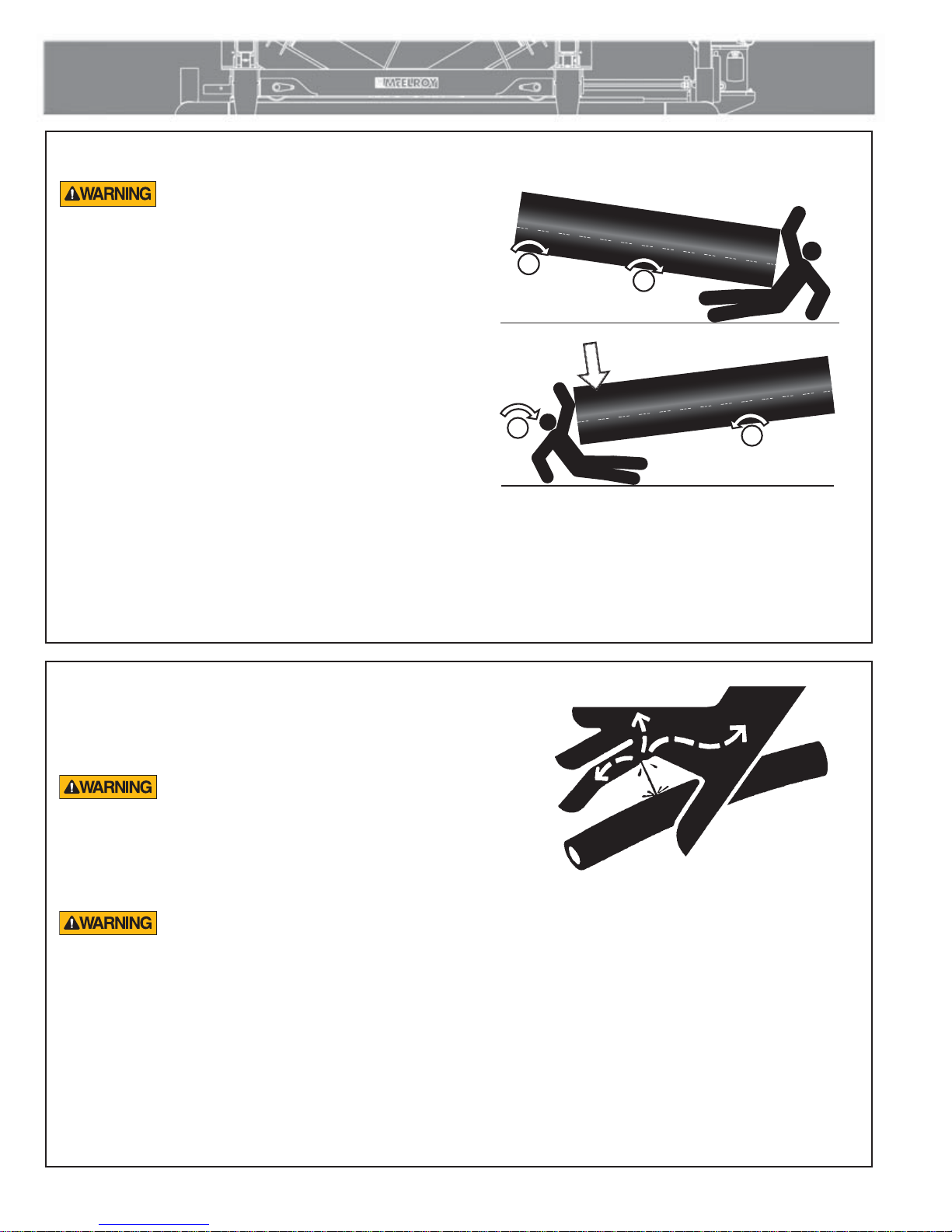

Units With Hydraulics

It is important to remember that a sudden hydraulic oil leak

can cause serious injury, or even be fatal if the pressure or oil

temperature is high enough.

Escaping fluid under pressure can penetrate the

skin causing serious injury. Keep hands and

body away from pinholes which eject fluid under

pressure. Use a piece of cardboard or paper to

search for leaks. If any fluid is injected into the

skin, it must be immediately removed by a doctor

familiar with this type of injury.

Unwanted movement of the machine could result

in serious injury or damage to machine. Unwanted

movement of the machine may take place if switches

do not match machine state when the machine power

is turned on.

NOTICE: Wear safety glasses, and keep face clear of area when

bleeding air from hydraulic system to avoid spraying oil into eyes.

WR00078-4-8-93

TX03007-04-18-16

1 - 4

Equipment Safety

Operating On A Grade

Never operate the pipe stand on a grade

steeper than 20 % (A 2 foot elevation

change in 10 feet). Pipe could fall off the

rollers or pipe stand could tip causing

serious injury or death.

Place pipe stand on as level ground as possible.

If it is necessary to operate machine on unlevel grade, make

sure that the ground is stable. Some unstable conditions include

ice, snow, mud and loose gravel.

TX03083-3-2-10

Lifting Safety

Follow all applicable federal, state, local, and industry specific

regulations when lifting.

CD00795-2-23-10

2

10

SAFE1st- 12- 14- 92

Safety warnings:

1. Do not exceed rated load or lift loads other than the McElroy

MegaMc Hydraulic Pipe Stand with the lifting sling.

2. Do not operate a damaged or malfunctioning lifting sling or

one missing parts.

3. Do not lift persons.

4. Do not lift a suspended load over persons.

5. Do not leave a suspended load unattended.

6. Do not remove or obscure warning labels.

7. Read and understand the operator’s manual before using the

device.

8. Stay clear of the suspended load.

9. Lift loads only as high as necessary.

10. Do not alter or modify the lifting sling.

11. Employ generally accepted safe lifting practices.

12. Do not shock or impact load the lifting sling.

WR00014-3-8-93

TX03087-3-2-10

1 - 5

Overview

MegaMc Pipe Stand

Parts of the Pipe Stand

1. Base Frame – supports the machine and rests on the ground.

2. Trolley – moves transversely and supports the boom.

3. Wheels – support trolley and allows transverse movement.

4. Boom – moves vertically and supports the rollers.

5. Rollers – support pipe and allow axial movement.

6. Pillow Block Bearings – supports rollers and allows them to roll.

7. HPU – Hydraulic Power Unit.

8. Controls – two levers to control movement.

9. Counter Balance Valve - hydraulically holds and regulates lowering of load.

10. Lift Cylinders - cylinders that raise or lower the boom

11. Guard Rail - guards the HPU and controls, and is used when stacking two pipe stands.

12. Transverse Cylinder - cylinder that moves the trolley toward or away from the operator.

13. Lifting Sling - used for lifting of the pipe stand. The lifting sling has a storage area inside the trolley tube.

14. Fork Pocket - used when lifting the pipe stand with a fork truck.

15. Literature Compartment - stores manuals.

6. Pillow Block Bearings

13. Lifting Sling

(inside tube)

14. Fork Pocket

3. Wheels

5. Rollers

2. Trolley

9. Counter

Balance Valve

4. Boom

11. Guard Rail

10. Lift Cylinders

7. HPU

8. Controls

15. Literature Compartment

TX03058-3-2-10

1. Base Frame

2 - 1

12. Transverse Cylinder

Overview

Hydraulic Power Unit

(A) Hydraulic fluid fill

(B) Gasoline fill

(C) Starter grip

(D) Engine oil check and fill

(E) System pressure gauge

(F) Pressure relief valve

The hydraulics are an open center flow system. The gauge will show

close to 0 psi until the controls are operated. The pressure relief valve

is set at 2500 psi.

A

B

C

PH04045-2-2-10PH04042-2-2-10PH04043-2-2-10

D

F

TX03085-3-2-10

Fuel Valve

The fuel valve should be turned off when transporting the equipment,

or when not being used.

Turn the valve control in to turn off. Turn the control out to turn on.

E

PH00823-4-26-96

TX00958-5-14-96

2 - 2

Overview

Engine Control Lever

All the way back to the left, shuts the engine off. All the way forward

to the right, is the choke position. Between these two positions, the

desired engine speed can be set.

IMPORTANT: Do not use the choke if the engine is warm or the

ambient temperature is high.

TX00959-5-14-96

Hydraulic Fluid

Proper fluid level is indicated on the sight gauge located on the

hydraulic tank.

Refer to the "Check Hydraulic Fluids" section of this manual for

instructions on checking hydraulic fluid.

PH04044--2-2-10

PH04046-2-2-10

TX03078-2-22-10

Hydraulic Controls

(A) Move trolley towards or away from operator.

(B) Raise or lower the pipe roller boom.

TX03086-2-23-10

A

PH04043-2-2-10

B

2 - 3

Operation

Read and Understand

Do not operate this equipment until you have carefully read,

and understand all the sections of this manual, and all other

equipment manuals that will be used with it.

Your safety and the safety of others depends upon care and

judgment in the operation of this equipment.

Follow all applicable federal, state, local, and industry specific

regulations.

McElroy Manufacturing, Inc. cannot anticipate every possible

circumstance that might involve a potential hazard. The warnings

in this manual and on the machine are therefore not all inclusive.

You must satisfy yourself that a procedure, tool, work method, or

operating technique is safe for you and others. You should also

ensure that the machine will not be damaged or made unsafe by

the method of operation or maintenance you choose.

WR00052-12-1-92

STOP-12-22-92

TX02946-4-15-09

Check Hydraulic Fluid

Periodically check the hydraulic fluid level in reservoir. All hydraulic

cylinders must be retracted (boom down and trolley toward HPU)

before checking fluid to get an accurate level. Maintain fluid at

HIGH Level.

Never allow dirt or foreign matter to enter the open tank.

Refer to the "Hydraulic Fluids" section of this manual for hydraulic

fluid recommendations.

TX03079-2-22-10

Check Engine Oil

Check the engine oil level with the engine stopped and in a level

position.

Remove the oil filler cap/dipstick and wipe it clean.

Insert the oil filler cap/dipstick into the oil filler neck, but do not

screw it in, then remove it to check the oil level.

If the oil level is near or below the lower limit mark on the dipstick,

fill with the recommended oil to the upper limit mark.

Do not overfill.

Screw in the filler cap/dipstick securely.

TX03080-3-2-10

PH04046-2-2-10PH040 55-2-2-1 0

3 - 1

Operation

Starting the HPU

Check that the fuel tank is full of clean unleaded gasoline. Check

that the air cleaner element is clean.

Make sure the fuel cut off valve under the air cleaner is open (A). It

is open when the black lever is in line with the fuel line. Set the red

throttle lever on the engine to start.

Pull the starter grip lightly until you feel resistance then pull briskly

a full stroke. Return the starter grip gently (do not allow it to snap

back against the engine).

After the engine starts, gradually move the throttle to fast (F) position

as the engine warms up. To restart a warm engine put the throttle

lever at fast (F).

To stop the engine, move the red throttle lever to the stop position.

The engine should be started each time the Pipe Stand is to be

adjusted and then stopped.

To stop the engine at the end of the work day, put the lever at the

slow position (S). Turn the black fuel valve lever to the off position

(perpendicular to the fuel line).

PH04045-2-2-10

PH00823-4-26-96

A

TX03061-1-25-10

Machine Controls

The machine is hydraulically actuated and the controls are on a

podium next to the HPU. Ensure that all personnel and equipment are

clear of the unit before actuating it.

The left lever (A) controls the transverse movement. Pushing the left

control lever up makes the trolley move away from the control podium.

Pulling the left control lever down makes the trolley move toward the

podium.

The right lever (B) controls the boom vertical movement. Pushing the

right control lever up raises the boom. Pulling the right control lever

down lowers the boom.

TX03062-3-2-10

SF

A

B

PH04044--2-2-10

PH04043-2-2-10

3 - 2

Operation

Stand Placement

Placement For Use On Movable Jaw Side Of Fusion Machine

Place the pipe stand to the right of the fusion machine so that the free stick of pipe (clamped in movable jaws) will

be supported by the stand. Place the pipe stand controls on the same side as the fusion machine’s controls so that

the operator does not have to cross the pipe. Place the pipe stand at least half the length of a stick of pipe away

from the fusion machine. This is so the pipe won’t teeter and lift off of the fusion machine jaws. This also allows lifting

equipment carrying a piece of pipe at its center to go between the fusion machine and Pipe Stand to load the pipe.

Center the base of the stand (not the trolley rollers) on the fusion machine jaws centerline. This allows the 24” of

lateral adjustment to be used 12” on either side of center.

Using proper lifting equipment, place the stick of pipe on the movable jaws and pipe stand rollers so that the end of

the pipe extends from the inner jaw the amount required for a proper face off.

Do not position yourself under supported or raised pipe or near the end of the pipe. Pipe could travel

uncontrolled on the rollers in either direction and cause serious injury or death.

NOTICE: Take care not to impact the fusion machine or pipe stand with the pipe. The pipe is heavy and can do

damage to the machines, especially raised jaws, facer and heater.

Placement On Fixed Jaw Side Of Fusion Machine

Place the second pipe stand to the left of the fusion machine so that the fused stick of pipe coming out of the machine

rests on it. Place the pipe stand controls on the same side as the fusion machine’s controls so that the operator does

not have to cross the pipe.

Additional pipe stands or rollers may be required to adequately support the length of fused pipe exiting the fixed jaw

side of the fusion machine.

More than half

the pipe length

Centerline of Pipe

Stand Base

MegaMc Pipe Stand

Fixed Jaw Side

Placement of MegaMc Pipe Stands

Centerline of Jaws

Fusion Machine And Pipe Stand

Controls On Same Side Of Pipe.

(Overhead View)

Fixed

Jaws

Movable

Jaws

Fusion Machine

Controls

Fusion Machine

More than half

the pipe length

Centerline of Pipe

Stand Base

MegaMc Pipe Stand

Movable Side

TX03059-3-2-10

3 - 3

Operation

Align Pipe with Fusion Machine

To align the pipe in the fusion machine, adjust the pipe stand so that the pipe fits inline with the jaws or inserts. Once

the adjustment is complete, stop the HPU engine.

On very uneven terrain or with bent pipe, the pipe stand may not go low enough to align the pipe in the fusion

machine jaws. Possible options for correcting alignment:

• Rotate the pipe so it bows sideways or up rather then down.

• Lower the pipe stand by digging out underneath it.

• Raise the fusion machine up with stable blocking.

Large diameter pipe in a large MegaMc fusion

machine, the pipe stand may not go low enough

to align the pipe in the fusion machine jaws.

Dig out the stand as needed.

On very uneven terrain or when using small pipe in a larger fusion machine, the pipe stand may not go high enough

to align the pipe in the fusion machine jaws. Possible options for correcting alignment:

• Raise the pipe stand with stable blocking.

• Dig out where the fusion machine is to lower it in relation to the pipe stand.

Small diameter pipe in a large

MegaMc fusion machine may be too

high for pipe stand to reach.

Block up stand as needed.

3 - 4

Operation

Pipe Stand Selection Chart

Fusion Machine

Pipe

Size

8

10

12

14

16

18

20

22

24

26

28

30

32

34

824 T630 1236 T900 1648

8-36 Pipe Stand

8-36 or 36-65

Pipe Stand

2065

1600

Blocked up

8-36 or 36-65

Pipe Stand

36

42

48

52

54

63

65

How to use this chart:

The MegaMc Hydraulic Pipe Stands are intended for use with the MegaMc fusion machines. The 8-36 pipe stand

is best matched to the 824, T630, 1236 and T900 fusion machines. The 36-65 pipe stand is best matched to the

1236, T900, 1648, 2065 and 1600 fusion machines. There is some capability overlap so this chart details all

the combinations of pipe size and MegaMc fusion machines that can be used with the 8-36 and 36-65 MegaMc

Hydraulic Pipe Stands.

To determine which pipe stand to use, locate the pipe size at left of chart and fusion machine at top of chart. Where

the two intersect will fall within the operating envelope of either the 8-36 or 36-65 pipe stand or both. The chart is

based on the fusion machine and pipe stand being on level ground. Uneven ground will shift the effective operating

envelopes. For heavy wall pipe, ensure that the weight of a stick of pipe does not exceed the pipe lift capacity of

9,000 lbs. for 8-36 and 16,000 lbs. for 36-65.

To reach some small pipe sizes in a 65 fusion machine, the pipe stand must be blocked up.

TX03063-3-5-10

36-65 Pipe Stand

3 - 5

Lifting and Storage

Lifting Safety

Follow all applicable federal, state, local, and industry specific

regulations when lifting.

Safety warnings:

1. Do not exceed rated load or lift loads other than the McElroy

MegaMc Hydraulic Pipe Stand with the lifting sling.

2. Do not operate a damaged or malfunctioning lifting sling or

one missing parts.

3. Do not lift persons.

4. Do not lift a suspended load over persons.

5. Do not leave a suspended load unattended.

6. Do not remove or obscure warning labels.

7. Read and understand the operator’s manual before using the

device.

8. Stay clear of the suspended load.

9. Lift loads only as high as necessary.

10. Do not alter or modify the lifting sling.

11. Employ generally accepted safe lifting practices.

12. Do not shock or impact load the lifting sling.

SAFE1st- 12- 14- 92

WR00014-3-8-93

TX03087-3-2-10

4 - 1

Lifting and Storage

Lifting the Pipe Stand

Lifting

A four cable lifting sling is provided for hook lifting the unit.

The lifting sling must only be used by a person trained and qualified in its use.

Before each lift of the machine, inspect the lifting sling for damage. Do not use a damaged lifting sling. The sling is

to lift one stand only. For the lift all four lifting sling hooks must be attached to the four lifting lugs. Before lifting the

machine, lower the boom fully.

The HPU on one end makes the pipe stand off balance. To improve the balance, move the trolley off center away

from the HPU (so the trolley’s weight balances that of the HPU). The 8-36 pipe stand has a plate on the trolley that

covers one of the four lifting lugs until the trolley has been moved sufficiently away from the HPU for good balance.

PH04047-2-2-10

Forking

The pipe stand has fork loops for lifting with a fork truck. The forks

must be at least 6 ft long. Fork extensions can be added to shorter

forks, but the lifting and tipping capacity of the fork truck must not

be exceeded.

Move the trolley so that the bottom of the Boom is not in line with

the fork loops. The left fork will go through the loops but the right

fork will just go under the frame. Ensure that the right fork contacts

the pipe frame and not the trolley lugs; adjust the trolley location as

needed.

Strap the Base Frame to the fork truck frame so the stand won’t slide

off of the forks when braking or going down a hill. If the machine

slips out on the forks, it could come off the far frame tube and

topple off of the forks.

Two stacked pipe stands that are securely strapped or banded

together may be lifted with a fork truck by forking the bottom pipe

stand. Do not exceed the lifting capacity or tipping capacity of the

fork truck.

TX03064-2-23-10

PH04043-2-2-10

Fork Loops Boom

4 - 2

Lifting and Storage

NOTICE: Boom must be clear of fork

loops. Move trolley to clear fork

loop. Failure to move the boom may

result in damage to pipe stand.

Fork Loop

Boom

NOTICE: Ensure fork is clear of trolley lugs and is supporting the frame.

NOTICE: Forks must be 6 feet long

or longer and extend past the rear

frame member

NOTICE: Strap base of frame to

fork truck to ensure it does not

slip off.

4 - 3

Lifting and Storage

Stacking Stands

Pipe stands of the same size can be stacked a maximum two high to reduce the floor space needed for storage or

shipping.

First lower the boom fully on both units and move the trolley away from the HPU to make the unit more balanced.

Remove the guard rail from the unit that will stack on top by lifting up on the rail and pulling it out of its sockets

on the base frame. Place the guard rail in the unit that will be on the bottom in the sockets on the end of the frame

opposite the HPU. The bottom pipe stand will have two guard rails and the top pipe stand will have none.

Attach the lifting sling to or fork, the top pipe stand. Place it on top of the bottom unit so that both guard rails

engage the notches in the feet and the U brackets on the bottom of the frame. For shipping, the top unit must be

securely held down by straps so it won’t slip off in transit.

Two stacked pipe stands that are securely strapped or banded together may be lifted with a fork truck by forking

the bottom pipe stand. Do not exceed the lifting capacity or tipping capacity of the fork truck. The sling is for

lifting one stand only.

PH04049-2-2-10

TX03065-3-2-10

Lifting Sling Storage

The lifting sling is stored inside the trolley cross tube.

The 36-65 stand cross tube is long enough for the sling to be inserted straight. The 8-36 stand cross tube is shorter

so flex (do not kink) the cables in the middle to double them over and slide the cables into the tube. The tube end

has small holes which can be used to lock (not included) the sling to the tube to deter theft of the sling and/or

machine.

Do not use a damaged lifting sling. The sling is for lifting one stand only.

PH040 50-2-2- 10PH04051-2-2-10

TX03066-3-2-10

PH040 52-2-2-10

4 - 4

Lifting and Storage

Extended Period Storage

If storing the pipe stand for an extended period of time, refer to

the engine operator's manual for long term storage procedures.

Grease all pins, wheels and bearings. Refer to the Maintenance

section of this manual for lubrication procedures.

TX03067-2-23-10

4 - 5

Maintenance

Preventative Maintenance

To insure optimum performance, the machine must be kept clean and

well maintained.

With reasonable care, this machine will give years of service.

Therefore, it is important that a regular schedule of preventive

maintenance be kept.

Store machine inside, out of the weather, whenever possible.

Service intervals are approximate for average service and may need

to be done more frequently in severe service conditions or can be

done less frequently if used minimally.

TX03068-1-25-10

Washing the Machine

An important factor in the service life of this machine is cleanliness.

The machine should be cleaned with soap and water as needed.

When exposed to dust and mud in a field location, the machine

should be washed at the end of each days work.

CD00142-11-2-94

CD00178-9-15-95

TX00601- 8 -10 -95

Check Hydraulic Fluid

Periodically check the hydraulic fluid level in reservoir. All

hydraulic cylinders must be retracted (Boom down and trolley

toward HPU) before checking fluid to get an accurate level.

Maintain fluid at HIGH Level.

Never allow dirt or foreign matter to enter the open tank.

Fill the reservoir from a clean container.

Refer to the "Hydraulic Fluids" section of this manual for

hydraulic fluid recommendations.

PH04046-2-2-10

PH04042-2-2-10

TX03081-2-23-10

5 - 1

Maintenance

Change Hydraulic Filter and Fluid

The hydraulic filter should be replaced every year.

The hydraulic fluid should be replaced every two years.

Fill the reservoir from a clean container.

Refer to the "Hydraulic Fluids" section of this manual for

hydraulic fluid recommendations.

PH04042-2-2-10PH04063-3-3-10

PH04042-2-2-10

TX03075-2-4-10

Pipe Stand Lubrication

• Use a grease gun to grease the following parts:

a) Cylinder Pins (6 points)

b) Boom Pins (2 points)

c) Roller Bearings (4 points)

d) Wheels (4 points)

• Check that the pillow block bearings (Rollers) rotate freely.

• Check that the trolley wheels rotate freely.

TX03069-3-2-10

5 - 2

Maintenance

Lifting Slings

Before each lift of the machine, inspect the lifting sling for

damage. Do not use a damaged sling. In addition, a thorough

yearly inspection should be done by a qualified person per

ASME Standard B30.9. In severe service it should be inspected

more frequently than yearly.

TX03072-3-2-10

Fasteners Must Be Tight

Check all nuts, bolts, and snap rings to make certain they are

secure and in place.

PH040 52-2-2-10PH04054-3-2-10

TX00437-9-13-94

HPU Engine

The HPU engine should be maintained per the maintenance

schedule in the engine operator's manual.

TX03073-1-25-10

PH04045-2-2-10

5 - 3

Troubleshooting

Problem Action

Load Lowers

Maintenance

a) May need to replace lift cylinder seals.

b) May need to replace counterbalance valve.

• If counterbalance valve requires replacement:

1. Lower pipe stand completely.

2. Remove pipe from pipe stand.

3. Turn valve adjustment fully clockwise.

4. Slowly and carefully remove valve cartridge from valve body.

c) May need to increase the counterbalance valve setting. Proper coun-

terbalance valve setting is 1-1/4 turns clockwise from fully counter

clockwise position.

Engine Will Not

Start

Load Will Not Raise

See the engine operator's manual for engine troubleshooting

a) Check fl uid level in hydraulic reservoir.

b) May need to replace counterbalance valve.

c) May need to increase relief valve setting on HPU.

To adjust relief valve:

Turn relief valve adjustment clockwise to increase setting. Proper setting,

2500 psi can only be achieved when actuating either control valve lever,

and the corresponding cylinder is bottomed-out.

TX03055-3-2-10

5 - 4

Hydraulic Fluids

Hydraulic Fluids

The use of proper hydraulic fluid is mandatory to achieve maximum performance and machine life. Use a clean, high

quality, anti-wear hydraulic fluid with a viscosity index (VI) of 135 minimum. It should have a maximum viscosity of

500 cSt (2000 SSU) at startup (ambient temperature) and a minimum viscosity of 13 cSt (65 SSU) at the maximum

fluid temperature (generally 80°F above ambient). Using hydraulic fluids that do not meet these criteria may cause

poor operation and/or damage to the hydraulic components.

The following table specifies the fluid temperature at various viscosities. Temperature rise of the hydraulic fluid

can vary from 30° F to about 80° F over the ambient temperature depending on the pressure setting, age of the

pump, wind, etc. Mobil Univis N46 hydraulic fluid is installed at our factory. The advantage of this fluid is a wider

temperature range, however, this fluid should not be used for continuous operation below 24°F.

TX03082-04-18-16

Hydraulic Fluids Characteristics

Manufacturer Fluid Name cSt cSt V.I. -20F -10F 0F 10F 30F 50F 70F 90F 110F 130F 150F Range Range

100F 210F °F °C

Mobil DTE 10 Excel 15 15.8 4.1 168 *********************************************** -16 - 113 -27 - 45

DTE 10 Excel 32 32.7 6.6 164 ********************************************* 12 - 154 -11 - 68

DTE 10 Excel 46 45.6 8.5 164 ********************************************* 23-173 -5 - 78

DTE 10 Excel 68 68.4 11.2 156 ******************************************* 37-196 3 - 91

Univis N-32 34.9 6.9 164 ******************************************** 12-150 -11 - 66

Univis N-46 46 8.5 163 ******************************************** 24-166 -4 - 74

Univis N-68 73.8 12.1 160 ***************************************** 39-193 4 - 89

NOTE: This chart is based on pump manufacturer recommendations of 13 to 500 cSt.

NOTE: Temperatures shown are fluid temperatures. – NOT ambient temperatures.

6 - 1

Specifications

MegaMc® Hydraulic Pipe Stand

8 - 36 36 - 65

Dimensions:

Length: (A) 114 in 136 in

Width: (B) 90 in 90 in

Height: (C) 40 in 41 in

Weight:

Lifting Capacity: 9,000 lbs 16,000 lbs

Capacity:

Pipe Size Range: 8 - 36 IPS 36 - 65 IPS

Minimum Pipe Size: 8 IPS 16 IPS

Vertical Lift Range: 34 in 34 in

Transverse Movement: 24 in 24 in

Hydraulic Power Unit

Power (hp) (self contained): 5.5 hp

Relief Pressure (psi): 2,500 PSI

Reservior Capacity: 5 gal

A

B

C

Flow (GPM @ 2000 PSI): 2 gpm

Starting System: Pull Start

Fuel Type: Unleaded

Gasoline

Fuel Tank Capacity: 1.16 qt

Engine Oil Type: Refer to Engine Manual

Engine Oil Capacity: 0.69 qt

Hydraulic Fluid: Refer to Hydraulic

Fluids Section

TX03074-1-25-10

7 - 1

About this manual . . .

McElroy Manufacturing continually strives to give customers the best quality products available.

This manual is printed with materials made for durable applications and harsh environments.

This manual is waterproof, tear resistant, grease resistant, abrasion resistant and the bonding

quality of the printing ensures a readable, durable product.

The material does not contain any cellulose based materials and does not contribute to the

harvesting of our forests, or ozone-depleting constituents. This manual can be safely disposed

of in a landfill and will not leach into ground water.

TX001660-8-19-99

Loading...

Loading...