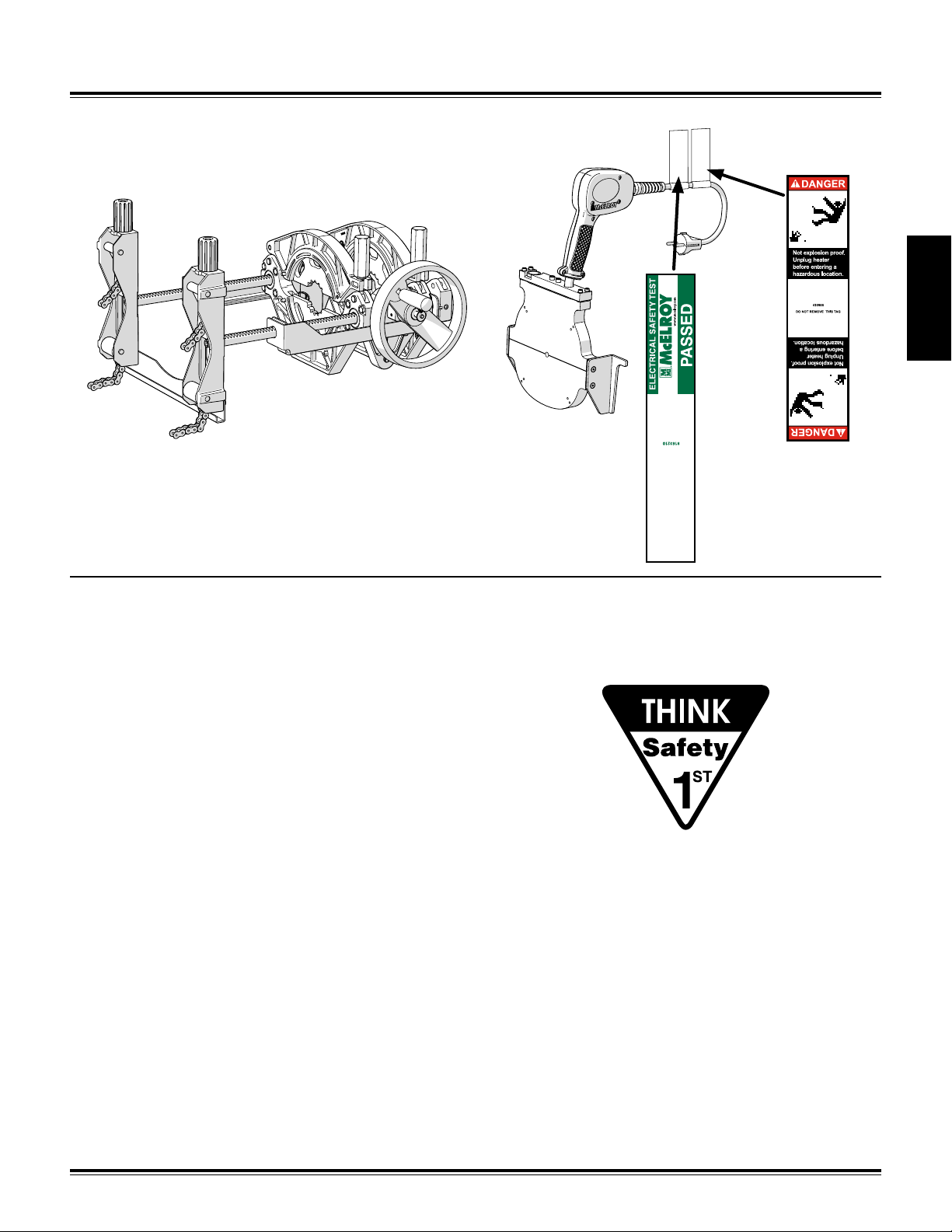

Hornet™ XL

Fusion Machine

Models: ASW31401, ASW31402

Foreword

Manual: SW31301

Revision A 09/19

Original Language: English

Operator’s

Manual

1 Hornet™ XL

Copyright 2019 McElroy Manufacturing, Inc.

All rights reserved.

P.O. Box 580550

Tulsa, Oklahoma 74158-0550, USA

Important Safety Information

8163361

Most accidents that involve product operation, maintenance and repair are caused by failure to observe basic safety rules or

precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person

must be alert to potential hazards. This person should also have necessary training, skills and tools to perform these functions properly.

Advanced training is offered through McElroy University. Course offerings are meant to enhance your efficiency, productivity and safety

in the proper use of McElroy equipment.

Improper operation, maintenance or repair of this product can be dangerous and could result in injury or death.

Do not operate this product until you have carefully read, and understand all the sections of this manual, and all

other equipment manuals that will be used with it.

Follow all applicable federal, state, local, and industry specific regulations.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as “DANGER”, “WARNING” or

“CAUTION”. The Safety Alerts are shown below.

The meaning of these safety alert symbols are as follows:

- Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

- Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

- Indicates a hazardous situation which, if not avoided, may result in minor or moderate injury.

Signal words “NOTICE” and “IMPORTANT” are used to bring attention to important information.

The meaning of these signal words are as follows:

“NOTICE” - Can keep you from doing something that might damage the machine or someone’s property. It may also be used to

alert against unsafe practices.

“IMPORTANT” - Can help you do a better job or make your job easier in some way.

McElroy cannot anticipate every possible circumstance that might involve a potential hazard. The warnings in this

publication and on the product are, therefore, not all inclusive. If a tool, procedure, work method or operating

technique that is not specifically recommended by McElroy is used, you must satisfy yourself that it is safe for you

and for others. You should also ensure that the product will not be damaged or be made unsafe by the operation,

maintenance or repair procedures that you choose.

The information, specifications, and illustrations in the publication are on the basis of information that was available at the time that the

publication was written. The specifications, pressures, measurements, adjustments, illustrations, and other items can change at any time.

These changes can affect the service that is given to the product. Obtain the complete and most current information before you start any

job. The most current information is available at our website

www.mcelroy.com.

TX05337-04-18

Cancer and Reproductive Harm www.P65warnings.ca.gov

When replacement parts are required for this

product McElroy recommends using McElroy

replacement parts or parts with equivalent

specifications including, but not limited to,

physical dimensions, type, strength and material.

Failure to heed this warning can lead to premature

failures, product damage, personal injury or death.

TABLE OF CONTENTS

FOREWORD

Literature Information ......................................................................................1-1

Safety ..................................................................................................1-1

Operation ...............................................................................................1-1

Maintenance ............................................................................................1-1

McElroy University ........................................................................................1-1

Patent Information ........................................................................................1-2

Replacement Literature .....................................................................................1-2

Nameplate Location ......................................................................................1-2

Replacement Parts ........................................................................................1-2

Limited Warranty .........................................................................................1-3

SAFETY

General Safety ...........................................................................................2-1

Safety Equipment .........................................................................................2-1

Heater Is Not Explosion Proof ...............................................................................2-2

Electric Motors are Not Explosion Proof ......................................................................2-2

Electrical Safety ..........................................................................................2-2

Power Tool Safety ........................................................................................2-2

Heater is Hot ............................................................................................2-2

Fusion Procedures ........................................................................................2-3

Do Not Modify Machine ...................................................................................2-3

GENERAL INFORMATION

Theory of Heat Fusion .....................................................................................3-1

Nomenclature ............................................................................................3-1

Attach Drill to Drill Adapter ................................................................................. 3-4

Attach Extension Chains ...................................................................................3-5

Install Heater Adapters ....................................................................................3-6

Detachable Handle .......................................................................................3-6

OPERATION - FUSION OUTLET

Attach Hornet™ XL to Pipe .................................................................................. 4-1

Prepare Heater ...........................................................................................4-2

Drill Main Pipe ...........................................................................................4-3

Insert Fitting ..............................................................................................4-4

Insert Heater ............................................................................................. 4-5

Heat Fitting and Pipe ......................................................................................4-5

Fuse Fitting and Pipe ......................................................................................4-6

Remove Hornet™ XL .......................................................................................4-6

OPERATION - SOCKET FUSE TO OUTLET

Prepare Pipe End .........................................................................................5-1

Prepare Heater ...........................................................................................5-1

Mark Insertion Depth ...................................................................................... 5-2

Clean Fitting and Pipe .....................................................................................5-2

Load Pipe ...............................................................................................5-2

Heat Fitting and Pipe ......................................................................................5-3

Fusion and Cooling .......................................................................................5-3

Remove Hornet™ XL .......................................................................................5-4

STORAGE/TRANSPORT

Storage/Transport ........................................................................................6-1

MAINTENANCE

Preventative Maintenance ..................................................................................7-1

Clean Machine ..........................................................................................7-1

Check Machine Operation .................................................................................7-1

Fasteners Are Tight ........................................................................................7-1

Changing Heater Plates/Adapters ...........................................................................7-1

Clean Chains ............................................................................................7-2

Clean Fitting Adapter ...................................................................................... 7-2

Clean Drill Adapter .......................................................................................7-2

Adjust Gearbox Chain Tension ..............................................................................7-2

SPECIFICATIONS

Specifications ............................................................................................8-1

NOTES

Notes ..................................................................................................9-1

For Digital Copy:

Press Alt + Left Arrow

to return to the link that was clicked.

FOREWORD

Literature Information

This manual should be stored in a protected location for

Foreword

future reference. Use the literature holder if provided with the

product. Digital copy will contain hyperlinks. Press Alt + Left

Arrow to return to the selected hyperlink.

This manual contains safety information, operation instructions,

transportation information, lubrication information and

maintenance information.

Some photographs or illustrations in this publication show

details or equipment that can be different from your machine.

Guards and covers might have been removed for illustrative

purposes.

Continuing improvement and advancement of product design

might have caused changes to your machine which are not

included in this publication. Read, study and keep this manual

with the machine.

Whenever a question arises regarding your machine, or this

publication, please contact McElroy Technical Services at 918831-9224 or techsupport@mcelroy.com

Safety

Some maintenance procedures may be referenced in a

manual pertaining to that component of the machine. For

example, maintenance for an engine component would have

its intervals and procedures in the engine operator’s manual.

Use the hour meter (if equipped) to determine servicing

intervals. Calendar intervals will be used instead of hour

meter intervals if no hour meter is equipped on a machine.

Recommended service should always be performed at the

interval that occurs first.

Under extremely severe, dusty or wet operating conditions,

more frequent lubrication than is specified in the maintenance

schedule might be necessary.

McElroy University

The safety section lists basic safety precautions. In addition,

this section identifies the text and locations of warning signs

and labels used on the machine.

Read and understand the basic precautions listed in the safety

section before operating or performing maintenance and

repair on this machine.

Operation

The operation section is a reference for the new operator

and a refresher for the experienced operator. This section

includes a discussion of gauges, switches, machine controls,

accessories and transportation.

Photographs and illustrations guide the operator through

correct procedures of setting up, checking and operating the

machine.

Operating techniques outlined in this publication are basic.

Proficiency develops as the operator gains knowledge and

experience with the machine and its capabilities.

Maintenance

The maintenance section is a guide to equipment care. The

maintenance schedule lists the items to be maintained at a

specific service interval. Items without specific intervals are

listed under the “As Needed” service interval. The schedule

lists the page for the step-by-step instructions required to

accomplish the scheduled maintenance. Use the schedule as

an index for all maintenance procedures.

For more than 30 years, McElroy has been the only pipe

fusion machine manufacturer to continuously offer advanced

training. Course offerings are meant to enhance your

efficiency, productivity and safety in the proper use of

McElroy machines. McElroy University classes are structured

so that the skills learned and the machines used in each class

closely match the machines found on pipelining jobsites. We

offer training at our facility or yours. Our uniquely qualified

McElroy University course instructors offer years of industry

experience.

Tuition for each course includes lunches, course materials and

a certificate of completion. Online registration, as well as

up-to-date course offerings and dates, is available at www.

mcelroy.com/university

This manual is intended as a guide only and does not take

the place of proper training by qualified instructors. The

information in this manual is not all inclusive and can not

encompass all possible situations that can be encountered

during various operations.

1-1Foreword Hornet™ XL

Patent Information

This product and other products could be protected by patents

or have patents pending. All the latest patent information is

available at patent.mcelroy.com

Replacement Literature

This product is shipped with a printed operator’s manual. If

the manual becomes lost or damaged, order a replacement

manual or download and print a copy of the manual at www.

mcelroy.com.

Nameplate Location

Every machine has a name plate that includes the machine’s

model number, serial number, and power requirements. The

model and serial numbers can be used to register the machine

online and activate the warranty. Reference warranty card for

information on registering your product.

Foreword

Machine Nameplate

CD02423-02-12-19

Replacement Parts

Refer to the McElroy parts finder at

www.mcelroy.com to locate parts for purchase. Reference the

model number on the nameplate of the machine when using

the parts finder.

Contact your McElroy distributor to order replacement parts.

Find your closest distributor on our website at www.mcelroy.

com.

TX05397-03-15-19

1-2 ForewordHornet™ XL

Limited Warranty

McElroy Manufacturing, Inc. (McElroy) warrants all products

Foreword

manufactured, sold and repaired by it to be free from defects

in materials and workmanship, its obligation under this

warranty being limited to repairing or replacing at its factory

and new products, within 5 years after shipment, with the

exception of purchased items (such as electronic devices,

pumps, switches, etc.), in which case that manufacturer’s

warranty applies. Warranty applies when returned freight

is prepaid and which, upon examination, shall disclose to

have been defective. This warranty does not apply to any

product or component which has been repaired or altered

by anyone other than McElroy or has become damaged due

to misuse, negligence or casualty, or has not been operated

or maintained according to McElroy’s printed instructions

and warnings. This warranty is expressly in lieu of all other

warranties expressed or implied. The remedies of the Buyer

are the exclusive and sole remedies available and Buyer shall

not be entitled to receive any incidental or consequential

damages. Buyer waives the benefit of any rule that disclaimer

of warranty shall be construed against McElroy and agrees

that such disclaimers herein shall be construed liberally in

favor of McElroy.

Return of Goods

Buyer agrees not to return goods for any reason except upon

the written consent of McElroy obtained in advance of such

return, which consent, if given, shall specify the terms and

conditions and charges upon which any such return may be

made. Materials returned to McElroy, for warranty work,

repair, etc., must have a Return Material Authorization

(RMA) number, and be so noted on the package at time of

shipment. For assistance, inquiry shall be directed to:

McElroy Manufacturing, Inc.

P.O. Box 580550

833 North Fulton Street Tulsa, Oklahoma 74158-0550

PHONE: (918) 836–8611, FAX: (918) 831–9285.

EMAIL: fusion@McElroy.com

Note: Certain repairs, warranty work, and inquiries may

be directed, at McElroy’s discretion, to an authorized service

center or distributor.

Disclaimer of Liability

McElroy accepts no responsibility of liability for fusion joints.

Operation and maintenance of the product is the responsibility

of others. We recommend qualified joining procedures be

followed when using McElroy fusion equipment.

McElroy makes no other warranty of any kind whatever,

express or implied; and all implied warranties of

merchantability and fitness for a particular purpose which

exceed the aforestated obligation are hereby disclaimed by

McElroy.

Product Improvement

McElroy reserves the right to make any changes in or

improvements on its products without incurring any liability

or obligation to update or change previously sold machines

and/or the accessories thereto.

Information Disclosed

No information of knowledge heretofore or hereafter

disclosed to McElroy in the performance of or in connection

with the terms hereof, shall be deemed to be confidential or

proprietary, unless otherwise expressly agreed to in writing by

McElroy and any such information or knowledge shall be free

from restrictions, other than a claim for patent infringement, is

part of the consideration hereof.

Proprietary Rights

All proprietary rights pertaining to the equipment or the

components of the equipment to be delivered by McElroy

hereunder, and all patent rights therein, arising prior to, or in

the course of, or as a result of the design or fabrication of the

said product, are exclusively the property of McElroy.

Law Applicable

All sales shall be governed by the Uniform Commercial Code

of Oklahoma, U.S.A.

Register your product online to activate your

warranty: www.McElroy.com/fusion

(Copy information listed on the machine nameplate here for

your records).

Model No.

Serial No.

Date Received

Distributor

TX05339-04-18

1-3Foreword Hornet™ XL

SAFETY

CD02424-02-12-19

Safety

410906

8163210

There can be several specific safety messages on this machine.

The exact location of the hazards and the description of

the hazards are reviewed in this section. Please become

familiarized with all safety messages.

Make sure that all of the safety messages on the machine

are legible. Clean the safety messages or replace the

safety messages if you cannot read the words. Replace if

the illustrations are not legible. When you clean the safety

messages, use a cloth, water and soap. Do not use solvent,

gasoline, or other harsh chemicals to clean the safety

messages. Solvents, gasoline, or harsh chemicals could loosen

the adhesive that secures the safety message or damage the

print of the safety message.

Replace any safety message that are damaged, or missing.

If a safety message is attached to a part that is replaced,

install a safety message on the replacement part. New safety

messages can be ordered from McElroy using the part number

listed.

General Safety

Safety is important. Report anything unusual that you notice

during set up or operation.

LISTEN for thumps, bumps, rattles, squeals, air leaks, or

unusual sounds.

SMELL odors like burning insulation, hot metal, burning

rubber, hot oil, or natural gas.

FEEL any changes in the way the equipment operates.

SEE problems with wiring and cables, hydraulic connections,

or other equipment.

REPORT anything you see, feel, smell, or hear that is different

from what you expect, or that you think may be unsafe.

SAFE1ST-2-21-18

Safety Equipment

Wear a hard hat, safety shoes, safety glasses, and other

applicable personal protective equipment.

Remove jewelry and rings, and do not wear loose fitting

clothing or long hair that could catch on controls or moving

machinery. Remove any loose safety equipment during an

operation that could be drawn into or caught in the machine.

Ensure proper fire prevention or other fire-fighting equipment

is available and all personnel know how and when to use it.

2-1 SafetyHornet™ XL

Heater Is Not Explosion Proof

This safety message is located on the cord of the heater.

This heater is not explosion proof. Operation of

heater in an explosive atmosphere without necessary

safety precautions will result in serious injury or

death.

Safety

When operating in an explosive atmosphere, the heater

should be brought up to temperature in a safe environment,

then unplugged before entering the explosive atmosphere for

fusion.

Electrical Safety

Always ensure equipment is properly grounded. It

is important to remember that if you are working in

a wet environment with electrical devices. Proper

ground connections help to minimize the chances of

an electric shock.

Frequently inspect electrical cords and unit for damage. Have

damaged components replaced and service performed by a

qualified electrician.

Do not carry electrical devices by the cord

NOTICE: Always connect units to the proper power source

as listed on the unit, or in the owner’s manual. Use GFCI

electrical connections when available.

WR00065-2-21-18

WR00080-2-21-18

Electric Motors are Not Explosion Proof

Electric motors are not explosion proof. Operation

of these components in an explosive atmosphere

without necessary safety precautions will result in

serious injury or death.

The drill motor cannot be used manually and must not be used

in an explosive atmosphere.

Power Tool Safety

Read and understand the all instructions provided

with your power tool. Failure to follow all the power

tool instructions, may result in electric shock, fire

and/or serious personal injury.

Heater is Hot

The heater is hot and will burn clothing and skin.

Keep the heater in its insulated heater stand or

blanket when not in use, and use care when heating

the pipe.

NOTICE: Use only a clean dry lint free non-synthetic cloth to

clean the heater plates.

WR00080-4-12-93

WR00080-2-21-18

WR00030-2-21-18

2-2Safety Hornet™ XL

Fusion Procedures

Obtain a copy of the pipe manufacturer’s fusion procedures

or appropriate joining standard for the pipe being fused.

Follow the procedure carefully, and adhere to all specified

parameters.

NOTICE: Failure to follow the pipe manufacturer’s fusion

procedures or appropriate joining standard could result in a

bad fusion joint.

Do Not Modify Machine

Make no modifications to your equipment unless specifically

recommended or requested by McElroy.

Safety

TX05398-03-15-19

2-3 SafetyHornet™ XL

GENERAL INFORMATION

General

Information

Theory of Heat Fusion

The principle of heat fusion is to heat two pipe surfaces to

a designated temperature, and then fuse them together by

application of force. This develops pressure which causes flow

of the melted materials, which causes mixing and thus fusion.

When the thermoplastic material is heated, the molecular

structure is transformed into an amorphous condition.

When fusion pressure is applied, the molecules from each

thermoplastic part mix. As the joint cools, the molecules return

to their form, the original interfaces are gone, and the fitting

and pipe have become one monolithic unit. A strong, fully

leak tight connection is the result.

The principle operations include:

Clamping The pipe and fitting must be held firmly to allow

all subsequent operations to take place.

Cleaning The area of pipe that the fitting will come in

contact with must be cleaned and roughed up,

as well as the base of the fitting.

Aligning The fitting must be properly seated on the pipe

and then clamped in the machine for proper

alignment.

Heating A melt pattern must be formed that penetrates

into the pipe and into the fitting.

Joining The melt patterns must be joined with a specified

force. The force must be constant around the

interface area.

Holding The molten joint must be held immobile with a

specified force until adequately cooled.

Inspecting Visually examine the entire circumference of the

joint for compliance with standards established

by your company, customer, industry, federal,

state, or local regulations.

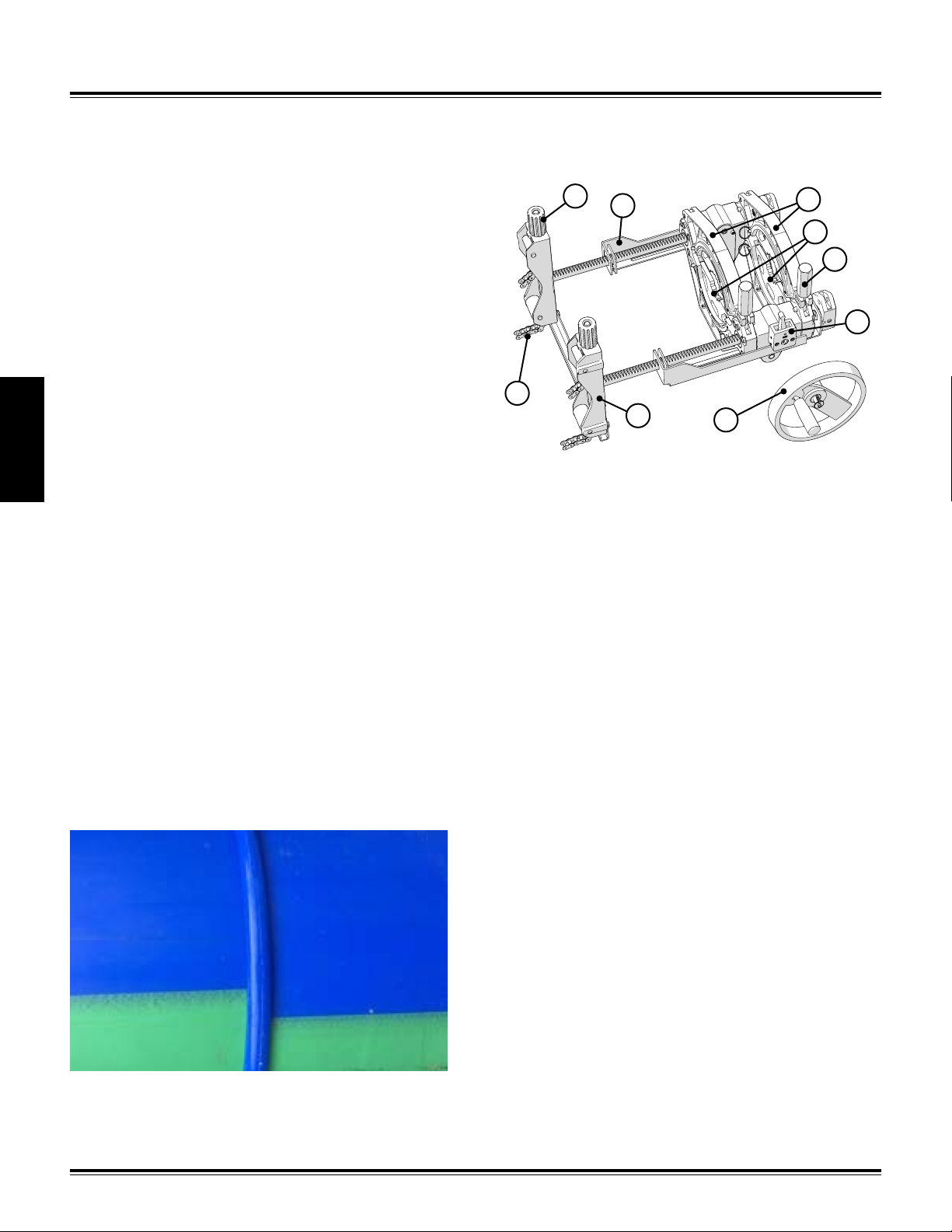

Nomenclature

Hornet™ XL Carriage

B

C

A

I

A - Main Pipe Chains

Chain used to secure the Hornet XL to the main pipe.

B - Main Pipe Clamp Knobs

Used to tighten the main pipe chain on the pipe.

C - Heater Stripper Bars

Strips the heater from the main pipe and the fitting.

D - 160mm Pipe Jaws

Jaws used to clamp onto pipe, fitting adapter or drill adapter.

E - 63mm Pipe Inserts

Size of inserts used to clamp the fitting adapter and drill

adapter.

F - Pipe Jaws Clamp Knobs

Used to tighten the pipe jaws to pipe, fitting adapter or drill

adapter.

G - Brake

Holds the position of the carriage when applied.

H - Detachable Handwheel

Rotates to open and close the carriage. The handle can be

folded in for storage. The handwheel is also detachable and

can be attached to the other side of the carriage.

I - Tailstock

The tailstock allows the Hornet XL to attach to any size main.

With the extension chains from the accessory kit, the Hornet XL

can attach to a 125mm to 630mm main pipe.

H

D

E

F

G

CD02425-02-11-19

CD05428-3-15-19

3-1General Information Hornet™ XL

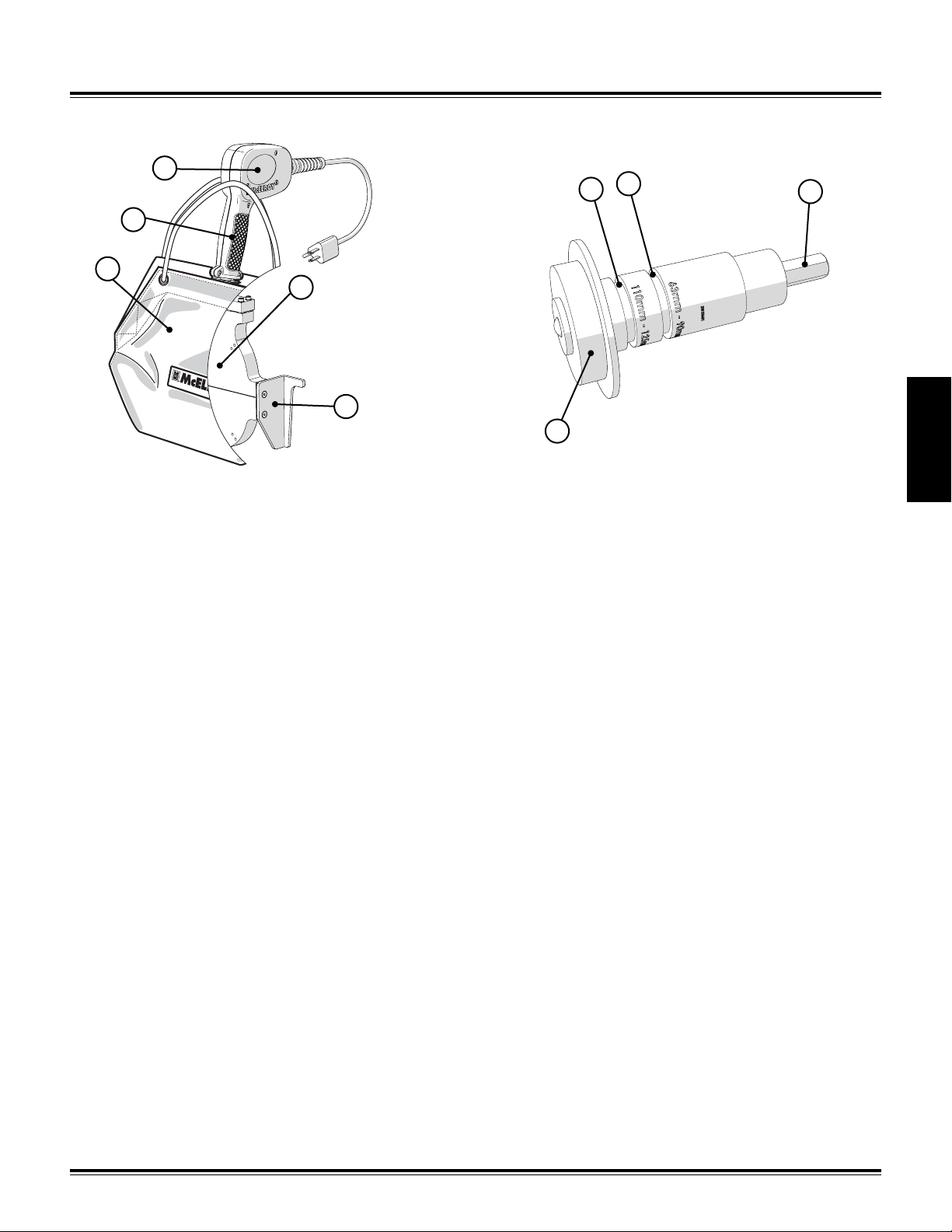

Heater

J

K

M

L

N

CD02482-02-13-19

J - Heater Information Label

Provides model number, power and indicator light information.

K - Heater Handle

Location to hold the heater and has a potentiometer to adjust

the heater temperature.

L - Heater Body

Non-stick coated heater adapters attach to the heater body.

M - Insulated Heater Bag

This bag insulates the heater while stored. Helps maintain the

set heater temperature.

N - Heater Support Bracket

Inserts into the stripper bars to allow the heater to be stripped

from the main pipe and fitting.

Fitting Adapter

Q

P

O

CD02427-02-13-19

O - Fitting Puck

Rubber puck that fits inside the inner diameter of the fitting. The

pucks are sized to fit a specific size fitting.

P - 110mm to 125mm Clamp Channel

Used with the 63mm pipe inserts to clamp the fitting adapter

in the carriage for 110mm to 125mm fittings.

Q - 63mm to 90mm Clamp Channel

Used with the 63mm pipe inserts to clamp the fitting adapter

in the carriage for 63mm to 90mm fittings.

R - Fitting Adapter Clamp Knob

Tighten knob to secure the fitting to the fitting adapter.

R

General

Information

3-2 General InformationHornet™ XL

Drill Adapter

S

U

T

V

General

Information

W

CD02428-03-15-19

X

S - Drill Adapter Chuck

Holds the hole saw (not included) used to drill the main pipe.

T - Drill Adapter

Attached to a drill (not included) so it can be clamped into

the jaws of the Hornet XL. The adapter fits drills with a circular

pilot size of 1-29/32" (48.5mm).

U - Drill Adapter Sleeve

Used inside the drill adapter for drills with a circular pilot size

of 1-13/16" (46mm).

V - 3/8" Square to 5/16" Hex Adapter

Attaches to one of the sockets to connect the drill to the hex of

drill adapter.

W - 7/16" Deep Socket, 3/8" Drive

Socket used to connect a standard drill with the drill adapter.

X - 7/16" Socket, 3/8" Drive

Socket used to connect a 90° drill with a long drill chuck with

the drill adapter.

3-3General Information Hornet™ XL

Attach Drill to Drill Adapter

Drill Pilot

Drill Sleeve

Drill Chuck

3) Insert the drill into the drill adapter. If the drill pilot

is 1-13/16" (46mm), then the drill sleeve must be

inserted into the drill adapter so that the drill adapter

can be tightened to the drill pilot. Align the slot on the

drill sleeve with the slot of the drill adapter.

Drill Adapter

Socket

Socket Adapter

CD02431-02-18-19

1) Attach the required socket to the socket adapter to

make up the length 4-7/8" between the end of the drill

pilot and the end of the socket.

The socket adapter with deep socket length is

3-13/16" (97mm).

The socket adapter with short socket length is 2-5/8"

(67mm).

4-7/8"

End of Socket

CD02433-02-18-19

End of Drill Pilot

Drill Sleeve - Only used

for a drill pilot size of

1-13/16" (46mm)

CD02434-02-18-19

4) Ensure the drill is fully inserted over the drill pilot of the

drill. If the drill will not insert completely, you may need

to adjust the socket adapter. Tighten the drill adapter

clamp.

General

Information

2) Insert the adapter and socket into the drill chuck. The

amount of adapter inserted into the chuck will need to

make the total measurement from the end of the drill

pilot to the end of the socket to equal 4-7/8". Tighten

the drill chuck.

4-7/8"

CD02430-02-18-19

Tighten Clamp

CD02435-02-18-19

5) Check the function of drill by pressing the trigger. The

chuck of the drill adapter should turn when operated.

If the drill adapter does not turn, remove the drill and

extend more of the socket adapter.

IMPORTANT: Dedicating a drill to the drill adapter will

defeat the need to remove and reattach the drill adapter to the

drill. Leave the drill attached and store it in the Hornet XL case.

3-4 General InformationHornet™ XL

General

Information

Attach Extension Chains

The Hornet™ XL comes equipped with base chains that will

attach the Hornet™ XL to a main pipe size up to 315mm (12"

OD). The accessory kit has extension chains that will allow the

Hornet™ XL to attach to a main pipe size up to 630mm (24"

OD).

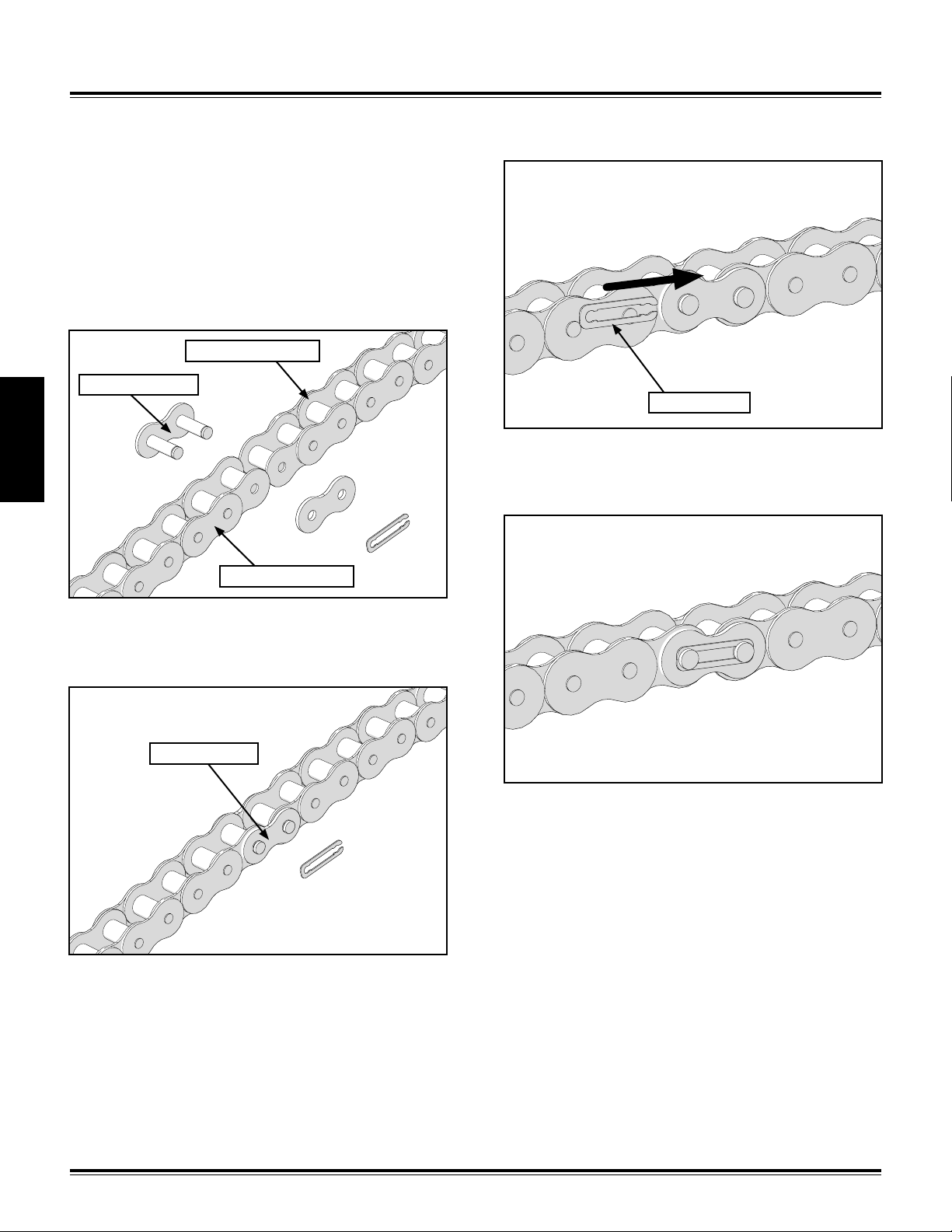

Attach Extension Chains:

1) Position the extension chain next to the end of the base

chain.

Base Chain

Master Link

3) Insert the link clip between the grooves of the master

link to secure the link cover.

Link Clip

CD02437-02-21-19

4) Ensure the clip is seated completely on the pins of the

master link. Repeat these instructions for the other chain.

Extension Chain

CD02439-02-21-19

2) Insert the pins of the master link into the base chain and

the extension chain. Place the link cover over the pins

of the master link.

Link Cover

CD02436-02-21-19

CD02438-02-21-19

3-5General Information Hornet™ XL

Install Heater Adapters

Correctly sized heater adapters must be installed before

performing a fusion with the Hornet™ XL. The adapters are

sized by the main pipe size and the fitting size.

Fitting Size

3) Rotate the adapters and align the marks on the

adapters with the mark on the heater body.

Heater Alignment

Mark

Adapter Alignment

Mark

CD02443-03-15-19

Main Pipe Size Alignment Mark

CD02441-03-15-19

Install Heater Adapters:

1) Position the fitting adapter between the bends of the

heater support bracket. Position the pipe adapter

opposite of the fitting adapter.

Pipe Adapter

Heater Support Bracket

CD02440-03-15-19

2) Insert the screw into the pipe adapter and tighten the

screw enough to hold the adapters to the heater body.

Fitting Adapter

Heater Alignment

Mark

CD02444-03-15-19

Adapter Alignment

Mark

4) After both adapter are aligned, tighten the screw to

secure the position of the adapters.

Detachable Handle

The handwheel can be removed and positioned on either side

of the carriage.

1) Push the button of the detent pin, grasp the handwheel

and pull away from the carriage.

2) Align the tab on the back of the handwheel with the slot

on the carriage to attach the handwheel.

General

Information

CD02442-02-21-19

3-6 General InformationHornet™ XL

Carriage Slot

Handwheel Tab

CD02493-03-15-19

Detent Pin Button

TX05399-03-15-19

OPERATION - FUSION OUTLET

Attach Hornet™ XL to Pipe

1) Determine the size of the main pipe and the size of

outlet that will be fused. If the main pipe size is greater

than 315mm (12" OD), the extension chains need to

installed. Refer to “Attach Extension Chains” section of

this manual for installation procedure.

2) Apply the carriage brake so the carriage will not move

while attaching the Hornet™ XL. The handwheel can

be removed and positioned on the other side of the

carriage if needed.

Carriage Brake

5) Pull the chain tight and insert the closest link of the

chain into the slot of the clamp bracket.

Clamp Bracket

CD02448-03-15-19

6) Tighten the clamp knob until the tailstock is firmly

secured to the main pipe. Repeat these steps for the

other chain.

Operation

Fusion Outlet

CD02446-02-25-19

3) Position the tailstock against the main pipe.

CD02445-02-25-19

4) Wrap the chains around the pipe and up to the clamp

knobs of the tailstock.

CD02448-02-25-19

The clamp knobs are equipped with a ball thrust bearing,

which permit the operator to develop high clamp forces with

minimal effort.

7) Clean the main pipe in the area where the fitting will be

fused.

CD02447-02-25-19

4-1Operation - Fusion Outlet Hornet™ XL

Prepare Heater

This heater is not explosion proof. Operation of

heater in an explosive atmosphere without necessary

safety precautions will result in serious injury or

death.

When operating in an explosive atmosphere, the heater

should be brought up to temperature in a safe environment,

then unplugged before entering the explosive atmosphere for

fusion.

1) Ensure the heater is cool. Install fusion outlet heater

adapters.

NOTICE: The heater should never be used without fusion

heater adapters installed. Refer to the “Install

Heater Adapters” section of this manual for

installation procedure.

CD02152-2-21-18

The heater has a green indicator light which will flash on and

off. This indicates that the controller is operating normally. If

the green indicator is not flashing then the controller may not

be operating properly. If this occurs, disconnect power and

have the heater repaired by an McElroy Authorized Service

Center.

The heater has a red indicator light on the handle at the

bottom of the temperature scale. When the heater is plugged

in and preheating the red light glows steadily until the set

temperature is reached. The red light then goes off and on as

the heater maintains temperature.

If the heater is not operating properly, the control will attempt

to turn the heater off and the red indicator light will flash

rapidly. If this occurs, disconnect the power and take it to a

McElroy Authorized Service Center for repair.

Operation

Fusion Outlet

CD02449-03-15-19

2) Place heater in insulated heater bag.

3) Plug heater into a proper power source. Refer to

Heater Information Label for power information.

Adjusting Heater Temperature:

4) Turn knob to desired temperature. Allow heater to reach

temperature. Measure the heater surface temperature

with a pyrometer. Any variance must be corrected to

the pyrometer reading.

Loosen set screw in the knob. Turn knob to point to the

temperature of the pyrometer reading. Tighten set screw

in the knob.

Turn knob to desired temperature. Allow heater to

stabilize at the new temperature (5 to 10 minutes) after

adjusting.

The thermometer on the heater body indicates internal

temperature and should be used as a reference only.

PH02571-2-21-18

5) Allow heater to warm-up to operating temperature.

4-2 Operation - Fusion OutletHornet™ XL

Drill Main Pipe

The drill adapter is used with a hole saw to drill a hole in the

main pipe.

Insert Drill Adapter in Carriage:

1) Attach drill (not included) to the drill adapter. Refer to

the “Attach Drill to Drill Adapter” section of this manual

for installation procedure.

2) Install a hole saw (not included) that matches the fitting

size to be fused. Contact fitting manufacturer for hole

saw recommendations.

Hole Saw

4) Unlock the brake on the carriage. Pull the trigger on

the drill and close the carriage toward the main pipe.

Apply extra pressure as needed to advance the hole

saw into the main pipe. Drill until the hole saw cuts

through the pipe wall completely.

CD02455-02-27-19

5) Release the drill trigger and open the carriage

completely and apply the brake.

Operation

Fusion Outlet

CD02454-02-27-19

3) Ensure the 63mm pipe inserts are installed in the jaws

of the carriage. Unlock the brake on the carriage and

open the carriage completely then lock the brake.

Insert the drill and drill adapter in the lower jaws of the

carriage. There are two steps in the drill adapter and

each one will rest in the pipe inserts. Close the jaws

and tighten the clamps to secure the adapter in the

carriage.

CD02456-02-27-19

6) Open the jaws of the carriage and remove the drill and

drill adapter.

Steps on Adapter

CD02453-02-26-19

CD02458-02-27-19

4-3Operation - Fusion Outlet Hornet™ XL

Insert Fitting

The fitting adapter secures the position and orientation of the

fitting in the carriage for 63mm - 125mm fittings.

If pipe is pupped to the fitting, the fitting can be clamped using

Acrobat™ pipe inserts instead of the fitting adapter.

For 160mm fittings the adapter is not required and the fitting

can be clamped directly in the machine.

Insert Fitting Adapter in Carriage (63mm to

125mm Fittings):

1) Open the jaws of the carriage.

2) Install a fitting puck for the size fitting to be fused.

4) Insert the fitting over the fitting puck and against the

backing plate of the adapter.

Fitting

Fitting Adapter

Clamp Knob

CD02452-03-15-19

Fitting Puck

CD02450-03-15-19

3) Ensure the 63mm pipe inserts are installed in the jaws

of the carriage. Insert the fitting adapter in the lower

jaws of the carriage. There are two grooves on the

adapter one for 110mm - 125mm fittings and the

other for 63mm - 90mm fittings. Ensure the adapter is

inserted with the appropriate groove in the lower jaw

closest to the main pipe. Close the jaws and tighten the

clamps to secure the adapter in the carriage

63mm - 90mm

Fitting Groove

5) Close the carriage and bring the fitting next to the main

pipe.

6) Adjust the fitting by rotating it to align the curve of the

fitting to the curve of the main pipe.

Curve of Fitting

Curve of Main

Pipe

CD02459-03-15-19

7) After alignment, tighten the fitting adapter clamp knob

to secure the fitting.

8) Clean the fitting where the fitting will make contact with

the main pipe.

Operation

Fusion Outlet

110mm - 125mm

Fitting Groove

CD02451-02-26-19

4-4 Operation - Fusion OutletHornet™ XL

Insert Heater

NOTICE: Incorrect heating temperature can result in

questionable fusion joints. Check heater adapters periodically

with a pyrometer and make necessary adjustments.

Refer to “Prepare Heater” section for how to adjust heater

temperature.

1) Check heater surface temperature with a pyrometer.

Refer to the pipe manufacturer’s recommendations or

appropriate joining standard for proper heater temperature.

IMPORTANT: The dial thermometer on the heater indicates

internal temperature which varies from the actual surface

temperature.

The dial thermometer can be used as reference once the

surface temperature has been verified and is never a substitute

for actual surface temperature.

4) Open carriage completely. Insert heater in the heater

strippers between the main pipe and fitting. Ensure the

tabs of the heater insert between the tabs of the heater

stripper.

CD02460-03-15-19

Operation

Fusion Outlet

This heater is not explosion proof. Operation of

heater in an explosive atmosphere without necessary

safety precautions will result in serious injury or

death.

2) Use a clean dry lint free non-synthetic cloth to clean the

fusion heater adapters.

CD02461-03-15-19

The heater is hot and will burn clothing and skin.

Keep the heater in its insulated heater stand or

blanket when not in use, and use care when heating

the pipe.

Heat Fitting and Pipe

1) Rotate the handwheel to close the carriage bringing the

heater into the pipe and the fitting into the heater.

IMPORTANT: Do not force the heater onto the pipe

and fitting. Allow the pipe and fitting to

melt onto the heater. Forcing the heater

onto the fitting and pipe will damage

the Hornet XL or create a questionable

melt pattern.

CD02462-03-15-19

Heating time starts when the heater adapters are fully

inserted into the pipe and fitting.

Heat fitting and pipe for the pipe manufacturer’s

specified period of time or appropriate joining

standard.

4-5Operation - Fusion Outlet Hornet™ XL

2) Engage the carriage brake to hold the position of the

carriage during heating time.

3) When the heating time is complete, release the

carriage brake. Open the carriage until there is enough

room to remove the heater. Quickly remove the heater

from heater strippers.

4) Quickly inspect the heated parts to make sure all

surfaces have been melted properly.

Fuse Fitting and Pipe

1) Close the carriage bringing the fitting and pipe

together. Continue to close the carriage until the fitting

is inserted completely into the pipe.

NOTICE: Be sure to complete the joint in the time

allowed by the pipe manufacturer or

appropriate joining standard.

2) Engage the carriage brake to hold the carriage

position after the fitting is completely inserted.

Allow the carriage to stay in place for the total cooling

time specified by the pipe manufacturer or appropriate

joining standard.

CD02463-03-15-19

2) Release the carriage brake. Open the carriage

completely and reapply the carriage brake.

CD02463-03-15-19

Remove Hornet™ XL

After completing the specified cooling time, inspect the joint

for compliance with the appropriate joining standard.

There should be no gaps or voids between the fitting and the

pipe.

If the joint is not acceptable, cut out the pipe section and fuse

a new pipe in the removed section.

1) Unclamp the fitting from the fitting adapter.

CD02468-03-15-19

3) If a pipe needs to be fused to the fitting, refer to

“Operation - Socket Fuse to Outlet” for a socket fusion.

4) Remove the carriage from the main pipe by loosening

the clamp knobs on the tailstock. Slide the chains from

the clamp brackets and lift machine from the main pipe.

IMPORTANT: Support the machine while unclamping to

avoid the machine falling or swinging around the main pipe.

5) Refer to “Attach Hornet™ XL to Pipe” section and start a

new fusion outlet.

Operation

Fusion Outlet

TX05400-03-15-19

4-6 Operation - Fusion OutletHornet™ XL

OPERATION - SOCKET FUSE TO OUTLET

After creating a fusion outlet on a main pipe, you can use

the Hornet™ XL to fuse a pipe to the fusion outlet. A 63mm to

125mm outlet requires a socket fusion to be performed. Leave

the machine attached in the same position after making the

fusion outlet. The jaw inserts and socket fusion heater adapters

are not included and will need to be obtained separately.

Prepare Pipe End

1) Cut off damaged or oval ends of pipe squarely with a

pipe cutter.

2) Remove shavings and burrs inside pipe end.

CD02479-03-15-19

3) Plug heater into a proper power source. Refer to

Heater Information Label for power information.

Adjusting Heater Temperature:

Fuse to Outlet

Operation - Socket

CD00999-2-21-18

Prepare Heater

This heater is not explosion proof. Operation of

heater in an explosive atmosphere without necessary

safety precautions will result in serious injury or

death.

When operating in an explosive atmosphere, the heater

should be brought up to temperature in a safe environment,

then unplugged before entering the explosive atmosphere for

fusion.

1) Ensure the heater is cool. Install socket fusion heater

adapters (not included) for 63mm to 125mm outlets.

Refer to “Changing Heater Plates/Adapters” in the

Maintenance section for information about heater

plates and adapters.

NOTICE: The heater should never be used without fusion

heater adapters installed.

2) Place heater in insulated heater bag.

CD02152-2-21-18

4) Turn knob to desired temperature. Allow heater to reach

temperature. Measure the heater surface temperature

with a pyrometer. Any variance must be corrected to

the pyrometer reading.

Loosen set screw in the knob. Turn knob to point to the

temperature of the pyrometer reading. Tighten set screw

in the knob.

Turn knob to desired temperature. Allow heater to

stabilize at the new temperature (5 to 10 minutes) after

adjusting.

The thermometer on the heater body indicates internal

temperature and should be used as a reference only.

The heater has a green indicator light which will flash on and

off. This indicates that the controller is operating normally. If

the green indicator is not flashing then the controller may not

be operating properly. If this occurs, disconnect power and

have the heater repaired by an McElroy Authorized Service

Center.

The heater has a red indicator light on the handle at the

bottom of the temperature scale. When the heater is plugged

in and preheating the red light glows steadily until the set

temperature is reached. The red light then goes off and on as

the heater maintains temperature.

5-1Operation - Socket Fuse to Outlet Hornet™ XL

If the heater is not operating properly, the control will attempt

to turn the heater off and the red indicator light will flash

rapidly. If this occurs, disconnect the power and take it to a

McElroy Authorized Service Center for repair.

PH02571-2-21-18

5) Allow heater to warm-up to operating temperature.

Clean Fitting and Pipe

1) Fitting and pipe must be clean and dry. Use a clean lint

free cloth to wipe the mating surfaces.

NOTICE: Do not touch fusion area with hands.

Mark Insertion Depth

1) Use a marking instrument and mark the insertion depth

according to the appropriate joining standard. The

mark can be made using the insertion depth gauge.

This mark is the insertion depth used when fusing the

pipe and fitting.

The chamfer/depth gauge tool may be used to

chamfer the end of the pipe as well as determine the

insertion depth. Mark the insertion depth along the

edge of the chamfer/depth gauge. The chamfer/depth

gauge is pipe size specific.

CD0120 9-2-21-18

CD02464-03-15-19

CD00999-2-21-18

Load Pipe

1) Ensure the Acrobat™ pipe inserts are installed for the

size of pipe to be fused.

2) Load the pipe into the jaws of the carriage. Allow

enough pipe to protrude so that the pipe can be

inserted to the insertion depth. Tighten the clamp knobs

on the carriage.

NOTICE: Overtightening the jaws could distort the pipe or

fitting resulting in a questionable fusion joint.

5) Open the carriage completely to allow the heater to be

inserted.

Fuse to Outlet

Operation - Socket

CD01238-2-21-18

Insertion Depth

Mark

CD02465-03-15-19

5-2 Operation - Socket Fuse to OutletHornet™ XL

Heat Fitting and Pipe

1) Use a pyrometer to check the temperature on the socket

faces.

2) Use a clean non-synthetic lint free cloth to clean the

heater socket adapter surfaces.

3) Insert the heater into the heater strippers in between

the pipe end and fitting. Rotate the handwheel moving

the pipe onto the heater and the heater onto the fitting.

Close the jaws until the heater is inserted completely

into the fitting and the pipe is inserted to the insertion

depth mark.

IMPORTANT: Do not force the heater onto the pipe

and fitting. Allow the pipe and fitting to

melt onto the heater. Forcing the heater

onto the fitting and pipe will damage

the Hornet XL or create a questionable

melt pattern.

2) Engage the carriage brake to hold the position of the

carriage during heating time.

3) When the heating time is complete, release the

carriage brake. Open the carriage completely. Quickly

remove the heater from heater strippers.

4) Quickly inspect the heated parts to make sure all

surfaces have been melted properly.

Fusion and Cooling

1) Close the carriage bringing the fitting and pipe

together. Close the carriage to the insertion depth mark

on the pipe. Engage the carriage brake to hold the

position of the carriage.

Fuse to Outlet

Operation - Socket

CD02466-03-15-19

Heating time starts when the pipe and fitting are fully

inserted onto the heater adapters.

Heat fitting and pipe for the pipe manufacturer’s

specified period of time or appropriate joining

standard.

CD02469-03-15-19

NOTICE: Be sure to complete the joint in the time

allowed by the pipe manufacturer or

appropriate joining standard.

Allow the jaws to stay in place for the total cooling

time specified by the pipe manufacturer or appropriate

joining standard.

CD02467-03-15-19

5-3Operation - Socket Fuse to Outlet Hornet™ XL

Remove Hornet™ XL

After completing the specified cooling time, inspect the joint

for compliance with the appropriate joining standard.

There should be no gaps or voids between the fitting and the

pipe.

If the joint is not acceptable, cut out the pipe section and fuse

a new pipe in the removed section.

1) Open the jaws of the carriage.

2) Remove the machine from the main pipe by loosening

the chains on the tailstock and removing the chains

from the chain brackets. Lift the machine away from the

pipe.

IMPORTANT: Support the machine while unclamping to

avoid the machine falling or swinging around the main pipe.

CD02470-03-15-19

Fuse to Outlet

Operation - Socket

TX05401-03-15-19

5-4 Operation - Socket Fuse to OutletHornet™ XL

STORAGE/TRANSPORT

Storage/Transport

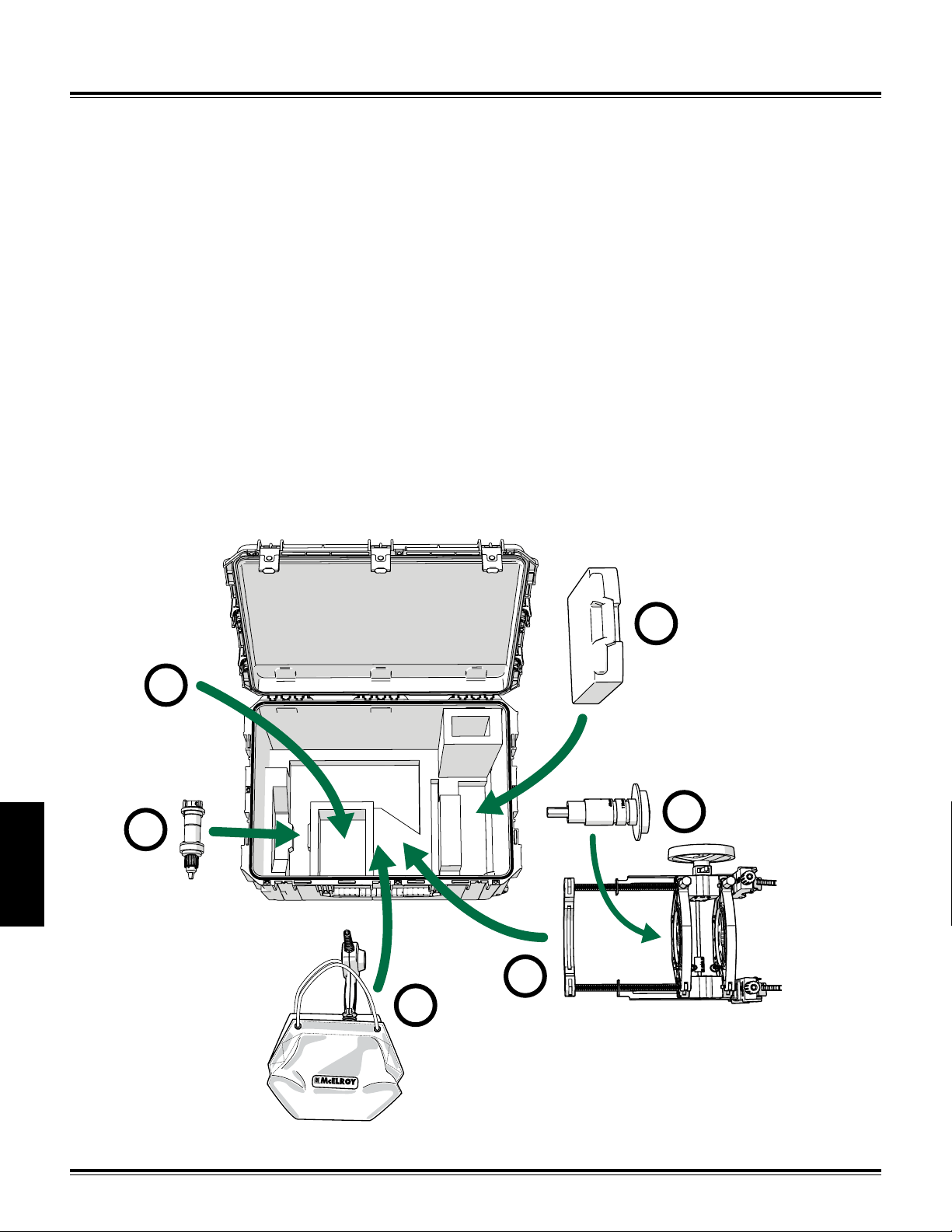

A storage/transport case is available to store the Hornet™ XL

fusion machine package. The case has wheels for mobility and

carrying handle options that aid in loading and unloading.

Foam inserts inside the case provide storage locations for each

component of the package.

Refer to the illustrations for component locations.

1) Drill Adapter - The drill adapter can be stored with the

drill attached. The drill is not included.

A) Additional Storage Area - Can be used to store drill

battery and charger (not included).

2) Hornet™ XL Fusion Machine - Clamp the fitting adapter

(B) in the fusion machine. Close the carriage against

tailstock and apply the carriage brake. Attach the

handwheel to the brake side of the carriage. Insert the

fusion machine into the case.

3) Hornet™ XL Accessory Case - Insert the accessory case

in front of the tailstock of the fusion machine.

4) Heater - Insert the heater into the insulated heater bag.

Position the heater with bag on top of fusion machine

with the heater cord pointing upward.

NOTICE: Ensure the heater is cool before inserting the

heater bag into the case. Damage to the foam

inserts could occur.

TX05402-03-15-19

3

A

B

1

Storage/Transport

2

4

Hornet™ XL Storage Case Storage Locations

6-1Storage/Transport Hornet™ XL

Hornet™ XL Storage Case with All Items Stored

6-2 Storage/TransportHornet™ XL

Storage/Transport

MAINTENANCE

Task As Needed Daily Monthly Yearly

Clean Machine

Check Machine Operation

Fasteners Are Tight

Changing Heater Plates/Adapters

Clean Chains

Clean Fitting and Drill Adapter

Adjust Gearbox Chain Tension

Preventative Maintenance

To insure optimum performance, the machine must be kept

clean and well maintained.

With reasonable care, this machine will give years of service.

Therefore, it is important that a regular schedule of preventive

maintenance be kept.

Store machine inside, out of the weather, whenever possible.

Clean Machine

1) Clean the machine with soap and water as needed.

Do not pressure wash.

Check Machine Operation

1) Open and close the carriage of the machine. If the

machine has resistance opening or closing, inspect the

carriage guide rods for debris in the rack and brush

any debris out of the rack.

2) Inspect the gearboxes and cross shaft for damage.

Ensure power is being transmitted from gearbox to

gearbox with a minimal amount of free play in the

handle.

3) Engage the carriage brake and orient the machine

vertically. Apply pressure on the carriage with hands. If

the brake slips and doesn't hold the carriage position,

replace the brake.

4) Inspect the jaw clamps for proper operation. Replace

Maintenance

any damaged jaw clamps.

5) Inspect chain clamps for proper operation. Replace

any damaged chain clamps.

l

l

l

l

l

l

l

Fasteners Are Tight

1) Inspect all machine fasteners for tightness. Tighten any

loose fasteners.

Changing Heater Plates/

Adapters

The heater body of this assembly is not coated. Coated heater

plates/adapters are available for all fusion applications.

Heater plates/adapters are installed with stainless steel cap

screws.

Care should be taken to assure that the heater adapters are

seated on the heater body, and that there is no foreign matter

trapped between these surfaces.

IMPORTANT: Do not over-tighten the bolts.

The surface of the heater adapters are coated with an antistick coating.

NOTICE: Only install heater adapters when the heater is

cool.

CD02479-03-15-19

7-1Maintenance Hornet™ XL

Clean Chains

Chains and extension chains can become dirty causing the

chains to slip on the pipe.

1) Clean any debris from the chains using a stiff bristled

brush.

Clean Fitting Adapter

1) Clean any debris from the adapter using a clean cloth.

Clean Drill Adapter

1) Clean any debris from the adapter using a clean cloth.

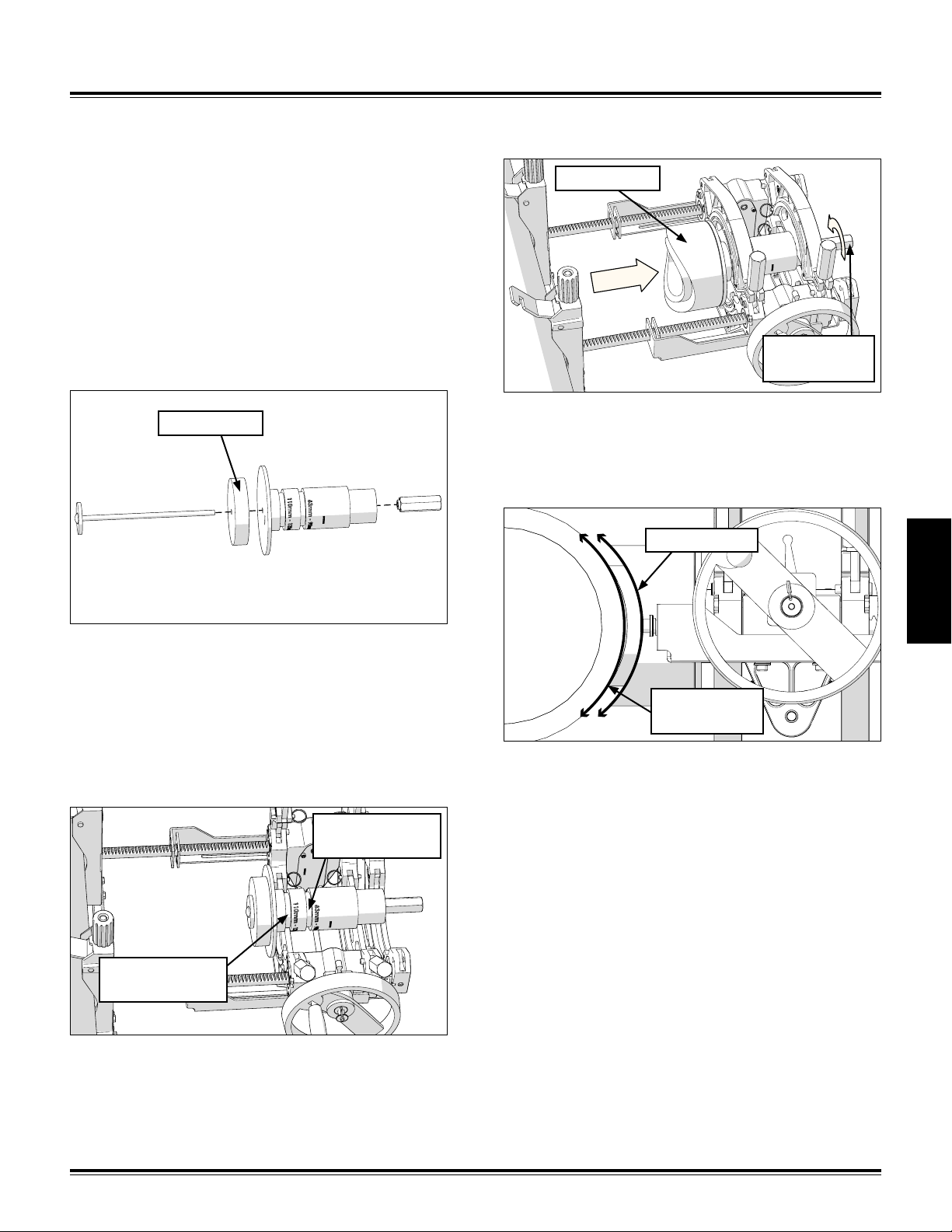

Adjust Gearbox Chain Tension

1) Tighten the set screw to adjust the chain tension.

NOTICE: Over-tightening the screw will apply too much chain

tension and will cause the carriage to not move easily and

damage the chain and gears of the gearbox.

2) Move the handwheel to the other gearbox and adjust

the chain tension on the second gearbox.

CD02478-03-15-19

Chain Tension

Foot

Chain Tension

Adjustment Screw

Maintenance

TX05403-03-15-19

7-2 MaintenanceHornet™ XL

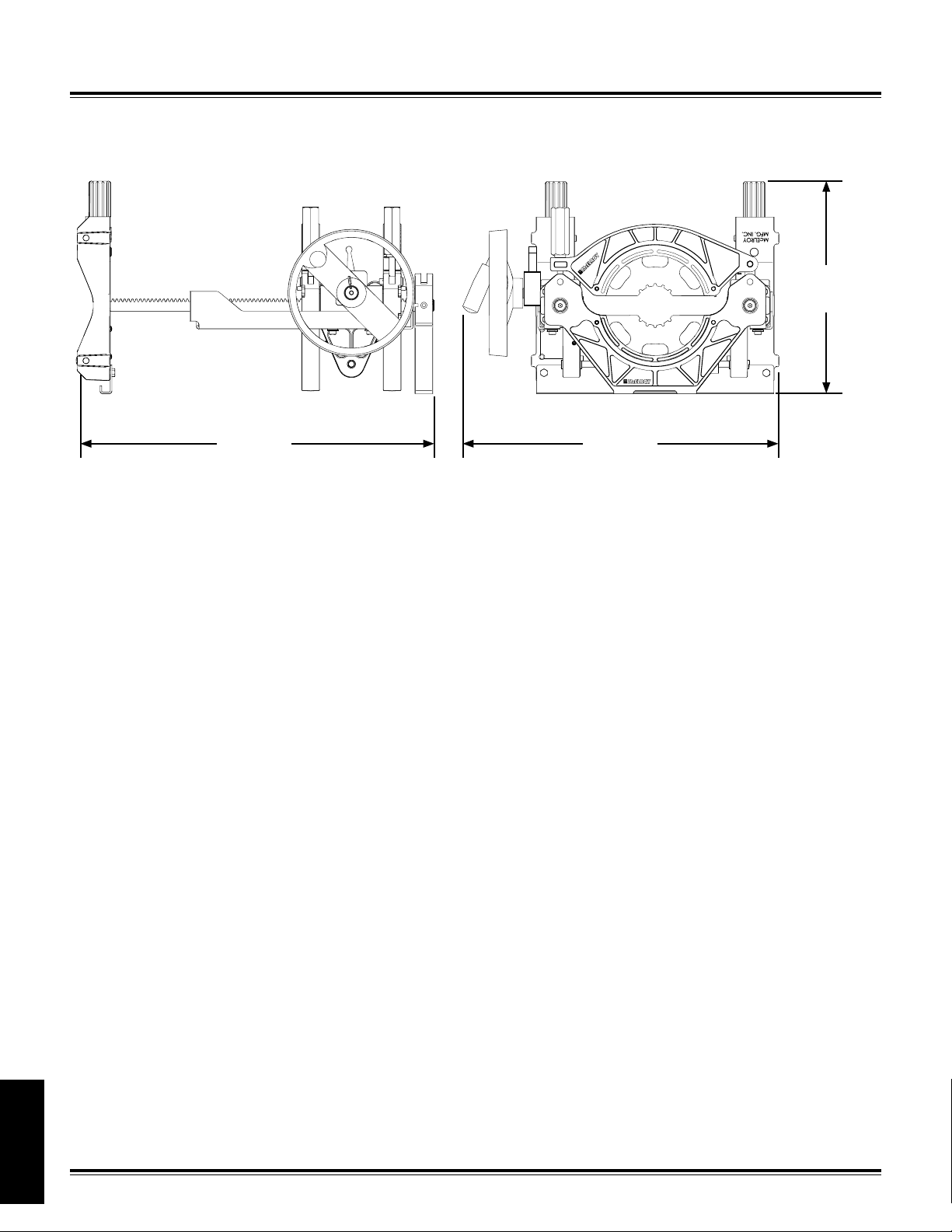

SPECIFICATIONS

13.5"

(343mm)

22.5"

(546mm)

19.5"

(495mm)

Specifications

Hornet™ XL Specifications

Models: ASW31401 - 120V Machine Package

ASW31402 - 240V Machine Package

Capacity: Fuses Outlet Sizes 63mm - 160mm (2" - 6")

Fuses to Main Sizes 125mm - 630mm (4" - 24")

Weight: Machine: 42 lbs. (19.0 kg)*

Dimensions: Length: 22.5" (546mm)

Width: 19.5" (495mm)

Height: 13.5" (343mm)

Power: Heater Power: 1,600 Watt

Package Inclusions:

Package includes Hornet™ XL carriage, heater, 63mm jaw inserts, drill adapter, drill adapter sleeve, 7/16" deep socket, 7/16"

socket, 3/8" square drive, fitting adapter, fitting clamp puck kit, chain extensions, accessory case and storage case. Drill and hole

saws are not included. Heater adapters/plates, other jaw inserts sold separately.

* Carriage weight can be reduced by removing upper jaws, lower jaw inserts, clamp handles and handwheel (all done without use of

tools) to 34 lbs. (15.5 kg).

TX05404-03-15-19

Specifications

8-1Specifications Hornet™ XL

NOTES

Notes

Notes

9-1 NotesHornet™ XL

Loading...

Loading...