McDonnell & Miller FS-5 Installation Manual

Installation & Maintenance

Instructions MM-616

Series FS-5

General Purpose

Liquid Flow Switch

OPERATION

This control is an independently mounted water flow

sensing device that makes or breaks an electrical

circuit when flow stops or starts.

• Before using product, read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application,

installation, and maintenance of plumbing, steam and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

• To prevent electrical shock, turn off the electrical power before making electrical

connections.

• To prevent an electrical fire or equipment damage, electrical wiring insulation must have a

rating of 167˚F (75˚C) if the liquid’s temperature exceeds 180˚F (82˚C).

• To prevent electrocution, when the electrical power is connected to the flow switch, do not

touch the terminals.

• Make sure flow switch electrical cover is secured before turning on electric power.

Failure to follow this warning could cause property damage, personal injury or death.

W

A

R

N

I

N

G

C

A

U

T

I

O

N

!

WARNING

Series FS-5

(specified models only)

®

CE Circuit Rating

7.4 (7.4)/120~ 0.3/120=

3.7 (3.7)/240~ 0.15/240=

2

Motor Switch Rating (Amperes)

Voltage Full Load Locked Rotor Pilot Duty

120 VAC 7.4 44.4

125 VA at

240 VAC 3.7 22.2

120 or 240 VAC

50 or 60 cycles

Maximum Liquid Pressure: 150 psi (10.5 kg/cm2)

Liquid Temperature Range (T

L): 32 - 250˚F (0 - 121˚C) (All models except “S”)

32 - 225˚F (0 - 107˚C) (“S” models)

Ambient Temperature Range (TS): 32 - 120˚F (0 - 49˚C)

Electrical Enclosure Rating: Nema Type 1 (IP 21)

Maximum V elocity: 10ft/sec (3M/sec)

Pipe Connection Thread Size:

3

/4” or 1” NPT (All models except “J”)

3

/4” or 1” BSPT (“J” models)

Models that meet CE Conformance:

FS5-J-3/4-E

FS5-J-1-E

• This Control: is for continuous operations

is not electronic

has Type 1C action (micro interruption

on operation)

• LVD 73/23/EEC

• EMC 89/33/EEC

For applications with loads between 0.5 and 3.7 Amps,

power factors exceeding 0.65, an anticipated system

switch operation rate of less than once per 2.5 minutes,

and any one cycle greater than 3 seconds on and 3

seconds off.

For applications with loads 0.5 and 38mA, power

factors exceeding 0.65, an anticipated system

switch operation rate of less than once per 5 minutes,

and any one cycle greater than 3 seconds on and 3

seconds off.

Additional suppression may be required for applications outside these ranges.

• Declaration of Conformity

Available on request.

SPECIFICATIONS

ELECTRICAL RATINGS

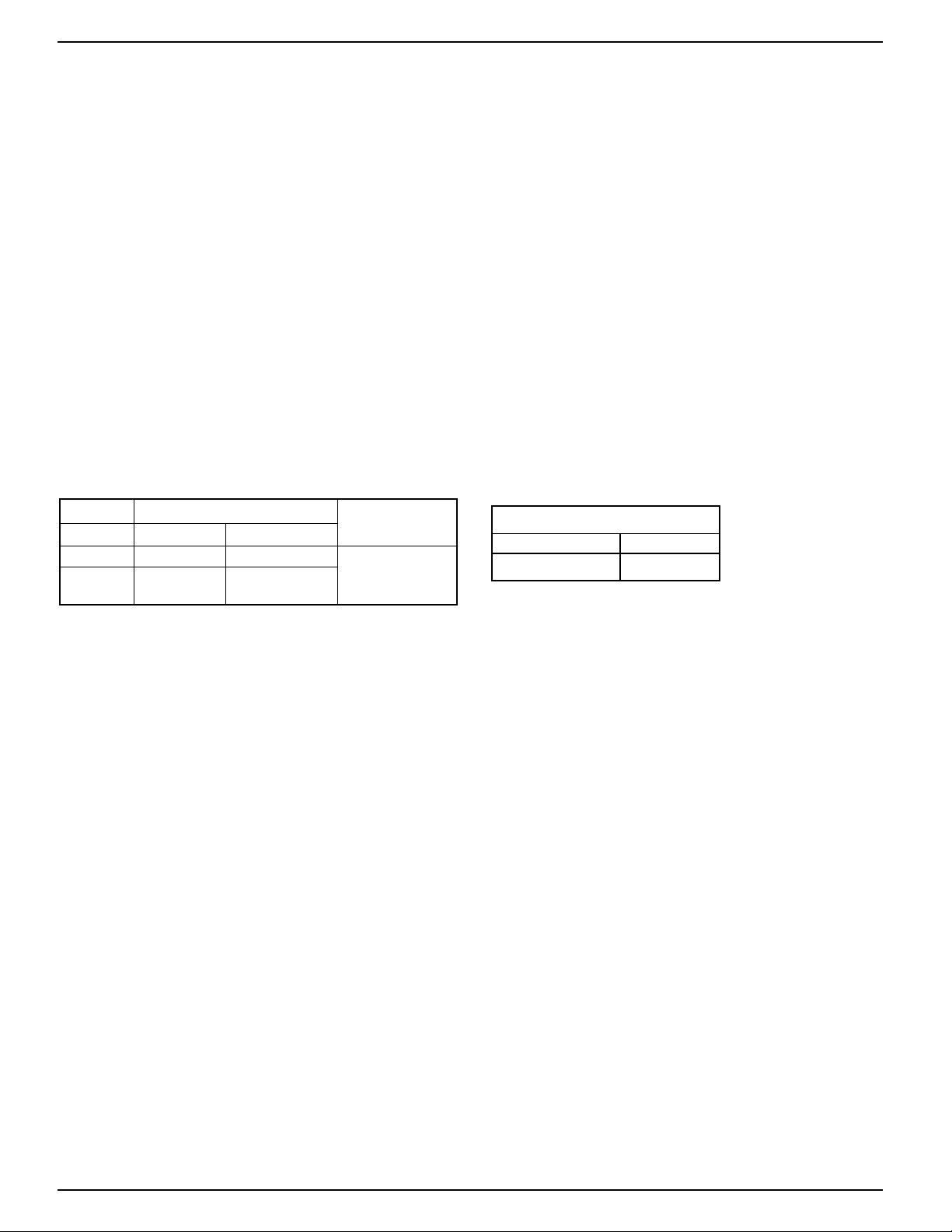

FLOW RATES

Flow rates required to activate flow switch are shown

in chart below. The values are calculated for sensing

water (potable, non-polluted) in a horizontal pipe.

Settings will vary when used to sense flow of other

fluids.

3

NOTE: DO NOT USE LIQUID FLOW

SWITCHES ON SYSTEMS WITH

FLOW VELOCITY GREATER THAN

10 FEET (3M) PER SECOND.

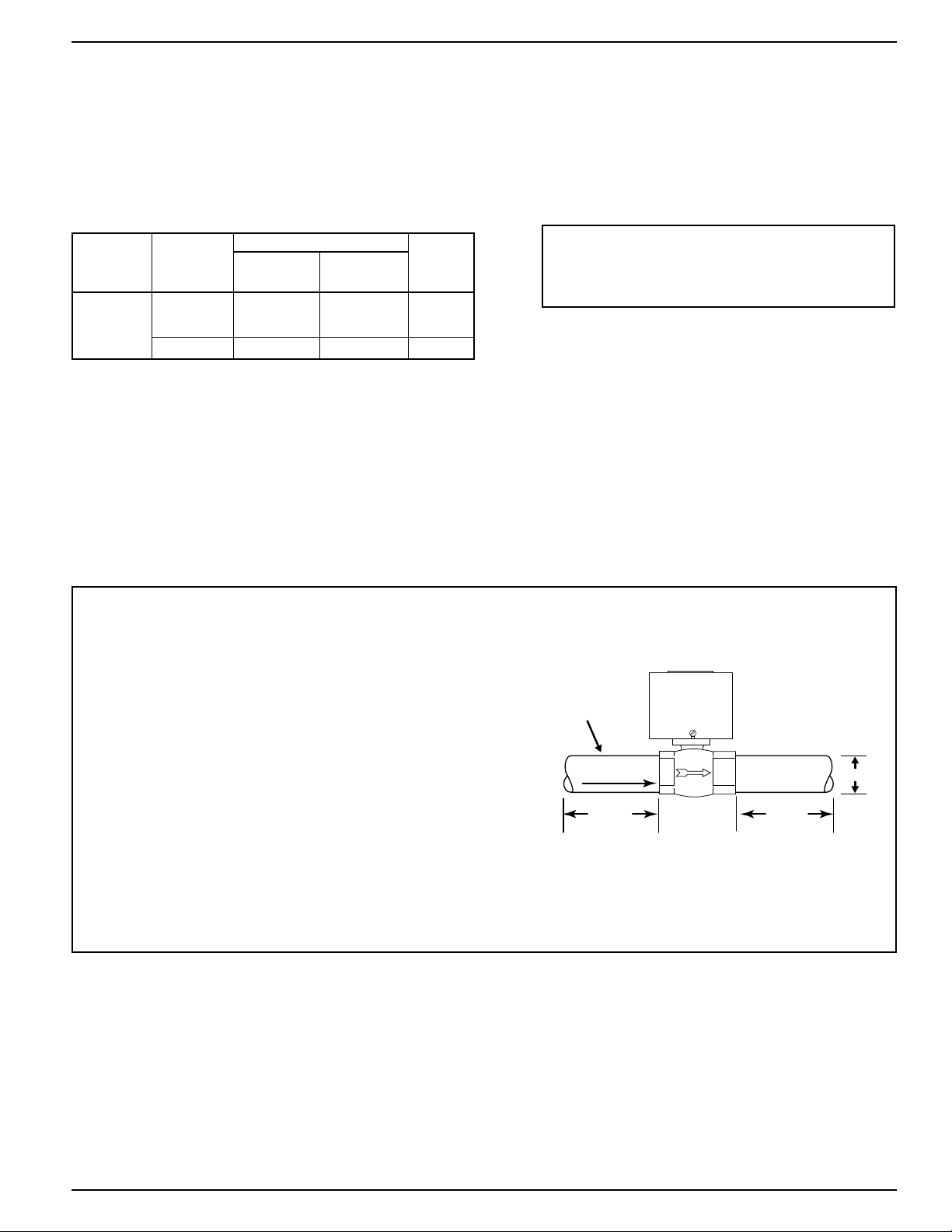

INSTALLATION –

STEP 1 - Determine the Location of the Flow Switch

Fluid Flow

3/4" or 1"

PIPE

5 x D

MINIMUM

D

D= PIPE DIAMETER

5 x D

MINIMUM

• The flow switch should be located in a horizontal

section of pipe where there is a straight horizontal run

of at least 5 pipe diameters on each side of the flow

switch.

• The flow switch must be installed in the upright

position as shown with arrow mark on side of casting

in the same direction as fluid will flow.

• Some system conditions that require more than 5 pipe

diameters are high viscosity fluid and high fluid velocity.

• The flow switch should be installed in the pump suction

piping when spring-loaded check valves and/or other

close coupled accessories are installed in the pump

discharge piping.

Flow Rates

Pipe

Mode of Operation

Size NPT Flow No Flow

in. (mm) Settings gpm (lpm) gpm (lpm)

3

⁄

4

(20)

Factory or

or Minimum 1.5 (5.7) 1.1 (4.2) 16.62 (63)

1 (25)

Maximum 15 (56.8) 10 (37.9) 27 (102)

Values are ±10%

Max. Flow

Rate gpm

(lpm) w/o

Paddle Damage

Loading...

Loading...