Page 1

Technical Manual

THERMflow

Boiler Model

McDonald Engineers UK

November 2017

THERM

flow

Boiler Model Technical Manual

HOT WATER SOLUTIONS SINCE 1945

Page 2

1

Contents

Design .................................................................................................................. 2

Preface ................................................................................................................. 2

Handling & Storage .............................................................................................. 2

What is a thermal store? ..................................................................................... 3

Basics of the Thermal Store ................................................................................. 3

Mains Water Supply ............................................................................................ 4

Water Treatment ................................................................................................. 4

THERMflow Combination General Schematic ..................................................... 5

THERMflow Cylinder General Schematic ............................................................. 6

THERMflow Connection Heights.......................................................................... 7

THERMflow with External PHE ............................................................................ 8

THERMflow Combination with PHE General Schematic ...................................... 9

THERMflow Cylinder with PHE General Schematic ........................................... 10

Commissioning................................................................................................... 11

Commissioning Best Practice ............................................................................. 12

Troubleshooting................................................................................................. 13

Schematics ......................................................................................................... 15

Ancillary Descriptions ........................................................................................ 18

Installing a Gravity System................................................................................. 20

Page 3

2

Design

An early adopter of the principal of domestic thermal stores, McDonald Engineers UK

first started manufacturing thermal stores in early 1990s. Manufactured by our trained

coppersmiths and designed based upon the experiences of our technical team. The

McDonald Engineers UK THERMflow provides the perfect solution to both mains

pressure hot water and space heating requirements.

Preface

The THERMflow Technical Manual should be read in conjunction with the installation

and servicing manuals issued by the manufacturer(s) of the heat source(s) used within

the thermal storage system, such as the boiler/solid fuel boiler, solar etc.

This information provided is intended to provide support with the installation of the

THERMflow storage system. Responsibility for selection and specification of our

equipment remains that of our customer and any experts or consultants concerned with

the installation(s). Our full Terms & Conditions of Sale are available on request.

The THERMflow thermal storage system is required to be fitted by a competent installer,

as defined by the relevant regulations e.g. Gas Safety Regulations. Please note that

while the THERMflow overcomes Part G Building Regulation discharge requirements

for unvented cylinders, the installation of the THERMflow may be notifiable to the

relevant building control.

Handling & Storage

It is important the THERMflow is handled with care and stored the correct way up in a

dry place at all times prior to, during and after installation. Any manual lifting will need

to comply with the requirements of the Manual Handling Operations Regulations issued

by the Health & Safety Executive. For installations on higher levels of properties such

as the 4th floor it is recommended as best practice for the THERMflow to be moved

vertically within a lift.

Page 4

3

What is a thermal store?

Often used in conjunction with a variety of alternative energy sources such as solid fuel,

wood burning stoves and solar, a thermal store captures input energy from heat sources

to allow that energy to be converted into mains pressure hot water and space heating

at a later time when the demand is greater. Energy from a heat source is captured within

the primary water of an open vented cylinder at a temperature of up to 80°C.

Cold water at mains pressure then passes through a High Efficiency Coil, which is

specifically designed as a heat exchanger, to draw heat from the thermal store at mains

pressure.

This heated water is subsequently blended with cold mains water through a

Thermostatically Controlled Mixing Valve, to provide mains pressure water at 55°C to

the taps. In addition, the primary water captured within the store can also be circulated

around the heating system allowing the householder to enjoy the benefits of mains

pressure water and heating produced from alternative and renewable heat sources.

Basics of the Thermal Store

The THERMflow Boiler Model utilises open vented boilers and/or Electric Immersion

Heaters as its primary heat source/s, with options available for wood burning, AGA, solid

fuel boiler and underfloor connections amongst others.

The main benefit of the Open Vented Thermal Store configuration is the open vented

nature allows the full power (kW) output of the boiler directly into the thermal store, as

no heat exchanger is required thus reducing energy usage and running costs. Input

energy from the boiler(s) is circulated from the thermal store to the central heating

system while the High Efficiency Secondary Coil is specifically designed to provide high

performance blended mains pressure hot water to the taps at 55°C.

Page 5

4

Mains Water Supply

The THERMflow’s performance is directly related to the cold water supply pressure and

volume incoming to the property. The THERMflow will operate with a minimum

incoming mains pressure of 1.0 Bar. A maximum incoming pressure of 3.0 Bar would be

the most optimal for performance. If the incoming mains pressure is higher than 3.0

Bar, a pressure reducing valve must be fitted downstream of where the incoming cold

supply enters the property at a lesser and appropriate pressure.

If the flow rate exceeds 20 Litres per minute at any tap, it should be restricted to

maintain the performance of the system as a whole.

Water Treatment

The THERMflow is part of the primary system and while it does not require any special

water treatment itself, the radiators and other parts of the primary circuit will require

the application of a protective scale and corrosion inhibitor such as Fernox to ensure

adequate protection. This should avoid having corrosive material in the primary system

and remove any build-up of sludge which can reduce the performance of the High

Efficiency Heat Exchanger Coil.

The volumes and concentration of inhibitor required should be calculated in accordance

with the manufacturer’s instructions. Please ensure that the thermal store volume is

also included as well as the radiator and pipework volume.

Please note that in all THERMflow models, the primary water within the thermal store

water is used as primary storage and the domestic hot water is heated instantaneously

by means of the High Efficiency Heat Exchanger Coil. Therefore, treating the primary

water will not have an effect on the domestic hot water supply.

Page 6

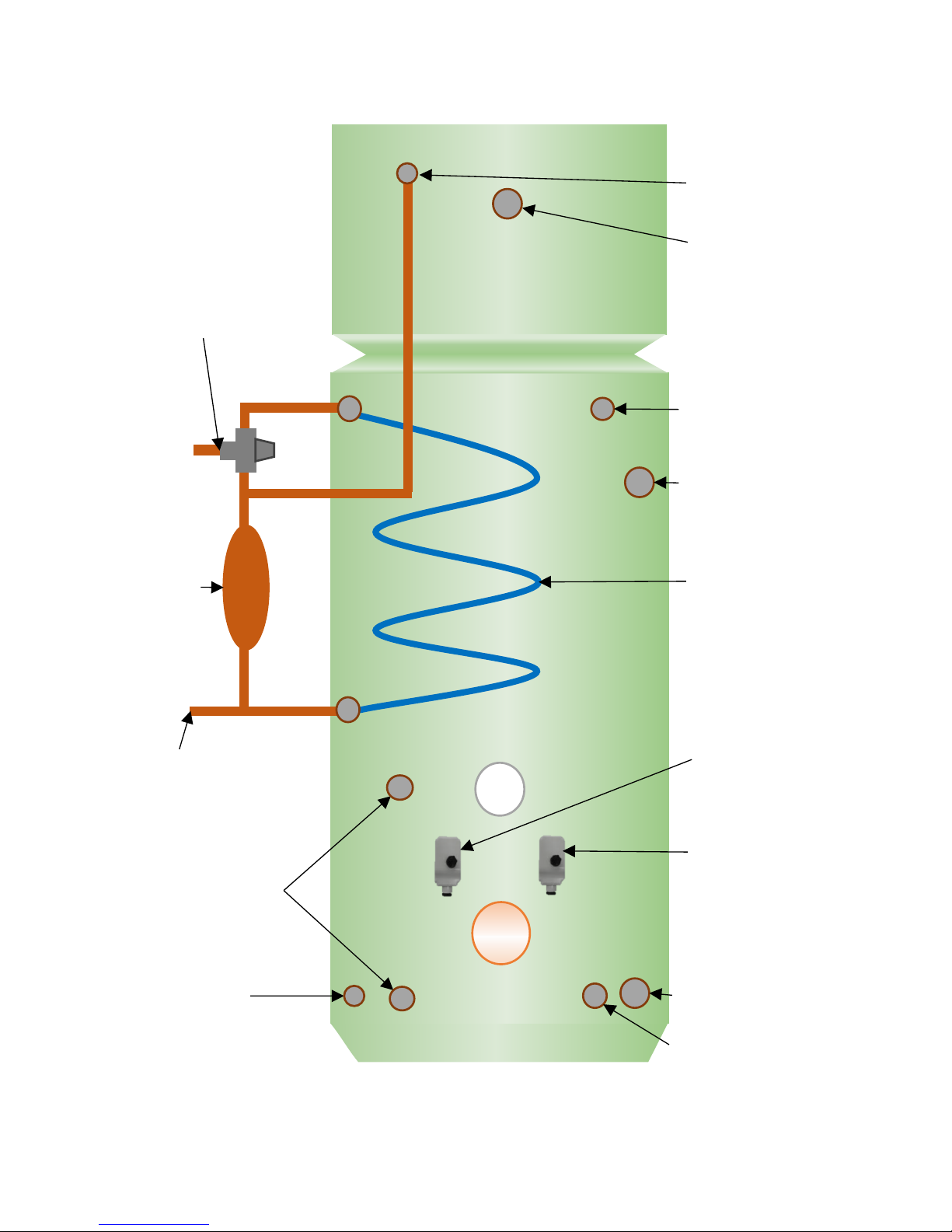

5

THERM

flow

Combination General Schematic

Immersion Heater

22mm Boiler Flow

(Other Sizes Available)

28mm Solid Fuel Return

(Other Sizes Available)

3kW

⁰C

Thermometer

22mm Central

Heating Flow &

Return Connections

(Other Sizes Available)

15mm Drain

Cold Mains

Secondary Water c/w

Check Valve & Strainer

Hot Out

c/w Thermostatic

Mixing Valve

2 Litre

Expansion

Bottle

High Efficiency

Secondary Coil

Maintenance Free

Jetseal Ballvalve

High-Limit

Stat

Control Stat

@ 75⁰C

Overflow

(Not fitted as standard)

22mm Boiler Return

(Other Sizes Available)

28mm Solid Fuel Flow

(Other Sizes Available)

Page 7

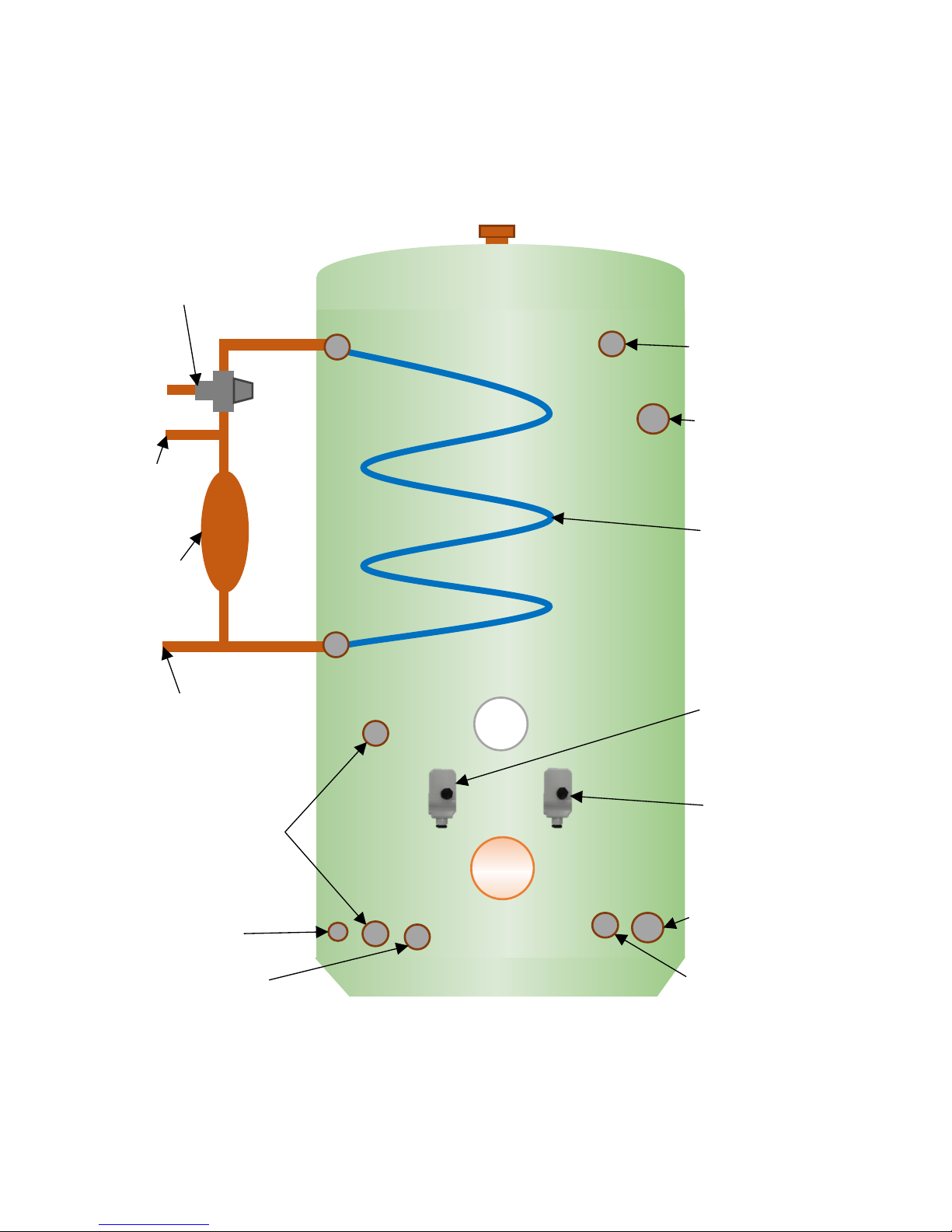

6

THERM

flow

Cylinder General Schematic

22mm Boiler Flow

(Other Sizes Available)

28mm Solid Fuel Return

(Other Sizes Available)

3kW

⁰C

Thermometer

22mm Vent

22mm Central Heating

Flow & Return

Connections

(Other Sizes Available)

15mm Drain

Immersion Heater

Cold Mains Secondary Water

c/w Check Valve & Strainer

Hot Out

c/w Thermostatic

Mixing Valve

22mm Cold Feed

2 Litre

Expansion

Bottle

Secondary Return

(Optional)

High Efficiency

Secondary Coil

High-Limit Stat

@ 90⁰C

Control Stat

@ 75⁰C

28mm Solid Fuel Flow

(Other Sizes Available)

22mm Boiler Return

(Other Sizes Available)

Page 8

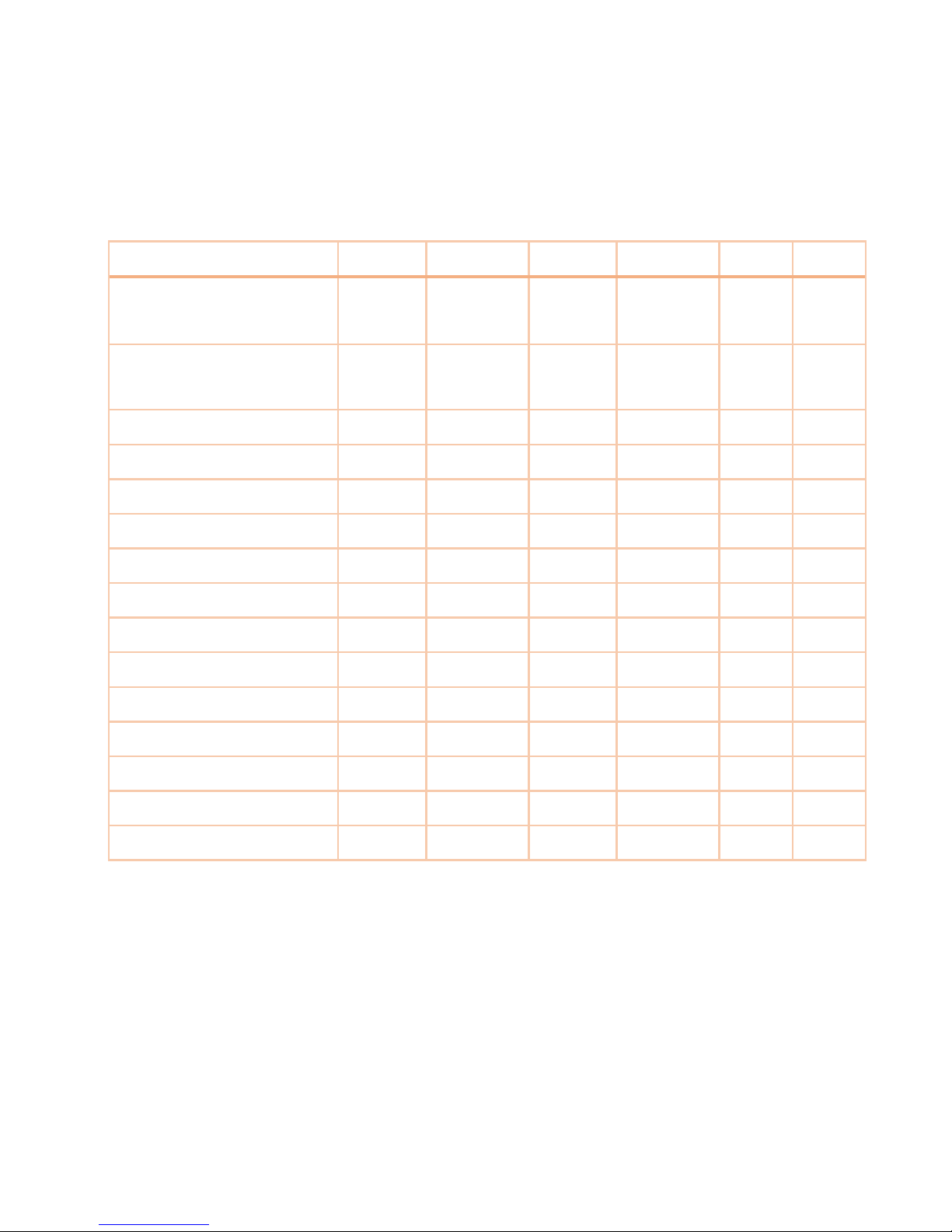

7

THERMflow Connection Heights

The connection heights shown below are taken from the ground (in mm). These

heights and the diagrams shown above are indicative of a typical arrangement of

connections, including optional extras. Bespoke options for specific installation are

available and will be supplied with a sketch prior to manufacturing of the THERMflow.

Capacity (Litres)

120

140

180

210

250

300

Shell Dimensions

900 x

450

1050 x

450

1300 x

450

1500 x

450

1500 x

500

1800 x

500

Overall Dimensions

950 x

550

1100 x

550

1350 x

550

1550 x

550

1550 x

600

1850 x

600

Cold Feed (Cyl. Only)

100

100

100

100

100

100

Drain

100

100

100

100

100

100

(3kW) IH

155

155

155

155

155

155

CH Flow

170

320

470

670

670

970

CH Return

100

100

100

100

100

100

Boiler Flow

700

850

1100

1300

1300

1600

Boiler Return

100

100

100

100

100

100

SF Flow

550

700

950

1150

1150

1450

SF Return

100

100

100

100

100

100

Thermostat

350

350

350

350

350

350

Thermometer

500

500

500

500

500

500

Hot Out

700

850

1100

1300

1300

1600

Cold In

220

370

520

720

720

1020

Page 9

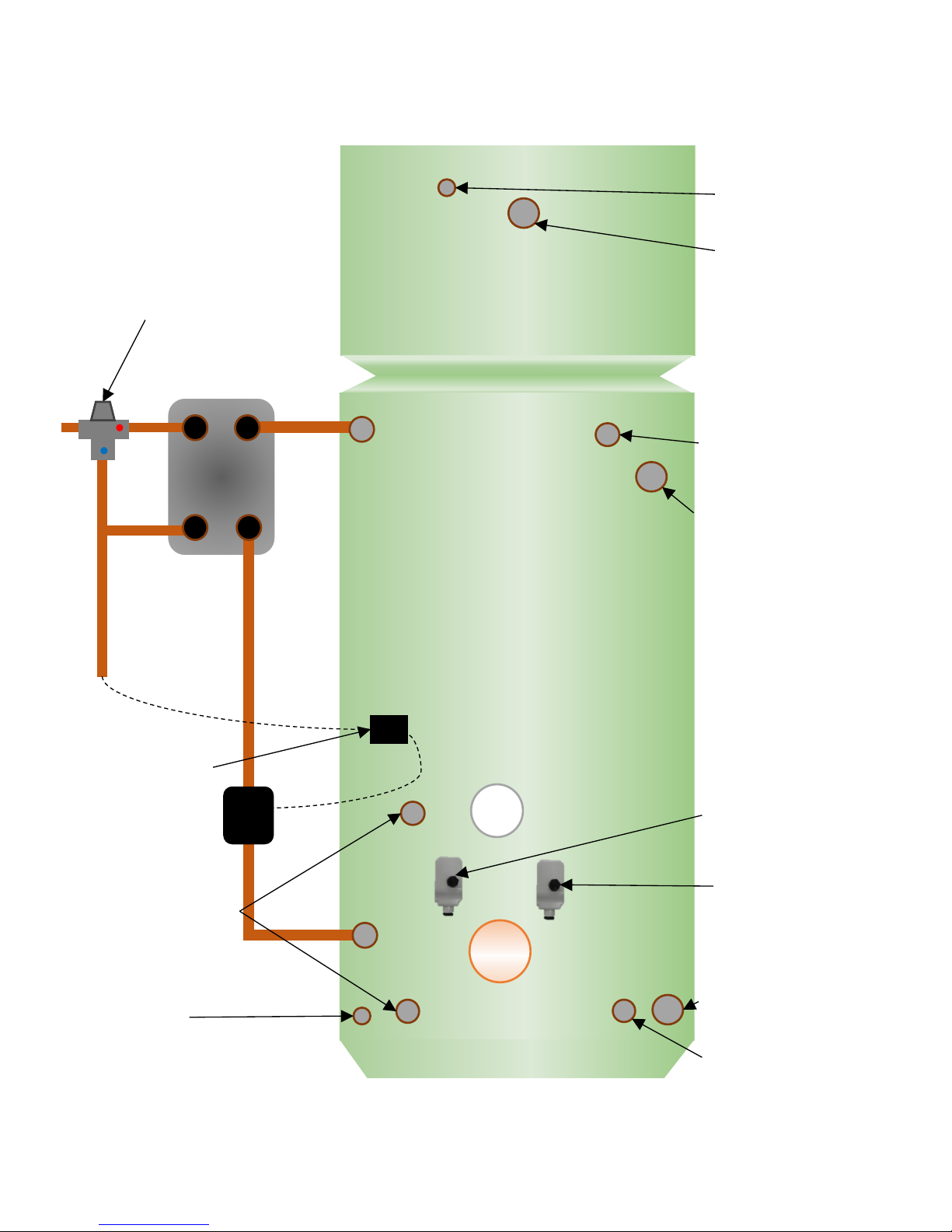

8

THERM

flow

with External PHE

An External Plate Heat Exchanger (PHE) can be fitted to a THERMflow in replacement

of the internal High Efficiency Coil. A THERMflow with an External PHE is an alternative

to the standard thermal store, for properties with varying hot water demands. Instead

of an internal High Efficiency Coil, a Plate Heat Exchanger is fitted to the external

pipework of the cylinder. In areas with high corrosion or limescale, it is easier to

replace the PHE as required.

The cold mains is fed through the Secondary flow of the PHE, whilst the primary water

storage is pumped through the Primary flow of the PHE, allowing for instantaneously

heated water. The Primary water storage flow is controlled by a Charging Pump, whilst

the Secondary flow is controlled by a Flow Switch Valve. Both the Pump and Switch

are controlled through a Wiring Centre, installed on the side of the cylinder.

It utilises similar heat sources (e.g. solid fuel, central heating etc.) for the primary

water storage, and has a similar set up of connections to the standard thermal store

combination/cylinder. However with Combination Units, a Ballvalve is not required

within the Header Tank if the cylinder is a Manual Fill, and is instead replaced with an

Overflow connection, as shown in the following diagram.

Page 10

9

THERM

flow

Combination with PHE General Schematic

22mm Boiler Flow

(Other Sizes Available)

28mm Solid Fuel Flow

(Other Sizes Available)

External Plate

Heat Exchanger

3kW

⁰C

Thermometer

Overflow

(Not fitted as standard)

22mm Central

Heating Flow &

Return Connections

(Other Sizes Available)

15mm Drain

Immersion Heater

Cold Mains

Secondary Water

c/w Flow Switch

Charging Pump

Hot Out

c/w Thermostatic

Mixing Valve

Wiring Centre

28mm Solid Fuel Return

(Other Sizes Available)

22mm Boiler Return

(Other Sizes Available)

High-Limit Stat

@ 90⁰C

Control Stat

@ 75⁰C

Maintenance Free

Jetseal Ballvalve

Page 11

10

THERM

flow

Cylinder with PHE General Schematic

22mm Central

Heating Flow &

Return Connections

(Other Sizes Available)

15mm Drain

Cold Mains

Secondary Water

Charging Pump

Wiring Centre

22mm Cold Feed

22mm Boiler Flow

(Other Sizes Available)

28mm Solid Fuel Flow

(Other Sizes Available)

External Plate

Heat Exchanger

22mm Vent

Hot Out

c/w Thermostatic

Mixing Valve

22mm Boiler Return

(Other Sizes Available)

28mm Solid Fuel Return

(Other Sizes Available)

3kW

⁰C

Thermometer

Immersion Heater

High-Limit Stat

@90⁰C

Control Stat

@75⁰C

Page 12

11

Commissioning

When commissioning the Boiler Model the following steps should be undertaken:

1. Connect the relevant central heating and boiler(s) flow and return pipework in

accordance with the corresponding connections on the store (as indicated on the

sketch provided).

2. Connect the mains to the Cold In and turn the mains on. Fit Pressure Reducing Valve

@ 3.0 Bar if required.

3. Check for leaks throughout the thermal storage system.

4. All normal procedures for a Vented Primary System apply. Drain the system, hot

flush and re-fill. Add Inhibitor as required (see Water Treatment section on Page

5), re-bleed the radiators and any high points of pipework.

5. Once complete, set the Boiler Pump to its highest speed setting (usually setting 3).

Set the boiler thermostat and also the Boiler Control Thermostat on the thermal

store to maximum.

6. Fire the boiler on the “Hot Water Only” setting and wait until the boiler goes off.

Turn the Boiler Control Thermostat down slowly till it clicks off, then turn it to 75°C.

(This should mean that the cylinder thermostat on the THERMflow controls the

system. This can be checked by running off some hot water which should lead

to the boiler re-firing)

7. Set the Solid Fuel Thermostat to ensure that the Central Heating Pump will pump

in an overheat situation or if the Room Stat requests for the heating to be turned

on (Normally 85 - 90⁰C).

8. Check that the hot water at the taps is at a suitable temperature for the

householder. The temperature can be increased or decreased by adjusting the

factory fitted Thermostatic Mixing Valve (which will be pre-set).

9. Once complete adjust the boiler and Central Heating Pumps to provide maximum

flow rate without emitting excessive noise.

10. Finally run all taps and other hot outlets to remove all air from the system.

Page 13

12

Commissioning Best Practice

The below is a recommended guide of actions and checks that should be undertaken

during commissioning:-

DO

Fit an Overflow with Copper piping to the thermal store system.

Check the incoming mains water pressure, if it exceeds 3.0 bar, fit a Pressure

Reducing valve set at 3.0 bar and where the cold supply enters the property as this

will create balanced pressure throughout.

Ensure that connections are fitted in accordance with the sketch supplied.

Fill the Feed & Expansion Tank manually and adjust ball valve so water is at lowest

level.

Ensure sufficient clearance above the Feed & Expansion Tank to allow for access.

Ensure sufficient clearance for External Plate Heat Exchanger & Pipework.

Ensure that 500mm height difference is in place between the highest point of the

radiator circuit and the bottom of the Feed & Expansion Tank.

Ensure that all exposed pipework is insulated to minimalise any heat losses.

Check the boiler pump setting is set as high as possible without emitting excessive

noise to prevent a boiler temperature differential of greater than 11°C.

Leave on the power after the thermal store has been filled to prevent the central

heating and boiler pump from sticking.

DON’T

Use a combined feed and vent.

Use tube smaller than 28mm between boiler and THERMflow if the boiler exceeds

an output of 60,000 Btu (17kW) output.

Place any clothing or other combustible materials against or on the THERMflow.

Page 14

13

Troubleshooting

Below contains a troubleshooting and solution guide to the thermal store system. If

this table does not resolve your problem, please contact either your installer or phone

McDonald Engineers UK Technical Team for further advice.

SYMPTOM

SOLUTION

The water at the tap

is lukewarm or cold.

The thermal store is designed to work best when the store

temperature is at or approaching 75°C - 80°C. While the thermal

store can provide hot water at lower temperature storage, the

available flow rates and volume will be reduced. Check the

thermometer is showing the store temperature is at or approaching

75°C - 80C. If this is not the case, ensure that the boiler is firing and

allow sufficient time for the store to reach working temperature.

The thermal store is

at 80°C and the

water at the taps is

still lukewarm or cold

1) If the store is at or approaching 75°C - 80C, check that the

Thermostatic Mixing Valve is turned to hot. The maximum

temperature of water from the Mixing Valve is 55C.

2) If the valve is turned fully to hot, check that the flow rate at any

outlet (e.g. bath tap) does not exceed 20 Litres per minute. If

the flow rate is above this, then turn the tap down slightly.

3) If Stage 1 and 2 has not resolved the problem a competent

installer should check the mixing valve for blockages within the

internal filter of the mixing valve.

Not enough hot

water and less than

80°C on the

thermometer.

Check the heat sources and their input in (kW) to the store as this will

be lower than the kW output which will result in the store not

producing enough heat for the exchanger to provide heated mains

pressure water.

THERMflow is set at

80°C but the mains

pressure

temperature drops

quickly when running

a tap (e.g. bath)

1) Check with the installer that inhibitor has been put in frequently.

If the DHW Coil is giving an initial heat transfer and then fading

this could be a sign of sludge build up surrounding the Heat

Exchanger Coil, which will reduce the performance of the store.

2) If Stage 1 does not resolve the problem, the balance of inputs

and outputs may be affecting performance. This can be tested

by drawing off the same flowrate of water when the output is

lower, such as turning your heating off.

There is a brownish

tint to the mains

pressure hot water.

This could be a symptom with the heat exchanger coil leaking inside

the thermal store. An installer should have this tested. If this is the

case, pay attention to the Feed & Expansion Tank as the pressure

within the store will increase causing the tank to overflow continually.

Page 15

14

Copper Feed & Expansion Tanks

The Feed & Expansion Tank (provided by the installer) must be sized correctly to

enable the expansion of the entire system volume, made up of the thermal store,

radiator and boiler circuit volumes. We recommend that the Feed & Expansion Tank

should be sized to approximately 15% capacity of the total system to cope with the

thermal expansion.

*Sizes indicated are from McDonald Engineers UK Feed & Expansion Tank Sizes

Given the high temperatures of up to

100°C that can be discharged from the

thermal store through inputs from

heat sources such as solid fuel, it is

recommended that the feed and

expansion tank is designed to

withstand temperatures over 100°C.

McDonald Engineers UK manufacture a Premium Grade Copper Feed & Expansion Tank

designed to withstand these temperatures, available as an optional extra, please

contact McDonald Engineers UK on 01592 611123 for more information.

Feed & Expansion Tank Capacity Calculator

Cylinder Capacity

(Litres)

120

140

180

210

250

300

Estimated

Primary Capacity

(Litres)

138

161

207

241.5

287.5

345

Recommended

F&E Capacity

(Litres)

20

20

30

30

40

50

Overall Height

and Diameter of F

& E Tank (mm)

400 x 420

400 x 420

375 x 470

375 x 470

470 x 470

500 x 520

½” c/w Jetseal

Maintenance Free Ball

Valve & Copper Float

100mm

1” Feed

1” Overflow

1” Expansion

Page 16

15

Schematics

Page 17

16

Pump Kit Wiring Diagram

Page 18

17

THERM

flow

with External PHE, Wiring Diagram

Flow Switch

Wiring Centre

Charging Pump

L

N

Mains

L

N

E

Page 19

18

Ancillary Descriptions

The following spare parts are available to purchase from the Website, with additional

information provided.

Follow the link below:

https://www.mcdonald-engineers.com/spares

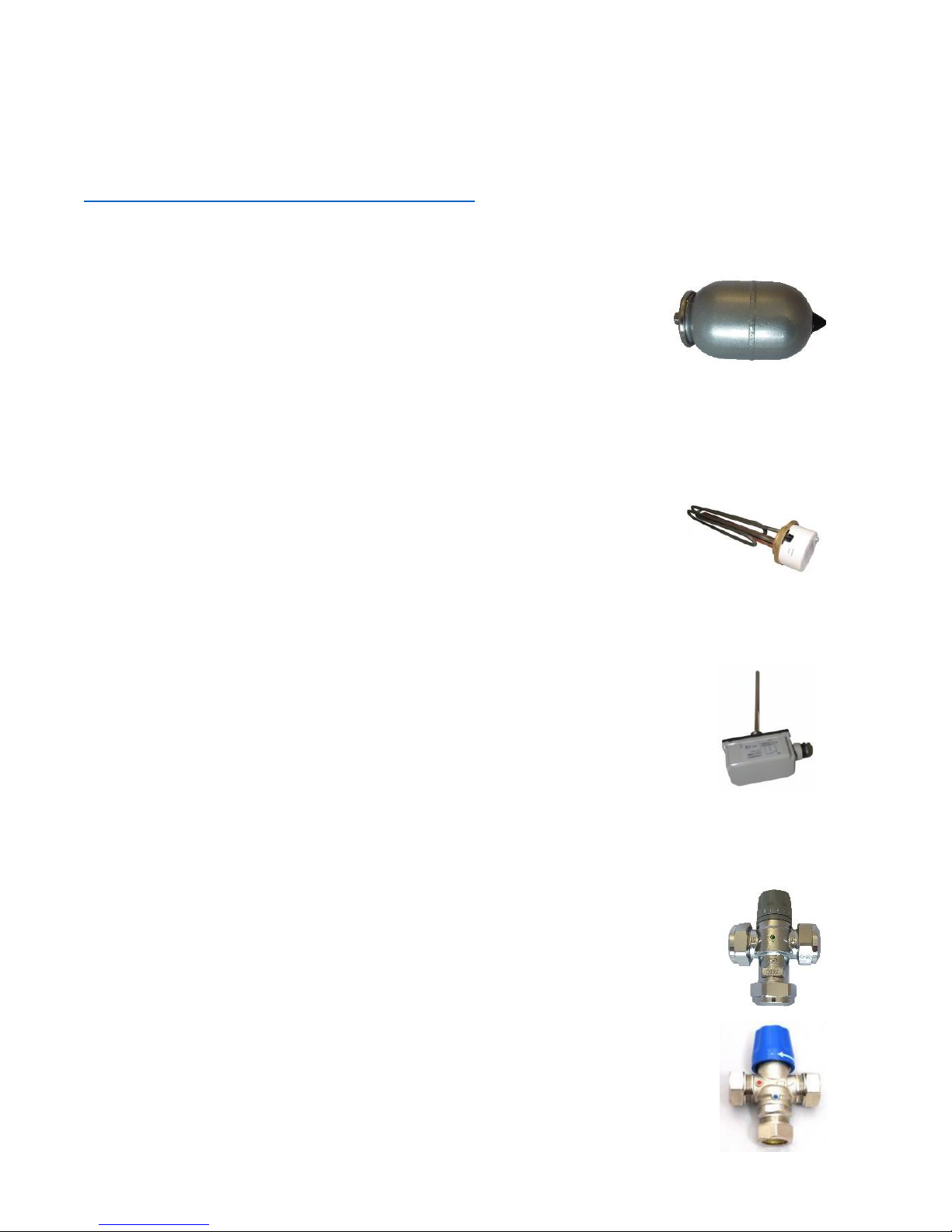

Expansion Vessels (WU2EV)

2 Litre Nitrogen Expansion Vessels are connected to the High

Efficiency Secondary Water Coil Heat Exchanger Pipework to absorb

the increase in pressure caused by thermal expansion within the

Coil. When the thermal expansion occurs the internal diaphragm

expands and contracts based upon the pressure set by the

Expansion Vessel. For best performance it is recommend setting the

Expansion Vessel to match the incoming pressure.

Low Watts Density Immersion Heaters (WIHLWD)

The THERMflow are fitted with a 3kW 16” Incoloy Immersion Heater

complete with Combined Control Thermostat and Resettable Safety

Cut-Out. The LWD Immersion Heater is designed with reduced noise

emission and a longer lifespan when used with higher temperatures

and are suitable for more aggressive water conditions.

Cylinder Thermostat (WTCT)

Cylinder Thermostats allow for highly responsive temperature control to

your central heating, and boiler(s) by switching on and off the heat

supply from the boiler(s) and to the heating. The THERMflow’s Boiler

Control Stat will be used to bring the thermal store up to a maximum of

75°C- 80°C and control the boiler. The Solid Fuel Stat will be linked to the

Central Heating Pump and will pump part of the contents of the

THERMflow to a heat leak radiator in order to cool down the thermal

store in the event of an overheat situation from an uncontrollable heat

source such as solid fuel.

Thermostatic Mixing Valve (WTTMV / WTTMVS)

The Thermostatic Mixing Valve blends the hot water leaving

the High Efficiency Secondary Coil which can often be over 60°C

with cold water to ensure constant, safe outlet temperatures

at 55°C to prevent scalding.

WTTMV

WTTMVS

Page 20

19

Thermometer (WTHERM)

The 2” Side Entry Thermometer allows for a temperature reading of the

thermal store to be taken from the side of thermal store to ensure the

thermal store is operating at the correct temperature.

Thermal Store Pump (WTP)

Designed with a three-speed motor to circulate round domestic heating

systems, the thermal store pump are designed to pump to the central

heating and boilers of domestic central heating systems of up to 35kW.

THERMflow Programmer (WTPROG)

The THERMflow programmer allows you to set “On” and “Off” time

periods to switch the central heating on and off to suit the user’s

requirements.

THERMflow Wiring Centre (WTWC)

Acting as the relay for the wiring cables from the programmer, boiler,

pumps and stats to ensure the thermal store operates correctly.

Pressure Reducing Valve (WUVPRC)

Designed to regulate the incoming mains pressure to a fixed pressure.

Plate Heat Exchanger (WTPHE)

Exchanges hot water temperature from cylinder with

secondary flow. Insulation is included. Flow rates must

be specified when ordering. (Only for THERMflow

models with External PHE).

Page 21

20

Installing a Gravity System

In absence of recommendations from the solid fuel boiler manufacturer as to the best

layout, McDonald Engineers UK would advise the following layout would be most

suitable to achieve the best performance from a gravity circulation layout, key points to

follow are:-

o Ensure the heat source is below the cylinder which gives the layout a good system

height

o Gravity pipework to be 28mm diameter or larger

o Avoid long horizontal runs aim for a ratio of 20:80 minimum between horizontal

and vertical

Page 22

Hot Water Solutions Since 1945

The HWA Charter Statement requires that all members adhere to the

following:

To supply fit for purpose products clearly and honestly described

To supply products that meet or exceed appropriate standards and

building and water regulations

To provide pre and post technical support

To provide clear and concise warranty details to customers

Loading...

Loading...