Page 1

~

,

"

t'

C

CHAIN

'

u~':~·

0 SAWS

O""NERS'MANUAI:

•

NlCCULLOCH!ImIl

01910

U.S.A. -McCULLOCH CORPORATION

. .

CORPORATION

®

83924

Page 2

7a&e~~

Fuel & Engine

Chain

Lubrication

Operating

Starting & Stopping

If

En

Breaking-in

Cutting

S::IW

Maintenance

Air

Spark

Exhaust

Carbur

rUll a

cham

~Iini-Mac

['~

The

adjacent

in

~

6 a

.

'~"~"~.m~~~'~"~"~"_"~'~"~"~"~Y~"~"~'~'~"~W~b='~f"~'~'~Y~"~'~

serial

10

case

the saw

2

Lubrication

Instructions

gine

Floods

With

Filter

numb

Plug.

etor

saw

101

the

Stack

e r

.

Adjustment

(and

easier

of

spark

is

lost

....

A New

Your

even

to

use.

Ihe

saw

plug.

or

stolen;

.

..

Engine

Saw

if

you

have)

is

scamped

Make a record

and

5

6

8

10

11

12

13

17

17

20

21

22

reading

'~"~"~d

on a metal

of

{he

the

record

keep

Dirt & Sawdust

Sprocket

Chain

Maintenance

Installing The

Chain

New

Chain

Chain

Keep

If

Chain

Bar

Maintenance

Cleaning

this

manual

~"~'i~,~m~"~"~

"~O[~'~b~"~'~'~f

tab,

attached

serial

number

in a safe

....

T

Chain

Lubrication

Sharpening

Chain

will

tOlhe

for

place.

Chain

ension

Break-in

Clean

Breaks

..

make

your

new

~Y_"_'_"_"

__

"_'_'_'

__

handle

'

rear

identification

•

~.1v~

..

24

24

27

27

28

29

29

30

35

35

36

36

__

Page 3

A

power

chain

saw

operation

sense

simple

Be

safe!

Start your saw without help.

Start the saw

Turn off your

Be sure of your footing and pre·plan a safe exit

from a

Watch

Refuel

Keep a firm grip on a running saw with both hands.

Beware of

Wear

safety hat

Obey

area.

Keep the chain snug on the guide bar.

Keep

of

other

handling

Do's

and

on

a firm surface.

saw

falling treo.

out

for falling limbs.

in

a safe place. Guard against fire hazards.

"kickback".

close fitting and protective clothing including

s,

goggles, shoes and gloves.

all

laws, rul

es

all

screws and fasteners tight.

mechanical

to

provide

Don'ts

when moving between cuts.

and regulations of the cutting

is a most

can

useful

safety

make

equipment,

as

all

and

well

the

efficient

as

difference.

woodcutting

however,

labor

saving

Be

sorry!

Fail

to

follow the instructions for

saw in this owner's manual.

on

Start a saw

Let a moving cha

Touch

hand.

Allow any

saw

Cut with a dull or loose chain.

Smoke

Spill fuel

Refuel a

Use

owner's manual.

Run the saw without an exhaust stack, muffler or

spark arrester.

Allow dirt, fuel

or outside

Forget the rules for fire prevention

protection.

your

in

or

try to stop a moving chain with your

other

person or animal close

or

where a tree is being

while operating the saw.

or

sta

rt

a saw whero you fuel it.

hot

saw., (Allow it to cool a few minutes.'

any

other

fuel than

or

of

the saw.

tool.

it

requires

performance.

leg

or

knee.

touch your clothing.

cut

that

recommended

sawdust to build up on the engine

As in the

common

operat

to

down.

A few

ion of the

a running

in

your

and forest

3

Page 4

FIGURE

1

OILER

BUTTOt-l

4

.1...

..

________

""

Page 5

Two-cycle

ratio

of

FUel

the

brand

claimed

oil

Mixture

best

two-cycle

of SAE

motor

Thoroughly

before

it

can

clean

seriously

,

U.S.

1.1/2

LITERS

1

5

U.S.

~

IMPERIAL

19

LITERS

filling

before

WITH

Gasoline

GALLONS

IMPERIAL

GALLONS

1etdad&~L~

engines

to

mix

GALLOHS

are

gasoline

Table.

40

lubricated

is

Use only

motor

two-cycle,

very

oil

oils.

the

gaSOline and

the

fuel tank of

filling

the

damage

FUEL MIXTURE TABLE

McCULLOCH

(40

TO

GALLONS

fuel tame. Do not

the

engine.

4Ch!

1

RAT

10)

1(60Z.)CAN

1(60Z.)CAN

1{60Z.)CAN

1

(16

1

(16

1

(16

by

oil

important.

regular

to

use.

grade

If

non-additive,

oil

in a container

your

saw.

OIL

Oil

02.)

CAN

OZ.)

CAH

OZ.)

CAN

mixed

into

the

Follow

gasoline.

the

ratio

gaSOline. McCulloch 40:1 Oil

it

isn't

motor

available,

oil.

use

Never

equipped with a

Wipe

the

fuel

cap

let

dirt

GASOLINE

WITH

Gasoline

1

U.S.

GALLON

llMPERIAL

4LITERS

2

U.S.

GALLONS

2

IMP

ERIAL

8

LITERS

SAE

get

TO

~o

( J 6

GALLON

GALLOHS

and

into

OIL RATIO

TWO-CYCLE

TO 1 RAT

the

1/2U.S.PINT

1/21MPERIAL

1/4

1

llMPERIAL

1/2

The

specified

any

well

use

dirty

flexible

the

area

fuel

tank.

MOTOR

10)

Oil

LITER

U.S.

PINT

LITER

correct

in

the

-known

or

re-

spout

around

Dirt

OIL

PIN

P

11'1

T

is

T

5

Page 6

Your

time

chain

you

fill

is

the

lubri

fuel tan1e

cate

d with

oil

from

the

chain

oil

tanle

Fill

the

oil

tank

each

We recommend

additives

for

mation

not

available,

SAE 10

Keep

surrounding

reclaimed

system.

non-additive

the

to

reduce

on

the

oil

the

motor

Never

using

bar

use

SAE 30

supply

fill

oils

operate

McCulloch

friction

and

chain

non-additive

motor

container

area

clean

under

your

Chain, Bar

and

wear

.

If

oil

at

lower

clean.

before

any

circumstances.

saw

if

and

McCulloch

motor

temperatures.

Wipe

filling

the

oiler

AUTOMATIC OILER ADJUSTMENT

Some

Mini

at

6

the

Mac 6 saws

factory

for

average

are

cutting

equipped

conditions. Oil

with

and

to

assist

Chain, Bar

oil

the

the

system

an

automatic

Sprocket

in

the

at

temperatures

oil

tank

oil

tank.

Dirt

can

does

now

may

Oil

which contains

prevention

and

Sprocket

cap

and

Do not

plug

the

not

work.

cha

in

oiler.

be

adjusted

above

the oil

use

chain

however,

of

pitch

Oil

is

40

and

tank

dirty

or

oiling

adjusted

Page 7

to

suit

individual

the

screw

The

automatic

screw

shou ld

than a qu

checking

justment.

em

pty

the chain oil

mately

ten

increased

short

periods,

pl

ement

use

of

the

automatic

ever

the

periods

oil

puddl

wasted

th e

in

oil.

saw

almost

clockwise

never

arter

turn

the

oil

Maximum o

minutes

oil

flow

it

the oil

flow

manual

oiler

engine

at

idle

es

beneath

It

off

is

between cuts

contin

uous use.

desires

oiler

flow

to

be t

at a ti

after

by

decrease

adjustment

urn

me

il

tan

k in approxi-

of

cutti

ng.

is

desired

is

better

by

mor e

oiler

button.

supplies oil

is

running.

speed

can

the

advisable

unless

an

adjustment

oil flow

ed

more

without

the

ad-

flow

can

Where

for

to

sup-

frequent

The

when-

Long

result

saw

and

to

turn

it

in

is

screw

at

and

the

counterclockwise

front of

the

to inc

saw.

rease it.

Turn

7

Page 8

tJlt~1~~

CHAIN

A too

it

Even though your ch

saw.

sti

by

your

TENSION

loos

e ch

will

wear

Chain tension

ll

be pull

hand

ed

whe n

hand. Chain

ain

rut

easily

IS

can

fast.

is

touching

IMPORTANT:

be

danger

ous - a

ain

is

installed, check

is

correct when

aroun

d the

sharp -protec

it.

bar

t

the

too

chain

tight

chain

can

chain tension

has a snug

be

expe

before

fit

on

nsive

you

the

start

bar

because

your

rut

ca

n

MOUNTING

NUT

",~~,~

8

Page 9

Follow

tension:

1.

Loosen

See

these

the

Figure

steps

bar

3.

to

adjust

mounting

chain

nut.

2. With

the

the

of

sion

adjusting

tighten

bar

the

counterclockwise

chain.

3.

When

tension

the

nose

the

bar.

See

Figure

chain

touch,

For

will

allow

A

the

oiled.

bar

held

chain.

See

Figure

of

Protect

5.

lengthen

more

nose

or

up!

turn

screw

clockwise

Turn

to

4.

is

correct!

the

bar

your

during

it

to cool

information

rounded

the

the

screw

loosen

up and

hand

the

before

on

end

ten-

to

the

tighten

then

from

first

checking

chain

the

bar

recheck

the

sharp

few

hours

tension.

maintenance,

mounting

chain

of

nut

tension

cutting

use.

Keep

tUrn to

while

by

teeth

If

the

chain

page

still

pulling

of

chain

and

27.

it

the

bar

holding

around

chain.

is

hot

groove

to

9

Page 10

STARTING & STOPPING

1.

Fill

the

fuel

tank

with

the

fuel

with

Sprocket

oiler

the

the

from behi

Figure

2.

Make

rect

tight

mixture. Fill

McCulloch

Oil.

lxItton until oil shows between

chain

and the

bar

where

6.

sure

tension

on

the

the

nd

the

and

saw.

the

chain

Chain,

Pump

bar

at

chain comes

the

clu

chain

has

that

Bar

the

the

teh

the

the

correct

oil

tank

and

manual

top

Qut

guard.

cor-

bar

of

is

3. Slide

4.

Turn

does

10

the

ignition

the

choke lever

not

r e

switch

to

quire the use

to the ON

the

fully

of

the

position.

closed

choke.

pOSition . A

However,

warm

when

engine

restarting

usually

an

ex-

Page 11

tremely

to

use

the

hot

choke

engine

to

or

one whi

clean

out

ch

the

has

just

vapors

been

in

the

r e

fueled,

carburetor.

it

may

be nec

ess

ary

5. Hold the

stroke.

two

een started recen

b

6. As

choke

Nev

7.

Pu

the

8.

To

to the

IF

ENGINE FLOODS

1.

Turn

throttle trigger

Guide the

or

three

soon

as

and

er

run

mp

the

chain

and

stop the

OFF

choke l

pulls.

the

thr

ott

the

chain oil

engine,

position.

ever

rope

tly

eng

ine

le

as necessary

engine

button

bar groo

release

to open

back

and pull the

back

or

if

starts,

full s

eve

ve

lubricat

position.

into the s

the fuel

turn

peed

the

Additional

at

starter

tarter.

pulls may

the

to keep the

unl

ry

ten

ed.

throttle trigger and

Move

tank

choke l

ess

to

fifteen

be

was

ever

engine

cuttin

igniti

handle with a

The

engine

r e

quired

empty

g wood.

seconds

on

prior

to

the

running

or

slide

switch

smooth,

shou

ld

to

positi

until

need

nition

start

being filled

on. U

warmed

ed

to

if

the engine hasn't

open

as

the ig

to ON.

rapid

with

.

se

up.

keep

switch

11

Page 12

2.

Hold

saw

with

muffler

side

down.

3. Hold

throttle

trigger

BREAKING IN A

Run

your

saw

half

thr

engine

at

all

bearing surfaces

performance.

The

saw

the

cut,

Make

several

after

each

properly

12

engine

ottle

for

three

part

throttl

shruld

but only when cutting

always

preliminary

preliminary

and

to

adjust

full

NEW

at

one-third

minutes

e for the

will

be

cut

chain

back

ENGINE

prior

first

be

properly

operated

under

cuLs

to

and

check

tension.

and

pull

starter

throttle

few

at

load conditions.

get

to

making

full

the

minutes

the

for

three

your

lubricated

throttl

feel

cha

in

handle

minutes

first

with

the

for

e when

of

your

to

make

until

cut.

correct

lon

ger

it

is

saw.

SUre

eng

and

By

operating

fuel

life

under

Stop

it

ine

then

at

mixture,

and

load

the

is

lubricated

starts.

one-

the

better

and

eng

ine

in

Page 13

CUTTING

The

most

Advice

is

helpful

dealer

FELLING

common

on how to

to

.

WITH

use a spike

YOUR

types

make

of

these

which

SAW

cutting

cuts

is

an

are

felling, limbin

is

given

accessory

in

the

paragraphs

available

g,

pruning

from

and

which

your

bucking.

follow,

McCulloch

It

Felling

or

require

tree,

the

A

end of the log

be about

to

and

is

seven

is

the

the term

inches

undercuts.

unless

side

of the

easy to make

one-third

undercut

the

felling

in

it

is leaning

undercut.

cut

square

on

cut

for

cutting

diameter

Undercuts

and

commonly

. Type C

of

the

the

felling

acts

as

down a tree.

are

determine

too

far

Types

diameter

cut. The

a hinge.

usually

in

of

undercuts

used

is a variation

the

wrong

for

of

the

uncut

Figures

cut

Small

trees

through

the

direction

direction,

are

small

tree.

band of wood

7 and 8.

in one cut.

shown in the

trees.

of Type A. The unde

Do

not

of up to

six

Larger

the

tree

will

Type B

cut

will fall. The

usually

illustration. Type

leaves

complete

between

the

and a half

trees

fall

toward

the

rcut

shou

ly

through

undercut

butt

ld

13

Page 14

Felling

Cut

FIGURE

If

th(;:re

are

felling,

that

working

before

for

out

might

Be

sure

the

undercut

Make the felling cut horizontal, moving

the

bar

14

yoo

making

dead

fall

in

7

is

bru

sh

around

clear a working

do

not

while

to

an

the

limbs

clean

so

arc.

trip

clear

you

the

the

, Have a

A

or

stumble

path of

felling

and

are

cut

tree

If

you

the

tree

space

when

retreat

cut.

Watch

bark

which

cutting.

wood out of

will fall

are

true.

using

you

so

D;,ect;on~

ofFoll<:>

FIGURE

a

I.'

' ['

" '1

I .

1'1,

.j;

'"J,',

,_

B

8

(

~

Page 15

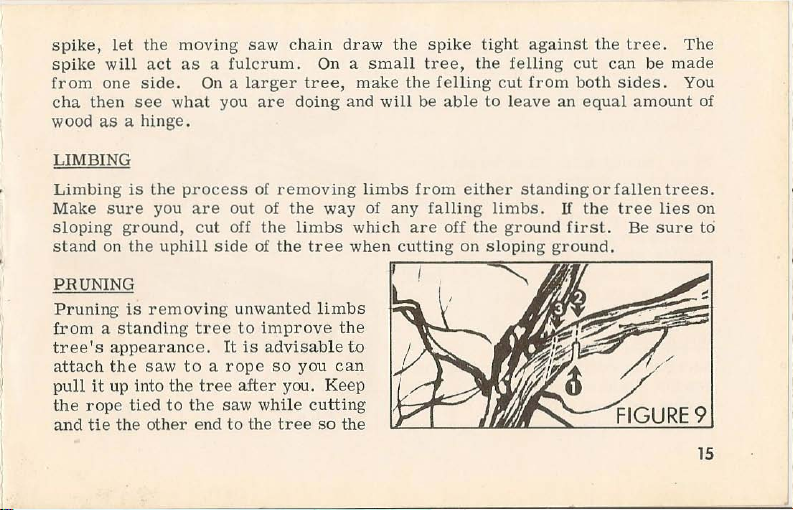

spike,

let

spike

from

cha

wood

the moving saw

will

act

one

side.

then

see

as a hinge.

LIM BING

Limbing

Make

sloping

stand

PRUNING

Pruning

from a standing

tree

attach

pull

the

and

is

sure

ground,

on

the

is

's

appearance

the

it

up into the

rope

tied

tie

the

the

you

uphill

removing

saw

to

other

as a fulcrum.

On a larger

what

you

are

process

are

to a rope

the

cut

side

tree

.

tree

end

of

out

of

off the

of

unwanted

to

improve

It

is

advisab

after

saw

while cutt

to

the

chain

On a

tree,

doing

removing

the

way

limbs

the

tree

limbs

le

so

you

can

you. Keep

tree

so

draw

make

and

which

when

the

to

ing

the

the

small

will

limbs

of any

cutting

the

be

from

are

spike

tree,

felling

able

falling

off

on

tight

the

to

either

limbs.

the

sloping

against

felling

cut

from

leave

standing

ground

the

cut

both

an

equal

or

If

the

first.

ground.

""-----,

tree.

can be

sides.

amount

fallen

tree

Be

made

trees.

lies

sure

The

You

of

on

to

15

Page 16

saw

can

fall

you

drop

to

the

the

tree

ha

nds On

When

pruning

inch

es

prevent

away

bark

do

wnward cut to meet the upward cut.

a

Finally,

second

a

to

remove

BUCKING

Bucking

length

footing

cutting

16

only a short

it.

Make

tree.

trunk

the

from

the

after the limb

downward cut next

is

s.

Make sur e you

am

on sloping

sure

A safety rcpe

will allow

saw.

make

the

trunk

falling

from the

the stub.

stand uphill of the log when

limb from

cutting a fallen log

grrund.

yoo

yru

an

undercut

first.

trunk.

has

Figure

distance

are

or

belt aroond

to use both

Then

fallen, make

to

have

If

if

secured

a f

ew

This will

tearing

mak

the

trunk

9.

into

good

poss

ibl

e,

e

FIGURE

10

Page 17

the

log

should

be

air.

an

undercut

will

Ii

the

prevent

log

is

halfway

the

supported

supported

log

through

from

so

that

at

both

the

log

pinching

the

ends

and

your

end

to

and you

then

bar

be

chain does not cut into the ground when bucking

the

chain.

While

with

McCulloch

AIR

The

air

The

run

properly

most

tools,

FILTER

filter

air

filter

Figure

of

the

maintenance

specialized

chain

saw

acts

like

must

because

10.

adjustments

serviceman.

the a ir

be

kept

the

dirt

clean

will

of

the

filter

.

Mini Mac 6

and

on a

If

the

block

the

repair

car.

filter

flow of

cut

must

make

and

as

this

can

work

It

keeps dirt

gets

off

is

cut

your

chain.

causes

be

dirty,

air

.

off

the

in

the

down

ward

Be

careful

rapid

done by

should

out

the

ground

middle,

cut.

dulling

anyone

be

done

of

the

engine

in

that

handy

eng

won't

the

make

This

the

of

by a

ine.

17

Page 18

4. R

18

einsta

on

ian

position,

down

until

ll

cover. Slide

housing,

smooth

it

engages

then

and

the

press

even

the re

To

clean

1.

Lift

cleaner cover and remove the

Figure 11.

2.

Lilt

u

res

clean

wash

air

3.

Retnstall

position -centered

of

hou s

lips

on forward end of cover

rear

end

of

all

tainin

around

g notch

at

the

the

at

the

air

the

spring

off the

air

12 and 13. Bl

wit h li ght a

it

in

keep

the

ll locating

in

g.

cover

fuel

away

screen

down

and

sma

edges.

the

back

of

filt

er

latch

Hlter

mix.

from

under

until

Push

the fan h

of

screen,

ow

the

ir pressure

Dry

openflame.

in its origin

within the

stu

ds on the fan

mating

it

snaps

the

spring latch

ous

the air

cover.

Fig-

filter

or

in

open

al

ring

flanges

into

in g.

Page 19

FIGURE

12

FIGURE

13

19

j

,

Page 20

SPARK

A

clean,

performance.

should

To

1. Remove the

2.

3.

4.

5.

PLUG

properly

be

cleaned

clean

and

gap

the

spark

plug.

Remove

plug wrench.

Clean

a

from

Adjust

Wipe

spark

the

all

the

the

electrodes

plug

spark

the

dirt

gapped

When

starting

and

the

sparl{

rubber

connector

Figure

spark

plug

cleaning

plug.)

side

electrode

off the white

spark

gapped.

plug

14.

with a spark

with

machine.

Blow

connector. .

20

plug"

is a major

or

performance

--

from

emery

clQth

It

is

all

dust

away.

to

a gap of 0.025 inch (0.635

porcelain

insulator

or

very

almost

factor

is

and

in

easy

not

satisfactory,

fine

sandpaper.

impossible

mm).

reinstall

starting

to

clean

the

spark

and

the

not

the

plug

best

plug

use

grit

and

Page 21

.'f

If

the

spark

plug

is

spark

plug

recommended

damaged

EXHAUST STACK

The

exhaust

saw

with two

should

cleaned

,build up

stricted.

ing

away aU of

then

wash

~craping

any

the

engine

particles

chamber.

rester

your

McCulloch

fire

hazardous

be

removed

of

carbon

until

Clean

it

because

falling

An

(screen)

stack

screw

engine

the

the

with a

while

into

accessory

is

dealer,

areas.

is

occasionally

deposits

heavier

by

attached

s.

The

exhaust

stack

by

deposits,

solvent.

the

stack

of

the

danger

the

combustion

spark

available

for

it

your

that

is

scrap-

use

will

not

McCulloch

to

the

stack

and

may

re-

Avoid

is

on

of

ar-

from

in

function

chain

properly.

saw

Install

serviceman.

only

the

new

21

Page 22

CARBURETOR

While

the

conditions

carelessly

Culloch

mediate

following the

making

often a dirty

needed

1.

22

carburetor

to

readjust

can

damage

chain

saw

need

until

steps

any

carburetor

air

filter

adjustment.

Carefully

speed

wise

not

or

you

needles

(turn coonterclockwise)

1

turn.

adjustment

until

turn

the

can

and

tUrn

resistance

needles

dama

their

ADJUSTMENT

was

set

at

As

carburetor

carbure

technician.

temporarily

make

the

and

high

clock-

felt.

too

tight

tips

of

Then

open

each

needle

the

the

air

Do

the

it.

the

service

your

serviceman

indicated,

adjustments

will

Cleaning

the

idle

needles

is

in

ge

the

seats.

factory,

tor

and

In

can

make

engine

.

it

adjustment

engine,

an

emergency

do

it

adjust

Sure

operate

may

be

it

should

properly,

the

carburetor.

the

air

as

necessary

is

critical

be

done

or

to

satisfy

you

can

by

NOTE:

filter

is

though

the~~~~

clean. Very

the

due

to

local

and

if

done

by a

Mc-

an im-

carefu

Before

carburetor

__

lly

,.

Page 23

2.

start

the

the

engine.

screw

clockwise

the

engine

screw

counterclockwise

engine

If

is

cold.

and

let

the

engine will not

until

the

If

it

it

warm

still

until

engine

moves

the

up

idle

idles.

chain

for

and

after

at least

keeps

The

the

stops.

three

stopping,

chain

engine

minutes.

turn

may

move

is

warmed

Do not

the

idle speed

slowly when

up I

turn

race

the

3. Hold

4. While

the

engine

position

turn

a

If

chain

engine

idles

of

open.

necessary, readjust

starts

cutting

best

power.

position

of

open.

5.

Check idle

needle

slightly

ne

edle

has

bar

idle

Turn

move.

nose

ly and

adjustment

the

smooth

the

to

wood with

Do not judge by

the

high

speed

operation

been

to

set.

again.

obtain

down and

accelerates

engine

the

idle

the

saw,

the

adjustment

It

best

turn

the

idle

adjustment needle

hesitation

usually

it

idl

es

to a

high

speed

needl

to

see

speed

adjust

without

e will

that

screw

the

sound; judge by the way

may

idle

needle

be

necessary

operation

should

to

after

or

stumbling. Final

be between 1/ 2 and 3/ 4 of

until

smoothly

point

adjust

the

in

just

below

adjustment

the

saw

be 1/ 2

to

the

idle

high

speed

all

positions.

where

needle

cuts.

3/ 4 of a

adjustment

adjustment

the

Final

turn

the

for

23

Page 24

DIRT & SAWDUST

U's

saw

natural

must

be

for

kept

any

clean

saw

to

for

acquire

proper

dirt

operation.

openings in the fan housing, the cooling fins and

must

be

kept

the

.... with solvent. A

clutch

reinstall

clean.

guard.

the

bottle

clutch

The

Scrape

brush

guard.

fins

the

and

dirt

or old

Tighten

sprocket

away with a

tooth

all

SPROCKET

The

sprocket

which

clutch

be

lubricated

grade

To

remove

lubrication

as

follows:

24

is

held

part

on

the

The

drum

frequently

is

rotor.

of non-fibrous

the

sprocket

or

replacement,

of

the clutch

crankshaft

bushing should

with

chassis

and

drum

drum

by

the

a good

grease

for

proceed

.

and

sawdust

In

area

blunt

brush

will help. When

attaching

addition

the

are

accessible

wooden

screws

when

area

it's

used.

to

the

air

around the

after

scraper

the

saw

and

nuts

But

filter,

sprocket

removing

or

wash

is

clean,

securely.

the

the

it

Page 25

1.

Remove

2.

Lock

the

wheel

rotor

3.

Remove

bushing.

After

lubri

with oppos

rotor

counterclockwise

cra

nkshaf

When

replacing

and

the

insure

fuel

Sing

bar

oil

18. Guide

hose

on the

pad

Figure

to

connections

The

hOU

the

the

clutch

flywheel

bosses

nut

t.

both

(not a

clockWISe to

the

sprocket

cation

ite leverage

and/

the fuel

connector

the

connections.

by

inspection.

connection

underside

past

the

guard,

with a

or

with

tank

edge of the

bar

screwdriver

hnL

and the

remove

and

replacement,

on

the

to intitall

tank

and

the

and

After

can

be

of

the

and

chain,

flywheel

it

and

drum

and

ticrewdriver

corresponding

cover

inspected

saw.

clutch

and

it.

The

front

cover,

carefully

installation

To

drum.

and

braced

nut.

the

clutch

lubricate

reinstallation,

and

clutch

be

tank

as

of tani" and

through

inspect

the

front

against

Figure

assembly.

the

cranks

remember

must

be

sure

to line up

receptacles

they

are

an

inspection

the

oil

connection,

cover

one of

17.

Turn

haft

lock

to tUrn the

secure

installed

cover,

and fuel

the

heavy

the

and

the

flywhee

ly

tight

the

fuel

as

shown in

on

check

hole in

look

tank.

clutch

drum

clutch

on

the

the

under

fly-

l

the

hose

saw

both

fan

25

Page 26

26

Page 27

Your

signed

used.

time

Mini Mac 6

for

maximum

The

chain

and

provide

is

equipped with a McCulloch S25

performance

requires

the

proper

care

if

kind of

with

it

is

service.

your

to

continue

saw

saw

and

This .is

to

chain.

no

cut

how

other

easily,

to

look

The

chain

to

after

chain

is

should

last a long

it.

de-

be

INSTALLING THE

1.

Remove

2.

Turn

the

bar.

the

the

chain

bar

toward

CAUTION!

it

can

cut

bar

mounting

tension

the

McCulloch

if

handled

CHAIN

nut and

screw

sprocket

saw

carelessly.

remove

counterclockwise

and

remove

chain

is

the

sharp!

the

clutch

as

old

Handle

guard.

far

chain.

as

it

Do not

it

carefully

will

go.

remove

for

Push

the

27

Page 28

3.

4.

5.

Place

chain

Fit

the

the

bar

Adjust

the

new

along

the

adjustment

mrunting

chain

tension.

chain

top

nut

around the

of

the

nut

tang

finger

bar

into

tight.

sprocket

face

the

toward

bar

and

and

the

install

bar.

nose.

The

the clut

cutting

ch

guard.

edges

of

Tighte

the

n

CHAIN

Chain

tension

on

the

bar, the

1.

Loosen

2.

Turn

held

While

3.

28

TENSION

is

chain

the

bar

the

chain

up.

still

holding

correct

can

mounting

tension

bar

when,

still

nut

screw

nose

with

be

easily

.

clockwise

up,

tighten

the

bar

pulled

until

the

nose

around

cha

bar

held

up

the

in

is

snug

mounting

and

bar.

nut

the

with

secure

chain

the

bar

ly.

snug

nose

Page 29

Check

chain

every

hour

justing

Maintain

NEW

CHAIN

it.

on an

Correct

it

at

tension

frequently

older

chain

all

times.

BREAK-IN

chain.

tension

on a new

If

the

chain

results

chain.

is

in

Check

hot, allow

easier

chain

it

to

cutting

tension

cool

before

and

at

least

ad-

operation.

1. Run the

oil

is

pumped

throttle

and

adjust

2.

After

using

check

chain

few

hours

CHAIN

Make

button. Oil

forward

LUBRICATION

sure

of the

chain

and

chain

the

of

the

should

at

slow

onto

the

run

chain

tension.

saw

tension.

operation.

manual

appear

sprocket

speeds

chain

for

for

the

Repeat

oiler

guard.

for

to

another

first

tension

works

between

Keep

at

flood

three

ten

before

the

least

the

minutes,

check

chain

the

oil

three

bar

groove.

minutes.

shut

several

starting

and

tank

minutes.

Stop

off

your

bar

at

filled

with

Make

Increase

the

engine

the

engine

times

during

saw.

the

top

clean

sure

speed

Pump

of

the

oil.

enough

and

and

the

the

bar

to

half

check

again

first

oiler

just

29

Page 30

Use

dry

plenty

on

the

of

bar.

oil

In

on

the

abrasive

bar

and chain

wood, pump

when

the

cutting.

oiler

Never

button

more

let

the

chain

frequently.

run

CHAIN

Chain

l

owering

Figure

The

tool and a McCulloch

recommended to make chain sharpening

a relatively easy

chai

clearance

you

feel

SHARPENING

sharpening

depth

19.

use

of a

McCulloch

n saw

serviceman

to

to

set

any

callan

require

free

is

divided

gauges.

The

Depth

File

into

names

Gauge

Guide

two

task. Your McCulloch

will

advise

your depth

advice

or

him.

help,

what

gauges.

always

is

30

If

main

steps -sharpening

of

the

parts

Tooth Top Pl

of

the

cutters

ate

cutter

are

Edge

FIGURE

teeth

shown

and

in

19

Page 31

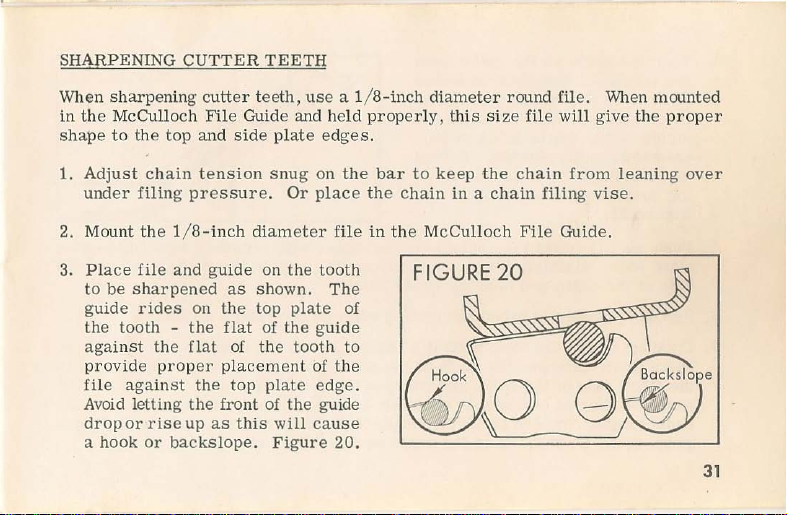

SHARPENING

When

sharpening

in

the McCulloch File Guide and held

shape

to

1.

Adjust

under

the

chain

filing

CUTTER

cutter

top

and

tension

pressure.

side

TEETH

teeth,

plate

snug

Or

use

edges.

on

place

a l iB

the

-inch

proper

bar

the

chain

diameter

ly J

this

to

keep

in a chain

round file. \Vhen mounted

size

file

will

give

the

the

chain

from

filing

leaning over

vise.

proper

2. Mount

3.

Place

to

be

guide

the

tooth -the

against

provide

file

Avoid

drop

a

hook

the liS

file

and

sharpened

rides

the

flat

proper

against

letting

rise

up

or

backslope.

the

or

-inch

guide

as

On

the

flat

of

placement

the

top

front of

as

diameter

on

shown.

top

of

the

plate

this

will

Figure

the

plate

the

tooth

the

rile

tooth

The

guide

of

the

edge.

guide

cause

20.

of

to

in

the

McCulloch

File

Guide.

31

Page 32

4.

Turn

the

are

parallel to

in

the

illustration.

level

and

inside

ened

toward

the

first

ing

pressure

Figure

5.

Push

the

plate

edge.

side

of

6.

Release

7. Continue

chain

first.

the

other

same

number

same

length.

gauge

too

32

guide

push

of

the

finger

21.

file

Maintain

the

chain

pressure

to

file

side

l.

Each

so

the

the

chain

Hold

the

cutter

the

outside.

to

assist

during

toward

and

against

the

Sharpen

of

the

of

strokes

You

can

mark

guide

lines

as

shown

the

file

being

the

tooth

chain

guide

from

the

sharpExtend

in

apply-

filing.

the

hold

the

check the length of

outside

same

the

the

until

teeth

and

on

all

on

the

See

of

relationship

guide

cutting

it's

at

the

sharpen

teeth

scale

the

cutter

level.

edge

sharp.

same

as

equals

on

Do

point

the

remaining

this

the

1/ 16

with

pressure

between

the

return

all

the

on the

will

help

teeth

with

inch.

the

teeth

teet

to

the

against

guide

stroke.

on one

bar.

h.

keep

scale

FIGU

lines

Then

Try

them

on the

side

to

RE

21

the

side

and

of the

move

use

all

depth

the

to

the

the

Page 33

8.

Rem

toward the

cutting

ove the

edges

file (rom

outside

during

the

file guide. With the

of

each

cutter

this

operation.

to

clean

handle held

out the

gullet.

high,

file down and

Do

not

touch

the

LOWERING

Depth

gauges

woods

, depth gau

the

chain befo

ta

d,

le

Use a McCulloch

For

most

is

best.

clearances.

are light

you

are

were

r e

ave

the

types

Use the

Both the McCulloch Depth Gauge tool and the McCulloch File Guide

and

convenient

using the saw.

DEPTH GAUGES

set

at

the

ges

should

lowering the

depth

gauges

Depth

of

cutting,

McCulloch

be

as

Gauge

whether

Depth

enough

factory

lowered

depth

they

tool

soft

so

they

for

average

for great

gauges

are.

and a flat

or

hard

Gauge

tool

can

.

be

If

cutting.

er

clearance.

the

chain

file

to

wood, a

with

carried

lower

clearance

the

in

Wh

feeds

the

0.025

your

en

Try

easily

depth

and

hip

cutting

cutting

into

gauges.

of 0.025

0.030

pocket

soft

with

the

inch

inch

when

33

Page 34

1.

Place

the dep

two

cutter

first

0.025

Figure

the

the

outside

lowering

off the

or two

the

same

gauges

23.

on the

teeth with

cutter

inch

22.

projecting

with

depth

of

ir leading

of

profile

and

bar

on the

the

tool.

2.

Remove

depth gauge

ac

ross

the

3.

After

rrund

strcke

tain

depth

ure

4. Always file depth

pl

ace

uniformity.

34

th

gauge

tool ove

the

depth gauge

project

the

flat

gauge

cha

in.

the

as

as

shown

gauges

in

order

ing

part of the

file. File

tool

depth

edges

file.

on

origi

at the

to

clearance slot

the

all

the fiat

thrrugh

of

the

toward

gauges,

with a

Main-

nal

in Fig-

same

assu

re

r

~

-

\

/

FIGURE

'\

FIGURE

Cl

~?r?

22

,

\

23

l\

0

~.

OJ

Page 35

4.

Always

uniformity.

file

depth

gauges

at

the

same

place

on

the

bar

in order

to

assu

r e

KEEP

After sharpening

oil

chain

to

it

button

is

remove

and

prevent

CHAIN

frequently.

very

dirty,

dirt

rust

CLEAN

chain

remove

and

filings. Soak

before

IF CHAIN BREAKS

If

the

chain

He

help

can

to

breaks,

repair

keep your

it.

take

He

chain

will

, pull

This

it

saw

it

slowly

will

help

it

from the saw

putting

to

your

also

check the

in

operating

around

flush

the

chain

it back

on

McCulloch

conditio

condition.

filin

and

in

the

the

gs

wash

SAE

saw

chain

bar

and

n of

while

dirt

it

30

.

saw

the

pumpin

off the

in

kerosene

motor

deal

bar

er

oil

or

and

g th e

manual

cha

in.

If

or solv

to

lubricate

serviceman.

sprocket

and

the

ent

35

Page 36

Do

not

freed,

try

to

use

use

force

the

bar

wedges

wood

to

or

apart

pry

an

objects.

axe

with

to

the

If

force

bar.

the

the

bar

wood

is

pinched

apart

and

in

wood

free

the

and

bar.

cannot

Never

be

CLEANING

After

foor

remove

the

holes

the

bar

Clean

sides

Reinstall

down to

or

the

sawdust

in

the

passage

groove. Use

all

sawdust

of

bar

bar

equalize

36

five

hours

bar

from

and

grime

side

of

between

wire

and

with

the

the

the

or

and

bar

opposite

wear.

of

operation,

saw.

from

the

bar

and

oil

holes

pipe

cleaner.

grime

mounting

Clean

oil

from

and

from

pad.

edge

I

-

:'~O:'~;'~~·

--

-----_/

FIGURE 24

~-

Bac

~

Gmaves

Page 37

For

shipping

tested.

orating

Under

these

manner:

down and

intake.

not

flood

duct

and

rope

will

be

necessary

run

by

itself.

air

filter

purposes,

Lack

of

all

fuel

circumstances,

Remove

inject

(An

oil

the

engine.

carburetor

draw

to

Replace

and

air

use

or a period

from

the

about

can

with

into

fuel

into

repeat

filter

the

air

1/2

Turn

fuel

engine.

it

filter

teaspoon

the

proper

the

the

crankcase.

the

combustion

the

injection

the

air

cover

is

removed

of

storage

can

be

cover

fuel

saw

so

filter

removed

easier

and

of fuel

mixture

as

to

Usually two

chamber

two

or

and

air

from

from

can

also

to

start

air

filter.

mixture

move

three

filter

the

the

engine

result

the

through

is

ideal

the

or

and

times

cover.

engine.

engine

Hold

(or

fuel

three

start

before

after

in

removing

in

the

saw

the

carburetor

this

purpose.)

mixture

pulls

the engine.

the

Never

the

engine

or

the

following

bar

through

of the

starter

It

engine will

cut

with

is

evap-

nose

air

Do

the

may

the

DO NOT USE

THIS

METHOD

FOR

REGULAR

STARTING.

37

Page 38

38

·NOTES·

Page 39

·NOTES·

39

Page 40

ImMcCULLDCH

MANUFACTURING

•

•

McCULLOCH

6101

INTERNATIONAL

McCULLOCH

77

McCULLOCH OF EUROPE,

ANTOON

CORPORAT\ON

WEST

CENTURY

BLVD.,

lOS

LOS

HONG

BELFielD ROAD, REXDAlE,.ONTARIO,

DIVISIONS:

ANGelES,

CALIF.,

KONG, B.

OF

CANADA

SPINOYSTRAAT

C.

ANGELES,

P.

O.

c.:

BOX

G.

P.

O.

LTD.

N.

V.

5,

MECHElEN, BELGIUM

McCULLOCH OF AUSTRALIA PTY.,

P.o.

BOX 165, SOUTH

McCulloch Corporation

change specifications

obligati

on

back-fit comp

the fa c

including the

tory.

one

nts

GRANVillE

reserves

without

obligati

for

units

, N.

the rig

(1)

prior

on to bac

previously

CALIFORNIA

45466

BOX

879

CANADA

LTD.

S.

W., AUSTRALIA

ht

to

nqtification

k-fit

shipped

modify

or

or

supply

90045

or

(2)

from

Loading...

Loading...